Page 1

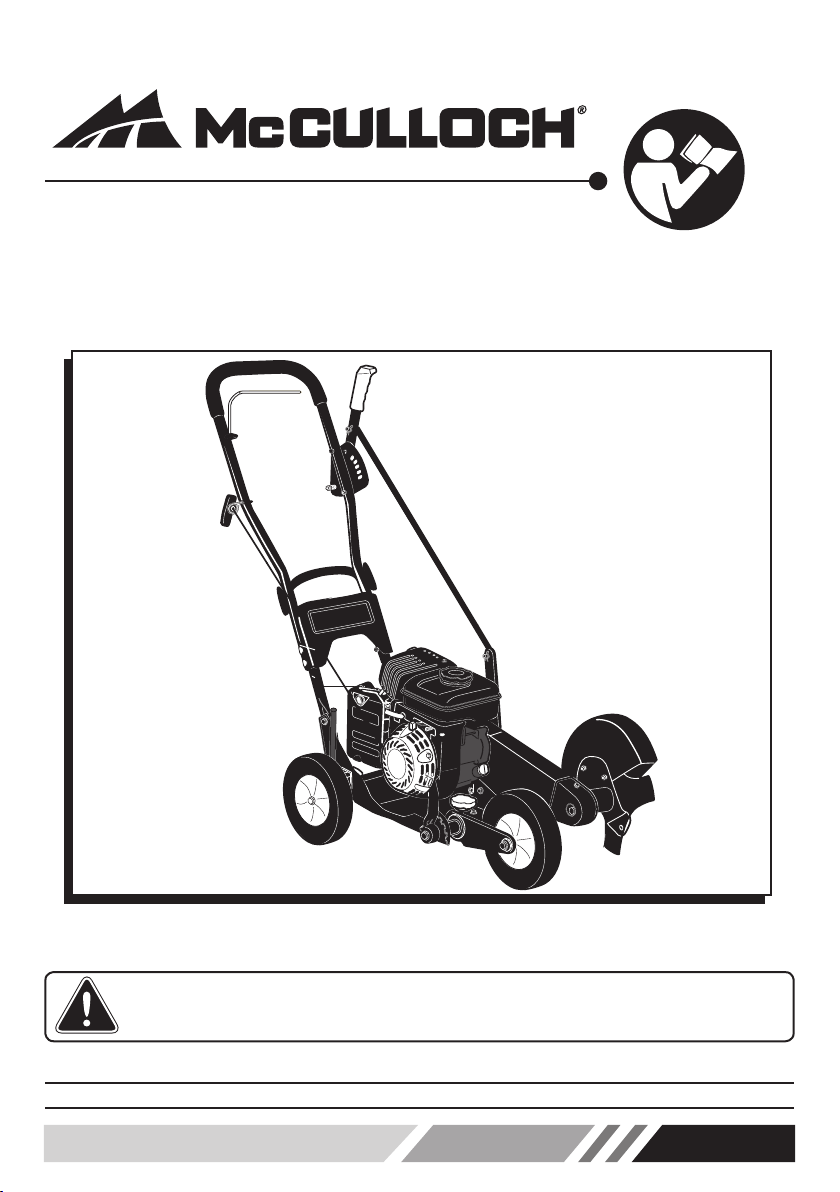

USER MANUAL

4 Stroke Petrol Edger

SAFETY OPERATION MAINTENANCE

Your edger has been engineered and manufactured to our high standard for dependability,

ease of operation, and operator safety.

WARNING: To reduce the risk of injury, the user must read and understand the

operator’s manual before using this product.

Thank you for your purchase.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Model No. ME240

Page 2

WARRANTY INFORMATION

PETROL EDGER WARRANTY

The benefits conferred by this warranty are in addition to all other conditions and warranties in respect of

this product which the consumer may have taken under the Trade Practices Act 1974 or by any legislation

of a State or Territory of Australia. This product is warranted by Husqvarna Australia (ABN 45 115 475 619)

(the “Company”) to be free from defects in material and workmanship for a period of 24 months from

the date of original purchase. The Company during the period of the warranty, will at its option, and subject

to the conditions stated herein, repair or replace without charge this product or any component part, which

upon examination by an Authorised Service Agent or by the Company is found to be defective.

Warranty conditions

This warranty will not apply:

(i) where this product has been subjected to misuse, abuse, accident or want of care;

(ii) where this product has been used for a purpose for which it was not designed or is not suited;

(iii) where the service of this product has been undertaken by a person not authorised by the

Company to carry out such work or where parts that have not been approved by the Company

have been used;

(iv) where this product has been used for industrial purposes.

Should service become necessary during the warranty period, the purchaser should contact an Authorised

Service Agent or the Company. In order to obtain warranty service, the purchaser must present the store

receipt showing the name of the retailer and the date of purchase together with a completed Warranty

Card. The period of the warranty begins from the original date of purchase, notwithstanding any subsequent

repair or parts replacement. No additional warranty or guarantee other than set out in this document,

whether written or verbal, is authorised to be made on the Company’s behalf. The purchaser shall be

responsible for delivery or causing the product to be delivered to the Company or the Authorised Service

Agent and the purchaser shall be responsible for all charges in connection with re-delivery of the product

and/or the delivery of parts. Damage in transit is not covered by this warranty and purchasers should

remove from the product any liquids (if a

damage.

pplicable) before sending and pack the product securely to p

revent

WARRANTY EXCLUSIONS

Normal wear parts or components are subject to seperate terms as follows: Normal wear parts,

components or service required when performing normal and regular maintenance of this product are not

covered by warranty unless it is found to be defective by an Authorised Service Agent or by the Company.

Normal wear parts include, but are not limited to:

Worn Blades.

Belt.

Spark Plugs.

Returns based on the above listed normal wear parts will not be accepted under this warranty as they are

considered consumable items and are at the expense of the purchaser.

Carburettor Tune-Ups.

Lubricants.

Engine Tune-Ups.

Filters.

Page 3

TABLE OF CONTENTS

n General Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

n Specific Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

n Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

n Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

n Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

n Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

n Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

n Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

INTRODUCTION

This tool has many features for making its use more pleasant and enjoyable. Safety, performance, and

dependability have been given top priority in the design of this product making it easy to maintain and

operate.

Page 4

GENERAL SAFETY RULES

This manual is written for a person with some

mechanical ability. Like most service books, not all

the steps are described. Steps on how to loosen

or tighten fasteners are steps anyone can follow

with some mechanical ability. Read and follow these

instructions before you use the unit.

Know your product: If you understand the unit

and how the unit operates, you will get the best

performance. As you read this manual, compare

the illustrations to the unit. Learn the location and

the functions of the controls. To help prevent an

accident, follow the operating instructions and the

safety rules. Keep this manual for future reference.

IMPORTANT: Many units are not assembled and

are sold in cartons. It is the responsibility of the

operator to make sure the assembly instructions in

this manual are exactly followed.

Other units are purchased in an assembled

condition. On assembled units, it is the responsibility

of the operator to make sure the unit is correctly

assembled. The operator must carefully check the

unit according to the instructions in this manual

before it is first used.

RESPONSIBILITY OF THE OPERATOR

The responsibility of the operator is to follow the

instructions below:

1. Carefully read and follow the rules for safe

operation.

2. Follow all the assembly and preparation

instructions.

3. Regularly inspect the edger. Make sure parts are

not bent, damaged, or loose.

4. Use this equipment for its intended purpose only.

5. Make sure that the operator of the unit knows

how to correctly use all standard and accessory

equipment.

6. Operate the unit only with guards, shields, and

other safety items in place and working correctly.

7. Correctly adjust the unit.

8. Service the unit only with authorised or approved

replacement parts.

9. Complete all maintenance on the unit.

SAFE OPERATION PRACTICES BEFORE USE

• Read, understand, and follow all instructions on the

machine and in the manuals. Be thoroughly familiar

WARNING

Look for this symbol to point out important

safety precautions. It means: “ Attention!

Become Alert! Your Safety Is Involved.”

WARNING

Engine Exhaust, some of its constituents, and

certain vehicle components contain or emit

chemicals known to cause cancer and birth

defects or other reproductive harm.

WARNING

To prevent accidental starting when setting up,

transporting, adjusting or making repairs, always

disconnect spark plug wire and put wire where

it cannot contact the spark plug.

with the controls and the proper use of the edger

before starting. Know how to stop the edger and

disengage the controls quickly.

• Familiarise yourself with all the safety and

operating decals on this equipment.

• Thoroughly inspect the area where the edger is

to be used and remove all foreign objects. Your

equipment can propel small objects at high speed

causing personal injury or property damage.

Stay away from breakable objects, such as house

windows, auto glass, greenhouses, etc.

• Check that all nuts and bolts are tight and

equipment is in good condition.

OPERATION SAFETY

• Never allow children or young teenagers to

operate the edger.

• Keep area of operation clear of all bystanders,

particularly small children and pets.

• Only allow responsible individuals, who are familiar

with the instructions, to operate the edger.

• Do not operate the edger while under the

influence of alcohol, drugs, or other medication

which can cause drowsiness or affect your ability

to operate this machine safely.

• Do not use this machine if you are mentally or

physically unable to operate the machine safely.

• Always wear ANSI/SAA compliant safety goggles

1

Page 5

GENERAL SAFETY RULES

or safety glasses with side shields when operating

edger to protect your eyes from foreign objects,

which can be thrown from the unit.

• Wear appropriate clothing such as a long sleeved

shirt or jacket. Also wear long trousers or slacks.

Do NOT wear shorts. Do NOT wear loose

clothing, which could get caught in this equipment.

• Always wear work gloves and sturdy footwear such

as leather work shoes or short boots. These will

protect ankles and shins from small sticks, splinters,

and other flying debris, and improve traction.

• It is advisable to wear protective headgear

to protect against being struck by small flying

particles, or being struck by low hanging branches,

twigs, or other objects, which may be unnoticed by

the operator.

• Do not put hands or feet near or under rotating

parts.

• Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traffic.

• Exercise caution to avoid slipping or falling.

Always besure of your footing; keep a firm hold

on the handle and walk; never run. Never operate

the edger at high transport speeds on slippery

surfaces.

• Look behind and use care when backing.

• Never operate the edger without good visibility

or light.

• Do not run the engine indoors or inside a closed

area. The exhaust fumes are dangerous, containing

CARBON MONOXIDE, an ODORLESS AND

DEADLY GAS.

• Never leave the edger unattended when the

engine is running. Stop the engine and make sure

all moving parts have stopped. Remove the wire

from the spark plug.

• Do not overload the edger capacity by attempting

to till too deep at too fast a rate.

• If the edger should start to vibrate abnormally,

stop the engine, disconnect the spark plug wire

and prevent it from touching the spark plug. Check

immediately for the cause. Vibration is generally a

warning of trouble.

• Watch for holes, ruts, bumps, or other rough

ground. Tall grass can hide obstacles.

2

Page 6

SPECIFIC SAFETY RULES

FUEL SAFETY

• Handle fuel with care; it is highly flammable.

• Use an approved container.

• Check fuel supply before each use, allowing space

for expansion as the heat of the engine and/or sun

can cause fuel to expand.

• Fill fuel tank outdoors with extreme care. Never

fill fuel tank indoors.

• Never remove petrol cap or add fuel with the

engine running. Allow engine to cool before

refueling.

• Do not smoke while refueling.

• After refueling, replace fuel tank cap securely and

wipe up spilled fuel.

• Never store fuel or edger with fuel in the tank inside

a building where fumes may reach an open flame.

STORAGE SAFETY

• Always refer to the operator’s manual instructions

for important details if the edger is to be stored

for an extended period.

• Never store the edger with fuel in the fuel tank

inside a building where ignition sources are

present such as water heaters, space heaters,

clothes dryers, etc.

• To reduce fire hazard, keep edger free of grass,

leaves, or other debris build-up.

• Allow the engine to cool before storing in any

enclosure.

REPAIR, MAINTAINANCE, AND ADJUSTMENT SAFETY

• After striking a foreign object, stop the engine.

Remove the spark plug lead from the spark plug

and keep the spark plug lead away from the plug

to prevent accidental starting. Thoroughly inspect

the edger for any damage. If damaged, have the

equipment repaired by a trained technician before

restarting and operating.

• Stop the engine before cleaning, repairing, or

inspecting the unit. Make sure all moving parts have

stopped. Let the engine cool, disconnect the spark

plug lead and move it away from the spark plug.

• Never attempt to make any adjustments while

the engine is running except when specifically

recommended by the manufacturer.

• Keep the edger in safe working condition. Check

all fasteners at frequent intervals for proper

tightness.

• When servicing or repairing the edger, do not

tip the machine over or up unless specifically

instructed to do so in this Manual. Service and

repair procedures can be done with the edger in

an upright position. Some procedures will be easier

if the machine is lifted on a raised platform or

working surface.

• Use only original equipment or authorised

replacement parts.

• Never tamper with safety devices. Check their

proper operation regularly.

• Do not change the engine governor setting or

over-speed engine.

• Clean and replace safety and instruction decals as

necessary.

• To guard against engine over-heating, always have

engine air filter mounted and clean.

CHILDREN SAFETY

• Tragic accidents can occur if the operator is not

alert to the presence of children. Children are

often attracted to the edger and the edging activity.

• Keep children out of the edging area and under the

watchful care of a responsible adult.

• Never assume that children will remain where you

last saw them.

• Be alert and turn edger off if children enter the

area.

• Before and while moving backwards, look behind

and down for small children.

• Never allow children to operate the edger.

• Use extra care when operating near blind corners,

shrubs, trees, or other objects that may obstruct

vision.

3

Page 7

SYMBOLS

CONTROL AND OPERATING SYMBOLS

IMPORTANT:

Many of the following symbols are located on your unit or on literature supplied with the product. Before

you operate the unit, learn and understand the purpose for each symbol.

ENGINE STOP ENGINE STOP

OIL

FUEL

RUN CHOKE OIL FILL

SAFETY ALERT SYMBOLS

Indicates danger, warning, or caution. Attention is required in order to avoid serious personal injury. The

signal word (DANGER, WARNING, OR CAUTION) is used with the alert symbol to alert you to special

instruction about a particular operation that may be hazardous if performed incorrectly or carelessly.

Observe them carefully.

SYMBOL EXPLANATION

DANGER

WARNING

CAUTION Failure to obey a safety warning may result in minor or moderate injuries.

CAUTION

Failure to obey a safety warning will result in serious personal injuries or

deaths.

Failure to obey a safety warning can result in serious personal injuries or

deaths.

When used without the alert symbol, could result in damage to your engine

or other property.

4

Page 8

SYMBOLS

SAFETY WARNING SYMBOLS

SYMBOL DEFINITION

Indicates WARNING, DANGER, or CAUTION.

Read operator’s manual before operating this machine. Failure to follow directions

could result in serious injury.

Thrown objects. Do not use if children or bystanders are present. Remove all objects

which could be thrown by machine. Read operator’s manual before operating this

machine.

Rotating parts can cause serious injury. Keep away from rotating parts. Stop engine

and disconnect spark plug wire before making adjustments.

Wear eye protection complying with SAA ANSI Z87.1 and hearing protection.

Disconnect spark plug wire before servicing unit.

Engine emits carbon monoxide. Do NOT run indoors or in enclosed area.

Do NOT touch hot muffler or cylinder. These parts are extremely hot from

operation and may remain hot for a short time after operation.

To reduce risk of fire, clean spilled gas and oil and keep unit free from debris. Petrol

is extremely flammmable. Allow machine to cool before refueling.

5

Page 9

FEATURES

Engine Displacement .... ...... . . . . . ....... 87cc

Petrol Capacity . ............ ............ .1.6 L

Petrol Type ..... . . . . . . . . . . . . . Unleaded Regular

Oil Type (API SG-SL) . ........ ........... SAE 30

Oil Capacity . . .... .... .... ..... ... ... [400 ml]

Spark Plug Model . . .... .... .... .... .... E7RTC

Spark Plug Gap . . .... . 0.027-0.031 in. [0.7-0.8 mm]

Edger Blade Size . . .... .... .... ... 9 in. [228 mm]

KNOW YOUR EDGER

READ THE OPERATOR’S MANUAL AND ALL SAFETY RULES BEFORE YOU OPERATE the edger. To

familiarise yourself with the location of the controls, compare Figure 1 with your edger. Save this manual for

future reference.

FRONT VIEW

Start Lever

Recoil Starter

Handle

Choke Control

Throttle Control

Clutch Lever

Control Rod

Oil Fill Cap/

Dipstick

Blade Guard

REAR VIEW

Spark Plug/

Spark Plug Lead

Angle Cut Lever

Adjustable Rear

Wheel

Throttle Control Controls the engine speed.

Start Lever Lever on handle which allows the

engine to run. When lever is released, engine will

stop.

Choke Control Restricts the air intake. This allows

for an enriched fuel-air mixture which helps to start

the engine.

Clutch Lever Use to start and stop the blade and

control the depth of cut.

Adjustable Rear Wheel Right rear wheel is

adjustable to level the edger when edging along a

curb (curb-hopping).

Adjustable Front Wheel Front wheel is adjustable

Adjustable Front Wheel

Figure 1

from side to side for balance. The front wheel can

also adjust down for curb-hopping.

Recoil Starter Handle The engine is equipped

with an easy pull recoil starter.

Angle Cut Lever Permits adjusting the cutting

angle to 15 degrees, 0 degrees (vertical), or -15

degrees. To change the angle, pull the lever and

rotate the quill assembly to the desired angle.

Blade Guard Use to prevent stones and debris

from being thrown at the operator.

Spark Plug/Spark Plug Lead Provides spark to

ignite air/ fuel mixture. The Spark Plug Lead must be

disconnected and moved away from the Spark Plug

when servicing the unit.

6

Page 10

ASSEMBLY

Read and follow the assembly and adjustment

instructions. All fasteners are in the parts bag. Do

not discard any parts or materials until the unit is

assembled.

WARNING

Before doing any assembly or maintenance to

the unit, remove the lead from the spark plug.

NOTE: Torque is measured in foot-pounds (metric

unit is Nm). This measurement describes how tight a

nut or bolt must be. The torque is measured with a

torque wrench.

WARNING

Always wear ANSI/SAA compliant safety glasses

with side shields while assembling the edger.

The following tools will be required for assembly of

the edger with the quantities shown in ( ):

(2) Adjustable Wrenches

(1) Utility Knife to Cut Carton

(1) Blade Type Screwdriver

(1) Pliers

(1) Oil Funnel

(1) Torque Wrench to Check Fastener Tightness

The following components will be found in the

carton with the quantities shown in ( ):

(1) Edger Operator’s Manual

(1) Upper Handle

(1) Lower Handle

(1) Handle Panel

(1) Control Rod

(1) 400 ml container of engine oil

(1) Parts Bag containing the following:

(4) Pipe Bolts

(4) M8X16 Bolts

(8) M8 Nuts

(2) Cotter pins

(2) Cable ties

Figure 2 shows the edger completely assembled.

References to the right or left side of the edger

are from the viewpoint of the operator’s position

behind the unit.

Figure 2

7

Page 11

ASSEMBLY

HOW TO ASSEMBLE THE HANDLE

1. Mount the lower handle to the inside of the edger

frame with the (4) M8X16 bolts

(See Figu

re 3). As you tighten the fasteners, pull back

on the handl

e. The torque for all nuts and bolts in the

handle should be 7.4-11.8

2. Assemble panel with nuts and bolts provided. Insure

that the

nuts are to the inside. Assemble the top

folding handle with the 2 handle lock levers and

bolts p

rovide. Tighten folding Handles in to position

by tightening locking handles by hand.

3.

Connect the wires using the plastic connectors fitted.

Secure wires with handle clips provided.

4)

4. Use the (2) cable ties to secure the loose cable

coming f

rom the start lever to the handle. Use (1)

cable tie on the right side of the upper handle and

(1) cable tie on the left side of the l

Ma

ke sure cable goes behind handle panel.

5. Slide one end of the control rod from left to right

th

rough the hole in the clutch lever. Secure with the

cotter pin

. (See Figure 5)

6. Move the clutch lever to the first depth position.

Attach the other end of the cont

suppo

rt arm with the cotter pin. (See Figure 5)

7. Move the clutch lever back to the “N” NEUTRAL

position.

NOTE: If it is difficult to move the clutch lever to the

“N” NEUTRAL position

the l

ower handle to the edger frame (See Figure 5). Raise

, loosen the fasteners that hold

the handle until the clutch l

“N” NEUTRAL position

. Tighten the fasteners.

8. When the clutch lever is in the NEUTRAL position,

the quill suppo

(See Figu

rt arm must be close to the screw.

re 6)

, and (4) M8 Nuts

foot-pounds [10-16 Nm].

(See Figure

ower handle.

rol rod to the quill

ever will easily move to the

Locking

Handles

Lower

Handle

Quill

Support

Arm

Upper

Handle

M8 Nut

Cotter Pin

Neutral

Locking

Handles

Position

Cotter

Pin

Figu

Cont

Rod

Figu

re 4

rol

Quill

Suppo

Arm

re 5

rt

M8x16

M8x16

Edger Frame

Edger Engine

M8 Nuts

M8x16

M8x16

Figure 3

rew

Sc

re 6

Figu

8

Page 12

OPERATION

ENGINE PREPARATION

ENGINE DOES NOT CONTAIN OIL OR PETROL WHEN SHIPPED

Before you use the unit, read the information on safety,

operation, maintenance, and storage. This edger was

shipped with a 400 ml contain er of SAE30 motor oil.

This oil is to be added to the engine before operating.

Follow the below procedure to fill the crankcase with

oil.

FIRST TIME FILL

1. Place the edger on a level surface and make sure the

adjustable wheels are set so the main frame of the

edger is level.

2. Remove the oil fill cap/dipstick.

Note: the crankcase is shipped empty. Fill with 400

ml of oil.

3. When adding oil, use a funnel or a nozzle for the oil

container to reduce spillage.

4. DO NOT OVERFILL. Check the oil level by

following the instructions below.

TO CHECK THE OIL LEVEL AND FILL TO PROPER LEVEL

1. Place the edger on a level surface and make sure the

curb-hoping wheels are set so the main frame of the

edger is level.

2. Remove the oil fill cap/dipstick and wipe clean with

cloth. (See Figure 7)

3. Replace dipstick and do NOT screw it. Remove and

check oil level.

4. When oil level is full, the oil will be at upper limit on

dip stick. (See Figure 8)

5. If the oil level is near or below the lower limit mark

on the dipstick (See Figure 8), add oil slowly and

recheck until oil level reaches upper limit of dipstick.

DO NOT OVERFILL.

6. Replace and tighten dipstick.

7. Clean up any spilled oil.

NOTE: When adding oil, frequently insert the oil fill

cap/dipstick and check the amount of oil in the engine.

DO NOT OVERFILL.

IMPORTANT: This unit is equipped with an internal

combustion engine and must not be used on or near

any forest-covered, brush-covered or grass-covered

land unless the engine’s exhaust system is equipped

with a spark arrestor meeting applicable local or state

laws. If a spark arrestor is used, the operator must

maintain it in effective working order.

CHECKLIST

For the best performance and satisfaction from this

quality product, please review the following checklist

before you operate the edger:

• All assembly instructions have been completed.

• Check carton to make sure no parts are remaining.

• All fasteners have been properly tightened.

As you learn how to use the edger, pay extra attention

to the following important items:

• Engine oil is at proper level.

• Fuel tank is filled with a fresh, clean, regular unleaded

petrol.

• Become familiar and understand the function of all

controls. Before you start the engine, operate all

controls.

Fuel Tank

Oil Fill Cap/

Dipstick

Figure 7

Oil Fill Cap/

Dipstick

WARNING

Follow the user manual instructions for the type

of petrol and oil to use. Always use a safety petrol

container. Do not smoke when adding petrol to

the engine. When inside an enclosure, do not

fill with petrol. Before you add petrol, stop the

engine. Let the engine cool for several minutes.

9

Upper Limit

Lower Limit

Figure 8

Page 13

OPERATION

WARNING

Debris thrown from the edger can result in

foreign objects being thrown into eyes, which

can cause severe eye damage. Always wear

ANSI/SAA compliant safety glasses or eye

shields when operating the edger. If you wear

eyeglasses, use a Wide Vision Safety Mask over

your eyeglasses.

HOW TO USE THE THROTTLE CONTROL

1. During normal use, run the engine at full speed.

2. Move the throttle control rearward to increase

engine speed, or forward to decrease engine

speed. (See Figure 9)

HOW TO USE THE CHOKE

To start the the engine, slide the choke lever to the

CHOKE position. After the engine has been

running for 2-5 seconds, slide the choke lever to the

RUN position. (See Figure 10)

HOW TO USE THE CLUTCH LEVER

1. To engage the cutting blade, move the clutch lever

forward. (See Figure 11)

2. Select the edging depth you need. There are five

selections down to approximately 70 mm deep.

Throttle Control

Increasing

Speed

Decreasing

Speed

IDLE

Figure 9

Choke Lever

RUN

Choke

FILLING TANK

1. Clean surface around fuel cap to prevent

contanimation.

2. Remove fuel cap slowly. Place the cap on a clean

surface.

3. Carefully pour fuel into the tank. Avoid spillage.

4. Prior to fitting the fuel cap, clean and inspect the

gasket.

5. Immediately refit fuel cap and hand tighten. Wipe

up any spillage.

NOTE: It is normal for smoke to be emitted from a

new engine after the first use.

10

Start

Lever

Figure 10

Clutch

Control

Forward

Neutral

Full

Depth

Figure 11

Page 14

OPERATION

HOW TO START THE ENGINE

NOTE: DO NOT BE ALARMED; your engine will

smoke the first time it is started. It is burning off

the protective coating that is on the internal engine

parts.

NOTE: Make sure engine is level before starting.

IMPORTANT: Before you start the engine, move

the edger to the desired location. Operate the

controls several times. Make sure all controls move

freely.

1. Check the oil.

2. Fill the fuel tank with regular unleaded petrol.

Make sure the petrol is clean. Leaded petrol will

increase deposits and shorten the life of the

valves.

NOTE: Do not use gasohol or methanol. Do not

use premium-unleaded petrol.

WARNING

Always use a safety petrol container. Do not

smoke when adding petrol to the fuel tank.

When inside an enclosure, do not add petrol.

Before you add petrol, stop the engine and let

the engine cool for several minutes.

DO NOT allow the starter rope to snap back. Let

the starter rope slowly rewind. If the engine does

not start in 5 or 6 tries, see the instruction in the

“Troubleshooting Chart”.

NOTE: THE START LEVER HAS TO BE

ALWAYS HELD AGAINST THE HANDLE

FOR THE ENGINE TO RUN.

10. After the engine starts, wait 2-5 seconds and

slide the choke back to the RUN position.

11. When the engine is running, move the throttle

control lever forward (SLOW Position) to

decrease speed or backwards (FAST position)

to increase speed. During normal use keep the

throttle in the FAST position. (See Figure 9)

HOW TO STOP THE EDGER

Release the start lever. This will ground the flameout

wires and stop the engine.

WARNING

Never run the engine indoors or in a poorly

ventilated area. Engine exhaust contains

carbon monoxide, an odorless and deadly gas.

Keep hands, feet, hair, and loose clothing away

from any moving parts. Avoid the muffler and

surrounding areas. Temperatures can exceed

150 degrees.

3. Make sure the spark plug lead is connected to the

spark plug.

4. Pull the clutch lever all the way back to raise and

disengage the blade

5. Move the throttle control lever all the way to full

throttle.

6. Slide the choke to the CHOKE position. (See

Figure 10)

7. Hold the recoil starter handle firmly with your

right hand.

8. Hold the edger handle firmly with your left hand,

pulling the start lever against the handle.

THE ENGINE WILL NOT START IF THE

START LEVER IS NOT PULLED AGAINST

THE HANDLE (FIGURE 11).

9. Pull the recoil slowly, until you feel tension in the

starter rope. Then quickly pull the recoil starter

handle to completely unwind the starter rope.

11

Page 15

OPERATION

HOW TO USE THE ANGLE CUT LEVER

FOR A BEVELED EDGE

The index lever has positions that will provide a

beveled edge (15, 0, -15 degrees). A bevel edge cut

along a sidewalk or driveway makes a trench and will

reduce the need to edge as often.

1. Stop the engine and disconnect the spark plug

wire from the spark plug.

2. Loosen the front wheel knob (See Figure 12). Slide

the front wheel all the way to the right side. This

will prevent the blade from hitting the wheel.

3. Securely tighten the front wheel knob.

4. Disengage the angle cut lever (See Figure 13).

Move the angle cut lever to the desired notch

(15, 0 or -15 degrees).

5. Before you start the engine, line up the edger as if

you were going to bevel cut. Move the clutch lever

down to test the blade location. Return the clutch

lever to the “N” NEUTRAL position.

6. Reconnect the spark plug wire to the spark plug.

7. Start the engine.

8. Move the clutch lever to the desired cutting

depth.

Front Wheel Knob

Front Wheel

Figure 12

12

Angle Cut Lever

Figure 13

Page 16

OPERATION

HOW TO USE THE CURB-HOPPING

FEATURE

Because the front wheel and the right rear wheel

are adjustable, the edger can be used on uneven

surfaces, such as a curb shown in Figure 14. Set the

wheel position as follows:

1. Stop the engine.

2. Disconnect the spark plug wire from the spark

plug.

3. Loosen the front wheel knob.

4. Slide the front wheel to the best position to clear

the curb and balance the unit.

5. Securely tighten the front wheel knob.

6. Use the curb height adjustment lever to lower the

front wheel. Lower the front wheel until the front

wheel is level with the left rear wheel and the unit

is sitting on the curb. (See Figure 14)

7. Loosen the rear wheel knob.

8. Lower the right rear wheel until the edger is level

and the left rear wheel is on the curb.

9. Securely tighten the rear wheel knob.

10. Connect the spark plug wire to the spark plug.

EDGING TIPS

WARNING

Read the Operator’s manual. Know location

and functions of all controls. Keep all safety

devices and shields in place. Never allow

children or uninstructed adults to operate the

edger. Shut off engine before unclogging blade

or making repairs. Keep bystanders away from

machine. Keep away from the blade and all

rotating parts, which cause injury.

• Edging is best performed when conditions are

dry. If the soil is too wet, dirt becomes packed

around the blade causing premature belt wear and

decreased performance.

• If dirt does become packed around the blade, stop

the engine and remove the wire from the spark plug.

Remove the front guard cover, clean around the

blade and then refit the guard cover.

• For deep edging, first cut at shallow depths. Then, cut

at greater depths until the desired depth is obtained.

• For uniform edging, make sure the blade guide

rides on the surface.

• Edging can be customised by varying the number

of passes and by the distance the blade is from the

Support Rod

Rear Wheel Knob

Right Rear Wheel

Front Wheel Adjustment Lever

Front Wheel Knob

Blade Guard

Front Wheel

13

Spark Plug Wire

Figure 14

Page 17

MAINTENANCE

PERIODIC MAINTENANCE SCHEDULE TABLE

Service Records Fill in dates

as you complete regular

service

After

First 2

Hours

Before

Each Use

Every 10

Hours

Every 25

Hours

Before

Each

Season

Before

Storage

Lubriate All Pivot Points

Lubricates Wheel Axles

Check Engine Oil

Check Spark Plug

Check Drive Belt

Check Fasteners for Tightness

Check Blade for Wear or

Damage

GENERAL RECOMMENDATIONS

The warranty on this edger does not cover items that have been subjected to operator abuse or negligence.

To receive full value from the warranty, the operator must maintain the edger as instructed in this manual.

Some adjustments must be made periodically to properly maintain your edger.

All adjustments in the Maintenance section of this manual must be checked at least once each season.

STORAGE AND TRANSPORTATION

FOLDING HANDLE

1. Remove retaining pin from control rod (upper) (Fig A)

2. Loosen lock knobs (Fig B)

3. Fold handle down (Fig C) make sure control rod is clear of other parts

Figure A Figure B Figure C

14

Page 18

MAINTENANCE

ENGINE MAINTENANCE

Use the following maintenance section to keep your

unit in good operating condition. Before you start the

engine, read this book.

LUBRICATION

1. After each 10 hours, apply a small amount of engine

oil to all pivot points

2. After each 25 hours, apply a small amount of engine

oil to the wheels.

HOW TO CHANGE THE OIL

1. Shut off engine and wait for it to cool.

2. Disconnect spark plug wire from the spark plug.

3. Remove the drain plug and washer. (See Figure 15)

4. Tilt edger to drain all the engine oil into a flat pan.

5. Fill the engine crankcase. DO NOT OVERFILL. Refer

to Engine Preparation section for instructions on

filling oil to proper level.

6. Connect the spark plug wire to the spark plug.

HOW TO REMOVE THE BELT

The belt is made of a special compound. If the belt

becomes worn or breaks, replace the belt with an

original equipment belt. The belt length is 32.6 in.

[828.04 mm] and the section is 4L.

1. Disconnect the spark plug wire from the spark plug.

2. Pull the clutch lever back to the “N” Neutral

position to release tension from the belt.

3. Remove the two screws and spacers from the top

of the engine pulley cover. Remove the engine pulley

cover. (See Figure 16)

4. Loosen, do not remove, the screw that holds the rear

belt guide. Then, move the belt guide away from the belt.

5. Remove the screws from the belt guard. Undo pulley

nut, remove pulley washer. (See Figure 17)

6. Remove the old belt from the engine and quill assembly

pulleys. Replace with an original equipment belt.

7. To install a new belt, reverse the above steps.

• The rear guard fasteners should be tightened to 7.4-

11.8 foot-pounds [10-16Nm].

• The front guard fasteners should be tightened to 7.4-

11.8 foot-pounds [10-16Nm].

• The rear belt guide fasteners should be tightened to

34-45 foot-pounds [47-61Nm].

• The front belt guide fasteners should be tightened to

7.4-11.8 foot-pounds [10-16Nm].

Rear

Guard

Screws

Front Guard

Screws

Belt Guard

Drain Plug and Washer

Figure 15

Spacer

Engine Pulley

Rear Belt

Guide

Screw

Engine

Pulley

Cover

Figure 16

Pulley Nut

Front Guard

Screws

Figure 17

15

Page 19

MAINTENANCE

HOW TO REPLACE THE BLADE

The blade is subject to wear and damage, such as nicks

and dents. This will not generally affect its function.

The blade is designed to not require sharpening. Do

not attempt to sharpen the blade. The blade is also

reversible. If nicks or dents are excessive, remove

the blade and turn it around. This will provide a fresh

cutting edge. Replace the blade if both sides are worn

or damaged.

WARNING

Do not sharpen the blade. Sharpening can

damage the blade and cause it to break, which

can cause injury to you or to others.

Wing Nuts

To replace the blade, follow the steps below.

(Figure 18A & 18B)

1. Disconnect the spark plug wire from the spark plug.

2. Remove blade cover by undoing the 3 wingnuts

(Fig 18A).

3. Remove blade locknut that holds the blade to the

drive shaft. (Fig 18B)

WARNING

To remove or tighten the blade locknut, always use

the method shown in Figure 18B. Always position

the holding wrench on the nut behind the blade.

4. Remove the blade.

5. Install a new blade and blade locknut. Tighten the

blade locknut to a torque of 40-45 foot-pounds

[54-61 Nm].

6. Refit blade cover.

Figure 18A

STORAGE

WARNING

Never store the edger indoors with fuel in the

fuel tank. Never store in an enclosed, poorly

ventilated area where fumes could reach an open

flame, a spark or a pilot light as on a furnace,

water heater or clothes dryer. Allow engine to

cool before storing unit.

WARNING

Do not remove petrol while inside a building,

near a fire, or while you smoke. Petrol fumes can

cause an explosion or a fire.

NOTE: A yearly checkup or tune-up at an authorised

service centre will make sure that the edger will

provide maximum performance for the next season.

When the edger is put in storage for thirty days or

more, the following steps should be followed to make

sure the edger is in good condition the next season.

Blade Lock Nut

1. Let the engine run until it is out of petrol.

2. Remove the spark plug from the cylinder. Pour few

drops of oil into the cylinder. Slowly pull the recoilstart grip so that the oil will protect the cylinder.

Install a new spark plug in the cylinder. Pull starter

handle slowly a few times to distribute oil.

3. Clean the dirt and debris from the cylinder cooling

fins and the engine housing.

4. Completely clean the edger. Remove all dirt,

grease,leaves, etc.

5. Check the edger for worn or damaged parts. Have

damaged parts replaced if necessary.

6. Tighten all loose hardware.

7. Apply lubrication as directed in Maintenance section.

8. Put the unit in a building that has good ventilation.

9. When engine completely cold, Cover the edger

with a suitable protective cover that does not retain

moisture. Do not use plastic. Plastic cannot breathe

which allows condensation to form and will cause

your unit to rust.

Figure 18B

16

Page 20

Problem Possible Cause Solution

Engine difficult to start

TROUBLESHOOTING

Stale fuel

Drain fuel tank. Fill with fresh fuel.

Clogged fuel filter

Engine runs erratically

Engine will not run at full

speed

Engine smokes

excessively

Cutting blade will not rotate Debris interfering with blade

Blade will not cut properly Damage or worn blade Reverse or replace the blade.

Excessive vibration Loose parts Stop engine immediately.

Dirt in fuel tank or out of fuel

Fouled spark plug

Dirty air filter

Choke is in the CHOKE position

Clogged air filter

Choke is in the CHOKE position

Loose blade

Defective V-belt

Replace fuel filter.

Clean fuel tank.

Clean and set spark plug gap.

Clean or replace air filter.

Slide choke to RUN position.

Clean or replace air filter.

Slide choke to RUN position.

Clean debris from blade.

Tighten blade nut.

Replace V-belt.

Tighten all fasteners. If vibration

continues, take the unit to an

Authorised Service Centre.

17

Loading...

Loading...