Page 1

Portable Gas Conditioning Unit Series

PSS

PSS-5, PSS-5/3

Instruction Manual

®

Version 1.00.03

Page 2

Dear customer,

This Instruction Manual does not claim completeness and may be

subject to technical modifications.

© 0

Germany GmbH. Reproduction of this

document or its content is not all

PSS

Version: 1.00.0

Thank you for buying our product. In this manual you will find all necessary information about this

M&C product. The information in the manual is fast and easy to find, so you can start using your M&C

product right after you have read the manual.

If you have any question regarding the product or the application, please don’t hesitate to contact

M&C or your M&C authorized distributor. You will find all the addresses in the appendix of this

instruction manual.

For additional information about our products, please go to M&C’s website www.mc-techgroup.com

There you can find the data sheets and manuals of our products in German and English.

.

5/2019 M&C Techgroup

®

is a registered trade mark.

3

2 PSS-5 | 1.00.03 www.mc-techgroup.com

owed without permission from M&C.

Page 3

List of Contents

1 General information .................................................................................................................. 4

2 Declaration of conformity ......................................................................................................... 4

3 Safety instructions .................................................................................................................... 5

4 Warranty .................................................................................................................................... 5

5 Used terms and signal indications .......................................................................................... 6

6 Introduction ............................................................................................................................... 8

7 Application ................................................................................................................................ 8

8 Technical data ........................................................................................................................... 9

9 Description .............................................................................................................................. 10

10 Receipt of goods and storage ............................................................................................ 12

11 Installation instructions ...................................................................................................... 13

12 Supply connections ............................................................................................................ 14

12.1 Tube connections ............................................................................................................... 14

12.1.1 Connecting the heated sample line with special adapter (option) ................................ 16

12.2 Electrical connections ........................................................................................................ 16

13 Commissioning ................................................................................................................... 18

14 Closing down ....................................................................................................................... 19

15 Maintenance ......................................................................................................................... 19

16 Trouble shooting ................................................................................................................. 21

17 Spare parts list .................................................................................................................... 23

18 Appendix .............................................................................................................................. 25

List of Figures

Figure 1 PSS-5 and PSS-5/3 gas flow diagram .............................................................................. 8

Figure 2 Design of the conditioning units PSS-5 and PSS-5/3 ...................................................... 10

Figure 3 Sample gas connection .................................................................................................. 14

Figure 4 Heated sample line connection with special adapter....................................................... 16

Figure 5 Electrical connection and main switch ............................................................................ 17

Figure 6 Circuit diagram PSS-5 and PSS-5/3, 115 V and 230 V ................................................... 26

www.mc-techgroup.com PSS-5 | 1.00.03 3

Page 4

HEAD OFFICE

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 – 0

Fax: 02102 / 935 – 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this operating manual has been examined before delivery and left our works

in perfect condition related to safety regulations. In order to keep this condition and to guarantee a

safe operation, it is important to heed the notes and prescriptions made in this operating manual.

Furthermore, attention must be paid to appropriate transportation, correct storage, as well as

professional installation and maintenance work.

All necessary information a skilled staff will need for appropriate use of this product are given in this

operating manual.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EU directives:

EMC-Instruction

The requirements of the EU directive 2014/30/EU “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EU directive 2014/35/EU “Low Voltage Directive“ are met.

The compliance with this EU directive has been examined according to DIN EN 61010.

RoHS Directive

The requirements of the RoHS2 (‘Restriction of Hazardous Substances 2’) directive 2011/65/EU and its

annexes are met.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

4 PSS-5 | 1.00.03 www.mc-techgroup.com

Page 5

3 SAFETY INSTRUCTIONS

Please take care of the following basic safety procedures when mounting, starting up or

operating this equipment:

Read this operating manual before starting up and use of the equipment. The information and

warnings given in this operating manual must be heeded.

Any work on electrical equipment is only to be carried out by trained specialists as per the regulations

currently in force.

Attention must be paid to the requirements of VDE 0100 (IEC 364) when setting high-power electrical

units with nominal voltages of up to 1000 V, together with the associated standards and stipulations.

Check the details on the type plate to ensure that the equipment is connected to the correct mains

voltage.

Protection against touching dangerously high electrical voltages:

Before opening the equipment, it must be switched off and hold no voltages. This also applies to any

external control circuits that are connected.

The device is only to be used within the permitted range of temperatures and pressures.

Check that the location is weather-protected. It should not be subject to either direct rain or moisture.

The gas conditioning systems PSS-5 and PSS-5/3 must not be used in hazardous areas.

Installation, maintenance, monitoring and any repairs may only be done by authorized personnel

with respect to the relevant stipulations.

4 WARRANTY

In case of a device failure, please contact immediately M&C or your M&C authorized distributor.

We have a warranty period of 12 months from the delivery date. The warranty covers only

appropriately used products and does not cover the consumable parts. Please find the complete

warranty conditions in our terms and conditions.

The warranty includes a free-of-charge repair in our production facility or the free replacement of the

device. If you return a device to M&C, please be sure that it is properly packaged and shipped with

protective packaging. The repaired or replaced device will be shipped free of delivery charges to the

point of use.

www.mc-techgroup.com PSS-5 | 1.00.03 5

Page 6

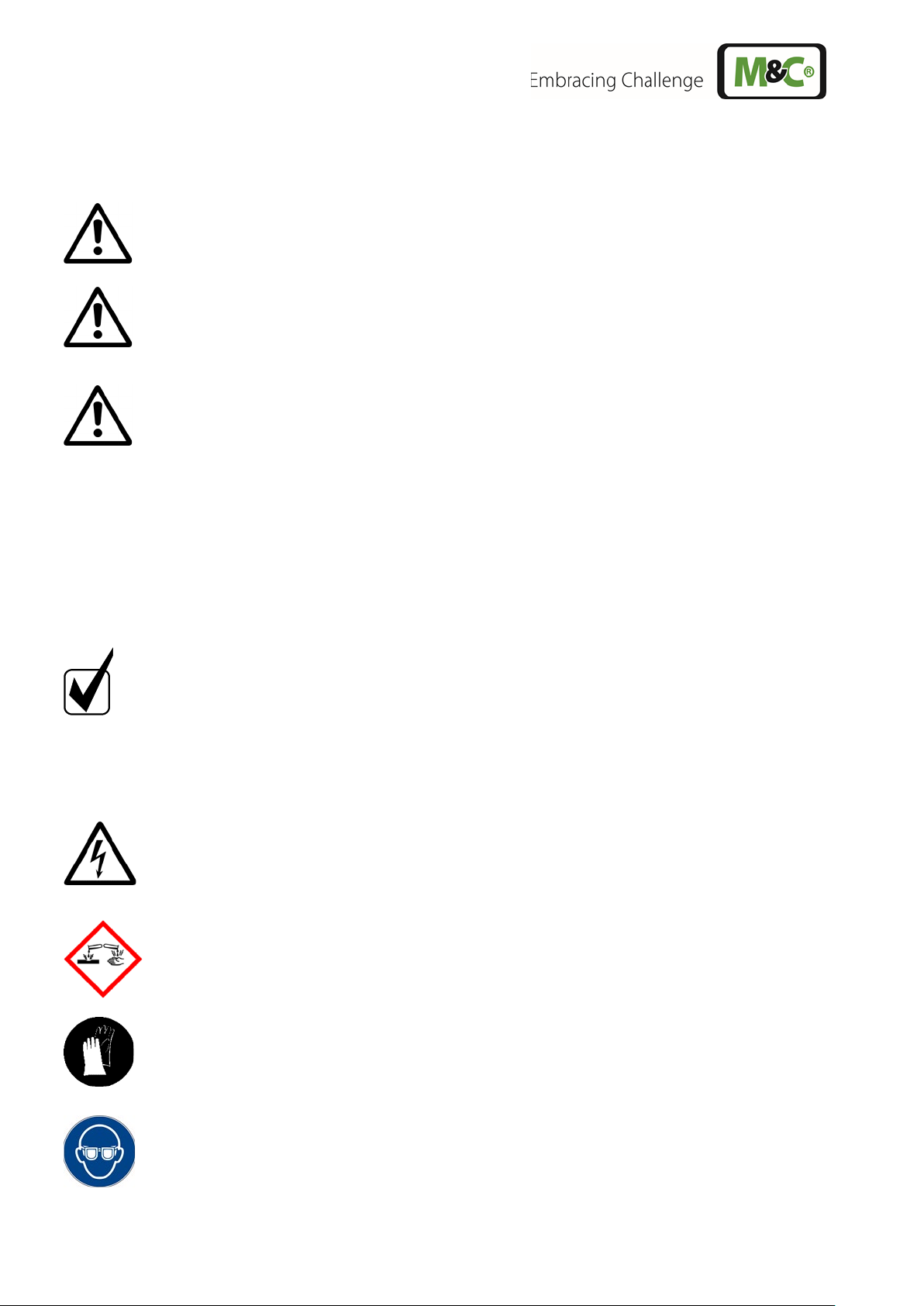

5 USED TERMS AND SIGNAL INDICATIONS

DANGER!

This means that death, severe physical injuries and/or important

This means that death, severe physical injuries and/or important

in case the respective safety

CAUTION!

This means that minor physical injuries may occur in case the

CAUTION!

Without the warning triangle means that a material damage may

ATTENTION

This means that an unintentional situation or an unintentional status

These are important information about the product or parts of the

QUALIFIED PERSONNEL

These are persons with necessary qualification who are familiar with

High voltages!

Corrosive!

Wear protective gloves!

objects or extremely high

Wear safety glasses!

objects.

material damages will occur in case the respective safety measures

are not fulfilled.

material damages may occur

WARNING!

measures are not fulfilled.

respective safety measures are not fulfilled.

occur in case the respective safety measures are not met.

NOTE!

may occur in case the respective note is not respected.

operating manual which require user’s attention.

installation, use and maintenance of the product.

Protect yourself and others against damages which might be caused

by high voltages.

These substances destroy living tissue and equipment upon contact.

Do not breathe vapors; avoid contact with skin and eyes.

Working with chemicals, sharp

temperatures requires wearing protective gloves.

Protect your eyes while working with chemicals or sharp

Wear safety glasses to avoid getting something in your eyes.

6 PSS-5 | 1.00.03 www.mc-techgroup.com

Page 7

Wear protective clothes!

ly high

Working with chemicals, sharp objects or extreme

temperatures requires wearing protective clothes.

www.mc-techgroup.com PSS-5 | 1.00.03 7

Page 8

6 INTRODUCTION

The portable gas conditioning systems PSS-5 and PSS-5/3 have been especially designed, so that

precise gas analysis can be carried out in any place and at any time.

The entire gas conditioning system is housed in a compact and robust aluminium framed protective

case which ensures that the components can be removed easily, and gas analysis carried out quickly,

safely and with a minimum amount of maintenance.

7 APPLICATION

The gas conditioning system is ideally suited for both intermittent and continuous operation.

The components of the PSS-5 and PSS-5/3 systems are intended for "standard use." We also provide

a wide range of additional equipment and other components if special measurements are required.

Gas sample probe, stainless steel 316, Ø 4/6 mm, length 0.5 m

Gas sample line, PVC hose, Ø 4/6 mm, length 3 m

Gas cooler ECP1000 or ECP3000

Fine filter FP-2T, filter element fineness 2 µm

Sample gas diaphragm pump N3KPE or N9KPE

Pre-filter PF 2

Peristaltic pump SR25.1 for continuous removal of condensate

Figure 1 PSS-5 and PSS-5/3 gas flow diagram

8 PSS-5 | 1.00.03 www.mc-techgroup.com

Page 9

8 TECHNICAL DATA

Gas Conditioning Type

PSS-5

PSS-5/3

Gas outlet dew point

Range of adjustment: +2 to +15 °C [35.6 to 59 °F], factory

Gas outlet dew point stability

At const. conditions: < ±0.1 °C [±0.18 °F]

Gas inlet temperature

Max. 80 °C* [176 °F*], optional: max. 180 °C* [356 °F*] with

Gas inlet water vapor saturation

Max. +80 °C* [176 °F*]

Gas flow rate

Max. 150 Nl/h*

Max. 350 Nl/h*

Ambient temperature

+5 to +40 °C* [41 to 104 °F*]

Storage temperature

-25 °C to +65 °C [-4 to 149 °F]

Pressure

0.7 to 1.4 bar abs.*

Total cooling capacity

Max. 50 kJ/h

Max. 90 kJ/h

Number of gas inlets

1

Number of gas outlets

1, optional: max. 4

Material of sample contacting parts

Stainless steel, glass, PPH, PVC, PVDF, PTFE, Novoprene®

Ready for operation

Approx. 10 min.

Mains power supply

230 V/50 Hz ±10 % or 115 V/60 Hz ±10 %

Power consumption

Max. 240 VA

Fuse protection

4 AT, 5 x 20 mm

10 AT, 5 x 20 mm

Electrical connection

Cold appliance plug with 2 m [6.6 ft] cable

Case protection

IP20 (EN 60529)

Case type

Portable aluminium framed protective case

Case dimensions (H x W x D)

440 x 540 x 255 mm [approx. 17.3“ x 21.3“ x 10“]

Weight

Approx. 18.5 kg [40.8 lbs]

Approx. 20.0 kg [44.1 lbs]

Options

Electrical equipment standard

EN 61010

setting: +5 °C [41 °F]

stainless steel bulkhead union

Medium connections Tube connections DN 4/6

Temperature controller:

Flow meter (optionally):

Optional: Viton® for gas sample line, Part No. 01G9025

Option temperature controller and heated sample line:

230 V max. 1620 VA

115 V max. 930 VA

With option temperature controller and heated sample line:

Range of control: 0 to 200 °C [32 to 392 °F]

PT100

Input:

7 to 70 Nl/h air, 15 to 150Nl/h air, 25 to 250 Nl/h air,

50 to 500 Nl/h air

Quantity: max. 4

PPH=Polypropylene, PTFE=Polytetrafluoroethylene (Teflon®), PVC=Polyvinyl chloride, PVDF=Polyvinylidenfluoride

Viton®, Teflon® are registered Trademarks of DuPont Performance elastomers

* Maximum values in technical data must be rated in consideration of total cooling capacity at 25 °C [77 °F] ambient

temperature and an outlet dew point of 5 °C [41 °F].

www.mc-techgroup.com PSS-5 | 1.00.03 9

Page 10

9 DESCRIPTION

Cooler

ECP

>°C

ON

<°C

EIN

Meßgas

AUS

AUS

Kondensat

max. 1800VA

GL18

GL25

11

255

540

440

PSS-5...

Type of cooler

Max. gas flow [Nl/h]

Sample gas pump

PSS-5

ECP1000

150

N 3 KPE

PSS-5/3

ECP3000

350

N 9 KPE

Figure 2 Design of the conditioning units PSS-5 and PSS-5/3

All components of the gas conditioning system are built into a portable case and are freely

accessible. The case door can be opened easily to the left by loosening the tension locks

mounted on the side and top of the case.

The installation of the gas cooler and a corresponding diaphragm measuring gas pump

depends on the required maximum gas volume flow. The possible combinations are summarised in

the following table:

The minimum amount of flow is determined by the sample gas pump (see chapter 8). If the required

minimum total flow rate is not reached, excessive overpressure can lead to premature destruction of

the pump diaphragm.

The gas cooler is equipped with a Duran glass heat exchanger as standard. Heat exchangers in

PVDF or stainless steel are optionally available.

The FP-2T fine filter (2 µm filter porosity) installed upstream of the sample gas pump provides

the necessary solids separation.

The overtemperature alarm contact (+8 °C [46.4 °F]) of the cooler automatically regulates the

switching on and off of the sample gas pump.

10 PSS-5 | 1.00.03 www.mc-techgroup.com

Page 11

The resulting condensate is continuously discharged by a peristaltic pump type SR25.1 .

A pre-filter type PF2 is installed in the condensate line between the heat exchanger and the

peristaltic pump. This protects the pump from particle contamination in the condensate.

The 4/6 mm tube connections for the condensate and sample gas lines

11 are located on the right

side of the case (see Figure 2 and Figure 5).

A stainless steel sample tube (length 0.5 m, Ø 6 mm) and 3 m PVC sample tubing (4/6 mm) are

included as standard.

The ventilation grids in the lid and in the left side wall of the case provide sufficient convex forced

ventilation.

Options:

The PSS-5 and PSS-5/3 sample gas conditioning unit can be equipped at the factory with a maximum

of four sample gas outlets. Each sample gas outlet can be controlled according to the specified volume

flow range (see table on page 9) by the optional installation of a flow meter type FM40 with needle

valve. Unused mounting holes for sample gas outputs or flow meters are closed by blind caps.

To protect the downstream analyzers against liquid ingress and to increase the operational reliability

of the entire system, we recommend the installation of a liquid alarm sensor type LA1S. For this

purpose, the FP-2T fine filter installed as standard is replaced at the factory by the FP-2T-D fine filter

with built-in liquid alarm sensor. The LA1.4 electronic controller is located on the terminal support rail

(Figure 2), in the upper part of the case. The LA electronics automatically shuts off the sample gas

pump in the event of a liquid alarm. The alarm is indicated by a red LED. If there is no alarm, a green

LED will be on.

The PSS-5 and PSS-5/3 sample gas conditioning units can optionally be equipped with a sample gas

inlet (see Figure 3, Part No. 01G9060) for connecting a heated sample line. The existing anti-kink

protection must only be used for heated sample lines of connection type "C" (Part No. 03B1012).

Assembly instructions can be found in the appendix.

It is also possible to connect the heated sample line Part No. 01B4036 in connection with the gas

sample probe PSP 4000.

The temperature controller 701 (Part No. 01G9055) required to control the heated line is factoryinstalled on the terminal support rail (Figure 2).

A 3-way ball valve (Part No. 01G9046) or a 5-way ball valve (Part No. 01G9045) can optionally be

installed in the inlet of the gas conditioning unit for test gas feed or sample gas switching.

www.mc-techgroup.com PSS-5 | 1.00.03 11

Page 12

10 RECEIPT OF GOODS AND STORAGE

The gas conditioning and sampling systems PSS-5 and PSS-5/3 are completely pre-installed units.

• Immediately after arrival take the gas conditioning system and possible special accessories

carefully out of the packaging material.

• Compare the goods with the items listed on the delivery note;

• Check the goods for any damage caused during delivery and, if necessary, notify your transport

insurance company without delay of any damage discovered.

The gas conditioning unit should be stored in a protected

NOTE!

frost-free area!

12 PSS-5 | 1.00.03 www.mc-techgroup.com

Page 13

11 INSTALLATION INSTRUCTIONS

The case should be placed on an even horizontal surface to

to the cooler. Condensate pre-separation is then not necessary.

ensure a secure and stable position.

NOTE!

The operating position is exclusively vertical. Only in this case is

the proper condensate separation and discharge in the heat

exchanger of the cooler guaranteed.

The gas conditioning case should be set up away from heat

sources and freely ventilated so that no unwanted heat

accumulation occurs.

For outdoor installation, adequate protection against direct

sunlight and moisture must be provided. In winter, the

installation site must be frost-free; observe the protection class

of the case.

To ensure the operational safety of the portable gas conditioning

unit and the downstream analyzers and to avoid false alarms,

the sample gas conditioning unit must not be used outside the

specified temperature range.

Downstream analyzers must always be operated at temperatures

well above the specified gas output dew point of +5 °C. The

temperature range of the downstream analyzers must not be

exceeded. This avoids any condensation of the gas in the

connecting lines to the analyzers.

Unheated gas sample lines must be installed with a gradient down

www.mc-techgroup.com PSS-5 | 1.00.03 13

Page 14

12 SUPPLY CONNECTIONS

NOTE!

Do not swap tube connections; connections are marked

Option:

Mounting of max. 4 FM40

flowmeters possible

EIN

Meßgas

AUS

AUS

Kondensat

1

1

2 3 4

2

3

4

Condensate

Outlet

Sample gas

Outlet

(Option: max. 4)

Sample gas

Inlet

Option:

Electrical connection

for

heated sample line

max. 6A, (230V/50Hz or 115V/60Hz)

12.1 TUBE CONNECTIONS

accordingly.

After connecting all lines, the tightness must be checked.

Figure 3 shows the possible medium connections. These are located recessed in a special mounting

frame on the right side of the sample gas conditioning case.

Figure 3 Sample gas connection

All tube connections are equipped with 4/6 mm sealing ring threaded hose couplings made of

polypropylene (PP) for gas input temperatures of up to a maximum of 80 °C [176 °F] (see chapter 8).

If heated sample lines are used, whereby the gas input temperatures are increased up to a maximum

of 180 °C [356 °F], additional bulkhead unions made of stainless steel are recommended.

Dimension 4/6 mm connecting tubes are used as standard.

14 PSS-5 | 1.00.03 www.mc-techgroup.com

Page 15

The sample gas tubes or condensation tubes, are to be assembled as follows:

NOTE!

The tightness of the connections can only be guaranteed if the

• Remove the union nut from the sealing ring couplings by turning it anti-clockwise. The nut should

be removed from the thread with great care so as to ensure that the loose sealing ring in the nut is

not lost.

• Place the union nut over the connecting tube.

• Place the sealing ring over the connecting hose with the thicker bead towards the nut.

• Place the hose over the nipple on the thread.

connecting tube has a straight rim (hose cutter).

• The union nut is to be screwed tight by hand.

The tube will no longer be able to slip off, and is now compression-proof.

The tubes are to be removed in the reverse order.

WARNING!

Aggressive condensate is possible.

Wear protective glasses and proper protective clothing!

www.mc-techgroup.com PSS-5 | 1.00.03 15

Page 16

12.1.1 CONNECTING THE HEATED SAMPLE LINE WITH SPECIAL ADAPTER (OPTION)

the equipment. When

the supply voltage

is identical with the information provided on the model type

For the erection of power installations with rated voltages up to

1000V, the requirements of VDE 0100 and relevant standards and

The main circuit is equipped with a fuse corresponding to the

technical data.

Sample gas IN

Bulkhead union

Back ferrule 6

mm Ø

ID

Back ferrule

10 mm Ø ID

Sealing ring

10 mm Ø ID

Sealing ring

6 mm Ø ID

Support sleeve

4 mm Ø OD

Union nut 10 mm Ø ID

Heated sample line

Adapter

Figure 4 Heated sample line connection with special adapter

• Place the special adapter on the PTFE tube according to the drawing seen above;

• Place the support sleeve into the PTFE tube;

• Insert the Teflon tube as far as possible into the 'Sample gas IN' bulkhead fitting and hand-tighten

the adapter;

• Tighten the adapter 1 1/4 turns with a wrench (SW 14), while holding the lock nut of the Schott

screw connection with a wrench (SW 15);

• Insert the 10mm pipe of the heating cable into the adapter as far as possible and hand-tighten with

the union nut;

• Tighten the union nut 1 1/4 turns with the wrench (SW 19), holding the adapter in place with the

wrench;

The screw connection is now cut gas-tight and can be loosened as often as required.

12.2 ELECTRICAL CONNECTIONS

False supply voltage can demage

WARNING!

connecting the equipment, please ensure that

plate!

specifications must be observed!

NOTE!

nominal current (over current protection); for electrical details see

16 PSS-5 | 1.00.03 www.mc-techgroup.com

Page 17

The PSS-5 and PSS-5/3 gas conditioning systems are available with either 230V/50 Hz or with

Main switch and

cold appliance plug socket

0

Ventilation grids

115V/60 Hz (for circuit diagram see Appendix). A 4 A fuse is used on all models as fuse protection.

The fuse is located on the clamp mounting rail (see Figure 2). When optionally using a temperature

controller with heated line, the overload protection increases to 10 A.

The electrical connection is made via a cold appliance plug with 2 m cable on the left side of the case.

The power socket is equipped with a two-pole main switch.

Figure 5 Electrical connection and main switch

Option “ heated sample line”:

For the electrical supply of a heated sample line with PT-100 sensor and/or the connection of other

heated components, e.g. heated sample gas probe or heated filter, a connection socket as shown in

Figure 3 is available. The maximum connected load is 6 A, 1380 W for the 230 V sample gas

conditioning or 6 A, 690 W for the 115 V version.

The maximum length of the usable heated sampling line is calculated as follows:

Max. connected load [W] - Power consumption of heated components (e.g. sample probe) [W]

L(m)=

Power consumption heated line per meter [W/m]

www.mc-techgroup.com PSS-5 | 1.00.03 17

Page 18

13 COMMISSIONING

NOTE!

When operating the sample gas conditioning system with a

heated sample gas line, the temperature must be checked at the

The following minimum gas flow rates result from the requirement

side load of the sample gas pumps N3

If the required minimum total flow rate is not reached, excessive

overpressure can lead to premature destruction of the pump

term measurements with a high dust content in the

sampling probe must be provided to

protect the sampling line from blockages.

Before commissioning, the plant-specific and process-specific safety measures must be observed.

Before connecting the equipment to the supply voltage, the

main switch must be in position “0”.

The following steps must be carried out before initial commissioning:

• Plug the power plug of the supplied power cable into the power socket;

• Connect the heated cable (optional);

WARNING!

temperature controller.

• Connect the mains plug to the mains;

• Switch the main switch to position 'I'.

• Set the desired temperature on the temperature controller.

Type 701: The digital display of the controller shows the actual value of the heated sample line after

switching on the sample gas conditioning unit. The controller is set to 0 °C [32 °F] on delivery. Briefly

press the P key to change the set point. SP appears in the display and then the display changes to

the adjusted set point. Use the arrow keys to set the desired value. After 60 seconds, the display

automatically changes to the actual value.

The sample gas cooler is ready for operation after approx. 10 minutes. The overtemperature alarm

contact of the cooler switches on the sample gas pump automatically when the cooler reaches the

temperature of +8°C [46.4 °F].

of the maximum pressureKPE and N9 KPE of 1.4 bar abs:

NOTE!

N 3 KPE approx. 60l/h air,

N 9 KPE approx. 200l/h air.

diaphragm.

For longsample gas, a suitable gas

18 PSS-5 | 1.00.03 www.mc-techgroup.com

Page 19

14 CLOSING DOWN

NOTE!

The installation site of the gas conditioning unit must remain frostfree even when the unit is switched off.

No special measures are to be taken in the event of short-term shutdowns of the gas conditioning

system.

In the case of long-term shutdowns, for example after a completed series of measurements, it is

recommended to purge the gas conditioning system with fresh air or inert gas. A flushing time of 3 to

5 minutes is sufficient under normal conditions. Condensate residues must also be removed from the

system.

WARNING!

Aggressive condensate is possible.

Wear protective glasses and proper protective clothing!

15 MAINTENANCE

Before carrying out maintenance work, the plant-specific and process-specific safety measures must

be observed!

Dangerous voltage.

WARNING!

The maintenance cycles depend on the process conditions and must therefore be determined for each

specific application.

All parts to be serviced are easily accessible and installed in the sample gas conditioning case. These

are (see Figure 2):

• The filter element of the preliminary filter FP-2T

Before carrying out any work on the gas conditioning unit, move

the main switch to position “0” and pull out the mains plug!

.

www.mc-techgroup.com PSS-5 | 1.00.03 19

Page 20

NOTE!

In order to protect downstream analyzers, the wet filter element

must always be replaced after a condensate ingress.

• Peristaltic pump pre-filter PF2 ; The pre-filter must be replaced at regular intervals if the

condensate is loaded with particles. The "disposable filter" is inserted into the pump tube on the

suction side (see Figure 2) and can be easily replaced;

• Check the tubing of the SR25.1

condensate pump every six months and replace it if necessary

(see operating instructions in the appendix);

• Check the diaphragm of the gas feed pump N3 KPE or N9 KPE

every six months and replace

if necessary.

20 PSS-5 | 1.00.03 www.mc-techgroup.com

Page 21

16 TROUBLE SHOOTING

Indication

Problem

Possible Cause

Check/Solution

Upper LED of

Interruption of

No voltage;

Needle valve closed.

Check supply voltage with model type plate;

Remove sample gas hose on analyser side and

Momentary overloading of the cooler due to

The following table aims to point out possible operational problems and offer solutions to such

problems (not applicable during the starting procedure).

the cooler lights

up red

Middle LED on

cooler is green;

Alarm LED on

the LA electronics is red (see

4);

gas flow;

Cooler in

operation but

gas flow

interrupted;

Cooler does not

function.

Cooler alarm registers

‘excess temperature’.

Cooler turns gas

measuring pump of

automatically.

Membrane pump

faulty;

Contamination of the

membrane pump;

Sample probe/hose

clogged up or lead

squashed;

Sample gas hose to

analyser clogged up or

squashed;

Optional liquid alarm

sensor:

Sensor turns

measuring pump off

automatically;

Optional flowmeter(s):

OK?

Check if supply voltage plug is inserted correctly

and if the main switch is turned in position “1”

OK?

Check fine fuse on connector block (Figure 2);

OK?

Ambient temperature too high.

OK?

Free convection in case impaired case

temperature too high;

OK?

Cooler error (check instruction manual

ECP1000/3000).

OK?

Check voltage on clamps X1/11 and X1/8;

OK?

Remove the hoses at head of pump and check;

OK?

Clean pump if necessary;

OK?

Remove tube at gas inlet (see chapter 12.1);

Gas flow?

Clean contaminated lead or replace;

No gas flow?

check via hose thread if sample gas flows;

No gas flow?

Clean contaminated leads or replace;

Gas flows?

excessive amount of condensate;

OK?

Check hoses for condensate removal;

OK?

Check Pre-filter and if necessary replace;

OK?

Check peristaltic pump tube (see manual SR25.1);

OK?

Check peristaltic pump (see manual SR25.1);

OK?

Check cooler according to instruction manual;

Adjust needle valve(s) to the desired flow.

www.mc-techgroup.com PSS-5 | 1.00.03 21

Page 22

Indication

Problem

Possible Cause

Check/Solution

Middle LED on

Cooler and

Pre-filter clogged

pump off.

Remove filter from condensate lead;

cooler is green;

LED of the LA

electronics is

green (see 4).

gas pump in

operation;

condensate in

sample gas

lead;

up;

Pump hose faulty;

Peristaltic pump

SR25.1 faulty;

Unsufficient drying of

sample gas;

Optional liquid alarm

sensor:

Sensor has not turned

Pump delivering?

Change filter;

Pump not delivering?

Change pump hose (see manual peristaltic pump

SR25.1);

OK?

Check peristaltic pump (see manual peristaltic

pump SR25.1);

OK?

Check cooler (see manual ECP1000/3000);

Check the LA electronics and if necessary

replace.

22 PSS-5 | 1.00.03 www.mc-techgroup.com

Page 23

17 SPARE PARTS LIST

Portable Sampling System Versions PSS-5, PSS-5/3

recommended quantity

operation [years]

C/R/S 1 2

3

Fine filter FP-2T: (see Fig. 2)

90F0002

Filter element F-2T, PTFE, 2 µm

C 6 12

20

90F0040

Viton O-ring, 26 for FP-

R 1 1

1

90F0056

PVDF filter element clamp F-P

S - -

1

90F0012

Filter body F-120G of glass

R 1 1

1

Fine filter FP-2T with Option LA1S:

90F0015

Filter body F-120G-D of glass

with GL25 condensate connection thread

R 1 1

1

90F0020

Union nut GL 25

R 1 1

1

90F0025

PTFE sealing ring GL 25 - 12mm Ø

R 1 1

1

Peristaltic pump SR25.1:

90P1007

SR25 pump hose with PVDF tube connectors

DN 4/6 mm

C 1 2

4

Diaphragm pump type N3 KPE/KP18; N5 KPE/KP18

90P2100

Square cap type D3, 1/8“i for N3/N5 KPE/KP18

Material: PVDF

S - -

1

90P2120

Diaphragm type S3, for N3/N5 KPE/KP18,

Material: Viton, PTFE coated

C 1 2

3

90P2111

Valve reed type V3 with O-ring type O3, for N3N5, 1 pc, material: Viton (2 pieces required)

C 2 4

6

90P2105

Intermediate plate type Z3, for N3/N5 PE/KP18

Material: PVDF

S - -

1

Diaphragm pump type N9 KPE/KP18

90P2200

Square cap type D9, 1/8“i for N9 KPE/KP18,

Material: PVDF

S - -

1

90P2220

Diaphragm type S9, for N9 KPE/KP18,

Material: Viton, PTFE coated

C 1 2

3

90P2211

Valve plate with seal for N9 KPE, 1 pc.,

material: Viton. (2 pcs./pump)

C 2 4

6

90P2205

Intermediate plate type Z9, for N9 KPE/KP18,

Material: PVDF

S - -

1

Option flowmeter FM40:

90A0015

Flowmeter glass for FM40

range 7-70 l/h air

S - 1

1

Wear, tear and replacement part requirements depend on specific operating conditions.

The recommended quantities are based on experience and are not binding.

For spare parts of components which are not presented in the following list please see the specific

instruction manuals or leaflets added in the appendix.

(C) consumable parts, (R) recommended spare parts, (S) spare parts

PSS-5 and PSS-5/3 being in

www.mc-techgroup.com PSS-5 | 1.00.03 23

Page 24

Portable Sampling System Versions PSS-5, PSS-5/3

(C) consumable parts, (R) recommended spare parts, (S) spare parts

recommended quantity

operation [years]

C/R/S 1 2

3

94F0010

Flowmeter glass for FM40

range 15-150 l/h air

S - 1

1

94F0015

Flowmeter glass for FM40

range 25-250 l/h air

S - 1

1

94F0020

Flowmeter glass for FM40

range 50-500 l/h air

S - 1

1

90A0018

Viton O-ring 9 for flowmeter glass FM40

R 2 4

6

Diverse:

90G0006

Pre-filter PF 2 for condensate pump SR25.1

C 5 10

15

90K6030

Fine fuse 4 A T, 5 x 20 mm for PSS-5, PSS-5/3

R 5 5

5

90G0020

Fine fuse 10 A T, 5 x 20 mm for PSS-5, PSS-5/3

with option temp. controller and heated sample line

R 5 5

5

Hose and hose fittings:

05V3230

Bulkhead union SV-PP DN 4/6

PSS-5 standard PPH = Polypropylene

R 2 2

2

05V3215

Bulkhead union SV-PVDF DN 4/6

PSS-5 optional PVDF = Polyvinylidenfluoride

R 2 2

2

05V6500

Sealing ring 4/6 PP

R 5 10

10

05V6600

Sealing ring 4/6 PVDF

R 5 10

10

05V6505

Union nut M10-4/6 PP

R 5 10

10

05V6605

Union nut M10-4/6 PVDF

R 5 10

10

01T4000

Hose PVC DN 4/6 (meters)

S 3 6

9

01T1000

Hose Viton DN 4/6 (meters)

S 1 2

3

01T2000

Hose Novoprene DN 3,2/6,4 (per meter)

S 1 2

3

02B1000

Hose PTFE DN 4/6 (per meter)

S 1 2

3

10T1000

Hose cutter

S 1 1

1

PSS-5 and PSS-5/3 being in

see above

see above

see above

see above

24 PSS-5 | 1.00.03 www.mc-techgroup.com

Page 25

18 APPENDIX

• Circuit diagram PSS-5 and PSS-5/3

More product documentation is available in our Internet catalogue:

www.mc-techgroup.com

• Instruction manual electric gas cooler ECP 1000, ECP 3000

• Data sheet: Universal-Filters FP, FT, FS, FSS

Document: 7.1

• Instruction manual diaphragm pump Series N

• Instruction manual peristaltic pump SR25.1, SR25.1-G

• Data sheet: Liquid alarm sensor LA1S and electronic controller type LA1.4

Document: 8.1

• Data sheet: Flow meter FM40

Document: 9.2

• Data sheet: Ball valves L/PV-1

Document: 11.1

• Data sheet: Temperature controller 701

Document: 4.2

www.mc-techgroup.com PSS-5 | 1.00.03 25

Page 26

Figure 6 Circuit diagram PSS-5 and PSS-5/3, 115 V and 230 V

26 PSS-5 | 1.00.03 www.mc-techgroup.com

Loading...

Loading...