Page 1

Portable Gas Conditioning Unit Series

PSS

®

PSS-5C, PSS-5/2C, PSS-5/3C

Instruction Manual

Version 1.02.02

Page 2

This instruction manual does not claim completeness and may be subject

to technical modifications.

©

Germany GmbH. Reproduction of this

document or its content is not allowed without permission from

PSS

Version: 1.0

Dear customer,

Thank you for buying our product. In this manual you will find all necessary information about this

M&C product. The information in the manual is fast and easy to find, so you can start using your M&C

product right after you have read the manual.

If you have any question regarding the product or the application, please don’t hesitate to contact

M&C or your M&C authorized distributor. You will find all the addresses in the appendix of this

instruction manual.

For additional information about our products, please go to M&C’s website www.mc-techgroup.com

There you can find the data sheets and manuals of our products in German and English.

.

11/2019 M&C Techgroup

®

is a registered trade mark.

2.02

2 PSS-5C | 1.02.02 www.mc-techgroup.com

M&C.

Page 3

List of Contents

1 General information .................................................................................................................. 5

2 Declaration of conformity ......................................................................................................... 5

3 Safety instructions .................................................................................................................... 6

4 Warranty .................................................................................................................................... 6

5 Used terms and signal indications .......................................................................................... 7

5.1 Type plate and labels on the device ..................................................................................... 8

6 Introduction ............................................................................................................................. 10

7 Function of the M&C Jet-Stream Heat Exchanger ................................................................ 10

8 Application .............................................................................................................................. 11

9 Technical data ......................................................................................................................... 13

10 Dimensions .......................................................................................................................... 18

11 Description ........................................................................................................................... 18

12 Operating instructions ........................................................................................................ 21

12.1 Main Menu ......................................................................................................................... 21

12.2 PIN Entry ........................................................................................................................... 22

12.3 Set Point Entry ................................................................................................................... 23

13 Parameter Setting ................................................................................................................ 24

13.1 Setting Temperature Alarm Limits ...................................................................................... 25

13.2 Fan Speed Setting ............................................................................................................. 26

13.3 Brightness Setting of Display ............................................................................................. 26

14 mA Output for the Temperature Measurement inside the Cooling Block ........................ 27

14.1 mA Output Range Selection ............................................................................................... 27

14.2 mA Output Calibration for the Temperature Measurement inside the Cooling Block .......... 27

15 Liquid Alarm Sensor (LA) type LA1S ................................................................................. 29

15.1 Activating the LA ................................................................................................................ 29

15.2 LA Sensitivity adjustment ................................................................................................... 30

15.3 LA Calibration .................................................................................................................... 31

16 Receipt of goods and storage ............................................................................................ 32

17 Installation instructions ...................................................................................................... 33

18 Supply connections ............................................................................................................ 34

18.1 Tube connections ............................................................................................................... 34

18.1.1 Connecting the heated sample line with special adapter (option) ................................ 36

18.2 Electrical connections ........................................................................................................ 36

19 Commissioning ................................................................................................................... 39

20 Closing down ....................................................................................................................... 40

21 Maintenance ......................................................................................................................... 41

22 Trouble shooting ................................................................................................................. 42

23 Spare parts list .................................................................................................................... 44

24 Appendix .............................................................................................................................. 46

www.mc-techgroup.com PSS-5C | 1.02.02 3

Page 4

List of Figures

Figure 1 Type plate ......................................................................................................................... 8

Figure 2 Labelling of the connections ............................................................................................. 8

Figure 3 Warning label on the device.............................................................................................. 9

Figure 4 Diagram of the heat exchanger function ......................................................................... 10

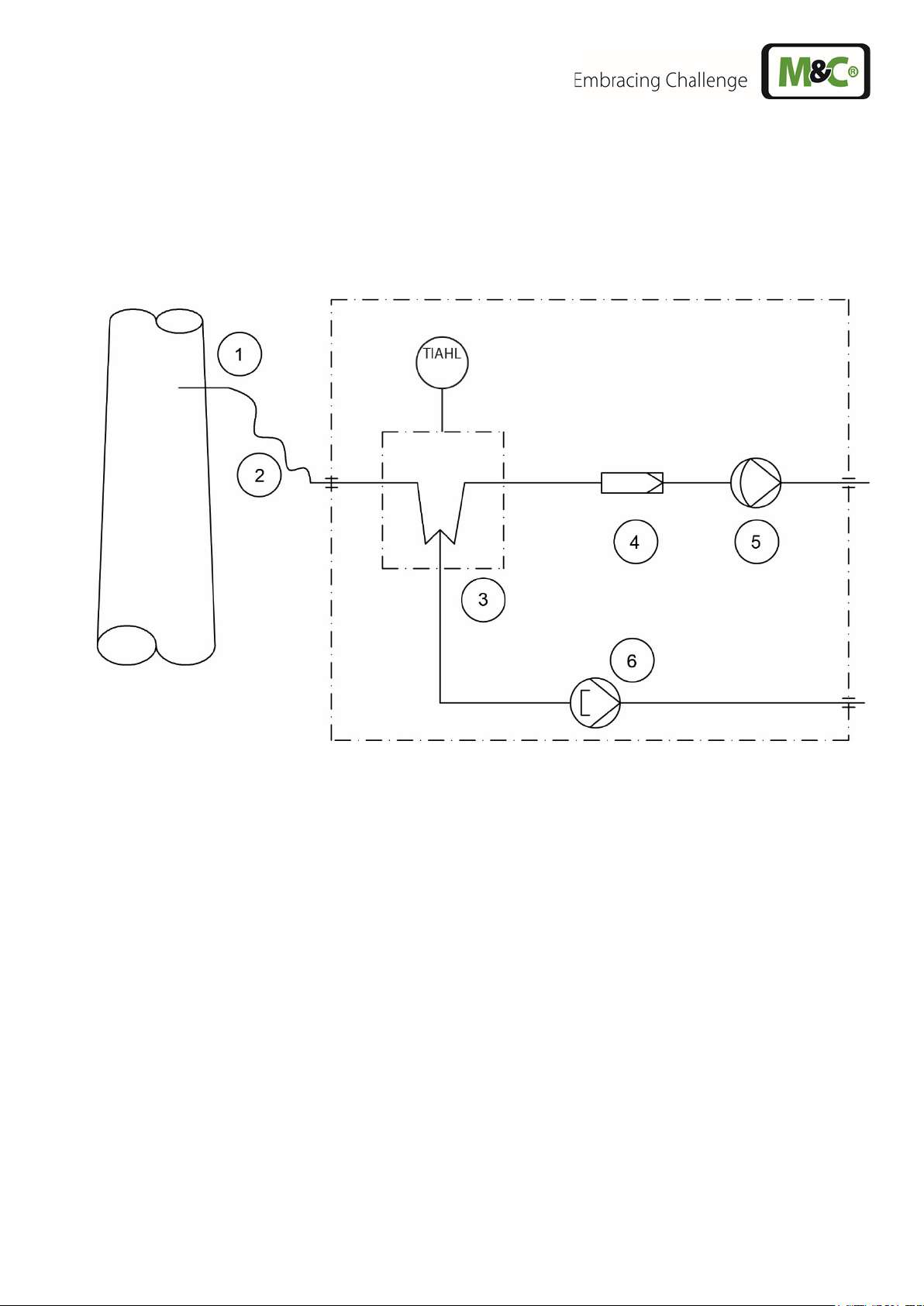

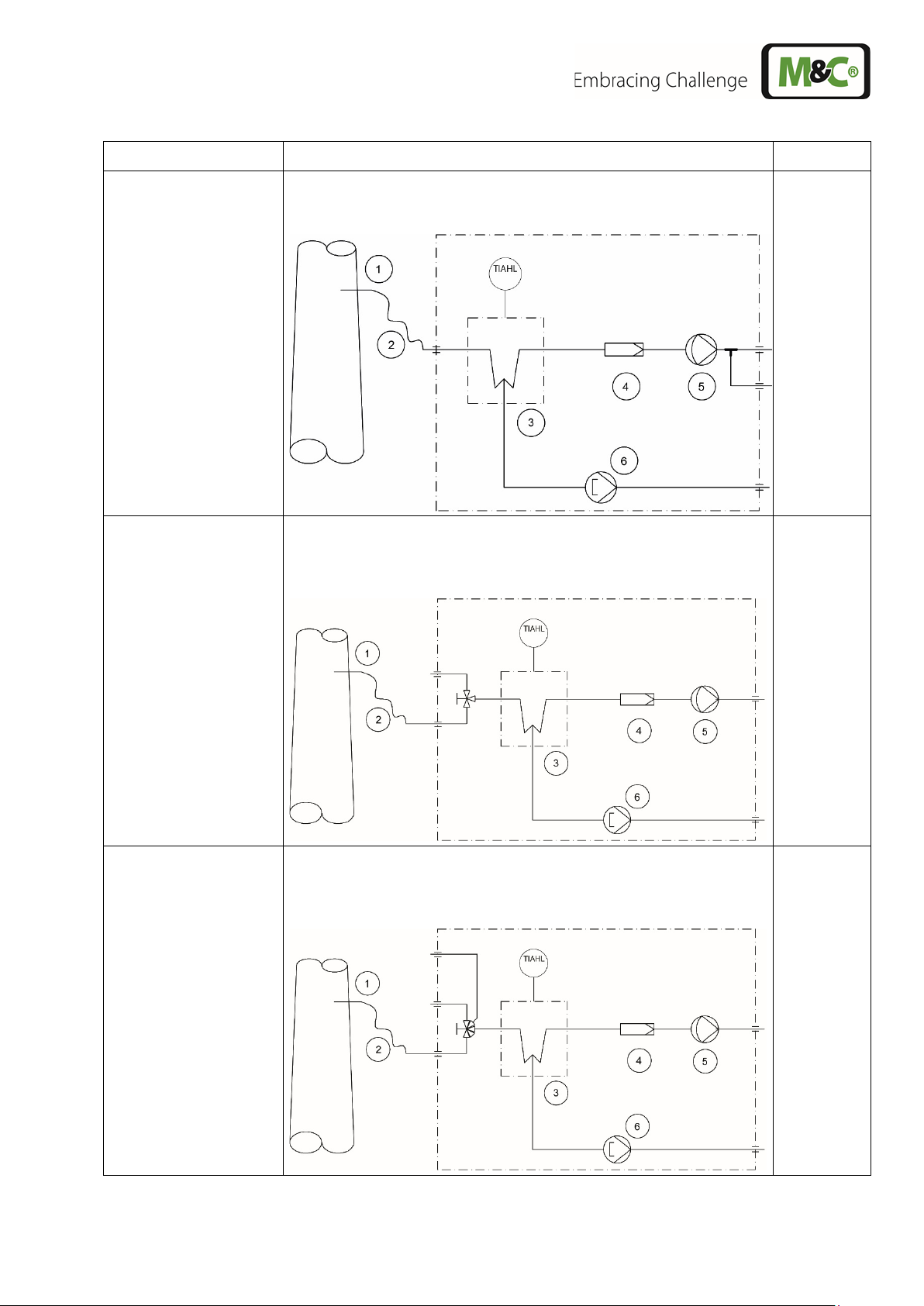

Figure 5 Gas flow diagram of PSS-5C and PSS-5/3C .................................................................. 11

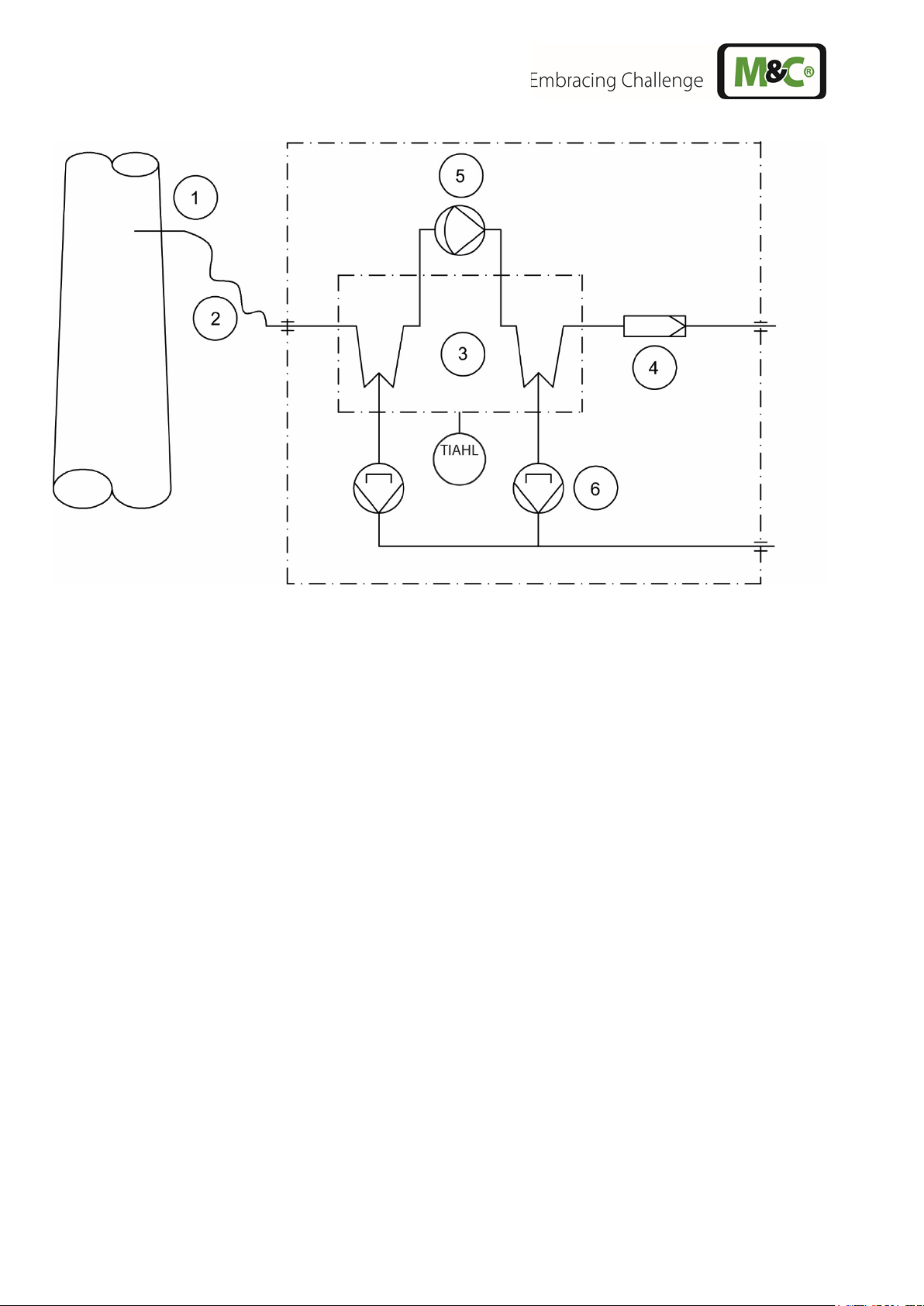

Figure 6 Gas flow diagram of PSS-5/2C ....................................................................................... 12

Figure 7 Dimensions ..................................................................................................................... 18

Figure 8 Case content: PSS-5C and PSS-5/3C ............................................................................ 19

Figure 9 Navigating through the main menu ................................................................................. 21

Figure 10 Reaching the set point entry from the ECP1000C/ECP3000C main menu ..................... 23

Figure 11 Temperature alarm limits and hysteresis ........................................................................ 25

Figure 12 LA alarm limits ............................................................................................................... 30

Figure 13 PSS-5C and PSS-5/3C medium connections ................................................................. 34

Figure 14 Connecting the heated sample line with special adapter (option) ................................... 36

Figure 15 Electrical connection ...................................................................................................... 37

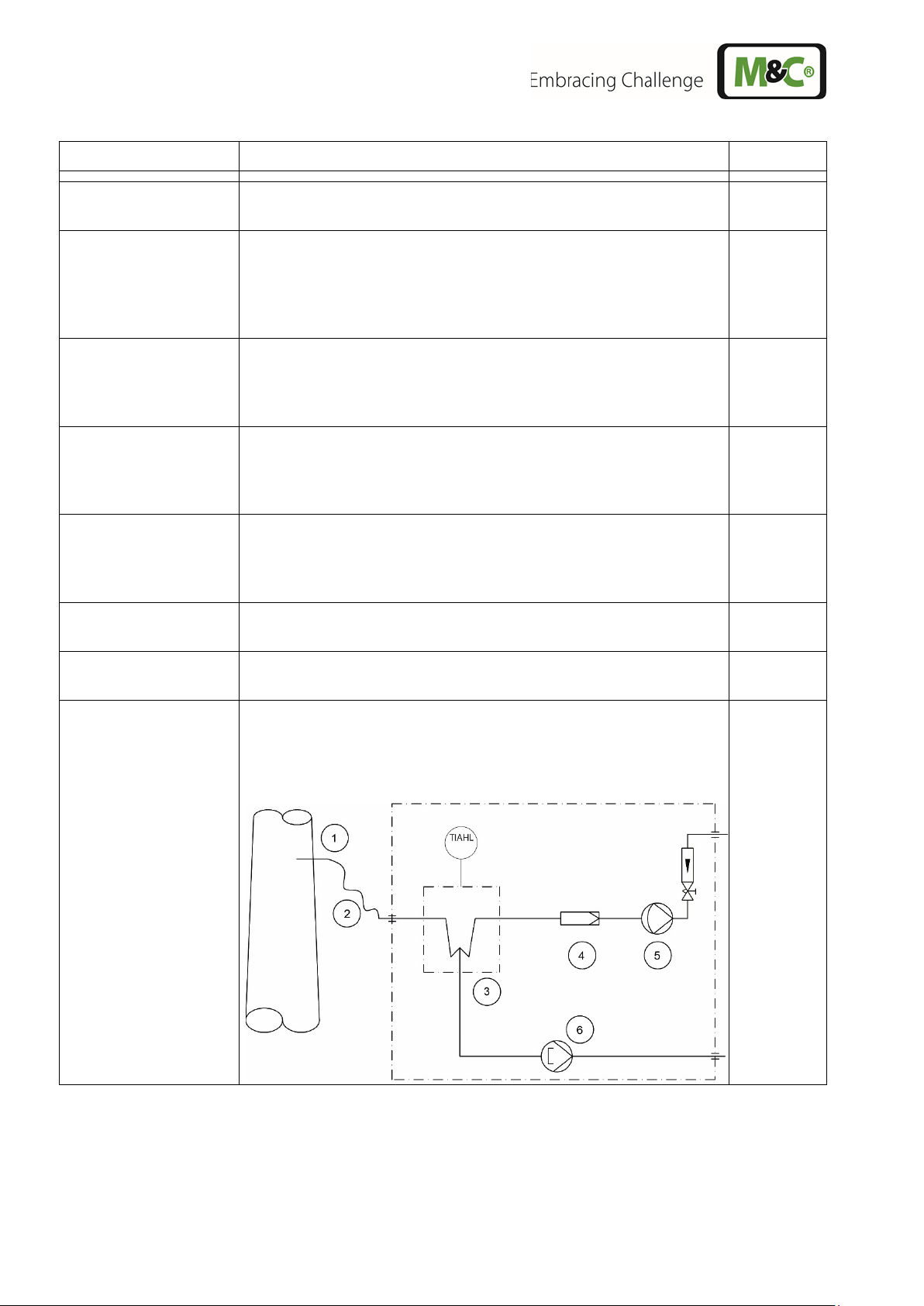

Figure 16 Circuit diagram PSS-5C ................................................................................................. 47

4 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 5

HEAD OFFICE

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 – 0

Fax: 02102 / 935 – 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 General information

The product described in this instruction manual has been built and tested in our production facility.

All M&C products are packed to be shipped safely. To ensure the safe operation and to maintain the

safe condition, all instructions and regulations stated in this instruction manual need to be followed.

This instruction manual includes all information regarding proper transportation, storage, installation,

operation and maintenance of this product by qualified personnel.

Follow all instructions and warnings closely.

Read this manual carefully before commissioning and operating the device. If you have any questions

regarding the product or the application, please don’t hesitate to contact M&C or your M&C authorized

distributor.

2 Declaration of conformity

CE - Certification

The product described in this operating manual complies with the following EU directives:

EMC-Instruction

The requirements of the EU directive 2014/30/EU “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EU directive 2014/35/EU “Low Voltage Directive“ are met.

The compliance with this EU directive has been examined according to DIN EN 61010.

RoHS Directive

The requirements of the RoHS2 (‘Restriction of Hazardous Substances 2’) directive 2011/65/EU and its

annexes are met.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

www.mc-techgroup.com PSS-5C | 1.02.02 5

Page 6

3 Safety instructions

Follow these basic safety procedures when mounting, starting up or operating this equipment:

Read this instruction manual before starting up and use of the equipment. The information and

warnings given in this instruction manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

The installation and commissioning of the device must conform to the requirements of VDE 0100 (IEC

364) ‘Regulations on the Installation of Power Circuits with Nominal Voltages below 1000 V’ and must

be in compliance with all relevant regulations and standards.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Ensure sun-protected installation.

The unit may only be operated upright and with the door closed. Unused connectors must be closed

with the appropriate caps. IP42 means protection against foreign objects ≥1 mm and dripping water

up to an angle of ≤ 15°.

Do not use the gas conditioning systems PSS-5C, PSS-5/2C and PSS-5/3C in hazardous areas.

Installation, maintenance, inspections and any repairs of the devices must be carried out only by

qualified skilled personnel in compliance with the current regulations.

4 Warranty

In case of a device failure, please contact immediately M&C or your M&C authorized distributor.

We have a warranty period of 12 months from the delivery date. The warranty covers only

appropriately used products and does not cover the consumable parts. Please find the complete

warranty conditions in our terms and conditions.

The warranty includes a free-of-charge repair in our production facility or the free replacement of the

device. If you return a device to M&C, please be sure that it is properly packaged and shipped with

protective packaging. The repaired or replaced device will be shipped free of delivery charges to the

point of use.

6 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 7

5 Used terms and signal indications

This means that death, severe physical injuries and/or important

This means that death, severe physical injuries and/or important

ety

This means that minor physical injuries may occur in case the

CAUTION

Without the warning triangle means that a material damage may

ATTENTION

This means that an unintentional situation or an unintentional status

These are important information about the product or parts of the

QUALIFIED PERSONNEL

These are persons with necessary qualification who are familiar with

High voltages!

Corrosive!

Wear protective gloves!

objects or extremely high

Wear safety glasses!

objects.

material damages will occur in case the respective safety measures

DANGER

WARNING

CAUTION

are not fulfilled.

material damages may occur in case the respective saf

measures are not fulfilled.

respective safety measures are not fulfilled.

occur in case the respective safety measures are not met.

NOTE

may occur in case the respective note is not respected.

operating manual which require user’s attention.

installation, use and maintenance of the product.

Protect yourself and others against damages which might be caused

by high voltages.

These substances destroy living tissue and equipment upon contact.

Do not breathe vapors; avoid contact with skin and eyes.

Working with chemicals, sharp

temperatures requires wearing protective gloves.

Protect your eyes while working with chemicals or sharp

Wear safety glasses to avoid getting something in your eyes.

www.mc-techgroup.com PSS-5C | 1.02.02 7

Page 8

Wear protective clothes!

Working with chemicals, sharp objects or extreme

ly high

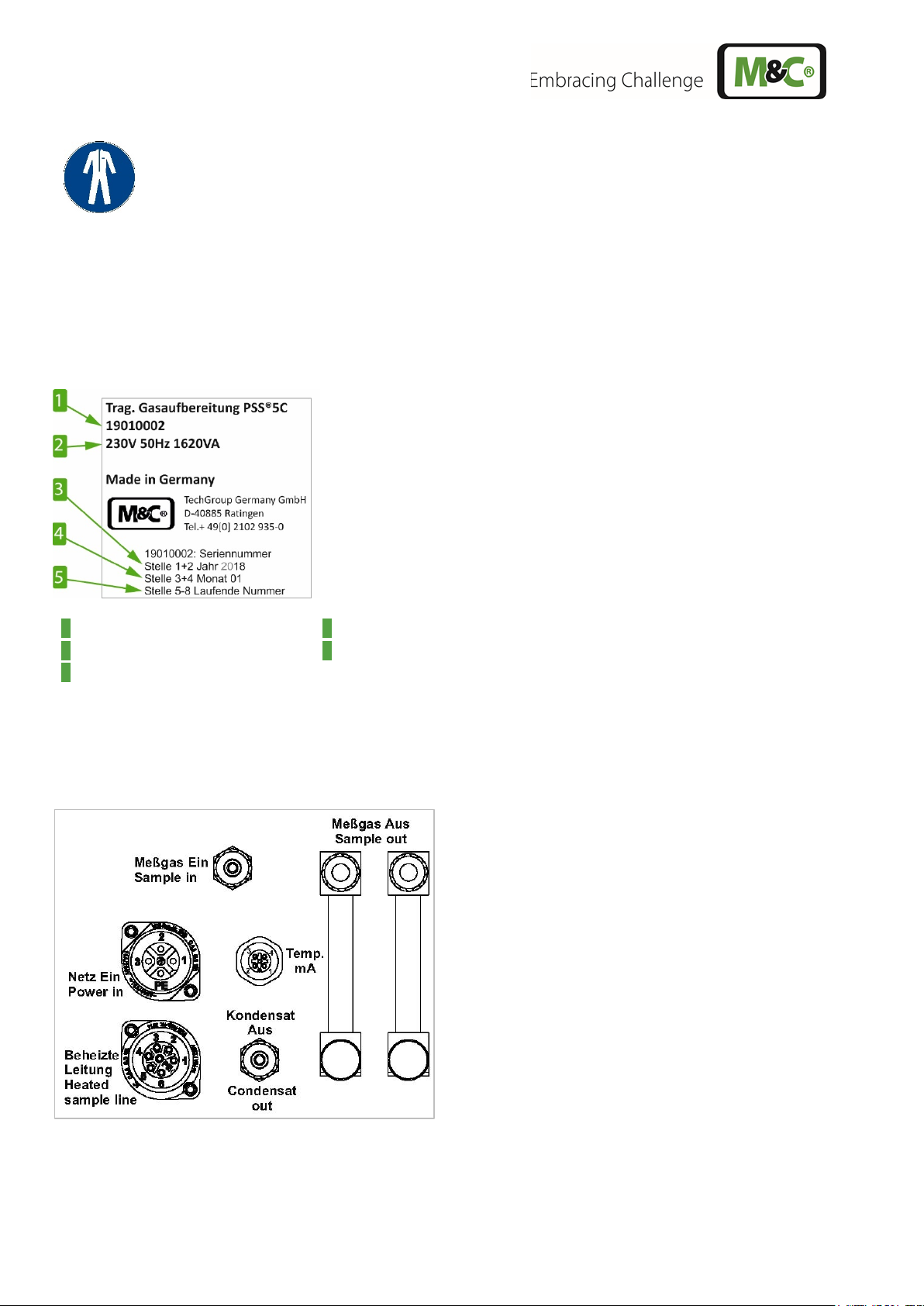

1 Serial number

4 S/N: digits 3+4: Month 01

2 Electrical connection data

5 S/N digits 5 to 8: consecutive number

3 S/N: digits 1+2: Year 2018

temperatures requires wearing protective clothes.

5.1 Type plate and labels on the device

A type plate, an information label and a warning label are located on the device.

The type plate contains the product name, the serial number including explanation, electrical connection

data and the manufacturer's address.

Figure 1 Type plate

The position of the electrical connections and gas connections are explained on the label below the

connections on the case side.

Figure 2 Labelling of the connections

8 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 9

The warning label indicates the necessary requirements for operating the device.

Figure 3 Warning label on the device

www.mc-techgroup.com PSS-5C | 1.02.02 9

Page 10

6 Introduction

+5°C

Sample gas

out

Sample gas

in

Condensate

out

Coolingblock

[41 °F]

The portable gas conditioning systems PSS-5C, PSS-5/2C and PSS-5/3C are designed especially for

applications where accurate gas analysis at constantly changing locations is required.

The entire gas conditioning system is housed in a compact and impact-resistant plastic case equipped

with an integrated trolley with extendable handle. This allows gas analysis at various locations to be

carried out quickly, reliably and with low maintenance.

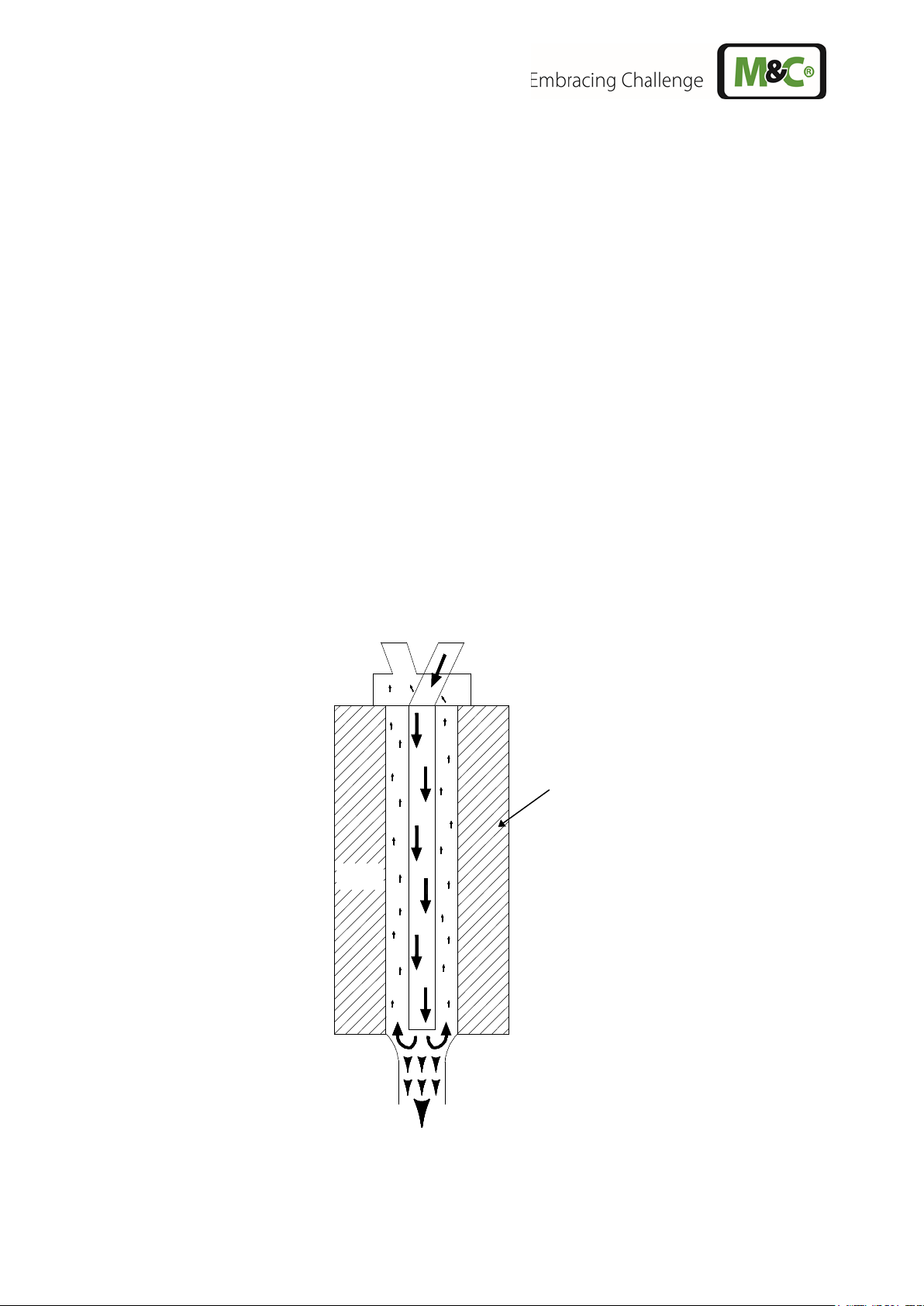

7 Function of the M&C Jet-Stream Heat Exchanger

The ECPX000C gas coolers, specially developed for analysis technology, are designed for maximum

flow rates of up to 350 Nl/h. They are also installed as system assemblies in the PSS-5C, PSS-5/2C

and PSS-5/3C.

Jet-Stream heat exchangers are available in Duran glass, stainless steel (316Ti) and PVDF

(polyvinylidene fluoride). The selection of the appropriate heat exchanger material is customerspecific. The heat exchangers are easily accessible and easily replaceable in a heat-insulated cooling

block. Figure 4 shows a schematic diagram of the heat exchanger function.

Figure 4 Diagram of the heat exchanger function

10 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 11

8 Application

The PSS-5C gas conditioning system is suitable for variable discontinuous use as well as for

continuous operation.

The upright, closed PSS-5C case with screwed in connectors complies with protection class IP42 as

required by the EN15267-4:2017 standard. It contains a standard gas temperature monitoring as well

as a temperature display visible from the outside.

Gas sample probe made of SS316Ti, Ø 4/6 mm, length 0.5 m

Gas sample line, PVC tube, Ø 4/6 mm, length 3 m

Peltier gas cooler with temperature alarm high/low (TIAHL)

Fine filter FP-2T, filter element porosity 2 µm

Sample gas pump N3 KPE (options: N5 KPE (Part No. 01G9090), N9 KPE (Part No. 01G9095))

Peristaltic pump SR25.2-W for continuous condensate removal

Figure 5 Gas flow diagram of PSS-5C and PSS-5/3C

www.mc-techgroup.com PSS-5C | 1.02.02 11

Page 12

Gas sample probe made of SS316Ti, Ø 4/6 mm, length 0.5 m

Gas sample line, PVC tube, Ø 4/6 mm, length 3 m

Peltier gas cooler with temperature alarm high/low (TIAHL)

Fine filter FP-2T, filter element porosity 2 µm

Sample gas pump N3 KPE (options: N5 KPE (Part No. 01G9090), N9 KPE (Part No. 01G9095))

Peristaltic pump2 2 x SR25.2-W for continuous condensate removal

Figure 6 Gas flow diagram of PSS-5/2C

12 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 13

9 Technical data

Gas Conditioning Type

PSS-5C

PSS-5/2C

PSS-5/3C

Part No.

01G4000

01G4250

01G4500

Sample gas outlet dew point

Range of adjustment: +2 to 15 °C [35.6 to 59 °F], factory setting:

ew point

stability

Sample gas inlet temperature

*Max. 80°C [176 °F], optional: *max. 180°C [356 °F] with stainless

Sample gas inlet water vapor

*Max. +80 °C [176 °F]

Heat exchanger gas flow rate

*Max. 150 Nl/h

*Max. 150 Nl/h per

*Max. 350 Nl/h

Ambient temperature

*5 to 40 °C [41 to 104 °F]

Storage temperature

-25 to +65 °C [-13 to +149 °F]

Pressure

0.7 bar to 1.4 bar abs.

Total cooling power*

Max. 80 kJ/h

Number of gas inlets

1

Medium connections

Tube connections 4/6 mm

Material of parts beeing in

Stainless steel, glass, PVDF, PTFE, Novoprene®

Ready for operation

Approx. 3 min. (with heated line approx. 1 h)

Mains power supply

115 or 230 V AC ±10 % 50/60 Hz

Power consumption

Max. 240 VA; with option temperature controller and heated

Fuse protection

4 A t, 5 mm x 20 mm; with option temperature controller: 10 A t,

Electrical connection

2 m [≈ 6.56 ft] length cable

Electrical equipment standard

EN 61010

IP42 EN 60529, with upright case and door closed. Unused

Housing

Portable impact-resistant case with integrated trolley system and

Housing color

Black

Housing dimensions

451 x 654 x 279 mm [≈ 17.8“ x 25.7“ x 11“] with casters and handle

Weight

Approx. 17 kg [≈ 37.5 lbs]

Sample gas outlet d

saturation

+5 °C [41 °F]

At const. conditions: < ±0.1°C [±0.18 °F]

steel bulkhead union

heat exchanger

Number of gas outlets 1, optional: max. 2

contact with the medium

sample line: 230 V, max. 1620 VA; 115 V, max. 920 VA

5 mm x 20 mm

Case protection

connectors must be closed with appropriate caps.

pull-out handle

(W x H x D)

PTFE=Polytetrafluoroethylene (Teflon®), PVDF=Polyvinylidenfluoride

* Maximum values in technical data must be rated in consideration of total cooling capacity at 25 °C [77 °F] ambient

temperature and an outlet dew point of 5 °C [41 °F].

www.mc-techgroup.com PSS-5C | 1.02.02 13

Page 14

Options

Type

Part No.

Sample tube

Sample tube out of Kanthal® ø 6 mm, length: 1 m, sampling

temperature: max. 1300 °C [2372 °F]

01G9030

Electronic

heated sample line

100 W/m

701 control range: 0 to 200 °C [32 to 392 °F], inlet PT100, power:

01G9055

Electronic tempera-

sample line 100 W/m

701 control range 0 to 200 °C [32 to 392 °F], inlet PT100, power:

01G9055a

Connecting adapter

PSS-5C connecting adapter with anti-kink protection for rigid

sleeve, material: SS316Ti

01G9060

Connecting adapter

DN 6/8 for heated

PSS-5C connecting adapter with anti-kink protection for rigid

sleeve, material: SS316Ti

01G9061

Sample gas pump

N5 KPE, replacement

Extra charge for replacing the standard N3 KPE by the N5 KPE

01G9090

Sample gas pump

N9 KPE, replacement

Extra charge for replacing the standard N3 KPE by the N9 KPE

01G9095

Flow meter including

FM40 7-70 Nl/h air

01G9072

temperature controller

for max. 12 m [39.4 ft]

ture controller for max.

6 m [19.7 ft] heated

DN 4/6 for heated

sample line

sample line

230 V/50 Hz, contact capacity: 250 V AC max. 10 A, completely

mounted incl.

7-pin plug 10 A

115 V/60 Hz, contact capacity: 250 V AC max. 10 A, completely

mounted incl.

7-pin plug 10 A

mounting of heated sample line with replaceable PTFE tube DN

4/6, consisting of special Swagelok fitting with 4 mm support

mounting of heated sample line with replaceable PTFE tube DN

6/8, consisting of special Swagelok fitting with 6 mm support

sample gas outlet,

max. 2 pieces

FM40 15-150 Nl/h air

FM40 25-250 Nl/h air

FM40 50-500 Nl/h air

01G9077

01G9082

01G9087

14 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 15

Options

Type

Part No.

Further sample gas

Parallel sample gas outlet, tubing via T-piece on lateral PVDF

01G9065

3-way ball valve

(Note: only one FM40

flow meter is possible

3L/PV-1 for switching over from test gas to sample gas, in the

01G9046

5-way ball valve

(Note: only one FM40

flow meter is possible

5L/PV-1 for switching over from test gas to sample gas, in the

01G9045

outlet w/o flow meter

with this version)

bulkhead fitting, DN 4/6, max. 1 piece

inlet of the sample gas conditioning unit, mounted with mounting

bracket, fittings in PVDF

inlet of the sample gas conditioning unit, mounted with mounting

bracket, fittings in PVDF

with this version)

www.mc-techgroup.com PSS-5C | 1.02.02 15

Page 16

Options

Type

Part No.

Needle valve

Needle valve in the bypass of the sample gas pump type

N3/N5/N9 for pressureless control, with PVDF screw

connections, mounting bracket and assembly

01G9050

Analog output

Analog output of the sample gas cooler temperature at the PSS-

5C 0/4 to

01G9010

mA output

Thermocouple type K for temperature measurement in heat

load 100 Ohm

01K9250

Liquid alarm sensor

Liquid alarm detection inside the PSS-5C case incl. switch-off

pump, liquid sensor type LA1S, for

01G9015

5C case with connection socket, mA output for PSS20 mA, galvanically isolated, burden: 500 Ohm

exchanger with output 4-20 mA for -10 to 50 °C [14 to 122 °F],

LA1S

function for sample gas

conductive media, completely wired, evaluation via front display

16 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 17

Options

Type

Part No.

SR25.3-W

For acid dosing by an additional peristaltic pump.

01P1320

(Note: only one FM40

flow meter is possible

with this version)

Other versions on request.

www.mc-techgroup.com PSS-5C | 1.02.02 17

Page 18

10 Dimensions

Figure 7 Dimensions

11 Description

The PSS-5C gas conditioning system is equipped with the powerful Peltier gas cooler of the new

series as standard.

The cooler is equipped with a jet-stream heat exchanger, which cools the sample gas constantly to

+5 °C [41 °F], independent of the ambient temperature. As soon as the operating temperature

< +8 °C [46.4 °F] is reached after commissioning, the sample gas pump N...KPE is automatically

switched on by the gas cooler status contact. The peristaltic pump SR 25.2-W ensures continuous

condensate removal. This also allows to easily accomplish long-term measurements with the gas

conditioning system. The corresponding particle filtration is carried out by the FP-2T fine filter.

For easy handling of the PSS-5C, the display and function of the cooler are visible from the outside.

The case only needs to be opened for maintenance.

The portable PSS-5C gas conditioning system is a complete conditioning system for most gas

analysis devices. The components installed in the PSS-5C are intended for “continuous use”.

For special measuring tasks, additional or other components from our extensive product range can

also be used.

18 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 19

1 Case door with display

5 Sample gas pump

2 Case

6 Peristaltic pump

3 Terminal mounting rail

7 Gas coolerr

4 Fine filter FP-2T

8 Heat exchanger

4

5

6

7

8

3

1 2

Figure 8 Case content: PSS-5C and PSS-5/3C

All components of the gas conditioning system are freely accessible and built into a portable case 2.

The case door 1 can be opened to the left by loosening the latches mounted on the side and top of the

case.

The installation of the gas cooler 7 and a corresponding diaphragm sample gas pump 5 depends on the

required maximum gas volume flow.

The minimum flow rate is determined by the sample gas pump 5. If the required minimum total flow rate

is not reached, excessive overpressure can lead to premature destruction of the pump diaphragm. The

maximum pressure is reduced by using an optional needle valve in the bypass of the sample gas pump

(Part No. 01G9050).

The gas cooler is equipped with a Duran glass heat exchanger 8 as standard. Heat exchangers in PVDF

or stainless steel are optionally available.

The FP-2T fine filter (2 µm filter porosity) 4, installed upstream of the sample gas pump 5, ensures the

necessary solids separation.

The overtemperature alarm contact (+8 °C [46.4 °F]) of the cooler automatically regulates the

switching on and off of the sample gas pump 5.

The resulting condensate is continuously discharged by a peristaltic pump type SR25.2-W 6.

www.mc-techgroup.com PSS-5C | 1.02.02 19

Page 20

The 4/6 mm tube connections for the condensate and sample gas lines are located on the side of the

case.

A stainless steel sample probe (length 0.5 m, Ø 6 mm) and a 3 m PVC sample tube (4/6 mm) are

included in the standard scope of delivery.

The ventilation grids in the door and in the left side wall of the case provide sufficient convex forced

ventilation.

Options:

The PSS-5... sample gas conditioning unit can be equipped at the factory with a maximum of two

sample gas outlets. Each sample gas outlet can be controlled by the optional installation of a flow

meter type FM40 with needle valve according to the specified volume flow range (see the option table

in chapter ‘9 Technical data’).

Unused mounting holes for sample gas outlets or flow meters are closed with blind caps.

I To protect the downstream analyzers against liquid ingress and to increase the operational reliability

of the entire system, we recommend the installation of a liquid alarm sensor type LA1S (Part No.

01G9015). For this purpose, the FP-2T fine filter installed as standard is replaced by the FP-2T-D fine

filter with mounted liquid alarm sensor at the factory. The evaluation electronics for the LA1S liquid

sensor are integrated as standard in the ECPX000C cooler.

The PSS-5... can also be equipped with a special sample gas inlet (Part No. 01G9060) for connecting

a heated line. The existing kink protection can only be used for heated lines with connection type "C"

(Part No. 03B1012). Assembly instructions can be found in chapter “18.1.1 Connecting the heated

sample line with special adapter (option)”.

It is also possible to connect the heated line (Part No. 01B4036) in connection with the gas sampling

probe PSP 4000.

The temperature controller 701 (Part No. 01G9055) which is necessary for the regulation of the heated

line is mounted on the terminal rail 3 (Figure 8) at the factory with the required option.

A 3-way ball valve (Part No. 01G9046) or a 5-way ball valve (Part No. 01G9045) can optionally be

installed in the inlet of the gas conditioning unit for test gas feeding or sample gas switching.

20 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 21

12 Operating instructions

NOTE

The complete instruction manual of the ECPX000C can be found at

Use the arrow keys to navigate through the menu and

The display and control panel of the ECPX000C are clearly visible on the front panel of the device.

The functions described here are excerpts from the operating instructions of the ECPX000C series. For

the complete documentation, read the ECPX000C instruction manual.

It can be downloaded free of charge from the M&C homepage.

www.mc-techgroup.com.

In the main menu, the cooler temperature, the ambient temperature, the set absolute or differential set

point and the current set point can be displayed. The set point entry and the menu for parameter

setting can be accessed via a PIN entry. PIN entry prevents unintentional adjustment of the set point

and the device configuration.

enter values. Press the "OK" key to confirm entries

and the "Exit" key to exit the input area or to reject an

entry.

12.1 Main Menu

After approx. 3 minutes the device is ready for operation. The current cooler temperature is displayed

first. Use the arrow keys to navigate through the main menu. The following figure shows an example of

how you can navigate through the main menu.

Figure 9 Navigating through the main menu

www.mc-techgroup.com PSS-5C | 1.02.02 21

Page 22

NOTE

Tap on the -key, to go back to the cooling temperature.

The cooler temperature is shown on the display.

The ambient temperature is indicated by a "°" sign on the left side of

The set point for absolute value control is indicated by an "A" and the

The display of the current signal value is indicated by a capital "P" on

NOTE

The PIN “1234“ looks like this on the display.

The cooling temperature is shown in the display as follows:

the displayed temperature.

set point for differential control by a small "d" before the temperature

value.

The absolute value control temperature can be set between 2 to

15 °C [35.6 to 59 °F]. The differential value control temperature can

be set between dT = 2 to 15 °C [dT = 3.6 to 27 °F].

the right-hand side. The signal value is a measure for the percentage

workload. The signal value can assume values from 0 to 99.

You will find the complete menu structure in the appendix of the

ECPX000C instruction manual.

12.2 PIN Entry

To enter the range of set point input or parameter setting, a PIN must be entered. The PIN "1234" is

factory-set and cannot be changed.

To enter the PIN, proceed as follows:

Press and hold the -key until "0000" appears in the display.

The "0" on the left side is blinking. Use the and - keys to enter

the first digit of the PIN.

Use the and - keys to switch to the other digits. If a digit is

blinking, the PIN digit can be entered.

Confirm the PIN with the -key.

22 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 23

After confirmation, immediately the display for the set point entry is shown. Press and hold the -key

NOTE

2 s

2 s

longer to access the parameter setting area.

The PIN is valid for 15 minutes. If you exceed this time, the display field reappears with "0000" when

you press and hold the

-key. The PIN must be entered there again.

12.3 Set Point Entry

If you tap the -key briefly after entering the PIN (see chapter “12.2 PIN Entry”), the set point for the

cooler temperature appears. This set point can belong to the operating mode "absolute control" ("A")

or "differential control" ("d").

The two digits start blinking. The absolute value control temperature can be set from 2 to 15 °C [35.6

to 59 °F] using the and -keys. The differential value control temperature can be set from dT = 2

to 15 °C [dT = 3.6 to 27 °F] using the and -keys. The factory setting is absolute value control

temperature of 5 °C [41 °C].

Use the and -keys to switch between the operating mode and

set point settings.

If the letter on the left side is blinking, you can use the and

-keys to switch between absolute and differential value control of

the set point temperature.

Tap the -key, then the entries are discarded and you return to the

cooler temperature.

As long as the PIN is active (see chapter “12.2 PIN Entry”), the set point entry can also be accessed

from the main menu. To change a set point, press the -

key for 2 seconds during the current

temperature or set point display. The display then changes to set point input. The two digits start

blinking. Values can be set here.

The following figure shows, using the example of an ECP1000C/ECP3000C, how to access the set

point input from the main menu.

Figure 10 Reaching the set point entry from the ECP1000C/ECP3000C main menu

www.mc-techgroup.com PSS-5C | 1.02.02 23

Page 24

13 Parameter Setting

NOTE

The codes for parameter settings can be found in the appendix of this

To adjust the device parameters, the code belonging to the

-keys to set the individual digits.

If you tap the -key after entering the PIN (see chapter “12.2 PIN Entry”), the set point for the cooler

temperature appears first. If the -key is pressed and held for a short moment, the display changes

to code entry. Here you can enter the codes that belong to the respective parameter settings.

You can also access the parameter setting from the main menu. To do this, keep the -key pressed

until the code entry is displayed. The PIN must be active in this case.

instruction manual.

parameter must be entered and confirmed in this display. The left

digit of the code entry is blinking. The first digit can be entered here.

Use the und -keys to switch between the digits and the and

A code can have up to 3 digits. Single-digit codes are device-specific, two-digit codes are important

basic settings (tens digit corresponds to the channel number), three-digit codes are used for

calibration (hundreds digit: "2" stands for LA, "3" for mA calibration).

The PIN is valid for 15 minutes. If you exceed this time, the display field reappears with "0000" when

you press and hold the -key. The PIN must be entered there again (see chapter “12.2 PIN Entry”).

If you enter an invalid code and press the -key, the display returns to the cooler temperature.

24 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 25

13.1 Setting Temperature Alarm Limits

The code for setting HIGH dT of the channel is "012". Confirm the

After confirming the code, the default value "3" appears. The value is

shows the cooler temperature again.

NOTE

If HIGH dT or LOW dT is reduced to “2”, the hysteresis is

t

T

Cooler

HIGH dT = 3 °C

5 °C

3 °C

8 °C

hysteresis = 1

hysteresis = 1

no alarm

lower temperature alarm limit

set

value

upper temperature alarm limit

alarm

alarm

no alarm

LOW dT = 2 °C

You use the temperature alarm limits to determine when the alarm is triggered. HIGH dT and LOW dT

are independently adjustable from dT = 2 to 8 °C [dT = 3.6 to 14.4 °F]. In the following figure, the

upper temperature alarm limit is set at 8 °C [46.4 °F] and the lower one at 3 °C [37.4 °F].

The hysteresis is set to "1".

Figure 11 Temperature alarm limits and hysteresis

To set the temperature limits:

1. Enter the PIN (see chapter “12.2 PIN Entry”).

2. Tap and hold the -key for a short moment.

3. The display shows the code entry.

code with the -key, then the display of the pre-set value appears.

blinking and you can enter values from dT = 2 to 8 °C [dT = 3.6 to

The code for setting LOW dT is "013". If you enter this code, you can change the lower temperature

alarm limit.

The hysteresis setting can be changed via code "014". The hysteresis ensures that no “fluttering”

occurs in the event of a temperature alarm. The differential value dT = 1 or 2 °C [1.8 or 3.6 °F] can be

entered.

14.4 °F] with the and -keys.

Press to confirm your change or to leave the code range

without making any changes. After changing or aborting the display

www.mc-techgroup.com PSS-5C | 1.02.02 25

automatically reduced to the differential value dT = 1 °C [1.8 °F].

Page 26

13.2 Fan Speed Setting

Now the default brightness value appears. The factory setting is "5".

The ECPX000C is equipped with a large cooling fin block which is forced-ventilated by a fan. The

minimum speed of the fan can be changed without affecting the final performance of the cooler.

To change the fan speed setting:

1. Enter the PIN (see chapter “12.2 PIN Entry”).

2. Tap and hold the -key for a short moment.

3. The display shows the code entry.

4. The code for setting the fan speed is "084". The setting range is between 0 and 5. At level 0

the fan rotates slower and is quieter. At higher values, the fan rotates faster and the air flow

rate is increased.

Level 2 is set by default This fan speed is necessary to reduce the temperature increase inside the

case.

13.3 Brightness Setting of Display

It may be necessary to change the brightness of the display due to different lighting conditions at the

locations where the cooler is used. The brightness of the display can be adjusted on the control panel

of the ECPX000C.

To change the brightness setting:

1. Enter the PIN (see chapter “12.2 PIN Entry”).

2. Tap and hold the -key for a short moment.

3. The display shows the code entry.

You can also enter the code from the main menu. To do this, keep the --key pressed until the code

entry is displayed. The PIN must be active in this case.

Enter the code "005" and confirm the code with the --key.

This value is blinking and can be set between "0" and "9" with the

and - keys. The brightness of the digits changes immediately. The

lower the value, the darker the display.

Select the desired brightness value and confirm the selection with

the -key or cancel the procedure with the key. Use the -key to

leave the range of codes without making any changes.

After changing the brightness or canceling, the display shows the cooler temperature again.

26 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 27

14 mA Output for the Temperature Measurement inside the Cooling Block

key, then the

The default value "4-20", which stands for 4 to 20 mA, appears on the

If the mA output is ordered when ordering the instrument, the mA

customer and retrofitted by the customer, the calibration must be

to the temperature range -10 °C to +50 °C [14 to 122 °F].

The mA outputs built-in by M&C are factory calibrated and set to the range "4-20 mA". Later purchased

mA outputs must be calibrated.

14.1 mA Output Range Selection

The optional mA output can be changed from 4-20 mA to 0-20 mA. To select the mA range, proceed as

follows:

1. Enter the PIN (see chapter “12.2 PIN Entry”).

2. Tap and hold the -key for a short moment.

3. The display shows the code entry.

Enter the code "015". Confirm the code with the display of the preset range appears.

display. The whole display is blinking here. Use the and -keys

to switch between "4-20" and "0-20".

Press to confirm your change or to leave the code range without

making any changes. After changing or aborting the display shows the

cooler temperature again.

14.2 mA Output Calibration for the Temperature Measurement inside the Cooling Block

The mA output built-in by M&C are factory calibrated. If required, the basic accuracy of the mA output

can be optimized by recalibration.

A later installed mA output must be calibrated. The mA output is suitable for a maximum load of 500 Ω

only.

During calibration, first the lower and then the upper value of the mA output will be calibrated.

output is calibrated at the factory. If a mA output is purchased by the

NOTE

carried out by the customer.

Optionally, the device can be sent to M&C for retrofitting.

The mA output is set to 4 - 20 mA as standard, but can be changed to

0 - 20 mA on the instrument. In both cases the mA range corresponds

Current limitation:

The current output limits in the case of 4 - 20 mA in the lower range to 3.8 mA and in the upper range

to 20.5 mA.

In the case of 0 - 20 mA, it limits the upper range to 20.5 mA.

www.mc-techgroup.com PSS-5C | 1.02.02 27

Page 28

If a calibration error occurs and the mA output has been calibrated, the

limiting values also change!

Enter the code "310" for the calibration of the lower value of the mA

1 mA as

Enter the code "C311" for the calibration of the upper value of the mA

possible. Accept the value with the -key.

NOTE

To calibrate an mA output, proceed as follows:

1. Enter the PIN (see chapter “12.2 PIN Entry”).

2. Tap and hold the -key for a short moment.

3. The display shows the code entry.

output.

Now connect a current meter to the connector of the mA output. This

current meter should measure a value close to 1 mA. You can now

adjust this value in 0.0054 mA steps with the up and down arrow keys.

After the adjustment, the current meter should display

accurately as possible. Accept the value with the -key.

output.

Now connect a current meter to the connector of the mA output. This

current meter should be used to measure a value close to 20 mA. You

can now adjust this value in 0.0054 mA steps with the up and down

arrow keys until the current meter displays 20 mA as accurately as

The cooler should then be in a steady state at 5 °C [41 °F] (absolute value control) and provide one of

the following values:

• 8 mA (in case of 4 - 20 mA)

• 5 mA (in case of 0 - 20 mA)

The cable length is not limited and the cable does not need to be shielded.

28 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 29

15 Liquid Alarm Sensor (LA) type LA1S

The code for activation is "010".

You can choose between the values "0", "1" and "2". With "1" you

he sensor is

deactivated accordingly.

The liquid alarm sensors LA1S installed by M&C are factory calibrated to tap water and activated. Later

purchased liquid alarm sensors must be activated and calibrated.

15.1 Activating the LA

A retrofit liquid alarm sensor must be activated.

To activate a liquid alarm sensor:

1. Enter the PIN (see chapter “12.2 PIN Entry”).

2. Tap and hold the -key for a short moment.

3. The display shows the code entry.

Confirm the code with the -key.

activate the sensor without cable break detection, with "2" you activate

the sensor with cable break detection. With "0" t

After activating the LA1S, the sensor needs to be calibrated.

www.mc-techgroup.com PSS-5C | 1.02.02 29

Page 30

15.2 LA Sensitivity adjustment

Enter the code "011" to change the sensitivity of the liquid sensor.

Sensor state

Sensitivity

Electrical conductivity

Dry

0 %

7

30 %

≈50 µS/cm

6

40 %

5 50 %

4 60 %

3 70 %

2

80 % (Standard)

≈300 µS/cm

1

90 %

Wet

100 %

W

et (100 %)

1

2

3

4

5

6

7

Dry (0 %)

Alarm limit for

cable b reak and

can celation

Open

LA cable break

alarm is canceled

LA cable break

alarm is actived

LA alarm at

default setting 2

Canceled: LA alarm at

default setting 2

2. Cancelation

t

LAvalue

The sensitivity can be changed by following these steps:

1. Enter the PIN (see chapter “12.2 PIN Entry”).

2. Tap and hold the -key for a short moment.

3. The display shows the code entry.

The default value is 2 and can be changed from 1 to 7. The sensitivity corresponds to the switching

threshold for the alarm and is to be understood as follows:

The cancellation limit is always 15 % below the sensitivity limit. If the sensitivity value of 2 is not changed,

the alarm is triggered at 80 % and is automatically cancelled as soon as it falls below 65 %.

The following diagram illustrates the correlations:

Figure 12 LA alarm limits

30 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 31

15.3 LA Calibration

First calibrate the "dry state" of the liquid alarm sensor.

To do this, leave the LA in the dry state and enter the code "210".

Then calibrate the "wet state" of the liquid alarm sensor.

The liquid alarm sensors LA1S installed by M&C are factory activated and calibrated. If required, the

basic accuracy of the liquid alarm sensors can be optimized by recalibration. Later-installed liquid

sensors must be activated and calibrated.

Make sure that the LA is activated. If a retrofitted LA is not activated,

the calibration has no effect and will be discarded.

NOTE

To calibrate a liquid alarm sensor, proceed as follows:

1. Enter the PIN (see chapter “12.2 PIN Entry”).

2. Tap and hold the -key for a short moment.

3. The display shows the code entry.

Confirm the displayed value with the -key.

Immerse the LA in the process-dependent condensate to calibrate the

100 % wet condition via code "211". Confirm the displayed value with

the -key.

www.mc-techgroup.com PSS-5C | 1.02.02 31

Page 32

16 Receipt of goods and storage

The gas conditioning and sampling systems PSS-5C, PSS5/2C and PSS5/3C are completely preinstalled units.

The sample tube, gas sample hose, connecting cable and instruction manual are located inside the

case door.

• Immediately after arrival take the gas conditioning system and possible special accessories

carefully out of the packaging material.

• Compare the goods with the items listed on the delivery note.

• Check the goods for any damage caused during delivery and, if necessary, notify your transport

insurance company without delay of any damage discovered.

The gas conditioning unit should be stored in a protected

NOTE

frost-free area!

32 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 33

17 Installation instructions

The case should be placed on a level, horizontal surface so that

Unheated gas sampling lines must be routed with a downward

separation is then not

necessary.

it is secure and stable.

NOTE

The operating position is exclusively upright. This is the only

way to ensure proper separation and removal of the condensate

in the cooler's heat exchanger.

The gas conditioning unit should be installed away from heat

sources and freely ventilated so that no disturbing heat

accumulation occurs

For outdoor installation, adequate protection against direct

sunlight and moisture must be provided. In winter, the

installation site must be frost-free; observe the protection class

of the case.

The device must only be operated upright and with the door

closed. Unused connectors must be closed with the appropriate

covers. IP42 means protection against foreign bodies ≥1 mm and

dripping water up to an angle of ≤ 15°.

In order to ensure the operational safety of the portable gas

conditioning system and the downstream analyzers and to avoid

false alarms, the sample gas conditioning system must not be

used outside the specified temperature range.

Downstream analyzers must always be operated at temperatures

well above the specified gas output dew point of +5°C [41 °F].

The temperature of the sample gas must not exceed the

specified temperature range. This avoids subsequent

condensation of the gas in the connecting lines to the analyzers.

gradient to the cooler. Condensate pre-

www.mc-techgroup.com PSS-5C | 1.02.02 33

Page 34

18 Supply connections

ections are marked

After all lines have been connected, the tightness must be

checked.

1 Sample gas IN

5 Connections description

2 Power supply

6 Type plate

3 Heated sample line connection

7 mA-output (temperature)

4 Condensate outlet

8 Flow meter(s) with sample gas OUT

18.1 Tube connections

Do not switch tube connections; conn

accordingly.

NOTE

Figure 13 shows the possible medium connections. These are located in the right-hand side of the

gas conditioning case at the rear in a specially immersed assembly frame.

Figure 13 PSS-5C and PSS-5/3C medium connections

All tube connections are equipped with 4/6 mm clamping ring tube fittings made of

polyvinylidenfluoride (PVDF) for gas inlet temperatures of up to a maximum of 80 °C [176 °F] (see

chapter ‘9 Technical data’). When heated sample lines are used, the gas inlet temperatures can

increase up to a maximum of 180 °C [356 °F]. In this case, the use of optional stainless steel bulkhead

fittings is recommended.

Connecting tubes of dimension 4/6 mm are used as standard.

34 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 35

Install the sample gas tubes and the condensate tube as follows:

NOTE

The tightness of the connections can only be guaranteed if the

• Remove the union nut from the clamping ring tube fittings by turning it anti-clockwise. The nut

should be removed from the thread with great care so as to ensure that the loose sealing ring in

the nut is not lost.

• Place the union nut over the connecting tube.

• Place the sealing ring over the connecting tube with the thicker bead towards the nut.

• Place the tube over the nipple on the thread.

connecting tube has a straight rim (hose cutter).

• Tighten the union nut hand-tight.

The tube will no longer be able to slip off, and is now compression-proof.

Disassemble the tubes in reverse order.

WARNING

Aggressive condensate possible.

Wear protective glasses and proper protective clothing!

www.mc-techgroup.com PSS-5C | 1.02.02 35

Page 36

18.1.1 Connecting the heated sample line with special adapter (option)

mage the equipment. When

the supply voltage is

For the erection of power installations with rated voltages up to

The main circuit is equipped with a fuse corresponding to the

technical data.

Sample gas IN

Bulkhead union

Back ferrule 6mm Øi

Back ferrule

10mm Øi

Sealing ring

10mm Øi

Sealing ring

6mm Øi

support sleeve

4mm ØOD

Union nut 10mm Øi

Heated sample line

Adapter

PSS...

Figure 14 Connecting the heated sample line with special adapter (option)

The heated line is connected to the gas conditioning with the connection adapter (Part No. 01G9060)

as follows:

• Place the special adapter (Part No. 01G9060) on the PTFE tube according to the drawing seen

above;

• Place the support sleeve into the PTFE tube;

• Insert the PTFE tube as far as it will go into the 'Sample Gas IN' bulkhead fitting and hand-tighten

the adapter;

• Tighten the adapter 1 1/4 turns with a wrench (SW 14), while holding the lock nut of the bulkhead

connection with a wrench (SW 15);

• Insert the 10 mm tube of the heating line into the adapter as far as it will go and hand-tighten it with

the union nut;

• Tighten union nut with wrench (SW 19) 1 1/4 turns; hold adapter with wrench against;

The screw connection is now cut gas-tight and can be loosened as often as required.

18.2 Electrical connections

Wrong supply voltage can da

WARNING

connecting the equipment, make sure that

identical with the information provided on the model type plate!

1000 V, the requirements of VDE 0100 and relevant standards and

NOTE

specifications must be observed!

nominal current (over current protection); for electrical details see

36 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 37

The PSS-5... gas conditioning system is available with either 230 V/50 Hz or with 115 V/60 Hz (for

1 mA-output (temperature)

3 Heated sample line connection

2 Power supply connection

4 Connections description

circuit diagram see Appendix). The device is protected by a 4 A fuse as standard. The fuse is located

on the terminal mounting rail (see Figure 8). In the event that a temperature controller is used in

conjunction with heated sample lines, the overload protection level is increased to 10 A.

The power supply connector is a round 4 pole connector (male). The heated sample line connector

is a round 7 pole connector (female). The mA-output connector is a round 4 pole signal connector

(female). All electrical connectors are located on the left-hand side of the case.

Figure 15 Electrical connection

Option “heated sample line”:

For the electrical supply of a heated line with PT-100 sensor a 7-pin connector 3 is available. For the

electrical supply of other heated components (e.g. heated sample gas probe or heated filter) a 4-pole

round plug connector is available at the heated lines Part No 01B4050 or 01B4040. The maximum

connected load is 6 A, 1380 W for the 230 V sample gas conditioning unit and 6 A, 690 W for the 115 V

version.

The maximum length of a possible heated sample line is calculated as follows:

Max. connection power [W] - Power consumption of heated components (i.e. sample probe) [W]

L(m)=

Power consumption of heated sample line [W/m]

www.mc-techgroup.com PSS-5C | 1.02.02 37

Page 38

Option "mA output; cooling block temperature Part No 01G9010":

The connection of the mA signal output is a 4-pole circular connector (female) 1.

The mA output signal is available at pin 1 + and 3 -.

Measuring range: -10 to 50 °C [14 to 122 °F], mA output 4 to 20 mA or 0 to 20 mA, factory setting 420 mA. To select the mA output range and to calibrate the mA output see chapter 14.1 and 14.2.

The load is 500 Ohm.

Option "mA output; temperature in heat exchanger Part No 01K9250":

The connection of the mA signal output is a 4-pole circular connector (female) 1.

The output signal is available at pin 2 + and 4 -.

Measuring range -10 to 50 °C [14 to 122 °F], mA output 4 to 20 mA, load 100 Ohm.

The range of the mA output is fixed and can only be changed at the factory.

38 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 39

19 Commissioning

temperature controller when

NOTE

The following minimum gas flow rates result from the requirement

side load of the sample gas pumps

Premature damage can be caused to the pump membrane if less

content in the

sample gas, a suitable gas sampling probe must be provided to

protect the sample line from being clogged.

Observe the facility and process-specific safety measures before commissioning.

Carry out the following steps before initial commissioning:

• Connect the round 4 pole connector (male) 2 on the device with the supplied mains connection

cable;

• Connect the heated sample line (option);

Check the temperature at the

operating the sample gas conditioning unit with a heated sample

WARNING

• Connect the mains plug of the supplied mains connection cable to the power supply;

• Set the desired temperature on the temperature controller.

Type 701:

The digital display of the controller shows the actual value of the heated line after switching on

the sample gas conditioning. The controller is factory set to 0 °C [32 °F]. Briefly press the P key to

change the set point. SP appears in the display and then the display changes to the adjusted set

point. Use the arrow keys to set the desired value. After 60 seconds, the display automatically

changes to the actual value.

gas line.

The complete instruction manual of the temperature controller

701 is available at www.mc-techgroup.com.

The gas cooler is ready for operation after approximately 3 minutes. If a heated line is connected, the

time in which the gas conditioning unit is ready for operation increases to approx. 1 hour.

The over temperature alarm contact of the cooler switches the sample gas pump automatically on as

soon as the temperature reaches +8 °C [46.4 °F].

of the maximum pressureN3 KPE, N5 KPE and N9-KPE of 1.4 bar abs:

NOTE

N3 KPE approximately 60 Nl/h air,

N5 KPE approximately 100 Nl/h air,

N9 KPE approximately 200 Nl/h air.

than the minimal total amount of flow is extracted as a result of over

pressure.

For long-term measurements with a high dust

www.mc-techgroup.com PSS-5C | 1.02.02 39

Page 40

20 Closing down

NOTE

The area where the gas conditioning unit is placed must remain

frost-free even when the unit is switched off.

No special measures are to be taken in the event of short-term shutdowns of the gas conditioning

system.

In the case of long-term shutdowns, for example after a completed series of measurements, it is

recommended to purge the gas conditioning system with fresh air or inert gas. A flushing time of 3 to

5 minutes is sufficient under normal conditions. Condensate residues must also be removed from the

system.

WARNING

Aggressive condensate is possible.

Wear protective glasses and proper protective clothing!

40 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 41

21 Maintenance

NOTE

In order to protect downstream analyzers, the wet filter element

NOTE

NOTE

Observe the facility- and process-specific safety measures before carrying out maintenance work!

Dangerous voltage!

WARNING

It is necessary to take the equipment off the mains before any

assembly, maintenance or repair work is carried out.

The frequency of the maintenance work depends on the operational process and can therefore only

be determined in each individual case.

All parts which might require maintenance work are easily accessible housed in the gas conditioning

system. The following parts might require maintenance work (see Figure 8):

• Check the filter element of the fine filter FP-2T and replace if necessary.

must always be replaced in the event of a condensate

breakthrough.

• Check the tube of the SR25.2-W condensate pump every six months and replace if necessary;

The complete instruction manual of the SR25.2-W is available at

www.mc-techgroup.com.

• Check the diaphragm of the gas feed pump N3 KPE (optional N5 KPE or N9 KPE) every six months

and replace if necessary.;

The complete instruction manual of N3 KPE, N5 KPE, N9 KPE is

available at www.mc-techgroup.com..

• Check fan grids for contaminations and clean if necessary.

www.mc-techgroup.com PSS-5C | 1.02.02 41

Page 42

22 Trouble shooting

Problem

Display

Possible Causes

Check/Solution

No display

No voltage

Check supply voltage with model type plate;

Error code: E5

Cooler does not work;

Ambient temperature too high.

case

Diaphragm pump

Check voltage on terminals X2/17 and X2/8;

Contaminated

Remove the tubes at the pump head and check;

Sample probe/line

Remove sample line at gas inlet (see 1 in Figure 13);

Sample line to

Disconnect the outlet tube on the analyzer side and

Liquid alarm on

Optional liquid alarm

Momentary overloading of the cooler due to

of the peristaltic pump (see manual

(see manual

Current cooler

Optional flowmeter(s):

Adjust needle valve(s) to the desired flow

The following table aims to point out possible operational problems and offer solutions to such

problems (not applicable during the starting procedure).

OK?

Check if the supply voltage plug is insert correctly;

OK?

Check the fine fuse on connector block 3 (Figure 8);

OK?

Gas flow

interruption

Cooler alarm detects

‘over temperature’.

Cooler turns sample

gas pump off

automatically.

OK?

Free convection in case impaired

temperature too high;

OK?

Cooler error (see instruction manual ECPX000C);

ok?

does not work

diaphragm pump

Current cooler

tmperature(s)

Cooler works,

but gas flow is

interrupted

display: LA1

clogged up or sample

line squashed

analyzer clogged up

or squashed

sensor:

Sensor turns

measuring pump off

automatically;

ok?

OK?

Clean pump if necessary;

OK?

Gas flow?

Clean contaminated sample line or replace;

No gas flow?

check whether sample gas flows at the tube fitting;

No gas flow?

Clean contaminated lines or replace;

Gas flows?

excessive amount of condensate;

OK?

Check tubes for condensate removal;

OK?

Check tubes

peristaltic pump SR25.2-W);

OK?

Check peristaltic pump SR25.2-W

peristaltic pump SR25.2-W);

OK?

Check ECPX000C cooler instruction manual;

42 PSS-5C | 1.02.02 www.mc-techgroup.com

tmperature(s)

Needle valve closed.

Page 43

Problem

Display

Possible causes

Check/Solution

Cooler and

pump tube defect

Replace pump tube (see manual peristaltic pump

ok?

Peristaltic pump

Check peristaltic pump (see manual peristaltic pump

Unsufficient drying of

sample gas

Check ECPX000C (se ECPX000C cooler

instruction manual);

Sensor has not turned

off pump.

Check the LA sensor function

sample gas

pump

running;

Condensate

in the sample

gas line

Current cooler

tmperature(s)

SR25.2-W does not

work

SR25.2-W);

SR25.2-W);

ok?

www.mc-techgroup.com PSS-5C | 1.02.02 43

Page 44

23 Spare parts list

Portable Conditioning System PSS-5C, PSS-5/2C, PSS-5/3

recommended quantity

being in operation

[years]

Part No.

Description

C/R/S 1 2

3

Fine filter FP-2T:

90F0002

Filter element F-2T, PTFE, 2 µm

C 6 12

20

90F0040

Viton O-ring, 26 for FP-

R 1 1

1

90F0056

PVDF filter element clamp F-P

S - -

1

90F0012

Filter body F-120G of glass

R 1 1

1

Fine filter FP-2T with Option LA1S: 4 (see Figure 8)

90F0015

Filter body F-120G-D of glass

with GL 25 condensate connection thread

R 1 1

1

90F0020

Union nut GL 25

R 1 1

1

90F0025

PTFE sealing ring GL 25-12 mm Ø

R 1 1

1

Peristaltic pump SR25.2-W:

90P1007

SR25 pump hose with PVDF tube connectors

DN 4/6 mm

C 1 2

4

Diaphragm pump type N3 KPE/KP18; N5 KPE/KP18

90P2100

Square cap type D3, 1/8“i for N3/N5 KPE/KP18

Material: PVDF

S - -

1

90P2120

Diaphragm type S3, for N3/N5 KPE/KP18,

Material: Viton, PTFE coated

C 1 2

3

90P2115

Sealing ring type O3, for N3/N5 KPE/KP18,

1 piece, Material: Viton (2 pc. required)

C 2 4

6

90P2110

Valve plate type V3, for N3/N5 KPE/KP18,

1 piece, Material: Viton (2 pc. required)

C 2 4

6

90P2105

Intermediate plate type Z3, for N3/N5 PE/KP18

Material: PVDF

S - -

1

Diaphragm pump type N9 KPE/KP18

90P2200

Square cap type D9, 1/8“i for N9 KPE/KP18,

Material: PVDF

S - -

1

90P2220

Diaphragm type S9, for N9 KPE/KP18,

Material: Viton, PTFE coated

C 1 2

3

90P2211

Valve plate with seal for N9 KPE, 1 pc.,

material: Viton. (2 pcs./pump)

C 2 4

6

Wear, tear and replacement part requirements depend on specific operating conditions.

The recommended quantities are based on experience and are not binding.

For spare parts of components which are not presented in the following list please see the specific

instruction manuals or leaflets added in the appendix.

(C) consumable parts, (R) recommended spare parts, (S) spare parts

PSS-5...

44 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 45

Portable Conditioning System PSS-5C, PSS-5/2C, PSS-5/3

(C) consumable parts, (R) recommended spare parts, (S) spare parts

recommended quantity

being in operation

[years]

Part No.

Description

C/R/S 1 2

3

90P2205

Intermediate plate type Z9, for N9 KPE/KP18,

S - -

1

Option flowmeter FM40:

90A0015

Flowmeter glass for FM40

range 7-70 l/h air

S - 1

1

94F0010

Flowmeter glass for FM40

range 15-150 l/h air

S - 1

1

94F0015

Flowmeter glass for FM40

range 25-250 l/h air

S - 1

1

94F0020

Flowmeter glass for FM40

range 50-500 l/h air

S - 1

1

90A0018

Viton O-ring 9 for flowmeter glass FM40

R 2 4

6

Diverse:

90K6030

Fine fuse 4 A T, 5 mm x 20 mm for PSS...

R 5 5

5

90G0020

Fine fuse 10 A T, 5 mm x 20 mm for PSS...

with option temp. controller and heated sample line

R 5 5

5

Hose and hose fittings:

05V3215

Bulkhead union SV-PVDF DN 4/6

PSS-5 optional PVDF = Polyvinylidenfluoride

R 2 2

2

05V6600

Sealing ring 4/6 PVDF

R 5 10

10

05V6605

Union nut M10-4/6 PVDF see above

R 5 10

10

01T4000

Tube PVC DN 4/6 (meters)

S 3 6

9

01T1000

Tube Viton DN 4/6 (meters)

S 1 2

3

01T2000

Tube Novoprene DN 3,2/6,4 (meters)

S 1 2

3

02B1000

Tube PTFE DN 4/6 (meters)

S 1 2

3

10T1000

Hose cutter

S 1 1

1

PSS-5...

Material: PVDF

see above

www.mc-techgroup.com PSS-5C | 1.02.02 45

Page 46

24 Appendix

• Circuit diagram PSS-5C

• Table of parameter codes

More product documentation is available in our Internet catalogue:

www.mc-techgroup.com

• Instruction manual: Electric gas cooler ECPX000C

• Data sheet: Universal-Filters FP, FT, FPK, FS, FSS

• Instruction manual: Diaphragm pump Series N

• Instruction manual: Peristaltic pump SR25.2-W

• Instruction manuals: Liquid alarm sensor LA1S and electronic controllers type LA1.4

• Data sheet: Flow meter FM40

• Data sheet : Ball valves L/PV-1

• Instruction manual: Temperature controller 701

46 PSS-5C | 1.02.02 www.mc-techgroup.com

Page 47

Figure 16 Circuit diagram PSS-5C

www.mc-techgroup.com PSS-5C | 1.02.02 47

Page 48

Table of Parameter Codes

No.

Description:

Default:

Range:

Note:

1

Software version

5

Brightness setting

of display

5

0 - 9

Brightest display setting is 9

10

LA on/off switching

0

0,1,2

0=off; 1= without cable break detection; 2= with

cable break detection

11

Sensitivity LA

2

1-7

The higher the value is, the sooner the alarm is

triggered.

12

HIGH dT

3

2 - 8

[°C]

Differential temperature between set point and

upper temperature alarm limit

13

LOW dT

3

2 - 8

[°C]

Differential temperature between setpoint and

lower temperature alarm limit

14

Hysteresis

alarm)

2

1,2 [°C]

As soon as a temperature alarm limit of "2" is

1

15

mA range

selection

4-20

0-20 / 420 [mA]

Corresponds to the temperature range: -10 °C to

+50 °C (4 – 20 mA: at 5 °C = 8 mA)

70

Operating time in

days

This value will not be deleted even after restarting

84

Fan speed

1

0-5

Value has no influence on the output power

210

Calibration LA dry

Connect the sensor and confirm with the -key.

211

Calibration LA wet

key.

212

Calibration LA

between this value and that of dry.

213

Display LA dry

Check here the current value

214

Display LA wet

Check here the current value

215

Display LA open

Check here the current value

310

mA output LOW

1 mA

-keys until the display matches 1mA.

311

mA output HIGH

20 mA

-keys until the display matches 20 mA.

(temperature

open / cable break

Calibration

Calibration

selected, the hysteresis is automatically reduced to

Hold the sensor in water and confirm with the -

Disconnect the sensor and confirm with the -key.

The cable break detection triggers in the middle

Connect the multimeter and press or hold or

Connect the multimeter and press and hold or

48 PSS-5C | 1.02.02 www.mc-techgroup.com

Loading...

Loading...