MCC 68AC353-102 MICROMAX Service Manual

T-348 Manual

OPERATION AND SERVICE

for

68AC353-102

MICROMAX

T-348

REV. 07/2012

© 2012 Mobile Climate Control

TABLE OF CONTENTS

SAFETY SUMMARY Safety-1...............................................................

DESCRIPTION 1-1....................................................................

1.1 INTRODUCTION 1-1.......................................................

1.2 CONFIGURATION IDENTIFICATION 1-1.....................................

1.3 OPTION DESCRIPTION 1-1.................................................

1.3.1 Condenser Cover (Skins) 1-1.............................................................

1.3.2 Condenser Electrical Kit 1-1..............................................................

1.3.3 Condenser Fan Kit 1-1..................................................................

1.3.4 Condenser Refrigeration Kit 1-1...........................................................

1.3.5 Evaporator Skins Kit 1-1................................................................

1.3.6 Evaporator Blower Kit 1-1...............................................................

1.3.7 Evaporator Connection Kit S/D 1-1.......................................................

1.3.8 Evaporator Connection Kit - Indash 1-1.....................................................

1.3.9 Evaporator Connection Kit (Heating) 1-1....................................................

1.3.10 Air Exchange Kit 1-2...................................................................

1.3.11 Controller Kit 1-2......................................................................

1.4 GENERAL DESCRIPTION 1-4...............................................

1.4.1 Compressor Assembly 1-4...............................................................

1.4.2 Discharge Check Valve 1-4...............................................................

1.4.3 Rooftop Unit 1-5......................................................................

1.4.4 Condensing Section 1-6.................................................................

1.4.5 Evaporator Section 1-7..................................................................

1.4.6 Fresh Air System 1-7...................................................................

1.4.7 System Operating Controls And Components 1-8.............................................

1.5 REFRIGERATION SYSTEM COMPONEN T SPECIFICATIONS 1-8.................

1.6 ELECTRICAL SPECIFICATIONS - MOTORS 1-8................................

1.7 ELECTRICAL SPECIFICATIONS - SENSORS AND TRANSDUCERS 1-9............

1.8 SAFETY DEVICES 1-9......................................................

1.9 AIR FLOW 1-10.............................................................

1.10 AIR CONDITIONING REFRIGERATION CYCLE 1-11............................

1.11 HEATING CYCLE 1-13.......................................................

1.12 CONTROL PANEL WITH GR60 RELAY BOARD 1-14.............................

1.13 CONTROL PANEL 1-15......................................................

1.14 LOGIC BOARD 1-16.........................................................

1.15 RELAY BOARD - GR60, 24VDC 1-17............................................

1.15 RELAY BOARD - GR60, 24VDC (Continued) 1-18..................................

1.16 RELAY BOARD, 24VDC 1-19..................................................

1.17 LOGIC BOARD, DATA COMMUNICATIONS 1-20...............................

1.18 CONTROL PANEL (Diagnostic Module) 1-21......................................

OPERATION 2-1......................................................................

2.1 STARTING, STOPPING AND OPERATING INSTRUCTIONS 2-1..................

© 2012 Mobile Climate Control T-348 Rev. 07/2012

1

TABLE OF CONTENTS - Continued

2.1.1 Power to Logic Board 2-1................................................................

2.1.2 Starting 2-1...........................................................................

2.1.3 Self-Test and Diagnostics (Check for Errors and/or Alarms) 2-1..................................

2.1.4 Stopping 2-1..........................................................................

2.2 PRE-TRIP INSPECTION 2-2..................................................

2.3 MODES OF OPERATION 2-2................................................

2.3.1 Temperature Control 2-3................................................................

2.3.2 Cooling Mode 2-3......................................................................

2.3.3 Heating Mode 2-3......................................................................

2.3.4 Boost Pump 2-3.......................................................................

2.3.5 Vent Mode 2-3........................................................................

2.3.6 Compressor Unloader Control 2-3.........................................................

2.3.7 Evaporator Fan Speed Selection 2-4........................................................

2.3.8 Condenser Fan Control 2-4..............................................................

2.3.9 Compressor Clutch Control 2-4...........................................................

2.3.10 Liquid Line Solenoid Control 2-4..........................................................

2.3.11 Alarm Description 2-4..................................................................

2.3.12 Hour Meters 2-4.......................................................................

2.4 MICROPROCESSOR DIAGNOSTICS 2-4.......................................

2.4.1 Control 2-5...........................................................................

2.4.2 Diagnostic Mode 2-5...................................................................

2.4.3 System Parameters 2-5..................................................................

2.4.4 Test Mode 2-6........................................................................

TROUBLESHOOTING 3-1................................................................

3.1 SELF DIAGNOSTICS 3-1....................................................

3.2 SYSTEM ALARMS 3-1.......................................................

3.2.1 Alarm Codes 3-1.......................................................................

3.2.2 Activation 3-1.........................................................................

3.2.3 Alarm Queue 3-1......................................................................

3.2.4 Alarm Clear 3-1.......................................................................

3.2.5 Exit Alarm Queue 3-2..................................................................

3.3 TROUBLESHOOTING 3-2...................................................

3.3.1 Troubleshooting No CAN Communication 3-2.....................................

3.3.2 System Will Not Cool 3-5................................................................

3.3.3 System Runs But Has Insufficient Cooling 3-5................................................

3.3.4 Abnormal Pressures 3-5.................................................................

3.3.5 Abnormal Noise Or Vibrations 3-5.........................................................

3.3.6 Control System Malfunction 3-6...........................................................

3.3.7 No Evaporator Air Flow Or Restricted Air Flow 3-6...........................................

3.3.8 Expansion Valve Malfunction 3-6..........................................................

3.3.9 Heating Malfunction 3-6.................................................................

SERVICE 4-1........................................................................

4.1 MAINTENANCE SCHEDULE 4-1.............................................

© 2012 Mobile Climate Control T-348 Rev. 07/2012

2

TABLE OF CONTENTS - Continued

4.2 OPENING TOP COVER ( E VAPORATOR) 4-2...................................

4.3 REMOVING TOP COVER (CONDENSER) 4-2..................................

4.4 SUCTION AND DISCHARGE SERVICE VALVES 4-3............................

4.4.1 Installing R-134a Manifold Guage Set 4-3....................................................

4.5 PUMPING THE SYSTEM DOWN OR REMOVING THE REFRIGERANT CHARGE 4-4

4.5.1 System Pump Down For Low Side Repair 4-4................................................

4.5.2 Refrigerant Removal From An Inoperative Compressor. 4-5.....................................

4.5.3 Pump Down An Operable Compressor For Repair 4-7.........................................

4.5.4. Removing Entire System Charge 4-7.......................................................

4.6 REFRIGERANT LEAK CHECK 4-7............................................

4.7 EVACUATION AND DEHYDRATION 4-8.....................................

4.7.1 General 4-8...........................................................................

4.7.2 Preparation 4-8........................................................................

4.7.3 Procedure for Evacuation and Dehydrating System (One Time Evacuation) 4-8......................

4.7.4 Procedure for Evacuation and Dehydrating System (Triple Evacuation) 4-8.........................

4.8 ADDING REFRIGERANT TO SYSTEM 4-8.....................................

4.8.1 Checking Refrigerant Charge 4-8..........................................................

4.8.2 Adding Full Charge 4-9.................................................................

4.8.3 Adding Partial Charge 4-9................................................................

4.9 CHECKING FOR NONCONDENSIBLES 4-9...................................

4.10 CHECKING AND REPLACING HIGH OR LOW PRESSURE SWITCH 4-9...........

4.11 FILTER-DRIER 4-10.........................................................

4.11.1 To Check Filter-Drier 4-10.................................................................

4.11.2 To Replace Filter-Drier 4-10..............................................................

4.12 SERVICING THE LIQUID LINE SOLENOID VALVE 4-11.........................

4.12.1 Coil Replacement 4-11...................................................................

4.12.2 Internal Part Replacement 4-11............................................................

4.12.3 Replace Entire Valve 4-11..................................................................

4.13 THERMOSTATIC EXPANSION VALVE 4-12....................................

4.13.1 Valve Replacement 4-12..................................................................

4.13.2 Superheat Measurement 4-12..............................................................

4.14 REPLACING EVAPORATOR RETURN AIR FILTERS 4-13.........................

4.15 COMPRESSOR MAINTENANCE 4-13..........................................

4.15.1 Removing the Compressor 4-13............................................................

4.15.2 Transferring Compressor Clutch 4-14........................................................

4.15.2 Transferring Compressor Clutch (Continued) 4-15..............................................

4.15.3 Shim-less Compressor Clutch 4-15..........................................................

4.15.4 Compressor Oil Level 4-16................................................................

4.15.5 Checking Unloader Operation 4-16.........................................................

4.16 TEMPERATURE SENSOR CHECKOUT 4-17.....................................

4.17 PRESSURE TRANSDUCER CHECKOUT 4-17....................................

© 2012 Mobile Climate Control T-348 Rev. 07/2012

3

TABLE OF CONTENTS - Continued

4.18 REPLACING SENSORS AND TRANSDUCERS 4-18...............................

4.19 LOGIC BOARD REPLACEMENT 4-19..........................................

ELECTRICAL 5-1......................................................................

5-1 INTRODUCTION 5-1.........................................................

LIST OF FIGURES

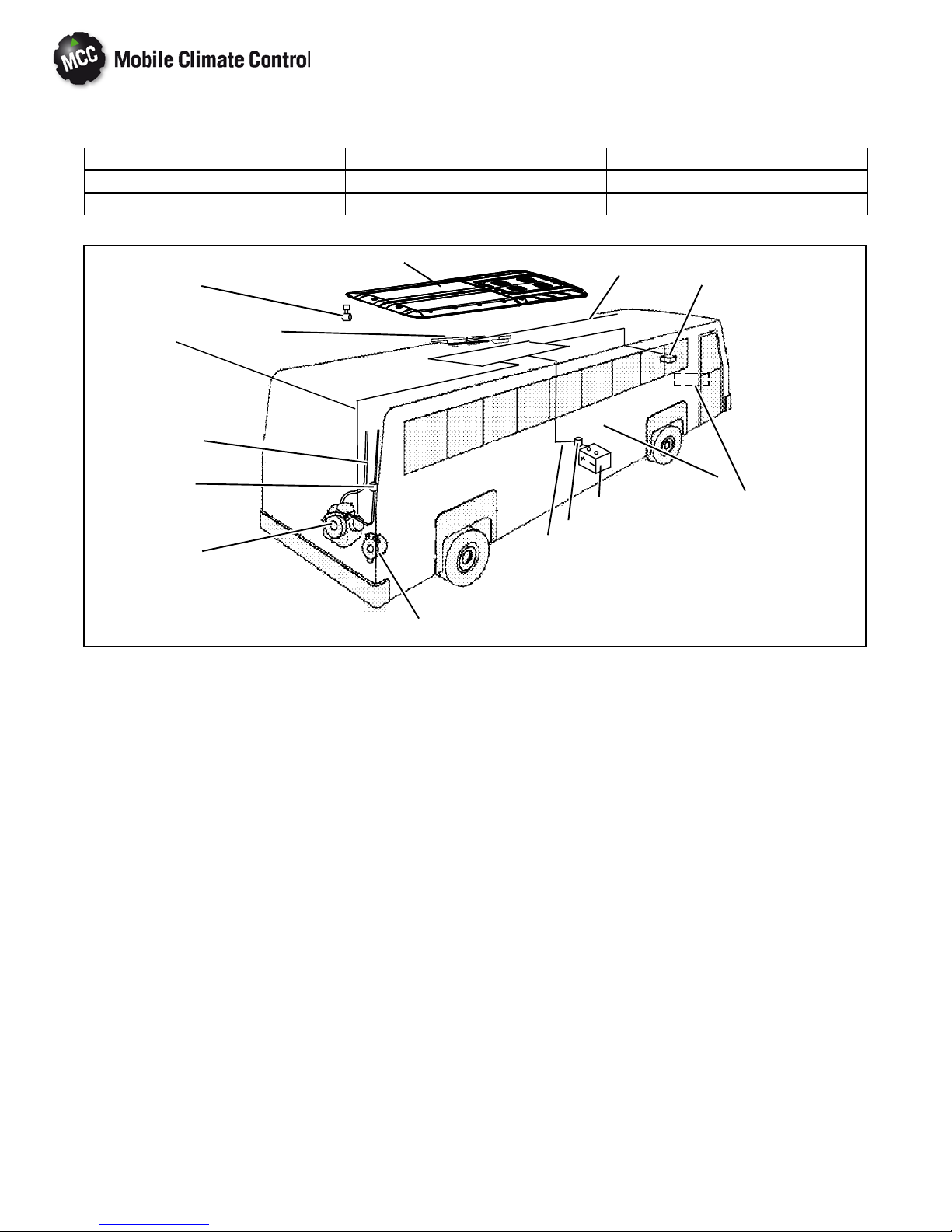

Figure 1-1 System Component Identification 1-4..........................................

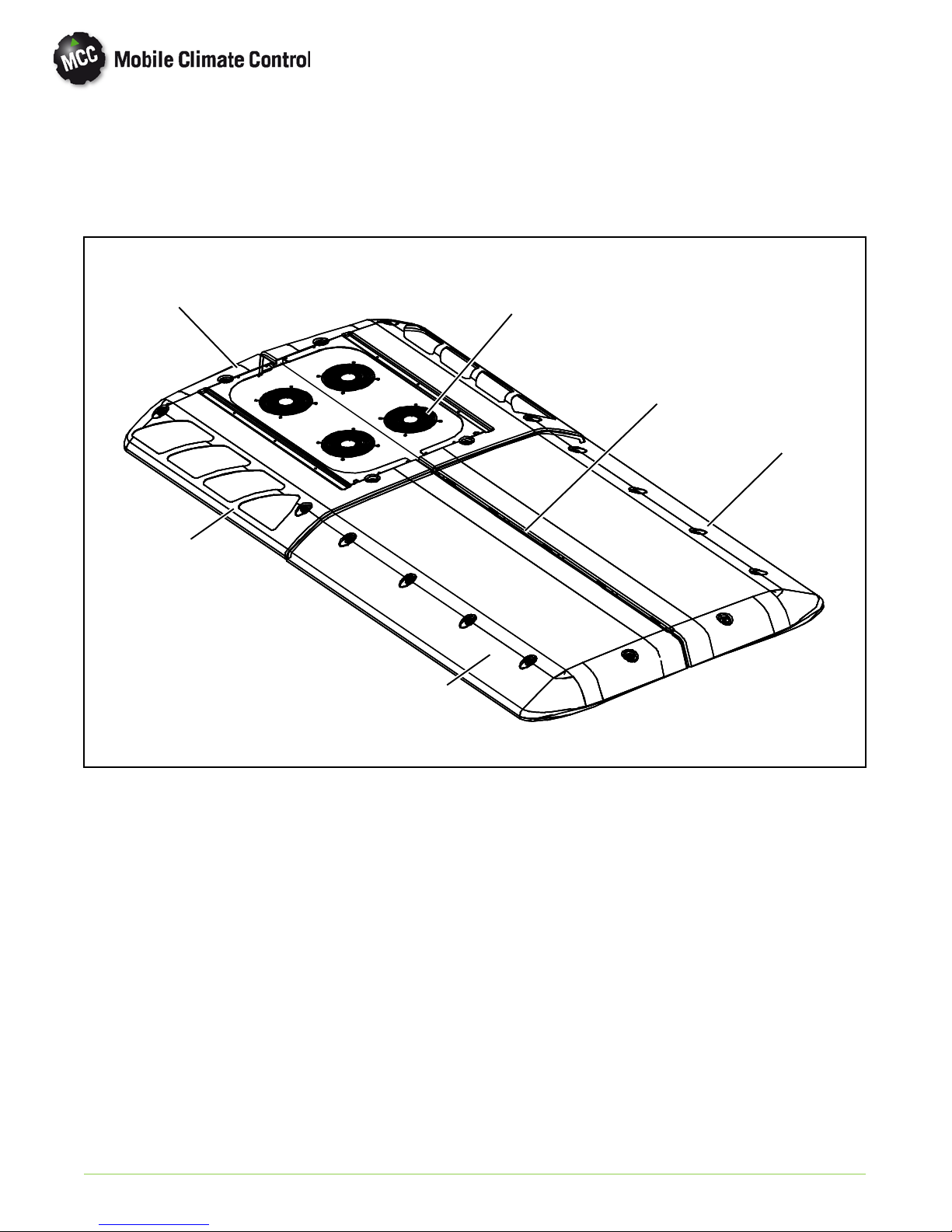

Figure 1-2 Rooftop Unit Components 1-5...............................................

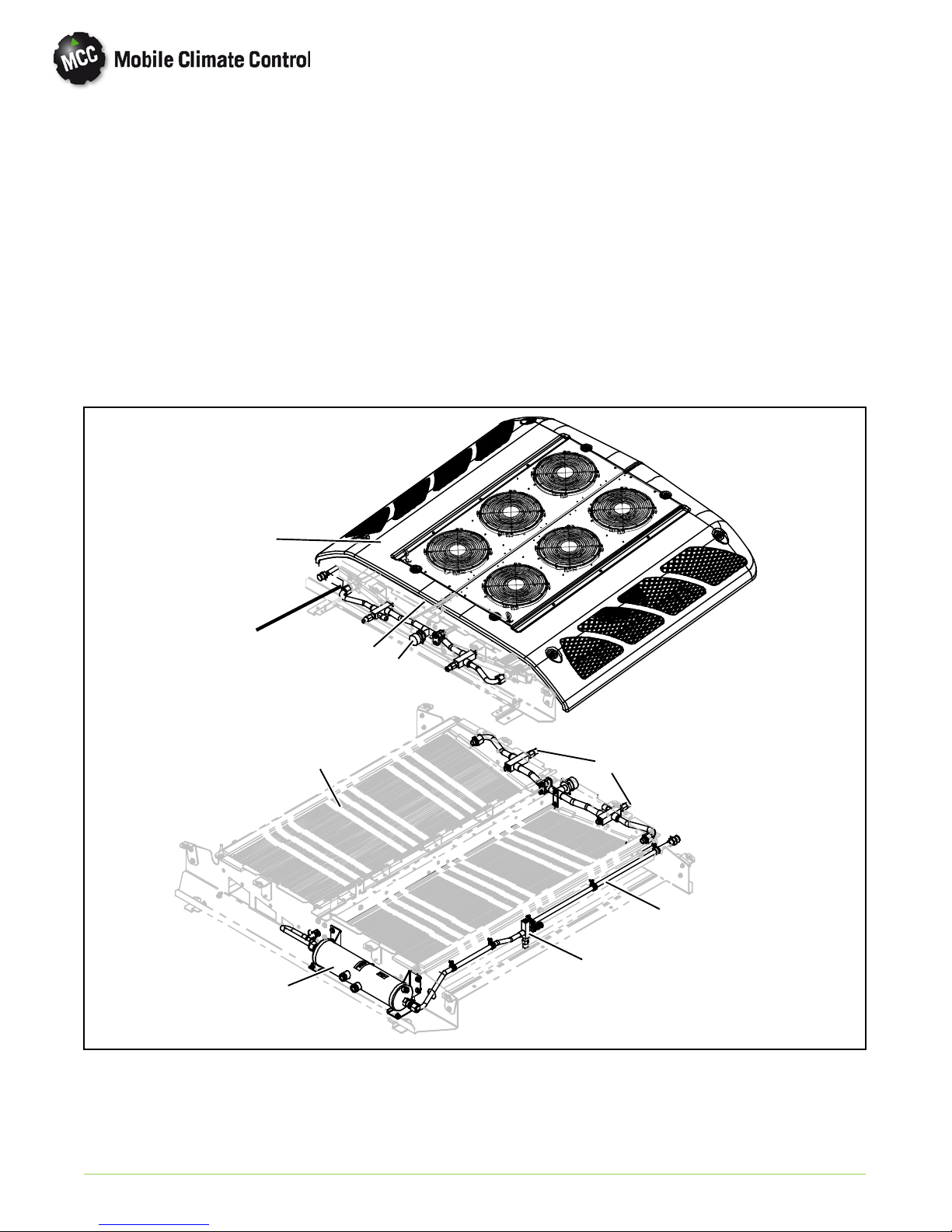

Figure 1-3 Condensing Section Components 1-6..........................................

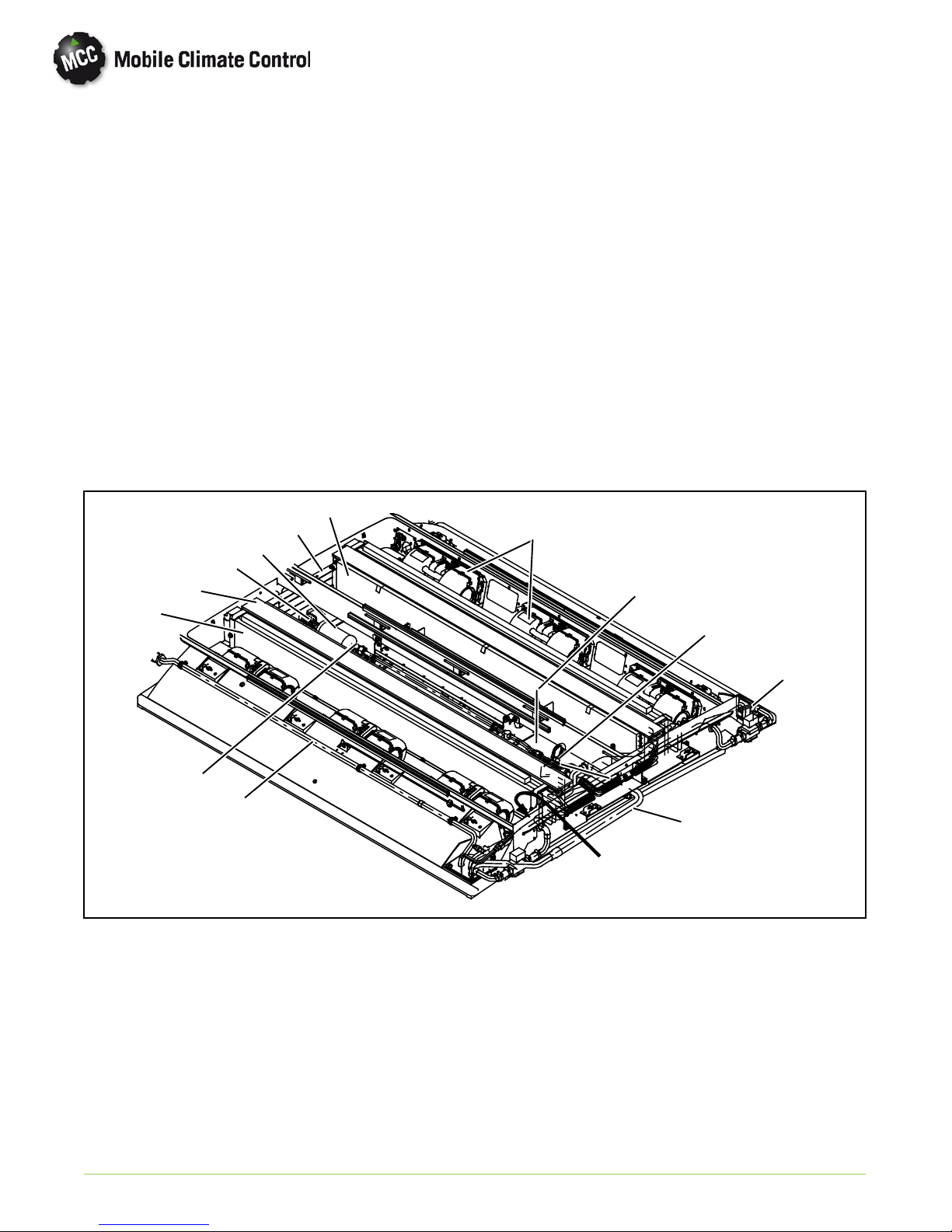

Figure 1-4 Evaporator Section Components 1-7...........................................

Figure 1-5 System Air Flow 1-10........................................................

Figure 1-6 Refrigerant Flow Diagram 1-12................................................

Figure 1-7 Heat Flow Diagram 1-13.....................................................

Figure 1-8 Control Panel 1-14..........................................................

Figure 1-9 Control Panel 1-15..........................................................

Figure 1-10 Logic Board 1-16..........................................................

Figure 1-11. Relay Board - GR60 1-17...................................................

Figure 1-11. Relay Board - GR60 (Continued) 1-18.........................................

Figure 1-12. Relay Board 1-19..........................................................

Figure 1-13 Logic Board, Data Communications 1-20.......................................

Figure 1-14 Micromate Control Panel 1-21................................................

Figure 2-1 Capacity Control Diagram 2-2................................................

Figure 4-1 Opening Top Cover (Evaporator) 4-2..........................................

Figure 4-2 Condenser Cover Removal 4-2...............................................

Figure 4-3 Suction or Discharge Service Valve 4-3.........................................

Figure 4-4 Manifold Gauge Set (R-134a) 4-4..............................................

Figure 4-5 Compressor Service Connections 4-5..........................................

Figure 4-6 Service Con n ections 4-6.....................................................

Figure 4-7 Checking High Pressure Switch 4-10............................................

Figure 4-8 Filter-Drier Removal 4-10....................................................

Figure 4-9 Liquid Line Solenoid Valve 4-11...............................................

Figure 4-10 Thermostatic Expansion Valve 4-12...........................................

Figure 4-11 Thermostatic Expansion Valve Bulb and Thermocouple 4-12........................

Figure 4-12 Compressor 4-14..........................................................

Figure 4-13 Removing Bypass Piston Plug 4-14............................................

Figure 4-14 Compressor Clutch 4-14....................................................

Figure 4-15 Transducer Terminal Location 4-17............................................

Figure 5-1. Wiring Schematic - Legend (PM Motors) - 68AC353-102, 102-4, 102-5 5-2.............

Figure 5-2. Wiring Schematic - Control Circuit (PM Motors) - 68AC353-102, 102-4, 102-5 5-3.......

© 2012 Mobile Climate Control T-348 Rev. 07/2012

4

Figure 5-3. Wiring Schematic - Power Circuit (PM Motors) - 68AC353-102, 102-4, 102-5 5-4........

Figure 5-4. Wiring Schematic - Legend (Brushless Motors) (CAN) - 68AC353-102-1, 102-3, 102-6 5-5.

Figure 5-5. Wiring Schematic - Control Circuit (Brushless Motors) (CAN) - 68AC353-102-1, 102-3, 102-6 .

5-6..............................................................................

Figure 5-6. Wiring Schematic - Power Circuit (Brushless Motors) (CAN) - 68AC353-102-1, 102-3, 102-6 . .

5-7..............................................................................

Figure 5-7. Wiring Schematic - Condenser Circuit (Brushless Motors) (CAN) - 68AC353-102-1, 102-3, 102-6

5-8..............................................................................

Figure 5-8. Wiring Schematic - Evaporator Circuit (Brushless Motors) (CAN) - 68AC353-102-1, 102-3, 102-6

5-9..............................................................................

Figure 5-9. Wiring Schematic - Legend (Brushless Motors) - 68AC353-102-2 & 102-7 5-10...........

Figure 5-10. Wiring Schematic - Control Circuit (Brushless Motors) - 68AC353-102-2 & 102-7 5-11....

Figure 5-11. Wiring Schematic - Control Board Power Circuit (Brushless Motors) - 68AC353-102-2 & 102-7

5-12..............................................................................

Figure 5-12. Wiring Schematic - Condenser Motor Power Circuit (Brushless Motors) - 68AC353-102-2 & 102-7

5-13..............................................................................

Figure5-13. WiringSchematic - EvaporatorMotor PowerCircuit (Brushless Motors) - 68AC353-102-2& 102-7

5-14..............................................................................

LIST OF TABLES

Table 1-1 Option Legend 1-3..........................................................

Table 1-2 Option Table 1-3............................................................

Table 1-3 Additional Support Manuals 1-4................................................

Table 2-1. Unloader UV1 Relay 2-4......................................................

Table 2-2. Unloader UV2 Relay 2-4......................................................

Table 2-3 Evaporator Fan Speed Relay Operation 2-4.......................................

Table 2-4. Controller Test List 2-6......................................................

Table 2-5. Parameter Codes 2-7........................................................

Table 3-1 Error Codes 3-1............................................................

Table 3-2 Alarm Codes 3-3............................................................

Table 3-3. General System Troubleshooting Procedures 3-5...................................

Table 4-1 Temperature Sensor Resistance 4-17..............................................

Table 4-2 Pressure Transducer Voltage 4-18................................................

Table 4-3 Logic Board Configuration 4-19.................................................

Table 4-4 R-134a Temperature - Pressure Chart 4-20.........................................

© 2012 Mobile Climate Control T-348 Rev. 07/2012

5

SAFETY SUMMARY

GENERAL SAFETY NOTICES

The following general safety notices supplement the specific warnings and cautions appearing elsewhere in this

manual. They are recommended precautions that must be understood and applied during operation and

maintenance of the equipment covered herein. A listing of the specific warnings and cautions appearing

elsewhere in the manual follows the general safety notices.

FIRST AID

An injury, no matter how slight, should never go unattended. Always obtain first aid or medical attention

immediately.

OPERATING PRECAUTIONS

Always wear safety glasses.

Keep hands, clothing and tools clear of the evaporator and condenser fans.

No work shouldbe performed on the unit until all start-stopswitches are placedin the OFF position,and power

supply is disconnected.

Always work in pairs. Never work on the equipment alone.

In case of severe vibration or unusual noise, stop the unit and investigate.

MAINTENANCE PRECAUTIONS

Beware of unannounced starting of the evaporator and condenser fans. Do not open the unit cover before

turning power off.

Be sure power is turned off before working on motors, controllers, solenoid valves and electrical controls. Tag

circuit breaker and p o wer supply to prevent accidental energizing of circuit.

Do not bypass any electrical safety devices, e.g. bridging an overload, or using any sort of jumper wires.

Problems with the system should be diagnosed, and any necessary repairs performed by qualified service

personnel.

When performing any arc welding on the unit, disconnect all wire harness connectors from the modules in the

control box. Do not remove wire harness from the modules unless you are grounded to the unit frame with a

static-safe wrist strap.

In case of electrical fire, open circuit switch and extinguish with CO2(never use water).

UNIT HAZARD LABEL IDENTIFICATION

To help identify the hazard labels on the unit and explain the level of awareness each on e carries, explanations

with appropriate consequences are provided below:

Indicates an immediate h azard which WILL result in severe personal injury or death.

Indicates hazards or unsafe conditions which COULD result in severe personal injury or death.

Indicates potential hazards or unsafe practices which COULD result in minor personal injury, product or

property damage.

© 2012 Mobile Climate Control T-348 Rev. 07/2012

DANGER

WARNING

CAUTION

Safety-1

SPECIFIC WARNING AND CAUTION STATEMENTS

The statements listed below are applicable to the refrigeration unit and appear elsewhere in this manual. These recommended

precautions must be understood and applied during operation and maintenance of the equipment covered herein.

SPECIFIC WARNINGS AND CAUTIONS

WARNING

Be sure to observe warnings listed in the safety summary in the front of this manual before

performing maintenance on the hvac system

WARNING

Read the entire procedurebefore beginning work. Park the coach on a level surface, with park

ing brake applied. Turn main electrical disconnect switch to the off position.

WARNING

Do not use a nitrogen cylinder without a pressure regulator

WARNING

Do not use oxygen in or near a refrigeration system as an explosion may occur.

WARNING

The filter-drier may contain liquid refrigerant.Slowly loosen the ORS hex nuts to avoid refriger

ant contact with exposed skin or eyes.

WARNING

Battery disconnect should be off.

WARNING

Extreme care must be taken to ensure that all the refrigerant has been removed from the com

pressor crankcase or the resultant pressure will forcibly discharge compressor oil.

Do not under any circumstances attempt to service the microprocessor. Should a problem de

velop with the microprocessor, replace it.

© 2012 Mobile Climate Control T-348 Rev. 07/2012

CAUTION

Safety-2

CAUTION

To prevent trapping liquid refrigerant in the manifold gauge set be sure set is brought to suc

tion pressure before disconnecting.

CAUTION

Use care when checking/manipulating wires/plugs attached to the Logic Board. Damage to

the board or wiring harness can occur.

© 2012 Mobile Climate Control T-348 Rev. 07/2012

Safety-3

SECTION 1

DESCRIPTION

1.1 INTRODUCTION

This manual contains Operating Instructions,

Service Instructions and Electrical Data for the

Model 68AC353 Air Conditioning and Heating

equipment furnished by Mobile Climate Control as

shown in Table 1-1 and Table 1-2. Additional

support manuals are referenced in Table 1-3.

The Mobile Climate Control model 68AC series

units are of lightweight frame construction,designed

to be installed on the vehicle roof.

Model 68AC353 systems consists of a condensing

section, evaporator section and an engine

compartment mou n ted compressor. To complete

the system, the air conditioning and heating

equipment interfaces with electrical cabling,

refrigerant piping, engine coolant piping (for

heating), duct work and other components

furnished by the bus manufacturer. See Figure 1-1.

Operation of the units is controlled automatically by

a microprocessor based Micromax Controller which

maintains the vehicle's interior temperature at the

desired set point.

1.2 CONFIGURATION IDENTIFICATION

Unit identification information is provided on a plate

located inside the condenser and evaporator

sections. The plate provides the unit model number,

the unit serial number and the unit parts

identification number (PID). The model number

identifies the overall unit configuration while the

PID provides information on specific optional

equipment and differences in detailed parts.

The following paragraphs provide descriptions of

the options provided. A tabular listing of unit model

numbers and PID numbers, used to assist the reader

in identifying the equipment supplied is provided in

Table 1-1 and Table 1-2.

1.3 OPTION DESCRIPTION

Various options may be factory or field equipped to

the base unit. These options are listed in the tables

and described in the following subparagraphs.

1.3.1 Condenser Cover (Skins)

The condenser section may be fitted with one of two

different cover assemblies dependent upon the

curvature of the bus roof. The assemblies available

are identified as the 10 M radius cover and the 6.5 M

radius cover.

1.3.2 Condenser Electrical Kit

The 68AC353 con denser kits are wired for either 24

Volt permanent magnet motors or 24 Volt brushless

motors.

1.3.3 Condenser Fan Kit

The 68AC353 condenser kits are available with either

4 or 6 fans, with either permanent magnet or

brushless motors.

1.3.4 Condenser Refrigeration Kit

The 68AC353 condensers are all fitted with a

condenser coil, a receiver with sight glasses and

fusible plug, a charge isolation valve and

interconnecting tubing.

1.3.5 Evaporator Skins Kit

The evaporator section may be fitted with one of two

different cover assemblies dependent upon the

curvature of the bus roof. The assemblies available

are identified as the 10 M radius cover and the 6.5 M

radius cover.

1.3.6 Evaporator Blower Kit

The 68AC353 evaporator kits are available with

either 4 or 6 blowers, with either permanent magnet

or brushless motors.

1.3.7 Evaporator Connection Kit S/D

The evaporator units are assembled to allow

orientation of the connections for different

mounting arrangements and may be supplied with

various refrigerant piping layouts for specific

applications.

1.3.8 Evaporator Connection Kit - Indash

The evaporator units are assembled to allow

connections for various refrigerant piping layouts for

remote evaporators.

1.3.9 Evaporator Connection Kit (Heating)

The evaporator units are assembled to allow

orientation of the connections for different

mounting arrangements and may be supplied with

various engine coolant piping layouts for specific

heating applications.

© 2012 Mobile Climate Control T-348 Rev. 07/2012

1--1

1.3.10 Air Exchange Kit

1.3.11 Controller Kit

The unit will be fitted with a fresh air exchange

assembly or an air exchange blank off plate. Fresh air

exchange assemblies may be of the 25% or 50 %

opening.

The Micromax Controller operates the system

through one of two relay boards and may be

interrogated through the optional CAN +/- Data

Communication Link.

© 2012 Mobile Climate Control T-348 Rev. 07/2012

1--2

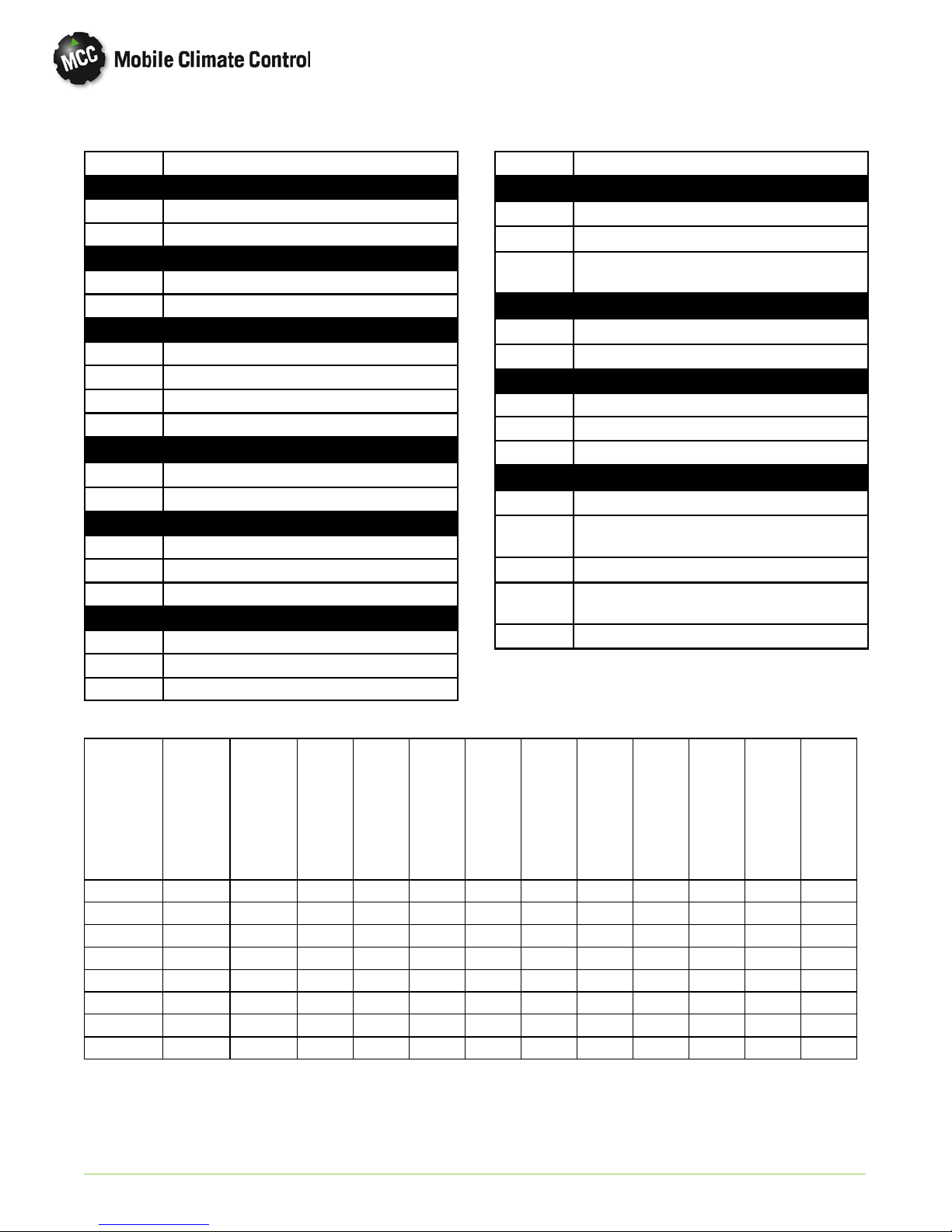

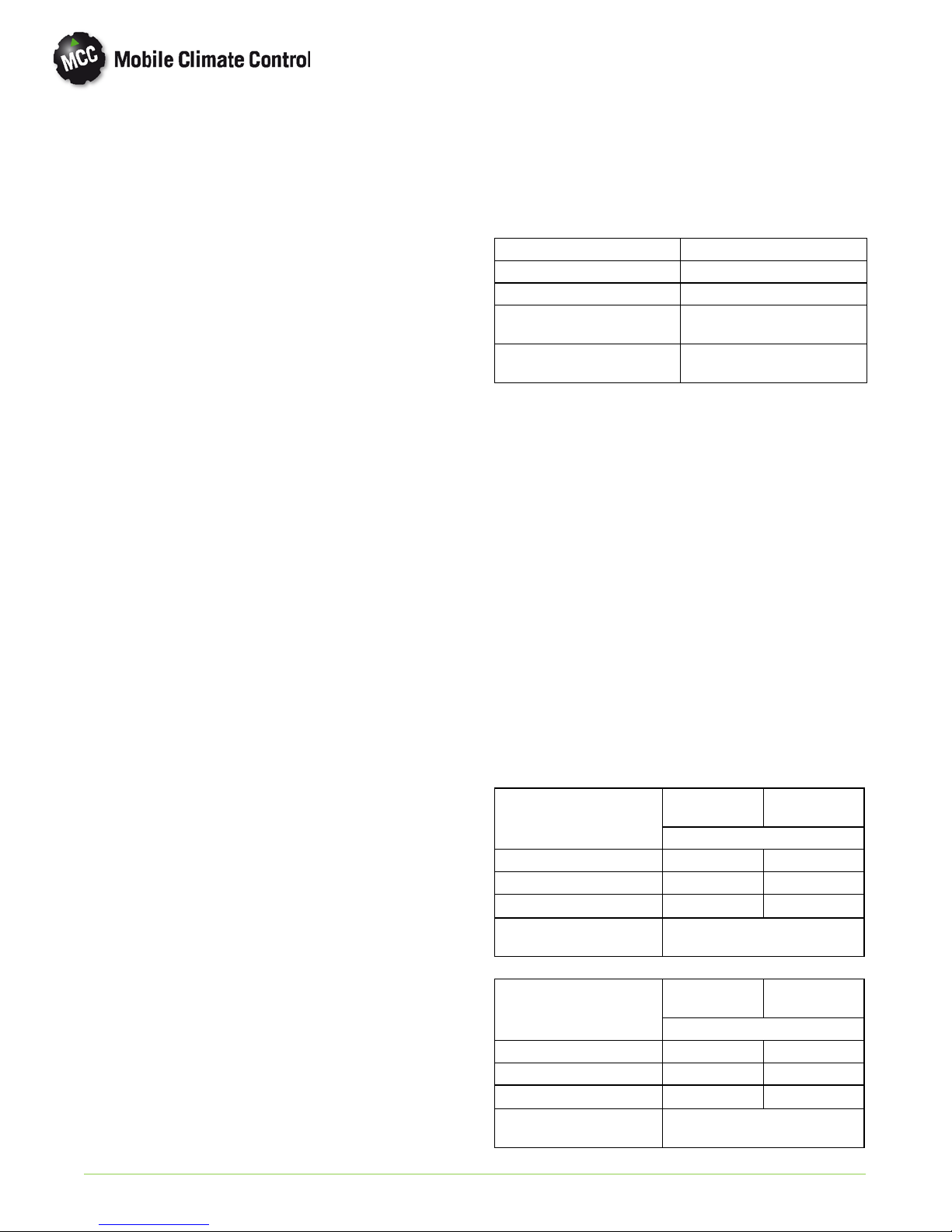

OPTION DESCRIPTION

Condenser Skins Kit

1 Standard Cover (R10M)

2 Cover (R6.5M)

Condenser Electrical Kit

1 Condenser Electrical Kit

2 Condenser Electrical Kit / Brushless

Condenser Fan Kit

1 24 Volt With 4 Brushless Motors

2 24 Volt With 4 PM Motors

3 24 Volt With 6 Brushless Motors

4 24 Volt With 6 PM Motors

Evaporator Skins Kit

1 Standard Cover (R10M)

2 Cover (R6.5M)

Evaporator Blower Kit

1 24 Volt With 6 Brushless Motors

2 24 Volt With 4 Brushless Motors

3 24 Volt With 6 PM Motors

Evaporator Refrigeration Kit

1 4 Row Coil Refrigeration Kit

2 5 Row Coil Refrigeration Kit

3 3 Row Coil Refrigeration Kit

Table 1-1 Option Legend

OPTION DESCRIPTION

Evaporator Connection Kit S/D

1 Left - ORS

2 Right - ORS

3

Evaporator Connection Kit - Indash

1 Right

2 Left

Air Exchange Kit

1 0 to 50%

2 None

3 0 to 25%

Controller Kit

1 Micromax With GR60 Relay Board (right)

2

3 Micromax Relay Board

4

5 Micromax With GR60 Relay Board (left)

Left - ORS With Out Front Box

Connection

Micromax Relay Board With CAN DATA

(right)

Micromax Relay Board With CAN DATA

(left)

Table 1-2 Option Table

MODEL

68AC353

AC353C

PID Condenser

AC353E

PID Evaporator

Skins Kit

Condenser

Condenser

Electrical Kit

Fan Kit

Condenser

Evaporator

Skins Kit

Evaporator

Blower Kit

Evaporator

S/D

Connection Kit

Evaporator

Connection Kit

In Dash

Evaporator

Refrigeration Kit

-102 00001 00001 1 1 2 1 3 1 1 1 3 1

-102-1 00002 00002 1 2 1 1 1 1 1 1 3 2

-102-2 00003 00003 1 2 3 1 1 2 2 1 3 3

-102-3 00004 00004 1 2 3 1 1 2 2 1 3 4

-102-4 00005 00005 1 1 2 1 3 2 2 1 3 5

-102-5 00006 00006 1 1 4 1 3 2 2 1 3 5

-102-6 00007 00007 1 2 1 1 1 2 2 1 3 4

-102-7 00008 00008 1 2 1 1 1 2 2 1 3 3

Kit

Air Exchange

Controller Kit

© 2012 Mobile Climate Control T-348 Rev. 07/2012

1--3

Table 1-3 Additional Support Manuals

MANUAL/FORM NUMBER EQUIPMENT COVERED TYPE OF MANUAL

T-348PL 68AC353 Parts List

62-10699 Micromate Diagnostic Tool (Card)

6

4

3

2

1

1. Compressor

2. Discharge Check Valve

3. Refrigerant Lines

4. Compressor Harness

5. Electronics Boards - Power Relay

6. Liquid Line Solenoid

7. AC353 (Rooftop) See Figure 1-2

5

7

11

10

13

8. Main Harness

9. Driver Control

10. Power Harness

11. Main Circuit Breaker

12. Battery

13. Alternator

12

8

9

Dash--Air

Option

1.4 GENERAL DESCRIPTION

1.4.1 Compressor Assembly

The compressor assembly is mounted in the engine

compartment (see Figure 1-1) and includes the

refrigerant compressor, clutch assembly, suction and

discharge service valves, high pressure switch, low

pressure switch, suction and discharge servicing

(charging) ports and electric solenoid unloaders.

The compressor raises the pressure and temperature

of the refrigerant and forces it into the condenser

tubes. The clutch assembly provides a means of belt

driving the compressor by the bus engine. The

suction and discharge service valves enable servicing

of the compressor. Suction and discharge servicing

(charging) ports mounted on the service valves

enable connection of charging h o ses for servicing of

the compressor, as well as other parts of the

© 2012 Mobile Climate Control T-348 Rev. 07/2012

Figure 1-1 System Component Identification

refrigerant circuit. The high pressure switch cont acts

open on a pressure rise to shut down the system

when abnormally high refrigerant pressures occur.

The electric unloaders provide a means of

controlling compressor capacity, which enables

control of t emperature inside the bus. For more

detailed information on the 05G compressor, refer

to the Operation and Service Manual number

62-02756.

1.4.2 Discharge Check Valve

A check valve is located in the discharge line close to

the compressor. (see Figure 1-1) The discharge

check valve is a spring loaded, normally closed valve

that opens with the flow of refrigerant from the

compressor. When the compressor clutch is

disengaged, the discharge check valve will close,

1--4

preventing the flow of high pressure liquid from the

condenser back into the compressor.

1.4.3 Rooftop Unit

The Rooftop unit (see Figure 1-2) is comprised of

the condensing section, evaporator section,

Micromax electronics, and the Fresh Air System. All

components are accessible by lifting the condenser

and evaporator top covers. Descriptions of the

systems are provided in the following sub

paragraphs.

1

3

4

6

5

2

1. Top Cover, Condenser

2. Top Cover, Evaporator

3. Condenser Section (See Figure 1-3)

© 2012 Mobile Climate Control T-348 Rev. 07/2012

4. Evaporator Section (See Figure 1-4)

5. Hinge, Evaporator Cover

6. Condenser Fan Grille

Figure 1-2 Rooftop Unit Components

1--5

1.4.4 Condensing Section

The condensing section (Figure 1-3) includes the

cover, left and right condenser coils, fan and motor

assemblies, receiver, service valves and an ambient

temperature sensor..

High pressure high temperature refrigerant gas from

the compressor passes thru the shipping shut-off

valves to the condenser coils.

The condenser coils provide heat transfer surface for

condensing refrigerant gas at a high temperature and

pressure. The condenser fans circulate ambient air

across the outside of the condenser tubes at a

temperature lower than refrigerant circulating inside

6

the tubes; t his results in condensation of the

refrigerant into a liquid.

The receiver collects and stores liquid refrigerant.

The receiver is also fitted with a fusible plug which

protects the system from unsafe high pressure

conditions and liquid level sight glasses to determine

proper refrigerant liquid level.

The liquid refrigerant then passes thru the liquid line

charge isolation valve to the evaporator.

An ambient temperature sensor measures ambient

temperature and sends an electrical signal to the

controller.

PID

Model/Serial

Number Tag

2

1. Coil Assembly

2. Receiver

3. Charge Isolation Valve

4. Discharge Line.

7

4

1

5. Liquid Line

6. Condenser Fan and Motor Assembly

7. Ambient Temperature Sensor

8. Shipping Shut-off Valves

8

5

3

© 2012 Mobile Climate Control T-348 Rev. 07/2012

Figure 1-3 Condensing Section Components

1--6

1.4.5 Evaporator Section

The evaporator section (Figure 1-4) includes the

evaporator coils, six blower and motor assemblies,

evaporator coil assemblies, heater coil assemblies,

filter drier, a thermostatic expansion valve, liquid line

solenoid, service valves and condensate drain

connections.

The evaporator coils provide heat transfer surface

for transferring heat from air circulating over the

outside coil area to the refrigerant circulating inside

the tubes; thus providing cooling. The heating coils

provide heat transfer surface for transferring heat

from engine coolant water circulating inside the

tubes to air circulating over the outside surface of the

tubes, thus providing heating. The fans circulate the

air over th e coils. The air filters remove dirt particles

from the air before it passes over the coils. The

3

13

5

10

filter-drier removes moisture and debris from the

liquid refrigerant before it enters the thermostatic

expansion valve in the evaporator assembly. Service

valves enable isolation of the filter-drier for service.

The thermostatic expansion valve meters flow of

refrigerant entering the evaporator coils. The liquid

line solenoid valve closes when system is shut down

to prevent flooding of the evaporator coils with

liquid refrigerant.

A heat valve controls the flow of engine coolant

water t o th e heating coils upon receipt of a signal

from the controller. The condensate drain

connections provide a means for connecting tubing

for disposing of condensate collected on the

evaporator coils during cooling operation.

6

1

2

9

8

1. Evaporator Coil Assembly

2. Heat Coil

3. Evaporator Return Air Filter

4. Expansion Valve

5. Filter Drier

6. Blower & Motor Assembly

7. Suction Line

12

4

11

7

PID

Model/Serial

Number Tag

8. Discharge Line

9. Service Valve

10. Liquid Line Solenoid

11. Heat Line Connection

12. Control Panel

13. Fresh Air Damper

1.4.6 Fresh Air System

The Fresh Air System consists of a damper and

damper operator. The damper operator may be

© 2012 Mobile Climate Control T-348 Rev. 07/2012

Figure 1-4 Evaporator Section Components

controlled by the driver, if a switch is provided. In the

automatic mode, it is controlled by the Micromax to

1--7

open and close the damper to allowaddition of fresh

air into the air entering the evaporator coil. For

additional information on air flow,refer to paragraph

1.9.

1.4.7 System Operating Controls And Components

The system is operated by a Mobile Climate Control

Micromax microprocessor controller which consist

of a relay board (Figure 1-11), logic board

(Figure 1-10), and manual operator switches. The

manual operating switches are located on the drivers

control and may consist of a single OEM supplied

ON/OFFswitch, additionalOEM supplied switches

or a Mobile Climate Control supplied Micromate

control panel (Figure 1-14). The logic board

regulates the operational cycles of the system b y

energizing or de-energizing relays on the relay board

in response to deviations in interior temperature.

Modes of operation include Cooling, Heat and Vent.

On systems fitted with only an ON/OFF switch and

on systems with the Micromate set in the AUTO

mode, the logic board will cycle the system between

the operating modes as required to maintain desired

set point temperature.

In the vent mode the evaporator fans are operated to

circulate air in the bus interior.

In the heat mode the heat valve is opened to allow a

flow of engine coolant through the heat coils of the

evaporator coil. The evaporator fans operate to

circulate air over the evaporator coil in the same

manner as the vent mode.

In the cooling mode the compressor is energized

while the evaporator and condenser fans are

operated to provide refrigeration as required. The

compressor is fitted with cylinder unloaders to

match compressor capacity to the bus requirements.

Once interior temperature reaches the desired set

point, the system may operate in the clutch cycle or

reheat mode. A controller programmed for clutch

cycle will de-energize t h e compressor clutch and

allow the system to operate in the vent mode until

further cooling is required. A controller

programmed for reheat will maintain compressor

operation and open the heat valve to allow reheating

of the return air. In the reheat mode interior

temperature is maintained at the desired set point

while additional dehumidification takes place.

Controls may also be provided to allow manual

operation of the evaporatorfans in low or high speed

and manual control of the fresh air damper in the

open or closed position.

1.5 REFRIGERATION SYSTEM COMPONENT SPECIFICATIONS

a. Refrigerant Charge

R-134a15.8 Lb (7.17 kg)

b. Compressor

UNIT MODEL

Compressor 05G

No of Cylinders 6

Weight - Dry

W/Clutch

Oil Charge 5.5 pints

Oil Level: Level in sight glass betweenMin.-Max marks on

compressor crankcase (curbside)

Approved Compressor Oils - R-134a:

Castrol: Icematic SW68C

Mobil: EAL Arctic 68

ICI: Emkarate RL68H

c. Thermostatic Expansion Valve:

Superheat Setting: 12 ±2°F(6.7±1°C)

d. High Pressure Switch (HPS):

Opens at: 350 ±10 psig (23.81 ±0.68bar)

Closes at: 250 ±10 psig (13.61 ±0.68bar)

e. Low Pressure Switch (LPS)

Opens at: 6 ±3psig (0.41 ±0.20 bar)

Closes at: 25 ±3psig(1.7±0.20 bar)

f. Water Temperature Switch (WTS)

Bus manufacturer supplied - suggested close on tempera

ture rise at 105°F(41°C).

AC353

145 lbs

(65.77 kg)

(2.6 liters)

1.6 ELECTRICAL SPECIFICATIONS - MOTORS

a. Evaporator Fan Motor

Evaporator Motor

Horsepower (kW) 0.53/0.39 0.4/0.3

Full Load Amps (FLA) 15.2 11.0

Operating Speed (RPM)

Bearing Lubrication Factory Lubricated

b. Condenser Fan Motor

Condenser Motor

Horsepower (kW) 0.24/0.18 0.25/0.20

Full Load Amps (FLA) 7.0 7.2

Operating Speed (RPM)

Bearing Lubrication Factory Lubricated

Brushless

3830 3013

(additional grease not required)

Brushless

2840 1900

(additional grease not required)

Permanent

Magnet

24 VDC

Permanent

Magnet

24 VDC

© 2012 Mobile Climate Control T-348 Rev. 07/2012

1--8

1.7 ELECTRICAL SPECIFICATIONS - SENSORS AND

TRANSDUCERS

a. Suction and Discharge Pressure Transducer

Supply Voltage: 4.5 to 5.5 vdc (5 vdc nominal)

Supply current: 8 mA maximum

Output Range: 8K ohms minimum

Input Range: -6.7 to 450 psig (-0.46 to 30.62 bar)

b. Temperature Sensors

Input Range: -52.6 to 158°F(-47to70°C)

Output: NTC 10K ohms at 77°F(25°C)

1.8 SAFETY DEVICES

System components are protected from damage

caused by unsafe operating conditions with safety

devices. Safety devices with Mobile Climate Control

supplied equipment include high pressure switch

(HPS), low pressure switch (LPS), circuit breakers

and fuses.

a. Pressure Switches

High Pressure Switch (HPS)

During the A/C mode, compressor operation will

automatically stop if the HPS switch contacts open

due to an unsafe operating condition. Opening HPS

contacts de-energizes the compressor clutch

shutting down the compressor. The high pressure

switch (HPS) is installed in the center head of the

compressor.

Low Pressure Switch (LPS)

The low pressure switch is installed in the

compressor and opens on a pressure drop to shut

down the system when a low pressure condition

occurs. In addition, if the microprocessor monitors a

pressure less than 10 psig (0.68 bar)by the suction

pressure transducer mounted in the evaporator

section, the system will be shut down for at least one

minute.

b. Fuses and Circuit Breakers

The system is protected against high current b y an

OEM supplied 125 amp fuse or circuit breaker.

Independent fuses or circuit breakers protect each

evaporator blower motor and condenser motor

assembly. 5 amp fuses p ro t ect each relay board

output, 10 amp fuses protect ignition circuit output.

c. Ambient Lockout

The ambient temp erature sensor located in the

condenser section measures the condenser inlet air

temperature. When the temperature has fallen below

the cut out set point the compressor is locked out

until the temperature rises above the cut in setting.

The set points willbe programmed to cut out at 45°F

〈7.2°C) and cut in at 50°F 〈10°C). This setting

protects the compressor from damage caused by

operation at low pressures.

d. Water Temperature Switch (WTS)

When the the engine coolant temperature has fallen

below the cut out set point, the evaporator fans are

locked out until the temperature rises above the cut

in set point. The set point willbe programmed to cut

in at 105°F(41°C).

© 2012 Mobile Climate Control T-348 Rev. 07/2012

1--9

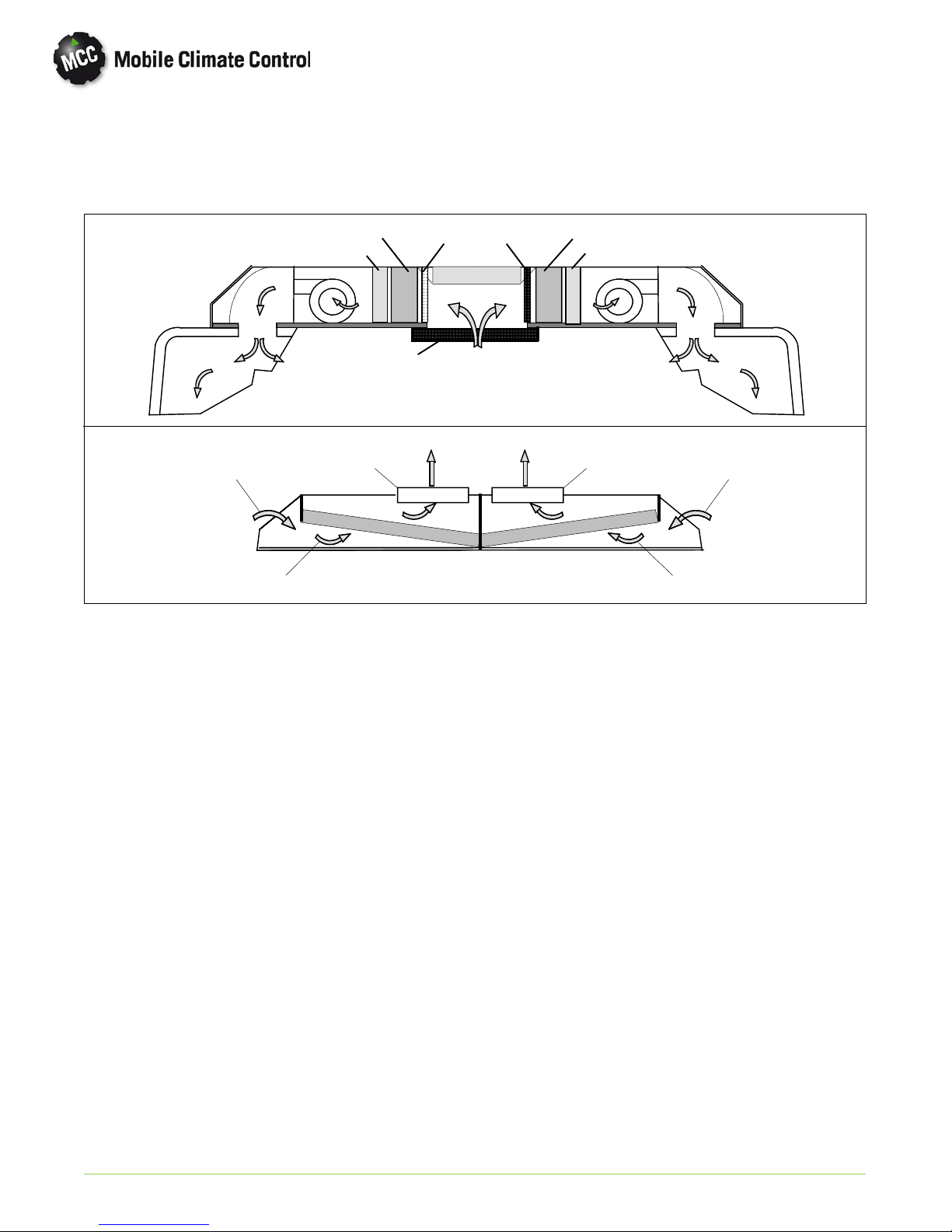

1.9 AIR FLOW

The paths for ambientair through the condenserand

coach air through the evaporator are illustrated in

Figure 1-5.

From Ambient

Through Condenser

EVAPORA T OR COIL

HEATER COIL HEATER COIL

COACH RETURN

AIR FILTER

COIL RETURN

AIR FILTERS

FRESH AIR

EVAPORA T OR COIL

EVAPORATOR

Return To Ambient

Through Fan

Through Fan

CONDENSER

Figure 1-5 System Air Flow

From Ambient

Through Condenser

© 2012 Mobile Climate Control T-348 Rev. 07/2012

1--10

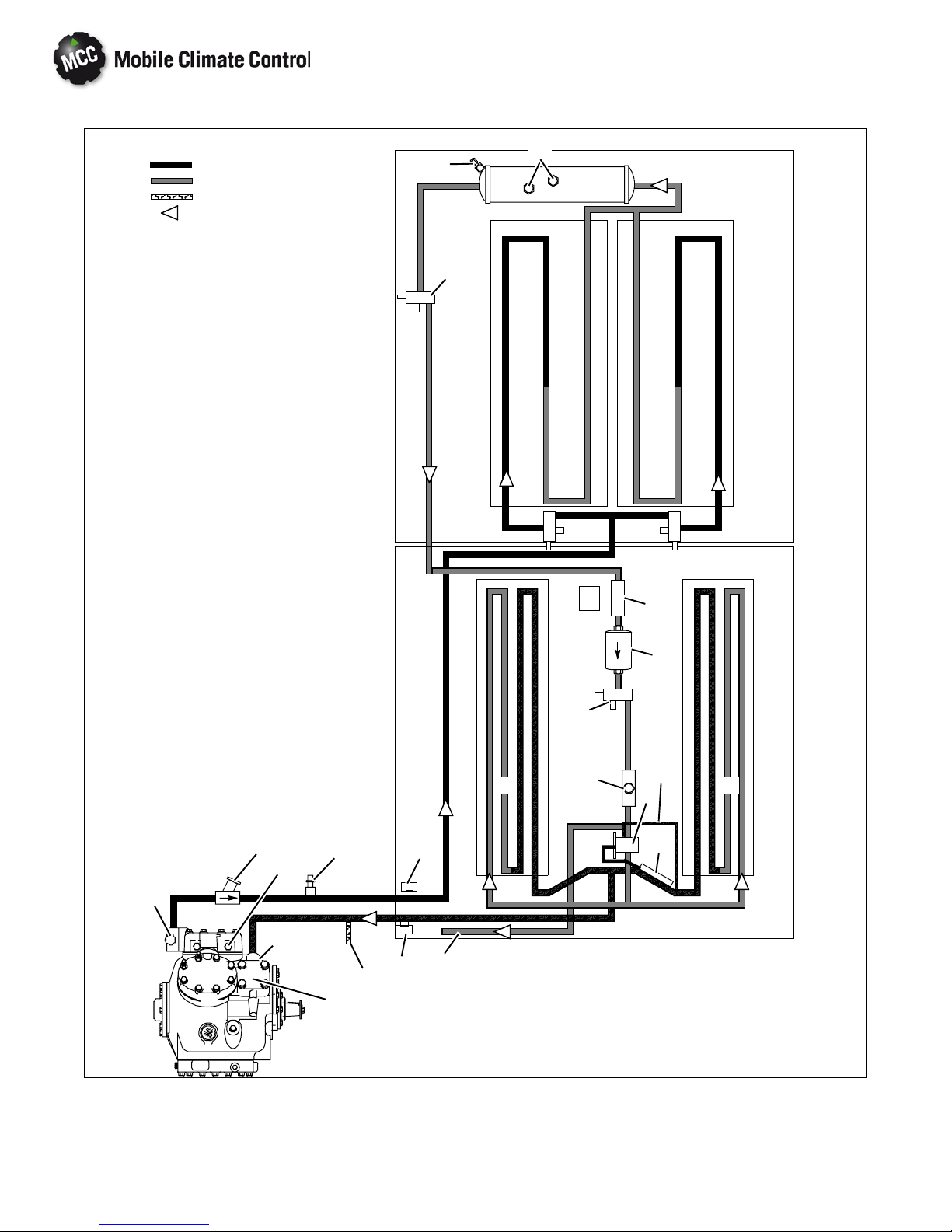

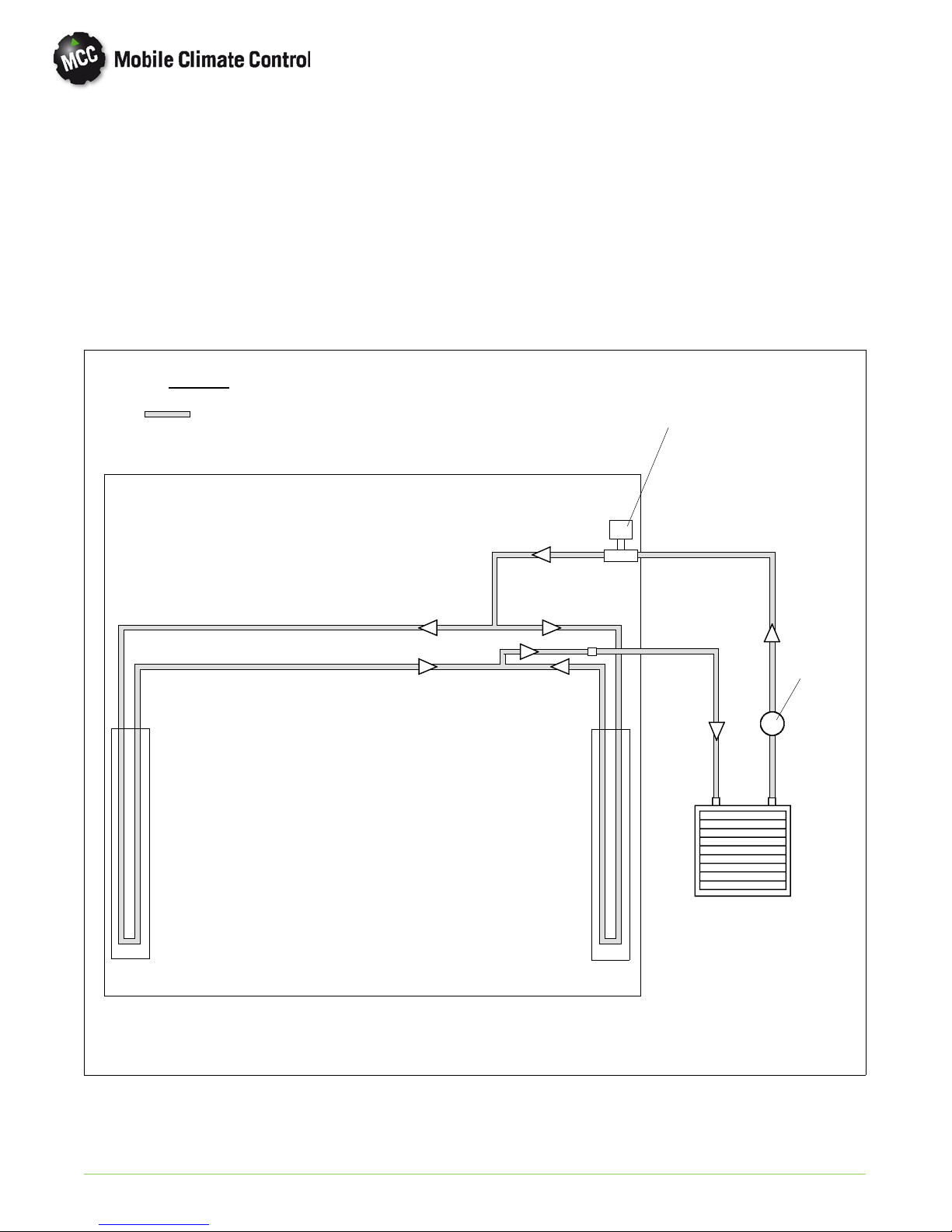

1.10 AIR CONDITIONING REFRIGERATION CYCLE

When air conditioning (cooling) is selected by the

controller, the unit operates as a vapor compression

system using R-134a as the refrigerant (See

Figure 1-6). The main components of the system are

the reciprocating compressor, air-cooled condenser

coils, receiver, filter-drier, th ermo static expansion

valve, liquid line solenoid valve and evaporator coils.

The compressor raises the pressure and the

temperature of the refrigerant and forces it into th e

condenser tubes. The condenser fan circulates

surrounding air (which is at a temperature lower than

the refrigerant) over the outside of the condenser

tubes. Heat transfer is established from the

refrigerant (inside the tubes) to the condenser air

(flowing over the tubes). The condenser tubes have

fins designed to improve the transfer of heat from

the refrigerant gas to the air; this removal of heat

causes the refrigerant to liquefy, thus liquid

refrigerant leaves the condenser and flows to the

receiver.

The receiver serves as a liquid refrigerant reservoir so

that a constant supply of liquid is available to the

evaporators as needed and acts as a storage space

when p u m ping down the system. The receiver is

equipped with two sight glasses to observe

refrigerant charge level.

The refrigerant leaves the receiver and passes

through the charge isolation valve to the liquid line

solenoid valve. From the liquid line solenoid valve

the refrigerant enters the filter-drier where an

absorbent keeps the refrigerant clean and dry.

From the filter-drier, the liquid refrigerant then flows

through the liquid line service valve to the

thermostatic expansion valve. The liquid line is

equipped with a sight glass to observe the refrigerant

for restricted flow. The thermostatic expansionvalve

reduces pressure and temperature of the liquid and

meters the flow of liquid refrigerant to the

evaporator to obtain maximum use of the

evaporator heat transfer surface.

The low pressure, low temperature liquid that flows

into the evaporator tubes is colder than the air that is

circulated over the evaporator tubes by the

evaporatorfans. Heat transfer isestablishedfrom the

evaporator air (flowing over the tubes) to the

refrigerant (flowing inside the tubes). The

evaporator tubes have aluminum fins to increase

heat transfer from the air to the refrigerant;therefore

the cooler air is circulated to the interior of the bus.

Liquid line solenoid valve closes during shut do wn to

prevent refrigerant flow.

The transfer of heat from the air to the low

temperature liquid refrigerant in the evaporator

causes the liquid to vaporize. This low temperature,

low pressure vapor passes through the suction line

and returns to the compressor where the cycle

repeats.

© 2012 Mobile Climate Control T-348 Rev. 07/2012

1--11

Legend

Discharge

Liquid

Suction

Refrigerant Flow

1. Discharge Service Valve

2. Discharge Check Valve

3. Service Port, Discharge

4. High Pressure Switch

5. Discharge Pressure Transducer

6. Low Pressure Switch (Crankcase)

7. Dash Air Liquid Line (Option)

8. Suction Service Valve/Port

9. Dash Air Suction Tee (Option)

10. Suction Pressure Transducer

11. Evaporator Coil

12. Thermal Expansion Valve (TXV)

13. TXV Bulb

14. TXV Equalizer Line

15. Liquid Line Solenoid Valve

16. Filter Drier

17. Liquid Line Service Valve

18. Liquid Line Sight Glass

19. Shipping Shut-off Valves

20. Condenser Coil

21. Receiver

22. Refrigerant Sight Glass

23. Fusible Plug

24. Charge Isolation Valve

23

24

22

20

19

17

CONDENSER

21

20

19

EVAPORATOR

15

16

2

4

1

6

© 2012 Mobile Climate Control T-348 Rev. 07/2012

11 11

10

5

7

3

9

8

Figure 1-6 Refrigerant Flow Diagram

1--12

18

14

12

13

1.11 HEATING CYCLE

Heating circuit (See Figure 1-6) components

furnished by Mobile Climate Control include the

heater coils and a solenoid operated heat valve.

Components furnished by the bus manufacturer

include auxiliary heater and boost water pump. The

controller automatically controls the heat valve

during the heating and reheat mo des to maintain

required temperaturesinside the bus. Engine coolant

LEGEND

is circulated through the heating circuit by the engine

and an auxiliary boost water pump. When the heat

valve solenoid is energized, the valve will open to

allow engine coolant to flow through the heater coil.

The valve is normally closed so that if a failure occurs,

the system will be able to cool.

COOLANT

HEAT VALVE (Normally Closed)

INLET

OUTLET

BOOST

PUMP

EVAPORATOR

AC 353

© 2012 Mobile Climate Control T-348 Rev. 07/2012

MAIN ENGINE /

RADIATOR

Figure 1-7 Heat Flow Diagram

1--13

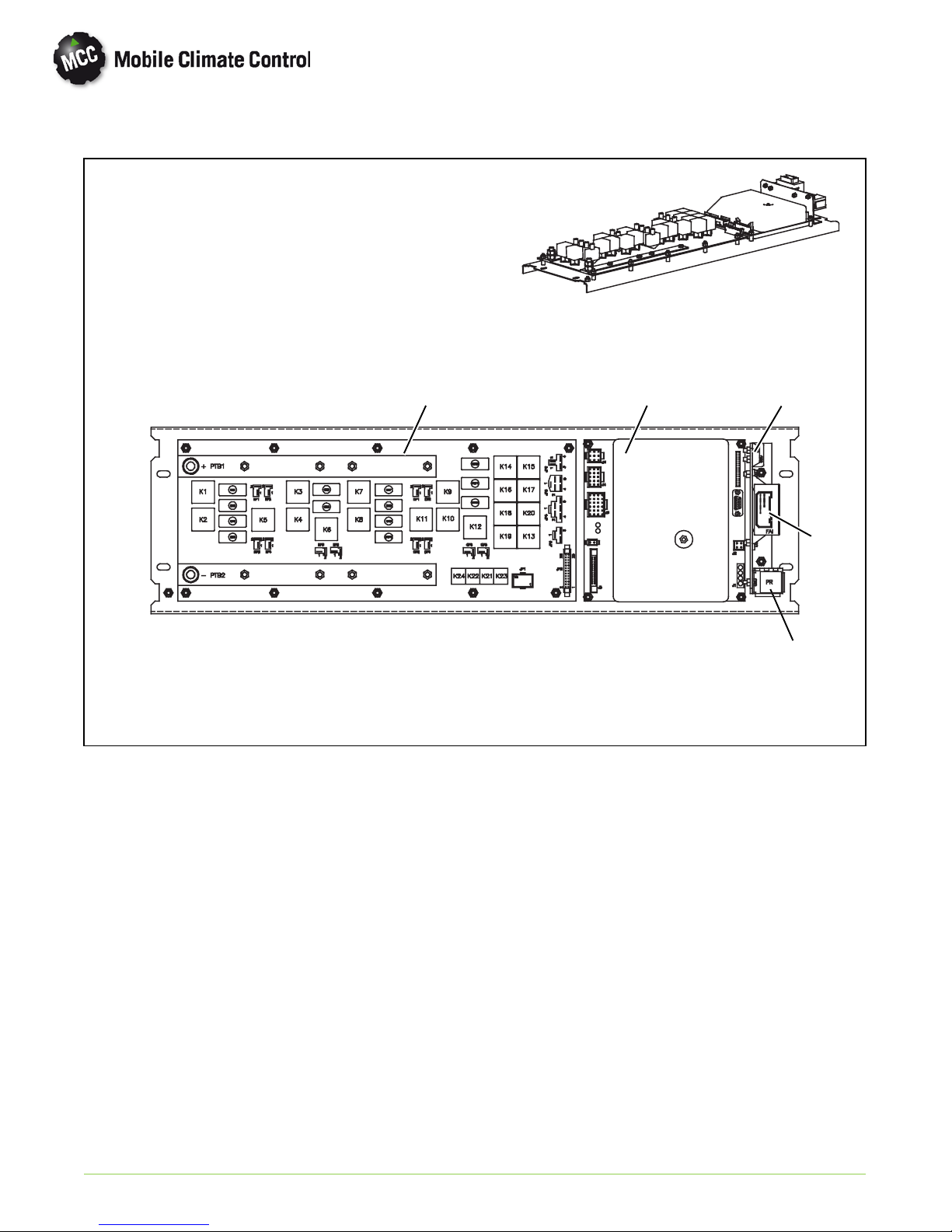

1.12 CONTROL PANEL WITH GR60 RELAY BOARD

1. Logic Board (See Figure 1-10)

2. RelayBoard-GR60(SeeFigure1-11)

3. Power Relay (ON)

Figure 1-8 Control Panel

2

15

4

3

4. Fresh Air

5. Terminal Block (TB)

© 2012 Mobile Climate Control T-348 Rev. 07/2012

1--14

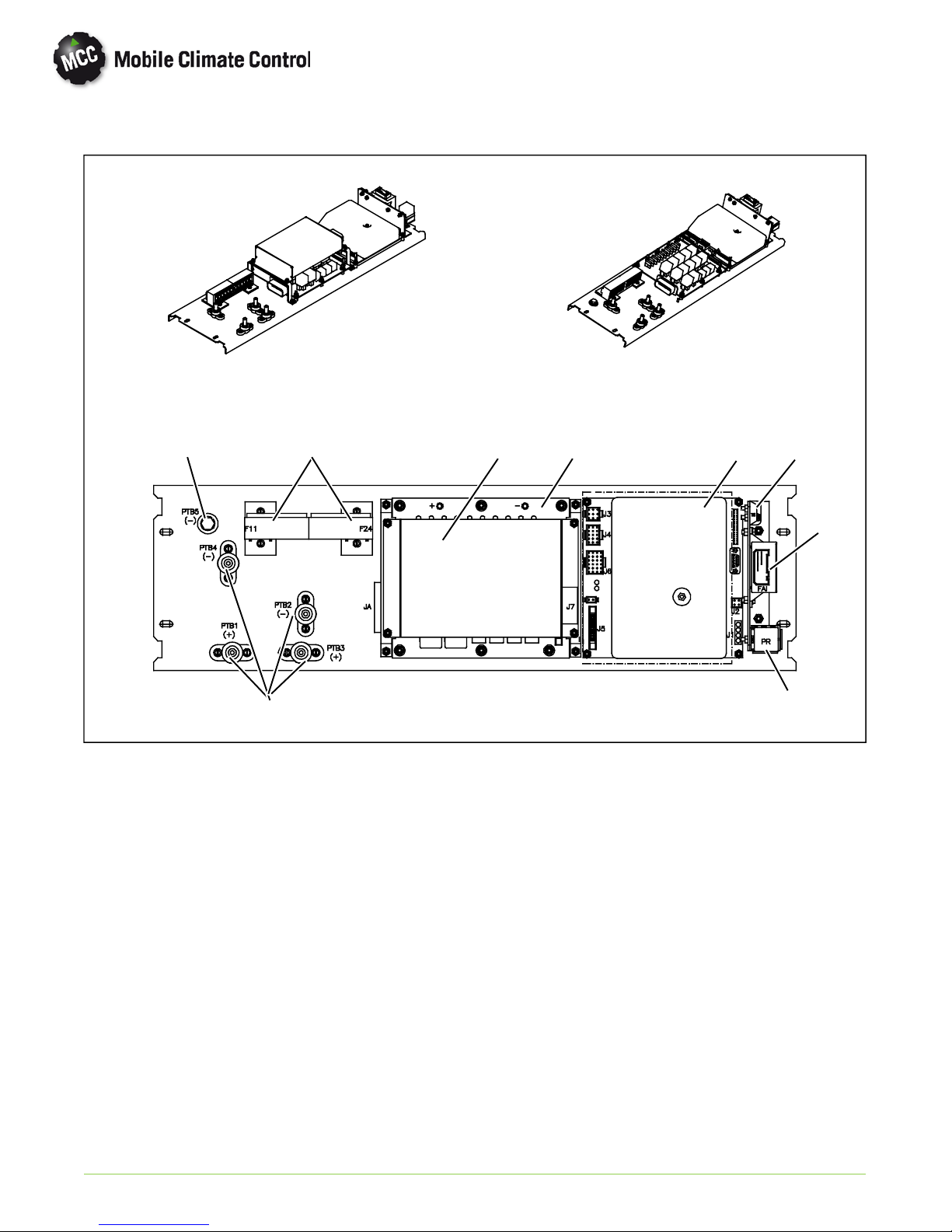

1.13 CONTROL PANEL

With CAN With/Out CAN

9

58

7

1. Logic Board (See Figure 1-10)

2. Relay Board (See Figure 1-12)

3. Logic Board, Data Communications

(See Figure 1-13

4. Power Relay (ON)

213

6

4

5. Fuses

6. Fresh Air

7. Power Terminal Block (PTB)

8. Terminal Block (TB)

9. Ground

Figure 1-9 Control Panel

© 2012 Mobile Climate Control T-348 Rev. 07/2012

1--15

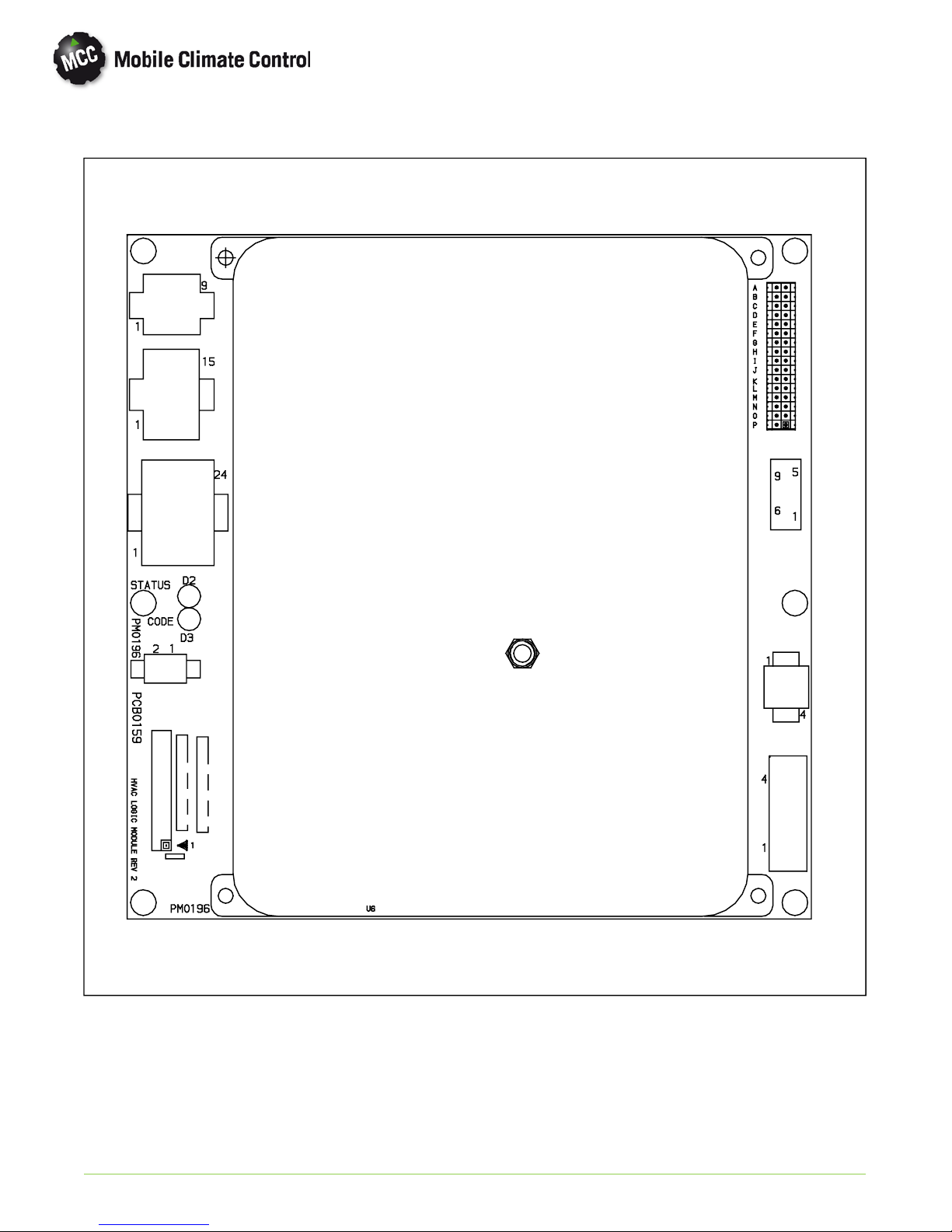

1.14 LOGIC BOARD

J3

J4

J

7

J6

J8

J

5

J7

J2

J1

J1 Logic board power in.

J2 Micromate Display interface.

J3 Manual control inputs.

J4 Interlock Inputs

(WTS, low side pressure switch etc.)

J5 Relay board interface.

J6 Sensor inputs (Thermistors, etc.).

© 2012 Mobile Climate Control T-348 Rev. 07/2012

J7 Diagnostics interface (RS232, DB9).

J8 Not used

D2 Blinks once per second in normal operation.

On steady to indicate alarms detected.

D3 Off In normal operation, blinks out alarm

codes (2 digits each) when alarms detected.

A-P Configuration Jumpers

Figure 1-10 Logic Board

1--16

Loading...

Loading...