Page 1

EC®

Ultra Low Gas Cooler

EC-30C

Instruction Manual

Version 1.00.02

Software Version 1.00

Page 2

Get help

For more information about using your M&C product, please contact

M&C TechGroup. We will answer your questions about commissioning,

handling and technical service. With our experience and know-how, we

will get your M&C product running in no time - and with no charge.

Please contact our service center in Ratingen, Germany,

for US Service Ventura, California

For faster service, please have this information ready when you contact

us:

Product model

Product serial number

M&C order or invoice number

Germany service center:

+49 2102 935 - 888

service-DE@mc-techgroup.com

US service:

+1 805-654-6970

info-usa@mc-techgroup.com

For online service and support information go to:

www.mc-techgroup.com

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 1

Page 3

Table of Contents

1 About this instruction manual 6

2 Important safety information 7

2.1 Intended use 7

2.2 Personal safety 7

2.3 Warning signs and definitions 7

2.4 Safety instructions 8

2.5 Working on electrical and electronic devices 9

2.6 Not certified in hazardous areas 9

3 Introduction 10

4 Product overview 11

4.1 Application 11

4.2 Principle 12

5 Technical Data 14

5.1 Max. possible water vapor dew point input [°C] / [°F] 15

5.2 Dimensions 16

6 Receiving the EC-30C 17

6.1 Product label and serial number 17

7 Using the EC-30C 18

7.1 Graphical user interface (GUI) 18

7.2 LED color coding and possible color combinations 18

7.3 Self-monitoring after powering-on the unit 19

7.4 Self-monitoring during operation 20

7.4.1 Power consumption readjustment 20

7.4.2 Pre-warning messages 20

7.5 Display during start-up of the EC-30C 21

7.6 Overview screen 23

7.7 Alarm and warning history 24

7.7.1 Error codes 27

7.7.2 Warning symbols 27

7.7.3 Alarm symbols 29

7.8 Temperature diagrams 32

7.8.1 Diagram of the pre-cooler unit (PCU) 32

7.8.2 Diagram of the deep cooling units (DCU 1 and DCU 2) 33

7.9 Parameter menu 34

7.9.1 Parameter settings 36

7.10 Device information 37

7.11 Service-Reset (qualified personnel only) 39

2 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 4

8 Installation instructions and mounting of the EC-30C 40

8.1 Installation instructions 40

8.2 Wall and rack mount 41

8.3 Mounting instructions for SR25.2 peristaltic pump (optional) 43

8.4 Tubing without heat exchanger purging (standard tubing) 44

8.4.1 Heat exchanger connections for tubing without purging 44

8.5 Tubing with heat exchanger purging for special requirements (optional) 46

8.5.1 Heat exchanger connections for tubing with purging 47

8.6 Duran-glass heat exchanger with GL-connections 48

8.7 PVDF- heat exchanger with PVDF-tube connectors 48

8.8 Electrical connections 49

8.8.1 mA-output 51

8.8.2 Liquid alarm sensor LA (optional) 51

8.8.3 Gas flow sensor FA 20 and gas flow meter FM 40 (optional) 52

9 Start-up 53

9.1 Preparation for start-up 53

9.2 Temperature chart of the start-up stages 54

10 Maintenance 58

10.1 Maintenance of the peristaltic pump type SR25.2 (optional) 58

10.1.1 Changing the pump tubing 59

10.1.2 Changing the contact pulley and springs 60

10.1.3 Cleaning the pump head 60

10.2 Changing the heat exchanger 61

10.3 Changing the 0-20 V-Module 62

10.4 Changing the buffer battery 63

10.5 Checking the temperature sensors 64

10.6 Changing the compressor unit 65

11 Decommissioning 66

12 Appendix 67

12.1 Overview of the EC-30C screens 67

12.2 How to configure the mA-output 68

12.2.1 How to calculate temperature based on measured mA-value 68

12.2.2 How to calculate mA-value based on measured temperature 69

12.3 Spare parts and consumables 70

12.4 Additional Information 71

12.5 Declaration of conformity 71

12.6 Certificates 72

12.7 Warranty 72

12.8 Liability and disclaimer 72

12.9 Storage 73

12.10 Shipping and handling 73

12.11 Proper disposal of the device 73

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 3

Page 5

13 About us 74

13.1 M&C‘s group of companies 74

13.2 The quality-oriented M&C catalog 75

13.3 Technical consulting services 76

13.3.1 Ideas, suggestions and feedback 76

4 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 6

Table of Illustrations

Fig. 1: Application example of the EC-30C 11

Fig. 2: Jet-Stream heat exchanger 12

Fig. 3: Front view: dimensions including optional peristaltic pumps 16

Fig. 4: Side view: dimensions including optional peristaltic pumps 16

Fig. 5: Graphic user interface 18

Fig. 6: Smiley symbols during self-test 19

Fig. 7: The smileys on the display after self-testing 19

Fig. 8: ‘Service‘-monitor: Self-test failed 20

Fig. 9: Start-up phase: first cooling phase 21

Fig. 10: Start-up phase: TKS reaches and/or exceeds ‘0 °C / 32 °F’-limit 22

Fig. 11: Start-up phase: Target temperature reached 22

Fig. 12: That’s how you reach the overview screen 23

Fig. 13: Overview screen 23

Fig. 14: How to reach the alarm and warning history 24

Fig. 15: Alarm and warning history 25

Fig. 16: How to chose an alarm or warning message 25

Fig. 17: How to scroll through stored messages 26

Fig. 18: Detailed information for a selected message 26

Fig. 19: How to reach the graphical temperature diagrams 32

Fig. 20: Temperature diagram of the pre-cooling unit 32

Fig. 21: Temperature diagram of the deep-cooling units 33

Fig. 22: How to reach the parameter menu (screen 1) 34

Fig. 23: Parameter menu, screen 1 34

Fig. 24: Parameter menu, screen 2 35

Fig. 25: How to reach the parameter settings 36

Fig. 26: How to reach the device information 37

Fig. 27: Device information 38

Fig. 28: Activating Service Reset (Qualified personnel only) 39

Fig. 29: Reset screen (Qualified personnel only) 39

Fig. 30: Min. assembly dimensions (unit with optional peristaltic pumps) 41

Fig. 31: Mounting rail for wall or rack mounting 42

Fig. 32: SR25.2: Mounting distance between pump motor and front panel 43

Fig. 33: Standard tubing: DCU 1 active, solenoid valve triggered, no FA 44

Fig. 34: Heat exchanger connectors (device with four optional peristaltic pumps) 45

Fig. 35: Tubing with purging: DCU 1 activ, solenoid valves triggered, no FA 46

Fig. 36: Heat exchanger connections, tubing with purging 47

Fig. 37: Electrical connections 50

Fig. 38: Temperature chart of the start-up stages 55

Fig. 39: Changing the pump tubing 59

Fig. 40: Resistor - temperature characteristic of the PT100 64

Fig. 41: Compressor: electrical connections 65

Fig. 42: Overview: screens 67

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 5

Page 7

1 About this instruction manual

Welcome to the M&C product manual. The goal of this document is to give a broad overview of the main functions of the EC-30C. It will help you to get started with using the

EC-3 0 C .

If you have any questions about this instruction manual, please contact M&C or one of our

official distributors.

Document: Instruction Manual EN for EC-30C

Version: 1.00.02

Software Version: 1.00

Release date: 10.2019

Copyright: © 2019 M&C TechGroup

Published by: M&C TechGroup Germany GmbH, Rehhecke 79

40885 Ratingen, Deutschland

This instruction manual does not claim to be complete and it may be subject to technical

modifications. We appreciate any feedback you may have to this document .

Any copy of this document or of its content is not allowed without explicit approval of

M&C.

With the release of this version all older manual versions will no longer be valid.

Registered trademarks

EC® is a registered trademark of M&C Techgroup Germany GmbH.

6 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 8

2 Important safety information

Please read this important safety information carefully before installing the EC-30C. Follow

these safety precautions during commissioning, start-up and regular operation.

2.1 Intended use

This product is designed to be used as an ultra-low cooler to reduce the dew-point of

humid sample gas to provide a stable and very low dew point.

Do not use this product for any other purpose. Improper use and handling can create

hazards and cause damage. For more information, please refer to the safety information in

this instruction manual.

2.2 Personal safety

Please read this instruction manual carefully before commissioning and operating the device. If you have any questions regarding the product or the application, please don’t hesitate to contact M&C or an M&C authorized distributor.

Please follow all instructions and warnings closely.

The product described in this instruction manual has been built and tested in our production facility. All ultra-low cooler are packed to be shipped safely. To ensure the safe operation and to maintain the safe condition, all instructions and regulations stated in this manual need to be followed.

This instruction manual includes all information regarding proper transportation, storage,

installation, operation and maintenance of this product by qualified personnel.

2.3 Warning signs and definitions

DANGER

WARNING

CAUTION

ATTENTION

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

ATTENTION is used to address practices not related to physical injury.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 7

Page 9

High

Voltage!

Caution, risk of electric shock!

High

Pressure!

Hot Surface! Caution, hot surface! Do not touch!

Hazardous

Gas!

Qualified

personnel

Safety

Gloves!

Pull Main

Plug!

Note

Caution, system might be under pressure.

Caution, hazardous and toxic gas! Do not inhale!

‘Qualified personnel’ are experts who are familiar with the installation,

mounting, commissioning and operation of these types of products.

Put on safety gloves for your protection.

Unplug power supply before opening!

‘Note’ indicates important information relating to the product or

highlights parts of the documentation for special attention.

Do you need

help?

Please contact M&C!

2.4 Safety instructions

Please follow these safety directions and instructions regarding installation, commissioning and operation of the EC-30C.

Qualified

personnel

Install the device only in protected areas, sheltered from sun, rain and moisture.

Operate the device only in the permitted temperature and pressure ranges. See details on

page 14 chapter ‘5 Technical Data’ .

Don‘t repair or maintain this product without M&C‘s specific maintenance- and service

instructions.

Installation, commissioning, maintenance, inspections and any repairs

of all M&C products and components must be carried out by qualified personnel in compliance with the current regulations.

8 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 10

When replacing parts, use only original M&C spare parts.

Pull Main

Plug!

If there is any indication that safe operation of the EC-30C is no

longer possible, turn off the power and disconnect the device from

the power supply immediately.

Then protect the defective device against accidental switch-on and mark it clearly as

defective.

2.5 Working on electrical and electronic devices

Only qualified and authorized personnel are permitted to work on equipment which operates on 115 or 230 VAC supply voltage. Please be sure to observe the generally accepted

engineering standards and all of your national and local regulations.

Note

High

Voltage!

Before connecting the device, please make sure that the supply

voltage matches the specified voltage on the product label.

Protect yourself and others against damages which might be caused

by high voltages. Disconnect the power supply before opening the

device for access. Make sure that all external power supplies are

disconnected.

Please make sure to take appropriate precautions even by working on unplugged or

low-voltage devices. Unplugged devices need to be properly grounded to prevent damage to internal electronics from electrostatic discharges (ESD).

2.6 Not certified in hazardous areas

This device is NOT certified to be installed or operated in hazardous areas.

Explosion hazard!

WARNING

For general purpose areas ONLY. Don’t use the EC-30C in hazardous

areas.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 9

Page 11

3 Introduction

Congratulations on your purchase of the EC-30C ultra-low cooler. We know from experience that you surely will enjoy this reliable and durable M&C product.

M&C is one of the premium and performance-driven companies in the business. With this

in mind, our customers benefit from a number of significant advantages. We offer proven,

durable and advanced products and solutions. We have listened to our customers needs,

when designing our products, allowing M&C to provide premium products at a comparatively lower cost over the entire life cycle.

Our products and special systems are designed and tested in our own facilities by our

highly skilled staff that are always quality-oriented. We carefully package our goods and

send them to our customers worldwide.

With our 30-years of experience in customer specific solutions for almost 30 different industries and applications, it is our goal to supply you with an excellent product. Our products offer fast commissioning, safe and reliable day-to-day operation and low

maintenance.

We expect that our products fully meet your expectations. If you have any question regarding the product or the application, please don’t hesitate to contact M&C or your M&C

authorized distributor. Our service does not end with delivery of the products.

Thanks again for your purchase.

We appreciate your business.

10 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 12

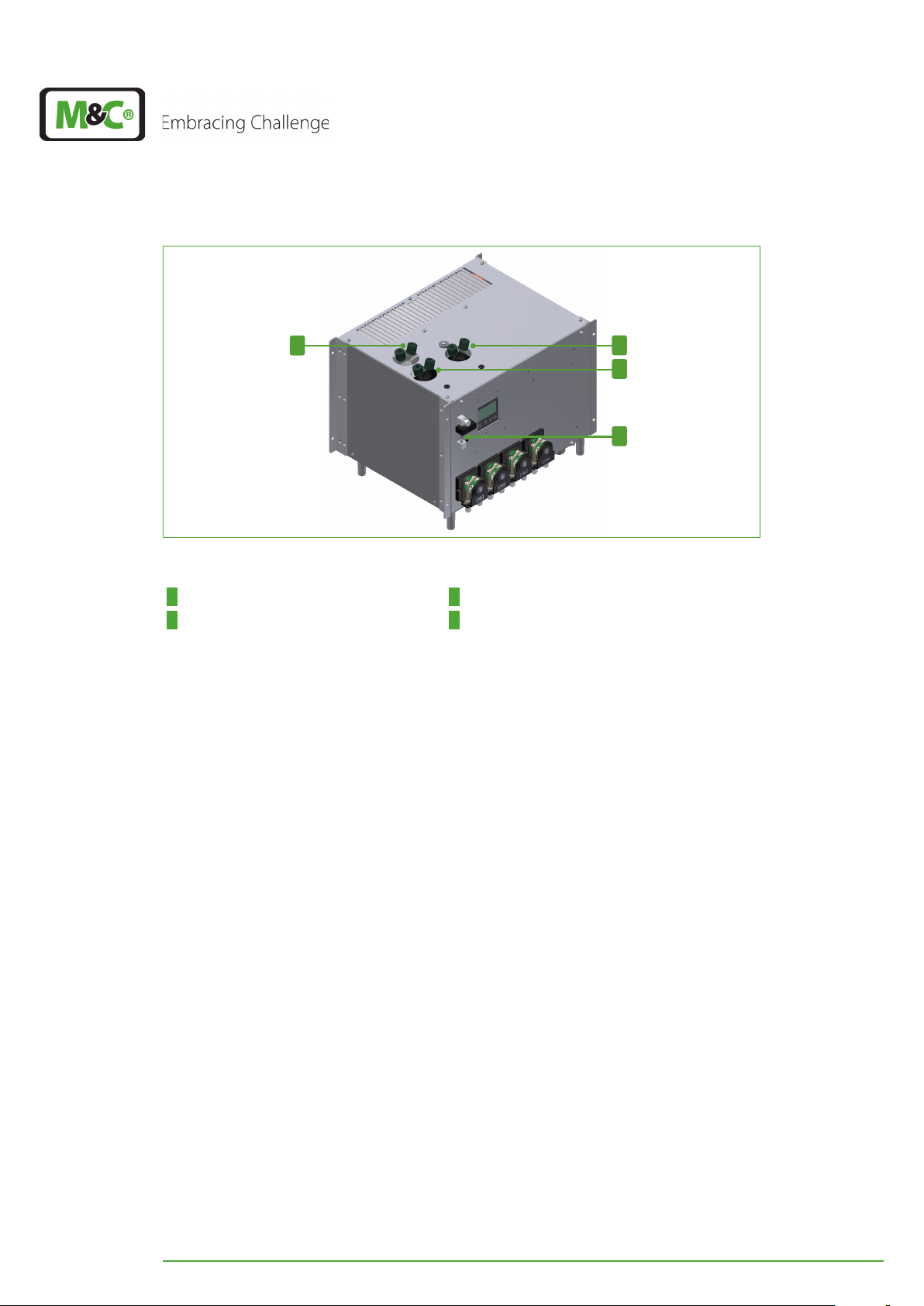

4 Product overview

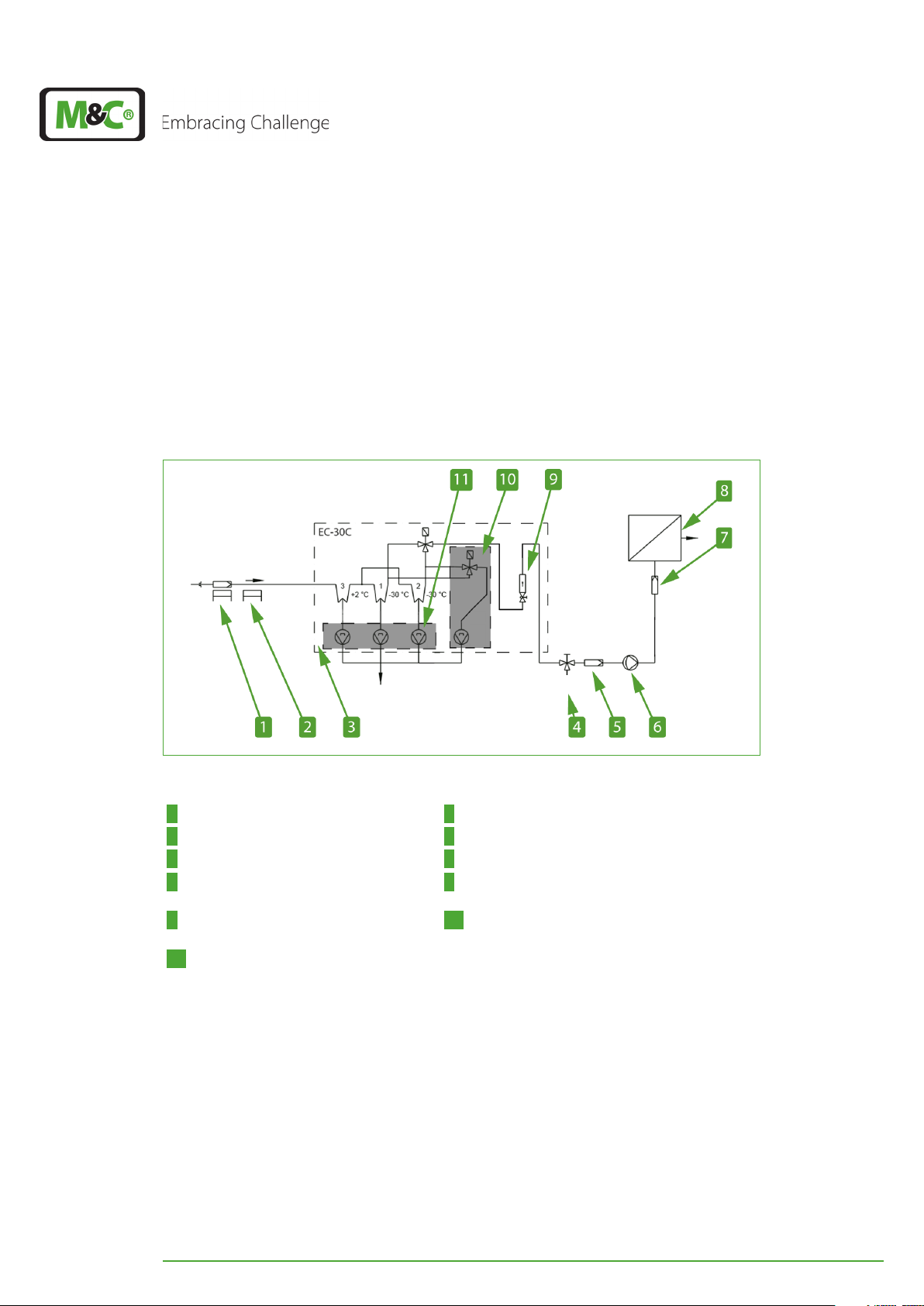

4.1 Application

The M&C ultra-low cooler EC-30C is used in the gas analysis technique to reduce the dew

point of humid sample gases and to provide a stable and very low dew point. This eliminates condensate built-up and aerosol formation in the analyzer.

Due to the extremely stable and low gas dew point, there are no water vapor cross-sensitivity and volumetric errors.

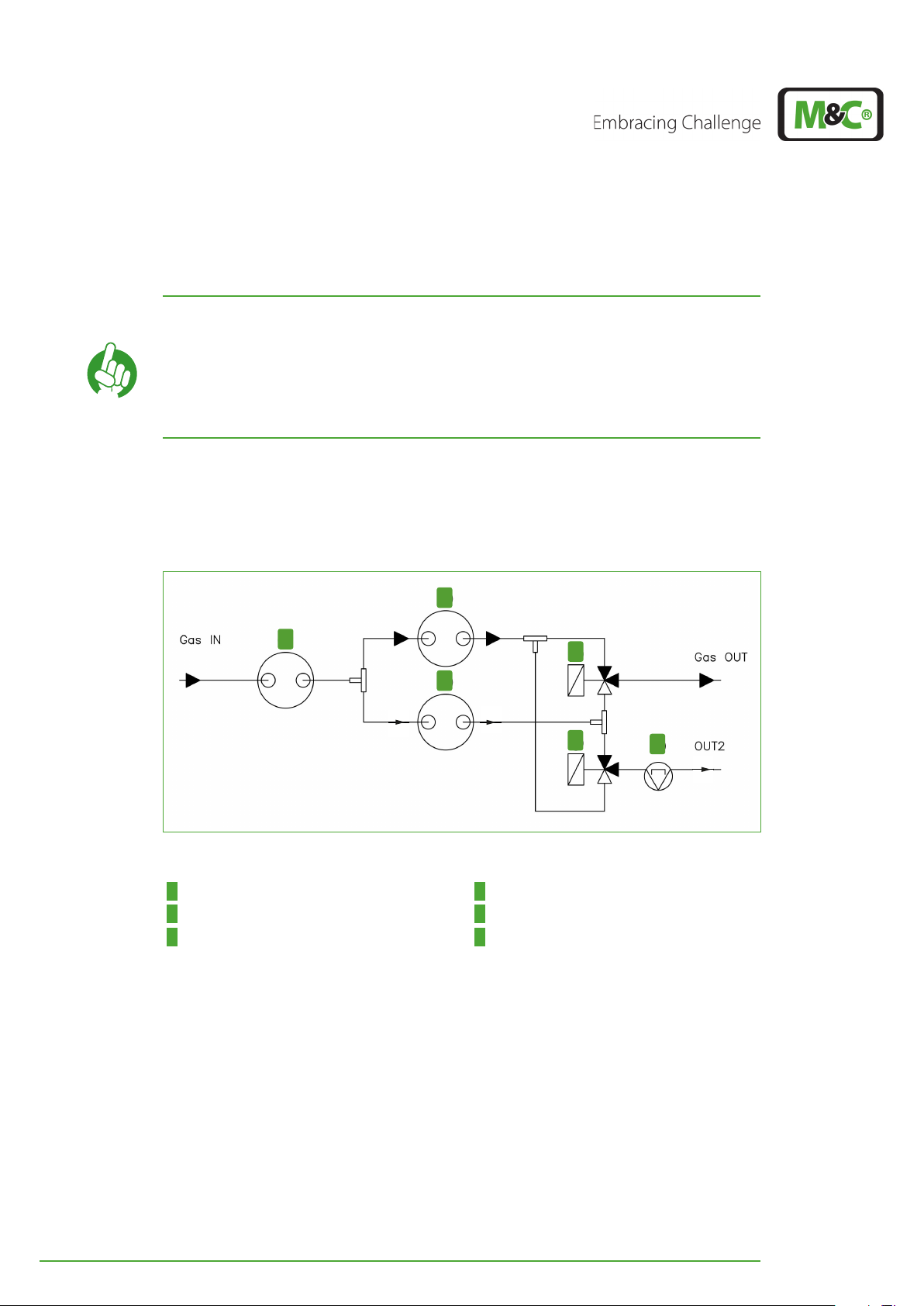

Sample gas IN

Condensate OUT

Test gas IN

Fig. 1: Application example of the EC-30C

1 Gas sample probe SP2000-H 2 Electrically heated sample line 4M4/6

3 Ultra-low cooler EC-30C 4 3-way ball valve 3L/PV-1

5 Filter 6 Bellows pump MP-F

7 Aerosol filter CLF -5/W optional depend-

ing on application

8 Analyzer, e.g. PMA1000

9 Flow meter FM40, 25-250 Nl/h 10 Option: 4.peristaltic pump with solenoid valve

(heat exchanger purging)

11 O ption: three SR25.2 peristaltic pumps

(condensate removal)

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 11

Page 13

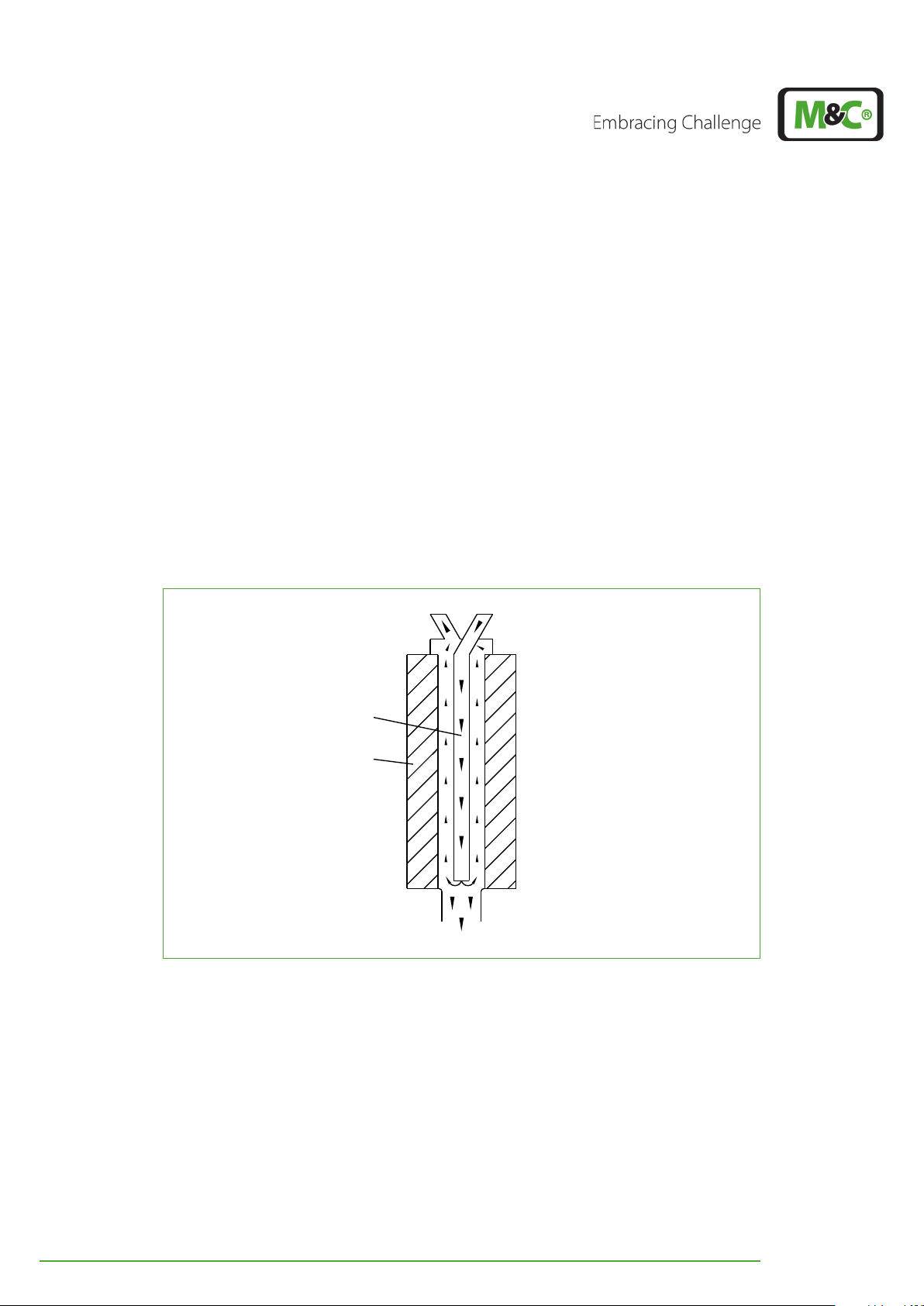

4.2 Principle

The M&C gas cooler EC-30C is a two stage combination of compressor and Peltier cooler.

The automatic defrost function of the dual deep freezer unit ensures 100 % availability

during operation.

The micro processor-controlled electronics of the EC-30C in combination with the graphical display, offers a high degree of functionality, convenience in use, and safe operation.

The EC-30C is built for 24/7 hours of operating time. The cooling capacity of 130 kJ/h is

constant, even under maximum allowed ambient temperature.

A capacity reserve compensates parts of the natural aging process and maximizes the

service life of the EC-30C.

The pre-cooler unit is equipped with a Jet-Stream heat exchanger. The heat exchanger is

cooled down to the constant temperature of +2 °C (35.6 °F) by a separate, microprocessor

controlled, compressor cooling unit.

Sample gas - OUT

M&C Jet-Stream

heat exchanger

Cooling block

Condensate - OUT

Sample gas - IN

Fig. 2: Jet-Stream heat exchanger

The Jet-Stream heat exchanger in the pre-cooler unit removes a large amount of condensate, this ensures a safe and reliable pre-drying of the sample gas. An additional external

vessel to separate the condensate is under normal conditions not necessary. The cooling

unit of the pre-cooler dissipates the heat of the Peltier elements.

The dual deep freezer unit is equipped with two modified Jet-Stream heat exchangers.

Two separate pairs of Peltier elements are cooling the heat exchangers down to a constant

temperature between -20 °C (~-4 °F) and -30 °C (~-22 °F). The factory setting is -30°C (~-22

°F).

12 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 14

The EC-30C switches automatically every 3 hours between the two deep freezer units. The

deep freezer which is currently not in use, will be defrosted to prevent freezing of the heat

exchanger and clogging of the gas lines. Upon special request, this cycle of 3 hours can be

reduced directly at your facility by M&C personnel.

The new graphical user interface is icon-based for easy and intuitive navigation. The messages are displayed in form of easy-to-understand icons. Features like time stamps for the

alarm message history, periodically self-monitoring and pre-warning messages to inform

about upcoming maintenance work ensure a maximum degree of comfort, ease-of-use

and safety of operation of the EC-30C.

The smart periodically self-monitoring of the EC-30C, helps to plan upcoming maintenance and service work to prevent unnecessary down time.

A configurable mA-output is part of the EC-30C standard version.

Three optional peristaltic pumps SR-25.2 for automatic condensate removal can be installed into the unit.

An internal flow meter including an optical flow sensor can be installed into the unit as an

option. Another option would be an external flow meter including an optical flow sensor

or an external humidity sensor.

A fourth optional peristaltic pump can be installed in combination with a second solenoid

valve to provide permanently fresh test gas to the inactive cooling unit. This makes sure

that even in systems, where water vapor cross sensitivity exists, there are no visible peaks

at switching of the dual deep freezer unit. This also prevents short peaks in the sample gas

concentration due to stagnant gas.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 13

Page 15

5 Technical Data

Series EC

Part No.: 02 K 6100 (a)*

Gas connection DN 4/6 tube connector

Condensate connections 3x tube connector GL25-12 mm

Material of sample contacting

parts

Single stream, gas flow rate 90 Nl/h – 250 Nl/h

Gas pressure max. 3 bar abs.

Ambient temperature +5 °C to +45 °C (+41 °F to +113 °F)

Storage temperature -20 °C to +60 °C (~-4 °F to +140 °F)

Sample outlet dew point -20 °C to -30 °C (default -30 °C) (~-4 °F to ~-22 °F, default

Sample inlet temperature max. 180 °C (+356 °F)

Water vapor dew point input max. 70 °C (+158 °F)

Cooling capacity max. 130 kJ/h** (at given input conditions)

Main power connection /

Power consumption

Start up time < 60 min

Dead space approx. 160 ml (5.41 fl. oz)

∆P at 250 Nl/h flow rate 5 mbar

Electrical connection 2.5 mm2 (0.0039 in2) terminals, cable glands PG (1 x 12

mA-output 0 - 20 mA / 4 - 20 mA, max. 500 Ohm load (including

Relay output alarm 1 changeover contact: 230 V AC 3 A, 24 V DC 3 A

Relay output warning 1 NO contact, 24 V (AC/DC), 0.5 A

Relay output freezer units I and II1 NO contact, 24 V (AC/DC), 0.5 A

Case protection IP20, EN 60529

Electrical equipment standard EN 61010

Method of mounting 19" rack or wall mount

Case color RAL 9003

Dimension (w x h x d) 84 HP x 8U (with connections) x 360 mm (14.17“)

Weight 39.34 kg (86.73 lbs)

©

Version EC-30C

Duran Glass, PTFE, PVDF

~-22 °F)

230 V, 50 Hz, 380 VA

or* Part-No. …-a=115 V, 60 Hz, 380 VA

mm, 2 x 16 mm, 2 x 20 mm)

cable resistance),

alarm: COM & NC closed

No alarm: COM & NO closed

warning: open

unit I on: closed

unit II on: open

* (a)Addition to the part number for EC-30C with 115 V

** For the given input conditions, please have a look at the table on page 15 chapter ‘5.1 Max.

possible water vapor dew point input [°C] / [°F]’ .

14 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 16

Options

Part-No.: 01 P 9145 Peristaltic pump SR25.2, to mount into the EC-30C (See

spare parts for SR25.2 on page 70 chapter ‘12.3

Spare parts and consumables’ )

Part-No.: 03 F 3000 Aerosol-Filter CLF-5: External mounting in the outlet of

an ultra low gas cooler EC-30C when sample tends to

form aerosols.

Technical data see data sheet 7.7 Fluid particle filter

CLF-5

Part-No.: 02 K 9700 (a)* Heat-exchanger purging: 4. peristaltic pump with

solenoid valve

Part-No.: 03 E 1001 LA 1S humidity sensor, 4 m (13.12 ft) cable with cable

breakage detection

Part-No.: 03 E 3500 FA 20 (Flow sensor with 0.45 m [1.48 ft] cable)

Part-No.: 02 K 9710 FM 40 (Flow meter, 25-250 Nl/h)

* (a)Addition to the part number for EC-30C with 115 V

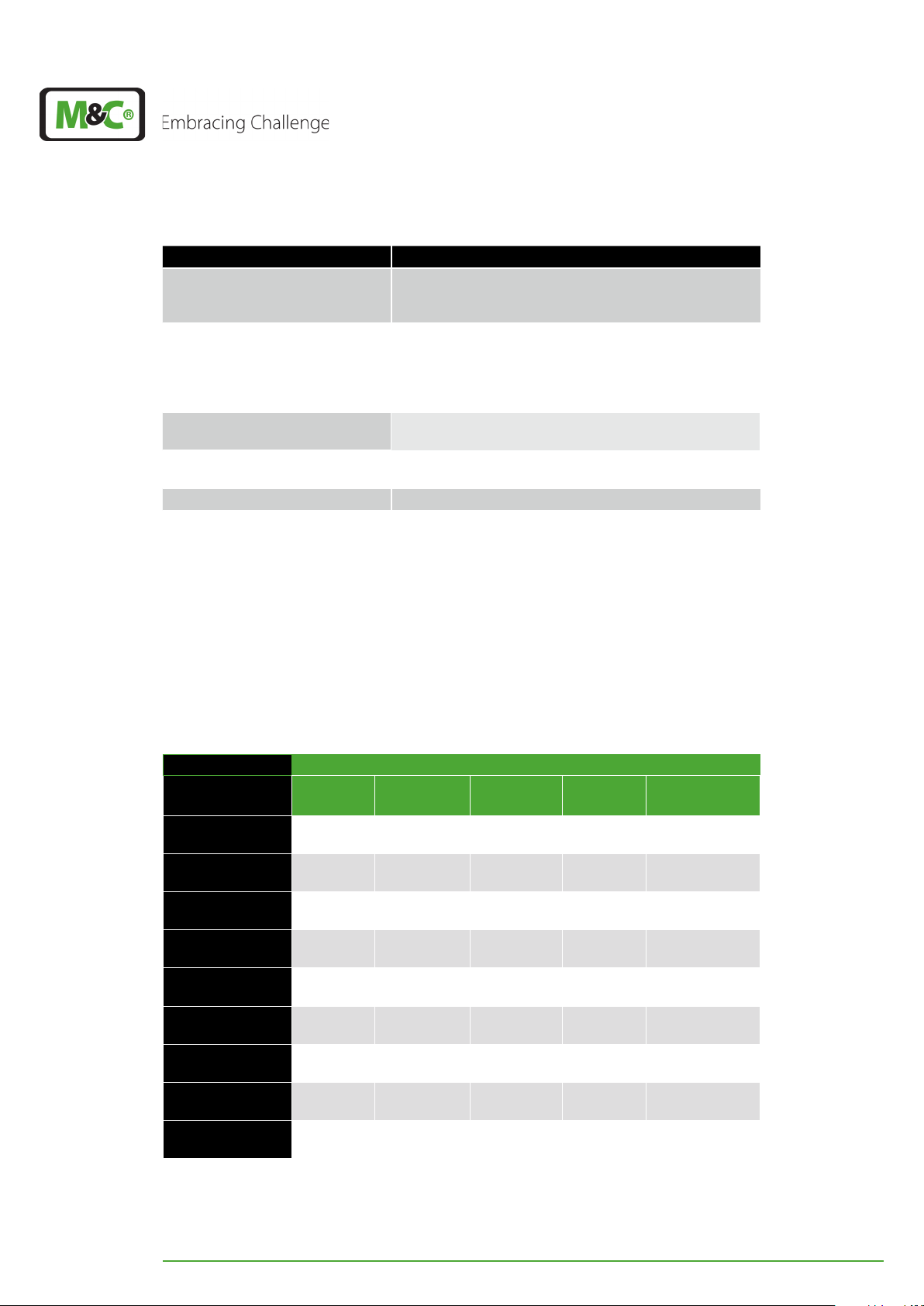

5.1 Max. possible water vapor dew point input [°C] / [°F]

This table shows the max. possible water vapor dew point input (°C) / (°F) depending on

the incoming gas temperature and the flow rate.

These values correspond to the maximum cooling capacity of 130 kJ/h. The maximum

possible water vapor dew point input (°C) / (°F) indicated must not be exceeded.

Incoming gas temperature in °C (°F)

Gas flow [l/h] 70

(158 °F)

90 70

(158 °F)

110 68

(154.4 ° F )

130 65

(149 °F)

150 62

(143.6 °F)

170 59

(138.2 °F)

190 57

(134.6 °F)

210 55

(131 ° F)

230 53

(127. 4 ° F)

250 52

(125.6 ° F)

90

(194 °F)

70

(158 °F)

67

(152. 6 °F)

64

(147.2 ° F )

61

(141. 8 °F)

58

(136.4 ° F )

56

(132. 8 ° F )

54

(129. 2 ° F )

52

(125.6 ° F)

50

(122 °F)

120

(248 °F)

69

(156.2 °F)

66

(150.8 ° F )

63

(145.4 °F)

59

(138.2 °F)

56

(132. 8 ° F )

54

(129. 2 ° F )

52

(125.6 ° F)

49

(120.2 °F)

47

(116.6 °F)

150

(302 °F)

68

(154.4 ° F )

65

(149 °F)

61

(141. 8 °F)

58

(136.4 ° F )

55

(131 ° F)

52

(125.6 ° F)

49

(120.2 °F)

47

(116.6 °F)

44

(111. 2 ° F)

180

(356 °F)

67

(152. 6 °F)

63

(145.4 °F)

59

(138.2 °F)

56

(132. 8 ° F )

53

(127. 4 ° F)

50

(122 °F)

46

(114 . 8 ° F)

43

(109.4 °F)

41

(105.8 °F)

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 15

Page 17

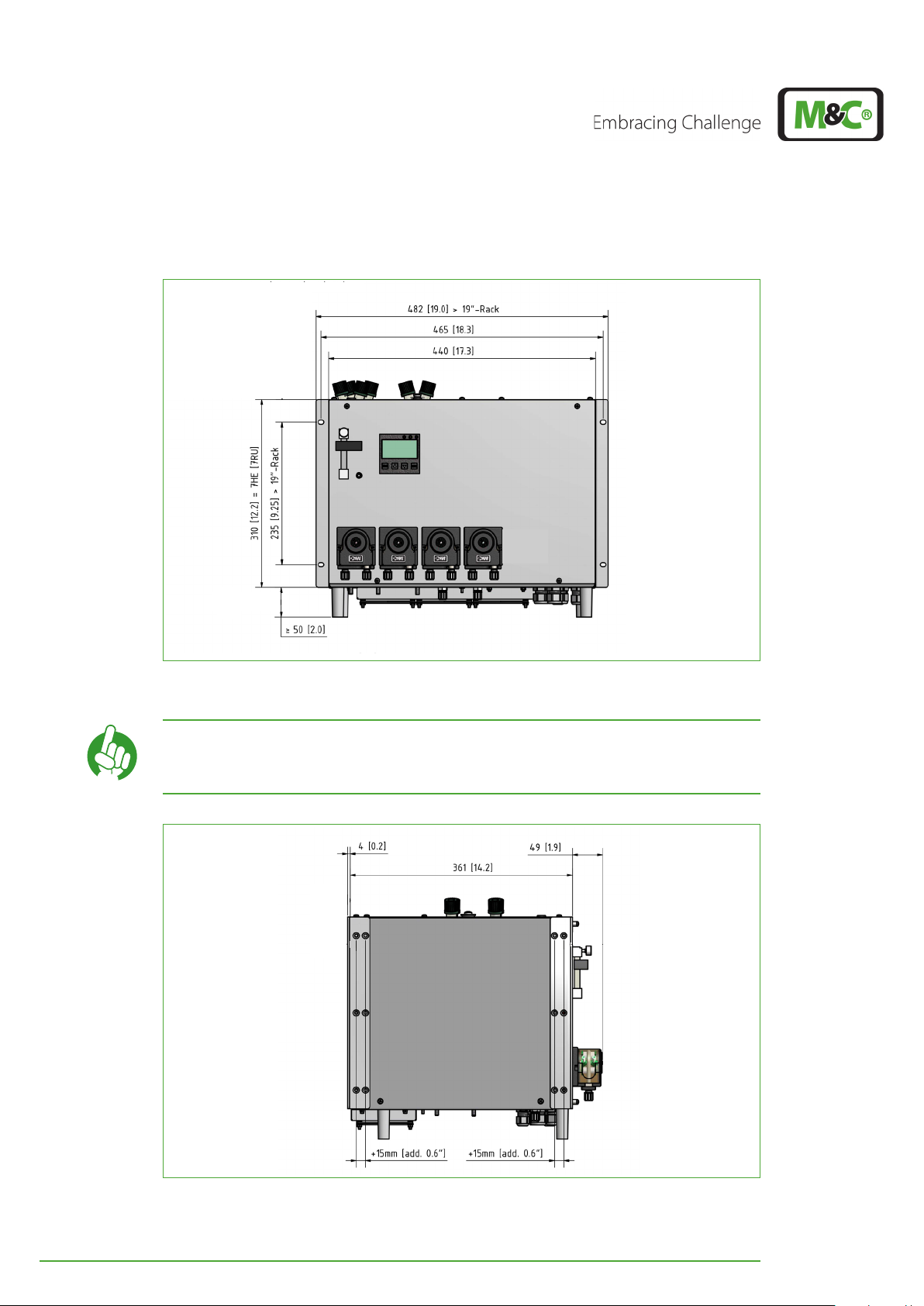

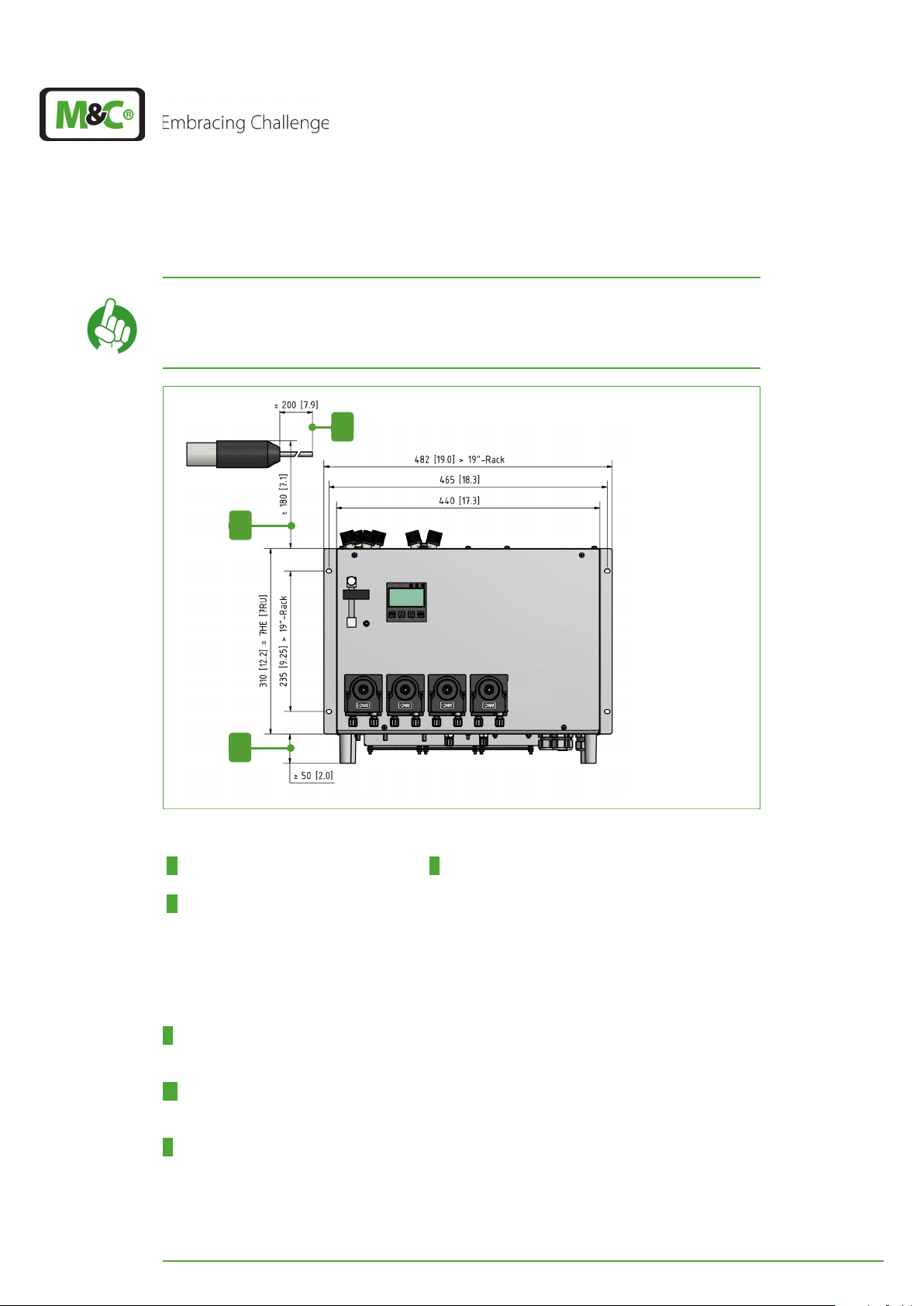

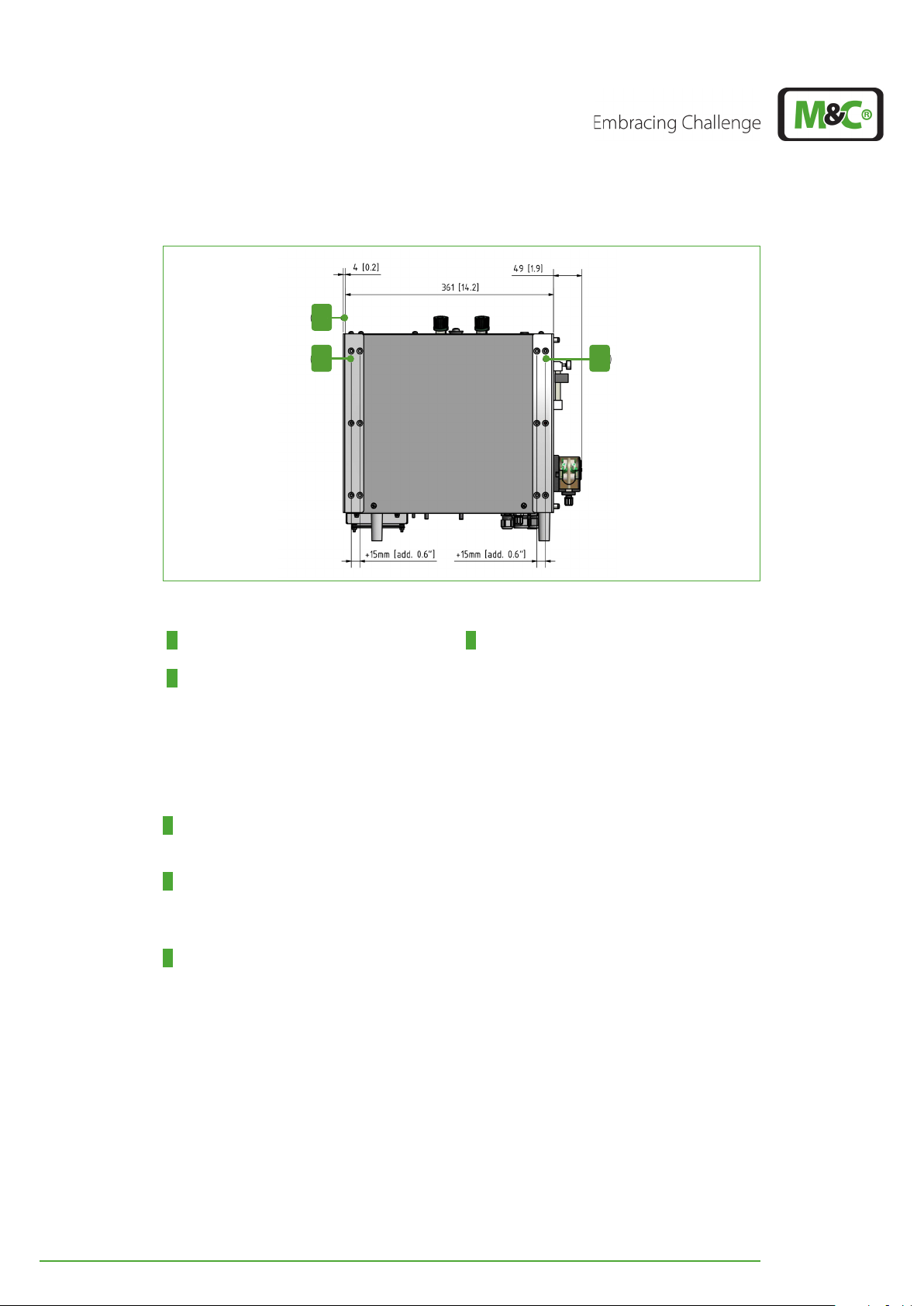

5.2 Dimensions

Dimensions in mm [Inch]

Fig. 3: Front view: dimensions including optional peristaltic pumps

Dimensions in mm [Inch]

Note

You will find mounting directions on page 40 chapter ‘8 Installation instructions and mounting of the EC-30C’ .

Fig. 4: Side view: dimensions including optional peristaltic pumps

16 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 18

6 Receiving the EC-30C

Heavy device!

CAUTION

Note

The ultra-low cooler EC-30C is a complete pre-installed unit.

Please remove the cooler carefully from the packaging. Check the scope of the delivery

specified on the delivery note. Please make sure that you have received all items stated on

the delivery note.

Please check the unit for any transport damages after receipt and report any complaints to

the transport company immediately.

For transport reasons, the heat exchangers are not mounted inside of the cooler. They are

included in the packaging, but wrapped separately. Connect the heat exchangers properly before commissioning.

Risk of injury when handling heavy equipment.

Do not lift, move or carry the device without help. A second person is

required to lift, move or carry the device.

The cooler should always be transported and stored in an upright

position, with the equipment feet facing downwards to ensure that

the oil in the closed compressor circuit cannot run out of the compressor case.

If the device is transported on its back, it needs to be standing in an

upright position for at least 2 hours before turning on.

Follow the instructions to connect the tubing to the heat exchangers

Note

on page 40 chapter ‘8 Installation instructions and mounting of the

EC-3 0 C’

6.1 Product label and serial number

There are two product labels on the EC-30C. One of them is located on the right side of the

cooler and the second one is inside the cooler housing on the bottom plate. Please refer

to this serial number if you have any questions about the device or if you need to order

spare parts or consumables.

Note

The EC-30C features two serial numbers. One serial number is for the

device and the other one for the display controller.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 17

Page 19

7 Using the EC-30C

PRG

ESC

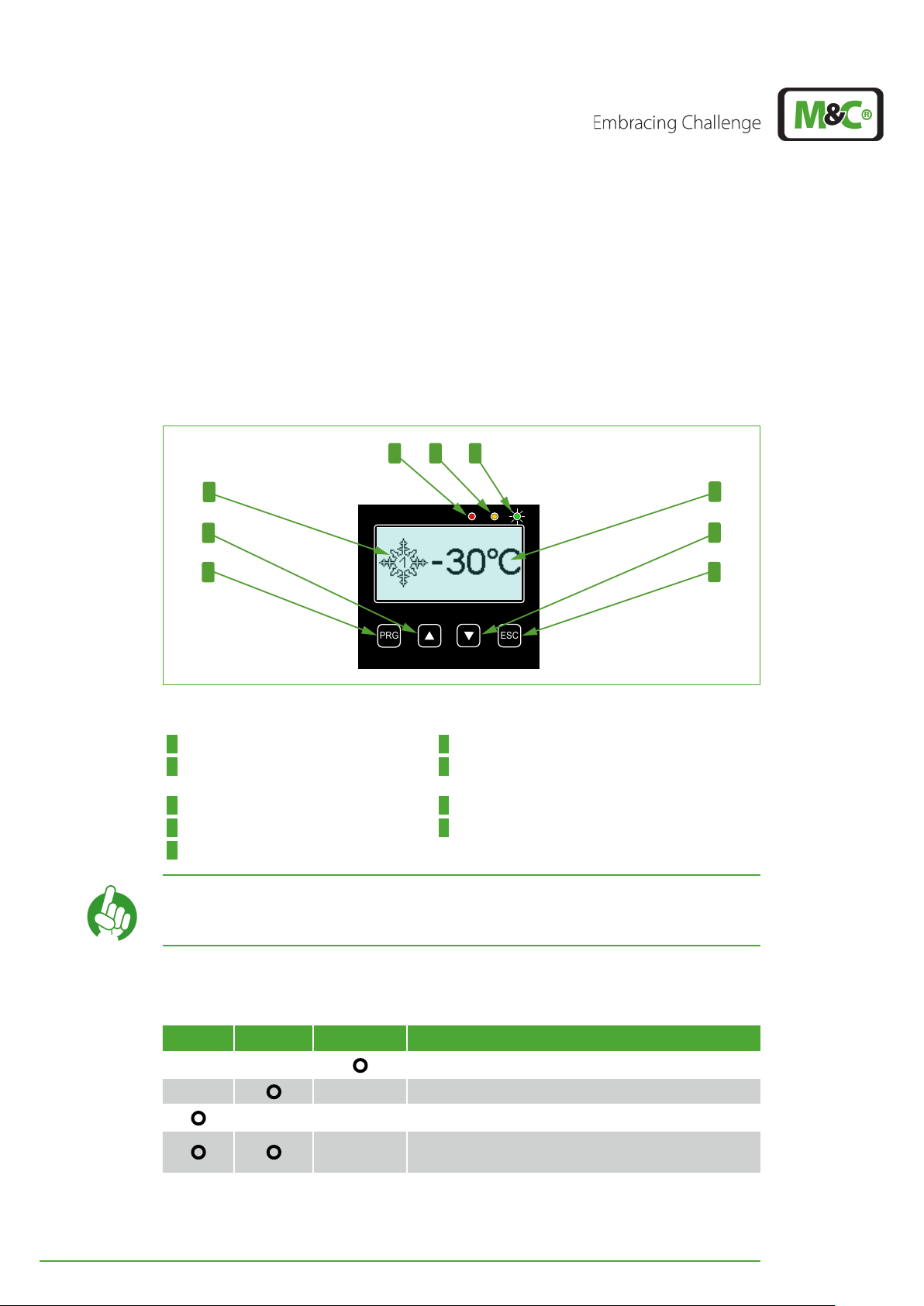

7.1 Graphical user interface (GUI)

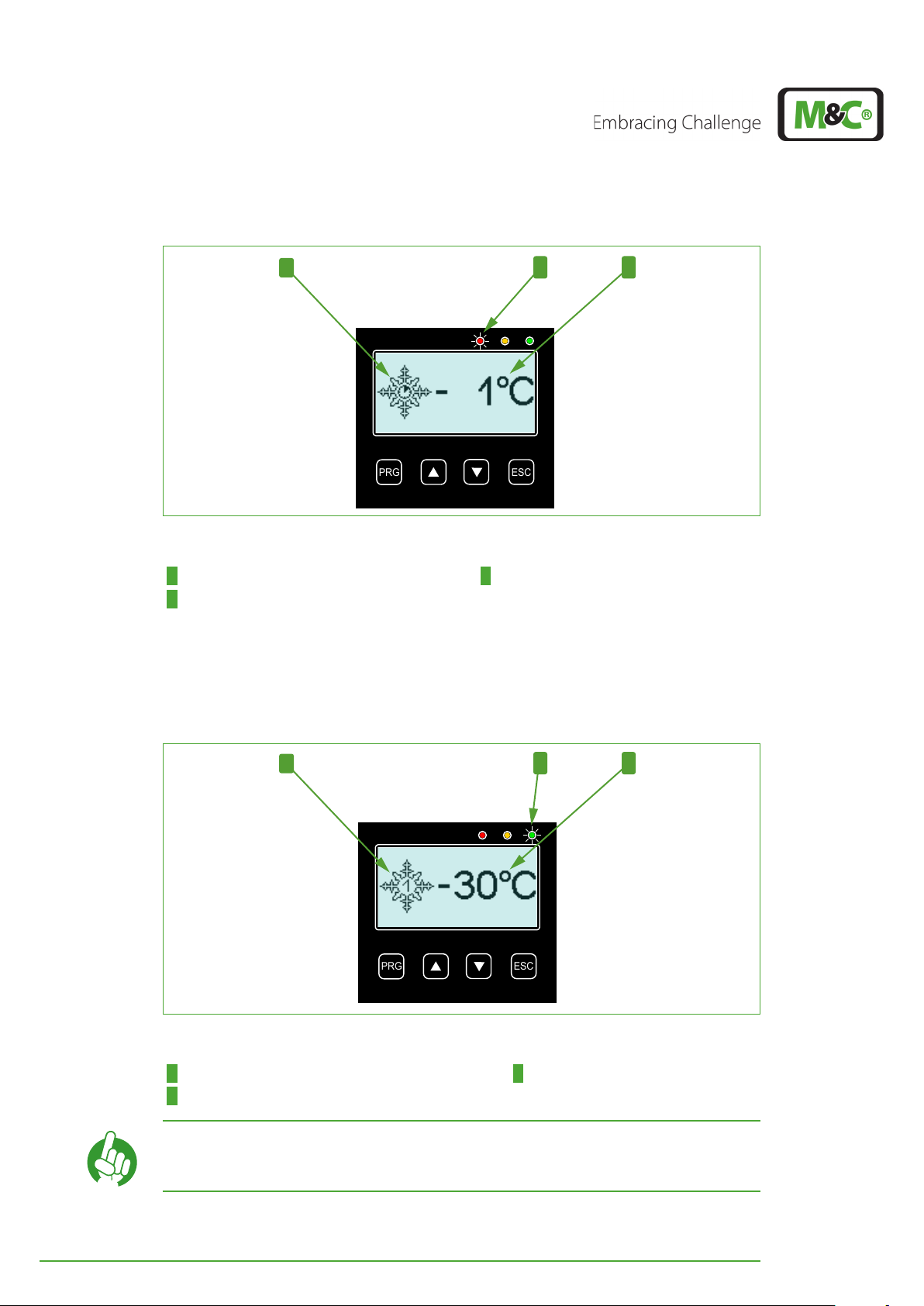

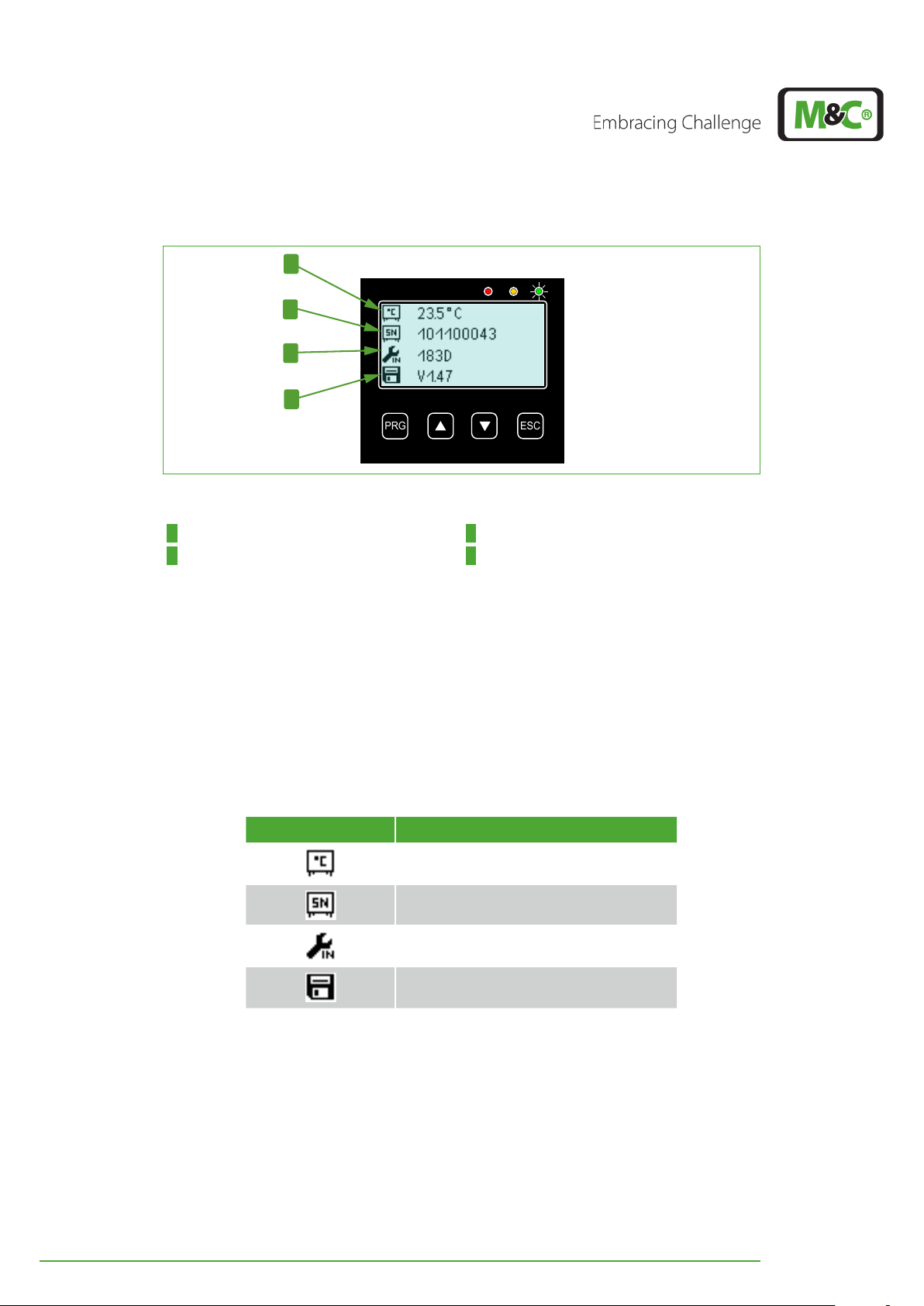

The EC-30C has a graphical, icon-based intuitive menu navigation. The graphic user interface includes three LED indicators, the display and the operating buttons. The figure below shows the screen, where the deep cooling unit has reached its target temperature of

-30 °C (~-22 °F), and describes the components of the user interface.

1 2 3

4

5

6

7

8

9

Fig. 5: Graphic user interface

1 Red LED (alarm message) 2 Yellow LED (warning message)

3 Green LED is on (OK) 4 Snow-flake-symbol with ‘1’ in its center (Tempera-

ture ≤ 0 °C and DCU 1 is active)

5 UP button (upwards pointing arrow) 6 PROGRAM button (PRG)

7 Temperature indication 8 DOWN button (downwards pointing arrow)

9 ESCAPE button (ESC)

Note

With the ESC button you will return to the start screen from any other

screen.

7.2 LED color coding and possible color combinations

Red Yellow Green Description

Everything is OK

One or more warning messages

One or more alarm messages

A combination of one or more alarm messages and

warning messages

18 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 20

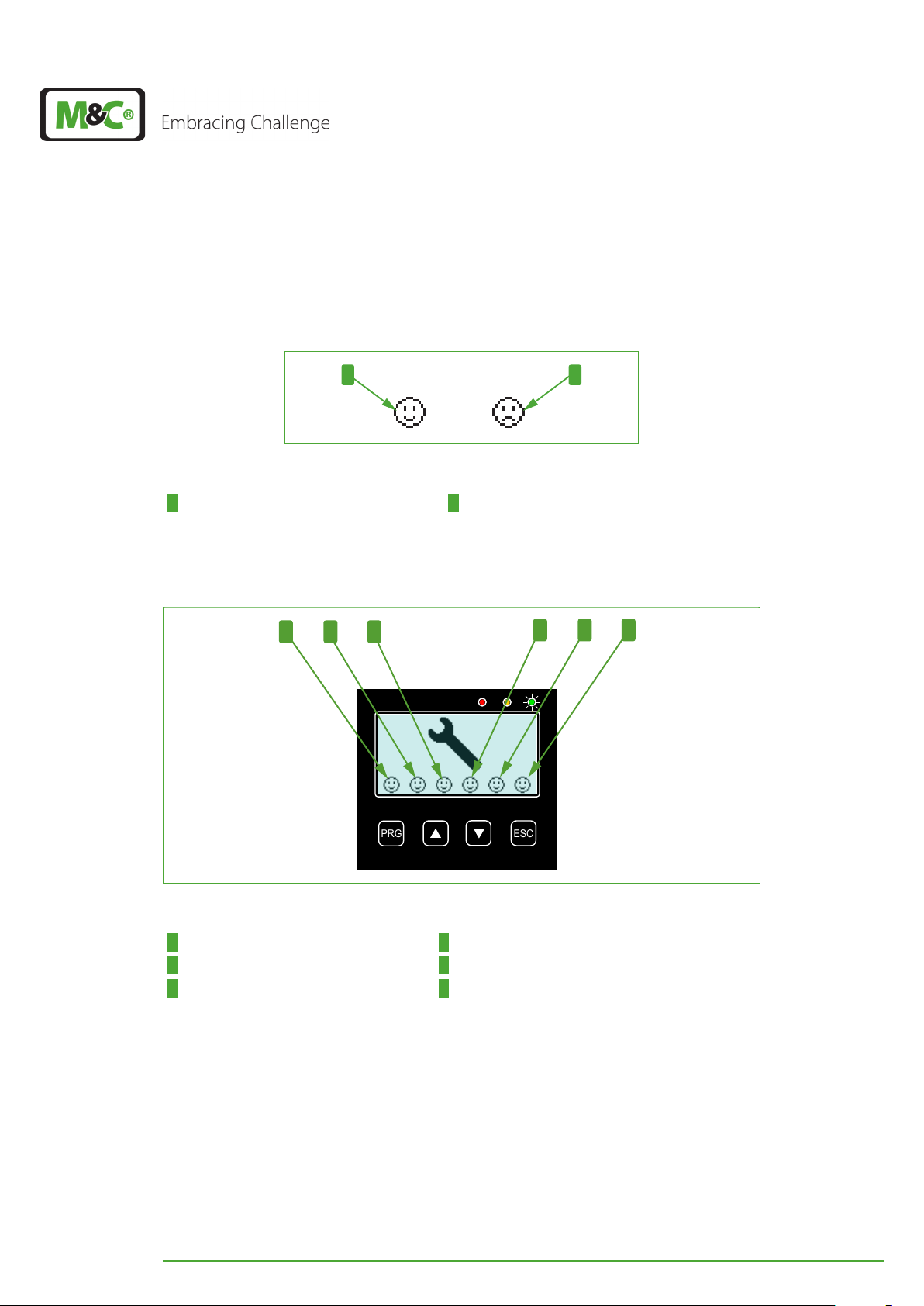

7.3 Self-monitoring after powering-on the unit

1

2

PRG

ESC

1 2 3

4 5 6

The EC-30C automatically monitors and controls its correct functioning and the wear out

of its components. The self-test includes six different tests, each of them being symbolized

by a smiley icon.

Fig. 6: Smiley symbols during self-test

1 ‘Test passed’-symbol 2 ‘Test failed’-symbol

Please switch on the EC-30C. After powering-on the unit starts the self-testing. After successful self-testing the display shows the following picture.

Fig. 7: The smileys on the display after self-testing

1 Internal low voltages 2 Power supply voltage

3 D/A converter 4 0-20 V-Module

5 Peltier elements 6 decoupling capacitor/ rectifier

If the self-test has succeeded, the unit enters the start-up phase and starts cooling.

If the display shows a ‘Test failed’-symbol, this means that an error has been detected

which prevents the correct operation of the unit.

In case of a failed self-test the display alternates between the monitor with smiley symbols

and the service monitor. These monitors will be shown on the display until the fault is

cleared.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 19

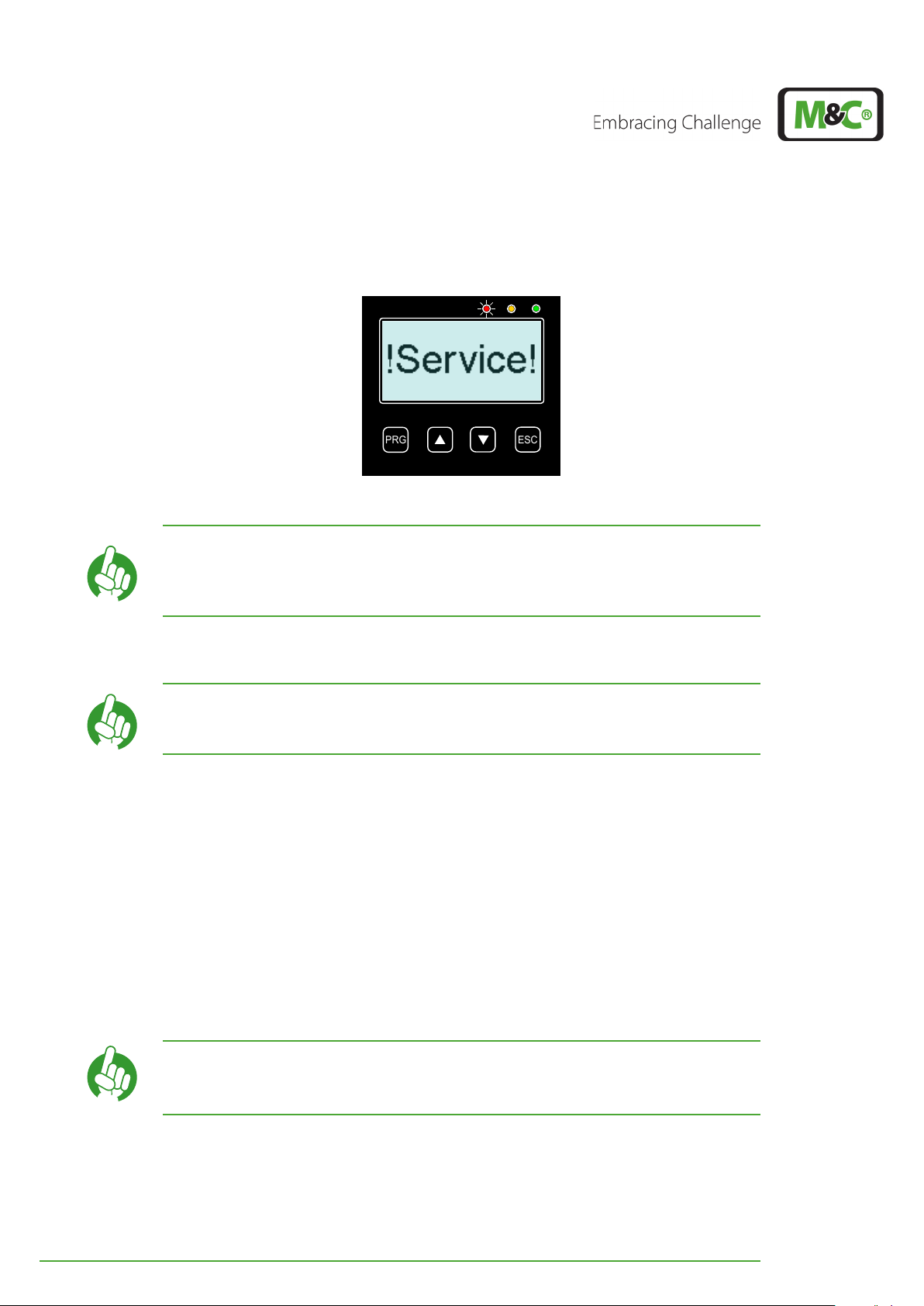

Page 21

Please contact the M&C Service in case of self-test failures. The M&C Service will recom-

PRG

ESC

mend suitable measures to repair the unit.

Fig. 8: ‘Service‘-monitor: Self-test failed

In some cases it is helpful to switch off the unit and to switch it on

Note

again after approx. one hour.

If a ‘Test failed’-symbol is shown again after that, please contact the

M&C Service!

7.4 Self-monitoring during operation

Note During its regular operation the unit runs automatic self-tests.

7.4.1 Power consumption readjustment

Over time the signs of aging of the Peltier elements increase gradually the value of the

internal resistance. As a consequence the power necessary to keep the target temperature

constant can not be supplied anymore. The projected capacity reserve compensates this

unavoidable aging effect and maximizes the service life of the EC-30C.

7.4.2 Pre-warning messages

If the capacity reserve has been exhausted up to a critical value, the unit will show a warning message about the upcoming failure. An exact definition of the remaining time, until

the breakdown of the unit, is not possible.

Please plan servicing the unit ahead of time. The remaining service

Note

life of the unit after the failure warning can not be determined

exactly.

If the reserve capacity is exhausted, an alarm message will occur. The unit still keeps on

cooling, but the target temperature will not be reached any more. The longer the unit will

be kept in this modus, the less it will be able to cool. The possible cooling temperature will

constantly rise.

20 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 22

If the operation process allows it, it is possible to set the target temperature a little bit

PRG

ESC

2 3

higher, e.g. to -25 °C or -20 °C (~-13°F or ~-4°F). This will delay the alarm message until the

capacity reserve will be exhausted even for this higher target temperature.

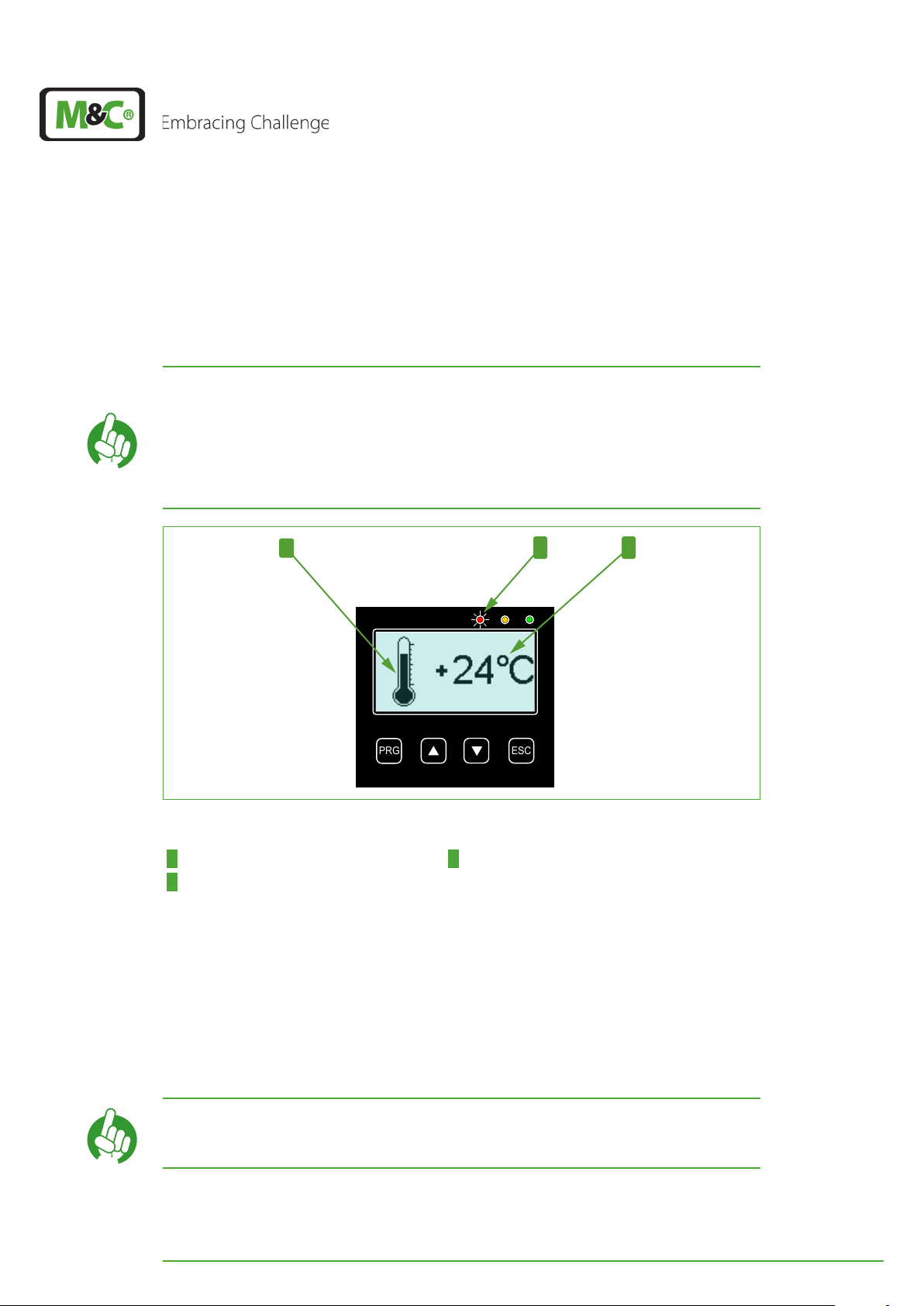

7.5 Display during start-up of the EC-30C

The start screen will always show the temperature of the active

deep-cooling unit (DCU).

At the beginning of the start-up phase the temperature will decrease

Note

very slowly, given that the active DCU is cooled only via the passive

pre-cooler unit (PCU). After the PCU reaches +2°C (35.6 °F), the active

cooling phase of the DCU starts. From this point on, the temperature

will decrease considerably faster.

1

Fig. 9: Start-up phase: first cooling phase

1 ’Falling’ thermometer 2 Red LED is on (alarm)

3 Temperature of the active DCU

Directly after the successful self-test, the EC-30C will start cooling the pre-cooling unit

(PCU) to +2°C (35.6 °F) (target temperature of the pre-cooling unit). Depending on the

load, the compressor of the pre-cooling unit will switch between 12 to 120 times per hour,

in order to reach this target temperature.

The ‘falling’ thermometer is the symbol for this first cooling phase. At this point the initial

dew point of the sample gas is still higher than 0 °C (32 °F), which means that the target

temperature has not been reached yet, and the EC-30C is still in alarm modus.

Note

The red LED shows the status of the alarm relay. Operation mode of

the relay (safety first): alarm active = red LED

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 21

Page 23

PRG

ESC

1

2 3

PRG

ESC

2 3

Fig. 10: Start-up phase: TKS reaches and/or exceeds ‘0 °C / 32 °F’-limit

1 Snowflake-symbol with a clock in its center 2 Red LED is on (alarm)

3 Temperature of the active DCU

As soon as the first DCU reaches the 0 °C (32 °F) temperature limit, the thermometer-symbol changes to a snowflake-symbol. The clock in its center stands for the start-up phase of

the active DCU. The EC-30C is still in alarm modus (red LED is on), because the DCU has not

reached its target temperature yet.

1

Fig. 11: Start-up phase: Target temperature reached

1 Snowflake-symbol with ‘1’ for DCU 1 2 Green LED is on (ready for operation)

3 Temperature of the active DCU (here DCU 1)

Note

The ‘1’ in the center of the snowflake stands for the active deep-cooling unit DCU 1.

22 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 24

As soon as the EC-30C reaches the target temperature of DCU 1, including the alarm hys-

PRG

ESC

PRG

ESC

3 7

teresis of 5 °C (41 °F), it changes from alarm modus to OK modus. The red LED goes out and

the green LED turns on.

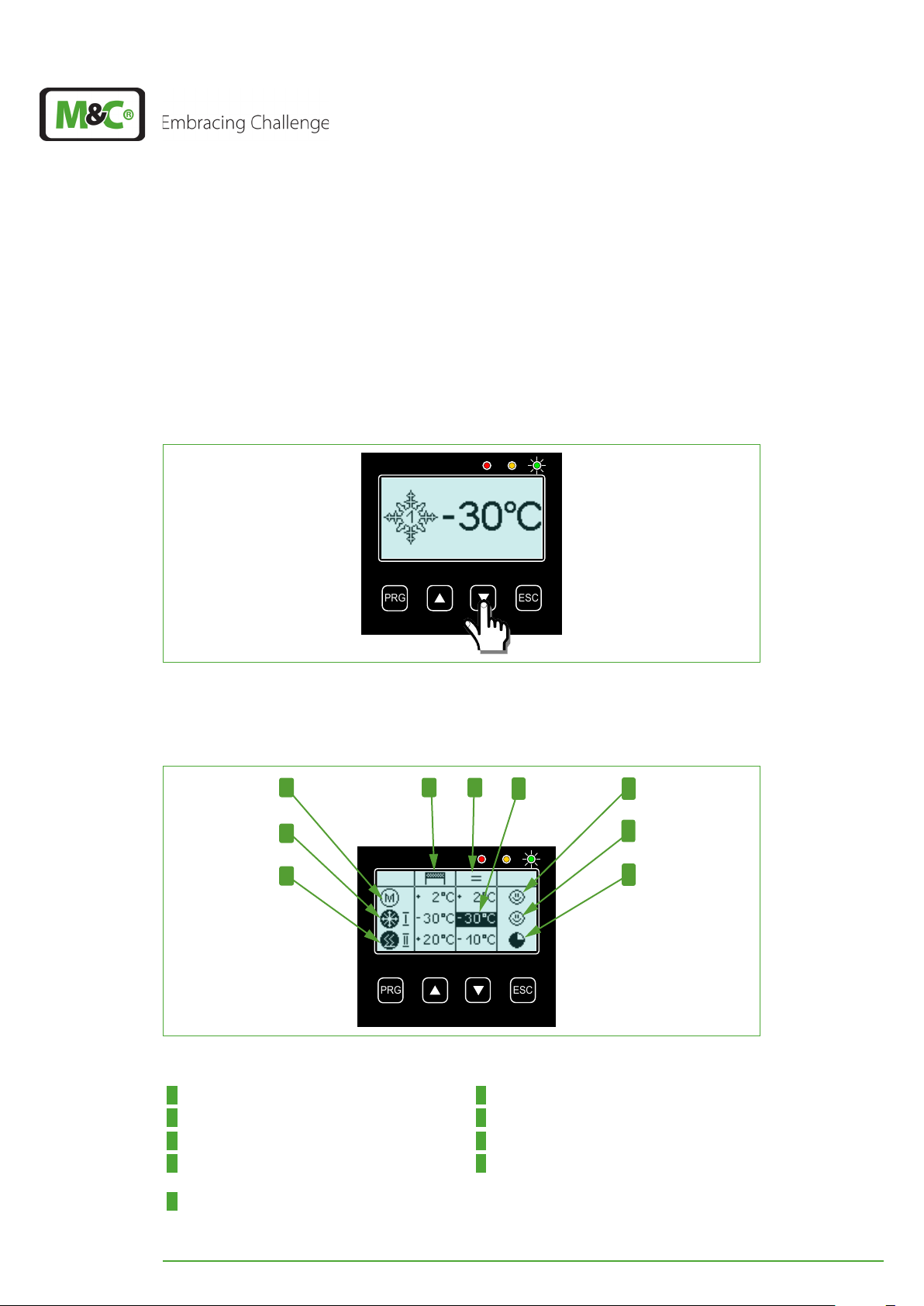

7.6 Overview screen

The overview screen shows detailed information about the pre-cooling unit PCU and the

two deep-cooling units DCU 1 and DCU 2. You can change from the start display to the

overview display by pressing the DOWN button.

Fig. 12: That’s how you reach the overview screen

The icons on the overview screen inform you about the current conditions of the three

cooling units.

4

5

6

Fig. 13: Overview screen

1 2

8

9

1 Column: target-temperatures 2 Column: current temperatures

3 DCU 1 temperature displayed on start screen 4 ‘M‘-symbol: PCU (not active)

5 DCU 1-symbol: cooling (active) 6 DCU 2-symbol: heating (active)

7 Smiley icon: PCU target temperature reached 8 Smiley icon: DCU 1 target temperature

reached

9 Clock icon: DCU 2 target temperature not

reached

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 23

Page 25

The following table shows the icons occurring on the display and their descriptions:

PRG

ESC

Symbol Description

Pre-cooling unit is cooling

Pre-cooling unit is not cooling

Deep-cooling unit I and/or II is cooling

Deep-cooling unit I and/or II is not

cooling

Deep-cooling I or II is heating

Status display:

The unit has reached its target

temperature.

Status display:

A warning or an alarm has occurred

Status display:

The unit has not reached its target

temperature yet

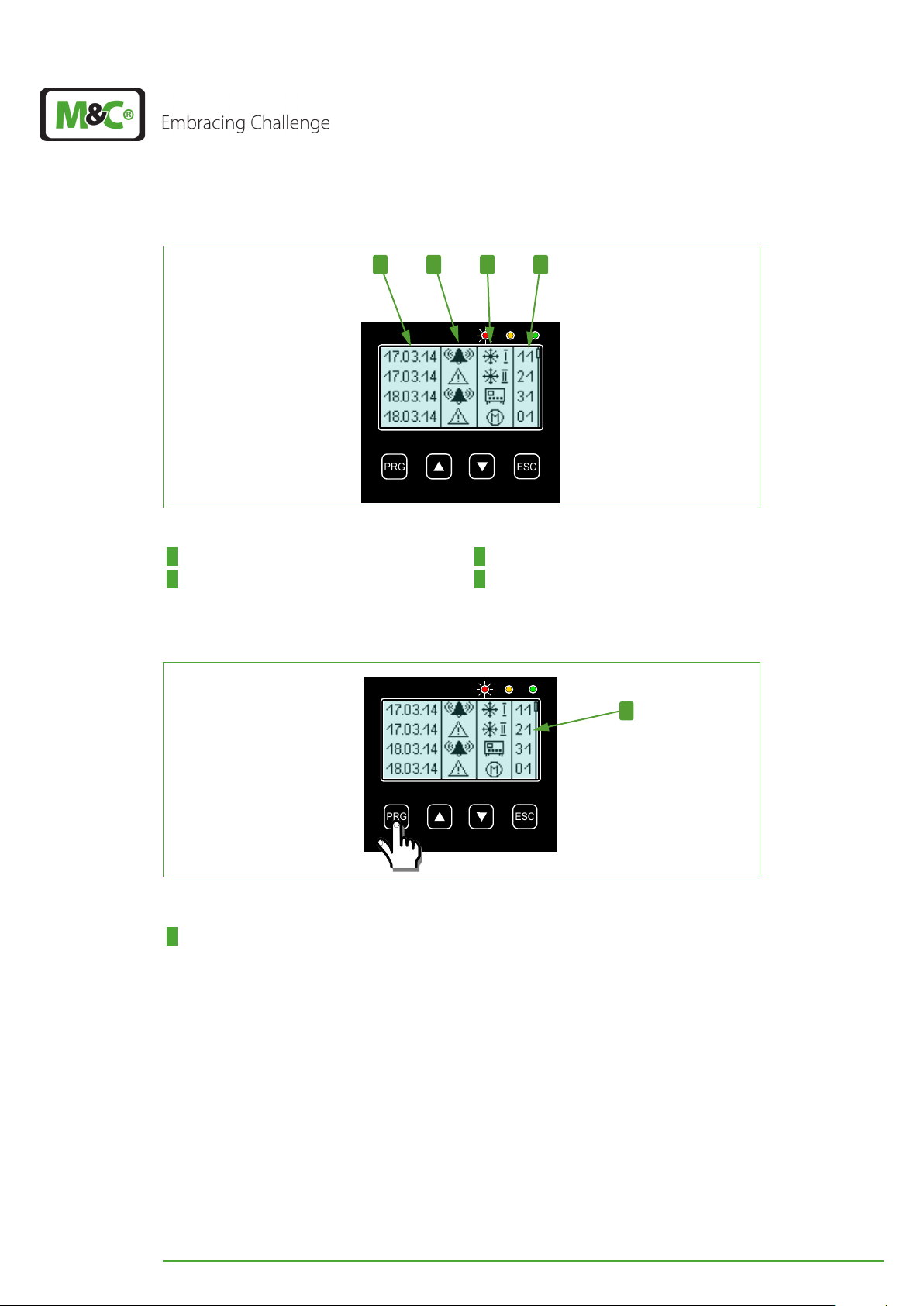

7.7 Alarm and warning history

The alarm and warning history shows in detail all warnings and alarms occurred.

The EC-30C is able to record 768 messages. In case of more than 768 messages the oldest

messages will be deleted and replaced automatically.

You can reach the alarm and warning history from the overview screen by pressing the

DOWN button.

Fig. 14: How to reach the alarm and warning history

24 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 26

PRG

ESC

41 2 3

PRG

ESC

Fig. 15: Alarm and warning history

1 Column: date or time 2 Column: alarm or warning icon

3 Column: component Icons 4 Column: error code

Please press the PRG button to see the messages in detail.

1

Fig. 16: How to chose an alarm or warning message

1 Line, which is highlighted in Fig. 17 and Fig. 18

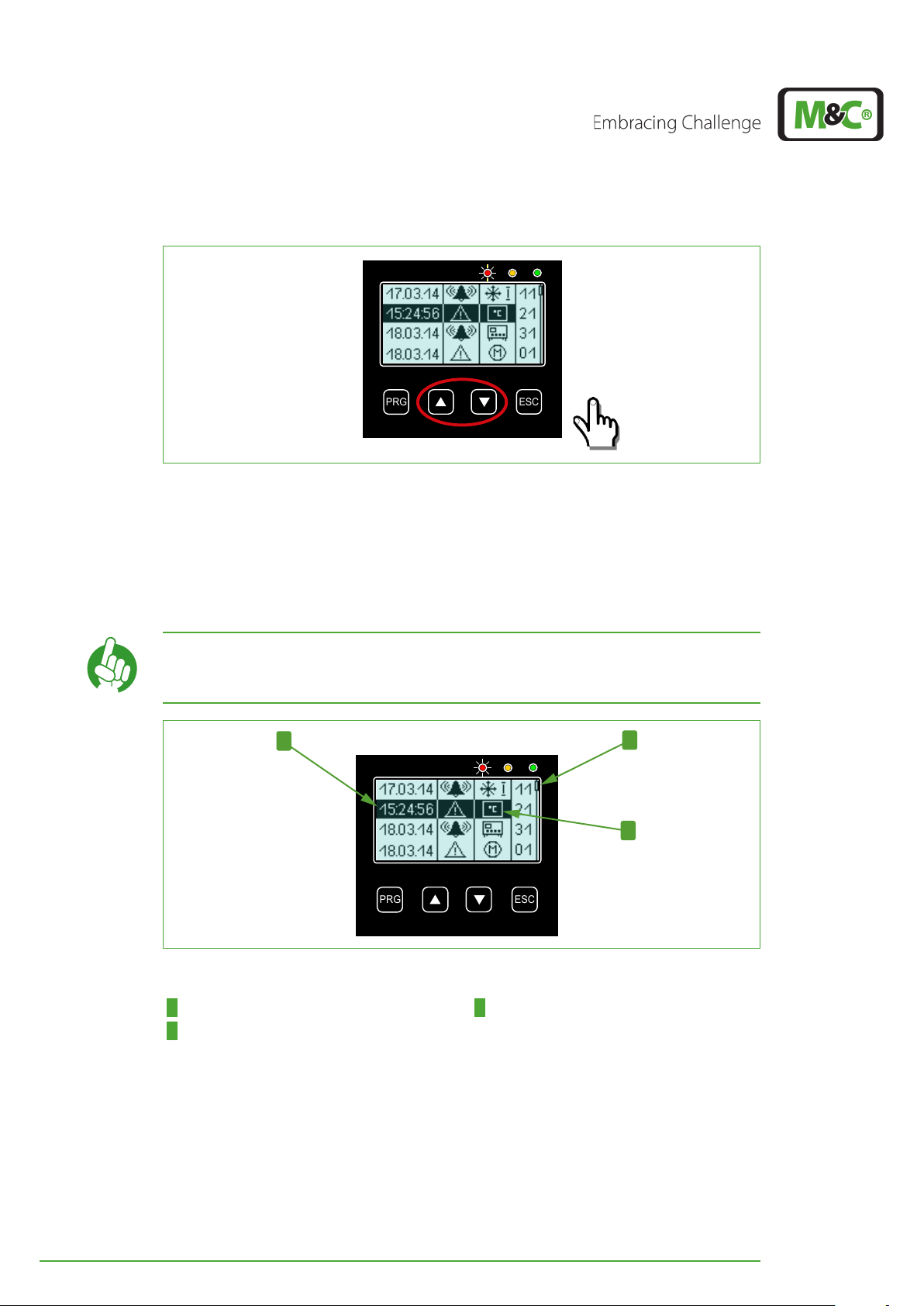

After pressing the PRG button the last line of the alarm and warning history screen will be

displayed inverted (highlighted).

With the UP and DOWN buttons you can scroll through the stored messages. You will

reach the highlighted message in Fig. 17 by pressing the UP button two-times.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 25

Page 27

PRG

ESC

Fig. 17: How to scroll through stored messages

PRG

ESC

2

1

3

The highlighted line will show the time instead of the date of the selected alarm or warning message. The column for component icons will display the component of the device,

the warning or alarm refers to.

In the selected line shown above the DCU 2-icon has changed into the temperature icon,

which means that the warning refers to the temperature of the second deep-cooling unit.

Note

A slider on the right side of the display indicates the current position

in the alarm and warning history.

Fig. 18: Detailed information for a selected message

1 Time of the selected message 2 Slider

3 Temperature icon

26 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 28

7.7.1 Error codes

The error code in an alarm and warning history consists of two digits. The first digit in the

error code refers to the component:

First digit Description

0 Pre-cooling unit

1 Deep-cooling unit I

2 Deep-cooling II

3 General device error

The second digit of the error code offers detailed information about alarm or warning

messages.

The following chapters describe the error codes for warning and alarm messages in

detail.

7.7.2 Warning symbols

In the alarm and warning history there are two different warning symbols:

Warning symbol Description

Warning

Canceled warning (warning triangle with

check mark)

The warning triangle stands for a warning. A canceled warning is symbolized by a warning

triangle with check mark.

When a warning has been canceled, the alarm and warning history will show a line displaying a warning triangle with check mark including date and hour of cancellation.

If you want to contact our service department to report a warning or

Note

alarm message, please keep ready the following information:

• Is the message an ‚alarm‘ or a ‚warning‘ message?

• Which error code is being displayed on the screen?

The following table shows the symbols that can occur in case of a warning and explains

their meaning.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 27

Page 29

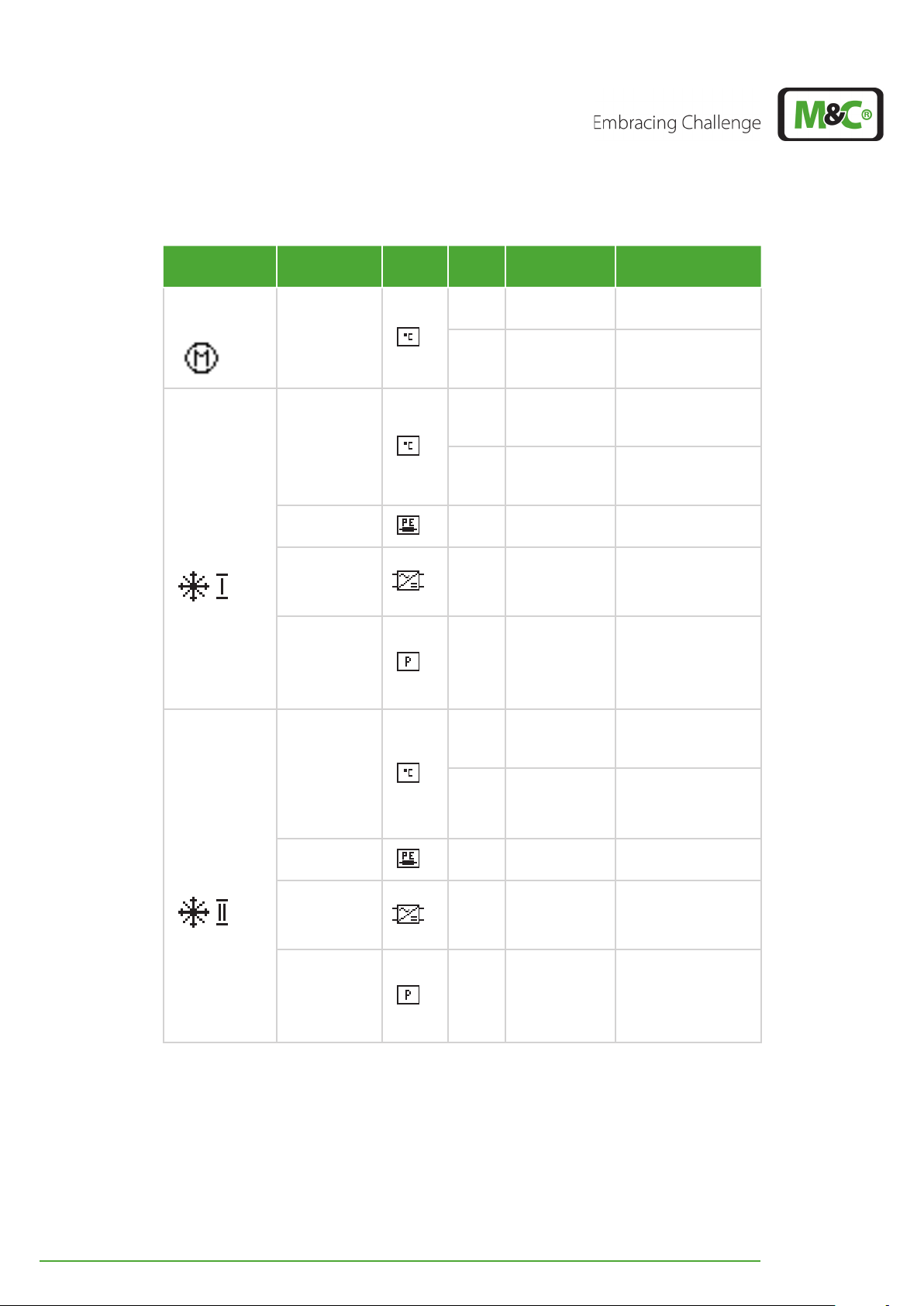

Components

Pre-cooling

unit

Deep-cooling

unit I

Deep-cooling

unit II

Warning

type

Symbol Code Description Comments

01

Temperature

02

10

Temperature

11

Peltierelement(s)

0 - 20 V

Module 1

12 Loss of power U

13

Temperature 14

20

Temperature

21

PeltierElement(s)

0 - 20 V

Module 2

22 Loss of power U

23

Temperature 24

Temperature

too low

PCU takes too

long to cool

down

Cooling

temperature

too low

Heating

temperature

too low

0 - 20 V

Module

deteriorated

Heating/

cooling takes

too long

Cooling

temperature

too low

Heating

temperaturetoo low

0 - 20 V

Module

deteriorated

Heating/

cooling takes

too long

T1 ≤ 0 °C (32 °F)

> 45 min.

T2 < T2

°F)

T2 < T2

°F) after heating

-3 °C (26.6

set

-5 °C (23

set

cycle

≥ 19 V

PE1

U

OUT

≤ U

OUT, set

-0.5 V

or

U

OUT

≥ U

OUT, set

+0.5 V

> 45 min.

Thermal load maybe

too high or ambient

temperature too

high

T3 < T3

°F)

T3 < T3

-3 °C (26.6

set

-5 °C

set

(23 °F) after heating

cycle

≥ 19 V

PE2

U

OUT

≤ U

OUT, set

-0.5 V

or

U

OUT

≥ U

OUT, set

+0.5 V

> 45 min.

Thermal load maybe

too high or ambient

temperature too

high

28 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 30

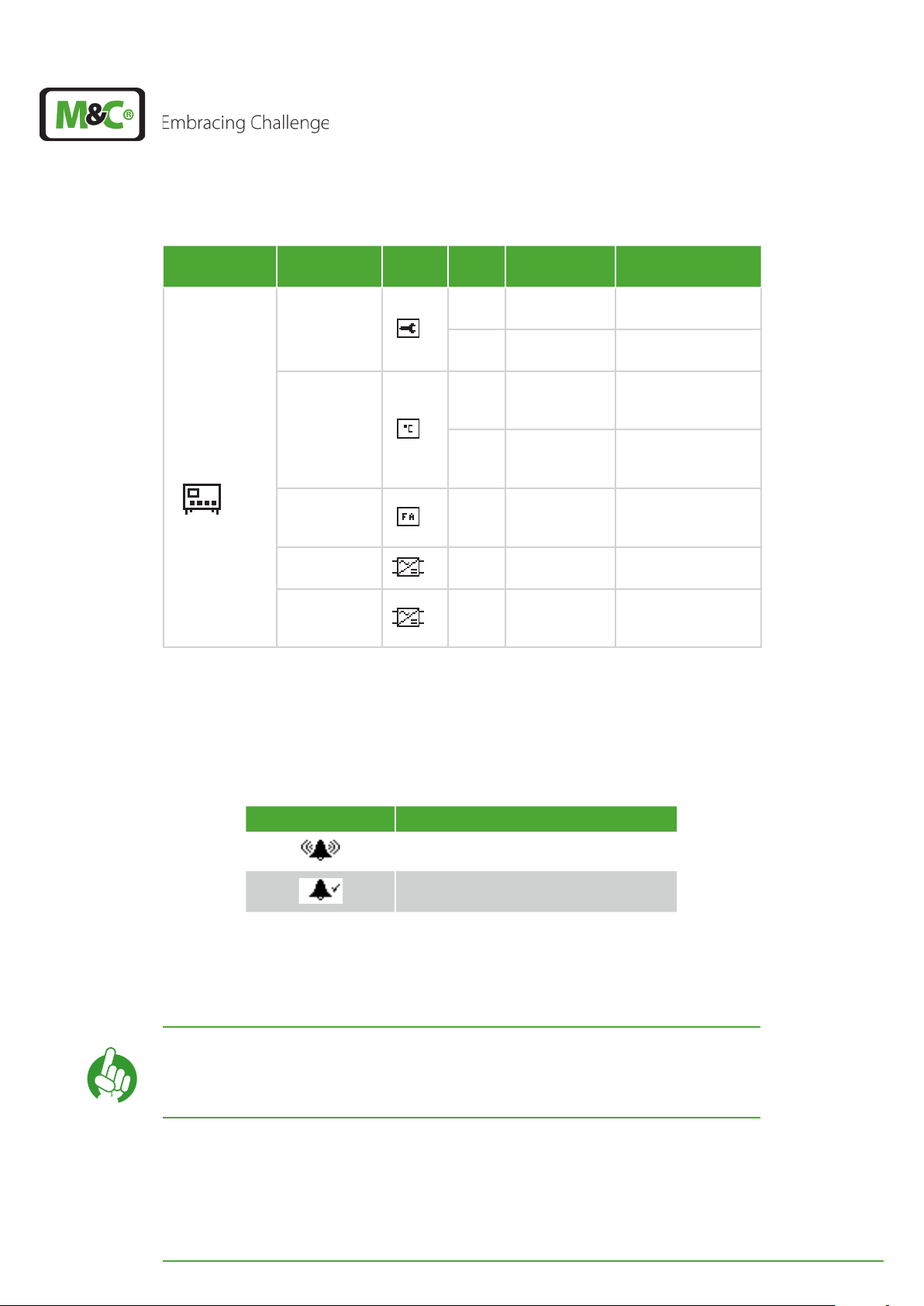

Components

General device

Warning

type

Service

Device

temperature

Gas flow

alarm

Back-up

battery

Decoupling

capacitor or

rectifier

Symbol Code Description Comments

30

31

Service due in

20 days

Service

expired

Service-remaining

time ≤ 20 days

Service-remaining

time ≤ 0 days

Device

32

temperature

too high

T

≥ +70°C (158°F)

device

Device

33

temperature to

low

T

≤ +5 °C (41 °F)

device

Heat exchanger

34 No gas flow

maybe frozen or gas

line defect

35

36

Back-up

battery empty

Power supply

needs to be

checked

≤ 2.3 V

Decoupling capacitor deteriorated or

rectifier defect

7.7.3 Alarm symbols

In the alarm and warning history there are two different alarm symbols:

Alarm symbol Description

Alarm

Canceled alarm (alarm symbol with check

mark)

The bell stands for an alarm. A canceled alarm is symbolized by a bell with check mark.

When an alarm has been canceled, the alarm and warning history will show a line displaying a bell with a check mark including the date and hour of cancellation.

If you want to contact our service department to report a warning or

Note

alarm message, please keep ready the following information:

• Is the message an ‚Alarm‘ or a ‚Warning‘ message?

• Which error code is being displayed on the screen?

The following table shows the symbols that can occur in case of an alarm, and explains

their meaning.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 29

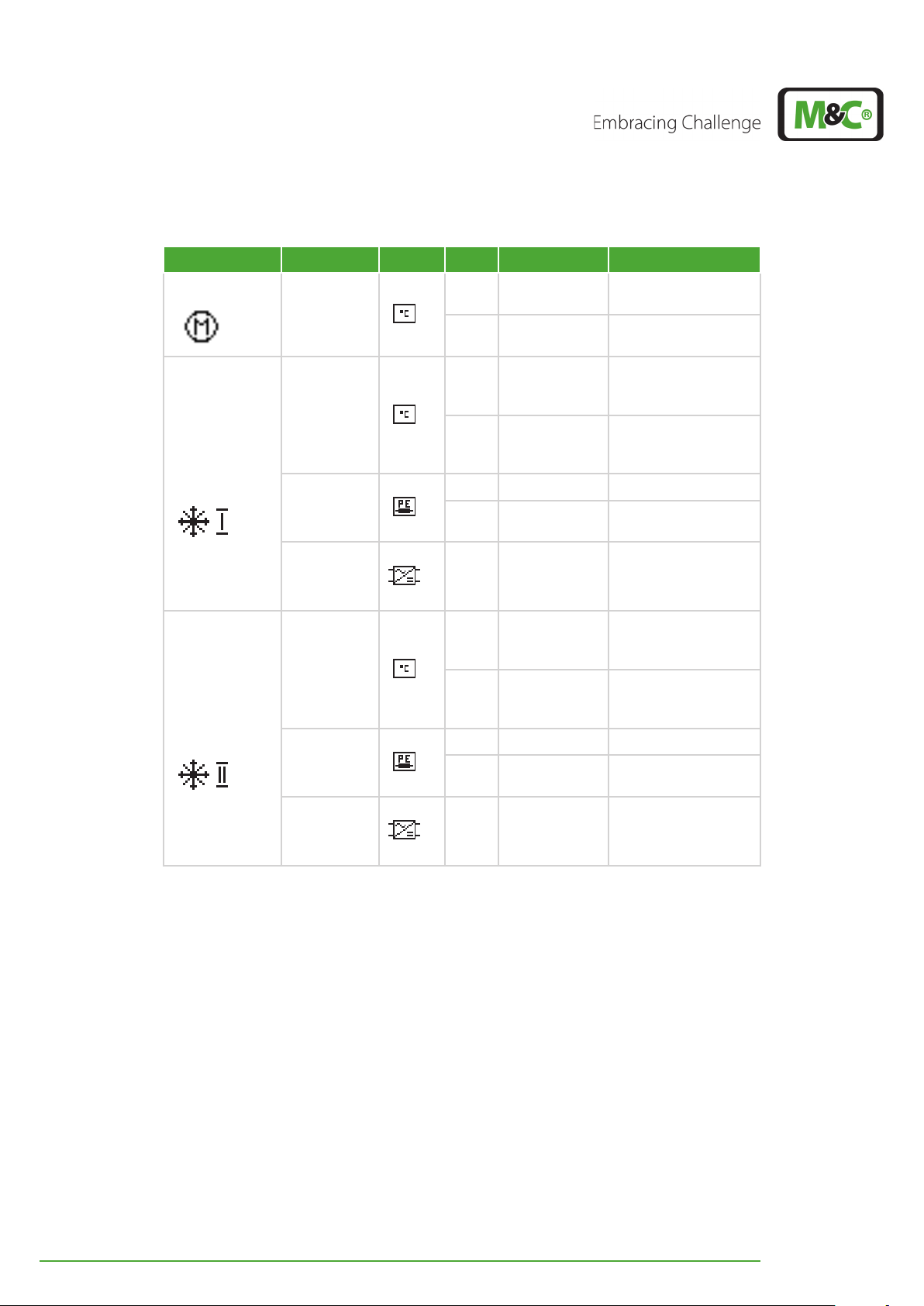

Page 31

Components Alarm type Symbol Code Description Comments

Pre-cooling unit

Deep-cooling

unit I

Deep-cooling

unit II

Temperature

Temperature

Peltierelement(s)

0 - 20 V

Module 1

Temperature

Peltierelement(s)

0 - 20 V

Module 2

01

02

10

11

12 Loss of power U

13 defect

14 defect

20

21

22 Loss of power U

23 defect

24 defect

Temperature

too high

Temperature

too low

Cooling

temperature

too high

Heating

temperature

too high

Cooling

temperature

too high

Heating

temperature

too high

T1 ≥ +5 °C (41 °F)

T1 ≤ -1 °C (30.2 °F)

T2 ≥ T2

°F)

+3 °C (37.4

set

T2 ≥ +30 °C (86 °F)

≥ 19.7 V

PE1

No cooling despite

the FET, relay etc. OK

U

≤ U

OUT

OUT, set

or

U

≥ U

OUT

OUT, set

T3 ≥ T3

°F)

+3 °C (37.4

set

T3 ≥ +30 °C (86 °F)

≥ 19.7 V

PE2

No cooling despite

the FET, relay etc. OK

U

≤ U

OUT

OUT, set

or

U

≥ U

OUT

OUT, set

-1 V

+1 V

-1 V

+1 V

30 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 32

Components Alarm type Symbol Code Description Comments

30

Liquid

alarm 1

Liquid

Liquid alarm

31

alarm 2

(only for M&C

service

personnel)

Device

32

Device

temperature

33

temperature

too high

Device

temperature

too low

T

≥ +80 °C (176 °F)

Gerät

T

≤ +2 °C (35.6 °F)

Gerät

Couplings

Voltage error 34

capacitor or

bridge rectifier

defect

General device

35

36

I2C communication doesn‘t

work

I2C communication doesn‘t

work

One IC doesn‘t

answer; probably IC

defect

All IC‘s don‘t answer

(probably power

cord defect or

removed)

One internal

Only for

M&C Service

Personnel

37

voltage supply

(5 V or 12 V) is

incorrect

5 V voltage < 4.5 V

12 V Voltage < 9 V

Cools down, but

38

H/K Relay unit

1 defect

does not heat up, or

heats up, but does

not cool down

Cools down, but

39

H/K Relay unit

2 defect

does not heat up, or

heats up, but does

not cool down

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 31

Page 33

7.8 Temperature diagrams

PRG

ESC

PRG

ESC

The EC-30C shows the temperature diagrams of the pre-cooling unit and the two

deep-cooling units. The temperature diagrams display a time period of 6 hours.

You can reach the temperature diagrams from the alarm and warning history screen by

pressing the DOWN button.

Fig. 19: How to reach the graphical temperature diagrams

With the UP and DOWN buttons you can switch between the

Note

graphical temperature diagrams of the pre-cooling unit and the two

deep-cooling units.

7.8 .1 Diagram of the pre-cooler unit (PCU)

You can reach the temperature diagram of the pre-cooler unit (PCU) from the alarm and

warning history screen by pressing the DOWN button.

Fig. 20: Temperature diagram of the pre-cooling unit

After the commissioning of the EC-30C, the temperature diagram starts adding measurement readings from right to left. Every three minutes the characteristic line is updated with

a new temperature value. The diagram always shows the measured temperature of the

last 6 hours. Temperature values older than 6 hours will be deleted.

The y-axis of the PCU temperature diagram shows a temperature range from -35 °C to +25

°C (~-31 °F to +77 °F). Measured values exceeding or going below this temperature range

will not be displayed.

32 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 34

7.8 . 2 Diagram of the deep cooling units (DCU 1 and DCU 2)

PRG

ESC

Starting from the pre-cooling unit (PCU) temperature diagram screen, please press the

DOWN button to reach the temperature diagram of the two deep-cooling units. Here

both deep-cooling units are displayed in one diagram.

The fine line shows the temperature characteristic of DCU 1 and the thicker line shows the

characteristic of DCU 2.

1 2

Fig. 21: Temperature diagram of the deep-cooling units

1 Diagram of DCU 1 2 Diagram of DCU 2

The temperature range of the y-axis is limited from -35 °C to +25 °C (~-31 °F to +77 °F).

Measured values exceeding or going below this temperature range will not be displayed.

Broken temperature lines are caused by switching the unit off and on

again.

Note

When the EC-30C is turned off, and for excample after 2 hours turned

on again, the temperature of the deep-cooling units will have

changed. This leads to a broken line in the diagram.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 33

Page 35

7.9 Parameter menu

PRG

ESC

PRG

ESC

1

2

3

The parameter menu is used for setting the individual parameters e.g. service interval or

deep-cooling temperature. The parameter menu has two screens. You can switch between these screens by using the UP and DOWN buttons.

You can reach the parameter menu from the temperature diagram of the deep-cooling

units by pressing the DOWN button.

Fig. 22: How to reach the parameter menu (screen 1)

The first parameter screen shows the following information:

Operating time of the EC-30C

Requested service interval

Settings for the mA-output

Fig. 23: Parameter menu, screen 1

1 Line 1: operating time 2 Line 2: Service interval in days

3 Line 3: mA-output

34 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 36

In the second part of the parameter menu, there are the following parameters:

PRG

ESC

1

2

3

Required deep-cooling temperature

Current date

Current time

Fig. 24: Parameter menu, screen 2

1 Line 1: Deep-cooling temperature 2 Line 2: Current date

3 Line 3: Current time

Note

You will find the permitted parameter ranges on page 36 chapter

‘7.9.1 Parameter settings’ .

Here are the definitions of the symbols used in the parameter menu:

Symbol Definition

Information about the time period the

unit has already been running

Setting of the required service interval

Setting of the mA-output and of the

correlated temperature interval

Setting the required deep-cooling

temperature

Information: current date

Information: current time

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 35

Page 37

7.9.1 Parameter settings

PRG

ESC

The parameters displayed on the screens can be adjusted within a defined parameter

range.

You can set the following parameters:

Parameter Parameter range Default value

Service interval

mA-output

(power range)

Off (0 days),

1-1095 Tage

0-20 mA,

4-20 mA

365 days

4-20 mA

Min.: -40 °C to -10 °C

mA-output

(correlated temperature range)

(Min: ~-40 °F to 14 °F)

Max.: +10 °C to +60 °C

-30 °C to +30 °C

(~-22 °F to +86 °F)

(Max: +50 °F to 140 °F)

Required deep-cooling temperature

Date

[Day, Month, Year]

Time

[Hour, Minute, Second]

-20 °C to -30 °C

(~-4 to °F to ~-22 °F)

Day: 01 to 31

Month: 01 to 12

Year: 15 to 99

Hour: 00 to 23

Minute: 00 to 59

Second: 00 to 59

-30 °C (~-22 °F)

01.01.16

12:00:00

To reach the program level for setting the parameters please start from the corresponding

parameter screen and press the PRG button.

Fig. 25: How to reach the parameter settings

36 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 38

The screens of the parameter menu are independent screen pages.

PRG

ESC

You can change only the parameters of the screen that is currently

Note

displayed. If you want to change parameters from a different parameter screen, you have to leave the current setting level first by pressing

the ESC button.

The first parameter of the parameter menu will be highlighted. You can switch between

the parameters of this screen page with the PRG button.

First you have to invert the parameter you want to change. Then you use the UP and

DOWN button to switch between the different parameter ranges.

You can exit this screen without changing any parameter by pressing the ESC button.

To accept the value shown on the display, please press the PRG button for about 3 seconds. The parameter will change from highlighted to not highlighted. This means that the

value has been set to the new parameter. You can also change more than one parameter

on the screen, and accept all of them by pressing the PRG button for 3 seconds.

You can exit this program level by pressing the ESC button.

Note

Please find more details about the program levels on page 67

chapter ‘12.1 Overview of the EC-30C screens’ .

7.10 Device information

Please start from the parameter menu (screen 2) and press the DOWN button to change

to the device information screen.

Fig. 26: How to reach the device information

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 37

Page 39

PRG

ESC

1

2

3

4

Fig. 27: Device information

1 Line 1: Device temperature 2 Line 2: Serial number of the display controller

3 Line 3: Days left until servicing 4 Line 4: Software version number

This screen displays the following device information:

Device temperature

Serial number of the device controller

Days left until servicing

Software version number

The symbols used on the device information screen are as follows:

Symbol Description

Device temperature

Serial number of the display controller

Days left until service

Software version number

38 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 40

7.11 Service-Reset (qualified personnel only)

PRG

ESC

Press for 3 seconds

simultaneously

PRG

ESC

Loss of data caused by service reset!

Note

The service reset can be activated from the start screen by pressing simultaneously the UP,

DOWN and ESC button for three seconds.

Fig. 28: Activating Service Reset (Qualified personnel only)

There is no security query, whether you really want to carry out the

service reset or not.

Service reset has to be carried out only by qualified personnel!

After activating service reset all messages from the error memory will be deleted. The

service time will also be reseted.

Fig. 29: Reset screen (Qualified personnel only)

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 39

Page 41

8 Installation instructions and mounting of the EC-30C

Heavy device!

CAUTION

The cooler EC-30C is suitable for both: wall and 19“ rack mounting.

8.1 Installation instructions

Follow these installation instructions:

The operating position of the cooler is exclusively upright. The operation in

vertical position ensures the faultless separation and removal of the condensate in the heat exchanger.

Mount the cooler in a ventilated place away from heat sources. This way you

avoid disturbing heat accumulations.

When mounted outdoors, the cooler has to be installed into a protective case.

Make sure that the place of operation is frost-free in winter and sufficiently

ventilated in summer. Avoid direct sunlight.

Risk of injury when handling heavy equipment.

Do not lift, move or carry the device without help. A second person is

required to lift, move or carry the device.

Take into consideration the required minimum assembly dimensions.

For optimum measurement results we recommend to use an electrically

heated gas sample line.

Heated sample gas lines need to end at least 20 cm (7.874“) before the gas line

reaches the cooler to make sure that the heated sample line and the cooler is

thermally decoupled. That means, the last 20 cm (7.874“) of the gas lines are not

isolated.

Un-heated sample gas lines need to be installed with a declining angle towards

the cooler. In this case, any built-up condensate in the gas lines can flow

towards the cooler and will be removed by the heat exchanger in the pre-cooler unit.

40 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 42

8.2 Wall and rack mount

The tubes for condensate removal will be directly connected to the

Note

DN10/12 mm connectors at the bottom of the heat exchangers.

These condensate removal connectors stick out of the bottom plate

of the cooler housing.

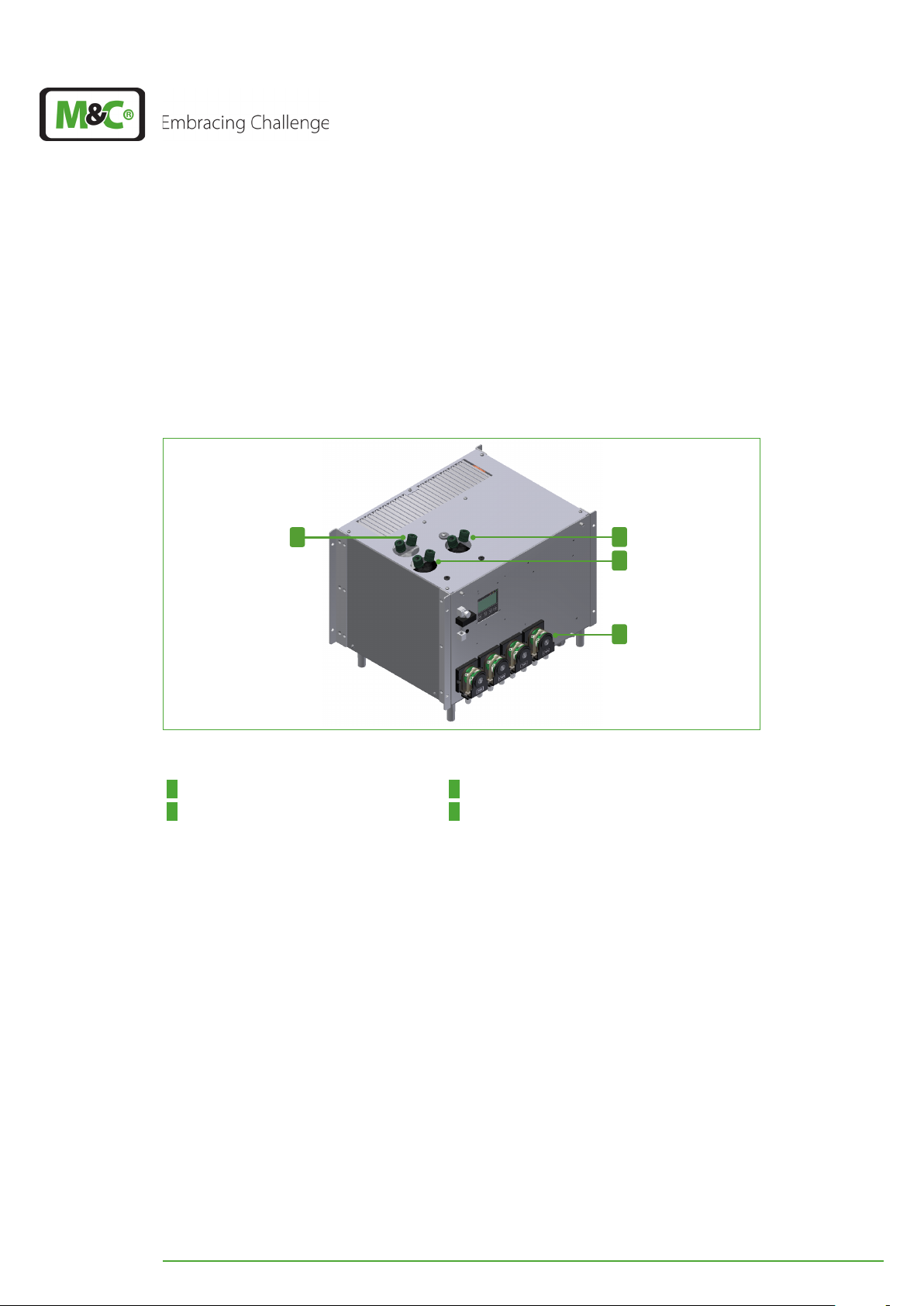

1

2

3

Abmessungen in mm [Inch]

Fig. 30: Min. assembly dimensions (unit with optional peristaltic pumps)

1 Min. distance between isolation and

attachment point of the unit

3 Min. installation space below the

EC-30C

Please follow these instructions for mounting of the EC-30C (numbers correspond to Fig.

30 on page 41):

1 For heated gas sample lines, the insulated part of the line must end at least 200 mm

(7.87“) before the line reaches the device.

2 Please provide a minimum of 180 mm (7.09“) installation space above the unit for the

tubing. Make sure that outgoing air can exit from the upper side of the device.

3 Provide a min. of 50 mm (1.97“) installation space below the unit for tubing, air intake

and maintenance access. Our recommendation: min. 100 mm (3.94“).

2 Min. installation space above the EC-30C

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 41

Page 43

1

2 3

Fig. 31: Mounting rail for wall or rack mounting

Abmessungen in mm [Inch]

1 Back-mounting rail for wall mounting: min.

4 mm (0.16“) wall distance

2 Back-mounting rail for wall mounting: max.

19 mm (0.75”) wall distance

3 Front-mounting rail for 19” rack: housing

front aligned to or 15 mm (0.6“) behind the

front of the mounting bracket

To mount the EC-30C with the provided mounting rails, please follow these instructions

(numbers correspond to Fig. 31 on page 42):

1 The mounting rails can be attached to the side panels close to the rear of the housing.

The minimum distance between the wall and the housing will be in this case 4 mm (0,16“).

2 The mounting rails can be attached to the side panels close to the rear of the housing.

The maximum distance between the wall and the housing will be in this case 19 mm

(0.75“).

3 The mounting rails can be attached to the side panels close to the front of the housing

(19“ rack mount). In this case the front of the housing can either be aligned with or 15 mm

(0.6“) behind the front of the mounting bracket.

42 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 44

8.3 Mounting instructions for SR25.2 peristaltic pump (optional)

Make sure to mount the pump to the front of the cooler with a minimum distance of 3.5

mm (0.138”) and a maximum distance of 5.5 mm (0.216”) between the pump motor and

the front panel.

The minimum distance avoids damages to the pump motor and the maximum distance

prevents the motor shaft from getting loose.

Fig. 32: SR25.2: Mounting distance between pump motor and front panel

1 Pump head (outside the EC-30C housing) 2 Front panel of the EC-30C

3 Recommended mounting distance 4 Pump motor (inside the EC-30C housing)

Note

For more mounting instructions, see the SR25.2 instruction manual.

The manual is available on our website www.mc-techgroup.com.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 43

Page 45

8.4 Tubing without heat exchanger purging (standard tubing)

Do not mix up the tube connectors for sample gas inlet and outlet.

The inlet and outlet connectors of the heat exchanger are marked

with arrows.

Note

Make sure that all the connections are sealed adequately.

To ensure free removal of the condensate, the stated diameters for

the condensate removal lines can not be decreased!

The standard version of the EC-30C is equipped with tubing without heat exchanger purging. This standard tubing includes one solenoid valve (valve 1), to switch between the two

deep-cooling units.

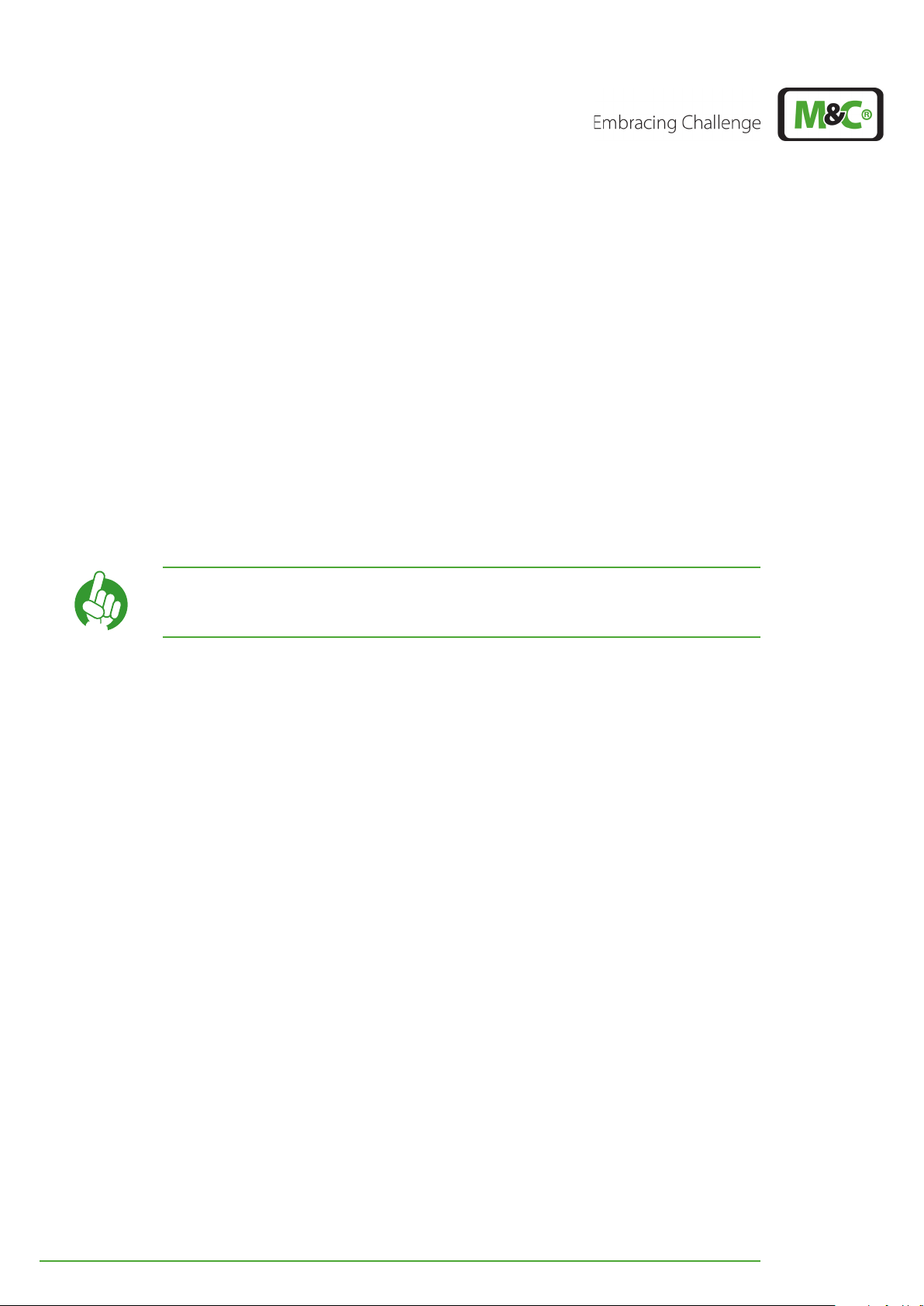

The standard tubing of the EC-30C is shown in the following figure.

2

1

3

4

Fig. 33: Standard tubing: DCU 1 active, solenoid valve triggered, no FA

1 Heat exchanger pre-cooling unit (PCU) 2 Heat exchanger DCU 1 (on the right, here:

active)

3 Heat exchanger DCU 2 (on the left, here:

not active)

Gas IN is the connector of the PCU heat exchanger. The sample gas enters the cooler at

this connection. Gas OUT is the connector at the solenoid valve 1, which sticks out of the

bottom plate of the cooler on the left-hand side. The sample gas leaves the cooler at this

connection.

8.4.1 Heat exchanger connections for tubing without purging

4 Solenoid valve 1

The EC-30C provides six connectors for three heat exchangers, which protrude through

the top panel of the device on the left hand-side. The sample gas enters the cooler at the

sample gas inlet of the PCU heat exchanger.

The sample gas outlet DN 4/6 protrudes through the bottom plate of the cooler close to

the front plate on the left-hand side.

44 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 46

1

2

3

4

Fig. 34: Heat exchanger connectors (device with four optional peristaltic pumps)

1 Heat exchanger pre-cooling unit 2 Heat exchanger DCU 1 (on the right)

3 Heat exchanger DCU 2 (on the left) 4 Flow alarm sensor FA (optional)

The PCU heat exchanger has two connectors which are marked with arrows as gas inlet

and gas outlet. The connectors of the DCU heat exchangers are also marked with arrows.

Connect the gas inlet connectors of the DCU heat exchangers with a tee connector to the

outlet of the pre-cooling heat exchanger.

Route the gas outlets of the DCU heat exchangers through the top panel of the EC-30C to

the inside of the housing. Inside of the device connect the gas outlets of the DCU to the

inlet connectors of the solenoid valve 1. Connect DCU 1OUT to the front and DCU 2OUT

to the back connector of solenoid valve 1.

If you are using an internal flow alarm sensor FA: Connect the outlet of the solenoid valve

1 on the right hand-side to the gas inlet of the flow meter FM 40. Connect the outlet of the

flow meter FM 40 to the gas outlet which protrudes through the bottom plate of the cooler close to the front panel on the left-hand side.

If you are using three optional peristaltic pumps: Connect the heat exchanger outlets to

the peristaltic pumps. Each heat exchanger outlet will be connected to one peristaltic

pump at the front panel of the cooler.

Keep the tubing of the heat exchanger condensate outlets as short and structured as

possible. The tubing does not need to be connected in order.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 45

Page 47

8.5 Tubing with heat exchanger purging for special requirements

(optional)

Do not mix up the tube connectors for sample gas inlet and outlet.

The inlet and outlet connectors of the heat exchanger are marked

with arrows.

Note

Make sure that all the connections are sealed adequately.

To ensure free removal of the condensate, the stated diameters for

the condensate removal lines can not be decreased!

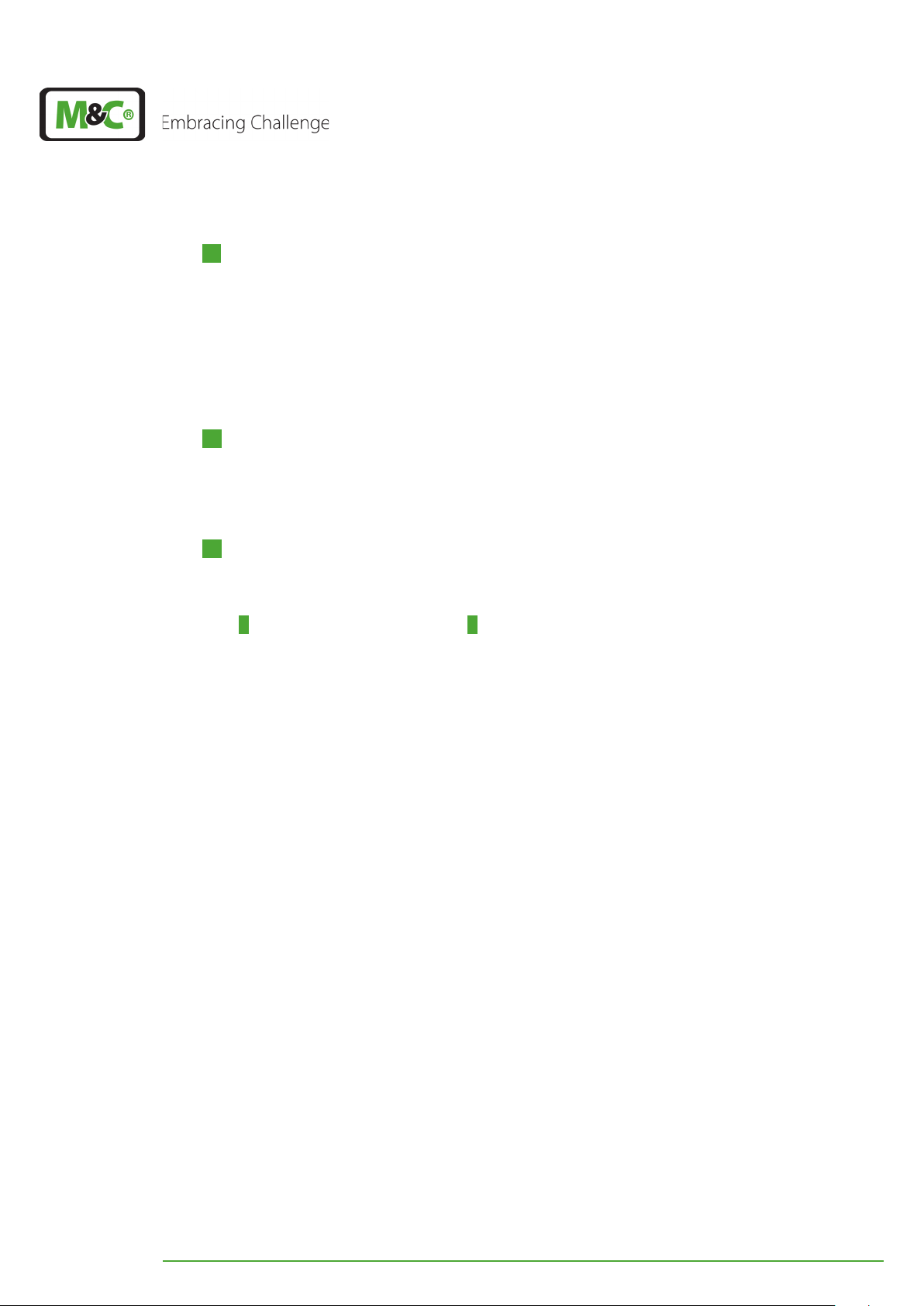

A fourth optional peristaltic pump can be installed in combination with a second solenoid

valve 2 to provide permanently and slowly (0.3 l/h) fresh sample gas to the inactive cooling

unit. This prevents short peaks of the sample gas concentration due to stagnant gas during

switching between the two deep cooling units.

The tubing with heat exchanger purging for special requirements is shown in Fig. 35:

2

90 - 250 l/h

1

3

4

0.3 l/h

5

6

Fig. 35: Tubing with purging: DCU 1 activ, solenoid valves triggered, no FA

1 PCU heat exchanger 2 DCU 1 heat exchanger (right, here: active)

3 Heat exchanger DCU 2 (left) 4 Solenoid valve 1 (right)

5 Solenoid valve 2 (left, optional for heat

exchanger purging)

Gas IN is the connector of the PCU heat exchanger. The sample gas enters the cooler at

this connection. Gas OUT is the connector at the solenoid valve 1, which sticks out of the

bottom plate of the cooler on the left-hand side. OUT2 is the optional connection to the

fourth peristaltic pump, the gas outlet for the heat exchanger purging.

6 Fourth peristaltic pump, optional for heat

exchanger purging

46 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 48

8.5.1 Heat exchanger connections for tubing with purging

The EC-30C provides six connectors for three heat exchangers, which protrude through

the top panel of the device. The sample gas enters the cooler at the sample gas inlet of the

PCU heat exchanger.

The sample gas outlet DN 4/6 protrudes through the bottom plate of the cooler close to

the front plate on the left-hand side.

1

2

3

4

Fig. 36: Heat exchanger connections, tubing with purging

1 Heat exchanger pre-cooling unit 2 Heat exchanger DCU 2 (on the left)

3 Heat exchanger DCU 1 (on the right) 4 Heat exchanger purging: 4. peristaltic pump

(here: on the right)

The PCU heat exchanger has two connectors which are marked with arrows as gas inlet

and gas outlet. The connectors of the DCU heat exchangers are also marked with arrows.

Connect the gas inlet connectors of the DCU heat exchangers with a tee connector to the

outlet of the PCU heat exchanger.

The outlet connector of solenoid valve 2 sticks out of the bottom plate of the cooler located in the middle, close to the front plate. Connect the gas outlet of solenoid valve 2 to the

fourth peristaltic pump.

Route the gas outlet of DCU 1 (on the right) through the top panel of the EC-30C to the

inside of the housing. Inside of the device connect the gas outlet of DCU 1 to the forward-facing connectors of solenoid valve 1 and 2 with a tee.

Route the gas outlet of DCU 2 (on the left) through the top panel of the EC-30C to the inside of the housing. Inside of the device connect the gas outlet of DCU 2 to the backward-facing connectors of solenoid valve 1 and 2 with a tee.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 47

Page 49

Connect the gas outlet of solenoid valve 1 on the right hand-side to the gas inlet of the

flow meter FM 40. Connect the outlet of the flow meter FM 40 to the gas outlet which

protrudes through the bottom plate of the cooler close to the front panel on the left-hand

side.

Connect the outlet of solenoid valve 2 (left) which protrudes through the bottom plate of

the cooler, in the middle, close to the front plate, to the fourth peristaltic pump.

If you are using three optional peristaltic pumps: Connect the heat exchanger outlets to

the peristaltic pumps. Each heat exchanger outlet will be connected to one peristaltic

pump at the front panel of the cooler.

Keep the tubing of the condensate outlets as short and structured as possible. The tubing

does not need to be connected in order.

8.6 Duran-glass heat exchanger with GL-connections

On mounting the glass heat exchangers, please follow these instructions:

Before mounting the GL connections, please check the PTFE/Silicone locking

rings for damages.

Mount the locking rings with the PTFE side facing the medium.

After assembly please check the leak tightness of the GL connections at the Duran glass

heat exchangers.

8.7 PVDF- heat exchanger with PVDF-tube connectors

Compared to Duran glass heat exchangers, the PVDF heat exchang-

Note

On mounting the PVDF heat exchangers with PVDF compression fittings, please follow

these instructions:

Carefully remove the nut from the screw-connection. Pay attention to the loose

ferrule inside the nut.

Push the union nut onto the 4/6 mm tubing.

Push the ferrule with the thick bulb facing the nut onto the tubing.

Push the tubing onto the support nipple in the screw-connection.

Tighten the union nut hand-tight.

ers have a lower heat conductivity. If you are using PVDF heat

exchangers, please keep in mind, that the cooling capacity of these

heat exchangers are lower.

48 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 50

Note

To tighten the connectors onto the PVDF heat exchanger, hold a

wrench against the spanner flats of the bushing!

After assembling all lines check the leak tightness of the PVDF tube connectors.

8.8 Electrical connections

Wrong supply voltage can destroy your cooler!

ATTENTION

There are two EC-30C versions available: 115 V and 230 V. Make sure to operate each version with the appropriate supply voltage stated on the model type plate.

Note

There are five cable fittings at the bottom of the EC-30C, where all electrical connections

can be lead through.

When connecting the equipment, make sure that the supply voltage

is identical with the information provided on the model type plate!

The installation and commissioning of the device must conform to

the requirements of VDE 0100 (IEC 364) ‘Regulations on the Installation of Power Circuits with Nominal Voltages below 1000 V’ and must

be in compliance with all relevant regulations and standards.

You can open the front of the EC-30C by loosening the four front screws. The front of the

cooler is hooked into the bottom plate with a guide rail and can be tilted to up to 90°

forwards. The power supply electronics are inside the housing on the right. All necessary

connections can be plugged in here without removing the shielding plate.

Fig. 37 shows all available electrical connections.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 49

Page 51

Transformer out

Fan out

Solenoid valve 1

Solenoid valve 2

Aggregate out

Relay

Relay

Relay

Relay Warning

Relay Warning

Relay

Relay

Fig. 37: Electrical connections

1 X37 2 X38

3 X39 4 X40

5 X41

The pins from Fig. 37 are marked as follows:

Pin No. Definition PIN 1 PIN 2 PIN 3 PIN 4 PIN 5 PIN 6 PIN 7

X37 Power IN PE L N --- --- --- ---

X38 Alarm Relais NO COM NC --- --- --- ---

X39 Warn+Ak.St. W:COM W:NO A.St:COM A.St:NO --- --- ---

X40 mA+LA+FA mA:+ mA:- LA:In LA:GND FA:+5V FA:IN FA:GND

X41 M&C BUS x x x x x x x

x: M&C BUS configuration, only for M&C service personnel.

50 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 52

Note

It is important that the load of the relay contact meets the requirements stated on page 14 chapter ‘5 Technical Data’ .

8.8.1 mA-output

By default, the EC-30C has a configurable mA-output. The mA-output value always corresponds to the temperature of the active deep-cooling unit and represents the current

outlet dew point.

You can assign the mA-output value range (0-20mA or 4-20 mA) to a temperature range

∆T. In this case the lower temperature limit T

mA or 4 mA, and the upper temperature limit T

corresponds to the mA-output signal of 0

min

corresponds to the mA-output signal of

max

20 mA.

This correlation makes it possible to influence the resolution of the mA signal and e.g. to

achieve an improved measuring accuracy for a smaller temperature range.

The measuring error based on the display of the controller is ±2 % of the measuring range

limit.

The maximum load of the mA output including the supply line is 500 Ohm.

You will find information on how to calculate the correlation between

Note

the mA output signal range and the temperature range in the annex

of this manual on page 68 chapter ‘12.2 How to configure the

mA-output’ .

8.8.2 Liquid alarm sensor LA (optional)

It is possible to connect an external liquid alarm sensor LA to monitor the EX30-C, in order

to protect any downstream analyzing equipment. The LA will detect a condensate leakage caused by a possible cooler defect or overload.

The EC-30C connected to the LA gives an alarm signal which will be registered in the alarm

and warning history. The cooler switches the alarm relay to stop the gas supply by either

turning off the sample gas pump or triggering a solenoid shut off valve.

The M&C liquid sensors are based on the principle of electric conduc-

Note

tivity starting from a conductive value of 50 μS/cm.

Learn more about the M&C liquid sensors on our website www.

mc-techgroup.com.

The connecting cable between cooler and external liquid sensor can not exceed a length

of 3 m (19.84 ft.).

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 51

Page 53

The EC-30C can be connected to a liquid sensor with or without cable breakage detection.

The default configuration of the EC-30C is for a sensor with cable breakage detection.

Sensors without cable breakage detection can be connected only to

devices with a specific configuration.

Note

When ordering the EC-30C, please let us know whether you are going

to use a sensor with or without cable breakage detection. We will

configure your EC-30C individually for the required sensor.

Do you need

help?

Do you need further information about liquid sensors? Please

contact the M&C Service!

8.8.3 Gas flow sensor FA 20 and gas flow meter FM 40 (optional)

The M&C gas flow alarm sensor FA 20 is used for monitoring of sample gas or test gas

failures in analyzing devices or analyzing systems. The EC-30C offers the option to process

data coming from the mono-stable gas flow alarm sensor. The gas flow sensor allows both

internal and external mounting.

In case of internal mounting of the FA20, it is necessary to mount into the EC-30C an additional flow meter FM40 with a scale of 0 to 250 l/h.

The flow meter FM40 will be added at the end of the internal tubing. When the flow meter

is triggered, the EC-30C gives a warning message which will be recorded in the alarm and

warning history. This allows to recognize a possible freezing up or leakage in the system at

an early stage.

The connecting cable of an external flow meter must not exceed a length of 3m (19.84 ft.).

Do you need

help?

Do you need further information about gas flow sensors or flow

meters? Please contact the M&C Service!

52 EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com

Page 54

9 Start-up

Wrong supply voltage can destroy your cooler!

ATTENTION

ATTENTION

When the EC-30C is started, one of the gas lines through the deep-cooler is always open.

The outlet status contact must be connected to an external sample gas pump or a valve

in the sample gas line to protect the entire analysis system by immediately cutting off the

gas supply in the event of error messages of the cooler.

Note

When connecting the equipment, make sure that the supply voltage

is identical with the information provided on the model type plate!

Damages of the downstream analyzers can occur! Observe the alarm

contacts!

Do not extract gas when the EC-30C is turned off or when the LED

light is red!

Disruption in operation possible!

Before starting up the gas cooler make sure that it has been placed in

its operating position for at least two hours! Transport or mounting

can lead to the redistribution of the cooling liquid within the system

and this can cause operating trouble when the cooler is turned on to

early.

Note

The start-up ambient temperature has to be +5 °C to +45 °C (+41 °F

to +113 °F).

9.1 Preparation for start-up

Please take into consideration all equipment and process specific security measures before

initial start-up.

Before initial start-up, follow these steps:

Open the front panel of the EC-30C and connect all cable connections required

(power, relay, mA etc.).

Connect all outputs required and - where necessary - connect them to the

measuring station.

Close and secure the device again.

Apply the correct supply voltage 115 V / 60 Hz o 230 V / 50 Hz according to the

specification plate.

Connect the cooler to the power supply.

The control electronics of the EC-30C permits automatic start up of the cooler, which ensures safe operation regardless of external influences such as a power failure. The error

diagnostic will report possible error sources.

EC-30C | 1.00.02 +49 2102 935 888 www.mc-techgroup.com 53

Page 55

9.2 Temperature chart of the start-up stages

When started up, the EC-30C carries out a self-test to check the main components of the

unit.

The self-test consists of six testing steps. Each of the test steps is symbolized by a smiley

icon. After successful self-testing the unit enters the starting phase and starts cooling.

When the display shows a ‘Test failed’-icon, the unit has detected an error. The cooler will

not enter the start-up phase.

If the self-test has failed, the display alternates between the screen with the smileys and

the service screen. These screens will remain on the display until the problem has been

solved.