Page 1

OV-7605-C8

Application Manual

June 2017 1/20 Rev. 1.0

Application

Manual

OV-7605-C8

Low Power Clock Oscillator

32.768 kHz

Page 2

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 2/20 Rev. 1.0

TABLE OF CONTENTS

1. OVERVIEW ..................................................................................................................................................... 3

GENERAL DESCRIPTION ......................................................................................................................... 3 1.1.

APPLICATIONS ......................................................................................................................................... 3 1.2.

ORDERING INFORMATION ...................................................................................................................... 4 1.3.

2. BLOCK DIAGRAM ......................................................................................................................................... 5

PINOUT ...................................................................................................................................................... 5 2.1.

PIN DESCRIPTION .................................................................................................................................... 5 2.2.

DEVICE PROTECTION DIAGRAM ........................................................................................................... 6 2.3.

3. ELECTRICAL SPECIFICATIONS .................................................................................................................. 7

ABSOLUTE MAXIMUM RATINGS ............................................................................................................ 7 3.1.

OPERATING PARAMETERS .................................................................................................................... 7 3.2.

TYPICAL CHARACTERISTICS ................................................................................................................. 8 3.3.

TIMING WAVEFORMS .............................................................................................................................. 8 3.4.

OSCILLATOR PARAMETERS .................................................................................................................. 9 3.5.

XTAL FREQUENCY VS. TEMPERATURE CHARACTERISTICS ..................................................... 9

3.5.1.

4. PACKAGE .................................................................................................................................................... 10

DIMENSIONS AND SOLDER PAD LAYOUT .......................................................................................... 10 4.1.

RECOMMENDED THERMAL RELIEF ............................................................................................. 10 4.1.1.

MARKING AND PIN #1 INDEX ................................................................................................................ 11 4.2.

5. MATERIAL COMPOSITION DECLARATION & ENVIRONMENTAL INFORMATION ............................... 12

HOMOGENOUS MATERIAL COMPOSITION DECLARATION ............................................................. 12 5.1.

MATERIAL ANALYSIS & TEST RESULTS ............................................................................................ 13 5.2.

RECYCLING MATERIAL INFORMATION .............................................................................................. 14 5.3.

ENVIRONMENTAL PROPERTIES & ABSOLUTE MAXIMUM RATINGS ............................................. 15 5.4.

6. APPLICATION INFORMATION ................................................................................................................... 16

OPERATING OV-7605-C8 ....................................................................................................................... 16 6.1.

SOLDERING INFORMATION .................................................................................................................. 17 6.2.

HANDLING PRECAUTIONS FOR MODULES WITH EMBEDDED CRYSTALS ................................... 18 6.3.

7. PACKING & SHIPPING INFORMATION ..................................................................................................... 19

8. COMPLIANCE INFORMATION ................................................................................................................... 20

9. DOCUMENT REVISION HISTORY .............................................................................................................. 20

Page 3

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 3/20 Rev. 1.0

OV-7605-C8

Low Power Clock Oscillator 32.768 kHz

1. OVERVIEW

Oscillator with built-in “Tuning Fork” crystal oscillating at 32.768 kHz

Very tight frequency tolerance: ±20 ppm

Excellent oscillator stability: < 3 ppm/V

High shock and vibration resistance

Wide operating voltage range: 1.6 V to 5.5 V

Very low power consumption: typ. 450 nA

Standard operating temperature range TA: -40 to +85°C

CLKOUT enable/disable

Low aging rate

Ultra-miniature ceramic SMT package, RoHS-compliant and 100% lead-free: 2.0 x 1.2 x 0.85 mm

Available for Medical Implantable applications

Automotive qualification according to AEC-Q200 available

GENERAL DESCRIPTION 1.1.

The OV-7605-C8 combines an advanced very low power CMOS oscillator circuitry together with a 32.768 kHz

“tuning-fork” crystal in an ultra-miniature ceramic package. No external components are required. The very low

power consumption over a wide supply voltage and temperature range is the key feature of this product.

The frequency output on CLKOUT pin can be enabled/disabled by the CLKOE pin. The CLKOUT frequency is

enabled when CLKOE pin is connected to VDD. When the CLKOE pin is tied to GND the frequency is disabled and

the CLKOUT pin is high impedance (Hi-Z) .

The OV-7605-C8 is available for Medical Implantable applications.

APPLICATIONS 1.2.

The OV-7605-C8 oscillator module combines very low power consumption with a ultra-small ceramic package:

Smallest oscillator module (embedded XTAL) in a ultra-small 2.0 x 1.2 x 0.85 mm lead-free ceramic

package

Price competitive

The unique size and the competitive pricing make this product perfectly suitable for many applications:

Communication: IoT / Wearables / Wireless Sensors and Tags / Handsets

Automotive: M2M / Navigation & Tracking Systems / Dashboard / Tachometers / Engine Controller

Car Audio & Entertainment Systems

Metering: E-Meter / Heating Counter / Smart Meters / PV Converter / Utility metering

Outdoor: ATM & POS systems / Surveillance & Safety systems / Ticketing Systems

Medical: Glucose Meter / Health Monitoring Systems / Implantable

Safety: Security & Camera Systems / Door Lock & Access Control

Consumer: Gambling Machines / TV & Set Top Boxes / White Goods

Automation: PLC / Data Logger / Home & Factory Automation / Industrial and Consumer Electronics

Page 4

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 4/20 Rev. 1.0

ORDERING INFORMATION 1.3.

Example: OV-7605-C8 -20/+20ppm TA QC

Code

Operating temperature range

TA (Standard)

-40 to +85°C

Code

Qualification

QC (Standard)

Commercial Grade

QA

Automotive Grade AEC-Q200

QM

Medical Grade

Page 5

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 5/20 Rev. 1.0

2. BLOCK DIAGRAM

OUTPUT

CONTROL

OSC

32.768 kHz

CRYSTAL

CLKOUT

CLKOE

V

DD

GND

4

2

1

3

Hi-Z

PINOUT 2.1.

PIN DESCRIPTION 2.2.

Symbol

Pin #

Description

CLKOUT

1

Clock Output; push-pull; controlled by CLKOE. If CLKOE is HIGH (VDD), the CLKOUT pin drives the

square wave of 32.768 kHz. When CLKOE is tied to Ground, the CLKOUT pin is high impedance

(Hi-Z).

GND 2 Ground.

CLKOE

3

Input to enable the CLKOUT pin. If CLKOE is HIGH, the CLKOUT pin is in output mode. When

CLKOE is tied to Ground, the CLKOUT pin is high impedance (Hi-Z).

VDD 4 Power Supply Voltage.

OV-C8 Package: (top view)

7605

#1 #2

#4 #3

#1 CLKOUT

#2 GND

#3 CLKOE

#4 VDD

Page 6

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 6/20 Rev. 1.0

DEVICE PROTECTION DIAGRAM 2.3.

GND

V

DD

CLKOUT

CLKOE

2

1

3

4

Page 7

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 7/20 Rev. 1.0

3. ELECTRICAL SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS 3.1.

Absolute Maximum Ratings according to IEC 60134:

SYMBOL

PARAMETER

CONDITIONS

MIN

MAX

UNIT

VDD

Power supply voltage

-0.5

6.0

V

VI

Input voltage

-0.5

6.0

V

VO

Output voltage

-0.5

6.0

V

T

OPRA

Standard operating temperature TA

-40

85

°C

T

STO

Storage temperature

Stored as bare product

-55

125

°C

T

PEAK

Maximum reflow condition

JEDEC J-STD-020C

265

°C

OPERATING PARAMETERS 3.2.

For this Table, VDD = 3.0 V; GND = 0 V; TA = 25 °C; unless otherwise indicated.

Operating Parameters:

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNIT

Supply

VDD

Power supply voltage

1.6 5.5

V

V

DDSR

VDD slew rate

±0.5

V/ms

IDD

VDD Supply Current. CLKOUT

disabled.

(1)

VDD = 3.0 V, TA = 25°C

450

650

nA

VDD = 5.0 V, TA = 25°C

680

900

VDD = 3.0 V, TA = -40 to 85°C

1300

VDD = 5.0 V, TA = -40 to 85°C

1800

Input CLKOE

VI

Input voltage

GND -0.5

VDD +0.5

V

VIL

LOW level input voltage

GND

0.3 VDD

V

VIH

HIGH level input voltage

0.7 VDD

VDD

V

Output CLKOUT

VOH

HIGH level output voltage

IOH = -400 µA, VDD = 1.6 to 5.5 V

VDD – 0.4

V

VOL

LOW level output voltage

IOL = 400 µA, VDD = 1.6 to 5.5 V

GND +0.4

V

IOZ

Hi-Z leakage current

CLKOE = GND,

CLKOUT = VDD or GND

±100

nA

tr

Output rise time

CL = 10 pF, 10% to 90% VDD

30

70

ns

tf

Output fall time

CL = 10 pF, 10% to 90% VDD

30

70

ns

t

CKH

CLKOUT enable time

(see following diagram)

0

0.5

µs

t

CKL

CLKOUT disable time

(see following diagram)

0 µs

(1)

When CLKOUT is enabled (CLKOE is HIGH) the additional VDD supply current ∆IDD can be calculated as follows: ∆IDD = CL x VDD x f

OUT

e.g. ∆IDD = 10 pF x 3.0 V x 32’768 Hz = 980 nA

Page 8

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 8/20 Rev. 1.0

TYPICAL CHARACTERISTICS 3.3.

Supply current IDD vs. Supply voltage VDD: TA = 25°C, CLKOUT disabled

0

1

2

3

4 5

VDD [V]

700

500

300

0

I

DD

[nA]

100

400

600

6

200

800

TIMING WAVEFORMS 3.4.

CLKOUT enable/disable time:

32.768 kHz

CLKOUT

CLKOE

t

CKH

t

CKL

= 0

32.768 kHz

CLKOUT

CLKOE

t

CKH

= 0

Hi-Z Hi-Z

Hi-Z Hi-Z

t

CKL

= 0

Page 9

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 9/20 Rev. 1.0

OSCILLATOR PARAMETERS 3.5.

For this Table, VDD = 3.0 V; GND = 0 V; TA = 25 °C; unless otherwise indicated.

Oscillator Parameters:

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNIT

Xtal General

f

Crystal Frequency

32.768

kHz

t

START

Oscillator start-up time

50

500

ms

δ

CLKOUT

CLKOUT duty cycle

40 60

%

Xtal Frequency Characteristics

Δf/f

Frequency accuracy

±10

±20

ppm

Δf/V

Frequency vs. voltage

characteristics

1.6 V ≤ V

DD

≤ 5.5 V

±3

ppm/V

Δf/f

TOPR

Frequency vs. temperature

characteristics

T

OPR

= -40°C to +85°C

VDD = 3.0 V

-0.035

ppm

/

°C

2

(T

OPR-T0

)2 ±10%

ppm

T0

Turnover temperature

20 30

°C

Δf/f

Aging first year max.

±3

ppm

XTAL FREQUENCY VS. TEMPERATURE CHARACTERISTICS 3.5.1.

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

20

-50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90

∆f/f [ppm]

T0 = 25°C (± 5°C)

-0.035 * (T-T0)2 ppm (±10%)

Temperature [°C]

Page 10

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 10/20 Rev. 1.0

4. PACKAGE

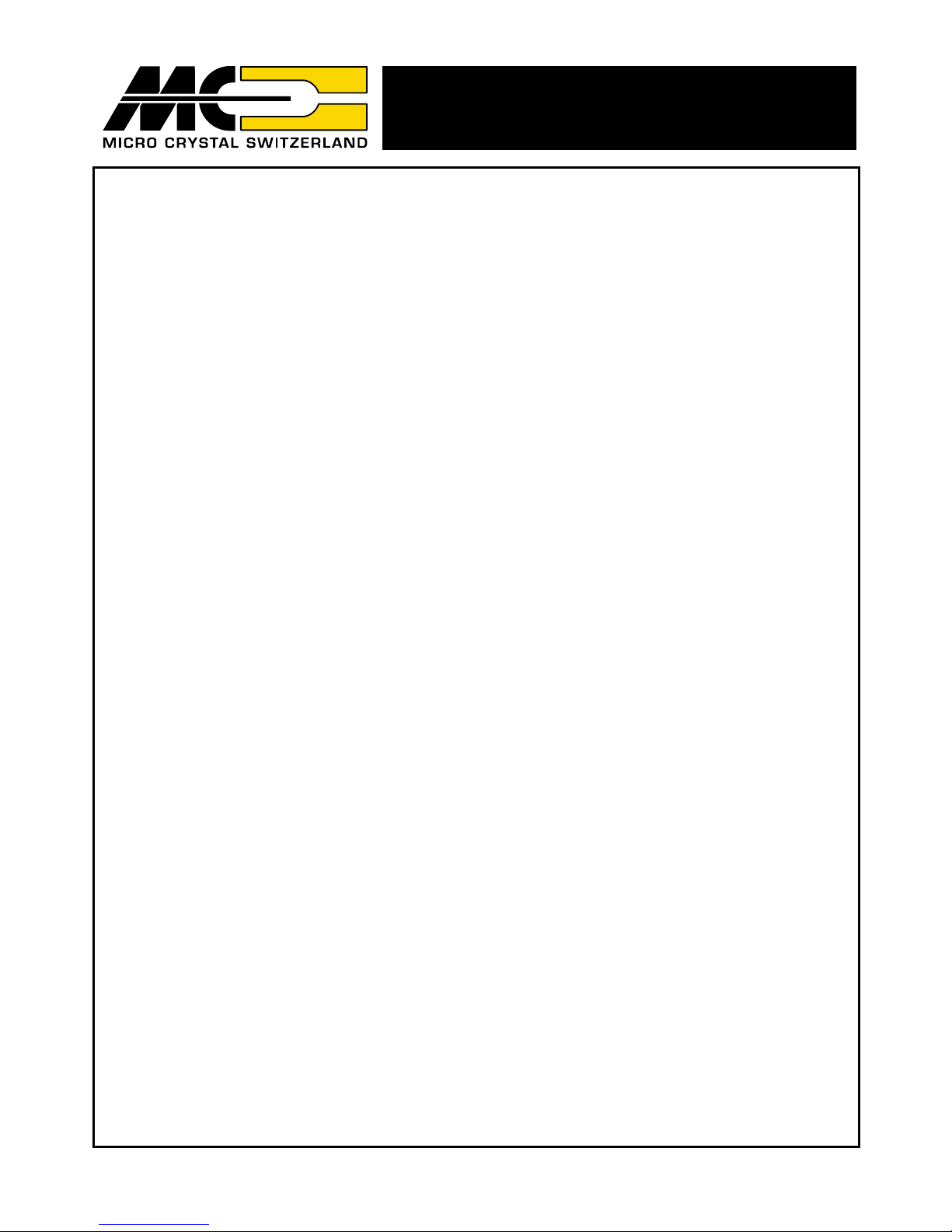

DIMENSIONS AND SOLDER PAD LAYOUT 4.1.

OV-C8 Package:

Package dimensions (bottom view): Recommended solder pad layout:

0,85 max

1,2

0,450,45

2.0

0,45

0,45

1

2

4

3

0,3

0,7 1,1 0,7

0,70,7

Tolerances: unless otherwise specified ± 0.1mm

Drawing: OV-7605-C8_Pack-drw_20170323

All dimensions in mm typical.

RECOMMENDED THERMAL RELIEF 4.1.1.

When connecting a pad to a copper plane, thermal relief is recommended.

GOOD

BAD

P

O

Page 11

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 11/20 Rev. 1.0

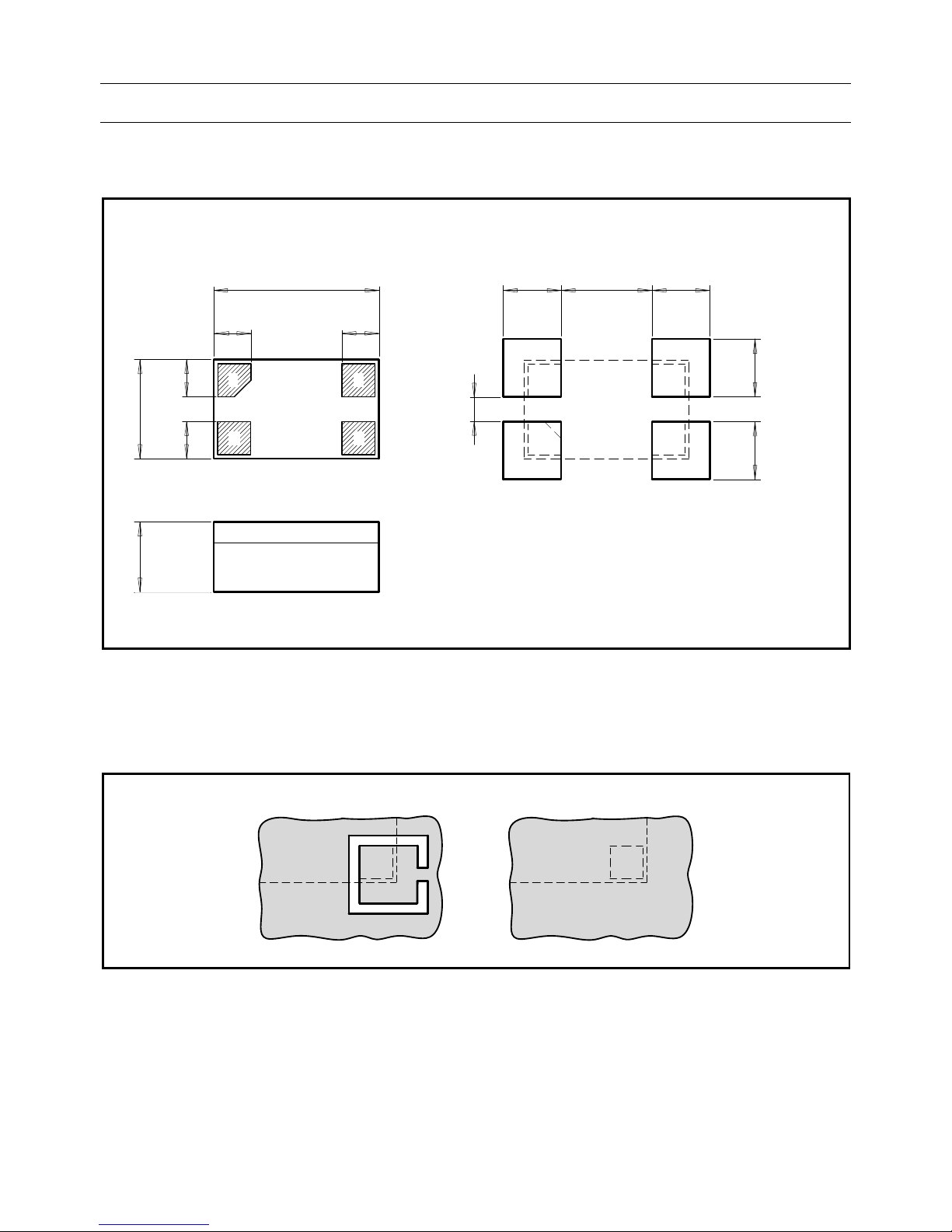

MARKING AND PIN #1 INDEX 4.2.

Laser marking OV-7605-C8 Package: (top view)

Automotive (QA) and Commercial (QC): Medical (QM):

M623A1

#1 #2

#4 #3

Production Date Code

Pin 1 Index

M1623A

#1 #2

#4 #3

Production Date Code

Pin 1 Index

Page 12

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 12/20 Rev. 1.0

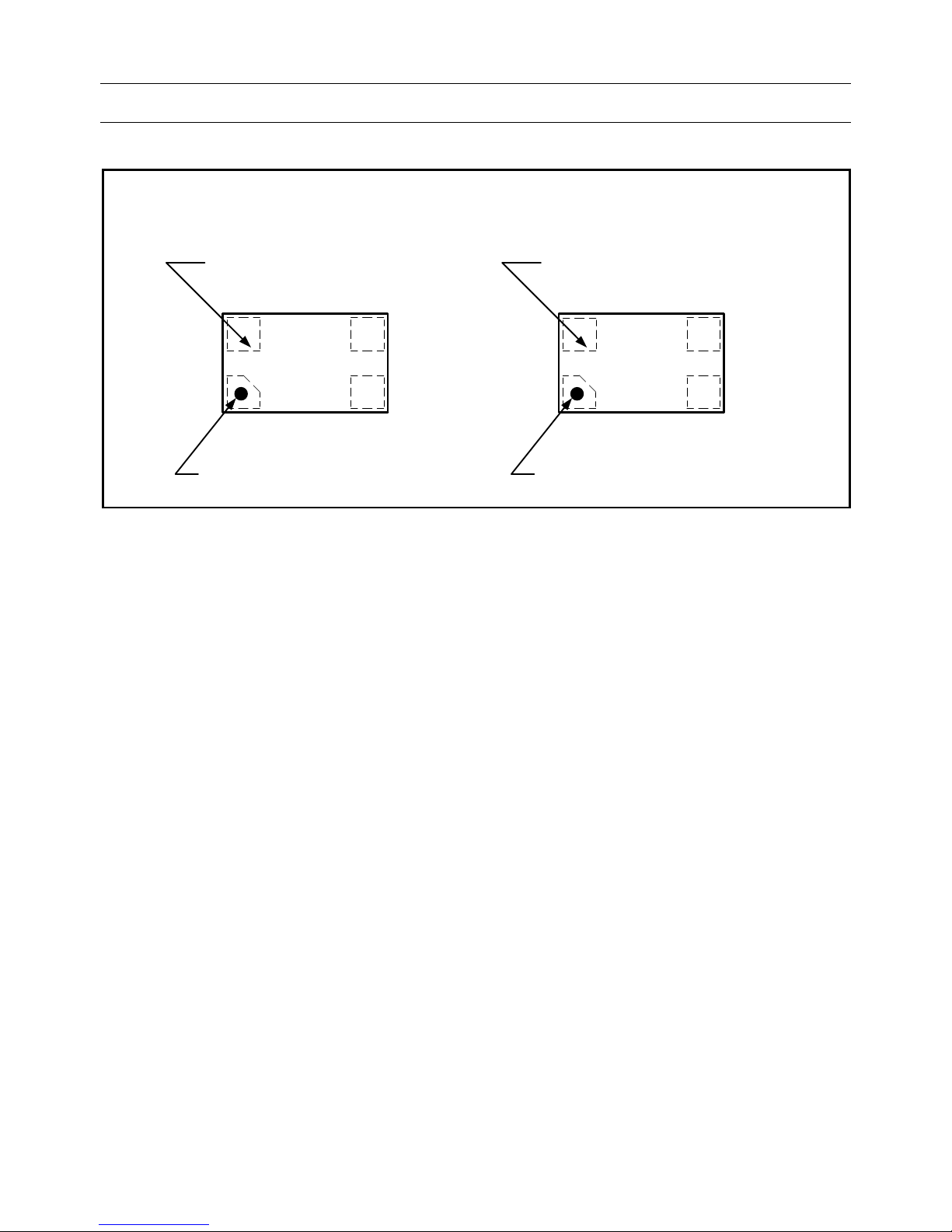

5. MATERIAL COMPOSITION DECLARATION & ENVIRONMENTAL INFORMATION

HOMOGENOUS MATERIAL COMPOSITION DECLARATION 5.1.

Homogenous material information according to IPC-1752 standard

Material Composition OV-7605-C8:

No.

Item

Component

Name

Sub Item

Material

Name

Material

Weight

Substance

Element

CAS

Number

Comment

(mg)

(%)

1

Resonator

Quartz Crystal

0.22

100%

SiO2 14808-60-7

2

Electrodes

Cr+Au

0.005

6%

Cr

Cr:

7440-47-3

94%

Au

Au:

7440-57-5

3

Housing

Ceramic

3.24

100%

Al2O3 1344-28-1

4

Lid

Ceramic

1.95

98.5%

Al2O3 1344-28-1

Ceramic Lid

Ni-plating

1.0%

Ni

Ni:

7440-02-0

Nickel plating

Au-plating

0.5%

Au

Au:

7440-57-5

Gold plating

5

Seal

Solder Preform

0.18

80%

Au80 / Sn20

Au:

7440-57-5

20%

Sn:

7440-31-5

6

Terminations

Internal and extrenal

terminals

0.30

80%

W

W:

7440-33-7

Tungsten

15%

Ni

Ni:

7440-02-0

Nickel plating

5%

Au 0.5 micron

Au:

7440-57-5

Gold plating

7

Resonator

attach

Gold bumps

0.012

100%

Au 7440-57-5

8

CMOS IC

Silicon

0.088

98%

Si

Si:

7440-21-3

Die pad plating

2%

Al

Al:

7429-90-5

9

Die attach

Gold bumps

0.018

100%

Au

Au:

7440-57-5

Unit weight

6.01

4

5 1 2

3

6

7

(Symbolic drawing)

8

9

Page 13

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 13/20 Rev. 1.0

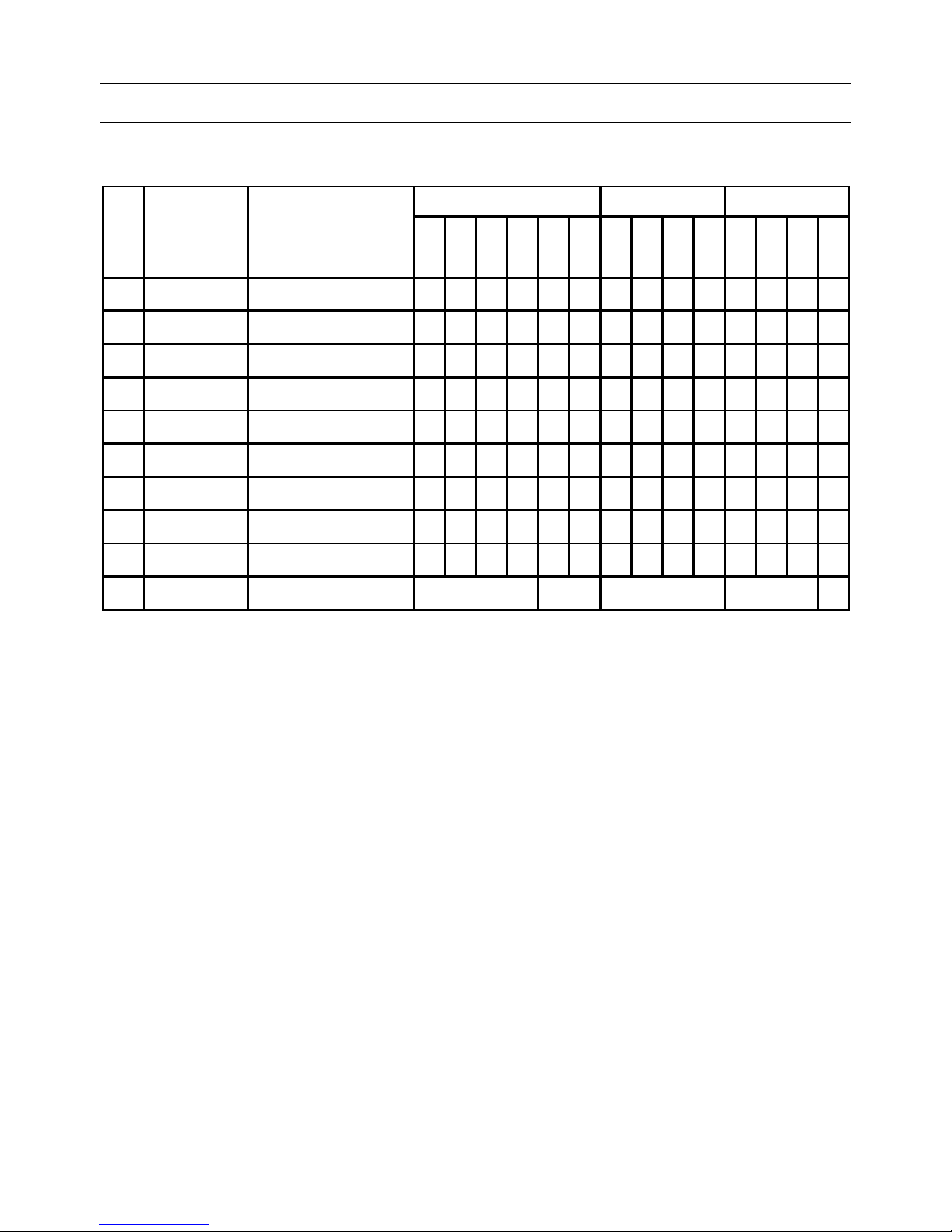

MATERIAL ANALYSIS & TEST RESULTS 5.2.

Homogenous material information according to IPC-1752 standard

No.

Item

Component

Name

Sub Item

Material

Name

RoHS

Halogen

Phthalates

Pb

Cd

Hg

Cr+6

PBB

PBDE F CI

Br I BBP

DBP

DEHP

DINP

1

Resonator

Quartz Crystal

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

2

Electrodes

Cr+Au

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

3

Housing

Ceramic

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd 4 Lid

Ceramic Lid & Plating

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd 5 Seal

Solder Preform

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

6

Terminations

Int. & ext. terminals

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

7

Resonator

attach

Gold bumps

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

8

CMOS IC

Silicon & Die pad plating

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd 9 Die attach

Gold bumps

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd MDL

Measurement Detection

Limit

2 ppm

5 ppm

50 ppm

0.003%

0.01%

nd = not detectable

Test methods:

RoHS Test method with reference to IEC 62321-5: 2013 MDL: 2 ppm (PBB / PBDE: 5 ppm)

Halogen Test method with reference to BS EN 14582:2007 MDL: 50 ppm

Phthalates Test method with reference to EN 14372 MDL: 0.003 % (DINP 0.01%)

Page 14

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 14/20 Rev. 1.0

RECYCLING MATERIAL INFORMATION 5.3.

Recycling material information according to IPC-1752 standard.

Element weight is accumulated and referenced to the unit weight of 6.01 mg.

Item

Material

Name

No.

Item

Component

Name

Material

Weight

Substance

Element

CAS

Number

Comment

(mg)

(%)

Quartz Crystal

1

Resonator

0.22

3.68

SiO2 14808-60-7

Chromium

2

Electrodes

0.0003

0.005

Cr

Cr:

7440-47-3

Ceramic

3 4 Housing

Lid

5.16

85.80

Al2O3 1344-28-1

Gold

2

4

5

6

7

9

Electrodes

Lid

Seal

Terminations

Resonator attach

Die attach

0.20

3.39

Au

Au:

7440-57-5

Tin 5 Seal

0.036

0.60

Sn

Sn:

7440-31-5

Nickel

4 6 Lid

Terminations

0.065

1.07

Ni

Ni:

7440-02-0

Tungsten

6

Terminations

0.24

4.00

W

W:

7440-33-7

Silicon

8a

CMOS IC

0.086

1.43

Si

Si:

7440-21-3

Aluminum

8b

CMOS IC

0.0018

0.029

Al

Al:

7429-90-5

Unit weight (total)

6.01

100

Page 15

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 15/20 Rev. 1.0

ENVIRONMENTAL PROPERTIES & ABSOLUTE MAXIMUM RATINGS 5.4.

Package

Description

SON-4

Small Outline Non-leaded (SON), ceramic package with ceramic lid

Parameter

Directive

Conditions

Value

Product weight (total)

6.01 mg

Storage temperature

Store as bare product

-55 to +125°C

Moisture sensitivity level (MSL)

IPC/JEDEC J-STD-020D

MSL1

FIT / MTBF

available on request

Terminal finish:

Ceramic

Tungsten

Nickel

Gold

5 µm

0.5 µm

Page 16

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 16/20 Rev. 1.0

6. APPLICATION INFORMATION

OPERATING OV-7605-C8 6.1.

OV-7605-C8 MCU

V

DD

GND

GND

CLKOUT

2

V

DD

V

DD

10 nF

1

CLKOE

GPIO

1

A 10 nF decoupling capacitor is recommended close to the device.

2

If CLKOE is HIGH (VDD), the CLKOUT pin drives the square wave of 32.768 kHz. When CLKOE is tied to

Ground, the CLKOUT pin is high impedance (Hi-Z).

Page 17

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 17/20 Rev. 1.0

SOLDERING INFORMATION 6.2.

Maximum Reflow Conditions in accordance with IPC/JEDEC J-STD-020C “Pb-free”

25

Time

Temperature

T

P

T

L

t

P

t

L

t 25°C to Peak

Ramp-up

ts

Preheat

Tsmin

Critical Zone

TL to T

P

Tsmax

Ramp-down

Temperature Profile

Symbol

Condition

Unit

Average ramp-up rate

(Ts

max

to TP)

3°C / second max

°C / s

Ramp down Rate

T

cool

6°C / second max

°C / s

Time 25°C to Peak Temperature

T

to-peak

8 minutes max

min

Preheat

Temperature min

Ts

min

150

°C

Temperature max

Ts

max

200

°C

Time Ts

min

to Ts

max

ts

60 – 180

sec

Soldering above liquidus

Temperature liquidus

TL

217

°C

Time above liquidus

tL

60 – 150

sec

Peak temperature

Peak Temperature

Tp

260

°C

Time within 5°C of peak temperature

tp

20 – 40

sec

Page 18

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 18/20 Rev. 1.0

HANDLING PRECAUTIONS FOR MODULES WITH EMBEDDED CRYSTALS 6.3.

The built-in tuning-fork crystal consists of pure Silicon Dioxide in crystalline form. The cavity inside the package is

evacuated and hermetically sealed in order for the crystal blank to function undisturbed from air molecules,

humidity and other influences.

Shock and vibration:

Keep the crystal / module from being exposed to excessive mechanical shock and vibration. Micro Crystal

guarantees that the crystal / module will bear a mechanical shock of 5000 g / 0.3 ms.

The following special situations may generate either shock or vibration:

Multiple PCB panels - Usually at the end of the pick & place process the single PCBs are cut out with a router.

These machines sometimes generate vibrations on the PCB that have a fundamental or harmonic frequency

close to 32.768 kHz. This might cause breakage of crystal blanks due to resonance. Router speed should be

adjusted to avoid resonant vibration.

Ultrasonic cleaning - Avoid cleaning processes using ultrasonic energy. These processes can damages

crystals due to mechanical resonance of the crystal blank.

Overheating, rework high temperature exposure:

Avoid overheating the package. The package is sealed with a seal ring consisting of 80% Gold and 20% Tin. The

eutectic melting temperature of this alloy is at 280°C. Heating the seal ring up to >280°C will cause melting of the

metal seal which then, due to the vacuum, is sucked into the cavity forming an air duct. This happens when using

hot-air-gun set at temperatures >300°C.

Use the following methods for rework:

Use a hot-air- gun set at 270°C.

Use 2 temperature controlled soldering irons, set at 270°C, with special-tips to contact all solder-joints from

both sides of the package at the same time, remove part with tweezers when pad solder is liquid.

Page 19

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 19/20 Rev. 1.0

7. PACKING & SHIPPING INFORMATION

Reel: 7” = 178 mm

Ø

61

,

5

Ø

178

max. 13

min. 8.4

Ø 13

60

°

60

°

1

,

8

Product Label

32

,

768

kHz

Carrier Tape:

Material: Polycarbonate

Width: 8 mm

Tape Leader and Trailer: Minimum length 300 mm

4

±0,1

2,23

±0,05

1,43

±0,05

2

±0,05

4

±0,1

Ø

1

,

0

+

0

,

25

Ø

1

,

5

+

0

,

1

3,5

±0,05

1,75

±0,1

8

+0,3

0,254

±0,02

0,83

±0,05

-0,1

0,061

Cover Tape

0,315

±0,05

All dimensions are in mm

OV-7605-C8_Tape-drw_20170327

Direction of feed

7605

7605

Cover Tape:

Tape: Polypropylene, 3M™ Universal Cover Tape (UCT)

Adhesive Type: Pressure sensitive, Synthetic Polymer

Thickness: 0.061 mm

Peel Method:

Medial section removal, both lateral stripes remain on carrier

Page 20

Micro Crystal

Low Power Clock Oscillator 32.768 kHz OV-7605-C8

June 2017 20/20 Rev. 1.0

8. COMPLIANCE INFORMATION

Micro Crystal confirms that the standard product Low Power Clock Oscillator OV-7605-C8 is compliant with “EU

RoHS Directive” and “EU REACh Directives”.

Please find the actual Certificate of Conformance for Environmental Regulations on our website:

CoC_Environment_OV&OM-Series.pdf

9. DOCUMENT REVISION HISTORY

Date

Revision #

Revision Details

June 2017

1.0

First release

Information furnished is believed to be accurate and reliable. However, Micro Crystal assumes no

responsibility for the consequences of use of such information nor for any infringement of patents or other

rights of third parties which may result from its use. In accordance with our policy of continuous

development and improvement, Micro Crystal reserves the right to modify specifications mentioned in this

publication without prior notice. This product is not authorized for use as critical component in life support

devices or systems.

Micro Crystal AG

Muehlestrasse 14

CH-2540 Grenchen

Switzerland

Phone +41 32 655 82 82

Fax +41 32 655 82 83

sales@microcrystal.com

www.microcrystal.com

Loading...

Loading...