Page 1

GENUINE Mazda Mobile Start

INSTALLATION INSTRUCTIONS

Thank you for purchasing a genuine Mazda accessory.

Before removal and installation, be sure to thoroughly read these instructions. Please read the contents of this

booklet in order to properly install and use the Mazda Mobile Start. Your safety depends on it.

Keep these instructions with your vehicle records for future reference.

WARNING

There are several WARNING and CAUTION sections in this booklet concerning safety when installing or

•

removing the Mazda Mobile Start. Always read and follow them in order to prevent injuries, accidents, and possible

damage to the vehicle.

WARNING: Indicates a situation in which serious injury or death could result if the warning is ignored.

CAUTION: Indicates a situation in which bodily injury or damage to the vehicle could result if the caution is ignored.

• For areas indicating the tightening torque in this instruction manual, tighten to the specified torque using a torque wrench. For

areas in which the tightening torque is indicated inside parentheses ( ), the tightening torque is indicated as a reference value,

however tightening using a torque wrench is not necessary.

• Do not modify the Mazda Mobile Start.

• Do not install the Mazda Mobile Start in any way other than described in the following instructions.

• If in any doubt, please ask your Mazda dealer to install the accessory in order to prevent errors in installation.

• If you have any questions about the use of the accessory, ask your Mazda dealer for proper advice before using it.

• Mazda and its suppliers are not responsible for injuries, accidents, and damage to persons and property that arise from the

failure of the dealer or installer to follow these instructions.

• To ensure safety and reliability of the work, installation, removal and disposal work must be carried out by an Authorized

Mazda Dealership.

• Be careful not to lose removed parts, and be sure that they are kept free from scratches, grease or other dirt.

PART NUMBER :

NOTE

To the dealer

Please turn over these instructions to the customer after installation.

•

To the customer

Keep these instructions after installation. The instructions may be necessary for

•

installing other optional parts or removal of this accessory.

Should the vehicle or this accessory be resold, always leave these instructions

•

with it for the next owner.

PART NAME :

VEHICLE :

Mazda Mobile Start (MMS)

Mazda 6

0000-8F-Z80 (MMS ECU Kit)

0000-8F-H28 (MMS Harness Kit)

[KD53-V7-629 (Hood Switch)]

1

090003-33260700

Page 2

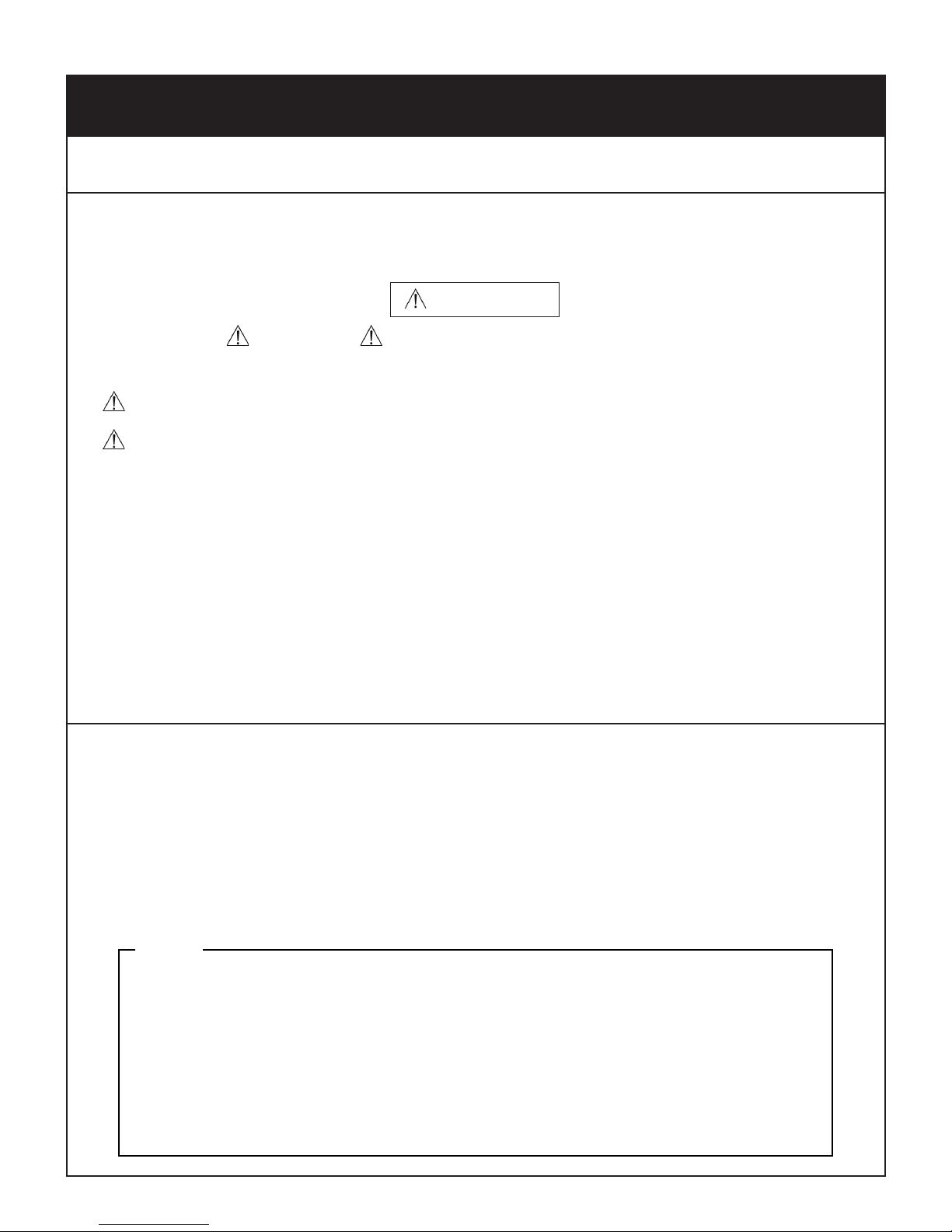

1. INSTALLATION VIEW

(Sold separately) Hood switch

(Only for vehicles without theft-deterrent or without i-ELOOP system)

GPS & TEL Antenna Cables

MMS 2P Connector

RES Diagnostic Connectors

GPS Antenna

MMS ECU

TEL Antenna

Harness (GND)

MMS Harness

LED Connector

2

Page 3

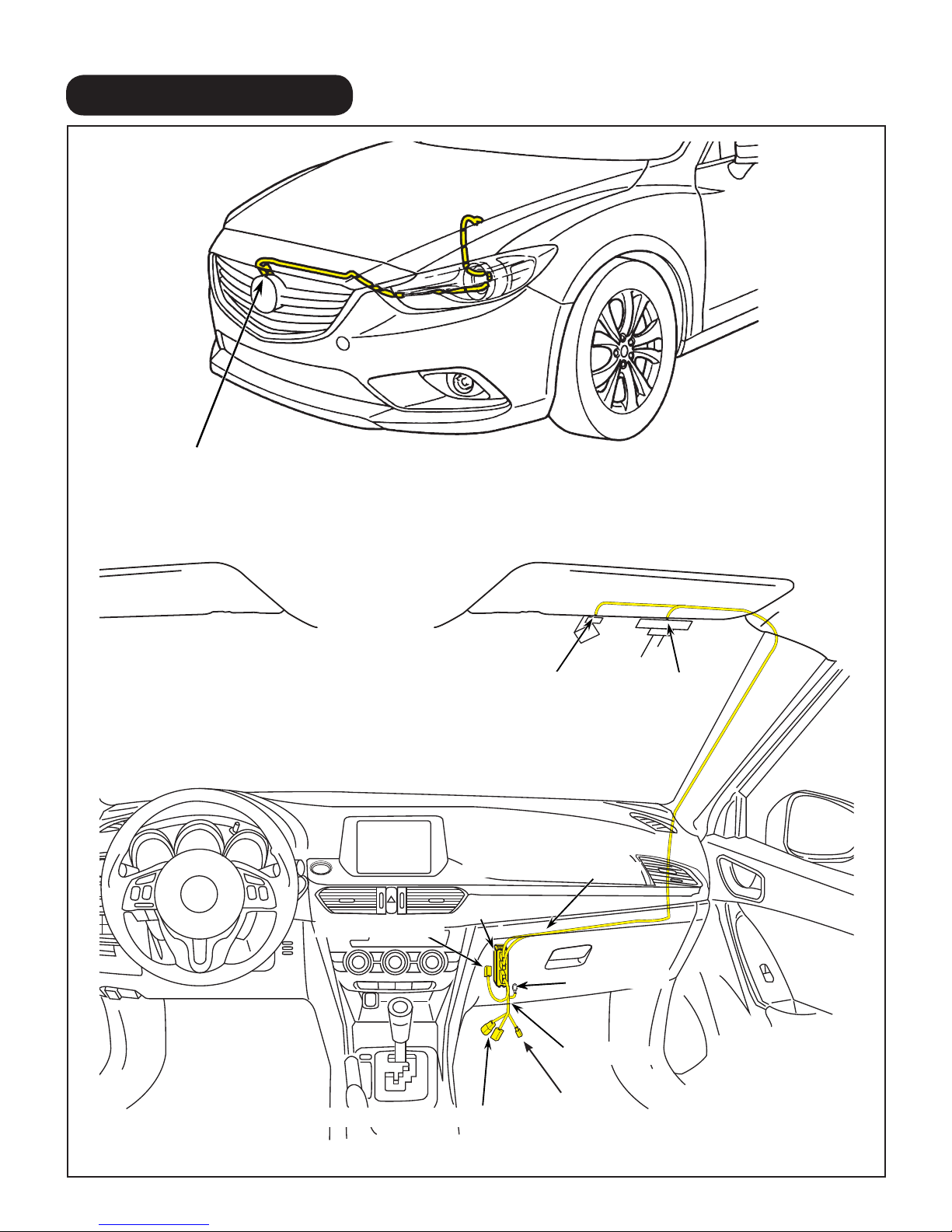

2. PARTS

Note

• Verify that the kit includes all the following parts and that they are free of dirt, scratches, or damage.

MMS ECU KIT (Part no. 0000-8F-Z80)

Part Part Name Qty. Part Part Name Qty. Part Part Name Qty.

MMS ECU

Double-sided

adhesive tape

(25 x 69mm)

Owner's Manual

1

1

1

Wire Tie

(White 200mm)

MMS Key Tag

: Part marked with a star mark is not used for this vehicle.

«

5

1

Urethane

Foam tape

(35 x 115mm)

«

Double-sided

adhesive tape

(25 x 25mm)

HARNESS KIT (Part no. 0000-8F-H28)

Part Part Name Qty. Part Part Name Qty. Part Part Name Qty.

MMS Harness

FH Protection

Sheet

TEL Film

Antenna

1

1

1

LED

GPS Film

Antenna

TEL Antenna

Cable

1

1

1

«

Harness Clamp

GPS Antenna

Cable

Antenna

Template

2

3

2

1

1

«

Electro tap

Installation

Instructions

(ENG/SPA/FRE)

: Parts marked with a star mark are only used on vehicles without theft-deterrent or without i-ELOOP system.

«

1

3

Wire Tie

(White 200mm)

A-Pillar Clip

(D651-68-162A)

15

1

Urethane

Foam tape

(35 x 115mm)

«

Wire Tie

(Black 200mm)

(Sold separately) The following parts are also necessary for installation.

Note

• These parts are not necessary for vehicles with theft-deterrent or with i-ELOOP system because the hood

switch is already equipped.

HOOD SWITCH KIT (Part no. KD53-V7-629)

Part Part Name Qty. Part Part Name Qty.

Hood switch

1

Screw

1

2

10

3

Page 4

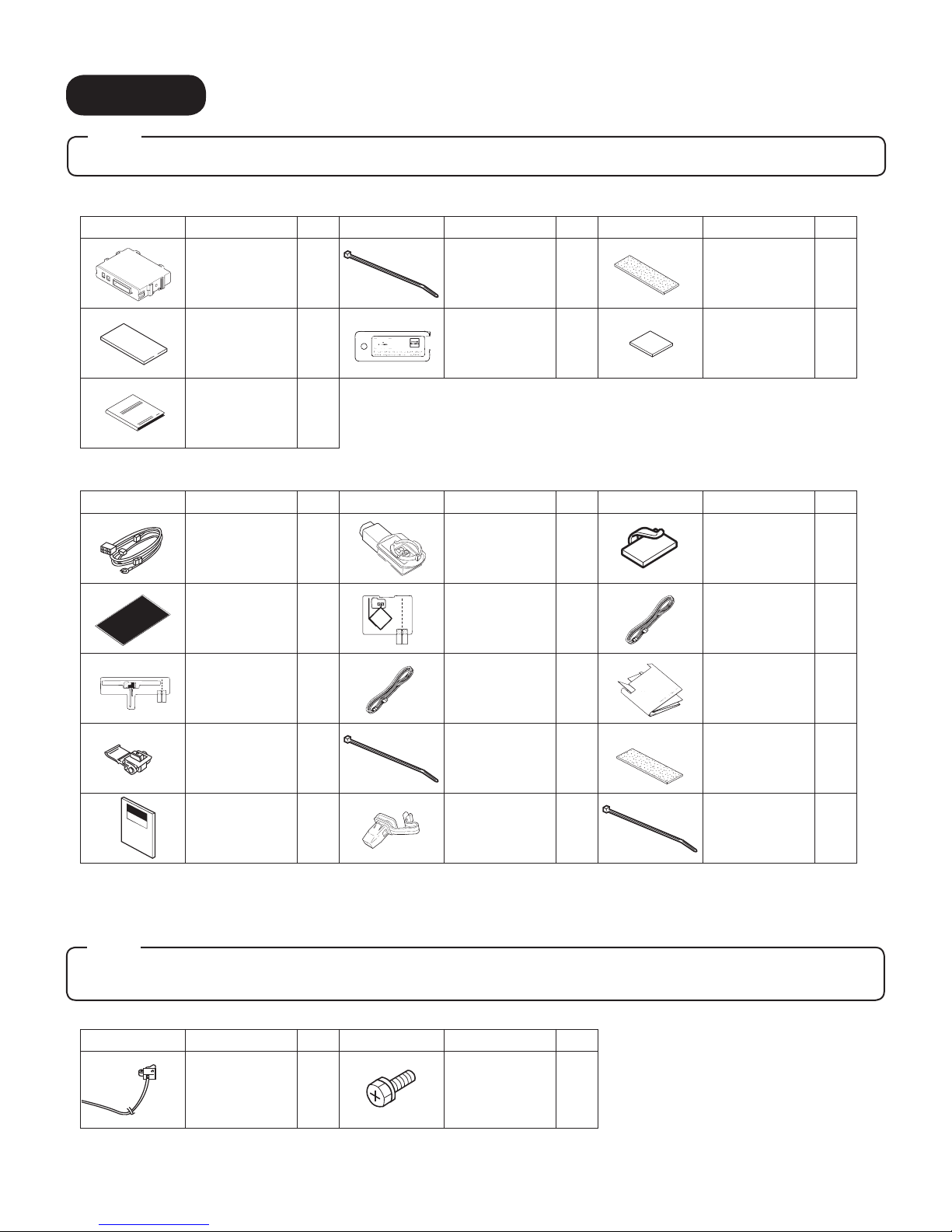

3. BEFORE INSTALLATION

WORKSHOP

MANUAL

REQUIRED TOOLS

• 10mm Socket Wrench • Scissors • Torque Wrench • Taped Flathead Screwdriver • Mat

• Electrical Tape • Panel Removal Tool • Soft clean cloth • Squeegee • Glass Cleaner • Nipper

• Pliers • Primer (3M Promoter-4298) • IPA (Isopropyl alcohol) • Phillips Screwdriver

WARNING

When the negative battery cable

is connected during operation, it

may cause electric shock or other

personal injuries. Disconnect the

negative battery cable before

removal/installation.

When connecting or disconnecting

connectors, grasp the connectors,

not the wires. Otherwise a short,

an accident from poor contact or

re may occur.

Do not pull the harness with

excessive force. Doing so can

cause a breakage or a shortrelated accident, as well as an

electrical short or re.

Park the vehicle on a level ground.

Set the vehicle on park (P) and

apply the parking brake. Be sure to

turn the ignition switch off, otherwise

the vehicle can move, causing

personal injury or vehicle damage.

CAUTION

Using improper tools may cause

damage and or broken parts.

Use the correct tool for the job.

Wrap protective tape around

screwdrivers and fastener

removal tools to prevent

scratching the vehicle.

Put the removed parts and the

parts in the kit on the protective

sheet to prevent scratches.

Excessive length of wire tie may

interfere with other parts and

cause damage. Cut unnecessary

part up to about 5 mm {0.19 in}

from the xed point.

• When the negative battery cable is removed, the clock, radio, trip meters and other memories will be erased.

Make sure to record the content of the memory.

• Refer to the Workshop Manual for removal and installation of vehicle parts. Not following the procedures for

removal/installation in the Workshop Manual could result in an accident or vehicle malfunction.

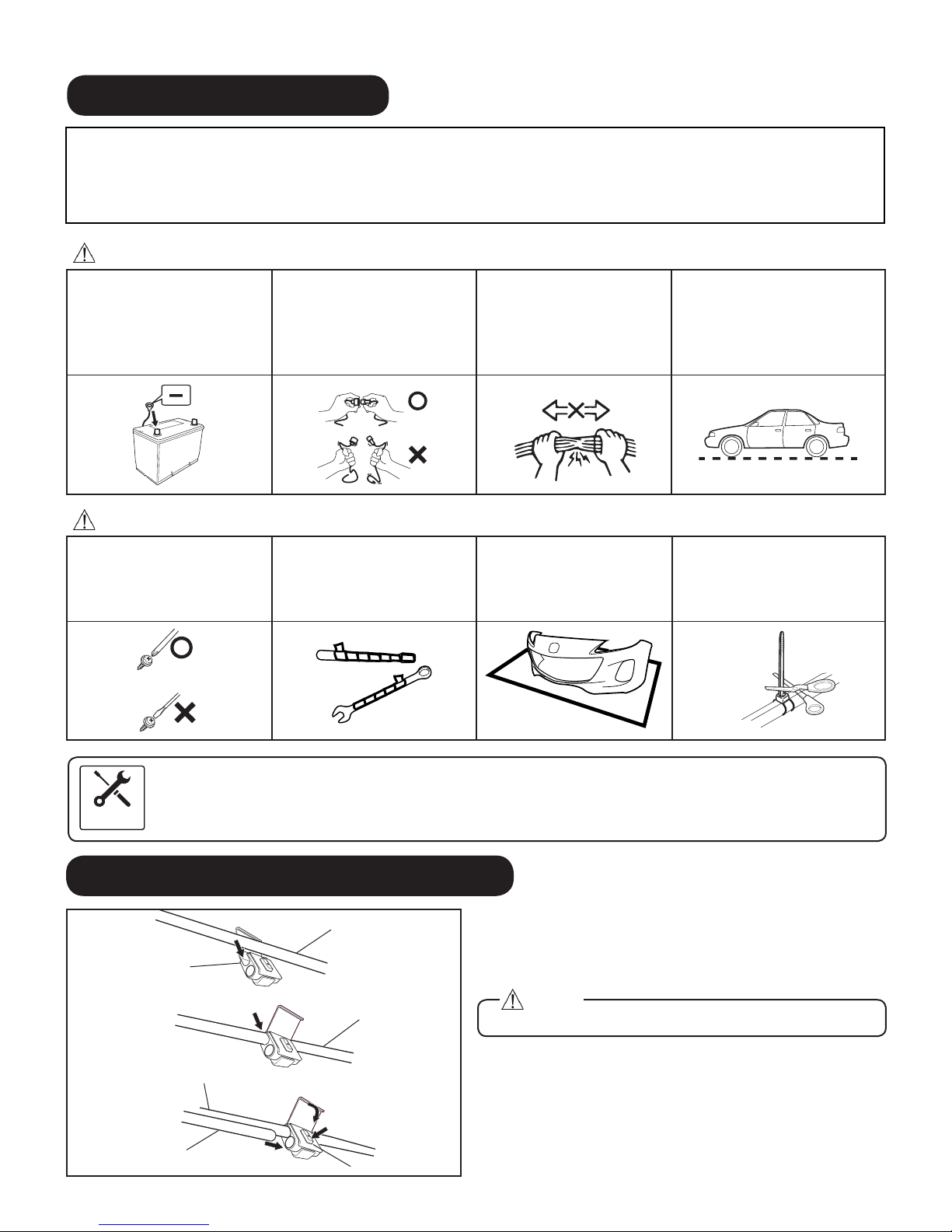

4. CONNECTION USING ELECTRO-TAP

Vehicle wiring harness

1

Electro tap

2

Vehicle wiring harness

Harness

3

Vehicle wiring harness

5

Lock

4

Firmly press using pliers

Terminal

Branch connection procedure using electro tap.

1. Insert the vehicle wiring harness into the electro tap.

2. Fold the electro tap as shown in the gure and lock it.

Caution

• Firmly engage the lock part until a click sound is heard.

3. Insert the harness to the end of the electro tap.

4. Firmly press the electro tap terminal using pliers.

5. Fold the electro tap in the direction of the arrow shown in

the gure and lock it.

4

Page 5

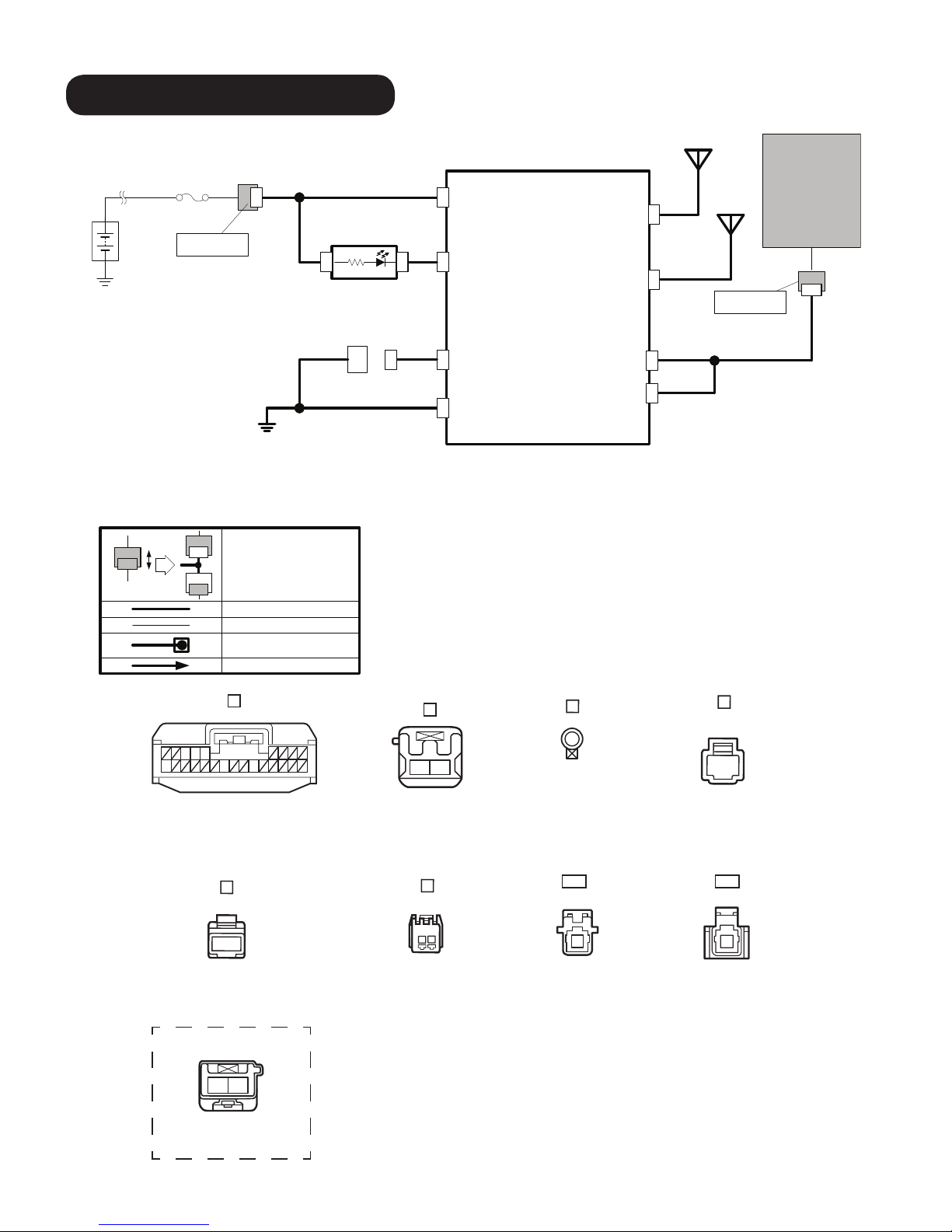

5. CONNECTION DIAGRAM

GPS

20XX-

CONNECTORS

MAZDA MOBILE START (MMS)MMSMAZDA

ROOM

Battery

Pre connector

Pin : 1

B1

RES LED

F2

RES Connector

ANTENNA

SSU

(Start

/

+B

A10

F1

LED

A5

MMS ECU

E1

D1

RDIG

A16

GPS

GPS

TEL

TEL

STX

A4

TEL

ANTENNA

Pre connector

Stop

control Unit)

Pin:2

B2

VEHICLE

CONNECTOR

10

GND (M6)

C1

**

Connector to Connector

**

MMS Wire

Vehicle Wire

Scotch lock connection

MMS or Vehicle Terminal Insert

A

5

34

16 19

(FEMALE PIN)

B

21

(

FEMALE PIN

SRX

GND

A19

A3

C

(TERMINAL PIN)

)

D

1

(MALE PIN)

E

1

(FEMALE PIN)

VEHICLE OPTION CONNECTOR

112

(

)

MALE PIN

F

(MALE PIN)

TEL

1

(

FEMALE PIN

)

GPS

1

(

FEMALE PIN

)

5

Page 6

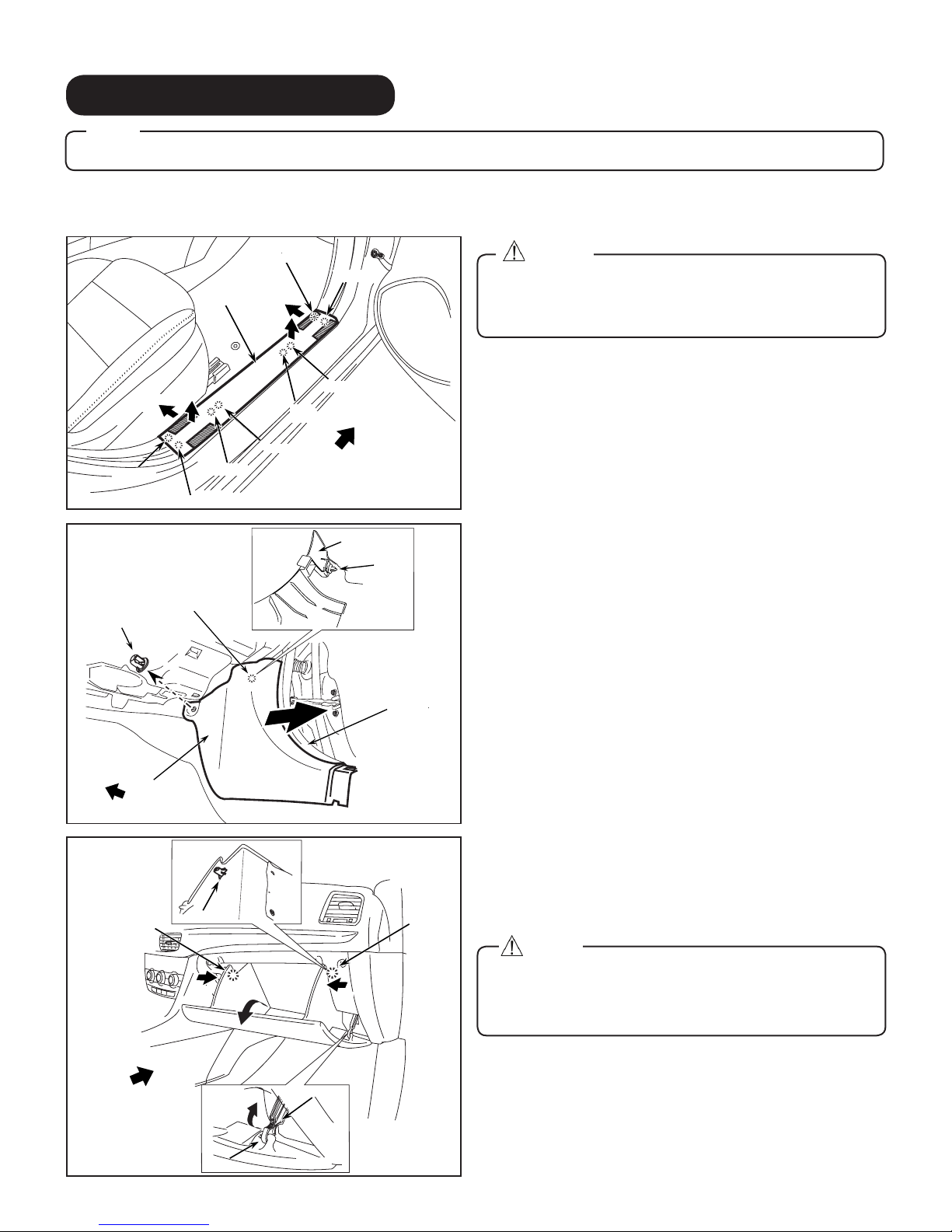

6. VEHICLE DISASSEMBLY

Note

• Be careful not to damage or lose any parts removed from the vehicle since they will be reused.

1. Place the vehicle in park with the parking brake engaged.

2. Disconnect negative battery terminal and wrap tape

around it to insulate.

Warning

• When the negative battery cable is connected during

operation, it may cause electric shock or personal injuries.

Disconnect the negative battery cable before removal/

installation.

Bolt tightening torque: 4.0 - 6.0 N•m (2.9 - 4.4 ft•lbf)

Front Scuff Plate

Tab A

Hook A

(1)

(2)

Tab B

Cap Nut

Cap Nut

Front Side Trim

Front Side Trim

Vehicle front

Vehicle front

Clip A

Pin A

Passenger side scuff plate removal

(4)

(3)

1. Use shaded area to pull (1) and lift (2) Passenger side

Front Scuff Plate to detach Tab A and Clip A.

2. Use shaded area to pull (3) and lift (4) Passenger side

Front Scuff Plate to detach Tab B and Clip B.

Passenger side front trim removal

1. Peel back the Seaming Welt.

Hook B

Clip B

Pin B

Vehicle front

Front Side Trim

Front Side Trim

(Backside)

(Backside)

Clip

Clip

2. Remove Cap Nut.

Clip

Clip

Seaming Welt

Weather strip

3. Remove Front Side trim.

Hook A

Vehicle front

Hook A

(1)

(2)

Dampener

(3)

Hook B

Glove box removal

1. Push both sides (1) and pull (2) Glove box to dislodge 2

Hooks (A).

Hook A

2. Pull (3) Dampener to detach Hook B.

Caution

• If the glove box is closed without being joined to the stay

(1)

dampener, the stay dampener may be damaged. Verify

that the stay dampener is joined to the glove box before

closing the glove box.

6

Page 7

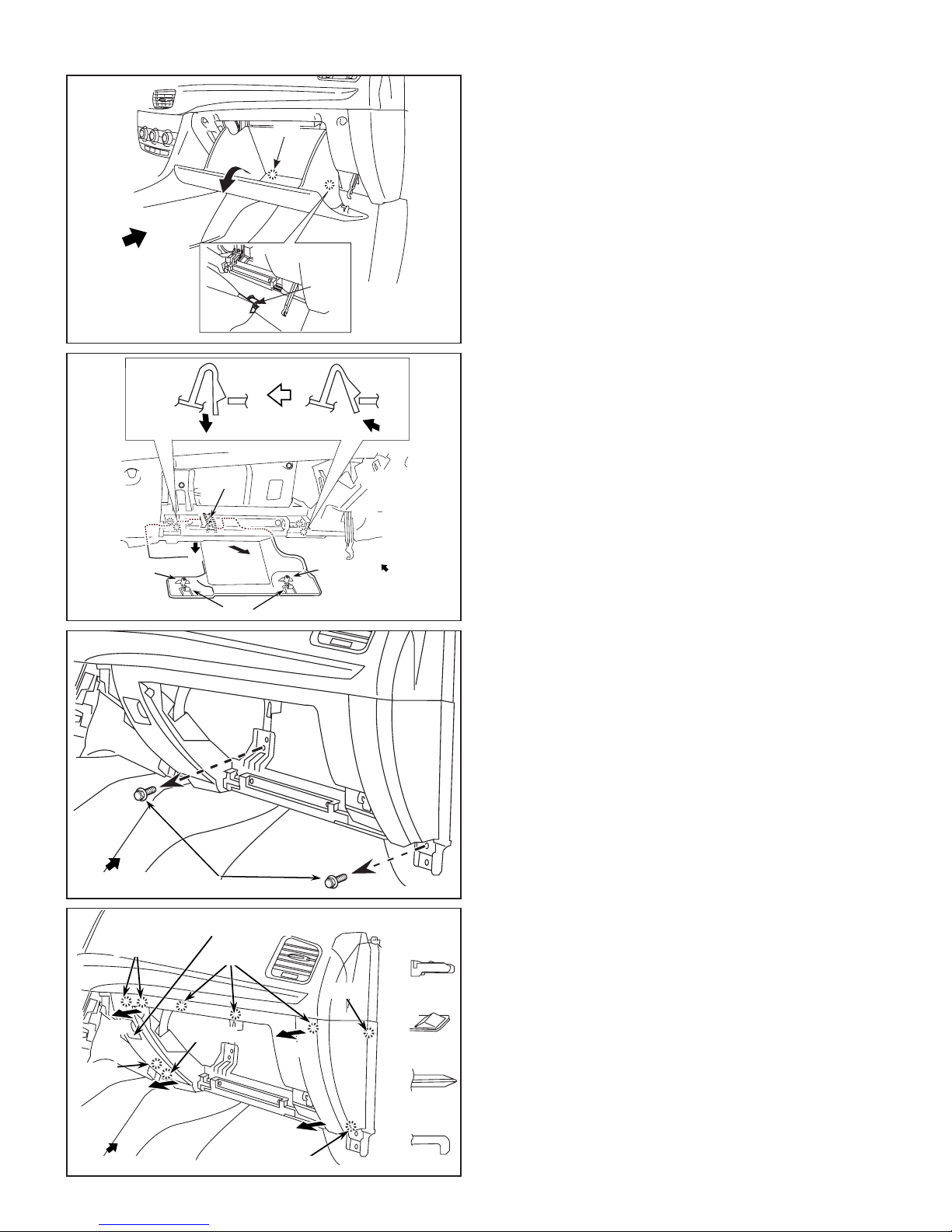

Vehicle front

3. Remove Glove box by detaching 2 bottom Hooks.

Hook

Hook

Hook A

Pin B

(2)

(2)

Guide C

(3)

Hook A

4. Remove Glove box under cover in order of arrows (1) - (3).

(1)

Pin B

Vehicle front

Passenger side lower panel removal

1. Remove 2 Bolts.

Bolt tightening torque: 2.0 - 6.0 N•m (1.5 - 4.4 ft•lbf)

Vehicle front

Vehicle Front

Clips B

Clips B

(3)

(3)

Clips B

Clips B

Vehicle Front

Vehicle front

Air Bag deactivation (PAD) switch

Bolts

Bolts

Air Bag deactivation (PAD) switch

Clips B

Clips B

Guide E

Guide E

(4)

(4)

(2)

(2)

Pin D

Pin D

(1)

(1)

Clips B

Clips B

Clips B

Clips B

Hook C

Hook C

Pin D

Pin D

Guide E

Guide E

2. Disconnect the passenger airbag deactivation (PAD)

switch connector. (Only for vehicles with passenger airbag

deactivation (PAD) switch)

3. Remove lower panel in order of arrows (1) - (4).

7

Page 8

Clip B

Clip B

Clip A

Clip A

Clip B

Clip B

A-Pillar trim removal

1. Partially peel back the seaming welt.

2. Dislodge the Passenger side A-pillar trim by pulling on the

shaded area to disengage Clip B and A.

Caution

(1)

• Do not use excessive force, A-pillar could be damaged.

Passenger Side A-Pillar

Passenger Side A-Pillar

Grommet Nipper

Grommet

Clip B

Part B

Nipper

Lead Wire

Tab

A-pillar trim

A-Pillar trim

Weather strip

Seaming welt

3. Cut the A-pillar tab wire connecting part B and the

grommet of the A-pillar tether clip.

4. Remove the A-pillar trim while detaching Guides.

A-pillar trim

A-Pillar trim

Vehicle Front

Vehicle Front

Guides

Guides

Hook

Grommet

Tape-wrapped athead screwdriver

Grommet

Grommet

Hook

Tape-wrapped at head screwdriver

A-Pillar inner panel

(1)

(1)

Tape-wrapped athead screwdriver

Front Pillar inner panel

(3)

(3)

(2)

(2)

Tape-wrapped athead screwdriver

Tape-wrapped at head screwdriver

Tape-wrapped athead screwdriver

Grommet

Grommet

5. Remove the Grommet from the A-pillar by using a flat

head screwdriver by following sequence (1) - (3).

6. Install the new supplied A-pillar tether clip into A-pillar

before proceeding.

Caution

• Ensure the new supplied tether clip is used in step 6.

8

Page 9

7. HOOD SWITCH INSTALLATION

Note

• This procedure is not necessary for vehicles with Theft-deterrent System or with i-ELOOP system because the

hood switch is already installed.

Fastener

Flathead screwdriver

Guides

Set plate

Fastener

Vehicle Front

Hood latch cover

1. Remove 2 Fasteners from the Vehicle Set Plate.

2. Remove the Vehicle Set Plate.

3. Remove the Hood Latch Cover.

Flathead scredriver insertion slot

(1)

Tab

Hood l atch

Main fuse cover

Main fuse cover

Tab

Tab

Vehicle Front

Vehicle Front

(2)

Tab

Vehicle Front

Hood l atch

4. Remove the Main Fuse cover.

9

Page 10

Fresh air duct

Bolts

5. Remove 2 Bolts from the Fresh air duct.

Bolt tightening torque: 7.8 - 10.8 N•m (5.7 - 7.9 ft•lbf)

Vehicle Front

Fresh air duct

Fastener Grille bracket

Fastener

Screw

Screw

6. Lift Fresh Air duct to remove Fastener.

7. Remove 1 Fastener and 2 Screws.

Screw tightening torque: 4.0 - 9.8 N•m (2.9 - 5.8 ft•lbf)

Vehicle Front

Hood Latch

Hood Switch

Vehicle front

8. Install the Hood switch to the Hood Latch and secure it

using the supplied Screw.

Screw

10

Page 11

Vehicle front

Vehicle front

Do not let hood switch harness

make contact with bolt

Harness Clamp

Hood switch harness

Upper Shroud member

Upper shroud member

Bolt

Wire Tie (Black)

Harness Clamp

Vehicle Front

Hood switch harness

Hood switch harness

9. Hook the Hood switch harness to the Hood latch and

secure it using a wire tie (black).

10. Peel the tape backings from the harness clamps and afx

them on the upper shroud member on 2 locations.

Caution

• Clean attachment surface using isopropyl alcohol and

cleaning towel.

11. Route the hood switch harness and secure them to the 2

harness clamps. Press firmly on clamp tabs to ensure

secure retention of hood switch harness.

12. Route the Hood switch harness between the Grille bracket

and the upper shroud member.

Grille bracket

Grille bracket

Hood switch harness

Hood Switch Harness

Pass behind vehicle

Pass behind vehicle

wiring harness

wiring Harness

Wire Tie (Black)

Tie Wrap (Black)

Hood switch harness

Hood switch harness

Vehicle Front

Vehicle front

Wire Tie (Black)

Tie Wrap (Black)

Wire Tie (Black)

Tie Wrap (Black)

Vehicle wiring harness

Vehicle wiring harness

Shroud panel Vehicle front

Shroud panel

Vehicle wiring harness

Vehicle wiring harness

13. Secure the Hood switch harness to the shroud panel using

1 wire tie (black).

14. Route the Hood switch harness along the Vehicle wiring

harness and secure it with 2 wire ties (black).

Caution

• Secure the Hood switch harness on the Vehicle wiring

harness so that the hood switch harness does not contact

the vehicle edge.

15. Route the Hood switch harness along the vehicle wiring

harness and secure it with 1 wire tie (black).

Pass behind vehicle

Pass behind vehicle

wiring harness

wiring harness

Vehicle front

Vehicle front

Wire Tie (Black)

Wire tie (Black)

11

Page 12

Vehicle wiring harness

<Terminal insertion procedure>

18 pin connector

Hood switch harness (White)

<Terminal insertion procedure>

Terminal

Terminal

Retainer

Retainer

(b) Insertion terminal

Terminal

(a) Remove retainer

(c) Reinstall retainer

Terminal

[Vehicle wiring harness 18 pin connector]

(Connector viewed from wiring harness side)

Insert hood switch harness (White)

terminal to empty terminal.

Type A

Vehicle wiring harness

18 pin connector

[Vehicle wiring harness 18 pin connector]

(Connector viewed from wiring harness side)

Terminal: A (Black)

Hood switch harness (Black)

Type B

Vehicle wiring harness

18 pin connector

[Vehicle wiring harness 18 pin connector]

(Connector viewed from wiring harness side)

B

Terminal: B (Black)

Hood switch harness (Black)

Insert Terminal

Vehicle front

Hood switch harness (Black)

Electro tap and

electrical vinyl tape

Vehicle front

Hood switch harness (Black)

Electro tap and

electrical vinyl tape

Vehicle front

16. Insert the Hood switch harness (White) terminal to the

empty terminal of the Vehicle wiring harness 18 pin

connector (terminal N).

Caution

• When connecting a terminal to a connector, always refer

to the following, <Terminal insertion procedure>.

• Connect the harness terminal to the specied signal line

because a system or vehicle malfunction may occur if it

is connected incorrectly.

Vehicles with wiring harness terminal A (Black) shown in

gure (Type A)

Note

• If there is no vehicle wiring harness (Black) in the specied

position, do not perform Step 17, skip to Step 18.

17. Connect the Hood Switch harness (Black) to the vehicle

wiring harness 18 pin connector (terminal A (Black)) using

an Electro tap, and wrap the Electro tap with electrical tape.

Vehicles with wiring harness terminal B (Black) shown in

gure (Type B)

18. Branch connect the Hood Switch harness (Black) to the

vehicle wiring harness 18 pin connector (terminal B (Black))

using an Electro tap, and wrap the Electro tap using

electrical tape.

Please note caution for step 17-18 above.

Caution

• Connect the electro tap to the specied signal line because

a system or vehicle malfunction may occur if it is connected

incorrectly.

• For branch connection procedure using electro tap, refer to

[4. CONNECTION USING ELECTRO TAP] on page 4.

Hood switch harness

Wire tie (Black)

Vehicle wiring harness

19. Route the Hood Switch harness along the vehicle wiring

harness and secure it with 1 wire tie (black).

Vehicle front

12

Page 13

8. MAZDA MOBILE START INSTALLATION

Vehicle harness

2P connector

MMS ECU

Double-sided

Adhesive tape

MMS ECU

Urethane

foam tape

1. Degrease the MMS ECU using primer; apply primer only

to indicated areas where tape is attached on both sides.

Caution

• Use 3M Promoter-4298 for primer.

• When degreasing using primer, only apply primer to indicated

area to prevent other parts from becoming discolored.

• After degreasing using primer, let it dry for 1 min. or more.

2. Apply Double-sided tape on the MMS ECU.

3. Flip over the MMS ECU and apply Foam tape.

4. Detach 2 Vehicle harness clamps from the Vehicle bracket.

5. Plug in MMS harness 2P connector to Vehicle harness 2P

connector.

6. Install the MMS harness Ground terminal to the Vehicle

Ground terminal bolt.

MMS 2P

connector

Ground

location

Clamps

SIDE VIEW FRONT VIEW

Bolt tightening torque: 8.8 - 12.7 N•m (6.4 - 9.3 ft•lbf)

7. Place the MMS ECU in between the Vehicle bracket and

Vehicle harness attaching the double-sided tape on the

Vehicle bracket.

Caution

• Clean attachment surface using isopropyl alcohol and

cleaning towel.

8. Create 2 extra large wire ties by using 2 sets of 2 wire

ties, where 1 set consists of 2 wire ties (white) connected

together to create 1 extra large wire tie.

9. Secure the Vehicle harness and MMS ECU together to the

Vehicle bracket using the 2 extra large wire ties (white).

13

Page 14

10. Plug in the MMS harness 24P connector to the MMS ECU.

11. Place the Antenna template face down on the windshield

outside the vehicle, aligning the top with the headliner and

the side to the passenger side A-pillar and temporarily

secure it with electrical tape.

Antenna template

GPS Film

Antenna

Green Tab

GPS Film Antenna Backing

GPS Film Antenna Backing

Blue Tab

Green Tab

Green Tab

GPS Film Antenna

GPS Film Antenna

GPS Film Antenna

GPS Film Antenna

Headliner

Headliner

Caution

• Use glass cleaner to clean the inside windshield attachment

surface indicated by the template before attaching the GPS/

TEL Film Antennas.

12. Use the Blue tab to remove the partial protective backing

from the GPS Film Antenna.

13. From inside the vehicle, align to the edge of the headliner

and within the specified template location, attach the

partially exposed adhesive side of the GPS Film Antenna

on the Windshield.

14. Use the Green tab to slowly peel off the remaining

protective backing while using a squeegee to attach the

GPS Film Antenna on the Windshield.

Caution

• Make sure to use a squeegee when attaching the GPS Film

Antenna on the windshield to eliminate any air bubbles.

Green Tab

Green Tab

14

Page 15

Vehicle front

GPS Film Antenna

2

GPS Film Antenna

Top Protective Sticker

Top Protective Sticker

GPS Film Antenna

GPS Film Antenna

t

Top Protective Sticker

Top Protective Sticker

15. Carefully and slowly peel off the top protective sticker

leaving only the GPS Film Antenna on the Windshield.

Caution

• Do not touch the GPS Film Antenna Terminal.

After installing the GPS Film Antenna, proceed to the

next step to install the TEL Film Antenna.

TEL Film Antenna

TEL Film Antenna

TEL Film Antenna

TEL Film Antenna

No. 2 Tab

16. Use no. 1 tab to peel off the partial protective backing of

Headliner

Headliner

the TEL Film Antenna.

17. From inside the vehicle, align to the edge of the headliner

12

and within the specified template location, attach the

partially exposed adhesive side of the TEL Film Antenna

on the Windshield.

2

18. Use no. 2 tab to slowly peel off the remaining Protective

Protective Backing

Protective Backing

Squeegee

backing while using a squeegee to attach the TEL Film

Antenna on the windshield.

Squeegee

Caution

• Make sure to use a squeegee when attaching the TEL Film

Antenna on the windshield to eliminate any air bubbles.

TEL Film Antenna

TEL Film Antenna

Top Protective Sticker

Top Protective Sticker

TEL Film Antenna

TEL Film Antenna

19. Carefully and slowly peel off the Top Protective Sticker

leaving only the TEL Film Antenna on the windshield.

Caution

• Do not touch the TEL Film Antenna Terminal.

Next, proceed to install the GPS Connector.

Vehicle front

15

Page 16

G

50mm

50mm

GPS Connector

50mm

50mm

3 x 1/2 Urethane

Foam tape

50mm

50mm

20. Cut 2 urethane foam tapes into 4 pieces of 1/2 sized

urethane foam tapes.

21. Wrap the GPS Connector cable with 1/2 piece of urethane

foam tape 50mm away from the GPS Connector.

22. Wrap 2 more 1/2 pieces of urethane foam tape 50mm

away from each other.

23. Peel the protective backing off the GPS Connector.

24. Attach the GPS Connector making sure to align to the

GPS Film Antenna line guide.

Caution

• Press the GPS Connector rmly against GPS Film Antenna

Terminal.

GPS Film Antenna

50mm

50mm

Next, proceed to install the TEL Connector.

GPS Connector

25. Wrap the TEL Connector Cable with the remaining 1/2 piece

of urethane foam tape 50mm away from the TEL Connector.

TEL Connector

1/2 Urethane

Foam tape

26. Peel the protective backing off the TEL Connector.

27. Attach the TEL Connector making sure to align to the TEL

Film Antenna line guide.

TEL Film Antenna

Caution

• Press the TEL Connector rmly against TEL Film Antenna

Terminal.

TEL Connector

16

Page 17

Vehicle Headliner

TEL Antenna Cable

GPS Connector Cable

28. Tuck both Antenna cables in between the headliner and

the windshield routing them toward the passenger side

A-pillar area.

GPS & TEL Antenna Cables

4 x Wire Ties

(White)

1/2 FH Protection sheet

29. Route the Antenna cables down the passenger side A-pillar

and secure to the vehicle harness using 4 wire ties (white).

Caution

• Ensure that Antenna cables does not interfere with airbag

operation. Do not secure wire ties to airbag or sunroof

drain tube.

Vehicle Harness

30. Cut the FH Protection sheet in half.

31. Wrap the Antenna cables starting from the bottom of the

A-pillar using the 2 pieces of 1/2 FH Protection sheet.

32. Secure the FH Protection sheet using electrical tape.

1/2 FH Protection sheet

GPS & TEL Antenna Cables

Vehicle right

33. Route both GPS & TEL Antenna Cables down towards the

Glove box area.

17

Page 18

IP reinforcement bar

Vehicle right

GPS & TEL Antenna Cables

34. Continue routing the Antenna cables from the A-pillar

behind the IP reinforcement bar.

GPS & TEL Antenna Cables

35. Route the Antenna Cables behind the vehicle bracket

towards the MMS ECU.

Vehicle Bracket

Vehicle front

Vehicle front

IP reinforcement

bar

MMS harness

24P Connector

IP reinforcement bar

Wire Tie

(White)

GPS 1P

Connector

TEL 1P

Connector

2 x Wire Ties

(White)

MMS ECU

Wire Tie

(White)

Vehicle

harness

36. Plug in both the GPS and TEL cable 1P connectors to the

MMS ECU.

37. Secure the Antenna Cables to the vehicle IP reinforcement

bar using 1 wire tie (white).

38. Secure the Antenna Cables to the vehicle IP reinforcement

bar using 2 wire ties (white).

39. Secure the Antenna Cables to the vehicle harness using

1 wire tie (white).

GPS & TEL Antenna Cables

18

Page 19

Vehicle Harness

GPS & TEL Antenna Cables

2 x Wire Ties

(White)

40. Bundle up the excess Antenna Cables and secure to the

vehicle harness using 2 wire ties (white).

MMS Harness

41. Connect the LED to the MMS Harness 2P White connector.

Complete Section 9 {MMS Registration Procedure}

& Section 10 {MMS Check Mode} before proceeding

to Section 11 {Reinstallation/Inspection}

LED

19

Page 20

Seconds

2X

Within

10 Seconds

ON

OFF

Security Indicator

ON for 3 Seconds

OFF

Security Indicator

Flashing

OFF

Connect for

3 Seconds

ON

OFF

9. MMS REGISTRATION PROCEDURE

Make sure of the following conditions:

1. In possession of 2 Advanced Keys that are already registered to the vehicle.

2. Do not open any doors during MMS registration procedure.

Steps MMS Registration Procedure

Connect the negative battery cable and close the hood.

1

Enter vehicle's passenger side and close the door.

• MMS Harness LED lights up, wait 30 seconds until the LED light

turns off

Response

when

successful

30

Response

when it fails

Connect and disconnect the RES Diagnostic Connectors twice

within 10 seconds.

2

3

4

5

60 seconds of completion of Step 2.

Steps 3 - 6 must be completed within

• MMS Harness LED makes 2 ashes.*

If the MMS Harness LED did not ash, this procedure has failed.

• Disconnect the battery and start over from step 1.

Hold up the Advanced Key over the Start Button switch, then

press the Start Button with the Advanced Key twice to the ON

position.

• Security indicator turns ON for 3 seconds, then turns off

f Security indicator does not turn ON, this procedure has failed.

I

• Disconnect the battery and start over from step 1.

Within 4 seconds of the security indicator turning off, press the

Start Button with the Advanced Key to the OFF position.

• The Security indicator ashes.

If Security indicator does not ash, this procedure has failed.

• Disconnect the battery and start over from step 1.

Repeat steps 3 and 4 for the 2nd Advanced Key.

After both Advanced keys have been authenticated, connect the

RES Diagnostic Connectors for at least 3 seconds then disconnect.

Observe the number of ashes from the MMS Harness LED.

• MMS Harness LED ash 2 times and Start Button light will turn

6

If this procedure failed, the ignition switch stays OFF. Look at the

table below to determine the cause of failed registration.

• Check and x the cause of failed registration.

• Disconnect the battery and start over from step 1.

ON automatically for a few seconds then shuts off, indicating a

successful registration. Proceed to next section MMS Check Mode.

2X

2X

1,3,4,5,6,7

# of LED Flashes Cause of Failed Registration

1 Missed operation or step

3 3 or more Advanced Keys are already registered

4 Vehicle condition is not satised or MMS ECU is already registered (proceed to MMS Check Mode)

5 Time limit have elapsed

*If LED makes 5 ashes on step 2, refer to table above for 3 ashes.

[After a successful MMS registration, proceed to next section for MMS Check Mode]

6 Advanced Keys are not registered.

7 Communication error between MMS and SSU.

20

Page 21

r

2X

2X

2X

2X

10. MMS CHECK MODE

The following procedure is performed to verify MMS operation after MMS registration. Make sure that MMS Registration was

successful prior to proceeding.

MMS check mode preparations:

1. Place 1 Advanced Key at least 5 feet away from the vehicle and keep 1 Advanced key in your possession.

2. Enter vehicle passenger's side and leave the door open.

3. Press the hazard lights switch on the center console and take note of where the hazard light indicators are on the dash.

Turn off hazard the lights.

Steps MMS Check Mode

Disconnect Afte

10 Seconds

1

2

within 15 seconds of

completion of step 1.

Step 2 must be completed

A. Connect RES Diagnostic connectors.

B. After 10 seconds, disconnect the Diagnostic connectors

and reconnect Diagnostic connectors.

• Horn will sound 2 times.

If the Horn does not sound, this procedure has failed.

• Disconnect the Diagnostic connectors and start over.

A. Press the Start Button 3 times to switch ignition to ON and

OFF.

B. Exit the vehicle with the Advanced key and place it at least

5 feet away from the vehicle.

C. Enter the vehicle and close the door.

• Horn will sound 2 times.

• Horn will sound 2 times again before the engine starts.

If the engine does not start or horn does not sound, this

procedure has failed.

• Disconnect the Diagnostic connectors and start over from

step 1.

Response

when

successful

ON

Response

when it fails

OFF

A. Let the engine run for at least 6 seconds.

B. Disconnect the Diagnostic connectors and observe

3

# Hazard Flashes Meaning of Hazard Flashes

2 Check mode successful

4 Communication Module and MMS ECU connection problem

6 TEL antenna connection problem

8 GPS antenna connection problem

10 Inadequate reception problem

MMS Check mode will end if any of the following conditions are met:

1. Engine has stopped when any one of the MMS engine stop conditions is met.

2. 10 minutes have elapsed.

3. RES Diagnostic connectors are disconnected.

4. MMS check mode will end if starting engine via MMS failed.

Hazard lights for number for ash.

• Engine stops, check table below for corresponding

hazard light ashes.

21

Page 22

11. REINSTALLATION / INSPECTION

2 x Wire Ties

(White)

MMS harness

RES Diagnostic

Connectors

1. Disconnect the LED from the MMS Harness and discard.

LED

2. Secure MMS harness LED connector and ground wire to

the vehicle harness with 1 wire tie (white).

3. Secure the RES Diagnostic connectors to the vehicle

harness with 1 wire tie (white).

Lower panel (Passenger's side)

Glove compartment

Standard value: 0.5-2.5mm

Standard value: 0.5-2.5mm

Vehicle Harness

4. Reinstall parts in the reverse order of the installation

procedure [Section 6 Vehicle Disassembly].

5. After installing the passenger's side lower panel and glove

compartment, measure the clearance, and verify that the

measurement value is within the specication shown in

the gure.

Caution

• If the measurement value is not within the specication after

measuring the clearance between the passenger's side

lower panel and glove compartment, adjust the passenger's

side lower panel to the proper position.

6. Refer to "Required servicing after disconnection/

connecting negative battery cable" in the vehicle workshop

manual or the owner's manual to restore the vehicle

functions.

7. Attach key tag to Advanced Key.

22

Page 23

Date:

VIN:

Approved

Checked

Person in

charge

INSTALLATION

INSPECTION

SHEET

Perform the following inspections.

MAZDA 6

Mazda Mobile Start (MMS)

0000-8F-Z80 (MMS ECU Kit)

0000-8F-H28 (MMS Harness Kit)

KD53-V7-629 (Hood Switch)

WARNING

Before starting the engine, make sure there are no persons in front of or behind the vehicle, or around the engine

•

compartment. Otherwise a serious accident could result by the vehicle suddenly moving.

Do not start the engine in a place like a garage or other placer with poor ventilation. Otherwise, poisoning or asphyxation

•

could result from accumulation of axhaust gas.

Always set the wheel blocks on level ground before performing the verification.

•

1. Inspection items after installation

Verify the fitting between the vehicle part and the installed part, and inspect for damage or dirt.

•

2. Vehicle parts reinstallation

Check

Inspection Parts Inspection Items

Negative battery cable Torque check Are the battery cables securely tightened to the terminals?

Ground Torque check Is the ground bolt tightened to the proper torque?

Function restore procedure

after removal / Installation

of battery

3. Installation of accessory, operation check

Inspection Parts Inspection Items

MMS ECU Registration

Operation

Inspection Check

Have the vehicle's functions been restored by referring to "Required

servicing after disconnecting connecting negative battery cable", in

the workshop manual or the owner's manual?

Inspection Check

Has the MMS ECU been registered and checked per Section 9

(MMS Registration Procedure) and Section 10 (MMS Check Mode)

of the installation instructions?.

23

Loading...

Loading...