User Manual

Reflow Batch Oven

Model: X-REFLOW305

schafft Vorsprung

MBR ELECTRONICS • SOLDER TECHNOLOGY

JONASTRASSE 8 • CH-8636 WALD • SWITZERLAND

Internet:www.mbr.ch • E-Mail: info@mbr.ch

Tel: +41(0)55 246 2400 • Fax: +41(0)55 246 2418

Contents PAGES

1. Introduction 3

2. Specifications 4

3. Safety 5

4. Unpacking and Set-Up 5

5. Panel View with Power ON 8

6. Entering a Temperature Profile 8

1 Entering a New Temperature Profile 9

2 Running a Pre-installed Profile 11

7. Running a Temperature Profile 13

8. Cooling Cycle 14

9. Open Circuit Thermocouple Detection 15

10. Warranty Statement 15

2

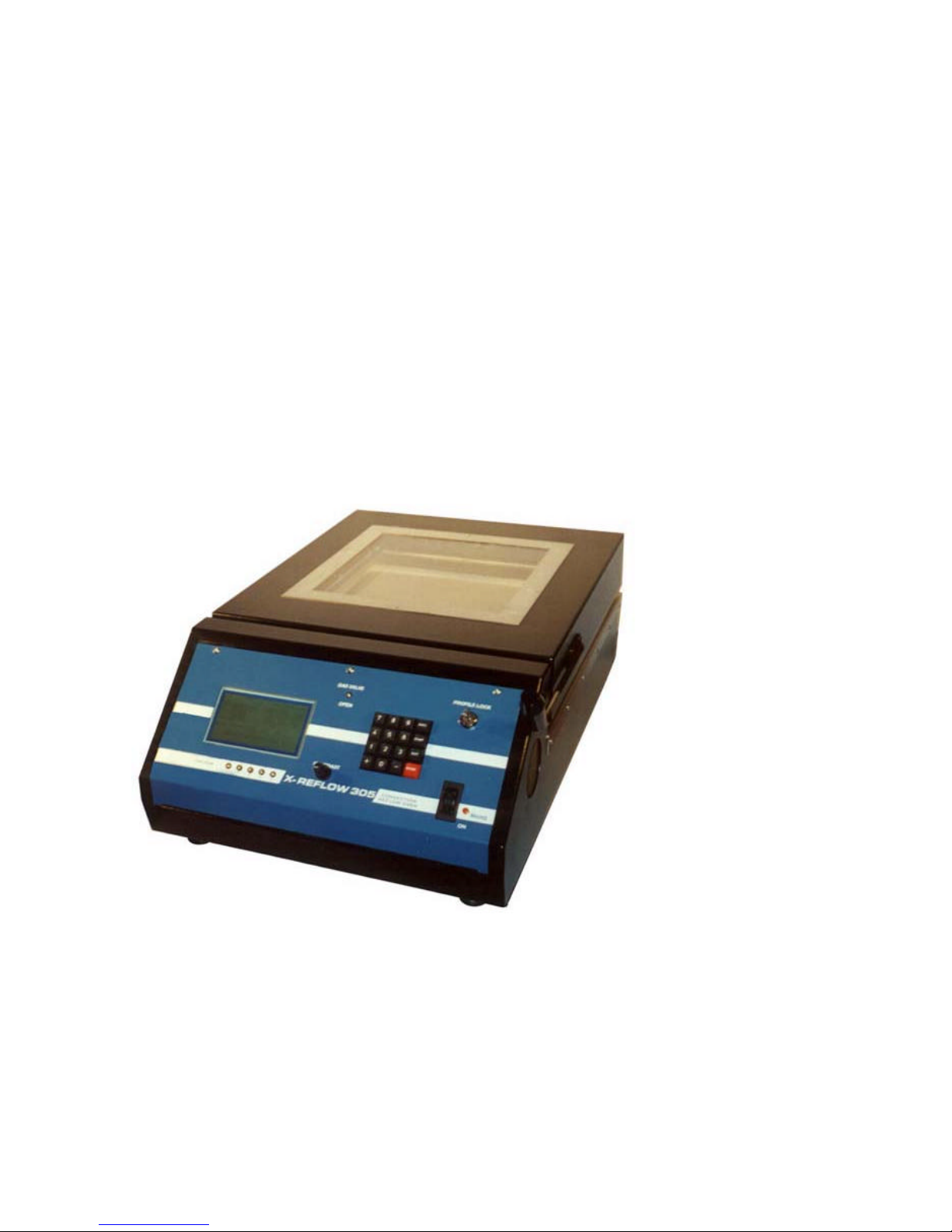

1. Introduction

Congratulations on your purchase of Batch Reflow Oven Model X-REFLOW305. XREFLOW305 is a uniquely designed full convection Reflow Batch Oven for use in low

volume production such as simulation of a mass-production Reflow Oven, heat resistance

test of components and laboratory experiments where precise and accurate heating is

required. The unit has several unique features, which enhance operation. Full convection

heating with independent control of front and rear heaters, which enable hot air

temperature and time setting in 4 steps and free setting of various profiles for various

PCBs. A large inspection window allows monitoring during operation also applicable with a

microscope. The built-in computer uses closed-loop monitoring to ensure absolute

repeatability of the temperature profiles and has the memory to store 255 profiles allowing

very quick profile changes perfect for low volume assembly. The large backlight display

shows either the specific temperatures or time digitally or graphically. A Nitrogen Gas inlet

is standard.

X-REFLOW305 View of the system

3

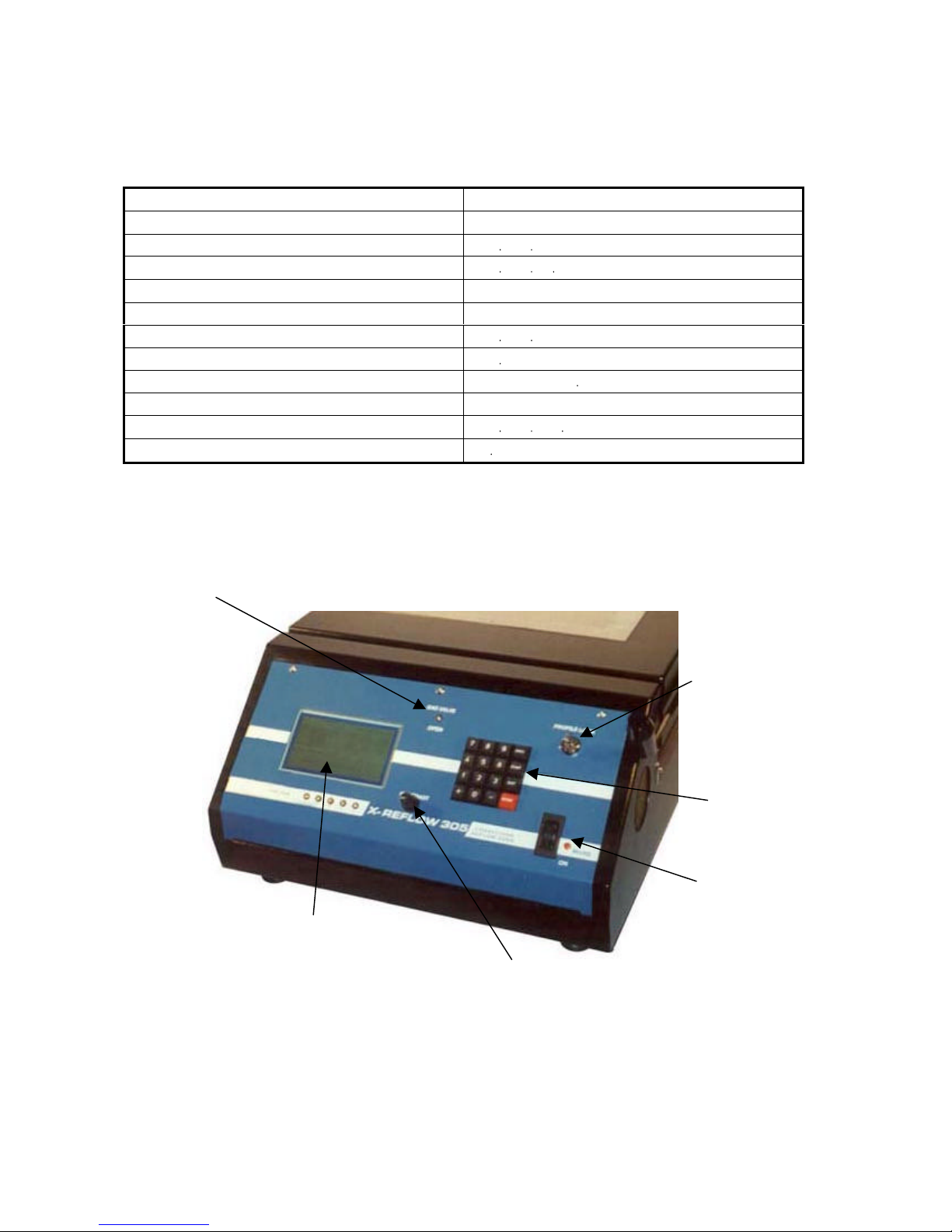

2. Specifications

Numerical

X-REFLOW305 Specifications

Temperature Profile 4 Steps (Temperature & Time)

Cooling Cycle 1 Step (Temperature only)

Monitoring Window Size

Maximum P.C.B. Size

Nitrogen Gas Connector Standard supply

Profile Memory Capacity 255 profiles

Temperature Control Range

Input Voltage

Heater Capacity

Power Cord 3m(without plug)

External Size/Dimensions

Weight

280 280

305 305 40

150 350 (At Center air over the mesh)

220 240VAC 50Hz or 60Hz. Single phase

4.8KW(2.4KW 2)

510 780 270

35

Gas Valve LED

Key Switch

Key

Power Switch

Display

Kontrast Control Knob

X-REFLOW305 Front Panel View

4

3. Safety

l The fumes emitted during soldering are irritants and therefore should be removed. A

pumped vent is located at the rear of the unit and should be ducted accordingly.

l Area close to the hood becomes hot, therefore care should be taken when working a

round this area.

l This oven must be properly grounded.

l Please read this operation manual carefully prior to use.

l Area around the viewing window becomes hot, therefore care should be taken when

working a round this area.

l After ending the cooling cycle, the inside of oven is still hot, therefore care should be

taken when removing and mounting the PCB.

l Be sure to wear the cotton gloves to prevent burns when taking out the PCB from the

oven and placing a new one. The PCB is still hot.

4. Unpacking and Set-Up

1 Connecting to the Power Supply

X-REFLOW305 must be connected to 50/60Hz. 220-240V single-phase 16A power

supply.

2 Operating Frequency

X-REFLOW305 has a changeover switch for 50Hz or 60Hz on the rear panel of the

unit, please set it to match your frequency. As the timing is dependent upon the

operating frequency, failure to set it on the correct value will result in timing errors

during the oven’s cycle. When the oven is first turned ON, the computer samples the

link and the set operating frequency displayed on LCD panel. Be sure to check that it

shows the correct frequency.

5

Circuit Breaker

There is a circuit breaker on the left-hand side of the rear panel, please turn it ON

prior to the operation.

3 Power Switch

There is a power switch on the front panel, please turn ON after turning ON the circuit

breaker.

4 Security Key Switch

A key switch is provided to prevent unauthorized access to the profile parameters and

the profile storage memory. The key must be in place and turned in the clockwise

direction “ON” before starting the oven or changing a profile. The key can only be

removed in the “OFF” position. Two keys are provided. One key is a spare, please

keep it in a safe place.

5 Display Contrast

The display contrast is adjusted by turning the round knob next to the display.

6 Nitrogen connection & Operation Procedure (Please refer to Illus. 1)

I. Attach the Nitrogen source(0.5 1 /2) to the Nitrogen input port on the rear

panel of the oven.

II. Be sure that Nitrogen switch is set in the up position on the rear panel of the

oven.

III. Start the temperature profile running and the Nitrogen valve within the oven

can be heard to activate and Nitrogen is then released into the oven heating

area. The LED (GAS VALVE) on the front panel should light.

Note: The nitrogen valve will open at the beginning of the profile (Preheat 1). To allow

enough time to purge the oven, Preheat 1 should be set for 3 to 4 minutes.

6

IV. Once the temperature profile has completed its running cycle the Nitrogen

Air 60Hz

Switch

Nitrogen 50Hz

ON

OFF

Main Label

valve will turn off automatically and the front panel LED (GAS VALVE) will go

off.

Note: Nitrogen will not enter the heating area with the Nitrogen changeover switch

(Nitrogen/Air) in the down (Air) position.

Nitrogen input port

Fuse holder (1A Fuse) Flex nose = 8 mm

Air/Nitrogen

Circuit

Breaker

Power Cord Main Frequency Switch

Illustration 1 X-REFLOW305 Rear Panel View

7

5. Panel view with Power “ON”

CONVECTION BATCH OVEN

PROFILE NO: XXX

SET TEMPERATURES FRONT REAR

PRE-HEAT 1 XXX XXX

PRE-HEAT 2 XXX XXX

PRE-HEAT 3 XXX XXX

REFLOW XXX XXX

COOLING

TARGET

ACTUAL TEMPERATURE XXX XXX

SECURITY SWITCH NOT ENABLED!

The above display is shown if the oven is switched ON without the security key in place. If

the key is turned ON or is already ON the display will be shown as:

CONVECTION BATCH OVEN

SET TEMPERATURES FRONT REAR

PRE-HEAT 1 150 150

PRE-HEAT 2 150 150

PRE-HEAT 3 150 150

REFLOW 150 150

COOLING

TARGET

XXX

PROFILE NO: NEW

100

TIME

XXXX

XXXX

XXXX

XXXX

TIME

0000

0000

0000

0000

ACTUAL TEMPERATURE OFF OFF

TAIYO ELECTRIC BATCH OVEN

HIGH TEMPERATURE OVEN

* It will display 60Hz if the changeover switch set on 60Hz.

*

50Hz VERSION

PRESS ANY KEY TO START

6. Entering Temperature profile.

In the opening display press any key. The user prompt dialog box changes to:

PRESS ”+” KEY FOR STORED PROFILE

PRESS ”-” KEY FOR NEW PROFILE

Pressing the “+”key enters the procedure for loading a profile from the computer’ memory

(Please refer to Page 10. Running a pre-installed profile).

Pressing the “-“ key allows new profile parameters to be entered using the numeric keys.

8

1 Entering New Temperature profile.

When the “-“key is pressed, the display changes to:

CONVECTION BATCH OVEN

PROFILE NO: NEW

SET TEMPERATURES FRONT REAR TIME

PRE-HEAT 1 #50 150 0000

PRE-HEAT 2 150 150 0000

PRE-HEAT 3 150 150 0000

REFLOW 150 150 0000

COOLING

150

TARGET

ACTUAL TEMPERATURE OFF OFF

ENTER SET TEMPERATURES AND ZONE TIMES

TEMPERATURES MAXIMUM 350 MINIMUM 150

ZONE TIMES MAXIMUM 9999 MINIMUM 0000

”ENTER” SAVE VALUE ”CANCEL” LAST VALUE

With the cursor flashing at the position “#”, pressing the ‘CANCEL’ key at this point

returns to the previous user dialog box.

PRESS ”+” KEY FOR STORED PROFILE

PRESS ”-” KEY FOR NEW PROFILE

IF the “ENTER” key is pressed, the value currently displayed at the cursor position is

saved (The set value of the front heater is saved) and the cursor moves to the rear

heater setting.

Note: If the “CANCEL” Key is now pressed, the cursor moves to the front heater setting.

Entering the 3 digit temperature setting value, the display shows the rear heater

setting and the same value is displayed. If the same value is required for both the

front and rear, pressing the ‘ENTER’ key will set the rear heater to the same set value

as the front heater. If the rear heater needs to be set at a different value from front

heater, enter the value using the numeric keys. When both heater values have been

entered the cursor is positioned at the ’TIME’ zone value. Enter the desired time using

the numeric keys. (Unit of TIME is seconds) Pressing the enter key results in the

present displayed time value being saved. A numeric input will change the time value

set. Pressing the ‘CANCEL’ key will move the cursor to the previous setting if an error

occurs.

9

This process is repeated for all 4 heating zones. The ‘CANCEL’ key is used to go

back to a previous zone if an error is made and re-enter the correct value.

The time zone LED will flash at the bottom of the Panel and showing the zone you are

in while inputting the set values. The LED flashing moves in the following order.

1 PRE-HEAT1

2 PRE-HEAT2

3 PRE-HEAT3

4 REFLOW

5 COOLING TARGET

TIME ZONE

1 2 3 4 5

The cursor is then positioned at the “cooling target” temperature (Cooling Cycle). This

value is the temperature that the oven must fall to before the profile is finished.

When the cooling target (cooling cycle) is entered, the user dialog box changes:

STORE NEW PROFILE

ENTER PROFILE NUMBER 001-255

PRESS ”CANCEL” KEY TO EXIT

The cursor is flashing in the profile number dialog box at the “#” position.

CONVECTION BATCH OVEN

PROFILE NO. #EW

If the ‘CANCEL’ key is pressed, the profile is not saved in the computer memory and

the oven will be ready to run. By pressing ‘START’ key, the oven starts the heating.

If wanting to save the profile in the computer memory, a 3-digit number must be

inputted.

10

If the number entered is already used for a profile stored, the user dialog box changes

to:

PROFILE STORE LOCATION IN USE

PRESS ”EDIT” KEY TO OVERWRITE

PRESS ”CANCEL” KEY TO EXIT

Pressing the “EDIT” key replaces the stored profile with the profile that has just been

created.

If the “CANCEL” key is pressed, the user dialog box returns to the previous display

where the new profile number can be entered.

When the profile has been successfully stored the user dialog box changes to:

PROFILE STORED

PRESS ANY KEY

When pressing any key, the oven is ready to run and the user dialog box on page 13.

7. . is shown.

2 Running a pre-installed profile.

PRESS ”+” KEY FOR STORED PROFILE

PRESS ”-” KEY FOR NEW PROFILE

In the user dialog box shown above, pressing the “+” key will change the user dialog

box to the following:

VIEWING PROFILE STORE

ENTER PROFILE NUMBER 001-255

”+” NEXT PROFILE ”-” PREVIOUS PROFILE

”EDIT” LOAD PROFILE ”CANCEL” EXIT

Pressing the ‘CANCEL’ key returns to the previous user dialog box. If the “+” key is

pressed, the main display shows the stored profile as Memory No.1. If the “+” key is

pressed, the display shows the next profile and this is repeated with a short delay in

between profiles.

Any unused Memory number is skipped. This continues until the last profile memory is

reached; at this point a buzzer sounds to indicate the last profile.

11

The ‘-‘ key is used the same way, but this time the profile memory is displayed in the

reverse order with the buzzer sounding when the newest profile is reached.

There is no cursor, but when a valid profile memory number is entered, the profile can

be called up. If valid profile is displayed, pressing the ‘EDIT’ key loads that profile into

the running profile memory and the oven is ready to run as explained on page 13 7. .

Note: 5 profiles are pre-stored prior to initial operation at profile No.001 to 005. If they

are not needed, you may over write.

If no profile is stored in the memory, the profile parameter display as shown below:

CONVECTION BATCH OVEN

PROFILE NO: ###

SET TEMPERATURES FRONT REAR TIME

PRE-HEAT 1 NIU NIU NIU

PRE-HEAT 2 NIU NIU NIU

PRE-HEAT 3 NIU NIU NIU

REFLOW NIU NIU NIU

COOLING

NIU

TARGET

ACTUAL TEMPERATURE OFF OFF

VIEWING PROFILE STORE

ENTER PROFILE NUMBER 001-255

”+” NEXT PROFILE ”-” PREVIOUS PROFILE

”EDIT” LOAD PROFILE ”CANCEL” EXIT

If the ‘CANCEL’ key is pressed twice, user dialog box shows the following and

pushing either “+” or “-“ key returns to the previous profile.

PRESS ”+” KEY FOR STORED PROFILE

PRESS ”-” KEY FOR NEW PROFILE

12

7. Running a Temperature profile.

1 When either a new or stored profile has been loaded the user dialog box changes to:

PRESS ”START” KEY TO START OVEN

PRESS ”CANCEL” KEY TO EXIT

2 At this point the actual temperature in the center over the mesh (compensate the

measured value at hot air outlet temperature) is displayed. If the temperature is lower

than 123 , the display shows ‘LOW’. If the temperature is higher than 376 , the

display shows ‘HOT’.

Pressing the ‘START’ key starts the oven with the user dialog box changing to:

PRESS ”CANCEL” KEY TO STOP OVEN

PRESS ”+” KEY FOR GRAPHIC DISPLAY

PRESS ”-” KEY FOR TEXT DISPLAY

The oven is now operating following the profile. The time display will decrease until it

reaches “0000”, then the next zone is starts to run. The cursor flashes to indicate the

present zone and the zone LED lights. Flashing of cursor and light of LED are

continuous until the reflow zone timer decreases to “0000” and the oven enters its

cooling cycle.

When the profile is over, the graphic display disappears and only a numeric mode is

shown. The graphic display is automatically reduced even if the cycle time is

extended to show the full scale.

13

8. Cooling Cycle

1 When the profile is completed (4 steps) or cancelled, the cooling cycle is entered and

user dialog box changes to:

OVEN COOLING

PRESS ”CANCEL” KEY TO EXIT

The oven will now wait until both heater temperatures are below the cooling target

temperature or the “CANCEL” key is pressed. The display then flashes and the

buzzer sounds to indicate that the profile is completed.

Pressing any key at this point change user dialog box to:

PRESS ”+” KEY FOR NEW PROFILE

PRESS ”-” KEY FOR SAME PROFILE

I. If the “-“ key is pressed, the user dialog box changes to:

PRESS ”START” KEY TO START OVEN

PRESS ”CANCEL” KEY TO EXIT

In the above display if pressing the “START” key, the oven is now ready to repeat

the profile. If the “CANCEL” key is pressed, user dialog box changes to:

PRESS ”+” KEY FOR STORED PROFILE

PRESS ”-” KEY FOR NEW PROFILE.

II. If the “+” key is pressed, the dialog box returns to:

PRESS ”+” KEY FOR STORED PROFILE

PRESS ”-” KEY FOR NEW PROFILE.

If the “+” Key is pressed, stored profile will be ready to run and if the “-“ key is

pressed, it will be ready to create a new profile.

Note: The security key must be switched ON to run a new profile; otherwise the

“SECURITY KEY NOT PRESENT!” is displayed.

14

9. Open Circuit Thermocouple Detection

If either of the thermocouples is in an open circuit, the profile is cancelled and the user

dialog box changes to:

THERMOCOUPLE OPEN CIRCUIT

PRESS ”CANCEL” KEY

The open circuit thermocouple is identified by the “O:C” displayed in the heater actual

value position. Pressing the “CANCEL” key returns to the display in 6. Entering a

Temperature profile.

Contact your dealer if it is displayed.

10. WARRANTY

• One-year parts and Labor.

• MBR ELECTRONICS cannot accept responsibility for damage to the PCBs processed

in the X-REFLOW305 due to incorrect setting or misuse by the operator. Read

carefully prior to use.

schafft Vorsprung

MBR ELECTRONICS • SOLDER TECHNOLOGY

JONASTRASSE 8 • CH-8636 WALD • SWITZERLAND

Internet:www.mbr.ch • E-Mail: info@mbr.ch

Tel: +41(0)55 246 2400 • Fax: +41(0)55 246 2418

Loading...

Loading...