Page 1

Trimmer

OPERATION

MANUAL

Trimmer

Page 2

Trimmer

CONTENTS

Introduction........................................................ 3

Specifications ..................................................... 3

Safety ................................................................. 4, 5

Installation .......................................................... 6-8

Setup .................................................................. 9

Control Panel ..................................................... 10

Operation ........................................................... 11, 12

Maintenance ....................................................... 13

Adjustments ....................................................... 14

Fuses Access ...................................................... 15

Preventive Maintenance ..................................... 15

Knife Removal & Installation ......................... 16-19

Clearing A Trimming Jam ............................... 19

Knife Care Tips ................................................. 20

Notes .................................................................. 21

Trouble Shooting ............................................... 22-25

2

Page 3

INTRODUCTION

MBM Corporation is proud to introduce another addition to its complete line of equipment for bookletmaking.

Now you have the ability to trim books in-line! This combination offers you reliability and versatility that

improves production and reduces downtime.

Trimmer Features:

In-line face trimming of booklets

Jam detection

Electrical interface for communication with StitchFold Bookletmaking System

Safety interlock

See-through top cover

TRIMMER SPECIFICATIONS

Unit Weight: 236 Pounds

Speed: Up to 2,400 booklets per hour (115Vac machine)

Capacity: Minimum

4.00" cut width x 4.13" to fold (trim length)

2 sheets 20# bond thickness

Maximum

12.71" cut width x 9.00" to fold (trim length)

50 sheets 20# bond thickness (0.20")

.625" maximum material trim

Booklets: 4.25" x 5.5", 5.5" x 8.5", 8.5" x 11", 4.75" x 4.75 "CD", & metric sizes

(All booklets with or without trim stock on one or three sides)

Output: Indexing conveyor

Footprint: 16.50" x 18.38"

Dimensions: Height 27.38" Width 26.42" Length without discharge table 25.90"

Length with fully extended discharge table 48.44"

Modes: Trim or No-trim

Electrical: Standard outlet - 115 Volts, 60 Hz, 6 Amps (1/4 HP)

Optional: 230Vac, 50 Hz, 3 Amps

3

Page 4

Trimmer

SAFETY PRECAUTIONS AND PROCEDURES

1. Make sure electrical power is turned off before performing any adjustment or maintenance.

2. Keep hands, hair, tools, and clothing clear of

trimming area.

SAFETY

5.

6.

NEVER REACH UNDER THE KNIFE Severe

lacerations or dismemberment could result.

NEVER OPERATE THE TRIMMER WITHOUT

THE B2000 BOOKLETMAKER AND SAFETY

INTERLOCK SYSTEM.

3. Become familiar with the moving components

of your machine. Keep fingers away from

areas that could pinch or cut.

BE EXTREMELY CAREFUL when changing

4.

the cutter knife. Severe lacerations or dismemberment could result from careless handling procedures.

6. A well maintained machine is a safer machine.

Clean and lubricate the machine at regular intervals. Check machine daily for broken or

worn parts. Replace as necessary. DO NOT

attempt to operate the machine if a part is broken.

7. See "SAFETY GUARDS" below! If you are

unsure how to safely operate your trimmer, contact

your Service Representative.

DANGER

KEEP HANDS CLEAR OF TRIMMING AREA AND ANY MOVING PARTS!

NEVER OPERATE MACHINE WITHOUT ALL GUARDS IN PLACE!

SAFETY GUARDS (figs 1 & 2)

A. Top Cover: Blocks access to mechanism that

drives the trimming knife and conveyor belts.

An electrical interlock keeps the machine

turned off unless this guard is closed. Do not

stick your fingers under the top guard!

B. Front Upper Cover: Blocks access to the trim-

ming knives and the mechanism that drives the

upper trimming knife.

C. Infeed Table Bottom Cover: Blocks access to

infeed conveyor belts.

D. Front Lower Cover: Blocks access to danger-

ous electric voltage and mechanisms that can

pinch or cut. Be sure to disconnect electrical

power before removing this cover.

4

E. Right Side Cover: Blocks access to low volt-

age connections and mechanisms that can pinch

or cut. Do not stick your fingers beyond this

cover!

F. Rear Upper Cover: Blocks access to danger-

ous electric voltage and control circuit connections. Be sure to disconnect electrical

power before removing this cover.

G. Rear Lower Cover: Blocks access to low volt-

age connections and mechanisms that can pinch

or cut. Do not stick your fingers beyond this

cover!

H. Left Side Cover: Blocks access to low volt-

age connections and mechanisms that can pinch

or cut. Do not stick your fingers beyond this

cover!

Page 5

A. Top Cover

B Front Upper

Cover

Infeed Table

C.

Bottom

Cover

D.

Front Lower

Cover

SAFETY GUARDS

E. Right Side

Cover

F. Rear Upper

Cover

G. Rear Lower

Cover

(Fig 1)

H. Left Side

Cover

(Fig 2)

5

Page 6

Trimmer

INSTALLATION

BEFORE UNCRATING:

Examine the crate for visible damage. If the crate

is damaged, the machine might be damaged. Notify

the carrier who delivered the machine.

UNCRATING THE MACHINE:

Carefully remove the machine from its container.

Lift the machine by grasping its strong framework.

Tugging on cables, covers, or other delicate components could cause damage.

Examine the machine for damages incurred during

shipping. Do not install a damaged machine.

Notify the carrier immediately, and be sure to get

a signed copy of the Carrier Inspector's Report of

the damage incurred. Your service representative

will assist you in determining the cost of repairs.

CB145A Nut

CB379 Screw

RTM1327A Key

Back Cover

of Bookletmaker

(Fig 3)

ELECTRICAL POWER:

The power cord can be plugged into any 115V, 60

Hz, 1 Phase, 15 Amp circuit. The machine draws

less than 6 amps.

SAFETY INTERLOCK SYSTEM:

WARNING

NEVER OPERATE THE TRIMMER

WITHOUT THE B2000

BOOKLETMAKER AND SAFETY

INTERLOCK SYSTEM CONNECTED.

Connect the safety interlock system as follows:

1. Remove the back cover (see fig 3) from the

Bookletmaker.

2. Put the bolt through the washer of the safety

key assembly and screw the bolt half way into

the back cover of the Bookletmaker (see fig 4).

3. Install and securely tighten the nut onto the end

of the bolt (see fig 5). The bolt must only be

removeable by removing the nut first.

4. Install the back cover onto the Bookletmaker

(see fig 5).

6

(Fig 4)

(Fig 5)

Page 7

(Fig 6)

(Fig 7)

TRIMMER TO BOOKLETMAKER CONNECTIONS:

1. Adjust the height of the trimmer so that the top

of the trimmer infeed table is about even with

the middle of the BookletMakers top discharge

roller (see fig 6).

2. Position the trimmer behind the BookletMaker

so that the trimmer's infeed table is centered

with the BookletMakers discharge, and slightly

away from the BookletMaker's top discharge

roller (see figs. 7&8).

3. Install the safety interlock key that is hanging

from the bottom of the back cover (see fig 9).

(Fig 8)

(Fig 9)

7

Page 8

Trimmer

(Fig 10) (Fig 11)

DISCHARGE CONVEYOR TABLE:

Install discharge conveyor table per illustrations

(figs 10, 11, & 12).

(Fig 12)

8

Page 9

SETUP

(Fig 13)

TRIMMER HEIGHT:

The height of the trimmer can be adjusted up or

down slightly by use of the threaded adjustable

casters and locking nuts on the bottom of the trimmer or trimmer stand (fig 13).

ward to the desired location. There is a pointer

on the side of the back stop assembly that points

to a trim length scale installed on the inside wall

of the trimmer. Once located in the desired

position tighten the two thumb screws.

(Fig 14)

TRIM LENGTH:

To set the back stop assembly for the desired trim

length, loosen the two thumb screws (fig 14) and

slide the back stop assembly forward or back-

(Fig 15)

DISCHARGE TABLE ROLLERS:

Set the discharge table rollers forward for small

booklets or backward for large booklets. To adjust

the rollers, loosen thumb screws (fig 15), move

roller brackets to desired location, then retighten

thumb screws.

9

Page 10

Trimmer

F E D C B A

CONTROL PANEL (figs. 16 & 17)

(Fig 16)

A. Power On/Off: Green rocker switch turns on

or off power to the machine. Pilot light in

switch glows when power is on.

B. Start/Reset: Black rocker switch energizes

control circuit, which turns on motor. In

addition, the discharge conveyor will run and

the work gate will be raised as long as the

switch is depressed.

Note: Opening the top guard shuts off the

machine. It must be restarted as above.

C. Emergency Stop: Cuts off power to the

machine's drive and control circuit when

depressed. The Emergency Stop botton locks

in the down (off) position until manually turned

allowing it to pop back up into the power on

position. Restart machine per B above.

D. Trimming On/Off: Selector switch chooses

mode of operation: "On" for trimming jobs or

"Off" to allow work to pass through without

trimming.

F. Paper Jam When Lit: Glows to indicate that

there is a paper jam.

G. Belt Drive: Rotary switch controls when the

work conveyor belts shut off after incoming

work is sensed. The choice range is 1 through

6. "1" for quick shut off to "6" for maximum

extended running of the work conveyor belts

after incoming work is sensed.

E. Knife Change: Black rocker cycles the

trimming knife up and down as long as it is

depressed.

10

G

(Fig 17)

(SK891C Scene 1)

Page 11

OPERATION

STARTUP:

1. The "BELT DRIVE" rotary switch should be

set to "1" position.

2. Depress "POWER ON" switch to turn on

power.

3. Depress "START/RESET" switch to energize

control cicuit. The electric motor will now

energize and begin the infeed and internal conveyors.

4. Select "TRIMMING ON". Run the

Bookletmaker so that a booklet is deposited on

the trimmer's infeed table. The booklet will be

transported into the trimmer, trimmed, and ejected

onto the output conveyor. The output conveyor

runs for a short duration each time a booklet is

sensed entering the trimmer. This ensures that

there is no gap between work on the discharge

table.

NORMAL OPERATION:

1. Work is deposited, from the Bookletmaker, onto

the trimmer's infeed conveyor table.

2. The infeed conveyor belts pull the work into

the trimmer.

3. As the work is pulled into the trimmer, the

work passes above photo sensor number one,

located at the end of the infeed conveyor table.

Number one photo sensor recognizes the work

and tells the control circuit that work is entering the machine.

4. The infeed conveyor throws the work over the

lower knife area and into the middle work

conveyor belts.

5. The middle work conveyour belts pull the work

over photo sensor number two, located near

the work back stop gate. Number two photo

sensor recognizes the work and tells the control circuit that work has entered the trimming

area.

6. The control circuit then lets the conveyor belts

continue to run, for a short period of time, to

allow the work to run into and square up

against the back stop gate. The conveyor belts

are then stopped.

7. At this time the control circuit energizes the

trimming clutch solenoid, which releases the

trimming clutch to begin the trimming cycle.

8. The knife bar assembly begins to cycle downward.

9. As the knife bar assembly cycles downward

the gate clamp begins to squeeze, flatten, and

hold the leading end (or fold) of the work.

The front clamp then begins to squeeze, flatten, and hold the trim end of the work.

10. As the knife bar assembly continues downward the knive begins to cut/trim the work.

11. The knife bar then begins cycling back up to

the top of it's stroke (starting position).

12. As the knife bar approaches the top of it's

stroke, it passes the knife bar proximity sensor. The proximity sensor tells the control

circuit that the knife bar has reached the top of

it's stroke.

13. The control circuit then denergizes the trimming clutch solenoid which stops/ends the trimming cyle.

14. The control cicuit then energizes the gate solenoid, which lifts up the gate, and energizes

the infeed and middle conveyor belts.

15. The trimmed work is then conveyed out of the

trimmer and deposited on the discharge table.

16. When the next work to be trimmed is sensed

by number one photo sensor (on infeed table)

the control circuit energizes the discharge table

clutch for a short time. While the discharge

clutch is energized it runs the discharge table

conveyor belts. The belts move the work on

the discharge table a short distance. The control circuit then cuts power to the discharge

table clutch. The discharge table conveyor

belts and work stop moving until the next piece

of work to be trimmed causes the discharge

table cycle to repeat.

JAM DETECTION:

If the work does not finish passing over number

one photo sensor, within normal operating time,

the control circuit recognizes this as a jam. The

trimmer drive shuts off. The "PAPER JAM

WHEN LIT" indicator light becomes lit. A normally closed relay in the control panel (used as

the jam output to another machine or device)

closes.

11

Page 12

Trimmer

DANGER

NEVER REACH UNDER THE

KNIFE! SEVERE LACERATIONS

OR DISMEMBERMENT COULD

RESULT!

JAM CLEARING & RESTART:

1. Turn off power to the trimmer.

2. Remove work jam. DO NOT REACH UN-

DER THE KNIFE! SEVERE LACERATIONS OR DISMEMBERMENT COULD

RESULT.

3. Close all safety covers.

4. Depress "POWER ON" switch to turn on

power.

3. Depress "START/RESET" switch to energize

control cicuit. The electric motor and conveyor clutches will energize so trimming may

resume.

JAM OUTPUT:

(SK891C Scene 1)

(Fig 19)

BELT DRIVE:

The purpose of the "BELT DRIVE" rotary switch

(fig 19) is to make sure the work will square up

against the back stop to provide a good square cut

booklet.

When a jam occurs a normally closed relay in the

control panel closes. This relay is connected to

a .141" diameter female phone jack outlet (fig 18)

located on the power cord bracket. Any device

plugged into the phone jack will receive a closed

circuit signal, which that device can use to shut

down any upstream machines feeding work to the

trimmer.

(Fig 18)

12

The "1" setting means that the internal conveyor

belts will shut off quickly after the work is sensed

allowing time for the work to square up against

the back stop.

If the work does not square up fully against the

back stop before being trimmed, rotate the switch

to postition "2". This position allows the internal

conveyor belts to run for an additional short period of time (after the work is sensed) so that the

work will square up before being trimmed.

Positions "3" through "6" allow for progressively

longer conveyor belt running time for unusual work,

such as work that may slip on the conveyor belts,

to square up against the back stop.

Page 13

MAINTENANCE

The instructions on the following

pages are for the use of trained

personnel only!

Attempting to perform repair and

replacement procedures without

proper training may cause

machine damage or operator

injury!

13

Page 14

Trimmer

ADJUSTMENTS

(Fig 21)

(Fig 20)

KNIFE BAR SENSOR ADJUSTMENT:

The knife bar must always stop at the top of it's

stroke in order for work to enter the trimmer. If

the knife bar stops too low work will not be able

to get past the front clamp and/or knife, and work

jams will result.

The function of the knife bar sensor is to signal the

control circuit when the knife bar has reached the

top of it's stroke so that the control circuit can

denergize the trimming clutch causing the knife

bar to stop at the top of it's stroke.

1. With power on and drive motor running, use

the knife change toggle switch to jog the knife

bar to the top of it's stroke. If you can not

stop the knife bar at exactly the top of it's

stroke, it is better to stop it slightly before top

of stroke rather than after top of stroke.

2. Turn off and unplug power.

3. Remove the left cover.

4. Loosen the screws of the knife bar sensor,

move the sensor so that the top of the sensor

is even with the top of the knife bar (fig 20).

5. Reinstall the left cover.

BACK STOP GATE ADJUSTMENT:

The function of the back stop gate is to provide a

surface for the work to square up against so that

the knife will cut the work squarely. The back

stop gate must be parallel to the bottom knife.

1. Run several pieces of work through the trim

cycle.

2. By looking at the work, determine how much

one side or the other of the back stop gate

must be moved forward or backward.

3. Turn off and unplug power.

4. Remove rear discharge table.

5. Remove rear upper cover.

6. Open top cover.

7. Slide backgage carriage to front of machine.

8. Using a 3/8" box wrench and a 1/8" hex

wrench loosen and shift one of the shoulder

screws (fig 21) locating the back stop gate

(which will also shift the back stop gate)

forward or backward the amount needed to

square up the trim. Note: It may be necessary

to first move one shoulder screw and then the

other in order to obtain the maximum amount

of adjustment.

9. Reinstall lower cover and discharge table.

14

Page 15

(Fig 22)

FUSE ACCESS

Turn power off and unplug the machine. Remove

the rear upper cover (removal of four screws

required) above the work discharge area of the

machine. There are two fuse holders mounted on

the din rail. To access the fuses, pull out the fuse

compartment (fig 22) of each fuse holder and remove the fuses.

A. Motor Fuse: Fuse protects the motor input lines

of the machine. If this fuse fails, the motor

will not run. Replace with 6 amp fuse

#RTM1303F for 115Vac machine or 3 amp fuse

#RTM1330F for 230Vac machine.

B. Control Circuit Fuse: Fuse protects transformer.

If this fuse fails, none of the 24VDC components will operate. Replace with 1 amp fuse

#RTM1302F for 115Vac machine or 0.5 amp

fuse #RTM1329F for 230Vac machine.

PREVENTATIVE MAINTENANCE

LUBRICATION:

Disconnect electrical power. Next, remove the

front cover and both side covers.

Use SAE-20 oil to lubricate porous bronze bearings, plastic bearings, chains, shafts, and cutter

bar linkages.

CLEANING:

Use alcohol to clean the belts.

HARDWARE:

Remove the covers to check all nuts and bolts for

tightness. Loose hardware is the cause of most

component wear and in the electrical area could

cause short circuits and/or shock.

15

Page 16

Trimmer

KNIFE REMOVAL & INSTALLATION

(Fig 24)

(Fig 23)

UPPER KNIFE REMOVAL & INSTALLATION:

CAUTION: Changing knives can be very dangerous unless safety precautions are observed

and extreme care is taken when handling

knives

Keep handling of unprotected knives to

an absolute minimum.

Warn people of any unprotected knife.

Knife changing is a ONE PERSON OPERATION. Having more than one person trying to change knives invites accidents.

1. Use the "Knife Change" rocker switch to move

the knife bar to the bottom of it's stroke.

2. Turn off power and unplug power cord.

3. Remove bottom cover of infeed table.

4. Remove front upper cover and the lower bar

that the front upper cover attaches to.

5. Remove the left and right side covers.

6. Remove the four screws and nuts holding the

top infeed table's conveyor bracket to the infeed

table.

16

(Fig 25)

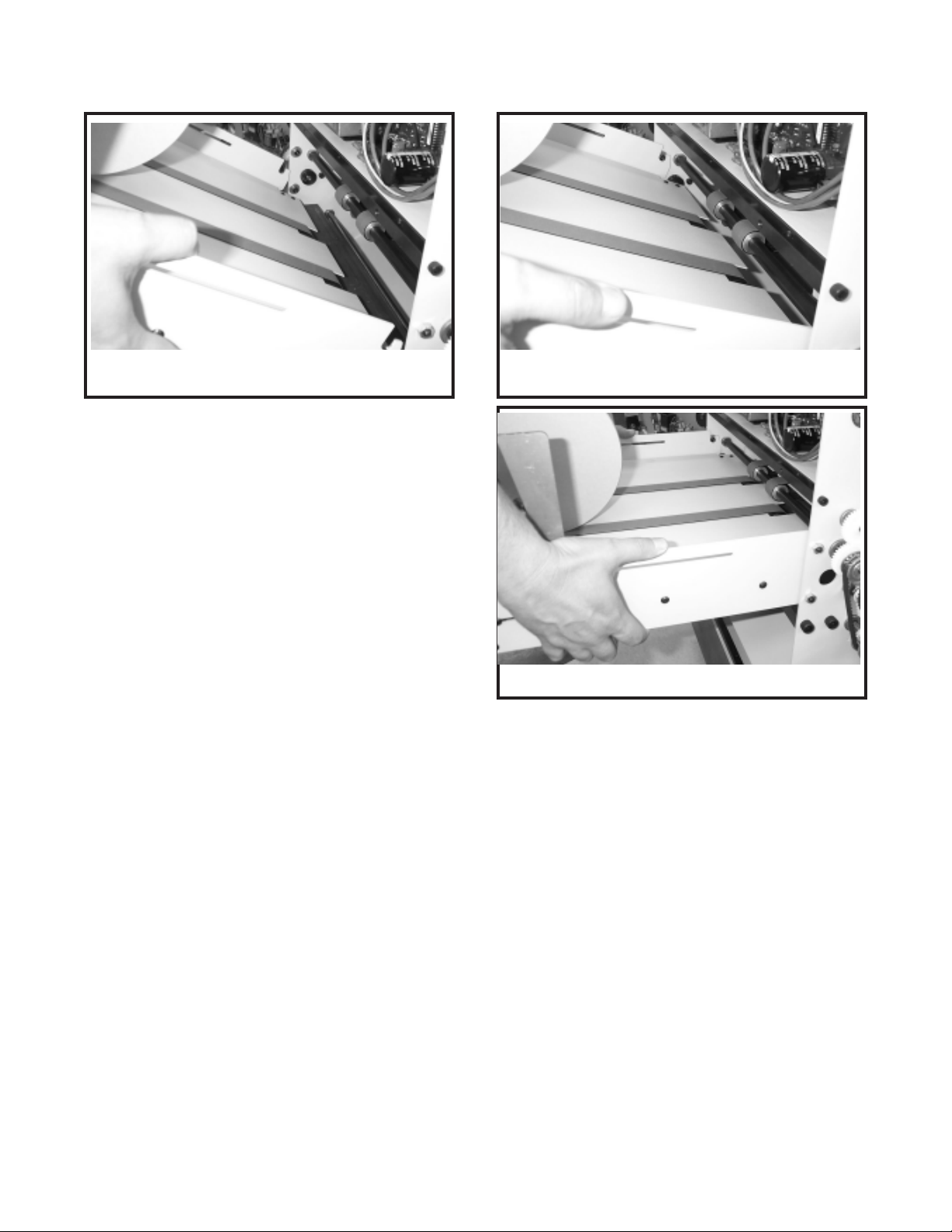

7. Carefully lift the right side of the upper infeed

conveyor bracket off the infeed table. Swing

it out and lay it on the infeed table (fig 23).

NOTE: Be sure the round belt does not come

off pulleys and be sure the separating finger

stays between belts where they cross or the

infeed table conveyors wil not operate properly when reassembled.

8. Loosen, BUT DO NOT REMOVE, all upper

knife screws so that the upper knife can be

slid away from the knife bar on the screws

about 1/8 inch (fig 24).

9. Remove only the four middle knife screws so

that the two end screws remaining are holding

the knife about 1/8 inch away from the knife

bar (fig 25).

Page 17

(Fig 26)

10. Insert a strong length of wire through the top

right screw hole in the knife. Pull the wire

through and securely tie the wire ends to make

a strong secure handle that will be used to lift

that end of the knife when the right screw is

removed (fig 26).

(Fig 27)

DANGER

NEVER PUT HAND OR FINGERS

BELOW KNIFE WHEN REMOVING

OR INSTALLING. SEVERE LAC-

ERATIONS OR DISMEMBERMENT

COULD RESULT.

11. Hold securely onto the wire handle and remove the right knife screw.

12. Use both hands to swing knife up, while pivoting on remaining lower left hand knife screw.

13. While holding knife securely with one hand,

remove last knife screw, and remove knife

from trimmer (fig 27).

14. Put blade in the scabbard immediately and

secure the knife retaining screws.

15. Reverse this procedure to install upper knife.

LOWER KNIFE REMOVAL:

THE UPPER KNIFE MUST BE REMOVED (per

steps 1-13 of Upper Knife Removal page 16 & 17)

BEFORE THE LOWER KNIFE IS REMOVED.

CAUTION: Changing knives can be very dangerous unless safety precautions are observed

and extreme care is taken when handling

knives

Keep handling of unprotected knives to

an absolute minimum.

Warn people of any unprotected knife.

Knife changing is a ONE PERSON OPERATION. Having more than one person trying to change knives invites accidents.

1. Once the upper knife is removed, cycle the knife

bar back up to the top of it's stroke by manually

releasing the trim clutch and turning the large

pulley on the clutch clockwise (fig 28) until the

knife bar is all the way up.

2. Loosen the five screws securing the lower

knife (fig 29).

3. Remove the lower knife.

17

Page 18

Trimmer

(Fig 28)

LOWER KNIFE INSTALLATION &

ADUSTMENT:

THE UPPER KNIFE MUST BE REMOVED (per

steps 1-13 of Upper Knife Removal pages 16-17)

BEFORE THE LOWER KNIFE IS INSTALLED.

1. Once the upper knife is removed, cycle the

knife bar back up to the top of it's stroke by

manually releasing the trim clutch and turning

the large pulley on the clutch clockwise (fig 28)

until the knife bar is all the way up.

WARNING

TURNING THE CLUTCH PULLEY

COUNTER CLOCKWISE AND/OR THE

KNIFE PULL DOWN DRIVE SHAFT IN

REVERSE WILL DAMAGE THE CLUTCH.

2. If installing a new or different lower knife, the set

screws which push the lower knife forward

against the upper knife, must be turned out so

that the lower knife will not be in the way of the

upper knife cycling down.

3. Install the five lower knife flat washers and

screws, but do not fully tighten because the

lower knife must be free to move during the

next steps of installation/adjustments.

4. Manually cycle the knife bar (similar to step

one ) to the bottom of it's stroke. Install and

secure the upper knife per upper knife removal & installation procedure page 16 & 17

5. Push lower knife firmly against the upper knife.

Turn the lower knife adjustment set screws

gently against the lower knife and secure with

the nuts. Manually release the trim clutch

and turn pulley until knife bar is at top of

stroke.

6. Tighten the lower knife securing screws. DO

NOT PLACE FINGERS OR HAND BELOW

UPPER KNIVE.

18

(Fig 29)

Lower Knife Securing Screws

Page 19

Lower Knife

Adjustment Screws

(Fig 30)

7. Manually release the trim clutch and cycle the

knife bar through one cycle to check that the

upper knife blade passes the lower knife

smoothly without obstruction.

8. Place a single sheet of paper (large size) between the upper and lower knives, manually

release the trim clutch and cycle the knife bar

through one cycle. KEEP HANDS CLEAR!

9. Check that a clean cut is obtained across the

full width of the knive blades.

10. If necessary loosen the lower knive securing

screws at the point where adjustment is

needed. Loosen the lower knife bar adjustment screws/nuts, move the lower knife closer

to the upper knife by turning the appropriate

adjustment screw (fig 30) (1/6 turn at a time),

retighten lower knife securing screws and nuts

of adjustment screws.

11. Perform another test cut and make further adjustments if necessary.

CLEARING A TRIMMING JAM:

If the maximum capacity of the trimmer is exceeded (50 sheets of 20# stock or 0.20" work

thickness) the trimming knife will stall near the

bottom of the trim cycle and not finish cutting the

work. If this happens the jam should be cleared

by removing the upper knife (follow steps 2 through

15 of UPPER KNIFE REMOVAL & INSTALLATION procedure page 16) and finishing the trim

cycle by hand (follow step 1 of LOWER KNIFE

INSTALLATION & ADJUSTMENT procedure

page 18).

WARNING

DO NOT TRY TO CLEAR THE TRIMMING

JAM BY TURNING THE CLUTCH PULLEY

COUNTER CLOCKWISE AND/OR BY

TURNING THE KNIFE PULL DOWN DRIVE

SHAFT IN REVERSE OR THE CLUTCH

WILL BE DAMAGED.

19

Page 20

Trimmer

KNIFE CARE TIPS

CAUTION: KNIFE SAFETY! Knives are

DANGEROUS!!! They are heavy and very

sharp, even after use. Keep the edge away

from your body and keep the area clear of

other people when handling knives. Never

touch the cutting edge! To prevent personal

injury and damage to the knife, always keep

knives in their holders with screws tightened. Others entering the area may not be

aware of the dangers. Never attempt to

hone, polish, or service the knife in any way.

Failure to follow safety procedures may result in severe lacerations or dismemberment.

Nicks are visible on the cutting edge of upper or lower knife.

Store knives in a dry environment to prevent corrosion.

Never attempt to service a knife in any way without proprer training. It is recommended to maintain a spare set of knives as a back up.

Knife blade life, or the time between sharpenings,

can be affected by many factors. One important

factor is the type of paper being cut. Abrasive

paper, such as recycled paper, soft paper such as

newsprint paper, and bound books can all significantly shorten knife blade life. Cutting pure

paper, such as bond paper with no recyled content

will cause less wear on the cutting blade. In all

cases the operator should continually check the

quality of the cut to determine when the knife

needs to be sharpened. Some characteristics that

indicate a blade needs sharpening are:

The knife hesitates or stalls while making a

cut.

The top sheets are not all cut to the same

length (usually the top few sheets are longer

than the rest of the sheets - this is sometimes

called "draw")

20

Cut marks appear on the cut face of the paper.

The knife and/or drive makes a "rough" sound

as the knife passes through the paper.

Page 21

NOTES:

21

Page 22

Trimmer

TROUBLE SHOOTING

PROBLEM:

1. The trimmer will not turn on.

2. Work is conveyed through trimmer

without being trimmed.

SOLUTION:

1. Plug unit into appropriate power supply.

2. Depress the "Power On/Off" switch.

3. If there is no green light:

a. Check for proper line voltage. (115V or 220V)

b. Make sure the top guard is closed.

c. Check the 1 amp control circuit fuse.

4. The green light is on, but the motor does not run.

a. Depress the "Start/Reset" toggle switch.

b. Check the 6A (115V) or 3A (220V) motor fuse.

1. Depress the "Trimming On/Off" switch to the "On"

position.

3. Trim is not square to book.

4. Work is not trimmed clean.

5. The upper knife does not go up far

enough to allow the work to pass below.

1. The work does not stop flat against the back stop gate.

a. Check that knife bar begins cycle at top of

stroke.

b. Make sure all lower and upper conveyor belts

on the infeed table and middle conveyor area

are clean and operating properly.

c. Switch the "Belt Drive" rotary switch to the

next higher number postion.

2. Backstop gate is not square to lower knife.

1. Dull and/or damaged upper and/or lower knife.

1. The proximity switch that senses the knife bar needs to

be adjusted upward.

22

Page 23

6. Knife stalls near bottom of trim cycle and

does not cut through work.

1. Maximum work thickness has been exceeded. Call MBM

dealer for service.

23

Page 24

Trimmer

Circuit Board: Light Layout

L10 L20 L19 L18 L17 L16 L15 L14 L13 L9 L8 L7 L6 L5 L4 L3 L2 L1

INPUTS L1-L9 (Yellow)

LIGHT APPLICATION

L1 Trim/No Trim Switch

L2 Knife Change Switch

L3 Knife Proximity Sensor

L4 Belt Drive Selector Switch

L5 Belt Drive Selector Switch

L6 Infeed Photosensor

L7 Gate Photosensor

L8 Start/Reset Switch

L9 Belt Drive Selector Switch

24

(RTM1172A-Layout1)

OUTPUTS L10-L20 (Red)

LIGHT APPLICATION

L10 Motor Power Relay

L13 Jam Light

L14 N/A

L15 N/A

L16 Discharge Clutch

L17 Conveyor Clutch

L18 Jam Detector Relay

L19 Gate Solenoid

L20 Cut Clutch

Page 25

Circuit Board: Normal Operation Light Sequences

PROCESS PERFORMED

1) Power Switch (on)

2) Start/Reset Button

3) Emergency Stop

4) Trimming Switch

5) Knife Change Switch

ILLUMINATED LIGHTS

L3, L6, L7,

L13, L18

L3, L6, L7,

L10, L17

NONE

See Side Note

*L3, L6, *L7,

L13, L18

SIDE NOTE

Have the belt drive position switch (fig. 19) in the zero

position, and also have the trimming switch on, this will

produce the desired light configuration. When the switch is

turned off there are no lights lit.

If holding the reset button down, L8, L16, and L19 will also

be lit. If only pushed and released, the previously mentioned

lights will only momentarily light. Both of these previously

mentioned conditions remain true for any subsequent start/

reset thereafter.

If the emergency stop button is twisted back into the nominal

position, the lights will display as in process number 1.

If the trimming switch is on, the lights will look the same as

in process 2. If the switch is off, the same is true but L1 is

also lit.

If holding the button down, the knife will cycle up and down

and the following lights will light. L2, L3, L6, L7, L10, L13,

L16, L17, L18, and L20 (L3 and L7 will flash on and off

simultaneously).

6) Belt Drive Knob

7) Open Lid

8) Passing Work

Through Trimmer

9) Infeed Photosensor

10) Gate Photosensor

See Side Note

NONE

L10, See Side Note

See Side Note

See Side Note

Starting at position 1: L4, L5, and L9 will be off. At position

2 L4 will turn on. At position 3 L4 will turn off and L5 will

turn on. At position 4 both L4 and L5 will be on. At position

5 L4 and L5 will be off and L9 will turn on. At position 6 L4

and L9 will be on.

If the lid is returned to the closed position, the lights will

display as in process 1.

Inputs: L6 first turns off and then relights. This is closely

followed by L7 turning off, and then L3 turning off. Outputs:

L17 turns off immediately followed by L20 turning on then off.

This is followed by L16, L17, and L19 turning on and then

L16 and L19 quickly turn off together. When done the light

pattern should be that of process 2.

Covering the front infeed photosensor will turn off L6. If L6

is covered for approximately 5 seconds, the machine

perceives a jam and L3, L7, L13, and L18 turn on.

Covering the gate photosensor will turn off L7. The

operational light sequence will follow that of process 8, but L6

will not relight before L7 turns off. Therefore if L6 and L7

are out together, all lights turn off except L3, L13, and L18.

A jam occurs when both the gate and infeed photosensors

are covered at the same time.

11) Auto Shut-Down

* Denotes that the light

may or may not be lit.

L3, L6, L7, See Side

Note

If the machine is on and running but not being used for

about 2 minutes, it will auto shutdown. L10 and L17 will turn

off, and L13 and L18 go on.

25

Page 26

3134 Industry Dr. N. Charleston, SC 29418

1-800-223-2508 1-843-552-2700

Fax: 1-843-552-2974

www.mbmcorp.com

FORM QF110 5-20-04

Loading...

Loading...