MLA1000

EN

Conductivity Meter for Flowing Light Oil

Description

Installation

Operation

Operating Instructions

Document information

Described product

Product name: MLA1000

Document identification

Title: MLA1000 Operating Instructions

Order number: 8011607

Version: 1.0

Date: 2019-10

Publisher

MBA Instruments GmbH

Friedrich-List-Str. 3-7 25451 Quickborn · Germany

Phone: +49 (0) 41 06 123 888-0

Fax: +49 (0) 41 06 123 888-9

Email: info@mba-instruments.de

Warranty information

The stated product characteristics and technical data do

not constitute warranty declarations.

© MBA Instruments GmbH. All rights reserved.

Glossary

ATEX Atmosphères explosibles: Abbreviation for

European standards relating to safety in explosionendangered areas

DC Direct current

IP xy International protection (also: Ingress Protection);

protection class for a device pursuant to IEC/DIN

EN 60529.

PE Polyethylene

PUR Polyurethane

PVC Polyvinyl chloride

TPE Thermoplastic elastomer

Warning symbols

Hazard (general)

Hazard from electrical voltage

Hazard in explosion-endangered areas

Hazard from explosive substances/ substance

mixtures

Hazard from noxious substances

Warning levels/signal words

WARNING

Hazard situation for people that could result in serious

injuries or death.

CAUTION

Hazard that could result in less serious or minor injuries

and/or risk of damage to property.

IMPORTANT

Hazard possibly resulting in damage to property.

Information symbols

Important technical information for this product

Important information about explosionendangered areas

Tip

Additional information

Reference to information elsewhere

Content

1 Safety Instructions ......................................................................................................................................................................................... 5

1.1 Important instructions for safe usage ....................................................................................................................................... 5

1.2 Principal installation instructions .............................................................................................................................................. 5

1.3 Principal operating instructions ................................................................................................................................................ 5

1.4 Responsibilities of the user ....................................................................................................................................................... 6

1.4.1 Only allow installation and use by specialist technicians .......................................................................................................... 6

1.4.2 Correct use ................................................................................................................................................................................ 6

1.4.3 Consideration of local conditions .............................................................................................................................................. 6

1.4.4 Safekeeping of the documentation ........................................................................................................................................... 6

2 Product Description ....................................................................................................................................................................................... 7

2.1 Intended usage .......................................................................................................................................................................... 7

2.1.1 Intended scope of application ................................................................................................................................................... 7

2.1.2 Application restrictions ............................................................................................................................................................. 7

2.1.3 Certification for explosion-endangered areas ........................................................................................................................... 7

2.2 Operating principle.................................................................................................................................................................... 8

2.3 Product components ................................................................................................................................................................. 9

2.3.1 MLA1000-S measuring probe .................................................................................................................................................... 9

2.3.2 MLA1000-A display unit ............................................................................................................................................................ 9

2.3.3 MLA1000-K probe cable ............................................................................................................................................................ 9

2.3.4 Options ...................................................................................................................................................................................... 9

2.4 Scope of delivery ..................................................................................................................................................................... 10

3 Installation of the Measuring Probe ........................................................................................................................................................... 11

3.1 Selecting the installation location for the measuring probe ................................................................................................... 11

3.1.1 Requirements for the measuring liquid at the installation location ........................................................................................ 11

3.1.2 Requirements for the installation location.............................................................................................................................. 11

3.2 Preparing the piping system .................................................................................................................................................... 12

3.3 Installation of the measuring probe with immersion pipe ...................................................................................................... 12

4 Installation of the Display Unit .................................................................................................................................................................... 14

4.1 Mounting the display unit ....................................................................................................................................................... 14

4.1.1 Criteria for the mounting location ........................................................................................................................................... 14

4.1.2 Securing the display unit without a mounting bracket ........................................................................................................... 14

4.1.3 Securing the display unit with a mounting bracket ................................................................................................................. 14

4.2 Connecting the potential equalisation .................................................................................................................................... 15

4.3 Opening the housing ............................................................................................................................................................... 15

4.4 Installing the cables ................................................................................................................................................................. 16

4.4.1 General information about installing the cables ..................................................................................................................... 16

4.4.2 Connecting the probe cable .................................................................................................................................................... 16

4.4.3 Connecting the measurement reading outputs ...................................................................................................................... 16

4.4.4 Connecting the supply voltage ................................................................................................................................................ 17

4.4.5 Closing the cable glands and housing ...................................................................................................................................... 17

5 Operation....................................................................................................................................................................................................... 18

5.1 Putting the MLA1000 into operation ...................................................................................................................................... 18

5.2 Checking the operating status ................................................................................................................................................. 18

5.2.1 Indications for a safe operating status .................................................................................................................................... 18

5.2.2 Indications for an unsafe operating status .............................................................................................................................. 18

5.3 Display screens ........................................................................................................................................................................ 18

5.3.1 Screen after switching on ........................................................................................................................................................ 18

5.3.2 Operating screen ..................................................................................................................................................................... 18

5.3.3 Malfunction screens ................................................................................................................................................................ 19

6 Maintenance .................................................................................................................................................................................................. 21

6.1 Removing the immersion pipe (with measuring probe) .......................................................................................................... 21

6.2 Testing the measuring function ............................................................................................................................................... 21

6.3 Cleaning the measuring probe ................................................................................................................................................ 22

6.4 Reinstalling the measuring probe............................................................................................................................................ 22

7 Troubleshooting ........................................................................................................................................................................................... 23

7.1 If the MLA1000 does not function at all ... .............................................................................................................................. 23

7.2 If the measurement readings are obviously incorrect... ......................................................................................................... 23

8 Appendix ....................................................................................................................................................................................................... 24

8.1 Technical data ......................................................................................................................................................................... 24

8.1.1 MLA1000-S measuring probe .................................................................................................................................................. 24

8.1.2 MLA1000-A display unit .......................................................................................................................................................... 24

8.1.3 MLA1000-K probe cable .......................................................................................................................................................... 24

8.2 Certification/suitability test..................................................................................................................................................... 24

8.3 Disposal Information ............................................................................................................................................................... 25

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

5

MLA1000 Continuous Conductivity Measurement

1 Safety Instructions

1.1 Important instructions for safe usage

Only use the MLA1000 in explosion-endangered areas if permitted by the specifications for the

zone, explosion group and temperature class (refer to the type plate on the display unit and

measuring probe).

Pay attention to and heed the "special conditions" stated on the type examination certificate.

Installation, commissioning, maintenance and testing may only be carried out by technicians who

possess requisite knowledge of the rules and regulations for explosion-endangered areas, e.g.

zoning

types of ignition protection

installation regulations, e.g. "Ordinance on electrical systems in explosion-endangered

locations (ElexV)"

Do not alter the product. Repairs may only be carried out by the manufacturer or by trained and

authorised technicians.

If the product was delivered with special information about it: Pay preferential attention to any

special information.

1.2 Principal installation instructions

IMPORTANT:

► Install the measuring probe so that the liquid flows past the probe in the required

direction (→ p.14, Fig. 3).

► Only use measuring probes and probe cables that have been approved by the

manufacturer for the intended measuring liquid.

► Only put the MLA1000 into operation when the entire housing and all the cable

glands have been correctly sealed.

1.3 Principal operating instructions

Intended usage → p.7, section 2.1.

Do not use the measurement readings if the requirements for the installation location

of the measuring probe have not been fulfilled, in particular if the flow velocity of the

measuring liquid is not within the specified range (→ p.7, section 2.1.1).

IMPORTANT:

► In explosion-endangered areas: Only open the terminal box for the display unit

(bottom part of the housing) after the supply voltage and all external power

supplies have been switched off.

► If the measuring probe could become soiled during operation: Clean the probe at

regular intervals (→ p.22, section 6.3).

► If the measurement readings cannot be correct: Check whether the measuring

probe is soiled.

► If necessary, clean the probe.

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

6

MLA1000 Continuous Conductivity Measurement

1.4 Responsibilities of the user

1.4.1 Only allow installation and use by specialist technicians

► Make sure that the MLA1000 is only installed and used by specialist technicians who, on account

of their specialist training and knowledge and their familiarity with the applicable regulations, are

able to assess the work assigned to them and recognise any hazards.

This applies in particular to:

– safety in explosion-endangered areas

– welding work

– handling of combustible substances

1.4.2 Correct use

► Only use the product as described in these operating instructions. The manufacturer will bear no

responsibility for any deviating usage.

► Carry out the described maintenance work.

► Do not carry out any work or repairs on the product which are not described in these operating

instructions.

► Do not remove, add or alter any components belonging to the product unless stipulated in official

information provided by the manufacturer. Otherwise,

– the manufacturer's warranty will become void,

– the product could become dangerous,

– the certification for use in explosion-endangered areas will become void.

1.4.3 Consideration of local conditions

► All local legislation, technical rules and operating regulations that apply at the location where the

product is to be used must be observed in addition to these operating instructions.

1.4.4 Safekeeping of the documentation

► These operating instructions and all the supplied documentation must be kept available for

reference purposes.

► Give the documentation to the new owner.

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

7

MLA1000 Continuous Conductivity Measurement

2 Product Description

2.1 Intended usage

IMPORTANT:

► If the product was delivered with special information about it:

► Pay preferential attention to any special information.

2.1.1 Intended scope of application

Measuring function

The MLA1000 is designed for continuously measuring the electrical conductance and

temperature of suitable flowing measuring liquids. Suitable measuring liquids: kerosene, light

fuels, lubricants, coolants, various chemical liquids.

It can only be guaranteed that the MLA1000 will function as intended when used in

flowing light fuel at a flow velocity of at least 0.2 m/s.

Application purpose

Liquids can become electrostatically charged during filling, pumping or filtration. In the

presence of an ignitable gas mixture in the ambient environment, there is also a risk that the

gas mixture will be ignited (i.e. explode) by discharge sparks. This risk is assessed by

measuring the electrical conductance of the liquid (see DIN 51 412-T02-79 "Determining

electrical conductance, field procedure").

The conductance is stated using the physical unit "pS/m" (picosiemens per meter).

The unit "c.u." (conductivity unit), which is still frequently used in the oil industry, has

an equal value:

1 pS ⁄ m = 1 c.u.

2.1.2 Application restrictions

► Only use the MLA1000 for measuring suitable measuring liquids.

► The measuring liquid must meet certain requirements (→ p.11, section 3.1.1).

► Heed the supplied manufacturer's information regarding restrictions and suitability.

Unsuitable liquids (e.g. acids, chlorinated hydrocarbon solvents) can damage the measuring

probe and probe cable.

WARNING: Risk of incorrect measurements

The measuring liquid must fulfil the stipulated requirements for the measuring probe

at the installation location (→ p.11, section 3.1.1) as otherwise the readings will not be

reliable.

► Make sure that the measuring fluid at the installation location of the measuring

probe fulfils the stipulated requirements.

► If the conductance measurement reading is being used to monitor the safe usage

of the measuring fluid (in particular for explosion protection purposes): Make sure

that the measurement readings are recognised as being invalid if the measuring

liquid at the installation location of the measuring probe does not fulfil the

stipulated requirements. If necessary, install appropriate safety mechanisms.

Unsafe operating conditions could otherwise arise in the monitored system.

2.1.3 Certification for explosion-endangered areas

● The MLA1000-S measuring probe (→ p.9, section 2.3.1) is certified for installation in containers (e.g.

piping systems) holding combustible liquids in Zone 0 hazardous areas.

● The MLA1000-A display unit (→ p.9, section 2.3.2) is certified for use in Zone 1 hazardous areas.

Numbers of the type examination certificates → p.24, section 8.2

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

8

MLA1000 Continuous Conductivity Measurement

1089 pS/m

20.1 °C

V0.95 5-2000

No.: xxxxxxx

xxxxATEXxxxx

1

MLA1000-A display unit

2

MLA1000-S measuring probe

3

MLA1000-K probe cable

4

Immersion pipe (optional)

2.2 Operating principle

● The measuring probe of the MLA1000 is installed in the container through which the measuring

liquid flows (e.g. a piping system). The measuring liquid must meet certain requirements (→ p.11,

section 3.1.1).

● The probe measures the conductance by sending an electrical current through the measuring

liquid by means of low auxiliary voltage. The greater the conductance, the stronger is the electrical

current. The electronics in the probe convert the measured current into a digital measurement

signal.

● The display unit supplies the probe with auxiliary voltage and processes the measurement signals

using a microprocessor. The measurement readings are displayed numerically and outputted as

an analogue signal.

Fig. 1 Product components

1 3

4

2

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

9

MLA1000 Continuous Conductivity Measurement

Option

Notes

Immersion pipe

– for the measuring probe

– with securing chain

Mounting bracket

– for the display unit

Sliding sleeve

– for the immersion pipe

Ball valve

– as sluice for the immersion pipe

2.3 Product components

2.3.1 MLA1000-S measuring probe

The measuring probe consists of two parts:

● Probe body (hexagonal) with core electrode and connection for the probe cable

● Sheathed electrode (cylindrical) with inlet and outlet opening

The sheathed electrode can be unscrewed for cleaning purposes.

The probe body has a screw thread for attaching the measuring probe.

The temperature sensor and probe electronics are integrated in the sensor body.

● Technical data → p.24, section 8.1.1.

● Functional test with ring magnet → p.21, section 6.2.

2.3.2 MLA1000-A display unit

The display unit housing consists of two parts:

● Top housing: Display section – contains the electronic components.

● Bottom housing: Terminal box – contains the connection terminals.

The top and bottom parts of the housing are separated by a gas-tight seal.

The electronic connection to the measuring probe is intrinsically safe.

IMPORTANT:

The connection between the housing parts must be supported (certification requirement).

► Secure both housing parts of the display unit on a solid subsurface such as a

mounting panel (instructions → p.15, section 4.1.2).

● Technical data → p.24, section 8.1.2

● Certification for explosion-endangered areas → p.7, section 2.1.3.

2.3.3 MLA1000-K probe cable

● Length: The probe cable is available in different lengths. The cable ends are ready for use:

– Ferrules for connection terminals

– Receptacle for the measuring probe plug connector

● Material: The sheath material used for the selected version of the probe cable must be chemically

resistant to the intended measuring liquid. The right type of probe cable is therefore dependent

upon the specific application.

Technical data → p.24, section 8.1.3.

2.3.4 Options

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

10

MLA1000 Continuous Conductivity Measurement

2.4 Scope of delivery

Basic components

● Measuring probe (→ p.9, section 2.3.1)

● Display unit (→ p.9, section 2.3.2)

● Probe cable (→ p.9, section 2.3.3)

● Ring magnet for functional testing (→ p.21, section 6.2)

Options / accessories

As ordered (→ p.9, section 2.3.4).

Standard delivery:

● If delivery includes an immersion pipe: The immersion pipe, measuring probe and

probe cable are already assembled.

● If delivery includes the mounting bracket: The immersion pipe and display unit are

already assembled.

Documentation

● Certificate of conformity

● Type examination certificate BVS 14 ATEX E047 X (for MLA1000-S probe)

● Type examination certificate BVS 14 ATEX E026 X (for MLA1000-A display unit)

● Operating instructions

● If delivery includes a ball valve: Directions for use from the manufacturer of the ball valve

● If delivery includes a sliding sleeve: Directions for use from the manufacturer of the sliding sleeve

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

11

MLA1000 Continuous Conductivity Measurement

Criterion

Action

The measuring liquid should flow at the

installation location as homogeneously

and evenly as possible.

► If possible, install the measuring probe in

a long, straight piece of tubing.

► After a pipe bend, select a distance

equivalent to at least five times the

inside diameter of the pipe (5d).

The measuring liquid at the installation

location should have an homogeneous

composition (fully mixed).

► Do not install the measuring probe

immediately after the mixing stations.

The flow velocity must lie between 0.2

and 7 m/s (→ p.24, section 8.1).

► Specifications → p.24, section 8.1.

Temperature and pressure must be

within

Criterion

Action

The probe cable between the measuring

probe and display unit can have a

maximum length of 24 m.

► Check the length of the supplied probe

cable.

The immersion pipe may have to be

removed after a certain number of

operating hours for cleaning or replacing

the measuring probe.

► Take into account the space required for

the piping system.

► As required: Install auxiliary devices for

disassembling the probe while the piping

system is in operation (sliding sleeve[1],

ball valve[1]).

WARNING: Risk of incorrect measurements

The measuring liquid must fulfil the stipulated requirements at the

measuring probe as otherwise the readings will not be reliable.

► Make sure that the measuring fluid at the installation location of the

measuring probe fulfils the stipulated requirements.

► If the conductance measurement reading is being used to monitor the

safe usage of the measuring fluid (in particular for explosion

protection purposes): Make sure that the measurement readings are

recognised as being invalid if the measuring liquid at the installation

location of the measuring probe does not fulfil the stipulated

requirements. If necessary, install appropriate safety mechanisms.

Unsafe operating conditions could otherwise arise in the monitored system.

3 Installation of the Measuring Probe

3.1 Selecting the installation location for the measuring probe

3.1.1 Requirements for the measuring liquid at the installation location

3.1.2 Requirements for the installation location

[1] Optional (→ p.9, section 2.3.4).

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

12

MLA1000 Continuous Conductivity Measurement

No.: xxxxxxx

xxxxATEXxxxx

No.: xxxxxxx

xxxxATEXxxxx

1

Marker arrow

2

Outlet

3

Direction of flow

3.2 Preparing the piping system

► Prepare the installation location so that the work can take place in a safe manner.

► On the piping system, mount the devices that are required for installing the immersion pipe.

► If delivery includes a ball valve: Install the ball valve in the piping system as described in the directions for

use provided by the manufacturer of the ball valve (separate document).

If delivery includes the optional immersion pipe, the measuring probe is installed in

the pipe.

WARNING: Danger of explosion

In explosion-endangered areas:

► Before beginning with the installation, carry out all the measures that are

necessary to safeguard against explosion during the installation work.

WARNING: Danger of explosion/fire hazard

Before welding:

► Completely empty the piping system.

► Remove all remaining measuring liquid from the piping system.

Vapours can otherwise occur during welding work that will produce an explosive

gas mixture; residues of the measuring liquid could catch fire.

3.3 Installation of the measuring probe with immersion pipe

Preparations for the installation → p.12, section 3.2.

IMPORTANT:

► Install the measuring probe so that the required direction of flow for the probe is

given.

Otherwise the measurement readings will not be reliable.

Marking the direction of flow

► Set the marker arrow on the immersion pipe so that it points in the direction of flow for the

measuring probe (→ Fig. 2).

Fig. 2 Marker arrow for the direction of flow

1

3

2

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

13

MLA1000 Continuous Conductivity Measurement

No.: xxxxxxx

xxxxATEXxxxx

Marking the installation depth

► On the immersion pipe, mark how far it has to be inserted in the slide fitting so that the

measuring probe is correctly positioned in the flowing media.

Slide a sealing ring onto the immersion pipe as marker.

Installing the immersion pipe

1 Carefully insert the immersion pipe (with measuring probe) over the device in the piping

system up to the marker for the immersion depth.

2 Turn the immersion pipe so that the marker arrow points in the direction of flow (→ Fig. 3).

3 Affix the immersion pipe in this position.

Connecting the probe cable

► Connect the probe cable. Secure the plug connector with the coupling nut on the

connector.

Fig. 3 Installed measuring probe

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

14

MLA1000 Continuous Conductivity Measurement

1089 pS/m

20.1 °C

V0.95 5-2000

1

Top housing

2

Bottom housing (terminal box)

2

1

4 Installation of the Display Unit

4.1 Mounting the display unit

Not applicable if the display unit and immersion pipe were delivered already assembled.

4.1.1 Criteria for the mounting location

● The display unit may be installed in a Zone 1 explosion-endangered area. An installation in Zone

0 is not permitted.

● The possible distance between the display unit and measuring probe is dependent upon the

length of the supplied probe cable (maximum length: 24 m).

● The display unit must be attached to a wall or a stable mounting.

● The display should be visible while the unit is being operated (for checking the operating status).

4.1.2 Securing the display unit without a mounting bracket

1 Secure the top housing of the display unit with 2 screws (Ø 8 mm) to a firm, flat subsurface (e.g. metal

wall, metal plate, smooth wall surface of a building).

2 Secure the bottom housing with at least 2 screws (Ø 6 mm) to the same subsurface.

4.1.3 Securing the display unit with a mounting bracket

The mounting bracket is a delivery option. If the delivery includes a mounting bracket, the display unit

is already mounted on it.

► Affix the mounting bracket with the unit on the immersion pipe (→ p.13, section 3.3).

Fig. 4 MLA1000-A display unit

1089 pS/m

1

°C

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

15

MLA1000 Continuous Conductivity Measurement

1089 pS/m

20.1 °C

V0.95 5-2000

1

Connection for the potential equalisation

2

Connecting terminals for the probe cable (→ p.17, section 4.4.2)

3

Connecting terminals for the supply voltage (→ p. 18, section 4.4.4) and measurement

reading outputs

(→ p.17, section 4.4.3)

4

Connection for the potential equalisation

2

3

1

4.2 Connecting the potential equalisation

► Join the two connections for the potential equalisation (→ Fig. 5) directly with the main potential (earthing).

4.3 Opening the housing

Fig. 5 Connecting terminals

WARNING: Risk of explosion in explosion-endangered areas

► Before opening the terminal box (bottom part of the display unit): The display unit

must be disconnected from the power supply.

Otherwise there could be a risk of explosion when the terminal box is opened.

1 If the display unit is already connected to the power supply: Switch off or disconnect the

power supply.

2 Open the bottom housing of the display unit.

1 2 3 4 5 6 7 1 2 3 4

1089

pS/m

20.1 °C

V0.95

5-2000

The top housing of the display unit does not need to be opened. It may only be

opened by authorised technicians for repair purposes.

► Leave the top housing closed.

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

16

MLA1000 Continuous Conductivity Measurement

4-pole terminal block

Connecting terminal

Colour code for probe cable

1

brown

2

black

3

blue

4

white

Output signal

Explanation

0 mA

Electrical connection has been interrupted.

MLA1000 is malfunctioning or defective.

4 to 20 mA

Current measurement reading

24 mA

Measurement readings cannot be generated.

Possible causes:

– The true physical value is greater than the

end value of the measuring range

(overflow).

4.4 Installing the cables

4.4.1 General information about installing the cables

► Use suitable cable materials → p.24, section 8.1.2.

► Run all the cables through the cable glands in the bottom housing of the display unit (→ Fig. 2).

When connecting the conductors:

► Strip the conductor insulation to a length of 7 mm.

► Tighten the clamping screw on the connecting terminal with a torque of at least 0.3 Nm.

WARNING: Danger of explosion

The cable glands are subject to approval for explosion-endangered areas.

► Only use cable materials with a suitable outside diameter.

► If the MLA1000 is being used in an explosion-endangered area: Do not replace

the cable glands with cable glands of a different type. Otherwise the certification

for explosion-endangered areas will become void and there will be a risk of

explosion in such areas.

4.4.2 Connecting the probe cable

► Connect the probe cable to the blue 4-pole terminal block (→ Table 1).

4.4.3 Connecting the measurement reading outputs

Table 1 Connecting terminals for the probe cable

The measurement reading outputs continually give out the actual measured values. The physical

measuring range is outputted in the signal range between 4 and 20 mA.

► Connect the measurement reading outputs as shown in the terminal diagram (→ Table 2).

Table 2 Output signals for the measurement reading outputs

Permitted output load → p.24, section 8.1.

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

17

MLA1000 Continuous Conductivity Measurement

7-pole terminal block

Connecting terminal

Function

1

Power supply +24 V DC

2

Power supply GND

3

Measurement reading output for temperature (+ mA)

4

Measurement reading output for conductance (+ mA)

5

Measurement reading outputs for GND (-mA)

6

7

– no function –

4.4.4 Connecting the supply voltage

► Install a fuse in the power supply lead for the MLA1000.

Fuse rating: max. 5 A (power consumption → p.24, section 8.1.2).

► Connect the power supply as shown in the terminal diagram (→ Table 3).

► Make sure that the current fed into the power supply lead cannot exceed 5 A.

Specification for the power supply → p.24, section 8.1

4.4.5 Closing the cable glands and housing

Table 3 Connecting terminals for the measurement reading output and power supply

After installing the cables:

► Seal the cable glands.

► Close the housing.

WARNING: Danger of explosion

Before putting the unit into operation in explosion-endangered areas:

► Seal all the cable glands so that they are "flame-tight" (practically gas-tight).

► Either close off any unused cable glands with a closure plug or replace them

completely with sealing caps.

– Closure plugs: Select suitable closure plugs for the permitted cable

diameters and install them instead of a cable.

– Sealing caps: Select sealing caps with thread M20 x 1.5 which are certified

for usage in explosion-endangered areas. Apply suitable adhesive to the

threads and sealing surfaces.

► Tightly close the display unit housing.

Otherwise there could be a risk of explosion.

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

18

MLA1000 Continuous Conductivity Measurement

MLA1000 V0.95

Conductivity

measurement

Explanation:

MLA1000 is starting up (approx. 3 seconds).

Actions:

► Wait until the operating screen appears (→ section 5.3.2).

► If the operating screen does not appear: Refer to the

information about the malfunction screens (→ section 5.3.3).

1089 pS/m

20.1 °C

V0.95 5-2000

Explanation:

MLA1000 is in the normal operating status (measuring mode).

1 = actual conductance measurement reading (sample value)

2 = actual temperature measurement reading (sample value)

3 = version number of the firmware (example)

Actions:

► Check/ensure that the requirements for safe operation are

fulfilled (see warning note).

1

2

5 Operation

5.1 Putting the MLA1000 into operation

1 Make sure that the display unit housing is tightly closed.

2 Switch on the supply voltage.

3 Wait for the display to light up after switching it on (→ p.19, section 5.3.1).

4 Check the operating status (→ section 5.2).

5.2 Checking the operating status

5.2.1 Indications for a safe operating status

1 The measuring liquid fulfils the requisite operating conditions at the measuring probe

(→ p.11, section 3.1.1, e.g. flow velocity).

2 The display on the display unit shows the measurement readings (→ section 5.3.2).

3 Measurement readings are returned at the measurement reading outputs.

Testing the measuring function → p.21, section 6.2.

5.2.2 Indications for an unsafe operating status

Nothing is shown on the display of the display unit.

A malfunction is shown on the display (→ p.20, section 5.3.3).

At least one measurement reading output returns "0 mA".

At least one measurement reading output returns "24 mA".

The measuring liquid does not have the required flow velocity at the measuring probe

(→ section 5.3.2).

The measuring liquid is not within the permitted temp. range at the measuring probe (→ section 5.3.2).

Measurement readings are being displayed that cannot be correct.

At least one measurement reading output returns readings that cannot be correct.

5.3 Display screens

5.3.1 Screen after switching on

5.3.2 Operating screen

WARNING: Requirements for safe operation

● The flow velocity of the measuring liquid at the measuring probe must be between 0.2

and 7 m/s.

● The measuring liquid temperature must be between -20 and +60 °C. Otherwise the

measurement readings will not be reliable.

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

19

MLA1000 Continuous Conductivity Measurement

High pS/m

20.1 °C

V0.95 5-2000

Explanation:

The actual conductance measurement reading is greater than

2000 pS/m.

Effects:

>>

The measurement reading output for the conductance is

returning 24 mA.

Recommended actions:

► Check whether the conductance of the measuring liquid at

the measuring point could actually be so high.

► Check whether the measuring liquid is passing by the

probe properly (→ p.13, 3.3).

► Clean the measuring probe (→ p.22, section 6.3).

Low pS/m

20.1 °C

V0.95 5-2000

Explanation:

The actual conductance measurement reading is less than 5

pS/m.

Effects:

>>

The measurement reading output for the conductance is

returning 0 mA.

Recommended actions:

► Check whether the measuring fluid is flowing (the flow

velocity is at least 0.2 m⁄s).

► Check whether the conductance of the measuring liquid at

the measuring point could actually be so low.

► Check whether the measuring liquid is passing by the

probe properly (→ p.13, 3.3).

Sensor

Error

V0.95 5-2000

Explanation:

The measuring probe is malfunctioning.

Effects:

>>

The measurement reading outputs are returning 0 mA.

Recommended actions:

► Carefully check the electrical connection between the

display unit and the measuring probe (condition of the

connecting cable, terminals; after installation:

wiring/terminal assignment).

► If that does not help: Notify the manufacturer (have the

probe replaced).

Fatal

Error

V0.95 5-2000

Explanation:

The MLA1000 is not functioning.

Effects:

>>

The measurement reading outputs are returning 0 mA.

Recommended actions:

► Shut down and disconnect the MLA1000 and then put it

back into operation.

► If that does not help: Clean the measuring probe (→ p.22,

section 6.3).

► If that does not help: Notify the manufacturer.

5.3.3 Malfunction screens

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

20

MLA1000 Continuous Conductivity Measurement

6 Maintenance

6.1 Removing the immersion pipe (with measuring probe)

● The MLA1000 does not have to be shut down for this work.

● If the MLA1000 remains in operation, the measuring function can be tested using

simple means (→ section 6.2).

CAUTION: Possible danger to health

If the measuring liquid could represent a health risk:

► Before removing the immersion pipe, take the appropriate protective measures suitable

for the measuring liquid (e.g. safety goggles, protective clothing, respirator).

For installations without a ball valve

1 Take the piping system out of operation (stop the liquid flow).

2 Remove the immersion pipe from the unit.

For installations with a ball valve

► Follow the instructions given by the manufacturer of the ball valve (separate document).

6.2 Testing the measuring function

● This procedure tests the electronic functionality of the measuring probe and

display unit.

● The supplied ring magnet is required for this procedure.

● Adjustment (electronic adjustment of the measuring probe and display unit)

are not necessary during operation.

A measuring probe that is clean, dry and functioning correctly the device displays

"low" in atmosperetic air.

1 Make sure

– that the sheathed electrode is firmly screwed onto the measuring probe,

– that the probe is clean and dry,

– that the probe is properly connected to the display unit (probe cable, plug-in connection on the

probe).

2 Place the ring magnets on the surface of the measuring probe opposite the labelled area.

For the test value for electrical conductivity, please refer to the test certificate.

► If the test value is not within the tolerance range: Notify the manufacturer's customer service or

return the MLA1000 to the manufacturer for repair.

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

21

MLA1000 Continuous Conductivity Measurement

Suitable solvents

Unsuitable solvents

Ethanol (ethyl alcohol)

Isopropyl alcohol

Benzene

Methanol

Acetone Chlorine hydrocarbons (CHC)

Acids

6.3 Cleaning the measuring probe

WARNING: Hazard in explosion-endangered areas

► Do not perform cleaning work in explosion-endangered areas.

IMPORTANT: Risk of damage from rough handling

● Exerting mechanical pressure on the probe body can destroy the plastic

moulding in the body (cause it to rupture).

● Deformations will lead to incorrect measuring results.

● Dirt in scratches can falsify the measurement readings.

► Do not deform the probe body or sheathed electrode.

► Do not clamp the measuring probe in a vice - neither the probe body nor the

sheathed electrode.

► Only use tools with a soft surface.

► Make sure that the plastic moulding is not scratched.

Fig. 6 MLA1000-S measuring probe

1 Unscrew the sheathed electrode.

If the sheathed electrode cannot be unscrewed by hand: Use a tool with a soft surface. Only apply

pincer-like tools at the bottom-most rim (closed end) of the sheathed electrode.

2 Carefully clean all the surfaces of the probe body and sheathed electrode using a soft cloth moistened with a

suitable solvent (→ Table 5).

The cleanliness of the parts determines the quality of the conductance measurements.

Table 5 Cleaning agents

IMPORTANT: Risk of damage from solvents

► Only use suitable cleaning agents. Other substances can damage the

measuring probe.

WARNING: Danger due to damaged measuring probes

► Do not use damaged measuring probes in explosion-endangered areas.

6.4 Reinstalling the measuring probe

1 Reassemble the measuring probe and immersion pipe (→ p.22, section 6.4).

2 Reinstall the immersion pipe (→ p.13, section 3.3).

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

22

MLA1000 Continuous Conductivity Measurement

Possible cause

Remarks

The power supply has failed.

► Check the mains power supply (e.g. external master

switch, external fuse, connecting cable).

The operating temperatures are

incorrect.

► Check the ambient temperatures (permitted ranges

→ p.24, section 8.1).

The internal software is not

functioning.

► Switch off the supply voltage to the MLA1000 and

then switch it back on again (reset) after a few

seconds.

Note: Can only occur in conjunction with complex

internal malfunctions or extreme external influences (e.g.

strong electromagnetic interference pulse).

The internal overcurrent fuse

(PTC resettable fuse) has been

tripped.

1 Switch off the supply voltage to the MLA1000.

2 Wait for several minutes.

3 Put the MLA1000 back into operation

(→ p.19, section 5.1).

If the overcurrent fuse is tripped again:

The MLA1000 is defective.

► Have it repaired.

Possible cause

Remarks

The MLA1000 is not ready for

operation.

► Check the operating status (→ p.19, section 5.2).

The requirements for the

measuring liquid are not being

fulfilled (e.g. flow velocity).

► Check the operating conditions at the measuring

probe (requirements → p.11, section 3.1.1).

If only the case at the

measurement reading output:

The output load is too great.

► Make sure that the internal resistance of the

connected devices does not exceed the permitted

output load (→ p.24, section 8.1).

The measuring probe is soiled.

► Visually check the condition of the measuring probe.

► Clean the probe if necessary (→ p.22, section 6.3).

The measuring probe is

defective.

► Visually check the condition.

► Test the measuring function (→ p.21, section 6.2).

The probe cable is damaged.

► Check the probe cable.

► Check the probe cable connections.

7 Troubleshooting

7.1 If the MLA1000 does not function at all ...

7.2 If the measurement readings are obviously incorrect...

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

23

MLA1000 Continuous Conductivity Measurement

Flow velocity

– minimum:

– maximum:

0.2 m/s

7 m/s

Permitted temperature:

-20 to +60 °C

Permitted pressure:

0 to +16 bar (versus atmosphere)

Protection class:

IP 66

Permitted ambient temperature:

-20 to +55 °C

Permitted ambient pressure:

atmospheric

Supply voltage:

24 V DC ± 10 %

Power consumption:

max. 150 mA

Conductor cross-section:

0.5 to 1.5 mm2

Cable diameter:

6 to 12 mm

Measuring range (standard)

– for conductance:

0 to 2000 pS/m

– for temperature:

-20 to +60 °C

Physical output area (standard)

– for conductance:

– for temperature:

0 to 2000 pS/m

-20 to +60 °C

Electronic output range:

4 to 20 mA

Electronic signal range:

0 to 24 mA

Permitted output load:

0 to 500 Ω

Conductor cross-section:

4x 0.5 mm2

Sheath material:

PVC, PUR, PE or TPE

Maximum length:

24 m

Type examination certificate:

BVS 14 ATEX E047 X

Identification marking:

II 1G Ex ia IIB T4 Ga

Type examination certificate:

BVS 14 ATEX E026 X

Identification marking:

II 2(1)G Ex de [ia Ga] IIB T4 Gb

8 Appendix

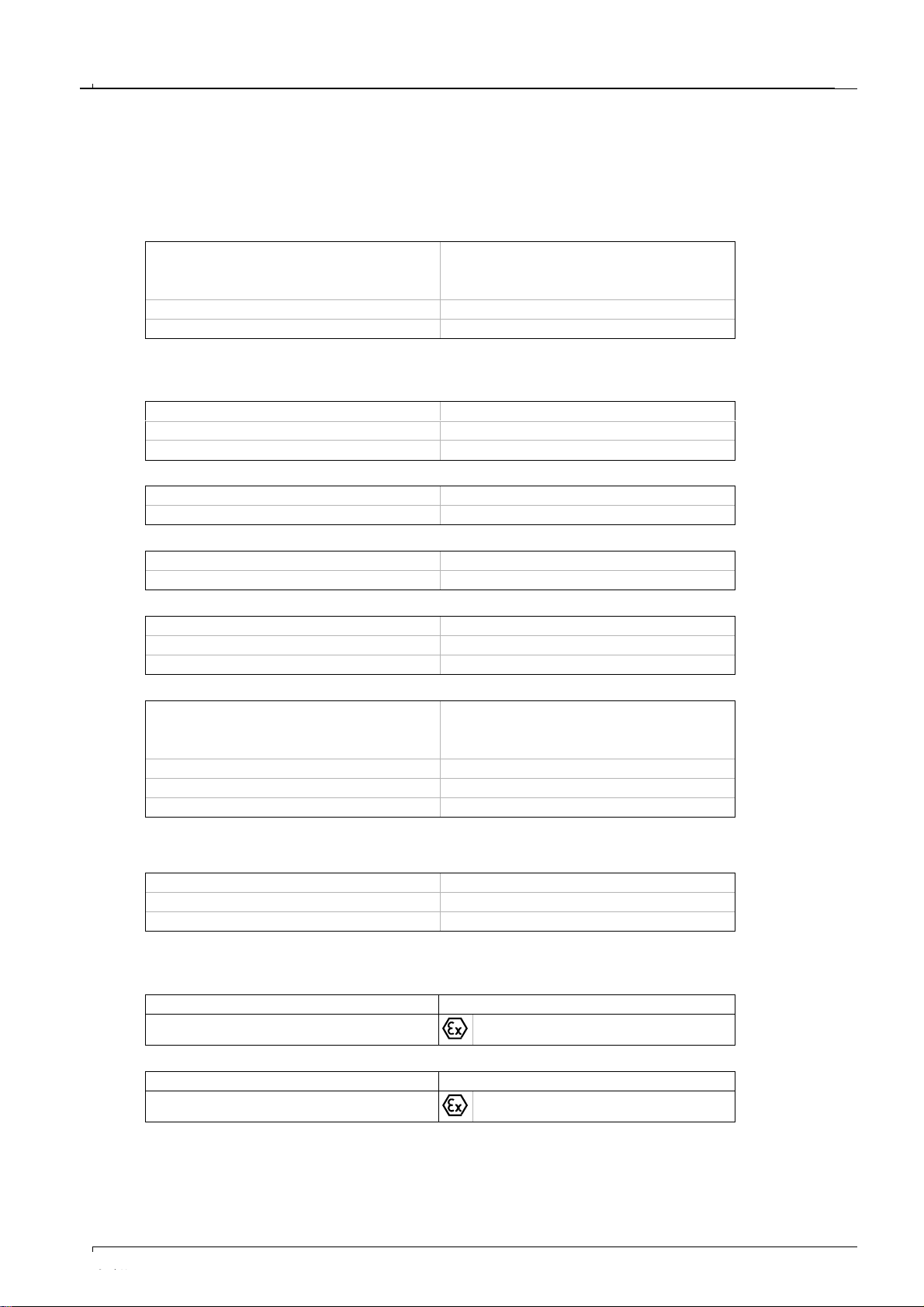

8.1 Technical data

8.1.1 MLA1000-S measuring probe

Operating conditions for the measuring liquid

8.1.2 MLA1000-A display unit

Housing, ambient conditions

Auxiliary power

Suitable connecting cable

Measurement reading display

Measurement reading outputs

8.1.3 MLA1000-K probe cable

8.2 Certification/suitability test

Measuring probe

Display unit

MLA1000 · Operating Instruction ·

8011607 V 1.0

· © MBA Instruments

24

MLA1000 Continuous Conductivity Measurement

8.3 Disposal Information

● The display unit contains electronic components that can be removed and disposed of separately.

● The measuring probe contains electronic components that are inseparably connected to the probe

body (plastic cast moulding).

● The conductor material of the probe cable could be recycled.

A

Connecting cable

– suitable cable material .......................................... 24

– installation instructions .......................................... 17

Scope of application ..................................................... 7

Application restrictions .................................................. 7

Display unit

– mounting ............................................................... 15

– description .............................................................. 9

– cable installation ................................................... 17

– connecting the potential equalisation .................... 16

– technical data ........................................................ 24

B

Type examination certificate ....................................... 24

Intended use ................................................................. 7

Operating display ....................................................... 19

Checking the operating condition (safe/unsafe) ......... 19

D

Display screens ................................................... 19 - 20

Direction of flow .......................................................... 13

E

Installation location ...................................................... 11

Removing the immersion pipe .................................... 21

Installing the immersion pipe ...................................... 14

Disposal ...................................................................... 25

Ex. identification ......................................................... 24

F

Fatal Error .................................................................. 20

Fault detection (troubleshooting). ............................... 23

Functional test ............................................................ 21

Operating principle ....................................................... 8

G

Glossary ....................................................................... 3

H

High (malfunction display) .......................................... 20

Auxiliary power ........................................................... 24

I

Operational start-up procedure ................................... 19

Installation

– mounting the display unit ...................................... 15

– selecting the installation location

for the measuring probe ........................................ 11

– closing the housing ............................................... 18

– information about installing the cables .................. 17

– cable glands .......................................................... 18

– installing the measuring probe

with immersion pipe .............................................. 13

– connecting the measurement reading outputs ...... 17

– preparing the piping system .................................. 12

– connecting the probe cable ................................... 17

– supply voltage, external fuse ................................ 18

Maintenance

– removing the immersion pipe/measuring probe .... 21

– testing the measuring function .............................. 21

– cleaning the measuring probe ............................... 22

K

Cable connection ....................... see "Connecting cable"

Cable glands

– properly plugging .................................................. 18

– technical data ........................................................ 24

Marking (certification) ................................................. 24

L

Scope of delivery ........................................................ 10

Low (malfunction display) ................................ ........... 20

Index

M

Marker arrow ....................................................... 13 - 14

Measuring liquid

– requirements at the installation location ................ 11

– suitable liquids ........................................................ 7

Testing the measuring function .................................. 21

Measuring probe

– requirements for the measuring liquid ................... 11

– description .............................................................. 9

– operating conditions for the measuring liquid ....... 24

– direction of flow ..................................................... 13

– selecting the installation location .......................... 11

– installing with immersion pipe ............................... 13

– cleaning ................................................................ 22

– technical data ........................................................ 24

Removing the measuring probe ................................. 21

Measuring methods .................................................... 25

Measuring methods (operating principle) ..................... 8

Measurement reading display .................................... 19

Measurement reading outputs

– connecting terminals ...................................... 17 - 18

– technical data ........................................................ 24

O

Options .................................................................. 9 - 10

P

Connecting the potential equalisation ......................... 16

Product description ....................................................... 7

Product components ............................................... 8 - 9

R

Preparing the piping system ....................................... 12

S

Sensor error ............................................................... 20

Safe usage ................................................................... 5

Safety instructions ........................................................ 5

– for operation ............................................................ 5

– for installation .......................................................... 5

– for safe usage ......................................................... 5

Fuse

– external (for supply voltage) .................................. 18

– internal overcurrent fuse ....................................... 23

Probe cable

– connecting terminals ............................................. 17

– length, material ....................................................... 9

– technical data ........................................................ 24

Malfunction screens (display) ..................................... 20

Troubleshooting .......................................................... 23

Power consumption .................................................... 24

Direction of flow ................................................... 13 - 14

T

Technical data ............................................................ 24

Test ............................................................................ 21

V

Responsibilities of the user ........................................... 6

Supply voltage

– connecting terminals ............................................. 18

– external fuse ......................................................... 18

– technical data ........................................................ 24

Z

Accessories ................................................................ 10

Certification

– description .............................................................. 7

– identification marking ............................................ 24

MLA1000 Continuous Conductivity Measurement

011607 (1.0) · 2019-10

MLA1000

MBA Instruments GmbH

Friedrich-List-Str. 3-7, 25451 Quickborn, Germany

Phone +49 4106/123 88-80

info@mba-instruments.de

Loading...

Loading...