Page 1

Operating ManualOperating Manual

Operating Manual

Operating ManualOperating Manual

SBAP 46/72/82 MESBAP 46/72/82 ME

SBAP 46/72/82 ME

SBAP 46/72/82 MESBAP 46/72/82 ME

VV

ertical Stacker Deliveryertical Stacker Delivery

V

ertical Stacker Delivery

VV

ertical Stacker Deliveryertical Stacker Delivery

with pressingwith pressing

with pressing

with pressingwith pressing

and marking deviceand marking device

and marking device

and marking deviceand marking device

Page 2

Operating Manual

SBAP 46/72/82-ME USA

Contents

Prologue ................................................................................................................. 4

1.0 Machine specification ............................................................................................ 4

1.1 Manufacturer .......................................................................................................... 4

1.2 Type:........................................................................................................................4

1.3 Technical data ........................................................................................................ 5

1.3.1 Sizes .................................................................................................................................................. 5

1.3.2 Floor plan: ......................................................................................................................................... 5

1.4 Documentation ....................................................................................................... 6

1.5 User information / Functioning description ......................................................... 7

2.0 BASIC SAFETY INSTRUCTIONS .......................................................................... 8

2.1 Warnings and symbols .......................................................................................... 8

2.2 Safety in the working place Destined use of the Vertical Stacker Delivery........ 8

2.3 Safety devices ...................................................................................................... 10

2.3.1 Protective hoods – Layout .............................................................................................................. 10

2.3.2 Protective hoods – Checklist .......................................................................................................... 10

2.3.3 Check list: warning labels (oder warning signs) ........................................................................... 11

3.0 Transportation, installation, and initial operation............................................... 15

3.1 Transportation ...................................................................................................... 15

3.2 Installation ............................................................................................................ 15

3.3 Erection ................................................................................................................. 16

3.4 Electrical connection ........................................................................................... 17

4.0 Service / Maintenance .......................................................................................... 18

4.1 Procurement of spare parts ................................................................................ 18

Alterations reserved

Stand 10/2006Page 2

Page 3

Operating Manual

SBAP 46/72/82-ME USA

4.2 Lubrication / Cleaning .......................................................................................... 19

4.3 Cleaning of transport tapes and pressing rollers .............................................. 20

4.4 Tensioning of tapes, belts and chains ................................................................ 21

4.4.1 Chains at main drive motor ............................................................................................................ 21

4.4.2 Drive chains for the transport tape at the collector table .............................................................. 22

4.4.3 Drive of pressing rollers and infeed tapes .................................................................................... 23

4.4.4 Transport tape at the collector table .............................................................................................. 24

4.4.5 Lower line-up tapes ........................................................................................................................ 24

4.4.6 Upper line-up tapes......................................................................................................................... 25

4.4.7 Pile transport tapes......................................................................................................................... 25

5.0 Operation (of the delivery) ................................................................................... 26

5.1 Control desk ......................................................................................................... 26

5.2 Infeed table ........................................................................................................... 27

5.2.1 Infeed tapes ..................................................................................................................................... 27

5.2.2 Multiple-up production ................................................................................................................... 28

5 2.3 Marking device ................................................................................................................................29

5.3 Pressing unit ........................................................................................................ 30

5.4 Collector table ...................................................................................................... 31

5.5 Line-up tapes and line-up table .......................................................................... 32

6.0 Putting out of service ........................................................................................... 34

6.1 Details of storage ................................................................................................. 34

6.2 Environmental waste disposal ............................................................................ 35

6.2.1 Disposal of the waste machine ...................................................................................................... 35

6.2.2 Disposal by instructing the supplier .............................................................................................. 35

6.2.3 Disposal by a disposal and demolition company ......................................................................... 35

6.2.4 Disposal by your own company ....................................................................................................35

6.2.5 Ground water preservation ............................................................................................................. 36

6.3 Final remarks ........................................................................................................ 36

Page 3Alterations reserved

Stand 10/2006

Page 4

Prologue

The MBO Vertical Stacker Delivery SBAP 46/72/82 - ME you have purchased is a valuable

piece of equipment. It is absolutely imperative that you comply with all Safety Regulations

and Safety Instructions. This Operating Manual is designed to instruct you to correctly operate

the machine, to comply with the Safety Regulations, and also to maintain the machine

properly.

1.0 Machine specification

Operating Manual

SBAP 46/72/82-ME USA

1.1 Manufacturer

MBO Binder & Co. Maschinenbau Oppenweiler

Grabenstrasse 4, D-71570 Oppenweiler, Germany

P.O. Box 1169, D-71567 Oppenweiler, Germany

Tel. +49 7191 460

Fax +49 7191 4634

1.2 Type:

Vertical Stacker Delivery SBAP 46/72/82 - ME

Alterations reserved

Stand 10/2006Page 4

Page 5

Operating Manual

SBAP 46/72/82-ME USA

1.3 Technical data

1.3.1 Sizes

SBAP 46-ME SBAP 72-ME SBAP 82-ME

Working width: 17 3/4“ 28 3/8“ 32 1/2

Maximum infeed height: 37 3/8“ 37 3/8“ 37 3/8“

Minimum infeed height: 15“ 15“ 15“

Sheet width / line-up height max.: 11 3/4“ 11 3/4“ 11 3/4“

Sheet width / / line-up height min.: 3 1/8“ 3 1/8“ 3 1/8“

Length of pile: 28 3/4“ 28 3/4“ 28 3/4“

Pressing power max.: 2000 kp 2000 kp 2000 kp

Speed: 40-155m/min 40-155m/min 40-155m/min

Power requirements: 1.3 kw 1.3 kw 1.3 kw

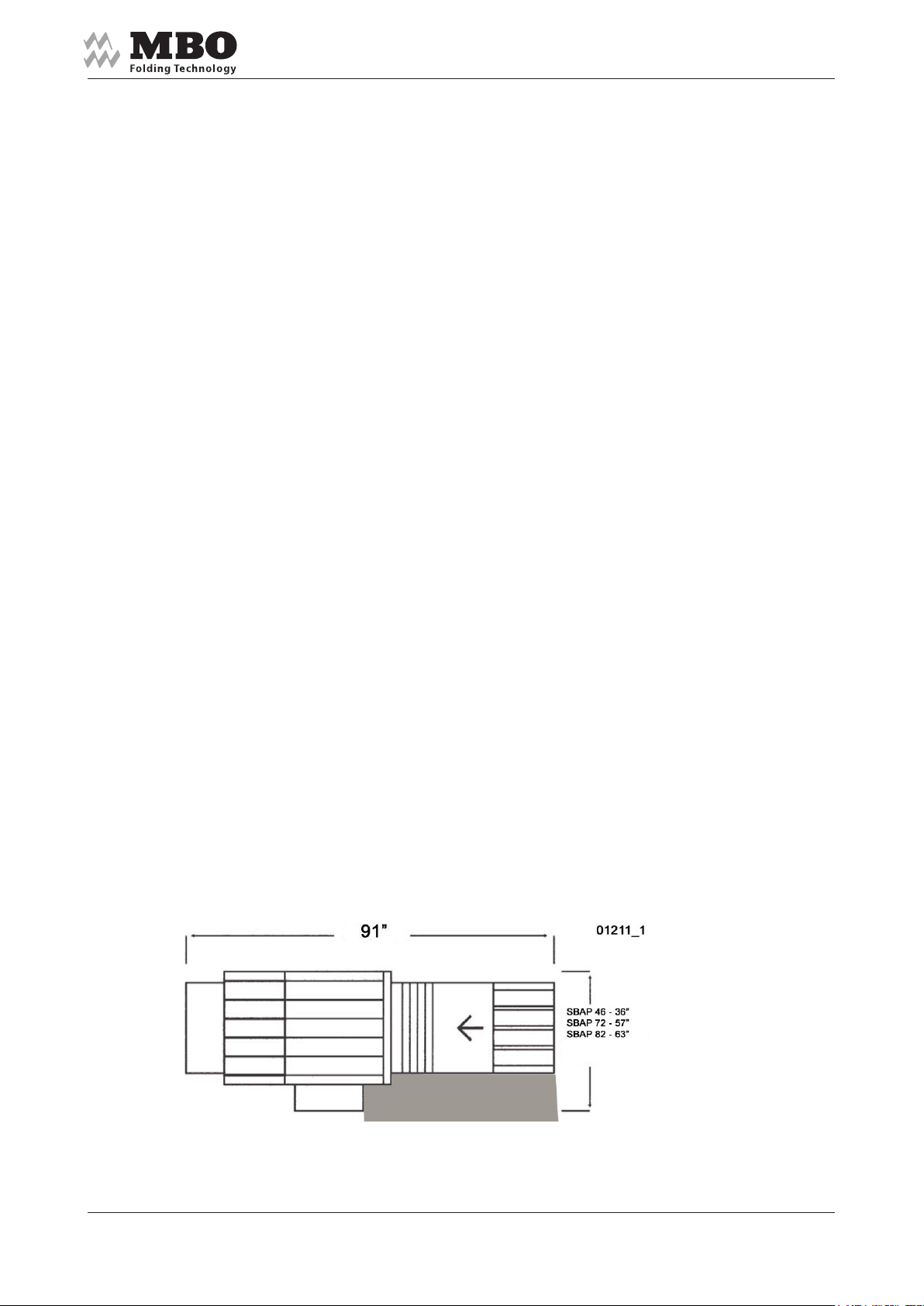

1.3.2 Floor plan:

The permitted working area during the operation is marked in grey.

(measure in inch)

Page 5Alterations reserved

Stand 10/2006

Page 6

Operating Manual

SBAP 46/72/82-ME USA

1.4 Documentation

Customer:

Machine configuration: Vertical Stacker Delivery SBAP 46/72/82 - ME

Machine No.:

Serial No.:

BA Batch Counter IVO:

Electrical data:

Wiring diagram no.:

Operational voltage V3/Hz:

Control voltage V/A:

Control voltage V/A:

Total nominal current A:

Fuse at power supply A:

Wiring diagram no’s.:

Test mark GS Nr.:

Test mark CE Nr.:

Certificate of Conformity:

Perceived noise level (dB/AI):

GS marking no.:

Alterations reserved

Stand 10/2006Page 6

Page 7

Operating Manual

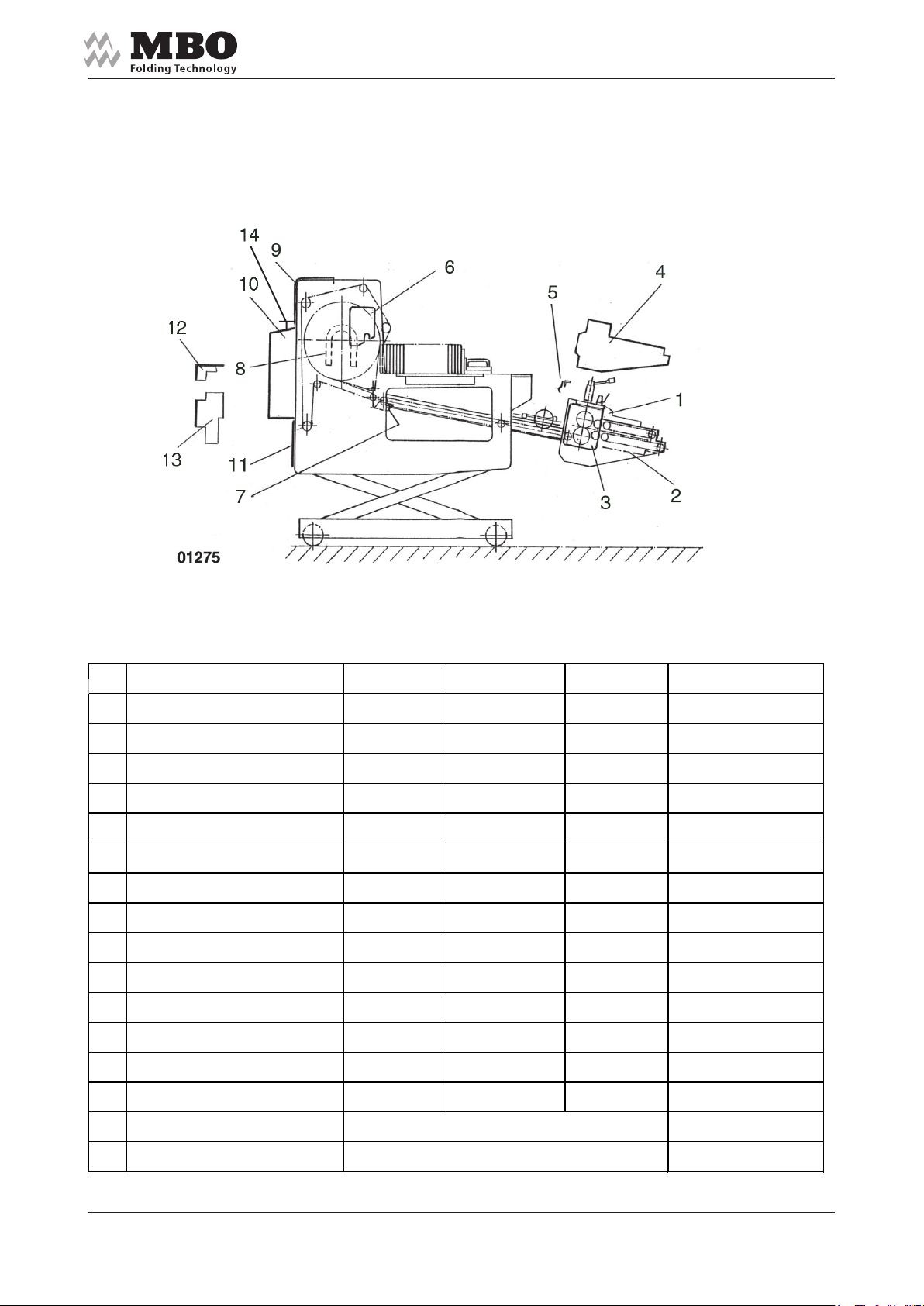

1.5 User information / Functioning description

The Vertical Stacker Delivery SBAP 46/72/82 - ME is a mobile, separate unit with self-drive to

vertically set up signatures with the spine downwards. The sheets are simultaneously pressed

and the batches may be counted through a batch counter and displaced to each other.

For multiple-up productions the different ups may be separated at the entry of the vertical

stacker delivery by slanting the round belts.

SBAP 46/72/82-ME USA

Page 7Alterations reserved

Stand 10/2006

Page 8

Operating Manual

2.0 BASIC SAFETY INSTRUCTIONS

2.1 Warnings and symbols

The following designations or symbols are used for very special instructions in this Operating

Manual:

>NOTICE< Special instructions in respect to the economical use of the machine.

>ATTENTION< Special instructions or requirements and prohibitions to avoid injuries and damage.

>DANGER< Instructions or requirements and prohibitions to prevent personal injuries or extensive

damage.

Only skilled and instructed qualified personnel is allowed to operate the machine.

The operator must be at least 18 years old

SBAP 46/72/82-ME USA

2.2 Safety in the working place Destined use of the Vertical Stacker Delivery

2.2.1 MBO units correspond to their prescribed Safety Technical Requirement at the time of their shipment.

For this purpose, any moveable and rotating parts are covered with protective hoods and

are mechanically or electrically interlocked to such an extent as to not unreasonably detract from

the operation.

- Single person operation only (insufficient view at the drive side).

2.2.2 With technical safety precautions it is extremely important that all operating personnel receive

sufficient technical safety instructions and are advised of all potential sources of danger. However,

it must be remembered that even with proper use of the machine, accidents can occur which

present a danger to life and limb of the operator or third parties. Respectively, it does not exclude

the detraction of the machine and other material assets.

2.2.3 The delivery should only be operated when in good working order. Any malfunctions that may

impair safety must be removed immediately by trained personnel of the manufacturer/supplier.

2.2.4 The delivery is exclusively designed to handle folded paper sheets. The processing of any other

materials should not be attempted as the manufacturer or supplier will not be liable for any resulting

damage.

2.2.5 Carefully read the complete Operating Manual, including the Safety and Service Requirements,

before you operate the machine.

2.2.6 The Operating Manual should be kept with the machine at all times.

2.2.7 Complete the Operating Manual, if necessary with internal Safety Instructions, as well as with

the legal regulations for the Prevention of Accidents.

Alterations reserved

Stand 10/2006Page 8

Page 9

Operating Manual

2.2.8 Make sure that all frequently substituted operators are thoroughly informed about the aforementioned

subjects and trained accordingly.

2.2.9 Never remove any protective or safety devices from the delivery, and do not make any changes

that may impair the safety of the delivery.

2.2.10 Never use any tools which are not in perfect condition, and make sure that no tools are left on the

delivery after completion of settings and maintenance work. Tools that fall into the delivery may

cause serious injuries and damage.

2.2.11 Note that all Safety Instructions are kept in a legible and visible condition.

2.2.12 Any audible and visible change on the delivery in relation to its safety must be reported

immediately to the supervisor or manager of your company.

2.2.13 All operating personnel should be aware that loose clothing, jewellery or long hair can cause serious

injuries if caught in the delivery.

2.2.14 It is absolutely prohibited to clean the transport tapes or pressing rollers, eliminate malfunctions,

or to undertake adjustments while the delivery is in operation.

>DANGER< Therefore, always activate the EMERGENCY STOP button.

SBAP 46/72/82-ME USA

2.2.15 Make sure that no other person starts the delivery while you are working on it, e.g. adjustment or

other works!

>DANGER< Therefore, always activate the EMERGENCY STOP button, or turn OFF the main

switch, or unplug the delivery.

2.2.16 Do not immediately turn the delivery ON if it has stopped for any inexplicable reason. Make sure

that the delivery is in good working condition and that no other person is working on the delivery.

2.2.17 Turn off the main switch and secure it, if necessary, with a lock if you are required to undertake

extensive mechanical or electrical maintenance and repair work.

2.2.18 Never open the main or subcontrol panel! Only authorised personnel should gain access to electronic

control cabinets as there are no user serviceable parts.

>DANGER< if control cabinet is open! All main terminals could be alive even though the

mains switch has been turned off.

2.2.19 Any damaged cables or electrical connections must be reported to the appropriate supervisor

of your company.

2.2.20 Machine connections must be installed in such a manner that no cables, tubes or hoses are left

trailing.

Page 9Alterations reserved

Stand 10/2006

Page 10

2.3 Safety devices

2.3.1 Protective hoods – Layout

Operating Manual

SBAP 46/72/82-ME USA

2.3.2 Protective hoods – Checklist

Pos De signation Function Visible control Result Rem ark

Guard at infeed

1

Cover infeed

2

below

Guard above

3

gear wheel

Protection hood at

4

drive

Guard for touching

5

Guard over

6

adjus ting chain

Guard over

7

belt drive s ystem

Guard over

8

drum drive

U p p er c o ve r

9

Electric box and

10

m iddle c over

Cover below

11

Cover over

12

drive chain

Cover over

13

drive chain

EM E RG E NCY -STOP switch in the operator field

14

control

date nam e signature

Alterations reserved

Stand 10/2006Page 10

Page 11

Operating Manual

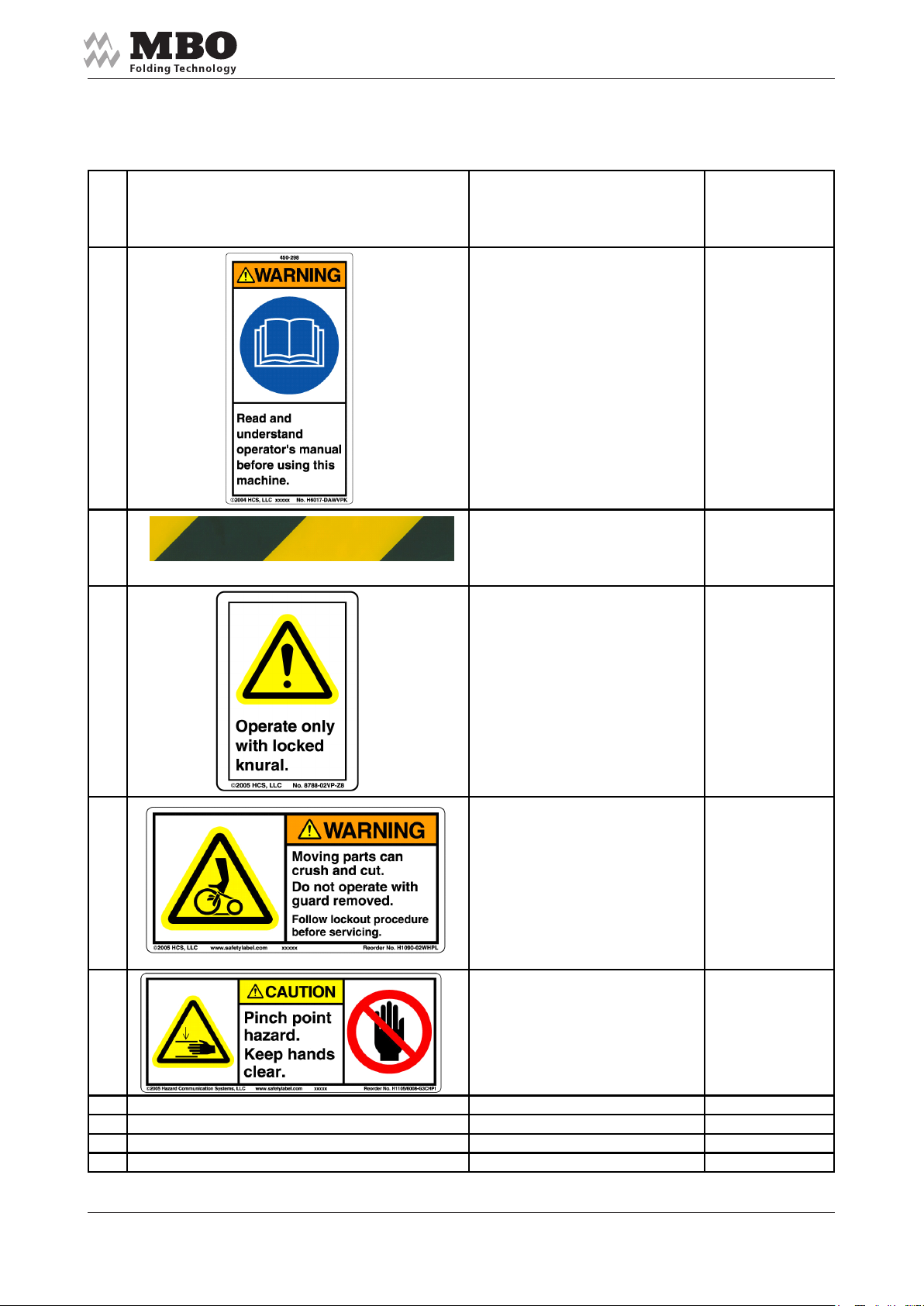

2.3.3 Check list: warning labels (oder warning signs)

SBAP 46/72/82-ME USA

Pos. Warnings Introduction

At first commissioning

(oder at initial operation)

(first customer)

1

2

3

Note

4

5

Date:

Name:

Signature:

Page 11Alterations reserved

Stand 10/2006

Page 12

Operating Manual

Pos. 1

Significance:

Please read and understand

the operating manual before you

start to work on the machine.

SBAP 46/72/82-ME USA

Pos. 2

Significance:

Danger from infeed point.

Keep away your hands from the

rotating shaft!

Pos. 2

Significance:

Danger of squeezing!

Keep away your hands when the

transportation plate is moving.

Alterations reserved

Stand 10/2006Page 12

Page 13

Operating Manual

Pos. 3

Significance:

Work only with a tightened lever.

Danger of jerky height adjustment in

case of non-tightened lever.

SBAP 46/72/82-ME USA

Pos. 4

Significance:

Danger of dragging through transport

tape. Keep away your hands from infeed

points!

Pos. 4

Significance:

Danger of dragging through transport

tape. Keep away your hands from infeed

points!

Page 13Alterations reserved

Stand 10/2006

Page 14

Pos. 5

Significance:

Non-observance may possibly

cause bruises to the hands.

Please keep your hands away

from this danger spot.

Operating Manual

SBAP 46/72/82-ME USA

Alterations reserved

Stand 10/2006Page 14

Page 15

Operating Manual

SBAP 46/72/82-ME USA

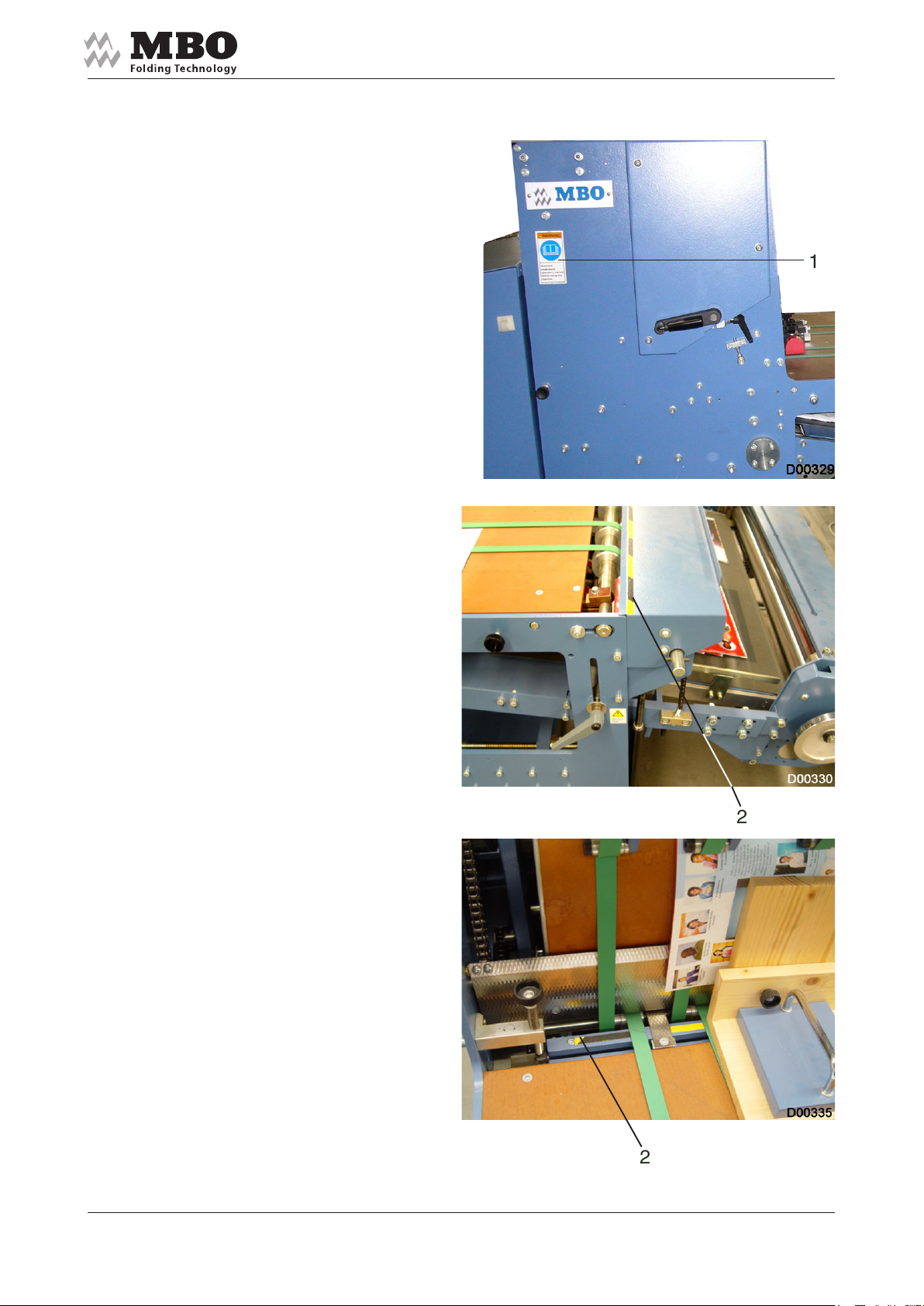

3.0 Transportation, installation, and initial operation

This part of the Operating Manual is specifically directed at service personnel and internal

authorised personnel responsible for transportation and installation.

3.1 Transportation

The Vertical Stacker Delivery

SBAP 46/72/82 – ME is shipped on a

pallet or in a crate.

Carry the pallet as close as possible to

its final destination by means of a forklift.

Unscrew the delivery from the pallet.

Remove the delivery from the pallet

or crate by lifting with a forklift

(see markings 1 on the frame).

>ATTENTION< There is a danger of risk

of injuries as the delivery may overturn!

>DANGER< The delivery must be

supported by two persons.

The ideal operating temperature is 10-35 °C.

3.2 Installation

Clean the SBAP46/72/82 - ME with rust preventing agents.

Page 15Alterations reserved

Stand 10/2006

Page 16

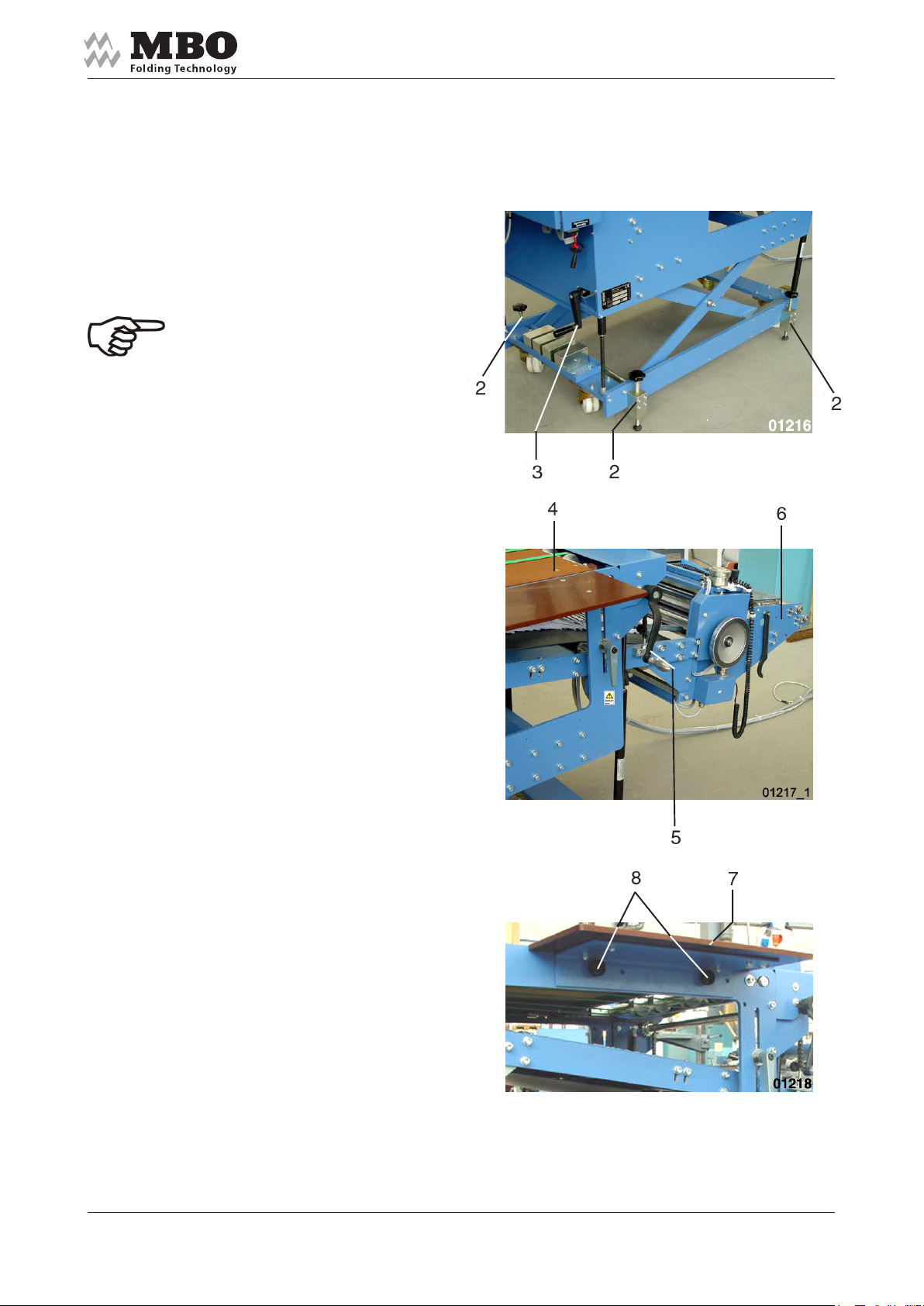

3.3 Erection

Position the SBAP 46/72/82 - ME

delivery next to the folding machine

and secure it with supporting screws 2

against displacement.

>NOTICE< The centre of the sheet

should be equal to the centre of the

delivery!

Position the line-up table 4 to

the suitable pick-up height by means

of the crank 3.

Operating Manual

SBAP 46/72/82-ME USA

The necessary height of the

infeed table 6 can be adjusted by means

of the crank 5.

This infeed height should match the

exit height of the folding machine.

Subsequently, fasten the knock-up

table 7 to the line-up table by

means of the knurled screws 8.

Alterations reserved

Stand 10/2006Page 16

Page 17

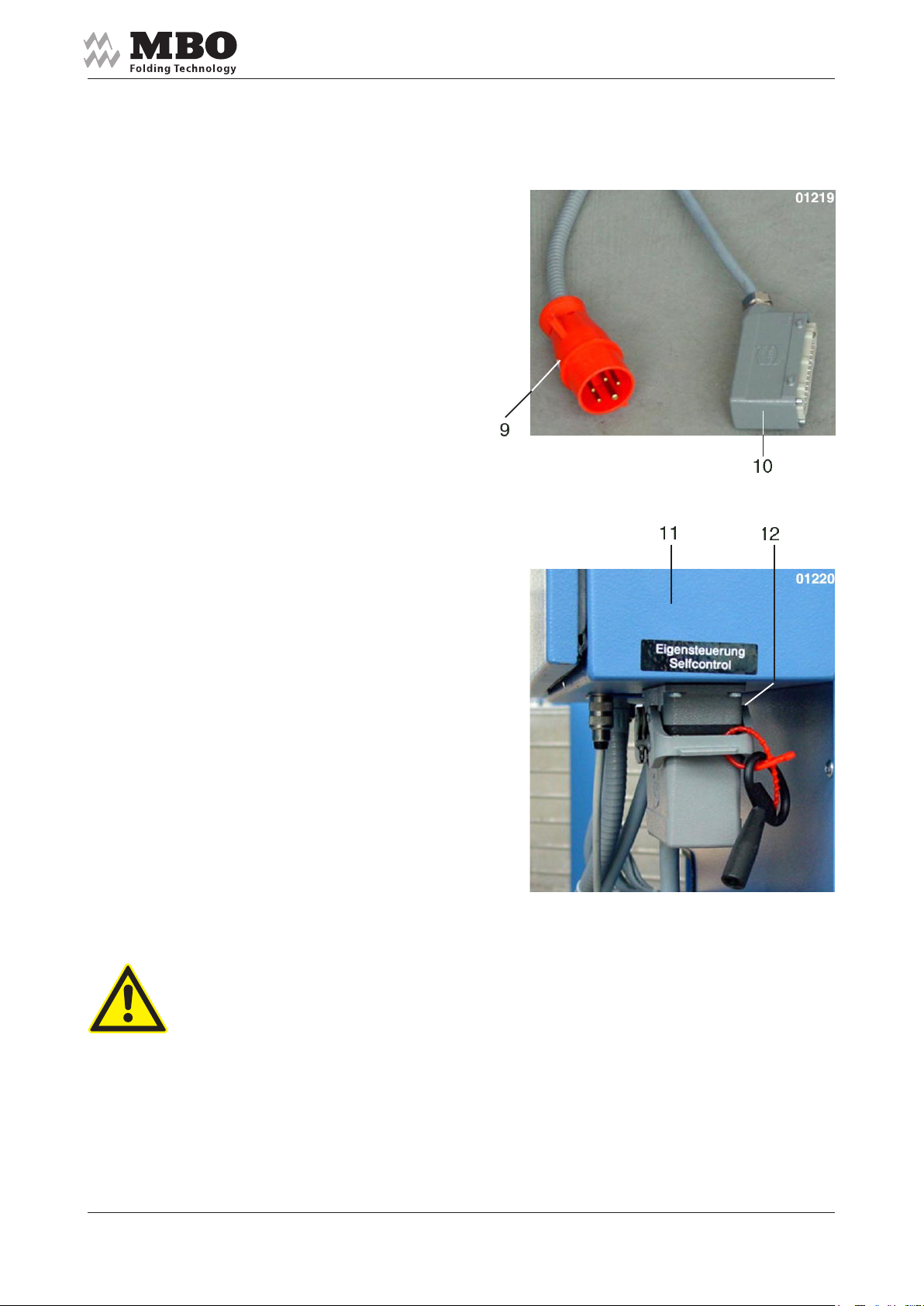

3.4 Electrical connection

Connect the SBAP 46/72/82 - ME to

the folding machine by means of

the power supply plug 9

and control plug 10.

Due to its self-control the

SBAP 46/72/82 - ME may also be

connected to foreign folding machines.

Operating Manual

SBAP 46/72/82-ME USA

For this purpose insert the power supply

plug into the supply circuit,

and the control plug into the socket

„Self-Control“ 12 at the control panel 11.

>DANGER< Please note that there is no joint OFF switch if the MBO Vertical Stacker Delivery is

connected to a foreign machine. We must expressly advise you that there is no safety cut-off if

the delivery is connected to a foreign machine. Both units must be turned ON and OFF separately!

The manufacturer shall not be liable for any damage or injuries caused by the lack of safety cut-off

devices!

Page 17Alterations reserved

Stand 10/2006

Page 18

Operating Manual

4.0 Service / Maintenance

This part of the Operating Manual is specifically directed at service personnel and internal

authorised personnel of the operating company responsible for service and maintenance.

>DANGER< Unless the delivery is isolated no service or maintenance work should be carried

out. Always activate the EMERGENCY STOP button or turn OFF the main switch and secure

it with a lock.

4.1 Procurement of spare parts

SBAP 46/72/82-ME USA

>ATTENTION< Only use spare parts that are supplied or recommended by the manufacturer.

For inquiries and spare parts orders it is necessary to provide the machine and serial number,

which may be obtained from the label 1.

Alterations reserved

Stand 10/2006Page 18

Page 19

4.2 Lubrication / Cleaning

Clean and lubricate the lubricating

nipple 2 behind the hand wheel 3 with a

few drops of oil monthly.

Operating Manual

SBAP 46/72/82-ME USA

The threaded spindle 6 for the height

adjustments should be cleared of dust

and slightly greased monthly.

The drive chain 7 for the transport tape

should be cleaned and provided with a

slight touch of oil monthly.

All drive chains (see chapter 4.4.1)

going from the main motor should be

cleaned and provided with a slight touch

of oil monthly.

For this purpose, remove the protective

hood 9 that has been fastened with the

screws 10. Thereafter, replace the

protective hood and re-fasten all the

screws.

Page 19Alterations reserved

Stand 10/2006

Page 20

Operating Manual

SBAP 46/72/82-ME USA

4.3 Cleaning of transport tapes and pressing rollers

>NOTICE< Generally, the delivery must be cleaned after each application! Particularly moveable or

rotating parts that are frequently changed for exchange of sheet size must be cleared of dust.

Heavy dust may detract the function.

>DANGER< Transport belts and pressing rollers should be cleaned while the delivery has been

turned OFF. Activate the EMERGENCY OFF switch, or turn OFF the main switch, or pull out the

power supply plug.

>NOTICE< Depending on the extent of dirt, transport tapes and pressing rollers must be cleaned

occasionally. Heavy contamination of printing powder or deposit of ink on the transport tapes and

pressing rollers may cause reduction in the quality of the folded products. The tapes should be

cleaned with a cleansing agent suitable for synthetic materials. Please contact your machine/delivery

supplier for further details. Unsuitable cleansing agents may swell the material or devastate the

proportion of adhesive material.

>DANGER< Do not use any aggressive cleaners! Protective gloves should be worn while you are

cleaning. Protect exposed parts of the body against splashes or contact. Dispose the soiled cleaning

material in the correct manner, i.e. environmentally friendly. Consider the flammability of the cleansing

agent. In regard to disposal and skin irritability, please also remember that a residual danger could

eventually exist after a period of time. Check the technical data sheet of the cleansing agent

manufacturer.

>NOTICE< MBO, the manufacturer of this Vertical Stacker Delivery, recommends a cleaning

material made by VARN for the fold rollers, bearing the designation „VARN-Wash VM 111“ or „VWM“.

Our recommendation is on a label near the fold rollers.

VARN is a worldwide supplier to the printing industry. Therefore, it cannot be excluded that in

certain countries different designations are used. Please take the individual order number from

VARN’s technical data sheet.

>DANGER< Make sure to check all technical data of the manufacturers cleansing agents for any

0

possible residual danger in respect of disposal, flammability, and skin irritablility.

Alterations reserved

Stand 10/2006Page 20

Page 21

Operating Manual

4.4 Tensioning of tapes, belts and chains

>NOTICE< Check the tension of drive tapes and chains once a month and, if necessary,

re-tension.

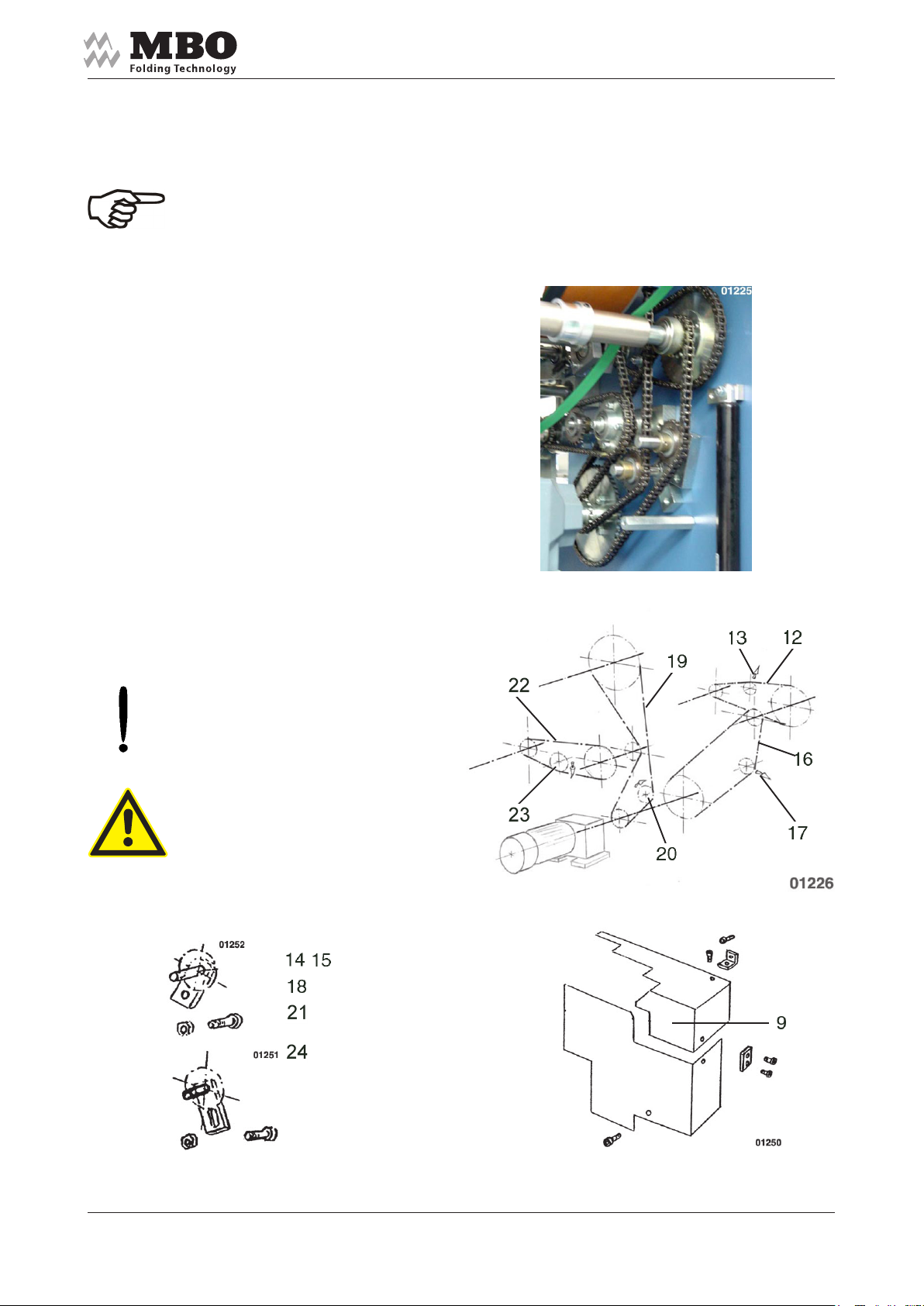

4.4.1 Chains at main drive motor

Remove the protective hood 9.

After loosening the screw 14 and

the nut 15 tension the chain 12 through

the chain tensioner 13.

After loosening the screw 18 tension

the chain 16 through the

chain tensioner 17.

After loosening the screw 21 tension

the chain 19 through the

chain tensioner 20.

SBAP 46/72/82-ME USA

After loosening the screw 24 tension

the chain 22 through the

chain tensioner 23.

>ATTENTION< Make sure that the

screws of chain tensioners are properly

re-tensioned after tensioning.

>DANGER< Make sure that no other

person is running the delivery while you

are working on it! Activate the

EMERGENCY STOP button,

or turn OFF the main switch,

or pull out the power supply plug!

Page 21Alterations reserved

Stand 10/2006

Page 22

Operating Manual

4.4.2 Drive chains for the transport tape at the collector table

The drive chain 29 for the

transport tape at the collector table 30

must be tensioned through the chain

tensioner 31.

For this purpose, remove the protective

hood 32 and loosen the screw 33 with

the externally located nut 34.

SBAP 46/72/82-ME USA

Subsequently, re-fasten the

screw with the nut and

replace the protective hood.

Alterations reserved

Stand 10/2006Page 22

Page 23

Operating Manual

4.4.3 Drive of pressing rollers and infeed tapes

Remove the protective hood over this

drive and loosen the Poly-V belt 35

through the belt tensioner 36 by

loosening the screw 37 with

the internally located nut 38.

The drive tape 39 should be

tensioned downward through the

tensioning roller 40.

SBAP 46/72/82-ME USA

For this purpose,

loosen the screw 41 with the

internally located nut 42.

After completion,

re-fasten the screws and

nuts and replace the protective hood.

Page 23Alterations reserved

Stand 10/2006

Page 24

Operating Manual

4.4.4 Transport tape at the collector table

The transport tape 43 at the collector

table may be tensioned on both sides.

For this purpose, loosen four screws 44

each on both sides and, upon loosening

the internally located nut 46,

unscrew the tensioning screw 45

counter-clockwise.

Make sure that the tape is equally

tensioned on both sides and does not

run off to the side.

Although the centre run is fixed laterally

through the disks 47, the tape should

not push too firm against the disks. After

you have completed the adjustments refasten all screws and nuts.

SBAP 46/72/82-ME USA

4.4.5 Lower line-up tapes

The lower line-up tapes 48 are

completely tensioned through the tape

shaft 49.

For this purpose, loosen the screws 50

and the counter nuts 51.

Consequently, the tape shaft is

tensioned by a constant clockwise turn

of both nuts 52.

After you have completed the tensioning

re-fasten all screws and nuts.

Alterations reserved

Stand 10/2006Page 24

Page 25

4.4.6 Upper line-up tapes

The upper line-up tapes 53 are

tensioned by weights 54.

For heavy, smooth paper sheets you

may hang up additional weights 55

which are delivered with the machine.

For this purpose, swing the control

cabinet 56 to the side, after you have

pulled the stop bolt 57 and removed the

guard plate 58.

>NOTICE< Do not use additional

weights when you process thin or

unstable paper sheets.

Operating Manual

SBAP 46/72/82-ME USA

After you have hung up the additional

weights, re-fasten the guard plate and

re-swing the control cabinet into its

previous position.

4.4.7 Pile transport tapes

The pile transport tapes 59 are

tensioned through the tape shaft 60.

For this purpose, loosen the screws 61

and the counter nut 62 on both sides.

Upon completion, re-fasten the screw

and counter nut.

Page 25Alterations reserved

Stand 10/2006

Page 26

Operating Manual

5.0 Operation (of the delivery)

5.1 Control desk

1 Key to „START“ the delivery.

2 Key to „STOP“ the delivery.

3 Red mushroom button on yellow background for „EMERGENCY STOP“.

4 Key for continuous sheet infeed.

5 Key for single sheet infeed.

6 Potentiometer for infinite speed regulation of the infeed tapes and pressing rollers.

7 Potentiometer for infinite speed regulation of the infeed tapes after the pressing rollers.

8 Selector switch to control the tapes after the pressing rollers:

a) Endurance run, e.g. to empty the delivery upon completion of a production run.

b) Photocell control during production; the tapes will stop if the sheet infeed has been

interrupted.

9 Batch counter „IVO“: only if the delivery is equipped with this option. See the attached Ope

rating Manual for functioning description. If no „IVO“ batch counter is provided, the „marking

device“ is controlled through the batch counter of the folding machine. Functioning description:

see the operating manual for the „folding machine“.

SBAP 46/72/82-ME USA

Alterations reserved

Stand 10/2006Page 26

Page 27

5.2 Infeed table

5.2.1 Infeed tapes

The products delivered from the folding

machine are taken by the round belts 1.

Positioning of tape rollers 2 and 3:

Loosen the screw 4 and displace the

guide 5.

The distance between the upper and

lower round belts may be adjusted for

product thickness by displacing the

upper tape rollers 8 and 2 and by

loosening the screws 7 at the collector

flange 7. Usually, this is only necessary

if you process very heavy products.

Remove the protective hood 6, loosen

the screws and nuts 7 and adjust the

tape rollers 2 or 8.

Make sure that they are adjusted

equally at both sides!

Operating Manual

SBAP 46/72/82-ME USA

Re-fasten the screws and nuts 7 and

replace the protective hood 6.

>DANGER< Before you perform these

actions it is absolutely imperative that

you activate the „EMERGENCY STOP“

or turn OFF the main switch of the

delivery. Otherwise risk of injury!

Page 27Alterations reserved

Stand 10/2006

Page 28

5.2.2 Multiple-up production

If signatures are cut into two- or threeup production in the folding machine:

Place the individual groups of round

belts 1, 2 and 3 diagonally to each other

or spread them!

Modify the position of the round belts 1,

2 and 3 only at the lateral side of the exit

of the infeed table – see item 5.2.1.

At least two round belts are necessary

for each production.

>DANGER< Before you perform these

actions it is absolutely imperative that

you activate the „EMERGENCY STOP“

or turn OFF the main switch of the

delivery.

Otherwise risk of injury!

Operating Manual

SBAP 46/72/82-ME USA

Two-up production

Three-up production

Alterations reserved

Stand 10/2006Page 28

Page 29

5 2.3 Marking device

>NOTICE< This device enables you to

exactly count and displace 1 batches to

each other in the desired number of

pieces to ensure the continuous take-off

of equally sized batches.

The desired number of pieces of

products of each batch must be entered

into the IVO – batch counter 9; see the

separately attached „IVO“ Operating

Manual.

If 9 does not exist, the marking device

will be controlled over the batch counter

of the folding machine. (see operating

manual „folding machine“)

Install a photocell 3 above the sheets.

Functioning check: The diode will light

up if a sheet is passing the photocell.

Operating Manual

SBAP 46/72/82-ME USA

As soon as the pre-selected number of

pieces of one batch is reached you

should displace the round belts to the

left or right side through the electromagnet 5 and marking bars 6.

Do not reach into rotating shafts!

>NOTICE< You should place the

photocell in such a way that it is not

influenced by the marking bars 6.

Page 29Alterations reserved

Stand 10/2006

Page 30

5.3 Pressing unit

How to adjust the pre-pressing rollers 1:

Insert a paper strip 2 into the calliper 3

(normally the full product thickness).

How to adjust the main

pressing rollers 4:

Insert a paper strip 5 into the calliper 6 -

(1/2 to 3/4 of the product thickness). For

opening turn the hooked key 7 left, and

for closing turn to the right (clockwise).

The micro switches 8 will turn the

complete delivery off if a product that is

too thick passes these micro switches.

>DANGER< Please be advised that

such switch-off will occur only if the

delivery is connected to an MBO

folding machine!

Operating Manual

SBAP 46/72/82-ME USA

Alterations reserved

Stand 10/2006Page 30

Page 31

5.4 Collector table

After the signature has passed the

pressing rollers the folded product will

fall onto the transport tape 1 of the

collector table 2.

The height of fall between the pressing

rollers and the collector table may be

adjusted at the adjustment grip 3 for

various products:

If you turn the adjustment grip

clockwise = you decrease the height of

fall; if you turn the adjustment grip

counter-clockwise = you increase the

height of fall.

>NOTICE< Unstable or thin products

require less height of fall; stable and

bulky products require more height of

fall.

Operating Manual

SBAP 46/72/82-ME USA

After the pressing rollers the sheet

passes the photocell 4. Functioning

check: The diode will light up if

a sheet is passing the photocell.

Thereby, it will set the

transport tape 1 into motion. The

collector rollers 6 should grasp the sheet

before the tape stops again after it has

left the photocell’s range of detection.

For positioning of the collector rollers it

is necessary to loosen both knurled

screws 7.

You may laterally displace the

collector rollers if you loosen the

knurled screws 8. The smoother bars 9

may be placed forward if you loosen the

knurled screw 10.

Wrinkled sheets after the pressing unit will cut off the delivery through the default switch 11.

The delivery will also be cut off if it is connected to an MBO folding machine. However,

if the delivery is connected to a foreign machine only the SBAP 46 - ME will cut off.

The second photocell and the second default switch will be used for two-up production.

The speed of the transport tape and therefore the adjustment of short or extensive

formation of shingles may be adjusted through the potentiometer at the control cabinet.

Page 31Alterations reserved

Stand 10/2006

Page 32

Operating Manual

5.5 Line-up tapes and line-up table

SBAP 46/72/82-ME USA

The shingled sheets are transferred by

the collector table 1 A between the

lower 1 and upper 2 line-up tapes and

transported by them around the drum 3

onto the collector table 4.

The speed of these line-up tapes

may be changed parallel to the

transport tape 1 A as they are driven

by the same motor. The height

adjustment of the line-up rollers 5 –

levelled to the upper edge of the folded

sheets 6 – may be performed through

the crank 7 after the clamping lever 8

has been loosened.

With short signatures, whose upper

edge 6 is deeper than the centre of the

drum 3, the pressure of the upper tape

onto the lower tape may be altered by

means of the line-up rollers:

Clockwise screwing of the red-marked

knurled nut 10 reduces pressure.

Counter-clockwise screwing of the redmarked knurled nut 10 increases

pressure.

A

Subsequently, you should secure the

position of the knurled screw by

countering the knurled nut 11.

The speed of the pile transport tapes 12

must be adapted to the production

speed and product thickness.

Low production speed and thin products

require less forward feed, but heavy

products and high production speed

require more forward feed.

continuation

Alterations reserved

Stand 10/2006Page 32

Page 33

Operating Manual

continuation

This forward feed can be adjusted

through the knurled screw 13:

Clockwise screwing of the knurled

screw 13 reduces forward feed.

Counter-clockwise screwing of the

knurled screw 13 increases forward

feed.

A retaining angle 14 is used to avoid the

tilt of the pile on the line-up table.

After loosening the knurled screw 16

the attachment plate 15 may be turned

or removed for various heights of

signatures.

Two retaining angles are used if you

process two-up productions.

SBAP 46/72/82-ME USA

The transport tapes 1, 2 and 12 should

only be displaced laterally in exceptional

cases.

At first, you should attempt to vary the

infeed position of the sheets into the

delivery by changing the position of the

delivery or by slanting the infeed tapes.

If you displace the transport tapes you

should ensure that all tape rollers for

each single transport tape are equally

displaced. We recommend using a tape

rule and measure from the delivery’s

side panel. Locking screws are fixed in

all tape rollers.

The lower transport tapes 1 are

displaced through the tape rollers 17

The upper transport tapes 2 are

displaced through the tape rollers 13,

and the pile transport tapes are

displaced through the tape rollers 19.

>ATTENTION< Make sure that these

tapes do not rub laterally as they may be

destroyed.

Page 33Alterations reserved

Stand 10/2006

Page 34

6.0 Putting out of service

6.1 Details of storage

• Check the premises in respect of temperature and humidity. The ideal storing temperature

rests between +15°C and +28°C. The higher the humidity the greater the danger of corrosion.

• It is essential that you take the weight details of the machine into con-sideration in respect of

the maximum load capacities.

• It is essential that you take the size details of the machine into consid-eration in respect of

the maximum load capacities.

• Prepare the gears/transmission for storage. You should also take into consideration that the

pre-requisites vary from case to case. Therefore, please contact the supplier of the

gears/ transmission and motor and fol-low the respective manual.

Operating Manual

SBAP 46/72/82-ME USA

• Clean dirt and dust carefully from the machine; do not use water - dan-ger of corrosion.

• Ensure that only an electrician disconnects the machine from the power supply.

• Use a fork lift to transport the machine.

• Cover the machine with foil.

Alterations reserved

Stand 10/2006Page 34

Page 35

Operating Manual

6.2 Environmental waste disposal

Dispose of single machine parts and all occurring waste materials from the K 800.2 Combi folding

machine environmentally according to:

For European . 75/442 EEC

Community member . 91/156 EEC

countries: . 91/692 EEC

For non-EC member Compatible with the country and district

countries: specific Waste Disposal Acts.

Ask about the possibility of municipal disposal or waste disposal by private waste disposal companies.

SBAP 46/72/82-ME USA

in connection with the country and district

specific Waste Disposal Acts.

On this occasion you should differ between:

. Destruction (destruction of records)

. Recycling (plastic packaging materials)

. Disposal (disposal of harmful substances)

6.2.1 Disposal of the waste machine

You may dispose of the waste machine:

. Through the supplier

. Through a disposal and demolition company, or

. Through your own company

6.2.2 Disposal by instructing the supplier

Instruct your supplier to dispose of the machine. The waste machine will be either part-exchanged or

professionally disassembled and environmentally disposed of.

As a result you are spared any further trouble.

6.2.3 Disposal by a disposal and demolition company

You may also instruct one of the nearby disposal and demolition companies who are also familiar

with this special field.

6.2.4 Disposal by your own company

You also have the alternative of demolishing the waste machine by your own expert personnel on

your own premises.

However, you should bear in mind that in some places you may require a separate official permit for

transportation and disposal. Make sure to obtain written confirmation of your professional disposal.

Page 35Alterations reserved

Stand 10/2006

Page 36

6.2.5 Ground water preservation

Please comply with the applicable provisions and acts to avoid ground water pollution:

For European . 80/68 EEC

Community member . 90/656 EEC

countries: . 91/692 EEC

For non-EC member Compatible with the country and district

countries: specific Waste Disposal Acts for the ground water protection.

Operating Manual

. 96/350 EC

. 96/59 EC

in connection with the country and district

specific Waste Disposal Acts.

SBAP 46/72/82-ME USA

6.3 Final remarks

You have now reached the end of this Operating Manual. We hope that you understood

everything, if so, then our efforts to prepare this Manual have been worthwhile. Of course, we

accept comments and wish to thank you for any suggestions to improve it. Even we are not

perfect! We wish you much pleasure and success with this machine. Should you, however,

still have problems with it, please do not hesitate to contact our technicians or supervisors

who will be able to assist you.

Alterations reserved

Stand 10/2006Page 36

Page 37

MBO-Group worldwide

MBO Deutschland

MBO Portugal

MBO Amerika

MBO Binder GmbH & Co. KG

Postfach 1169

D-71567 Oppenweiler

Tel.: +49 (0) 71 91 / 46 – 0

Fax: +49 (0) 71 91 / 46 – 34

http://www.mbo-folder.com

info@mbo-folder.com

MBO Binder GmbH & Co.

Maquinas Graficas, Lda

Rua Joaquim Alves da Silva 240, 420 e 570

P-4455-473 Perafita / Portugal

Tel.: +351 (22) 99 82 - 200

Fax: +351 (22) 99 82 - 201

info@mbo-folder.com

MBO Binder GmbH & Co. of America

400 Highland Drive

Westampton, NJ 08060 / USA

MBO Frankreich

MBO Herzog & Heymann

Tel.: +1 (6) 09267 - 2900

Fax: +1 (6) 09 267 - 14 77

http://www.mboamerica.com

MBO France SAS

Z. A. Burospace n° 3

Route de Gisy B.P. 33

F-91571 Bievres Cedex

Tel.: +33 (1) 69 35 50 - 90

Fax: +33 (1) 69 35 50 - 99

info@mbofrance.fr

Herzog & Heymann GmbH + Co. KG

Postfach 110355

D-33663 Bielefeld

Tel.: +49 (0) 71 91 / 46 – 0

Fax: +49 (0) 71 91 / 46 – 34

http://www.herzog-heymann.com

info@herzog-heymann.com

Stand 10/2006 Haug/Nol

Page 38

Operating ManualOperating Manual

Operating Manual

Operating ManualOperating Manual

SBAP 46/72/82 MESBAP 46/72/82 ME

SBAP 46/72/82 ME

SBAP 46/72/82 MESBAP 46/72/82 ME

VV

ertical Stacker Deliveryertical Stacker Delivery

V

ertical Stacker Delivery

VV

ertical Stacker Deliveryertical Stacker Delivery

with pressingwith pressing

with pressing

with pressingwith pressing

and marking deviceand marking device

and marking device

and marking deviceand marking device

Page 39

Operating Manual

SBAP 46/72/82-ME ENG

Contents

Prologue.................................................................................................................. 4

1.0 Machine specification............................................................................................ 4

1.1 Manufacturer .......................................................................................................... 4

1.2 Type:........................................................................................................................4

1.3 Technical data ........................................................................................................ 5

1.3.1 Sizes.................................................................................................................................................. 5

1.3.2 Floor plan (measures in cm)............................................................................................................ 5

1.4 Documentation ....................................................................................................... 6

1.5 User information / Functioning description......................................................... 7

2.0 BASIC SAFETY INSTRUCTIONS ........................................................................... 8

2.1 Warnings and symbols.......................................................................................... 8

2.2 Safety in the working place Destined use of the Vertical Stacker Delivery ...... 8

2.3 Safety devices ...................................................................................................... 10

2.3.1 Protective hoods – Layout ............................................................................................................. 10

2.3.2 Protective hoods – Checklist ......................................................................................................... 10

Alterations reserved

Stand 01/2004Page 2

Page 40

Operating Manual

SBAP 46/72/82-ME ENG

3.0 Transportation, installation, and initial operation ............................................. 11

3.1 Transportation ...................................................................................................... 11

3.2 Installation ............................................................................................................ 11

3.3 Erection................................................................................................................. 12

3.4 Electrical connection ........................................................................................... 13

4.0 Service / Maintenance.......................................................................................... 14

4.1 Procurement of spare parts ................................................................................ 14

4.2 Lubrication / Cleaning ......................................................................................... 15

4.3 Cleaning of transport tapes and pressing rollers ............................................. 16

4.4 Tensioning of tapes, belts and chains................................................................ 17

4.4.1 Chains at main drive motor ........................................................................................................... 17

4.4.2 Drive chains f or the transport tape at the collector tab le............................................................ 18

4.4.3 Drive of pressing rollers and inf eed tapes ................................................................................... 19

4.4.4 Transport tape at the collector table ............................................................................................. 20

4.4.5 Lower line-up tapes ........................................................................................................................ 20

4.4.6 Upper line-up tapes........................................................................................................................ 21

4.4.7 Pile transport tapes........................................................................................................................ 21

5.0 Operation (of the delivery) .................................................................................. 22

5.1 Control desk ......................................................................................................... 22

5.2 Infeed table ........................................................................................................... 23

5.2.1 Infeed tapes .................................................................................................................................... 23

5.2.2 Multiple-up production................................................................................................................... 24

5 2.3 Marking de vice ............................................................................................................................... 25

5.3 Pressing unit ........................................................................................................ 26

5.4 Collector table ...................................................................................................... 27

5.5 Line-up tapes and line-up table ......................................................................... 28

6.0 Final remarks........................................................................................................ 30

Page 3Alterations reser ved

Stand 01/2004

Page 41

Prologue

The MBO Vertical Stacker Delivery SBAP 46/72/82 - ME you have purchased is a valuable

piece of equipment. It is absolutely imperative that you compl y with all Safety Regulations

and Safety Instructions. This Operating Man ual is designed to instruct you to correctly operate

the machine, to comply with the Safety Regulations, and also to maintain the machine

properly.

1.0 Machine specification

Operating Manual

SBAP 46/72/82-ME ENG

1.1 Manufacturer

MBO Binder & Co. Maschinenbau Oppenweiler

Grabenstrasse 4, D-71570 Oppenweiler , Germany

P.O. Bo x 1169, D-71567 Oppenw eiler , Germany

Tel. +49 7191 460

Fax +49 7191 4634

1.2 Type:

Vertical Stacker Delivery SB AP 46/72/82 - ME

Alterations reserved

Stand 01/2004Page 4

Page 42

Operating Manual

SBAP 46/72/82-ME ENG

1.3 Technical data

1.3.1 Sizes

SBAP 46-ME SBAP 72-ME SB AP 82-ME

Working width: 46 cm 72 cm 82 cm

Maximum infeed height: 95 cm 95 cm 95 cm

Minimum infeed height: 38 cm 38 cm 38 cm

Sheet width / line-up height max.: 30 cm 30 cm 30 cm

Sheet width / / line-up height min.: 8 cm 8 cm 8 cm

Length of pile: 73 cm 73 cm 73 cm

Pressing power max.: 2000 kp 2000 kp 2000 kp

Speed: 40-155m/min 40-155m/min 40-155m/min

Po wer requirements: 1.3 kw 1.3 kw 1.3 kw

1.3.2 Floor plan (measures in cm)

Page 5Alterations reser ved

Stand 01/2004

Page 43

Operating Manual

SBAP 46/72/82-ME ENG

1.4 Documentation

Customer:

Machine configuration: Vertical Stacker Delivery SBAP 46/72/82 - ME

Machine No.:

Serial No.:

BA Batch Counter IVO:

Electrical data:

Wiring diagram no.:

Operational voltage V3/Hz:

Control voltage V/A:

Control voltage V/A:

Total nominal current A:

Fuse at power supply A:

Wiring diagram no’s .:

Test mark GS Nr.:

Test mark CE Nr.:

Certificate of Conformity:

Perceiv ed noise le v el (dB/AI):

GS marking no.:

Alterations reserved

Stand 01/2004Page 6

Page 44

Operating Manual

1.5 User information / Functioning description

The Ve rtical Stacker Delivery SBAP 46/72/82 - ME is a mobile, separate unit with self-drive to

vertically set up signatures with the spine downwards. The sheets are simultaneousl y pressed

and the batches may be counted through a batch counter and displaced to eac h other.

For multiple-up productions the different ups may be separated at the entry of the vertical

stacker delivery by slanting the round belts.

SBAP 46/72/82-ME ENG

Page 7Alterations reser ved

Stand 01/2004

Page 45

Operating Manual

2.0 BASIC SAFETY INSTRUCTIONS

2.1 Warnings and symbols

The following designations or symbols are used f or v ery special instructions in this Operating

Manual:

>NOTICE< Special instructions in respect to the economical use of the machine.

>ATTENTION< Special instructions or requirements and prohibitions to avoid injuries and damage .

>DANGER< Instructions or requirements and prohibitions to pre vent personal injuries or extensive

damage.

SBAP 46/72/82-ME ENG

2.2 Safety in the working place Destined use of the Vertical Stacker Delivery

2.2.1 MBO units correspond to their prescribed Safety T echnical Requirement at the time of their shipment.

For this purpose, any mov ea ble and rotating parts are covered with protective hoods and

are mechanically or electrically interlocked to such an extent as to not unreasonab ly detract from

the operation.

- Single person operation only (insufficient view at the drive side).

2.2.2 With technical safety precautions it is extremely impor tant that all operating personnel receive

sufficient technical safety instructions and are advised of all potential sources of danger . Ho w ev er ,

it must be remembered that even with proper use of the machine, accidents can occur which

present a danger to life and limb of the operator or third parties. Respectively, it does not exclude

the detraction of the machine and other material assets.

2.2.3 The delivery should only be operated when in good working order. Any malfunctions that may

impair safety must be remov ed immediately by tr ained personnel of the manufacturer/supplier.

2.2.4 The delivery is exclusively designed to handle folded paper sheets. The processing of any other

materials should not be attempted as the manufacturer or supplier will not be liable f or any resulting

damage.

2.2.5 Carefully read the complete Operating Manual, including the Safety and Ser vice Requirements,

before you operate the machine .

2.2.6 The Operating Manual should be k ept with the machine at all times .

2.2.7 Complete the Operating Manual, if necessary with internal Safety Instructions, as well as with

the legal regulations for the Prev ention of Accidents.

Alterations reserved

Stand 01/2004Page 8

Page 46

Operating Manual

2.2.8 Make sure that all frequently substituted operators are thoroughly informed about the aforementioned

subjects and trained accordingly .

2.2.9 Nev er remo v e any protective or safety devices from the delivery, and do not make any changes

that may impair the safety of the deliv ery.

2.2.10 Nev er use any tools which are not in perfect condition, and make sure that no tools are left on the

delivery after completion of settings and maintenance work. Tools that fall into the deliver y may

cause serious injuries and damage.

2.2.11 Note that all Safety Instructions are kept in a legible and visible condition.

2.2.12 Any audible and visible change on the deliv ery in relation to its safety must be reported

immediately to the supervisor or manager of your company.

2.2.13 All operating personnel should be aware that loose clothing, je wellery or long hair can cause serious

injuries if caught in the delivery.

2.2.14 It is absolutely prohibited to clean the transport tapes or pressing rollers, eliminate malfunctions,

or to undertake adjustments while the delivery is in operation.

>DANGER< Therefore, always activate the EMERGENCY STOP button.

SBAP 46/72/82-ME ENG

2.2.15 Make sure that no other person starts the delivery while you are working on it, e.g. adjustment or

other works!

>DANGER< Therefore, always activate the EMERGENCY STOP button, or turn OFF the main

switch, or unplug the delivery.

2.2.16 Do not immediately turn the delivery ON if it has stopped for any inexplicable reason. Make sure

that the delivery is in good working condition and that no other person is working on the delivery.

2.2.17 Turn off the main switch and secure it, if necessary, with a lock if you are required to underta ke

extensive mechanical or electrical maintenance and repair work.

2.2.18 Never open the main or subcontrol panel! Only authorised personnel should gain access to electronic

control cabinets as there are no user serviceable parts.

>DANGER< if control cabinet is open! All main terminals could be alive even though the

mains switch has been turned off.

2.2.19 Any damaged cables or electrical connections must be reported to the appropriate supervisor

of your company.

2.2.20 Machine connections must be installed in such a manner that no cables, tubes or hoses are left

trailing.

Page 9Alterations reser ved

Stand 01/2004

Page 47

2.3 Safety devices

2.3.1 Protective hoods – La yout

Operating Manual

SBAP 46/72/82-ME ENG

2.3.2 Protective hoods – Checklist

Pos Designa tion Function V isible control Result Com m ent

G uard at infeed

1

Cover infeed

2

below

G uard above

3

gear wheel

P rotection hood at

4

drive

G uard for touc hing

5

G uard over

6

a d jus t ing c h a in

G uard over

7

belt drive sy stem

G uard over

8

drum drive

Upper cover

9

E lectric box and

10

middle cover

Cover belo w

11

Cover over

12

drive c hain

Cover over

13

drive c hain

control

date name signature

Alterations reserved

Stand 01/2004Page 10

Page 48

Operating Manual

3.0 Transportation, installation, and initial operation

This part of the Operating Manual is specifically directed at service personnel and internal

authorised personnel responsible for transportation and installation.

3.1 Transportation

The V ertical Stacker Delivery

SBAP 46/72/82 – ME is shipped on a

pallet or in a crate.

Carry the pallet as close as possible to

its final destination by means of a forklift.

Unscrew the delivery from the pallet.

Remove the deliv ery from the pallet

or crate by lifting with a f orklift

(see markings 1 on the frame).

SBAP 46/72/82-ME ENG

>ATTENTION< There is a danger of risk

of injuries as the delivery may overturn!

>DANGER< The delivery must be

supported by two persons.

3.2 Installation

Clean the SBAP46/72/82 - ME with rust preventing a gents.

Page 11Alterations reser ved

Stand 01/2004

Page 49

3.3 Erection

Position the SBAP 46/72/82 - ME

delivery next to the folding machine

and secure it with supporting screws 2

against displacement.

>NOTICE< The centre of the sheet

should be equal to the centre of the

delivery!

Position the line-up table 4 to

the suitable pick-up height b y means

of the crank 3.

Operating Manual

SBAP 46/72/82-ME ENG

The necessary height of the

infeed table 6 can be adjusted b y means

of the crank 5.

This infeed height should match the

exit height of the folding machine.

Subsequently , f asten the knock-up

table 7 to the line-up table b y

means of the knurled screws 8.

Alterations reserved

Stand 01/2004Page 12

Page 50

3.4 Electrical connection

Connect the SBAP 46/72/82 - ME to

the folding machine by means of

the power supply plug 9

and control plug 10.

Due to its self-control the

SBAP 46/72/82 - ME may also be

connected to foreign folding machines.

Operating Manual

SBAP 46/72/82-ME ENG

For this purpose insert the power supply

plug into the supply circuit,

and the control plug into the socket

„Self-Control“ 12 at the control panel 11.

>DANGER< Please note that there is no joint OFF switch if the MBO Vertical Stacker Delivery is

connected to a foreign machine. We must expressly advise yo u that there is no safety cut-off if

the delivery is connected to a foreign machine. Both units must be turned ON and OFF separately!

The manufacturer shall not be liable for any damage or injuries caused by the lack of saf ety cut-off

devices!

Page 13Alterations reser ved

Stand 01/2004

Page 51

Operating Manual

4.0 Service / Maintenance

This part of the Operating Manual is specifically directed at service personnel and internal

authorised personnel of the operating company responsible for service and maintenance.

>DANGER< Unless the delivery is isolated no service or maintenance work should be carried

out. Always activ ate the EMERGENCY STOP button or turn OFF the main s witch and secure

it with a lock.

4.1 Procurement of spare parts

SBAP 46/72/82-ME ENG

>ATTENTION< Only use spare parts that are supplied or recommended by the manufacturer .

For inquiries and spare parts orders it is necessary to provide the machine and serial number,

which may be obtained from the label 1.

Alterations reserved

Stand 01/2004Page 14

Page 52

4.2 Lubrication / Cleaning

Clean and lubricate the lubricating

nipple 2 behind the hand wheel 3 with a

few drops of oil monthly.

Operating Manual

SBAP 46/72/82-ME ENG

The threaded spindle 6 for the height

adjustments should be cleared of dust

and slightly greased monthly .

The drive chain 7 for the transport tape

should be cleaned and provided with a

slight touch of oil monthly.

All drive chains (see chapter 4.4.1)

going from the main motor should be

cleaned and provided with a slight touch

of oil monthly .

For this purpose, remove the protective

hood 9 that has been f astened with the

screws 10. Thereafter, replace the

protective hood and re-fasten all the

screws.

Page 15Alterations reser ved

Stand 01/2004

Page 53

Operating Manual

SBAP 46/72/82-ME ENG

4.3 Cleaning of transport tapes and pressing rollers

>NOTICE< Generally , the delivery must be cleaned after each application! Particularly moveable or

rotating parts that are frequently changed for exchange of sheet size must be cleared of dust.

Heavy dust may detr act the function.

>DANGER< Transport belts and pressing rollers should be cleaned while the delivery has been

turned OFF. Activate the EMERGENCY OFF switch, or turn OFF the main switch, or pull out the

power supply plug.

>NOTICE< Depending on the extent of dirt, transport tapes and pressing rollers must be cleaned

occasionally. Heavy contamination of printing powder or deposit of ink on the transport tapes and

pressing rollers may cause reduction in the quality of the folded products. The tapes should be

cleaned with a cleansing agent suitable for synthetic materials. Please contact your machine/deliv ery

supplier for further details. Unsuitable cleansing agents may swell the material or devastate the

proportion of adhesive material.

>DANGER< Do not use an y aggressive cleaners! Protective gloves should be worn while you are

cleaning. Protect e xposed parts of the body against splashes or contact. Dispose the soiled cleaning

material in the correct manner, i.e. environmentally friendly. Consider the flammability of the cleansing

agent. In regard to disposal and skin irritability , please also remember that a residual danger could

eventually exist after a period of time. Check the technical data sheet of the cleansing agent

manufacturer.

>NOTICE< MBO, the manufacturer of this V ertical Stacker Delivery, recommends a cleaning

material made by V ARN for the fold rollers, bearing the designation „V ARN-W ash VM 111“ or „VWM“.

Our recommendation is on a label near the fold rollers.

VARN is a wor ldwide supplier to the printing industry. Therefore, it cannot be excluded that in

certain countr ies different designations are used. Please take the individual order number from

V ARN’s technical data sheet.

>DANGER< Make sure to check all technical data of the manufacturers cleansing agents for any

0

possible residual danger in respect of disposal, flammability , and skin irritab lility.

Alterations reserved

Stand 01/2004Page 16

Page 54

Operating Manual

4.4 Tensioning of tapes, belts and chains

>NOTICE< Check the tension of drive tapes and c hains once a month and, if necessary ,

re-tension.

4.4.1 Chains at main drive motor

Remove the protectiv e hood 9.

After loosening the screw 14 and

the nut 15 tension the chain 12 through

the chain tensioner 13.

After loosening the screw 18 tension

the chain 16 through the

chain tensioner 17.

After loosening the screw 21 tension

the chain 19 through the

chain tensioner 20.

SBAP 46/72/82-ME ENG

After loosening the screw 24 tension

the chain 22 through the

chain tensioner 23.

>ATTENTION< Make sure that the

screws of chain tensioners are properly

re-tensioned after tensioning.

>DANGER< Make sure that no other

person is running the delivery while you

are working on it! Activate the

EMERGENCY STOP button,

or turn OFF the main switch,

or pull out the power supply plug!

Page 17Alterations reser ved

Stand 01/2004

Page 55

Operating Manual

4.4.2 Drive chains for the transport tape at the collector tab le

The drive chain 29 for the

transport tape at the collector table 30

must be tensioned through the chain

tensioner 31.

For this purpose, remove the protective

hood 32 and loosen the screw 33 with

the externally located nut 34.

SBAP 46/72/82-ME ENG

Subsequently , re-f asten the

screw with the nut and

replace the protective hood.

Alterations reserved

Stand 01/2004Page 18

Page 56

Operating Manual

4.4.3 Drive of pressing rollers and infeed tapes

Remove the protective hood ov er this

drive and loosen the Poly-V belt 35

through the belt tensioner 36 by

loosening the screw 37 with

the internally located nut 38.

The drive tape 39 should be

tensioned downward through the

tensioning roller 40.

SBAP 46/72/82-ME ENG

For this purpose,

loosen the screw 41 with the

internally located nut 42.

After completion,

re-fasten the screws and

nuts and replace the protective hood.

Page 19Alterations reser ved

Stand 01/2004

Page 57

Operating Manual

4.4.4 Transport tape at the collector table

The transport tape 43 at the collector

table may be tensioned on both sides .

For this purpose, loosen four screws 44

each on both sides and, upon loosening

the internally located nut 46,

unscrew the tensioning screw 45

counter-clockwise.

Make sure that the tape is equally

tensioned on both sides and does not

run off to the side.

Although the centre run is fixed laterally

through the disks 47, the tape should

not push too firm against the disks. After

you have completed the adjustments refasten all screws and nuts .

SBAP 46/72/82-ME ENG

4.4.5 Lower line-up tapes

The lower line-up tapes 48 are

completely tensioned through the tape

shaft 49.

For this purpose, loosen the screws 50

and the counter nuts 51.

Consequently, the tape shaft is

tensioned by a constant clockwise turn

of both n uts 52.

After you have completed the tensioning

re-fasten all scre ws and nuts .

Alterations reserved

Stand 01/2004Page 20

Page 58

4.4.6 Upper line-up tapes

The upper line-up tapes 53 are

tensioned by weights 54.

For heavy, smooth paper sheets you

may hang up additional weights 55

which are delivered with the machine.

For this purpose, swing the control

cabinet 56 to the side, after you have

pulled the stop bolt 57 and removed the

guard plate 58.

>NOTICE< Do not use additional

weights when you process thin or

unstable paper sheets.

Operating Manual

SBAP 46/72/82-ME ENG

After you hav e hung up the additional

weights, re-fasten the guard plate and

re-swing the control cabinet into its

previous position.

4.4.7 Pile transport tapes

The pile transport tapes 59 are

tensioned through the tape shaft 60.

For this purpose, loosen the screws 61

and the counter nut 62 on both sides.

Upon completion, re-fasten the screw

and counter nut.

Page 21Alterations reser ved

Stand 01/2004

Page 59

Operating Manual

5.0 Operation (of the delivery)

5.1 Control desk

1 Key to „START“ the delivery.

2 Key to „STOP“ the deliv ery.

3 Red mushroom button on yellow bac kground for „EMERGENCY STOP“.

4 Key for contin uous sheet inf eed.

5 Key for single sheet inf eed.

6 Potentiometer for infinite speed regulation of the infeed tapes and pressing rollers .

7 Potentiometer for infinite speed regulation of the infeed tapes after the pressing rollers .

8 Selector switch to control the tapes after the pressing rollers:

a) Endurance run, e.g. to empty the deliv ery upon completion of a production run.

b) Photocell control during production; the tapes will stop if the sheet infeed has been

interrupted.

9 Batch counter „IVO“: only if the delivery is equipped with this option. See the attached Ope

rating Manual for functioning description. If no „IV O“ batch counter is pro vided, the „marking

device“ is controlled through the batch counter of the folding machine. Functioning description:

see the operating manual for the „f olding machine“.

SBAP 46/72/82-ME ENG

Alterations reserved

Stand 01/2004Page 22

Page 60

5.2 Infeed table

5.2.1 Infeed tapes

The products delivered from the folding

machine are taken by the round belts 1.

Positioning of tape rollers 2 and 3:

Loosen the screw 4 and displace the

guide 5.

The distance between the upper and

lower round belts may be adjusted for

product thickness by displacing the

upper tape rollers 8 and 2 and by

loosening the screws 7 at the collector

flange 7. Usually, this is only necessary

if you process very heavy products.

Remove the protectiv e hood 6, loosen

the screws and nuts 7 and adjust the

tape rollers 2 or 8.

Make sure that they are adjusted

equally at both sides!

Operating Manual

SBAP 46/72/82-ME ENG

Re-fasten the screws and nuts 7 and

replace the protective hood 6.

>DANGER< Bef ore you perf orm these

actions it is absolutely imperative that

you activate the „EMERGENCY STOP“

or turn OFF the main switch of the

delivery . Otherwise risk of injury!

Page 23Alterations reser ved

Stand 01/2004

Page 61

5.2.2 Multiple-up production

If signatures are cut into two- or threeup production in the folding machine:

Place the individual groups of round

belts 1, 2 and 3 diagonally to each other

or spread them!

Modify the position of the round belts 1,

2 and 3 only at the lateral side of the exit

of the infeed table – see item 5.2.1.

At least two round belts are necessary

for each production.

>DANGER< Bef ore you perform these

actions it is absolutely imperative that

you activate the „EMERGENCY STOP“

or turn OFF the main switch of the

delivery.

Otherwise risk of injury!

Operating Manual

SBAP 46/72/82-ME ENG

Tw o-up pr oduction

Three-up production

Alterations reserved

Stand 01/2004Page 24

Page 62

5 2.3 Marking device

>NOTICE< This de vice enab les you to

exactly count and displace 1 batches to

each other in the desired number of

pieces to ensure the continuous take-off

of equally sized batches.

The desired number of pieces of

products of each batch must be entered

into the IVO – batch counter 9; see the

separately attached „IVO“ Operating

Manual.

If 9 does not exist, the marking device

will be controlled over the batch counter

of the folding machine. (see operating

manual „folding machine“)

Install a photocell 3 above the sheets.

Functioning check: The diode will light

up if a sheet is passing the photocell.

Operating Manual

SBAP 46/72/82-ME ENG

As soon as the pre-selected number of

pieces of one batch is reached you

should displace the round belts to the

left or right side through the electromagnet 5 and marking bars 6.

>NOTICE< You should place the

photocell in such a way that it is not

influenced by the marking bars 6.

Page 25Alterations reser ved

Stand 01/2004

Page 63

5.3 Pressing unit

How to adjust the pre-pressing rollers 1:

Insert a paper strip 2 into the calliper 3

(normally the full product thickness).

How to adjust the main

pressing rollers 4:

Insert a paper strip 5 into the calliper 6 -

(1/2 to 3/4 of the product thickness). F or

opening turn the hooked key 7 left, and

for closing turn to the right (clockwise).

The micro switches 8 will turn the

complete delivery off if a product that is

too thick passes these micro switches .

>DANGER< Please be advised that

such switch-off will occur only if the

delivery is connected to an MBO

folding machine!

Operating Manual

SBAP 46/72/82-ME ENG

Alterations reserved

Stand 01/2004Page 26

Page 64

5.4 Collector table

After the signature has passed the

pressing rollers the folded product will

fall onto the transport tape 1 of the

collector table 2.

The height of fall between the pressing

rollers and the collector table may be

adjusted at the adjustment grip 3 for

various products:

If you turn the adjustment grip

clockwise = you decrease the height of

fall; if y ou turn the adjustment grip

counter-clockwise = you increase the

height of fall.

>NOTICE< Unstable or thin products

require less height of fall; stab le and

bulky products require more height of

fall.

Operating Manual

SBAP 46/72/82-ME ENG

After the pressing rollers the sheet

passes the photocell 4. Functioning

check: The diode will light up if

a sheet is passing the photocell.

Thereby, it will set the

transport tape 1 into motion. The

collector rollers 6 should grasp the sheet

before the tape stops again after it has

left the photocell’s range of detection.

For positioning of the collector rollers it

is necessary to loosen both knurled

screws 7.

You may laterally displace the

collector rollers if you loosen the

knurled screws 8. The smoother bars 9

may be placed forw ard if y ou loosen the

knurled screw 10.

Wrinkled sheets after the pressing unit will cut off the delivery through the default switch 11.

The delivery will also be cut off if it is connected to an MBO folding machine. However,