Page 1

McCulloch U.S.A.

12802 Leffingwell Rd.

Santa Fe Springs,

CA 90670

USA

Made in China / Fabriquè à Chine / Hecho en China

STOP

ARRÊT

ALTO

For problems or questions, DO NOT return

this product to the store. Contact your

Customer Service Agent .

En cas de problèmes ou pour des questions,

NE PAS retourner ce produit au point de vente. S'adresser

au préposé du Service à la clientèle en composant.

Para problemas o preguntas, NO devolver este producto a la tienda

Contacte a su Agente de Servicio al Cliente.

U.S.A. & CANADA

1-800-521-8559

For Consumer Assistance Please Call

L'Aide Du Consommateur Necessitez S'il Vous Plait

Para La Ayuda Del Consumidor Llame Por Favor

USER MANUAL

Electric Chipper/Shredder

Model : MCS2001

SAFETY

OPERATION

MAINTENANCE

ARNING • PLEASE READ

W

For your own safety please read this manual before attempting to operate your new unit. Failure to follow instructions can

result in serious personal injury. Spend a few moments to familiarize yourself with your shredder before each use.

inted in China

PN 6096-200126

Pr

Page 2

INTRODUCTION 1 - GENERAL INFORMATION

PLEASE READ

Dear Customer,

Thank you for purchasing a McCulloch product.With proper operation and maintenance, it will provide you with years of serv-

ice.

In order to make the best use of your investment, be CERTAIN to familiarize yourself with the contents of the ENTIRE user

manual before attempting to operate and maintain your unit.

Be sure to carefully follow the step-by-step instructions in this manual to start, operate and maintain your new product.

In the manual there will be the following call-outs: NOTE:, WARNING / CAUTION and WARRANTY.

A NOTE: is used to convey additional information, to highlight a particular explanation, or to expand a step description.

A WARNING or CAUTION identifies a procedure which, if not undertaken or if improperly done, can result in serious person-

al injury and/or damage to the unit.

op Hopper

T

Top Hopper

Safety Screws

Side Chute

ON-OFF

Switch

Overload

Protection Switch

ARRANTY SYMBOL)

The

void the warranty and repairs will be at owner’s expense.

Pay particular attention to the safety precautions. They are written for your protection and contain important information you

must know to safely operate your chain saw.

(W

FOR WARRANTY OR SERVICE CONTACT THE NEAREST AUTHORIZED SERVICE CENTER - LOCATE YOUR NEAREST

SERVICE CENTER BY CALLING THE TOLL FREE NUMBER IN THIS MANUAL.

ves notice that unless instructions or procedures are followed, any damage caused will

ser

Wheel

Cover

Wheel (L)

Leg (L)

Axle

Discharge chute

access knobs

Discharge Chute

Wheel (R)

Leg (R)

SPECIFICATIONS

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120V~, 60Hz, 14 Amp

No Load Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3300 RPM

Hopper Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13.4”x8.5”x7.9” (340x215x200mm)

Max.

Cutting dia. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1/2” (38mm)

Wheel Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7” (180m)

Net Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78.3 Lbs. (35.6 Kg)

2 3

Page 3

2 - SAFETY PRECAUTIONS

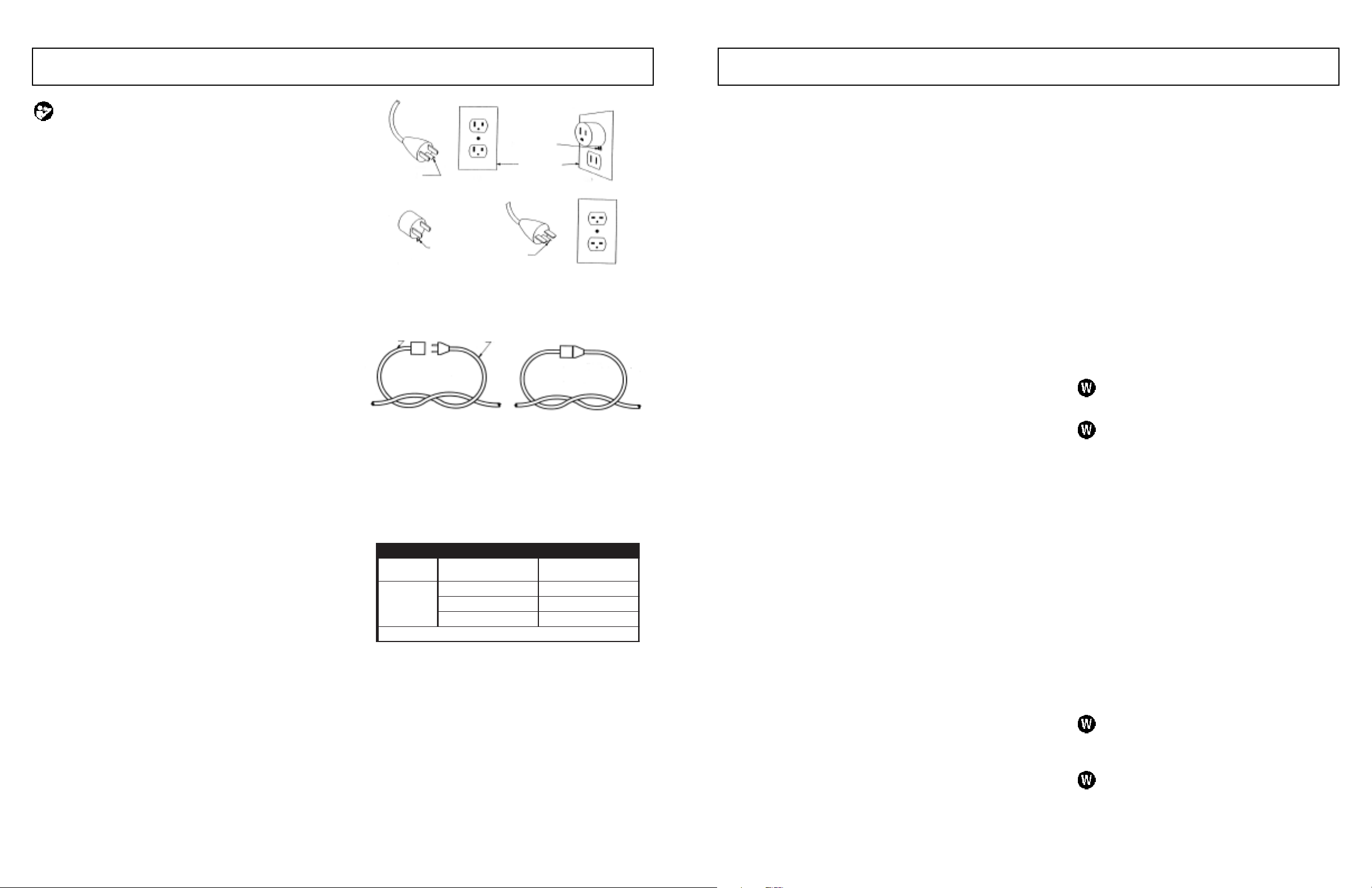

MINIMUM WIRE GAUGE RECOMMENDATIONS

VOLTS

EXTENSION CORD

LENGTH

WIRE SIZE

REQUIRED

120

25 feet / 7.5m 18 A.W.G.*

50 feet / 15m 16 A.W.G.*

100 feet / 30m 16 A.W.G.*

*American Wire Gauge

2 - SAFETY PRECAUTIONS

PLEASE READ - SAVE THESE

INSTRUCTIONS

When using power equipment, basic precautions should

ays be followed to assure maximum safety and optimum

alw

performance. Read this manual before assembling and

operating this chipper shredder. Failure to comply with

instructions may result in electrical shock, burns, fire, or

personal injury.

WARNING

2-1. TO REDUCE THE RISK OF ELECTRIC

SHOCK, BURNS, FIRE OR PERSONAL

INJURY:

1. FOLLOW ALL SAFETY INSTRUCTIONS listed in

this manual before/during operation of this shredder

2. TO REDUCE THE RISK OF ELECTRIC SHOCK this

shredder must be grounded. It is equipped with a cord

having an equipment-grounding conductor and

grounding plug to reduce the risk of electric shock.

Plug into an appropriate outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

DANGER: Improper connection of the equipmentgrounding conductor can result in a risk of electric

shock in the event of a malfunction. Contact a qualified electrician if you are in doubt as to whether the

receptacle is properly grounded. Do not modify the

plug provided with the shredder.

INSPECT UNIT FOR DAMAGE to the housing, cord

3.

or plug. Keep all fasteners tight. Do not use if the

witch does not turn the unit off properly. Never use

s

unit if cord or plug has been damaged, the motor or

unit itself is not working as it should or has been

dropped, damaged, left outdoors or dropped in water.

Never operate with any air opening blocked. Keep air

openings free of debris that may reduce air flow.

Replace damaged parts that are chipped, cracked or

damaged in any way. This product is double insulated

- there are no serviceable parts inside..

UCTIONS

OUNDING

GR

4.

grounded while in use to reduce the risk of electric

shock to the operator. The tool is equipped with a 3conductor cord and 3-prong g

proper grounding receptacle. If your unit is for use on

less than 150 volts, it has a plug as illustrated in

etch A in Figure 2-1A.

sk

volts, it has a plug as illustrated in sketch D, Fig.2-1A

An adapter, sketches B and C, is available for connecting plugs as illustrated in sketch A to 2-prong

receptacles. The green-colored rigid ear, lug, or the

like, must be connected to permanent ground, such

as a properly grounded outlet box. No adapter is available for the plug illustrated in sketch D.

INSTR

This tool should be

rounding plug to fit the

If it is f

or use on 150 to 250

DO NOT ABUSE POWER CORD - Never carry power

equipment by cord or pull cord to disconnect from out-

GROUNDING

PIN

ADAPTER

METAL

SCREW

COVER OF

GROUNDED

OUTLET BOX

6.

7.

Keep cord clear of operator and obstacles at all

let.

times. Do not expose cord to heated surfaces, oil or

water. Do not pull cord around sharp edges, corners

or close door on cord.

Avoid dangerous environment. Do not use power

equipment in damp or wet locations.

Don’t use in rain. Water entering a power tool will

increase the risk of electric shock.

GROUNDING

PIN

2-1A

8. Do not abuse cord. Never pull on power cord to dis-

connect from receptacle. Keep cord away from heat,

oil, sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk

of electric shock.

PERSONAL SAFETY

9. Keep children away. All bystanders should be kept at

CORD

SET

GROUNDING

MEANS

Method of securing extension cord

APPLIANC

E CORD

a safe distance from work area.

Dress properly. Do not wear loose clothing or jewel-

10.

ry. They can be caught in moving parts. Use of gloves

and substantial footwear is recommended when work-

(A) TIE CORD AS SHOWN (B) CONNECT PLUG AND

RECEPTACLE

2-1B

5.

EXTENSION CORD - Use only three-wire outdoor

extension cords that have three-prong grounding

plugs and grounding receptacles that accept the

appliance’s plug.

ing outdoors. Wear protective hair covering to contain

long hair.

Use safety glasses. Always use face or dust mask if

11.

operation is dusty.

Stay alert, watch what you are doing and use com-

12.

mon sense when operating a power tool. Do not

use tools while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while

operating power tools may result in serious personal

injury.

13. Avoid unintentional starting. Do not move plugged-

in power equipment with finger on switch. Be sure

witch is off when plugging in.

s

14.

Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enables better

control of the tool in une

15.

No accessories or attachments are necessary for

le

ab

T

the operation of this gar

xpected conditions

dening tool.

.

The use of an

y

accessories or attachments for this gardening tool is

a. When using the chipper shredder, an extension cord

ust be used for safety and to pre-

of adequate siz

ent loss of po

v

e m

er and o

w

erheating.

v

b. The extension cord must be specifically intended for

outdoor use and marked “SJ” or “SJT” and with the

suffix “WA”. In Canada, the extension cord must be

marked “SFTW”.

Inspect extension power cord for loose or exposed

c.

wires and damaged insulation.

If damaged, replace

before using appliance.

not recommended. Such use of any attachment or

accessory may increase the risk of injury to the user.

Do not use force. The correct tools will do the job

16.

or which it is designed.

better and saf

17.

Disconnect the plug fr

er at the r

ate f

om the po

wer source before

making any adjustment, changing accessories, or

storing the tool.

Such pre

entive safety measures

v

reduce the risk of starting the tool accidentally.

18. Store tools indoors.When not in use

, tools should

be stored indoors in dry, and high or locked-up place,

out of reach of children.

4 5

19. Maintain tools. Keep cutting tools sharp and clean for

best performance and to reduce the risk of injury.

ollow instructions for lubricating and changing

F

accessories. Inspect tool cord periodically, and if damaged, have it repaired by an authorized service facility. Keep handling surface dry, clean, and free from oil

and grease.

20. Check damaged parts. Before further use of the tool,

a guard or other part that is damaged should be carefully checked to determine that it will operate properly

and perform its intended function. check for alignment

of moving parts, binding of moving parts, breakage of

parts, mounting, and any other condition that may

affect its operation. A guard or other part that is damaged should be properly repaired or replaced by an

ized service center unless indicated elsewhere

author

in this manual.

2-2. PRECAUTIONS FOR USING CHIPPER/

SHREDDER

1. Extreme caution should be taken to ensure

shreddable material does not contain metal,

rocks, bottles, cans or other foreign objects.

2. Do not allow hands or any other part of the body,

or clothing to enter inside the feeding chambers

or discharge chute, while machine is operating.

3. Wear gloves while operating the machine.

4. Before starting the machine, ensure that all screws

and other fasteners are properly secured.

5. Machine should be operated on firm level surfaces

only.

6. Before starting the machine, check that the cutting

chamber is empty.

7. Motor should be kept clean of debris and other accu-

mulations.

8. Keep all guards and deflectors in good working condi-

tion.

9. Stand clear of discharge chute at all times.

10. Do not over reach and keep face and body back form

eed opening.

the f

11. Never pull the machine by the power cord and keep

cord away from water or sharp edges.

12. Disconnect the power cord when the machine is not in

use

.

13.

If machine should become clogged, s

, disconnect the po

ts are completely stopped bef

all mo

the motor

ving par

er cord, mak

w

ing clogged debris.

14. Ensure the power cord is always in good condi-

A cord with brok

tion.

en insulation is extremely

dangerous and can result in fire, electric shock or serious personal injury.

witch off

e sure

ore clean

-

Page 4

2 - SAFETY PRECAUTIONS 3 - ASSEMBLY INSTRUCTIONS

15.

The operation of any tool can result in foreign

objects being thrown into your eyes, which can

result in severe eye damage. Before operating power

tool, alw

side shields and a full face shield when needed.We recommend wide Vision Safety Mask for use over eyeglasses or standard safety glasses with side shields.

ays wear safety goggles or safety glasses with

2-3. EXPLANATION OF NOTE, WARNING,

AND WARRANTY SYMBOL

1. A NOTE is used to convey additional information, or

highlight a particular explanation, or to expand a

instruction.

2. A WARNING identifies a procedure which, if not

undertaken or if improperly done, can result in a serious personal injury or damage to the unit and/or both.

3. (WARRANTY SYMBOL) serves notice that

unless instructions or procedures are followed,

any damage will void the warranty and repairs will be

at owner’s expense. Service other than user maintenance should be performed by a McCulloch

Authorized Service Center. Damage or conditions

caused BY improper maintenance practices which

render this product inoperable will void the manufacturer’s warranty.

FOR WARRANTY OR SERVICE contact the nearest

4.

McCulloch Authorized Service Center.

2-4. INTERNATIONAL SYMBOLS

1. Never place hands into discharge chute as serious

y will occur (Figure 2-1).

injur

2. Use of these personal safety items is highly recom-

mended to reduce the risk of accidental injury (Figure

2-2).

SAVE THESE

INSTRUCTIONS

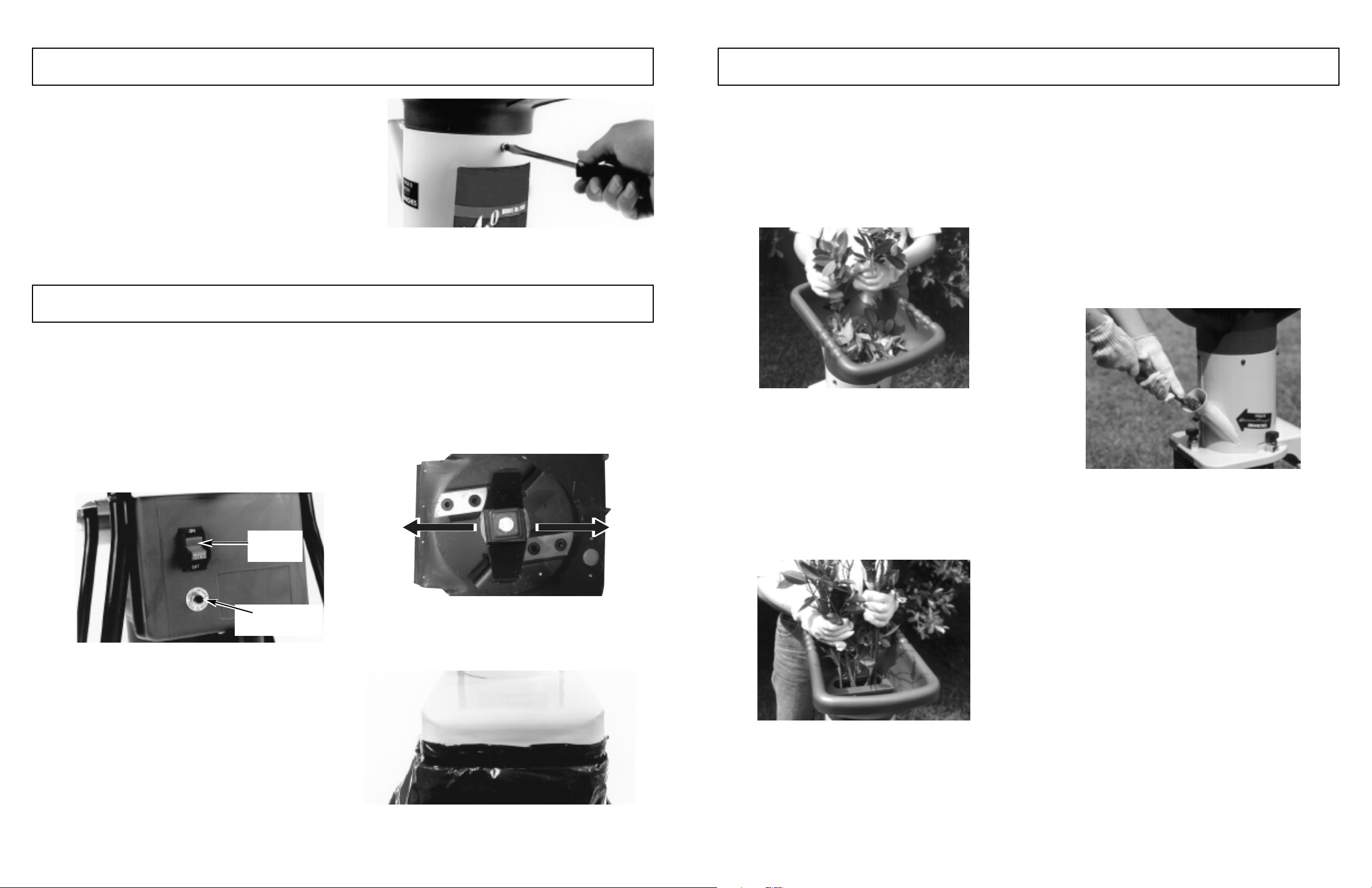

3-1. CONNECTING WHEEL ASSEMBLY

NOTE: Locate small bag of hardware containing two Allen

x screws, two large flat washers, two small flat washers

he

and two split pins.

Place one wheel on the axle followed by a large flat

1.

washer. Secure by inserting a split pin through the

hole in the end of the axle, bend the ends over using

pliers. See Figure 3-1A.

2. Press wheel cover on wheel.

3. Position the axle assembly on the inside of the support tube as shown in Figure 3-1B, aligning the hole in

the axle with the hole in the support. Place a lockwasher and small flat washer on the Allen hex screw

and guide them up through the hole in support tube

and into the hole in the axle.The flat washer should be

next to the axle.

4. Assemble the other tube support to the other end of

the axle in the same manner.

5. Attach the second wheel to the axle using the same

method as described in step 1.

Axle

Flat Washer

and Split Pin

3-2. ATTACHING WHEEL ASSEMBLY TO

UNIT

1. Remove feeder tube by loosening & spring loaded

knobs. Figure 3-2A.

2. Lay motor assembly down on flat surface with plug

facing down.

3. Place a 2x4 under bottom of motor to obtain correct

angle to attach wheel kit.

4. Wheels should be toward floor (same as plug).

5. Align top of support tubes (2 holes) with 2 holes in

motor housing. Using hardware (fiat washers of lock

washers, and 4 hex bolts attach support tubes to

motor housing & tighten.

6.

Stand unit of and reattach feeder. Tube by tightening 3

spring loaded knobs.

WARNING

Use caution when tightening set screws to avoid contact

with sharp cutting blades.

Feed

Tube

Chute

Discharge chute

access knobs

Use of these personal safety items is

highly recommended to reduce the risk

.

of accidental injur

y

Never place hands into discharge

chute as ser

ious injur

2-1

y will occur.

2-2

Suppor

Tube

Allen hex screw,

small flat washer

asher

and loc

kw

Screws

3-1A

e

t

3-1B

Axle

ube

T

Insert

Flang

3-2A

Set Scre

3-2B

Blade

ws

6 7

Page 5

3 - ASSEMBLY INSTRUCTIONS

4 - OPERATING INSTRUCTIONS

3-3. HOPPER ASSEMBLY

NOTE: Locate small bag of hardware containing five one

ay security screws and washers.

w

1. Place the hopper on top of the feed tube, align the

. Secure with the safety screws and washers.

holes

Figure 3-3A

4 - OPERATING INSTRUCTIONS

4-1. OPERATION

Read and understand the safety instructions in this owners

manual before using your shredder. Failure to comply can

result in accidents involving fire, electric shock, or serious

personal injury.

1. Connect the shredder to a suitable power outlet.

2. To start and stop the shredder, depress the switch

located at the rear of the Motor.

3. To stop the shredder, switch to the off position. (Fig .

4-1)

ON-OFF

Switch

3-3A

IMPORTANT

Before replacing top cover assembly ensure that the V-cutter is positioned as shown in (Fig. 4-2).

Replace the top cover assembly together with the top cover

screw knob ensuring this is tight. If the top cover screw

knob is not tight the motor will not start due to the motor

lock out switch not being activated.

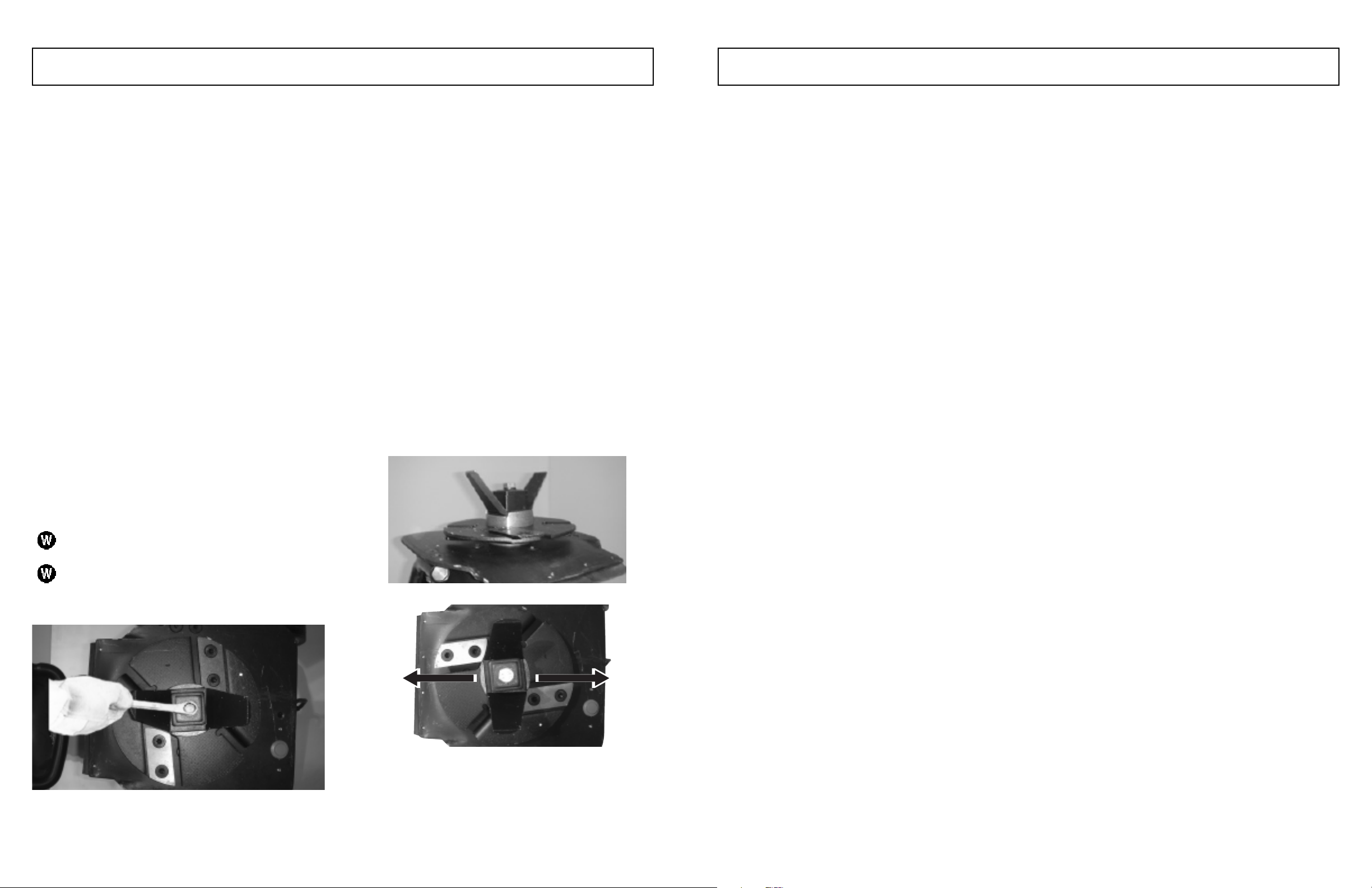

4-4. FEEDING LEAVES AND SMALL GAR-

DEN CLIPPINGS - TOP HOPPER

The sloping chute of the top hopper is designed to accept

leaves and small garden clippings.

Shredding and mulching is achieved by natural suction of

the debris through the blade chamber. Do not overfeed and

do not feed wet, soggy material into the garden shredder as

this may clog the blade chamber and the discharge chute.

(Fig. 4-4)

4-4

4-5. FEEDING TWIGS AND SMALL BRANCH-

ES - TOP HOPPER

The smaller back chute of the top Hopper accepts medium

to larger size garden clippings.

Shredding and mulching is achieved through the same

action as the front chute. If a finer type mulch is required

than is initially achieved, re-feed the mulch through again

until the desired result is obtained. (Fig. 4-5).

Do not feed solid branches through the two Top Hopper

chutes.

4-6. SIDE CHUTE

The elongated chute located at the rear of the machine is

specially designed to accept solid garden clippings and

branches up to 1-1/2" (38mm) in diameter.

IMPORTANT

When feeding long, large diameter material, control the

rate of feed by pulling back on the material so as not to stall

or overload the motor. (Fig. 4-6)

WARNING

Do not under any circumstances, place hands inside the

feeding chutes while the machine is operation. Force feeding of debr

action of the shredder.

is is not necessary due to the natural suction

4-6

Overload

Protection Switch

4-1

4-2. OVERLOAD PROTECTION AND MOTOR

JAMMING If overfeeding clogs the machine the overload

protection switch may cut out the motor. To restart, switch

er cord.

the machine off and disconnect the po

Loosen discharge chute access knobs and remove top

, then remove any clogged debris from the

er assemb

v

co

cutting chamber

jammed and will not lift off, turn the V-cutter by pushing a

piece of w

rotate the

removed. Reset motor overload protection switch. (See Fig.

4-1)

ly

If the top co

.

ood through the bac

-cutter to enab

V

le the top co

k chute of the top hopper to

w

er assemb

v

er assemb

v

ly becomes

ly to be

4-2

ACHING MULCH BAG

4-3. A

Place a heavy duty trash bag using the mulch bag strap.

(Fig. 4-3)

8

TT

4-3

4-5

9

Page 6

5 - MAINTENANCE INSTRUCTIONS

6 - TWO YEAR LIMITED WARRANTY

Your Shredder has been designed for a low level of mainte-

, involving routine cleaning and inspection.The motor

nance

of the Shredder is maintenance free and requires no attention. For the best results the blades must be kept sharp at

all times. The blades have dramatically less cutting power

when blunt.

The Shredder will tear rather than cut when the blades are

blunt. When this occurs rotate the double sided blades or

replace the blades immediately.

WARNING

Before attempting any maintenance switch the machine off

and disconnect the power cord.

5-1. V-CUTTER MAINTENANCE

• Switch the machine off and disconnect the power cord

ensuring all moving parts are completely stopped.

• Wear gloves when attempting any maintenance to the

cutting blades.

JAMMING If blades become jammed see disassembly.

DISASSEMBLY

1. Loosen discharge chute access knobs and remove

the top cover assembly.

2. Rotate the cutter base counter clockwise and wedge

a piece of wood between the cutter base and cutting

chamber wall so as to stop the cutting base from rotating. (Fig. 5-1A)

3. Remove the center hold down bolt by turning it count-

er clockwise using a 16 mm wrench.

4. Remove the square washer, square bushing, V-cutter

to expose cutter base.

ake extreme care not to come in contact with cutting

T

blades.

If discharge chute becomes clogged or cutting blades

become jammed, under no circumstances should y

place your hands in discharge chute to try to clear

obstruction, as this will lead to serious injury.

5-1A

ou

5-2. SHREDDING BLADES MAINTENANCE

WARNING

Before removing Top Hopper knob, insure the machine is

switched off, the red safety switch and extension lead is

removed and wait until the machine comes to a complete

stop.

To inspect or replace the double sided shredding blades

there is no need to remove the cutter base.To remove simply undo the counter sunk screws with the 6mm hex

wrench supplied with the machine and turn them through

180˚ These blades are double ground and can be used on

both sides. When blunt on both sides replace and insure

they are screwed in tightly.

ASSEMBLY This is carried out in the reverse sequence to

that of disassembly but with careful inspection of all components. Ensure that cutter base is assembled with the

scraping plates facing down towards the motor and that

the square washer is situated under the head of the center hold down bolt. (Fig. 5-2A)

Before replacing the top cover assembly ensure that the Vcutter is positioned as shown in (Fig. 5-2B) Replace the top

cover assembly and secure tightly the discharge chute

access knob. If discharge chute access knob are not tight

the motor will not start due to the motor lock out switch not

being activated.

5-2A

5-2B

5-3. CLEANING

After use, always wipe clean the outside of the shredder to

remove any build up of material with a damp cloth. Clean

e an

the inside of the cutting chamber and remo

material, Do not hose down with water.

10

v

y left o

ver

1. DURATION

The duration of the warranty for this McCulloch product is as follows: TWO (2) YEARS from date of original purchase only

when used for personal, family, household, farm or ranch, purposes, provided the unit is not used for rental purposes;

NINETY (90) DAYS from date of original purchase when used for commercial, professional, institutional or rental purposes. This warranty gives you specific legal rights. You may also have other rights which vary from state to state. MCCULLOCH CORPORATION HEREBY DISCLAIMS ALL IMPLIED WARRANTIES AFTER THE APPLICABLE EXPIRATION

DATES OF THIS EXPRESS LIMITED WARRANTY. (Some states do not allow limitations on how long an implied warranty lasts, so the above limitations may not apply to you.)

2. WHO GIVES THIS WARRANTY

McCulloch U.S.A 1-800-521-8559

12802 Leffingwell Rd. Santa Fe Springs, CA90670 USA

3. WHO RECEIVES THIS WARRANTY

A. The buyer (other than for purposes of resale) of the McCulloch Product.

B. Any person to whom such product is lawfully transferred within the duration of the implied or written warranty applica-

ble to the product.

C. Any other person who is entitled by the terms of the warranty or under applicable state law to enforce against the

Warrantor the obligation of the warranty.

(The above mentioned parties are hereinafter referred to as “User.”)

4. WHAT IS COVERED UNDER THIS WARRANTY

Any failure that occurs within the applicable duration of the warranty period that is the result of defects in materials or workmanship.

5. WHAT IS NOT COVERED UNDER THIS WARRANTY

A. Any incidental or consequential damages that may result from the failure or malfunction of the McCulloch product.

(Some states do not allow the exclusion or limitation of incidental or consequential damages, so these limitations may

not apply to you.)

B. Any failure that results from an accident, User abuse, neglect or failure to operate the product in accordance with the

instructions provided in the User Manual(s) supplied with the product, or that results from improper servicing by an

unauthorized repair facility.

C. Normal adjustments which are explained in the User Manual(s) provided with the product.

D. Any component(s) or accessories not sold or manufactured by the Warrantor.

E. Predelivery setup or assembly of units.

anty does not apply to accessories, normal maintenance or adjustment(s) of the product set forth in the User

arr

This w

.

F

Man

ual(s).

6. RESPONSIBILITIES OF THE WARRANTOR UNDER THIS WARRANTY

A. Repair or replace components which have failed within the duration of the applicable warranty period at no cost to the

User.

. Ensure that the authorized repair station is reimbursed for parts and labor costs incurred due to performance of a war-

B

anty policies and procedures

arr

mal w

11

umber

lished w

.

anty repair in accordance with estab

r

7. RESPONSIBILITIES OF THE USER UNDER THIS WARRANTY

A. The User must deliver or ship the McCulloch product covered under this warranty to the dealer from whom it was orig-

inally purchased or to the nearest Authorized Service Center. Proof of purchase is required.

B. Freight costs, if any, will be borne by the user.

Use reasonable care in maintenance, operations and storage of the product as explained in the User Manual(s).

.

C

ARRANT

WHEN

8.

A.

B. Repair time which exceeds ten (10) days from the time the product was delivered to the servicing agent will extend

C

W

Repair of w

ing on the availability of replacement parts.

the warranty coverage by the number of days the product remains inoperable.

. If User does not receive satisfactory results from local servicing outlet, User must contact McCulloch Corporation, by

calling our toll-free telephone n

OR WILL PERFORM OBLIGATION UNDER THIS WARRANTY

le products will be scheduled according to the nor

antab

arr

.

w at the servicing location, depend-

k flo

or

Page 7

MANUEL DE UTILISATION

Coupage/Tonte Électriques

Modèle : MCS2001

SECURITE

FONCTIONNEMENT

ENTRETIEN

INTRODUCTION

A LIRE ATTENTIVEMENT

Cher client,

Merci de v

Il est IMPERATIF que vous preniez connaissance de LA TOTALITE du contenu de ce manuel avant d’utiliser l’outil ou de

procéder aux opérations d’entretien.

Conformez-vous scrupuleusement aux instructions et illustrations étape par étape concernant le démarrage, l’utilisation et

l’entretien de votre nouvel outil.

Ce manuel contient également des mises en gardes et informations intitulées: REMARQUE, AVERTISSEMENT /

ATTENTION et GARANTIE.

Une

plus en détail.

Un AVERTISSEMENT ou ATTENTION est utilisé pour identifier une procédure qui, si elle est négligée ou incorrectement exé-

cutée, peur entraîner des dommages matériels et/ou corporels graves.

Le (SYMBOLE DE GARANTIE) indique que si les procédures ou instructions ne sont pas respectées, les dommages ne

seront pas couverts par la garantie et les réparations seront à la charge du propriétaire.

Les réparations autres que les entretiens à effectuer par l’utilisateur devront être confiées à un Centre de réparation McCulloch

agréé. La garantie du fabricant sera nulle en cas de dommages ou de conditions rendant le produit inutilisable à la suite d’un

entretien inadéquat.

otre achat d’un produit McCulloch. Correctement utilisé et entretenu, il vous procurera des années de satisfaction.

REMARQUE est destinée à fournir des informations complémentaires, éclaircir un point particulier ou expliquer une étape

POUR TOUT ENTRETIEN, VEUILLEZ APPORTER VOTRE OUTIL AU CENTRE DE SERVICE

APRES-VENTE McCULLOCH AGREE LE PLUS PROCHE DONT LE NOM FIGURE SOUS LA

RUBRIQUE «SCIE» DES PAGES JAUNES DE L’ANNUAIRE.

McCulloch Corporation

Service de Réparation

AVERTISSEMENT • LIRE ATTENTIVEMENT

Pour votre sécurité, lisez entièrement ce manuel avant d’utiliser votre nouvel outil. Le non respect des instructions peut

résulter en des accidents graves. Prenez quelques instants pour vous familiariser avec le tondeuse avant chaque utilisation.

1312

Page 8

1 - GENERALITES

Sautoir du Haut

Vis de Sûreté du

Sautoir du Haut

Interrupteur de Protection

Descentes

Latérales

Bouton d'accès à la

glissière de décharge

Roues (L)

Chute de Décharge

Roues (R)

Roue

Couvre

Axe

Pied (L)

CARACTERISTIQUES

Entrée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120V~, 60Hz, 14 Amp

Vitesse sans charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3300 RPM

Taille du sautoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13.4”x8.5”x7.9” (340x215x200mm)

Miamètre maximal de coupage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1/2” (38mm)

Taille de roue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7” (180m)

Poids Net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78.3 Lbs. (35.6 Kg)

Interrupteur

Marche/Arrêt

de Surcharge

Pied (R)

2 - MEASURES DE SECURITE

LIRE ET CONSERVER CES

INSTRUCTIONS

Lorsque vous utilisez l'équipement, des précautions de base

ent toujours être suivies pour assurer une sécurité maxi-

doiv

male et des performances optimales. Lisez ce manuel avant

d'assembler et de faire fonctionner cette déchiqueteuse. Ne

pas respecter les instructions peut aboutir à une électrocution, des brûlures, un incendie, ou des blessures personnelles.

AVERTISSEMENT

2-1. POUR RÉDUIRE LES RISQUES DE

BRÛLURES, D'INCENDIE, DE SECOUSSES ÉLECTRIQUES OU DE

BLESSURES :

1. RESPECTER TOUTES LES MESURES DE

SÉCURITÉ incluses dans ce manuel avant et durant

l'opération de cette tondeuse.

POUR RÉDUIRE LES RISQUES DE SECOUSSES

2.

ÉLECTRIQUES, cette tondeuse doit etre reliée au

sol. Elle est équipée avec un cordon électrique ayant

un conducteur de mise à terre de l'équipement ainsi

qu'une fiche de terre pour réduire tout risque d'électrocution. Branchez-la dans une prise appropriée

installee et mise à terre selon les instructions des

codes et ordonnancees locaux.

DANGER: Toute connexion incorrecte du conducteur

de mise à terre de l’équipement risque de provoquer

une électrocution en cas de dysfonctionnement.

Contactez un électricien qualifié si vous n'êtes pas sur

de votre prise domestique. Ne modifiez jamais la fiche

forunie avec la tondeuse.

INSPECTER L'APPAREIL À LA RECHERCHE DE

3.

DOMMAGES qu'auraient pu subir le carter, le cordon

ique ou à la fiche. Toutes les fixations doivent

électr

être bien serrées. Ne pas utiliser l'appareil si la

gâchette ne permet pas de l'arrêter adéquatement.

Ne jamais utiliser l'appareil si le cordon électrique ou

la fiche est endommagé, si le moteur ou le coupeherbe lui-même ne f

s'il est tombé, s'il a été endommagé, laissé à l'e

térieur ou plongé dans l'eau. Ne pas utiliser l'appareil

si les trous de ventilation sont bouchés. Toujours

enlever les débris qui risqueraient de limiter la circulation de l'air par les trous de v

pièces endommagées qui sont ébréchées, cassées

ou qui ont été endommagées d'une manière ou d'une

autre et qui r

isquer

graves blessures. Ce produit possède une double isolation - il n'y a aucune par

onctionne pas correctement ou

entilation.

Remplacer les

aient d'être projetées et causer de

le à l'intérieur.

tie répar

ab

x

4.

INSTRUCTIONS DE MISE À LA MASSE Cet outil

doit être mis à la masse lors de son utilisation afin de

réduire tout r

isque d’électrocution pour l’utilisateur.

L’outil est équipé d’un cordon électrique à 3 conducteurs et d’une prise à 3 broches avec masse afin de

s’adapter au réceptacle de masse adéquate. Si votre

appareil est destinéà être utilisésous une tension

inférieur à 150 volts, il possède une prise comme celle

illustrée dans le schéma A de la figure 2-1A. S’il est

destiné à être utilisé sous 150 ou 250 volts, il possède

une prise comme illustré dans le schéma D Fig. 2-1A.

Un adaptateur, schéma B et C, est disponible pour

brancher les prises femelles à broches comme illustré

sur le schéma 2-1A. Les oreilles rigides, poignées ou

autres de couleur verte, doivent être connectées à

une masse per

manente, telle qu’un boîtier de prise

avec une prise de terre correcte. Aucun adaptateur

n’est fourni pour la prise illustrée dans le schéma D.

VIS

MÉTALLIQUE

CACHE DU

BROCHE DE

MISE À LA

TERRE

ADAPTATEUR

PLOT DE

MISE À LA

TERRE

BROCHE DE

BOÎTER DE

PRISE AVEC

TERRE

MISE À LA

TERRE

2-1A

MÉTHODE POUR BRANCHER CORECTEMENT UNE RALLONGE

OLLONGE

R

-

(A) NOUER AINSI QU’IL

EST DÉCRIT

CORDON DE

L’APPAREIL

(B) CONNECTER LA

PRIS MÂLE A

VEC LA

PRISE FEMELLE

2-1B

5.

CORDON PROLONGATEUR - Utilisez seulement

des rallonges pour utilisation en extérieur à trois fils

qui possède trois broches avec prise de terre et une

ise femelle qui soit compatible avec la prise de l’ap-

pr

pareil.

1514

Page 9

2 - MEASURES DE SECURITE

RECOMMANDATIONS DE CALIBRE DE FIL MINIMUM

TENSION

LONGUEUR DU

CORDON

CALIBRE DE FIL

REQUIS

120

25 pieds / 7,5m 18 A.W.G.*

50 pieds / 15m 16 A.W.G.*

100 pieds / 30m 16 A.W.G.*

*American Wire Gauge (CALIBRE AMERICAIN)

2 - MEASURES DE SECURITE

Tableau 1

a. En utilisant le déchiqueteuse, un cordon prolongateur

de taille adéquate doit être utilisé pour la sécurité et

pour empêcher les pertes de puissance et la surchauffe.

b. Le cordon prolongateur doit être spécialement conçu

pour usage extérieur et porter la mention «SJ» ou

«SJT» et le suffixe «WA». Au Canada, le cordon prolongateur doit por

c. S'assurer que le cordon prolongateur ne comporte

pas de fils dénudés ni desserrés et que l'isolant n'est

pas endommagé. En cas de dommages, remplacer le

cordon prolongateur avant d'utiliser l'appareil.

NE MALTRAITEZ PAS LE CORDON D'ALIMENTA-

- Ne transportez jamais l'équipement électrique

TION

par le cordon et ne tirez jamais sur le cordon pour le

débrancher de l'embase. Laissez le cordon dégagé de

l'opérateur et des obstacles à tout moment. N'exposez

pas le cordon aux surfaces chauffées, à l'huile ou

l'eau. Ne tirez pas sur le cordon autour de bords tranchants, de coins et ne refermez pas la porte sur le

cordon.

Eviter un environnement dangereux. N'utilisez pas

6.

d'équipement électrique dans des emplacements

humides.

7. Ne pas utiliser sous la pluie. L'eau pénétrant dans

un outil électrique augmente le risque d'électrocution.

. Ne pas maltraiter le cor

8

cordon d'alimentation pour le débrancher du réceptacle. Tenez le cordon éloigné de la chaleur, de l'huile,

des bords tranchants et des pièces mobiles.

Remplacez immédiatement les cordons endommagés. Des cordons endommagés augmentent le

isque d'électrocution.

r

SÉCURITÉ PERSONNELLE

enir les enfants à l’écar

9. T

cart de la zone de travail.

10.

Porter des vêtements appropriés: Ne porter ni

bijoux ni vêtements amples; ils peuvent se faire prendre dans une partie mobile de l’appareil. L’utilisation

de gants et chaussures en caoutchouc est recom

mandée pour travail à l’extérieur. Couvrir les cheveux

longs.

ter des lunettes de pr

or

11. P

masque ou autre pour vous protéger de la poussière.

12. Restez vigilan;

faites.

utilisez un appareil électrique.

Utilisez v

ter la mention «SFTW»

don.

Ne tirez jamais sur le

t:

enir tout le monde à l’é

T

otection

faites attention à ce que v

otre sens comm

- por

un quand v

N’utilisez pas l’ap-

ter un

ous

ous

pareil par moments de fatigue ou sous l’influence de

drogues, alcool ou médicaments. Un instant d’inattention peut causer de graves blessures.

13. Eviter les démarrages accidentels: Ne déplacez

pas l'équipement électrique branché avec le doigt sur

le commutateur. Soyez certain que le commutateur

est sur arrêt quand vous branchez.

Ne pas tenir l’appareil à bout de bras: Veuillez à

14.

toujours bien être campé et gardez toujours votre

équilibre. Une bonne posture et équilibre vous permettent de mieux contrôler l’outil en toutes circonstances.

15. Aucun accessoire ou pièce n’est nécessaire avec

cet outil de jardin.

mandée car cela risque d’augmenter les risques de

blessures

16.

N'utilisez pas la force. L’utiliser à la puissance

conçue et il aura une meilleure performance et les

risques de blessure seront réduites.

Débrancher l’outil avant de l’ajuster, changer les

17.

accessoires ou le remiser.

démarrer l’outil accidentellement.

18. Stockez les outils à l'intérieur. Lorsqu’il n’est pas en

utilisation, remiser l’appareil dans un endroit sec,

inaccessible aux enfants

Entretenez les outils. Garder la partie tranchante

19.

propre et aiguisée pour une performance optimale et

un moindre risque de blessures. Suivre les instructions de lubrification et de changements de pièces.

Contrôler le cordon d’alimentation de votre taille-haie

périodiquement, et si endommagé, le faire réparer par

un service après vente agréé. Vérifier les prolongateurs périodiquement et les remplacer si endommagés. Garder les poignées sèches, propres et

exemptes de toute trace d’huile ou graisse.

Vérifier les pièces endommagées: Avant toute utili-

20.

sation de l’outil, toute pièce endommagée doit être

soigneusement inspectée afin de déterminer si son

fonctionnement est adéquat à sa fonction prévue.

Contrôler le montage, l’alignement et les fixations des

pièces mobiles, vérifier qu’il n’y a pas de pièces

cassées ou tout autre problème qui affecteraient son

fonctionnement. Toute pièce endommagée devrait

être réparée correctement ou remplacée par un centre de service agréé sauf indication contraire dans ce

.

ue

-

-

man

2-2.

1.

2.

PRÉCAUTION CONSERNANT L'UTILISATION DE

V

de

de pierres

objet étr

Ne mettez pas v

du cor

ment ou de la descente de déchargement, v

aussi à ce que les habits n'entrent pas à l'intér

la chambre ou de la descente lorsque la machine

onctionne

f

PONCEUSE/TONDEUSE

eillez par

ant être bro

v

, de bouteilles

.

anger

ps à l'intér

.

Leur utilisation n’est pas recom-

Cela empêche de faire

ticuliérement à ce que les matiéres

y es ne contiennent pas de métal,

, de canettes ou tout autre

os mains ou toute autre par

ieur de la chambre de charge

tie

eillez

ieur de

-

3. Portez des gants lorsque vous vous servez de la

machine.

4. Avant de mettre la machine en route, assurez-vous

que toutes les vis et autres dispositifs d'assemblage

sont correctement fixés.

5. La machine doit être utilisée seulement sur un sol

plan et ferme.

6. Avant de mettre la machine en route assurez-vous

que la chambre de chargement est vide.

7. Le moteur doit être propre de tout d bris ou de tout

autre dépôt.

8. Maintenez toutes les protections et tous les

déflecteurs en bon état de marche.

9. A tout moment restez à l'écart de la descente de

déchargement.

10. Ne vous approchez pas trop et gardez votre visage et

votre corps à l'écart de l'ouverture de chargement.

11. Ne tirez jamais la machine par son fil d'alimentation et

maintenez le fil à l'écart de l'eau et de tout objet

coupant.

12. Débranchez le fil d'alimentation lorsque la machine

n'est pas utilisée.

13. Si la machine venait à se bloquer, éteignez le

moteur, débranchez le fil d'alimentation,

assurez-vous que toutes les parties mobiles sont

complètement arrêtées avant de dégager les d bris

responsables du bourrage.

14. Assurez-vous que le fil d'alimentation est toujours en bon état. Un fil comportant une isolation

défectueuse est extrêmement dangereux et peut

occasionner un incendie, une électrocution ou de

sévères blessures corporelles.

15. L'utilisation de n'importe quel outil peut conduire

à la projection de corps étrangers dans vos

eux, pouvant aboutir à des dommages graves aux

y

yeux. Avant d'utiliser un outil électrique, portez toujours des lunettes de sécurité ou des verres de sécu-

ec des protections latérales et une protection

v

ité a

r

complète du visage quand nécessaire. Nous recom-

’utilisation des ces dispostifs de sécurité est foretement

L

recommandé afim de réduire tout risque de blessures

accidentelles

.

Ne placez jamais les mains dans la

glissière de décharge sous peine de

ve

a

lessure g

b

r

2-1

mandons un grand masque de sécurité pour la vision,

à utiliser par-dessus des lunettes ou des verres de

sécurité standard avec protections latérales.

2-3. EXPLICATION DES NOTA, AVERTISSE-

MENTS ET SYMBOLES DE LA

GARANTIE

1. Une REMARQUE sert à transmettre des informations

complémentaires, à mettre en évidence une explication particulière, ou à étendre une instruction.

2. Un AVERTISSEMENT identifie une procédure qui

risque de causer de graves blessures corporelles ou

de graves dommages à l'appareil et/ou les deux si elle

n'est pas respectée ou si elle est mal effectuée.

Le (SYMBOLE DE GARANTIE) indique que si

3.

les procédures ou instructions n'ont pas été

respectées, les dommages causés annuleront la

antie et que les réparations seront à la charge du

gar

propriétaire. Pour des services autres que ceux d'entretien à effectuer par l'utilisateur, s'adresser à un

Centre de réparation agréé McCulloch. La garantie du

fabricant sera nulle et non avenue si des dommages

ou des conditions causés par de mauvaises pratiques

d'entretien rendent le produit inutilisable.

POUR TOUT ENTRETIEN OU SERVICE AU TITRE

4.

DE LA GARANTIE, s'adresser à un Centre de service agréé McCulloch dont le nom figure sous la

rubrique «SCIES» des pages jaunes de l'annuaire.

2-4. SYMBOLES INTERNATIONAUX

1. Ne placez jamais les mains dans la glissière de

décharge sous peine de blessure grave (Figure 2-1).

2. Il est fortement recommandé de respecter les con-

signes de sécurité personnelle pour réduire les

risques d'accident ou de blessures (Figure 2-2).

CONSERVER CES

INSTRUCTIONS

2-2

1716

Page 10

3 - INSTRUCTIONS POUR MONTAGE

3 - INSTRUCTIONS POUR MONTAGE

3-1. MONTAGE DES ROUES

REMARQUE: Cherchez le petit sachet de quincaillerie qui

contient deux vis creuses à tête he

rondelles plates, deux petites rondelles plates et deux

goupilles fendues.

1. Placez une roue sur l'axe, suivie d'une rondelle plate.

Fixez à l'aide d'une goupille fendue insérée dans l'orifice pratiqué à l'extrémité de l'axe, et pliez les extremites de la goupille à l'aide d'une pince. Voir Figure 31A.

2. Placez les garde-roues sur la roue en appuyant.

3. Positionnez l'ensemble d'axe à l'intérieur du tube support ainsi qu'illustré dans la Figure 3-1B, en alignant

l'orifice de l'axe avec l'orifice dans le support. Placez

une rondelle frein et une petite rondelle plate sur la vis

creuse à tête hexagonale, puis guidez-les à travers

l'orifice du tube support et l'orifice de l'axe. Le rondelle

plate doit s'appuyer sur l'axe.

4. Assemblez l'autre tube support sur l'autre extrémité

de l'axe en procédant de la même façon.

5. Fixez la seconde roue sur l'axe en procédant de la

façon décrite dans l'étape 1

3-1A

ube

T

Suppor

Vis creuse à tête

hexagonale, petite

ondelle plate et

r

rondelle frein

t

xagonale, deux grandes

.

Axe

Rondelle plate

et goupille

fendue

Inser

ube

T

t de

3-2. ASSEMBLAGE DU TUBE CHARGEUR

1. Enlever le tube d'alimenteur en desserrant & le printemps a chargé des boutons. Calculer 3-2A.

2. Poser l'assemblée moteur en bas sur la surface plate

avec le revêtement de bouchon en bas.

3. Placer un 2x4 sous le fond de moteur pour obtenir

l'angle correct pour attacher la trousse de roue.

4. Les roues doivent être vers le plancher (même

comme le bouchon).

5. Aligner le sommet de tubes de soutien (de 2 trous)

avec de 2 trous dans le logement moteur. Le matériel

d'utilisation (les rondelles de fiat de rondelles frein, et

4 boulons de sort attachent les tubes de soutien au

logement moteur & resserre.

6. Tenir l'unité de et rattacher l'alimenteur. Le tube en

resserrant 3 printemps a chargé des boutons.

AVERTISSEMENT

Faites attention lorsque vous serrez les vis d'assemblage

afin d'éviter tout contact avec les lames de coupe qui sont

très affutées.

Tube

chargeur

Goulotte

3-2A

Flasque

Bouton d'accès

à la glissière de

décharge

Vis

Lames

3-3. MONTAGE DE LA TRÉMIE

REMARQUE: Cherchez le petit sachet de quincaillerie

contenant cinq vis de fixation à sens unique et des ron

delles.

Placez la trémie au sommet du tube chargeur, alignez

1.

les orifices. Fixez à l'aide des vis de fixation et des

rondelles. Veuillez vous reporter a la Figure 3-3A de

votre manuel de l'utilisateur.

4 - INSTRUCTIONS D’UTILISATION

4-1. OPERATION

Lisez et comprenez toutes les instructions de sécurité

incluses dans ce manuel avant d'utiliser votre tondeuse. Ne

pas respecter ces précautions risque de provoquer des

accidents y compris un incendie, une électrocution ou toute

blessure corporelle grave.

1. Connectez la tondeuse sur une prise électrique conforme.

2. Pour faire démarrer la tondeuse, dépressez le bouton

situé sur l'arriere du moteur.

3. Pour arrêter la tondeuse, placez le bouton en position

Arrêt ( Schéma 4-1 )

Interrupteur

Marche/Arrêt

Interrupteur de

Protection de

Surcharge

4-1

-

3-3A

4-2. PROTECTION DE SURCHARGE ET

MOTEUR

BLOQUAGE En cas de bloquage de la machine, la protection de surcharge peut couper le moteur. Pour redémarrer,

eteignez la machine et deconnectez le cordon d'alimentation.

Desserrez les boutons de cage et enlevez l'assemblage du

couvercle superieur; sortez tout debris bloque depuis la

chambre de coupage. Si l'assemblage du covuercle

supérieur se bloque et n'est pas dégageable, tournez le

couteau-V en poussant un morceau de bois au travers de

la chute du wagon supérieure pour tourner le couteau-V et

permettre l'enlevement de l'assemblage du couvercle.

Reprogrammez enfin le bouton de protection de surcharge

(Voir Schéma 4-1 ).

IMPORTANT

Avant de replacer l'ensemble du couvercle supérieur

assurez-vous que le coupeur en V est positionné ainsi qu'il

est montr sur la (Fig. 4-2).

Replacez l'ensemble du couvercle supérieur avec le bouton écrou de couvercle supérieur et assurez-vous qu'il est

bien serré. Si le bouton écrou du couvercle supérieur n'est

pas serré fermement, le moteur ne démarrera pas étant

donné que l'interrupteur de fermeture ne sera pas activé.

3-1B

Axe

D’assemb

3-2B

la

e

g

4-2

1918

Page 11

4 - INSTRUCTIONS D’UTILISATION

5 - ENTRETIEN

4-3. FIXATION DU SAC À COMPOSTE

Placez un sac à ordures à forte résistance en utilisant la

sangle de fixation de sac à composte. (Fig. 4-3)

4-3

4-4. ALIMENTER DES FEUILLES ET DES

PETITES HAIES DE JARDIN - WAGON

DU HAUT

La chute en pente du wagon du haut est prévue pour

accepter des feuilles et des petites haies de jardin.

Le coupage et l'emincage sont réalisés par aspiration

naturelle des débris vers la chambre de coupage. Ne suralimentez pas et n'alimentez pas avec des débris humides

car ils risquent de bloquer la chambre de lame ainsi que la

chute de décharge ( Schéma 4-4 ).

4-4

4-5. ALIMENTER DES BRINDILLES ET DES

BRANCHES - WAGON DU HAUT

La plus petite chute arrière du wagon du haut accepte des

brindilles de jardin de toutes tailles.

Le coupage et l'émincage sont réalisés par la même action

qu'avec la chute avant. Si un éminçage plus fin est requis

que ce qui est réalisé, ré-alimentez l'éminçage jusqu'à ce

que vous obteniez le résultat voulu. (Fig. 4-5 )

N'alimentez pas des branches solides au travers les deux

chutes du haut.

4-5

4-6. DESCENTES LATÉRALES

Les descentes allongées situées à l'arrière de la machine

sont conçues spécialement pour recevoir des débris de

jardin plus importants et des branches allant jusqu' à 38mm

de diamètre.

IMPORTANT

Lorsque vous chargez de longs et gros matériaux, contrôlez la vitesse de chargement en retenant les matériaux

afin de ne pas coincer ou de faire forcer le moteur. (Fig. 4-

6)

AVERTISSEMENT

En aucune circonstance vous ne devez introduire vos

mains dans les descentes pendant que la machine est en

route. Il n'est pas nécessaire de forcer le chargement des

débris étant donné l'action de succion naturelle du Trisecta.

4-6

Votre tondeuse est concue pour un faible niveau d'entretien, y compr

Le moteur de cette tondeuse n'exige aucun entretien particulier. Pour les meilleurs résultats possibles, les lames

doivent être maintenues aiguisées à tout moment. Lorsque

les lames sont émoussées, elles coupent beaucoup moins.

La tondeuse elle-même sera moins efficace lorsque les

lames sont émoussées. Si cela arrive, tournez les lames à

double côté ou changez immédiatement les lames.

is un nettoyage et une inpsection de routine.

ATTENTION

Avant tout éntretien,, eteignez la machine et déconnectez

le cordon d'alimentation.

5-1. ENTRETIEN DE LAME

• Eteignez l'appareil et déconnectez le cordon d'alimentation en vous assurant que toutes les parties en mouvement se soient complètement arrêtées.

• Portez des gants avant de commencer tout entretien

des lames coupantes.

BLOQUAGE. Si les lames commencent à se bloquer,

tournez le bouton sous le moteur. Si les lames ne peuvent

se libérer, veuilelz consulter le sinstructions d'assemblage

puis enlever l'obstruction.

DÉMONTAGE

1. Desserrez les boutons de capot et retirez l'assemblage du couvercle supérieur.

2. Faites tourner la base de coupe dans le sens inverse

des aiguilles d'une montre et placez une pièce de bois

entre la base de coupe et la paroi de la chambre de

coupe afin de coincer la base de coupe. (Fig. 5-1A)

3. Retirez l'écrou de retenue central en le tournant dans

le sens nverse des aiguilles d'une montre au moyen

d'une clé de 17 mm.

4. Retirez la rondelle carrée, du r ceptacle carré, du

coupeur en V afin de découvrir la base de coupe.

Faire très attention à ne pas toucher les lames

coupantes

Si la chute d'

loquent, ne placez J

b

d'éjection pour essayer de clarifier l'obstruction, car

ous r

v

.

jection ou que les lames coupantes se

é

AMAIS v

isquez de vous blesser gravement.

5-1A

os mains dans la chute

5-2. ENTRETIEN DES LAMES DE COUPAGE

AVERTISSEMENT

Avant d'enlever le bouton du Wagon du Haut, assurez-vous

que l'appareil soit bien éteinte et que la tete d'extension soit

bien ôtée; attendez que la machine se soit completèment

arrêtée.

Pour vérifier ou changer les lames de coupe à double tranchant il n'est pas nécessaire de retirer la base de coupe.

Pour les retirer dévissez simplement les écrous prisonniers

à l'aide de la clé hexagonale de 6 mm fournie avec la

machine et tournez les à 180. Ces lames sont à double

tranchant et peuvent être utilisées sur chaque face.

Lorsqu'elles sont émoussées sur les deux côtés changezles et assurez-vous qu'elles sont fixées fermement.

ASSEMBLAGE Procédez de la façon inverse utilisée pour

le démontage mais en vérifiant soigneusement chaque élément. Assurez-vous que la base de coupe est assemblée

avec les plateaux

racleurs dirigés vers le moteur et que la rondelle bloquante

est située sous l'écrou central de fixation. (Fig. 5-2A)

Avant de replacer l'ensemble du couvercle supérieur

assurez-vous que le cooupeur en V est positionné ainsi

qu'il est montré sur la Fig. 5-2B. Replacez l'ensemble du

couvercle supérieur et fixez fermiiment les boutons de

capot. Si le bouton de capot n'est pas serré fermement, le

moteur ne démarrera pas étant donné que l'interrupteur de

fermeture ne sera pas activé.

5-2A

5-2B

5-3. NETTOYAGE

Après l'utilisation, frottez toujours l'extérieur de la tondeuse

avec un chiffon propre et humide pour enlever toute saleté.

ez l'intér

y

Netto

tout résidu. N'arrosez pas avec de l'eau.

2120

ieur de la chambre de coupage et enle

vez

Page 12

6 - GARANTIE LIMITÉE DE DEUX ANS

1. DURÉE

La durée de la garantie des produits McCulloch s'établit comme suit : DEUX (2) ANS à compter de la date initiale de l'achat

à condition que l'appareil soit utilisé à des fins personnelles, domestiques, pour des travaux de ferme ou de ranch, et qu'il

ne soit pas utilisé à des fins de location;

produits sont utilisés à des fins commerciales, professionnelles, institutionnelles ou de location.Cette garantie vous donne

des droits légaux spécifiques. Vous pouvez également bénéficier d'autres droits qui varient selon les états ou provinces.

PAR LA PRÉSENTE, MCCULLOCH DÉCLINE TOUTE RESPONSABILITÉ EN CE QUI CONCERNE TOUTE GARANTIE

IMPLICITE APRéS LES DATES D'EXPIRATION APPLICABLES DE CETTE GARANTIE LIMITÉE EXPRESSE. (Certains

états ou certaines provinces ne permettant pas de limitation de la durée des garanties implicites. Les limitations ci-dessus

peuvent donc ne pas s'appliquer à votre cas.)

2. PAR QUI LA GARANTIE EST-ELLE OFFERTE

McCulloch U.S.A 1-800-521-8559

12802 Leffingwell Rd. Santa Fe Springs, CA90670 USA

3. QUI EST COUVERT PAR CETTE GARANTIE

A. L'acheteur d'un produit McCulloch (à condition que le produit ne soit pas destiné à la revente).

B. Toute personne à qui le produit est légalement cédé pour la durée de la garantie implicite ou écrite applicable au pro-

duit.

C. Toute autre personne autorisée, aux termes de la garantie ou des lois applicables, à demander au Garant de respecter

ses obligations. (Les parties sus-mentionnées sont ci-aprés désignées sous le nom de «Utilisateur.»)

4. CE QUI EST COUVERT PAR CETTE GARANTIE

Toute défaillance survenant pendant la période de garantie applicable et qui découle de défauts de matériaux ou de fabrication.

5. CE QUI N'EST PAS COUVERT PAR CETTE GARANTIE

A. Tout dommage indirect ou consécutif découlant possiblement de la défaillance ou du mauvais fonctionnement d'un

produit McCulloch. (Comme certains états ou certaines provinces n'autorisent pas l'exclusion ou la limitation des dommages indirects ou consécutifs. Ces limitations peuvent ne pas s'appliquer à votre cas.)

B. Toute défaillance découlant d'un accident, d'un usage abusif, d'une négligence ou du défaut d'utiliser le produit con-

formément aux directives fournies dans la ou les Notices d'utilisation qui accompagnent le produit, ou découlant d'une

réparation inadéquate par un Centre de réparation non agréé.

C. Les réglages normaux décrits dans la ou les Notices d'utilisation fournies avec le produit.

D. Tout composant ou accessoire qui n'est pas vendu ou fabriqué par le Garant.

E. Les préparations ou assemblages préalables à la livraison.

F. Cette garantie ne s'applique pas aux accessoires ni à l'entretien ou aux réglages normaux du produit décrits dans la

ou les Notices d'utilisation.

6. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE

atuitement pour l'utilisateur les composants qui s'a

Réparer ou remplacer g

A.

antie applicab

gar

B. S'assurer que le Centre de réparation agréé est remboursé pour les frais de matériaux et de main-d'oeuvre engagés

pour eff

7. RESPONSABILITÉS DE L'UTILISATEUR AUX TERMES DE CETTE GARANTIE

A.

L'utilisateur doit livrer ou expédier le produit McCulloch couvert par la garantie au concessionnaire chez qui le produit

a été acheté ou au Centre de répar

B. Les frais d'expédition, le cas échéant, sont à la charge de l'utilisateur.

C. Veiller à l'entretien, à l'utilisation et au remisage du produit avec une diligence raisonnable, tel qu'il est expliqué dans

la ou les Notices d'utilisation.

8. MOMENT POUR LE GARANT DE S'ACQUITTER DE SES OBLIGATIONS AUX TERMES DE CETTE GARANTIE

Les dates de répar

A.

normale de travail et suivant la disponibilité des piéces.

B. Si le délai pour la réparation excéde dix (10) jours à compter de la date de livraison au réparateur agréé, la garantie

sera prolongée du nombre de jours supplémentaires pendant lesquels le produit est inutilisable.

C. Si l'utilisateur n'obtient pas entiére satisfaction auprés de son Centre de réparation local, il doit se mettre en rapport

McCulloch,ou composer le n

ectuer les réparations au titre de la garantie conformément aux politiques et procédures de garantie établies.

le

r

.

ation des produits sous gar

uméro sans fr

QUATRE-VINGT-DIX (90) JOURS à compter de la date d'achat initial lorsque les

iode de

ation ag

vérent déf

Une preuv

réé le plus proche

antie seront fixées pour le Centre de répar

.

ais

.

e d'achat est requise.

ectueux pendant la pér

ation en f

onction de la charge

MANUAL DEL USUARIO

Astillador Eléctrica Destrozador

Modelo : MCS2001

SEGURIDAD

OPERACION

MANTENIMIENTO

OR DE LEER

V

TENCIA • F

VER

AD

Para su propia seguridad, favor de leer este manual antes de intentar operar su unidad nueva. Si no se siguen estas

instrucciones se pueden provocar serias heridas personales. Favor de dedicar un trizadora para familiarizarse cada vez

que se utilice la unidad.

A

2322

Page 13

INTRODUCCION 1 - RENSEIGNMENTS GENERAUX

FAVOR DE LEER

Estimado Cliente,

Gracias por comprar un producto McCulloch. Con una operación y mantenimiento adecuados le proporcionará años de ser-

vicio.

Con el objeto de hacer un mejor uso de su inversión, ASEGURESE de familiarizarse con el contenido de TODO el Manual

del Usuario antes de intentar operar o dar mantenimiento a su unidad.

Asegurarse de seguir cuidadosamente las ilustraciones graduales de este manual para poner en marcha, operar y dar man-

tenimiento a su nuevo producto.

En el manual se encontrarán las siguientes señales:

Una NOTA se utiliza para comunicar una información adicional, para enfatizar una explicación particular, o para extender la

descripción de un paso.

VERTENCIA

AD

Una

puede provocar serias heridas personales o daños a la unidad y/o ambas cosas.

La (

sado anulará la garantía y las reparaciones correrán a cuenta del propietario.

Todo el servicio que no sea el mantenimiento del usuario se llevará a cabo en un Centro de Servicio Autorizado McCulloch.

Los daños o las condiciones que hagan inoperable este producto debido a las prácticas inadecuadas de mantenimiento anularán la garantía del fabricante.

SIMBOLO DE GARANTIA) notifica que a menos que se sigan las instrucciones o procedimientos, cualquier daño cau-

PARA GARANTIA O SERVICIO CONTACTE A SU CENTRO DE SERVICIO AUTORIZADO McCULLOCH MAS

CERCANO LISTADO BAJO “SIERRAS” EN LAS PAGINAS AMARILLAS DE SU DIRECTORIO TELEFONICO.

o PRECA

UCION

identifica un procedimiento que

NOTA, ADVERTENCIA / PRECAUCION y GARANTIA.

, si no se lleva a cabo o se hace en forma inadecuada,

olva

T

Superior

Tolva Superior

de Seguridad

Enrosca

Conducto

Lateral

Ruedas (L)

ON-OFF

Interruptor

Interruptor de prot

EcciónContra carga

Excesiva

Mandos de acceso a la

tobera de descarga

Rampa de Descarga

McCulloch Corporation

Departamento de Servicio

Ruedas (R)

Tapas

de la

Rueda

Árbol

Perna (L)

Perna (R)

ESPECIFICACIONES

Entrada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120V~, 60Hz, 14 A

Velocidad de no Carga. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3300 RPM

Tamaño de Tolva . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13.4”x8.5”x7.9” (340x215x200mm)

Dia.

de Corte Máximo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1/2” (38mm)

Tamaño de Rueda . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7” (180m)

Peso neto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78.3 Lbs. (35.6 Kg)

2524

Page 14

2 - PRECAUTIONES DE SEGURIDAD

RECOMENDACIONES PARA EL CALIBRE

MINIMO DEL ALAMBRE

VOLTIOS

LONGITUD DE

CABLE DE

EXTENSION

TAMAÑO

REQUERIDO DEL

ALAMBRE

120

25 pies / 7.5m 18 A.W.G.*

50 pies / 15m 16 A.W.G.*

100 pies / 30m 16 A.W.G.*

*Calibre para Alambre de los E.U.A.

2 - PRECAUTIONES DE SEGURIDAD

FAVOR DE LEER - CONSERVE

ESTAS INSTRUCCIONES

Durante el uso del equipo deberán respetarse

una serie de precauciones básicas para asegurar la máxima seguridad y un nivel de rendimiento óptimo. Lea este manual antes de montar y utilizar este triturador. Si no respeta las instrucciones siguientes podría provocar descargas

eléctricas, incendios o lesiones personales.

ADVERTENCIA

2-1. PARA REDUCIR EL RIESGO DE

CHOQUEN ELECTRICO, INCENDIO O

HERIDAS PERSONALES:

1. SIGA TODAS LAS INSTRUCCIONES DE SEGURIDAD indicadas en el presente manual antes/durante

la operación de esta Trizadora.

PARA REDUCIR EL RIESGO DE CHOQUE ELEC-

2.

TRICO

equipa con un cordón contando con un conductor de

equipo a la tierra y enchufe a la tierra para reducir el

riesgo de choque eléctrico. Enchufa en una salida

apropiada que es exactamente instalada y conectada

con la tierra de acuerdo con todos códigos y ordenanzas locales.

PELIGRO: Incorrecta conexión del conductor de

equipo a la tierra puede resultar en un riesgo de

choque electrico en caso de funcionamiento defectuoso. Ponga contacto con un eléctricista autorizada si

Ud. duda de que el recéptaculo sea exactamente

conectado con la tierra. No modifique el enchufe provisto de la trizadora.

REVISE LA UNIDAD POR SI HAY DAÑOS en el

3.

bastidor, el cable o el enchufe. Mantenga todos los

sujetadores apretados. No la use si el interruptor no

apaga su unidad adecuadamente. Nunca la opere si

el cab

funciona como debería, o si la unidad ha sido golpeada, dañada o dejada caer en agua. Nunca la haga

funcionar con alguna aper

Conserve todas las aperturas libres de desechos que

puedan reducir el flujo de aire. Reemplace las partes

dañadas que estén astilladas

estado, de manera que puedan volar y causar alguna

her

piezas servibles en el interior.

4.

REVISE LA UNIDAD POR SI HAY DAÑOS en el

bastidor, el cable o el enchufe. Mantenga todos los

sujetadores apretados

apaga su unidad adecuadamente. Nunca la opere si

el cable o el enchufe han sido dañados, si el motor no

funciona como debería, o si la unidad ha sido golpea

da, dañada o dejada caer en agua. Nunca la haga

, esta trizadora debe ser puesta en la tierra. Se

le o el enchufe han sido dañados, si el motor no

tura de aire bloqueada.

, cuarteadas o en mal

Este producto es dob

ida ser

ia.

No la use si el interr

.

le aislado - no ha

uptor no

funcionar con alguna apertura de aire bloqueada.

Conserve todas las aperturas libres de desechos que

puedan reducir el flujo de aire. Reemplace las partes

dañadas que estén astilladas

estado, de manera que puedan volar y causar alguna

herida seria. Este producto es doble aislado - no hay

piezas servibles en el interior.

TORNILLO DE

PIN DE

TIERRA

APTADO

AD

TOMA DE

TIERRA

PIN DE

TIERRA

2-1A

, cuarteadas o en mal

METAL

COVERTURA

DE LA SALID

DE TIERRA

A

MÉTODO DE FIJAR EL COABLE DE EXTENSIÓN

SET E

CABLE

(A) ATE EL CABLE TAL

COMO SE MUESTRA

CABLE DE EXTENSION -

5.

extensión trifasicas exteriores que tengan clavijas de

tres puntas de tomatierra y receptáculos que acepten

la clacija del apar

y

-

CABLE DEL

APARATO

(B) CONECTE LA

CLAVIJA Y EL

RECEPTACULO

2-1B

Use solamente cables de

ato.

Tableau 1

a. Durante el uso de la herramienta, utilice un cable pro-

longador del tamaño adecuado para evitar pérdidas

de energía y sobrecalentamiento.

b. El cable de extensión debe estar diseñado específica-

mente para uso en exteriores y marcado con “SJ” o

“SJT” y con el sufijo “WA”. En Canadá, el cable de

extensión debe estar marcado con “SFTW”.

c. Revise la extensión del cable de energía por si hay

alambres sueltos o expuestos, o por si el aislamiento

está dañado. En caso de que sea así, reemplácelo

antes de utilizar el aparato.

NO ABUSE DEL CABLE DE ALIMENTACIÓN - No

transporte el equipo por el cable, ni tire del mismo

para desconectarlo de una toma eléctrica. Mantenga

el cable lejos del operador y asegúrese en todo

momento de que no suponga un obstáculo.No exponga el cable a superficies calientes, aceite o agua. No

tire del cable alrededor de esquinas pronunciadas ni

cierre puertas a su paso.

Evite los entornos peligrosos. No utilice el equipo

6.

en lugares húmedos o mojados.

7. No utilizar bajo la lluvia. Si penetra agua en la herramienta aumentará el riesgo de descarga eléctrica.

8. No abuse del cable de alimentación. No tire del

cable para desconectarlo del receptáculo. Mantenga

el cable alejado de fuentes de calor, aceite o bordes

afilados o piezas móviles. Reemplace los cables deteriorados inmediatamente. Los cables deteriorados

aumentan el riesgo de descarga eléctrica.

SEGURIDAD PERSONAL

9. Mantenga a los niños alejados. Todo visitante

deberá de mantenerse a una distancia suficiente para

que no resulte lastimado

10. Vístase apropiadamente. No utilice ropa floja o joyería, pudieran ser atrapadas en partes en movimiento. Utilice guantes de hule y zapatos apropiados para

trabajar en el exterior. Utilice protector en el pelo para

contener pelo largo.

11. Utilice lentes pr

utilice mascar

su unidad.

12.

Este alerta, fíjese lo que hace y utilice sentido

común cuando opere su herramienta. No utilice la

herramienta cuando se encuentre fatigado o bajo la

influencia del alcohol o drogas o medicamentos. Un

momento de descuido mientras opere su herramienta

podría resultar en graves daños a su persona.

13. Evite el arranque no intencionado. No transporte el

equipo mientr

uptor está desactiv

interr

14.

No se estire en demasía. Manténgase bien posicionado y balanceado al operar su unidad. Un buen

balance de su cuer

otectores de seguridad.

a protector

as está conectado

.

Siempre

a la car

a par

ado al enchuf

po le ayudara a tener mejor control

a cuando opere

. Asegúrese de que el

.

lo

ar

2726

de la herramienta en condiciones inesperadas.

15.

No existen accesorios necesarios para la

operación de esta herramienta de jardinería. El

uso de cualquier accesorio o aditamento en esta herramienta de jardinería no son recomendados. El uso

de estos accesorios o aditamentos incrementaran el

riesgo de accidente y daños al usuario.

No force la herramienta. La herramienta correcta

16.

hará su trabajo mejor y más seguro a la velocidad a

que fue diseñada.

Desconecte la clavija de la fuente eléctrica antes

17.

de pretender hacer algún ajuste o almacenamiento de su unidad.

su herramienta se active accidentalmente.

18. Almacene la herramienta en un lugar interior

mientras no se encuentre en uso. Cuando no utilice

su herramienta esta deberá ser almacenada en el

interior en lugares secos y alejados del alcance de

niños.

Herramientas de mantenimiento. Mantenga los adi-

19.

tamentos de corte bien afilados y limpios para un

mejor desempeño y para reducir el riesgo de una

lesión. Siga las instrucciones para lubricar y cambiar

los accesorios. Inspeccione el cable eléctrico periódicamente, y si esta dañando repárelo de inmediato

en un centro de servicio autorizado. Mantenga el

maneral de su herramienta limpio libre de aceite,

agua y grasa.

Revise partes dañadas. Antes de usar su her-

20.

ramienta, la guarda u otra parte dañada de su herramienta, deberá ser checada cuidadosamente para

determinar que operara apropiadamente y desarrollara su función. Revise la alineación de partes en

vimiento

mo

ción que afecte la operación. La guarda u otra parte

dañada deberá ser repar

, a menos que se indique alguna otr

izado

autor

en este manual.

Tal medida de prevención evita que

as de partes y cualquier otra condi-

, rotur

ada por un centro de ser

vicio

a cosa

2-2. PRECAUCIONES PARA EL USO DE LA

PICADOR/TRIZADOR

1. Se debe usar sumo cuidado para asegurarse de

que los materiales a picar no contengan metal,

piedras, botellas, latas u otros objetos extraños.

2. No permita que las manos, u otra parte del cuer-

po o la ropa, entren a los conductos de ali

mentación o al conducto de descarga mientr

máquina esté funcionando.

3. Use guantes al hacer funcionar la máquina.

Antes de hacer par

4.

todos los tornillos y otras sujeciones estén correctamente ajustados.

tir la máquina, asegúrese de que

as la

-

Page 15

2 - PRECAUTIONES DE SEGURIDAD

3 - INSTRUCCIONES DE ENSAMBLE

5. La máquina se debe usar sólo en superficies firmes a

nivel.

6. Antes de hacer partir la máquina, asegúrese de que

la caja de corte esté vacía.

7. Se debe mantener el motor limpio de desperdicios y

otras acumulaciones.

8. Mantenga todas las protecciones y deflectores en

buenas condiciones de uso.

9. Manténgase alejado en todo momento del conducto

de descarga.

10. No se estire demasiado y mantenga su cara y cuerpo

alejados de la entrada de alimentación.

11. Nunca tire la máquina del cordón electrico y mantenga el cordón alejado del agua y de los bordes afilados.

12. Desconecte el cordón eléctrico cuando no se esté

usando la máquina.

13. Si la máquina se obstruye, apague el motor,

desconecte el cordón eléctrico y asegúrese de

que todas las partes móviles se hayan detenido antes

de quitar los desperdicios atascados.

14. Asegúrese de mantener siempre el cordón eléctrico en buenas condiciones. Un cordón con el

aislador roto es sumamente peligroso y puede resultar en un incendio, golpe eléctrico o serias lesiones

personales.

15. El uso de cualquier herramienta puede provocar

que se lancen objetos a los ojos, lo cual podría

producir serias lesiones oculares. Utilice protección

ocular y un protector facial completo.

Recomendamos el uso de una máscara de seguridad

sobre las gafas o protectores oculares con escudos

laterales.

El uso de estos ar

mente recomendado para reducir el riesgo de lesiones

accidentales

ticulos de seguridad personal es alta-

.

2-3. EXPLICACION DE NOTA, ADVERTEN-

CIA Y SIMBOLO DE GARANTIA

Una NOTA

1.

adicional, llamar la atención sobre una explicación

particular, o para ampliar una instrucción.

2. Una

3. EL (

procedimientos deben llevarse al cabo, cualiquier daño

invalidará la garantía y los gastos de la reparaciones

serán asumidos por el dueño. Cualquier otro servicio,

con excepción del mantenimiento del usuario, deberá

ser realizado por un Centro de Servicio Autorizado

McCulloch. Los daños o condiciones causadas por

practicas de mantenimiento inadecuadas, las cuales

hagan que el producto sea inoperable invalidarán la

garantía del fabricante.

PARA LA GARANTIA O EL SERVICIO contacte al

4.

Centro de Servicio Autorizado McCulloch más cercano

registrado bajo la sección de “sierras” en las páginas