Page 1

WebDAQ 316

User's Guide

July 2017. Rev 1

Internet Enabled Thermocouple Data Logger

© Measurement Computing Corporation

Page 2

HM WebDAQ 316

Trademark and Copyright Information

Measurement Computing Corporation, InstaCal, Universal Library, and the Measurement Computing logo are

either trademarks or registered trademarks of Measurement Computing Corporation. Refer to the Copyrights &

Trademarks section on mccdaq.com/legal

for more information about Measurement Computing trademarks.

Other product and company names mentioned herein are trademarks or trade names of their respective

companies.

© 2017 Measurement Computing Corporation. All rights reserved. No part of this publication may be

reproduced, stored in a retrieval system, or transmitted, in any form by any means, electronic, mechanical, by

photocopying, recording, or otherwise without the prior written permission of Measurement Computing

Corporation.

Notice

Measurement Computing Corporation does not authorize any Measurement Computing Corporation product for

use in life support systems and/or devices without prior written consent from Measurement Computing

Corporation. Life support devices/systems are devices or systems that, a) are intended for surgical implantation

into the body, or b) support or sustain life and whose failure to perform can be reasonably expected to result in

injury. Measurement Computing Corporation products are not designed with the components required, and are

not subject to the testing required to ensure a level of reliability suitable for the treatment and diagnosis of

people.

2

Page 3

Table of Contents

Preface

About this User's Guide ....................................................................................................................... 5

What you will learn from this user's guide ......................................................................................................... 5

Conventions in this user's guide ......................................................................................................................... 5

Where to find more information ......................................................................................................................... 5

Hazardous voltages ............................................................................................................................................. 5

Hazardous locations .......................................................................................................................................................... 5

Chapter 1

Introducing the WebDAQ 316 .............................................................................................................. 6

Powered by Raspberry Pi®.................................................................................................................................. 6

Integrated operating system and web service ..................................................................................................... 6

Ethernet interface ................................................................................................................................................ 6

Functional block diagram ................................................................................................................................... 7

Unpacking........................................................................................................................................................... 7

Chapter 2

Setting up the WebDAQ 316................................................................................................................. 8

Connecting to a local area network..................................................................................................................... 8

Connecting to a network with DHCP enabled .................................................................................................................. 8

Connecting directly to a PC .............................................................................................................................................. 8

Connecting the external power adapter .............................................................................................................. 8

Detecting the device on the network ................................................................................................................... 8

Accessing the WebDAQ web interface ............................................................................................................................. 9

Configuring the network router for communication across networks ................................................................ 9

Security ............................................................................................................................................................. 10

Restoring factory default settings ..................................................................................................................... 10

Chapter 3

Functional Details ............................................................................................................................... 11

Front panel components .................................................................................................................................... 11

Screw terminal .................................................................................................................................................................11

Spring terminal ................................................................................................................................................................12

Rear panel components ..................................................................................................................................... 13

External power connector ................................................................................................................................................13

Power button ....................................................................................................................................................................13

Function button ................................................................................................................................................................13

LED status indicators .......................................................................................................................................................14

SD card slot......................................................................................................................................................................14

Factory reset button .........................................................................................................................................................14

Ethernet connector ...........................................................................................................................................................14

Ground connector ............................................................................................................................................................15

USB connectors ...............................................................................................................................................................15

Analog input circuitry ....................................................................................................................................... 15

Open thermocouple detection ..........................................................................................................................................15

Input Impedance ..............................................................................................................................................................15

Overvoltage protection.....................................................................................................................................................15

Thermocouple measurement accuracy .............................................................................................................................15

Replacing the battery ........................................................................................................................................ 16

Updating WebDAQ firmware ........................................................................................................................... 16

Recovering from a failed update ......................................................................................................................................17

Calibrating the hardware................................................................................................................................... 17

3

Page 4

WebDAQ 316 User's Guide

Chapter 4

Specifications ...................................................................................................................................... 18

Thermocouple input .......................................................................................................................................... 18

Temperature measurement accuracy ................................................................................................................ 19

Digital input/output........................................................................................................................................... 21

Network ............................................................................................................................................................ 22

Ethernet connection .........................................................................................................................................................22

Network interface ............................................................................................................................................................22

Network factory default settings ......................................................................................................................................22

Processor / Memory .......................................................................................................................................... 22

USB ports ......................................................................................................................................................... 23

SD memory card slot ........................................................................................................................................ 23

LED indicators .................................................................................................................................................. 23

Push buttons ...................................................................................................................................................... 24

Ground connector ............................................................................................................................................. 24

Power ................................................................................................................................................................ 24

Mechanical ....................................................................................................................................................... 25

Environmental .................................................................................................................................................. 25

Safety voltages .................................................................................................................................................. 25

Signal connectors .............................................................................................................................................. 25

Screw terminal .................................................................................................................................................................26

Spring terminal ................................................................................................................................................................26

EU Declaration of Conformity ............................................................................................................ 27

4

Page 5

Preface

About this User's Guide

What you will learn from this user's guide

This user's guide describes the Measurement Computing WebDAQ 316 data acquisition device, the WebDAQ

web interface, and lists device specifications.

Conventions in this user's guide

For more information

Text presented in a box signifies additional information related to the subject matter.

Caution! Shaded caution statements present information to help you avoid injuring yourself and others,

damaging your hardware, or losing your data.

bold text Bold text is used for the names of objects on a screen, such as buttons, text boxes, and check boxes.

italic text Italic text is used for the names of manuals and help topic titles, and to emphasize a word or phrase.

Where to find more information

Additional information about WebDAQ 316 hardware is available on our website at www.mccdaq.com. You

can also contact Measurement Computing Corporation with specific questions.

WebDAQ web interface: Open the Help page for information about using WebDAQ software; see page 9.

Knowledgebase: kb.mccdaq.com

Tech support form: www.mccdaq.com/support/support_form.aspx

Email: techsupport@mccdaq.com

Phone: 508-946-5100 and follow the instructions for reaching Tech Support

For international customers, contact your local distributor. Refer to the International Distributors section on our

website at www.mccdaq.com/International

.

Hazardous voltages

Take the following precautions if you connect hazardous voltages to the WebDAQ 316 spring

terminals. A hazardous voltage is a voltage greater than 42.4 V

Caution! Ensure that hazardous voltage wiring is performed only by qualified personnel adhering to local

electrical standards.

Do not mix hazardous voltage circuits and human-accessible circuits on the same device.

Make sure that devices and circuits connected to the WebDAQ 316 are properly insulated from

human contact.

Hazardous locations

or 60 VDC to earth ground.

pk

The WebDAQ 316 is not certified for use in hazardous locations.

5

Page 6

Chapter 1

Introducing the WebDAQ 316

The WebDAQ 316 is part of the WebDAQ Series of Internet enabled data loggers. WebDAQ 316 is a

thermocouple acquisition and logging device that provides the following features:

16 differential thermocouple inputs

75 S/s aggregate sample rate

250 Vrms channel-to-earth isolation

Overvoltage protection between any two inputs

50/60 Hz noise rejection

Cold junction compensation (CJC)

Auto zero channel

Four bidirectional, isolated DIO

10/100 Ethernet interface

Support for USB mass storage devices and SD cards for data logging or file transfer

Powered by a +9 VDC external supply (included)

WebDAQ Series devices are designed with an integrated operating system and web interface. You

communicate with the device over a network connection using the web interface opened in a web browser.

Mobile support – access the WebDAQ 316 from any device with a web browser, such as a phone or tablet

Remote monitoring and control

Run simple to complex logging operations

Flexible task scheduling

Powered by Raspberry Pi®

The WebDAQ 316 is designed with the Raspberry Pi Compute Module, featuring a quad core processor with

speeds up to 1.2 GHz, 1GB RAM and 4 GB Flash memory.

Integrated operating system and web service

The WebDAQ 316 is a complete data acquisition system containing an embedded operating system and web

server. The operating system resides in internal flash memory, and includes a web service and device driver. All

configuration, acquisition, and data management is performed using the web interface.

Ethernet interface

The WebDAQ 316 has a built-in 10/100 BASE-T auto-negotiation, high-speed communication port. You can

access and configure your WebDAQ 316 from anywhere with access to the network to which it is connected.

A unique MAC address is assigned to each device at the factory. You configure the Ethernet connection settings

through a web interface. The default network name uses the format

lower six digits of the factory-assigned MAC address. You can change this name with the web interface.

webdaq-xxxxxx, where xxxxxx are the

6

Page 7

WebDAQ 316 User's Guide Introducing the WebDAQ 316

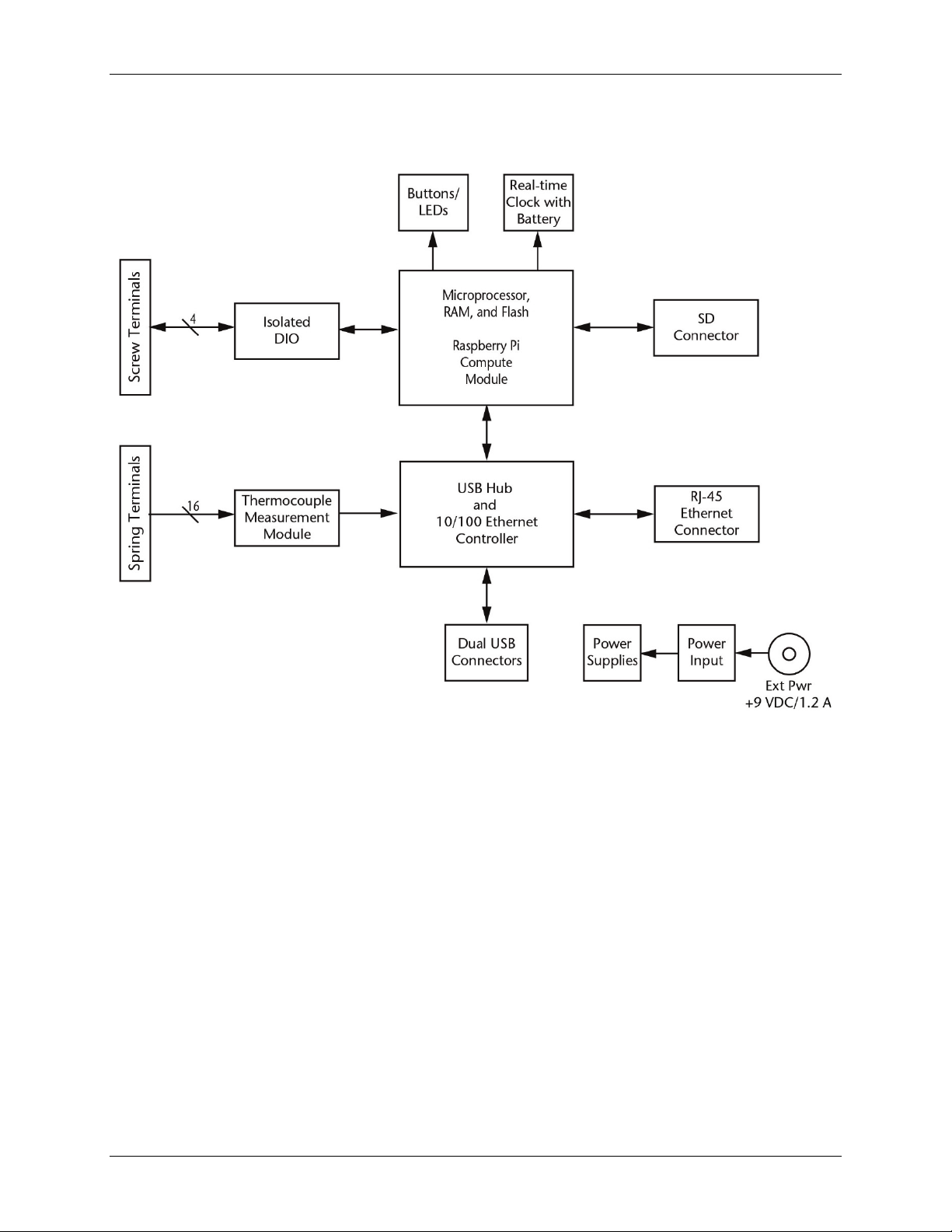

Functional block diagram

Device functions are illustrated in the block diagram shown here.

Figure 1. WebDAQ 316 functional block diagram

Unpacking

As with any electronic device, you should take care while handling to avoid damage from static

electricity. Before removing the board from its packaging, ground yourself using a wrist strap or by simply

touching the computer chassis or other grounded object to eliminate any stored static charge.

7

Page 8

Chapter 2

Setting up the WebDAQ 316

Connecting to a local area network

The WebDAQ 316 requires a TCP/IP connection to a network or the Ethernet port of a computer. A standard

Ethernet cable is shipped with the device.

The WebDAQ 316 IP address type is set by default for DHCP/Link-Local. When connected to a network, the

device first attempts to receive an IP address from a DHCP server. If this fails, a link-local address is used. Use

of a static address requires configuration via the web interface. The IP address identifies the WebDAQ 316 on

the network, and is used to access the web interface.

Connecting to a network with DHCP enabled

Connect one end of the Ethernet cable to the connector on the WebDAQ 316 rear panel, and connect the other

end to a 10Base-T or 100Base-TX compatible Ethernet port, hub, or switch.

Once the device is detected, DHCP assigns an address. A different address may be assigned each time the

hardware is connected to the network.

Connecting directly to a PC

Connect one end of the Ethernet cable to the connector on the WebDAQ 316 rear panel, and connect the other

end directly to the Ethernet port on a PC. The WebDAQ 316 attempts to communicate with the host PC using

169.254.100.100 – the link-local address stored on the device. The host PC may accept this address or use a

different address. The link-local address is valid only for communications between the WebDAQ 316 and the

host PC to which it is connected.

Connecting the external power adapter

Connect the network cable before connecting to external power

Connecting to the external supply before installing on a network results in the device attempting to autonegotiate a network address before one is available.

WebDAQ 316 ships with a 9 volt, 1.67 amp external power adapter included with the shipment (MCC p/n

PS-9V1AEPS230V).

Connect the adapter cord to the power connector labeled

AC adapter into an electrical outlet.

POWER LED on the rear panel turns yellow as the hardware starts up, and then green to indicate it is ready

The

for use. Refer to Figure 7 on page 13 for the location of this LED.

EXT PWR on the device rear panel, and plug the

Detecting the device on the network

WebDAQ uses the "zeroconf" zero-configuration protocol to announce its presence on a local area network.

Zeroconf uses a device name which can be accessed from other computers on the network.

Zero-configuration networking is helpful to find your WebDAQ hardware on the network

The easiest way to add zeroconf support to Windows is to install Bonjour Print Services. Bonjour software is

Apple's implementation of zero-configuration networking, and is readily available as a free download – open a

browser window and search for Bonjour Print Services.

Zeroconf is built into popular applications such as Apple ITunes® and instant messaging software, so your

computer may already support it.

Many Linux systems will have the avahi version of zeroconf installed by default, so it’s likely zeroconf is

available if you’re running Linux.

8

Page 9

WebDAQ 316 User's Guide Setting up the WebDAQ 316

Accessing the WebDAQ web interface

To access the WebDAQ web interface, open a browser* window and enter http://webdaq-xxxxxx.local, where

xxxxxx is the last 6 digits of the MAC address. The MAC address is on a label at the bottom of the WebDAQ

enclosure.

If your network supports zeroconf protocol, the WebDAQ web interface opens.

If the web interface does not open or an error is returned, install a device discovery tool such as Bonjour

Print Services. Refer to the note about zero-configuration networking on page 8.

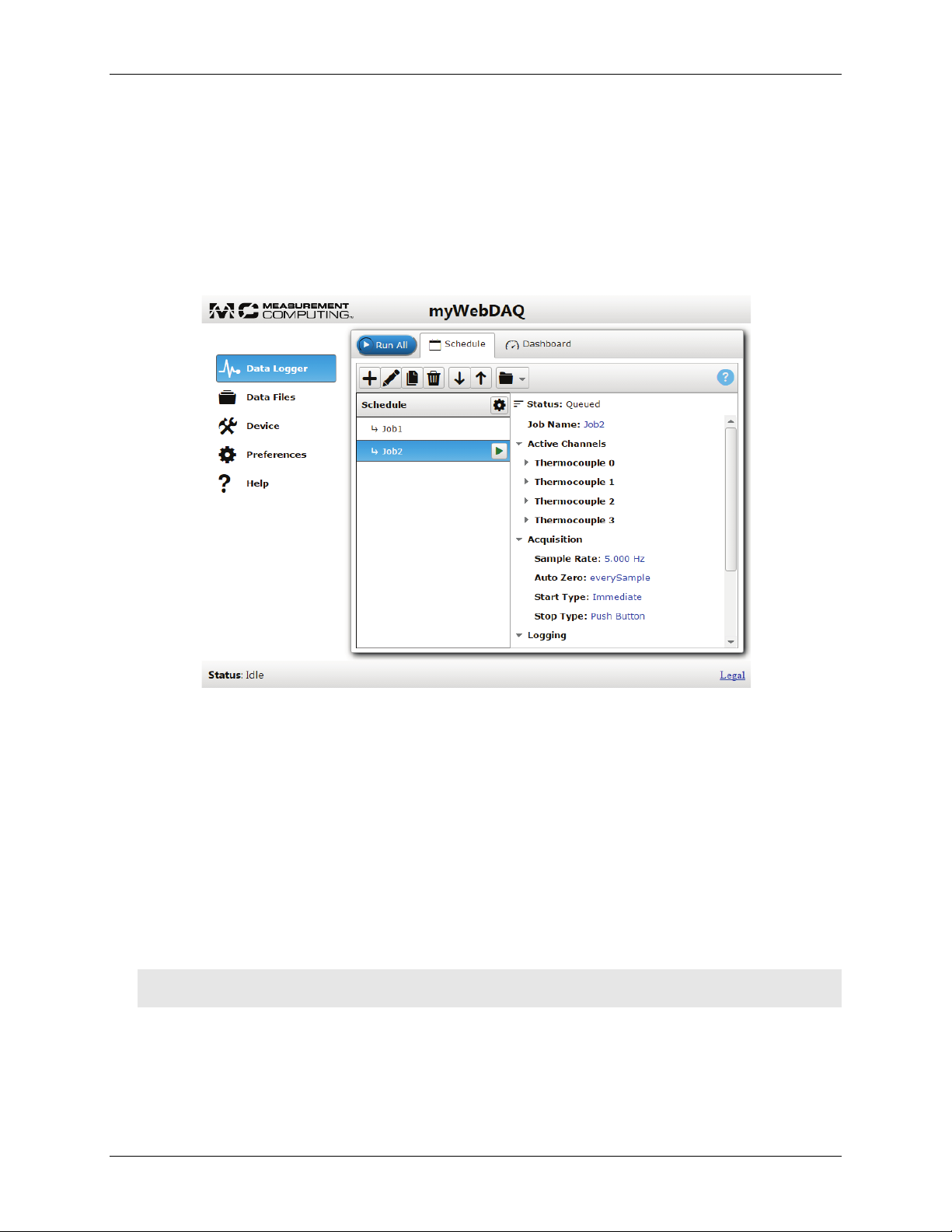

The WebDAQ web interface is shown in Figure 2.

Figure 2. WebDAQ 316WebDAQ web interface

Use the WebDAQ web interface to configure hardware and acquisition options, schedule and run jobs, and to

view and manage data. The Help window provides details about all components on the web interface.

Once a connection is established and you can communicate to the device, you can change the configuration for

other network scenarios.

* The latest version of Chrome, Firefox, Safari, UC Browser, or Opera recommended. Compatible with IE v11

with the latest Windows Updates installed. Not recommended for use with other IE versions or the Edge

browser.

Configuring the network router for communication across networks

To communicate with the WebDAQ 316 over the internet from a computer connected to a different network,

you must change the network configuration of the network router.

Caution! This procedure should only be performed by a network administrator or computer professional.

Incorrect settings can significantly disrupt a network.

In the following procedure, the WebDAQ 316 is installed on the host LAN, the computer is installed on the

client LAN, and it is assumed that you have successfully connected the device to a local network.

1. Determine the IP address of the WebDAQ 316 – open the Device window from the web interface, and note

the IP Address value in the Network Settings tab.

2. Configure your router so that the address determined above is a static address. The procedure for

accomplishing this varies between routers; refer to your router documentation for instructions.

9

Page 10

WebDAQ 316 User's Guide Setting up the WebDAQ 316

IP address

192.168.0.101

Gateway

192.168.0.1

DHCP setting

DHCP + link-local enabled

Security level

Off

User name

admin (case-sensitive)

3. Configure the firewall/router to forward an unused port to port 80 on the WebDAQ 316 at the IP address

configured for the device.

Note the static IP address assigned to the router – this is referred to as the WAN address.

4. To access your WebDAQ from a remote location, enter the WAN address followed by the port selected

above preceded by a colon in the web browser.

The format of the address entered in the browser is: 000.000.000.000:00000 (WAN address of router:port

selected for the WebDAQ).

Security

Use the web interface to set the level of access to the website and to change the administrator password.

High: access to the web page requires a password.

Medium: access to the web page is permitted for any user, and data can be read by any user, but changes to

the device configuration or files require a password.

Off: full access is permitted for all users; no password is required.

By default, security access is set to "Off", and the administrator password is set to "admin".

To change the security level or password, open the web interface and go to the Device window, Security tab.

Use the device Reset button to restore security settings to factory default values.

Restoring factory default settings

To restore network configuration and security settings to the factory default values, use a paper clip to press the

CONFIG RESET button. When pressed, the default network and security settings are written to the device and

the WebDAQ 316 is rebooted.

Factory default

Parameter Specification

subnet mask 255.255.255.0

Password admin (case-sensitive; editable)

You can change the network settings, security level, and password with the web interface. The user name

"admin" cannot be changed.

10

Page 11

1

Screw terminal

2

Spring terminal

Functional Details

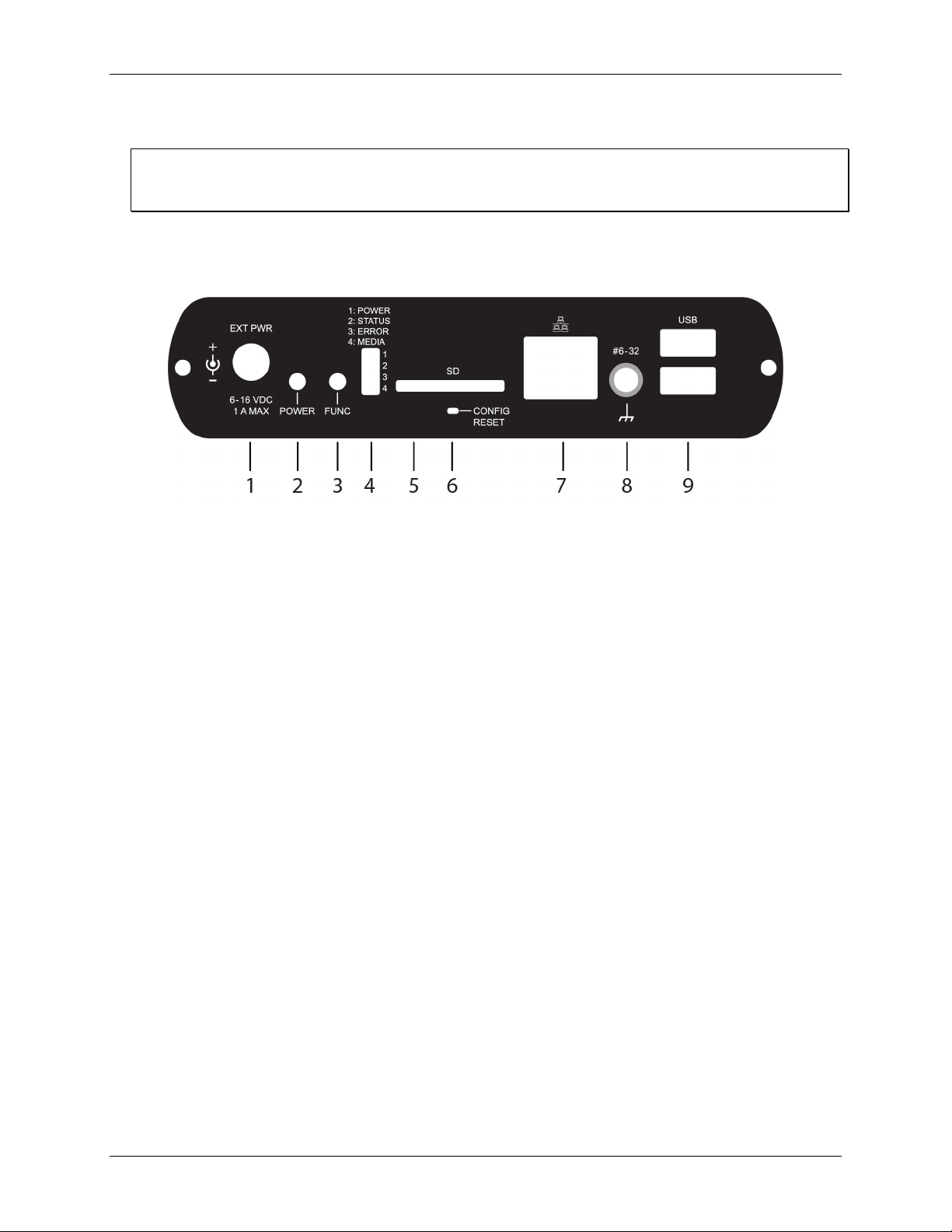

Front panel components

Front panel components are shown in Figure 3.

Detachable screw terminal

Detachable spring terminal

Chapter 3

Figure 3. Front panel

Screw terminal

Connect up to four digital I/O lines (DIO0 to DI03) to the detachable screw terminal. Refer to Figure 4 for signal

locations.

Figure 4. Screw terminal pinout

The digital ground (GND) terminals provide a common ground for the digital bits.

Digital connections

The digital I/O lines are electrically isolated from the thermocouple circuits. Each bit is individually

configurable for input or output, and features Schmitt trigger inputs and open drain outputs. All DIO channels

are pulled high to 5 V.

Any digital bit can be configured with the web interface as a trigger to start or stop an acquisition. Any digital

bit can also be configured to trigger an alarm, and be driven high or low when an alarm occurs.

11

Page 12

WebDAQ 316 User's Guide Functional Details

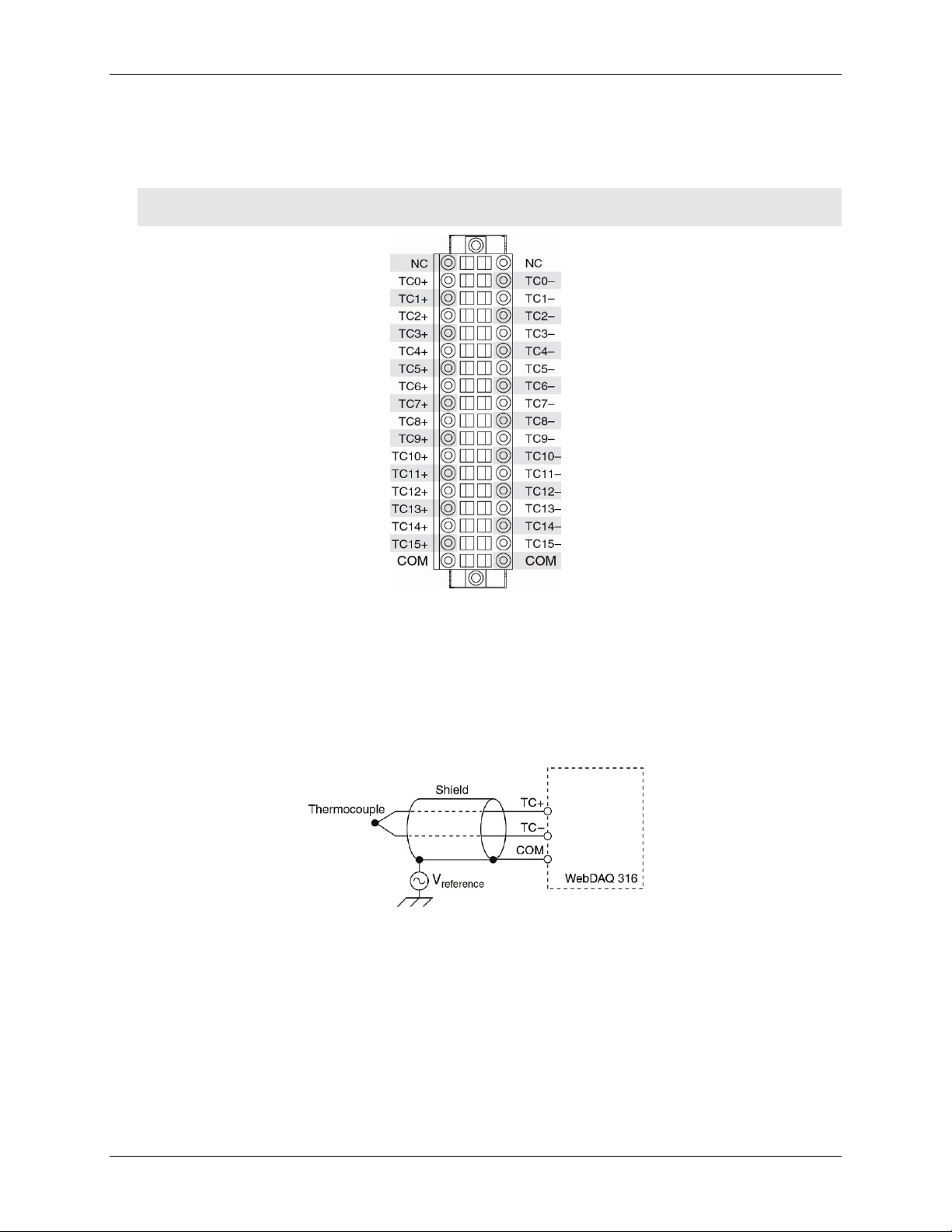

Spring terminal

Connect up to 16 thermocouples (TC0+/TC0– to TC15+/TC15–) and two common reference connections (COM)

to the 36-position detachable spring terminal. Refer to Figure 5 for signal locations.

Caution! MCC strongly recommends that you ground yourself using a wrist strap before handling the

thermocouple sensors.

Figure 5. Spring terminal pinout

The common terminals (COM) provide a common reference for the thermocouple inputs.

Thermocouple connections

A thermocouple consists of two dissimilar metals that are joined together at one end. When the junction of the

metals is heated or cooled, a voltage is produced that correlates to temperature.

The WebDAQ 316 supports type J, K, S, R, B, E, T, N thermocouples (TC), and provides overvoltage

protection between any two inputs. A typical thermocouple connection is shown in Figure 6.

Figure 6. Typical thermocouple connection

Connect the shield to a common mode voltage reference on the thermocouple. A valid reference is voltage

within ±1.2 V of all the connected thermocouples.

Minimizing thermal gradients

Changes in the ambient air temperature near the thermocouple connectors or a thermocouple wire conducting

heat directly to terminal junctions can cause thermal gradients. Observe the following guidelines to minimize

thermal gradients and improve system accuracy:

Use small-gauge thermocouple wire. Smaller wire transfers less heat to or from the terminal junction.

Run thermocouple wiring together near the spring terminal connector to maintain a consistent temperature.

Avoid running thermocouple wires near hot or cold objects.

12

Page 13

WebDAQ 316 User's Guide Functional Details

1

External power connector

4

LED status indicators (4)

7

Ethernet connector

3

Function button

6

Factory reset button

9

USB connectors

Minimize adjacent heat sources and air flow across the terminals.

Keep the ambient temperature as stable as possible.

Increasing the thermocouple length

If you need to increase the length of your thermocouple, use the same type of TC wires to minimize the error

introduced by thermal EMFs.

Rear panel components

Rear panel components are shown in Figure 7.

Figure 7. Rear panel

2 Power button 5 SD card slot 8 Ground connector

External power connector

Connect the external AC adapter that shipped with the device to the connector labeled EXT PWR on the rear

panel. The power supply provides 9 VDC, 1.2 A power to the WebDAQ 316.

If using a different power supply than what was shipped with the hardware, ensure that the supply has a positive

center pin.

Power button

The button labeled POWER turns the WebDAQ device on and off.

Press briefly to turn the device on.

Press for approximately 1 second to begin shutting down the operating system and WebDAQ hardware;

release the button when the

POWER LED blinks yellow. The operating system automatically powers off

the WebDAQ device at the end of the shutdown procedure.

If the WebDAQ device stops responding for any reason, you may press the power button and hold it for

approximately 4 seconds to force the device to power off. Any unsaved changes may be lost when

powering down using this method.

Function button

The button labeled FUNC has two functions; it can be used to eject external media or to start/stop an acquisition.

Eject external media (default): Pressing the button unmounts all removable media so they can be safely

removed from the device.

Start or stop an acquisition (requires configuration with the web interface): When configured, pressing

this button starts an acquisition, or stops an acquisition that is currently running.

Use the web interface to safely unmount removable media, when present.

When removable media is plugged into the WebDAQ 316, the operating system opens it for writing. To safely

remove the media, you must unmount it first.

13

Page 14

WebDAQ 316 User's Guide Functional Details

1: POWER

Steady yellow

Device is booting up

Steady green

Device boot is successful

Blinking yellow

Device is shutting down

Off

Device is off

2: STATUS

Blinking yellow

Device is configuring hardware

Steady green

Hardware configuration is complete

Flashing green

Waiting for a scheduled start condition to be met

Blinking heartbeat

Scheduled start condition is met; waiting for job start condition to be met.

Blinking green

Data is being acquired (job start condition is met)

Off

No error detected.

3: ERROR

Blinking yellow

Error condition is detected. This LED blinks even when the software is

Off

No error detected

4: MEDIA

Blinking yellow

A job is configured to log to external media, but the job hasn't started yet;

Steady yellow

External media is inserted into the SD card slot or USB storage port

Blinking green

Currently logging to an external SD card or USB storage device

Steady green

Media has been made safe for removal using the function button, but has not

When a job is configured to log data to external media, pressing FUNC while the job is running will not eject

the media.

MEDIA LED is steady green when all media is unmounted and safe to remove, and off when all media is

The

removed.

LED status indicators

The WebDAQ 316 has four LEDs on the rear panel that indicate the status of power and host communications.

The following table defines the LED states during normal operation.

LED states – normal operating mode

Label State Description

100 ms on/2s off)

configured to ignore the error

Error state is cleared when the next schedule starts.

pushbutton will not let you eject media

been removed

WebDAQ LEDs behave differently when software is updated on the device. For information about LED states

during software update mode, refer to Updating WebDAQ firmware on page 16.

SD card slot

The SD slot accepts SD (Secure Digital), SDHC, SDXC, MMC, and TransFlash memory cards. Memory cards

can be ejected using the web interface or the hardware

FUNC button, unless the button is configured to

start/stop an acquisition.

When removable media is plugged into the WebDAQ 316, the operating system opens it for writing. Use the

FUNC button (page 13) or web interface to unmount the SD card before removing.

Factory reset button

The recessed button labeled CONFIG RESET restores network and alarm settings to factory default values.

When pressed, the default settings are written to the device and the WebDAQ 316 is rebooted. Refer to page 10

for a list of the default settings that are restored.

Ethernet connector

The WebDAQ 316 has one 10 Base-T/100 Base-TX, auto-negotiation, high-speed communication port. The

port connector is an RJ-45, eight-position connector. The Ethernet port accepts shielded or unshielded twisted

pair cable. The maximum communication distance without using a repeater is 100 m (328 ft).

14

Page 15

WebDAQ 316 User's Guide Functional Details

Ground connector

Measurement Computing recommends grounding the WebDAQ device by connecting a #6-32 ground screw to

the connector labeled

#6-32.

USB connectors

The two high-speed USB ports can be used for connections to a mass storage device.

When removable media is plugged into the WebDAQ 316, the operating system opens it for writing. Use the

FUNC button (page 13) or web interface to unmount the USB device before removing.

Use a self-powered hub when external media requires high current

USB-powered hard drives may use an excessive amount of current during operation. The WebDAQ device

could shut down or experience other errors if the power requirements of a connected device exceed the power

available. Use a self-powered hub if the current requirement of external media exceeds 500 mA.

We recommend that you connect USB-powered hard drives before powering up the WebDAQ 316.

Analog input circuitry

Each channel passes through a differential filter and then is multiplexed and sampled by a 24-bit ADC. The

channels share a common ground (COM) that is isolated from the digital subsystem.

The circuitry for one thermocouple channel is shown in Figure 8.

Figure 8. Input circuitry of one TC channel

Open thermocouple detection

Each channel has an open thermocouple detection (OTD) circuit which consists of a current source between the

TC+ and TC– terminals. If an open thermocouple is connected to the channel, the current source forces a fullscale negative voltage across the terminals.

Input Impedance

Each channel has a resistor that produces an input impedance between the TC and COM terminals. The gain

and offset errors resulting from the source impedance of connected thermocouples are negligible for most

applications. Thermocouples with a longer lead length can introduce more significant errors.

Overvoltage protection

WebDAQ 316 provides 30 V overvoltage protection between any two inputs.

Thermocouple measurement accuracy

Thermocouple measurement errors depend partly on the type and accuracy of the thermocouple, the temperature

being measured, the resistance of the thermocouple wires, and the cold-junction temperature.

For increased accuracy, follow the guidelines listed on page 12 to minimize thermal gradients, and use the auto

zero channel to compensate for offset errors.

15

Page 16

WebDAQ 316 User's Guide Functional Details

Cold-junction accuracy

Heat dissipated by nearby heat sources can cause errors in thermocouple measurements by heating the

WebDAQ 316 terminals to a different temperature than the cold-junction compensation sensor. Thermal

gradient across the terminals can cause the terminals of different thermocouple channels to be at different

temperatures, which creates accuracy errors and affects the relative accuracy between channels.

The temperature measurement accuracy specifications include errors caused by the thermal gradient across the

WebDAQ 316 terminals for configurations with the terminals facing forward or upward.

Auto zero channel

The WebDAQ 316 has an internal auto zero channel which can be subtracted from each thermocouple reading

to compensate for offset errors. Use the web interface to enable auto zero. WebDAQ 316 specifications assume

that auto zero is enabled and applied to every sample.

Replacing the battery

A button cell lithium battery provides the time reference for WebDAQ hardware when the device is powered

off. The average lifespan of the battery is approximately 10 years.

Caution! The discharge of static electricity can damage some electronic components. Before removing the

WebDAQ 316 from its housing, ground yourself using a wrist strap or touch the computer chassis

or other grounded object to eliminate any stored static charge.

Perform the following procedure to replace the battery.

1. Power down the WebDAQ 316 and disconnect the power supply.

2. Remove the spring terminal and screw terminal from the front panel.

3. On the rear panel, remove the Ethernet cable, and any removable media.

4. Remove the two rear panel screws and bezel.

5. Slide out the circuit board.

6. Remove the battery by sliding it forward toward the slot, and replace with a 3 V button cell battery – type

BR1225, CR1225 or similar.

7. Slide the circuit board back into the enclosure.

8. Attach the rear bezel and rear faceplate, and secure with the two screws removed in step 4.

9. Connect the spring and screw terminal headers to the front panel.

Set the device system clock from the Device window, Device Info tab on the web interface.

Updating WebDAQ firmware

Device firmware is bundled with the operating system and web server in a software update (*.swu) file.

Firmware updates are posted on the Measurement Computing Firmware Updates page and are available for

download. Use the web interface to install the *.swu file.

Perform the following procedure to update device firmware.

1. Download WebDAQ 316 firmware from the Measurement Computing Firmware Updates

directory on a USB mass storage device or SD card.

2. Connect the external media to the WebDAQ 316 device.

3. Open a browser window enter

address.

4. Open the

All device LEDs turn yellow as the update begins. The software waits 10 seconds to search for the update

file to allow for slower devices to enumerate, or to insert removable media containing the update file.

Device window, Device Info tab, and click the Update button on the Firmware panel.

http://webdaq-xxxxxx.local, where xxxxxx is the last 6 digits of the MAC

page to the root

16

Page 17

WebDAQ 316 User's Guide Functional Details

All LEDs

Solid yellow

Software update is starting

POWER

Blinking yellow

Software update is running

STATUS

Blinking green

Update file is located; device is being updated

Blinking yellow

Update file cannot be located; insert media with update file

ERROR

Blinking green

Update is successful; device will reboot in approximately 5 seconds

Blinking yellow

Update failed; user must retry

The STATUS LED blinks yellow if the software cannot locate the update file; if this occurs, verify that the

*.swu file is present and in the root of the media.

5. The

6. The

STATUS LED blinks green when the update file is detected.

The

POWER LED blinks yellow as the update file is installed.

ERROR LED blinks green when the software update is complete, and the device reboots in

approximately 5 seconds.

ERROR LED blinks yellow if the update is not successful. If this occurs, verify that the *.swu file is

The

available, and repeat the procedure.

The table below summarizes the LED behavior during a software update.

LED states – software update mode

LED State Description

Recovering from a failed update

If the update process is not successful, perform the following procedure to update the software image:

1. Press the

Power button to power down the WebDAQ 316. If the device is not responsive, press the Power

button for 4 seconds to force the device to power off. Power down the device; unsaved changes may be

lost.

2. Press the

FUNC button and POWER button at the same time to power on the WebDAQ 316 and update the

software image. Refer to page 13 for more information about these buttons.

Updating the software using this method is the same as initiating a firmware update using the web

interface.

Calibrating the hardware

The Measurement Computing Manufacturing Test department performs the initial factory calibration. Return

the device to Measurement Computing Corporation when calibration is required. The recommended calibration

interval is one year.

17

Page 18

16 thermocouple channels

1 internal cold-junction compensation channel

ADC resolution

24 bits

Type of ADC

Delta-Sigma

Sampling mode

Scanned

Voltage measurement range

±78.125 mV

Temperature measurement

ranges

Works over temperature ranges defined by NIST

(J, K, T, E, N, B, R, S thermocouple types)

Sample Rate (all channels): 1 S/s

High-speed mode:

Common-mode voltage

range

Channel-to-COM: ±1.2 V min

COM-to-earth ground: ±250 V

High-resolution mode at DC

and 50 to 60 Hz

Channel-to-COM: 100 dB

COM-to-earth ground: >170 dB

Channel-to-COM: 70 dB

High-resolution mode

14.4 Hz

High-speed mode

78 Hz

High-resolution noise

Overvoltage protection

±30 V between any two inputs

impedance

Input current

50 nA

High-resolution mode

200 nVrms

High-speed mode

7 µVrms

0.03% typ at 25 °C

0.15% max at 0 °C to 60 °C

0.16% max at 0 °C to 60 °C

High-resolution mode

4 µV typ, 6 µV max

High-speed mode

14 µV typ, 17 µV max

Offset error from source

Add 0.05 µV per Ω, when source impedance

Specifications

All specifications are subject to change without notice.

Typical for 0 °C to 50 °C unless otherwise specified.

Thermocouple input

Table 1. Thermocouple input specifications

Parameter Condition Specification

Chapter 4

Number of channels

Timing mode

Common-mode rejection

ratio (CMMR)

Input bandwidth

Automatically set for either highresolution or high-speed mode based

on the requested scan rate,

regardless of the number of

channels.

High-speed mode at 0 to 60 Hz

1 internal auto zero channel

High resolution mode:

Requested scan rate: ≤1 Hz

Conversion Time (per channel): 55 ms

Requested scan rate: >1 Hz

Conversion Time (per channel): 740 µs

Sample Rate

COM-to-earth ground: >150 dB

(all channels): 75 S/s

rejection

Differential input

Input noise

Gain error

Offset error

impedance

50 Hz and 60 Hz 60 dB

78 MΩ

High-resolution mode

High-speed mode

0 °C to 60 °C

0.07% typ at 0 °C to 60 °C

0.04% typ at 25 °C

0.08% typ at 0 °C to 60 °C

>50 Ω

18

Page 19

WebDAQ 316 User's Guide Specifications

Cold-junction compensation

accuracy

The device is lying flat or facing

temperature.

Measurement sensitivity

High-resolution mode

Type J, K, T, E, N: <0.02 °C

High-speed mode

Type J, K, T, E: <0.25 °C

Type R, S: <2.8 °C

Parameter Condition Specification

0.8 °C typ, 1.7 °C max

Warm-up time

upward and is in a constant ambient

15 minutes recommended

Temperature measurement accuracy

Measurement sensitivity represents the smallest change in temperature that a sensor can detect. It is a function

of noise. The values assume the full measurement range of the standard thermocouple sensor per

ASTM E230-87.

Table 2. Temperature accuracy specifications

Parameter Condition Specification

Type B, R, S: <0.15 °C

Type N: <0.35 °C

Type B: <1.2 °C

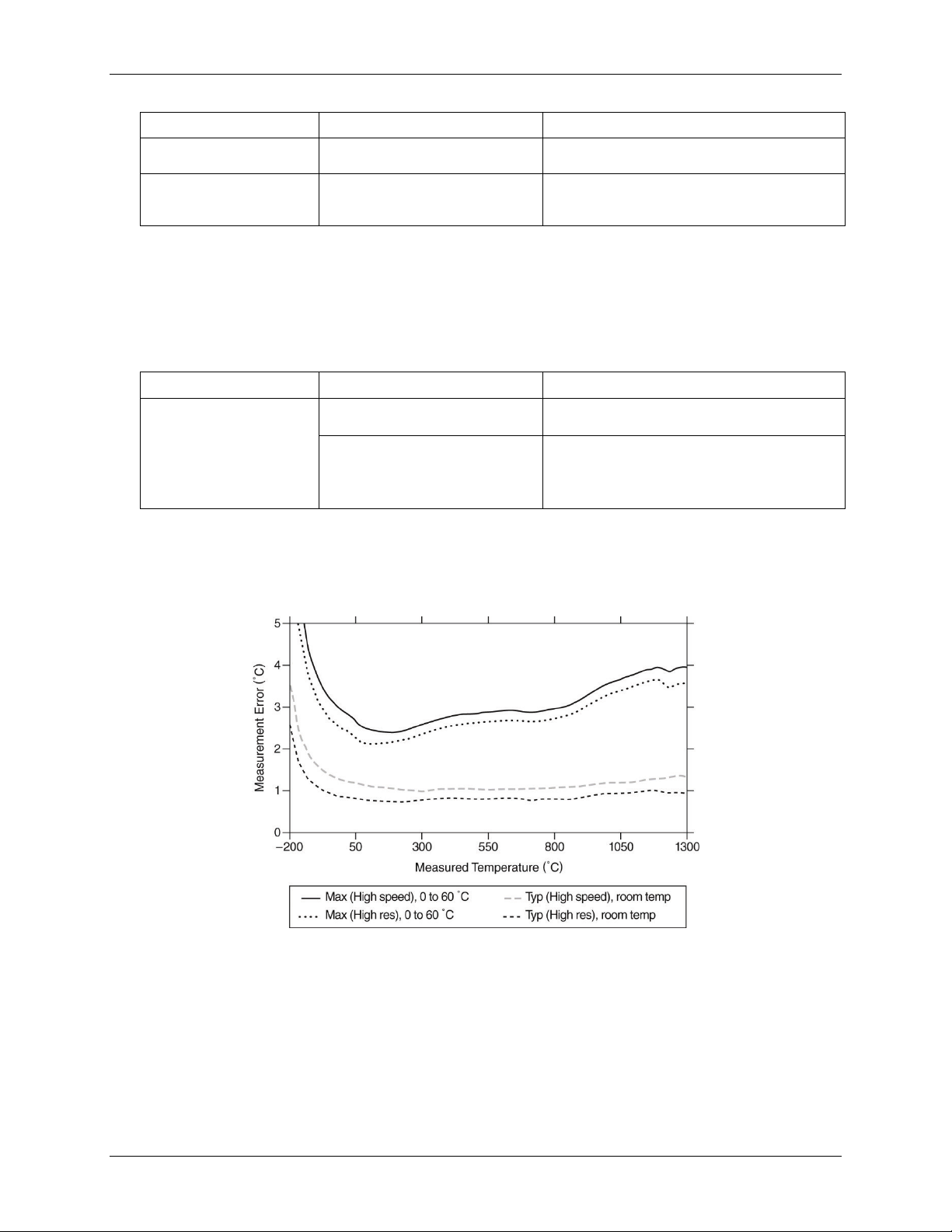

The following figures show the errors for each thermocouple type when connected to the WebDAQ 316 with

auto zeroing performed. The figures display the maximum error over a full temperature range, and the typical

error at room temperature. The figures account for gain errors, offset errors, differential and integral

nonlinearity, quantization errors, noise errors, 50 Ω lead wire resistance, and cold-junction compensation errors.

The figures do not account for the accuracy of the thermocouple itself.

Thermocouple Types J and N Errors

19

Page 20

WebDAQ 316 User's Guide Specifications

Thermocouple Type K Errors

Thermocouple Types T and E Errors

Thermocouple Type B Errors

20

Page 21

WebDAQ 316 User's Guide Specifications

Digital type

CMOS (Schmitt trigger) input / open drain output

Number of I/O

One port of 4 bits

Configuration

Each bit can be independently configured for input or output

Power on conditions

Power on reset is input mode

Pull-up configuration

Each bit is pulled up to 5 V with a 100 kΩ resistor

Input frequency range

DC – 10 kHz (Note 1)

Input high voltage threshold

1.9 V min, 3.6 V max

Input low voltage threshold

2.3 V max, 1.0 V min

Schmitt trigger hysteresis

0.6 V min, 1.7 V max

Input high voltage limit

15 V max

–0.5 V absolute min

0 V recommended min

0 V to +5 V (no external pull up resistor)

0 V to +15 V max (Note 2)

Output off state leakage

current

capability

Output transistor onresistance (drain to source)

Thermocouple Types R and S Errors

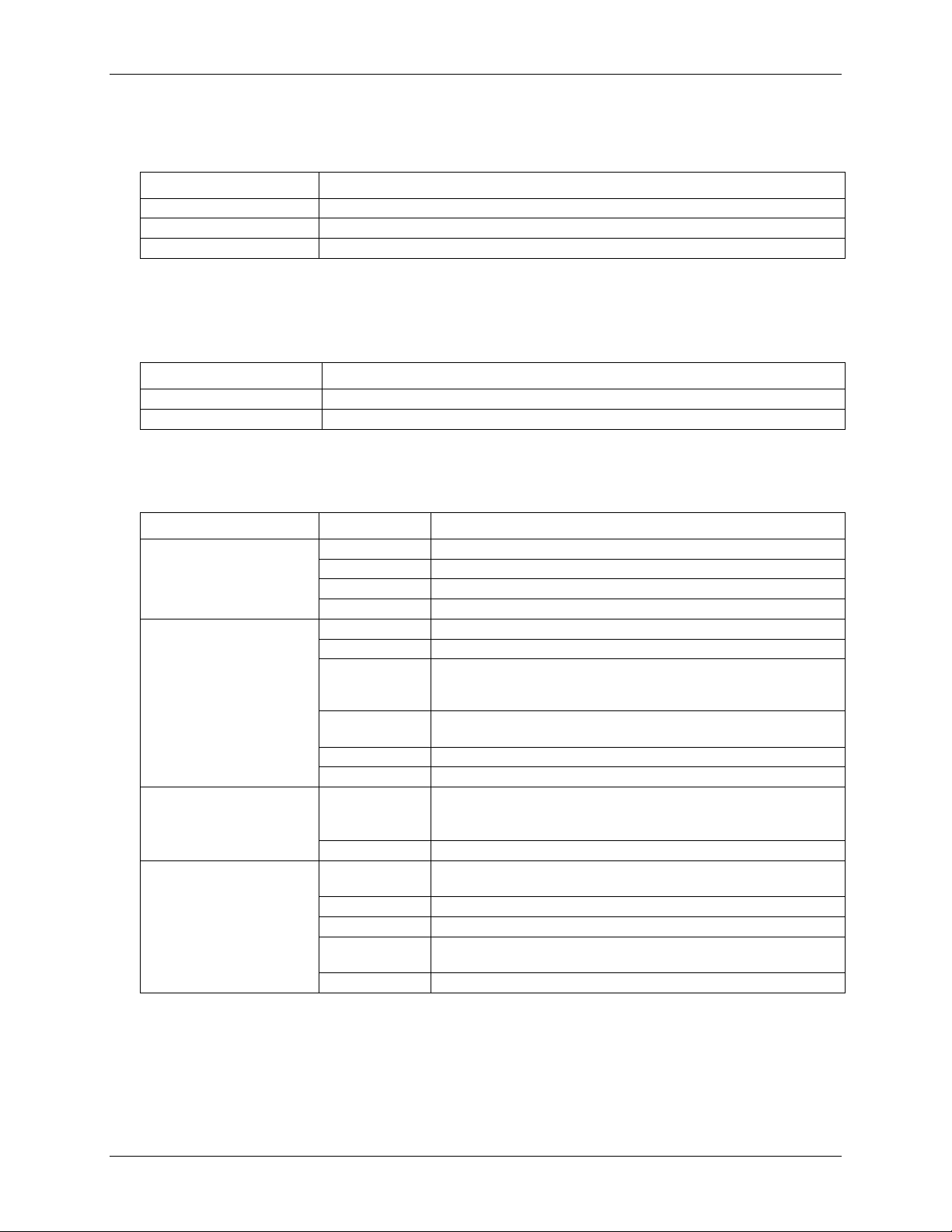

Digital input/output

Table 3. Digital input/output specifications

Parameter Specification

Input low voltage limit

Output voltage range

10 µA max

Output sink current

Note 1: Applying a signal with a frequency higher than this specification will adversely affect system performance and

could cause errors.

Note 2: The external pull-up resistor is connected between the digital output bit and an external supply. Adding an external

pull-up resistor connects it in parallel with the internal 100 kΩ pull-up resistor of that particular digital

input/output bit to the internal 5 V supply. Careful consideration should be made when considering the external

pull-up resistor value and the resultant pull-up voltage produced at the load.

100 mA max (continuous) per output pin

1.6 Ω

21

Page 22

WebDAQ 316 User's Guide Specifications

100 Base-TX

10 Base-T

Communication rates

10/100 Mbps, auto-negotiated

Connector

RJ-45, 8 position

Cable length

100 meters (328 feet) max

Additional parameters

HP Auto-MDIX support

DHCP, link-local, static

back to link-local and request the IP address 169.254.100.100.

The default name is webdaq-xxxxxx, where xxxxxx are the lower 6 digits of the

device MAC address. This name may be changed using the web interface.

Network name publication

By mDNS

Factory default IP address

192.168.0.101

Factory default subnet mask

255.255.255.0

Factory default Gateway

192.168.0.1

Factory default DHCP

setting

Factory default password

admin, case sensitive; can be modified with the web interface

Factory default user name

admin, case sensitive; cannot be changed.

Microprocessor

Type: Quad core Broadcom BCM2837

Memory

RAM: 1 GB LPDDR2

Network

Ethernet connection

Table 4. Ethernet connection specifications

Parameter Specification

Ethernet type

Network interface

Table 5. Factory default specifications

Parameter Specification

Network IP configuration

Network name

DHCP may be disabled by the user and a static IP address assigned

If DHCP is enabled but is unsuccessful at obtaining an IP address, the device will fall

Network factory default settings

Table 6. Factory default specifications

Parameter Specification

DHCP + link-local enabled

Processor / Memory

Table 7. Processor / memory specifications

Parameter Specification

Speed: 1.2 GHz

Flash: 4 GB eMMC (3 GB available for user data storage)

22

Page 23

WebDAQ 316 User's Guide Specifications

Number of USB ports

Two

USB device type

USB 2.0 (high-speed)

Device compatibility

USB 1.1, USB 2.0, USB 3.0

Memory card type

SD, SDHC, SDXC, MMC, TransFlash

File systems supported

FAT16, FAT32, exFAT, ext2/3/4, NTFS

1: POWER

Steady yellow

Device is booting up.

Steady green

Device boot is successful.

Blinking yellow

Device is shutting down.

Off

Device is off.

2: STATUS

Blinking yellow

Device is configuring hardware.

Steady green

Hardware configuration is complete.

Flashing green

Waiting for the schedule start condition to be met. (Note 4)

Blinking

The configured schedule start condition is met; waiting for job start

Blinking green

The configured job start condition is met – the job is running. (Note 4)

Off

Device is off.

3: ERROR

Blinking yellow

Error condition is detected. LED blinks even when the software is

Error state is cleared on the next schedule start.

Off

No error is detected, or the device is off

4: MEDIA

Blinking yellow

A job is configured to log to external media, but the job hasn't started

yet; push button will not let you eject media.

Steady yellow

External media is inserted into the SD card slot or USB storage port.

Blinking green

Currently logging to an external SD card or USB storage device.

Steady green

Media has been made safe for removal using the FUNC button, but is

still inserted in the device.

Off

No external media is detected, or the device is off.

USB ports

Table 8. USB specifications

Parameter Specification

Note 3: The USB ports are provided for connection to a mass storage device.

SD memory card slot

Table 9. SD card specifications

Parameter Specification

LED indicators

Table 10. LED specifications – normal operating mode

Label State Description

100 ms on,

2s off

heartbeat

condition to be met. (Note 4)

configured to ignore the error.

Note 4: Use the WebDAQ software to configure start and stop settings for jobs and schedules.

23

Page 24

WebDAQ 316 User's Guide Specifications

All LEDs

Solid yellow

Software update is starting.

1. POWER

Blinking yellow

Software update is running.

2. STATUS

Blinking green

Update file is located; device is being updated.

Blinking yellow

Update file cannot be located; insert media containing the update file.

3. ERROR

Blinking green

Update is successful; device reboot in approximately 5 seconds.

Blinking yellow

Update failed; user must retry.

Power button

POWER

Variable function:

Function button

FUNC

Dual function:

interface

Factory reset button

CONFIG

Restores network settings to factory default values

Ground connector

#6-32

Connector port for recommended #6-32 ground screw

Input voltage

Center positive

6 VDC to 16 VDC

Input wattage

4 W typ, 10 W max

External power adapter

MCC p/n PS9V1AEPS230V

9 V, 1.67 A, 110 VAC to 240 VAC input range

Battery

One 3 V button cell lithium battery (BR1225 or CR1225) required to

maintain time of day clock when device is powered off.

Table 11. LED specifications – software update mode

LED State Description

Push buttons

Table 12. Push button specifications

Component Label Description

Press briefly: turns the device on

Press for ~1 second: shuts down the device; release the button when

the POWER LED blinks yellow

Press and hold ~4 seconds: forces the device to power off

Ejects, or safely unmounts, all removable media for safe removal

from the device (default)

o This function is disabled when a job that uses external media is

running

o The MEDIA LED is steady green when all media is unmounted

but still inserted in the device

Starts or stops an acquisition; requires configuration via the web

RESET

Ground connector

Table 13. Ground connector specifications

Component Label Description

Power

Table 14. Power specifications

Parameter Conditions Specification

24

Page 25

WebDAQ 316 User's Guide Specifications

Dimensions (L × W × H)

158.8 × 146.1 × 38.1 mm (6.25 × 5.75 × 1.50 in.)

177.0 × 146.1 × 38.1 mm (6.97 × 5.75 × 1.50 in.) includes spring terminal

Weight

635 g (1.45 lb)

Operating temperature range

0 °C to 50 °C max

Storage temperature range

–40 °C to 85 °C

Ingress protection

IP30

Operating humidity

10% to 90% RH, noncondensing

Storage humidity

5% to 95% RH, noncondensing

Maximum altitude

2,000 m (6,562 ft)

Pollution Degree

2

Between any two terminals

±30 V max

Channel-to-channel isolation

None

Channel-to-earth ground

Continuous

250 Vrms, Measurement Category II (Note 6)

Withstand

2300 Vrms, verified by a 5 second dielectric withstand test

Connector types

36-position spring terminal for thermocouple connections

6-position screw terminal for digital connections

Terminal wiring

18 to 28 AWG copper conductor wire with 7 mm (0.28 in.) of insulation stripped from the

Mechanical

Table 15. Mechanical specifications

Parameter Specification

Environmental

Table 16. Environmental specifications

Parameter Specification

Note 5: WebDAQ 316 operation is intended for indoor use only, but may be used outdoors if installed in a suitable

enclosure.

Safety voltages

Connect only voltages that are within the limits specified in this table.

Table 17. Safety specifications

Parameter Conditions Specification

isolation

Note 6: Measurement Category II is for measurements performed on circuits directly connected to the electrical

distribution system. This category refers to local-level electrical distribution, such as that provided by a standard

wall outlet, for example 115 V for US or 230 V for Europe.

Caution! Do not connect the device to signals or use for measurements within Measurement Categories

III or IV.

Signal connectors

Table 18. Screw terminal specifications

Parameter Specification

end

25

Page 26

WebDAQ 316 User's Guide Specifications

#

Label

Use # Label

Use

1

GND

Digital ground

4

DIO2

Digital bit 2

3

DIO1

Digital bit 1

6

GND

Digital ground

#

Label

Use # Label

Use 1 NC

No connection

29

NC

No connection

2

TC0[+]

Channel 0 HI

30

TC0[–]

Channel 0 LO

3

TC1[+]

Channel 1 HI

31

TC1[–]

Channel 1 LO

4

TC2[+]

Channel 2 HI

32

TC2[–]

Channel 2 LO

5

TC3[+]

Channel 3 HI

33

TC3[–]

Channel 3 LO

6

TC4[+]

Channel 4 HI

34

TC4[–]

Channel 4 LO

8

TC6[+]

Channel 6 HI

36

TC6[–]

Channel 6 LO

10

TC8[+]

Channel 8 HI

38

TC8[–]

Channel 8 LO

11

TC9[+]

Channel 9 HI

39

TC9[–]

Channel 9 LO

12

TC10[+]

Channel 10 HI

40

TC10[–]

Channel 10 LO

13

TC11[+]

Channel 11 HI

41

TC11[–]

Channel 11 LO

14

TC12[+]

Channel 12 HI

42

TC12[–]

Channel 12 LO

15

TC13[+]

Channel 13 HI

43

TC13[–]

Channel 13 LO

17

TC15[+]

Channel 15 HI

45

TC15[–]

Channel 15 LO

Screw terminal

Table 19. Screw terminal pinout

Terminal Terminal

2 DIO0 Digital bit 0 5 DIO3 Digital bit 3

Spring terminal

Table 20. Spring terminal pinout

Terminal Terminal

7 TC5[+] Channel 5 HI 35 TC5[–] Channel 5 LO

9 TC7[+] Channel 7 HI 37 TC7[–] Channel 7 LO

16 TC14[+] Channel 14 HI 44 TC14[–] Channel 14 LO

18 COM Common 46 COM Common

26

Page 27

EU Declaration of Conformity

According to ISO/IEC 17050-1:2010

Manufacturer: Measurement Computing Corporation

Address: 10 Commerce Way

Norton, MA 02766

USA

Product Category: Electrical equipment for measurement, control and laboratory use.

Date and Place of Issue: May 31, 2017, Norton, Massachusetts USA

Test Report Number: EMI7018.17

Measurement Computing Corporation declares under sole responsibility that the product

WebDAQ 316

is in conformity with the relevant Union Harmonization Legislation and complies with the essential

requirements of the following applicable European Directives:

Electromagnetic Compatibility (EMC) Directive 2014/30/EU

Low Voltage Directive 2014/35/EU

RoHS Directive 2011/65/EU

Conformity is assessed in accordance to the following standards:

EMC:

Emissions:

EN 61326-1:2013 (IEC 61326-1:2012), Class A

EN 55011: 2009 + A1:2010 (IEC CISPR 11:2009 + A1:2010), Group 1, Class A

Immunity:

EN 61326-1:2013 (IEC 61326-1:2012), Controlled EM Environments

EN 61000-4-2:2008 (IEC 61000-4-2:2008)

EN 61000-4-3 :2010 (IEC61000-4-3:2010)

EN 61000-4-4 :2012 (IEC61000-4-4:2012)

EN 61000-4-5 :2014 (IEC61000-4-5:2014)

EN 61000-4-6 :2013 (IEC61000-4-6:2013)

EN 61000-4-11:2004 (IEC61000-4-11:2004)

Safety:

EN 61010-1 (IEC 61010-1)

Environmental Affairs:

Articles manufactured on or after the Date of Issue of this Declaration of Conformity do not contain any of the

restricted substances in concentrations/applications not permitted by the RoHS Directive.

Carl Haapaoja, Director of Quality Assurance

Page 28

Measurement Computing Corporation NI Hungary Kft

10 Commerce Way H-4031 Debrecen, Hátar út 1/A, Hungary

Norton, Massachusetts 02766 Phone: +36 (52) 515400

(508) 946-5100 Fax: +36 (52) 515414

Fax: (508) 946-9500 http://hungary.ni.com/debrecen

E-mail: info@mccdaq.com

www.mccdaq.com

Loading...

Loading...