Page 1

1

GENUINE PARKING SENSORS (Rear)

INSTALLATION INSTRUCTIONS

Thank you for purchasing a genuine Mazda accessory.

Before removal and installation, be sure to thoroughly read these instructions.

Please read the contents of this booklet in order to properly install and use the parking sensors

(Rear). Your safety depends on it.

Keep these instructions with your vehicle records for future reference.

There are several WARNING and CAUTION sections in this booklet concerning safety when

installing or removing the parking sensors (Rear). Always read and follow them in order to prevent

injuries, accidents, and possible damage to the vehicle.

WARNING: Indicates a situation in which serious injury or death could result if the warning

is ignored.

CAUTION: Indicates a situation in which bodily injury or damage to the vehicle could result if the

caution is ignored.

For areas indicating the tightening torque in this instruction manual, tighten to the specified torque using

a torque wrench.

Do not modify the parking sensors (Rear).

Do not install the parking sensors (Rear) remove in any way other than described in the following

instructions.

If in any doubt, please ask your Mazda dealer to install the accessory in order to prevent errors in

installation.

If you have any questions about the use of the accessory, ask your Mazda dealer for proper advice

before using it.

Mazda and its suppliers are not responsible for injuries, accidents, and damage to persons and property

that arise from the failure of the dealer or installer to follow these instructions.

To ensure safety and reliability of the work, installation, removal and disposal work must be carried out

by an Authorized Mazda Dealership.

Be careful not to lose removed parts, and be sure that they are kept free from scratches, grease or

other dirt.

PART NAME: Parking Sensors (Rear)

VEHICLE: MAZDA CX-5

PART NUMBER: KB7W V7 290A (Parking Sensors, Main Kit)

C860 V7 281A (Parking Sensors, Sensor Kit)

KD33 V7 282

(Optional ON-OFF switch)

To the dealer

Please turn over these instructions to the customer after installation.

To the customer

Keep these instructions after installation. The instructions may be necessary

for installing other optional parts or removal of this accessory.

Should the vehicle or this accessory be resold, always leave these instructions

with vehicle for the next owner.

NOTE

06DE4313B

WARNING

Page 2

2

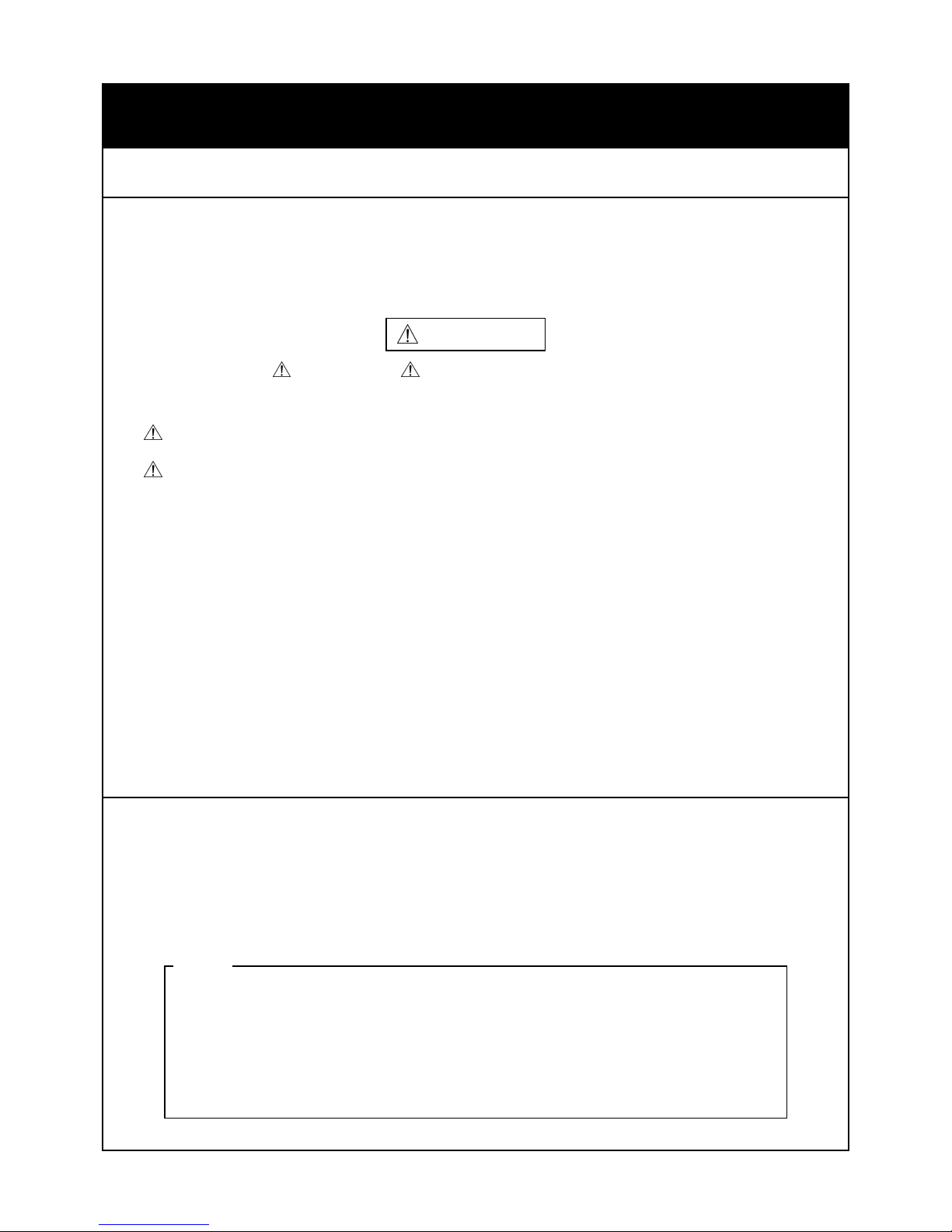

1. INSTALLATION VIEW

Back sensor

Grommet

Buzzer

Electro tap

Ground wire

Rear sensor harness

Control unit

Main harness

Rear sensor

【Optional ON-OFF switch installed】

Optional ON-OFF switch

Trunk side trim (LH)

Rear sensor

Back-up sensor ON-OFF

switch (Label)

Page 3

3

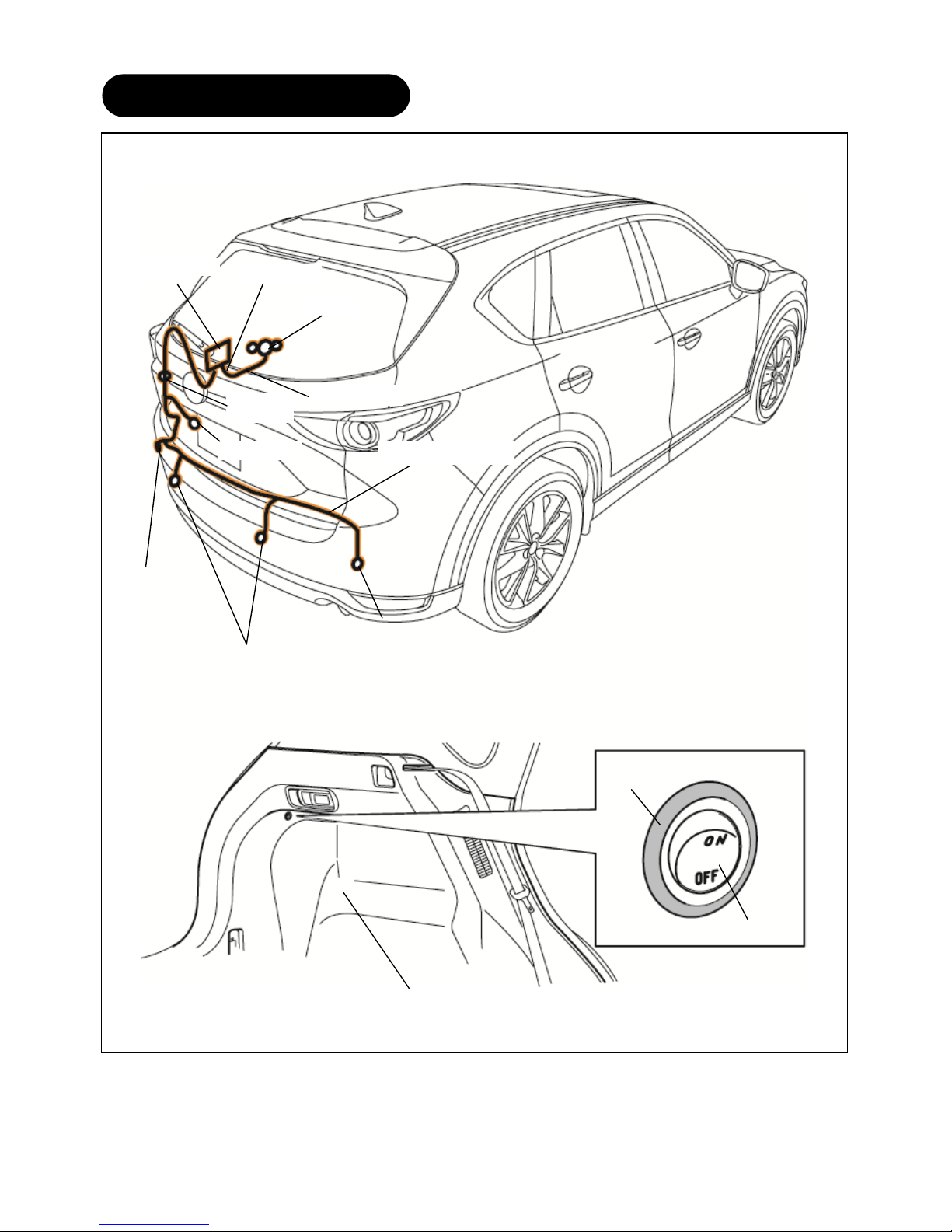

KB7W V7 290 (Parking Sensors, Main kit)

Part Part name Qty. Part Part name Qty. Part Part name Qty.

Control unit 1

Buzzer 1

Main harness 1

Electro tap 1

Mount base 9

Sensor harness

1

Tie wrap

30

Double-sided

adhesive tape

(Control unit)

1

Double-sided

adhesive tape

(Buzzer)

1

Cushioning tape

2

Grommet 1

Crump tie wrap 1

Female contact

housing

1

Installation

instructions

1

User manual 1

C860-V7-281A (Parking Sensors, Sensor kit : needed x2 sets for a vehicle)

Part Part name Qty. Part Part name Qty. Part Part name Qty.

Sensor 2

rubber

2

Sensor spacer

2

KD33-V7-282 (Optional ON-OFF switch)

Part Part name Qty. Part Part name Qty. Part Part name Qty.

Optional

ON-OFF switch

1

Harness

(With electro taps)

1

Back-up sensor

ON-OFF switch

(Label)

1

2. PARTS

Verify that the kit includes all the following parts and that the parts are not dirty, scratched, or damaged.

Note

Page 4

4

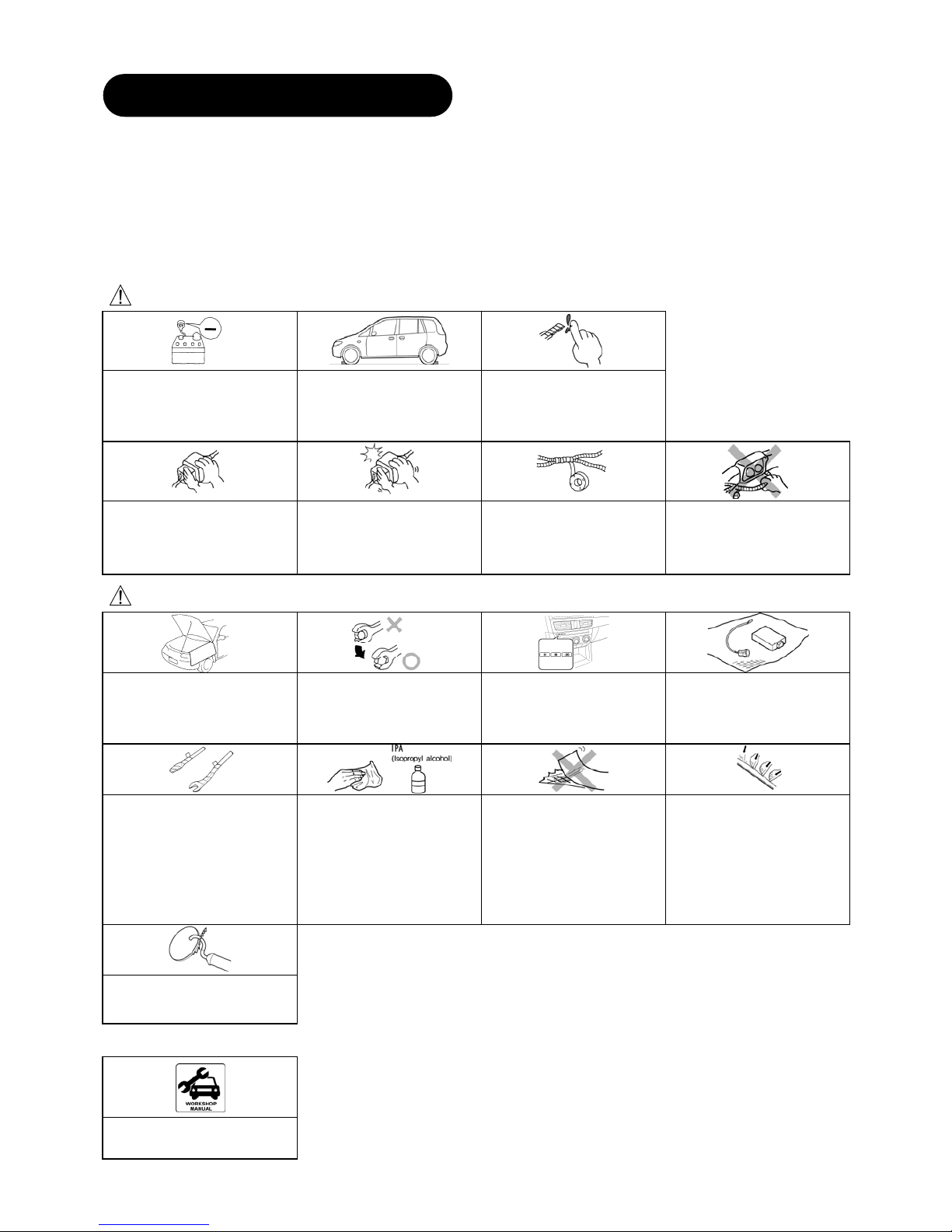

REQUIRED TOOLS

☆Screwdriver (Flathead) ☆Screwdriver (Phillips) ☆Socket wrench

☆Box-end wrench/Combination wrench ☆Torque wrench ☆Nipper

☆Pliers ☆Hole saw (20mm) ☆Drill (1.5mm,3mm)

☆Punch ☆Pincers ☆Remover tool

☆Flathead screwdriver wrapped with protective tape ☆Fastener remover wrapped with protective tape ☆Flat, round file

☆Round file ☆Deburring Tool ☆Masking tape

☆Soft clean cloth ☆Electrical vinyl tape ☆Mat

☆IPA (Isopropyl alcohol)

WARNING

If the negative battery is

connected while performing the

work, it may cause electrocution

or other personal injuries.

Disconnect the negative cable

before /installation.

Before performing any work,

park the vehicle on level ground,

apply the parking brake

securely, and then block the

wheels.

Be careful when handling drills

and other sharp objects.

If not handled properly, it could

result in serious injury.

When connecting/disconnecting

connectors, grasp the connectors,

not the wires. Otherwise, a fire or

other accident could occur due to

a short circuit or poor contact.

Make sure the connector is

securely pressed in until a click

sound is heard.

Otherwise, a fire or other

accident may occur due to an

open circuit or poor contact.

Secure the wiring harness with

the tape (part included) so that

they are not left dangling.

Otherwise, a fire or other

accident may occur due to a

short circuit.

Do not pull a wiring harness with

excessive force. Doing so can

cause breakage which could

result in a short circuit or a fire.

CAUTION

Be sure to cover the vehicle body

with protectors or mats to prevent

stains, scratches and damage

when removing/installing the

vehicle parts.

Using improper tools may

damage parts. Use the correct

tool for the job.

When the negative battery cable

is removed, the initial value or

memory for the power windows,

clock, i-stop, steering angle

sensor reference point will be

cleared. Perform re-initialization.

Put the removed parts and the

kit accessory parts on a

protective sheet to prevent

scratches.

Wrap protective tape around

screwdrivers and fastener

remover tools to prevent

scratching the vehicle.

If there is dust, dirt or grease on

the adhesion surface, the

adhesive strength of the

double-sided adhesive tape will

be weakened. Wash and

degrease the surface of the

adhesion area before applying

the double-sided adhesive tape.

Be sure to wash interior and

exterior parts using IPA

(

isopropyl alcohol).

If tape or a mount base is

removed and then re-adhered,

the adhesive strength will be

weakened. Before adhering,

accurately determine the

adhesion position.

To assure sufficient

adhesiveness of the

double-sided adhesive tape,

press the adhesive surface of

the tape to the adhesion surface

evenly.

In particular, press sufficiently at

the ends of the double-sided

adhesive tape where the

adhesion surface is curved.

Make sure to remove burrs from

the surface so that the bumper

surface is smooth.

Advice

Refer to the Workshop Manual

for removal and installation of

vehicle parts.

3. BEFORE INSTALLATION

Page 5

5

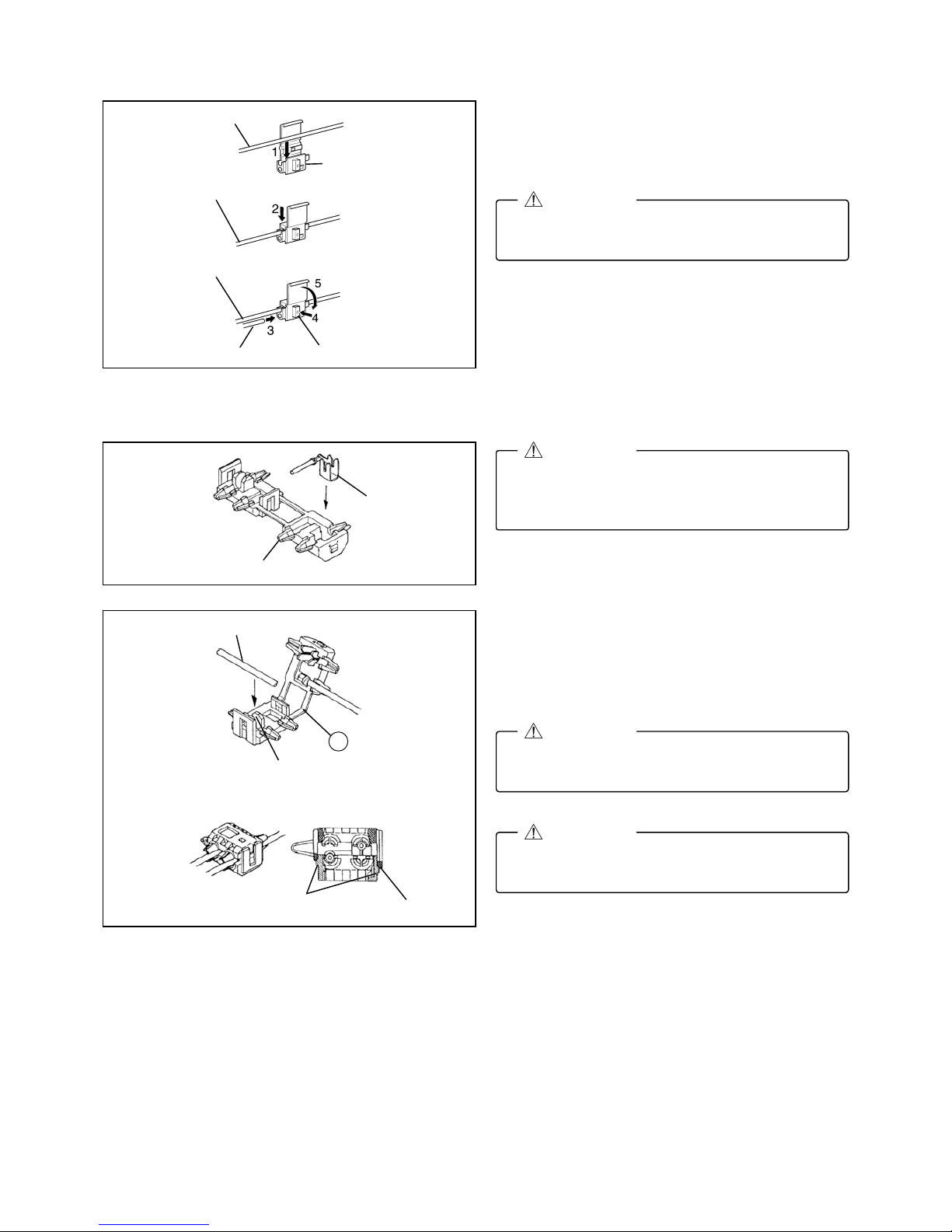

■ Branch connection procedure using electro tap

1. Insert the harness and vehicle wiring harness into

the electro tap.

2. Fold the electro tap as shown in the figure and lock

it.

3. Insert the harness to the end of the electro tap.

4. Firmly press the electro tap terminal using pliers.

5. Fold the electro tap in the direction of the arrow

shown in the figure and lock it.

6. Soundproof using urethane tape.

■ Branch connection procedure using electro-tap (Optional ON-OFF switch installed)

1. Put the harness to be branch-connected into the

guide groove.

2. Fold back the electro-tap from the A part as shown

in the figure.

3. Lock the electro-tap temporarily.

4. Firmly press the electro tap terminal using pliers.

Firmly engage the lock part until a click sound

is heard.

CAUTION

The temporary lock is provided on only one

side. Stop short of lockin

g

the final locks.

CAUTION

Pinch the electro-tap until a clicking sound is

heard from the final locks on the both sides.

CAUTION

Electro tap

Harness

Firmly press

using pliers

Vehicle wiring harness

Lock

Lock

Vehicle wiring harness

Terminal

Vehicle wiring harness

The terminal is embedded in the insulator. If it

is not, insert the terminal as shown in the figure

and press it in until it is securely fixed.

CAUTION

Terminal

Insulator

Guide groove

Harness

A

Temporary lock

Final lock

Page 6

6

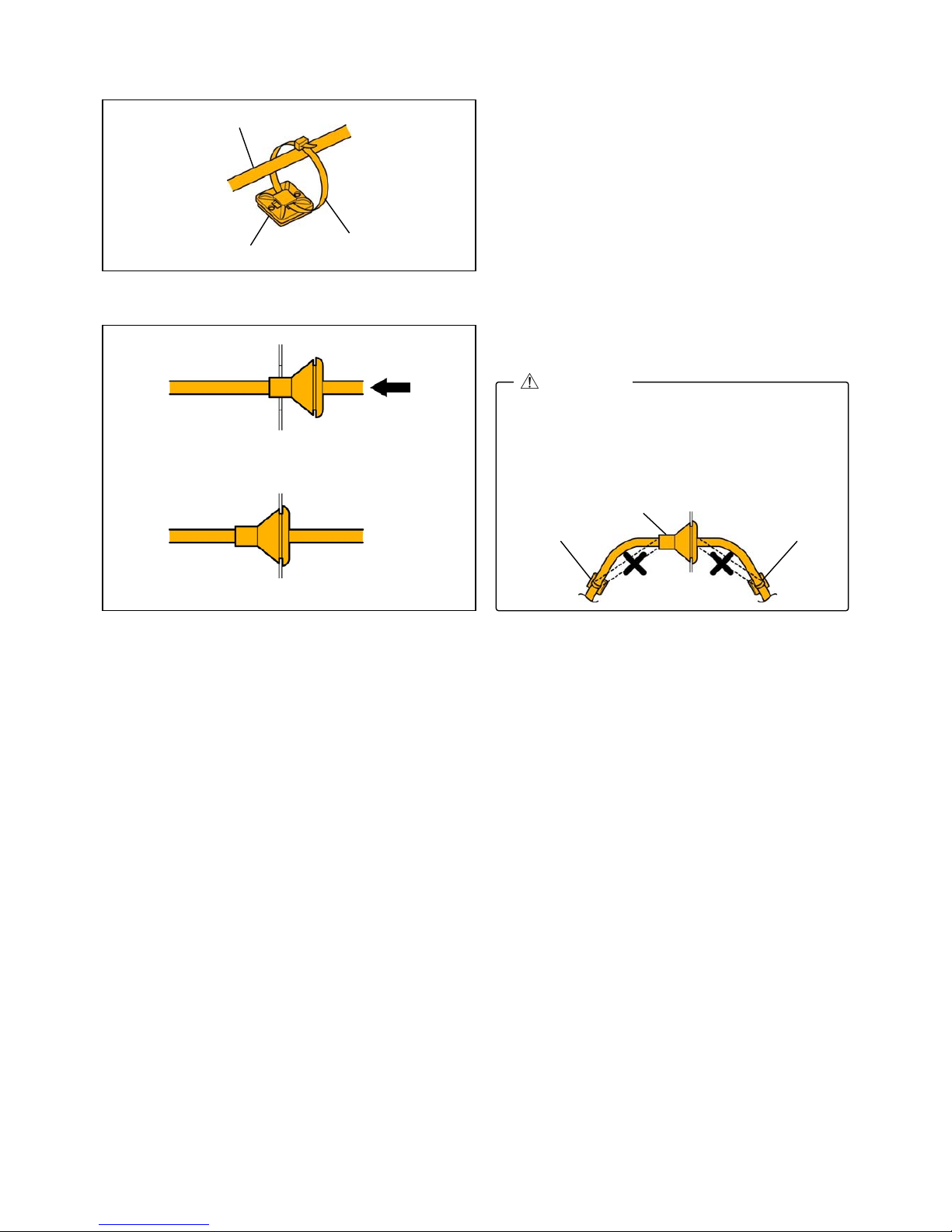

■ Securing harness

1. When the wiring harness is secured using a mount

base, passing a tie wrap through the mount base

and temporarily tightening the wiring harness as

shown in the figure will make the operation easier.

■ Securing grommet

1. When inserting the grommet, firmly press in the

entire circumference by hand.

Completely encapsulate with no eversion on

the grommet. Otherwise, water may penetrate

the cabin causing rust or a malfunction.

When securing the tie wrap, be careful not to

deform the grommet or separate it at the ends.

Grommet

Tie wrap Tie wrap

CAUTION

Tie wrap

Mount base

Harness

Press in

Vehicle interior Vehicle exterior

Installed condition

Vehicle interior Vehicle exterior

Page 7

7

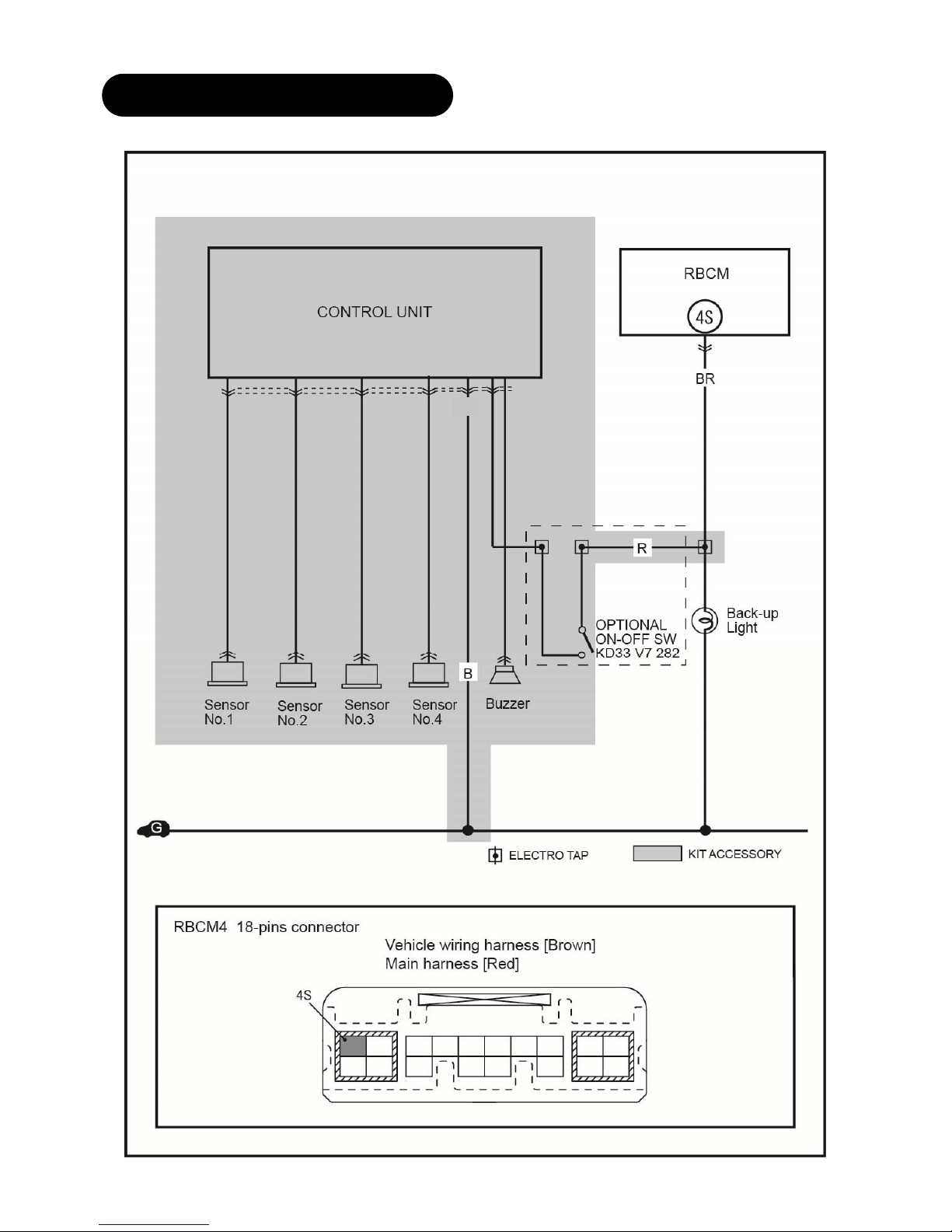

4.CONNECTION DIAGRAM

Figure shows connector viewed from harness side.

Wire color indicated in figure is wiring harness color for

parking sensor kit.

GR

Page 8

8

Negative battery cable disconnection

1. Set the selector lever to P range.

(AT vehicles only)

2. Disconnect the negative battery cable and wrap

tape around it to insulate.

Tightening torque : 4.0-6.0 N・m

Tonneau cover removal

1. Hold the shaded areas shown in the figure and move

the tonneau cover in the direction of the arrow.

2. Remove the tonneau cover in the direction of the

arrow shown in the figure.

5. VEHICLE PART REMOVAL

Be careful not to damage or lose any parts removed from the vehicle since they will be reused.

CAUTION

When removing/installing the parts, park the

vehicle on level ground and apply the side

brake securely. Be sure to turn the ignition

switch off, otherwise the vehicle can move,

causing personal injury or vehicle damage.

WARNING

If the negative battery cable is connected while

performing the work, it may cause electrocution

or other personal injuries. Disconnect the

negative battery cable before

removal/installation.

WARNING

Negative battery cable

Vehicle front

Tonneau cover

Tonneau cover

Page 9

9

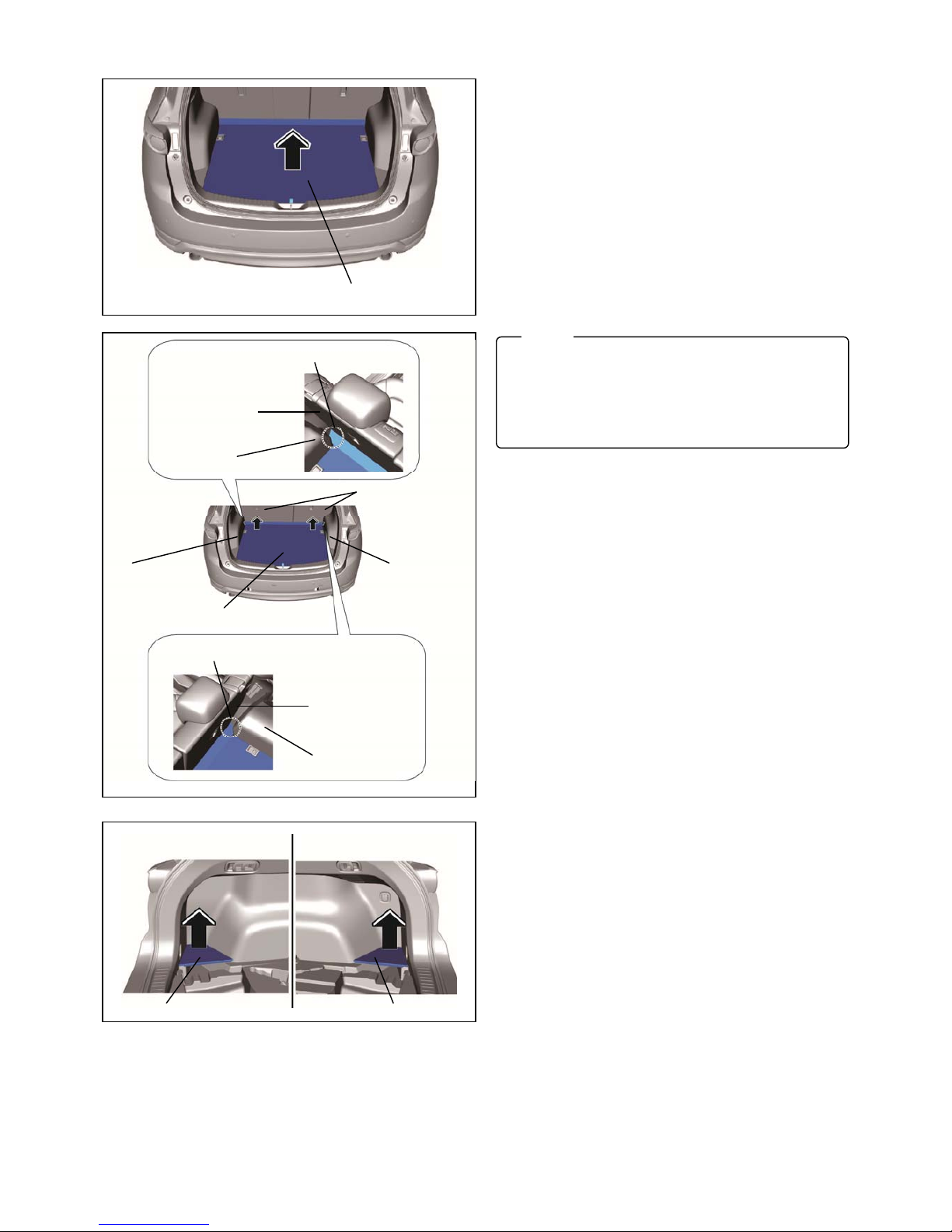

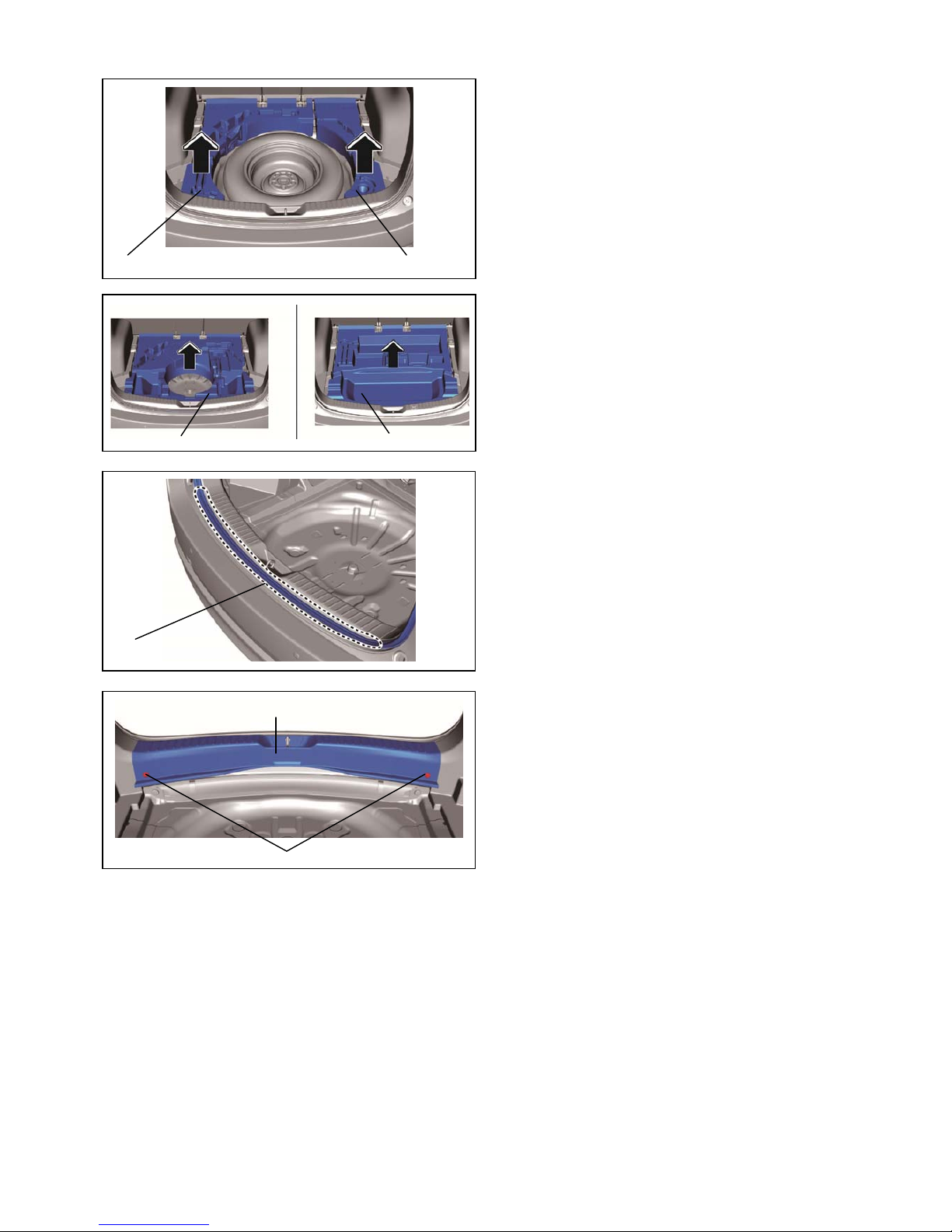

Trunk board removal

1. Remove the center trunk board.

2. Remove the trunk board RH and trunk board LH.

Center trunk board

Move the center trunk board in the direction of

the arrows shown in the figure, and remove the

ends of the center trunk board from the gap

between the trunk side trim and the rear seat

back.

Note

Trunk board RHTrunk board LH

End of center trunk board

End of center trunk board

Rear seat back

Trunk side trim

Rear seat back

Trunk side trim

Rear seat back

Trunk side trim Trunk side trim

Center trunk board

Page 10

10

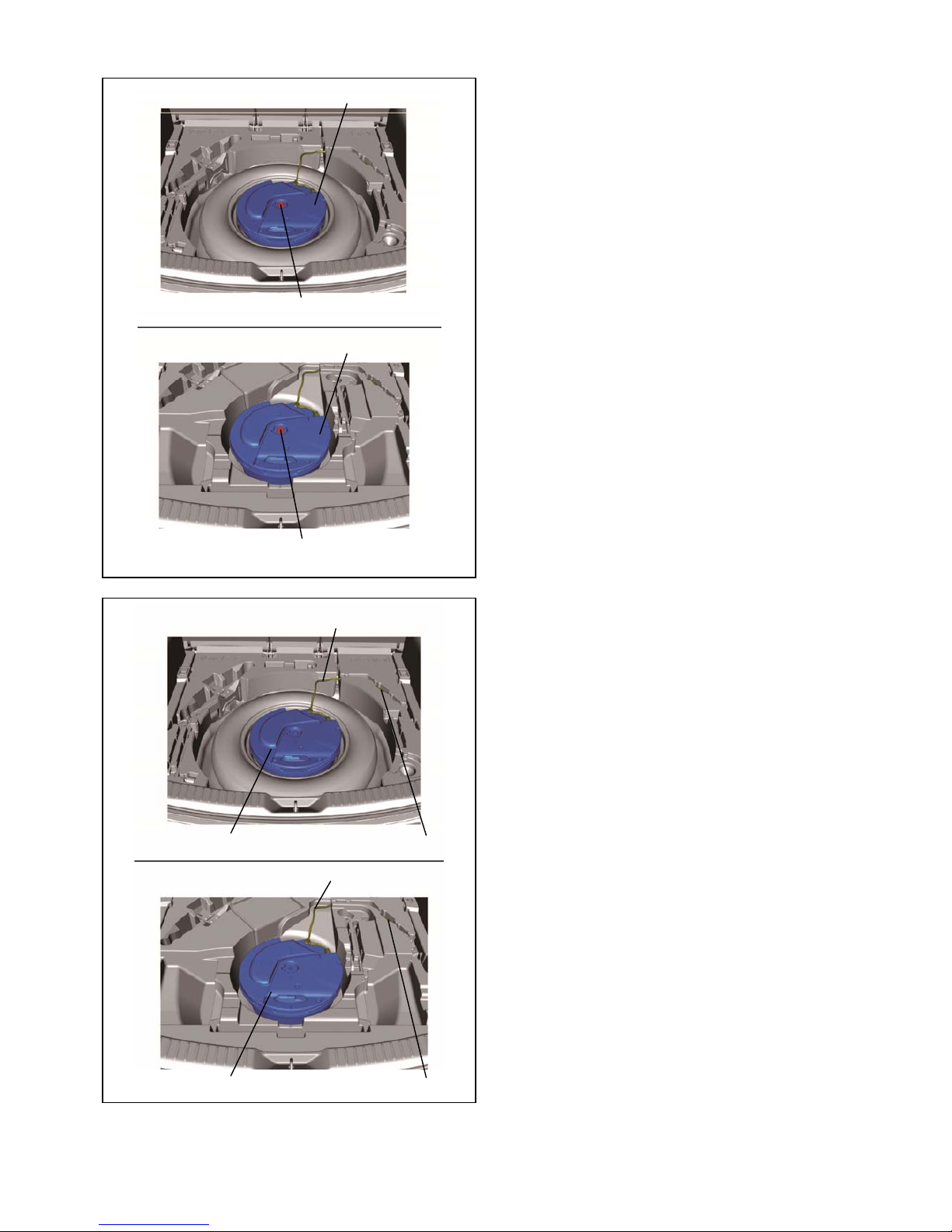

Bass-box removal

1. Remove the bolt.

2. Disconnect the connector.

3. Remove the bass box and short cord as a single

unit.

With spare tire

Short cord

Without spare

ConnectorBass box

ConnectorBass box

Short cord

Bolt : 4.0—8.0 N·m

{41—81 kgf·cm, 36—70 in·lbf}

Bolt : 4.0—8.0 N·m

{41—81 kgf·cm, 36—70 in·lbf}

With spare tire

Without spare tire

Bass box

Bass box

Page 11

11

Sub-trunk removal

[With spare tire]

1. Remove sub-trunks No.1 and No.2 in the direction

of the arrows shown in the figure.

[Without spare tire]

2. Remove the sub-trunk in the direction of the arrow

shown in the figure.

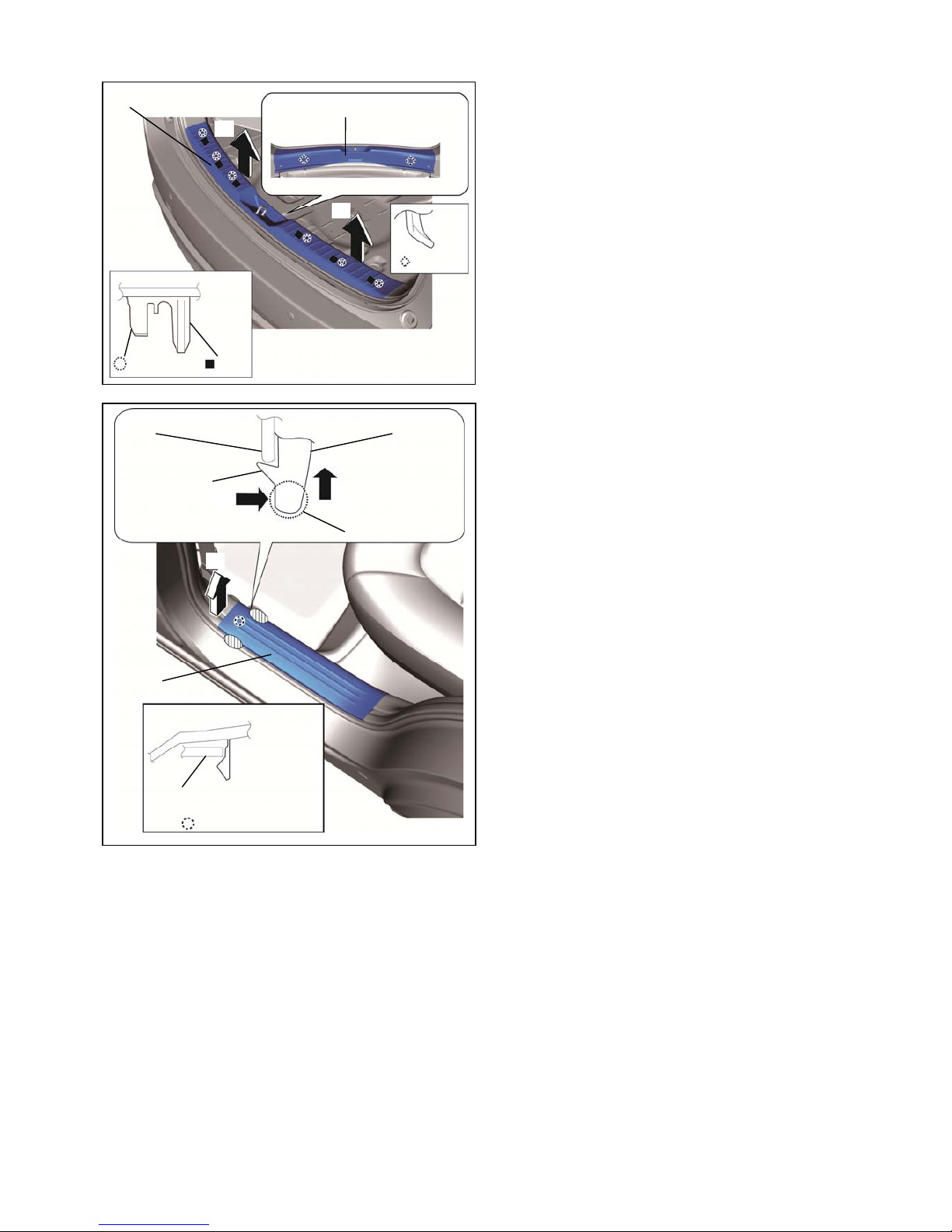

Trunk end trim removal

1. Partially peel back the weatherstrip.

2. Remove the fasteners.

Sub-trunk No.1 Sub-trunk No.2

Weatherstrip

Fastener

Tr

u

nk end trim

Sub-trunk

Sub-trunk

Page 12

12

3. Move the trunk end trim in the order of arrows (1) and

(2) shown in the figure, remove it while detaching the

clips, pins, and the guides.

Rear scuff plate removal

1. Hold part A shown in the figure, open the rear scuff

plate in the direction of arrow (1), move it in the

direction of arrow (2), and detach tab A of the rear

scuff plate from the B-pillar lower trim.

2. Hold the shaded areas shown in the figure, move

the rear scuff plate in the direction of arrow (3),

and detach tab B of the rear scuff plate from the

B-pillar lower trim.

B-pillar lower trim

B-pillar lower trim

Rear scuff plate

Rear scuff plate

Tab A

Part A

(2)

(3)

(1)

: Tab B

Trunk end trim

Trunk end trim

: Guide

: Clip : Pin

(1)

(2)

Page 13

13

3. Hold the shaded areas shown in the figure, move

the rear scuff plate in the direction of arrow (1),

detach the clip from the inner panel, and pull out

the pin.

4. Hold the shaded areas shown in the figure, move

the rear scuff plate in the direction of arrow (3),

and remove it while detaching tab B of the rear

scuff plate from the trunk side trim.

5. Hold part A shown in the figure, open the rear scuff

plate in the direction of arrow (1), move it in the

direction of arrow (2), and detach tab A of the rear

scuff plate from the trunk side trim.

6. Hold the shaded areas shown in the figure, move

the rear scuff plate in the direction of arrow (3),

and remove it while detaching tab B of the rear

scuff plate from the trunk side trim.

(1)

(2)

Rear scuff plate

Inner panel

: Clip

: Pin

Rear scuff plate

(2)

Tab A

Part A

: Tab B

Trunk side trim

(1)

(3)

Trunk side trim

Rear scuff plate

Page 14

14

Trunk side trim removal

1. Insert a tape-wrapped flathead screwdriver into the

position shown in the figure, move it in the direction

of arrow (1), and while detaching the hooks of the

remote handle lever, open the cover in the direction

of arrow (2).

2. Remove the screw.

3. Remove the screw.

4. Remove the fastener.

Tape-wrapped flathead screwdriver

Hook

Hook

Remote handle leve

r

Cover

Cover

Hook

(2)

Hook

Remote handle leve

r

(1)

Remote handle lever

Scre

w

Scre

w

Trunk side trim

Trunk side trim

Fastener

Page 15

15

5. Remove the bolts.

6. Remove the cargo net hooks.

7. Partially peel back the weatherstrips.

8. Remove the rear seat cushion.

9. Fold the rear seat back.

10. Insert a tape-wrapped flathead screwdriver into

the position shown in the figure, move it in the

direction of the arrows, and remove the clips.

Tape-wrapped flathead screwdrive

r

: Clip

Trunk side trim

Bolt : 9—12 N·m {92—122 kgf·m, 80—106 ft·lbf}

Cargo net hook

Trunk side trim

Bolt

Cargo net hook

Bolt

Weatherstrip Weatherstri

p

Page 16

16

11. Move the trunk side trim in the order of arrows (1),

(2), (3), and (4) shown in the figure, and remove

the clips and hooks.

12. Move the trunk side trim in the order of arrows (1),

(2), (3), and (4) shown in the figure, and remove

the clips, hooks, and the clip of the remote handle

lever.

13. Insert a hand into the back side of the trunk side

trim, press the tabs of the remote handle lever in

the direction of arrows (1) shown in the figure,

and remove the remote handle lever in the

direction of arrow (2).

Tab

Trunk side trim

Remote handle lever

Trunk side trim

(1)

(1)

(2)

Tab

Tab

Remote handle lever

: Clip of remote

: Clip

: Hook

(1)

(2)

(3)

(4)

Trunk side trim

Right side only

Trunk side trim

: Cli

p

: Hook

(1)

(2)

(3)

(4)

Left side only

Page 17

17

14. Set the remote handle lever aside.

15. Move the position of the rear seat back in the

direction of arrows (1) and (2) shown in the figure,

while adjusting it at a position where the trunk

side trim can be removed, move the trunk side

trim in the direction of arrow (3) shown in the

figure, and remove it in the direction of arrow (4).

16. Disconnect the rear accessory socket connector.

Remote handle lever

Trunk side trim

Rear seat back

(1)

(2)

(3)

(4)

Rear accessory

socket connector

Trunk side trim

Rear accessory socket

Right side only

Page 18

18

Rear combination light removal

1. Insert the remover tool into the service hole at the

position shown in the figure.

2. Move the remover tool in the direction of arrow (1)

shown in the figure and pull out the service hole

cover tab from the rear combination light.

3. Remove the service hole cover.

4. Remove the screws.

Rear combination light

Vehicle frontVehicle front

Rear combination light

Tab

Service hole cove

r

Remover tool

(1)

Rear combination light

Screw

Service hole cover

Rear combination light

Service hole

When removing the rear combination light from

the body, it could interfere with the body and

cause scratching or damage to the body. When

removing the rear combination light from the

body, apply protective tape to the body.

CAUTION

Fogging or condensation on the inside of the

rear combination lights may occur due to a

natural phenomenon occurring as a result of a

temperature difference between the interior and

exterior of the combination lights. However, it

has no effect on the light performance because

the temperature inside the rear combination

lights rises after illuminating a rear turn light or

a period of time has elapsed.

Note

Page 19

19

5. To prevent scratches or damage, affix protective

tape to the position shown in the figure.

6. Pull the rear combination light in the direction of

arrow (1) shown in the figure and pull out the rear

combination light from the body.

7. Remove the clip from the rear combination light.

8. Turn the socket counterclockwise and remove it in

the direction of arrow (1) shown in the figure.

Protective tape Rear combination light

Socket

Rear combination light

Clip

Rear combination light

Clip

(1)

Rear combination light

View from A

Stud bolt

Hook

(1)

A

Page 20

20

9. Turn the grommet counterclockwise and remove it

in the direction of arrow (1) shown in the figure.

10. Disconnect the connector and remove the rear

combination light from the body.

11. Remove the grommet and from the body.

12. Remove the fasteners.

Screw installation note

1. Install the screws in the order of (1) and (2).

Grommet

Fastene

r

Rear combination light

Screw (1)

Screw (2)

Rear combination light short cord

Connector

Rear combination light

Grommet

(1)

When removing the rear combination light from

the body, the rear combination light may fall off

and be damaged. Remove the rear combination

light from the body while holding the rear

combination light on the lens side by hand.

CAUTION

Page 21

21

Rear splash shield removal

1. Remove the fastener.

2. Remove the fastener.

3. Pull the rear over fender in the direction of the arrow

shown in the figure and disengage the clips shown in

the figure.

Rear over fender

Fastener

Rear over fender

Fastene

r

Rear over fender

Cli

p

Page 22

22

4. Remove the fasteners.

5. Remove the screws.

6. Detach the tabs from the rear bumper and remove

the rear splash shield.

Rear splash shield

Fastene

r

Screw

Fastener

Vehicle front

Scre

w

Tab

Rear s

p

lash shield

Page 23

23

Rear bumper removal

1. Affix the protective tape to the position shown in the

figure to prevent scratches and damage.

2. Remove the cap.

3. Remove the screws A and B.

4. Remove the screws.

Protective tape

Ca

p

Cap

Screw A

Scre

w

B

ScrewA

ScrewB

Screw B : 6.9—9.8 N·m {71—99 kgf·cm, 62—86 in·lbf}

Screw Screw

Page 24

24

5. Remove the fasteners.

6. Press the tab of rear under cover and remove it.

7. Remove the fasteners.

8. Detach the rear bumper from the rear bumper slider

while holding the rear end of the rear bumper, moving

it in the direction of the arrows shown in the figure,

and detaching the hooks.

9. Move the rear bumper in the direction of the arrow

shown in the figure and detach it from rear bumper

bracket.

Fastener Rear bumper

Hook Hook

Rear bumper Rear bumper bracket

Rear under cover

Tab

Fastener

With rear under cover

Page 25

25

10. Disconnect the connectors.

11. Detach the wiring harness clip.

12. Remove the rear bumper.

[With blind spot monitoring system]

13. If the rear bumper is replaced, perform the blind spot

monitoring (BSM) radar test.

If the rear bumper installation position is changed

or individual differences (coating film/thickness)

occur, the blind spot monitoring control module

radar angle will deviate which could result in the

module not detecting a vehicle approaching from

the rear correctly. If the rear bumper is replaced,

perform the blind spot monitoring (BSM) radar

test.

CAUTION

Rear fender panel

Protective tape

Rear over fende

r

After removing rear bumper, it may hit the rear

over fender and cause a damage and/or injury.

Perform the following procedure to prevent the

rear over fender from being damaged.

― Fix the rear over fender and rear fender

panel with protective tape.

CAUTION

Rear bumpe

r

Connector

Clip

With rear parking sensor

Page 26

26

1. Masking not required.

2. Coat the sensor surface with the body color paint.

3. Use two-component urethane paint. (Main

component: acrylicpolyol, curing agent: isocyanate)

Maximum paint thickness: primer 30 um, paint and

coating 95 um in total.

4. When painting, use a spray gun to apply the paint

evenly.

Paint infiltration into connector must be avoided;

pin contact must be guaranteed after painting.

Maximum paint curing: 90 C for 1 hour.

5. After baking, do not touch the painted product until

it has cooled down completely.

Hot storage temperature: 85 C.

6. When the painting is dried, remove the sensors and

the bezels from plastic base.

6. PAINT SENSOR

Paint characteristics vary according to paint

type. Check manufacturer specifications

before painting.

CAUTION

Do not use lacquer paints because their

weatherproofing and adhesion characteristics

are poor.

CAUTION

Be careful not to peel off the paint when

removing the sensors and the bezels from

plastic base.

CAUTION

SURFACE TREA TMENTT

a: Paint same as body color

b: Masking not required

Page 27

27

■ Cutting the cushioning tape

7. Cut the cushioning tape into thirds as shown in the

left figure.

■ Sensor installation

1. Tap the punch into the center of the scribed cross-hair lines for sensor installation on the back side of the

bumper.

7. PREPARATION FOR INSTALLATION

Rear sensor

scribed cross-hair lines

Rear bumper back side

Installation view

Note

20mm

Rear bumper surface

Rear sensor

scribed cross-hair lines

Back sensor

scribed cross-hair lines

Cushioning tape

1/3

1/3

1/3

1/3

1/3

1/3

Page 28

28

2. Wrap the drill bit with duct tape as shown in the

figure.

3. Set the drill rotation to low speed.

4. With the drill bit pointed perpendicular to the

bumper, drill 3mm holes in the marked positions.

3mm hole

5. Drill 20mm holes in the center of each sensor hole

using a hole saw.

6. Using a utility knife, cut a notch into the upper part

of each sensor hole at the dimensions shown in the

figure on the left.

Always use a drill with a rotation speed

adjustment, otherwise the rear bumper may

deform.

Be careful when handling drills and other sharp

objects.

To prevent scratching and over-drilling,

always wrap the drill bit with duct tape.

CAUTION

Be careful when handling drills and other sharp

objects.

If not handled properly, it could result in serious

injury.

WARNING

Duct tape

10mm

Drill 3mm

Over-drilling prevention

Drill

Drill bit (shoulder)

(Drill at low speed)

Sensor hole

Rear bumper back side

Drill (3mm)

Center of the sensor hole

Hole sa

w

: 20mm

1 mm

1 mm

Page 29

29

7. Remove the bezel from the sensor and install it to the surface of the rear bumper with the bezel dot mark on the

top.

8. First install the spacer, then sensor with rubber to the back side of the rear bumper.

The shapes of the washers differ, therefore verify the shape before installing them.

Insert the sensor projection into the washer recess.

After installing, make sure the rear sensor and back sensor are securely pressed into the rear bumper.

CAUTION

Rear bumper back side

Rubber

Rear sensor

Sensor

spacer

Rear sensor

Back sensor

Rear bumper

back side

Rear bumper

back side

Rear bumper

back side

Rubber

Rubber

Rear bumper surface

Dot mark

Sensor

spacer

Sensor

spacer

(1)

(1)

(1)

(2)

(2)

(2)

(3)

(3) (3)

Page 30

30

■Control unit installation

1. Affix double-sided adhesive tape to the control unit.

2. Peel off the double-sided adhesive tape backing and adhere the

control unit to the body panel of the lower part inside of the trunk

side trim (driver’s side).

■Buzzer installation

1. Affix double-sided adhesive tape to the buzzer.

2. Peel off the double-sided adhesive tape backing and secure the

rear buzzer to the body panel of the upper inside part of the

trunk side trim (driver’s side).

Always remove dirt or oil because the adhesive strength of

the double-sided adhesive tape weakens.

CAUTION

Always remove dirt or oil because the adhesive strength of

the double-sided adhesive tape weakens.

CAUTION

Always remove dirt or oil because the adhesive strength of

the double-sided adhesive tape weakens.

CAUTION

Always remove dirt or oil because the adhesive strength of

the double-sided adhesive tape weakens.

CAUTION

Control unit

Double-sided

adhesive

Double-sided

adhesive

Buzzer

Control unit

Front

Buzzer

Front

Page 31

31

[ Main harness ]

8.INSTALLATION OF THE HARNESS

RBCM4 18-pin connector [Blue]

(View from harness side)

Cut the vehicle

wiring harness tube.

6cm (0.2 ft)

(1) Connect an electro-tap to the position shown in the figure.

(2) Wrap cushioning tape around the electro-tap.

RBCM

Cushioning tape

(1) Connect the main harness to the control unit.

Vehicle wiring harness

(5) Secure the main harness to the

vehicle wiring harness using ▲ tie wraps.

(3) Install the main harness.

To ②

When affixing the main wiring harness to the vehicle

harness using a tie wrap, do not affix the harness

together with the fuel filler lid opener cable.

CAUTION

Electro tap

Vehicle front

(4) Tie redundant part

using

▲

tie wrap.

Vehicle front

Vehicle wiring harness [Brown]

Main harness [Red]

Control unit

(2) Connect the main harness to the buzzer.

Buzzer

Sensor

harness

To ⑤

Connect an electro-tap for the main harness to the indicated signal line securely. Misconnection may

cause a system or vehicle malfunction.

For branch connection procedure using electro tap, refer to [Branch connection procedure using electro tap]

on page 5.

CAUTION

▲ Tie wrap (4)

Page 32

32

[ Sensor harness (1) ]

Vehicle with BSM

※ Install the wiring harness to the cabin interior from the rear bumper side.

Vehicle front

(1) Remove the hole cover

▲ tie wrap (1)

◆ Crump tie wrap (1)

Sensor harness

Connector for left rear sensor

Connector for right back sensor

♦

Mount base (7)

▲ Tie wrap (8)

Vehicle front

Sensor harness

(2) Affix grommet

From ③

Connector for back sensor

For affixing the grommet, refer to the

[Affixing grommet] on page 6.

CAUTION

To ②

The removed hole cover

is not reused with this

accessory.

Note

Center mark (white tape)

Page 33

33

[ Sensor harness (1) ]

Vehicle without BSM

※ Install the wiring harness to the cabin interior from the rear bumper side.

Vehicle front

♦

Mount base (1)

▲ Tie wrap (2)

Connector for left rear sensor

Connector for right back sensor

♦

Mount base (8)

▲ Tie wrap (8)

Sensor harness

Connector for back sensor

To ②

Center mark (white tape)

(1) Remove the hole cover

Sensor harness

Vehicle front

(2) Affix grommet

From ③

The removed hole cover

is not reused with this

accessory.

Note

For affixing the grommet, refer to the

[Affixing grommet] on page 6.

CAUTION

Page 34

34

[ Sensor harness (2) ]

※ Install the wiring harness to the cabin interior from the rear bumper side.

Sensor harness

Vehicle front

From ②

(1) Insert sensor harness terminals to female contact housing.

(2) Connect the sensor harness connector to the control unit.

Control unit

Sensor harness

Female contact housing

(Blue)

(Black)

(Red)

Page 35

35

[ Sensor harness (3) ]

Control unit

Vehicle front

Vehicle wiring harness

(3) Secure the main harness and sensor harness to

the vehicle wiring harness using ▲ tie wraps.

(2) Secure the main harness to the

vehicle wiring harness using ▲ tie wraps.

(1) Install the main harness and sensor harness

(1) Install the ground wire.

Vehicle wiring harness

Vehicle front

To ⑤

From ④

Ground bolt tightening torque : 8.8-12.7 N・m

(2) Tie redundant part

using

▲

tie wrap.

(3) Tighten together

with guround bolt.

▲ Tie wrap (4)

▲ Tie wrap (2)

Page 36

36

■Optional ON-OFF switch installation

2. Mark the back side of the driver-side trunk side trim

in the position shown in the figure using a punch.

3. Wrap the drill bit with duct tape as shown in the

figure.

4. Set the drill rotation to low speed.

5. With the drill bit pointed perpendicular to the

trunk side trim, drill 1.5mm holes in the marked

positions.

1.5mm hole (2 locations)

9.

INSTALLATION OF OPTIONAL ON-OFF SWITCH FOR USE WHEN TOWING

This procedure is not necessary if the [optional on-off switch for use when towing] is not installed.

Go to 9. CAUTIONS WHEN RE-INSTALLING.

Note

Always use a drill with a rotation speed

adjustment, otherwise the rear trunk side trim

may deform.

Be careful when handling drills and other sharp

objects.

To prevent scratching and over-drilling,

always wrap the drill bit with duct tape.

CAUTION

Be careful when handling drills and other sharp

objects.

If not handled properly, it could result in serious

injury.

WARNING

Duct tape

10mm

Drill 1.5mm

Over-drilling prevention

Drill

Drill bit (shoulder)

(Drill at low speed)

Reference line

Back side of driver-side trunk side trim

Vehicle front

20mm

43mm

10mm

Punch

Center of the Optional

ON-OFF switch hole

Notch area

Trunk side trim

back side

Page 37

37

6. Drill a hole in the center of each Optional ON-OFF

switch hole using a hole saw 20mm.

7. Remove the paper backing from the back-up

sensor ON-OFF switch (label) and adhere the label

to the driver-side trunk side trim.

8. Install the Optional ON-OFF switch harness by

passing it through from the surface of the

driver-side trunk side trim.

9. Secure the switch harness to the underside of the

trunk side trim (driver's side) as shown in the figure

on the left using cushioning tapes.

Optional ON-OFF switch hole

Drill (1.5mm) Notch hole

Driver-side trunk side trim

Drill (1.5mm)

Center of the Optional ON-OFF switch hole

Hole saw 20mm

Optional ON-OFF switch harness

Convex part

Back-up sensor

ON-OFF switch (label)

Convex part

Optional ON-OFF

switch

Back-up sensor

ON-OFF switch (label)

Driver-side trunk side trim

Vehicle front

Driver-side trunk side trim

Cushioning tape

Vehicle front

Page 38

38

■ Harness installation

1. Cut the main harness (Red wire) at the position

shown in the

figure.

2. Strip the main harness insulation and wrap

electrical vinyl tape around the tip of the stripped

main harness for insulation.

3. Connect the wiring harness included in the optional

on/off switch kit to the main harness stripped in

Step 1. with electro taps. (No polarity)

4. Wrap the electro taps in the 2 locations and the

harness connector with cushioning tapes.

Electro taps

Vehicle front

Harness connector

Cushioning tape

Cushioning

tape

RBCM

Always insulate the main harness.

CAUTION

For branch connection procedure using electro

tap, refer to [Branch connection procedure using

electro tap (Optional ON-OFF switch installed)]

on

pag

e 5.

CAUTION

Main harness

Vehicle front

Cut

Strip insulation

Wrap with electrical vinyl tape

Main harness

RBCM

Page 39

39

1. Reinstall parts in the reverse order of the installation procedure in “VEHICLE PARTS REMOVAL”.

Connect the main wiring harness to the rear sensor.

Connect the optional on-off switch harness to the harness.

2. Refer to “Required servicing after disconnecting/connecting negative battery cable” in the vehicle workshop

manual or the owner’s manual to restore the vehicle functions.

3. Perform reinstallation and inspection of the vehicle parts.

10.CAUTIONS WHEN RE-INSTALLING

Harness connector

Optional ON-OFF switch harness connector

Back side of driver-side trunk side trim

Vehicle front

When re-assembling, make sure the optional ON-OFF switch

harness does not become caught.

When re-assembling, make sure the optional ON-OFF switch

harness does not interfere with the seat belt.

CAUTION

Page 40

40

■ Is available when the ignition is switched ON and shift lever is in the R position.

■ The sensor detects obstructions when the shift lever is in the R position.

・ Alarm (beeper) sound

■ The beeper operates (sounds) as follows while the system is operating.

* The closer the obstruction is approached the faster the continuous sound is emitted.

Malfunction symptom Inspection Action

Alarm sound (buzzer) does not activate even though

there is an obstruction around the sensor.

Is the ignition switched ON? Switch the ignition ON.

Is each part connected correctly?

(Each connector, reverse signal line,

ground terminal)

Connect each part correctly.

Is there a device generating ultrasonic

waves near the vehicle?

(Air compressor, high-pressure car

washer, impact wrench, or electric drill)

Take the device away from the

ultrasonic wave generation

source.

Is the shift lever in the R position? Shift the shift lever to the R

position.

Alarm sound (buzzer) activates even though there is

no obstruction around the sensor.

Is the ground detected?

* If beep sound stops after placing

cardboard on the ground, the ground

may be detected.

Install the sensor correctly.

11.OPERATION CONDITION

12.TROUBLESHOOT

◇ Rear sensor ◇Back sensor

Distance between the vehicle

and the obstruction

Beeper

sound*

Slow

intermittent

sound

Fast

intermittent

sound

Continuous

sound

Slow

intermittent

sound

Fast

intermittent

sound

Continuous

sound

Distance between the vehicle

and the obstruction

Beeper

sound*

Approx.130-100cm (4.3-3.3 ft)

Approx.100-50cm (3.3-1.6 ft)

Within approx.40cm (1.3 ft)

Approx.60-50cm (2.0-1.6 ft)

Approx.50-40cm (1.6-1.3 ft)

Within approx.40cm (1.3 ft)

06DE4313B

Loading...

Loading...