M&C PSS Series, PSS-5C, PSS-5/2C, PSS-5/3C Instruction Manual

Portable Gas Conditioning Unit Series

PSS

®

PSS-5C, PSS-5/2C, PSS-5/3C

Instruction Manual

Version 1.02.02

This instruction manual does not claim completeness and may be subject

to technical modifications.

©

Germany GmbH. Reproduction of this

document or its content is not allowed without permission from

PSS

Version: 1.0

Dear customer,

Thank you for buying our product. In this manual you will find all necessary information about this

M&C product. The information in the manual is fast and easy to find, so you can start using your M&C

product right after you have read the manual.

If you have any question regarding the product or the application, please don’t hesitate to contact

M&C or your M&C authorized distributor. You will find all the addresses in the appendix of this

instruction manual.

For additional information about our products, please go to M&C’s website www.mc-techgroup.com

There you can find the data sheets and manuals of our products in German and English.

.

11/2019 M&C Techgroup

®

is a registered trade mark.

2.02

2 PSS-5C | 1.02.02 www.mc-techgroup.com

M&C.

List of Contents

1 General information .................................................................................................................. 5

2 Declaration of conformity ......................................................................................................... 5

3 Safety instructions .................................................................................................................... 6

4 Warranty .................................................................................................................................... 6

5 Used terms and signal indications .......................................................................................... 7

5.1 Type plate and labels on the device ..................................................................................... 8

6 Introduction ............................................................................................................................. 10

7 Function of the M&C Jet-Stream Heat Exchanger ................................................................ 10

8 Application .............................................................................................................................. 11

9 Technical data ......................................................................................................................... 13

10 Dimensions .......................................................................................................................... 18

11 Description ........................................................................................................................... 18

12 Operating instructions ........................................................................................................ 21

12.1 Main Menu ......................................................................................................................... 21

12.2 PIN Entry ........................................................................................................................... 22

12.3 Set Point Entry ................................................................................................................... 23

13 Parameter Setting ................................................................................................................ 24

13.1 Setting Temperature Alarm Limits ...................................................................................... 25

13.2 Fan Speed Setting ............................................................................................................. 26

13.3 Brightness Setting of Display ............................................................................................. 26

14 mA Output for the Temperature Measurement inside the Cooling Block ........................ 27

14.1 mA Output Range Selection ............................................................................................... 27

14.2 mA Output Calibration for the Temperature Measurement inside the Cooling Block .......... 27

15 Liquid Alarm Sensor (LA) type LA1S ................................................................................. 29

15.1 Activating the LA ................................................................................................................ 29

15.2 LA Sensitivity adjustment ................................................................................................... 30

15.3 LA Calibration .................................................................................................................... 31

16 Receipt of goods and storage ............................................................................................ 32

17 Installation instructions ...................................................................................................... 33

18 Supply connections ............................................................................................................ 34

18.1 Tube connections ............................................................................................................... 34

18.1.1 Connecting the heated sample line with special adapter (option) ................................ 36

18.2 Electrical connections ........................................................................................................ 36

19 Commissioning ................................................................................................................... 39

20 Closing down ....................................................................................................................... 40

21 Maintenance ......................................................................................................................... 41

22 Trouble shooting ................................................................................................................. 42

23 Spare parts list .................................................................................................................... 44

24 Appendix .............................................................................................................................. 46

www.mc-techgroup.com PSS-5C | 1.02.02 3

List of Figures

Figure 1 Type plate ......................................................................................................................... 8

Figure 2 Labelling of the connections ............................................................................................. 8

Figure 3 Warning label on the device.............................................................................................. 9

Figure 4 Diagram of the heat exchanger function ......................................................................... 10

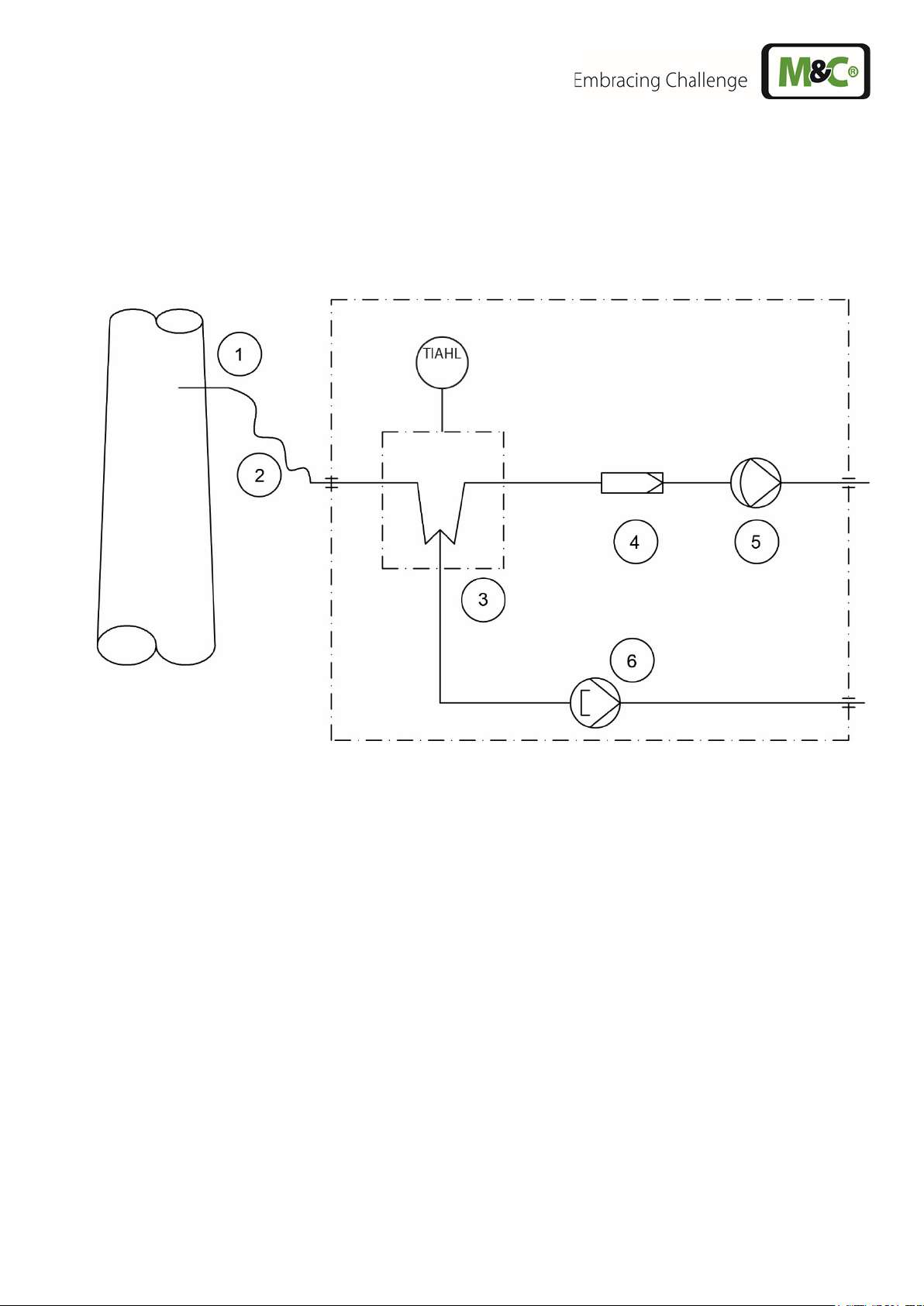

Figure 5 Gas flow diagram of PSS-5C and PSS-5/3C .................................................................. 11

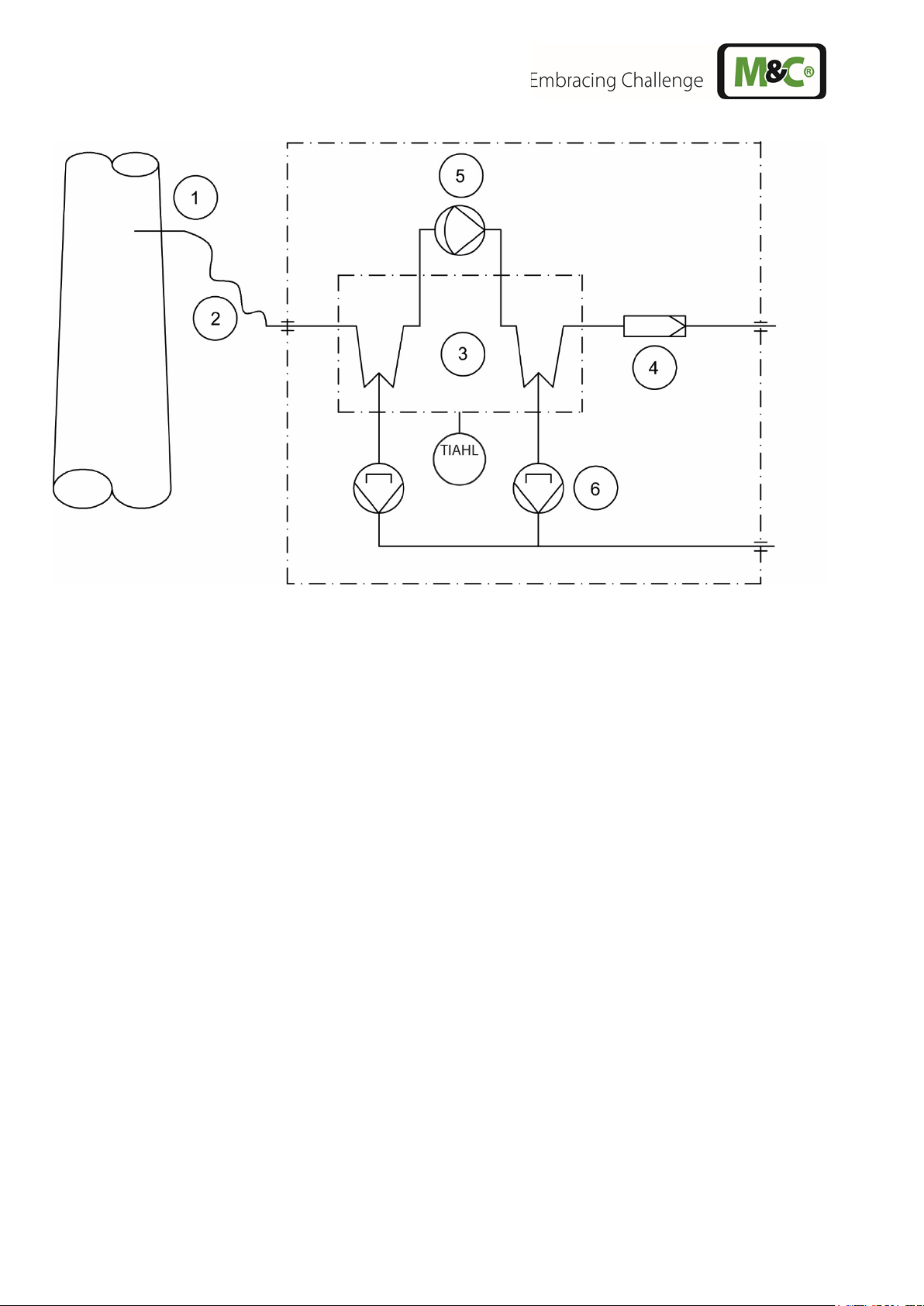

Figure 6 Gas flow diagram of PSS-5/2C ....................................................................................... 12

Figure 7 Dimensions ..................................................................................................................... 18

Figure 8 Case content: PSS-5C and PSS-5/3C ............................................................................ 19

Figure 9 Navigating through the main menu ................................................................................. 21

Figure 10 Reaching the set point entry from the ECP1000C/ECP3000C main menu ..................... 23

Figure 11 Temperature alarm limits and hysteresis ........................................................................ 25

Figure 12 LA alarm limits ............................................................................................................... 30

Figure 13 PSS-5C and PSS-5/3C medium connections ................................................................. 34

Figure 14 Connecting the heated sample line with special adapter (option) ................................... 36

Figure 15 Electrical connection ...................................................................................................... 37

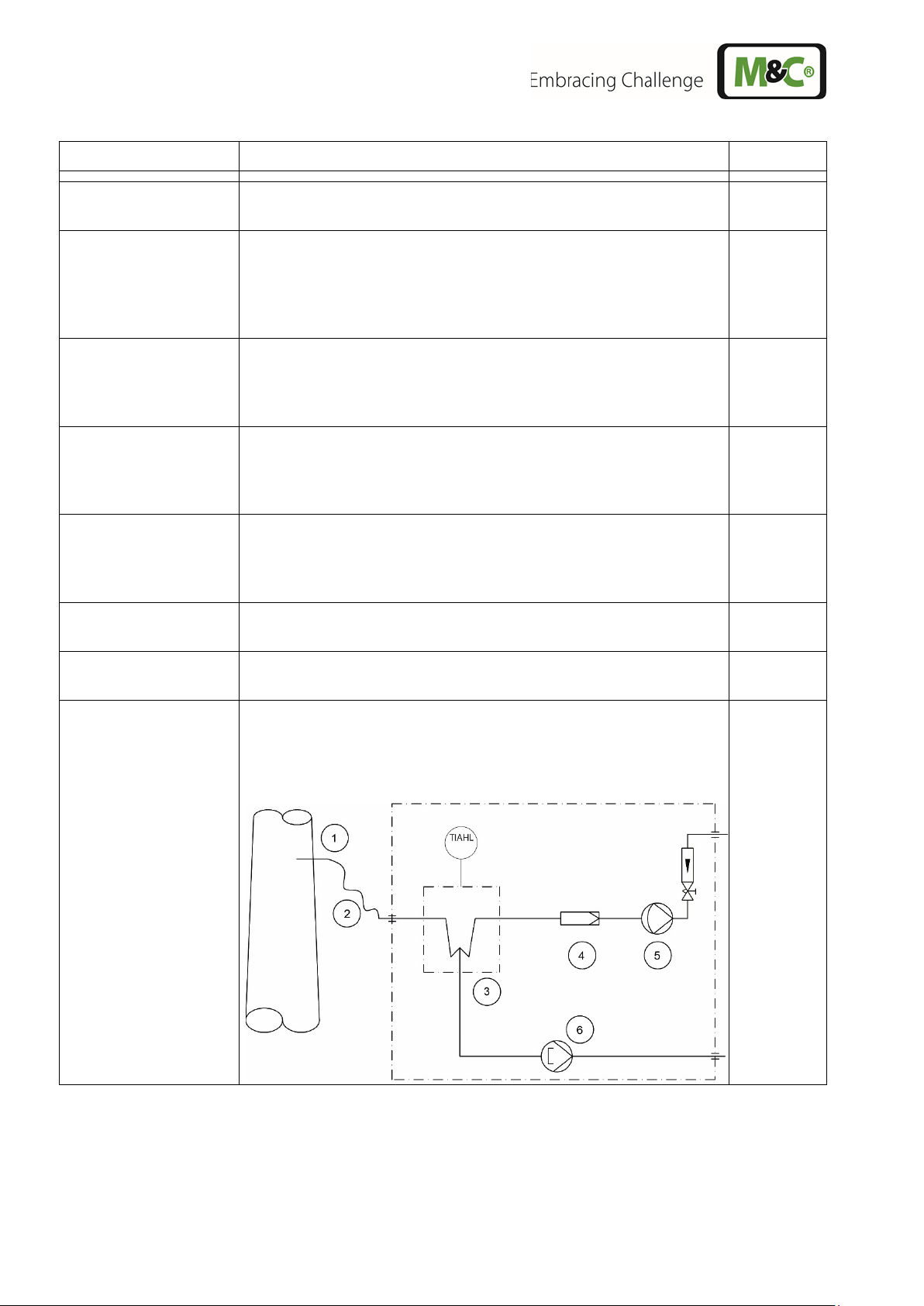

Figure 16 Circuit diagram PSS-5C ................................................................................................. 47

4 PSS-5C | 1.02.02 www.mc-techgroup.com

HEAD OFFICE

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 – 0

Fax: 02102 / 935 – 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 General information

The product described in this instruction manual has been built and tested in our production facility.

All M&C products are packed to be shipped safely. To ensure the safe operation and to maintain the

safe condition, all instructions and regulations stated in this instruction manual need to be followed.

This instruction manual includes all information regarding proper transportation, storage, installation,

operation and maintenance of this product by qualified personnel.

Follow all instructions and warnings closely.

Read this manual carefully before commissioning and operating the device. If you have any questions

regarding the product or the application, please don’t hesitate to contact M&C or your M&C authorized

distributor.

2 Declaration of conformity

CE - Certification

The product described in this operating manual complies with the following EU directives:

EMC-Instruction

The requirements of the EU directive 2014/30/EU “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EU directive 2014/35/EU “Low Voltage Directive“ are met.

The compliance with this EU directive has been examined according to DIN EN 61010.

RoHS Directive

The requirements of the RoHS2 (‘Restriction of Hazardous Substances 2’) directive 2011/65/EU and its

annexes are met.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

www.mc-techgroup.com PSS-5C | 1.02.02 5

3 Safety instructions

Follow these basic safety procedures when mounting, starting up or operating this equipment:

Read this instruction manual before starting up and use of the equipment. The information and

warnings given in this instruction manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

The installation and commissioning of the device must conform to the requirements of VDE 0100 (IEC

364) ‘Regulations on the Installation of Power Circuits with Nominal Voltages below 1000 V’ and must

be in compliance with all relevant regulations and standards.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Ensure sun-protected installation.

The unit may only be operated upright and with the door closed. Unused connectors must be closed

with the appropriate caps. IP42 means protection against foreign objects ≥1 mm and dripping water

up to an angle of ≤ 15°.

Do not use the gas conditioning systems PSS-5C, PSS-5/2C and PSS-5/3C in hazardous areas.

Installation, maintenance, inspections and any repairs of the devices must be carried out only by

qualified skilled personnel in compliance with the current regulations.

4 Warranty

In case of a device failure, please contact immediately M&C or your M&C authorized distributor.

We have a warranty period of 12 months from the delivery date. The warranty covers only

appropriately used products and does not cover the consumable parts. Please find the complete

warranty conditions in our terms and conditions.

The warranty includes a free-of-charge repair in our production facility or the free replacement of the

device. If you return a device to M&C, please be sure that it is properly packaged and shipped with

protective packaging. The repaired or replaced device will be shipped free of delivery charges to the

point of use.

6 PSS-5C | 1.02.02 www.mc-techgroup.com

5 Used terms and signal indications

This means that death, severe physical injuries and/or important

This means that death, severe physical injuries and/or important

ety

This means that minor physical injuries may occur in case the

CAUTION

Without the warning triangle means that a material damage may

ATTENTION

This means that an unintentional situation or an unintentional status

These are important information about the product or parts of the

QUALIFIED PERSONNEL

These are persons with necessary qualification who are familiar with

High voltages!

Corrosive!

Wear protective gloves!

objects or extremely high

Wear safety glasses!

objects.

material damages will occur in case the respective safety measures

DANGER

WARNING

CAUTION

are not fulfilled.

material damages may occur in case the respective saf

measures are not fulfilled.

respective safety measures are not fulfilled.

occur in case the respective safety measures are not met.

NOTE

may occur in case the respective note is not respected.

operating manual which require user’s attention.

installation, use and maintenance of the product.

Protect yourself and others against damages which might be caused

by high voltages.

These substances destroy living tissue and equipment upon contact.

Do not breathe vapors; avoid contact with skin and eyes.

Working with chemicals, sharp

temperatures requires wearing protective gloves.

Protect your eyes while working with chemicals or sharp

Wear safety glasses to avoid getting something in your eyes.

www.mc-techgroup.com PSS-5C | 1.02.02 7

Wear protective clothes!

Working with chemicals, sharp objects or extreme

ly high

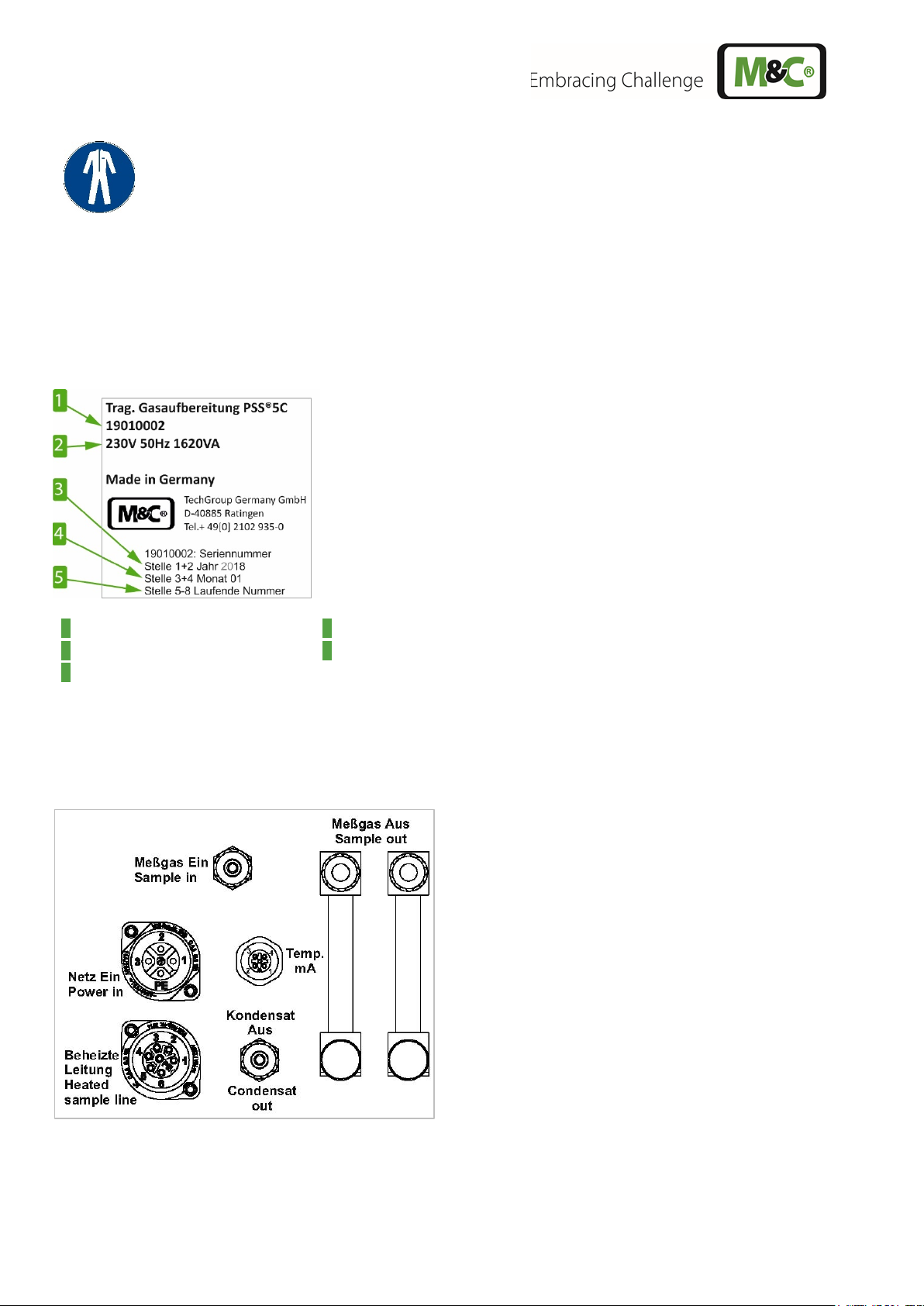

1 Serial number

4 S/N: digits 3+4: Month 01

2 Electrical connection data

5 S/N digits 5 to 8: consecutive number

3 S/N: digits 1+2: Year 2018

temperatures requires wearing protective clothes.

5.1 Type plate and labels on the device

A type plate, an information label and a warning label are located on the device.

The type plate contains the product name, the serial number including explanation, electrical connection

data and the manufacturer's address.

Figure 1 Type plate

The position of the electrical connections and gas connections are explained on the label below the

connections on the case side.

Figure 2 Labelling of the connections

8 PSS-5C | 1.02.02 www.mc-techgroup.com

The warning label indicates the necessary requirements for operating the device.

Figure 3 Warning label on the device

www.mc-techgroup.com PSS-5C | 1.02.02 9

6 Introduction

+5°C

Sample gas

out

Sample gas

in

Condensate

out

Coolingblock

[41 °F]

The portable gas conditioning systems PSS-5C, PSS-5/2C and PSS-5/3C are designed especially for

applications where accurate gas analysis at constantly changing locations is required.

The entire gas conditioning system is housed in a compact and impact-resistant plastic case equipped

with an integrated trolley with extendable handle. This allows gas analysis at various locations to be

carried out quickly, reliably and with low maintenance.

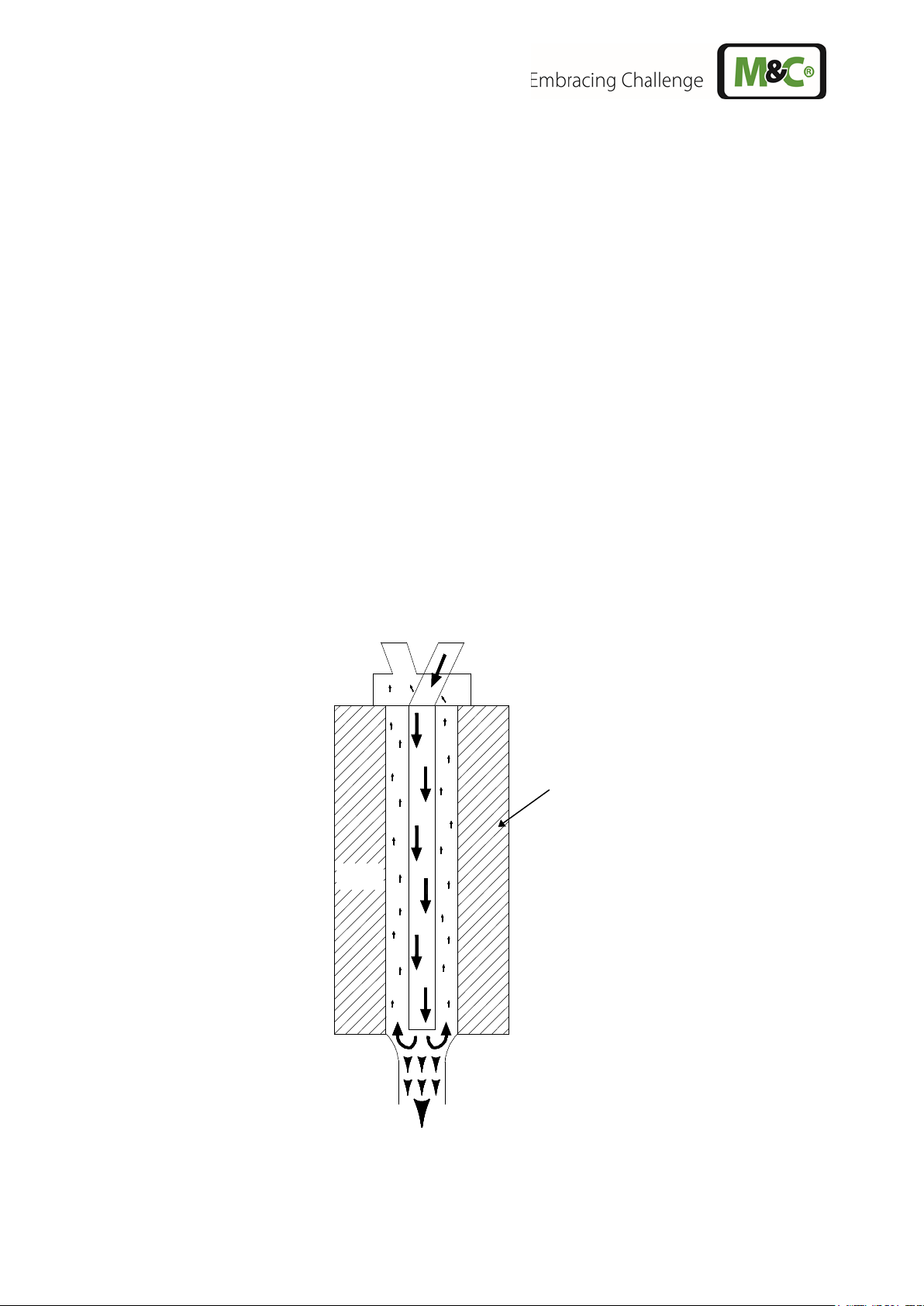

7 Function of the M&C Jet-Stream Heat Exchanger

The ECPX000C gas coolers, specially developed for analysis technology, are designed for maximum

flow rates of up to 350 Nl/h. They are also installed as system assemblies in the PSS-5C, PSS-5/2C

and PSS-5/3C.

Jet-Stream heat exchangers are available in Duran glass, stainless steel (316Ti) and PVDF

(polyvinylidene fluoride). The selection of the appropriate heat exchanger material is customerspecific. The heat exchangers are easily accessible and easily replaceable in a heat-insulated cooling

block. Figure 4 shows a schematic diagram of the heat exchanger function.

Figure 4 Diagram of the heat exchanger function

10 PSS-5C | 1.02.02 www.mc-techgroup.com

8 Application

The PSS-5C gas conditioning system is suitable for variable discontinuous use as well as for

continuous operation.

The upright, closed PSS-5C case with screwed in connectors complies with protection class IP42 as

required by the EN15267-4:2017 standard. It contains a standard gas temperature monitoring as well

as a temperature display visible from the outside.

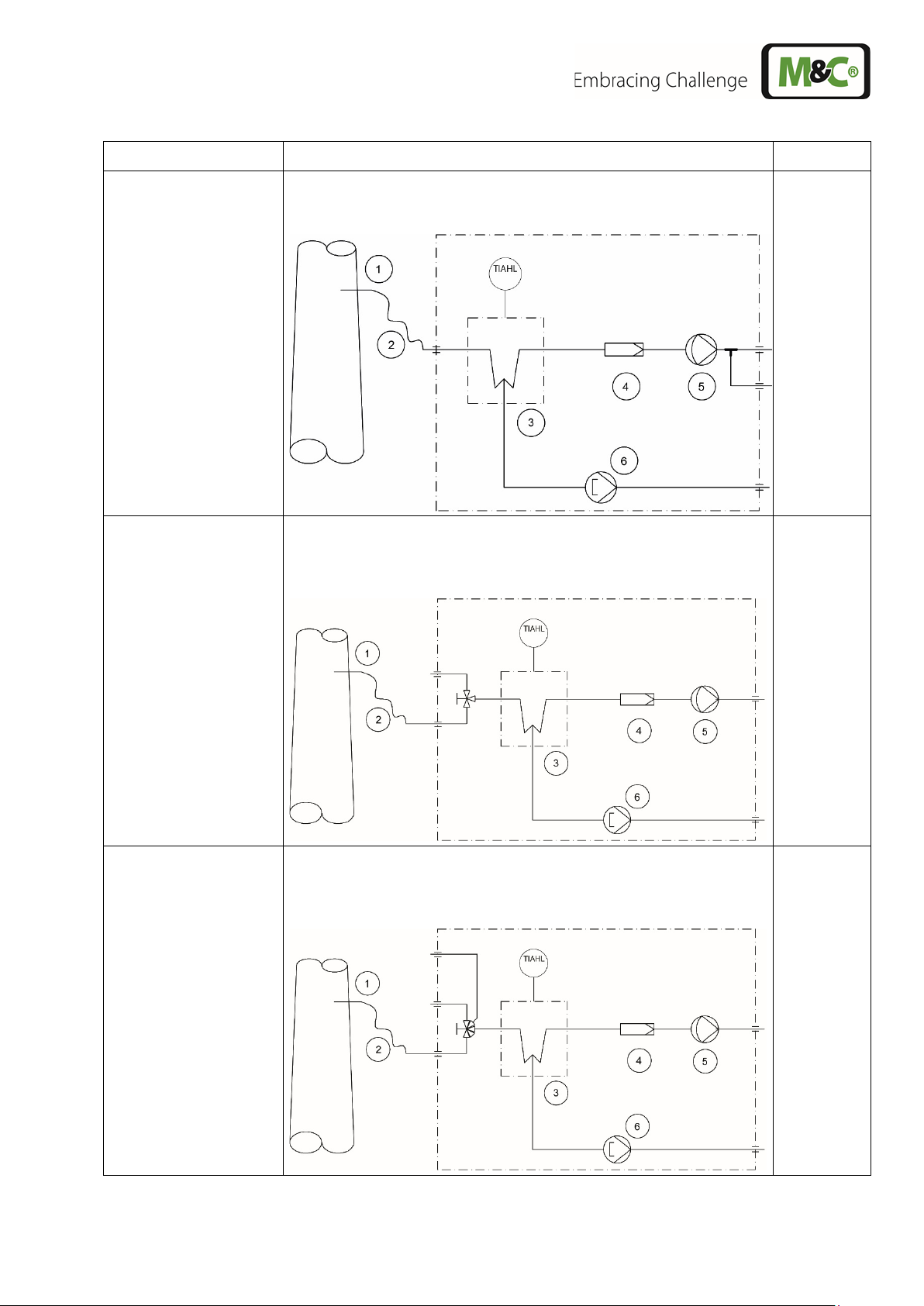

Gas sample probe made of SS316Ti, Ø 4/6 mm, length 0.5 m

Gas sample line, PVC tube, Ø 4/6 mm, length 3 m

Peltier gas cooler with temperature alarm high/low (TIAHL)

Fine filter FP-2T, filter element porosity 2 µm

Sample gas pump N3 KPE (options: N5 KPE (Part No. 01G9090), N9 KPE (Part No. 01G9095))

Peristaltic pump SR25.2-W for continuous condensate removal

Figure 5 Gas flow diagram of PSS-5C and PSS-5/3C

www.mc-techgroup.com PSS-5C | 1.02.02 11

Gas sample probe made of SS316Ti, Ø 4/6 mm, length 0.5 m

Gas sample line, PVC tube, Ø 4/6 mm, length 3 m

Peltier gas cooler with temperature alarm high/low (TIAHL)

Fine filter FP-2T, filter element porosity 2 µm

Sample gas pump N3 KPE (options: N5 KPE (Part No. 01G9090), N9 KPE (Part No. 01G9095))

Peristaltic pump2 2 x SR25.2-W for continuous condensate removal

Figure 6 Gas flow diagram of PSS-5/2C

12 PSS-5C | 1.02.02 www.mc-techgroup.com

9 Technical data

Gas Conditioning Type

PSS-5C

PSS-5/2C

PSS-5/3C

Part No.

01G4000

01G4250

01G4500

Sample gas outlet dew point

Range of adjustment: +2 to 15 °C [35.6 to 59 °F], factory setting:

ew point

stability

Sample gas inlet temperature

*Max. 80°C [176 °F], optional: *max. 180°C [356 °F] with stainless

Sample gas inlet water vapor

*Max. +80 °C [176 °F]

Heat exchanger gas flow rate

*Max. 150 Nl/h

*Max. 150 Nl/h per

*Max. 350 Nl/h

Ambient temperature

*5 to 40 °C [41 to 104 °F]

Storage temperature

-25 to +65 °C [-13 to +149 °F]

Pressure

0.7 bar to 1.4 bar abs.

Total cooling power*

Max. 80 kJ/h

Number of gas inlets

1

Medium connections

Tube connections 4/6 mm

Material of parts beeing in

Stainless steel, glass, PVDF, PTFE, Novoprene®

Ready for operation

Approx. 3 min. (with heated line approx. 1 h)

Mains power supply

115 or 230 V AC ±10 % 50/60 Hz

Power consumption

Max. 240 VA; with option temperature controller and heated

Fuse protection

4 A t, 5 mm x 20 mm; with option temperature controller: 10 A t,

Electrical connection

2 m [≈ 6.56 ft] length cable

Electrical equipment standard

EN 61010

IP42 EN 60529, with upright case and door closed. Unused

Housing

Portable impact-resistant case with integrated trolley system and

Housing color

Black

Housing dimensions

451 x 654 x 279 mm [≈ 17.8“ x 25.7“ x 11“] with casters and handle

Weight

Approx. 17 kg [≈ 37.5 lbs]

Sample gas outlet d

saturation

+5 °C [41 °F]

At const. conditions: < ±0.1°C [±0.18 °F]

steel bulkhead union

heat exchanger

Number of gas outlets 1, optional: max. 2

contact with the medium

sample line: 230 V, max. 1620 VA; 115 V, max. 920 VA

5 mm x 20 mm

Case protection

connectors must be closed with appropriate caps.

pull-out handle

(W x H x D)

PTFE=Polytetrafluoroethylene (Teflon®), PVDF=Polyvinylidenfluoride

* Maximum values in technical data must be rated in consideration of total cooling capacity at 25 °C [77 °F] ambient

temperature and an outlet dew point of 5 °C [41 °F].

www.mc-techgroup.com PSS-5C | 1.02.02 13

Options

Type

Part No.

Sample tube

Sample tube out of Kanthal® ø 6 mm, length: 1 m, sampling

temperature: max. 1300 °C [2372 °F]

01G9030

Electronic

heated sample line

100 W/m

701 control range: 0 to 200 °C [32 to 392 °F], inlet PT100, power:

01G9055

Electronic tempera-

sample line 100 W/m

701 control range 0 to 200 °C [32 to 392 °F], inlet PT100, power:

01G9055a

Connecting adapter

PSS-5C connecting adapter with anti-kink protection for rigid

sleeve, material: SS316Ti

01G9060

Connecting adapter

DN 6/8 for heated

PSS-5C connecting adapter with anti-kink protection for rigid

sleeve, material: SS316Ti

01G9061

Sample gas pump

N5 KPE, replacement

Extra charge for replacing the standard N3 KPE by the N5 KPE

01G9090

Sample gas pump

N9 KPE, replacement

Extra charge for replacing the standard N3 KPE by the N9 KPE

01G9095

Flow meter including

FM40 7-70 Nl/h air

01G9072

temperature controller

for max. 12 m [39.4 ft]

ture controller for max.

6 m [19.7 ft] heated

DN 4/6 for heated

sample line

sample line

230 V/50 Hz, contact capacity: 250 V AC max. 10 A, completely

mounted incl.

7-pin plug 10 A

115 V/60 Hz, contact capacity: 250 V AC max. 10 A, completely

mounted incl.

7-pin plug 10 A

mounting of heated sample line with replaceable PTFE tube DN

4/6, consisting of special Swagelok fitting with 4 mm support

mounting of heated sample line with replaceable PTFE tube DN

6/8, consisting of special Swagelok fitting with 6 mm support

sample gas outlet,

max. 2 pieces

FM40 15-150 Nl/h air

FM40 25-250 Nl/h air

FM40 50-500 Nl/h air

01G9077

01G9082

01G9087

14 PSS-5C | 1.02.02 www.mc-techgroup.com

Options

Type

Part No.

Further sample gas

Parallel sample gas outlet, tubing via T-piece on lateral PVDF

01G9065

3-way ball valve

(Note: only one FM40

flow meter is possible

3L/PV-1 for switching over from test gas to sample gas, in the

01G9046

5-way ball valve

(Note: only one FM40

flow meter is possible

5L/PV-1 for switching over from test gas to sample gas, in the

01G9045

outlet w/o flow meter

with this version)

bulkhead fitting, DN 4/6, max. 1 piece

inlet of the sample gas conditioning unit, mounted with mounting

bracket, fittings in PVDF

inlet of the sample gas conditioning unit, mounted with mounting

bracket, fittings in PVDF

with this version)

www.mc-techgroup.com PSS-5C | 1.02.02 15

Loading...

Loading...