Page 1

IDEAL 4815

GB Operating InstructionsGuillotines

IDEAL 4850

Page 2

•

IDEAL 4815 • IDEAL 4850

D Bitte lesen Sie vor Inbetriebnahme der Maschine unbedingt diese Betriebsanleitung

und beachten Sie die Sicherheitshinweise. Die Betriebsanleitung muss jederzeit

verfügbar sein.

GB Please read these operating instructions before putting the machine into operation

and observe the safety precautions. The operating instructions must always be

available.

F Nous vous prions de lire attentivement le mode d’emploi avant d’utiliser la machine,

et attirons votre attention sur les consignes de sécurité. Les instructions d'utilisation

et les consignes de sécurité doivent toujours être disponibles. Les instructions

d'utilisation et les consi.

NL Leest u voor de ingebruik name van het apparaat a.u.b. deze gebruiksaanwijzing

goed door en neemt u de veiligheidsinstructies n acht. De gebruiksaanwijzing en

de veiligheids-voorschriften moeten altijd binnen handbereik zijn.

I Per favore legga questo manuale di istruzione prima di mettere in funzione il

distruggidocumenti e osservi le regole di sicurezza. Le istruzioni d’uso devono

essere sempre disponibili.

E Le recomendamos lea las instrucciones antes de poner en funcionamiento esta

máquina y cumpla las normas de seguridad. Las instrucciones de servicio y

seguridad deben estar siempre disponibles.

S Läs igenom denna bruksanvisning innan ni startar maskinen. Var noga med

säkerhetsföreskrifterna. Instruktionsmanualen måste alltid finnas tillgänglig.

FIN Lue nämä käyttö-ohjeet läpi ennenkuin käynnistät laitteen !

Noudata turvaohjeita. Käyttöohjeiden on oltava aina saatavilla.

N Lees gjennom denne bruksannvisningen før De tar i bruk maskinen

Vær oppmerksom på sikkerhetsforskriftene. Opperatørmanualen

må alltid være tilgjengelig.

PL Proszę uważnie przeczytać instrukcję obsługi przed uruchomieniem urządzenia i

stosować się do przepisów bezpieczeństwa. Instrukcje obsługi muszą być

zawsze dostępne.

RUS Пожалуйста, прочитайте инструкцию по эксплуатации перед установкой

аппарата, соблюдайте технику безопасности. Инструкция по

эксплуатации должна находиться в доступном для пользователя месте.

H A gép üzembe helyezése elott figyelmesen olvassa el a kezelési utasítást és tartsa

be a biztonsági eloírásokat.Kezelési utasításnak mindig elérhetonek kell lennie.

TR Lütfen makineyi çalýþtýrmadan önce bu kullanma talimatlarýný dikkatli bir þekilde

okuyunuz ve belirtilen güvenlik önlemlerine uyunuz. Kullanma Talimatlarý

her zaman kullanýma hazýr olmalýdýr.

DK Før installation af maskinen bedes De venligst læse brugervejledningen

og være opmærksom på sikkerhedsanvisningerne. Brugervejledningen

skal altid være tilgængelig.

CZ Prosím přečtěte si instrukce k obsluze a dodržujte bezpečnostní

upozornění. Návod k obsluze musí být vždy dostupný.

P Por favor leiam o manual de instruções antes de colocar a máquina em operação

e vejam as precauções de segurança. As instruções de operação deverão estar

sempre disponíveis.

GR РБСБКБЛЩ ДЙБВБУФЕ ФЙУ ПДЗГЙЕУ ЧСЗУЕЩУ КБЙ ФЙУ РСПЦХЛБОЕЙУ

БУЦБЛЕЙБУ РСЙН ВБЛЕФЕ ФП МЗЧБНЗМБ УЕ ЛЕЙФПХСГЙБ.

ПЙ ПДЗГЙЕУ ЧСЗУЗУ РСЕРЕЙ НБ ЕЙНБЙ РБНФБ ДЙБИЕУЙМЕУ.

SLO Prosimo preberite navodila za uporabo ter upoštevajte varnostna opozorila

preden zaženete naparavo. Navodila naj bodo vedno pri roki.

SK Starostlivo si preštudujte tento návod na obsluhu pred uvedením stroja do

prevádzky a najmä bezpecnostné predpisy. Držte tento návod na obsluhu na

dostupnom mieste.

EST Palun lugege enne masina käivitamist käesolevat kasutusjuhendit ning järgige

ohutusnõudeid. Kasutusjuhend peab alati käepärast olema.

CHI

Safety precautions

•

UAE

- 2-

Page 3

Safety precautions

•

•

D Keine Bedienung durch Kinder!

GB Children must not operate the machine!

F Pas d‘utilisation par un enfant!

NL Geen bediening door kinderen!

I Non lasciare utilizzare il tagliacarte a bambini!

E No dejar que la utilicen los niños!

S Installera maskinen utom räckhåll för barn!

FIN Asentakaa laite lasten ulottumattomiin !

N Installer maskinen utenfor rekkevidde for barn!

PL Dzieciom nie wolno obsługiwać urządzenia !

RUS

Не допускайте детей к пользованию аппаратом!

H Gyerekek a gépet nem kezelhetik

TR Makinayý Çocuklar Kullanmamalýdýr.

DK Må kun betjenes af voksne

CZ Stroj nesmí být obsluhován dětmi!

P As crianças não devem trabalhar com a máquina!

GR БРБГПСЕХЕФБЙ З ЧСЗУЗ БРП РБЙДЙБ.

SLO Otroci ne smejo uporabljati naprave

SK So strojom nesmú pracovat deti!

EST Lapsed ei tohi masinat kasutada!

CHI

UAE

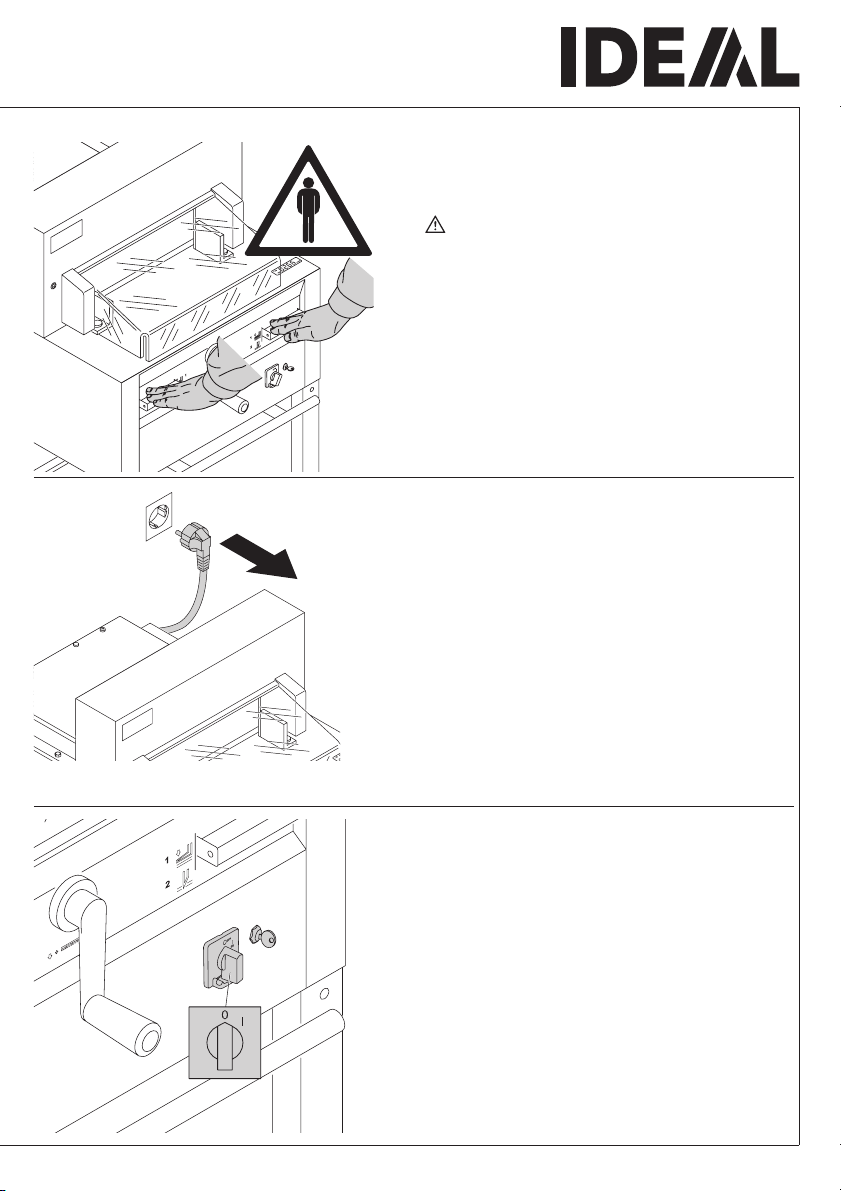

D Nicht unter das Messer fassen!

GB Do not reach beneath the blade!

F Ne pas passer les mains sous la lame!

NL Niet met de handen onder het mes komen!

I Non toccare la lama nella parte inferiore!

E ¡No tocar debajo de la cuchilla!

S Sträck inte in handen under kniven!

FIN Älä laita kättäsi terän alle !

N Plasser aldri hender ol. under kniven !

PL Nie wkładać rąk pod noże!

RUS

Избегайте попадания рук под лезвие!

H Ne nyúljon a kés alá!

TR

Elinizi býçaðýn altýna sokmayýnýz!

DK Stik ikke hænderne ind under knivbladet!

CZ Nesahejte pod ostří nože!

P Não tocar na parte inferior da faca!

GR МЗН БГГЙЖЕФЕ ФП КБФЩ МЕСПУ ФЗУ ЛЕРЙДБУ!

SLO Ne segajte z roko pod rezilo!

SK Nevkladajte ruky pod nôž!

EST Ärge pange kätt tera alla!

CHI

UAE

- 3 -

Page 4

•

IDEAL 4815 • IDEAL 4850

D Messer nie lose liegen lassen!

Messer nur mit Messerwechselvorrichtung oder im

Messertransportkasten befördern!

(siehe Seite 27 und 29).

GB Never leave the blade unattended!

NL Laat nooit de messen alleen achter.

FIN Käsittele terää aina varoen. Älä siirrä tai kuljeta

PL Nigdy nie pozostawiać noży bez nadzoru.

RUS Не оставляйте открытое лезвие без присмотра! Не

Warnung! Verletzungsgefahr!

Do not extract or transport the blade without protection!

(See page 27 and 29).

Danger! Risk of injury!

F Ne jamais laisser la lame sans protections !

Elle ne doit être démontée qu’à l’ aide du dispositif de

changement de lame (cf. page 27 et 29), ou transportée dans

son étui en bois !

Danger! Risques de coupures !

Transporteer de messen niet zonder de houten bescherming

(zie pagina 27 en 29).

Waarschuwing! Opgelet voor ongevallen!

I Non lasciare mai la lama incustodita. Non rimuovere o

trasportare la lama senza protezione. (Vedi pagina 27 e 29).

Attenzione! Rischio di infortunio!

E ¡No quitar la cuchilla sin prestar atención. No desmontar no

transportar la cuchilla sin protección! (vérase pág. 27 y 29)

¡Advertencia! ¡Peligro de hacerse daño!

S Lämna aldrig maskinen obemannad. Ta inte ur eller

transportera kniven utan skydd. (se sid 27 och 29).

Skaderisk!

terää ilman suojaa ! (katso sivu 27 ja 29

Loukkaantumisen vaara !

N La aldri kniven ligge ubeskyttet. Ta aldri ut kniven eller

transporter den uten beskyttelse (Se side 27 og 29)

FARE ! Muligheter for skade !

Nie wyciągać lub transportować noży bez osłon!

(zobacz strona 27 i 29).

Ryzyko skaleczenia sie!

пытайтесь извлечь или транспортировать лезвие без

специальных мер предосторожности!

(См. страницы 27 и 29)

Соблюдайте выше перечисленные правила

для избежания травм!

H Soha ne hagyja a kést őrizetlenül!

Ne vegye ki vagy ne szállítsa a kést védőtok nélkül!

(Lásd 27. és 29. oldal)

TR Býçaðý hiçbir zaman gözetimsiz býrakmayýnýz!

- 4 -

Veszély! Sérülésveszély!

Býçaðý muhafazasýz olarak yerinden çýkartmayýnýz veya

taþýmayýnýz! (Sayfa 27 ve 29’e bakýnýz)

Dikkat! Yaralanma riski!

Safety precautions

•

Page 5

Safety precautions

•

•

DK Knivbladet må aldrig efterlades uden opsyn.

Forsøg ikke at afmontere eller transportere knivbladet uden

beskyttelse! (Se side 27 og 29)

FARE! Risiko for legemlig beskadigelse.

CZ Nikdy nenechávejte nůž bez krytu.

Nikdy nevyjímejte nebo neprepravujte nuz bez ochranného

krytu (viz. strany 27 a 29)

Nebezpecí! Riskujete zranení

P Deixar a faca sempre em local seguro!

Não retirar ou transportar a faca sem protecção!

(Ver pág. 27 e 29)

Perigo! Risco de dano!

GR МЗН БЦЗНЕФЕ ФЗН ЛЕРЙДБ БНЕРЙФЗСЗФЗ!

МЗН БЛЛБЖЕФЕ ¹ МЕФБЦЕСЕФЕ ФЗН ЛЕРЙДБ ЧЩСЙУ

РСПЦХЛБОЗ (ДеЯфе учефйкЬ уфйт уелЯдет 27 & 29)

РСПУПЧЗ ! КЙНДХНПУ ФСБХМБФЙУМПХ !

SLO Nikoli ne puščajte rezila nazaščitenega. Nikoli ne prenašajte

rezilo brez zaščite. ( glej stran 27 in 29).

Pozor! Nevarnost poškodbe.

SK Nenechávajte nôž nechránený (nezabezpecený)!

Nevyberajte alebo netransportujte nôž bez ochrany

(vid s. 27 a 29

! Riziko úrazu !

EST Ärge jätke lõiketera kunagi järelevalveta!

Ärge pikendage ega teisaldage tera kaitseseadmeteta!

(Vt lk 27 ja 29)

Oht! Vigastuste oht!

CHI

UAE

- 5 -

Page 6

IDEAL 4815 • IDEAL 4850

D Keine harten und splitternden Materialien schneiden!

GB Do not cut hard materials or materials which may splinter!

F La coupe de matériaux trop durs ou risquant des projections

est interdite !

NL Snij geen harde materialen of materiaal dat kan splinteren!

I Utilizzare il tagliacarte esclusivamente per il taglio di risme

di carta o materiali analoghi!

E ¡No cortar materiales duros o materiales que puedan

astillarse!

S Förstör inte hârt material eller material som kan splittras!

FIN Asentakaa laite lasten ulottumattomiin !

N Ikke kutt hardt metall eller materiale som kan splintre !

PL Nie ciąć twardych materiałów lub materiałów, które mogą

ulec odpryśnięciu!

RUS

Данный резак не предназначен для резки твердых

материалов или материалов, которые могут

расщепляться!

H Ne vágjon kemény vagy olyan anyagot, amely repedhet!

TR Sert veya parçalanabilecek malzemeleri kesmeyiniz!

DK Der må ikke skæres i hårde materialer eller i materialer, der

kan splintre!

CZ Neřežte tvrdý materiál, při kterém mohou ustřelovat ostré

úlomky!

P Não cortar materiais duros ou materiais que possam lascar!

GR МЗН КПВЕФЕ УКЛЗСБ ХЛЙКБ ¹ ХЛЙКБ РПХ

ИСХММБФЙЖПНФБЙ!

SLO Nikoli ne režite trdih materialov ali materialov, ki se lahko

razcepijo.

SK Nerežte tvrdé materiály, alebo materiály, z ktorých môžu

vystrelovat ostré úlomky.

EST Ärge lõigake kõvasid materjale ega materjale, mis võivad

pilbasteks puruneda!

CHI

UAE

Safety precautions

•

•

- 6 -

Page 7

Safety precautions

•

•

The machine is designed for cutting stacks of

paper to a specified size.

This machine is constructed for "one-man

operation" only!

Warning! Clips or similar damage the

cutting blade.

Disconnect from the mains before starting any

service work or before removing the panels!

- 7 -

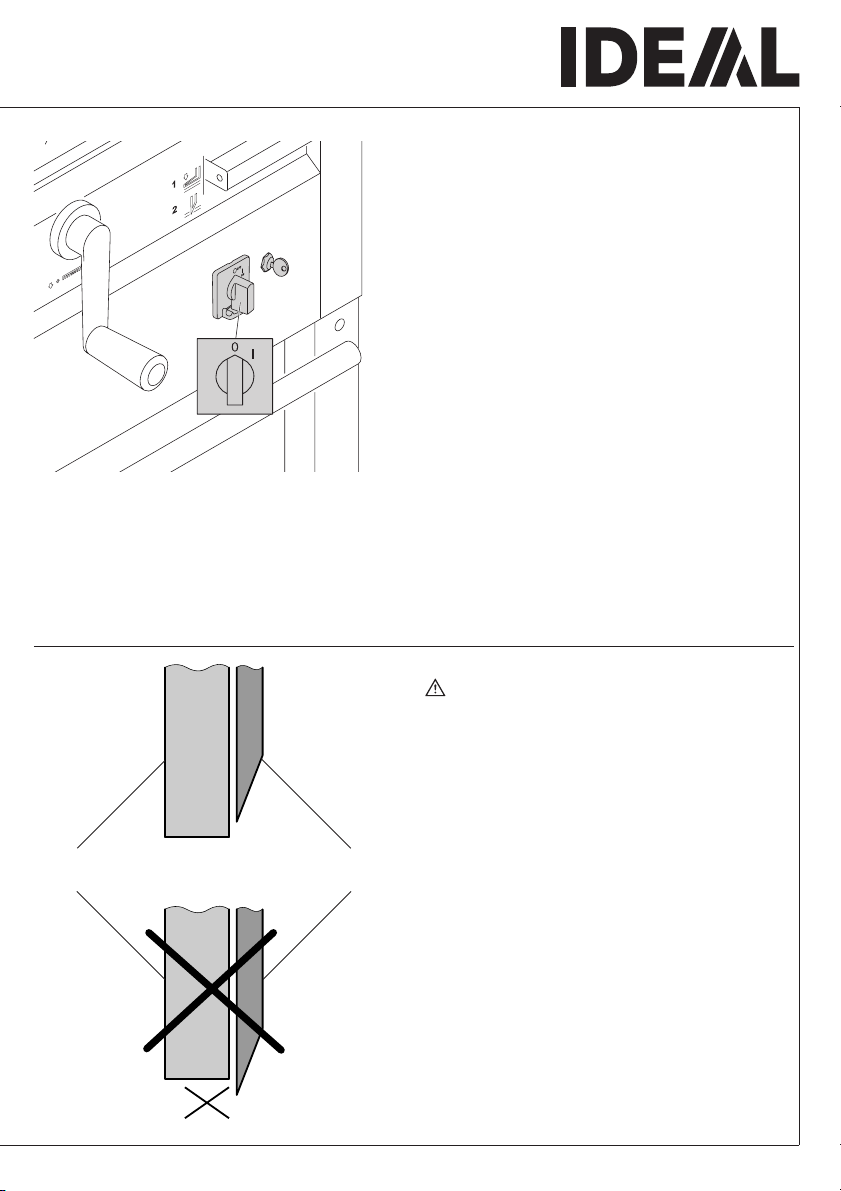

Replacement of blade and cutting stick may

be performed only when the main switch is

switched off!

Page 8

IDEAL 4815 • IDEAL 4850

C

A

C

B

A

A

A

Safety precautions

•

All components which could endanger the

operator are covered by a guard!

•

- 8 -

Operating the machine without safety device is

forbidden!

(Front safety guard (A), rear screwed safety

guard (B) and panel (C).

Page 9

Safety precautions

•

A

•

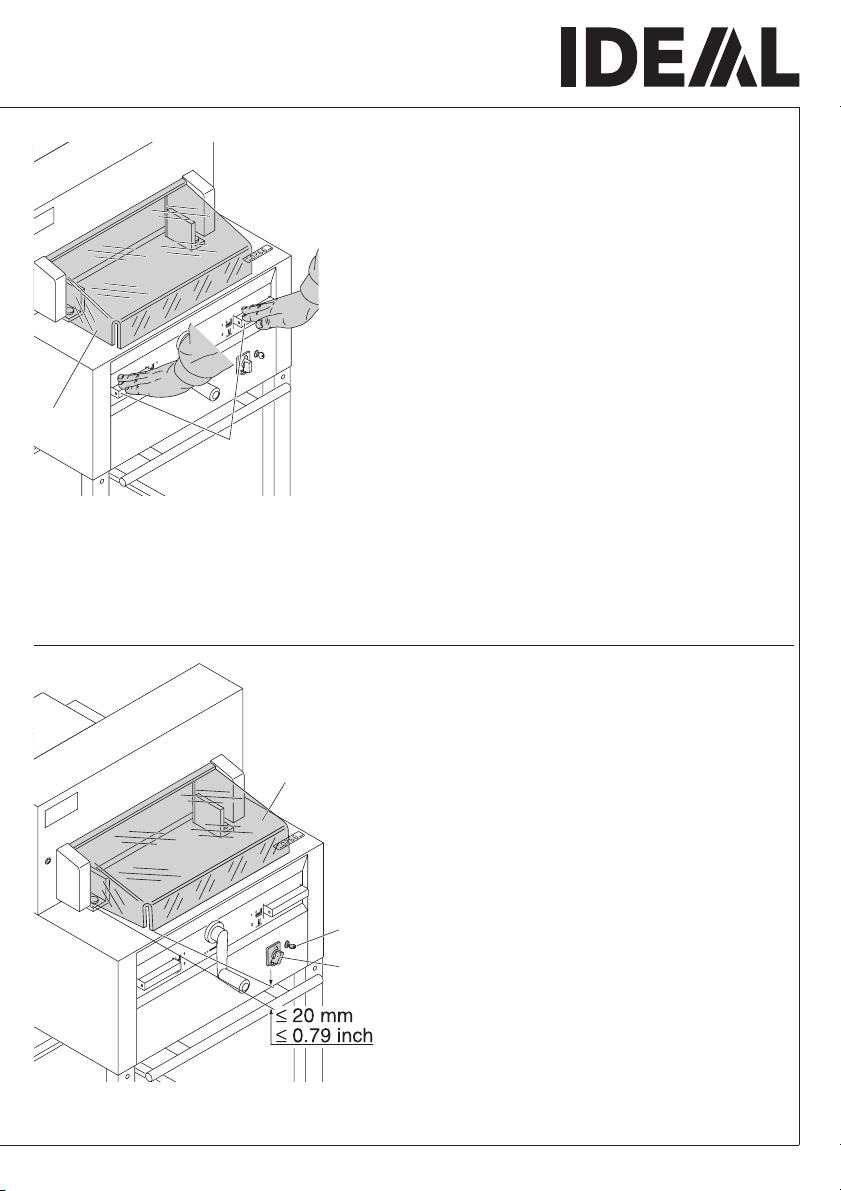

The dangerous cutting movement is

safeguarded by a movable guard (A) and a

safety two-handed control system! (B)

B

A

C

B

- 9 -

Before working with the machine and after

every blade replacement the automatic cut-off

function of safety guard (A),(correct if distance

between cover and table is < 20 mm) main

switch (B) and control panel (C) must be

checked.

Page 10

IDEAL 4815 • IDEAL 4850

230V / 10A min

115V / 15A min

Safety precautions

•

Protect mains cable against heat, oil and

sharp edges!

Connect the power cord to a single phase

socket.

•

- 10 -

Ensure free access to mains!

Page 11

Safety precautions

•

•

When not in use for a longer period switch off.

(Main switch to "0").

OK

Clamping

Blade

OK

- 11 -

Warning by IDEAL 4815

Danger!

Blade must always be covered by the

pressing bar.

Page 12

IDEAL 4815 • IDEAL 4850

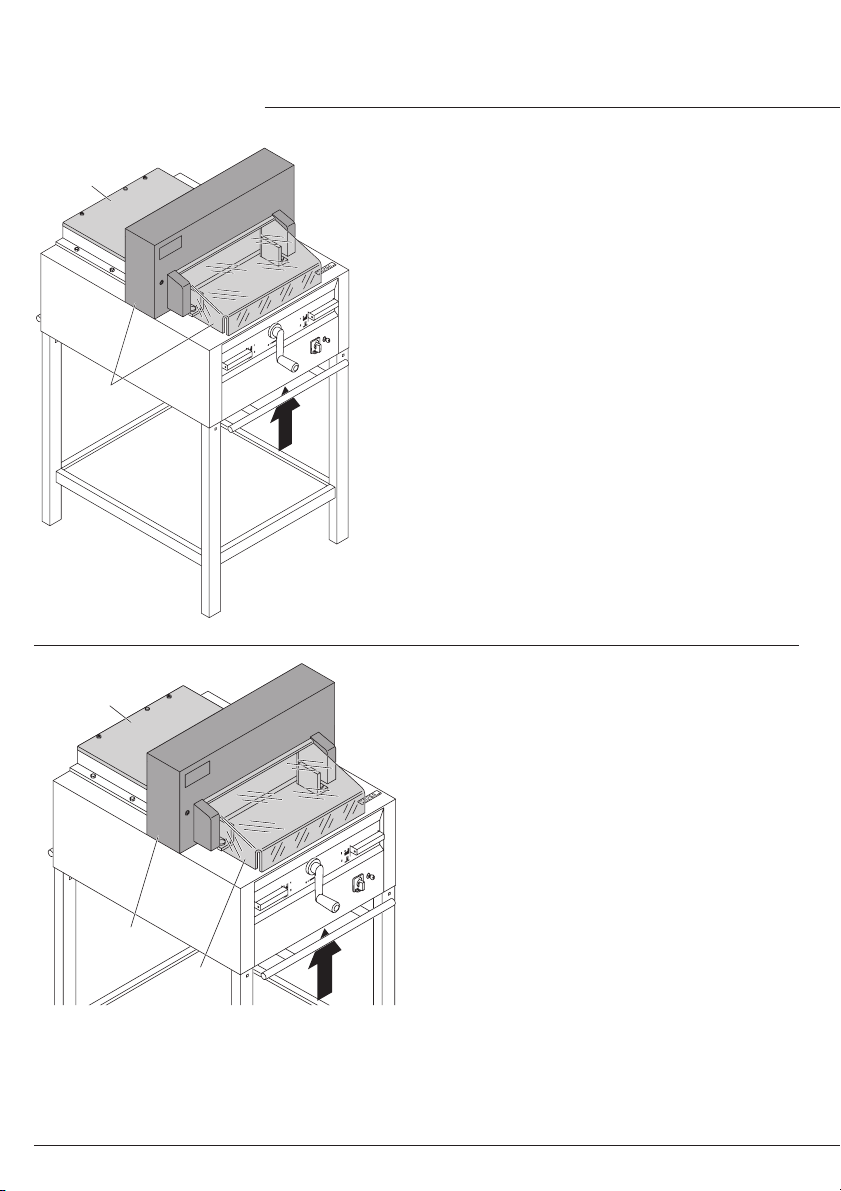

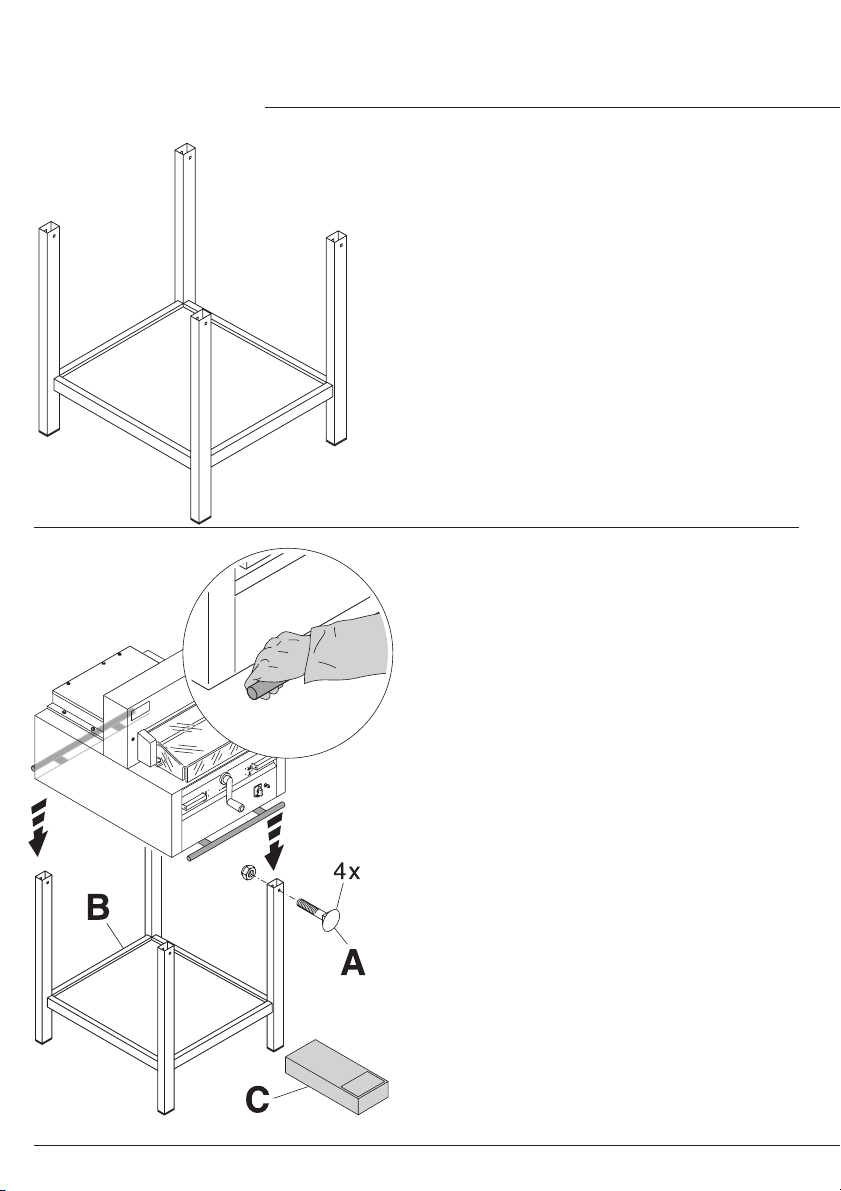

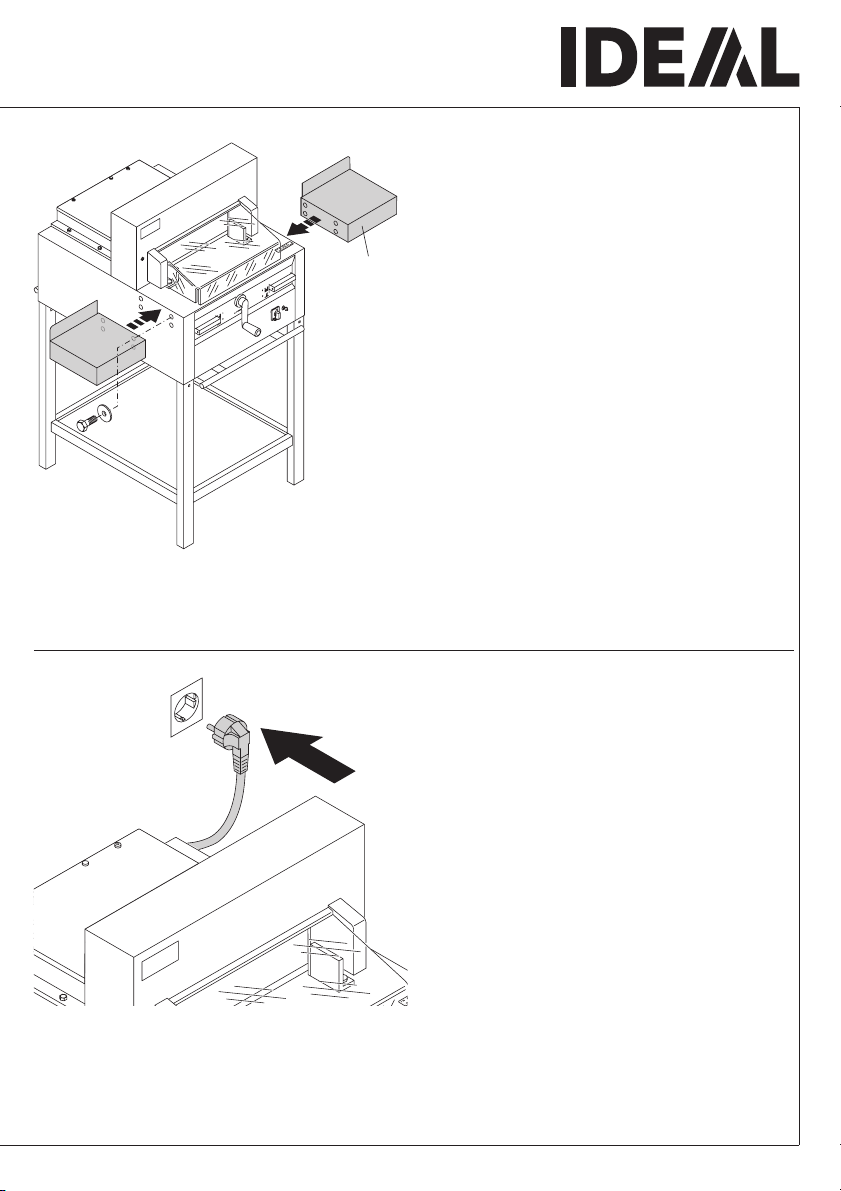

Installation

•

Remove the stand from the wooden pallet.

4 strong people are required to lift the machine

from the pallet and place it on the stand.

Secure with 4 screws (A). Put the shelf (B) on

the stand. (Parts and tools are in the tool set

(C).

•

- 12 -

Page 13

Installation

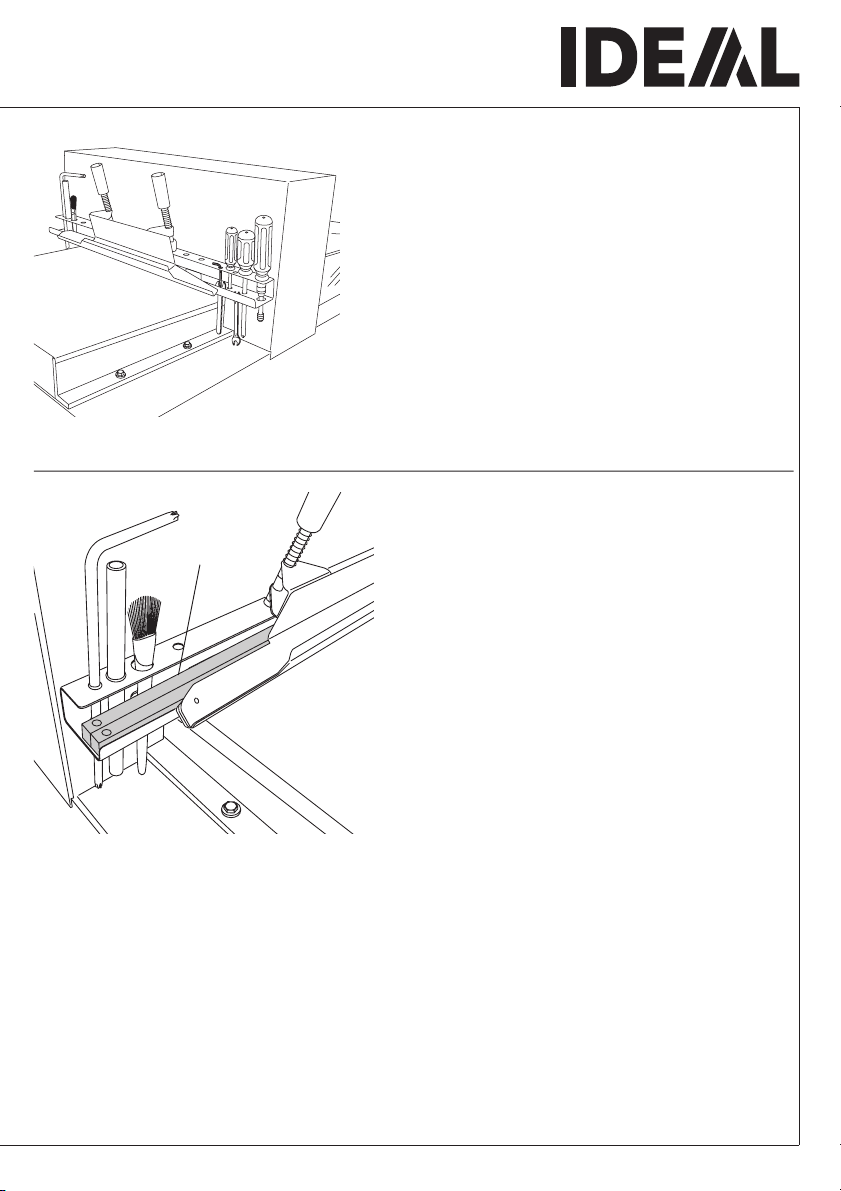

•

•

Tools can be kept in the holder provided .

Cutting sticks (A) can be put in the tool holder

A

- 13 -

Page 14

IDEAL 4815 • IDEAL 4850

A

C

C

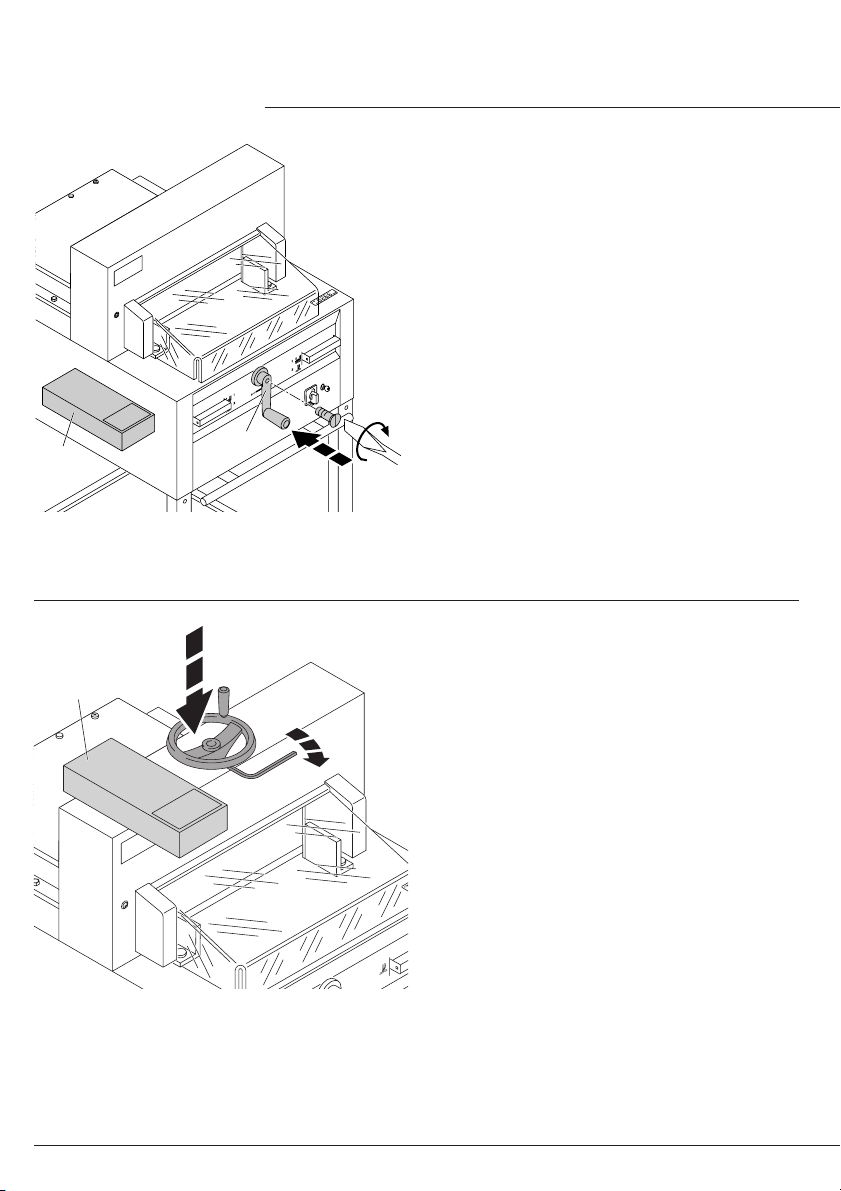

Installation

•

Tighten the backgauge crank (A). Parts and

tools are in the tool set (C).

Only IDEAL 4815

Attach the enclosed hand-wheel for clamping.

Parts and tools are in the tool set (C).

•

- 14 -

Page 15

Installation

•

•

Side tables (A), left and right are available

as an option (Nr. 9000 528).

A

Plug into socket.

The machine must be connected directly to the

socket.

- 15 -

Page 16

IDEAL 4815 • IDEAL 4850

A

A

A

Operation

•

It is forbidden to operate the machine if the

operating and safety instructions have not been

understood. Please check the safety devices

are functioning and complete before use.

All covers have to be mounted (A).

•

The release for cutting is allowed only if

•

the cover is closed and the two-hand safety

device is operated at the same time (B)

If the front cover closes by itself the

•

gas spring (X) needs replacing.

We recommend you keep a record of your test

results.

•

A

B

X

- 16 -

Page 17

Operation

•

•

7

9

8

9

3

1

6

4

5

2

1

Operating elements

- Safety two-handed control system

A

Pre-clamping (only IDEAL 4850)

and cutting

- Overload switch

B

Blade drive IDEAL 4815

Blade drive, clamp drive,

IDEAL 4850

- Display cutting size (cm or inch)

C

- Main switch

D

- Crank handle for backgauge

E

setting

- Key switch

F

- Paper clamp (only IDEAL 4815)

G

- Backgauge

H

- Side lay left and right

I

- Front safety guard

J

- Measuring unit (cm or inch)

K

- Display cutting size (cm or inch)

L

- Changeover (cm/inch)

M

11 12 13

- 17 -

Warning!

Before cutting a measurement please check

that the measurement scale (cm or inch) is

adjusted correctly. See left picture.

Cutting activation

Warning!

• Run backgauge to the front for turning the

paper stack.

• Do not interrupt the upward movement of the

blade by performing switching procedures.

• Close the front safety guard

• Blade must always be at the top and be

covered by the clamp. Do not touch the

blade.

(see safety information on page 32).

Risk of injury!

J

.

Page 18

IDEAL 4815 • IDEAL 4850

Operation

•

Position the main switch D to "I" (A). Insert the

key F for the control system and move it to the

right (B). Open the safety guard

machine is now ready for use.

(C). The

J

•

C

B

A

- 18 -

Page 19

A

B

Operation

•

C

D

E

•

The measurement is set with the backgauge

crank.(A) The symbol – rotary direction –

moves to the right on the display (B) (see

picture C). The rotary direction of the

backgauge crank (A) is indicated on the right.

Keep turning the backgauge crank to the right

until a measurement appears (see picture E).

The reference position is reached.

The cutting size can now be set with the

handle (A).

If the backgauge is right at the front the

symbol – rotary direction – will move to the left

(see picture D). Turn the backgauge crank to

the left until the rotary direction appears on the

right

Afterwards turn the backgauge crank to the

right until a measurements appears (see

picture E). The reference position is reached.

The cutting size can now be set with the

handle (A). Proceed to position from the

rear.

Measurement is shown on the display in

inches or cm (B).

Information:

When the machine is only switched off by

the Key switch

is not necessary to advance to the reference

point.

in the display (see picture C).

(main switch D is still ON) it

F

- 19 -

Page 20

IDEAL 4815 • IDEAL 4850

A

B

Operation

•

Cut according to markings

Optical cutting line (A) that indicates the exact

position of the cut. Blade cuts on the front

edge (B) of the light beam. (Only use when no

exact cut is required).

Adjust the backgauge with the crank handle

•

to the back.

E

Insert paper and move by means of the

•

stacking angle to the backgauge

lay on the left

Turn the crank handle E to the right until the

•

marking on the paper to be cut is below the

cutting line indicator.

I.

and side

H

•

- 20 -

Pull out the handle to avoid the measurement

being wrongly adjusted.

Page 21

Operation

•

A

B

•

Position the paper on the backgauge (A) and

B

side lays left or right (B).

To move paper stacks, please use the paper

knock-up block (C) provided.

(Run backgauge to the front for turning the

paper stack).

C

Only 4815

Clamping is released by the hand-wheel.

Before every cut lower the clamp by turning the

hand-wheel to the right and tighten with a light

twist.

IDEAL 4815

Press both actuators of the two-handed control

system activation (A) simultaneously and them

pressed until the paper is completely cut.

A

- 21 -

Page 22

IDEAL 4815 • IDEAL 4850

A

Operation

•

IDEAL 4850

The clamp moves automatically when cutting

is activated.

The paper can also be pressed in advance.

Clamping and cutting is activated by

pressing actuators (A) on the front table.

IDEAL 4850

The actuator has 2 switching steps:

1. pre-clamping

2. automatic clamping and cutting

•

IDEAL 4850

Switch position 1

+ =

+ =

+ =

+ =

+ =

- 22 -

+ =

Switch position 2

Pre-clamping

Press down both actuators to step 1

Clamp returns

Press down completely one of the actuators

Cutting sequence with automatic clamping

Press down both actuators to step 2

Page 23

Operation

•

•

Close the safety guard.

Cutting activation:

Press both buttons of the two-handed control

system activation (A) simultaneously and them

pressed until the paper is completely cut.

A

To interrupt or stop cutting:

To interrupt or stop cutting, release

both buttons (A) of the two-hand control.

A

- 23 -

Page 24

IDEAL 4815 • IDEAL 4850

Blade and cutting stick replacement

•

If the cutting quality decreases:

Check the cutting depth (see page 32).

•

Check the cutting stick (see page 28).

•

Replace or grind the blade (see page

•

24 - 32).

The blade cannot be ground if the blade

height is less than 83 mm/3,29 inches.

A new blade must be used.

The blade may only be ground by a qualified

supplier or from the manufacturer

Krug & Priester, D-72336 Balingen.

Danger! Risk of injury!

The blade is extremely sharp. Do not

extract or transport the blade without

protection. Changing the blade may only be

performed by trained staff.

•

- 24 -

Page 25

Blade and cutting stick replacement

•

•

1.

Turn the blade depth adjustment screw to the

left until it stops. (Screwdriver found in tool set

(A).

Close the safety guard (1.).

Lower the blade by pressing both cutting

actuators (2.). Keep one actuator pressed and

turn off the main switch (3.).

2.

3.

- 25 -

Page 26

IDEAL 4815 • IDEAL 4850

C

A

B

Blade and cutting stick replacement

•

The 3 eccentrics are now exposed and should

be turned counter clockwise to position "0"

with the special wrench and attachable

extension pipe (A) (in the tool set). The slot

must correspond to position "0" (B).

Unscrew the blade screws (C) on the right

hand side.

Remove the special wrench and turn on the

main switch until the blade returns to the home

position.

•

OK

OK

Blade

Clamping

- 26 -

Warning by IDEAL 4815

Do not turn main switch to position "0"

whilst blade is moving upwards!

The clamp must always overlap the blade!

Danger! Risk of injury!

Page 27

Blade and cutting stick replacement

•

2.

1.

3.

1.

•

Position the main switch to "0" (1.)

Remove the 2 blade screws on the elongated

holes (2.). Then put the blade changing tool (A)

into place and fasten it to the blade (3.).

A

Remove 2 blade screws (1.).

Loosen the grips (2.) of the blade changing

tool (A) lightly and allow the blade to be taken

downwards out of the machine (3.). Place the

blade into the blade carrier (B) and screw it

into place (4).

A

3.

2.

B

4.

- 27 -

Page 28

IDEAL 4815 • IDEAL 4850

Blade and cutting stick replacement

•

Take out the cutting stick with a small screwdriver. If needed the cutting stick can be turned

or exchanged. (The cutting stick can be used

eight times).

•

- 28 -

Replacing the cutting stick (not the blade).

• Turn the blade adjusting screw (A) to the left

until it stops. (Otherwise the first cut will be

too deep).

• Remove the cutting stick according to top

picure.

• Turn the cutting stick (the non-used side

must be near to the blade) and plug it into the

holding bolt.

Danger! Risk of injury!

Cutting test after replacing the cutting stick

(not the blade)

• Insert the paper and release the cut.

• If the last sheet of paper is not cut along the

entire length turn the blade adjusting screw

(A) ¼ turn to the right.

• If the last sheet is still not completely cut

repeat this process until the last sheet is cut

along the entire length.

Page 29

Blade and cutting stick replacement

•

A

11 mm

0.43 inch

B

B

C

•

Take the exchange blade carefully out of the

blade box and screw it to the blade changing

tool (A).

• Make sure there is a space ot 11 mm or

0.43 inches! (B).

• Blade must be covered! (C).

Danger! Risk of injury!

C

A

1.

2.

- 29 -

Place the blade to be exchanged with the

blade changing tool (A) mounted (1.), into the

blade carrier and push it up to the top and

screw it into place with the grips (2.).

Page 30

IDEAL 4815 • IDEAL 4850

B

1.

3.

A

2.

Blade and cutting stick replacement

•

Lightly tighten 2 of the 5 blade screws with

washers (1.). Remove the blade changing

tool (2.). Lightly tighten the remaining blade

screws with washers (3.).

Lightly screw in the right blade screw with the

washer (A) when the blade is lowered.

•

1.

2.

- 30 -

Remove all tools and distribute paper along

the entire cutting length (1.).

Turn main switch to position "I" (2.).

Page 31

Blade and cutting stick replacement

•

•

1.

Close the safety guard (1.) Lower the blade by

pressing both cutting buttons (2.). Keep one

button pressed and turn off the main switch (3.).

3.

2.

4.

5.

A

2.

Open the safety guard (4.). With the special

wrench (B) the 3 eccentrics should be screwed

down (5.)until the paper is cut along the

entire length of the blade (The blade must

remain parallel, not too deep into cutting stick).

A

Tighten the blade screws (A) on the right hand

side.

Turn main switch to position "I" (1.). Blade will

return to upper position. Tighten the blade

screws (2.) firmly.

Warning by IDEAL 4815

Do not turn main switch to position

"0" whilst blade is moving upwards! The

clamp must always overlap the blade!

(see page 32).

Danger! Risk of injury!

1.

- 31 -

Page 32

IDEAL 4815 • IDEAL 4850

A

Blade and cutting stick replacement

•

Paper cutting test. If the last sheet or several

sheets are not completely cut, gradually turn

the knob for blade depth adjustment (A)

¼ turn to the right until the paper is cut along

the entire length. Do not set too low as blade

will become blunt sooner.

Warning by IDEAL 4815

Danger!

Blade must always be covered by the

pressing bar (see picture below at the left).

•

OK

Clamping

Blade

OK

- 32 -

Page 33

Maintenance and cleaning

•

D

•

Maintenance work may only be performed by

trained staff.

Danger! Disconnect the mains before

starting any service work or before

removing the cover.

Grease the backgauge (A) control weekly with

a grease gun. Advance the backgauge as far

as possible to the front. (Use non-resinous oil

or grease).

Grease the remaining parts twice a year (see

picture).

The main switch must be on "0" (B).

Remove panel (C). Tools in tool set.

• Remove any paper.

• Grease the machine.

• Check the 4 joining bolts and 2 pushing bars

for wear (D). If necessary inform your service

personnel.

• Mount the machine.

- 33 -

= Greasing points on the machine.

Page 34

IDEAL 4815 • IDEAL 4850

Maintenance and cleaning

•

Safety test

The safety regulations are according to the

regulations of the country where the cutting

machine is operated. The manufacturer

recommends a safety check is made every 5

years by an authorised service team.

•

- 34 -

Page 35

Possible malfuntions

•

•

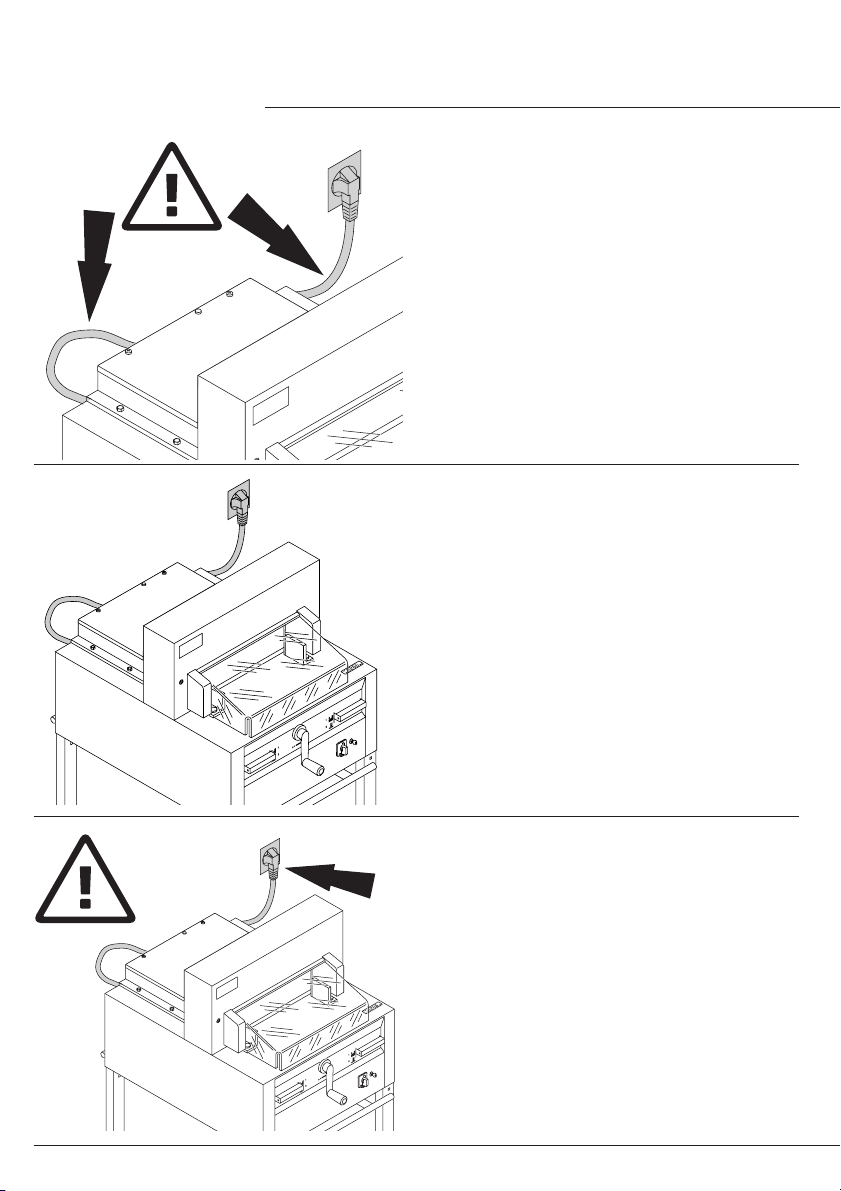

Machine does not function!

Is the machine plugged in?

B

A

- 35 -

Main switch to position "I"? (A)

Control system activated? (B)

(Turn key to the right)

Check the units fuse and the on-site circuit

breaker!

Release a cut see page 21 and 22.

Page 36

IDEAL 4815 • IDEAL 4850

Possible malfuntions

•

Cut cannot be made.

If cover is open:

•

close it.

If cover is closed:

•

open and re-close it. (Security check).

•

- 36 -

Page 37

Possible malfuntions

•

•

Machine turns off:

Machine overloaded.

•

Safety button (A) ejects.

(Allow 1 minute cooling time and reset the

safety button (A).

Machine blocked.

•

Blade is blunt.

•

Eliminate the cause, and push the safety

button (A).

Only IDEAL 4850

Clamping drive blocked

•

Safety button (B) ejects.

Eliminate the cause, and push the safety

A,B

button (B).

Safety button for:

- 37 -

Blade drive

A =

Clamping drive

B =

Page 38

IDEAL 4815 • IDEAL 4850

A

B

Possible malfuntions

•

Does not cut through the last sheet:

Turn or turn around the cutting stick (A),

•

readjust the blade by means of the blade

adjusting knob (B)

(see page 32).

Poor cutting quality or blade stays in the

paper stack.

Change the blade (C) (see pages 24 - 32.

•

•

C

- 38 -

Page 39

Possible malfuntions

•

•

A

Motor runs but blade does not move

downwards.

Security brake has been activated!

•

Inform the Service Team!

www.ideal.de "Service"

•

service@krug-priester.com

Display illumination off

Machine is plugged in? (A)

•

Main switch on position "I"? (B)

•

Push in the safety button! (C)

•

Check the units fuse and the on-site circuit

•

breaker!

B

C

- 39 -

Page 40

IDEAL 4815 • IDEAL 4850

Possible malfuntions

•

None of the above mentioned methods

helped to solve the problem:

Contact Service Team under

www.ideal.de "Service"

•

service@krug-priester.com

•

- 40 -

Page 41

Accessories

•

•

Recommended accessories:

Blade

Nr. 9000 021

•

Cutting stick (6 pieces)

Nr. 9000 022

•

Blade changing tool

Nr. 9000 518

•

Paper knock-up block

Nr. 9000 521

•

Side tables left and right

Nr. 9000 528

•

1

Included in delivery

1

1

- 41 -

Page 42

IDEAL 4815 • IDEAL 4850

Technical data:

Power supply: 230V/50Hz/1~,120V/60Hz/1~

•

Cutting height: 80 mm

•

Sound level EN 13023: < 70 dB (A)

•

Leakage current < 3,5mA

•

Power cord gauge min. 1,5mm2 (230V).

•

Power cord gauge AWG 14 (15A) (120V)

•

(IDEAL 4815)

Power cord gauge AWG 12 (20A) (120V)

•

(IDEAL 4850)

The exact technical specifications can be

found on the technical specifications sticker (A)

on the machine. A wiring diagram is found in

the electrical switch box.

To claim under guarantee, the machine must

still carry its original identification label.

Cutting-

length

mm

Table-

depth

mm

Minimum space

requirement

(B X T X H) mm

IDEAL 4815 475 458 765* x 1080 x 1435 212**

IDEAL 4850 475 458 765* x 1080 x 1300 225***

Technical data

•

Weight

kg

•

* with side tables: 1365 mm

** with side tables: IDEAL 4815 / 221 kg

*** with side tables:IDEAL 4850 / 234 kg

- 42 -

Page 43

Technical data

•

•

This machine is approved by independent

safety laboratories and is in compliance with

the EC-regulations 2006/42/EG and

2004/108/EG.

Sound level information:

The sound level is < 70 db (A) as defined by

EN 13023.

Subject to alteration without notice.

- 43 -

Page 44

IDEAL 4815 • IDEAL 4850

Technical data

•

Krug + Priester has a certified quality

management system according to DIN EN

ISO 9001:2008 and a certified environmental

management system according to DIN ISO

14001:2009.

•

- 44 -

Page 45

D EG-KONFORMITÄTSERKLÄRUNG

GB EC-declaration of conformity

F Déclaration de conformité CE

- Hiermit erklären wir, daß die Bauart von

- Herewith we declare that

- Par la présente, nous déclarons que

GS- IDENT. Nr. UL- IDENT. Nr.

4815 11481001 10481001

4850 11485001 10485001

- folgenden einschlägigen Bestimmungen entspricht

- complies with the following provisons applying to it

- sont conformes aux dispositions pertinentes suivantes

2006/42/EG:

Maschinenrichtline, EC Machinery directive, EC Directives machines.

2004/108/EG:

EMV Richtline, EMV Electromagnetic compatibility directive,

EMV directives compatibilité électromagnétique

2011/65/EU

RoHS Richtlinie, RoHS directive, RoHS directives.

- Angewendete harmonisierte Normen insbesondere

- Applied harmonised standards in particular

- Normes harmonisées utilisées, notamment

EN 60204-1; EN 1010-1; EN 1010-3; EN 55014-1; EN 55014-2;

EN 61000-3-2; EN 61000-3-3; EN ISO 12100;

EN ISO 13857; EN ISO 11204; EN 13023; EN ISO 13849-1

29.12.2009

Datum

- Geschäftsführer-

- 45 -

Bevollmächtigter für technische Dokumentation

Authorized representative for technical documentation

Représentant autorisé pour la documentation technique

Krug & Priester GmbH u. Co KG

Simon-Schweitzer-Str. 34

D-72336 Balingen (Germany)

Page 46

IDEAL 4815 • IDEAL 4850

Remarks:

- 46 -

Page 47

Remarks:

- 47 -

Page 48

IDEAL • Made in Germany

• Document Shredders •

IDEAL

•

• Trimmers and Guillotines •

72336 Balingen • Germany

•

www.ideal.de

•

Printed in Germany • IDEAL 08/2013

•

Loading...

Loading...