Page 1

McCulloch U.S.A.

12802 Leffingwell Rd.

Santa Fe Springs,

CA 90670

USA

Made in China / Fabriquè à Chine / Hecho en China

STOP

ARRÊT

ALTO

For problems or questions, DO NOT return

this product to the store. Contact your

Customer Service Agent .

En cas de problèmes ou pour des questions,

NE PAS retourner ce produit au point de vente. S'adresser

au préposé du Service à la clientèle en composant.

Para problemas o preguntas, NO devolver este producto a la tienda

Contacte a su Agente de Servicio al Cliente.

U.S.A. & CANADA

1-800-521-8559

For Consumer Assistance Please Call

L'Aide Du Consommateur Necessitez S'il Vous Plait

Para La Ayuda Del Consumidor Llame Por Favor

USER MANUAL

Gas String Trimmer

Model : MCT3362VA

SAFETY

OPERATION

MAINTENANCE

For your own safety please read this manual before attempting to operate your new unit. Failure to follow instructions can result in serious personal injury. Spend a few moments to familiarize yourself with

your trimmer before each use.

PN 9096-336202 Printed in China

WARNING • PLEASE READ

Page 2

INTRODUCTION 1 - GENERAL INFORMATION

PLEASE READ

Dear Customer,

Thank you for purchasing a McCulloch product. With prop-

er operation and maintenance, it will provide you with years

of service.

In order to make the best use of your investment, be CER-

TAIN to familiarize yourself with the contents of the

ENTIRE user manual before attempting to operate and

maintain your unit.

Be sure to carefully follow the step-by-step instructions in

this manual to start, operate and maintain your new product.

In the manual there will be the following call-outs: NOTE:,

WARNING / CAUTION and WARRANTY.

A NOTE: is used to convey additional information, to high-

light a particular explanation, or to expand a description.

A WARNING or CAUTION identifies a procedure which, if

not undertaken or if improperly done, can result in serious

personal injury and/or damage to the unit.

The (WARRANTY SYMBOL) serves notice that unless

instructions or procedures are followed, any damage

caused will void the warranty and repairs will be at owner’s

expense.

Pay particular attention to the safety precautions. They are

written for your protection and contain important information you must know to safely operate your trimmer.

FOR WARRANTY OR SERVICE CONTACT THE NEAREST

McCULLOCH AUTHORIZED SERVICE CENTER - LOCATE

YOUR NEAREST SERVICE CENTER BY CALLING THE

TOLL FREE NUMBER IN THIS MANUAL.

TABLE OF CONTENTS

1 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . .2

1-1. General Identification

1-2. Safety Features

1-3. Specifications

2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2-1. What To Do

2-2. What Not To Do

2-3. International Symbols

3 ASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . .6

3-1. “P” Handle Assembly

3-2. Debris Shield

4 FUEL AND LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . .8

4-1. Fuel

4-2. Mixing Fuel

4-3. Fuel Mixing Table

4-4. Recommended Fuels

4-5. Fuel and Lubrication Symbols

5 OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . .9

5-1. Starting a Cold Engine

5-3. To Stop Engine

5-2. Warm Engine Start

5-4. Idling/Carburetor Adjustment

6 TRIMMING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . .11

6-1. Additional Safety Precautions

6-2. Stringhead Line Release

6-3. Trimming Procedures

7 MAINTENANCE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . .13

7-1. Replacing Cutter Line

7-2. Air Filter

7-3. Fuel Cap / Fuel Filter

7-4. Carburetor Adjustment

k Plug

Spar

7-5.

7-6. Spark Arrester Screen

7-7. Debris Shield Knife Sharpening

7-8. Storing a Unit

7-9. Removing a Unit From Storage

8 TROUBLESHOOTING THE ENGINE . . . . . . . . . . . . . . . . . .17

9 TROUBLESHOOTING THE STRINGHEAD . . . . . . . . . . . . .18

10 ONE YEAR LIMITED WARRANTY . . . . . . . . . . . . . . . . . . .19

5

4

3

1

2

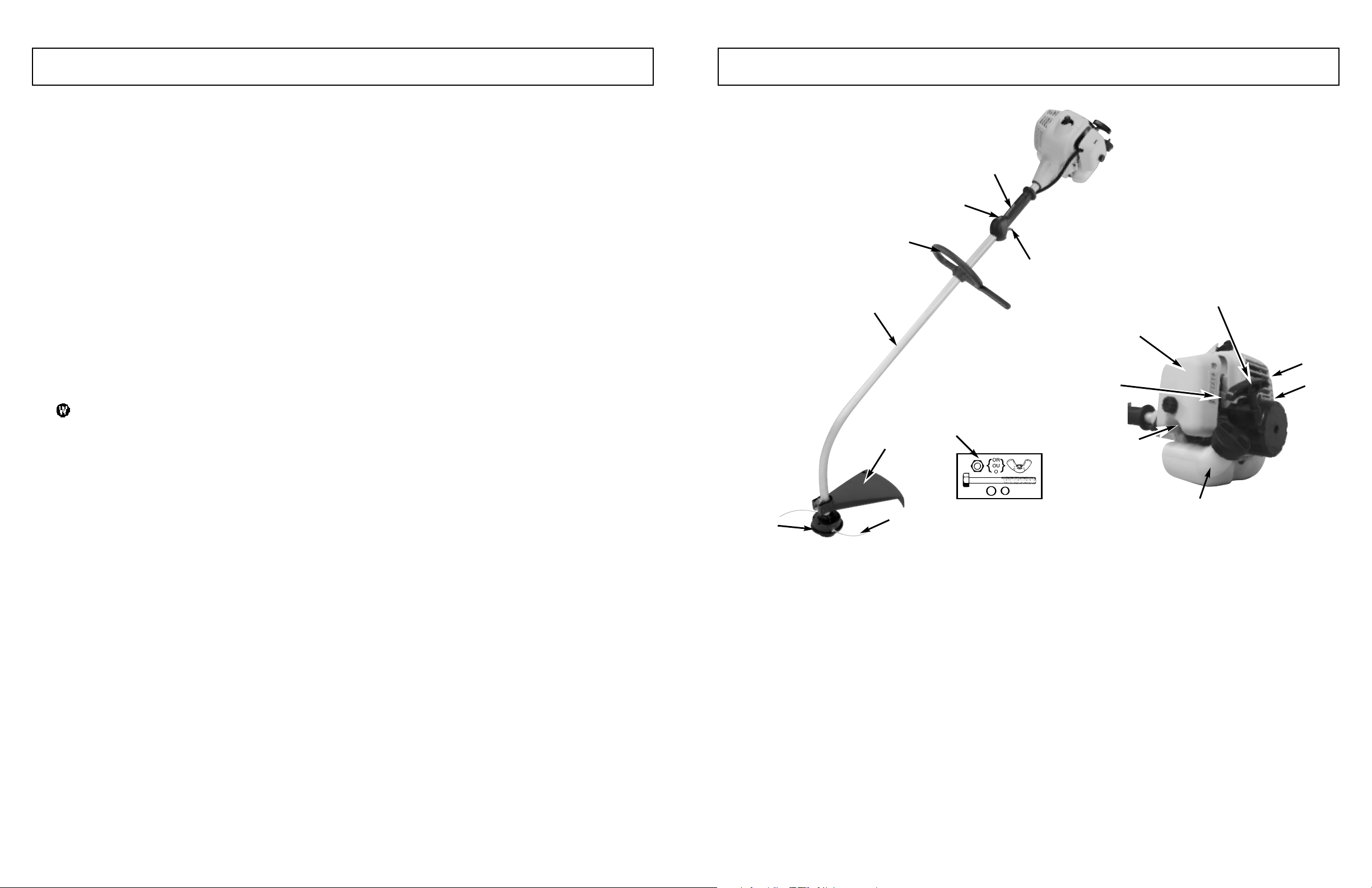

1-1. GENERAL IDENTIFICATION

UMP FEED HEAD*

B

1.

CUTTING LINE

2.

3. DEBRIS SHIELD*

DRIVE SHAFT ASSEMBL

4.

P-HANDLE

5.

6. THROTTLE TRIGGER

IGNITION ON/OFF SWITCH

7.

SAFETY

8.

9. CHOKE LEVER

FUEL TANK

10.

11.

AIR FIL

TER CO

12. STARTER HANDLE

MUFFLER SHIELD

13.

PRIMER B

14.

15. SPARK ARRESTER SCREEN*

16. DEBRIS SHIELD HARDWARE

TE:

NO

* items are w

DO NO

ear/m

*

TRIGGER

VER

ULB

T use b

lades on these models.

Y

16

8

7

6

12

11

13

9

15

14

10

1-2. SAFETY FEATURES

Numbers preceding the descriptions correspond to numbers above to help you locate the safety feature.

3 DEBRIS SHIELD m

from being thrown at the user and prevent the string

from extending longer than necessary.

13 MUFFLER SHIELD helps prevent hands, body and/or

combustible materials from making contact with a hot

muffler.

15 SPARK ARRESTER SCREEN retains carbon and

other flammab

xhaust flo

from e

NOTE: Compliance with local, state and federal laws

and/or regulations governing the use of a spark arrester

screen is the user’s responsibility. See Safety

Precautions (Section 3) and Maintenance Instructions

(Section 8) for additional information.

ust be installed to prevent debris

le particles over 0.023" (.6 mm) in size

.

w

2 3

Page 3

1 - GENERAL INFORMATION

2 - SAFETY PRECAUTIONS

1-3. SPECIFICATIONS

Engine Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Air-cooled, 2-Cycle, Chrome Cylinder

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26cc / 1.8ci

Dry Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.78 lbs. / 4.9 kg

Fuel Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .550 ml

Drive Shaft Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52” (132cm)

Cutting Swath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17" / 43cm

Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .“P” Handle

Carburetor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Primer / Diaphragm Type

Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Electronic

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Clutch

Maximum Engine Performance . . . . . . . . . . . . . . . . . . . . . . . . . .0.78 kW

Maximum RPMS at Wide Open Throttle . . . . . . . . . . . . . . . .7600 min

Idle Speed With no Stringhead Movement . . . . . . . . . . . . . . . . .3000±300 min

4 5

-1

-1

2-1. WHAT TO DO

READ

(IF ANY ENCLOSED) THOROUGHLY BEFORE OPERATING YOUR UNIT.

1. CLOTHING - Always wear heavy, long pants, boots,

2 FUELING - Mix and pour fuel outdoors where there

3. COMPLY WITH ALL FIRE PREVENTION REGULA-

4. TURN UNIT OFF before setting it down.

5. ALWAYS HOLD UNIT FIRMLY WITH BOTH HANDS,

6. KEEP ALL SCREWS AND FASTENERS TIGHT.

7. KEEP HANDLES DRY, clean and free of fuel mixture.

8. KEEP STRINGHEAD AS CLOSE TO GROUND AS

9. CHECK AREA YOU WILL BE TRIMMING FOR

10. KEEP ALL PARTS OF YOUR BODY AND CLOTHING

11. STOP ENGINE before examining cutting line.

12.

13. ALWAYS KEEP the debris shield, stringhead, and

14.

YOUR USER MANUAL AND ALL SUPPLEMENTS

gloves and long sleeve shirt. Do not wear loose clothing, jewelry, short pants, sandals, or go barefoot.

Secure hair so it is at shoulder level. Always wear a

hard hat, a safety face shield, or safety glasses for eye

protection and a good grade of ear plugs or other

sound barriers for hearing protection.

are no sparks and flames. Slowly remove the fuel cap

only after stopping the engine. Do not smoke while

fueling or mixing fuel. Wipe spilled fuel from the unit.

Move at least 30 ft (9m) away from the fueling source

(gas can) and site before starting unit.

TIONS. COMPLIANCE WITH ALL LOCAL, STATE,

OR FEDERAL LAWS IN THE UNITED STATES IS

THE USER’S RESPONSIBILITY. Your unit comes with

a spark arrester screen. Replacement spark arrester

screen kits are available at your nearest McCulloch

Authorized Service Center listed under “SAWS” in

your Telephone Directory Yellow Pages.

the thumb and fingers encircling the handles.

Never operate this equipment if it is improperly adjusted or not completely and securely assembled.

PRACTICAL. Avoid hitting small objects with string-

ing

ered w

w

w str

ys be

a

ater

When cutting on a slope

head.

head.

DEBRIS that may be struck or thrown during operation.

AWAY FROM STRINGHEAD when starting or running

ore star

Bef

.

engine

will not come in contact with any obstacle.

STORE EQUIPMENT AWAY FROM POSSIBLE IGNITION SOURCES

heaters, clothes dryers, or oil-fired furnaces, portable

heaters, etc.

engine free of debris build-up.

OPERA

restricted to mature and properly instructed individuals

TION OF EQ

.

ting engine, make sure stringhead

, such as gas-po

UIPMENT should alw

, stand belo

2-2. WHAT NOT TO DO

1.

2. DO NOT SMOKE while refueling or operating equip-

3. DO NOT OPERATE UNIT WITHOUT A MUFFLER

4. DO NOT TOUCH or let your hands or body come in

5. DO NOT OPERATE UNIT IN AWKWARD POSI-

6. DO NOT RAISE STRINGHEAD above ground level

7. DO NOT USE UNIT FOR ANY PURPOSES OTHER

8. DO NOT OPERATE UNIT FOR PROLONGED PERI-

9. DO NOT OPERATE UNIT WHEN TIRED, ILL OR

10. DO NOT OPERATE UNIT UNLESS DEBRIS SHIELD

11. DO NOT ADD, REMOVE OR ALTER ANY COM-

-

12. DO NOT operate your unit near or around flammable

13.

DO NOT USE ANY OTHER FUEL than that rec-

ommended in your manual. Always follow

instructions in the Fuel and Lubrication section of this

manual. Never use gasoline unless it is properly

mixed with 2-cycle engine lubricant. Permanent damage to engine will result, voiding manufacturer’s warranty.

ment.

and properly installed muffler shield.

contact with a hot muffler or spark plug wire.

TIONS, off balance, outstretched arms, or one-handed. Always use two hands when operating unit with

thumbs and fingers encircling the handles.

while unit is operating. Injury to operator could result.

than trimming lawn or garden areas.

ODS. Rest periodically.

UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS OR MEDICATION.

AND/OR GUARD IS INSTALLED AND IN GOOD

CONDITION.

PONENTS OF THIS PRODUCT. Doing so could

cause personal injur

the manufacturer’s warranty.

liquids or gases whether in or out of doors. An explosion and/or fire ma

inside a closed room or building, breathing exhaust

fumes can kill.

DO NO

MENT. Use only Genuine McCulloch replacement par

specifically to enhance the perf

mize the safe operation of our products. Failure to do

so ma

Use only the str

not use any other cutting attachment. Use of such

hments will v

attac

could result in ser

T USE ANY O

ts and accessor

y cause poor perf

y and/or damage the unit v

y result. Never start or run the unit

THER CUTTING A

, which are designed

ies

mance and maxi

or

ormance and possible injury.

inghead supplied with this product.

oid your factory warranty

.

ious bodily injur

y

oiding

TT

A

CH

Do

and

-

-

Page 4

2 - SAFETY PRECAUTIONS 3 - ASSEMBLY INSTRUCTIONS

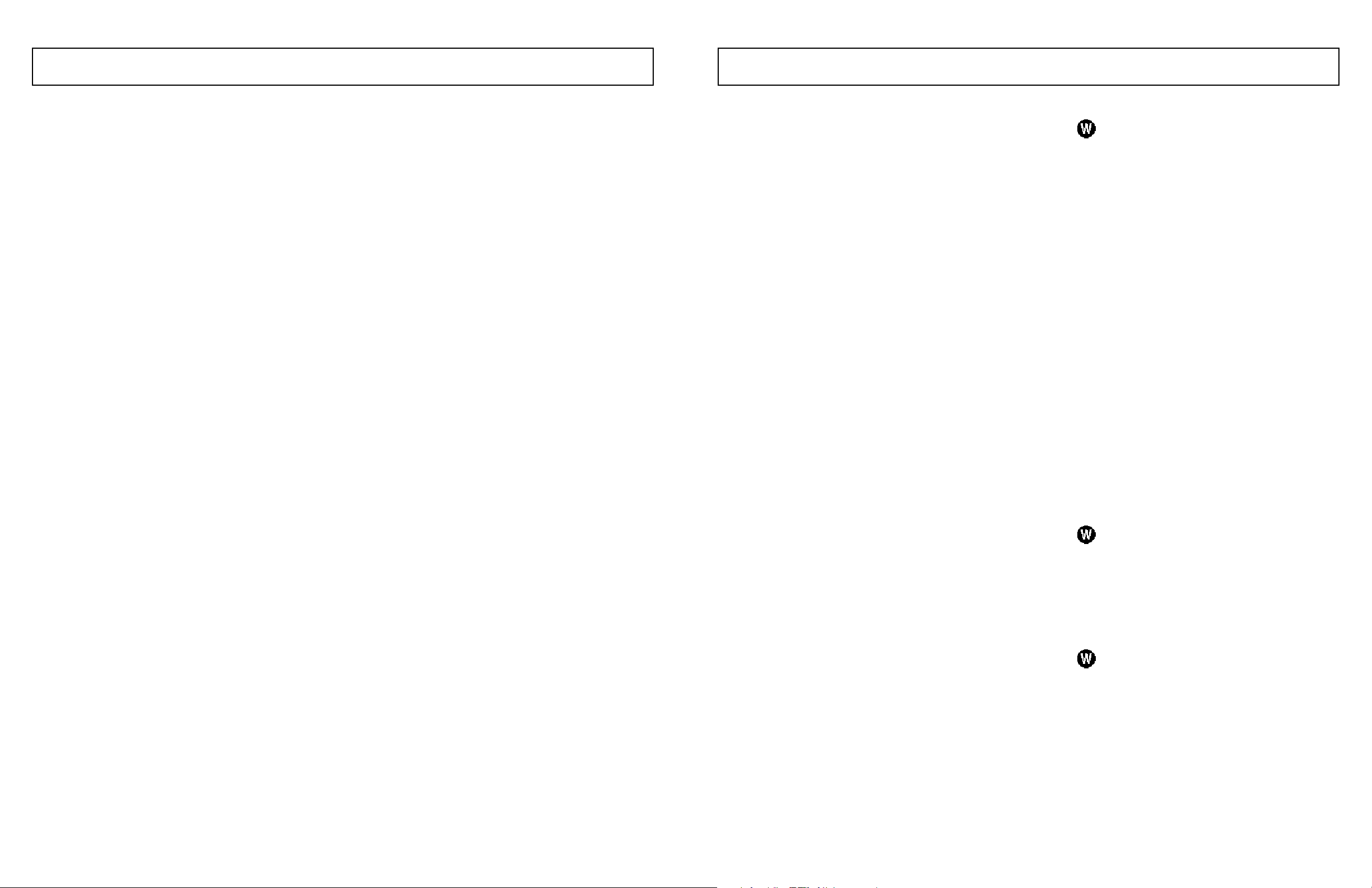

2-3. INTERNATIONAL SYMBOLS

Minimum operating distance

Use of these personal safety items is highly recommended to

reduce the risk of accidental injury.

Read the User Manual.

Do not use blade on this unit.

3-1. “P” HANDLE ASSEMBLY

1. To install handle onto unit, you will need the following

components from your user kit: “P” handle (A & B),

screws (C) and nuts (D). (Figure 3-1).

2. Install the handle (B) on the shaft 6.0” to 7.87” (160200mm) from throttle and tighten the 2 screws (C) and

nuts (D).

A

C

B

D

3-1A

3-2. DEBRIS SHIELD

F

E

D

C

3-2B

Pump the primer bulb 10 times.

WARNING

The debris shield must be installed (Figure 3-2A) to properly dispense cutter line and protect operator.

Shield fits snug on shaft. Some force may be required.

1. Seat shield (A) onto shaft bracket (B). (Fig. 3-2A)

2. Insert bolt (C), washer (D), lock washer (E) and wing

nut (F), tighten securely. (Fig. 3-2B)

B

A

3-2A

6 7

Page 5

4 - FUEL AND LUBRICATION

5 - OPERATING INSTRUCTIONS

4-1. FUEL

Use regular grade unleaded gasoline mixed with Genuine

McCulloch 40:1 2-cycle engine oil for best results. Use mix-

atios in Section 5-3.

ing r

Never use straight gasoline in your unit. This will

cause permanent engine damage and void the manufacturer’s warranty for that product. Never use a fuel mixture that has been stored for over 90 days.

If 2-cycle lubricant other than Genuine McCulloch

Lubricant is to be used, it must be a premium grade

oil for 2-cycle air cooled engines mixed at a 40:1 ratio. Do

not use any 2-cycle oil product with a recommended mixing ratio of 100:1. If insufficient lubrication is the cause of

engine damage, it voids the manufacturer’s engine warranty.

4-2. MIXING FUEL

Add oil to an approved fuel container followed by the gasoline to allow incoming gasoline to mix with oil. Shake container to ensure thorough mix.

Lack of lubrication voids engine warranty. Gasoline

and oil must be mixed at 40:1.

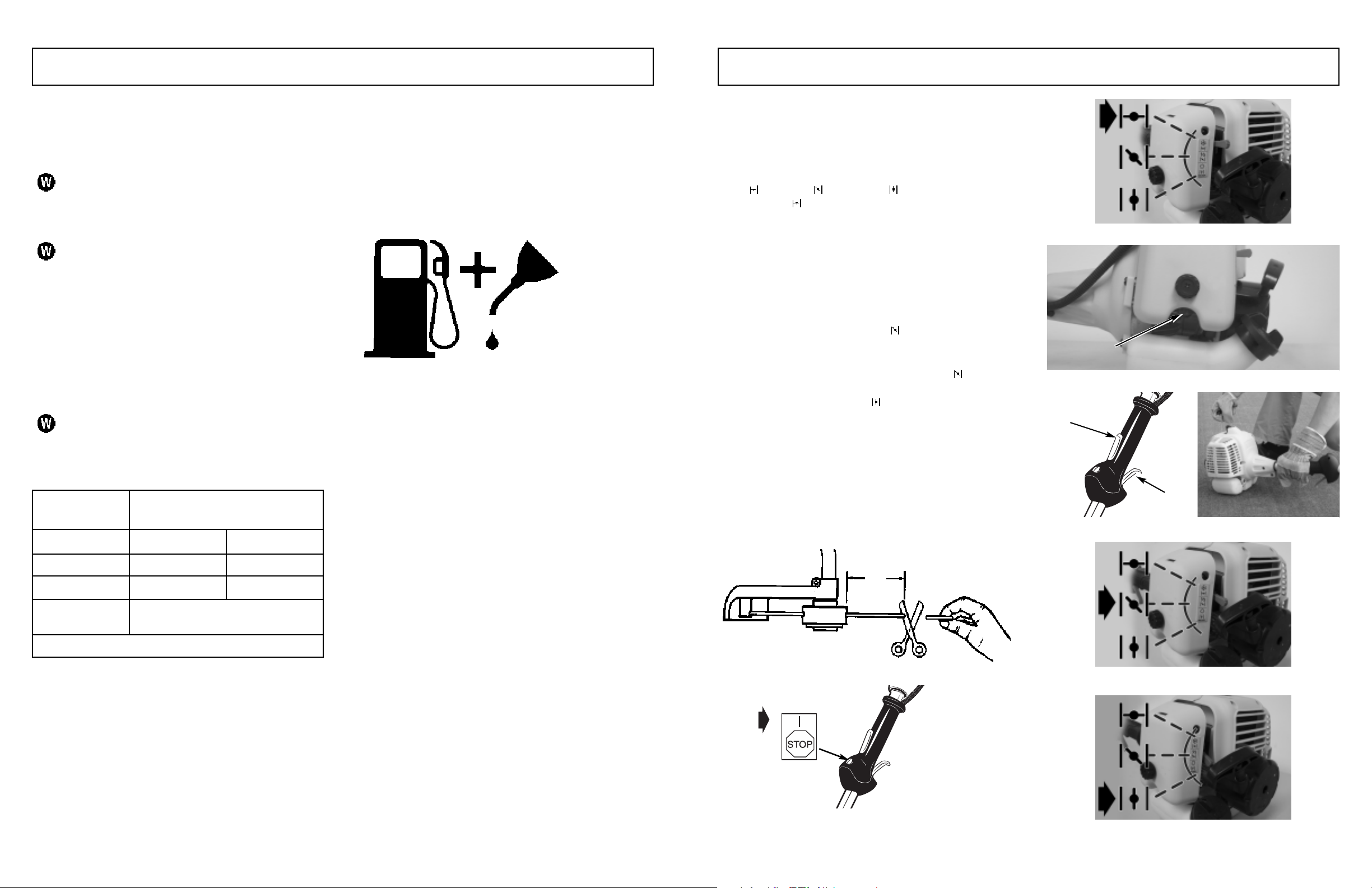

4-3. FUEL MIXING TABLE

GASOLINE

McCulloch 40:1 Ratio

Lubricant

1 U.S. Gal. 3.2 oz. 95ml (cc)

4-4. RECOMMENDED FUELS

Some con

genates such as alcohol or an ether compound to meet

clean air standards

operate satisfactorily on any gasoline intended for automotive use including oxygenated gasolines.

ventional gasolines are being blended with oxy-

. Your McCulloch engine is designed to

4-5. FUEL AND LUBRICATION SYMBOLS

Gasoline and Oil

Mix 40:1

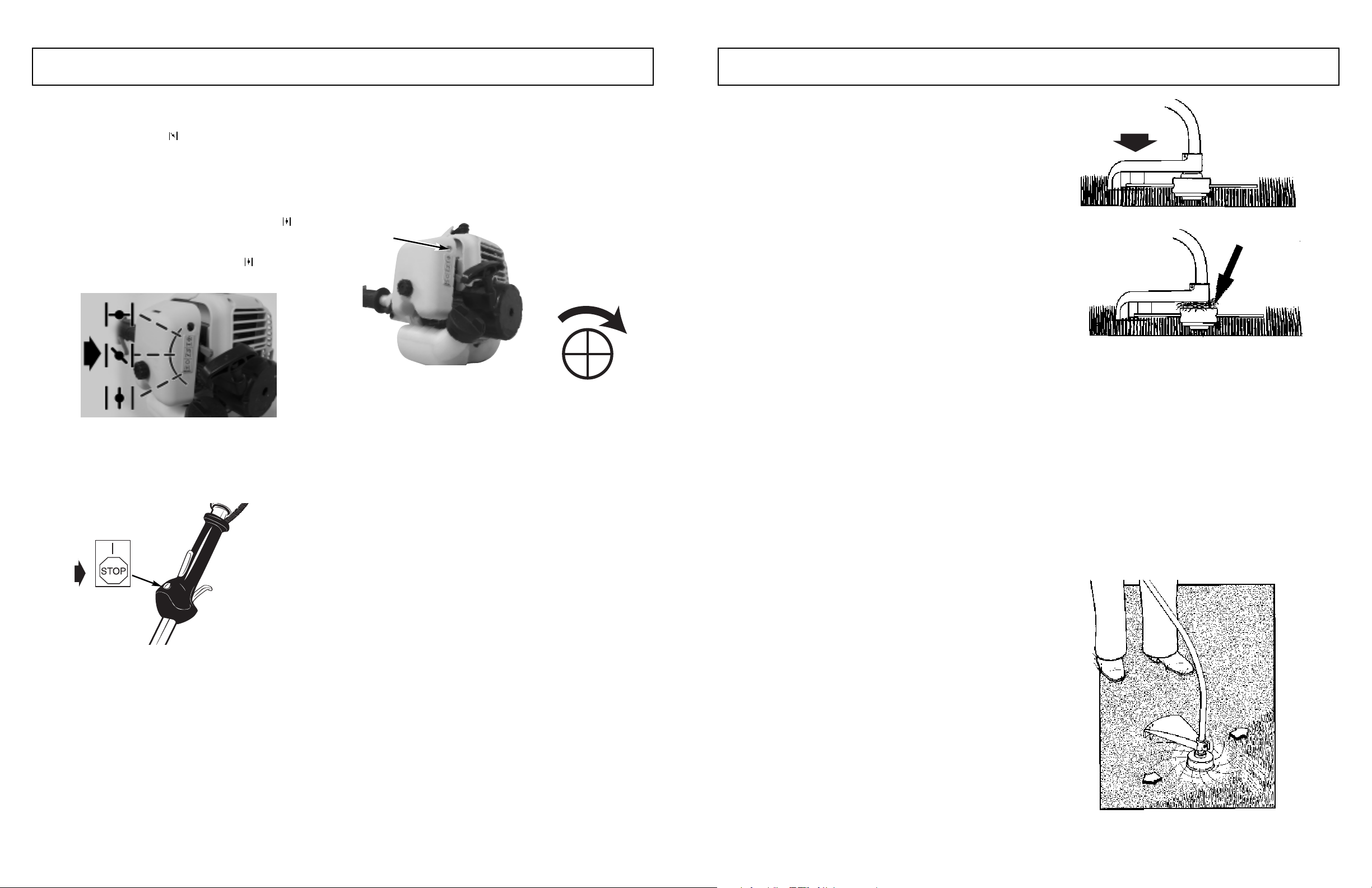

5-1. STARTING A COLD ENGINE

NOTE: To minimize load on engine during starting and

arm-up, trim excess cutting line to 5” (13cm) (Fig. 5-1A).

w

1. Move ignition switch to the “RUN (I)” position (Fig. 51B).

2. Your unit is designed with a 3 position choke: CHOKE

“ ”, START “ ”, and RUN “ ”. Move choke lever to

CHOKE “ ” position (Fig. 5-1C).

3. Prime the carburetor. Pump the primer bulb (A) 10

times (Fig. 5-1D).

4. Grip handle firmly – depress safety trigger (B) & throttle trigger (C) to the FULL THROTTLE position (Fig. 51E).

5. Pull starter rope until resistance is felt (about 4”) (Fig.

5-1F). A smooth rapid pull is required for a strong

spark. Pull starter rope briskly 4 times.

6. Move choke lever to START “ ” position (Fig. 5-1G).

7. Pull starter rope again 4 times while trigger is in the

full throttle position.

8. Once engine starts, leave in the START “ ” position

for 10 seconds.

9. Move the choke to RUN “ ” position (Fig. 5-1H).

10. If engine fails to start, repeat steps 1 through 9.

NOTE: If engine fails to start after repeated attempts, refer

to trouble shooting section.

NOTE: Always pull starter rope straight out. Pulling starter

at an angle will cause rope to rub against the eyelet. This

friction will cause the rope to fray and wear more quickly.

Always hold starter handle when rope retracts. Never allow

rope to snap back from extended position.This could cause

rope to snag or fray and also damage the starter assembly.

5-1C

A

5-1D

B

C

5-1E

5-1F

5 Liters 4.3 oz. 125ml (cc)

1 lmp. Gal. 4.3 oz. 125ml (cc)

Mixing

Procedure

40 Parts Gasoline to

1 Part Lubricant

1ml=1cc

5" (13cm)

5-1A

5-1B

8 9

5-1G

5-1H

Page 6

5 - OPERATING INSTRUCTIONS

6 - TRIMMING INSTRUCTIONS

5-2. WARM ENGINE START

1. Move ignition switch to the “RUN (I)” position.

2. Place choke in START “ ” position (Fig. 5-2).

3. Grasp throttle handle firmly, squeeze throttle trigger to

FULL position.

4. Pull starter rope briskly until engine starts, but no more

than 6 times. Keep throttle at FULL position until engine

runs smoothly.

5. If engine does not start, place choke in RUN “ ” position and pull starter rope 5 more times. If engine still

does not start it is probably flooded. Wait 5 minutes and

repeat procedure with choke in RUN “ ” position and

throttle full open.

5-2

5-3. TO STOP ENGINE

Release throttle trigger. Let engine return to idle. Move

switch to “STOP” position. (Fig. 5-3)

5-3

5-4. IDLING/CARBURETOR ADJUSTMENT

1. Occasionally, due to atmospheric conditions such as

altitude it might be necessary to make slight adjustment

to idle speed.

2. Insert phillips or flat screwdriver into access hole A (figure 5-4A). Turn 1/8 turn clockwise to increase idle

speed and 1/8 turn counterclockwise to decrease idle

speed. WARNING: String head should not move at idle.

A

6-4A

6-1. ADDITIONAL SAFETY PRECAUTIONS

ore operating your unit, review ALL SAFETY PRECAU-

Bef

TIONS in this manual.

WARNING / CAUTION

• IF UNFAMILIAR WITH TRIMMING techniques, practice the procedures with ENGINE in “OFF” position.

• ALWAYS CLEAR WORK area of debris such as cans,

bottles, rocks, etc. Striking objects can cause serious

injury to operator or bystanders and also damage

equipment. If an object is accidentally hit, immediately

TURN ENGINE OFF and examine equipment. Never

operate unit with damaged or defective equipment.

• ALWAYS TRIM OR CUT AT HIGH ENGINE SPEEDS.

Do not run engine slowly at start or during trimming

operations.

• DO NOT use equipment for purposes other than trimming or mowing weeds.

• NEVER raise stringhead above knee height during

operation.

• DO NOT operate unit with other people or animals in

the immediate vicinity. Allow a minimum of 50 feet (15

meters) between operator and other people and animals when trimming or mowing. Allow a distance of

100 feet (30 meters) between operator and other people and animals when SCALPING with stringhead cutter.

• IF OPERATING UNIT ON A SLOPE, stand below the

cutting attachment. DO NOT OPERATE on a slope or

hilly incline if there is the slightest chance of slipping

or losing your footing.

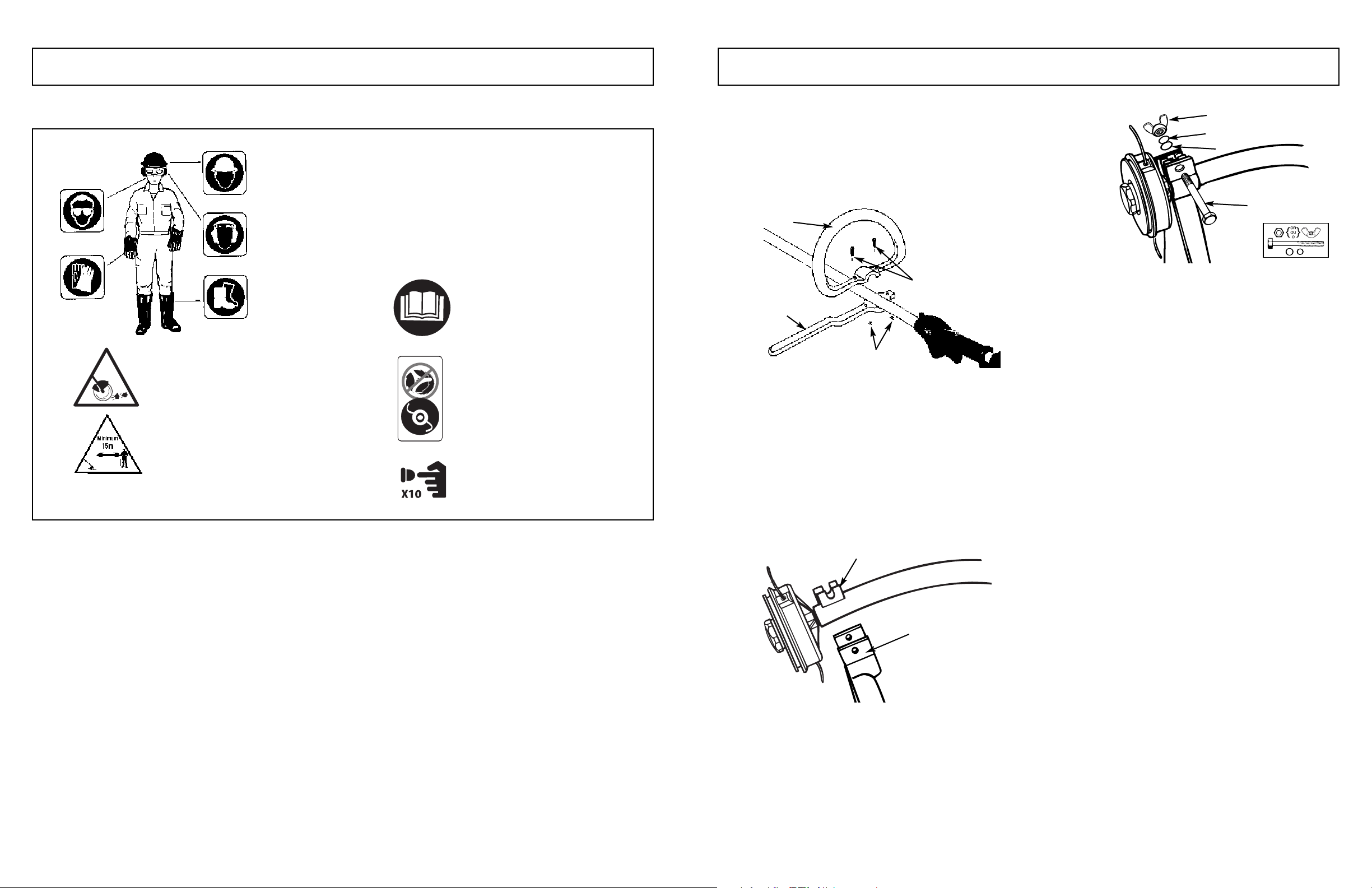

6-2. STRINGHEAD LINE RELEASE

WARNING / CAUTION

DO NOT use steel wire or plastic-coated steel wire of any

ious operator injury can

kind with y

result.

To release fresh line, run engine at full throttle and “bump”

inghead against la

str

The knif

our str

e in debr

inghead.

wn.

is shield will tr

Ser

Line will automatically release

xcess line (Figure 6-2A).

im e

CAUTION

Be sure engine is off and string head has stopped before

attempting to remove weeds wrapped around the shaft.

iodically w

er

P

need to be removed or they will prevent the shaft from

being properly cooled and could result in damage. Use a

sharp object like a screw driver to remove them. (Fig. 6-2B)

eeds will wrap around the shaft. They will

BUMP

6-2A

6-2B

6-3. TRIMMING PROCEDURES

When properly equipped with a debris shield and stringhead, your unit will trim weeds and tall grass in those hardto-reach areas - along fences, walls, foundations and

around trees. It can also be used for scalping to remove

vegetation down to the ground for easier preparation of a

garden or to clean out a particular area.

NOTE: Trimming around foundations, brick or stone walls,

curves, etc., will result in above normal string wear.

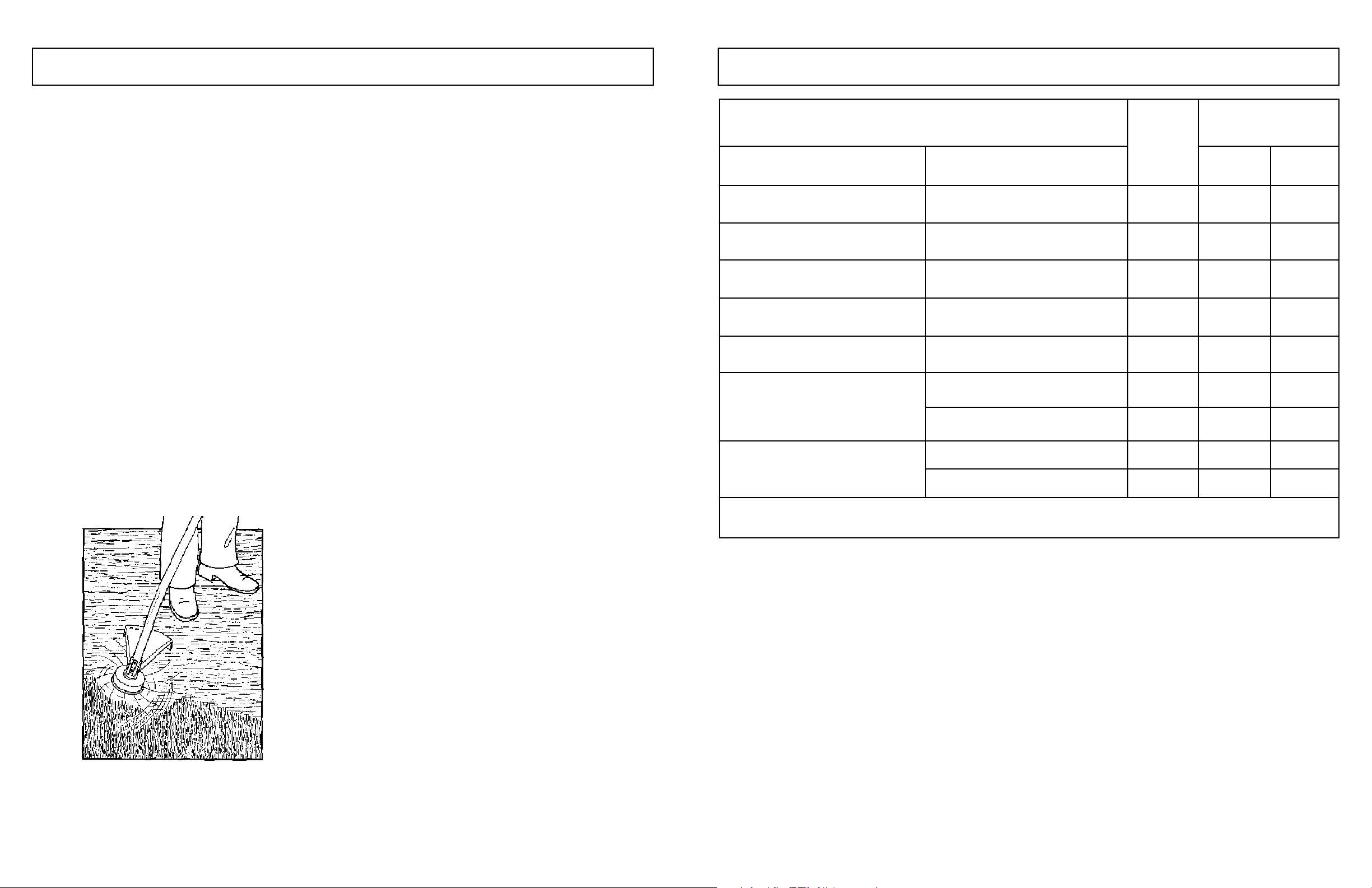

TRIMMING / MOWING

Swing trimmer from side to side. Do not tilt the stringhead

during the procedure. Test area to be trimmed for proper

cutting height. Keep stringhead at same level for even

depth of cut (Figure 6-3A).

.

10 11

6-3A

Page 7

6 - TRIMMING INSTRUCTIONS

7 - MAINTENANCE INSTRUCTIONS

CLOSER TRIMMING

osition trimmer straight ahead with a slight tilt so bottom

P

of stringhead is above ground level and string contact

occurs at proper cutting point. Always cut away from operator. Do not pull trimmer in toward operator.

FENCE / FOUNDATION TRIMMING

Approach trimming around chain link fences, picket fences,

rock walls and foundations slowly to cut close without whipping string against the barrier. If the string comes in contact

with rock, brick walls, or foundations, it will break or fray. If

string snags fencing, it will snap off.

TRIMMING AROUND TREES

Trim around tree trunks with a slow approach so string

does not contact bark. Walk around the tree trimming from

left to right. Approach grass or weeds with the tip of the

string and tilt stringhead slightly forward.

WARNING

Use extreme caution when SCALPING. Keep a distance of

100 feet (30 meters) between operator, other people and

animals during these operations.

SCALPING

Scalping refers to removal of all vegetation down to the

ground. To do this, tilt the stringhead to about a 30 degree

angle to the left. By adjusting the handle you will have better control during this operation. Do not attempt this procedure if there is any chance flying debris could injure operator, other people or cause damage to property (Figure 63B).

WARNING

DO NOT SWEEP WITH TRIMMER

Sweeping refers to tilting stringhead to sweep away debris

from walkways, etc. Your trimmer is a powerful tool and

small stones or other such debris may be hurled 50 feet (15

meters) or more, causing injury or damage to nearby property such as automobiles, homes and windows.

MAINTENANCE CHECKLIST

CH USE

EA

ITEM ACTION 10 20

SCREWS / NUTS / BOLTS INSPECT / TIGHTEN

AIR FILTER CLEAN OR REPLACE

FUEL FILTER REPLACE

SPARK PLUG CLEAN / ADJUST / REPLACE

SPARK ARRESTER SCREEN CLEAN OR REPLACE

INSPECT

FUEL HOSES

*REPLACE AS REQUIRED

INSPECT

STRINGHEAD

*REPLACE AS REQUIRED

* Recommended maintenance by an McCulloch authorized service center technician using Genuine Factory McCulloch

Replacement parts.

✔

✔

✔

✔

HOURS OF

OPERATION

✔

✔

✔

6-3B

12 13

Page 8

7 - MAINTENANCE INSTRUCTIONS

7 - MAINTENANCE INSTRUCTIONS

7-1. REPLACING CUTTING LINE

1. Turn knob (A) COUNTERCLOCKWISE and remove

(Figure 7-1A).

2. Remove spool (B) and spring (C) from spindle (D).

3. Remove any remaining cutting line (H).

4. Fold over evenly a 14' (4.3m) length of .095 or .080"

(.24 or .20cm) cutting line. Place the looped center in

one of the slots (G) of the spool divider (Figure 7-1B).

5. Wind cutting line clockwise as shown in illustration

(Figure 7-1C), keeping tension, with each half separated by the spool divider. Wind to within 6" (15cm) of

the ends.

6. Lock each end of line into a slot (F) on opposite sides

of the spool (Figure 7-1D).

7. Install the spring (C) over the spindle (D). Insert each

end of the line through an eyelet (G) in the housing (E)

(Figure 7-1E).

8. Lower the spool into the housing (E) while feeding the

line through the eyelets (G). Ensure the spring seats

itself into the spool (Figure 7-1E).

9. Once the spool is in place, apply pressure on the

spool compressing the spring. Pull each end of the

line (H) sharply to unlock the line from the slots

(Figure 7-1F).

10. Continue to apply pressure to the spool until the knob

can be threaded CLOCKWISE onto the spindle.

Tighten the knob securely by hand only (Figure 7-1G).

11. Trim the excess line to approximately 5" (13cm). This

will minimize load on engine during starting and

warm-up (Figure 7-1H).

7-2. AIR FILTER

CAUTION

NEVER oper

must be kept clean. If it becomes damaged, install a new filter.

To Clean Air Filter:

1. Remove knob (A) holding air filter cover in place,

remove cover (B) and lift filter (C) from air box (Figure

F

7-1D

G

7-2A).

2. Wash filter in soap and water. DO NOT USE GASO-

LINE!

3. Air dry filter.

4. Reinstall filter.

NOTE: Replace filter if frayed, torn, damaged or unable to

be cleaned.

ate trimmer without the air filter. The air filter

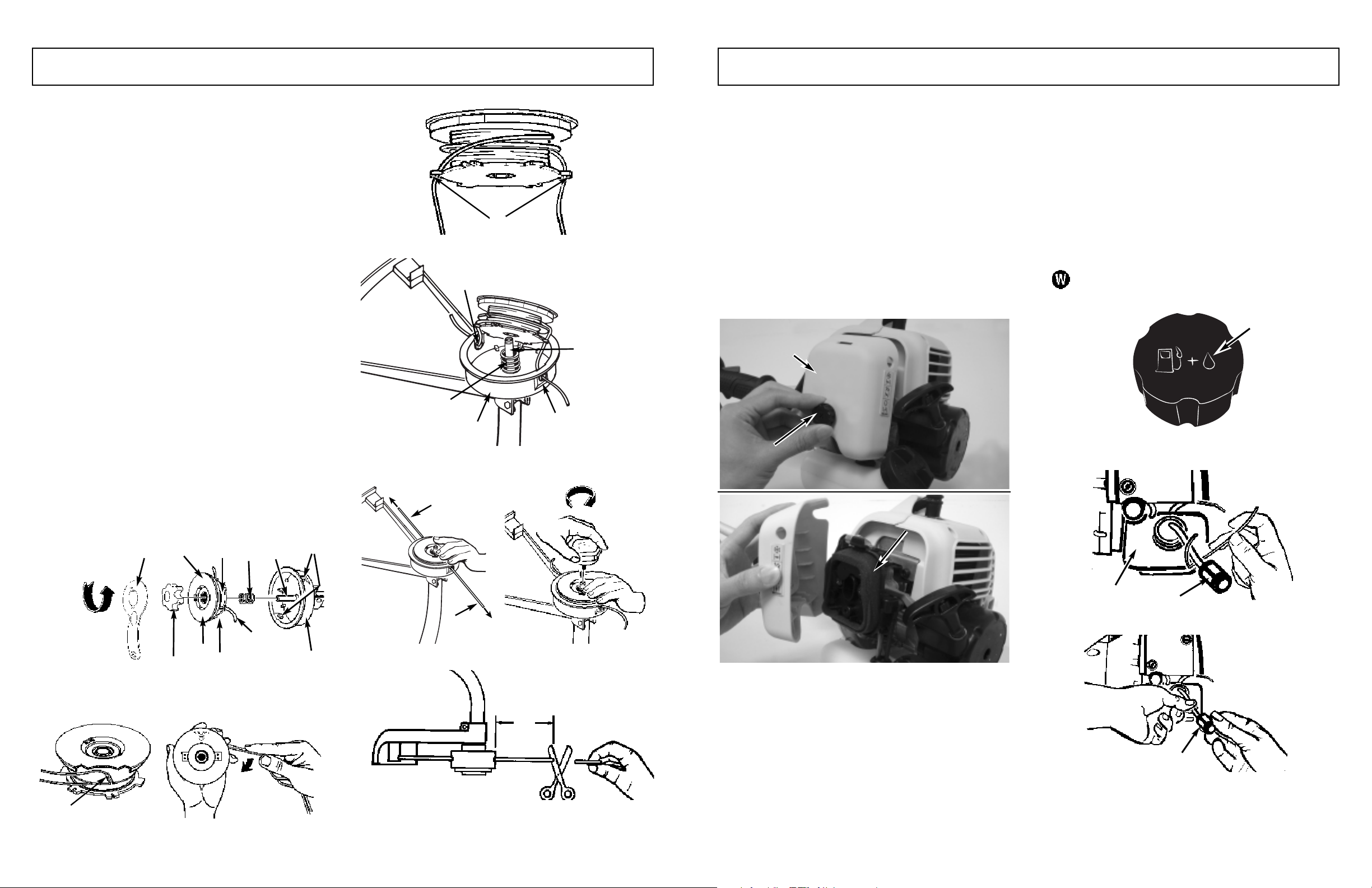

7-3. FUEL CAP / FUEL FILTER

CAUTION

ve fuel from unit and store in approved container

Remo

before starting this procedure. Open fuel cap slowly to

release any pressure which may have formed in fuel tank.

NOTE: Keep vent (A) on fuel cap clean of debris (Figure 73A).

Fuel Filter:

1. Completely remove fuel cap from fuel tank (B) to be

able to remove fuel filter (C) from tank. (Figure 7-3B)

2. Pull filter (D) off with a twisting motion. (Figure 7-3C)

3. Replace fuel filter (D). (Figure 7-3C)

NOTE: Never operate the trimmer without the fuel filter. Internal engine damage could result!

A

D

C

E

7-1E

H

G

B

A

7-3A

C

KNOB

A.

B.SPOOL

C.SPRING

D.SPINDLE

HOUSING

E.

F. SLOTS

G.EYELETS

H.CUTTING LINE

J. WRENCH

G

7-1B

J

H

F

D

C

G

B

H

C

7-3B

H

A

7-1A

B

F

E

7-1F 7-1G

7-2A

5"

(13mm)

D

7-3C

7-1H

7-1C

14 15

Page 9

7 - MAINTENANCE INSTRUCTIONS 8 - TROUBLESHOOTING THE ENGINE

7-4. CARBURETOR ADJUSTMENT

The carburetor was pre-set at the factory for optimum performance.The only adjustment should be to idle speed see

section 5-4, Idling/Carburetor adjustment.

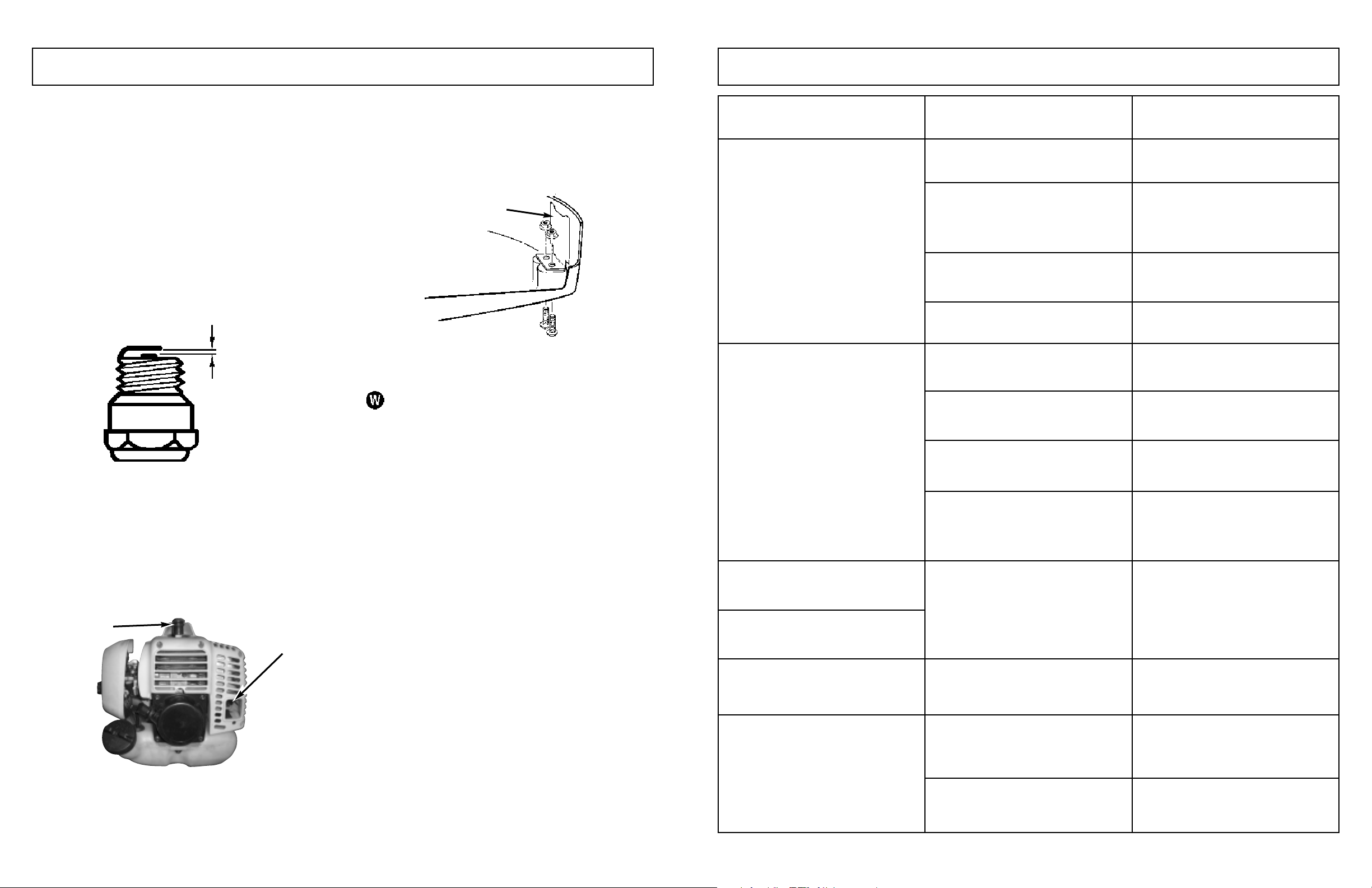

7-5. SPARK PLUG

1. To remove spark plug B (figure 7-6A) for cleaning or

replacement: make sure engine is off, spark plug is cool

then grasp spark plug boot firmly and remove from

spark plug. Remove spark plug with correct spark plug

tool. Inspect, clean or replace as needed.

2. Spark plug gap = .025" (.635mm) (Figure 7-5A).

3. Torque to 105 to 130 inch pounds (12 to 15 N•m).

Connect spark plug boot.

If necessary, replace with Champion RZ7C or equiva-

4.

lent.

.025" (.635mm)

7-5A

7-6. SPARK ARRESTER SCREEN

1. To replace spark arrester screen (A) (Figure 7-6A), use

a needle nose pliers, pinch an edge of the spark

arrester screen. Pull the whole spark arrester screen

out.

Use the needle nose pliers to push in a ne

2.

arrester screen.Then open the pliers a little to press the

inner surf

ace of the spar

k arrester screen to fasten it.

w spar

B

A

7-6A

7-7. DEBRIS SHIELD KNIFE SHARPENING

1. Remove cutter knife (A) from debris shield (B) (Figure

7-7A).

2. Place knife in a bench vise. Sharpen knife using a flat

file, being careful to maintain the angle of cutting edge.

File in one direction only.

A

Unit won’t start or starts but will not run.

B

7-7A

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Incorrect starting procedures. Follow instructions in the User Manual.

Incorrect carburetor mixture adjustment

setting.

ouled spark plug

F

Fuel filter plugged. Replace fuel filter.

Incorrect lever position on choke. Move to RUN position.

Have carburetor adjusted by an

McCulloch Authorized Service Center.

Clean / gap or replace plug.

7-8. STORING A UNIT

Failure to follow these steps may cause varnish to

form in the carburetor and difficult starting or perma-

nent damage following storage.

1. Perform all the general maintenance recommended in

the Maintenance Section of your User Manual.

2. Clean exterior of engine, drive shaft assembly, debris

shield and stringhead.

3. Drain fuel from the fuel tank.

4. After fuel is drained, start engine.

5. Run engine at idle until unit stops. This will purge the

carburetor of fuel.

6. Allow engine to cool (approx. 5 minutes).

k

7. Using a spark plug wrench, remove the spark plug.

8. Pour 1 teaspoon of clean 2-cycle oil into the

combustion chamber. Pull starter rope slowly several

times to coat internal components. Replace spark plug.

9. Store unit in a cool, dry place away from any source of

ignition such as an oil burner, water heater, etc.

Unit starts, but engine has low power.

Engine hesitates.

No power under load.

Dirty spark arrester screen. Replace spark arrester screen.

Dirty air filter. Remove, clean and reinstall filter.

Incorrect carburetor mixture adjustment

setting.

Incorrect carburetor mixture adjustment

setting.

Have carburetor adjusted by an

McCulloch Authorized Service Center.

Have carburetor adjusted by an

McCulloch Authorized Service Center.

7-9. REMOVING A UNIT FROM STORAGE

1. Remove spark plug.

Pull star

2.

ustion chamber

b

3. Clean and gap spark plug or install a new spark plug

with proper gap

Prepare unit f

4.

5. Fill fuel tank with proper fuel / oil mixture. See Fuel and

Lubr

ter rope briskly to clear excess oil from com-

.

.

or oper

ication Section.

ation.

Runs err

Smokes excessively.

atically.

Incorrectly gapped spar

Incorrect carburetor mixture adjustment

setting.

k plug.

Clean / gap or replace plug.

Have carburetor adjusted by an

McCulloch Authorized Service Center.

Incorrect fuel mixture Use properly mixed fuel (40:1 mixture).

16 17

Page 10

9 - TROUBLESHOOTING THE STRINGHEAD 10 - ONE YEAR LIMITED WARRNATY

PROBLEM PROBABLE CAUSE SOLUTION

Line won’t feed

Line snaps off or frays.

Unab

le to remove stringhead knob.

Stringhead and shaft are hot to the

touch.

ve spool from unit; disassemble.

Remo

Line is tangled inside stringhead.

Upon removing spool, line appears to

be melted together.

Line wound in wrong direction inside

stringhead.

Insufficient line inside stringhead.

Internal damage to stringhead caused

by bumping too hard on ground while

advancing line.

Improper tr

quality line.

Str

inghead knob overtightened.

Weeds wrapped around shaft Remove weeds (see Section 6-2).

imming procedures

, or poor

Untangle line and wind correctly in

direction indicated on spool (see

Section 7-1).

Trim off damaged line and rewind line

(see Section 7-1).

Remove spool. Check to be certain line

is wound in direction indicated on line

element (see Section 7-1).

Remove spool and install new line (see

Section 7-1).

Disassemble stringhead and examine

parts for damage. Replace parts or

entire head (see Section 7-1).

imming Procedures (see section

r

T

See

6-3) or replace line (see section 7-1)

Use anti-seize compound and reinstall

knob HAND TIGHT ONLY.

1. DURATION

The duration of the warranty for this McCulloch product is as follows: ONE (1) YEAR from date of original purchase only

when used for personal, family, household, farm or ranch, purposes, provided the unit is not used for rental purposes;

NINETY (90) DAYS from date of original purchase when used for commercial, professional, institutional or rental purposes. This warranty gives you specific legal rights. You may also have other rights which vary from state to state. MCCULLOCH CORPORATION HEREBY DISCLAIMS ALL IMPLIED WARRANTIES AFTER THE APPLICABLE EXPIRATION

DATES OF THIS EXPRESS LIMITED WARRANTY. (Some states do not allow limitations on how long an implied warranty lasts, so the above limitations may not apply to you.)

2. WHO GIVES THIS WARRANTY

McCulloch U.S.A 1-800-521-8559

12802 Leffingwell Rd. Santa Fe Springs, CA90670 USA

3. WHO RECEIVES THIS WARRANTY

A. The buyer (other than for purposes of resale) of the McCulloch Product.

B. Any person to whom such product is lawfully transferred within the duration of the implied or written warranty applica-

ble to the product.

C. Any other person who is entitled by the terms of the warranty or under applicable state law to enforce against the

Warrantor the obligation of the warranty.

(The above mentioned parties are hereinafter referred to as “User.”)

4. WHAT IS COVERED UNDER THIS WARRANTY

Any failure that occurs within the applicable duration of the warranty period that is the result of defects in materials or workmanship. All work must be preformed by a McCulloch Authorized Service Center.

5. WHAT IS NOT COVERED UNDER THIS WARRANTY

A. Any incidental or consequential damages that may result from the failure or malfunction of the McCulloch product.

(Some states do not allow the exclusion or limitation of incidental or consequential damages, so these limitations may

not apply to you.)

B. Any failure that results from an accident, User abuse, neglect or failure to operate the product in accordance with the

instructions provided in the User Manual(s) supplied with the product, or that results from improper servicing by an

unauthorized repair facility.

C. Normal adjustments or wear items which are explained in the User Manual(s) provided with the product.

D. Any component(s) or accessories not sold or manufactured by the Warrantor.

E. Predelivery setup or assembly of units.

anty does not apply to accessories, normal maintenance, wear items or adjustment(s) of the product set

This w

.

F

f

6. RESPONSIBILITIES OF THE WARRANTOR UNDER THIS WARRANTY

A. Repair or replace components which have failed within the duration of the applicable warranty period at no cost to the

User.

. Ensure that the McCulloch Authorized Service Center is reimbursed for parts and labor costs incurred due to perform-

B

ance of a w

7. RESPONSIBILITIES OF THE USER UNDER THIS WARRANTY

A. The User must deliver or ship the McCulloch product covered under this warranty to the dealer from whom it was orig-

inally purchased or to the nearest McCulloch Authorized Service Center. Proof of purchase is required.

B. Freight costs, if any, will be borne by the user.

Use reasonable care in maintenance, operations and storage of the product as explained in the User Manual(s).

.

C

WHEN

8.

Repair of w

A.

ing on the availability of replacement parts.

B. Repair time which exceeds ten (10) days from the time the product was delivered to the service center will extend the

warranty coverage by the number of days the product remains inoperable.

. If User does not receive satisfactory results from local service center, User must contact McCulloch Corporation, by

C

calling our toll-free telephone n

arr

orth in the User Manual(s).

anty repair in accordance with estab

arr

ARRANT

W

OR WILL PERFORM OBLIGATION UNDER THIS WARRANTY

le products will be scheduled according to the nor

antab

arr

umber

anty policies and procedures

lished w

.

arr

mal w

w at the servicing location, depend-

k flo

or

.

18 19

Page 11

INTRODUCTION

MANUEL DE UTILISATION

Coupe-herbes à essence

Modèle : MCT3362VA

SECURITE

FONCTIONNEMENT

ENTRETIEN

A LIRE ATTENTIVEMENT

Cher Client,

Nous vous remercions de l’achat d’un produit McCulloch.

Correctement utilisé et entretenu, il vous procurera des

années de satisfaction.

Il est IMPERATIF que vous preniez connaissance de LA

TOTALITE de ce manuel avant d’utiliser l’outil ou de

procéder à des opérations d’entretien.

Veillez à bien suivre les instructions pas à pas données

dans le présent manuel pour démarrer, mettre en oeuvre et

maintenir votre nouveau produit en condition.

Ce manuel contient également des mises en garde et renseignements intitulés:

ATTENTION et GARANTIE.

Une REMARQUE: fournit des renseignements complé-

mentaires, éclaircit un point ou explique une étape à suivre en plus de détails.

La notice

pour identifier une procédure qui, si négligée ou incorrectement exécutée, peut entraîner des dommages matériels

et/ou corporels graves.

Le SYMBOLE DE GARANTIE indique que si les

procédures ou instructions ne sont pas respectées, les

dommages ne seront pas couverts par la garantie et les

réparations seront à la charge du propriétaire.

Les précautions de sécurité sont pour votre protection;

Veuillez les lire attentivement; vous devez connaitre ces

importants renseignements afin d’utiliser correctement

votre coupe-herbes.

POUR LA GARANTIE OU LES RÉPARATIONS, VEUILLEZ

PRENDRE CONTACT AVEC LE CENTRE DE MAINTE-

NANCE AGRÉÉ LE PLUS PROCHE DE CHEZ VOUS -

POUR SA

LE PLUS PROCHE,APPELEZ LE NUMÉRO GRATUIT

AVERTISSEMENT ou ATTENTION est utilisée

V

OIR QUEL EST LE CENTRE DE RÉPARATION

DONNÉ DANS PRÉSENT MANUEL.

REMARQUES, AVERTISSEMENT /

TABLE DES MATIERES

1 GENERALITES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

1-1. Identification des principaux

1-2. Idispositifs de securite

1-3. Caracteristiques

2

MEASURES DE SECURITE . . . . . . . . . . . . . . . . . . . . . . . . .24

2-1. Choses a faire

2-2. Choses a ne pas faire

2-3. Symboles internationaux

3 INSTRUCTIONS POUR MONTAGE . . . . . . . . . . . . . . . . . . .26

3-1. Installation de la “P” poignée

3-2. Para-debris

4 CARBURANT ET LUBRIFICATION . . . . . . . . . . . . . . . . . .27

4-1. Carburant

4-2. Melange du carburant

4-3. Tableau des proportions

4-4. Carburants recommandes

4-5. Symboles de carburant et lubrification

5 FONCTIONNEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5-1. Demarrage d’un moteur froid

5-2. Demarrage du moteur chaud

5-3. Pour arret du moteur

5-4. Idling/carburetor adjustment

6 INSTRUCTIONS POUR LA COUPE . . . . . . . . . . . . . . . . . .30

6-1. Mesures de securite supplementaires

6-2. Avance du fil de coupe

6-3. Instructions pour la coupe

7 ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7-1. Remplacement du fil de coupe

7-2. Filtre a air

7-3. Bouchon du reservoir/filtre a carburant

7-4. Reglage du carburanteur

Bougie

7-5.

7-6. Ecran pare-etincelles

7-7. Affutage de la lame pare-debris

7-8. Emmagasiner l’appareil

7-9. Preparatioon apres emmagasinage

8 DEPANNAGE DU MOTEUR . . . . . . . . . . . . . . . . . . . . . . . . .36

9 DEPANNAGE DE LA TETE DE COUPE . . . . . . . . . . . . . . .37

10 GARANTIE LIMITÉE DE UN ANNÉE . . . . . . . . . . . . . . . . .38

AVERTISSEMENT • LIRE ATTENTIVEMENT

Pour votre sécurité, lisez entièrement ce manuel avant d’utiliser votre nouvel outil. Le non respect des

instructions peut résulter en des accidents graves. Prenez quelques instants pour vous familiariser

avec le coupe-herbe avant chaque utilisation.

20

21

Page 12

1 - GENERALITES

1 - GENERALITES

1-3. CARACTERISTIQUES

Type de moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Refroidi par air, 2 temps, Cylindre Chrome

Cylindrée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26cc / 1.8ci

8

7

5

6

12

4

Poids à sec . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.78 lbs. / 4.9 kg

Capacité du réservoir de carburant . . . . . . . . . . . . . . . . . . . . . . .550 ml

PLongueur de l’arbre de transmission . . . . . . . . . . . . . . . . . . . .52” (132cm)

Largeur de coupe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17" / 43cm

Poignée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .“P” Poignée

Carburateur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Amorçage / diaphragme

Allumagea . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Electronique

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Embrayage

Puissance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.78 kW

Vitesse de rotatioin maximale . . . . . . . . . . . . . . . . . . . . . . . . . . .7600 min

Vitesse de ralenti moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3000±300 min

-1

-1

11

13

16

3

1

2

1-1.IDENTIFICATION DES PRINCIPAUX

TETE D'ALIMENT

1.

2. FIL DE COUPE*

3. PARE-DEBRIS*

ARBRE DE

4.

5. POIGNEE-P

MANETTE DES GAZ

6.

7. BOUTON DE CONTACT

8. DECLENCHEUR DE SECURITE

MANETTE DU ST

9.

10. RESERVOIR A CARBURANT

11. COUVERCLE DU FILTRE A AIR

POIGNEE DU LANCEUR

12.

13. CAPOT DU SILENCIEUX

14. POMPE D’AMORCAGE

15. PARE-ETINCELLES*

16. MATERIEL DE PROTECTION CONTRE LES

DEBRIS

REMARQ

* Inclus dans le kit de l’utilisateur

UE :

NE P

ATION DE BROUSSIN*

TRANSMISSION

ARTER

AS utiliser de lames sur ces modéles

9

15

14

10

1-2. DISPOSITIFS DE SECURITE

Pour vous permettre de localiser les dispositifs de sécurité

uméros précédente les descriptions correspondent à

les n

ceux la page précédente.

3 Le P

13 Le CAPOT DU SILENCIEUX empêche le contact des

15 Le P

REMARQ

locales

de l’utilisateur.

(Section 3) et Entretien (Section 8) pour plus de détails

.

ARE-DEBRIS doit être installé pour empêcher l’u

De plus

tilisateur

dépasser la longueur nécessaire.

mains ou de toute autre partie de corps et des

matières combustibles avec l’échappement brûlant.

bone et autres particules inflammables de plus de 0,6

mm (0,023") de l’échappement.

.

ARE-ETINCELLES empêche la projection de car-

UE :

Le respect des lois et/ou réglementations

, d’état ou gouvernementales est la

, il empêche le fil de coupe de

responsabilité

oir les sections Mesures de Sécur

V

-

ité

.

2322

Page 13

3 - MEASURES DE SECURITE 3 - MEASURES DE SECURITE

2-1. CHOSES A FAIRE

LIRE LE MANUEL D’UTILISATION ET (LE CAS

ECHEANT) TOUS LES SUPPLEMENTS AVANT D’UTILISER LE COUPE-HERBE.

1. HABILLAGE - Portez toujours des pantalons longs,

des bottes lourdes, des gants et une chemise à

manche longue. Ne portez jamais de vêtements flottants, de bijoux, des shorts, des sandales et ne soyez

jamais pieds nus. Sécurisez les cheveux afin qu'ils ne

retombent jamais sur vos épaules. Portez toujours un

casque rigide, une protection faciale ou des lunettes

de sécurité avec des bouchons pour les oreilles pour

vous protéger du bruit.

2. REMPLISSAGE DU FUEL - Mélangez et versez le

fuel en extérieur dans un endroit sans étincelle ni

flammes. Enlevez doucement le capuchon du fuel

seulement après arrêté le moteur. Ne fumez pas tout

en rempissant avec du fuel ou en mélageant le fuel.

Frottez le fuel repandu depuis l'unité. Eloignez-vous

d'au moins 9 m depuis la source de fuel (bouteille de

gaz) avant de faire demarre l'unité.

3. RESPECTER TOUTES LES REGLEMENTATIONS

DE PREVENTION D’INCENDIES. LA CONFORMITE

AVEC LES LOIS ET/OU REGLEMENTATIONS

LOCALES, D’ETAT OU GOUVERNEMENTALES EST

LA RESPONSABILITE DE L’UTILISATEUR. Un pareétincelles est inclus dans le kit de l’utilisateur livré

avec le coupe-herbe. Des kits de remplacement de

l’écran pare-étincelles sont disponibles auprès de

votre Centre de réparation McCulloch agréé, dont

vous trouverez le numéro de téléphone sous la

rubrique «SCIES» des pages jaunes de l’annuaire.

4. ARRETER LE MOTEUR avant de poser l’outil.

5. TOUJOURS TENIR FERMEMENT L’OUTIL DES

DEUX MAINS, le pouce et les doigts encerclant les

poignées.

6. VEILLER A CE QUE TOUTES LES VIS ET PIECES

DE FIXA

utiliser l’outil s’il n’est pas correctement réglé et

solidement assemblé.

VEILLER A CE Q

7.

PRES

GARDER LA

8.

SOL QUE POSSIBLE. Eviter de heurter de petits

objets avec la tête de coupe. Sur un terrain incliné, se

placer en aval de la tête de coupe.

VERIFIER

9.

DEBRIS EVENTUELS qui pourraient être heurtés ou

projetés.

10. GARDER TOUTES LES PARTIES DES VETEMENTS

OU DU CORPS A L’ECART DE LA TETE DE COUPE

lorsque le moteur tourne. Avant de faire démarrer le

moteur, s’assurer que la tête de coupe ne risque pas

de heurter des obstacles.

11. ARRETER LE MOTEUR avant d’examiner le fil de

coupe.

12. ENTREPOSER L’EQUIPEMENT A L’ECART DES

SOURCES D’ALLUMAGE telles que chauffe-eau à

gaz, séchoirs à linge, chaudières à mazout, radiateurs

por

TION SOIENT BIEN SERREES. Ne jamais

UE LES POIGNEES SOIENT PRO-

, sèches et non souillées de carb

TETE DE COUPE A

VOTRE LIEU DE TRAVAIL POUR TOUS

, etc.

tatifs

ur

USSI PRES DU

ant.

13. GARDER TOUJOURS le pare-débris, la tête de

coupe et le moteur exempt de débris.

14. L’USAGE DE L’EQUIPEMENT doit être exclusivement

confié à des personnes mûres familiarisées avec son

fonctionnement.

2-2. CHOSES A NE PAS FAIRE

1. NE PAS UTILISER DE CARBURANT AUTRE

que celui recommandé dans le manuel. Se conformer aux instructions de la section Carburant et

lubrification. Ne jamais utiliser d’essence qui n’est pas

mélangée à de l’huile pour moteur à 2 temps, ce qui

causerait des dommages irréparables au moteur et

entraînerait l’annulation de la garantie du fabricant.

2. NE PAS FUMER lors de l’approvisionnement en carburant ou pendant l’utilisation de l’outil.

3. NE PAS UTILISER L’OUTIL NON POURVU DU

SILENCIEUX ou du capot silencieux correctement

installés.

4. NE PAS TOUCHER ou laisser les mains ou une autre

partie du corps entrer en contact avec l’échappement

chaud ou le fil de la bougie.

5. NE PAS UTILISER L’OUTIL EN POSITION DE DESEQUILIBRE, les bras tendus ou d’une seule main.

Toujours le maintenir fermement des deux mains, les

doigts et le pouce encerclant les poignées.

6. NE PAS SOULEVER LA TETE DE COUPE au-dessus

du niveau du sol pendant le fonctionnement de l’appareil (l’utilisateur pourrait se blesser).

7. N’UTILISER L’APPAREIL que pour les bordures de

gazon et des sections de jardins.

8. NE PAS UTILISER L’OUTIL PENDANT DES PERIODES PROLONGEES sans le laisser refroidir de

temps à autre.

9. N’OPEREZ PAS L’UNITE EN ETANT FATIGUE,

MALADE OU SOUS INFLUENCE DE L’ALCOOL OU

DES MEDICAMENTS.

10. N’UTILISER L’OUTIL QUE SI LE PARE-DEBRIS EST

CORRECTEMENT INSTALLE ET EN BON ETAT.

11. NE MODIFIER OU RETIRER AUCUNE PIECE

OU COMPOSANT DE CE PRODUIT. Ceci pour-

rait causer des dommages corporels et/ou matériels

icant.

aîner l’ann

et entr

12. A l’extérieur ou à l’intérieur, NE PAS UTILISER votre

l’outil près de tout produit inflammable (liquides,

gas…).

une picèce renfermée ou un immeuble, car respirer de

la fumée peut tuer.

13. NE PAS UTILISER D’AUTRES ACCESSOIRES

accessoires de rechange McCulloch spécifiquement

conçus pour augmenter le rendement et maximiser la

durée de fonctionnement de nos produits. Ne pas

respecter cette recommandation peut causer de mauvais rendements et des blessures. N’utiliser que la

tête de coupe f

d’autres accessoires de coupe. L’utilisation de tels

accessoires annulera la garantie de l’usine et ris-

quera de causer des blessures corporelles graves.

Ne f

DE COUPE.

ulation de la gar

aítes jamais démarrer ni n’opérez dans

N’utiliser que des pièces et que des

ec ce produit.

v

nie a

our

antie du f

abr

Ne pas utiliser

2-3. SYMBOLES INTERNATIONAUX

Distance minimale d’opération.

L’utilisation des ces dispostifs de sécurité est foretement

recommandé afim de réduire tout risque de blessures

accidentelles.

Lire le manuel d’utilisation.

Ne pas utiliser de lames sur ce

modèle.

Appuyer 10 fois sur la pompe

d’amorçage.

2524

Page 14

3 - INSTRUCTIONS POUR MONTAGE

4 - CARBURANT ET LUBRIFICATION

3-1. INSTALLATION DE LA “P” POIGNÉE

1. Pour installer la poignée sur l'unité, vous aurez besoin

des composants suivants de votre kit utilisateur :

Poignée “P” (A & B), vis (C) et écrous (D). (Fig. 3-1)

2. Installez la poignée P (B) sur l'axe et suivez la flèche

sur l'autocollant (étiquette de mise en garde E ), placer

la poignée (A) et serrez les deux vis (C) et écrous (D).

A

C

B

D

3-1A

3-2. PARA-DEBRIS

AVERTISSEMENT

Le pare-débis doit être installé (Fig. 3-2A) pour assurer une

bonne distribution du fil de coupe et assurer la protection

de l’operateur.

L’écran s’adapte fermement sur l’arbre. Une certaine force

peut être requise.

1. Fiare reposer l’écran (B) sur les supports de l’arbre

(C). (Fig. 3-2A)

2. Insérez le boulon (D), la rondelle (E), la rondelle de

errouillage (F) et l'écrou (G), puis serrez fermement.

v

(Fig. 3-2B)

3-2B

F

E

D

C

4-1. CARBURANT

Utilisez un mélange d'essence sans plomb standard et

d'huile moteur deux temps Genuine McCulloch 40:1

Custom.

la Section 4-3.

l’annulation de la garantie du fabricant. Ne jamais utiliser

un mélange entreposé depuis plus de 90 jours.

sable que ce soit une huile de qualité supérieure pour

moteur à deux temps à refroidissement par air mélangée

selon une proportion de 40:1. N'utilisez pas d'huile deux

temps dont la proportion de mélange recommandée est de

100:1. En cas de dommages causés au moteur du fait

d'une lubrification insuffisante, la garantie moteur du fabricant est annulée.

Utilisez les proportions de mélange données dans

Ne jamais utiliser d’essence pure dans cet outil. Ceci

causerait des dommages irréparables et entraînerait

Si vous utilisez un lubrifiant deux temps autre qu'un

lubrifiant Genuine McCulloch Custom, il est indispen-

4-4. CARBURANTS RECOMMANDES

Certains carburants conventionnels sont mélangés avec

des oxydisants tels l’acool ou l’éther afin de se conformer

aux standards pour la pureté de l’air. Votre moteur

McCulloch est conçu de manière à pouvoir utiliser toute

essence pour automobile carburants avec oxydisants

inclus, tout en vous procurant un fonctionnement satisfaisant.

4-5. SYMBOLES DE CARBURANT ET LUBRI-

FICATION

Gasoline and Oil

Mix 40:1

4-2. MELANGE DU CARBURANT

Mélangez le carburant avec une huile deux temps Genuine

McCulloch placée dans un conteneur agréé. Utilisez le

tableau desmélanges pour les proportions correctes carburant/huile. Secouez le conteneur pour assurer un bon

mélange.

Un manque de lubrifiant annule le garantie de moteur.

4-3. TABLEAU DES PROPORTIONS

ESSENCE

Lubrifiant Spécial

McCulloch à 40:1

1 U.S. Gal. 3,2 oz. 95ml (cc)

5 Liters 4,3 oz. 125ml (cc)

B

3-2A

1 lmp. Gal. 4,3 oz. 125ml (cc)

Proportions

de Mélange

40 volumes d’Essence pour

un Volume d’Huile

1ml=1cc

A

2726

Page 15

5 - FONCTIONNEMENT

5 - FONCTIONNEMENT

5-1. DEMARRAGE D’UN MOTEUR FROID

REMARQUE : Pour minimiser la charge su le moteur pendant le démarr

à 13cm (5") (Fig. 5-1A).

Mettre le contact en position de MARCHE «I » (Fig. 5-

1.

1B).

2. Votre unité est conçue avec 3 positions des gaz :

PLEIN GAZ « », PARTIEL « », et DEMARRAGE

« ».Déplacer le régulateur des gaz vers la position

PLEIN GAZ « »(Fig. 5-1C).

3. Amorcer le carburateur. Appuyer 10 fois sur la poire

(A) d'amorçage du carburant (Fig. 5-1D).

4. Attrapez fermemente la poignée – enfoncez le

déclencheur de sécurité (B) & le déclencheur d’accélération (C) en position ACCELERATION MAXI.

(Fig. 5-1E).

5. Tirer su le cordon du lanceur jusqu’à ce qu’une résis-

tance se fasse sentir environ 10,5cm (4") (Figure 51H). Un mouvement rapide et uniforme est nécessaire

pour obtenir une bonne étincelle. Tirer vigoureusement 4 fois su le cordon.

6. Placer le volet de départ en position MI-GAZ « »

(Fig. 5-1G).

7. Tirer à nouveau 4 fois sur le cordon du lanceur.

8. Dés que le moteur a démarre, laisser le volet du de

départ sur la position MI-GAZ « » pendant 10 secondes.

9. Le déplacer ensuite sur la position MARCHE « »

(Fig. 5-1H).

10. Si le moteur ne démarre pas, répétez les étapes 1 à

9.

REMARQUE : Si après plusieurs tentatives le moteur ne

démarre toujours pas, consultar la section Dépannage.

REMARQ

pour éviter qu’il ne frotte sur le rebord de l’oeillet, cd qu

l’userait prématurément. Toujours retinir la poignée du cordon lorsqu’il se rétracte. ne jamais le lâcher en pleine

xtension ce qui pourrait l’effilocher et endommager le

e

.

ter

star

age et le réchauffage, couper le fil de coupe

UE :Toujours tirer le cordon bien à la v

erticale

5-2. DEMARRAGE DU MOTEUR CHAUD

1. Déplacer le commutateur de l'allumage en position

«DEMARRAGE (I) »

2. Placer les gaz en position MI-GAZ « » (Fig. 5-2).

Saisir fermement la poignée des gaz, appuyer a

3.

FOND sur la manette (pleins gaz).

4. Saisir fermement la poignée du régulateur tout en

relâchant la commande du frein de sécurité et amener le régulateur des gaz en position PLEIN

5-1B

A

5-1C 5-1D

B

C

GAZ.Garder le régulateur en position PLEIN GAZ

jusqu'à ce que le moteur tourne sans à-coup.

5. Si le moteur ne démarre pas, placer le starter en position MARCHE « » et actionner le lanceur encore 5

fois. Si le moteur ne démarre toujours pas il est probablement noyé. Attendre 5 minutes et répeter la

procédure, le starter étant en position MARCHE « »

et les gaz ouverts en grand.

5-2

5-4. RÉGLAGE DU RALENTI/DU CARBURA-

TEUR

1. Occasionnellement, dû aux conditions atmosphériques telles que l'altitude il pourrait être nécessaire d'effectuer un léger ajustement à la vitesse à

vide.

2. Insérer le tournevis Phillips ou plat dans le trou d'accès A (Figure 5-4A). Tourner 1/8 de tour dans le sens

des aiguilles d'une montre pour augmenter la vitesse

à vide et 1/8 de tour dans le sens contraire des aiguilles d'une montre pour diminuer la vitesse à vide.

A

6-4A

5-3. POUR ARRET DU MOTEUR

5-1E

5-1F

Lâcher la manette des gaz. Laisser le moteur revenir au

ralenti. Bougez le bouton d'allumage en position “STOP”

pour arrêter la machine. (Fig. 5-3)

5" (13cm)

5-1A

5-1G

5-1B

5-1H

2928

Page 16

6 - INSTRUCTIONS POUR LA COUPE

6 - INSTRUCTIONS POUR LA COUPE

6-1. MESURES DE SECURITE SUPPLEMEN-

TAIRES

Avant d’utiliser votre outil, revoir TOUTES LES MESURES

DE SECURITE de ce manuel.

AVERTISSEMENT / ATTENTION

• SI VOUS N’ETES PAS FAMILIARISE AVEC LES

TECHNIQUES DE COUPE, pratiquer le MOTEUR

AL’ARRET.

• ZONE DE TRAVAIL - Clarifiez la zone à couper avant

chaque utilisation. Enlevez tous les objets du genre

pierres, débris de verre, clous, ou bandelette risquant

de se prendre dans la piece de découpage

est touché accidentellement, ETEIGNEZ

IMMEDIA

l'équipement.

équipement endommagé ou défectueux. Clarifiez la

zone ou se trouvent des passants et des animaux. Au

minimum, conservez les enfants, les passants et les

animaux en-dehors d'un radian de 15m. Encouragez

les passants à porter une protection occulaire.

• TOUJOURS COUPER OU TAILLER AVEC LE

MOTEUR A HAUT REGIME. Ne pas laisser le moteur

tourner lentement ni au démarrage ni pendant la

coupe.

• NE PAS utiliser l’outil pour des travaux autres que la

tonte ou la coupe de l’herbe.

• NE PAS soulever la tête de coupe au dessus des

genoux pendant l’utilisation. Ceci est dangereux.

• N'OPEREZ PAS l'uinité avec d'autres personnes ou

des animaux dans un voisinage. Laissez une distance

de 30m entre l'opér

animaux en DECOUPANT avec le couteau.

• SI L'OPERATION S'EFFECTUE SUR UNE PENTE,

restez debout en retrait de la pièce de découpage.

N'OPEREZ jamais sur une pente ou un sommet incliné

s'il y a la moindre chance que vous glissiez ou tombiez.

SI ON S'APPR

•

pièce de découpage

avec des lames, il y a un risque pour les passants de

ise dans les lames en mouv

pr

poussée des lames ou de toute réaction inattendue de

la part de la scie.

• CONTROL DE L'UNITE - L'attache de coupage doit

être tournée durant les ajustements du carburateur.

or

P

les instructions de sécurité. Pour les unités équipées

avec un embrayage, assurez-vous que l'attache de

coupage s'arrête lorsque le moteur est au point mor

Quand l'unité est éteinte, assurez-vous que l'attache de

coupage soit bien arrêtée avant de buger l'unité.

TEMENT LE MOTEUR et examinez

N'opérez jamais l'unité avec un

ateur et les autres personnes ou les

OCHE DE VOUS, arrêtez le moteur et la

our ce qui concer

P

.

ement en cas de

tez un équipement de protection et respectez toutes

. Si un objet

ne les unités

6-2. AVANCE DU FIL DE COUPE

AVERTISSEMENT / ATTENTION

NE JAMAIS utiliser de fil de coupe en acier ou acier revêtu

de plastique sur votre tête de coupe. Ceci est extrêmement

dangereux.

Pour faire avancer une longueur de fil, «taper» la tête de

coupe sur le sol. La lame placée à l’intérieur du pare-débris

coupe le fil à la longueur voulue (Figure 6-2A).

ATTENTION

S'assurer que le moteur est éteint et que la tête à fils a

arrêté de tourner avant d'essayer cette procédure. Enlever

périodiquement l'enveloppe de mauvaises herbes pour

empêcher la surchauffe de l'arbre d'entraînement.

L'enveloppe de mauvaises herbes se produit quand les

torons de mauvaises herbes s'empêtrent autour de l'axe

sous la protection contre les débris (Figure 6-2B). Cette

condition empêche l'axe d'être correctement refroidi.

Enlever l'enveloppe de mauvaises herbes avec le tournevis

ou un appareil semblable.

TAPER

6-3. INSTRUCTIONS POUR LA COUPE

Correctement équipe d’un pare-débr

coupe à fil, l’outil permet de tailler les hautes herbes et les

mauvaises herbes, si désagréables à voir, dans les

endroits difficiles à atteindre - le long des clôtures, des

murs, des fondations et autour des arbres. Il peut également être utilisé pour raser la végétation et pour faciliter la

préparation d’un jardin ou de dégager une zone particulière.

REMARQUE : Même en procédant avec le plus grand soin,

la taille autour des fondations, murs de pierres ou de

briques, trottoirs, etc. causera une usure plus rapide du fil

de coupe.

is et d’une tête de

POUR TONDRE OU EGALISER

Utiliser un mouvement de balancement latéral semblable à

celui d’une faux. Ne pas incliner la tête de coupe. Faire un

essai sur la zone à tondre pour vérifier la hauteur de coupe.

Garder la tête de coupe à hauteur constante pour une tonte

uniforme (Figure 6-3A).

POUR TONDRE DE PLUS PRES

Tenir le coupe-herbe droit devant soi et l’incliner légèrement de manière à ce que le fil de coupe se trouve à l’angle voulu sans que le dessous de la tête de coupe ne

touche le sol. Toujours tondre vers l’avant, ne jamais tirer le

coupe-herbe à soi.

POUR TAILLER AUTOUR DES ARBRES

Approcher la base de l’arbre lentement de manière à ce

que le fil de coupe ne fouette pas l’écorce. Faire le tour de

l’arbre dans le sens des aiguilles d’une montre. Couper

avec la pointe du fil de coupe en inclinant légèrement le

coupe-herbe vers l’avant.

AVERTISSEMENT

Lors des opérations de RASAGE, procéder avec une

extrême prudence. Veiller à ce qu’aucune personne ou

aucun animal ne soit présent dans un rayon de 30 mètres

(100 pieds).

RASAGE

Le rasage consiste à couper la végétation au ras du sol.

Pour ce faire, incliner la tête de coupe vers la gauche à un

angle d’environ 30 degrés. Le réglage de la poignée permettra de mieux contrôler le coupe-herbe pendant cette

opération. Ne pas essayer de raser une zone où des débris

risquent d’être projetés et de causer des dommages personnels ou matériels (Figure 6-3B).

POUR TAILLER AUTOUR D’OBSTACLES

Pour tailler autour des clôtures grillagées ou en bois, des

murs et des fondations, procéder en approchant lentement

de manière à couper l’herbe au ras de l’obstacle sans que

6-2A

6-2B

le fil de coupe ne vienne le fouetter ce qui risquerait de le

casser ou de l’effilocher. Si le fil entre en contact avec une

clôture grillagée, il se casse.

6-3B

AVERTISSEMENT

NE PAS UTILISER LE COUPE-HERBE POUR

BALAYER

C’est à dire or

débris des trottoirs, entrées etc. Votre coupe-herbe est un

outil puissant capab

mètres (50 pieds) et de b

mager voitures, vitres ou habitations proches.

t.

ienter la tête de coupe pour éliminer les

le de projeter des débris à plus de 15

lesser quelqu’un ou d’endom

-

3130

Page 17

7 - ENTRETIEN

7 - ENTRETIEN

LISTES DES VERIFICATIONS D’ENTRETIEN

CHAQUE

HEURES

D’OPERATION

USAGE

PIECE ACTION

VIS / ECROUS / BOULONS INSPECTER / RESSERRER

FILTRE A AIR NETTOYER OU REMPLACER

FILTRE ESSENCE REMPLACER

BOUGIE NETTOYER / REGLER / REMPLACER

ECRAN PARE-ETINCELLES NETTOYER OU REMPLACER

INSPECTER

DURITS D’ESSENCE

✔

✔

✔

10 20

✔

✔

✔

* REMPLACER SUIVANT LES BESOINS

INSPECTER

TETE DE COUPE

✔

* REMPLACER SUIVANT LES BESOINS

* Recommandé pour la maintenance par un technicien de centre de service autorisé en utilisant les pièces de rechange

d'origine d'usine.

7-1. REMPLACEMENT DU FIL DE COUPE

1. Tourner le bouton (A) VERS LA GAUCHE et le retirer

7-1A).

(Fig.

2. Retirer la bobine (B) et le ressort (C) de l’axe (D).

Retirer le restant de fil (H).

3.

4. Doubler une longueur de 4,3m (14') de fil de coupe de

0,24 ou 0,20cm (0,095” ou 0,080"). Glisser le centre

bouclé dans une des encoches du séparateur de

bobine (Fig. 7-1B).

5. Enrouler comme illustre (Fig. 7-1C), en tenant tendu,

chaque moitié étant séparée par le séparateur de

bobine. Enrouler jusqu’à 15cm (6") des extrémités.

6. Bloquer chacune des extrémités de fil dans les

encoches (F) diamétralement opposées de l’extérieur

de la bobine (Fig. 7-1D).

7. Placer le ressort (C) sur l’axe (D). Insérer chaque

extrémité du fil dans les oeillets (G) du boîtier (E) (Fig.

7-1E).

8. Enfoncer la bobine (E) tout en faisant avancer le fil

dans les oeillets (G). Vérifier que le ressort se positionne correctement dans la bobine (Fig. 7-1E).

9. Une fois la bobine en place, appuyer pour compress-

er le ressort. Tirer fermement sur chaque extrémité du

fil (H) pour le dégager des encoches (Figure 7-1F).

10. Continuer d’appuyer sur la bobine jusqu’à ce que l’axe

dépasse suffisamment pour permenttre de visser le

bouton. Visser le bouton DE GAUCHE A DROITE

(Fig. 7-1G).

11. Couper l’excédent de fil à environ 13cm (5"). Ceci

minimisera la charge sur le moteur pendant le démarrage et le réchauffage (Figure 7-1H).

F

7-1D

G

D

C

E

G

7-1E

H

A. BOUTON

BOBINE

B.

C. RESSORT

D.AXE

AISANT

F

E

F. ENCOCHES

G.OEILLETS

FILE DE COUPE

H.

CLE PLATE

J.

G

7-1A

7-1B

J

H

F

D

C

G

H

H

B

A

F

E

7-1C

3332

7-1F 7-1G

5"

(13mm)

7-1H

Page 18

7 - ENTRETIEN

7 - ENTRETIEN

7-2. FILTRE A AIR

ATTENTION

AMAIS utiliser le coupe-herbe sans filtre à air. Le filtre

NE J

à air doit rester propre. Si endommagé, remplacer.

Nettoyage du filtre à air:

1. Retirer les bouton (A) retenant le couvercle du filtre à

air, retirer le couvercle (B) et retirer le filtre (C) du boitier (Fig. 7-2A).

2. Lavef le filtre à l’eau savonneuse. NE PAS UTILISER

D’ESSENCE!

3. Sécher le filtre à l’air.

4. Replacer le filtre.

REMARQUE : Si le filtre est effiloché, déchiré, endommagé ou síl ne peut pas être nettoyé, le remplacer.

B

A

C

7-2A

7-3. BOUCHON DU RESERVOIR / FILTRE A

CARBURANT

ATTENTION

Vider l’essence conten

dans un récipient homologué avant de commencer cette

opéeration. Ovrir le bouchon de essence lentement pour

soulager la pression éventuellement accumulée dans le

réservoir.

REMARQUE : Veiller à ce que l’évent du bouchon (A) soit

exempt de débris (Fig. 7-4A).

Filtre à Carburant:

1. Enlevez complètement le capuchon depuis le réservoir

de carburant (B) pour permettre d'enlever le filtre de

carburant (C) depuis le réservoir. (Fig. 7-4B).

2. Retirer le filtre (D) avec un mouvement de torsion. (Fig.

7-4C)

3. Remplacer le filtre à carburant (D). (Fig. 7-3D)

REMARQUE : Ne jamais utiliser le coupe-herbe sans

le filtre à carburant car ceci pourrait causer des dom-

mages internes au moteur!

B

ue dans le réservoir et la placer

A

7-3A

C

7-3B

D

7-3C

7-4. REGLAGE DU CARBURATEUR

Le carb

optimale. Veuillez consulter la section 5-4, pour des informations sur le point mort du moteur.

urateur a été réglé en usine pour une performance

7-5. BOUGIE

1. Pour enlever la bougie d'allumage B (Fig. 7-6A) pour

le nettoyage ou le remplacement: s'assurer que le

moteur est éteint, la bougie d'allumage est froide puis

saisir la gaine de la bougie fermement et enlever la de

la bougie d'allumage. Retirer la bougie avec un outil

de bougie approprié. Inspecter, nettoyer ou remplacer

selon le besoin.

2. L’écartement de bougie = 0,635mm (0,025") (Fig. 75A).

3. Replacer la bougie et la serrer à 12 à 15 N•m (105 à

130 pouces-livres). Reconnecter le fil de la bougie.

4. Au besoin, remplacez avec le champion RZ7C ou

l'Èquivalent.

.025" (.635mm)

7-5A

7-6. ECRAN PARE-ETINCELLES

1. Pour changer l’écran stoppeur détincelles (A) (Fig. 7-

tez en suite

Sor

.

pincez un

ace

6A), utilisez des pinces à bout d’aiguille;

bord de l’écr

an stoppeur d’étincelles

l’écr

2. Utilisez les pinces à bout d’aiguille pour posser un

nouvel écran stoppeur d’étincelles. Ouverez ensuite

un petit peu les pinces pour presser sur la surf

interne de l’écran stoppeur et pour le serrer fermement.

an stoppeur d’étincelles

.

B

A

7-6A

7-7. AFFUTAGE DE LA LAME PARE-DEBRIS

Retirer la lame (A) du pare-débris (B) (Fig. 7-7A).

1.

Serrer la lame dans un étau d’établi. L’affûter a l’aide

2.

d’une lime plate en veillant à maintenir l’angle de

coupe. Limer toujours dans la même direction.

A

B

7-7A

7-8. EMMAGASINER L’APPAREIL

Le non respect des instructions ci-dessous peut

entraîner la formation de vernis dans le carburateur et

résulter en des difficultés de démarrage ou des dommages

permanents après l’emmagasinage.

1. Effectuer tous les entretiens d’ordre général recom-

mandés dans la section «Entretien» du manuel d’utilisation.

2. Nettoyer l’extérieur du moteur, l’arbre de transmission,

le pare-débris et la tête de coupe.

3. Vidanger le réservoir de carburant.

4. Une fois le réservoir vide, faire démarrer le moteur.

5. Laisser tourner le moteur au ralenti jusqu’à ce qu’il

s’arrête, afin de purger le carburateur de carburant.

Laisser refroidir le moteur (environ 5 mn).

6.

7. Retirer la bouge à l’aide d’une clé à bougie.

8. Verser 1 cuillerée à thé d’huile 2 temps propre dans la

chambre de combustion. Tirer lentement le cordon du

lanceur plusieurs fois de manière à lubrifier les composants internes. Remonter la bougie.

9. Placer l’appareil dans un endroit sec, frais et éloigné

de toute source d’allumage telles brûleur à mazout,

chauffe-eau, etc.

7-9. PREPARATION APRES

EMMAGASINAGE

1. Retirer la bougie.

2. Tirer vigoureusement sur le cordon du lanceur de

manière à éliminer l’excès d’huile dans la chambre de

combustion.

3. Nettoyer les électrodes de la bougie et régler l’écarte-

ment ou installer une nouvelle bougie.

4. Préparer le coupe-herbe pour son utilisation.

5. Remplir le réservoir à carburant d’un mélange

huile/essence approprié. Voir la section Carburant et

Lubrification.

3534

Page 19

8 - DEPANNAGE DU MOTEUR

9 - DEPANNAGE DE LA TETE DE COUPE

PROBLEME CAUSE PROBABLE SOLUTION

L’outil ne démarre pas ou démarre et

cale.nit won’t start or starts but will not

run.

Le moteur démarre mais manque de

puissance.

oir les instructions du manuel

rocédure de démarrage incorrecte.

P

Mauvais reglagle du carbureteur.

Bougie noyée

Filtre à carburant colmaté. Remplacer le filtre à carburant.

Position du starter incorrecte.

Fare-étincelles encrassé. Remplacar l’écran pare-étincelles.

Filtre à air encrassé. Retirer le filtre, le nettoyer et el replacer.

Mauvais réglage du carburateur.

V

d’utilisation.

Faire régler le carburateur par un

McCulloch service agréé.

Nettoyer la bougie, réglar l’écartement

des électrodes ou remplacer la bougie.

Placer le starter su la position RUN

(MARCHE).

Faire régler le carburateur par un

McCulloch service agréé.

PROBLEME CAUSE PROBABLE SOLUTION

Le fil de coupe n’avance pas.

Le fil est emmêlé dans la tête de coupe.

Les 2 lignes sembient être fondues

ensemble dans la tête de coupe.

La ligne est enrouléé dans le mauvais

sens à l’interieur de la tête de coupe.

Il ne reste plus assez de fil sur la

bobine.

Dommages á l’intérieur de la tête de

coupe dus á des chocs trop violents

pour faire avancer la ligne de coupe.

Retirer la bobine et la démonter (v

Section 7-1). Démêler la ligne et

l’enrouler correctement sur la bobine

dans la sens indiqué.

Couper la section de fil endommagé et

réenrouler la ligne (voir la Section 7-1).

Retirer la bobine et vérifier que la ligne

est bien enroulée dans le sens indiqué

(voir la Section 7-1)

Retirer la bobine et (voir Section 7-1)

installar une nouvelle ligne de coupe.

Démonter la tête de coupe (voir Section

7-1) et examinar les pièces en vue de

dommages. Remplacer les pièces ou la

tête de coupe.

oir la

Le moteur a des ratés.

Manque de puissance sous la charge

Ne tour

Fumée e

ne pas régulièrement.

xcessive.

Mauvais réglage du carburateur.

.

ais écartement des électrodes de

Mauv

la bougie

Mauv

Mélange huile / essence incorrect. Utiliser un mélange adéquat (40:1).

.

ais réglage du carb

ur

ateur.

Faire régler le carburateur par un

McCulloch service agréé.

yer la bougie, réglar l’écartement

Netto

des électrodes ou remplacer la bougie

Faire régler le carburateur par un

McCulloch service agréé.

La ligne casse ou s’effiloch

Le bouton de la tête de coupe ne peut

pas être desserré.

.

La tête de coupe et l’arbre de

transmission sont chauds au toucher.

Procédures de coupe incorretes ou

ligne de qualité médiocre.

Bouton e

Enroulement d’herbe

xcessiv

ement serré.

.

3736

Voir les procédures d'élagage (voir la

section 6-3) ou remplacer la ligne (voir

la section 7-1)

Appliquer un antigrippant su le filetage

visser le bouton.

et re

MAIN UNIQUEMENT.

Eliminer l’herbe enroulée autouor de

l’arbre (voir la Section 6-2)

SERRER A LA

Page 20

10 - GARANTIE LIMITÉE DE UN ANNÉE

1. DURÉE

La durée de la garantie des produits McCulloch s'établit comme suit: un (1) ANNÉE à compter de la date initiale de l'achat

à condition que l'appareil soit utilisé à des fins personnelles, domestiques, pour des travaux de ferme ou de ranch, et qu'il

ne soit pas utilisé à des fins de location;

produits sont utilisés à des fins commerciales, professionnelles, institutionnelles ou de location.Cette garantie vous donne

des droits légaux spécifiques. Vous pouvez également bénéficier d'autres droits qui varient selon les états ou provinces.

PAR LA PRÉSENTE, MCCULLOCH DÉCLINE TOUTE RESPONSABILITÉ EN CE QUI CONCERNE TOUTE GARANTIE

IMPLICITE APRéS LES DATES D'EXPIRATION APPLICABLES DE CETTE GARANTIE LIMITÉE EXPRESSE. (Certains

états ou certaines provinces ne permettant pas de limitation de la durée des garanties implicites. Les limitations ci-dessus

peuvent donc ne pas s'appliquer à votre cas.)

2. PAR QUI LA GARANTIE EST-ELLE OFFERTE

McCulloch U.S.A 1-800-521-8559

12802 Leffingwell Rd. Santa Fe Springs, CA 90670 USA

3. QUI EST COUVERT PAR CETTE GARANTIE

A. L'acheteur d'un produit McCulloch (à condition que le produit ne soit pas destiné à la revente).

B. Toute personne à qui le produit est légalement cédé pour la durée de la garantie implicite ou écrite applicable au pro-

duit.