Page 1

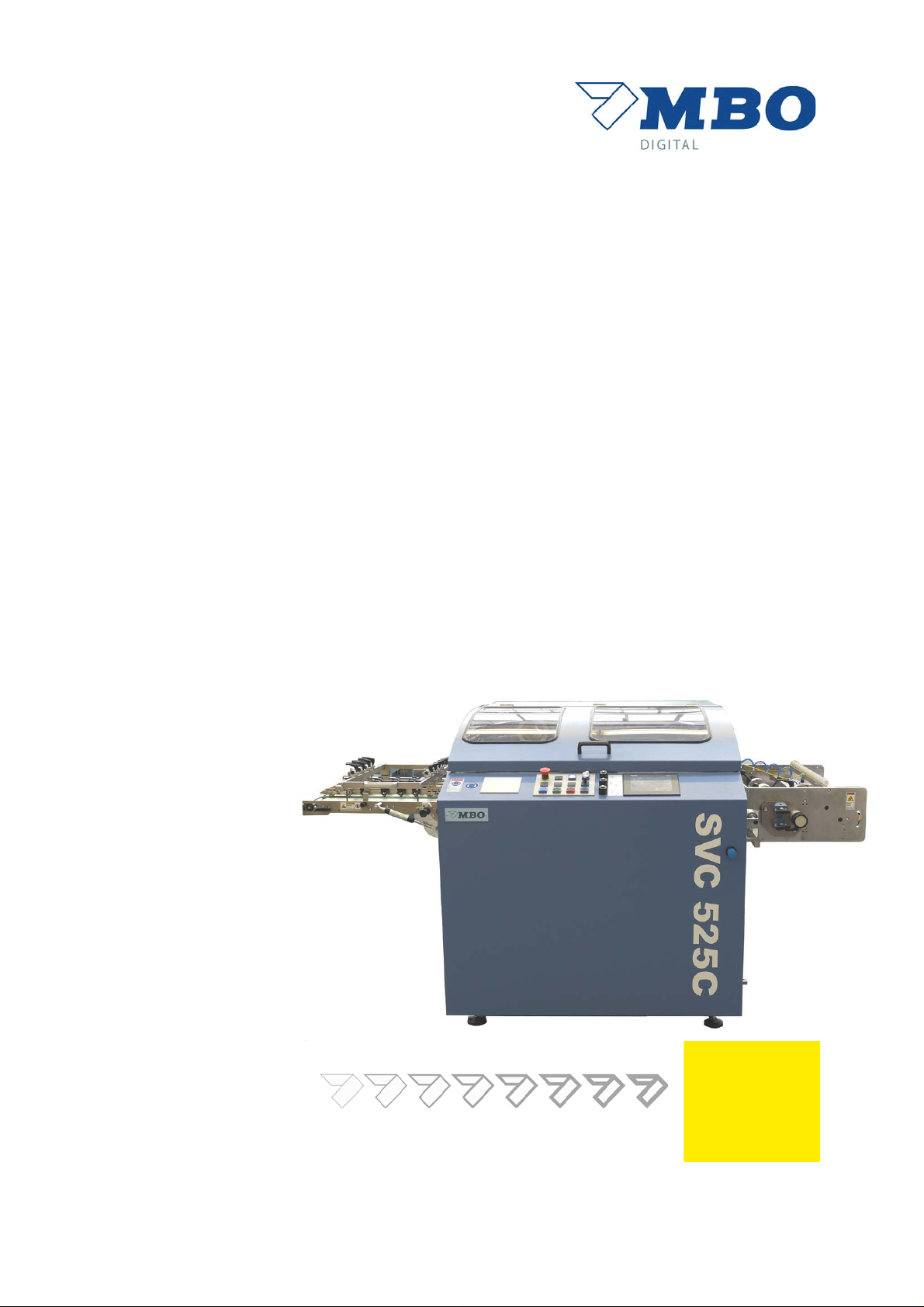

Sheeter

Translation of the original operating manual

Keep for future reference!

SVC525C

Page 2

Type of machine:

Sheeter

Configuration:

Type of document:

Version:

Status as

V1.1

11/04/2014

of:

Language:

English

Manufacturer:

Subject to alterations!

SVC 525C

Translation of the original operating manual

Author:

Wolfgang Matzner

Machine no.:

File name:

MBO Maschinenbau Oppenweiler Binder GmbH & Co. KG

PO Box 1 169

71567 Oppenweiler

GERMANY

Tel.: +49 7191 46 0

Fax: +49 7191 46 34

http://www.mbo-folder.com

info@mbo-folder.com

BA_SVC525C

_V1.1_us-en

Copyright: This documentation is subject to copyright law. The claimed copyright includes

all forms and types of copyright-protected materials and information that are

currently permitted. No part of the documentation may be copied, otherwise

duplicated, edited or translated into other languages, regard less of the manner

in which or with which tools this takes place.

Electronically-stored information provided by the manufacturer (CD-ROM, Internet) may be printed out by the user if the created print medium serves the

purpose of use or service of the product described.

Page 3

Name plate and

1

2

3

5

4

CE marking:

For all questions relating to your machine, please contact your

MBO agency.

You can find the address on our home page: www.mbo-folder.com.

For the identification of the machine and the most important machine data,

see the name plate on the machine.

1 CE marking

2 Type of machine

3 Commission number

Illustration 1: Name plate

4 Year of manufacture

5 Name plate

Always specify these details for inquiries, service and spare parts orders:

• Commission number

• Type of machine

Sheeter SVC 525C

Page 4

EC Declaration of Conformity

according to EC Machine Directive 2006/42/EC, Annex II, No. 1 A.

The manufacturer

MBO Maschinenbau Oppenweiler Binder GmbH & Co. KG

Grabenstraße 4-6

71570 Oppenweiler

GERMANY

hereby declares that the machine described below

Designation Sheeter

Type SVC 525C

Commissioning no.

complies with the provisions of the following EC directives

Machinery Directive 2006/42/EC

Low Voltage Directive 2006/95/EC

Harmonized standards applied:

EN ISO 12100:2010

EN 1010-1:2004+A1:2010

EN 1010-4:2004+A1:2009

EN ISO 60204-1:2006

Authorized representative for compiling the technical file:

Name Wolfgang Matzner

Address Grabenstraße 4-6

71570 Oppenweiler

GERMANY

Oppenweiler, 11/4/2014

_________________________________

Frank Eckert - Managing Director

Sheeter SVC 525C

Page 5

Table of contents

Table of contents

1 About this manual

1.1 Additional documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.1 Supplier documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Structure of the operating manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Signs and symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Description of safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.4.1 Signal words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4.2 Structure of safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.4.3 Safety sign . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4.4 Marking of danger spots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.5 User assessment of the operating manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2 Basic safety instructions

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Reasonable foreseeable misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3 Obligation and liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5 Residual risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5.1 Transport, interim storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5.2 Set-up, commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5.3 Adjustment and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5.4 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5.5 Decommissioning, storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.5.6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6 Product-specific hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6.1 Entanglement hazard and crushing hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6.2 Cutting hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6.3 Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.7 Life time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.7.1 Life time of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.7.2 Life time of the control-technical safety components . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.8 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.8.1 Transport, interim storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.8.2 Set-up, commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.8.3 Normal operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.8.4 Setting up/equipping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Sheeter SVC 525C

1

Page 6

Table of contents

2.8.5 Maintenance and repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.8.6 Work on electrical equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.9 Personnel, qualification and duties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2.9.1 Qualification of the personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.9.2 Duties of the operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.9.3 Duties of the operating personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.9.4 Duties of the maintenance personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.10 Personal protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.10.1 Operation and adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.10.2 Operational maintenance (cleaning) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.11 Work areas and workstations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.11.1 Layout from right to left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.12 Markings on the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.12.1 Position and meaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.13 Directions for emergencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.13.1 Emergency call numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.13.2 Behavior in case of accidents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3 Product description

3.1 Important notices about the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.1.1 View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.1.2 Standard equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.1.3 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.2.1 Floor plan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.2.2 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.2.3 Shipping and transport data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.2.4 Electrical supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.2.5 Compressed air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.2.6 External extraction system (to be provided by the customer) . . . . . . . . . . . . . . . . . . 42

3.2.7 Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.2.8 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Structure and function

4.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.1.1 Components of the sheeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.2 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

4.2.1 Cutting sequences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.2.2 Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.3 Infeed table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.3.1 In-feed unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.3.2 Sheeter unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2

Sheeter SVC 525C

Page 7

Table of contents

4.3.3 Discharge table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.3.4 External extraction system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.3.5 Compressed air connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4 Variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.4.1 Variant SVC 525 C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.5 Protective devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.5.1 Definition of terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.5.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.5.3 Protective hood with guard locking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.5.4 Guard door with guard locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.5.5 EMERGENCY STOP palm button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.5.6 Guards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.5.7 Faulty protective devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.5.8 Checking protective devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.5.9 Checklist for protective devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5 Operating and display elements, operating modes

5.1 Main switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.2 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.3 Touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.3.1 Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.3.2 Structure of the pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.3.3 Structure of the pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.3.4 Description of the pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.4 Temperature indicator, heating of cutting unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.5 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.5.1 Off-line mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.5.2 In-line mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

5.5.3 Inching mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6 Transport, interim storage

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.1.1 Qualification of personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.2 Packaging of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.2.1 Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.2.2 Accessories/options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.2.3 Incoming inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.2.4 In case of damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.3 Transporting the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.4 Interim storage of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.4.1 Outdoors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Sheeter SVC 525C

3

Page 8

Table of contents

6.4.2 In a storage room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7 Set-up, commissioning

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

7.1.1 Qualification of personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.1.2 Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.2 Setting up the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.3 Making the stationary mains connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

7.3.1 Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.3.2 Heed network prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.3.3 Observe the design of the stationary mains connection . . . . . . . . . . . . . . . . . . . . . . 92

7.3.4 Connecting to the stationary mains connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7.3.5 Connecting additional protective equipotential bonding . . . . . . . . . . . . . . . . . . . . . . 94

7.3.6 Checking the protective conductor connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

7.4 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

7.5 Final check of the protective devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.6 Inspection after initial operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

7.7 Connecting units to the sheeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

7.7.1 Description of the connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8 Adjustment and operation

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

8.1.1 Qualification of personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.1.2 Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

8.2.1 Press the EMERGENCY STOP palm button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8.2.2 Opening/closing the nip rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.2.3 Operating the sheeter in inching mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.2.4 Starting/stopping the sheeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8.3 Brief instructions for adjusting the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

8.4 Adjusting the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

8.4.1 Adjusting the nip rollers on the first infeed shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.4.2 Feeding in the web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

8.4.3 Smoothing the web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

8.4.4 Adjusting the guide plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

8.4.5 Adjusting the nip rollers on the second infeed shaft . . . . . . . . . . . . . . . . . . . . . . . . . 111

8.4.6 Adjusting the smoothers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

8.4.7 Adjusting the short belts after the cutting cylinder unit . . . . . . . . . . . . . . . . . . . . . . 113

8.4.8 Adjusting the smoothers after the cutting cylinder unit . . . . . . . . . . . . . . . . . . . . . . 114

8.4.9 Adjusting belts on the conveyor table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.4.10 Adjusting smoothers on the conveyor table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.4.11 Adjusting the longitudinal cut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

4

Sheeter SVC 525C

Page 9

Table of contents

8.4.12 Adjusting <Paper jam> sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

8.4.13 Adjusting <Web break> sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

8.4.14 Positioning the <Print mark> sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.4.15 Teaching the <Print mark> sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

8.4.16 Adjusting the format on the touchscreen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

8.4.17 Set upper cutting cylinder for chip-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

8.4.18 Angle of the cutting cylinder unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

8.4.19 Adjusting the print mark control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

8.4.20 Adjusting the cutting position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

8.4.21 Adjusting the air for paper transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

8.5 Creating production readiness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

8.6 Identification and handling of malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

8.6.1 Error display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

8.6.2 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

8.6.3 Troubleshooting/Cause/Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

9 Maintenance

9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

9.1.1 Qualification of personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

9.1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

9.2 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

9.2.1 Ordering spare and wear parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

9.3 Operational maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

9.3.1 Checking protective devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

9.3.2 Cleaning of the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

9.3.3 Cleaning the optical sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

9.3.4 Cleaning/replacing the filter of the vacuum pump VT 4.25. . . . . . . . . . . . . . . . . . . . 144

9.4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

9.4.1 Checking the pneumatic lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

9.4.2 Checking the guide shaft bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

9.4.3 Changing the knives of the longitudinal cutting unit . . . . . . . . . . . . . . . . . . . . . . . . . 147

9.4.4 Changing the knives of the cutting cylinder unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

9.4.5 Changing the plastic ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

9.4.6 Changing the nylon mat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

9.4.7 Checking the vacuum pump VT 4.25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

9.4.8 Checking the fan in the control cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

9.5 Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

9.6 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

10 Decommissioning, storage

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

10.1.1 Qualification of personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Sheeter SVC 525C

5

Page 10

Table of contents

10.1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

10.2 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

10.2.1 Temporary shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

10.2.2 Final decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

10.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

11 Disposal

11.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

11.1.1 Qualification of personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

11.1.2 Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

11.2 Disposal/recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

6

Sheeter SVC 525C

Page 11

1 About this manual

Everybody who will transport, set up, connect, operate, maintain, repair,

and dismantle this machine must read this operating manual.

Safe use of the machine is only possible once everybody has understood

the content of and follows all points of the operating manual. This applies

especially to the chapter on safety.

This operating manual contains important notes on how to operate the machine safely, correctly, and economically.

About this manual

Following these

notices helps

Supplementation • The operator must add instructions regarding national regulations for

Retention • This operating manual forms part of the machine. It must be available

If you sell the

machine

• To avoid hazards.

• To minimize repair costs and downtimes.

• To increase the reliability and service life of the machine.

accident prevention to this operating manual.

on the machine throughout the machine's entire service life.

• Give this operating manual to any subsequent owner or user of the machine.

We reserve the right to make technical changes to improve the machine,

even if these changes are not taken into account in this operating manual.

Sheeter SVC 525C

7

Page 12

About this manual

Additional documents

1.1 Additional documents

In addition to this operating manual, there are these documents about the

machine:

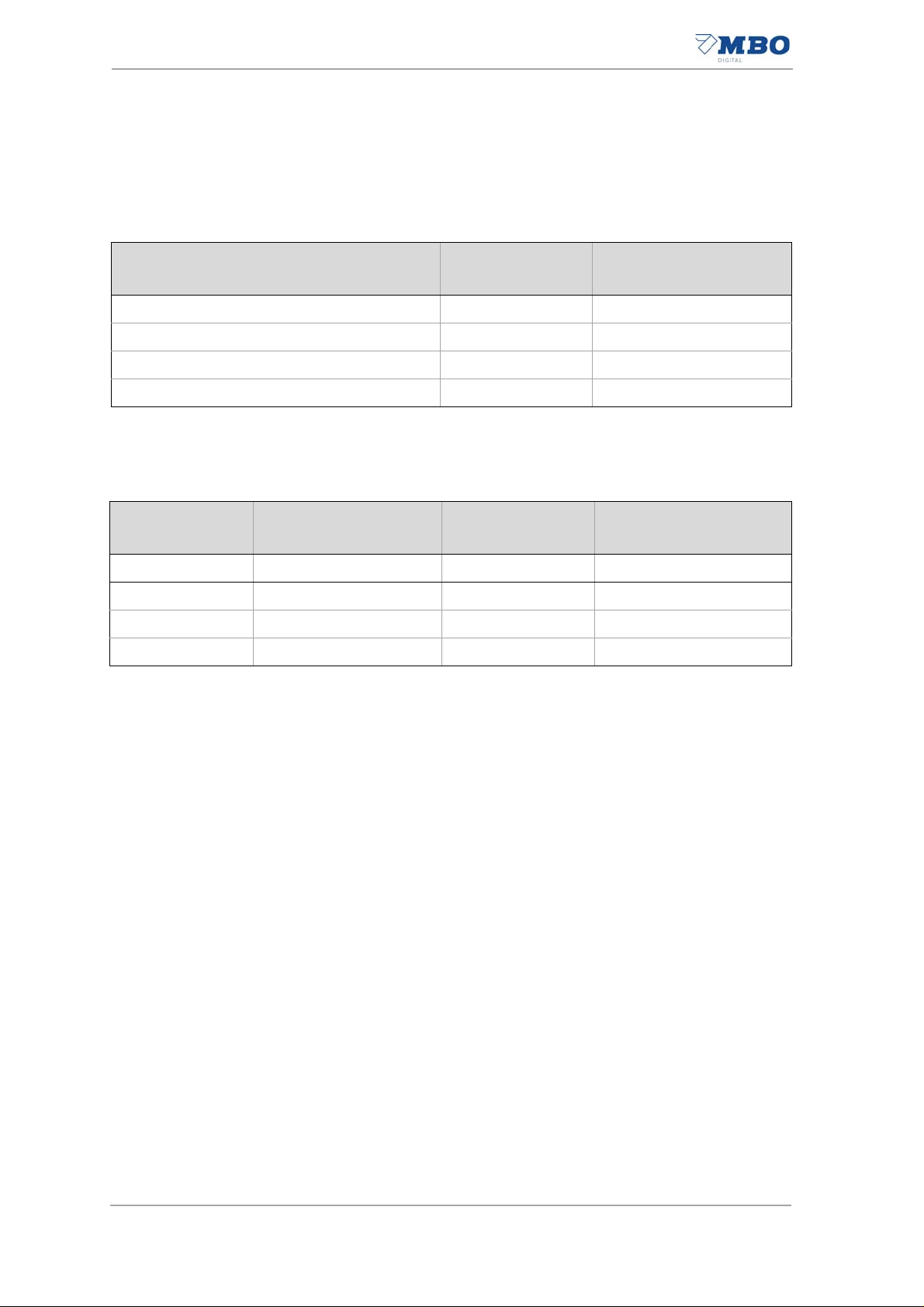

Designation

Wiring diagram

Pneumatic diagram

Spare parts list

Supplier documentation

Table 1: Additional documents

1.1.1 Supplier documentation

Manufacturer Designation

Becker Vacuum pumps

Rittal Temperature display

Rittal Filter fan

Table 2: Supplier documentation

Type

MBO part number

Type

MBO part number

Use

Use

1.2 Structure of the operating manual

The table lists the chapters of the operating manual. It also describes the

essential content of these chapters as well as the target groups at whom

the chapters are directed.

8

Sheeter SVC 525C

Page 13

About this manual

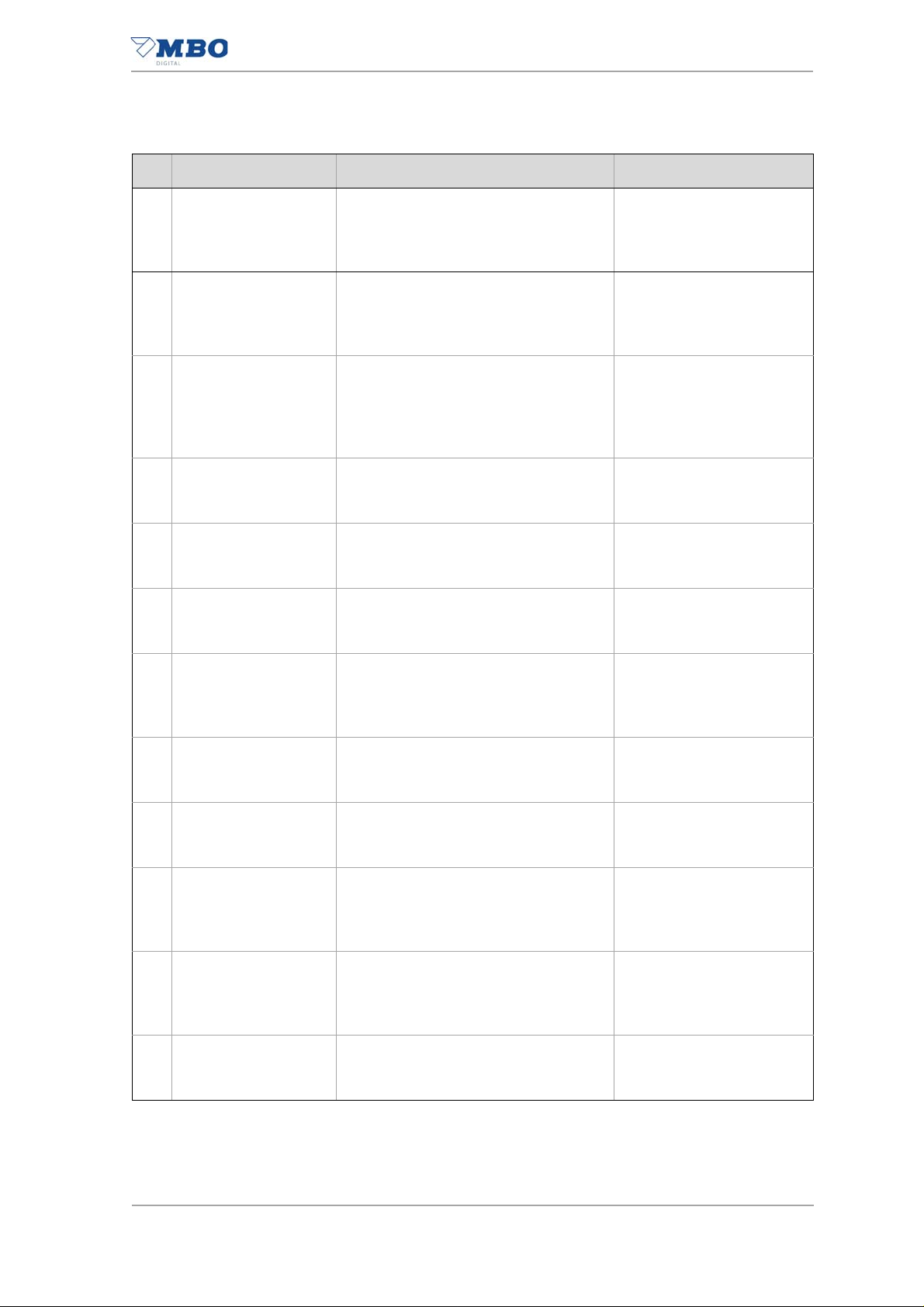

Structure of the operating manual

No. Chapter Contents Target group

Table of contents The detailed table of contents serves

as a search tool

1 About this manual Important notes about this operating

manual

2 Basic safety instruc-

tions

Details about:

• Residual risks and hazards with

intended use.

• Foreseeable misuse.

• Avoidance of the risks.

3 Product description • Important notices about the product

• Technical data

4 Structure and function Description of:

• Structure and function

• Protective devices

5 Operating and display

elements,

operating modes

Description of the:

• Operating and display elements

• Operating modes

• Owner/operator

• Operating personnel

• Maintenance personnel

• Service technicians

• Owner/operator

• Operating personnel

• Maintenance personnel

• Service technicians

• Owner/operator

• Operating personnel

• Maintenance personnel

• Service technicians

• Owner/operator

• Operating personnel

• Maintenance personnel

• Operating personnel

• Maintenance personnel

• Service technicians

• Operating personnel

• Maintenance personnel

• Service technicians

6 Transport, interim

storage

Details about:

• Packaging

• Transportation

• Interim storage

7 Set-up and

commissioning

Details for:

•Set-up

• Commissioning

8 Adjustment and

operation

Details for:

• Operation

• Adjustment

9 Maintenance Details for the:

• Operational maintenance

• Maintenance

• Repair

10 Decommissioning,

storage and putting

the machine back into

operation

Details for the:

• Decommissioning

• Storage

• Recommissioning

1 1 Disposal Details for the environmentally friendly

disposal

Tab le 3: Structure of the operating manual

• Transport personnel

• Maintenance personnel

• Service technicians

• Maintenance personnel

• Service technicians

• Operating personnel

• Maintenance personnel

• Service technicians

• Operating personnel,

• Maintenance personnel

• Service technicians

• Owner/operator

• Operating personnel

• Maintenance personnel

• Service technicians

• Owner/operator

• Maintenance personnel

• Service technicians

Sheeter SVC 525C

9

Page 14

About this manual

Signs and symbols used

1.3 Signs and symbols used

The signs and symbols in this manual should help you to use the manual

and the machine quickly and safely.

Symbol Explanation

Indicates an instruction for action.

The sequence is not specified.

1) ...

2) ...

3) ...

Here you will find the result of a sequence of instruc-

<STOP> Push button with the label between the brackets (e.g.

Table 4: Symbols, terms, and abbreviations

Numbered instructions for action.

The defined sequence of the instructions for action

makes it easier for you to use the machine correctly and

safely.

tions for action.

Stop).

Additional information for use of the machine.

Important notice, please observe.

10

Sheeter SVC 525C

Page 15

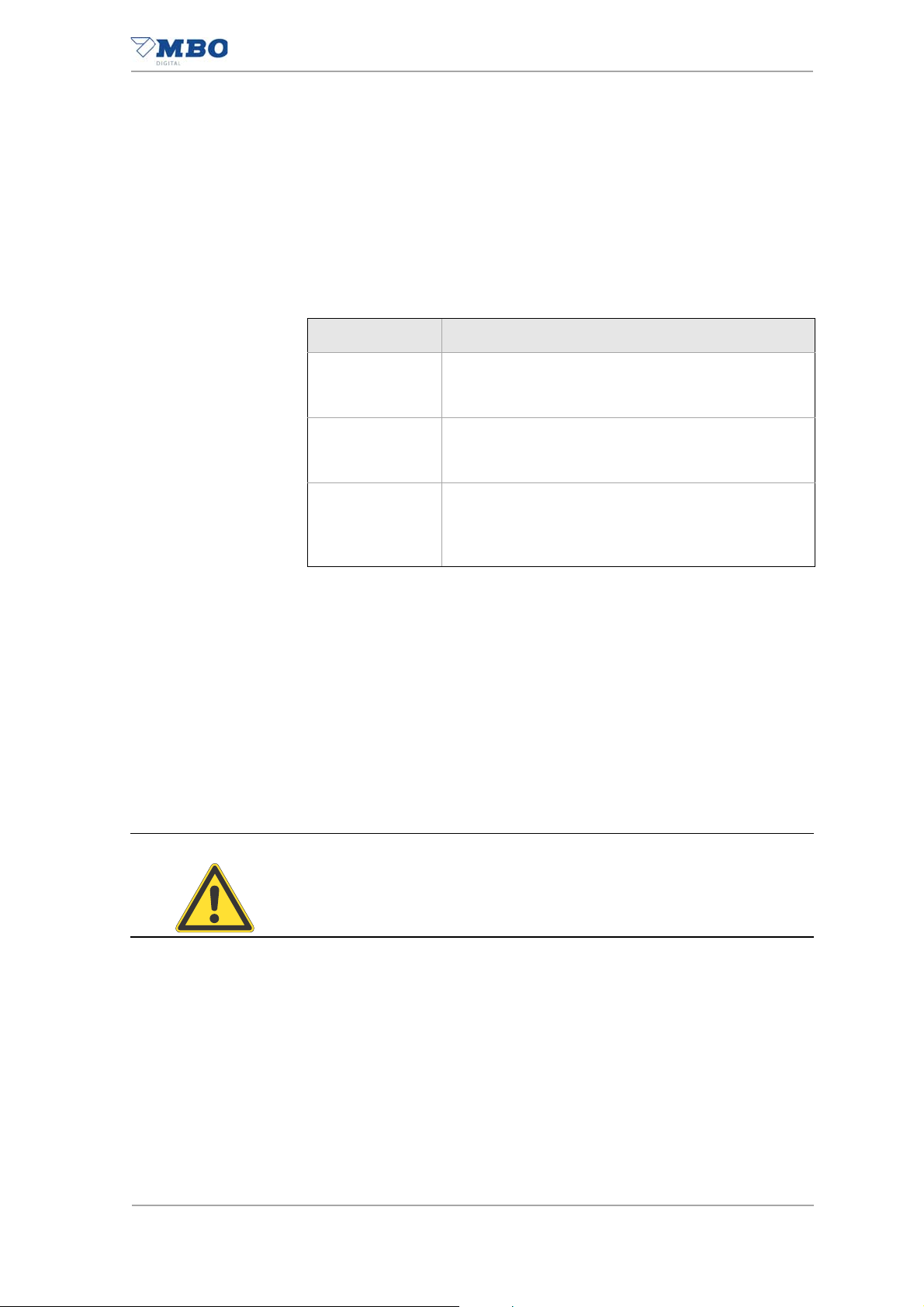

1.4 Description of safety messages

Safety messages are marked by a safety sign and a signal word.

1.4.1 Signal words

The signal words draw your attention to the severity of the hazard. They are

structured according to a classification system.

.

Signal word Meaning

DANGER Signal word to indicate a hazardous situation with

high risk level which, if not avoided, will result in

death or serious injury.

WARNING Signal word to indicate a possible hazardous situa-

tion with medium risk level whic h, if not avoided,

could result in death or serious injury.

CAUTION Signal word to indicate a possible hazardous situa-

tion with minor risk level which, if not avoided, could

result in minor or moderate injury or property damage.

About this manual

Description of safety messages

Table 5: Signal word meanings

1.4.2 Structure of safety messages

Each safety message is structured as follows:

• Safety sign

• Signal word to identify the hazard level

• Type and source of th e hazard

• Possible consequences of the hazard

• Measure(s) for avoiding the hazard

Example:

DANGER! WARNING! CAUTION! (Signal word)

Type and source of the hazard.

Possible consequences of the hazard.

Measure(s) for avoiding the hazard

Sheeter SVC 525C

11

Page 16

About this manual

Description of safety messages

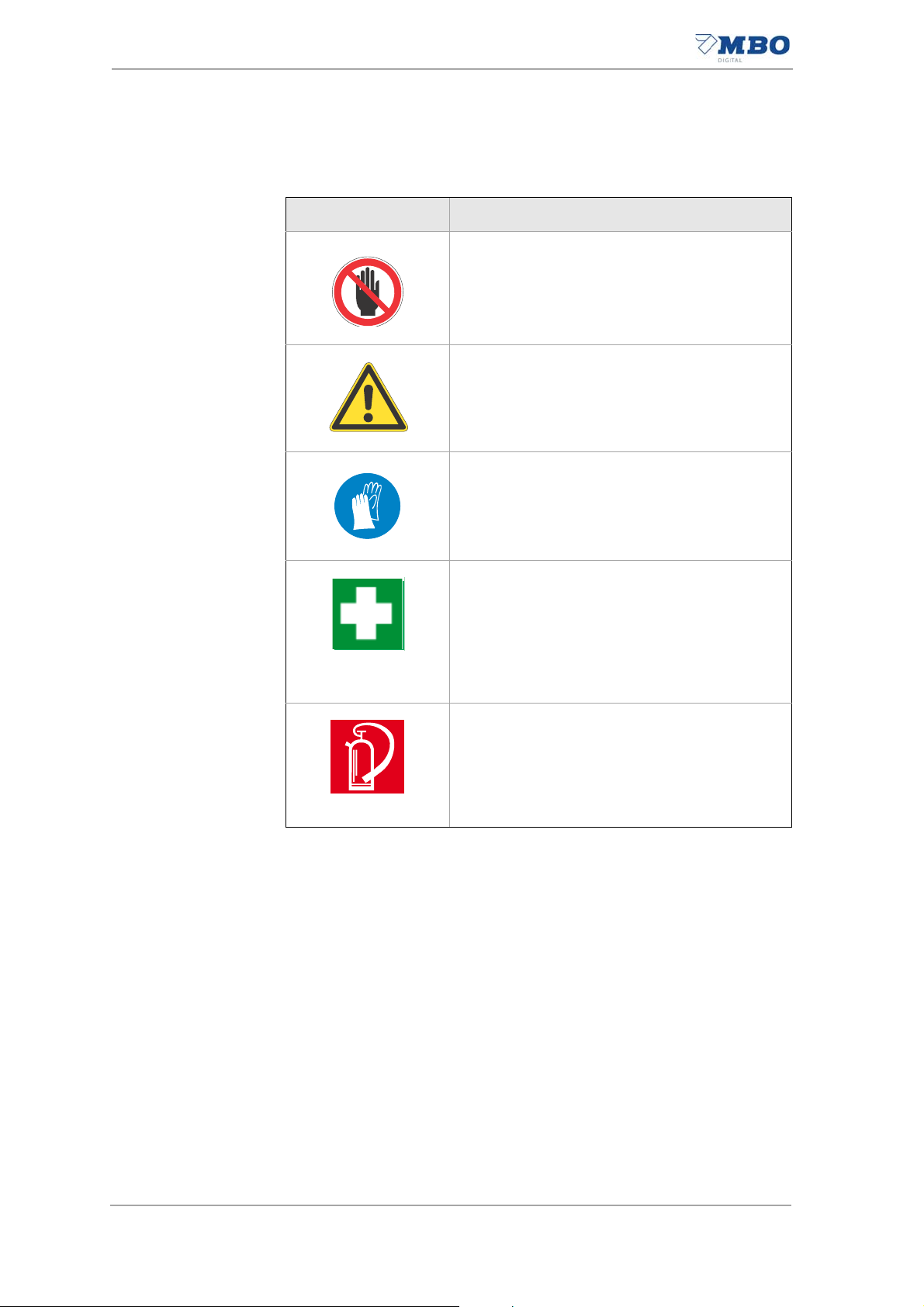

1.4.3 Safety sign

Depiction Meaning

Prohibition sign

Red border, white background, black symbol.

Safety sign that forbids a behavior that could

cause a hazard.

Warning sign

Yellow background, black symbol.

Safety sign that warns about a hazard.

Mandatory sign

Blue background, white symbol.

Table 6: Safety sign

Safety sign that prescribes a particular behavior.

Rescue sign

Green background, white symbol.

Safety sign that identifies the rescue path or

the path to a place where you can get help or

find rescue equipment in case of an emergency.

Fire protection sign

Red background, white symbol.

Safety sign, which in case of hazard marks the

location of fire alarm and fire extinguishing

equipment and/or the path to this equipment.

12

Sheeter SVC 525C

Page 17

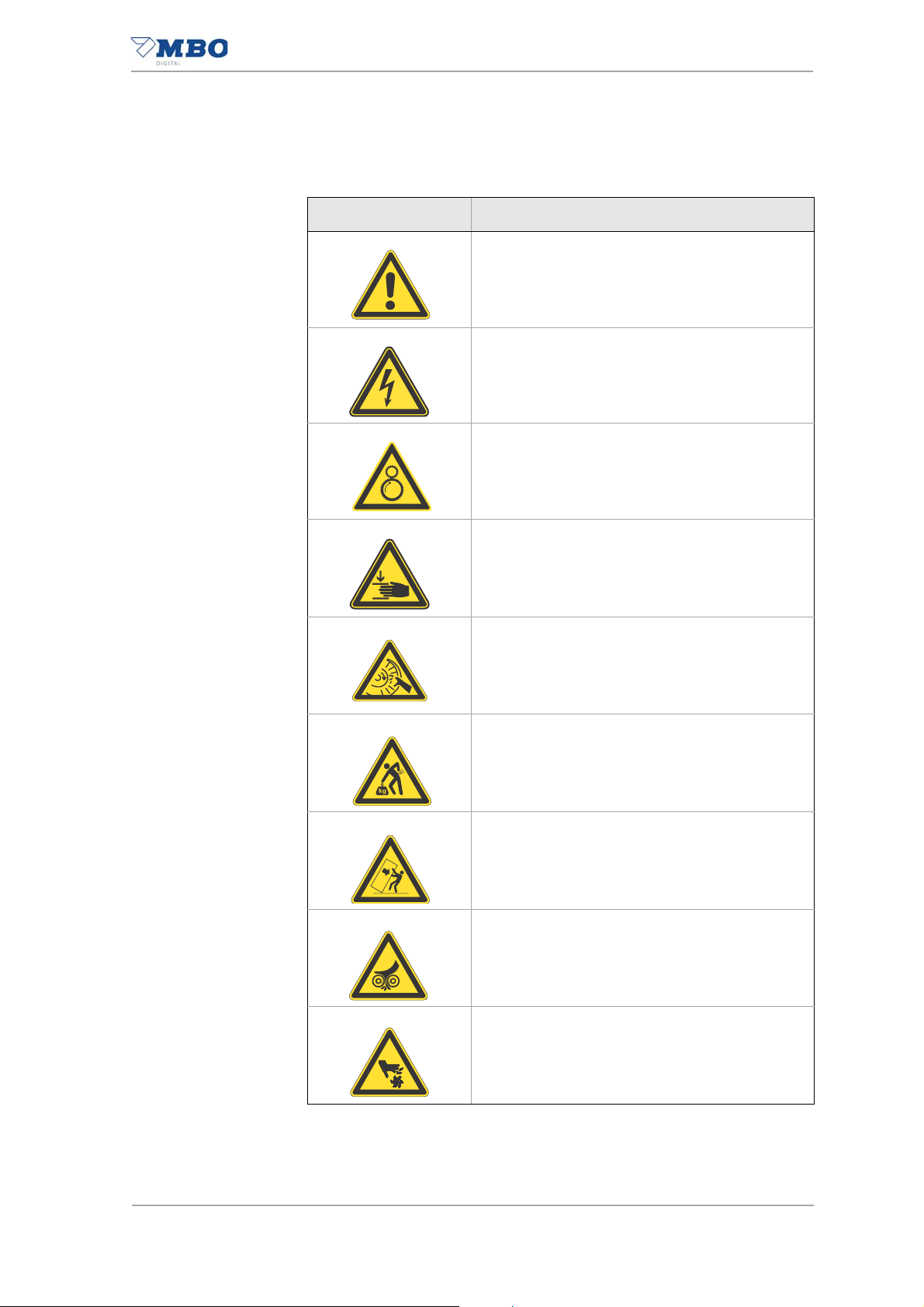

1.4.3.1 Warning sign

About this manual

Description of safety messages

Depiction Meaning

Warning about a general hazard.

You will see this warning-triangle next to activities during which several causes can create

hazards.

Warning of hazardous voltage.

You will see this warning-triangle next to activities during which there is a hazard of electrical

shock, possibly with deadly consequences.

Warning of rotating rollers.

You will see this warning triangle next to activities during which there is a hazard of crushing,

possibly with deadly consequences.

Warning of crushing of hand.

You will see this warning-triangle next to activities during which there is a hazard of crushing

the hand.

Warning of rotating machine parts.

You will see this warning-triangle next to activities during which there is a hazard of cutting

injuries, possibly with deadly consequences.

Warning of lifting heavy machine parts.

You will see this warning triangle next to activities during which there is a hazard of overloading due to lifting heavy loads.

Warning of tipping machine parts.

You will see this warning-triangle next to activities during which there is a hazard of crushing

due to tipping loads.

Warning of entanglement zone.

You will see this warning-triangle next to activities during which there is a entanglement hazard.

Sheeter SVC 525C

Warning of sharp knives.

You will see this warning-triangle next to activities during which there is a hazard of cutting

injuries, possibly with deadly consequences.

Table 7: Warning sign

13

Page 18

About this manual

Description of safety messages

Depiction Meaning

Warning of substances harmful to health.

You will see this warning-triangle next to activities during which there is a hazard of substances harmful to health, possibly with deadly

consequences.

Warning of oxidizing substances.

You will see this warning-triangle next to activities during which there is a hazard of oxidizing

substances, possibly with deadly consequences.

Warning of hot surfaces.

You will see this warning-triangle next to activities during which there is a hazard of burns,

possibly with long-term consequences.

Warning of tripping points.

You will see this warning-triangle next to activities during which there is a tripping hazard,

possibly with deadly consequences.

Table 7: Warning sign

14

Sheeter SVC 525C

Page 19

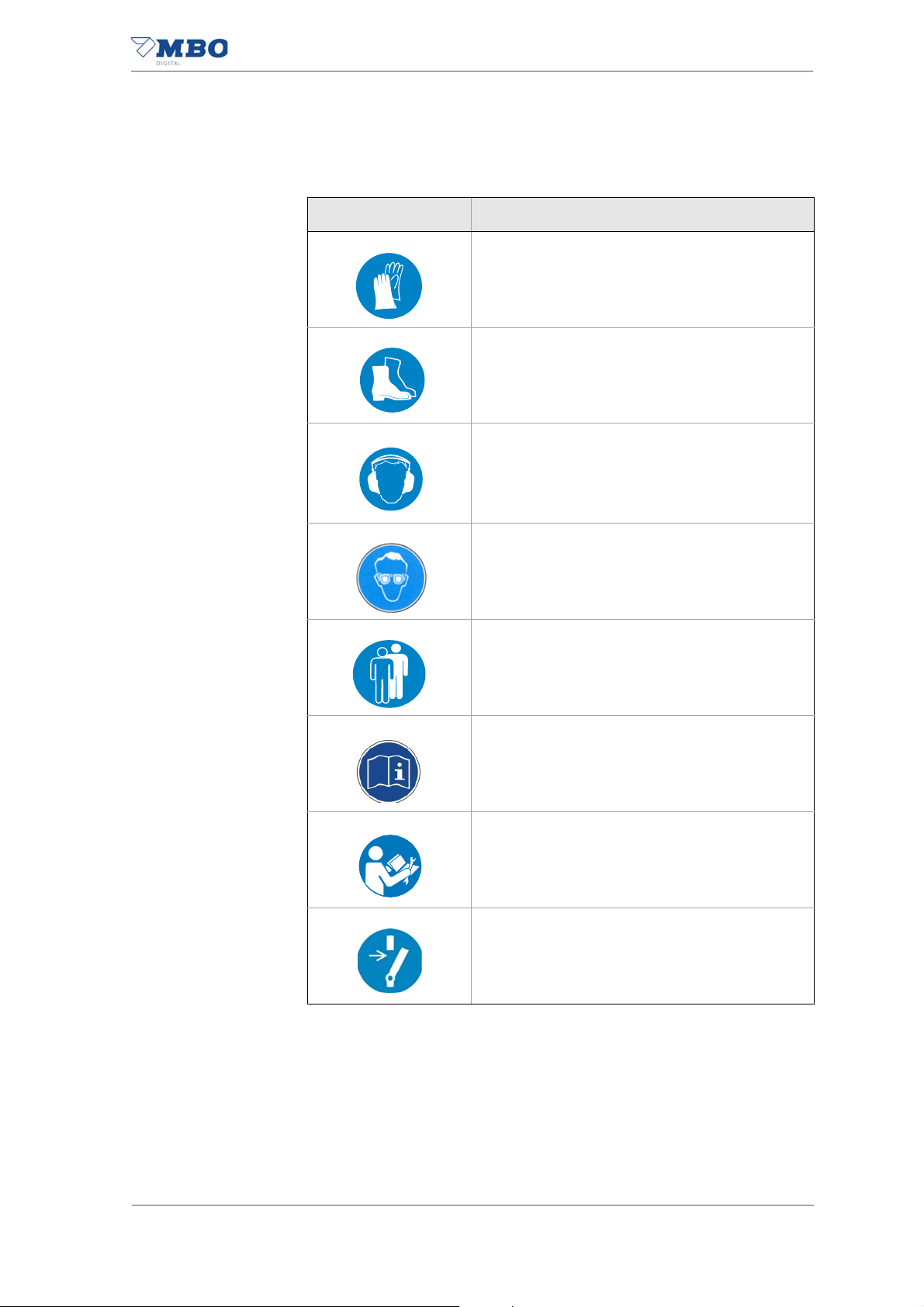

1.4.3.2 Mandatory sign

Depiction Meaning

About this manual

Description of safety messages

Use hand protection.

You will see this mandatory sign next to activities for which safety gloves should be worn.

Use foot protection.

You will see this mandatory sign next to activities for which safety shoes should be worn.

Use ear protection.

You will see this mandatory sign next to activities for which ear protection should be worn.

Use eye protection.

You will see this mandatory sign next to activities for which eye protection should be worn.

Get help.

You will see this mandatory sign next to activities for which you should ask for the help of

other people.

Follow the operating manual.

You will see this mandatory sign next to activities for which you should follow the operating

manual.

Heed the maintenance chapter.

You will see this mandatory sign next to activities for which you should heed the maintenance chapter.

Activate before maintenance or repair.

You will see this mandatory sign next to activities for which the machine must be de-energized.

Sheeter SVC 525C

Table 8: Mandatory sign

15

Page 20

About this manual

User assessment of the operating manual

1.4.4 Marking of danger spots

Permanent hazards and danger spots are marked with yellow and black

stripes.

Depiction Meaning

Heed danger spot or hindrance.

This hazard marking is affixed to constant danger spots and hindrances.

Table 9: Marking of danger spots

1.5 User assessment of the operating manual

Our operating manuals are updated regularly. Help us with your suggestions for improvement; they make the manuals user-friendly.

16

Sheeter SVC 525C

Page 21

2 Basic safety instructions

The basic requirement for the safe handling and fault-free oper ation of this

machine is knowledge of the basic safety instructions and the safety regulations.

• The operating manual must be heeded by all peo ple who wo rk on or a t

the machine.

• Read and understand the operating manual before working with the machine.

• Always keep the operating manual where the machine is being used.

• The operating manual must always be freely available to the o perating

and maintenance personnel.

• Also heed the applicable accident prevention and environmental protection rules and regulations for the place where the machine is used.

2.1 Intended use

• The machine is intended exclusively for the processing of paper webs.

The specifications relative to format and grammage in the "Technical

data" chapter must be complied with.

• The machine is intended exclusively for one-man operation.

• The machine is intended exclusively for operation in a flawless technical

state.

Any failures that may endanger safety must be remedied immediately

by trained maintenance personnel, or a specialist from the m anu facturer or supplier.

• The machine may only be operated by specially-trained and instructed

personnel.

• The machine may only be operated with the required personal protective equipment.

• Troubleshooting, maintenance and service must be carried out by

trained maintenance personn el only.

• Follow all instructions in this operating manual.

• Heed the local safety regulations and accident prevention regulations.

• Adhere to the inspection and maintenance intervals.

• Use only original wearing parts and spare parts.

Basic safety instructions

Intended use

Sheeter SVC 525C

Use the machine only as intended and when the protective device is

working perfectly.

This is the only way to guarantee the machine's oper at ing saf ety.

17

Page 22

Basic safety instructions

Reasonable foreseeable misuse

2.2 Reasonable foreseeable misuse

Reasonable foreseeable misuses are :

• The processing of materials other than easily tearing webs.

• Operation in an area subject to explosion.

• Operation with removed protective dev ic es .

• Operation of the machine without training or briefing of the operating

personnel.

• Operation of the machine without the required personal protective

equipment.

• Exceeding of the technical values specified for normal operation.

• Individual changes and rebuilding.

• Maintenance and cleaning intervals not adhered to.

• Maintenance and repair work that is not performed correctly.

• Wearing parts not replaced.

• Unintended use.

EMC behavior The electromagnetic compatibility (EMC) of the machine can be impaired

by additions or changes of any kind.

Therefore, do not make any additions or changes to the machine without

consulting the manufacturer and procuring written permission.

Spare and wear parts The use of spare parts and wear pa rts from third -party manufactur ers can

cause risks.

Use only original parts or parts approved by the manufacturer.

The manufacturer assumes no liability for damage from the use of spare

parts and wear parts not approved by the manufacturer.

18

Sheeter SVC 525C

Page 23

2.3 Obligation and liability

The machine is built using the latest technology and according to acknowledged safety rules.

Nonetheless risks and damage can occur when using it:

• to the body and life of the operator or third parties,

• to the machine itself,

• to other property.

If the machine is:

• operated by untrained or uninstructed personnel,

• not used according to its intended use,

• not maintained or not maintained properly or serviced.

The machine is only to be used:

• For the intended use.

• If it is in perfect condition with respect to safety.

Faults that can compromise safety must be remedied immediately.

Basic safety instructions

Obligation and liability

Sheeter SVC 525C

19

Page 24

Basic safety instructions

Warranty

2.4 Warranty

Our "General sales and delivery conditions" apply here.

Warranty and liability claims for personal injury and property damage are

excluded if they are due to one or more of the following causes:

• Non-intended use of the machine.

• Improper assembly, start-up, operation or m aintenance of th e machine.

• Operation of the machine with improperly-mounted or defective protec-

• Failure to follow the instructions in the operating manual with respect to

• Individual constructional changes to the machine.

• Failure to adhere to maintenance and cleaning intervals that exclude a

• Defective monitoring of machine parts that are subject to wear, such as

• Installation of spare and wearing parts that were not ordered from the

• Cases of catastrophe and acts of God.

tive devices.

transport, installation, commissioning, operation, set-up, maintena nce,

and storage of the machine.

breakdown of the machine.

belts, tapes, brushes, and couplings.

manufacturer.

20

Sheeter SVC 525C

Page 25

2.5 Residual risks

A risk analysis with risk assessment was conducted for this machine in accordance with DIN EN ISO 12100:2010.

The construction and model of the machine based on this analysis corresponds to the state of technology.

Y ou ca n avoid residual ri sks by heeding and implementing these spe cifications:

• Safety messages on the machine.

• General safety instructions and special warnings in this operating manual.

• Operating manual of the machine/syst em ma nu fa ctu r er.

• Operator directives.

The existing residual risks are listed in the following chapters according to

the various life phases of the machine.

Basic safety instructions

Residual risks

2.5.1 Transport, interim storage

• Crushing hazard during transport of the machine and machine parts.

• Use of unsuitable fork lifts.

• Tipping machine parts during the unloading process.

• Insufficient properties and condition of the underfloor.

• Wrong interim storage

2.5.2 Set-up, commissioning

• Use of unsuitable fork lifts.

• Tipping machine parts during the installation process.

• Insufficient properties and condition of the underfloor.

• Improper alignment of the machine components.

• Hazardous voltage.

• Incorrect supply voltage

• Incorrect use of the sockets.

• Discharge currents greater than 10mA.

• Disconnected protective conductor connections.

• Dismounted protective devices.

• Tripping points due to connecting cables lying around.

• Operating the sheeter when it is cold.

Sheeter SVC 525C

21

Page 26

Basic safety instructions

Residual risks

2.5.3 Adjustment and operation

• Dismantling, bridging or bypassing protective devices.

• Operation without protective covers.

• Operating the sheeter when it is cold.

• High sound pressure level.

• Rotating machine parts.

• Rotating machine parts in setup mode.

• Cutting hazard due to quickly-running, open web

• Cutting hazard on the longitudinal cutting unit.

• Web break

• Paper jam.

• Tripping points due to connecting cables lying around.

2.5.4 Maintenance

Operational maintenance:

• Rotating machine parts.

• Heavy contamination.

• Improper cleaning

• Unsuitable cleaning agents.

• Incorrect use of cleaning agents.

• Used cleaning cloths.

• Use of compressed air.

• Defective pneumatic lines.

• Incorrect maintenance intervals during multi-shift operation.

Maintenance:

• Hazardous voltage.

• Dismantling, bridging or bypassing protective devices.

• Operation without protective covers.

• Rotating machine parts.

•Crushing.

• Winding up.

• Wrong/poor maintenance tool.

• Improper maintenance.

• Incorrect maintenance intervals during multi-shift operation.

22

Repair:

• Improper repair.

Sheeter SVC 525C

Page 27

2.5.5 Decommissioning, storage

• Incorrect storage.

2.5.6 Disposal

• Improper disposal.

2.6 Product-specific hazards

2.6.1 Entanglement hazard and crushing hazard

The sheeter , due to the transport and cutting process, has rolls, rollers and

knives rotating in opposite directions.

As a result, there is an increased drawn-in hazar d an d cr ushing hazar d in

all setting work.

How to avoid injuries:

Never reach into the machine while the machine is running.

All adjustment or testing/inspection work may be carried out only when

the machine is stopped and secured against switching on.

Press the EMERGENCY STOP palm button.

Adjustment and testing work must always be performed by one person

only.

There is a drawn-in hazard and crushing hazard even when the ma-

chine is in inching mode!

Injuries will be avoided.

Basic safety instructions

Product-specific hazards

2.6.2 Cutting hazard

The longitudinal cut device tools are razor-sharp.

During all work on the tools of the length cut device, there is therefore an

increased cutting hazard on hands and arms, such as when:

• Handling the longitudinal cut device.

• Installing and removing the knives.

• Removing paper jams in the area around the longitudinal cut device.

This is how to avoid cutting injuries:

Never reach towards the knives while the machine is running.

All work on the knives may be carried out only when the machine is

stopped and secured against switching on.

Press the EMERGENCY STOP palm button.

Always wear cut-proof safety gloves and safety shoes when working on

the knives.

Work on the machine must always be performed by one person only.

There is a risk of injury even when the machine is in inching mode.

Cutting injuries will be avoided.

Sheeter SVC 525C

23

Page 28

Basic safety instructions

Life time

2.6.3 Noise

On the sheeter , there is a high noise pressure level at high production

speeds and with heavy papers.

This high sound pressure level can cause hearing damage.

See chapter “3.2.6.1 Geräuschemission”.

This is how to avoid hearing damage:

Always wear ear protection when working on the machine.

Hearing damage will be avoided.

2.7 Life time

2.7.1 Life time of the machine

The life time of this machine is designed for 20 years.

2.7.2 Life time of the control-technical safety components

All components of the control-technical safety circuits have a life time of

more than 20 years.

24

Sheeter SVC 525C

Page 29

2.8 General safety instructions

2.8.1 Transport, interim storage

• Only specially-trained and authorized personnel may transport the machine.

2.8.2 Set-up, commissioning

• Only specially-trained and authorized personnel may set up and commission the machine.

2.8.3 Normal operation

• Only instructed operating personnel may operate the machine.

• The machine may be operated only if all protective devices such as protective hoods and EMERGENCY STOP palm buttons, are present and

fully functional.

• The machine may only be operated with the required personal protective equipment.

• At least once per shift, the machine must also be checked for externallyvisible damage. Changes, including to the operating behavior, must be

reported immediately.

• Machine parts may not be used as climbing aids. If you need to reach

higher-up machine parts, use a suitable working sta ge or other platform.

Make sure that it

spect to height, stability, etc.

corresponds to the safety re quirements, e.g. with re-

Basic safety instructions

General safety instructions

2.8.4 Setting up/equipping

• Only specially-trained and authorized personnel may set up the machine.

• The machine may only be set up with the required personal protective

equipment.

• Inform operating personnel before beginning set-up.

• If the machine is switched off for set-up, it must be secured ag ainst unauthorized or inadvertent switching on again.

Use a padlock to secure the main switch against switching on. If necessary, attach a warning sign to the main switch.

• Machine parts may not be used as climbing aids. If higher machine

parts must be reached, a suitable working stage or other platform must

be used, which fulfills the safety-technical requirements such as height,

stability, etc.

• If larger components or parts are replaced, corr esponding lift equipment

must be used to transport the components. Only use suitable and technically-perfect lift equipment and load suspension devices with suff icient carrying capacity. Secure components and parts so that they

present no hazard.

Do not linger or work under suspended loads.

Sheeter SVC 525C

25

Page 30

Basic safety instructions

General safety instructions

• After completion of the work, do not leave any tools or other loose objects lying on the machine.

2.8.5 Maintenance and repair

• Maintenance and repair work may only be performed by specially

trained technical personnel.

• Maintenance and repair work may only be operated with the required

personal protective equipment.

• Inform operating personnel before beginning service and main tenance

work. Secure the service area if necessary.

• For all repair and maintenance work, heed the switch-on and switch-off

procedures according to the operating manual.

• Heed the prescribed maintenance and maintenance intervals according

to the operating manual.

• If the machine is switched off for service and/or maintenance work, it

must be secured against unauthorized or inadvertent switching on

again. Use a padlock to secure the main switch against switching on. If

necessary, attach a warning sign to the main switch.

• If the dismounting of protective devices is necessary during maintenance and repair work, it must be replaced and checked to make sure

it is functional immediately after completion of the work.

• After completion of the work, do not leave any tools or other loose objects lying on the machine.

• All operating and consumables as well as spare parts no longer needed

must be disposed of safely and in environmentally-appropriate fashion.

2.8.6 Work on electrical equipment

• Only an electrically qualified person is permitted to perform work on the

electrical systems or equipment.

• In case of faults in the electrical power supply, the machine must be

switched off immediately.

• Only use original fuses with the prescribe d am p er age.

26

Sheeter SVC 525C

Page 31

2.9 Personnel, qualification and duties

All activities at or on the machine must be carried out by authorized personnel only.

Authorized personnel is divided into several groups:

• Owner/operator

• Operating personnel

• Maintenance personnel

The authorized personnel must:

• have reached the age of 16,

• know and be able to apply the accident prevention regulations and safety instructions for the machine,

• have read chapter “2 Basic safety instructions” and be able to apply

and implement it in practice,

• be trained and instructed according to the rule s of conduct in the event

of a fault,

• have the physical and mental abilities to carry out his or her responsibilities, tasks, and activities on the machine,

• be trained and instructed in accordance with his or her responsibilities,

tasks, and activities on the machine,

• have understood and can implement practically the operating manual

with respect to responsibilities, tasks, and activities for the machine.

Basic safety instructions

Personnel, qualification and duties

2.9.1 Qualification of the personnel

This table lists the necessary qualification of the personnel related to the

various activities at or on the machine.

Sheeter SVC 525C

27

Page 32

Basic safety instructions

Personnel, qualification and duties

Transportation X- -

Interim storage X--

Set-up --X

Specially trained

personnel

Instructed operating

personnel

Instructed personnel

with specialized training

(mechanical/ electrical

engineering)

Electrical

--X

connections

Stationary mains

--X

connection

Commissioning --X

Troubleshooting

(mechanical/electrical

--X

Installation, set-up XX-

Operation -X-

Operational mainte-

-X-

nance (cleaning)

Maintenance X-X

Repair --X

Decommissioning --X

28

Storage X--

Disposal X--

Table 10: Qualification of personnel

Legend: X permitted, - not permitted

Sheeter SVC 525C

Page 33

2.9.2 Duties of the operator

The owner/operator is responsible for

• the machine being operated only as intended,

• the machine being operated only when it is fully functional, safe and reliable,

• the machine being maintained and cleaned according to the specifications in the maintenance and cleaning schedule,

• the machine is protected against unauthorized use,

• the necessary personal protective equipment being available,

• the necessary personal protective equipment being worn,

• only authorized personnel having access to the machine,

• the authorized personnel being adequately qualified,

• the authorized personnel being instructed in all applicable questions of

workplace safety, accident prevention, and environmental protection,

• the authorized personnel has read and understood the operating manual,

• the operating manual is always kept where the machine is used and it

is freely accessible to the operating and maintenance personnel,

• the safety and notice signs on the machine are kept in an easily legible

condition,

• a risk assessment of the entire system being carried out and its results

being summarized in an operator directive,

• identified defects or abnormal operating states/jams being remedied immediately,

• operation of the machine being ceased during troubleshooting.

Basic safety instructions

Personnel, qualification and duties

Heed the national laws and European directives abou t occupational safety

and health of employees at work.

Germany The requirements of the German Labor Protection Act (ArbSchG) and the

German Health and Safety at Work Regulations (BetrSichV) must be adhered to.

EC countries The requirements of the directives 89/391/EEC and 2009/104/EU must be

adhered to.

Sheeter SVC 525C

29

Page 34

Basic safety instructions

Personnel, qualification and duties

2.9.3 Duties of the operating personnel

The operating personnel must:

• be trained and instructed,

• use the machine as intended,

• wear the necessary personal protective equipment,

• observe the basic regulations regarding workplace safety a nd accident

prevention,

• read and heed the chapter “2 Basic safety instructions” and the safety

messages in this operating manual,

• immediately take the machine out of operation in the event of defects or

abnormal operating states/malfunctions,

• immediately report any identified defects or abnormal operating states/

malfunctions.

The operating personnel is responsible for

• ensuring that the machine is protected against unauthorized use,

• ensuring that the machine is operated only when it is fully functional,

safe and reliable,

• cleaning is performed according to the cleaning plan.

2.9.4 Duties of the maintenance personnel

The maintenance personnel must:

• be trained and instructed,

• use the machine as intended,

• wear the necessary personal protective equipment.

The maintenance personnel is responsible for

• protecting the machine against unauthorized use,

• the maintenance being carried out according to the maintenance schedule.

30

Sheeter SVC 525C

Page 35

2.10 Personal protective equipment

2.10.1 Operation and adjustment

This personal protective equipment must be provided and worn for the operation and set-up of the machine:

• Ear protection

• Cut-resistant safety gloves

• Safety shoes

Basic safety instructions

Personal protective equipment

2.10.2 Operational maintenance (cleaning)

This personal protective equipment must be provided and worn for the

proper maintenance (cleaning) of the machine:

• Safety shoes

• Cut-resistant safety gloves

Sheeter SVC 525C

31

Page 36

Basic safety instructions

X

Unit of measurement in cm

1

Work areas and workstations

2.11 Work areas and workstations

• The machine is intended exclusively for operation by one person.

• The figure shows the most important workstations as well as the working area and service area of the machine.

• The necessary work areas for operation, installation, commissioning,

and maintenance are highlighted in gray and should be at least 100 cm.

• The service area is marked with hatching.The possible workplaces are

marked with an "X".

2.1 1.1 Layout from right to left

1 Workstation

Illustration 1: Work area and workstation SVC 525C

32

Sheeter SVC 525C

Page 37

Basic safety instructions

2.12 Markings on the machine

These markings must be on the machine and in an easily legible co ndition.

If the markings are damaged or illegible, they must be replaced.

For the appropriate MBO part number, see chapter “2.12.1 Position and

meaning”.

2.12.1 Position and meaning

Pos. 1 MBO part number:10.5171.025

Markings on the machine

Meaning: Name plate

Illustration 2: Name plate

Pos. 2 MBO part number: 10.5171.026

Meaning: Electric name plate

Illustration 3: Electric name plate

Sheeter SVC 525C

33

Page 38

Basic safety instructions

Markings on the machine

Pos. 3 MBO part number:4002643

Meaning: <Read operating manual> mandatory sign

Illustration 4: <Read operating manual> mandatory sign

Pos. 4 MBO part number:4002562

Meaning: <Wear ear protection> mandatory sign

Illustration 5: <Wear ear protection> mandatory sign

Pos. 5 MBO part number:4003327

Meaning: <Drawn-in hazard> warning sign

Illustration 6: <Drawn-in hazard> warning sign

34

Sheeter SVC 525C

Page 39

Pos. 6 MBO part number: 0100699

Meaning: <Hot surface> warning sign

Illustration 7: <Hot surface> warning sign

Pos. 7 MBO part number: 4003326

Basic safety instructions

Directions for emergencies

Meaning: <Crushing hazard> warning sign

Illustration 8: <Crushing hazard> warning sign

Pos. 8 MBO part number: 0128301

Meaning: <Hazardous voltage> warning sign

Illustration 9: <Hazardous voltage> warning sign

2.13 Directions for emergencies

The operator must add instructions regarding national regulati ons for accident prevention to this operating manual.

Sheeter SVC 525C

35

Page 40

Basic safety instructions

Directions for emergencies

2.13.1 Emergency call numbers

Police

European Union

Fire department

Ambulance

Police

Germany

Fire department

Ambulance

Police

USA

Fire department

Ambulance

Police

China

Fire department

Ambulance

Table 11: Emergency call numbers

2.13.2 Behavior in case of accidents

1 Immediate measures

• Stay calm.

• Secure the accident location.

• Heed your own safety.

• If necessary , rescue person from th e danger zone.

• Check consciousness and breathing/check for

type of injury.

• If necessary, take lifesaving measures right away.

112

112

112

110 or 112

112

112

911

911

911

110

119

120

2 Emergency call

3 First aid

Table 12: Behavior in case of accidents

• Where is the accident location?

• What happened?

• How many injured?

• What injuries?

• Who's calling?

• Wait for queries!

• Provide help as necessary.

• Check consciousness and breathing.

• Protect against heat loss.

• Provide support and assistance.

36

Sheeter SVC 525C

Page 41

3 Product description

3.1 Important notices about the product

3.1.1 View

Product description

Important notices about the product

Illustration 10: Overall view

3.1.2 Standard equipment

• Completely automatic conversion of format and chip-out.

• Variable format length up to a maximum of 2.032 mm.

• Variable chip-out possible (4 - 80 mm).

• External length cut cassette.

• Air-assisted sheet running.

• Discharge table, foldable.

• Window function.

3.1.3 Options

• Gully cut in longitudinal direction SVC-GC.

• Interfaces (digital printer, folding machines).

• Print mark control software (watchdog).

Sheeter SVC 525C

37

Page 42

Product description

Unit of measurement cm

Technica l data

3.2 Technical data

3.2.1 Floor plan

3.2.1.1 Layout from right to left

Illustration 11: Floor plan SVC 525 C, right to left

38

Sheeter SVC 525C

Page 43

3.2.2 Performance characteristics

Product description

Technical data

Speed Minimum

Maximum

7 m/min 250 m/min

Web format width

Grammage

2)

Cutting accuracy Longitudinal cut

Cross-cut

Lateral web guide

150 mm 520 mm

40 g/m

2

250 g/m

± 0.5 mm

± 0.5 mm

± 0.2 mm

accuracy

Format lengths

Continuously variable 76 mm 2,032 mm

Continuously variable with

127 mm 2,032 mm

chip out

Chip-out sizes Without chip-out

Continuously variable

Table 13: Performance characteristics

1) The maximum working speed depends on paper properties, format, fold type, temperature, and humidity, as well

as various states at the operator that the manufacturer cannot influence.

2) All values refer to simple volume paper.

0mm 4mm 80mm

1)

2

Sheeter SVC 525C

39

Page 44

Product description

Technica l data

3.2.3 Shipping and transport data

Weight Net Gross

Without packaging Approx. 1380 kg With shipping pallet - Approx. 1500 kg

With shipping crate - Approx. 1700 kg

Dimensions

L x W x H

Without packaging 180 x 160 x 133 (cm)

With shipping pallet 200 x 180 x 175 (cm)

With shipping crate 205 x 185 x 180 (cm)

Fork lift

1)

Carrying capacity / load (Q)

2)

Min. 2000 kg

Fork tine length Min. 150 cm

Floor conditions

Table 14: Shipping and transport data

1) Minimum requirements of the fork lift

2) Heed operating manual for the fork lift, load capacity depends on the load center of gravity (c).

3) Minimum load capacity of the floor where the machine will be set up

4) In the area of the machine, the total height difference may not exceed 20 mm.

3)

Cargo

Levelness

> 20 kN/m

4)

< 10 mm/m

2

40

Sheeter SVC 525C

Page 45

3.2.4 Electrical supply

Product description

Technical data

Electrical supply

1)

Nominal voltage

3 x 400 V + N + PE

Connecting line

2)

4)

Fuse

Protective equipotential

bonding conductor

5)

Wiring diagram no. See electrical name pla te

Required mains configu-

3)

ration

TN - C - S power mains

Clockwise rotating field required

TN - S - power

Voltage 400 V AC +/-10%

Frequency 50Hz +/-1%

Control voltage: 24 VDC/10 A

Cross-section (IEC)

mm

2

Cross-section (UL)

Max. line length m

Min. network impedance mOhm

Short-circuit current rating

6kA

(SCCR) according to UL

508A

IEC 63 A characteristic C

UL 63 A

Cross-section according

10 mm

2

to IEC

Connected loads

Operational readiness

(stand-by)

Tab le 15: Electrical supp ly 400V network

1) Stationary mains connection

2) If the existing nominal voltage varies from the supply voltage specified above, an isolating transformer must be installed.

If the nominal voltage is 380 V or 415 V at 50 Hz, the tolerance of the power mains must be checked.

If the tolerance is between 360 V – 440 V, an isolating transformer is not required.

3) N - line is loaded; a fault-current circuit breaker (FI) may not be used.

4) According to EN ISO 60204:2006 Table 10.

5) According to EN 60204:2006.

6) The total connected load depends on the number and equipment of the connected machines.

6)

Total

Power kW

Current rate A

Approx. 14 kW

Sheeter SVC 525C

41

Page 46

Product description

Technica l data

3.2.5 Compressed air supply

Compressed air supply

Connected loads

Necessary network pressure

Average consumption

Quality:

Connecting line

Table 16: Compressed air supply

1) Required volume flow according to ISO 1217 or DIN 1945

2) Corresponds to ISO 8573-1 Class 5

3) According to ISO 8573-1

Connection type PK 6 hose with qu ick opening device

1)

6 bar +1 bar

60 l/min

Filter unit 40 µm

Dried and oiled

2)

3)

3.2.6 External extraction system (to be provided by the customer)

External extraction system

Suction power

Connection type

Volume

1800 m

Flow speed 25 m/sec

1)

Edge trim 2 x open tube with 50 mm diameter

3

/h

Gully cut

1 x open tube with 50 mm diameter

(optional)

Chip-out Open tube with 100 mm diameter

Table 17: External extraction system

1) Optionally a collection system can be provided, to which all internal machine suction hoses are connected. The

connection to the external extraction system is then made with a single open tube with a 150 mm diameter.

42

Sheeter SVC 525C

Page 47

Product description

Technical data

3.2.7 Emissions

3.2.7.1 Noise emissions

Noise emissions

Specified two-digit noise emissions value according to DIN EN 4871 Idling Load

A-weighted sound power level L

Uncertainty K

WA

in dB

A-weighted emission sound pressure level L

In dB re 20 Pa at the operating place

Uncertainty K

WA

in dB

in dB re 1 pW

WA

PA

-

-

<70

2.5

99

2.5

79

2.5

The values were determined in accordance with the noise emission standard DIN EN ISO 13023

1)

using the basic standards DIN EN ISO 3746 and DIN EN ISO 11204

Tab le 18: Noise emissions

1) Noise measurement EN 13023 F.2 - class 2

3.2.8 Ambient conditions

Room temperature

Storage temperature

Relative humidity

Set-up height

2)

Optimal

Minimum

Maximum

17 ... 35 °C

10 ... 35 °C

40 - 60 %

30 %

80 % (non-condensing)

Max. 800 above sea level

1)

Tab le 19: Ambient conditions

1) At temperatures below or above the permissible room temperature, special measures must be taken.

2) For installation at an altitude of 800 m above sea level or higher, special measures are necessary for the pressure

vacuum pumps.

Learn more about this from the manufacturer.

Sheeter SVC 525C

43

Page 48

Product description

Technica l data

44

Sheeter SVC 525C

Page 49

4 Structure and function

1

2

3

4

In this chapter you will find a description of the components and function

of the sheeter.

4.1 Structure

4.1.1 Components of the sheeter

The components are distributed across the four sides of the sheeter.

Structure and function

Structure

1 Control cabinet side

2 Infeed side

Illustration 12: Views of the sheeter

Sheeter SVC 525C

3 Operator side

4 Outfeed side

45

Page 50

Structure and function

2

1

Structure

4.1.1.1 Components of the control cabinet side

1 Control cabinet 2 Connection of extraction device for chip-out

Illustration 13: Components of the control cabinet side

46

Sheeter SVC 525C

Page 51

4.1.1.2 Components of the infeed side

1

2

3

4

7

8

6

5

Structure and function

Structure

1 Temperature regulation, cutting unit

2 Main switch

3 Fan, control cabinet

4 Transport rollers

Illustration 14: Components of the infeed side

5 Adjustable feet

6 Suction device, longitudinal cutting device

7 Infeed table with longitudinal cutting device

8 Manometer, nip rollers

Sheeter SVC 525C

47

Page 52

Structure and function

2

3

4

5

1

Structure

4.1.1.3 Components of the operator side

1 Protective hood with guard locking

2 Pressure regulator for nip rollers

3 Touchscreen

Illustration 15: Components of the operator side

4 Control panel

5 Guard door with guard locking

48

Sheeter SVC 525C

Page 53

4.1.1.4 Components of the outfeed side

1

2

3

4

5

Structure and function

Structure

1 Waste sheet deflector

2 Adjustable feet

3 Conveyor table, foldable

Illustration 16: Components of the outfeed side

4 Transport rolls

5 Fan, control cabinet

Sheeter SVC 525C

49

Page 54

Structure and function

2

3

1

Format A

Format B

Format C

Format D

Format A

Format B

Format C

Format D

Format A

Format B

Format C

Format D

Functional description

4.2 Functional description

The SVC525C sheeter is a completely electronically-controlled sheeter

with variable and infinite adjustment with respect to format and chip out

size.

The sheeter can either be operated in-line (i.e. after a digital printer) or offline (with its own unwinder).

4.2.1 Cutting sequences

Illustration 17: Cutting sequences

4.2.2 Control panel

The following cutting sequences are possible:

1 Sequential cutting: Multiple formats (max. 6) and 1 chip-out in one sequence

(max. 2 m).

2 Sequential cutting: Multiple formats (max. 6) and multiple chip-outs in one

sequence (max. 2 m).

(The number of maximum possible chip-outs is limited by the mechanical setting in the chip-out disposal).

3 Fully variable cutting: Cut is made from print mark to print mark in a different

sequence with constant chip-out.

The control panel with EMERGENCY STOP palm button provides the control functions.

The touchscreen is used to adjust the sheeter unit.

50

Sheeter SVC 525C

Page 55

4.3 Infeed table

Infeed rolls The infeed rolls introduce the web into the sheeter.

The infeed position of the web changes according to the upstream machine.

Structure and function

Infeed table

Longitudinal cut

cassette

The longitudinal cut cassette is used for cutting (principle of rotating scissor

cutting) of the web fed in for:

• Edge trim.

An external extraction system is required for this.

• Separator cut

• Gully cut (optional).

An external extraction system is required for this.

4.3.1 In-feed unit