MC550

Operator's manual / /96083000300 / 2010-01

01.12.10 AP

433691 Printed in the U.S.A.

SAFETY RULES

Safe Operation Practices for Walk-Behind Powered Ro ta ry Tillers

TRAINING

• Read the Owner’s Manual care ful ly. Be thor ough ly

fa mil iar with the controls and the proper use of the

equip ment. Know how to stop the unit and disengage

the controls quickly.

• Never allow children to operate the equipment. Never

allow adults to op er ate the equipment without proper

instruction.

• Keep the area of operation clear of all persons, par tic u lar ly small children, and pets.

PREPARATION

• Thoroughly inspect the area where the equipment is

to be used and remove all foreign objects.

• Disengage all clutches and shift into neutral before

starting the engine (mo tor).

• Do not operate the equipment with out wearing ad e quate

outer gar ments. Wear footwear that will im prove footing

on slippery surfaces.

• Handle fuel with care; it is highly flammable.

• Use an approved fuel container.

• Never add fuel to a running engine or hot engine.

• Fill fuel tank outdoors with extreme care. Never fill fuel

tank indoors.

• Replace gasoline cap securely and clean up spilled

fuel before restarting.

• Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive motors

or electric starting motors.

• Never attempt to make any adjustments while the

engine (motor) is running (except where specifically

rec om mend ed by manufacturer).

OPERATION

• Do not put hands or feet near or under rotating parts.

• Exercise extreme caution when op er at ing on or cross ing gravel drives, walks, or roads. Stay alert for hidden

hazards or traffic. Do not carry pas sen gers.

• After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, thoroughly in spect

the tiller for any damage, and repair the damage before

restarting and op er at ing the tiller.

• Exercise caution to avoid slipping or falling.

• If the unit should start to vibrate ab nor mal ly, stop the

engine (motor) and check immediately for the cause.

Vi bra tion is generally a warning of trouble.

• Stop the engine (motor) when leaving the operating

position.

• Take all possible precautions when leav ing the ma chine

unattended. Disengage the tines, shift into neutral, and

stop the engine.

• Before cleaning, repairing, or inspecting, shut off the

engine and make certain all moving parts have stopped.

Disconnect the spark plug wire, and keep the wire away

from the plug to prevent accidental starting. Disconnect

the cord on electric motors.

• Do not run the engine indoors; exhaust fumes are

dangerous.

• Never operate the tiller without proper guards, plates,

or other safety protective devices in place.

• Keep children and pets away.

• Do not overload the machine capacity by attempting

to till too deep at too fast a rate.

• Never operate the machine at high speeds on slippery

surfaces. Look behind and use care when backing.

• Never allow bystanders near the unit.

• Use only attachments and accessories approved by

the manufacturer of the tiller.

• Never operate the tiller without good visibility or light.

• Be careful when tilling in hard ground. The tines may

catch in the ground and propel the tiller forward. If this

occurs, let go of the handlebars and do not restrain the

machine.

MAINTENANCE AND STORAGE

• Keep machine, attachments, and accessories in safe

work ing condition.

• Check shear pins, engine mounting bolts, and other

bolts at frequent intervals for proper tightness to ensure

the equip ment is in safe working condition.

• Never store the machine with fuel in the fuel tank inside

a building where ignition sources are present, such

as hot water and space heaters, clothes dryers, and

the like. Allow the engine to cool before storing in any

enclosure.

• Always refer to the operator’s guide instructions for

im por tant details if the tiller is to be stored for an extended period.

- IMPORTANT -

CAUTIONS, IMPORTANTS, AND NOTES ARE A MEANS OF

ATTRACTING ATTENTION TO IMPORTANT OR CRIT I CAL

IN FOR MA TION IN THIS MANUAL.

IMPORTANT: USED TO ALERT YOU THAT THERE IS A

POS SI BIL I TY OF DAM AG ING THIS EQUIP MENT.

NOTE: Gives essential information that will aid you to better un der stand, incorporate, or execute a particular set of

instructions.

Look for this symbol to point out im por tant safety precautions. It means

CAUTION!!! BE COME ALERT!!! YOUR

SAFE TY IS INVOLVED.

CAUTION: Always disconnect spark

plug wire and place wire where it can not contact spark plug in order to pre vent ac ci den tal starting when setting

up, trans port ing, adjusting or making

re pairs.

WARNING

The engine exhaust from this product con tains chem i cals known to the State of Cal i for nia to cause cancer, birth defects, or other

reproductive harm.

2

PRODUCT SPECIFICATIONS

Gasoline Capacity: 0.9 Quarts (0,85 L)

Unleaded Regular

Oil (API-SG-SL): SAE 10w-30(Above 32°F/0°C)

(Capacity: 20 oz./0.6L) SAE 5w-30(Below 32°F/0°C)

Spark Plug: Champion RJ19LM or J19LM

(Gap: .030"/0.76mm)

CONGRATULATIONS on your purchase of a new tiller. It

has been designed, en gi neered and manu fac tured to give

you the best pos sible de penda bil ity and per form ance.

Should you experience any prob lems you can not easily

remedy, please contact your nearest authorized service

center. We have com pe tent, well-trained tech ni cians and

the proper tools to service or repair this unit.

Please read and retain this manual. The in struc tions will

enable you to assemble and main tain your tiller prop erly.

Always observe the “SAFETY RULES”.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for

and using your tiller.

• Follow instructions under “Maintenance” and “Stor age”

sections of this Manual.

IMPORTANT: THIS UNIT IS EQUIPPED WITH AN INTERNAL

COMBUSTION ENGINE AND SHOULD NOT BE USED ON

OR NEAR ANY UNIMPROVED FOREST-COVERED, BRUSHCOVERED OR GRASS COVERED LAND UNLESS THE

ENGINE'S EXHAUST SYSTEM IS EQUIPPED WITH A SPARK

ARRESTER MEETING APPLICABLE LOCAL LAWS (IF ANY).

IF A SPARK ARRESTER IS USED, IT SHOULD BE MAINTAINED

IN EFFECTIVE WORK ING ORDER BY THE OPERATOR.

IN THE STATE OF CALIFORNIA, A SPARK ARRESTER IS

REQUIRED BY LAW (SECTION 4442 OF THE CALIFORNIA

PUBLIC RESOURCES CODE). OTHER STATES MAY HAVE

SIMILAR LAWS. FEDERAL L AWS APPLY ON FEDERAL LANDS.

SEE YOUR AUTHORIZED SERVICE CENTER/DEPARTMENT

FOR SPARK ARRESTER.

TABLE OF CONTENTS

SAFETY RULES ............................................................ 2

PRODUCT SPECIFICATIONS ....................................... 3

CUSTOMER RESPONSIBILITIES ................................. 3

ASSEMBLY ................................................................. 4-5

OPERATION ...............................................................6-9

MAINTENANCE SCHEDULE ...................................... 10

MAINTENANCE .....................................................10-12

SERVICE & ADJUSTMENTS ................................. 13-14

STORAGE .................................................................... 15

TROUBLESHOOTING ................................................. 16

PARTS ..................................................................... 17-21

3

ASSEMBLY

LOWER HANDLE

COLUMN

Your new tiller has been assembled at the factory with exception of those parts left unassembled for shipping purposes.

To ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely. Use

the correct tools as necessary ensure proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier. Standard

wrench sizes are listed.

(1) Utility Knife

OPERATOR’S POSITION (See Fig. 1)

When right or left hand is mentioned in this manual, it

means when you are in the operating position (standing

behind tiller handles).

FRONT

RIGHTLEFT

OPERATOR'S POSITION

Fig. 1

CONTENTS OF HARDWARE PACK

(1) Washer

Manual

(3) Handle Knobs

UNPACK CARTON & INSTALL HANDLE

(See Fig. 2 and 3)

CAUTION: Be careful of exposed

sta ples when handling or disposing of

carton material.

IMPORTANT: WHEN UNPACKING AND AS SEM BLING TILLER,

BE CAREFUL NOT TO STRETCH OR KINK CABLE(S).

• Cut cable ties securing handle column.

• Remove all packing from carton.

• Remove lower handle column from carton.

• Position lower handle column between bent tubes,

lining up holes as shown.

• Secure lower handle column using two (2) 4-1/2" carriage bolts, two (2) washers and two (2) handle knobs.

Tighten securely.

LOWER HANDLE

COLUMN

BOLTS

Fig. 2

• Remove upper handle column from carton.

• Route cable(s) as shown and slide upper handle column

onto lower handle column.

• Secure upper handle column using two (2) 2-1/2" carriage bolts and two (2) handle knobs. Tighten se cure ly.

• Cut away carton.

• Cut cable ties securing tiller to skid. Re move tiller from

skid by pulling backwards.

UPPER

HANDLE

COLUMN

BENT

TUBES

KNOBS

WASHERS

(1) Carriage Bolt

5/16”-18 unc x 4-1/2”

(2) Carriage Bolts

5/16”-18 unc x 2-1/2”

(1) Clevis Pin

(1) Hairpin Clip

TINE

CONTROL

CABLE

Fig. 3

BOLTS

KNOBS

4

ASSEMBLY

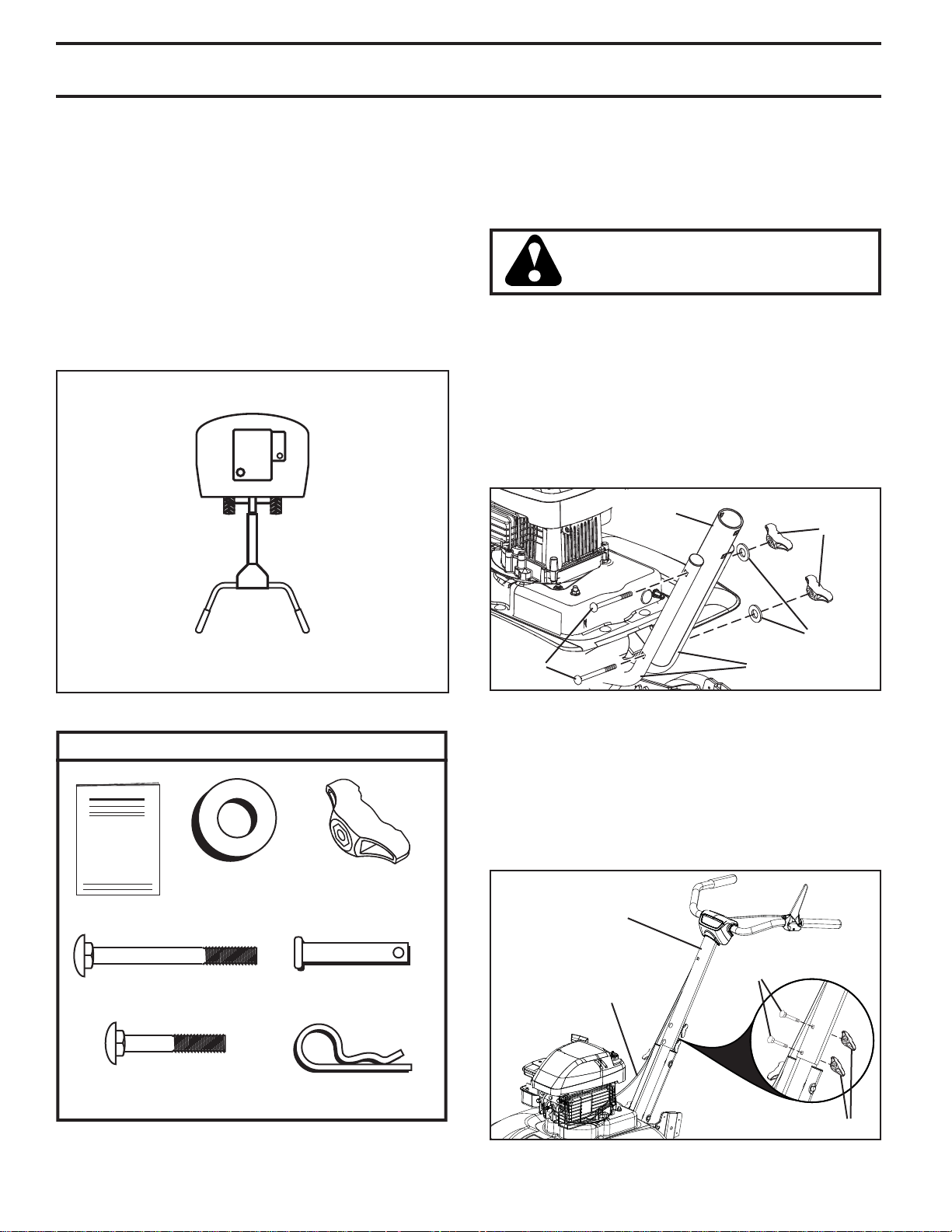

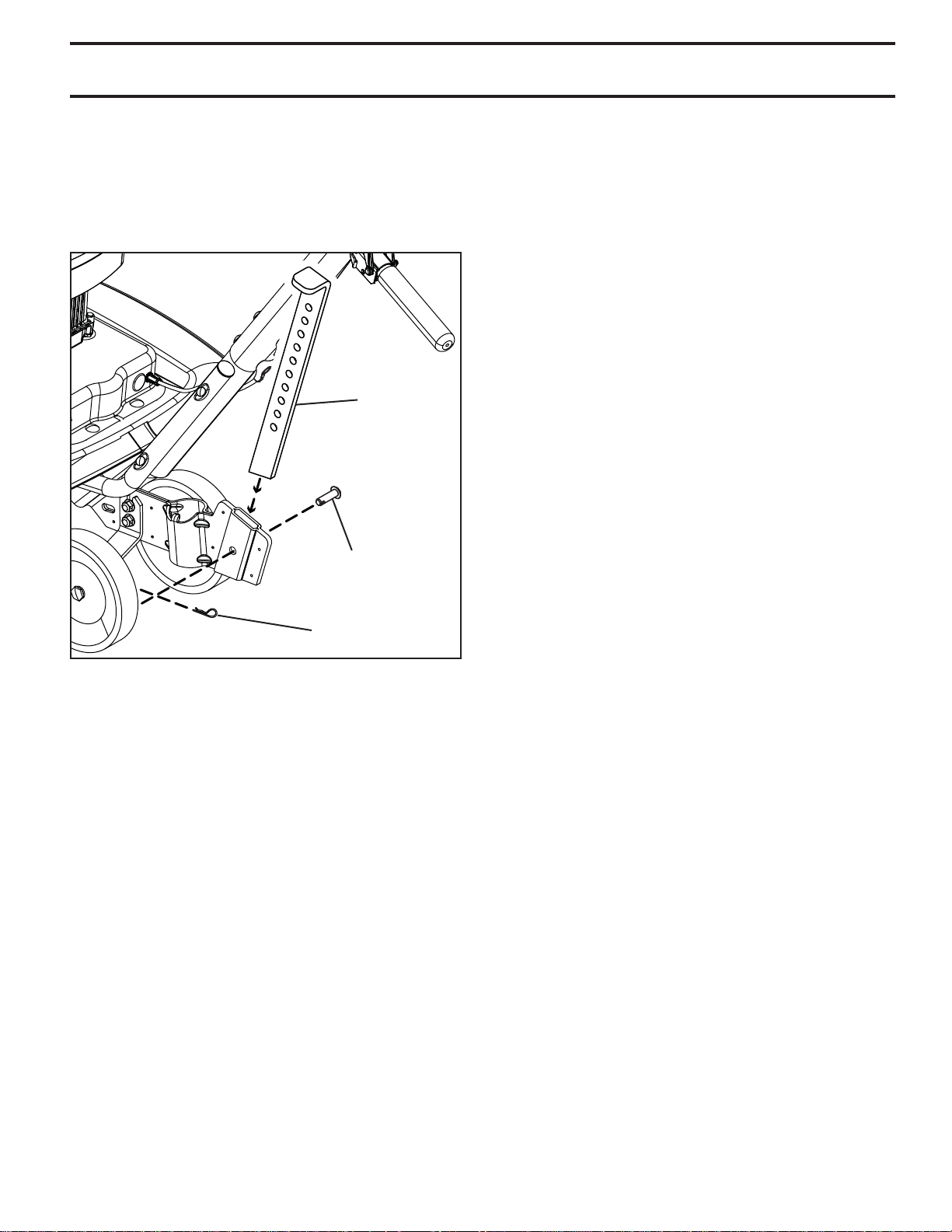

TO INSTALL DEPTH STAKE (See Fig. 4)

• Remove screw(s) securing depth stake to skid and

discard the screw(s).

• Slide depth stake down into transport arm track, lining up a hole in the depth stake with hole in transport

arm.

• Install clevis pin and hairpin clip.

DEPTH

STAKE

CLEVIS PIN

HAIRPIN CLIP

Fig. 4

TILLING WIDTH

• Tilling width may be adjusted to better handle your

tilling con di tions (See “TINE ARRANGEMENT” in the

Service and Adjustments section of this manual.)

TINE OPERATION

• Check tine operation before first use. (See “TINE

OPERATION CHECK” in the Service and Adjustments

section of this manual.)

5

OPERATION

KNOW YOUR TILLER

READ THIS MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TILLER.

Compare the illustrations with your tiller to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

These symbols may appear on your Tiller or in literature supplied with the product. Learn and understand their meaning.

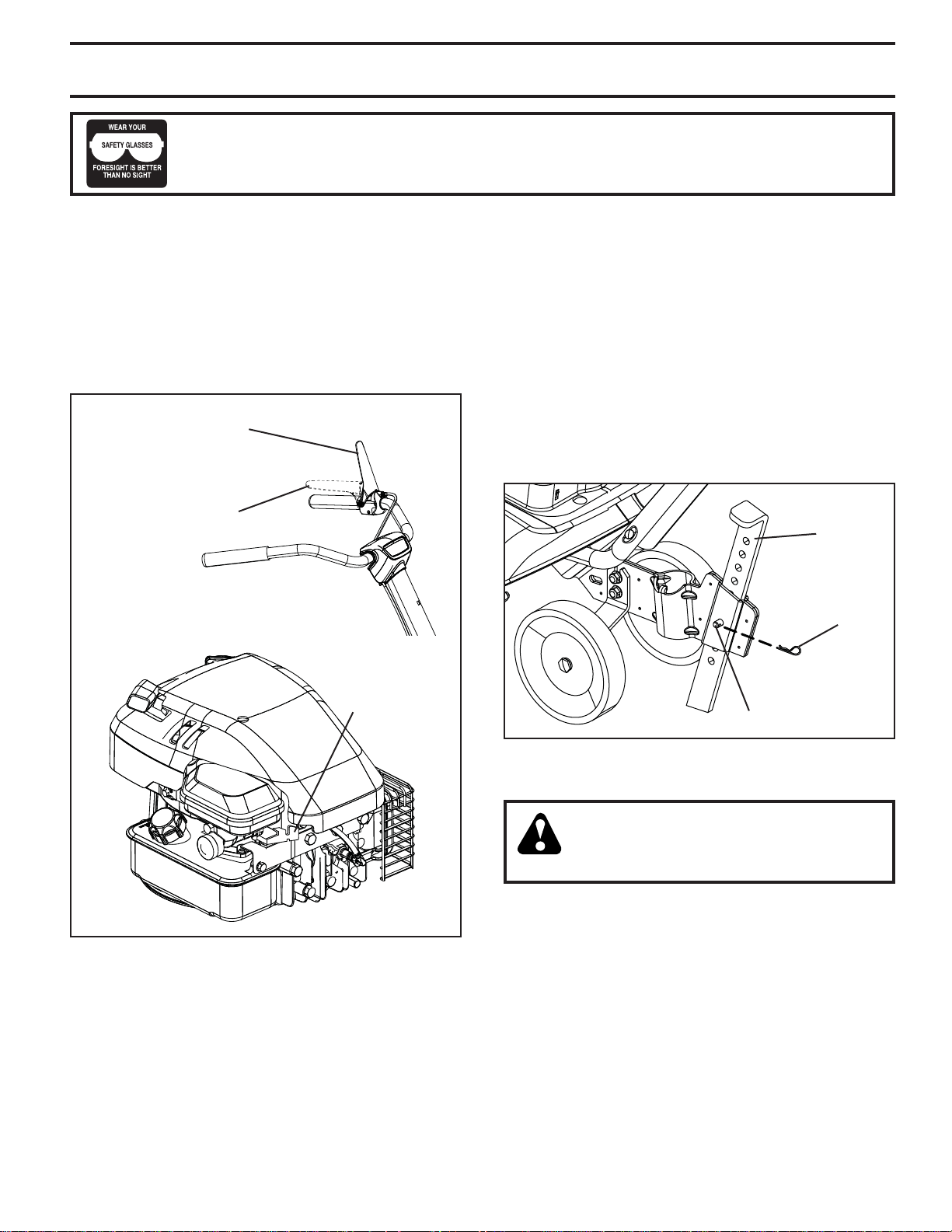

FORWARD TINE CONTROL

PRIMER

RECOIL

STARTER

HANDLE

DEPTH STAKE

Fig. 5

THROTTLE

CONTROL

MEETS ANSI SAFETY REQUIREMENTS

Our tillers conform to the safety standards of the American National Standards Institute.

DEPTH STAKE - Controls forward speed and the depth at

which the tiller will dig.

FORWARD TINE CONTROL - Engages tines in forward

direction.

RECOIL STARTER HANDLE - Used to start the engine.

direction.

THROTTLE CONTROL - Controls engine speed.

PRIMER - pumps additional fuel from the carburetor to the

cylinder for use when starting a cold engine.

6

OPERATION

The operation of any tiller can result in foreign objects thrown into the eyes, which can result in

severe eye damage. Always wear safety glasses or eye shields before starting your tiller and while

tilling. We recommend a wide vision safety mask for over spectacles or standard safety glasses.

00155

HOW TO USE YOUR TILLER

Know how to operate all controls before adding fuel and

oil or attempting to start engine.

STOPPING (See Fig. 6)

TINES

1. Release tine control to stop move ment.

ENGINE

2. Move throttle control to "STOP" position.

TINE CONTROL

“OFF” (UP) PO SI TION

TINE CONTROL

“ON” (DOWN) PO SI TION

TILLING

The speed and depth of tilling is regulated by the position

of the depth stake.

The depth stake should always be below the wheels for

digging. It serves as a brake to slow the tiller’s forward

motion to enable the tines to penetrate the ground. Also,

the more the depth stake is lowered into the ground the

deeper the tines will dig.

DEPTH STAKE (See Fig. 7)

Adjust depth stake by removing the hairpin clip and clevis

pin. Change depth stake to desired position. Replace the

clevis pin and hairpin clip.

• For normal tilling, set depth stake at the second or third

hole from the top.

DEPTH

STAKE

HAIRPIN

CLIP

Fig. 6

TINE OPERATION (See Fig. 6)

• Squeeze tine control to handle.

THROTTLE

CONTROL

CLEVIS PIN

Fig. 7

TO TRANSPORT

CAUTION: Before lifting or trans port ing, allow tiller engine and muffler to

cool. Disconnect spark plug wire. Drain

gasoline from fuel tank.

AROUND THE YARD

• Adjust depth stake so clevis pin is in bottom hole.

• Push tiller handles down, raising tines off the

ground.

• Push or pull tiller to desired location.

AROUND TOWN

• Disconnect spark plug wire.

• Drain fuel tank.

• Transport in upright position to prevent oil leakage.

7

Loading...

Loading...