M&C CSS Series, CSS-M Series, CSS-W Series Instruction Manual

Gas conditioning unit Series CSS®

CSS-M/W wall mount

Instruction Manual

Version 1.02.00

2 CSS-M/W | 1.02.00 www.mc-techgroup.com

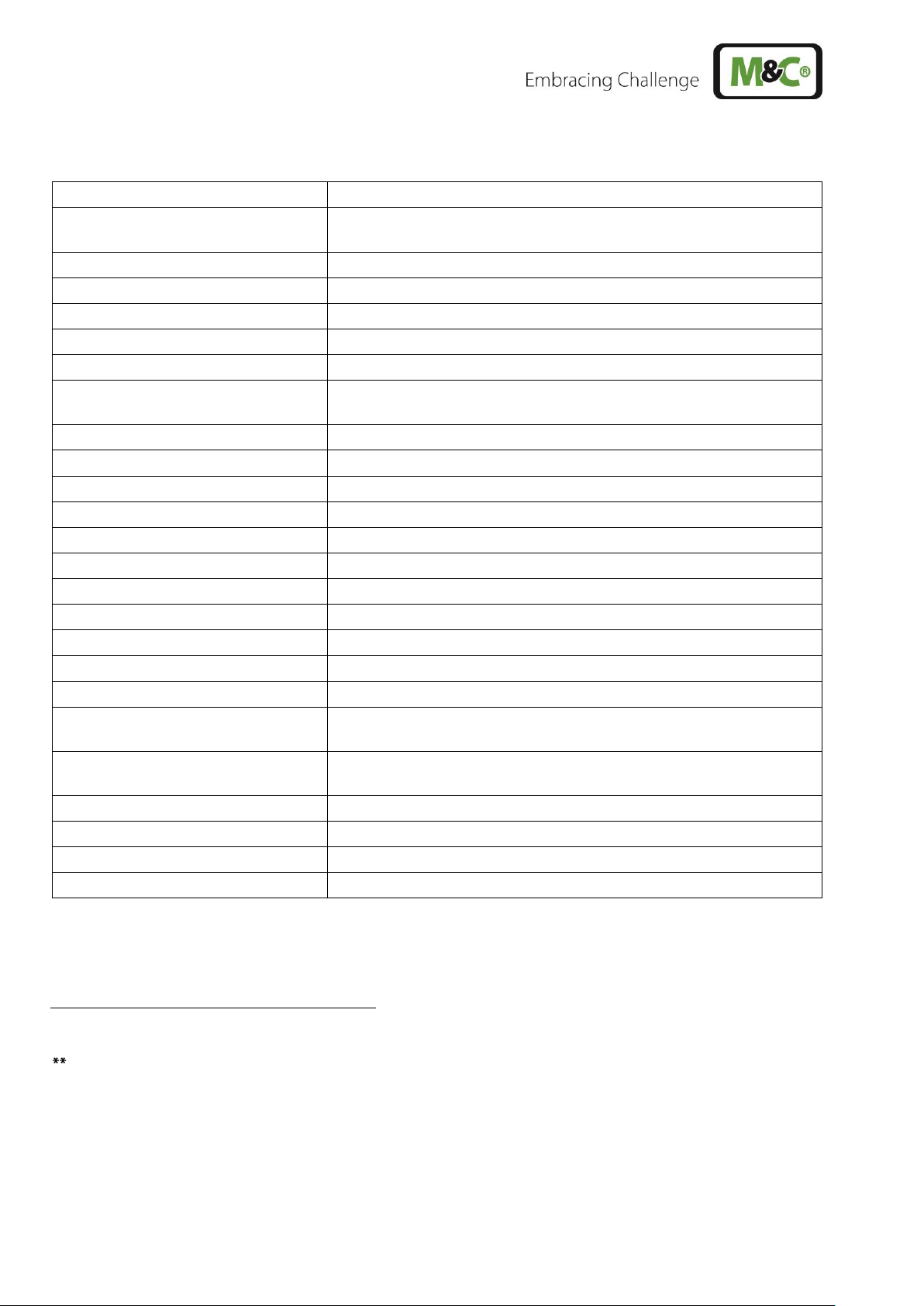

Contents

1 General information .................................................................................................................... 4

2 declaration of conformity ........................................................................................................... 4

3 Safety instructions ...................................................................................................................... 5

4 Warranty ...................................................................................................................................... 5

5 Used terms and signal indications ................................ ............................................................ 6

6 Introduction ................................ ................................................................................................ . 7

7 Application .................................................................................................................................. 7

8 Technical Data ............................................................................................................................. 8

9 Description .................................................................................................................................. 9

10 Receipt of marchendise and storage ................................................................................... 10

11 Installation instructions ................................................................................................ ....... 10

12 Supply connections ............................................................................................................... 11

12.1 Hose connections ................................................................................................................ 11

12.2 Electrical connections .......................................................................................................... 12

13 Starting ................................................................................................................................... 13

13.1 Cooler regulation .................................................................................................................. 13

13.2 New pump switch since 06/2007 .......................................................................................... 14

14 Closing down ......................................................................................................................... 14

15 Maintenance ........................................................................................................................... 15

15.1 Replacement of the filter element and the O-Ring ............................................................... 16

15.2 Dismountage of the sample gas pump for examination or maintenance .............................. 16

15.3 Maintenance of the integrated peristaltic pump type SR 25.2 .............................................. 16

16 Operating of the integrated electronic temperature regulator ........................................... 20

16.1 Changing the set value ........................................................................................................ 20

17 Trouble shooting ................................................................................................................... 21

18 Spare part list ........................................................................................................................ 23

19 Appendix ................................................................................................................................ 24

List of Illustrations

Figure 1 Scheme of gas flow ........................................................................................................... 7

Figure 2 Dimensions CSS-M/W ....................................................................................................... 9

Figure 3 Hose connections CSS-M/W ........................................................................................... 11

Figure 4 Electronic board CSS-M.. ................................................................................................ 14

Figure 5 Replacement of the filter element and the O-ring ............................................................ 16

Figure 6 Replacement of the pump hose ....................................................................................... 17

Figure 7 Disassembly of pump head and driver ................................ ............................................. 18

Figure 8 Check of axes and rolls ................................................................................................... 18

Figure 9 Front view of the temperature regulator ........................................................................... 20

Figure 10 Circuit diagram CSS-M/W ............................................................................................. 25

www.mc-techgroup.com CSS-M/W | 1.02.00 3

Dear customer,

Thank you for buying our product. In this instruction manual you will find all necessary information

about this M&C product. The information in the instruction manual is fast and easy to find, so you can

start using your M&C product right after you have read the manual.

If you have any question regarding the product or the application, please don’t hesitate to contact

M&C or your M&C authorized distributor. You will find all the addresses in the appendix of this

manual.

For additional information about our products and our company, please go to M&C’s website

www.mc-techgroup.com. There you will find the data sheets and manuals of all our products in

German and English.

This Operating Manual does not claim completeness and may be

subject to technical modifications.

© 12/2016 M&C TechGroup Germany GmbH. Reproduction of this

document or its content is not allowed without permission from M&C.

CSS® is a registered trade mark.

Version: 1.02.00

4 CSS-M/W | 1.02.00 www.mc-techgroup.com

Head Office

M&C TechGroup Germany GmbH Rehhecke 79 40885 Ratingen Germany

Telephone: 02102 / 935 - 0

Fax: 02102 / 935 - 111

E - mail: info@mc-techgroup.com

www.mc-techgroup.com

1 GENERAL INFORMATION

The product described in this manual has been built and tested in our production facility.

All M&C products are packed to be shipped safely. To ensure the safe operation and to maintain the

safe condition, all instructions and regulations stated in this manual need to be followed. This manual

includes all information regarding proper transportation, storage, installation, operation and

maintenance of this product by qualified personnel.

Please follow all instructions and warnings closely.

Please read this manual carefully before commissioning and operating the device. If you have any

questions regarding the product or the application, please don’t hesitate to contact M&C or your M&C

authorized distributor.

2 DECLARATION OF CONFORMITY

CE - Certification

The product described in this operating manual complies with the following EU directives:

EMV-Instruction

The requirements of the EU directive 2014/30/EU “Electromagnetic compatibility“ are met.

Low Voltage Directive

The requirement of the EU directive 2014/35/EU “Low Voltage Directive“ are met.

The compliance with this EU directive has been examined according to DIN EN 61010.

Declaration of conformity

The EU Declaration of conformity can be downloaded from the M&C homepage or directly requested

from M&C.

www.mc-techgroup.com CSS-M/W | 1.02.00 5

3 SAFETY INSTRUCTIONS

Please follow these safety directions and instructions regarding installation, commissioning

and operation of the CSS-M/W:

Read this manual before commissioning and operating the product. Please make sure to follow all

safety instructions.

Installation and commissioning of electrical devices must be carried out only by qualified skilled

personnel in compliance with the current regulations.

The installation and commissioning of the device must conform to the requirements of VDE 0100 (IEC

364) ‘Regulations on the Installation of Power Circuits with Nominal Voltages below 1000V’ and must

be in compliance with all relevant regulations and standards.

Before connecting the device, please make sure to compare the supply voltage with the specified

voltage on the product label.

Protection against damages caused by high voltages:

Disconnect the power supply before opening the device for access. Make sure that all extern power

supplies are disconnected.

Operate the device only in the permitted temperature and pressure ranges. For details please refer to

the technical data sheet or manual.

Install the device only in protected areas, sheltered from rain and moisture. The product should not be

exposure to the elements.

This device is NOT certified to be installed or operated in explosive hazardous areas.

Installation, maintenance, inspections and any repairs of the devices must be carried out only by

qualified skilled personnel in compliance with the current regulations.

4 WARRANTY

In case of a device failure, please contact immediately M&C or your M&C authorized distributor.

We have a warranty period of 12 months from the delivery date. The warranty covers only

appropriately used products and does not cover the consumable parts. Please find the complete

warranty conditions in our terms and conditions.

The warranty includes a free-of-charge repair in our production facility or the free replacement of the

device. If you return a device to M&C, please be sure that it is properly packaged and shipped with

protective packaging. The repaired or replaced device will be shipped free of delivery charges to the

point of use.

6 CSS-M/W | 1.02.00 www.mc-techgroup.com

5 USED TERMS AND SIGNAL INDICATIONS

DANGER!

This means that death, severe physical injuries and/or important

material damages will occur in case the respective safety

measures are not fulfilled.

WARNI NG !

This means that death, severe physical injuries and/or important

material damages may occur in case the respective safety

measures are not fulfilled.

CARE!

This means that minor physical injuries may occur in case the

respective safety measures are not fulfilled.

CARE !

Without the warning triangle means that a material damage may

occur in case the respective safety measures are not met.

ATTEN T IO N!

This means that an unintentional situation or an unintentional

status may occur in case the respective note is not respected.

NOTE!

These are important information about the product or parts of the

operating manual which require user’s attention.

SKILLED STAFF

These are persons with necessary qualification who are familiar

with installation, use and maintenance of the product.

www.mc-techgroup.com CSS-M/W | 1.02.00 7

6 INTRODUCTION

The gas conditioning unit CSS-M/W for wall mounting is a completely pre-assembled compact gas

conditioning system working continuously and delivering a sample gas quantity of max. 70Nl/h.

The entire gas conditioning unit is housed in a compact and robust steel sheet case which ensures

that the gas analyses can be carried out quickly, safely and with a minimum amount of maintenance.

The gas conditioning unit CSS-M/W for wall mounting must not be used for sampling of explosive

gas/air or gas/oxygen mixtures, for sampling of combustible gases which may result in an explosive

mixture in combination with air or oxygen nor in explosive atmospheres and hazardous areas.

7 APPLICATION

The gas conditioning unit CSS-M/W for wall mounting has been developed for continuous operation.

The components integrated in the system CSS-M/W are intended for „standard use“.

Figure 1 Scheme of gas flow

Gas cooler ECP

Front panel filter FPF-2-0,3GF, 0.3 µm porosity with integrated liquid alarm

Sample gas pump N3 KPE

Flowmeter FM40

Peristaltic pump SR25.2 for continuous automatic condensate removal

8 CSS-M/W | 1.02.00 www.mc-techgroup.com

8 TECHNICAL DATA

Gas Conditioning Unit Type

CSS-M/W

Sample outlet dew point

Range of adjustment: +2 °C (+35.6 °F) ..... +15 °C (+59 °F),

factory setting: +5 °C (+41 °F)

Dew point stability

at constant conditions < ± 0.1 °C (± 0.18 °F)

Sample inlet temperature

**max. 80 °C (+176 °F)**

Gas inlet water vapour saturation

**max. +50 °C (+122 °F)

Gas flow rate

**max. 70 l/h

Ambient temperature

**+10 °C to +45 °C (+50 °F to 113 °F) **

Air humidity

75 % year’s average, rare and slight dewing of 95% on 30

days per year admissible

Storage temperature

-25 °C to +65 °C (~-13 °F to +149 °F)

Pressure

0.7 bar to 1.4 bar abs.*

Total cooling capacity

max. 40 kJ/h

Number of gas inlets

1

Number of gas outlets

1*

Sample gas connections

Hose connection 4/6 mm

Material medium-touched parts

Glass, PVDF, PVC, Novoprene®, FPM, PPH

Ready for operation

Approx. 10 min.

Mains power supply

230 V 50 Hz ± 10 % or 115 V 60 Hz ± 10 %

Power consumption

max. 240 VA

Fuse protection

4 A, time-lag, 5 x 20 mm (approx. 0.2” OD x 0.79” length)

Electrical mains supply

mains cable 3 x 1 mm2 (approx. AWG 17), signal cable 3 x 0.5

mm2 (approx.. AWG 20), 3 m (9.84 ft) length

Status alarm, 1 change over

contact, potential free

contact rating 250 VAC, 2 A, summary alarm for gas flow, liquid

and cooler temperature

Case protection

IP20 (EN 60529)

Housing version

Sheet steel case

Case dimensions (H x W x D)

177 mm x 220 mm x 300 mm (6.97” x 8.66” x 11.81”)

Weight

Approx. 11 kg (24.25 lbs)

PVDF=Polyvinylidenefluoride

PVC=Polyvinyl chloride

FPM=Fluor caoutchouc

PPH=Polypropylene hard

Specifications for components see appendix

* Standard

Maximum values in technical data must be rated in consideration of total cooling capacity at 25 °C (77

°F) ambient temperature and an outlet dew point of 5 °C (41 °F).

Loading...

Loading...