Page 1

Buckle Folding Machine

Original Manual

Preserve for future appliance!

B21

Continuous

Feeder

Page 2

Operating Manual B21-C - en

Machine type: Buckl e F ol di ng Machi ne B21

Model: Continuous feeder

Ma nufa cturer: MBO Binder Máquina s Gráficas SA

Rua Joaquim Alves da S il va

Apart ado 5093

4456-951 Perafita/ Portugal

Tel.: + 351 22 998 22 00

Fax : +351 22 998 22 01

Document type:

Stand: 13-09-2006 Professional : S. Mat os; M . Wiec h

Version: 09/06 Language: English

Altera ti o n s re served!

Operating manual / A NSI

Page2Alterations reserved Version 05/2008

Page 3

Operating Manual B21-C - en

Prologue

With the MBO folding machine you have purchased a valuable product. However, it is absolutely

imperative to comply with all Safety Regulations and Safety Instructions. This Operating Manual

should instruct you how to operate correctly the MBO folding machine and to comply with the

Safety Regulations and to maintain the machine properly .

Keep this operator manual for future apply at the machine.

Copyright

All rights reserved.

Any use of any of the marks appearing throughout the Products and Services, copy or relay to

third party without the express written consent of MBO-Binder S.A., as appropriate, is strictly

prohibited.

Warranty

Our products are contractually regularized. However, MBO´s warranty does not cover the following:

• Self-assembling/installations and alterations at the machine.

• Damages caused biy self-assembling/installations, faulty maintenance and self-repair .

• Assembling of spare parts when not purchased from an authorized MBO dealer .

• Not definded apply .

• Removing of guards or safety devices and resultant damages.

Customer´s information

MBO machines and spare parts can be purchase from our dealers worldwide, also close to you.

For questions, request for technical support or service please contact your dealer.

Allways indicate these statements for the sevice orders and spare part orders which can be read-off

from the machine label.

• Fabrication number

• Serial number

• Machine type

Use only spare parts, which are supplied or recommended by the manufacturer .

Alterations reserved

Page 3

Version 05/2008

Page 4

Operating Manual B21-C - en

Page4Alterations reserved Version 05/2008

Page 5

Operating Manual B21-C - en

Indice

1 General....................................................................................... 9

1.1 Content and diagram conventions............................................................... 9

1.2 Important references to the operating manual .......................................... 9

1.2.1 Marking of the product .....................................................................................10

1.2.2 Working area ...................................................................................................10

1.3 Product data .................................................................................................. 11

1.3.1 Floor plan B21/44X...........................................................................................11

1.3.2 Floor plan B21/64X.......................................................................................... 11

1.4 Technical Data............................................................................................... 12

1.5 Supplyed documents .................................................................................... 13

1.6 Equipment ...................................................................................................... 14

1.6.1 Buckle folding machine.................................................................................... 14

1.6.2 Folding unit one ............................................................................................... 14

1.6.3 Folding unit two ............................................................................................... 14

1.6.4 Knife folding unit „X“ ......................................................................................... 14

1.6.5 Hook on stream delivery................................................................................... 14

1.7 Functioning description ................................................................................ 15

1.7.1 Functioning description buckle fold .................................................................. 15

1.7.2 Functioning description knife fold ..................................................................... 15

2 Safety ......................................................................................... 17

2.1 Representation of alerts ...............................................................................17

2.2.1 Safety references and colours.......................................................................... 17

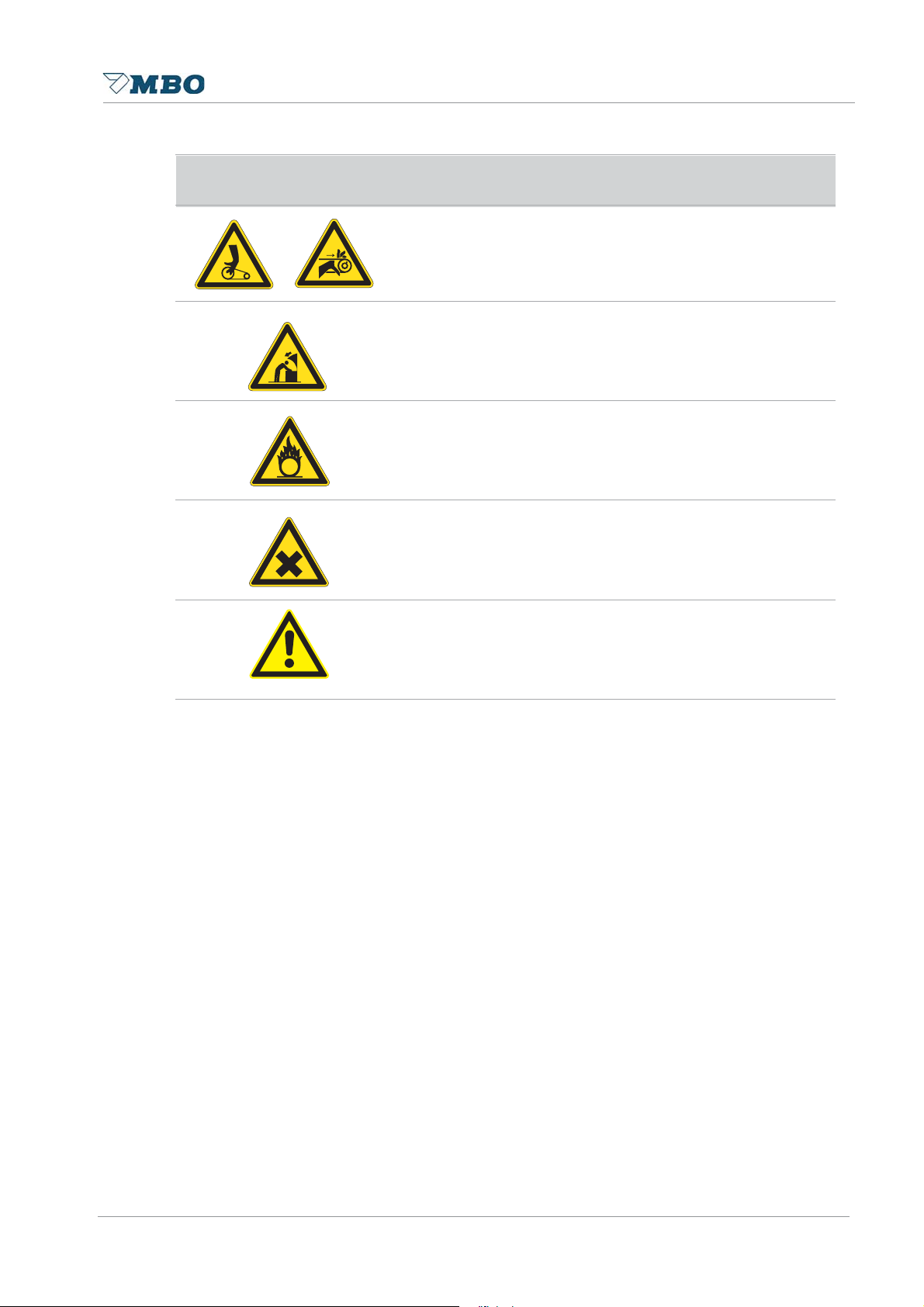

2.1.2 General dangers signs .....................................................................................18

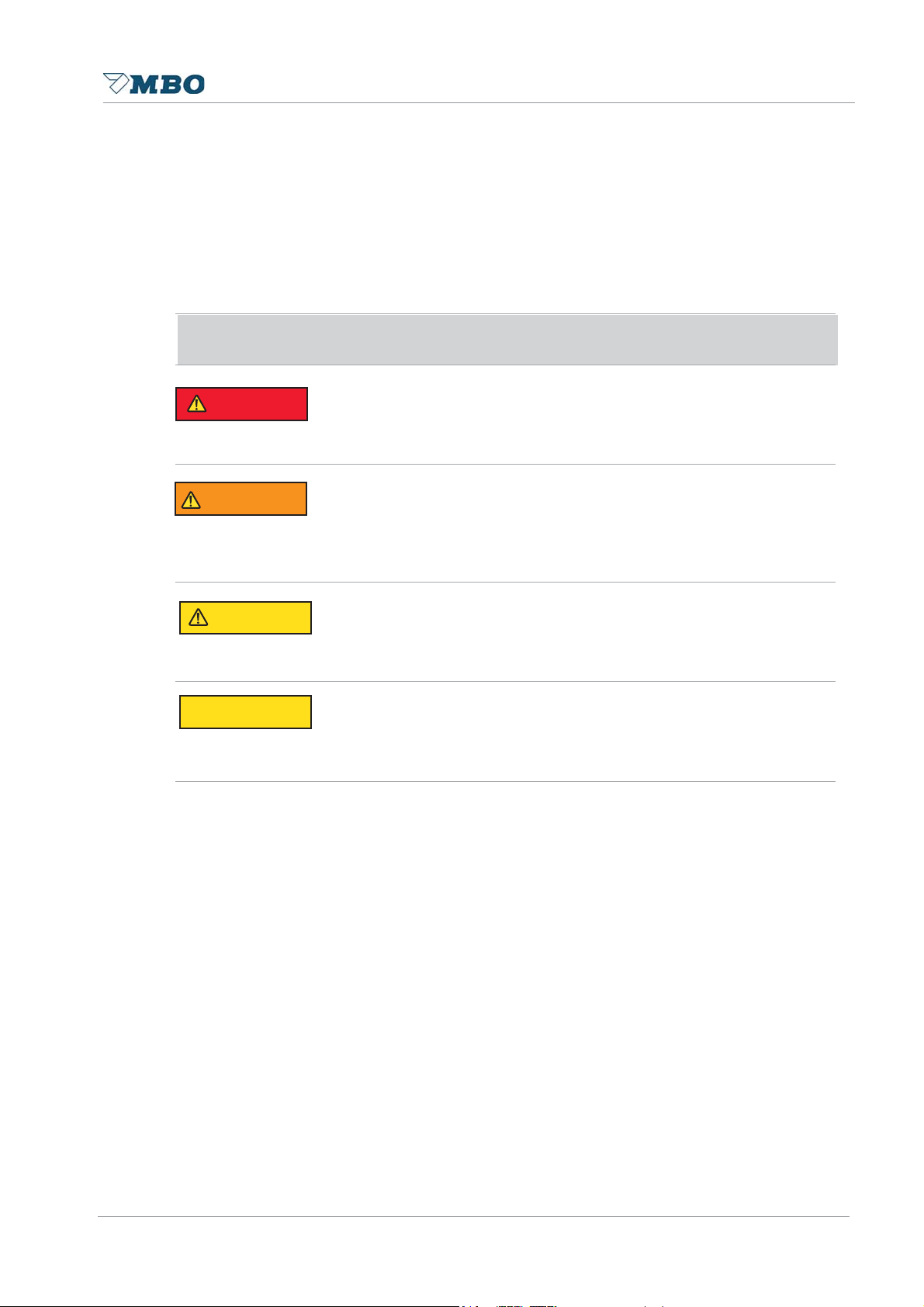

2.1.3 Danger level ..................................................................................................... 20

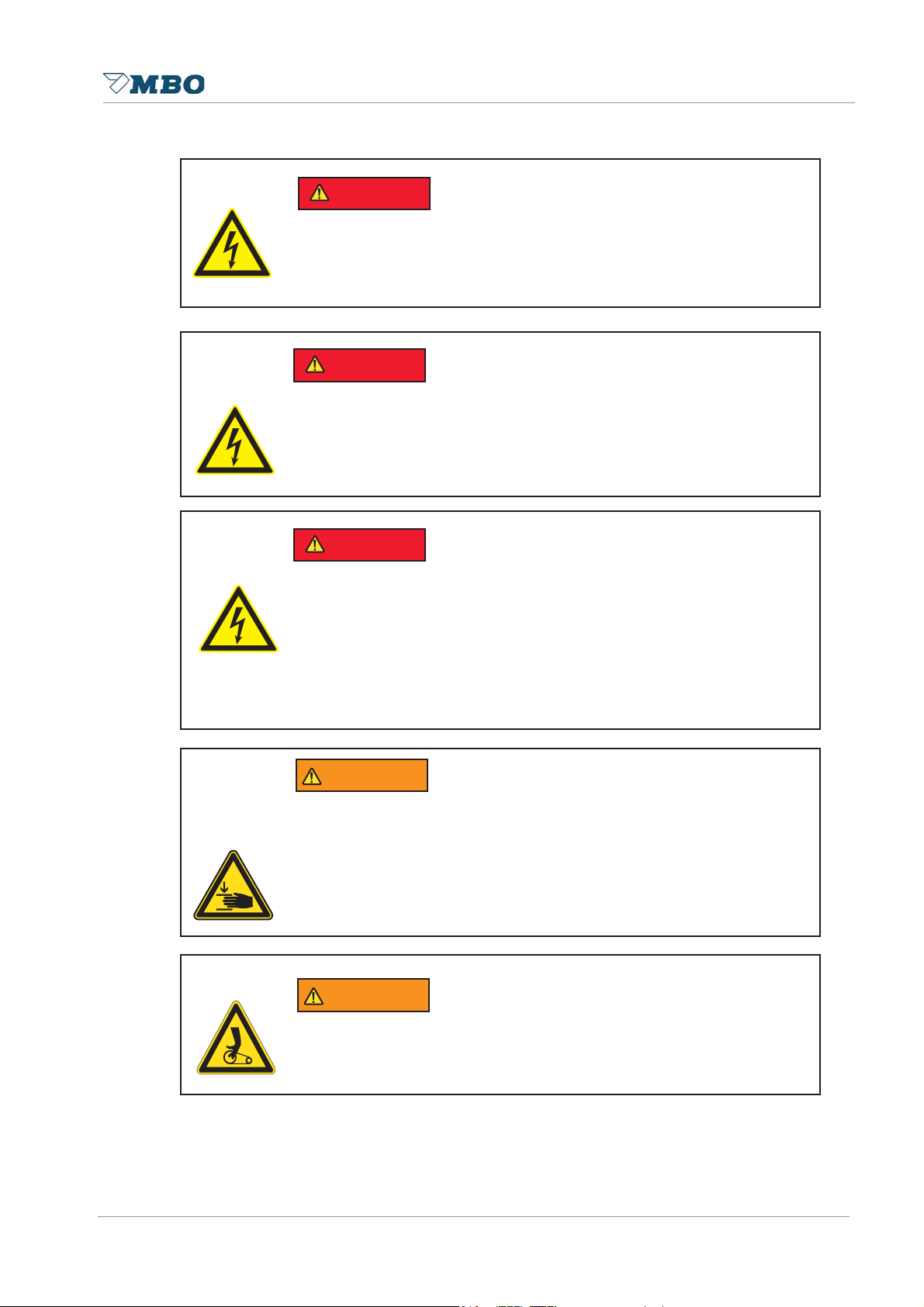

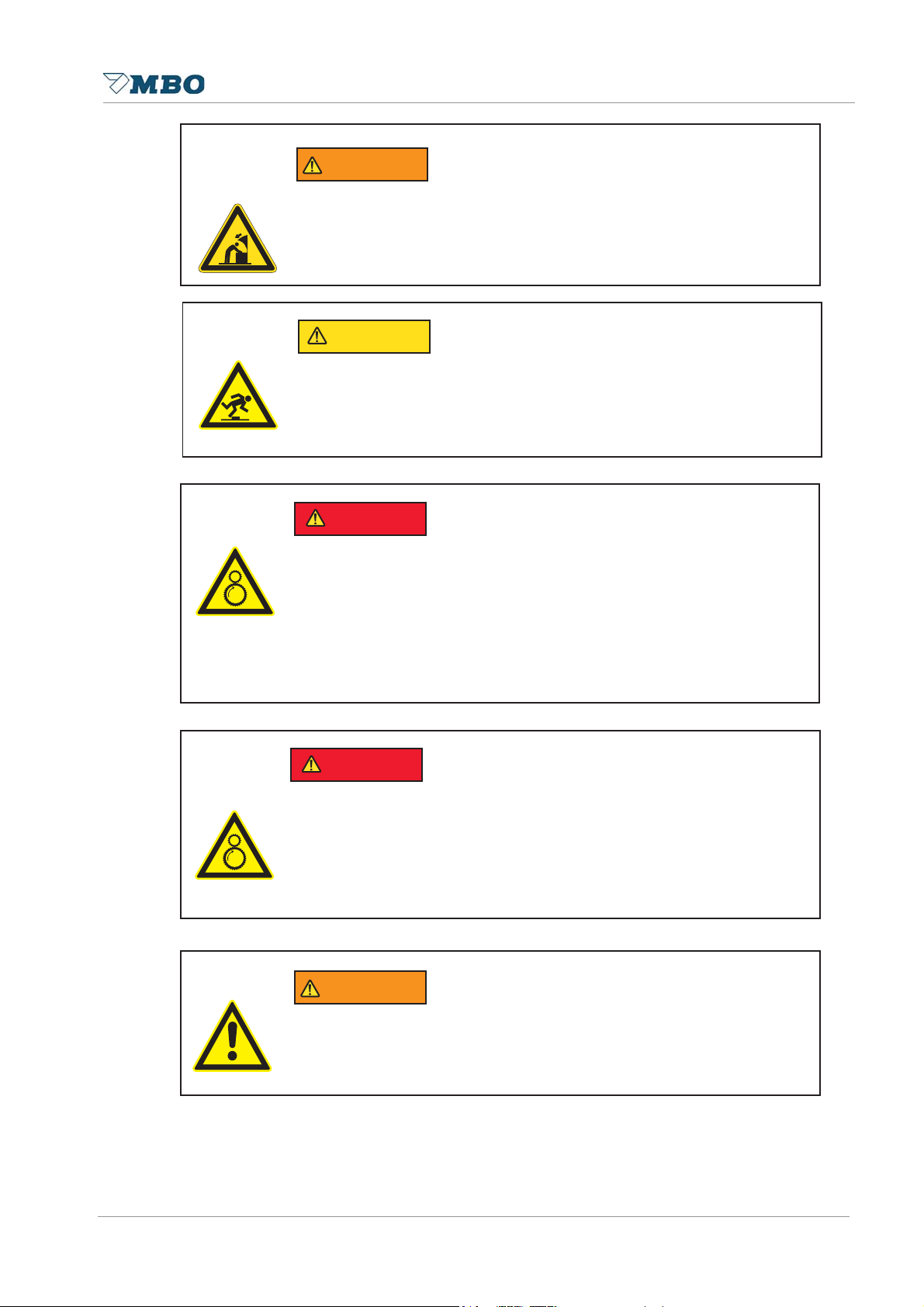

2.1.4 Safety advises at the operators manual............................................................21

2.1.5 Dangerous zones / Warning signs at the machine ........................................... 25

2.2 Product security............................................................................................. 33

2.2.1 Obligation and liability...................................................................................... 33

2.2.2 Due use ...........................................................................................................34

2.2.3 Inappropriate use is: ........................................................................................ 34

2.3 Protection guard -general plan.................................................................... 35

2.3.1 Protection guard - general plan of machine ...................................................... 35

2.3.2 Protection guard list 8 and 16pg unit ................................................................ 36

2.3.3 Protection guard list knife folding unit „X“..........................................................37

2.3.4 Protection guard list Delivery A56..................................................................... 38

2.4 Organisational and personnel ..................................................................... 39

2.4.1 Working safety................................................................................................. 39

2.4.2 Demands on the operating personnel ............................................................... 39

2.4.3 Qualification and training.................................................................................. 39

Alterations reserved

Page 5

Version 05/2008

Page 6

Operating Manual B21-C - en

2.5 Personal protection equuipment ................................................................. 40

2.6 Tasks for Emergency ..................................................................................... 40

2.6.1 Rescue of persons ...........................................................................................40

2.6.2 Emerging substances ......................................................................................41

3.0 Transport ation, assembly and inst allation..............................42

3.1 Transportation ............................................................................................... 42

3.1.1 Feeder ............................................................................................................. 42

3.1.2 Parallel unit...................................................................................................... 43

3.1.3 8 and 16pg unit................................................................................................ 43

3.1.4 Mobile knife folding unit “X”............................................................................... 44

3.1.5 Mobile stream delivery ..................................................................................... 44

3.2 Assembly and installation of machine..................................... 45

3.3 Electrical connection .................................................................................... 45

3.3.1 Control cabinet................................................................................................. 47

3.3.2 Main current connection................................................................................... 47

3.3.3 Stream delivery ................................................................................................47

4.0 Maintenance ..............................................................................48

4.1 Tensioning or exchange of belts/tapes ....................................................... 49

4.1.1 Upper feeder transport tape.............................................................................. 49

4.1.2 Lower feeder transport tape.............................................................................. 49

4.1.3 Feeder chain.................................................................................................... 50

4.1.4 Alignment tape at register table ....................................................................... 50

4.1.5 Drive belt for suction wheel............................................................................... 51

4.1.6 Drive belt for foldrollers and slitter shaft at parallel unit .....................................51

4.1.7 Main drive of parallel unit..................................................................................51

4.1.8 Drive belt for foldrollers at parallel unit and slitter shafts at subsequent unit......52

4.1.9 Drive belt at register table of following folding unit............................................. 52

4.1.10 Drive belt for foldrollers and slitter shafts of knife folding unit “X” .......................53

4.1.1 1 Setting of air gap for knife coupling of knife folding unit “X”................................53

4.2 Lubrication / Cleaning ..................................................................................54

4.2.1 Main machine including register table ..............................................................54

4.2.2 Continuous feeder F......................................................................................... 54

4.2.3 Guides of pressure bars / Bearings of foldrollers ..............................................54

4.2.4 Coupling of knife folding unit “X”........................................................................ 55

4.2.5 Guide rails / sheet stop (knife folding unit “X”) .................................................. 55

4.2.6 Cleaning of foldrollers ....................................................................................... 55

4.2.7 Compressor .....................................................................................................56

Page6Alterations reserved Version 05/2008

Page 7

Operating Manual B21-C - en

5.0 Operation of the machine .........................................................57

B 1.0 Main control panel ........................................................................................ 58

B 2.0 Continuous feeder C ..................................................................................... 59

2.1 Generally settings............................................................................................ 59

2.2 Air support ..................................................................................................... 60

2.3 Transportation system - ventilation.............................................................. 61

2.4 Suction wheel ............................................................................................... 64

2.5 Vacu-Infeed (Option) ..................................................................................... 65

B 3.0 Register table with ball rail, double sheet control, sheet infeed

control .................................................................................................... 66

3.1 Ball rail .......................................................................................................... 66

3.1.1 Vacu-Alignment (Option) .................................................................................. 67

3.2 Double sheet control..................................................................................... 69

3.3 Sheet infeed .................................................................................................. 69

B 4.0 Parallel folding unit ...................................................................70

4.1 Setting of foldrollers ..................................................................................... 70

4.2 Buckle plates .................................................................................................71

4.3 Deflectors ....................................................................................................... 72

4.4 Combi buckle plates FTK (Option) .............................................................. 73

B 5.0 Slitter shafts...............................................................................74

5.1 Perforating..................................................................................................... 74

5.2 Special perforating knife (Option) ...............................................................75

5.3 Cutting ............................................................................................................ 75

5.4 Scoring ........................................................................................................... 75

5.5 Gully cut ......................................................................................................... 76

5.6 Edge trimming ............................................................................................... 7 7

5.7 Slitter shaft guard.......................................................................................... 78

B 6.0 Mobile buckle folding unit ........................................................ 79

6.1 Installation ..................................................................................................... 79

6.2 Setting and sheet transportation ................................................................. 79

6.3 Electrical connection .................................................................................... 80

6.4 Control panel................................................................................................. 80

6.5 Foldrollers and slitter shafts at subsequent folding units .......................... 80

Alterations reserved

Page 7

Version 05/2008

Page 8

Operating Manual B21-C - en

B 7.0 Mobile knife folding unit “X” .................................................... 81

7.1 Installation .....................................................................................................81

7.2 Electrical connection .................................................................................... 81

7.3 Setting and sheet transportation ................................................................. 82

7.3.1 Knife folding unit “X” as first crossfold...............................................................82

7.3.2 Knife folding unit “X” as 2nd crossfold (threefold) ..............................................84

7.3.3 Foldrollers / Slitter shafts of the knife folding unit “X” ........................................ 84

7.3.4 Knife setting..................................................................................................... 85

B 8.0 Noise damping device ..............................................................87

B 9.0 Stream delivery .........................................................................88

9.1 Mobile stream delivery A56.......................................................................... 88

9.2 Hook-on stream delivery SE500/3 ................................................................89

D10.0 Instructions to the use.............................................................. 90

D10.1 Setting instructions for the most commonly folds ......................................90

10.1.1 Parallelfold .......................................................................................................90

10.1.2 Crossfold .........................................................................................................92

10.1.3 Threefold ..........................................................................................................93

M 1.0 Installation instruction ..............................................................94

1.1 Conveyer table for unit “X”.......................................................................... 94

M2.0 Maintenance protocol............................................................... 95

M 3.0 Pulley and belt drive ................................................................. 96

M 4.0 Out of order ........................................................................................100

4.1 Statements for the storage ...........................................................................100

4.2 Environment and disposal ............................................................................100

4.3 Disposal of the old machine.........................................................................101

4.3.1 Disposal with order at the supplier ...................................................................101

4.3.2 Disposal with order at a disposal and wrecking ................................................101

4.3.3 Disposal over the own firm ...............................................................................101

4.4 Ground-water protection .............................................................................. 101

Page8Alterations reserved Version 05/2008

Page 9

Operating Manual B21-C - en

1 General

1.1 Content and diagram conventions

That construct organizes itself this user information in:

Chapter 1: General

Chapter 2: Safety

Chapter 3: Transportation/Set up/Installation

Chapter 4: Adjustment/Setup

Chapter 5: Operation

Chapter 6: Out of order

the sequnce of these chapters enables you a uniformly progressive trained success with the

unse of the machine. The single chapters gives first a surveyover the subject handled, going

progressively into detail.

Working hint and information:

6$)(7<),567

127,&(

This sign marks information that seve the securityand the protection of the

machine.

This sign marks information for procedure, that guarantee a simple and

helpful mode of operation.

1.2 Important references to the operating manual

The existing user information is aligned on the operator of the machine. It should make the operator

trusted with the operation method, operating mode, security references and the maintenance of this

machine.

This user information is a part of your product. It must be stored during the service life of the product

at the machine. Give this instruction to each following owner or user of the product.

Keep this user information allways updated. Introduce every update in this document.

Our machine corresponds at the moment of delivery to the newest state of technology . As we work

permanently at further developments, we reserve ourselves changes.

User judgment of the operating instructions:

Our operating instructions are regularly updated. Help us with your proposals to form user-friendly

operating instructions.

Alterations reserved

Page 9

Version 05/2008

Page 10

1.2.1 Marking of the product

$

$

$

$

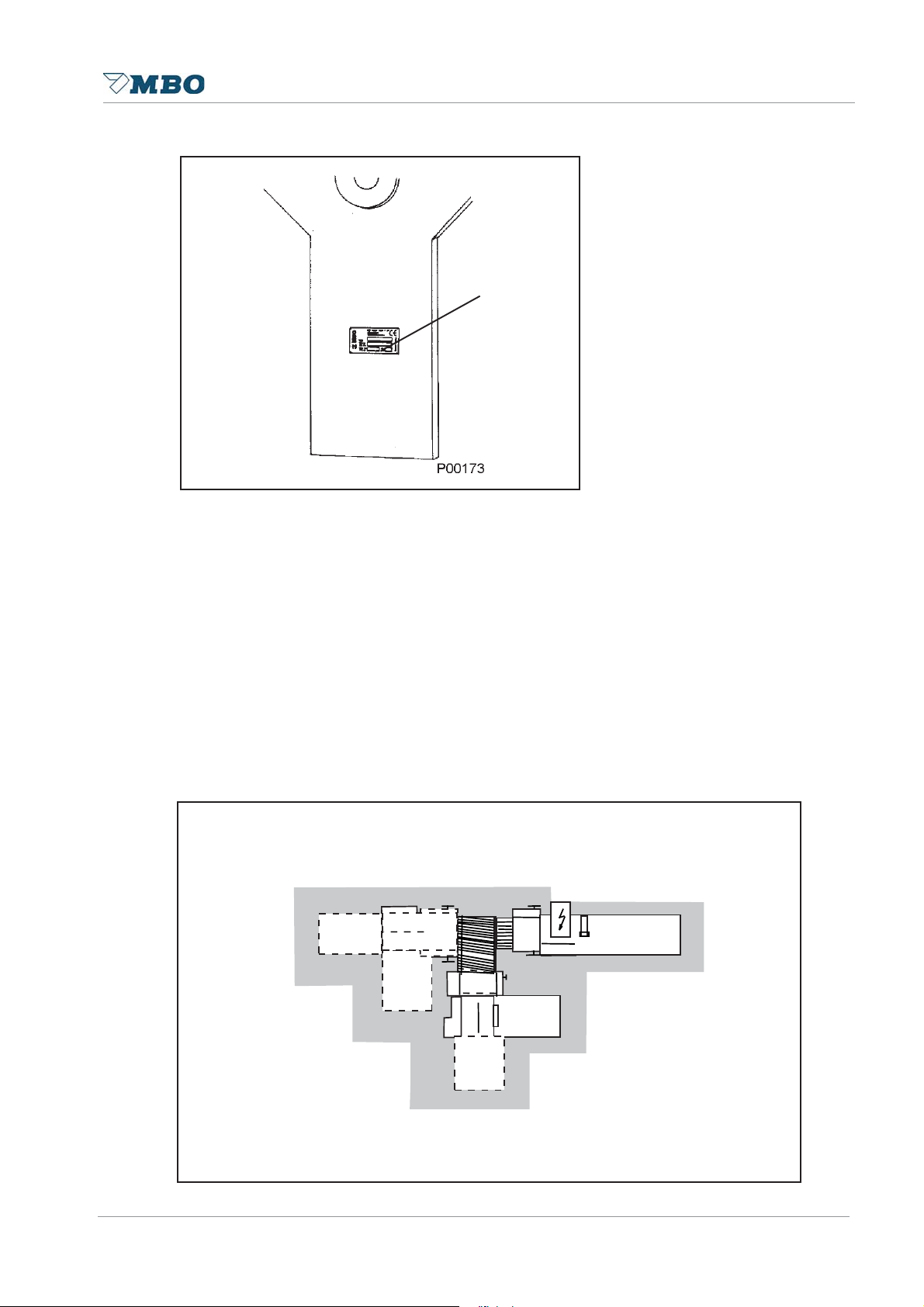

The identification of the machine as well as the most important machines data can be seen at the

machine in the type sign (1).

Operating Manual B21-C - en

1

Allways indicate these statements for the sevice orders and spare part orders:

• Fabrication number

• Serial number

• Machine type

1.2.2 Working area

The represented graphics show the single working area of the machine. The permitted work field

during the operation is marked in grey .

3

Page10Alterations reserved Version 05/2008

Page 11

1.3 Product data

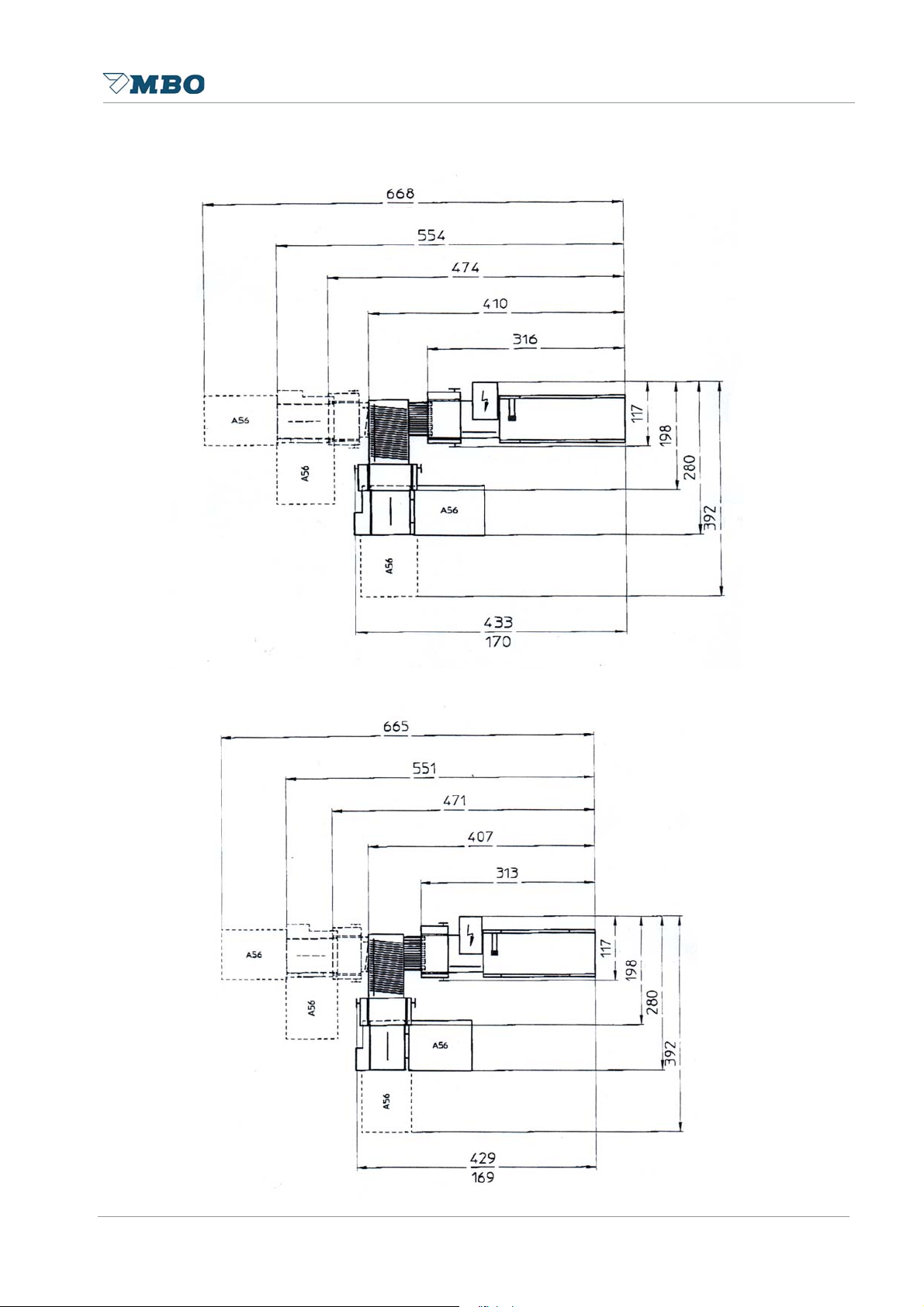

1.3.1 Floor plan B21/44X

Operating Manual B21-C - en

1.3.2 Floor plan B21/64X

Measurements in inch

Alterations reserved

Page 11

Measurements in inch

Version 05/2008

Page 12

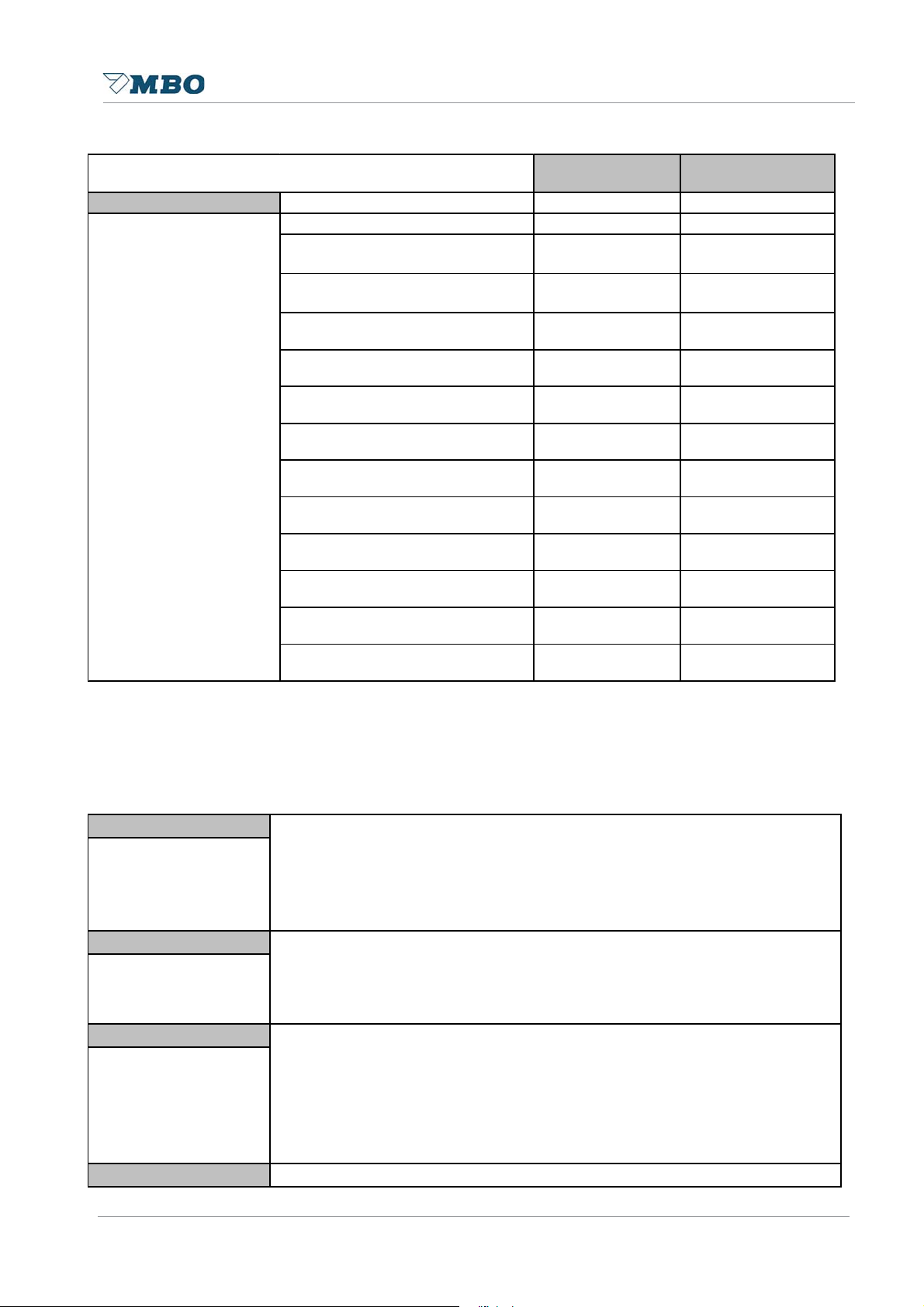

1.4 Technical Data

Operating Manual B21-C - en

Machine data:

Certif icat ion: Conf ormity certif icat ion:

Sound e mission: Sound emission (Al):

Elect rica l data: W iring diagram no.:

Name:

Customers address:

Machine conf iguration:

Machine- and serial no.:

F eeder t yp:

C o m p r e sso r typ :

G S -Sign no .:

8 page un it

16 page unit

Knif e unit " X"

St ream deliv er y:

O perat ion voltage (V: /Hz:)

Control voltage (V: /A :)

T ot al nominal current (V: /A:)

Main supply f use (A : )

Buckle fol ding machi ne B21

4; 4X; 44; 44X; 6; 6X; 64; 64X; 66; 66X

Continuo us feeder - C

For mats: Minimal format :

Maximal format:

Connect ed wat t age: Parellel unit

(220V;50HZ) Compressor:

Cont inuous feeder 0,1 KW

8 page un it

Knif e unit " X"

St ream deliv er y SE500/ 3; A 56

Wo rk ing speed Min. work ing speed:

Max . w ork ing speed:

6 x 6 inch

21 x 33 inch

0,75 K W

1,5 KW

0,75 K W

0,55 K W

0,12 K W

400 inch/ min.

8000 inch/ min

Page12Alterations reserved Version 05/2008

Page 13

Operating Manual B21-C - en

Net lbs Br ut lbs

Weight in lbs: Continuous feede r 4 buck les 1219 1585

Continuous feede r 6 buck les

Parallel unit 4 buc kles with noise hood 990 1631

Parallel unit 4 buc kles without noise

hood

Parallel unit 6 buc kles with noise hood 1047 1752

Parallel unit 6 buc kles without noise

hood

8pg 4 buckle unit with noise hood

8pg 4 buckle unit withou t noise hood

8pg 6 buckle unit with noise hood

8pg 6 buckle unit withou t noise hood

1234 1600

Knif e unit " X" T530- 4X 595 881

Knife unit " X" T530- 44X 637 926

St ream deliv ery SE 500/ 3 79 235

St ream deliv ery A 56 218 383

1.5 Supplyed documents

Users ma nual: Counter:

Air produc er:

Sequence stat i on:

Wiring diagram no.: Machine:

Sequence stat i on:

Spa re pa rts manual: Mac hi ne: B21 Cont i nuous feeder

Knife unit "X": B21

St ream deli very: SE 500/3 / A56

Sequence uni t :

Knife li st: TM 35/2

Alterations reserved

Page 13

Version 05/2008

Page 14

1.6 Equipment

1.6.1 Buckle folding machine

The buckle folding machine works exclusively in accordance with the principle of buckle folding.

The MBO buckle folding machine B21 with pile feeder has been developed to process sheets in

the sizes of 6 x 6 inch up to 21 x 33 inch. The production speed can be regulated between 400

and 8000 inch/min. However, this result depends on the type and size of sheet and type of fold.

The basic machine consists of a folding unit one with pile feeder as well as the well-proven MBO

register table.

1.6.2 Folding unit one

The folding unit one is equipped with four (optional six) stainless-steel buckle plates, sheet stop

fine adjustment and integrated swing deflectors. Moreover , it is also equipped with the well-proven

MBO spiral foldrollers, which may be adjusted through the quick-setting elements located on top

of the machine, combined with the low-noise belt drive system and solid, quickly removeable

slitter shafts through plug bearings.

1.6.3 Folding unit two

The folding unit two is a mobile buckle folding unit with own drive, register table, a maximum

working width of 21 inch as well as four buckle plates as descriped above.

Operating Manual B21-C - en

1.6.4 Knife folding unit „X“

The knife folding unit “X”, which is equipped with belt drive system, maximum working width of

21inch, and electronical knife control is useable as a folding unit two or three.

The knife folding unit “X” has an own drive and self-control.

1.6.5 Hook on stream delivery

The hook-on stream delivery SE500/3 is available in the configurations B21/4 ; B21/6 ; B21/44 ;

B21/64; B21/66 as standard. The mobile delivery A56 is optional. Machines with a unit ”X”

configuration, 4X ; 6X ; 44X; 64 or 66X, must choose the optional A56 ,because SE500/3 can

not be suspended at the ”X” unit.

The following description from the feeder to the machine should enable the operator to achieve a

general understanding of the machine.

Page14Alterations reserved Version 05/2008

Page 15

Operating Manual B21-C - en

1.7 Functioning description

1.7.1 Functioning description buckle fold

The principle of buckle fold is that

the sheet is always pushed into

the buckle plate.

three foldrollers and one buckle plate

are necessary to prepare a buckle fold.

Foldrollers 1 and 2 carry the sheet into

the buckle plate 4 to the sheet stop.

A buckle occurs during transporation

through these foldrollers to the direction

of foldrollers 2 and 3 by which the sheet

is folded through its passage.

1.7.2 Functioning description knife fold

4

Two foldrollers 1 und 2 as well

as one knife 3 are necessary

to prepare aknife fold.

The sheet is transported under

the knife to a sheet stop and aligned.

After the knife has been released

it moves the sheet between

the foldrollers where it is folded

during its passage.

3

21

Alterations reserved

Page 15

Version 05/2008

Page 16

Operating Manual B21-C - en

Page16Alterations reserved Version 05/2008

Page 17

Operating Manual B21-C - en

2 Safety

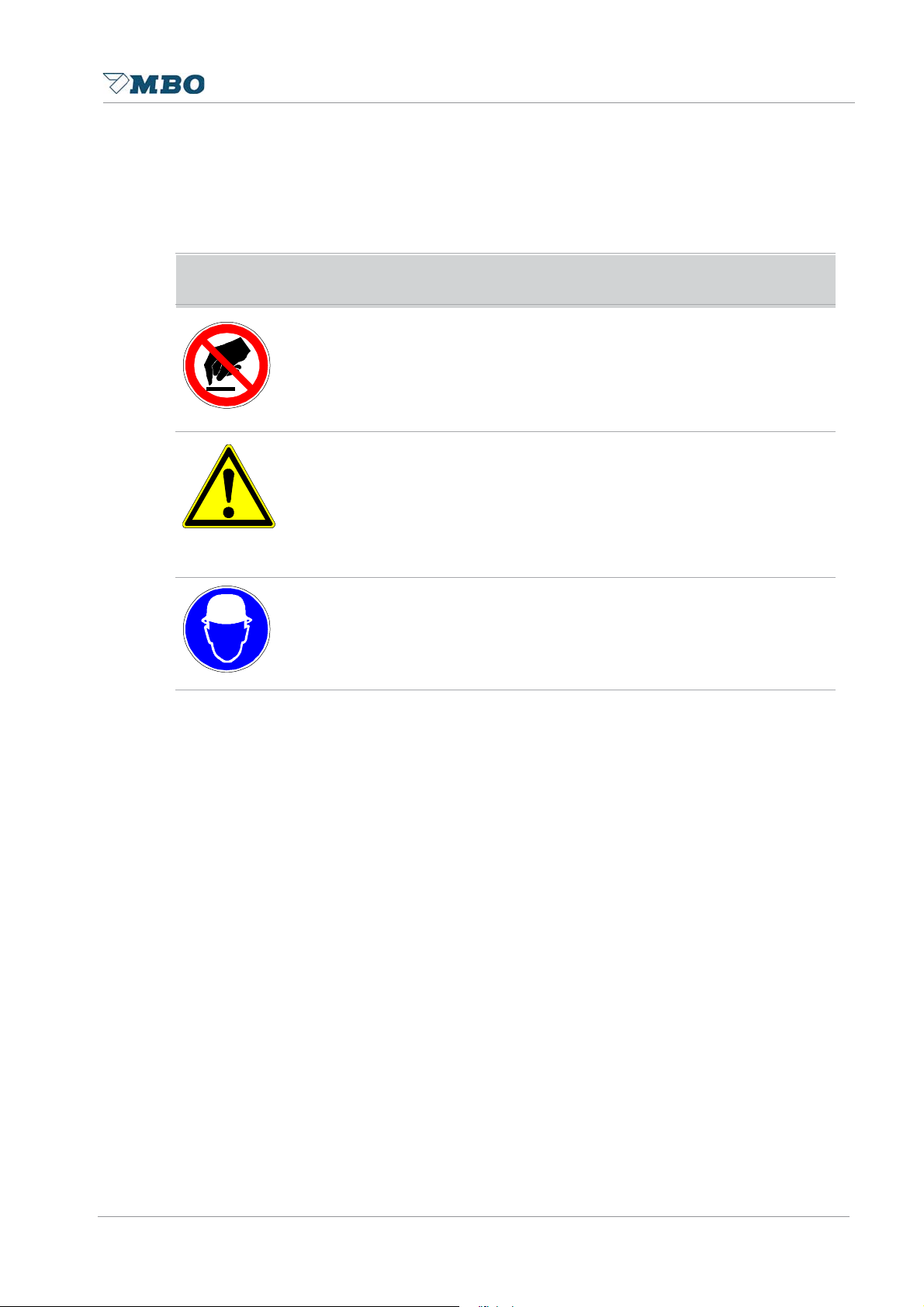

2.1 Representation of alerts

2.2.1 Safety references and colours

Representation Meaning

Forbid

Red border

White background

Black symbol

Warning

Y ellow background

Black symbol

Commandment

Blue background

White symbol

Alterations reserved

Page 17

Version 05/2008

Page 18

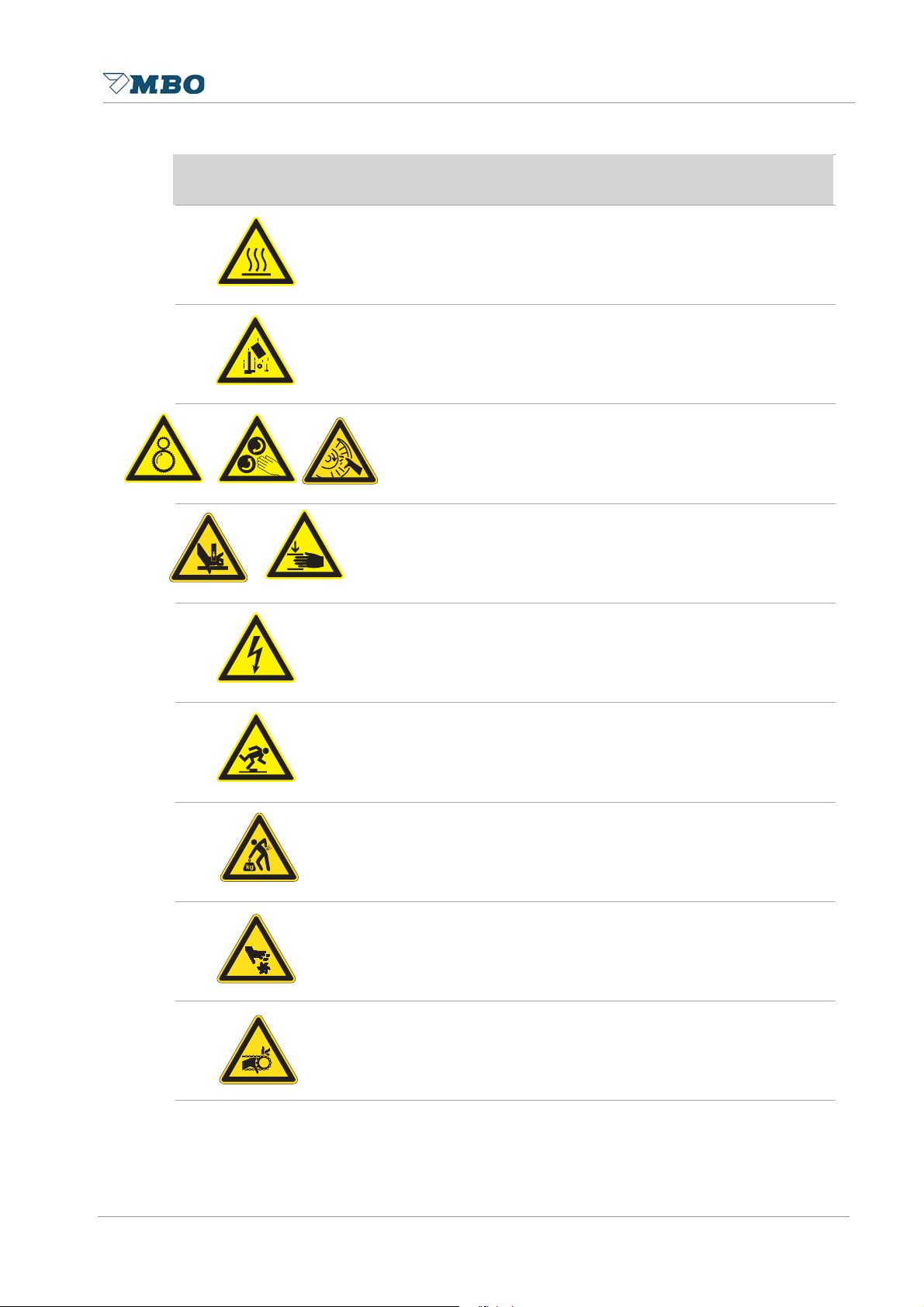

2.1.2 General dangers signs

Representation Meaning

Operating Manual B21-C - en

Warning of hot surface

Warning of falling objects

Warning of rotating machine parts

Warning of hand injuries

Warning of dangerous electric tension

Caution, danger through stumble places

Caution, lifting of heavy machine parts

Caution, danger through rotating slitter shafts

Caution, danger through rotating chain drive

Page18Alterations reserved Version 05/2008

Page 19

2.1.2 General dangers signs

Representation Meaning

Operating Manual B21-C - en

Caution, danger through rotating belt drives.

Caution before falling down of the opened protection hood.

Caution before flammable agents.

Danger before used cleaning agents and rags.

Warning of a dangerous place.

Alterations reserved

Page 19

Version 05/2008

Page 20

2.1.3 Danger level

Danger level give a reference to the heavy of the danger. They are constructed after a classification

system, which differs through different signal words:

• Danger (Safety signs presented)

• Warning (Safety signs presented)

• Caution (Safety signs presented)

• Caution (without Safety signs)

Danger levels Meaning

'$1*(5

:$51,1*

Operating Manual B21-C - en

A directly threatening danger that leads to heavy injuries or to death.

A possibly dangerous situation that can lead to heavy injuries or to

death.

&$87,21

&$87,21

A possible dangerous situation that can lead to easy personal injury .

A possible dangerous situation that can lead to material damage.

Page20Alterations reserved Version 05/2008

Page 21

Operating Manual B21-C - en

2.1.4 Safety advises at the operators manual

'$1*(5

Danger of electric tension.

Negligence can cause, heavy injuries or death.

Report damaged electrical connections to respnsible supervisor.

'$1*(5

Danger of electric tension at head clams with main switch off.

Negligence can cause, heavy injuries or death.

Work at the electronics can only be carried out of authorized persons or

skilled personnel.

'$1*(5

Danger of electric tension.

Negligence can cause, heavy injuries or death.

• Keep the main control cabinet and the lower distributor cabinet always

locked against unauthorized persons.

• During maintenance working at the control cabinet turn off main switch

and disconnect the network connector.

• Turn off and lock out system power before servicing.

:$51,1*

Danger of running machine parts.

Negligence can cause heavy personal injuries or extensive damages.

Report each audible/visible security-related change of the machine to the

responsible for that in your business.

Alterations reserved

:$51,1*

Danger before running belt-drive.

Negligence can cause, bruise emerges at the hands.

This work should be carried out by one person only !

Page 21

Version 05/2008

Page 22

Operating Manual B21-C - en

:$51,1*

Danger before falling down of the opened protection hood.

Negligence can cause heavy injuries through bruise of body part.

Be sure that in work with opened noise hoods this is completely opened to

the attack.

&$87,21

Danger of stumble places through lying around cables.

Negligence can cause personal injuries.

Place the machines connections (cables, hoses, tubes) so, that they form

no stumble places.

'$1*(5

Danger of running machines part.

Negligence can cause, heavy injuries or death.

• Keep hairs always together bandage and protected.

• T ake by operation and maintenance working at the machine your

jewellery off.

• Carry during operation or maintenance on the machine only adjoining

garment.

'$1*(5

Danger of running machines part.

Negligence can cause, heavy injuries or death.

In sudden stop of the machine, review before turning on:

• That no further person is at the machine.

• That the machine is in a flawless condition.

:$51,1*

Danger of sound pressure.

Negligence can cause, ear damage can emerge.

Use an ear protection for work at the folding machine.

Page22Alterations reserved Version 05/2008

Page 23

Operating Manual B21-C - en

:$51,1*

Danger through maintenance tool.

Negligence can cause heavy personal injuries or extensive damages.

• Use only tools in good working condition.

• Pay attention that after adjustment or maintenance working at the

machine, all tools are removed.

'$1*(5

Danger of running machine parts during the installation work.

Negligence can cause heavy personal injuries or extensive damages.

• Allow service and cleaning works only to be carryed.

• Turn off the machine during maintenance and restoration work by the

main switch.

• Neutralize the electrical cabinet against unintentional switch on.

• Check before turning on, that no further person is at the machine.

&$87,21

Danger through heavy machines components.

Negligence can cause heavy personal injuries or extensive damages.

If the weight amounts more than 25 kg, a further person must be aid for

taken of the components.

:$51,1*

Danger of running machine parts.

Negligence can cause heavy personal injuries or extensive damages.

• Safety switches at the protection and noise hoods can not be

manipulated or modified.

• Adjustments by opened protection hoods are only permited for

setup. Setups can only be performed on machines with electronical

speed regulation.

• Machines with mecanical speed regulation can only be adjusted with

opened protection hoods throught the hand wheel.

Alterations reserved

Page 23

Version 05/2008

Page 24

Operating Manual B21-C - en

:$51,1*

Danger of slitter shafts.

Negligence can cause cut injuries.

• During maintenance work at the slitter shafts, the use of

protection gloves and safteyshoes is required.

• Do not hold the slitter shafts by the tool but always at the

shaft.

:$51,1*

Danger before wrong use of cleansing agents.

Negligence can cause health defects.

• Avoid skin contact.

• Protect yourself against splashes in the eyes.

• Use for cleansing protection gloves.

• Inform yourself through the cleaner manufacturer about remaining

dangers and compatibility for human skin.

&$87,21

Danger before used cleansing rags.

Negligence can cause health defects.

• Note the fire dangers through the flammability of the cleaner .

• Detoxifythe cleaning rags.

• Inform yourself at the cleaner manufacturer about remaining dangers as

well as over the correct disposal.

:$51,1*

Danger of running machines part during the installation working.

Negligence can cause heavy personal injuries or extensive damages.

• Never grasp into the running machine in!

• Keep protection hood close during production.

Page24Alterations reserved Version 05/2008

Page 25

Operating Manual B21-C - en

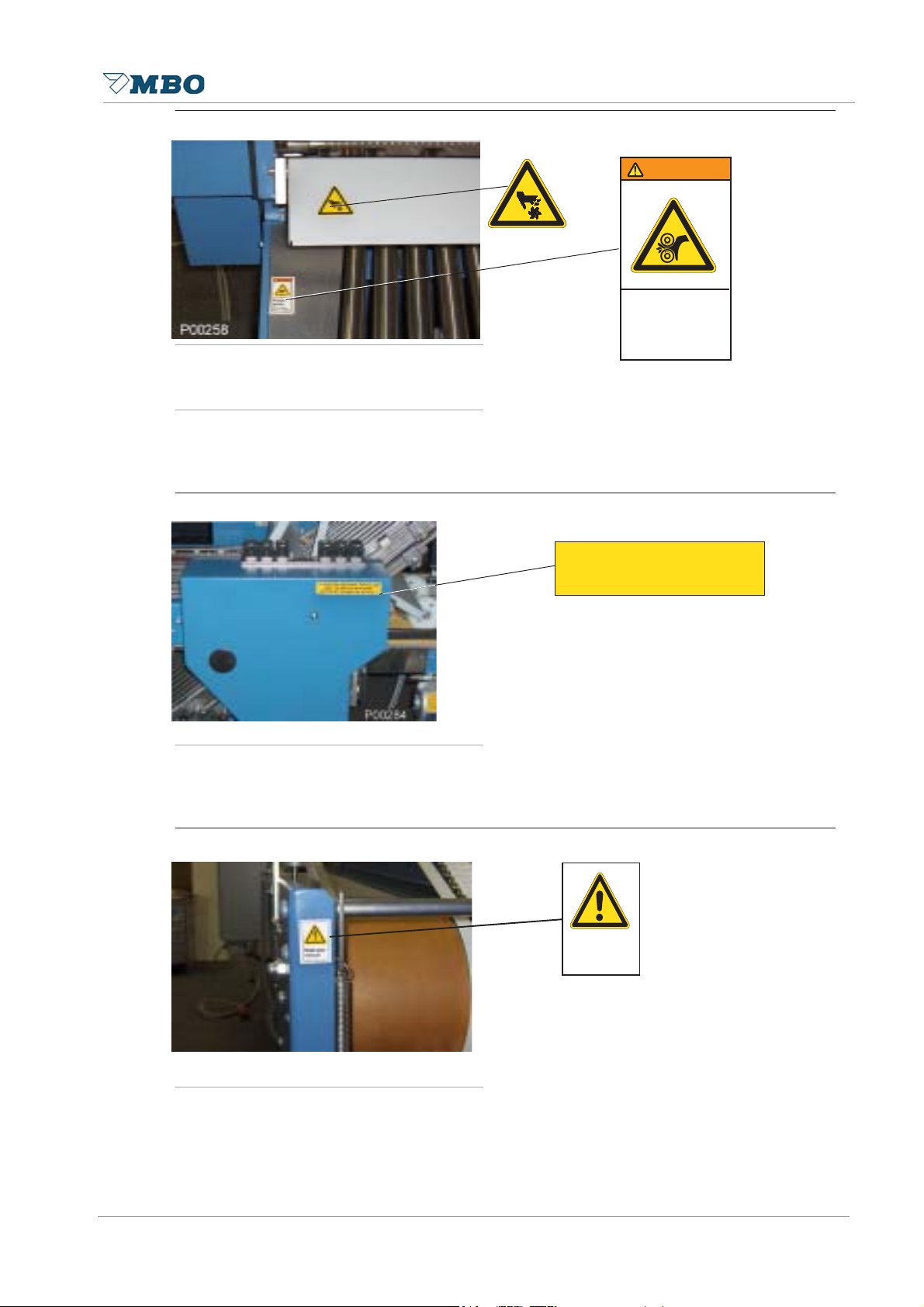

2.1.5 Dangerous zones / Warning signs at the machine

2.1.5.1 Overview

48

9

5

6

7

3

2

10

1

17

11

15

16

1 Suction wheel

2 Ball bar

3 Fold head - operator side cover

4 Slitter shaft protection

5 Mobile knife folding unit „X“

6 Hand wheel at X-unit

7 Mobile stream delivery A56 (Option)

8 Hand wheel shaft/cleaner roller support

9 Sheet transport 8 and 16 page unit

10 Fold head drive side cover

11 Compressor

12 Main cabinet parallel unit

13 Control cabinet 8 and 16 page unit

14 Control cabinet mobile knife folding unit „X“

15 Control cabinet stream delivery A56

16 Control cabinet hook on stream delivery SE 500/3

17 Feeder drum

14

13

12

Alterations reserved

Page 25

Version 05/2008

Page 26

Operating Manual B21-C - en

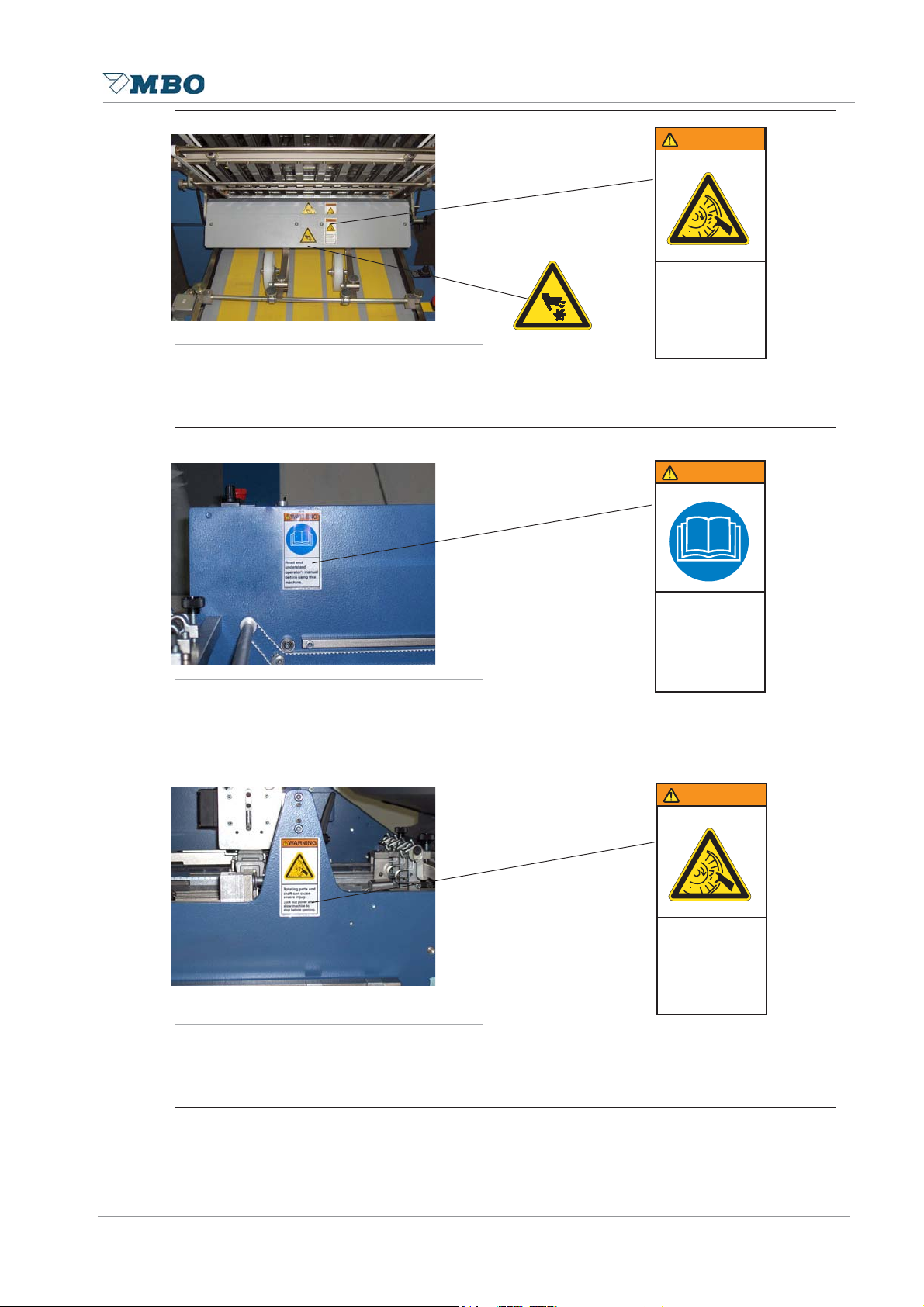

2.1.5.2 Danger references-arrangement and meaning

Pos. 01 Suction wheel

Meaning:

Danger before running suction wheel. Negligence can cause bruises on your hands.

Keep your hands away from the running suction wheel.

Pos. 02 Ball bar

&$87,21

3LQFKSRLQW

KD]DUG

.HHSKDQGV

FOHDU

&$87,21

3LQFKSRLQW

KD]DUG

.HHSKDQGV

FOHDU

Meaning:

Danger before ball bar. Negligence can cause bruises on your hands.

Keep your hands away from this dangerous place.

Pos. 03 Fold head - operator side cover

Meaning:

Warning before moving machine part s in area of fold head - operator side cover. Work only under

super vision of a second person at the machine.

Read and understand operator´s manual before using this machine.

:$51,1*

Ä&$87,21029,1*3$576'2

12723(5$7(0$&+,1(

:,7+287*8$5',13/$&(³

5HDGDQG

XQGHUVWDQG

RSHUDWRUV

PDQXDOEHIRUH

XVLQJWKLV

PDFKLQH

Page26Alterations reserved Version 05/2008

Page 27

Pos.04 Slitter shaft protection

:$51,1*

5RWDWLQJSDUWVDQG

VKDIWFDQFDXVH

VHYHUHLQMXU\

/RFNRXWSRZHUDQG

DOORZPDFKLQHWR

VWRSEHIRUHRSHQLQJ

5HDGDQG

XQGHUVWDQG

RSHUDWRUV

PDQXDOEHIRUH

XVLQJWKLV

PDFKLQH

:$51,1*

:$51,1*

5RWDWLQJSDUWVDQG

VKDIWFDQFDXVH

VHYHUHLQMXU\

/RFNRXWSRZHUDQG

DOORZPDFKLQHWR

VWRSEHIRUHRSHQLQJ

Meaning:

Danger before rotating slitter shafts. Negligence can cause cut or tear off of body parts.

Lock out power and allow machine to stop before opening.

Pos.05 Mobile knife folding unit „X“

Operating Manual B21-C - en

Meaning:

Read and understand operator´s manual before using this machine.

Meaning:

Danger before rotating slitter shafts. Negligence can cause cut or tear off of body parts.

Lock out power and allow machine to stop before opening.

Alterations reserved

Page 27

Version 05/2008

Page 28

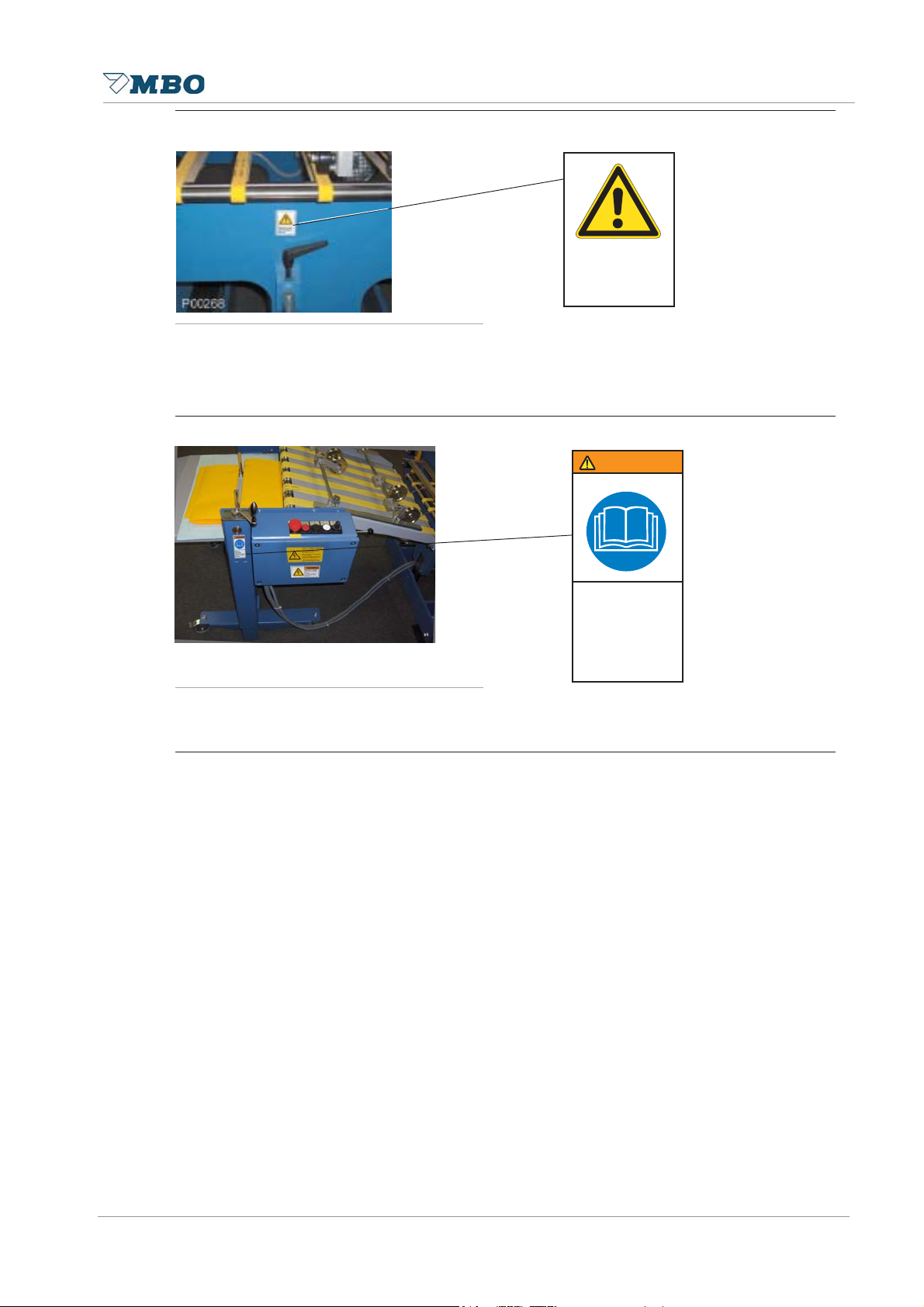

Pos. 06 Hand grip at X-Unit

5HDGDQG

XQGHUVWDQG

RSHUDWRUV

PDQXDOEHIRUH

XVLQJWKLV

PDFKLQH

:$51,1*

Meaning:

Danger before material damages.

Operate X-Unit only with locked hand grip.

Pos.07 Mobile stream delivery A76

Operating Manual B21-C - en

2SHUDWHRQO\

ZLWKORFNHG

NQXUO

Meaning:

Read and understand operator´s manual before using this machine.

Page28Alterations reserved Version 05/2008

Page 29

Operating Manual B21-C - en

.HHSKDQGV

FOHDURIUROOHUV

3LQFKSRLQW

:$51,1*

Pos.08 Hand wheel shaft/cleaner roller support

1

Pos. 1

Pos. 2

:$51,1*

1

1

5RWDWLQJSDUWVDQG

VKDIWFDQFDXVH

VHYHUHLQMXU\

/RFNRXWSRZHUDQG

DOORZPDFKLQHWR

VWRSEHIRUHRSHQLQJ

2

1

Meaning Pos. 1

Danger before rotating machine shafts. Negligence can cause cut or tear off of body parts.

Keep your hands clear of rollers.

Meaning Pos. 2

Danger before rotating slitter shafts. Negligence can cause cut or tear off of body parts.

Lock out power and allow machine to stop before opening.

Alterations reserved

Page 29

Version 05/2008

Page 30

Operating Manual B21-C - en

.HHSKDQGV

FOHDURIUROOHUV

3LQFKSRLQW

:$51,1*

5HDGXVHU

PDQXDO

Pos 09 Sheet transport 8 and 16 page unit

Meaning Pos.1

Danger before rotating machine shafts. Negligence can cause cut or tear off of body parts.

Keep your hands clear of rollers.

Meaning Pos.2

Danger before rotating transport rollers at the sheet transport. Negligence can cause bruises on

your hands. Keep hands clear of rollers.

Pos. 10 Fold head drive side cover

Pos. 1

Pos. 2

Meaning:

Warning before moving machine parts in area of parallel fold head-drive side cover . W ork only

under super vision of a second person at the machine.

Pos. 11 Sheet guide support

Ä&$87,21029,1*3$576'2

12723(5$7(0$&+,1(

:,7+287*8$5',13/$&(³

Meaning:

Read and understand the operator manual before using this machine.

Page30Alterations reserved Version 05/2008

Page 31

Pos. 12 Main cabinet parallel unit

Operating Manual B21-C - en

9256,&+7$77(17,21$7(17,21

9RUGHPgIIQHQ6FKUDQNLQQHUHV

VSDQQXQJVORVPDFKHQ

3ULRUWRRSHQLQJEHVXUHWKDWLQVLGH

RIFDELQHWLVGHDG

$YDQWGRXYULUYpULILH]TXHOLQWpULHXU

GHODUPRLUHVRLWVDQVWHQVLRQ

$QWHVGHDEULUDVHJXUDUVHTXHHO

LQWHULRUGHODUPDULRHVWHVLQGWHQVLyQ

+D]DUGRXVYROWDJH

5LVNRIHOHFWULFVKRFN

RUEXUQ

7XUQRIIDQGORFNRXW

V\VWHPSRZHUEHIRUH

VHUYLFLQJ

&KDUDFWHULVWLFIRU

DOOIXVHV

PHGLXPWLPHODJ

86(&233(5

:,5(21/<

Pos.1

:$51,1*

Pos.2

Pos.3

Pos.4

Meaning Pos.1 und Pos. 2:

Hazardous voltage. Negligence can cause electric shock or burn.

Turn off and lock out system power before servicing.

Meaning Pos.3:

Replacement of fuses only with same specification.

Meaning Pos.4:

Use copper wire only!

Pos. 13 Control cabinet 8 and 16 page unit

Meaning:

Hazardous voltage. Negligence can cause electric shock or burn.

Turn off and lock out system power before servicing.

9256,&+7$77(17,21$7(17,21

9RUGHPgIIQHQ6FKUDQNLQQHUHV

VSDQQXQJVORVPDFKHQ

3ULRUWRRSHQLQJEHVXUHWKDWLQVLGH

RIFDELQHWLVGHDG

$YDQWGRXYULUYpULILH]TXHOLQWpULHXU

GHODUPRLUHVRLWVDQVWHQVLRQ

$QWHVGHDEULUDVHJXUDUVHTXHHO

LQWHULRUGHODUPDULRHVWHVLQGWHQVLyQ

:$51,1*

+D]DUGRXVYROWDJH

5LVNRIHOHFWULFVKRFN

RUEXUQ

7XUQRIIDQGORFNRXW

V\VWHPSRZHUEHIRUH

VHUYLFLQJ

Alterations reserved

Page 31

Version 05/2008

Page 32

Operating Manual B21-C - en

Pos. 14 Control cabinet mobile knife folding unit „X“

Meaning:

Hazardous voltage. Negligence can cause electric shock or burn.

Turn off and lock out system power before servicing.

Pos.15 Control cabinet stream delivery A56

9256,&+7$77(17,21$7(17,21

9RUGHPgIIQHQ6FKUDQNLQQHUHV

VSDQQXQJVORVPDFKHQ

3ULRUWRRSHQLQJEHVXUHWKDWLQVLGH

RIFDELQHWLVGHDG

$YDQWGRXYULUYpULILH]TXHOLQWpULHXU

GHODUPRLUHVRLWVDQVWHQVLRQ

$QWHVGHDEULUDVHJXUDUVHTXHHO

LQWHULRUGHODUPDULRHVWHVLQGWHQVLyQ

:$51,1*

+D]DUGRXVYROWDJH

5LVNRIHOHFWULFVKRFN

RUEXUQ

7XUQRIIDQGORFNRXW

V\VWHPSRZHUEHIRUH

VHUYLFLQJ

9256,&+7$77(17,21$7(17,21

9RUGHPgIIQHQ6FKUDQNLQQHUHV

VSDQQXQJVORVPDFKHQ

3ULRUWRRSHQLQJEHVXUHWKDWLQVLGH

RIFDELQHWLVGHDG

$YDQWGRXYULUYpULILH]TXHOLQWpULHXU

GHODUPRLUHVRLWVDQVWHQVLRQ

$QWHVGHDEULUDVHJXUDUVHTXHHO

LQWHULRUGHODUPDULRHVWHVLQGWHQVLyQ

Meaning:

Hazardous voltage. Negligence can cause electric shock or burn.

Turn off and lock out system power before servicing.

Pos. 16 Control cabinet hook on stream delivery SE 500/3

Meaning:

Hazardous voltage. Negligence can cause electric shock or burn.

Turn off and lock out system power before servicing.

:$51,1*

+D]DUGRXVYROWDJH

5LVNRIHOHFWULFVKRFN

RUEXUQ

7XUQRIIDQGORFNRXW

V\VWHPSRZHUEHIRUH

VHUYLFLQJ

9256,&+7$77(17,21$7(17,21

9RUGHPgIIQHQ6FKUDQNLQQHUHV

VSDQQXQJVORVPDFKHQ

3ULRUWRRSHQLQJEHVXUHWKDWLQVLGH

RIFDELQHWLVGHDG

$YDQWGRXYULUYpULILH]TXHOLQWpULHXU

GHODUPRLUHVRLWVDQVWHQVLRQ

$QWHVGHDEULUDVHJXUDUVHTXHHO

LQWHULRUGHODUPDULRHVWHVLQGWHQVLyQ

Page32Alterations reserved Version 05/2008

Page 33

2.2 Product security

2.2.1 Obligation and liability

Note references in the operation instructions:

Prerequisite for safety and free interference working with this machine is the knowledge of the

basic safety references and the safety prescript.

This operating instruction is to be noted by all persons, who work at the machine. In addition all rules

valid for accident prevention has to be noted.

Potential danger while operating with machine:

The Buckle folding machine is after the state of the technology and that acknowledged safety

rules constructed. Nevertheless dangers for body and life of the unser or third and/or inpairment

can emerge in its use at the machine or at other material asset.

The machine is to be used only:

• For the due use

• In safety flawless condition

Interferences, which can impair the safety , are to be removed immediately .

Operating Manual B21-C - en

Guarantee and liability

Herefor our general sale and delivery conditions has to be concerned. The Guarantee and liability

claims with personal injuries and equipment damages are not excluded if they are to be led back to

one or several of the following causes:

• Due use of the machine,

• Improber installation, do into operation, serving and maintenance of the machine,

• Operating of the machine in defective safety arrangements or not regular appropriate or not

operable safety devices and protection devices,

• Not following of the references in the operating instructions regarding carrier, storage,

assembling, starting, operating, maintenance and mobilizing of the machine,

• Independent structural variations at the machine,

• The not keeping of maintenance and cleaning intervals that exclude a standstill of the

machine,

• Deficient supervision of machines part, that a wear be subject,

• Bad servicing and damages through foreign objects.

Alterations reserved

Page 33

Version 05/2008

Page 34

2.2.2 Due use

• The machine is intended only for the folding, designing, perforating and cutting of paper.

• The machine is displayed only for the one-man-operation.

• The machine can only be operated in a flawless technical condition. Interferences, which

endanger the safety , must immediately be removed by instructed persons or from

manufacturer or from supplier.

• The machine can only be operated of seviced by skilled and autorized personnel. Machine can

only be operated/serviced by persons older than 18 years.

2.2.3 Inappropriate use is:

• An other use of the machine as folding, designing, perforating and cuttting of paper .

• Working of other materials as a paper .

• Manipulating and independent modification of the machine.

• Removing of protection and safety devices from the machine.

• Operating of the machine without instructed or trained personal.

• Operating / maintenance by persons younger than 18 years.

• Operating of the machine without instructed or trained personel.

The manufacturer and/or supplier is not responsible for all damages, that develop from inappropriate

use.

Operating Manual B21-C - en

Page34Alterations reserved Version 05/2008

Page 35

Operating Manual B21-C - en

2

6

5

41311

0

617

2.3 Protection guard -general plan

2.3.1 Protection guard - general plan of machine

1

8 1

1

1

1

5

3

6

2

4

9

7

1

1

Alterations reserved

Page 35

Version 05/2008

Page 36

Operating Manual B21-C - en

0

2.3.2 Protection guard list 8 and 16pg unit

123

1

5

9

6

4

7

8

Page36Alterations reserved Version 05/2008

Page 37

Operating Manual B21-C - en

2.3.3 Protection guard list knife folding unit „X“

6

5

4

7

3

2

1

Alterations reserved

Page 37

Version 05/2008

Page 38

Operating Manual B21-C - en

2.3.4 Protection guard list Delivery A56

3

1

2

Page38Alterations reserved Version 05/2008

Page 39

Operating Manual B21-C - en

2.4 Organisational and personnel

2.4.1 Working safety

• Preserve the operationg instructions manual permanently at the machine regarding to the

operating instructions the universally valid local regulations to the accident prevention and to

the environmental protection.

• Keep all safety references and dangers references at the machine in readable conditions.

• Review the safety references and dangers references occasionally .

2.4.2 Demands on the operating personnel

This table represents the jurisdictions and the different activities of person groups, which work at

the machine.

Instructed

Persons

Transport and pack i ng

Mechanic firm

Custom er s ervi c e

Responsable

supervisor

Starting

Operation

Troubleshoot i ng mec hanic all y

Interference removal el ectric all y

Arrange, mobi li z ing

Maintenance

Restoration

Out of order, storage

2.4.3 Qualification and training

Ensure that the operating personal was trained with the machine and that the operating manual

was read. A correct operating of the machine can prevent severe injuries to the operator and third

persons as well as material damages.

Attend to following references:

• Permit only trained and on manner personnel work at the machine.

• The user information must be read and understood by the operating and maintenance

personnel.

• Determine clearly the responsibility of the personnel for operating, converting and

maintenance.

• Let only trained personnel work at the machine under supervision of a trained person.

• Instruction must be receipt in written form.

Alterations reserved

Page 39

Version 05/2008

Page 40

Operating Manual B21-C - en

2.5 Personal protection equuipment

:$51,1*

Danger of sound pressure.

Negligence can cause, ear damage.

Use an erar protection for work at the folding machine.

:$51,1*

Danger before slitter shafts.

Negligence can cause, cut injuries can emerge.

Carry protection gloves and safety shoes while maintenance

work.

2.6 Tasks for Emergency

2.6.1 Rescue of per son s

1 Urgent measures Rescue the injured person.

2 Emergency call Telephone no.:.................. (Register number)

3 First aid Secure the accident place

Replace vital functions again, hold this

uprightly

Avoiding further damage.

Who reports?

What happened?

How many are injured?

Where happened?

Which type of injuries?

Wait for check response!

Further care of the injured: Confortable and correct situation

Calming encouragement

St able if fractures

Place bandages on open wounds.

4 Further measures Advise/inform rescue service

Keep curious persons away .

Page40Alterations reserved Version 05/2008

Page 41

Operating Manual B21-C - en

2.6.2 Emerging substances

Concern the factory directives with its statements in the fire case. Depend on the given directions.

Is this not by hand advance so:

2.6.2.1 Solvent degreasing out of hydrocarbons

• Inform superior.

• Emerging of the material: in larger quantities supply immediately for fresh air and leave the

location.

• Slight spill quantities absolve with allocated binding agent.

• In case of fire extinguish only with extinguisher located to this.

• Notify immediately First helper and supervisor.

• Wash off in skin contact with much water and skin cleaner.

• By eye contact rise with much water (eye shower).

• After inhaling of softening, reach for fresh air .

• Carry unconscious persons immediately to the fresh air.

2.6.2.2 Inflammable degreasing solvents out of not water mixable hydrocarbons (ex. petroleum,

test gasoline, Naphtene: Cyclohexan)

• Disengage inflammation of the material: Unit, leave dangers area and inform layer master.

• Use extinguish: Coal dioxide (CO2), foam, powder extinguisher or water as spray ray .

• Leakage: Slight spill quantities absolve with allocated binding agent.

• Gather remainder materials and refuse in containers planned for that.

• Eyes: Rise immediately with much water at least 10 minutes and search for physician.

• Skin: Rise concerned skin place with much water.

• Inhaling: Worry immediately for fresh air. Keep quietly and hold warm search for physician.

• Swallowing: Search immediately for medical help.

2.6.2.3 Cleaner with watery alkaline cleaning solution:

• Leakage: Inform superior. S pill quantities absolve with allocated binding agent. Clean slight

quantities with much water.

• Accidents: Inform first helper and superior.

• Irritation of skin or eyes rise with much water.

• In swallowing of the concentrate rise mouth drink much water.

• Search for after swallowing of concentrate or continuous irritation medical help.

2.6.2.4 Cleaner BG5-9, weakly alkaline:

• Leakage: Neutralize of initiating running out of little quantities into the discharge channel.

• Eyes: Rise immediately with a lot water at least 10 minutes and search for physician.

• Skin: Rise concerned skin with a lot water.

• Inhaling: Go immediately for fresh air. Keep calm and hold warm and contact medical

assistance.

• Swallowing: Immediately contact medical assistance and show label safety data sheet.

Alterations reserved

Page 41

Version 05/2008

Page 42

Operating Manual B21-C - en

3.0 Transportation, assembly and inst allation

This part of the Operating Manual is directed to the service personnel and internal authorized

personnel.

&$87,21

Danger through heavy machines components.

Negligence can cause heavy personal injuries or extensive damages.

If the weight amounts more than 25 kg, a further person must be aid for

taken of the components.

:$51,1*

Danger before turn of component during the unloading and

assembling process.

Negligence can cause heavy personal injuries or extensive damages.

• Note the weight statement for the carrier under chapter „technical data“.

• Use the forklift for transportation.

• Arrange additional personnel for unloading and setting up. Some

machine groups must be additionaly secured and supported.

3.1 Transportation

3.1.1 Feeder

The folding unit one and the continuous

feeder are delivered in separate crates.

Carry the pallet with a fork lift as close

as possible to its final position.

Unscrew continuous feeder from the

pallet. You should hang tm ropes on the

points 6 and 7 and lift it minimal with the

use of a fork lift. Remove the pallet and

set the continuous feeder to its final

position.

6

7

Page42Alterations reserved Version 05/2008

Page 43

3.1.2 Parallel unit

The folding unit I, completely mounted with

pile feeder, is delivered in one crate. Carry the

pallet with a fork lift as close as possible to

its final position. Unscrew the machine off the

pallet and set the fork lift to the tiebars 1.

Remove the pallet and set the folding unit to

its final position.

Operating Manual B21-C - en

1

3.1.3 8 and 16pg unit

Make sure that machine rollers 3 and guide

roller 5 will not be damaged when taking the

unit of the pallet.

Unscrew the folding unit II off the pallet and

set the fork lift to the tiebar 4.

Two additional persons are also required to

hold the unit. Remove the pallet and carry the

unit to its final position.

3

4

5

Alterations reserved

Page 43

Version 05/2008

Page 44

Operating Manual B21-C - en

3.1.4 Mobile knife folding unit “X”

:$51,1*

Danger before turn of component during the unloading and

assembling process.

Negligence can cause heavy personal injuries or extensive damages.

• Secure the knife folding unit to prevent it from falling over or sliding!

Arrange additional personnel for unloading and setting up.

Unscrew the knife folding unit “X” off the

pallet, set the fork lift onto the frame 1,

and remove the pallet. Affix the four guide

wheels 2 and let the knife folding unit

carefully down

3.1.5 Mobile stream delivery

:$51,1*

Danger before turn of component during the unloading and

assembling process.

Negligence can cause heavy personal injuries or extensive damages.

• Secure the mobile stream delivery in addition with two persons off. Be

careful that by dropping it is not damaging the guide rollers and

machine rollers.

Unscrew the stream delivery and lift it

with two additional persons off the pallet.

2

1

A56

Clean all machine parts (folding units and deliveries) with rust preventing agents!

Page44Alterations reserved Version 05/2008

Page 45

Operating Manual B21-C - en

3.2 Assembly and installation of machine

Carry the machine to its final position.

Plastic feets 3 must be placed

underneath the eight levelling bolts. Level

out the machine by means of these

levelling bolts. Alignments should be

made in crossdirection on the upper, free

accessible foldroller 2.

Levelling should be made also in

longitudinal direction on side frames 1

at left and right side.

Insert the buckle plates. Detach the

guide rails at register table and affix

slitter shafts. All these works are

descriped under the following category

“Operation of the Machine”.

3.3 Electrical connection

2

1

4

3

1

3

3

'$1*(5

Danger of electric tension.

Negligence can cause, heavy injuries or death.

Report damaged electrical connections to respnsible supervisor .

'$1*(5

Danger of electric tension at head clams with main switch off.

Negligence can cause, heavy injuries or death.

Work at the electronics can only be carried out of authorized persons or

skilled personnel.

Alterations reserved

Page 45

Version 05/2008

Page 46

Operating Manual B21-C - en

'$1*(5

Danger of electric tension.

Negligence can cause, heavy injuries or death.

• Keep the main control cabinet and the lower distributor cabinet always

locked against unauthorized persons.

• During maintenance working at the control cabinet turn off main switch

and disconnect the network connector.

• Turn off and lock out system power before servicing.

3.3.1 Control cabinet

Unpack the control cabinet 5 and fasten

it onto the side panel of the register table

6 as well as onto the angled backplate 7

at the feeder. Insert the plugs of the

feeder and the machine into the sockets

of the control cabinet. Plugs as well as

sockets bear the same marking.

Connect the cable of the feeder motor,

machine motor , sockets for auxiliary

folding units as well as the connection

cable of the compressor directly to the

motor protective switch inside the main

control panel according to the attached

wiring diagram.

5

7

6

Page46Alterations reserved Version 05/2008

Page 47

3.3.2 Main current connection

&$87,21

Make sure that power supply and frequency correspond with the data of

your machine! These data should be checked with the label on the side of

the control cabinet.

&$87,21

Consider Clockwise rotating field! A fter wiring has been completed the

terminals must be protected with cover plates provided .

'$1*(5

Operating Manual B21-C - en

After connections have been completed check the rotating field of motors

as described under item 3.3.1. However, if one of these motors should

have the wrong rotating field, change the connection of the individual motor

at the terminal. Turn OFF the machine immediately, if direction of pile plate

does not correspond with switch position 1.10 at main control panel.

Otherwise the limit switch control will not function properly and switch

OFF! This may cause serious personal injuries or extensive damage to the

feeder !

Insert the cable in the base of the control cabinet and connect it with the main terminals provided

according to the attached wiring diagram.

3.3.3 Stream delivery

Danger, the printed circuit board (p.c.b.) of the stream delivery is

provided with 220 voltages!

Negligence can cause heavy injuries or death.

If you are working on the opened cabinet of the delivery make sure that no

power is supplied or do not touch this p.c.b!

'$1*(5

Alterations reserved

Page 47

Version 05/2008

Page 48

4.0 Maintenance

This part of the Operating Manual is directed to the competent service personnel and internal

authorized personnel.

Danger through maintenance tool.

Negligence can cause heavy personal injuries or extensive damages.

• Use only tools in good working condition.

• Pay attention that after adjustment or maintenance working at the

machine, all tools are removed.

Danger of running machine parts.

Negligence can cause heavy personal injuries or extensive damages.

• Safety switches at the protection and noise hoods can not be

manipulated or modified.

• Never carry out foldroller settings while machine is still running.

• Even manual foldroller setting by the handwheel.

Operating Manual B21-C - en

:$51,1*

'$1*(5

Danger of running machine parts during the installation work.

Negligence can cause heavy personal injuries or extensive damages.

• Allow service and cleaning works only to be carryed.

• Turn off the machine during maintenance and restoration work by the

main switch.

• Neutralize the electrical cabinet against unintentional switch on.

• Check before turning on, that no further person is at the machine.

:$51,1*

Danger of slitter shafts.

Negligence can cause cut injuries.

• During maintenance work at the slitter shafts, the use of

protection gloves and safteyshoes is required.

• Do not hold the slitter shafts by the tool but always at the

shaft.

Page48Alterations reserved Version 05/2008

Page 49

Operating Manual B21-C - en

4.1 Tensioning or exchange of belts/tapes

127,&(

The tension of drive belts, and especially for foldrollers and slitter shaft drives should be checked

periodically , i.e. monthly . The drive belt s must be tensioned to such an extent that the foldrollers

cannot manually be held if the machine is turned by handwheel.

:$51,1*

Danger before running belt-drive.

Negligence can cause, bruise emerges at the hands.

This work should be carried out by one person only !

4.1.1 Upper feeder transport tape

For an undisturbed transport, the upper

transport tape (1) must be strained

tightly . Re-strain the tape if required:

Turn both screws (2).

The adjustment must be undertaken on

both sides equal.

The tape will be led by disks (3)

4.1.2 Lower feeder transport tape

For an undisturbed transport, the upper

transport tape (1) must be strained

tightly . Re-strain the tape if required:

Turn both screws (2). The adjustment

must be undertaken on both sides equal.

The tape will be led by disks (3).

1

3

2

4

6

Alterations reserved

Page 49

5

2

Version 05/2008

Page 50

Operating Manual B21-C - en

4

4.1.3 Feeder chain

T est the feeder chain occasionally for it s

tension and re-strain if necessary .

Strain the drive chain (2) with the chain

tensioner (1).

4.1.4 Alignment tape at register table

1 2

Loosen screw 5 and 6 release tension of

tape. For threading/rethreading unhinge

the lattice-type alignment table at pos. 3.

Loosen screw 2, push back the rod 1 in

direction of drive side, remove tape from

the rollers and rethread at pos. 4. Install

new tape in the opposite sequence and

tension it through

screw 6.

Adjustment for centre running of tape

occurs through screw 8.

For this purpose loosen the screw 9

(screw 8 and 9 are located at the internal

side) and fasten it again after completion.

Thereafter, check again and, if

necessary , make necessary corrections.

1

2

3

65

4

8 9

Page50Alterations reserved Version 05/2008

Page 51

Operating Manual B21-C - en

4.1.5 Drive belt for suction wheel

The drive belt 2 is tensioned by means of

tensioning lever 1.

1 2

4.1.6 Drive belt for foldrollers and slitter shaft at parallel unit

The drive belt 4 is tensioned by means of

tensioning lever 3.

4.1.7 Main drive of parallel unit

The poly-V-belt 5 coming from the main

drive shaft 7 to the parallel unit is

tensioned by means of tensioning

lever 6.

3

4

5

6

7

Alterations reserved

Page 51

Version 05/2008

Page 52

Operating Manual B21-C - en

4.1.8 Drive belt for foldrollers at parallel unit and slitter shafts at subsequent unit

See item 4.1.3 page 49.

4.1.9 Drive belt at register table of following folding unit

:$51,1*

Danger befor running belt drive.

Danger of injuries to fingers.

This work should be carried out by one person only !

The drive belt 6 should be tensioned by

means of tape tensioner 5.

5

6

&$87,21

Danger, overstretching of the drive belt.

Negligence can cause material damage.

Let the folding unit run by turning the hand wheel. At the same time the

cross rollers must be easy to stop with the other hand.

Page52Alterations reserved Version 05/2008

Page 53

Operating Manual B21-C - en

4.1.10 Drive belt for foldrollers and slitter shafts of knife folding unit “X”

The drive belt 5 is tensioned by means of

tensioning lever 6.

127,&(

All tapes and belts should be correctly

tensioned as described under item 4.1.

4.1.11 Setting of air gap for knife coupling of knife folding unit “X”

The nominal air gap can be set easily

and without any difficulties through two

setting screws. It is not necessary to

dismantle the COMBIBOX. All you need

is a hexagon key , a C-wrench as well as

a feeler gauge to check the nominal air

gap.

Setting instruction 4.5

1. Remove both access plugs.

2. Loosen both counter nuts.

3. Insert feeler gauge at both sides

between rotor and armature and

turn in the locking screws to such

an extent that you reach the

nominal air gap of 0.15 - 0.20 mm.

Check if gap is equal at both

sides.

4. Retension counter nuts whereby

the locking screws should not

change the position previously set.

5. Mount both access plugs.

Alterations reserved

Page 53

Version 05/2008

Page 54

Operating Manual B21-C - en

4.2 Lubrication / Cleaning

127,&(

Generally , the machine should be cleaned after each job, particularly moveable part s which have

been changed due to change of sheet size, because heavy dust may cause reduction of function.

4.2.1 Main machine including register table

1 2

Clean dust off guide shaft 2 for change of

sheet size at register table as well as

drive shaft 1 and supply a slight touch of

oil.

Safety handwheels should also

occasionally be relubricated at nipples 3.

4.2.2 Continuous feeder R

Clean drive chain 4 grease slightly .

3

4

4.2.3 Guides of pressure bars / Bearings of foldrollers

Supply a slight touch of oil to all

pressure bars of foldrollers and slitter

shafts in all folding units 6 as well as

between the machine panel and bearing

levers 5, monthly (also parallel unit).

Page54Alterations reserved Version 05/2008

5

6

Page 55

Operating Manual B21-C - en

4.2.4 Coupling of knife folding unit “X”

Provide a slight touch of oil to all knife

guides with ball-type nipple, monthly .

127,&(

Just use a few drops of oil because too

much lubricant may drop onto the sheets

through the knife guide!

4.2.5 Guide rails / sheet stop (knife folding unit “X”)

1

Clean dust off the guide rails of the

sheet stop 2 from to ensure perfect

condition of stop guides.

4.2.6 Cleaning of foldrollers

:$51,1*

Danger before wrong use of cleansing agents.

Negligence can cause health defects.

• Avoid skin contact.

• Protect yourself against splashes in the eyes.

• Use for cleansing protection gloves.

• Inform yourself through the cleaner manufacturer about remaining

dangers and compatibility for human skin.

2

Alterations reserved

:$51,1*

Danger before running machine elements.

Negligence can cause bruise at the hands.

Fold rollers should be cleaned only if the machine is not in motion! Push

the Emergency Stop button and/or turn OFF main switch. Ensure that the

machine cannot be re-started!

Page 55

Version 05/2008

Page 56

Operating Manual B21-C - en

&$87,21

Danger before used cleaning rags.

Negligence can cause health defects.

• Note the fire dangers through the flammability of the cleaner .

• Detoxifythe cleaning rags.

• Inform yourself at the cleaner manufacturer about remaining dangers as

well as over the correct disposal.

Depending on the extent of ink build-up, the foldrollers must be cleaned from time to time. The

affect of printing powder or ink build-up on the foldrollers may decrease the quality of the folding.

The rollers must be cleaned with a cleansing agent suitable for the synthetic material. Please

contact your machine supplier . Improper cleaner may cause decomposure or swelling of the

foldroller coating.

MBO - the manufacturer of this folding machine recommends a cleaning material for the foldrollers

made by V ARN, bearing the no. V ARN -W ash VM 111 or VWM. Our recommendation is on a label

near the foldrollers.

The V ARN company is a worldwide supplier for the printing industry . Therefore, it cannot be

excluded that in certain other countries different indications are used. Please take the individual

order no. from the technical data sheets of V ARN.

4.2.7 Compressor

Essential maintenance:

T o ensure full efficiency , however , the

Filter cartridge at suction side should be

checked and cleaned occasionally . The

Filtre cartridge must be cleaned every 50

HOURS OF OPERATION (see page 58)

and be exchanged every 3.000 hours of

operation, according to manufacturers

statement. Dirty or damaged cartridges

must be replaced immediately . Do not

remove the filter cartridge with the

compressor running, otherwise

penetration of foreign substances may

damage the compressor. Make sure that

compressor is turned OFF during

maintenance work.

Exchange of admission filter:

Turn the compressor switch OFF and / or the main supply OFF. Make sure that no other person

can turn ON the pump.

Open the clips 3, remove the guard 4 and the cartridge 5. Clean the cartridge (blow throught

inside to outside) and replace it if it is necessary.

Replacement occures every 6 mounth.

Page56Alterations reserved Version 05/2008

Page 57

Operating Manual B21-C - en

5.0 Operation of the machine

In addition to the numbers the operating sequences to operate the machine are marked with B.

'$1*(5

Danger of running machines part.

Negligence can cause, heavy injuries or death.

• Keep hairs always together bandage and protected.

• T ake by operation and maintenance working at the machine your

jewellery off.

• Carry during operation or maintenance on the machine only adjoining

garment.

:$51,1*

Danger of sound pressure.

Negligence can cause, ear damage can emerge.

Use an ear protection for work at the folding machine.

'$1*(5

Danger of running machines part.

Negligence can cause, heavy injuries or death.

In sudden stop of the machine, review before turning on:

• That no further person is at the machine.

• That the machine is in a flawless condition.

:$51,1*

Danger of running machine parts.

Negligence can cause heavy personal injuries or extensive damages.

• Never carry out foldroller settings while machine is still running.

• Even manual foldroller setting by the handwheel.

Alterations reserved

Page 57

Version 05/2008

Page 58

B 1.0 Main control panel

2

8

920

123

7

6

5

413

7

4

629

0

8112225

For more information see separated operating manual “MS - Control”.

127,&(

Operating Manual B21-C - en

2

2

9

1

1

2

2

1

1

1

1

1

1

8

2

1 2 3 4

1.1 MAIN SWITCH

1.2 Turn ON/OFF switch for compressor

1.3 EMERGENCY -STOP button

1.4 Red button for machine STOP

1.5 Black button for machine ST ART

1.6 White button for SHEET INFEED

1.7 White button for SINGLE SHEET INFEED

1.8 Green indicator light for MACHINE RELEASE

1.9 8- digit display

1.10 Button suction length

1.11 Button suction gap

1.12 Button with double function 7 / +

1.13 Button with multliple function 4/ speed up delievery/ Kicker/ marking device

1.14 Button with double function 8 / -

1.15 Button with double function 9 / speed indication

1.16 Button with double function 5 / interruption suction wheel

1.17 Button with double function 6 / current productions speed / hrs

1.18 Button with double function 3 / total counter at infeed

1.19 Button with double function 2 / total counter at exit

1.20 Button Clear (delete)

1.21 Button 0

1.22 Button 1

1.23 Button Enter (confirm)

1.24 Button Batch preselection

1.25 Button Code

1.26 Diagnosis LED photocell at exit B 43 (Option)

1.27 Diagnosis LED photocell at suction wheel B 2

1.28 Diagnosis LED slot initiator B 1

1.29 Potentiometer for electronical speed regulation

5

6 7

Page58Alterations reserved Version 05/2008

Page 59

B 2.0 Continuous feeder C

2.1 Generally settings

For pile transportation use the blue push button 1.6

(see page 30) at main control panel or the blue push

button on the feeder 1. Use the locking handle 3 to

adjust lateral sheet guide 2,. set to 112 of sheet wid th.

(Lateral sheet guide can be used on either left or

right side, if you want to load the feeder at drive side!).

The tapes 4 have to be set in accordance with the

sheet size.

If large sheets have to be processed use the four

tapes, for smaller sheets use less tapes.

The outer tapes should be positioned approximately

2 cm away from the sheet edge by means of setting

element 14. The tape in the

middle should be centred.

127,&(

Operating Manual B21-C - en

After setting the tapes of the feeder let

it run some turns. This will provide a better setting

of the tapes.

T o be able to transport sheets around the drum

without damaged edges T eflon t apes 5 should

be affixed onto the sides of the bar 6 and placed

around the drum down to the lower table 7. As a

transition between the chains and the lower table,

affix three spring steel tapes 8 on the lower table.

The angularity 9 between the upper table and the

tapes may be changed by means of the knurled

nut 10.

127,&(

The angularity should be adjusted on the

left and right side at the same time. With a too plane

angle the sheet edges may be damaged.

T o adjust the pressure of the. tape 4 use the staring crank 11 for the setting element 12

(clockwise = more tension on the tapes, anti-clockwise = less tension on the tapes). The sheets

should be guided which means pressure around the drum 13 if gapping occurs on the lower table 7

(sometimes on very smooth sheets) the pressure should be reduced, which causes a minor ‘loop

formation’ of the sheets underneath the drum. When using heavy sheets the pressure must be

reduced.

The small lower table 7 is mobile. It is adjusted by means of the two feelers

tongue 15. The feeler tongue is hanged with a holder 16, which has two rust points, at a shaft 17. The

adjustment of the feeler tongue may be bigger or smaller according to the height and format of the

pile.

Lower position more prestressirig

Upper position less prestressing

Alterations reserved

Page 59

Version 05/2008

Page 60