Page 1

256 LS

FOLDER

OPERATING MANUAL

REV. 03/05

MBM Corporation / 800-223-2508 / www.mbmcorp.com

Page 2

i

Rev. 03/05

Operating Manual Contents

Introduction

Thank You ......................................................................................................................1

Description ......................................................................................................................1

Product Features ..............................................................................................................1

Controls And Indicators ..................................................................................................2

Customer Assistance ........................................................................................................6

Terminology ....................................................................................................................6

Important Safety Information..........................................................................................8

Set Up

Support............................................................................................................................9

Power ..............................................................................................................................9

Feed Table Extension ......................................................................................................9

Exit Conveyor................................................................................................................10

Stacker ..........................................................................................................................11

Document Preparation And Loading ............................................................................12

Standard Folds

General Set Up ..............................................................................................................14

Fold Length Settings......................................................................................................15

Length Adjustments ......................................................................................................17

Folding Sequences..........................................................................................................18

Skew Adjustments..........................................................................................................19

Custom Folds

General Set Up ..............................................................................................................20

Fold Measurements And Settings ..................................................................................20

Adjustments ..................................................................................................................20

Maintenance And Troubleshooting

Paper Jams ....................................................................................................................21

Cleaning ........................................................................................................................27

Troubleshooting ............................................................................................................29

Contents

Page 3

1

Rev. 03/05

Operating Manual Introduction

Thank You

Thank you for purchasing the MBM 256 LS “Light Set” document folder.

Properly used and maintained, this machine will provide many years of

reliable service.

Description

The 256 LS imparts both standard and custom folds to cut-sheet documents from 3.25" x 5" (A6) up to 11" x 17" (A3).

Fold type and dimensions are set using the scales on the top tables and documents to be folded are stacked between guides on the feed table. The feed rolls

take the top sheet from the stack and feed it into the folding process. Finished

documents exit the folding process and are neatly stacked on the exit conveyor.

Product Features

The 256 LS incorporates advanced features for ease of operation, office

friendliness and reliability.

• Variable operating speed.

• Standard folds easily set with fold knob, paper size knob, and guide lights.

• Large, 400 sheet, document capacity.

• Top feed system takes a square stack of documents – no fanning needed.

• Fold tables are arranged in a “V” pattern for easy operator access and visibility.

• Quick, flip-slide-snap macro adjustments for paper stops in the center of

the fold tables.

• Convenient micro adjustment knobs for paper stops at the top ends of the

fold tables.

• Easy paper thickness and skew adjustments.

• Out-feed stacking rollers at the exit conveyor self-set for standard folds.

They can also be adjusted for custom folds.

• Powered exit conveyor provides neat stacking.

• Extended exit tray accumulates a large output.

• Insulated for noise reduction.

• Heavy gauge steel chassis for an extremely strong machine assuring perfect alignment.

• Split style fold tables allow easy maintenance by removal of only the top

portion of the tables – easy, light and free of power connections.

• Removable top roller for easy access and cleaning.

Page 4

2

Rev. 03/05

Introduction Operating Manual

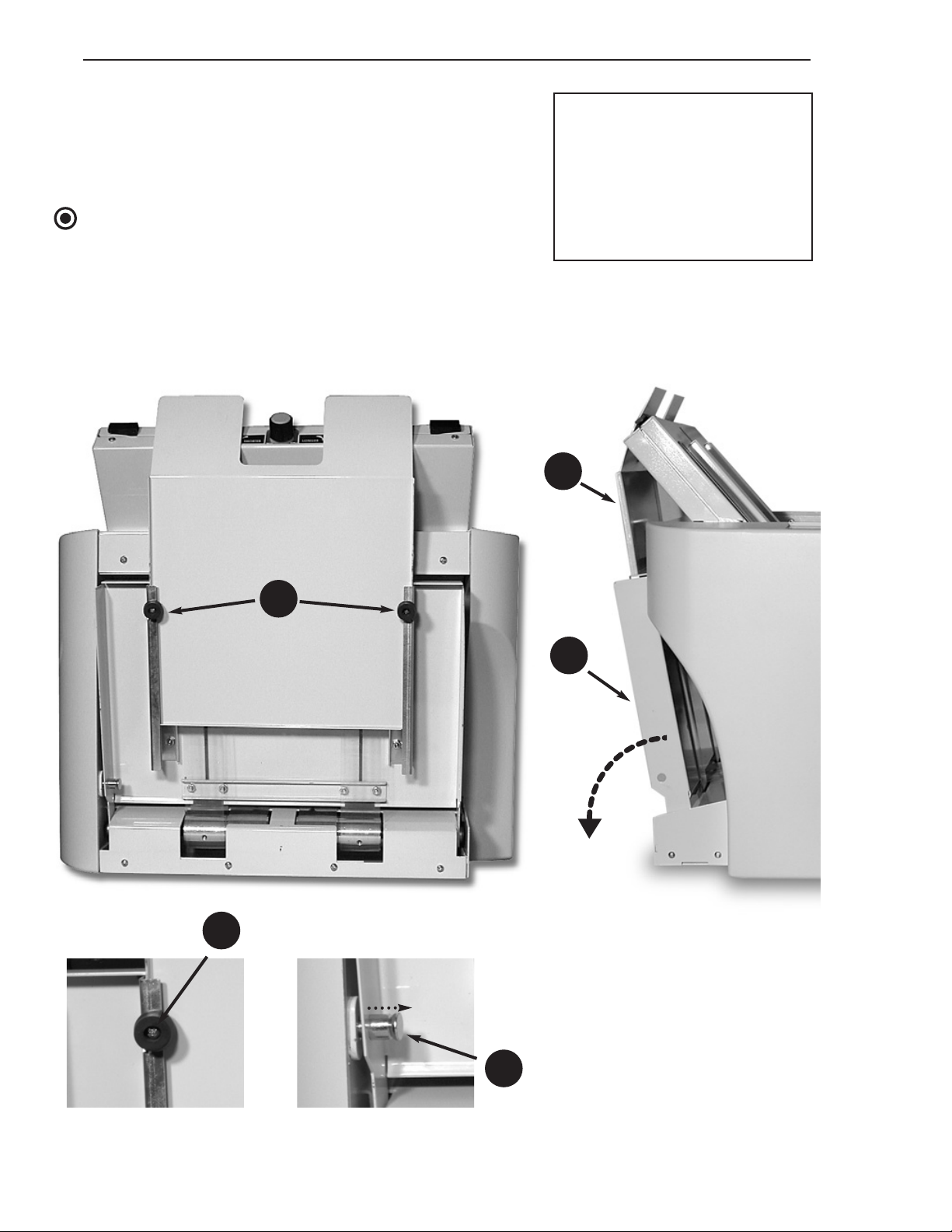

1. Exit Tray Retaining Screw

(No. 2 Phillips)

2. Exit Conveyor Foot

3. Exit Conveyor Latch

(pull to release)

4. Exit Conveyor (folds down)

5. Exit Tray

Controls and Indicators

This page and the next page show the folding machine

with the feed and exit devices folded to conserve table

space when the machine is not in use.

NOTE

The stacker assembly must be removed (see page 11) in

order to fold up the exit conveyor and tray.

See pages 4 and 5 for additional controls and indicators.

1

2

3

4

5

Page 5

3

Rev. 03/05

Operating Manual Introduction

6. Feed Table Extension (folds

down)

7. Feed Table Extension Latch

(pull to release)

8. Skew Adjustment Knob

9. Power Cord Socket

10. Fuse Drawer

11. Main Power Switch

33. Feed Table Lever

6

7

9

10

11

8

33

Page 6

4

Rev. 03/05

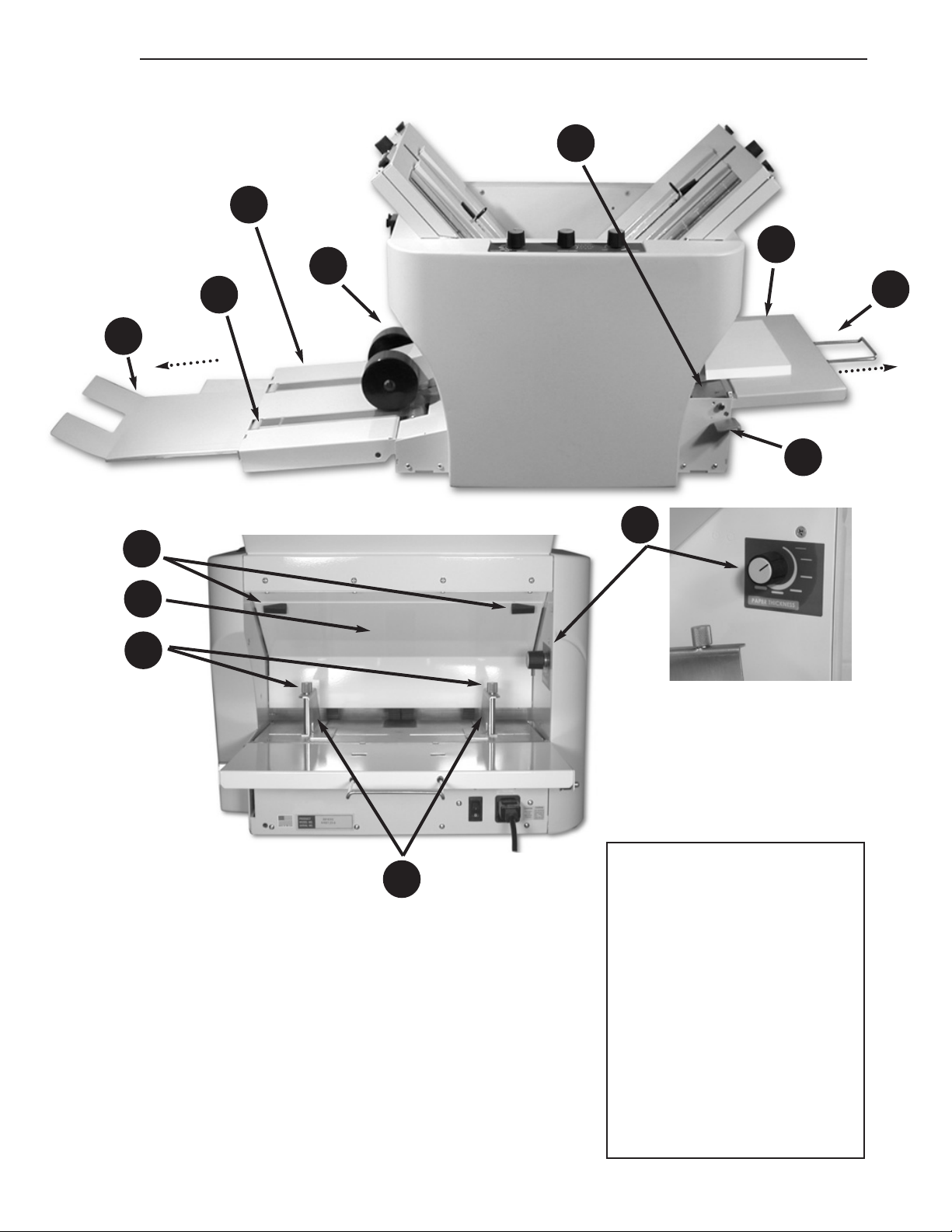

Introduction Operating Manual

12. Fold Table (first fold)

13. Fold Table (second fold)

14. Fold Stop Lever

15. Fold Stop Latch

16. Fold Length Fine

Adjustment Knob

17. Fold Table Scales

18. Control Cluster

A. Fold Selector Knob

B. Paper Selector Knob

C. Off/On/Speed Control Knob

19. Stacker Assembly Center

Knob (adjustment)

20. Stacker Assembly Thumb

Screw (attachment)

21. Stacker Assembly

22. Exit Conveyor Belt

23. Exit Area Access Door

24. Exit Area Door Latch

(pull to release)

25. Top Roller Release Lever

(rotate down to release roller)

Controls and Indicators

This page and the next page show the folding machine

with all its elements in their operating positions.

See pages 2 and 3 for additional controls and indicators.

NOTE

See page 11 for additional

stacker assembly detail.

23

24

12

13

18

A B C

19

14

15

20

21

16

16

17

17

22

25

Page 7

5

Rev. 03/05

Operating Manual Introduction

33

34

23

5

6

32

4

31

26

30

27

28

29

4. Exit Conveyor

5. Exit Tray

6. Feed Table Extension

26. Paper Guides

27. Paper Guide Lock Knobs

28. Paper Thickness

Adjustment Knob

29. Feed Area Access Panel

30. Feed Area Access Panel

Latch

31. Feed Table

32. Long Paper Support

33. Feed Table Lever

34. Stacker Assembly Roller

Page 8

6

Rev. 03/05

Introduction Operating Manual

Customer Assistance

Should you encounter any problems with this machine or not

understand its many features, please refer to this manual.

If you require further assistance after reading this manual,

please contact the authorized MBM Dealer or Distributor for

your location. These authorized Representatives employ factory

trained service technicians and stock genuine spare parts.

Terminology

Several terms have specific meanings as they are used in this manual:

DOUBLE-PARALLEL FOLD

A fold that divides the sheet into four panels. Useful for inserting

legal size sheets into business envelopes. This fold cannot be

made in sheets smaller than legal size.

EXIT END

The left end of the folding machine where the folded documents

exit the machine.

FEED END

The right end of the folding machine where the flat documents

are placed to enter the folding process.

FOLD TABLE

The sloping portion of the folding machine that controls the

position of the fold on the document. The first fold is formed

when the document is in the fold table to the right; the second

fold is formed when the document is in the fold table to the left.

GATE FOLD

A fold that divides the sheet into one panel that is half the length

of the sheet and two overlapping panels one quarter the length of

the sheet.

Page 9

Operating Manual Introduction

7

Rev. 03/05

Terminology

LEADING EDGE

The edge of the document that enters the folding process first.

LETTER FOLD

A fold that divides the sheet into three panels with the front of

the top and bottom parts of the sheet facing in. (Sometimes

called a “C” fold.)

OPERATOR SIDE

The side of the folding machine that is nearest the operator.

Operating controls can be conveniently reached from this side.

No controls are on the opposite side.

SINGLE FOLD

A fold that divides the sheet into two panels. This is the first fold

in the sheet and there is not a second fold.

STANDARD FOLD

Any of the five folds for which icons are shown on the fold table

scales when made in standard (8.5" x 11", 8.5" x 14" & 11" x

17") size sheets. Those five folds become custom folds when

made in other sheet sizes as do variations of the five folds in any

size sheet.

TRAILING EDGE

The edge at the last part of the document to be drawn into the

machine.

ZIG-ZAG FOLD

A fold that divides the sheet into three panels with the front of the

top part of the sheet facing out and the front of the bottom part

of the sheet facing in. This fold is often used to allow the address

to show through a window envelope. (Sometimes called a “Z” fold

or accordion fold.)

Page 10

8

Rev. 03/05

Introduction Operating Manual

Important Safety Information

To make the most of the folding machine, it must be operated and

maintained properly. Please read these operating and maintenance

instructions carefully before using the folder.

Special attention must be paid to the

WARNING and

CAUTION statements in this manual.

WARNING

Statements identify conditions that could result in personal injury or

loss of life.

CAUTION

Statements identify conditions that could cause damage to equipment

or documents being folded.

NOTE

Statements identify conditions that do not warrant a warning or caution,

but are unusual or may not be unexpected. They are also used to point

out available alternatives or to add emphasis to important points.

Before operating or maintaining the folding machine, please read

these general warnings and cautions.

WARNINGS

NEVER clean, clear or disassemble the machine without first unplug-

ging the power cord.

ALWAYS keep loose clothing, ties, scarfs, and hair away from all mov-

ing parts.

NEVER place fingers between or near moving parts.

CAUTIONS

DO NOT disassemble the machine further than removing access panels

and fold tables as shown in this manual. There are no user serviceable

parts in the unexposed areas.

NEVER allow liquids to splash or spray into the machine.

ALWAYS stop the feeding of documents at the first indication of jams

or improper folds.

TRY OUT new folds on blank paper before loading documents that

cannot be readily replaced.

Page 11

9

Rev. 03/05

Operating Manual Set Up

Support

Place the folding machine on a solid table or

stand in a position where the operator has

access to both ends of the machine as well as to

the operator side of the machine.

WARNING

Always use two people to lift and position the

machine. In addition to its weight, the size of

the machine can place a single person in an

awkward or unbalanced position.

Adequate space should be provided near the

machine for flat and folded documents.

Power

Connect the folding machine to a 120V or 220V

power outlet with the supplied cord to match

the voltage for which the machine is set. The

cord plugs into the socket (9) at the bottom

right corner of the feed end of the machine.

After set up is complete, the main power switch

(11) can be turned on to activate the machine.

The fuse drawer (10) contains two T3.15AL250V

fuses, one in the hot line and one in the neutral.

Both fuses must be in place for the folding

machine to operate.

WARNING

Unplug the power cord before removing the

fuse drawer.

Feed Table Extension

If the feed table extension (6) has been folded

up, pull the feed table extension latch (7) and

lower the extension to the operating position.

For sheets longer than 14”, pull out the long

paper support (32) to support the trailing edge

of the documents.

9

10

11

32

6

7

6. Feed Table Extension

7. Feed Table Extension Latch

(pull to release)

9. Power Cord Socket

10. Fuse Drawer

11. Main Power Switch

32. Long Paper Support

Voltage Setting

Indicator

Page 12

10

Rev. 03/05

Set Up Operating Manual

5

4

Exit Conveyor

If the exit conveyor (4) has been folded

up, pull the exit conveyor latch (3) and

lower the exit conveyor to the operating

position.

The exit tray (5) can be extended if more

than a few documents are to be folded in

a batch.

NOTE

After lowering the exit conveyor, re-attach

the stacker assembly (see page 11).

NOTE

If the exit tray (5) has not been assembled

to the exit conveyor (4), slide the exit tray

into the guides in the underside of the exit

conveyor and assemble the exit tray retaining screw (1) with the exit conveyor foot

(2) into the pre-drilled holes in the guides.

3

5

4

1

2

1. Exit Tray Retaining Screw

2. Exit Conveyor Foot

3. Exit Conveyor Latch

(pull to release)

4. Exit Conveyor

5. Exit Tray

Page 13

11

Rev. 03/05

Operating Manual Set Up

20

20

19

21

35

36

37

Ready to Attach

Attached

Stacker

To attach the stacker assembly (21) to the machine, position it

above the exit conveyor and fasten it with the stacker assembly

thumb screws (20) as shown in the two illustrations at left.

After the stacker assembly is attached to the machine:

FOR STANDARD FOLDS:

1. Move the fold stop lever extension (36) to about the midpoint of the table.

2. Engage the extension with the stacker connection slider

(35) and insert the snap pin (37). The stop lever extension

fits into the slot in the stacker connection slider and their

holes must be aligned to insert the snap pin as shown in

the detail illustration.

3. Allow the stacker to self-adjust its position to each fold.

CAUTION

The stacker assembly center knob (19) must be loose (turned

fully counter-clockwise) when the stacker is connected to the

stop lever extension.

FOR CUSTOM FOLDS:

1. Pull the snap pin (37) to disconnect the stacker assembly

from the stop lever extension.

2. Place a sample of the custom folded sheet at the machine

exit.

3. Manually position the stacker assembly rollers (34) about

1” from the folded sheet.

4. Tighten (clockwise) the stacker assembly center knob (19)

to keep the stacker in position.

19. Stacker Assembly Center

Knob (adjustment)

20. Stacker Assembly Thumb

Screw (attachment)

21. Stacker Assembly

34. Stacker Assembly Roller

35. Stacker Connection Slider

36. Fold Stop Lever Extension

37. Snap Pin

36

37

35

34

Page 14

12

Rev. 03/05

Set Up Operating Manual

33

Document Preparation

And Loading

The stack of documents to be loaded should

be squared up as much as possible — to look

similar to the stack that comes out when a

new ream of paper is unwrapped.

To load the document stack:

1. Depress the feed table lever (33) to lower

the leading edge of the feed table (31).

2. Insert the document stack all the way into

the machine until it rests firmly against the

stop.

NOTE

The documents should be inserted with the

printed or front side up.

3. Move the self-aligning paper guides (26)

inward until they are just snug against the

document stack.

4. Tighten the paper guide lock knobs (27) on

both guides to keep them snug against the

stack.

5. After the guides have been locked, return

the feed table to its level position by raising

the feed table lever (33).

The stack will be captured between the feed

table at the bottom and the feed rollers at

the top.

26

27

33

RAISE

DEPRESS

ADJUST

INSERT

31

26. Paper Guides

27. Paper Guide Lock Knobs

31. Feed Table

33. Feed Table Lever

Page 15

13

Rev. 03/05

Operating Manual Set Up

Document Preparation

And Loading

After raising the feed table, adjust the paper

thickness adjustment knob (28) to match the

stock on which the documents are printed.

The knob has six detented positions to adjust

for paper from thin to thick. The knob is

shown at the second tick mark for 20 pound

paper. As paper thickness increases, rotate the

knob clockwise.

NOTE

Paper feed characteristics vary depending on

humidity, paper surface, type of ink used to

print the document, and other factors.

Therefore, settings for one document of a given

thickness may not be the same as those for

another document of the same thickness. A certain amount of trial and error may be necessary

with this adjustment.

NOTE

Heated processes such as in copiers and laser

printers can cause paper to curl. Be sure the

documents are flat before loading them into

the folding machine. If necessary, reverse curl

the documents to flatten them.

NOTE

It may be possible to fold thicker sheets or specially finished paper on the folding machine. If

these will not run with the available range of

user settings, contact the local authorized

MBM Dealer or Distributor for assistance.

28

28. Paper Thickness

Adjustment Knob

Page 16

14

Rev. 03/05

Standard Folds Operating Manual

To set up the folding machine:

1. Make initial length settings for the first and

second folds. (see pages 15 and 16).

2. Load a few sheets of blank paper between the

paper guides on the feed table (see page 12).

3. Turn the off/on/speed control knob (18) to

fold two or three sheets.

4. Check that the fold is as desired.

5. Make fine adjustments in the fold length (see

page 17) and skew (see page 19). Test until

the fold is as desired.

6. Remove trial material, load the document

stack and turn on the switch.

Standard Folds

The scales on the folding machine fold tables contain

symbols and guide lights for the five most popular

folds and colored bands for the three most popular

paper sizes. This makes it easy to adjust the machine

for these folds.

Only the simple controls at the top of the folding

machine are needed to set up the machine.

NOTE

Before changing fold settings or making

fine adjustments, be sure the folding

area of the folding machine is cleared of

all sheets. Either:

• Let the feed area run out of paper.

• Press thumb or finger lightly on top of

the stack on the feed table while the

machine is running. (See illustration

at the top of page 16.) Feeding will

stop and the machine will clear itself.

This allows repeated trials without

reloading paper each time.

12

13

18

14

15

16

16

17

17

12. Fold Table (first fold)

13. Fold Table (second fold)

14. Fold Stop Lever

15. Fold Stop Latch

16. Fold Length Fine

Adjustment Knob

17. Fold Table Scales

18. Control Cluster

A. Fold Selector Knob

B. Paper Selector Knob

C. Off/On/Speed Control Knob

A B C

Page 17

15

Rev. 03/05

Operating Manual Standard Folds

Initial Fold Length Settings –

Using Guide Lights

The most convenient means of making the initial fold

length settings is by use of the control knobs (18) and

the guide lights (46) that show through the inch scales

on the fold table scales (17).

This illustration shows the control knobs (18) and the

location of all of the guide lights (46) on the scales.

However, only one guide light will show on each scale

at any given time.

To make the initial fold length settings:

1. Rotate the fold knob (18 A) to the

desired standard fold type.

2. Rotate the paper size knob (18B) to the

desired standard paper size.

3. Observe the guide lights on the fold

tables.

4. Move the indicators (38) so they are

adjacent to the lights (See page 17).

The illustration below shows the guide light

and indicator in position for the second fold

of a letter or zig-zag fold in an 8.5” x 11” sheet.

NOTE

The indicator may be slightly off center

after adjustment to get a perfect fold.

Different paper types and weights will

have slightly different positions on the

paper stop indicator.

14. Fold Stop Lever

15. Fold Stop Latch

18. Control Cluster

A. Fold Selector Knob

B. Paper Selector Knob

38. Fold Length Indicator

46. Guide Light

46

15

46

38

14

38

18A

18B

Page 18

16

Rev. 03/05

Standard Folds Operating Manual

Initial Fold Length Settings –

Using Scales

Instead of the guide lights fold lenth setting’s can be made using the symbols on

the colored scales

The scales (17) on the fold tables are as

shown (second fold scale illustrated) with

bands of:

• Light blue for 11" x 17"

• Medium blue for 8.5" x 14" (legal size)

• Dark blue for 8.5" x 11" (letter size).

Fold symbols on the colored bands have

leader lines to show where the indicator

(38) should be positioned for that fold.

The illustrated example shows the indicator position for the second fold in an 11" x

17" sheet for either a single fold or a gate

fold. The setting for the first fold will

determine which of the two will result

from this second fold.

Move the indicator to the leader line corresponding to the desired fold and paper size

(see page 17).

NOTE

The indicator may be slightly off center

after adjustment to get a perfect fold.

Different paper types and weights will have

slightly different positions on the paper

stop indicator.

14. Fold Stop Lever

15. Fold Stop Latch

38. Fold Length Indicator

PRESS

15

38

14

Page 19

17

Rev. 03/05

Operating Manual Standard Folds

To move the indicator to the desired fold position, rotate the latch (15) up to the stop lever

(14) and slide the stop lever up or down the

table. The indicator will move with it.

Rotate the latch down to lock the lever and

indicator in place.

Length Adjustments –

After Initial Settings

Fine adjustment of the fold length is accomplished with the fine adjustment knob (16).

When adjusting fold length with this control,

at least one full rotation of the knob will be

required to make a noticeable change.

To make fine adjustments in the fold length:

1. Evaluate whether the first fold needs to be

nearer to the leading edge of the sheet or

further away from it. Then, evaluate

whether the second fold needs to be nearer

to the first fold or further away from it. (See

page 17 for fold sequences.)

2. Turn the fine adjustment knob (16) in the

shorten direction if the first fold needs to

be nearer the leading edge. Turn it in the

lengthen direction to move the fold further

down from the leading edge. Make corresponding adjustments for the second fold

if needed.

Latch Down–Adjustment Locked

14

15

16

14. Fold Stop Lever

15. Fold Stop Latch

16. Fold Length Fine

Adjustment Knob

Fold Settings

Page 20

18

Rev. 03/05

Standard Folds Operating Manual

Length Adjustments

Example:

Two imperfect letter folds and their corrections demonstrate examples of using

the fine adjustment knob.

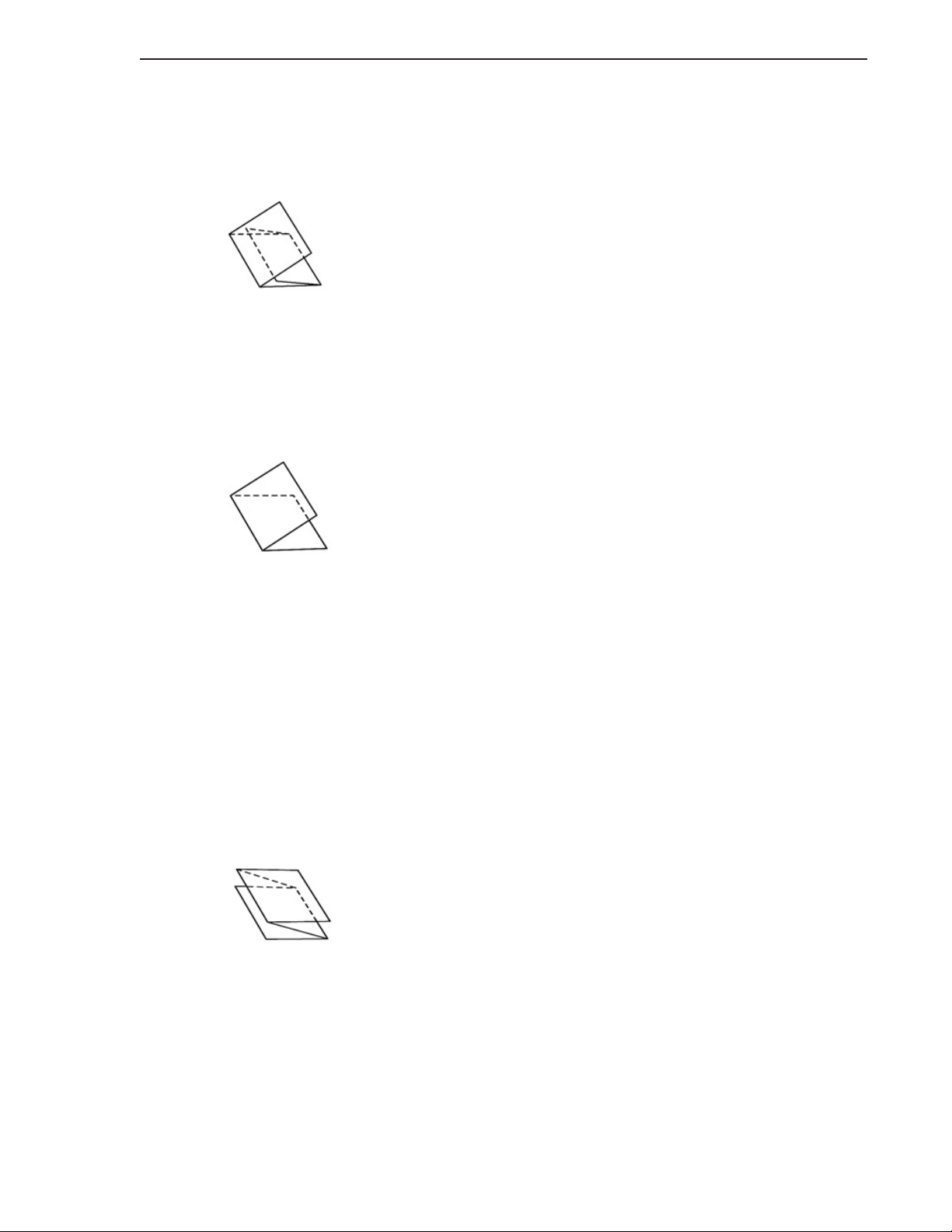

Folding Sequences

The following illustrations of the five

preset folds can be used to evaluate the

finished product. All measurements are

from the leading edge of the sheet.

NOTE

When fed into the folding machine as

shown to the left, the letter and zig-zag

folds will position the letterhead and

address properly as shown.

Corrective action:

• Shorten first fold

• Lengthen second fold

Corrective action:

• Lengthen first fold

• Shorten second fold

Trailing Edge

Trailing Edge

Zig- Zag Fold

Address Outside

LETTERHEAD

Letter Fold

Address Inside

Feed Direction

Page 21

19

Rev. 03/05

Operating Manual Standard Folds

Skew Adjustments

Folds that are not perfectly parallel to the

leading and trailing edges of the sheet can

be corrected with the skew adjustment

knob (8).

NOTE

Before making any skew adjustments, be

sure the paper thickness adjustment (see

page 13) is properly set for the paper

being folded. Running thick paper with a

setting for thin paper can sometimes cause

skewed folds.

To evaluate skewed folds:

1. Unfold the skewed sheet.

2. Observe whether the end of the fold at

the right side of the sheet is further or

closer to the leading edge of the sheet

than the end of the fold at the left side.

NOTE

The top of the skew adjustment knob can

be reached without folding up the feed

table or unloading paper from the feed

area.

To make a skew adjustment:

1. Rotate the skew adjustment knob two

or three turns in the appropriate direction

2. Remove and reload the paper stack.

3. Fold three or four trial sheets and

observe the effect on the squareness of

the folds.

4. Further adjust the skew knob and make

trial folds until the folds are parallel

with the leading and trailing edges of

the sheet.

8

Leading Edge

LETTERHEAD

Unfolded Sheet

Skew to left

Adjust Clockwise

Folded Sheet

Skew to left

8. Skew Adjustment Knob

LETTERHEAD

Page 22

20

Rev. 03/05

Custom Folds Operating Manual

Custom Folds

The folding machine can be used to fold a

variety of sheet lengths and widths into the

preset fold types or into variations of them.

All custom folds are set up by first folding a

sample sheet into the desired fold, then

measuring two distances:

1. From the leading edge to the first fold.

2. From the first fold to the second fold.

(See page 18 for folding sequences)

These distances are then set using the inch

scales on the fold tables. In the illustration,

the indicator (38) is set at 8.5".

The dimension of the first fold should be set

on the first fold table (to the right) and the

second on the second fold table (to the left).

Two measurement examples are illustrated.

Make fine adjustments to the fold lengths in

the same way as described for standard folds

(see page 17).

NOTE

The guide lights are not used to make settings for custom folds.

NOTE

Treat a single fold as if it were the second

fold. Set the indicator on the first fold table

all the way down to the single fold icons.

Then set the dimension to the fold on the

inch scale on the second fold table.

Trailing Edge

Trailing Edge

38

Zig-Zag Fold

First Fold

Second Fold

LETTERHEAD

First

Measurement

Second

Measurement

Letter Fold

First Fold

Second Fold

LETTERHEAD

First

Measurement

Second

Measurement

38. Fold Length Indicator

Inch

Scale

Page 23

21

Rev. 03/05

Operating Manual Maintenance and Troubleshooting

Paper Jams

Paper jams can occur at all three

stages of the folding process. In the:

• Feed area

• Central folding area

• Exit area.

All these areas are easily accessible

without the use of tools as shown in

the following sections.

WARNING

Before attempting to clear any jam or

open any access panels, turn off the

main power switch (11) and remove

the power cord from the socket (9)

(see page 9).

CAUTION

Do not attempt to clear jams by poking sharp objects into the openings

or by cutting sheets wrapped around

rollers. Permanent damage to both

the resilient and metal rollers is likely as a result of any use of knives or

sharp objects. Remove jammed

sheets only by carefully pulling them

out or unwrapping them using only

your hands and fingers.

Feed Area Clearing

To clear a jam in the feed area:

1. Remove the document stack from

the feed table (31).

2. Release the two access panel latches (30) by rotating them down

and remove the access panel (29)

by pulling it out.

3. Clear the paper from the feed area.

30

29

30

REMOVE

LOWER

31

28

28. Paper thickness adjustment knob

29. Feed area access panel

30. Feed area panel latch

31. Feed table

Page 24

22

Rev. 03/05

Maintenance and Troubleshooting Operating Manual

Feed Area Clearing

NOTE

The feed rollers can be turned

by hand (in one direction only)

by pulling on the top of a roller

or by turning the axle.

After the jam is cleared:

1. Insert the access panel, keeping it above the paper thickness adjustment knob (28)

and being sure the notches

on the access panel (29)

engage the pins near the feed

roller axle.

2. Refasten the access panel by

raising it fully up to the mating

flange and rotating the two

latches to the locked position.

RAISE

FEED ROLLERS

PINS

NOTCHES

Page 25

23

Rev. 03/05

Operating Manual Maintenance And Troubleshooting

Central Folding

Area Clearing

The folding process takes place in the

area within the fold tables. To reach

this area, both of the fold table tops

must be removed.

To clear a jam in the central folding area:

1. Release the two latches (39) at the

top of each fold table.

2. Move the fold stop levers (14) near

the center of the table to provide

clearance for removing the fold

table tops.

3. Slide each fold table top upward a

few inches to clear the guides at the

bottom, then lift it off the machine.

The top roller (40) and lower fold

tables will be visible.

25

39

40

25. Top roller release lever

39. Fold table latch

40. Top roller

Page 26

24

Rev. 03/05

Maintenance and Troubleshooting Operating Manual

Central Folding Area

Clearing

4. Release the two top roller release

levers (25) in the exit area.

5. Grasp the top roller and lift slightly.

Push straight into the far side until

the near end is clear of the side

frame. Rotate the near end of the

roller up and the roller out of the

bearing seat to remove it.

6. Clear the paper from the fold area.

NOTE

The bottom roller (41) can be rotated

by hand to unwrap sheets

7. Re-assemble the center fold area by

reversing the dis-assembly steps.

NOTE

Roller bearings are pressed onto the

ends of the top roller. When re-inserting the roller into the machine, be sure

the roller is centered between the side

frames and the bearings have settled

into their seats.

NOTE

Do not forget to re-engage (rotate

upward) the two top roller release

levers (25) in the exit area.

NOTE

The bottom roller is the most important one to be cleaned. Whenever it is

exposed, check it and clean if necessary

(see page 28).

BEARING

TOP ROLLER

BEARING SEAT

41

41. Bottom Roller

Page 27

25

Rev. 03/05

Operating Manual Maintenance And Troubleshooting

Central Folding Area

Clearing

NOTE

When sliding the fold table tops down

into position during re-assembly, be

sure both of them fit under the fold

table top guides (42) and the table tops

are slid completely in before rotating the

latches down to lock them in place. The

silver alignment tabs between the latches must be in the slots in the end of the

fold table top and flush with its surface.

Exit Area Clearing

To open the exit area of the folding

machine, the stacker assembly (21)

must first be removed. Refer to page 11

describing the installation of the stacker assembly and remove it by reversing

the installation process.

NOTE

The top roller release levers (25) must

be engaged (up position) to allow the

door to swing down.

To clear a jam in the exit area:

1. Pull the two exit area door release

latches (24) and lower the door (23).

23

20

21

24

25

20. Stacker assembly thumb screw

21. Stacker assembly

23. Exit area access door

24. Exit area door latch

25. Top roller release lever

42. Fold table top guide

42

24

Page 28

26

Rev. 03/05

Maintenance and Troubleshooting Operating Manual

Exit Area Clearing

2. With the exit area access door

(23) fully lowered, grasp the foam

exit roller (43) at both ends and

pull it straight out of its C-shaped

bearing seats.

3. Clear the paper from the exit area.

4. Re-assemble the exit roller into its

bearing seats (44) by pushing it

straight into the bearing seats

until a light click is heard or felt.

5. Close the door and re-install the

stacker assembly.

43

43

44

23. Exit area access door

43. Exit roller

44. Exit roller bearing seat

Page 29

27

Rev. 03/05

Operating Manual Maintenance And Troubleshooting

Cleaning

As the folding machine is used, the feed, fold

and exit rollers can become coated with a

build-up of paper dust, ink or toner transferred

from printed documents. This build-up can

cause roller traction to change and result in

improper folds due to slippage or hang-up

between the rollers and documents. It can also

result in smudges on folded documents from

ink or toner being re-transferred off the rollers.

If folds start to change without changing

machine settings or if smudges are observed,

stop the folding process and clean the rollers.

WARNING

Turn off the main power switch and pull the

power cord plug out of its socket before beginning any cleaning process.

To clean the rollers:

1. Refer to the paper jams section (pages 21 to

26) for instructions on gaining access to the

feed, fold and exit areas of the folding

machine.

2. Use a clean cloth and isopropyl alcohol to

wipe the roller surfaces. If alternative cleaners are to be used, be sure they will evaporate

completely without leaving a soapy film on

the rollers.

FEED END

The four feed rollers can be rotated by hand.

Pull on the top surface of one of the rollers to

expose the entire surfaces for cleaning.

FEED ROLLERS

Page 30

28

Rev. 03/05

Maintenance and Troubleshooting Operating Manual

FOLD AREA

The top roller (40) can be cleaned after it has been

removed. With the top roller removed, the bottom roller (41) can be rotated by hand in both

directions to reach the whole surface. The bottom

roller should be thoroughly cleaned all the way

around. This is critical to proper operation.

EXIT END

The removable exit roller (43) can be cleaned

outside the machine. The fixed exit roller (45)

can be rotated on its axle by hand. It will also

move when one of the fold rollers is rotated.

Either way, the whole surface of the fixed exit

roller can be exposed.

3. Allow all surfaces to dry before reassembling

the components and closing the access panels.

CAUTION

Do not use strong solvents in the cleaning

process. The compounds in the rollers may be

damaged.

NOTE

Whenever the folding machine is opened to clear

paper jams, it is a good idea to look at the rollers

and clean them if needed.

45

43

41

40

40. Top roller

41. Bottom roller

43. Exit roller (removable)

45. Fixed exit roller

Page 31

29

Rev. 03/05

Operating Manual Maintenance And Troubleshooting

Troubleshooting

The following tables provide areas to check and corrective actions for some problems that may

arise.

NOTE

The guide lights along the folding scales should glow red when the main power switch is turned

on and all latches are properly closed to activate their associated safety interlocks. If the guide

lights do not glow, perform the checks in the first table until the guide lights are illuminated.

Machine will not run when start/stop switch is turned on:

WARNING

Before taking corrective action to clean rollers, be sure the power cord is disconnected.

Paper does not feed when start/stop switch is turned on:

Correction

Verify that the wall outlet has power and push plugs

all the way into sockets.

Turn on the main power switch.

Remove the power cord from the socket and check

the fuses (see page 9). Replace fuse if blown.

• Check that the fold tables are fully seated and that

the silver alignment tabs are in their slots

(see page 25).

• Close all fold table latches to activate safety

switches.

Clear paper jam.

Check

Is power cord plugged

into a live outlet and fully

inserted in the socket on

the machine?

Is the main power switch

turned on?

Is a fuse blown?

Are the fold tables fully

seated and latched?

Is there a paper jam in

the machine?

Correction

• Check for paper in feed area.

• Check that the feed table lever is up.

• Check that the paper has been fully inserted to the

stop before raising the feed table.

• Clean the feed rollers (see page 27).

• Change paper if possible. Some types of paper

(especially coated stock) do not feed well.

Loosen guides and readjust to be just snug against

the paper stack. Retighten guide lock knobs.

Check

Is paper properly loaded?

Are feed rollers slipping on

the top sheet of the paper

stack?

Are paper guides too tight?

Page 32

30

Rev. 03/05

Maintenance and Troubleshooting Operating Manual

Paper feeds irregularly:

WARNING

Before taking corrective action to clean rollers, be sure the power cord is disconnected.

FACTORY TRAINED SERVICE

If the problem cannot be solved using these troubleshooting methods, contact the authorized

MBM Dealer or Distributor for your location to obtain help from a factory trained technician.

Should the problem be severe enough that the folding machine must be returned to the

factory, the authorized MBM Dealer or Distributor will properly package the machine to

avoid damage in transit.

Correction

Clean the feed rollers (see page 27).

Adjust the knob to the paper thickness being used

(see page 13).

Remove paper, bend the paper stack back and forth

to break the bonds, re-square the stack and reload.

Be sure that all sheets in the stack are even with one

another.

Remove and reverse curl the paper to flatten it, then

reload.

Check

Are the feed rollers clean?

Is the paper thickness knob

set properly?

Are paper sheets stuck to

each other?

Is the paper stack square?

Is the paper curled?

Fold quality is poor:

Correction

• Reset the fold dimensions and fine adjustments on

the fold tables (see pages 14 to 20).

• Clean the fold rollers under the fold tables (see

page 28)

• Be sure paper is loaded squarely on the feed table.

• Skew can be caused by running thick paper with

the paper thickness adjustment set for thin paper.

Adjust the knob (see page 13).

• Too much paper in the stack can cause skew.

Reduce stack to 400 sheets or less.

• Make correction with the skew adjustment knob

(see page 19).

• Clean the feed and fold rollers

(see pages 27 and 28).

Check

Are fold dimensions as

desired?

Are the folds square with

the edges of the paper?

Loading...

Loading...