MBH Ni-HARD Maintenance Manual

Instruction, Installation, Operation

and Maintenance Manual

Ni-HARD SUBMERSIBLE PUMP

© 2018 mbh pumps (gujarat) pvt. ltd.

ISO 9001

Certied Company

A Mark of Quality

A Mark of Quality

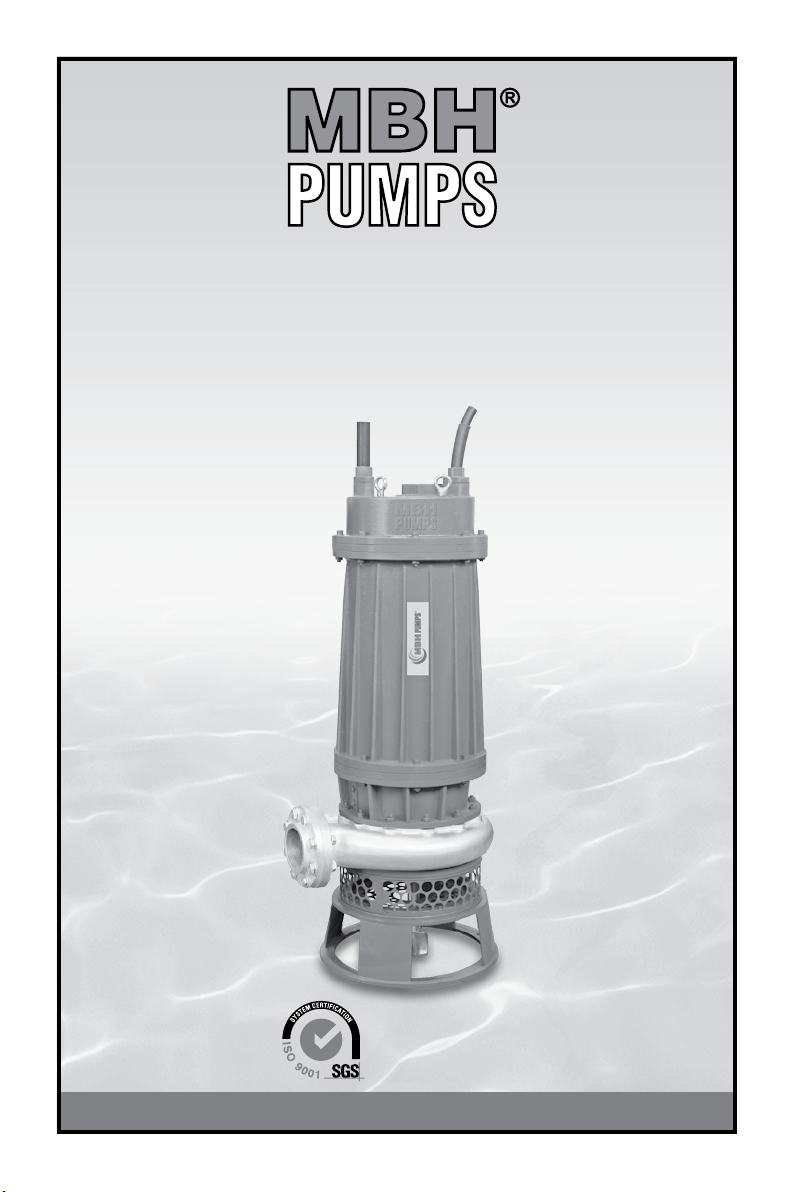

CROSS SECTION DRAWING

RECOMMENDATIONS

NO. DESCRIPTION MATERIAL

1 CABLE

2 GLAND COVER C.I. IS-210 FG260

3 EYE BOLT S.S.

4 TOP COVER C.I. IS-210 FG260

5 BEARING COVER C.I. IS-210 FG260

6 HEX BOLT S.S.

7 TOP BRG. COVER C.I. IS-210 FG260

8 HEX NUT S.S.

9 WINDING COPPER

10 END RING M.S.

11 STATOR STAMPING M-47

12 STATOR BODY C.I. IS-210 FG260

13 ROTOR SHAFT S.S. 410

14 BALL BEARING (D.E.) STD. MAKE

15 OIL CHAMBER C.I. IS-210 FG260

16 MECH. SEAL UPPER CR./ S.S.

17 MECH. SEAL LOWER SIC / SIC.

18 VOLUTE NI. HARD

19 IMPELLER NI. HARD

20 IMPELLER NUT S.S.

SPIRAL PLATE

21

(WEAR PLATE)

22 STRAINER S.S.

23 PUMP STAND M.S.

24 CUTTER S.S.

25 NECK RING S.S.

26 OIL PLUG S.S.

27 OIL HYLUBE MILCY Gr, 40

28 BALL BEARING (NDE) STD. MAKE

PVC. INSULATED

SHEATHED

NI. HARD

1. Follow maintenance schedule strictly, so as to avoid costly repairs in the long run.

2. ‘MBH’ Ni-hard submersible pumpsets are being supplied with special features

like over heating protection (Thermistor) and seal monitor sensor, control panel is

a mandatory supply with each and every pumpset. Ensure that pumpset is connected

properly to the control panel.

3. If pumping media available is falling short of the pump capacity, it will result in spurt, which

is harmful for the pump. In such a case reduce discharge by throttling.

4. Ensure that pump rotates in correct direction (clockwise). Counter clockwise rotation

result in lower discharge and increased wear. At instant of starting Ni-hard pump

should give anticlockwise jerk.

The rotation of impeller should match the arrow on the pump casing.

In case of reverse rotation the current consumption will rise and pumpset will produce

unwanted noise.

5. Avoid too many creases in the hosepipe (in case of portable installation), it results

in increased friction losses. Use the shortest possible delivery line.

6. Protect cable from damage-during storage, transportation and operation. A damaged

cable may give shock or burn the motor.

7. Always earth the unit, before starting.

8. Never hoist the pumpset up or down by the connecting cable.

9. Use NRV if pipe length is more than 4.5 mtrs.

PRECAUTION FOR LONG STORAGE

Clean the pump set with fresh water and wipe the cable. Put pump set in cool, dry

place in vertical position and the cable wrapped on top of the pump.

Do not leave cable on the oor where it is likely to get damaged.

CONSTRUCTION OF NI-HARD SUBMERSIBLE PUMPSET

‘MBH’ Ni-hard submersible pumps are of close couple compact design and have pump

below and motor above construction hence sump cleaning is possible to the minimum

level. These are powered by squirrel cage induction dry motors suitable for operation at

400/440 volts, 3 phase, 50 Hz, A.C. Supply; bearing of these pumps are grease packed.

Being a Submersible pump, it saves a lot of cost of construction compared to other

conventional pumps and also provides noise free operation. Pumps are tted with high

efciency non-clog or free ow impeller for smooth and economical pumping operation.

Since they work under pumping liquid, suction is always ooded, hence no need of

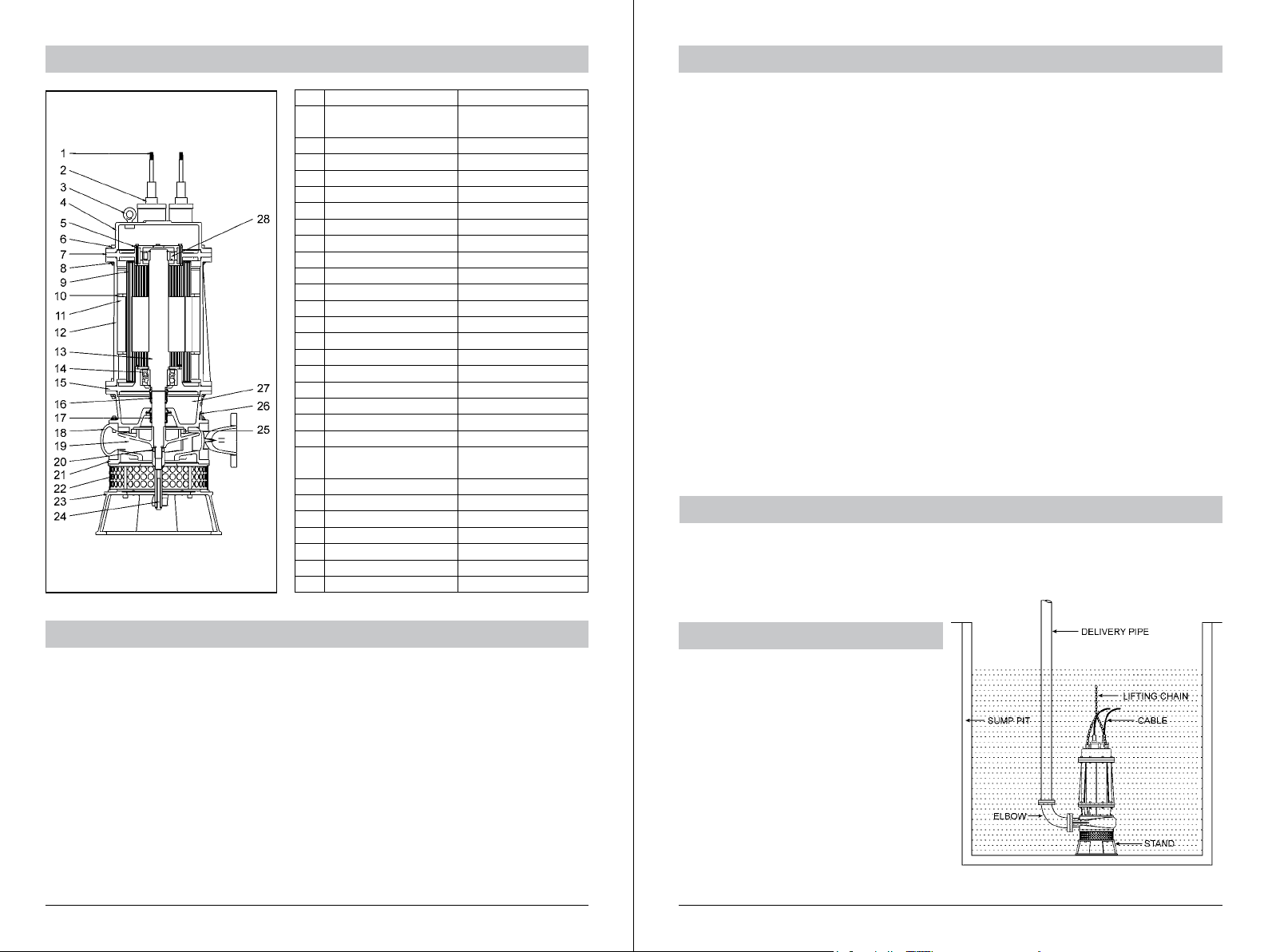

PORTABLE MOUNTING

The pump must be installed in vertical

motor position above on a solid oor.

For portable mounting, stand is supplied

along with the pumpset.

Suspend the pump from the chain and

shackle attached to the eye bolt which is

on the top cover.

priming or suction pipe. Pumps are tted with double mechanical seals to separate

motor chamber from oil chamber and oil chamber from liquid being pumped. Pumps

are provided with special safety devices like moisture detection sensor and thermistor

protection against high winding temperature. That can also be provided with special

lowering arrangement for easy access of the pump for maintenance.

© 2018 mbh pumps (gujarat) pvt. ltd. © 2018 mbh pumps (gujarat) pvt. ltd.

2

Ni-Hard Submersible Pump

3

Ni-Hard Submersible Pump

Loading...

Loading...