MBM 1800S Service Manual

Sales • Service • Repair

Professional Service – Fast Nationwide Shipping

1-866-455-9900

www.OnlineSkyline.com

CustomerService@onlineskyline.com

SERVICE MANUAL

MBM Air Suction Folder

Model 1800S

MBM Corporation

Ver. 03 160939 NW

2

CONTENTS

1. Safety Instructions …………………………….……………………... 4

2. Caution during Maintenance Service ………………………………. 7

3. P

arts Names ………………………………………………………….. 8

4. Designation and Functions of Operati

on Panel ……………..……. 10

5. Operations …………………………………………...……………… 1

1

6. St

ructure of the sections

6-1 Layout Drawing of Overall Machine ............................................................. 12

6-2 Covers ............................................................................................................. 13

6-3 Layout of Motor and Solenoid ....................................................................... 14

6-4 Layout of Sensors, Switch (SW) and Solenoids ............................................ 15

6-5 Wiring Diagram .............................................................................................. 16

6-6 Suction Section ............................................................................................... 17

6-7 Paper Height Detection Section ..................................................................... 17

6-8 Drive Section .................................................................................................. 18

6-9 Separating Air Section .................................................................................... 18

6-10 Paper Transport Section .................................................................................. 19

6-11 Paper Feed Table ............................................................................................ 19

6-12 Control Section ............................................................................................... 20

6-13 Option ............................................................................................................. 20

7. Skew Adjustment ………………………………………..…………...21

8. Dis

assembling Suction Belt Assembly (Exchanging Suction Belt)...23

9. E

xchanging Clutch Unit……………………………...………………27

10. E

xchanging Solenoid Unit ……………………...…………………..28

11

. Replacing Separator

Rubber …………...………………………… 28

12. Repl

acing Timing Belt …………………………………………….. 29

3

13. Replacing Interceptor ……………………………………….......... 31

14. Rem

oving Paper Guide at Transport Section (Replacing

Feed Sensor and/or Ultrasonic Double Feed Sensor) ………...…. 31

15. Rem

oving Paper Feed Table (Replacing Paper

Empty

Sensor and/or Paper Sensor for inch size paper) ………...………32

16. Replacin

g Other Sensors (

Paper Floating Height Sensor, Top Cover

Switch, Paper Ejection Sensor and Others

) …………...…………….… 33

17. Repl

acing Paper Ejection Belt and Replacing Ejection Roller

Home Position Switch ………………………...………………..…. 34

18. Zer

o Setting of Folding Tables 1 and 2 ………….. ……………… 35

19. T

est Mode ………………………………………………...………... 36

20. Check Lamps, Err

or Codes and Troubles ……………………….. 37

21. T

roubleshooting ……………………………………………...……. 39

22. E

rror Codes …………………………………………….

………….. 42

23. Other

Troubleshooting and Cleaning ……………...………………43

24. Other

Adjustable Functions (Weight Arm an

d

T

able 2 Base Plate) ………………………………………………… 44

4

1. Safety Instructions

Definition of Symbols and Notes

The following names and signs stand for possible dangers.

Danger

This symbol stands for immediate danger. Disregarding these instructions may cause severe injury.

Caution

This symbol stands for a potentially dangerous situation. Disregarding these instructions may lead to

injuries or damage to property.

Danger

Make sure that the machine is electrically grounded to prevent electrical shock.

Operate the machinery within reasonable voltage range. There is a risk of electrical shock or fire if a higher or

lower voltage is used, or if an electric current is utilized with a frequency not within the range stated above.

Do not place any object on top of this machine. There is a risk of electrical shock or fire if water or any

foreign object enters the machine.

Handle the power cord with care. There is a risk of electrical shock or fire if the cord is damaged, broken,

or placed under a heavy object.

Do not insert or remove the power plug when water is present.

Do not remove the cover of this machine. There is a risk of an electrical shock.

Do not reconfigure the electronics of this machine. There is a risk of an electrical shock or fire.

Do not operate the machine if it is emitting smoke or a strange odor. Turn off the machine, unplug it from

the outlet and contact your dealer.

Do not operate the machine if the power cord is generating heat or emits a strange smell. Turn off the

machine, unplug it from the outlet and contact your dealer.

If a foreign object enters into the machine, turn off the power switch and unplug the power plug, then

consult your dealer.

In the event of a thunderstorm, unplug the machine.

Caution

Keep hair, clothing, and jewelry away from the machine while operating. Serious injury may result.

Do not put the machine on an unstable or slanted surface. Doing so may cause the machine to drop or fall

over, causing damage and possible injury.

Store and operate the machine in a clean, dust-free environment with low humidity. Avoid areas with high

moisture, extreme temperatures and excessive dust, as these conditions may cause machine failure or

electrical shock.

Operate the machine at the temperature of 5 degrees to 35 degrees C.

Be sure to grasp the power cord by the plug when unplugging it from the electrical outlet. Not doing so may

cause damage to the cord and possible electrical shock or fire.

Be sure to pull the power plug out of the electric outlet before moving the machine. Not doing so may cause

damage to the cord and possible electrical shock or fire.

Unplug the power plug from the electrical outlet when this machine is not in use.

The socket-outlet shall be installed near the equipment and shall be easily accessible.

5

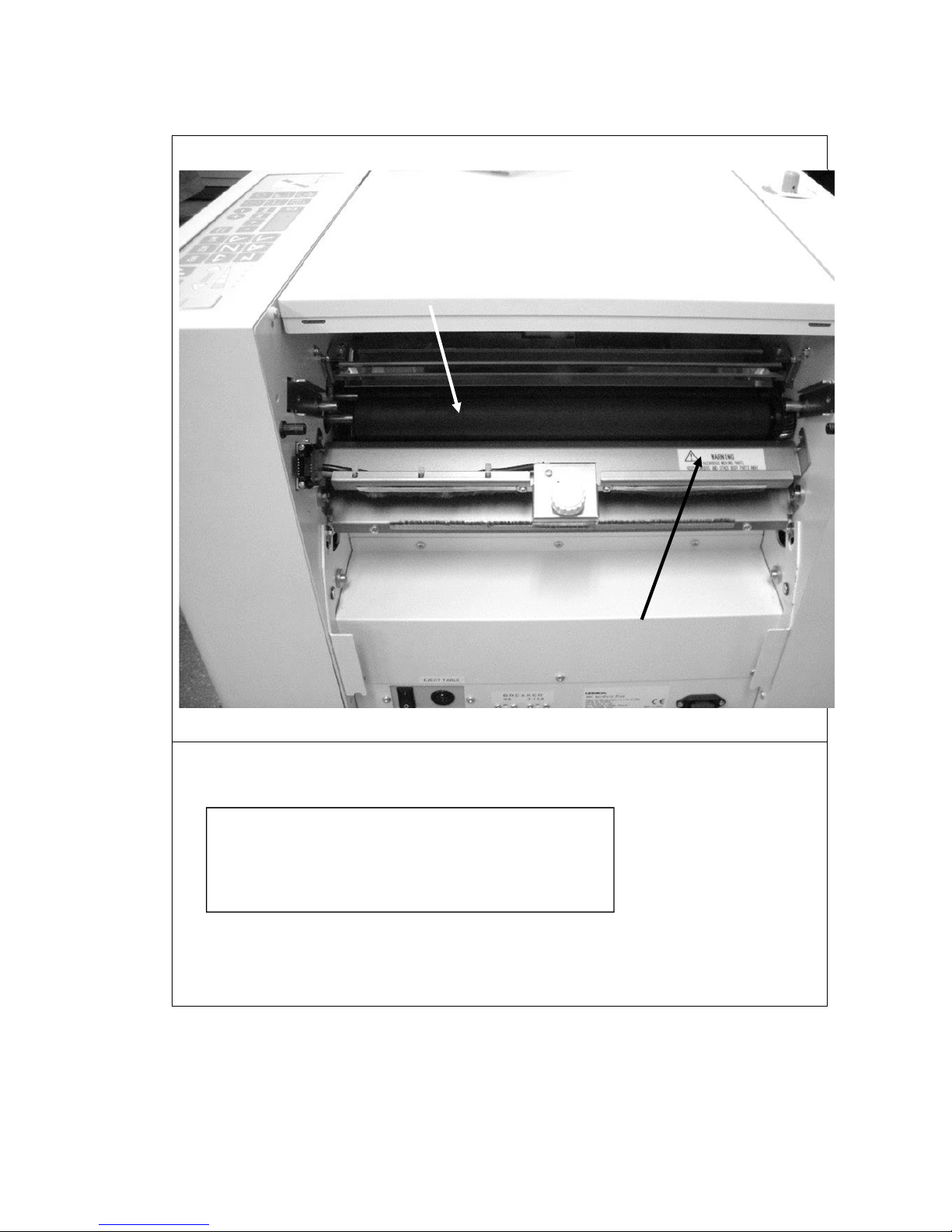

WARNING 1

①:Moving Parts

②:Warning Label

WARNING

HAZARDOUS MOVING PARTS

KEEP FINGERS AND OTHER BODY PARTS AWAY.

①

②

6

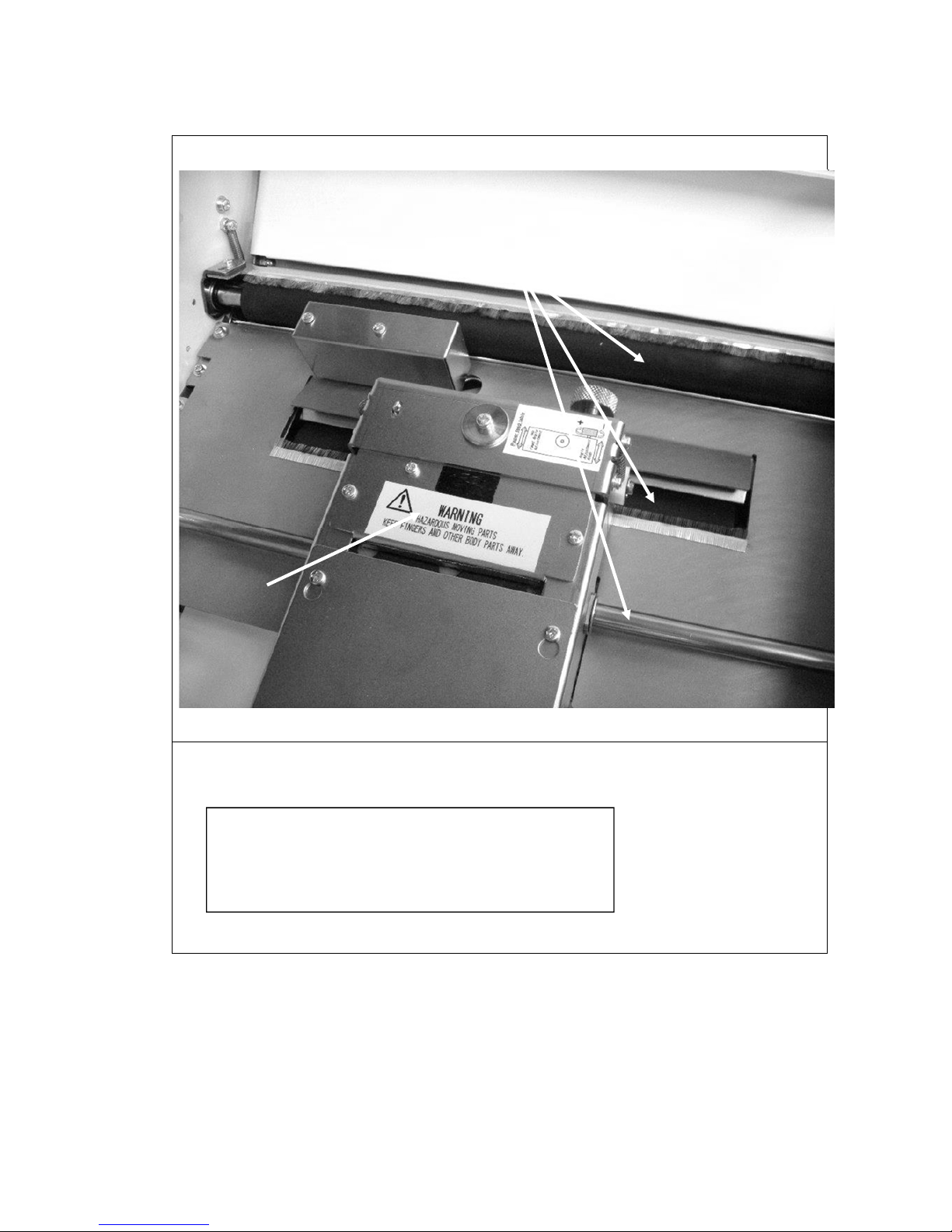

WARNING 2

①:Moving Parts

②:Warning Label

WARNING

HAZARDOUS MOVING PARTS

KEEP FINGERS AND OTHER BODY PARTS AWAY.

②

①

7

2. Caution during Maintenance Service

Turn off the machine and unplug the power plug to avoid electrical shock.

(1) Hold the connector to avoid damaging cables when plugging or unplugging the connector.

(2) When wiring, pay attention on over-tension or over-slack of wire harness to avoid touching to

movable or rotary part.

(3) Clean the photo sensor to avoid the machine error.

(4) Clean the belts, rollers and other related area to avoid paper feed error.

(5) When cleaning, use a towel after wringing out water.

(6) Do not use an organic solvent to avoid machine trouble.

(7) After cleaning, operate the machine only in the status that machine is not dry.

8

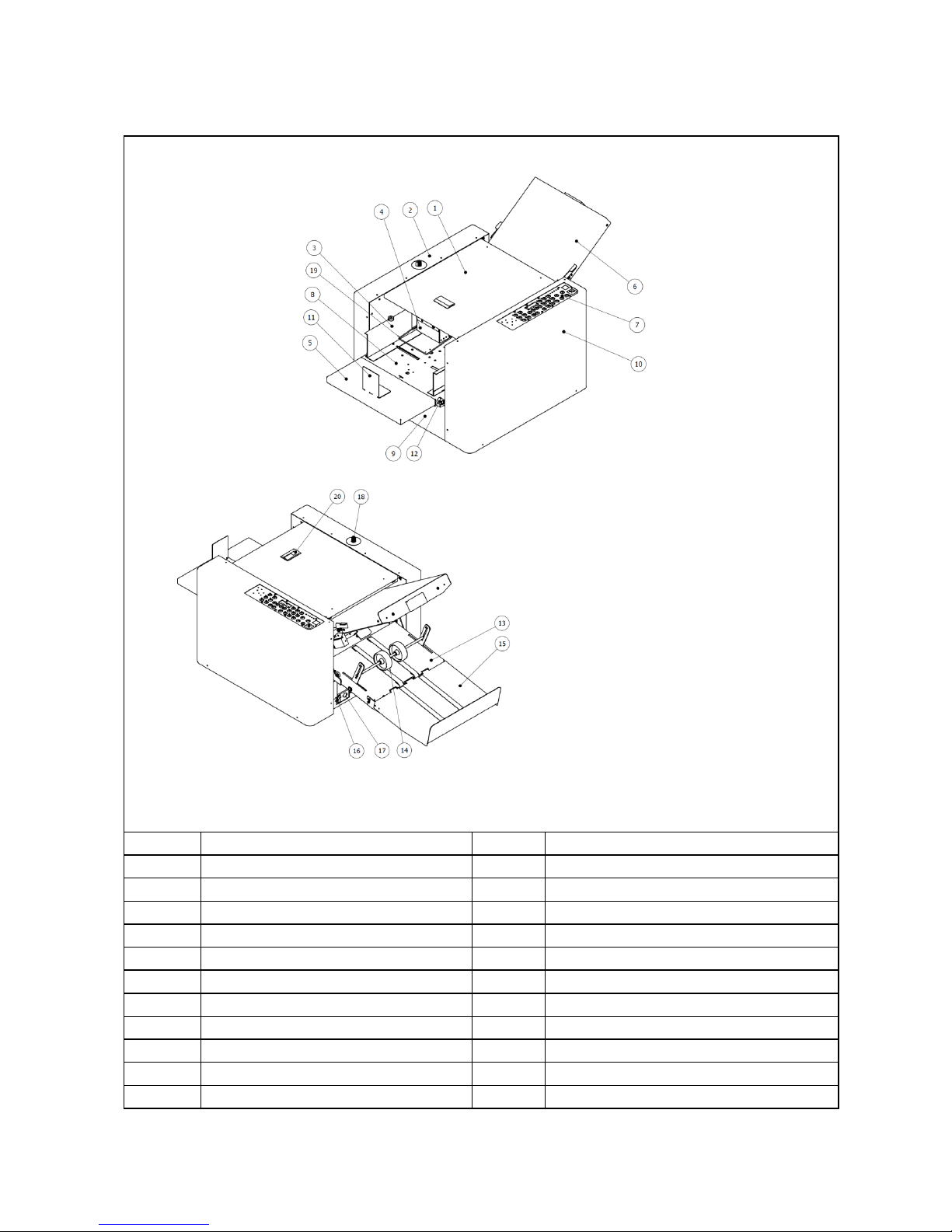

3. Part Names

Name Number Name

① Top cover ⑫ Skew Adjustment Knob

② Left side cover ⑬ Paper Ejection Table

③ Paper Guide(Left & Right ) ⑭ Paper Ejection Roller

④ Paper Height Detection Sensor ⑮ Auxiliary Paper Ejection Table

⑤ Auxiliary Feed Table ⑯ Power Switch

⑥ Table 1 ⑰ Paper Ejection Table Socket

⑦ Operation Panel ⑱ Air Adjustment Knob

⑧ Paper Feed Table ⑲ Weight Arm

⑨ Door for Table 2 ⑳ Top cover Knob

⑩ Right side cover

Table 2

⑪ L Stopper guide

Table 2 is set under the Paper Feed Table in the machine, which you find when opening the door ⑨ for the table 2.

9

Upper Cover is open to adjust

belt feeder assembly.

Belt Feeder Assy

Paper Floating Height Adjuster

Suction Air Adjuster

Error Code Chart

Feed Angle Adjustment Dial

10

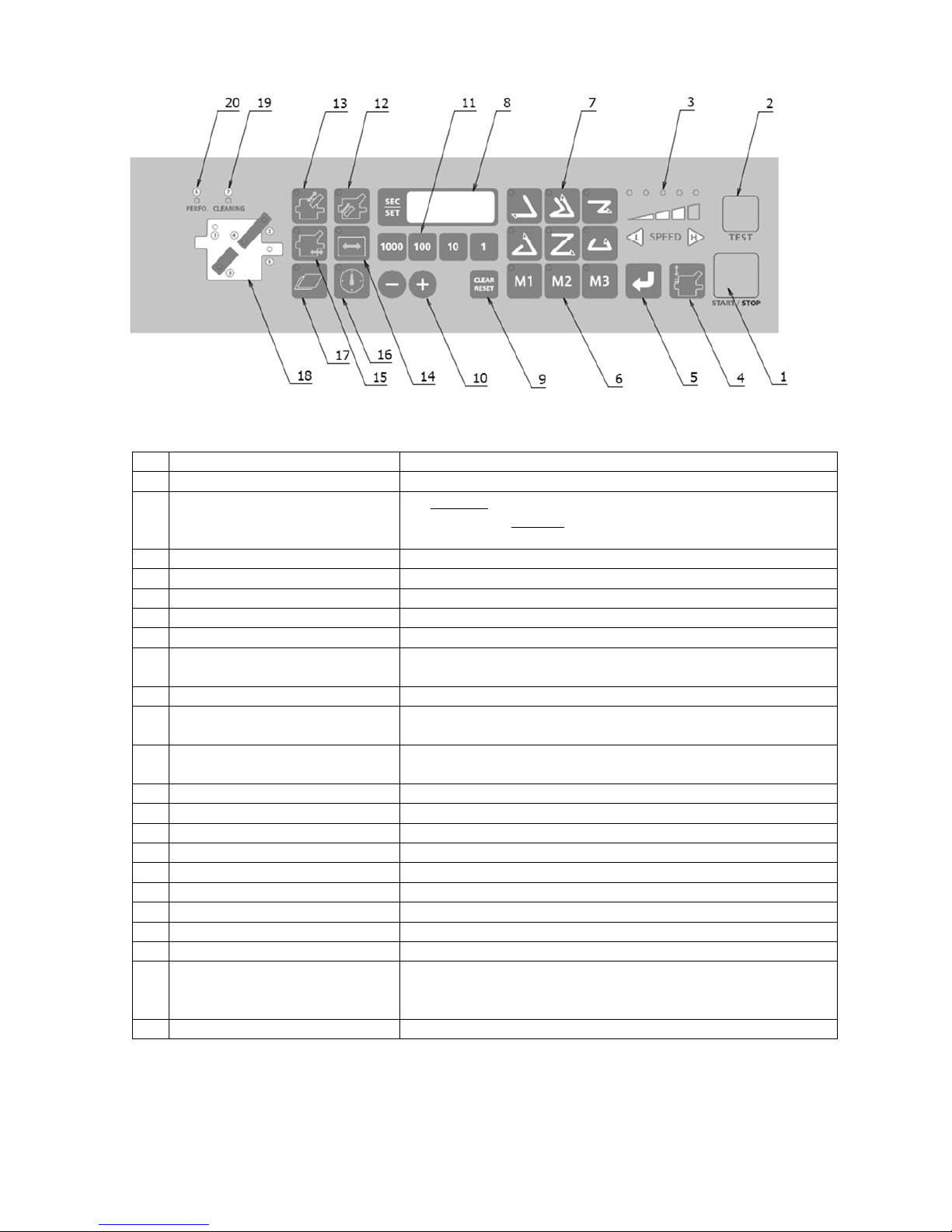

4. Designation and Functions of Operations Panel

No.

Designation/Indication Function

①

STAR T/STOP key

Starts and stops machine.

②

TEST key

1)Test folds two sheets without counting.

2) Also used fo r test bl ow wit hout fol ding (presse d more th an 2

seconds until buzzer sounds.)

③

Speed adjustment key Select 5 speed.

④

Paper feed table up/down key Moves up and down the Paper Feed Table

⑤

Store key Memorize fold position after adjustment is done.

⑥

Memory 1/2/3 key

Memorize three special fold types.

⑦

Fold type key Select 6 fold types and store job routine.

⑧

Counter

Shows the number of sheets, position of the stopper of Table 1 and 2,

and paper size.

⑨

Clear/Reset key

Clears the counter / resets after an error.

⑩

+/- key

Use for adjusting position of the stopper of Table 1 and 2, the position

of paper ejection roller, and inputting paper length

⑪

Numerical key

Use for inputting the number of sheets to be folded, length of nonstandard size paper, factors of interval function and others.

⑫

Table 2 stopper move mode key Use to adjust Table 2 Stopper position.

⑬

Table 1 stopper move mode key Use to adjust Table 1 Stopper position.

⑭

Paper length input mode key Use to input paper length for non standard norm paper.

⑮

Paper ejection roller move key Use to adjust position of Paper Ejection Roller.

⑯

Interval key Sets time and number of interval function during folding work.

⑰

Double Feed Error Detection key Sets double feed error detection ON/OFF.

⑱

Trouble Locating Map

①②③④

⑤ Indicates location of trouble.

In case

of Double Feed ①④⑤ lamps flash at the same time. Display indicates E-13.

⑲

Cleaning lamp

Indicates when cleaning of the FEED section (belt, roller) is necessary.

It lights every 10,000 sheets of folding.

Can disable this function. Refer detailed section.

⑳

Perforation mode lamp Indicates when the optional perforating unit is installed.

11

5. Operations

1) Turn power switch on.

2) Set papers

3) Folding T est

3-1) Press one of the fold type keys to test.*

3-2) Set speed.

3-3) Press the TEST key.

3-4) Stoppers of Table 1 and Table 2 moves to home position once.

Then, stoppers of the Tables move to appropriate folding positions.

3-5) After folding two pieces of papers, machine stops. Examine 2nd folded paper.

*: If fold type key is not pushed, machine operates based on previously set folding pattern and

speed.

4) Fold by Adding Counter

4-1) Clear the numbers of counter and set it to zero.

4-2) Press START key.

4-3) Folding continues until out of paper in the Feed Table.

5) Fold by Subtracting Counter

5-1) Set desired number of fold.

5-2) Press START key.

5-3) The folding stops at the time when reached to the setting numbers.

6) The machine can be stopped anytime by pressing STOP key or when error occurred.

Refer operation manual for details.

12

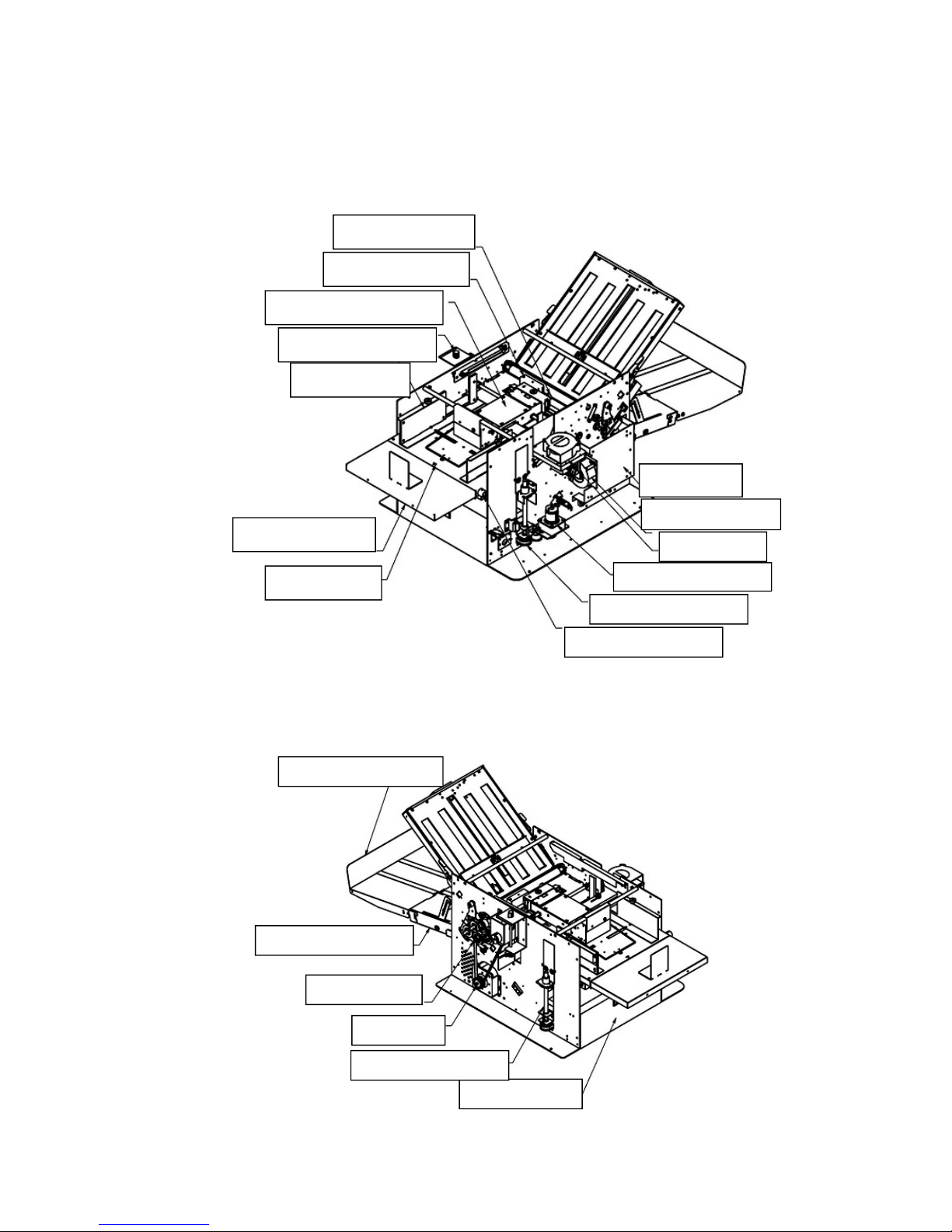

6. Structure of the sections

1) Layout Drawing of Overall Machine

Suction Belt Feeder Assy.

Air Adjustment Knob

Paper Guide

Double Feed Sensor

Feed Angle Adj. Dial

Table Up/Down Drive

Skew Adjustment Knob

Paper Feed Table

Auxiliary Feed Table

Control PCB

Separation Blower

Suction Blower

Drive Section

Paper Ejection Table

Aux. Paper Ejection Table

Door for Table 2

Table Up/Down Screw

Main Moto

r

13

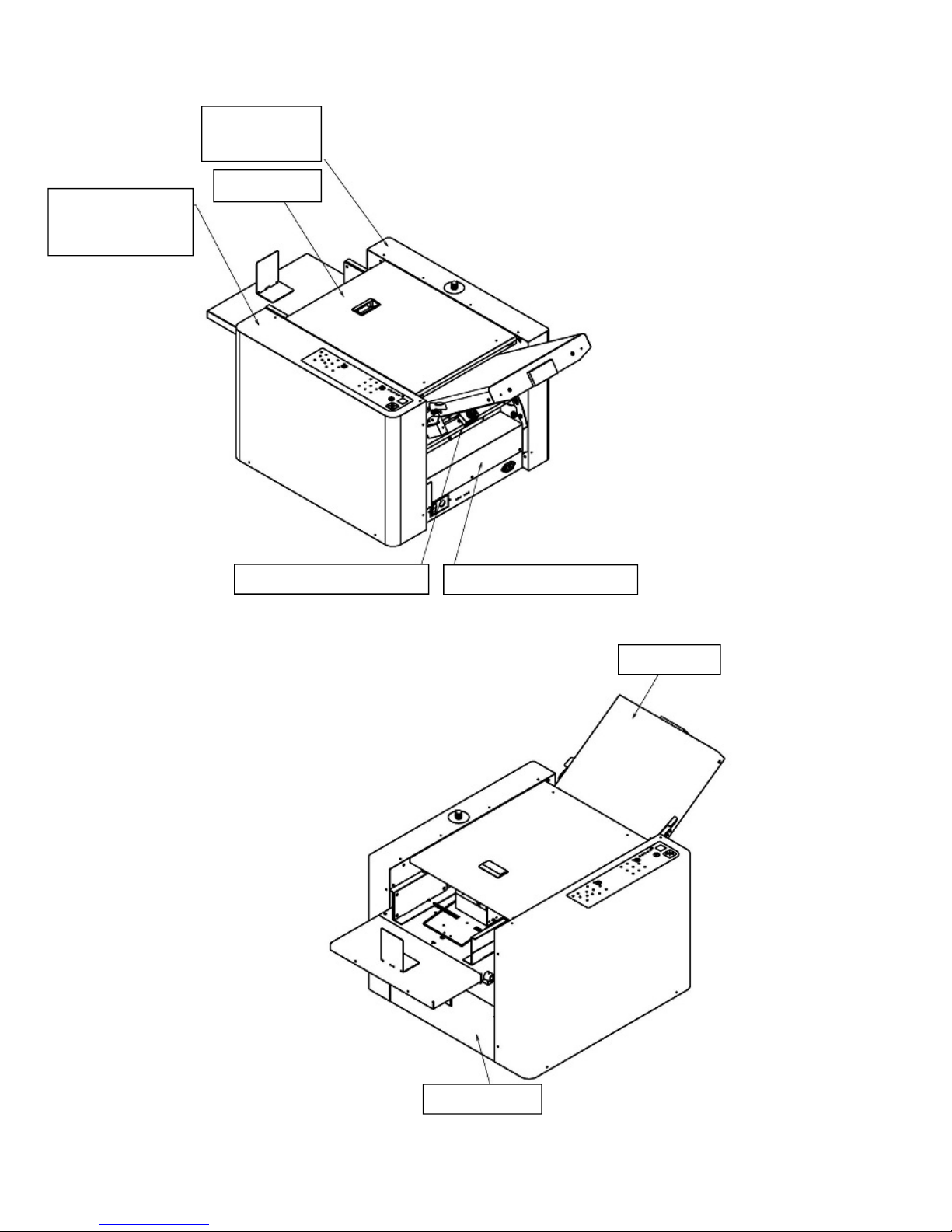

2) Covers

Paper Ejection Lower Cove

r

Left Side Cover

Door for Table 2

Table 1 Cover

Top Cover

Right Side Cover

(Front Cover)

Paper Ejection Upper Cover

14

3) Layout of Motor and Solenoid

Separation Blowe

r

Table Up/Down Moto

r

Suction Section Solenoi

d

Suction Blower

Paper Ejection Belt Driving Motor

Paper Ejection Roller Positioning Moto

r

Table 1 Drive Motor

Main Motor

Table 2 Drive Motor

Loading...

Loading...