McCue BOL-WALKWAY Instructions Manual

McCue Corporation

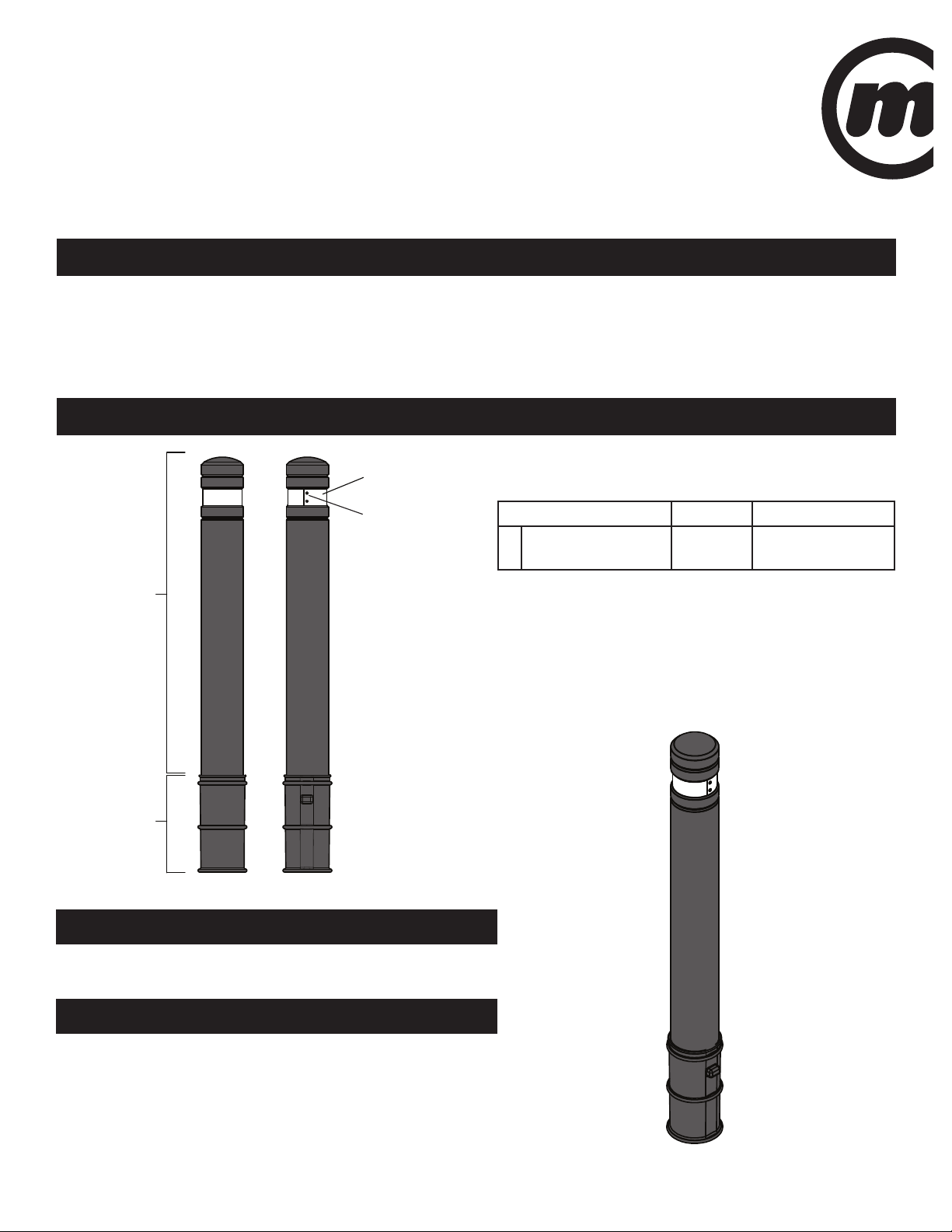

FRONT

REFLECTIVE

STRIP

BOLLARD

SLEEVE

RIVETS

BACK

34 cm

[ 13.5 in ]

25 cm

[ 10 in ]

GROUND

GROUND

EXCAVATED

HOLE

SIDE

CUT-AWAY

TARMAC OR

CONCRETE

FRONT

REFLECTIVE

STRIP

BOLLARD

SLEEVE

RIVETS

BACK

34 cm

[ 13.5 in ]

25 cm

[ 10 in ]

GROUND

GROUND

EXCAVATED

HOLE

SIDE

CUT-AWAY

TARMAC OR

CONCRETE

Walkway Bollard

Installation Instructions

Tools and Hardware Required

String Line or similar•

Spirit or Bubble Level•

Tape Measure•

Marking Pen or Pencil•

Appropriate Excavation Tools for •

bollard hole

Concrete Mixing Tools including •

water

Assembly

Figure 1

1. Layout

Identify the intended bollard location(s) using the Tape

Measure and String Line, and mark for excavation.

80lb bag of 4000 psi Concrete •

25lb bag of Sand •

Damp Cloth•

In The Box

Discription Quantity Part Number

1 Walkway Bollard/

Sleeve Assembly

Check to ensure the WalkWay Bollard arrived fully

assembled and undamaged. A fully assembled

unit can be seen in Figure 1.

Bollard and Sleeve components are locked

together, DO NOT try to separate.

1 BOL-WALKWAY

REV20100422

2. Marking & Drilling

Check with site agents and managers before proceeding to ensure

they agree with the bollard location(s). If the floor is not finished,

enquire about the thickness of the finished ground-works, be it

tarmac, concrete or paving stones.

McCue Corporation | 35 Congress Street, Suite 150, Salem MA 01970

Phone: 800.800.8503 or 978.741.8500 | Fax: 978.741.2542 | www.mccuecorp.com

© 2010 McCue Corpotation

Figure 1a

\\Mccue-san1\Shares\us\MKT\Intallation Instruction Source Files\CartStop\WalkWayBollard\WalkWay Bollard Installation Instructions.indd

Pg. 1

Pg. 2

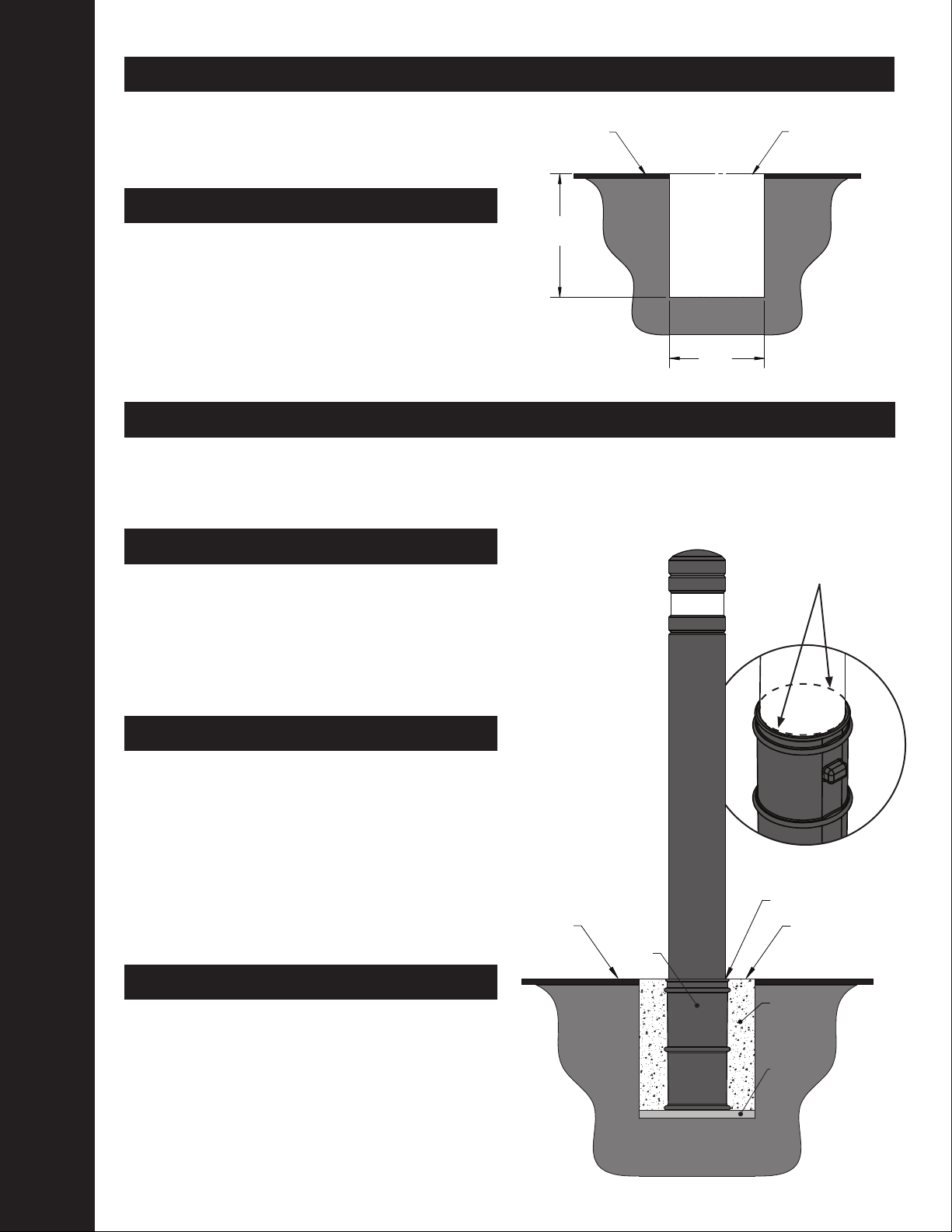

FINISHED

FLOOR

LEVEL

TOP EDGE

OF SLEEVE

CONCRETE

SAND

GROUND

34 cm

[ 13.5 in ]

25 cm

[ 10 in ]

GROUND

FINISHED

FLOOR

LEVEL

GROUND

EXCAVATED

HOLE

SIDE

CUT-AWAY

TARMAC OR

CONCRETE

TARMAC OR

CONCRETE

SLEEVE

34 cm

[ 13.5 in ]

25 cm

[ 10 in ]

GROUND

FINISHED

FLOOR

LEVEL

GROUND

EXCAVATED

HOLE

SIDE

CUT-AWAY

TARMAC OR

CONCRETE

3.

Excavate a hole with a diameter between 20 and 30 cm

(8 to 12 inches) and to a depth of 33 to 35 cm (13 to 14

inches) from the finished floor level. See Figure 2.

4.

Pack the bottom of the excavated hole with layer of

sand, 2.5 to 5 cm thick (1 to 2 inches) and insert the

fully assembled WalkWay Bollard into the hole as

shown in Figure 3.

This step is critical for proper installation, DO NOT SKIP!

5. IMPORTANT!

4. Apply Shell

Ensure the top edge of the Sleeve is flush and parallel with the finished floor level by adding or removing sand. Refer

again to Figure 3. A straight edge run along the finished floor can be used to check the height of the Sleeve. Also,

check to ensure the Bollard is centered within the hole and plumb (perfectly vertical) by using a Spirit or Bubble Level.

6.

The bollard should also be rotated so that the exposed

rivets on the Bollard’s reflective strip are facing away

from the most common line of sight. If multiple Bollards

are being installed near one another, all the rivets

should be facing the same direction.

7.

4. Apply Shell

With the WalkWay Bollard now correctly positioned and

orientated in the hole, carefully pack premixed concrete

around the perimeter. Do not allow concrete to fall in

between the Bollard and the Sleeve.

IMPORTANT: The finished concrete surface should be

flush with the top edge of the Sleeve and the finished

floor. See Figure 3.

8.

Clean the Bollard with a damp cloth and if necessary

use wooded supports to set the bollard over night to

avoid accidental movement before the concrete sets.

Figure 2

Figure 3

TOP EDGE OF

SLEEVE

Figure 3a

WalkwayBollard Installation Instructions

Loading...

Loading...