Page 1

2004-2009

CONTENTS

Mazda3

Bodyshop

Manual

FOREWORD

This bodyshop manual is intended for

use by technicians of Authorized Mazda

Dealers to help them service and repair

Mazda vehicles. It can also be useful to

owners and operators of Mazda vehicles in

performing limited repair and maintenance

on Mazda vehicles.

For proper repair and maintenance, a

thorough familiarization with this manual is

important, and it should always be kept in a

handy place for quick and easy reference.

All the contents of this manual, including

drawings and specifications, are the latest

available at the time of printing.

As modifications affecting repair or

maintenance occur, relevant information

supplementary to this volume will be made

available at Mazda dealers. This manual

should be kept up-to-date.

Title Section

GENERAL INFORMATION 00

CONSTRUCTION 80A

PANEL REPLACEMENT

BODY

STRUCTURE

WATER-PROOF AND RUST

PREVENTIVE TREATMENT

DIMENSIONS 80D

PLASTIC BODY PARTS

APPLICATION:

This manual is applicable to vehicles beginning

with the Vehicle Identification Numbers (VIN),

shown on the following page.

© 2003 Mazda Motor Corporation

PRINTED IN U.S.A., OCTOBER 2003

Form No. 3386–1U–03J

Part No. 9999–95–036F–04

80B

80C

80E

Mazda

reserves the right to alter the specifications

and contents of this manual without

obligation or advance notice.

All rights reserved. No part of this book may

be reproduced or used in any form or

by any means, electronic or mechanical

including photocopying and recording and

the use of any kind of information storage

and retrieval system-without permission in

writing.

North American Operations

Mazda Motor Corporation

HIROSHIMA, JAPAN

Page 2

VEHICLE IDENTIFICATION NUMBERS (VIN)

JM1 BK123✻4# 100001—

JM1 BK223✻4# 100001—

JM1 BK323✻4# 100001—

JM1 BK12F✻4# 100001—

JM1 BK22F✻4# 100001—

JM1 BK32F✻4# 100001—

JM1 BK143✻4# 100001—

JM1 BK243✻4# 100001—

JM1 BK343✻4# 100001—

Page 3

GENERAL INFORMATION

Toc of SCT

GENERAL INFORMATION . . . . 00-00

Toc of SCT

00–00 GENERAL INFORMATION

00

SECTION

00–00

HOW TO USE THIS MANUAL . . . . . . . . . 00–00–2

Efficient Replacem ent of

Body Panels . . . . . . . . . . . . . . . . . . . . 00–00–2

Symbols of Panel Replac ement . . . . . . 00–00–2

Body Dimensions

(Flat-plane Dimensions ) . . . . . . . . . . . 00–00–3

Body Dimensions

(Straight-line Dimensi ons ). . . . . . . . . . 00–00–4

Symbols of Body Dimensions. . . . . . . . 00–00–4

SERVICE PRECAUTIONS . . . . . . . . . . . . 00–00–5

Arrangement of Workshop . . . . . . . . . . 00–00–5

Safety Precaution s . . . . . . . . . . . . . . . . 00–00–5

Vehicle Protection . . . . . . . . . . . . . . . . . 00–00–5

Remove Dangerous Articles . . . . . . . . . 00–00–5

Use of Pulling Equipment . . . . . . . . . . . 00–00–5

Prevent Short Circuits. . . . . . . . . . . . . . 00–00–6

EFFICIENT REMOVAL OF

BODY PANELS . . . . . . . . . . . . . . . . . . . 00–00–6

Body Measurements . . . . . . . . . . . . . . . 00–00–6

Prevention of Body Deformatio n . . . . . . 00–00–6

Selection of Cut-and-join Locations . . . 00–00–7

Removal of Associated Parts . . . . . . . . 00–00–7

End of Toc

Rough Cutting of Damaged Panel . . . . 00–00–7

INSTALLATION PREPARATIONS . . . . . 00–00–7

Rough Cutting of New Parts . . . . . . . . . 00–00–7

Determination of Welding Method . . . . 00–00–7

Making Holes for CO2 Arc Welding . . . 00–00–8

Application of Weld-throu gh Prime r . . . 00–00–8

EFFICIENT INSTALLATION OF

BODY PANELS . . . . . . . . . . . . . . . . . . . 00–00–8

Checking Preweld Measurements

And Watching. . . . . . . . . . . . . . . . . . . 00–00–8

Welding Notes . . . . . . . . . . . . . . . . . . . 00–00–9

Spot Welding Notes . . . . . . . . . . . . . . . 00–00–9

Checking Weld Strength. . . . . . . . . . . . 00–00–10

ANTICORROSION, SOUND

INSULATION, AND VIBRATION

INSULATION . . . . . . . . . . . . . . . . . . . . . 00–00–11

Body Sealing . . . . . . . . . . . . . . . . . . . . 00–00–11

Application of Undercoating . . . . . . . . . 00–00–11

Application of Rust Inhibitor . . . . . . . . . 00–00–11

Application of Floor Silencer. . . . . . . . . 00–00–12

ABBREVIATION . . . . . . . . . . . . . . . . . . . 00–00–12

00–00–1

Page 4

GENERAL INFORMATION

HOW TO USE THIS MANUAL

C3U000000000B01

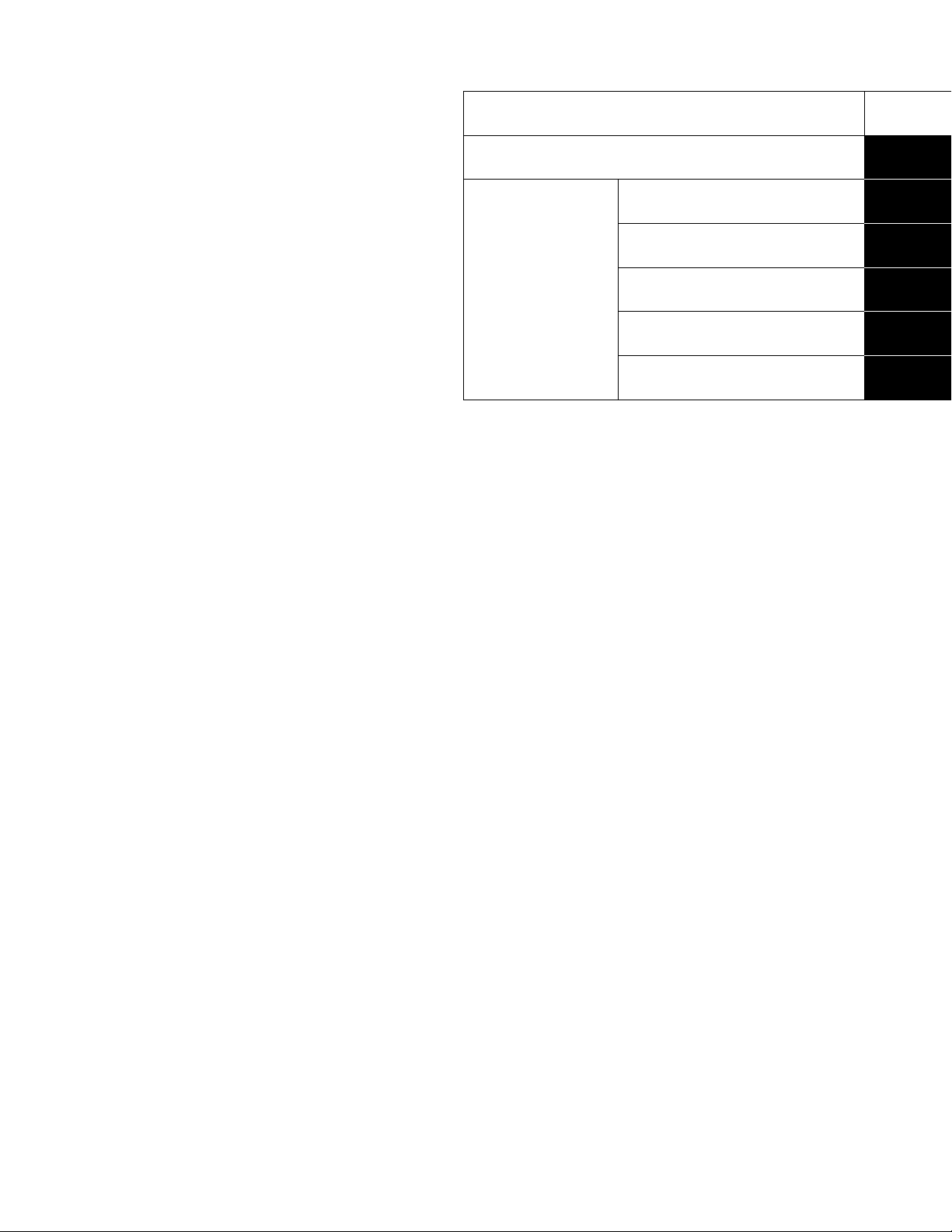

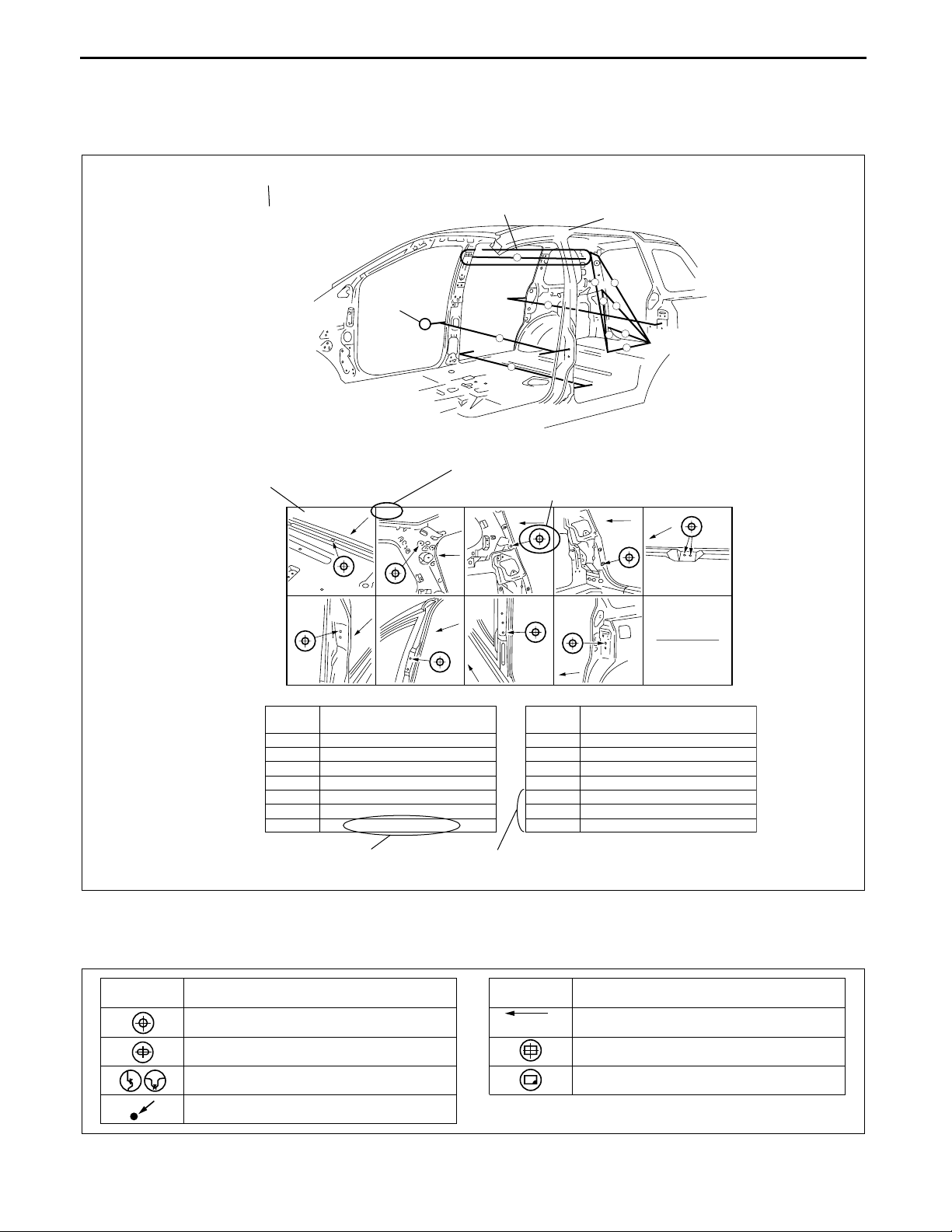

Efficient Replacement of Body Panels

• This section contains information on the body panels in regard to the welding types, number of spot welds, and

cut-and-join locations that are necessary for panel removal and installation.

• The type of weld and position are indicated by symbols.

• Some sections have notes concerning the operation being performed. Thoroughly read and understand the

notes before carrying out any procedures.

Example

REAR FENDER PANEL REMOVAL

Caution

Avoid cutting with a flame as the insulator (shaded) is flammable.

1.The rear fender panel and wheel house are joined with glue at the wheel arch line.

NOTE

Drill the 24 weld locations indicated by (A), from the room side.

Shows a dimensions

250mm

{9.84in}

CUT-AND-JOINT LOCATION

ROUGH CUT LOCATION

Shows operation section

A

BB

Shows procedure, caution and note

Shows a cross location

A

BRAZE WELDING

17

ROUGH CUT LOCATION

30mm

{1.18in}

CUT-AND-JOINT LOCATION

(A)24

8

Shows a insulator

BOTTOM SIDE 1

19

Shows number of weld

Shows welding region

4

Shows a cross

A-A

B-B

Symbols of Panel Replacement

• The following 6 symbols are used to indicate the type of weld that is used when replacing body panels.

SYMBOL

MEANING

Spot welding

2

arc welding (plug welding)

CO

2

spot welding

CO

SYMBOL

MEANING

Continuous MIG welding (Cut-and-join location)

Braze welding

Rough cut location

MZZ2010B001

MZZ2010B002

00–00–2

Page 5

GENERAL INFORMATION

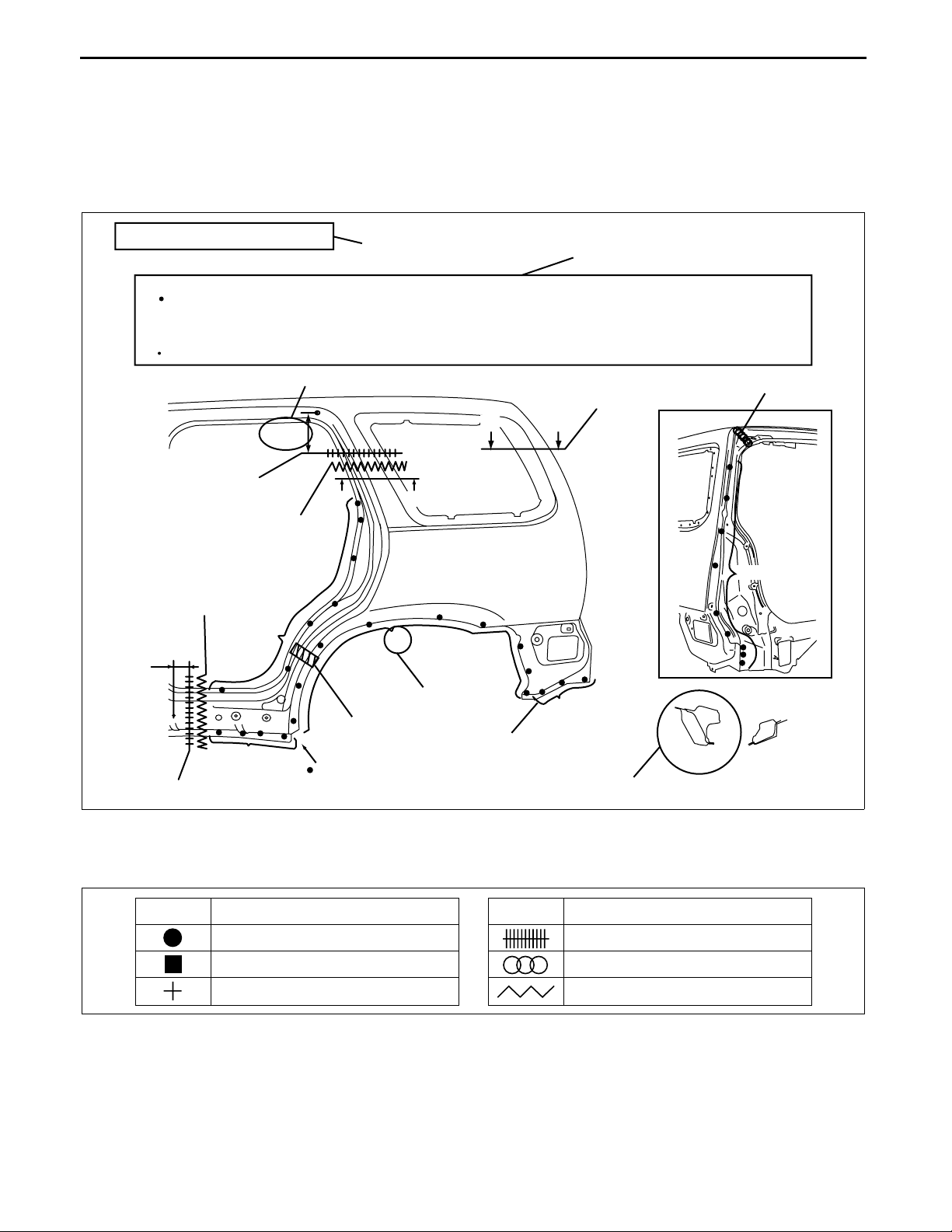

Body Dimensions (Flat-plane Dimensions)

• Flat-plane dimensions are the dimensions measured by projecting certain reference points onto a plane

surface.

• When there are no specific indications, the standard points and dimensions are symmetrical in regard to the

center of the vehicle.

• The hypothetical lines may differ according to the vehicle model.

Example

00–00

UNDERBODY FLAT-PLANE DIMENSIONS

1,030 {40.55}

Shows dimension

The dimensions on the left

and right in regard to the center

of the vehicle are different.

Shows hypothetical

standard line

Shows vehicle section

495

{19.48}

918 {38.14}

1,162 {45.78}

485

{19.09}

A

B

C

619

{24.38}

185

{7.28}

725

{28.55}

{19.27}

489

1,211

{2.19}

{47.68}

{12.40}

55

609

315

527

{24.00}

690 {27.17}

D

{20.75}

425

{16.73}

Shows outline drawing

800 {31.50}

F

E

487

{19.19}

1,240

{48.82}

When there are no specific indications, all of

units are in millimeters (mm).

mm {in}

1,220 {48.03}

G

587

98

{3.86}

H

547

{23.11}

{12.62}

{21.54}

320

1,089 {42.87}

I

624

{24.56}

716

{28.21}

J

1,060 {41.73}

Shows point

symbol

700

{27.58}

Point

symbol

Crossmember No,1 standard

A

hole

B

Front side frame standard hole

Front suspension mounting

C

block surface hole center

Front suspension mounting

D

bolt

Front frame rear standard hole

E

Designation

Hole diameter

or bolt or nut

size mm {in}

φ 16 {0.62}

φ 16 {0.62}

φ 80 {3.14}

M14 {0.55}

φ 16 {0.62}

Shows bolt size

Point

symbol

F

Front frame rear standard hole

Rear side frame standard hole

G

Link bracket

H

I

Rear suspension housing

J

Rear side frame standard hole

Designation

Hole diameter

or bolt or nut

size mm {in}

φ 18 {0.62}

φ 16 {0.62}

17 × 29.5

{0.66×1.16}

φ 12 {0.47}

φ 16 {0.62}

Shows hole diameter

00–00–3

Shows

slot

MZZ2010B003

Page 6

GENERAL INFORMATION

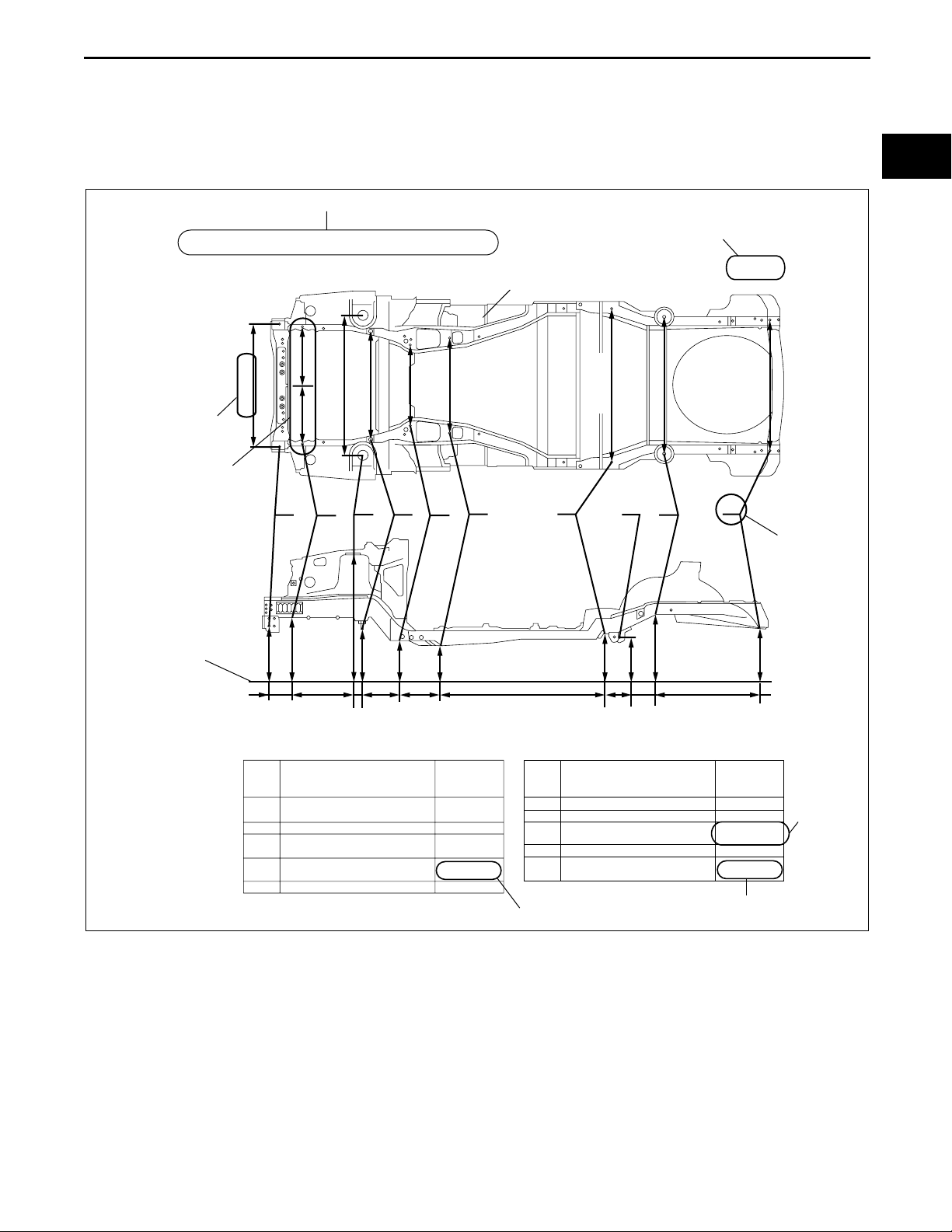

Body Dimensions (Straight-line Dimensions)

• Straight-line dimensions are the actual dimensions between two standard points.

• When there are no specific indications, the standard points and dimensions are symmetrical in regard to the

center of the vehicle.

Example

ROOM STRAIGHT-LINE DIMENSIONS (2)

Shows vehicle section

Shows details of the standard

point location

A

F-F

Fr

,

Fr

Shows dimension location

Shows point

symbol

F

Shows point indication

Without apostrophe:RH

With apostrophe:LH

Shows position and shape of the points

,

B-B

G-G

,

C-C

Fr

H-H

Fr

Shows outline drawing

G

9

I

8

H

,

,

,

F

10

Fr

B

1

5

C

D-D

I - I

2

6

D

7

3

A

,

H

,

,

,

E. E

4

,

E-E

Fr

Fr

11

Fr

Measured

location

1

2

3

4

5

6

7

Dimension mm {in}

1,184 {46.61}

1,064 {41.89}

919 {36.18}

690 {27.17}

1,185 {46.65}

901 {35,47}

607 {23.90}

Shows dimension

No indication are shown within the

outline drawing.

Symbols of Body Dimensions

• The following 8 symbols are used to indicate the standard points.

SYMBOL

Center of circular hole

MEANING

SYMBOL

(arrow only)

Center elliptical hole

Notch

Panel seam, bead, etc.

Measured

location

8

9

10

11

B-B'

C-C'

D-D'

Fr

Dimension mm {in}

1,642 {64.65}

1,463 {57.60}

1,667 {65.63}

1,672 {65.83}

1,037 {40.83}

1,290 {50.79}

1,208 {47.56}

MZZ2010B004

MEANING

Bolt tip

Center of rectangular-shaped hole

Edge of rectangular-shaped hole

End Of Sie

00–00–4

MZZ2010B016

Page 7

GENERAL INFORMATION

SERVICE PRECAUTIONS

C3U000000000B02

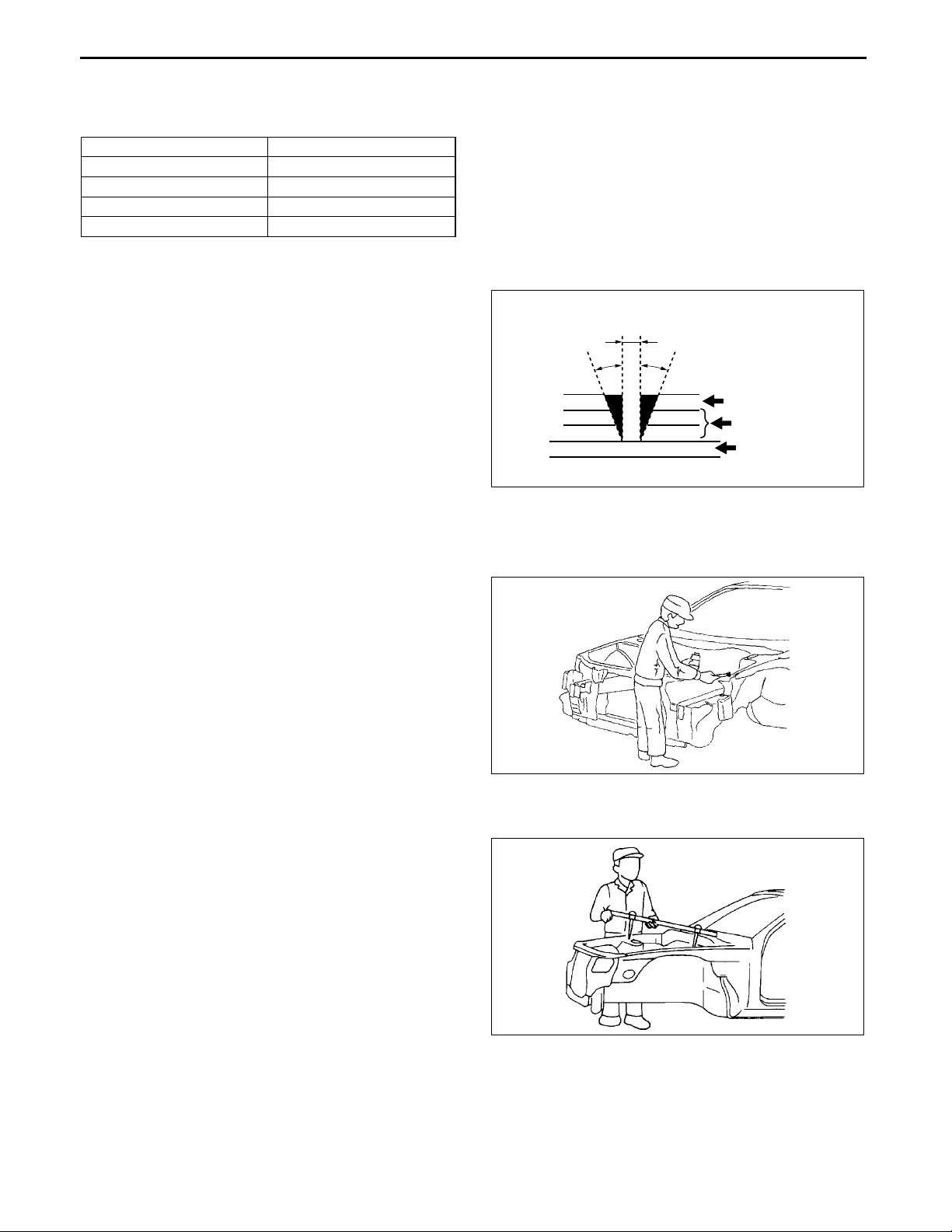

Arrangement of Workshop

• Arrangement of the workshop is important for safe and efficient work.

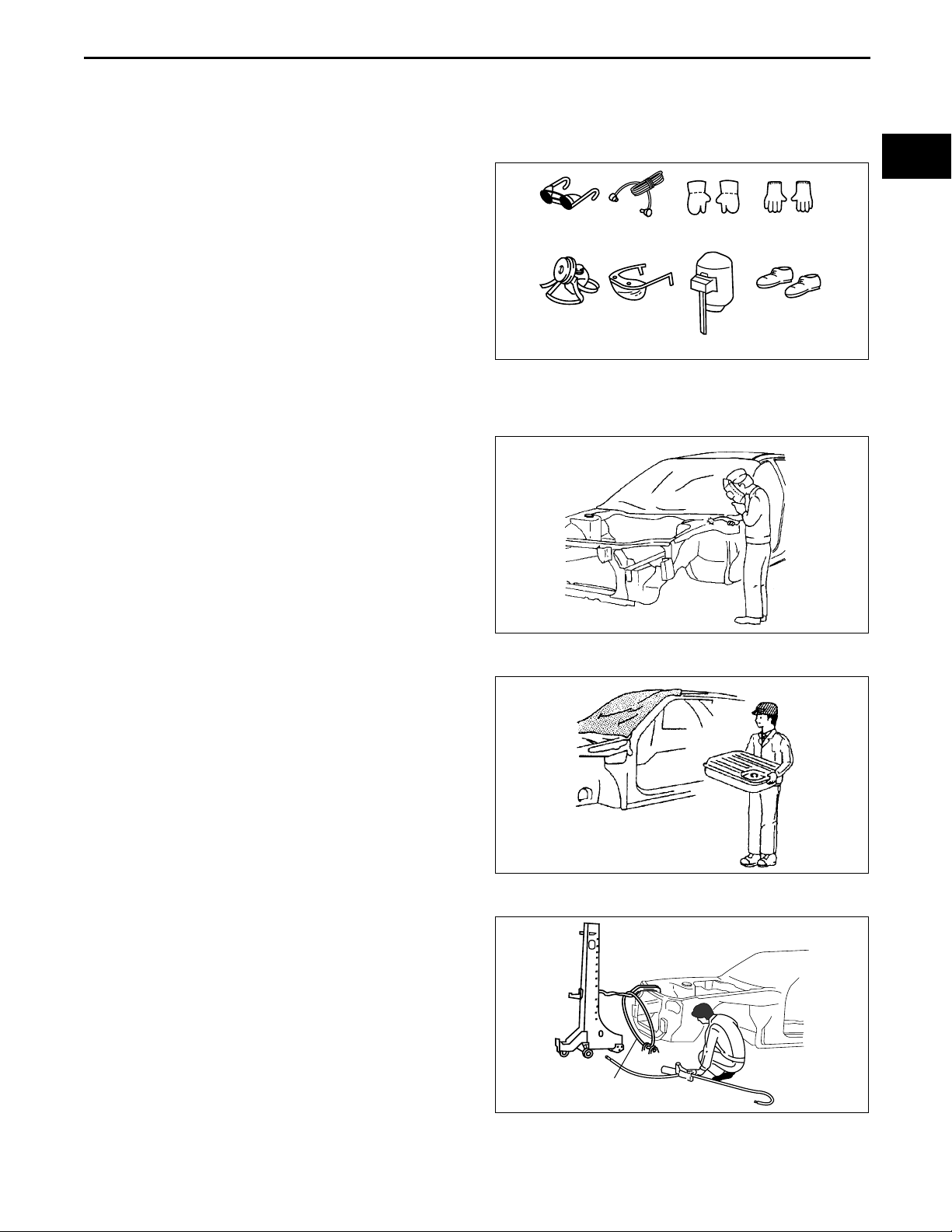

Safety Precautions

• Protective head covering and safety shoes should

always be worn. Depending upon the nature of

the work, gloves, safety glasses, ear protectors,

face shield, etc., should also be used.

Welding

glasses

Dust mask Safety glasses

Ear

protectors

Weldlng

gloves

Face shield

Cotton

gloves

Safety shoes

Vehicle Protection

• Use seat covers and floor covers.

• Use heat-resistant protective covers to protect glass areas and seats from heat or sparks during welding.

• Protect items such as moldings, garnishes, and

ornaments with tape when welding.

00–00

MZZ2036B001

Remove Dangerous Articles

• Remove the fuel tank before using an open flame

in that area. Plug connection piping to prevent

fuel leakage.

Use of Pulling Equipment

• When using pulling equipment, keep away from

the pulling area and use safety wires to prevent

accidents.

MZZ2036B002

MZZ2036B003

Safety wires

MZZ2036B004

00–00–5

Page 8

GENERAL INFORMATION

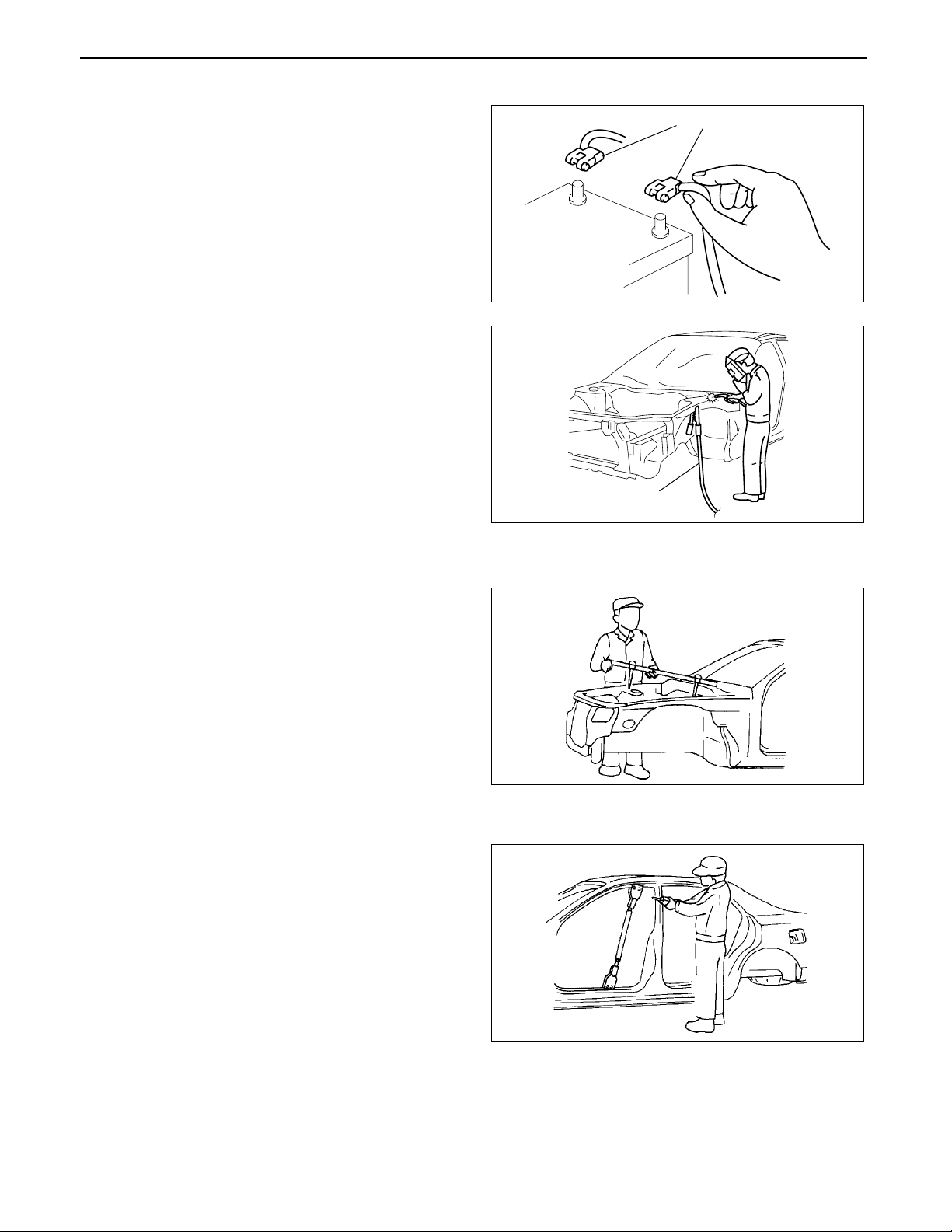

Prevent Short Circuits

• Turn the ignition switch to the LOCK position.

• Disconnect the battery cables.

• Securely connect the welding machine ground

near the welding area.

End Of Sie

Battery cable

MZZ2036B005

EFFICIENT REMOVAL OF BODY PANELS

Body Measurements

• Before removal or rough-cutting, first measure the

body at and around the damaged area against

the standard reference dimension specifications.

If there is deformation, use frame repair

equipment to make a rough correction.

Prevention of Body Deformation

• Use a clamp or a jack for removal and reinforce at

and around the rough-cutting location to prevent

deforming of the body.

Ground

MZZ2036B006

C3U000000000B03

MZJ2038B001

00–00–6

MZJ2038B002

Page 9

GENERAL INFORMATION

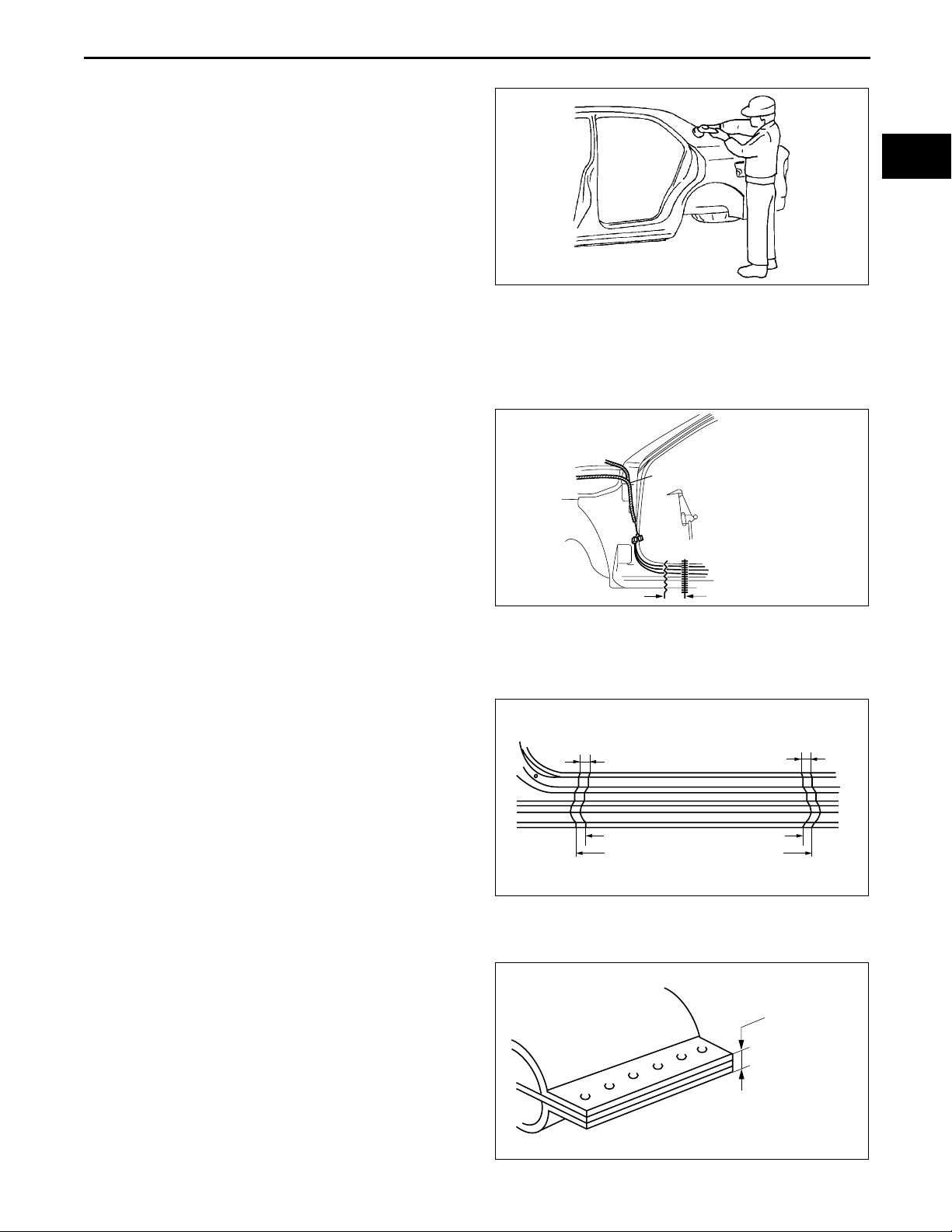

Selection of Cut-and-join Locations

• For parts where complete replacement is not

feasible, careful cutting and joining operations

should be followed. If the location to be cut is a

flat area where there is no reinforcement, the

selected cutting location should be where the

welding distortion will be minimal.

MZJ2038B003

Removal of Associated Parts

• Protect moldings, garnishes, and ornaments with tape when removing associated parts.

Rough Cutting of Damaged Panel

• Verify that there are no parts (such as pipes, hoses, and wiring harness) nearby or on the opposite side of a

panel which could be damaged by heat.

• For cut-and-join areas, allow for an overlap of

30—50 mm {1.18—1.97 in} and then rough-cut

the damaged panel.

End Of Sie

Wiring harness

00–00

Rough cut location

INSTALLATION PREPARATIONS

Cut-and-join location

MZZ2038B001

C3U000000000B04

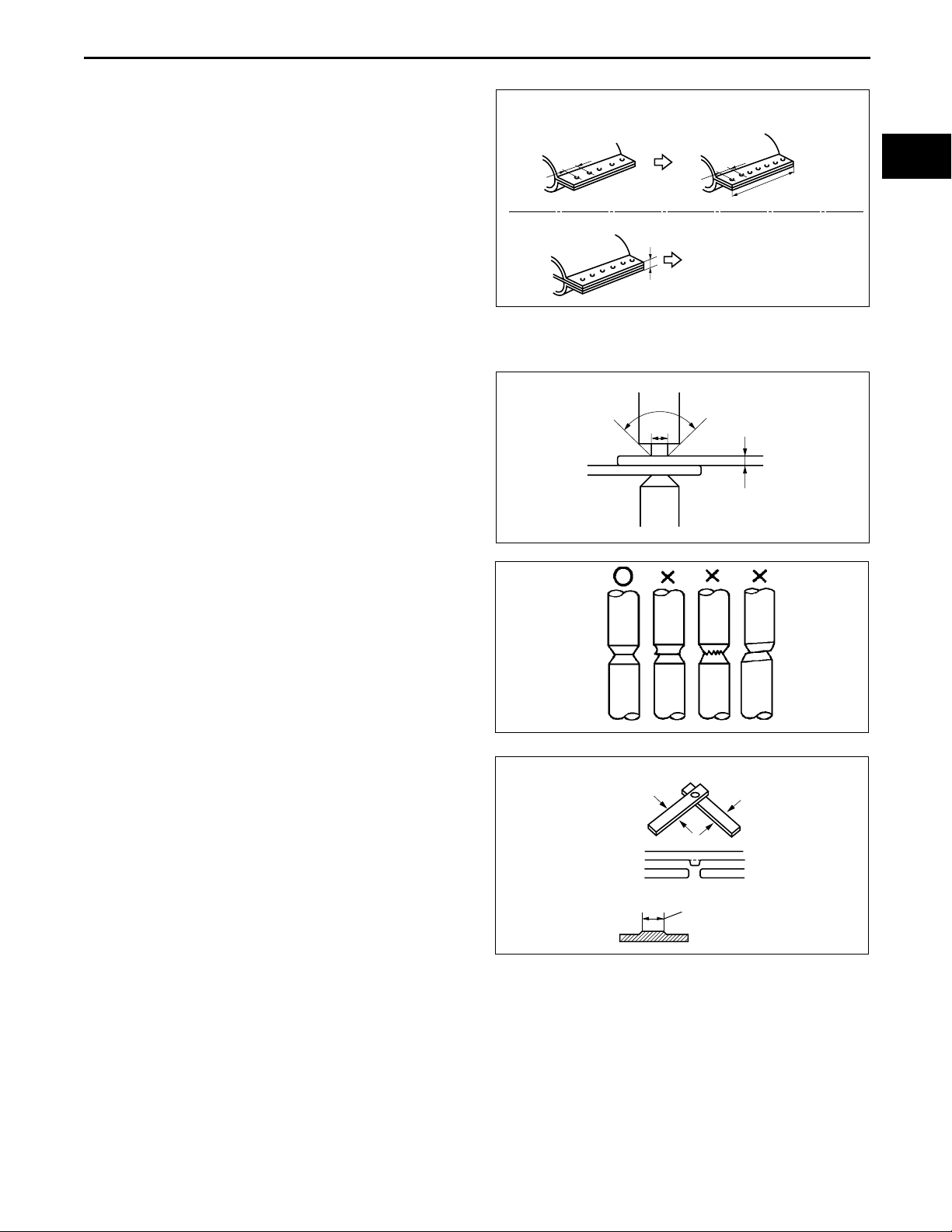

Rough Cutting of New Parts

• For cut-and-join areas, allow for an overlap of 30—50 mm {1.18—1.97 in} with the remaining area on the body

side and then rough-cut the new parts.

30-50mm{1.18-1.97in}

Over lap

Body side rough cut location

New part rough cut location

30-50mm{1.18-1.97in}

Over lap

MZZ2038B002

Determination of Welding Method

• If the total thickness at the area to be welded is 3 mm {0.12 in} or more, use a CO

gas shielded-arc welder to

2

make the plug welds.

3mm

{0.12in}or more

MZZ2038B003

00–00–7

Page 10

GENERAL INFORMATION

Making Holes for CO2 Arc Welding

• For places that cannot be spot welded, make a hole for CO

(mm {in})

Panel thickness (ø) Hole diameter (ø)

0.60—0.90 {0.02—0.03} 5 {0.19}

0.91—1.20 {0.04—0.05} 6 {0.23}

1.21—1.80 {0.051—0.07} 8 {0.31}

1.81—4.50 {0.071—0.17} 10 {0.39}

• Grind the shaded section indicated in the diagram below and create a hole in the part where the 3—4 plates

are put together. Also, weld the plates together tightly so that gaps do not develop.

arc welding using a punch or drill as follows.

2

φ

10mm{0.39in}

30°

30°

Outer panel

Middie panel

Inner panel

MZZ2038B004

Application of Weld-through Primer

• For treatment against corrosion, remove the paint grease, and other material from the portion of new part and

body to be welded, and apply weld-through primer.

End Of Sie

MZJ2038B008

EFFICIENT INSTALLATION OF BODY PANELS

Checking Preweld Measurements And Watching

• Align to the standard reference dimensions,

based upon the body dimensions illustration, so

that new parts are installed in the correct position.

C3U000000000B05

00–00–8

MZJ2038B009

Page 11

GENERAL INFORMATION

Welding Notes

• For the number of weld points, welding should be

performed in accordance with the following

reference standards.

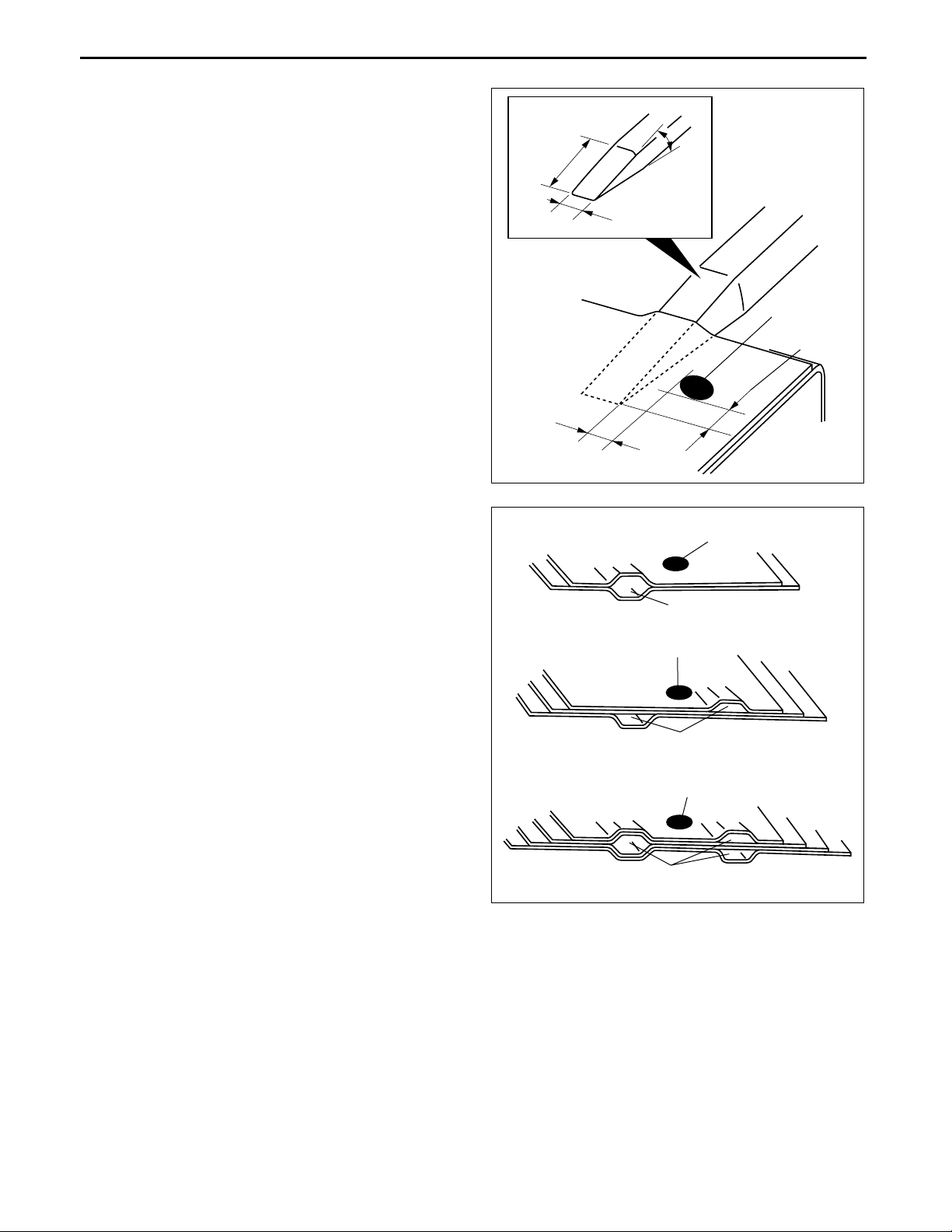

Spot Welding Notes

• The shape of the spot welder tip is D=(2×t)+3. If

the upper panel thickness is different from that of

the under panel, adjust to the thinner one.

Spot welding

Original weld

Pitch: 50mm{1.97in}

2

CO

arc welding

Original spot weld

Repair weld

Pitch: within 35mm{1.38in}

Original number of welds x 1.3 or more

If 3mm

{0.12in} or more

Original number of welds

or more

70 - 120°

D

Repair weld

MZZ2038B005

t

00–00

• Because the weld strength is affected by the

shape of the spot welder tip, the optimum

condition of the tip should always be maintained.

• Spot welds should be made at points other than

the originally welded points.

• Before spot welding, make a trial weld using the

same material as the body panel to check the

weld strength.

MZZ2038B009

MZJ2038B012

Test piece method

Nagget diameter

:4/5 of tip

MZZ2038B006

00–00–9

Page 12

GENERAL INFORMATION

Checking Weld Strength

• Installation locations of the engine, chassis, and

seat belts are designated as important safety

locations for weld strength. Check weld strength

by driving a chisel between the panels at every

fourth or fifth weld spot, and every tenth regular

weld location.

• Drive the chisel between the panels according to

the number of panels as shown below.

• To determine weld strength, drive the chisel

between the panel and check whether the panels

come apart. If the panels come apart, make

another weld near the original weld.

• Restore the shape of the checked area.

End Of Sie

Chisel dimensions

25mm

{0.98in}

Within 5mm

{0.20in}

Two panels

Three panels

20°

8mm{0.31in}

Weld location

Within 5mm

{0.20in}

MZZ2038B007

Weld location

One location

Weld location

Four panels

Two location

Weld location

Three location

MZZ2038B008

00–00–10

Page 13

GENERAL INFORMATION

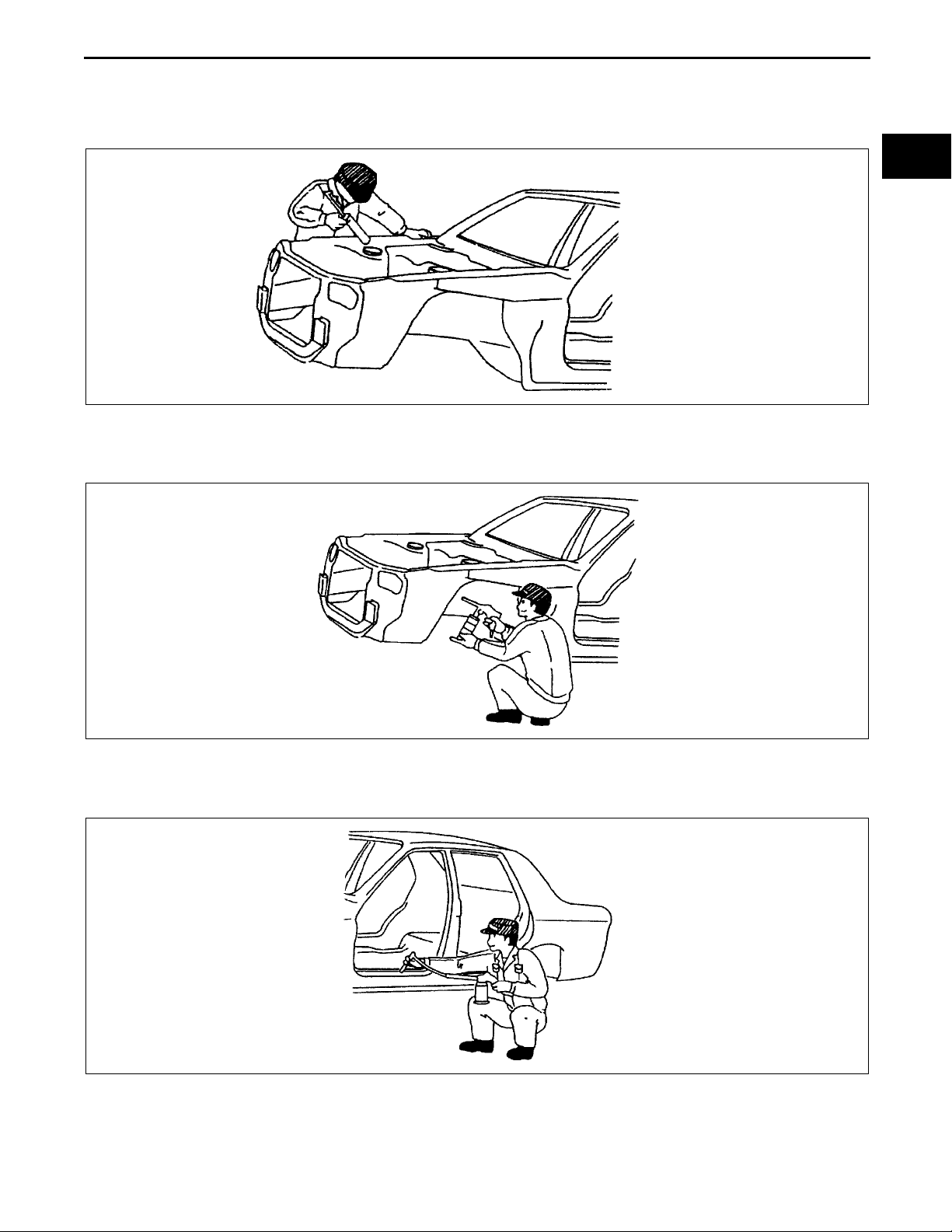

ANTICORROSION, SOUND INSULATION, AND VIBRATION INSULATION

Body Sealing

• Apply body sealer where necessary.

• For locations where application of body sealer is difficult after installation, apply it before installation.

Application of Undercoating

• Apply an undercoat to the required location of the body.

C3U000000000B06

00–00

YMU980PAR

Application of Rust Inhibitor

• Apply rust inhibitor (wax, oil, etc.) to the back of the welded areas.

YMU980PAS

YMU980PAT

00–00–11

Page 14

GENERAL INFORMATION

Application of Floor Silencer

• Apply floor silencer by heating with an infrared ray lamp.

End Of Sie

ABBREVIATION

CM Control module

Ctr Center

DSC Dynamic stability control

Fr Front

HU Hydraulic unit

LH Left

M Metallic

MC Mica

RH Right

Rr Rear

YMU980PAU

C3U000000000B07

End Of Sie

00–00–12

Page 15

BODY & ACCESSORIES

Toc of SCT

CONSTRUCTION . . . . . . . . . . . 09-80A

PANEL REPLACEMENT . . . . .09-80B

WATER-PROOF AND RUST

PREVENTIVE TREATMENT. . 09-80C

Toc of SCT

09–80A BODY STRUCTURE [CONSTRUCTION]

DIMENSIONS . . . . . . . . . . . . . . 09-80D

PLASTIC BODY PARTS . . . . . 09-80E

09

SECTION

09–80A

BODY COMPONENTS CONSTRUCTION09–80A–2

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80A–2

End of Toc

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80A–5

09–80A–1

Page 16

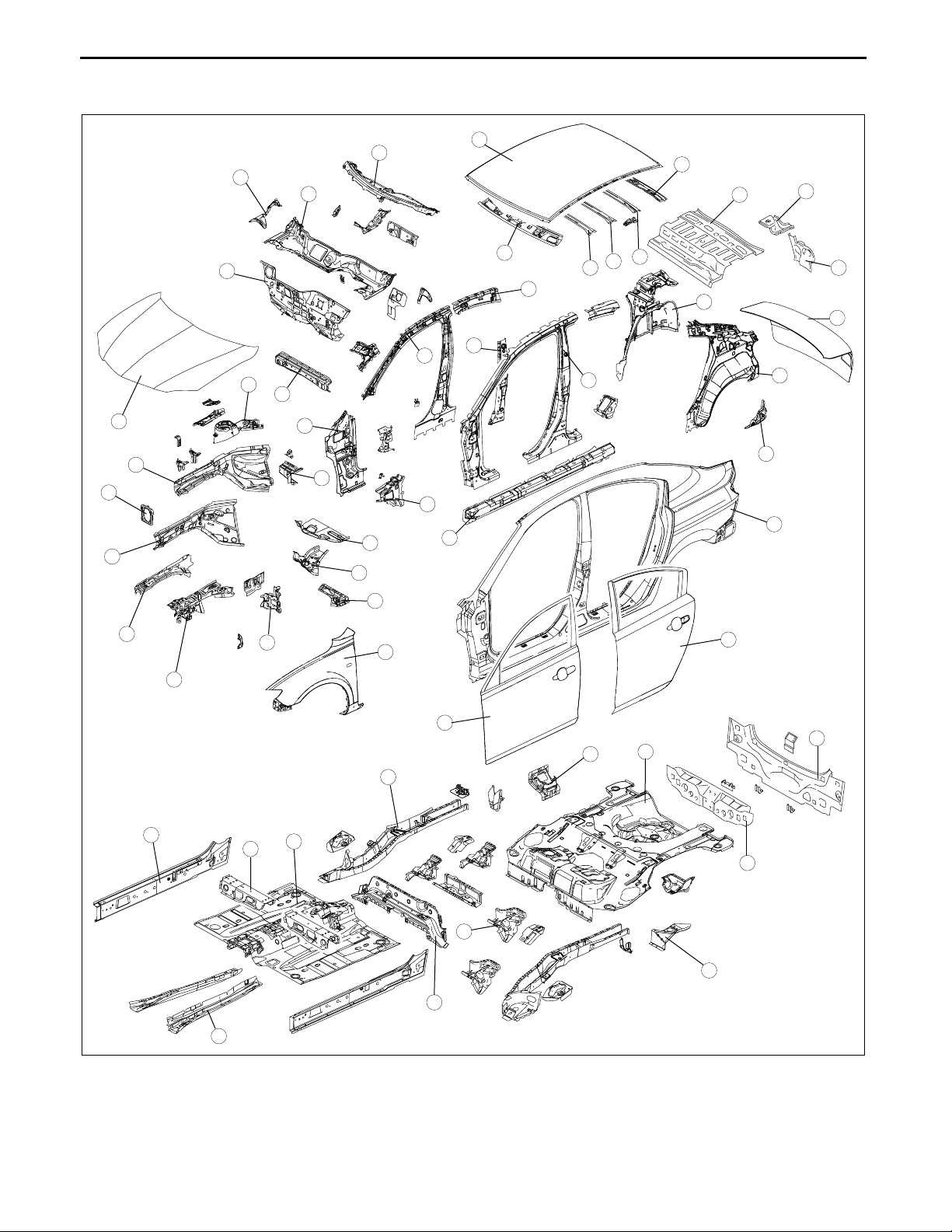

BODY STRUCTURE [CONSTRUCTION]

BODY COMPONENTS CONSTRUCTION

4SD

16

17

15

8

14

1

20

3

10

2

4

12

11

18

21

19

25

22

34

29

23

30

24

31

32

33

26

35

C3U098007000B01

36

37

38

27

28

39

13

5

7

9

40

6

41

53

50

51

48

42

44

45

52

47

49

46

43

.

B3U0980B041

09–80A–2

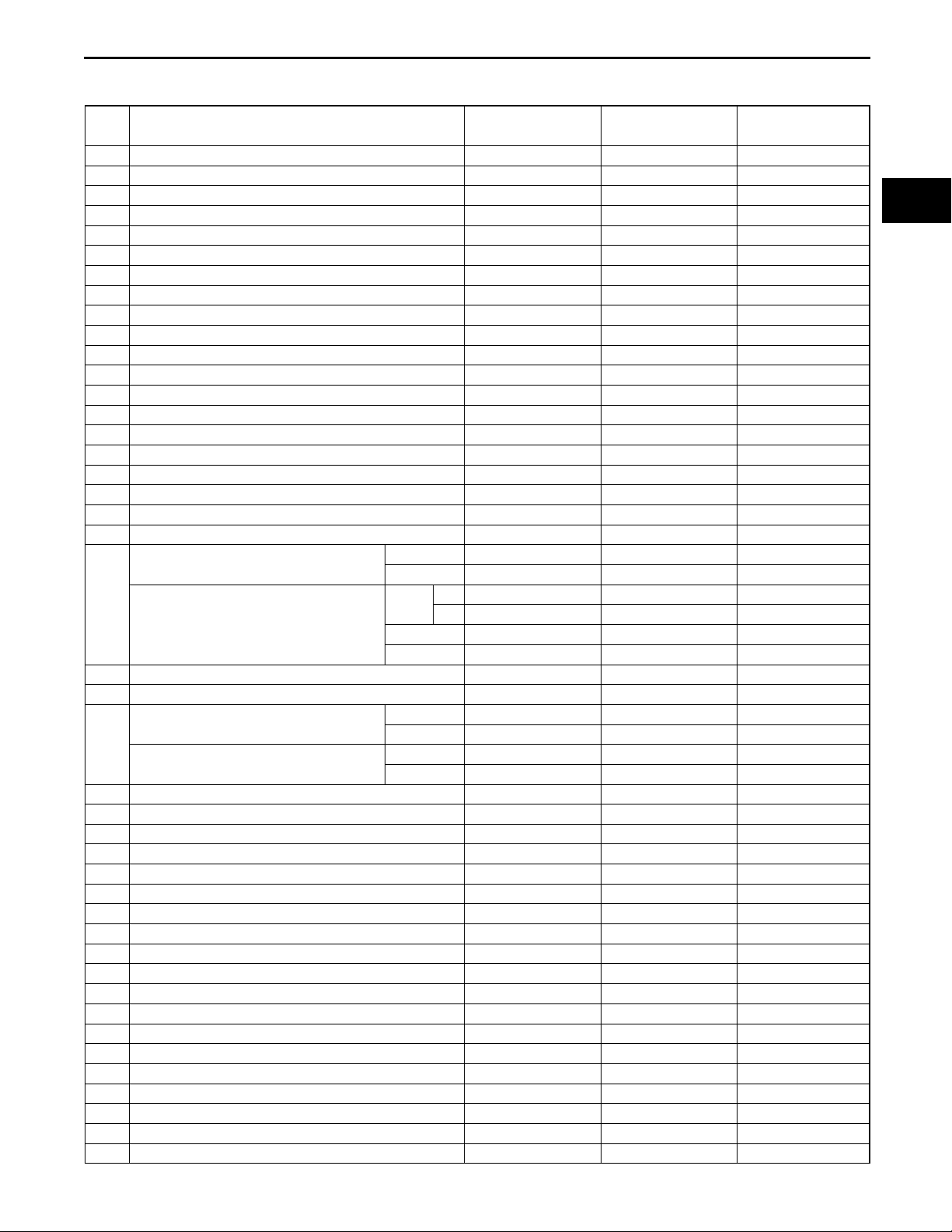

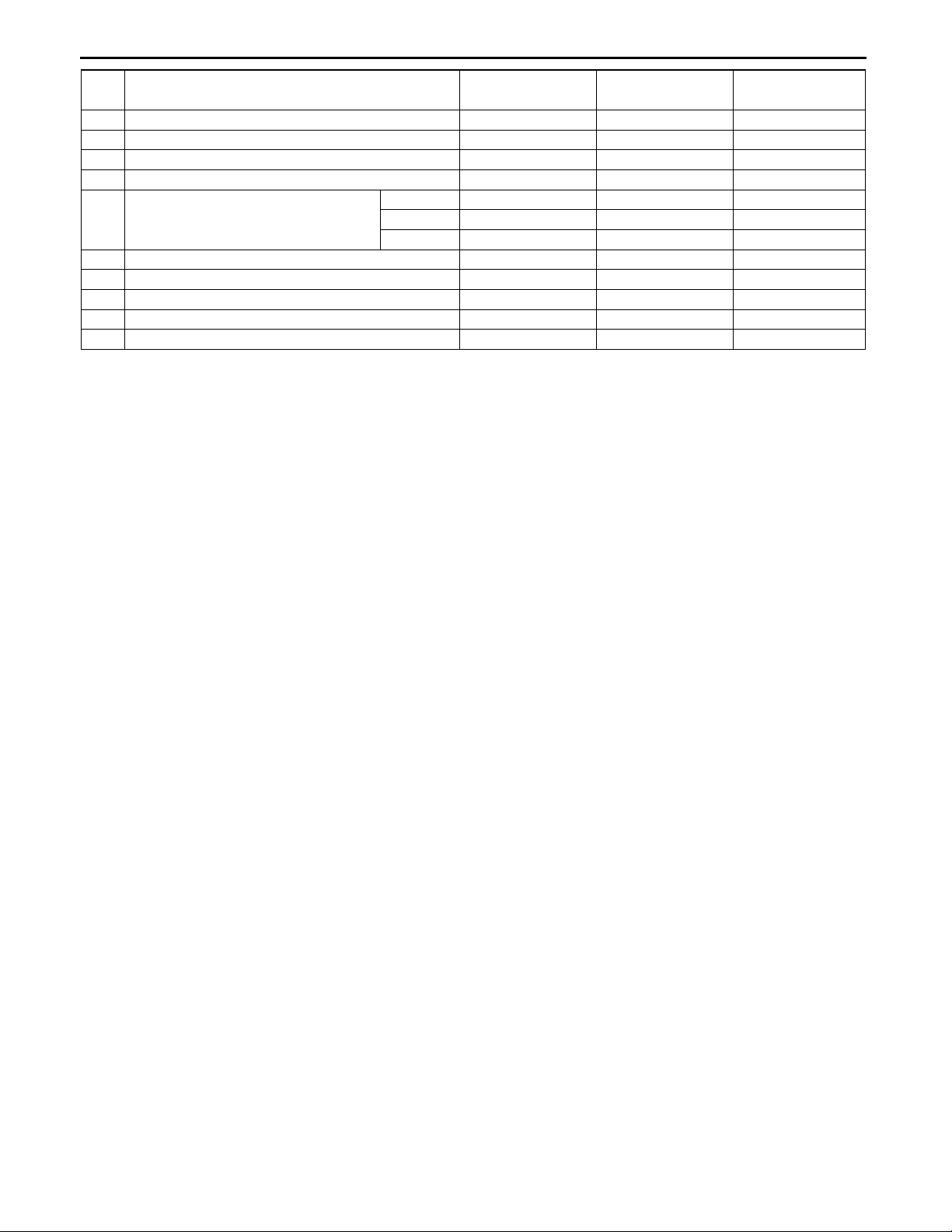

Page 17

BODY STRUCTURE [CONSTRUCTION]

x:Applied

-:Not applied

No. Part Name High- tension steel Rust proof steel

1 Hood - x 0.70 {0.028}

2 Front bumper bracket x x 2.90 {0.114}

3 Front side frame (inner) x x 1.60 {0.063}

4 Front side frame (outer) x x 1.60 {0.063}

5 Apron reinforcement (lower) - x 0.70 {0.028}

6 Apron reinforcement (upper) - x 1.00 {0.039}

7 Shroud side panel x x 1.00 {0.039}

8 Suspension housing - x 2.60 {0.102}

9 Front fender panel x x 0.65 {0.026}

10 Side member deck - x 1.80 {0.071}

11 Front frame rear reinforcement x x 0.80 {0.031}

12 Front frame (rear) x x 1.80 {0.071}

13 Torque box - x 1.60 {0.063}

14 Dash lower member x x 1.40 {0.055}

15 Dash lower panel x 0.80 {0.031}

16 Wiper bracket - x 1.40 {0.055}

17 Dash upper panel - x 0.85 {0.033}

18 Cowl panel - x 0.80 {0.031}

19 Cowl side reinforcement - x 0.70 {0.028}

20 Hinge pillar (inner) x x 1.60 {0.063}

Front pillar (inner)

21

Center pillar (inner)

22 Center pillar reinforcement (inner) x - 1.80 {0.071}

23 Roof rail (inner, rear) x - 1.00 {0.039}

Front pillar reinforcement

24

Center pillar reinforcement

25 Side sill reinforcement x - 1.40 {0.055}

26 Wheel house (inner) - x 0.70 {0.028}

27 Rear pillar (inner) - x 0.65 {0.026}

28 Rear fender lower panel - x 0.70 {0.028}

29 Front header - - 0.65 {0.026}

30 Roof reinforcement (front) - - 0.55 {0.021}

31 Roof reinforcement center - - 1.00 {0.039}

32 Roof reinforcement (rear) - - 1.00 {0.039}

33 Rear header - - 0.70 {0.028}

34 Roof panel - - 0.70 {0.028}

35 Package tray - - 0.60 {0.024}

36 Rear fender rain rail - x 0.70 {0.028}

37 Corner plate - x 0.70 {0.028}

38 Trunk lid panel x x 0.70 {0.028}

39 Side panel (outer) - x 0.70 {0.028}

40 Rear door - x 0.65 {0.026}

41 Front door - x 0.70 {0.028}

42 Side sill (inner) x x 1.40 {0.055}

43 Front B frame x x 0.90 {0.035}

LH x - 1.40 {0.055}

RH x - 1.60 {0.063}

Upper

Center x - 1.20 {0.047}

Lower x - 1.00 {0.039}

Upper x - 1.80 {0.071}

Lower x - 1.80 {0.071}

Upper x - 1.40 {0.055}

Lower x - 1.20 {0.047}

LH x - 1.60 {0.063}

RH x - 1.80 {0.071}

Thickness

(mm) {in}

09–80A

09–80A–3

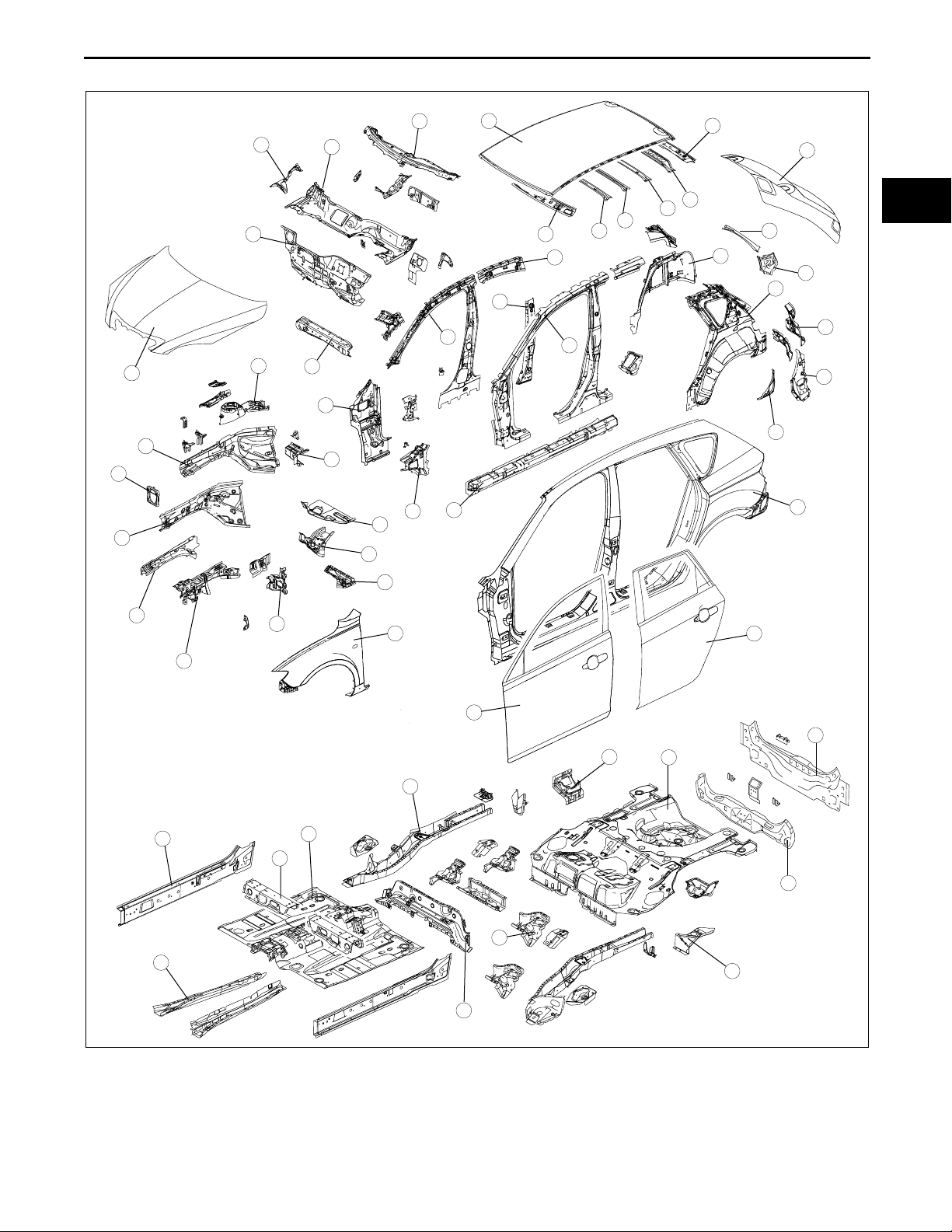

Page 18

BODY STRUCTURE [CONSTRUCTION]

No. Part Name High- tension steel Rust proof steel

44 Crossmember No.2 x - 1.20 {0.047}

45 Front floor pan - x 0.70 {0.028}

46 Crossmember No.3 x x 1.60 {0.063}

47 Crossmember No.4 gusset - x 1.40 {0.055}

Front x x 2.00 {0.079}

48 Rear side frame

49 Crossmember No.3 (front) - x 1.60 {0.063}

50 Suspension housing - x 0.75 {0.030}

51 Rear floor pan - x 2.00 {0.079}

52 Rear end member - - 0.60 {0.024}

53 Rear end panel - x 0.60 {0.024}

Center x x 2.60 {0.102}

Rear x x 1.80 {0.071}

Thickness

(mm) {in}

09–80A–4

Page 19

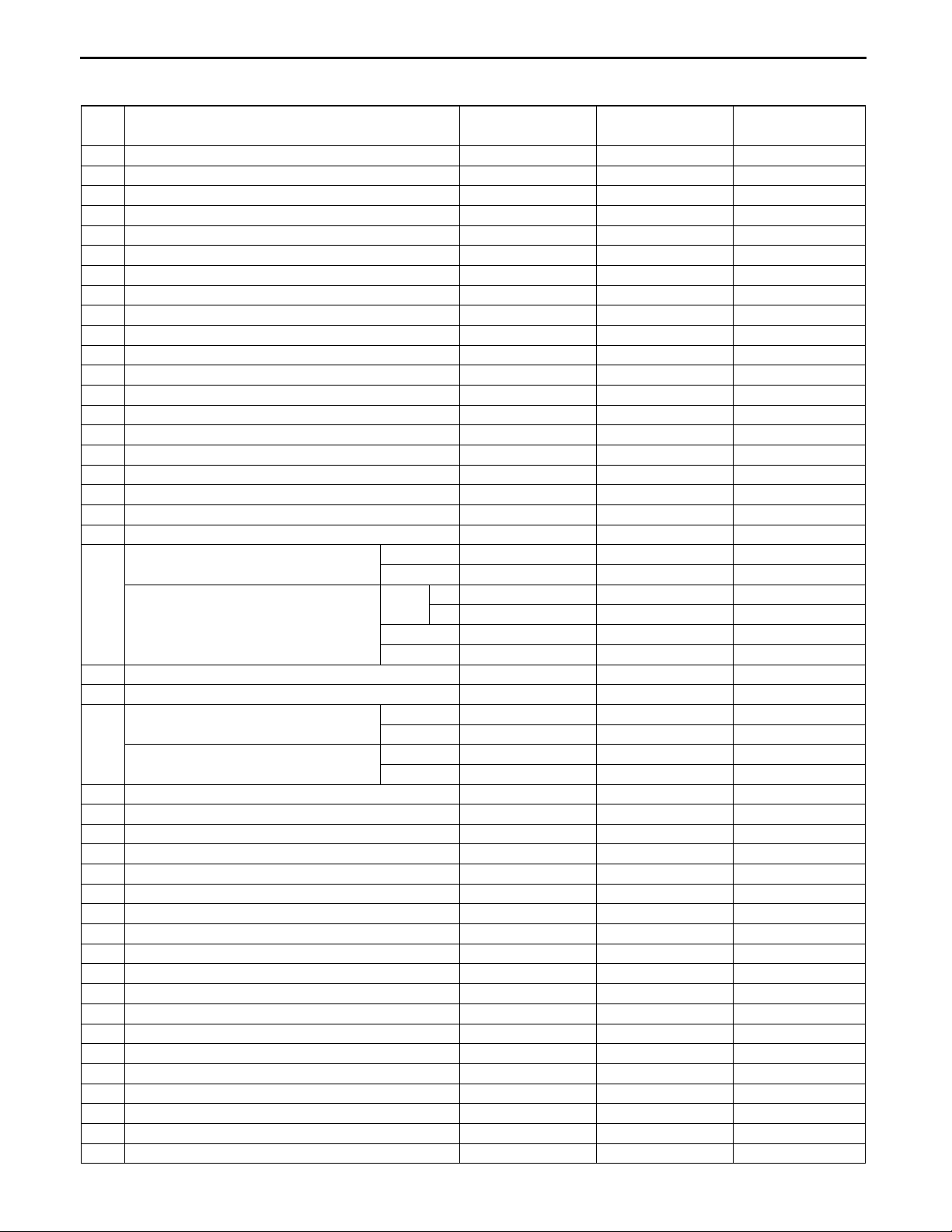

5HB

BODY STRUCTURE [CONSTRUCTION]

15

16

18

17

38

33

23

34

35

36

37

39

40

09–80A

28

26

29

27

22

21

1

8

14

24

30

31

20

32

3

10

2

19

25

41

11

4

12

13

5

7

9

42

6

43

55

53

52

50

44

47

46

54

49

45

51

48

B3U0980B043

.

09–80A–5

Page 20

BODY STRUCTURE [CONSTRUCTION]

x:Applied

-:Not applied

No. Part Name High- tension steel Rust proof steel

1 Hood x x 0.70 {0.028}

2 Front bumper bracket x x 2.90 {0.114}

3 Front side frame (inner) x x 1.60 {0.063}

4 Front side frame (outer) x x 1.60 {0.063}

5 Apron reinforcement (lower) - x 0.70 {0.028}

6 Apron reinforcement (upper) - x 1.00 {0.039}

7 Shroud side panel x x 1.00 {0.039}

8 Suspension housing - x 2.60 {0.102}

9 Front fender panel x x 0.65 {0.026}

10 Side member deck - x 1.80 {0.071}

11 Front frame rear reinforcement x x 0.80 {0.031}

12 Front frame (rear) x x 1.80 {0.071}

13 Torque box - x 1.60 {0.063}

14 Dash lower member x x 1.40 {0.055}

15 Dash lower panel x 0.80 {0.031}

16 Wiper bracket - x 1.40 {0.055}

17 Dash upper panel - x 0.85 {0.033}

18 Cowl panel - x 0.80 {0.031}

19 Cowl side reinforcement - x 0.70 {0.028}

20 Hinge pillar (inner) x x 1.60 {0.063}

Front pillar (inner)

21

Center pillar (inner)

22 Center pillar reinforcement (inner) x - 1.80 {0.071}

23 Roof rail (inner, rear) x - 1.00 {0.039}

Front pillar reinforcement

24

Center pillar reinforcement

25 Side sill reinforcement x - 1.40 {0.055}

26 Wheel house (inner) - x 0.70 {0.028}

27 Rear pillar (inner) - x 0.65 {0.026}

28 Rear pillar (outer) - x 0.70 {0.028}

29 Corner plate - x 0.70 {0.028}

30 Rear side panel - - 0.70 {0.028}

31 Rear pillar reinforcement - - 0.70 {0.028}

32 Rear fender lower panel - x 0.70 {0.028}

33 Front header - - 0.65 {0.026}

34 Roof reinforcement (front) - - 0.55 {0.021}

35 Roof reinforcement center (front) - - 1.00 {0.039}

36 Roof reinforcement center (rear) - - 0.75 {0.030}

37 Roof reinforcement (rear) - - 0.55 {0.021}

38 Rear header - - 0.75 {0.030}

39 Roof panel - - 0.75 {0.030}

40 Liftgate panel - x 0.70 {0.028}

41 Side panel (outer) - x 0.70 {0.028}

42 Rear door - x 0.65 {0.026}

43 Front door x x 0.70 {0.028}

LH x - 1.40 {0.055}

RH x - 1.60 {0.063}

Upper

Center x - 1.20 {0.047}

Lower x - 1.00 {0.039}

Upper x - 1.80 {0.071}

Lower x - 1.80 {0.071}

Upper x - 1.40 {0.055}

Lower x - 1.20 {0.047}

LH x - 1.60 {0.063}

RH x - 1.80 {0.071}

Thickness

(mm) {in}

09–80A–6

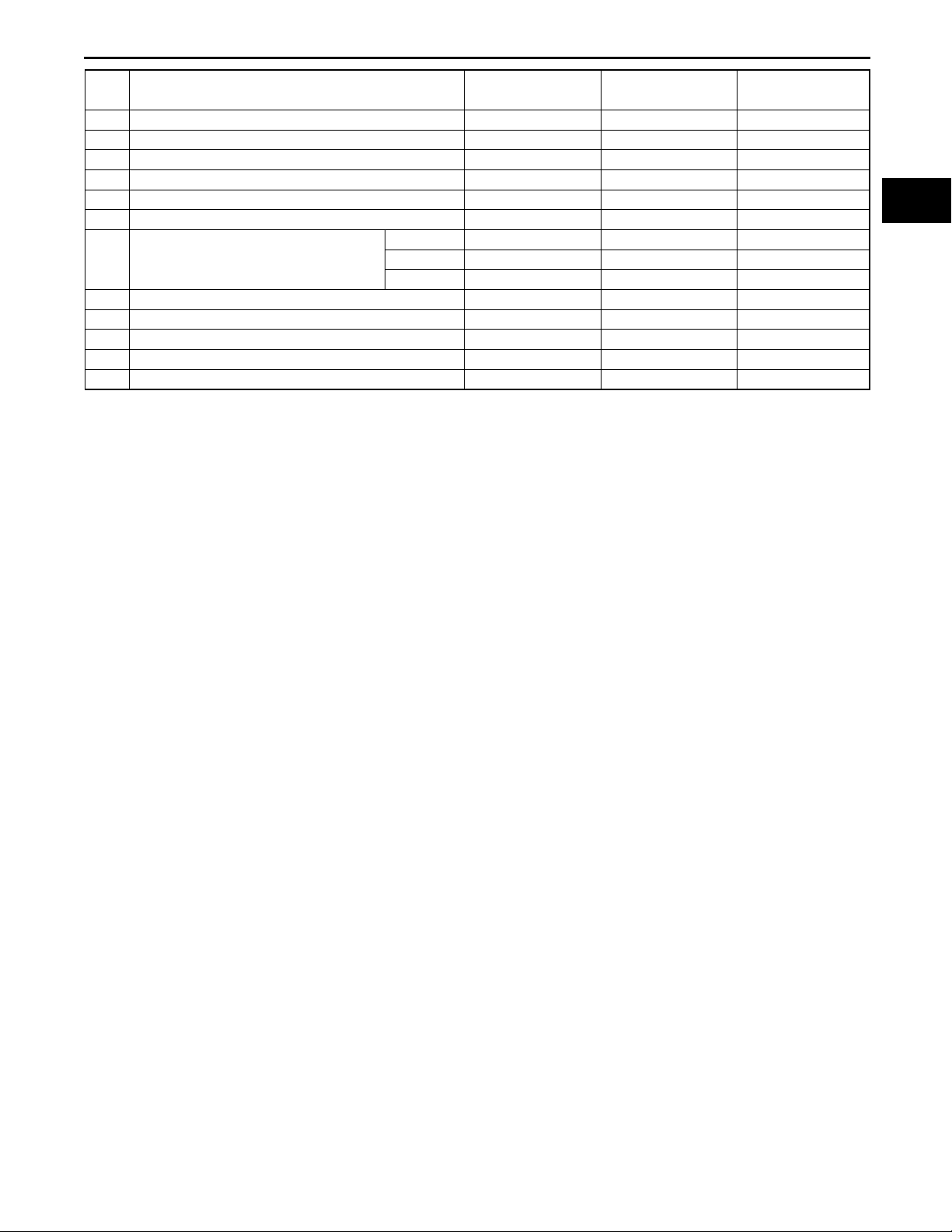

Page 21

BODY STRUCTURE [CONSTRUCTION]

No. Part Name High- tension steel Rust proof steel

44 Side sill (inner) x x 1.40 {0.055}

45 Front B frame x x 0.90 {0.035}

46 Crossmember No.2 x - 1.20 {0.047}

47 Front floor pan - x 0.70 {0.028}

48 Crossmember No.3 x x 1.60 {0.063}

49 Crossmember No.4 gusset - x 1.40 {0.055}

Front x x 2.00 {0.079}

50 Rear side frame

51 Crossmember No.3 (front) - x 1.60 {0.063}

52 Rear floor pan - x 0.75 {0.030}

53 Suspension housing - x 2.00 {0.079}

54 Rear end member - - 1.20 {0.047}

55 Rear end panel - x 0.60 {0.024}

Center x x 2.60 {0.102}

Rear x x 1.80 {0.071}

Thickness

(mm) {in}

End Of Sie

09–80A

09–80A–7

Page 22

BODY STRUCTURE [PANEL REPLACEMENT]

09–80B BODY STRUCTURE [PANEL REPLACEMENT]

FRONT BUMPER BRACKET

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . 09–80B–2

FRONT BUMPER BRACKET

INSTALLATION. . . . . . . . . . . . . . . . . . . 09–80B–3

SHROUD SIDE PANEL REMOVAL . . . . 09–80B–4

SHROUD SIDE PANEL

INSTALLATION. . . . . . . . . . . . . . . . . . . 09–80B–5

COWL SIDE REINFORCEMENT

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . 09–80B–6

COWL SIDE REINFORCEMENT

INSTALLATION. . . . . . . . . . . . . . . . . . . 09–80B–7

APRON REINFORCEMENT (LOWER)

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . 09–80B–8

APRON REINFORCEMENT (LOWER)

INSTALLATION. . . . . . . . . . . . . . . . . . . 09–80B–9

APRON REINFORCEMENT (PARTIAL

CUTTING) REMOVAL . . . . . . . . . . . . . . 09–80B–10

APRON REINFORCEMENT (PARTIAL

CUTTING) INSTALLATION. . . . . . . . . . 09–80B–12

WHEEL APRON PANEL (FRONT)

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . 09–80B–14

WHEEL APRON PANEL (FRONT)

INSTALLATION. . . . . . . . . . . . . . . . . . . 09–80B–15

FRONT SIDE FRAME COMPONENT

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . 09–80B–15

FRONT SIDE FRAME COMPONENT

INSTALLATION. . . . . . . . . . . . . . . . . . . 09–80B–19

FRONT SIDE FRAME (PARTIAL

CUTTING) REMOVAL . . . . . . . . . . . . . . 09–80B–22

FRONT SIDE FRAME (PARTIAL

CUTTING) INSTALLATION. . . . . . . . . . 09–80B–22

TORQUE BOX REMOVAL . . . . . . . . . . . 09–80B–25

TORQUE BOX INSTALLATION . . . . . . . 09–80B–26

FRONT FRAME (REAR) REMOVAL . . . 09–80B–27

FRONT FRAME (REAR)

INSTALLATION. . . . . . . . . . . . . . . . . . . 09–80B–28

FRONT PILLAR REMOVAL . . . . . . . . . . 09–80B–28

FRONT PILLAR INSTALLATION . . . . . . 09–80B–32

CENTER PILLAR REMOVAL . . . . . . . . . 09–80B–35

CENTER PILLAR INSTALLATION . . . . . 09–80B–37

REAR FENDER PANEL REMOVAL . . . . 09–80B–40

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–40

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–41

REAR FENDER PANEL

INSTALLATION . . . . . . . . . . . . . . . . . . . 09–80B–42

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–42

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–43

REAR FENDER LOWER PANEL

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . 09–80B–44

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–44

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–45

REAR FENDER LOWER PANEL

INSTALLATION . . . . . . . . . . . . . . . . . . . 09–80B–46

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–46

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–47

SIDE SILL PANEL REMOVAL. . . . . . . . . 09–80B–48

SIDE SILL PANEL INSTALLATION. . . . .09–80B–49

REAR END PANEL REMOVAL . . . . . . . . 09–80B–50

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–50

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–51

REAR END PANEL INSTALLATION . . . . 09–80B–52

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–52

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–53

REAR FENDER RAIN RAIL AND

CORNER PLATE REMOVAL . . . . . . . . . 09–80B–54

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–54

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–55

REAR FENDER RAIN RAIL AND

CORNER PLATE INSTALLATION . . . . 09–80B–56

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–56

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–57

REAR FLOOR PAN REMOVAL . . . . . . . . 09–80B–58

REAR FLOOR PAN INSTALLATION. . . . 09–80B–60

REAR SIDE FRAME (PARTIAL CUTTING)

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . 09–80B–62

REAR SIDE FRAME (PARTIAL CUTTING)

INSTALLATION . . . . . . . . . . . . . . . . . . . 09–80B–63

ROOF PANEL REMOVAL . . . . . . . . . . . . 09–80B–64

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–64

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–65

ROOF PANEL INSTALLATION . . . . . . . . 09–80B–66

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–66

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80B–67

09–80B

End of Toc

09–80B–1

Page 23

BODY STRUCTURE [PANEL REPLACEMENT]

FRONT BUMPER BRACKET REMOVAL

1. Remove the front bumper bracket.

Caution

•••• Only the procedure for the left side is described. The shape for the right side is different.

FRONT BUMPER BRACKET

C3U098053896B01

End Of Sie

09–80B–2

B3E0980B047

Page 24

BODY STRUCTURE [PANEL REPLACEMENT]

FRONT BUMPER BRACKET INSTALLATION

C3U098053896B02

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. After temporarily installing new parts, make sure the related parts fit properly.

FRONT BUMPER BRACKET

09–80B

End Of Sie

B3E0980B048

09–80B–3

Page 25

BODY STRUCTURE [PANEL REPLACEMENT]

SHROUD SIDE PANEL REMOVAL

1. Remove the shroud side panel.

1

2

C3U098053140B01

3

1

3

SHROUD SIDE PANEL LH

1

1

2

3

4

End Of Sie

09–80B–4

SHROUD SIDE PANEL RH

B3E0980B049

Page 26

BODY STRUCTURE [PANEL REPLACEMENT]

SHROUD SIDE PANEL INSTALLATION

C3U098053140B02

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

1

2

2

1

3

1

09–80B

SHROUD SIDE PANEL LH

1

1

2

3

4

End Of Sie

SHROUD SIDE PANEL RH

B3E0980B050

09–80B–5

Page 27

BODY STRUCTURE [PANEL REPLACEMENT]

COWL SIDE REINFORCEMENT REMOVAL

1. Remove the cowl side reinforcement.

Caution

•••• Be careful not to damage the windshield when drilling the 2 locations indicated by (A).

(A)2

4

1

2

C3U098053290B01

7

End Of Sie

COWL SIDE REINFORCEMENT

2

8

B3E0980B051

09–80B–6

Page 28

BODY STRUCTURE [PANEL REPLACEMENT]

COWL SIDE REINFORCEMENT INSTALLATION

C3U098053290B02

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

2

4

1

7

2

09–80B

End Of Sie

COWL SIDE REINFORCEMENT

2

8

B3E0980B052

09–80B–7

Page 29

BODY STRUCTURE [PANEL REPLACEMENT]

APRON REINFORCEMENT (LOWER) REMOVAL

1. Remove the apron reinforcement (lower).

3

C3U098053260B01

APRON REINFORCEMENT (LOWER)

10

End Of Sie

12

B3E0980B053

09–80B–8

Page 30

BODY STRUCTURE [PANEL REPLACEMENT]

APRON REINFORCEMENT (LOWER) INSTALLATION

C3U098053260B02

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

3

APRON REINFORCEMENT (LOWER)

10

09–80B

End Of Sie

12

B3E0980B054

09–80B–9

Page 31

BODY STRUCTURE [PANEL REPLACEMENT]

APRON REINFORCEMENT (PARTIAL CUTTING) REMOVAL

1. Rough cut at the locations shown in the figure to remove damaged parts.

2. Remove the apron reinforcement.

ROUGH CUT LOCATION FOR

APRON REINFORCEMENT

C3U098053260B03

CUT-AND-JOIN LOCATION

APRON REINFORCEMENT

(LOWER)

50mm {1.97 in}

200mm {7.87 in}

120mm {4.72 in}

APRON REINFORCEMENT

(LOWER)

CUT-AND-JOIN LOCATION FOR APRON

REINFORCEMENT (UPPER)

APRON REINFORCEMENT

(UPPER)

09–80B–10

B3E0980B055

Page 32

BODY STRUCTURE [PANEL REPLACEMENT]

APRON REINFORCEMENT

5

3

09–80B

End Of Sie

B3E0980B056

09–80B–11

Page 33

BODY STRUCTURE [PANEL REPLACEMENT]

APRON REINFORCEMENT (PARTIAL CUTTING) INSTALLATION

C3U098053260B04

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

CUT-AND-JOIN LOCATION FOR

APRON REINFORCEMENT (LOWER)

50mm {1.97 in}

120mm {4.72 in}

APRON REINFORCEMENT

(LOWER)

CUT-AND-JOIN LOCATION FOR

APRON REINFORCEMENT (UPPER)

3

APRON REINFORCEMENT

(UPPER)

09–80B–12

B3E0980B057

Page 34

BODY STRUCTURE [PANEL REPLACEMENT]

APRON REINFORCEMENT

5

7

09–80B

End Of Sie

B3E0980B058

09–80B–13

Page 35

BODY STRUCTURE [PANEL REPLACEMENT]

WHEEL APRON PANEL (FRONT) REMOVAL

1. Remove the wheel apron panel (front).

4

6

C3U098053210B01

DRIVER,S SIDE: 4

WHEEL APRON PANEL (FRONT)

End Of Sie

ENGINE MOUNT

REINFORCEMENT

4

B3E0980B059

09–80B–14

Page 36

BODY STRUCTURE [PANEL REPLACEMENT]

WHEEL APRON PANEL (FRONT) INSTALLATION

C3U098053210B02

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

4

DRIVER,S SIDE: 4

WHEEL APRON PANEL (FRONT)

6

09–80B

End Of Sie

ENGINE MOUNT

REINFORCEMENT

4

B3E0980B060

09–80B–15

Page 37

BODY STRUCTURE [PANEL REPLACEMENT]

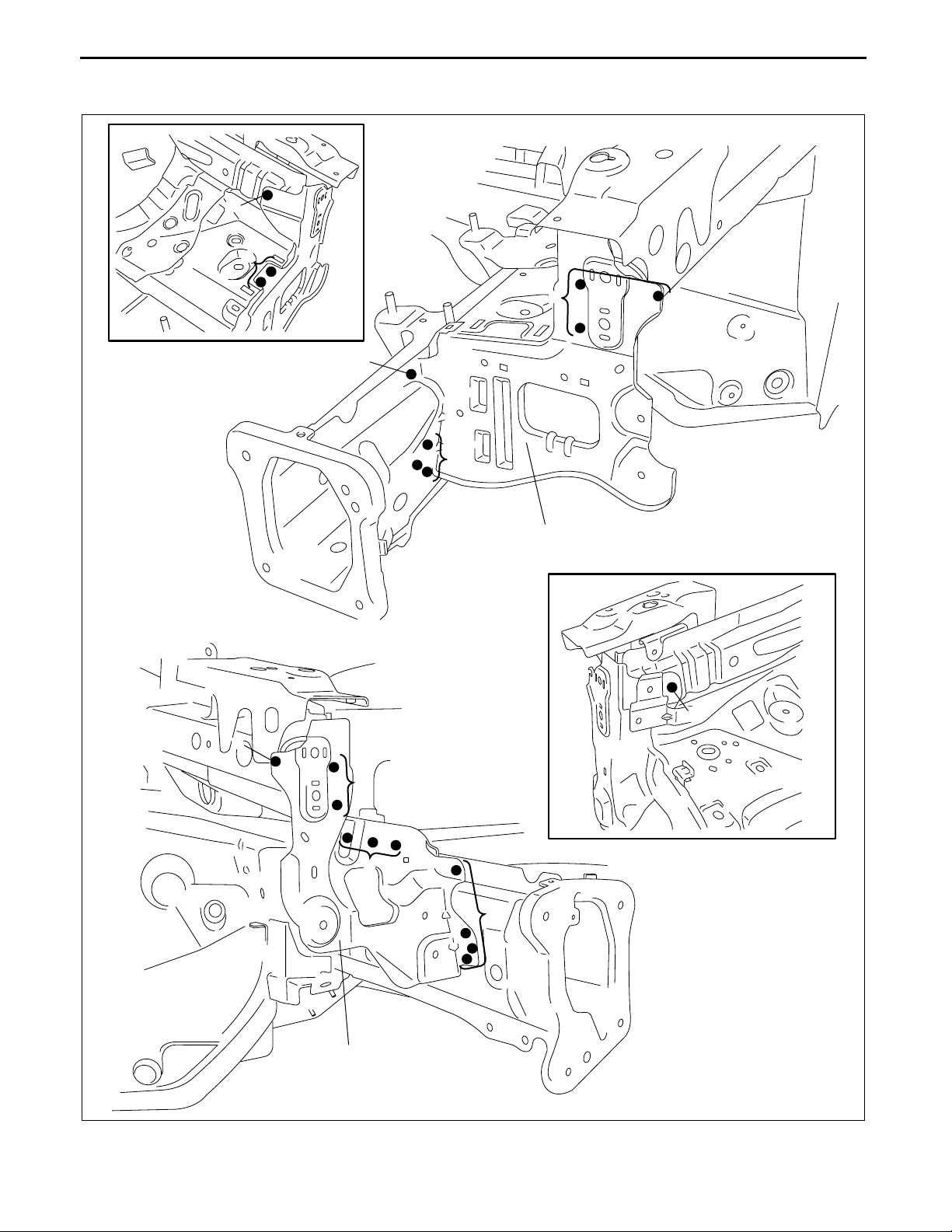

FRONT SIDE FRAME COMPONENT REMOVAL

1. Drill the 26 locations indicated by (A).

(A)4

(A)4

C3U098053300B01

SIDE MEMBER DECK

(A)4

(A)5

FRONT SIDE FRAME

(A)9

B3E0980B061

09–80B–16

Page 38

BODY STRUCTURE [PANEL REPLACEMENT]

2. Drill the 65 locations indicated by (B), 4 locations on the driver’s side indicated by (C), and 3 locations on the

passenger’s side.

3. Drill the 5 locations indicated by (D) from the bottom.

4. Drill the 1 location indicated by (E) from the bottom, as it cannot be seen from the interior.

(B)5

(B)10

(B)3

(B)11

(B)7

(B)3

(C)

DRIVER,S SIDE: 4

PASSENGER,S SIDE: 3

(B)6

(B)6

(B)14

09–80B

(D)3

(D)2

(E)1

B3E0980B062

09–80B–17

Page 39

BODY STRUCTURE [PANEL REPLACEMENT]

5. Drill the 9 locations indicated by (F), 6 locations on the driver’s side indicated by (G), 5 locations on the

passenger’s side.

6. When the front side frame component is being removed, the hinge pillar (inner) may interfere with the apron

reinforcement (upper) and make removal difficult, drill the 2 locations indicated by (H), 3 locations indicated by

(I), and then open the front pillar (outer) outward.

7. Drill the 3 locations indicated by (J), and remove the front side frame component.

(F)6

DRIVER,S SIDE: 6

(G)

PASSENGER,S SIDE: 5

(F)3

COWL PANEL

(H)2

(I)2

APRON REINFORCEMENT (UPPER)

SUSPENSION HOUSING (UPPER)

(I)1

FRONT PILLAR (OUTER)

End Of Sie

09–80B–18

(J)3

B3E0980B063

Page 40

BODY STRUCTURE [PANEL REPLACEMENT]

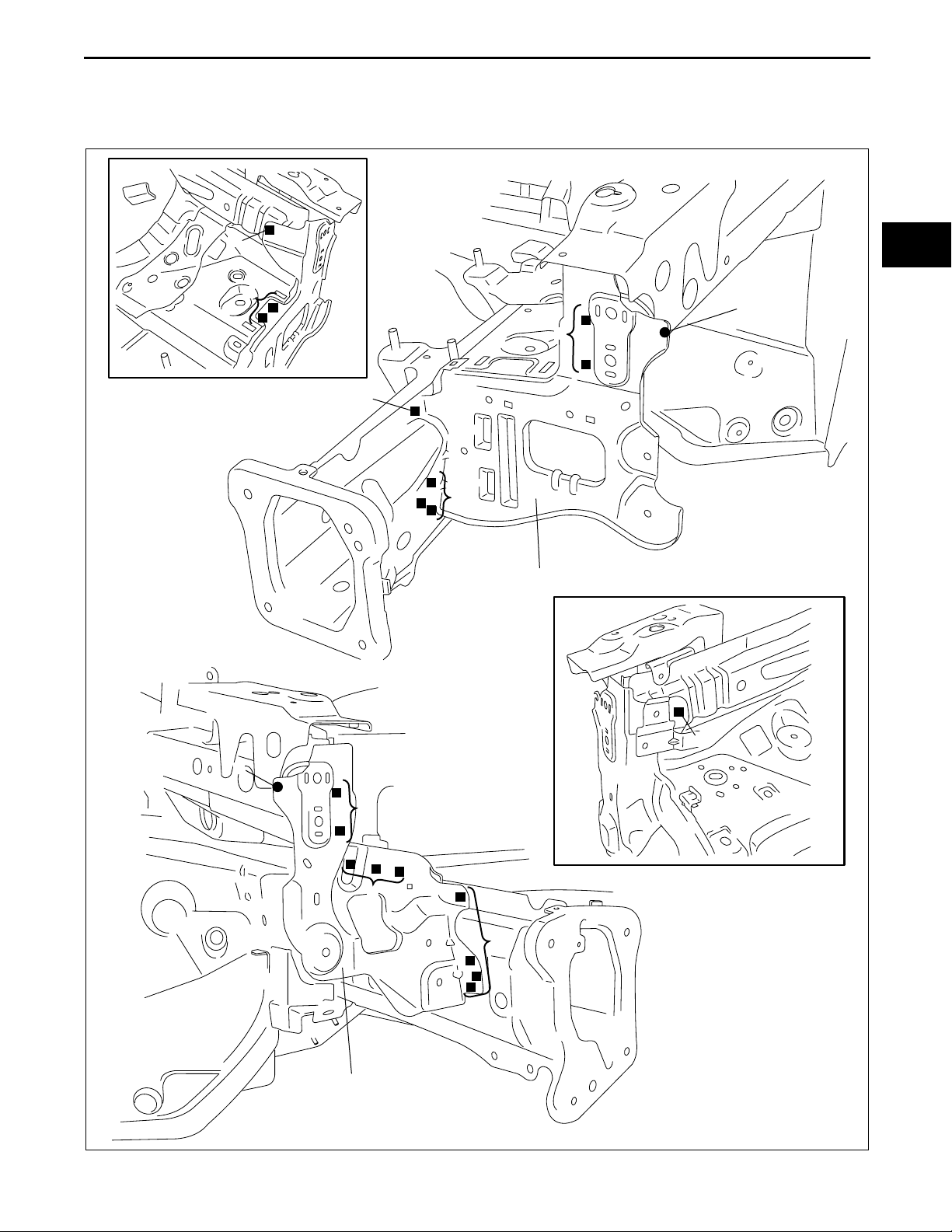

FRONT SIDE FRAME COMPONENT INSTALLATION

C3U098053300B02

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. Weld the 3 locations indicated by (A) and temporarily install the front side frame component.

4. After temporarily installing new parts, make sure the related parts fit properly.

5. Weld the remaining weld locations and install the front side frame component.

(A)3

09–80B

COWL PANEL

2

2

APRON REINFORCEMENT (UPPER)

1

FRONT PILLAR (OUTER)

SUSPENSION HOUSING (UPPER)

6

DRIVER,S SIDE: 6

PASSENGER,S SIDE: 5

3

B3E0980B064

09–80B–19

Page 41

BODY STRUCTURE [PANEL REPLACEMENT]

3

7

10

5

11

3

DRIVER,S SIDE: 4

PASSENGER,S SIDE

6

6

14

: 3

09–80B–20

2

3

1

B3E0980B065

Page 42

BODY STRUCTURE [PANEL REPLACEMENT]

4

4

09–80B

SIDE MEMBER DECK

4

5

FRONT SIDE FRAME

9

End Of Sie

B3E0980B066

09–80B–21

Page 43

BODY STRUCTURE [PANEL REPLACEMENT]

FRONT SIDE FRAME (PARTIAL CUTTING) REMOVAL

1. Rough cut and remove the damaged part of the front side frame.

CUT-AND-JOIN LOCATION FOR

ROUGH CUT LOCATION

FOR OUTER

5

6

40mm

{1.57 in}

APRON OUTER

130mm {5.12 in}

C3U098053300B03

FRONT SIDE FRAME

CUT-AND-JOIN LOCATION FOR

INNER

ROUGH CUT LOCATION

FOR INNER

310mm {12.20 in}

40mm

{1.57 in}

End Of Sie

FRONT SIDE FRAME (PARTIAL CUTTING) INSTALLATION

Caution

•••• The cut-and-joint area indicates the maximum size range of the installation position.

B3E0980B067

C3U098053300B04

1. Make a reinforcement panel using the material of the front side frame.

2. To cut-and-join the new and existing parts, cut at the locations for the new part indicated in the figure below and

bevel the locations where the new and existing parts are joined.

3. When installing the new parts, trial-fit new and existing parts, and then measure and adjust the body to conform

with standard dimensions.

09–80B–22

Page 44

BODY STRUCTURE [PANEL REPLACEMENT]

4. To install the inner, trial-fit the new and existing parts, weld the existing parts and the reinforcement, and then

butt weld the new and existing parts.

5. Because the outer cannot be welded to the existing parts from the inside of the frame, drill 2 plug weld holes at

the locations indicated by (A) on the existing parts. Install the reinforcement and the existing parts by plug

welding from the outside of the frame, then butt weld the new and existing parts.

6. Grind the area where the inner and outer are butt welded with a disk grinder to finish the surface.

30mm {1.18 in}

65mm {2.56 in}

REINFORCEMENT

OUTER : t=1.6mm

{0.06 in}

INNER : t=1.6mm

{0.06 in}

L=10mm {0.39 in} x 6

REINFORCEMENT

09–80B

L=10mm {0.39 in} x 2

NEW FRONT SIDE FRAME (INNER)

FRONT SIDE FRAME (INNER)

310mm {12.20 in}

CUT-AND-JOIN LOCATION FOR

INNER

B3E0980B068

09–80B–23

Page 45

REINFORCEMENT

CUT-AND-JOIN LOCATION

FOR OUTER

BODY STRUCTURE [PANEL REPLACEMENT]

L=10mm {0.39 in} x 2

NEW FRONT SIDE FRAME (OUTER)

End Of Sie

5

(A)2

130mm {5.12 in}

6

FRONT SIDE FRAME (OUTER)

B3E0980B069

09–80B–24

Page 46

BODY STRUCTURE [PANEL REPLACEMENT]

TORQUE BOX REMOVAL

1. Remove the torque box.

C3U098053381B01

3

3

6

4

09–80B

End Of Sie

2

7

TORQUE BOX

B3E0980B070

09–80B–25

Page 47

BODY STRUCTURE [PANEL REPLACEMENT]

TORQUE BOX INSTALLATION

C3U098053381B02

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

3

3

6

4

End Of Sie

2

7

TORQUE BOX

B3E0980B071

09–80B–26

Page 48

BODY STRUCTURE [PANEL REPLACEMENT]

FRONT FRAME (REAR) REMOVAL

1. Remove the front frame (rear).

18

C3U098053390B01

1

FRONT FRAME (REAR)

6

1

10

09–80B

End Of Sie

2

B3E0980B072

09–80B–27

Page 49

BODY STRUCTURE [PANEL REPLACEMENT]

FRONT FRAME (REAR) INSTALLATION

C3U098053390B02

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

1

FRONT FRAME (REAR)

6

18

1

10

2

B3E0980B073

End Of Sie

FRONT PILLAR REMOVAL

1. Rough cut area (A) and drill the 69 locations indicated by (B).

Caution

•••• Avoid cutting with a blowtorch or similar tools as the insulator (shaded area) is flammable.

2. When the front pillar (outer) is being removed, the cowl panel may interfere with the front pillar (outer) and

make removal difficult. Therefore, drill the 2 locations indicated by (C) and then open the cowl panel outward.

3. Remove the front pillar (outer).

C3U098074090B01

09–80B–28

Page 50

COWL PANEL

BODY STRUCTURE [PANEL REPLACEMENT]

09–80B

(B)11

A-A B-B

60mm

{2.36 in}

(B)1

(C)2

(B)2

(B)1

(B)3

(B)8

(B)2

550mm {21.65 in}

(B)3

(B)4

(B)23

INSULATOR

B

A

A

(A) ROUGH CUT

LOCATION FOR

OUTER

FRONT PILLAR (OUTER)

40mm

{1.57 in}

50mm

{1.97 in}

CUT-AND-JOIN

LOCATION FOR

OUTER

(B)11

B

(A) ROUGH CUT

LOCATION FOR

OUTER

CUT-AND-JOIN

LOCATION FOR

OUTER

B3E0980B074

09–80B–29

Page 51

BODY STRUCTURE [PANEL REPLACEMENT]

4. Rough cut area (D) and drill the 10 locations indicated by (E).

5. Drill the 6 locations indicated by (F) from the interior.

6. Remove the front pillar reinforcement.

7. Rough cut area (G) and remove the side sill reinforcement.

50mm

{1.97 in}

(E)1

(E)1

FRONT PILLAR

REINFORCEMENT

60mm

{2.36 in}

CUT-AND-JOIN LOCATION

FOR REINFORCEMENT

(D) ROUGH CUT LOCATION

FOR REINFORCEMENT

(F)3

(E)2

(E)5

(G) ROUGH CUT LOCATION FOR

SIDE SILL REINFORCEMENT

CUT-AND-JOIN LOCATION FOR

SIDE SILL REINFORCEMENT

50mm

{1.97 in}

140mm

{5.51 in}

(F)3

(E)1

SIDE SILL REINFORCEMENT

09–80B–30

SIDE SILL REINFORCEMENT (UPPER)

SIDE SILL GUSSET

B3E0980B075

Page 52

BODY STRUCTURE [PANEL REPLACEMENT]

8. Rough cut area (H), drill the 9 locations indicated by (I), and then remove the front pillar (inner).

CUT-AND-JOIN LOCATION

FOR INNER

(H)ROUGH CUT LOCATION

FOR INNER

110mm

{4.33 in}

65mm

{2.56 in}

(I)7

FRONT PILLAR (INNER)

(I)2

09–80B

End Of Sie

B3E0980B076

09–80B–31

Page 53

BODY STRUCTURE [PANEL REPLACEMENT]

FRONT PILLAR INSTALLATION

C3U098074090B02

1. When joining and cutting the new and existing parts, trial fit the new part in position, and then measure and

adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

Note

• In areas where the outer, reinforcement, inner, and other parts are in 3-4 layers, drill holes for plug welds

in all but the innermost panel.

3. After temporarily installing new parts, make sure the related parts fit properly.

CUT-AND-JOIN LOCATION

FOR INNER

110mm

{4.33 in}

FRONT PILLAR (INNER)

2

7

B3E0980B077

09–80B–32

Page 54

BODY STRUCTURE [PANEL REPLACEMENT]

CUT-AND-JOIN LOCATION FOR

SIDE SILL REINFORCEMENT

140mm

{5.51 in}

SIDE SILL REINFORCEMENT (UPPER)

09–80B

SIDE SILL GUSSET

SIDE SILL REINFORCEMENT

60mm

{2.36 in}

CUT-AND-JOIN LOCATION

1

1

FRONT PILLAR

REINFORCEMENT

FOR REINFORCEMENT

3

3

1

2

5

B3E0980B078

09–80B–33

Page 55

COWL PANEL

BODY STRUCTURE [PANEL REPLACEMENT]

11

1

2

610mm

{24.01 in}

CUT-AND-JOIN LOCATION

FOR OUTER

1

2

3

8

3

23

2

4

FRONT PILLAR (OUTER)

50mm

{1.97 in}

End Of Sie

09–80B–34

11

CUT-AND-JOIN LOCATION

FOR OUTER

B3E0980B079

Page 56

BODY STRUCTURE [PANEL REPLACEMENT]

CENTER PILLAR REMOVAL

C3U098070350B01

1. Rough cut area (A), drill the 59 locations indicated by (B), and then remove the center pillar (outer).

Caution

•••• Avoid cutting with a blowtorch or similar tools as the insulator (shaded area) is flammable.

2. Rough cut area (C), drill the 18 locations indicated by (D), and then remove the center pillar reinforcement.

3. Rough cut area (E), drill the 4 locations indicated by (F), and then remove the side sill reinforcement.

4. Drill the 19 locations indicated by (G) and remove the center pillar (inner).

INSULATOR

80mm {3.15 in}

30mm {1.18 in}

5HB

A-A

CUT-AND-JOIN

LOCATION FOR

OUTER

(A) ROUGH

CUT LOCATION

FOR OUTER

80mm {3.15 in}

30mm {1.18 in}

CUT-AND-JOIN LOCATION

FOR OUTER

(A) ROUGH CUT LOCATION

A

A

FOR OUTER

09–80B

B-B

30mm

C-C

{1.18 in}

B

B

CUT-AND-JOIN LOCATION

FOR OUTER

CENTER PILLAR (OUTER)

INSULATOR

45mm

{1.77 in}

(A) ROUGH CUT LOCATION

FOR OUTER

(B)2

(B)20

(B)2

(B)18

(A) ROUGH CUT LOCATION

FOR OUTER

C

C

(B)17

45mm

{1.77 in}

95mm

{3.74 in}

CUT-AND-JOIN LOCATION

FOR OUTER

B3E0980B080

09–80B–35

Page 57

BODY STRUCTURE [PANEL REPLACEMENT]

(D)2

(D)1

15mm {0.59 in}

30mm {1.18 in}

(D)1

(D)10

CUT-AND-JOIN LOCATION

FOR REINFORCEMENT

(C) ROUGH CUT LOCATION

FOR REINFORCEMENT

(D)1

CENTER PILLAR REINFORCEMENT

(D)1

(D)2

(E) ROUGH CUT LOCATION

FOR SIDE SILL

REINFORCEMENT

CUT-AND-JOIN LOCATION

FOR SIDE SILL

REINFORCEMENT

80mm

{3.15 in}

40mm

{1.57 in}

End Of Sie

(F)4

SIDE SILL

REINFORCEMENT

(E) ROUGH CUT LOCATION

FOR SIDE SILL

REINFORCEMENT

CUT-AND-JOIN LOCATION

FOR SIDE SILL

REINFORCEMENT

40mm

{1.57 in}

25mm

{0.98 in}

(G)8

CENTER PILLAR (INNER)

(G)11

B3E0980B081

09–80B–36

Page 58

BODY STRUCTURE [PANEL REPLACEMENT]

CENTER PILLAR INSTALLATION

1. When joining and cutting the new and existing parts, trial fit the new part in position, and then measure and

adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

Note

• In areas where the outer, reinforcement, inner, and other parts are in 3-4 layers, drill holes for plug welds

in all but the innermost panel.

3. Install in the following order: inner, reinforcement, and outer.

4. Weld the 30 locations indicated by (A) and install the center pillar reinforcement (inner) to the center pillar

reinforcement.

5. After temporarily installing new parts, make sure the related parts fit properly.

C3U098070350B02

09–80B

09–80B–37

Page 59

BODY STRUCTURE [PANEL REPLACEMENT]

8

CENTER PILLAR (INNER)

CUT-AND-JOIN LOCATION

FOR SIDE SILL

REINFORCEMENT

4

CUT-AND-JOIN LOCATION

FOR SIDE SILL

REINFORCEMENT

80mm

{3.15 in}

7

CENTER PILLAR

REINFORCEMENT

SIDE SILL

REINFORCEMENT

15mm

{0.59 in}

1

(A)3

(A)11

25mm

{0.98 in}

CUT-AND-JOIN LOCATION

FOR REINFORCEMENT

1

(A)13

CENTER PILLAR

REINFORCEMENT (INNER)

09–80B–38

1

2

10

(A)3

1

2

B3E0980B082

Page 60

BODY STRUCTURE [PANEL REPLACEMENT]

80mm {3.15 in}

CUT-AND-JOIN LOCATION

FOR OUTER

2

09–80B

CUT-AND-JOIN LOCATION

FOR OUTER

End Of Sie

CENTER PILLAR (OUTER)

30mm {1.18 in}

20

17

2

95mm {3.74 in}

18

CUT-AND-JOIN LOCATION

FOR OUTER

B3E0980B083

09–80B–39

Page 61

BODY STRUCTURE [PANEL REPLACEMENT]

REAR FENDER PANEL REMOVAL

C3U098074100B01

4SD

Caution

•••• Avoid cutting with a blowtorch or similar tools as the insulator (shaded area) is flammable.

1. The rear fender panel and the rear pillar (inner) are joined with glue at the wheel arch line. Use a chisel or

similar tool to separate the rear fender panel from the rear pillar (inner), then remove the rear fender panel.

CUT-AND-JOIN

A-A

B-B

LOCATION

50mm

{1.97 in}

A

A

ROUGH CUT

LOCATION

90mm

{3.53 in}

7

5

REAR FENDER PANEL

170mm

{6.69 in}

CUT-AND-JOIN

LOCATION

50mm

{1.97 in}

B

8

B

ROUGH CUT

LOCATION

16

7

INSULATOR

2

7

7

09–80B–40

B3E0980B084

Page 62

BODY STRUCTURE [PANEL REPLACEMENT]

5HB

Caution

•••• Avoid cutting with a blowtorch or similar tools as the insulator (shaded area) is flammable.

1. The rear fender panel and the rear pillar (inner) are joined with glue at the wheel arch line. Use a chisel or

similar tool to separate the rear fender panel from the rear pillar (inner), then remove the rear fender panel.

6

A-A B-B C-C

09–80B

CUT-AND-JOIN

LOCATION

170mm

{6.69 in}

ROUGH CUT

LOCATION

50mm

{1.97 in}

C

100mm

{3.94 in}

40mm

{1.57 in}

17

B

B

A

A

20mm

{0.79 in}

40mm

{1.57 in}

7

INSULATOR

7

CUT-AND-JOIN LOCATION

ROUGH CUT LOCATION

REAR FENDER PANEL

7

CUT-AND-JOIN

LOCATION

End Of Sie

C

ROUGH CUT

LOCATION

9

3

7

B3E0980B085

09–80B–41

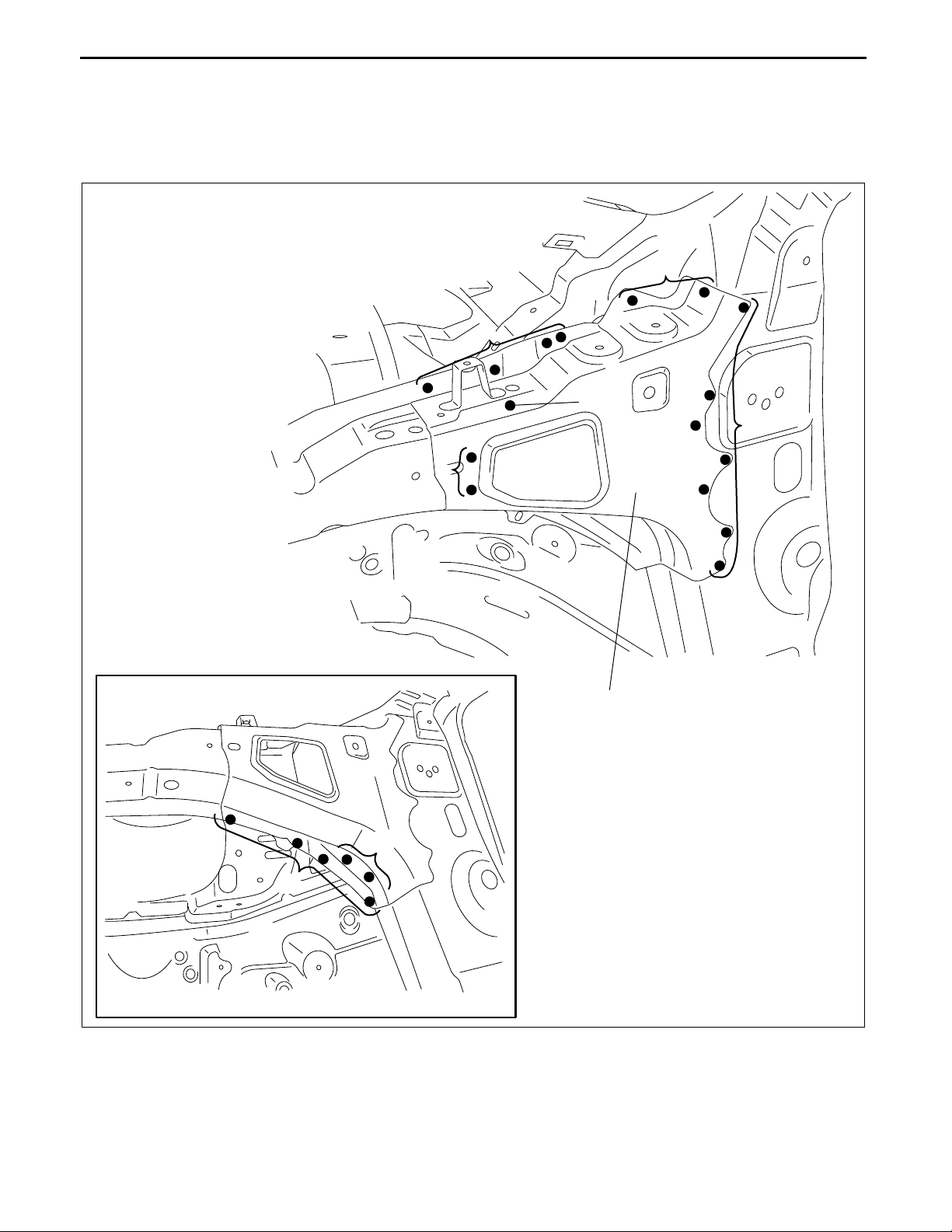

Page 63

BODY STRUCTURE [PANEL REPLACEMENT]

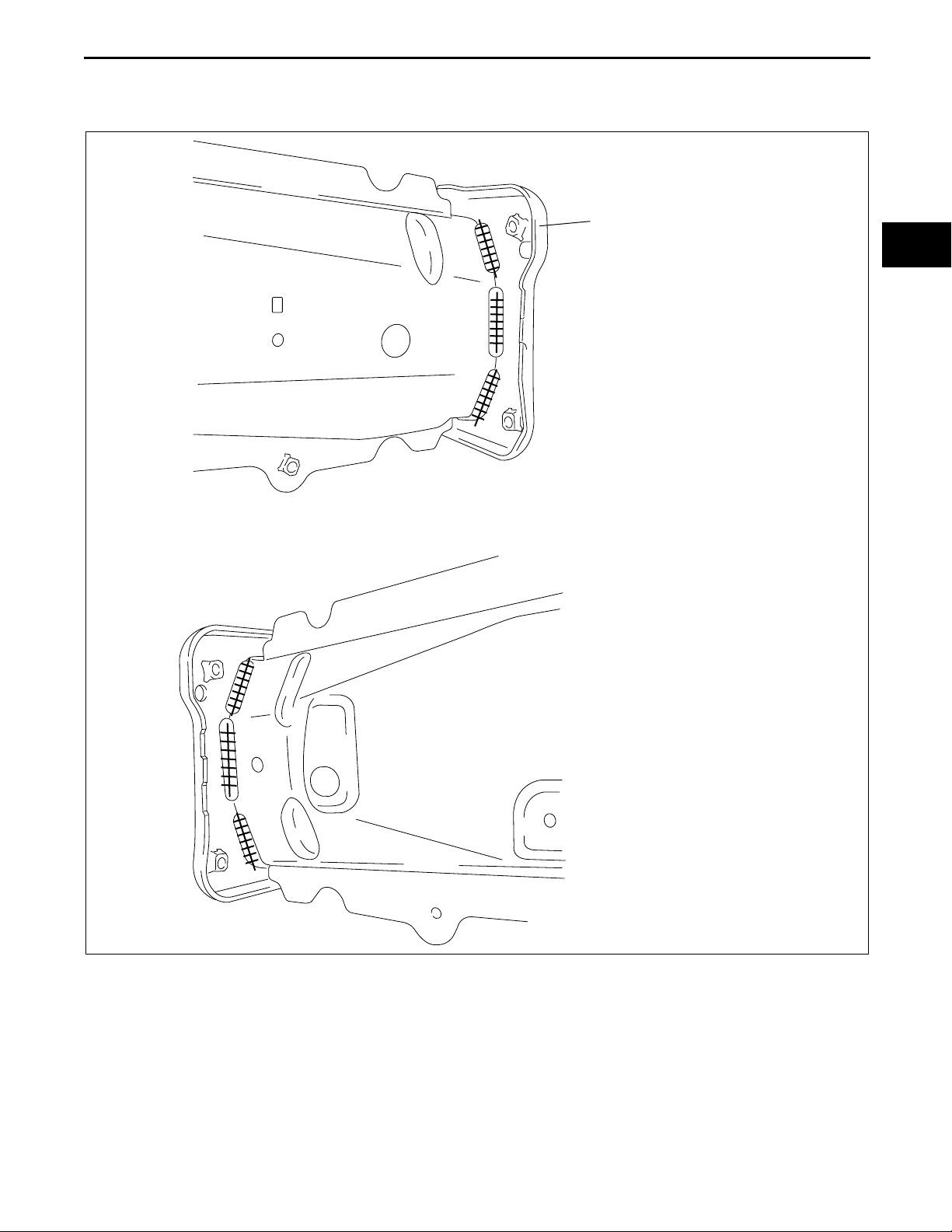

REAR FENDER PANEL INSTALLATION

C3U098074100B02

4SD

1. When joining and cutting the new and existing parts, trial fit the new part in position, and then measure and

adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. Before installing new parts, apply spot weld sealer to the wheel arch line.

4. After temporarily installing new parts, make sure the related parts fit properly.

CUT-AND-JOIN LOCATION

140mm

{5.51 in}

2

4

5

7

170mm

{6.69 in}

CUT-AND-JOIN

LOCATION

REAR FENDER

16

7

8

2

7

7

PANEL

09–80B–42

B3E0980B086

Page 64

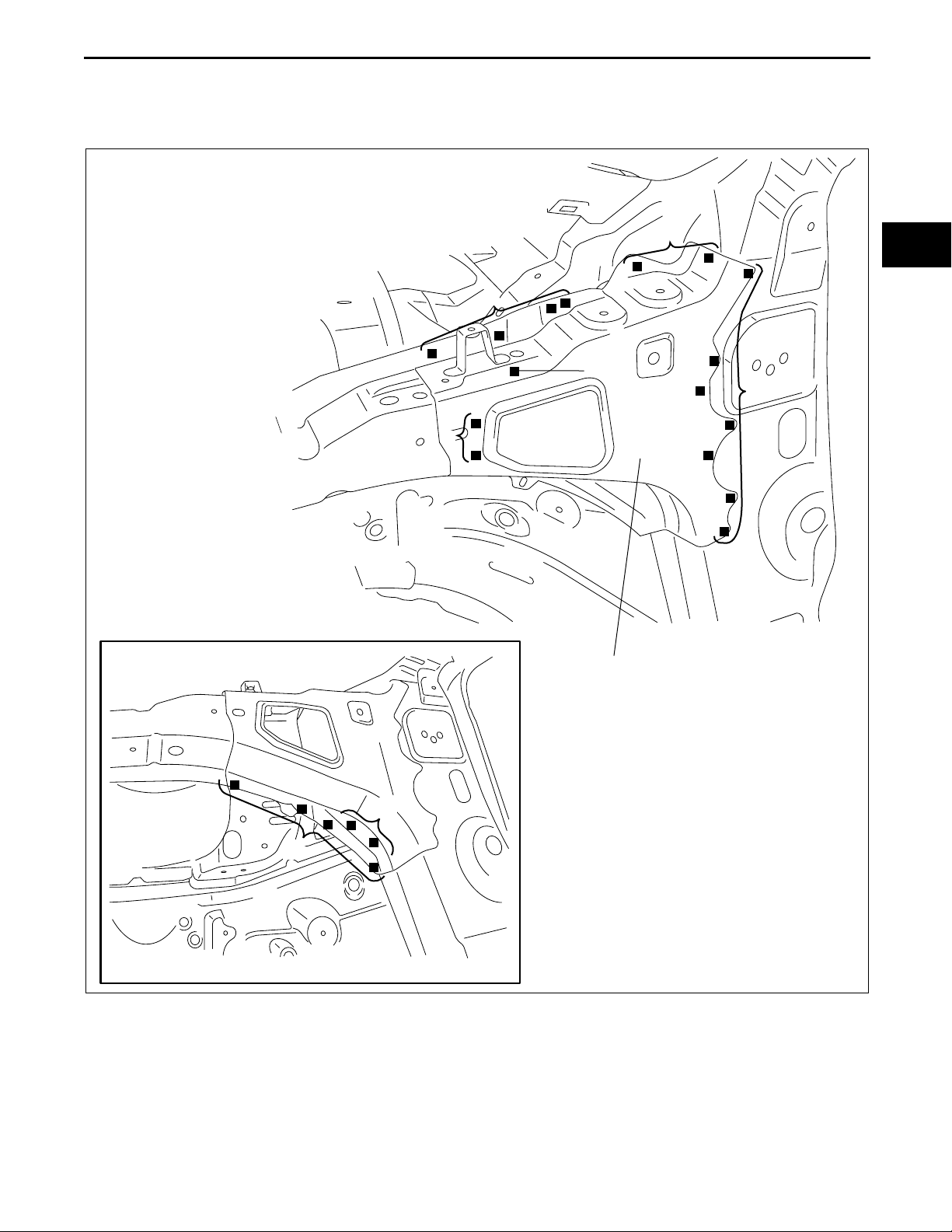

BODY STRUCTURE [PANEL REPLACEMENT]

5HB

1. When joining and cutting the new and existing parts, trial fit the new part in position, and then measure and

adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. Before installing new parts, apply spot weld sealer to the wheel arch line.

4. After temporarily installing new parts, make sure the related parts fit properly.

6

09–80B

CUT-AND-JOIN LOCATION

100mm

{3.94 in}

2

4

17

170mm

{6.69 in}

20mm

{0.79 in}

7

7

CUT-AND-JOIN LOCATION

REAR FENDER PANEL

7

End Of Sie

CUT-AND-JOIN

LOCATION

7

9

3

B3E0980B087

09–80B–43

Page 65

BODY STRUCTURE [PANEL REPLACEMENT]

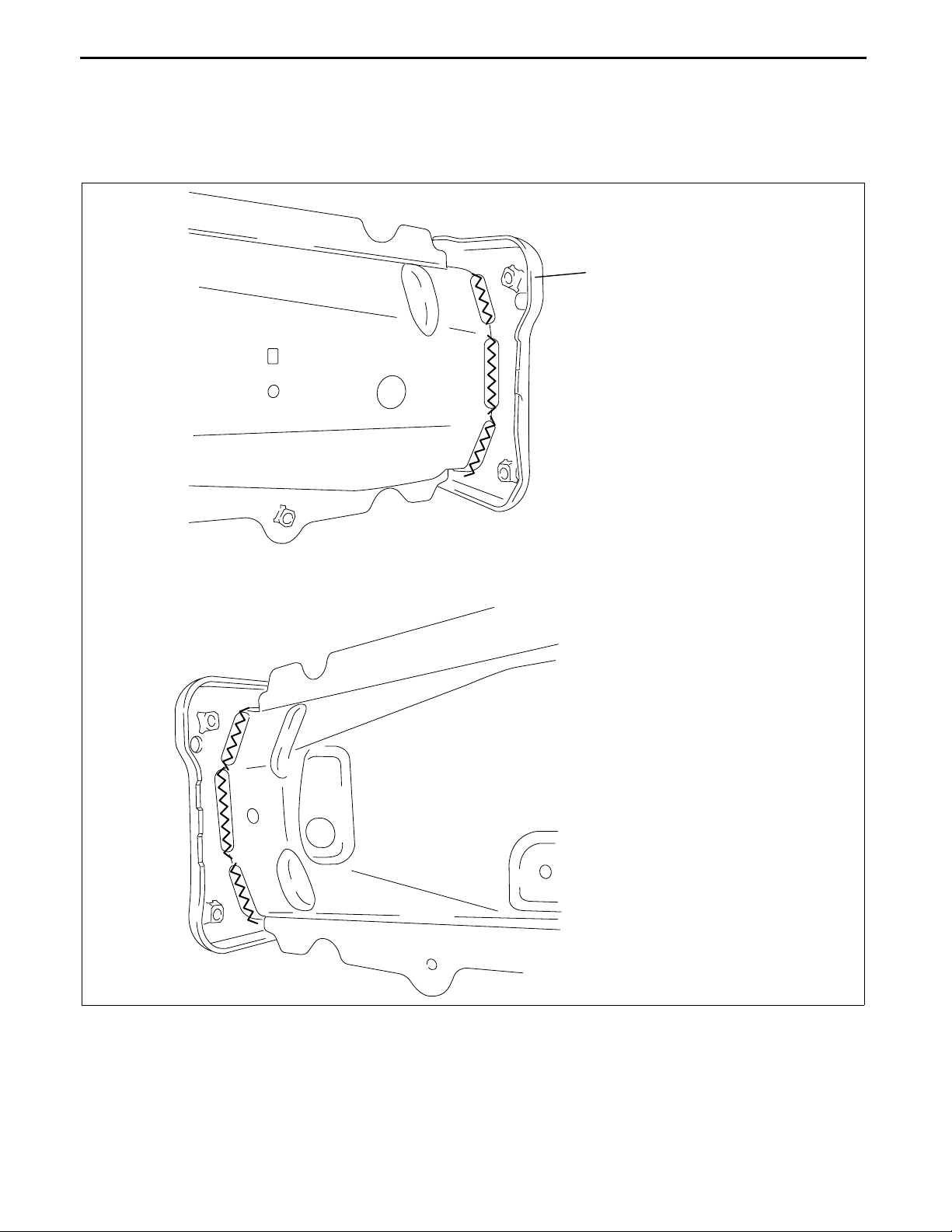

REAR FENDER LOWER PANEL REMOVAL

4SD

1. Remove the rear fender lower panel.

4

C3U098074100B03

REAR FENDER LOWER PANEL

6

5

B3E0980B088

09–80B–44

Page 66

BODY STRUCTURE [PANEL REPLACEMENT]

5HB

1. Drill the 16 locations indicated by (A).

2. Drill the 2 locations indicated by (B) and remove the rear fender lower panel.

(A)1

REAR FENDER LOWER PANEL

(A)4

(A)3

(A)8

09–80B

End Of Sie

REAR END PANEL

(B)2

B3E0980B089

09–80B–45

Page 67

BODY STRUCTURE [PANEL REPLACEMENT]

REAR FENDER LOWER PANEL INSTALLATION

C3U098074100B04

4SD

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

REAR FENDER LOWER PANEL

6

4

5

B3E0980B090

09–80B–46

Page 68

BODY STRUCTURE [PANEL REPLACEMENT]

5HB

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. Weld the 2 locations indicated by (A) and install the rear fender lower panel.

4. After temporarily installing new parts, make sure the related parts fit properly.

REAR END PANEL

(A)2

09–80B

End Of Sie

1

REAR FENDER LOWER PANEL

4

3

8

B3E0980B091

09–80B–47

Page 69

BODY STRUCTURE [PANEL REPLACEMENT]

SIDE SILL PANEL REMOVAL

C3U098070270B01

1. Rough cut area (A), drill the 99 locations indicated by (B), the 2 locations (4SD) or 3 locations (5HB) indicated

by (C), and then remove the side sill (outer).

Caution

•••• Avoid cutting with a blowtorch or similar tools as the insulator (shaded area) is flammable.

2. Rough cut area (D) and drill the 3 locations indicated by (E).

3. Drill the 4 locations indicated by (F) from the interior and remove the side sill reinforcement.

CUT-AND-JOIN

LOCATION FOR

OUTER

(A)ROUGH CUT

B

LOCATION FOR

OUTER

(B)18

INSULATOR

130mm

{5.12 in}

30mm

{1.18 in}

C

C

CUT-AND-JOIN

LOCATION FOR

OUTER

(A)ROUGH CUT

LOCATION FOR

OUTER

(B)4

(C)

4SD:2

5HB:3

260mm

{10.24 in}

30mm

{1.18 in}

CUT-AND-JOIN LOCATION

FOR OUTER

(A)ROUGH CUT

AA

(B)8

INSULATOR

LOCATION FOR

OUTER

(B)24

240mm

{9.45 in}

35mm

{1.38 in}

SIDE SILL (OUTER)

B

(B)2

(B)43

50mm

{1.97 in}

30mm

{1.18 in}

End Of Sie

(F)4

A-A B-B C-C

CUT-AND-JOIN LOCATION FOR

REINFORCEMENT

(D)ROUGH CUT

LOCATION FOR

REINFORCEMENT

55mm {2.17 in}

25mm {0.98 in}

(E)1

(E)1

SIDE SILL REINFORCEMENT

CUT-AND-JOIN LOCATION

FOR REINFORCEMENT

(D)ROUGH CUT

LOCATION FOR

REINFORCEMENT

(E)1

B3U0980B092

09–80B–48

Page 70

BODY STRUCTURE [PANEL REPLACEMENT]

SIDE SILL PANEL INSTALLATION

C3U098070270B02

1. When joining and cutting the new and existing parts, trial fit the new part in position, and then measure and

adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

Note

• In areas where the outer, reinforcement, inner, and other parts are in 3-4 layers, drill holes for plug welds

in all but the innermost panel.

3. Weld the 7 locations indicated by (A) and temporarily install the side sill reinforcement.

4. After temporarily installing new parts, make sure the related parts fit properly.

(A)4

09–80B

50mm

{1.97 in}

260mm

{10.24 in}

CUT-AND-JOIN LOCATION

FOR REINFORCEMENT

55mm

(A)1

CUT-AND-JOIN LOCATION

FOR OUTER

8

{2.17 in}

(A)1

SIDE SILL REINFORCEMENT

240mm

{9.45 in}

2

24

CUT-AND-JOIN LOCATION

FOR REINFORCEMENT

(A)1

CUT-AND-JOIN LOCATION

FOR OUTER

130mm

{5.12 in}

18

CUT-AND-JOIN

LOCATION FOR

OUTER

4

End Of Sie

43

SIDE SILL (OUTER)

4SD:2

5HB:3

B3E0980B093

09–80B–49

Page 71

BODY STRUCTURE [PANEL REPLACEMENT]

REAR END PANEL REMOVAL

4SD

1. Remove the rear end panel.

6

7

1

3

5

REAR END PANEL

15

C3U098070750B01

6

1

3

5

7

B3E0980B094

09–80B–50

Page 72

BODY STRUCTURE [PANEL REPLACEMENT]

5HB

1. Remove the rear end panel.

2

09–80B

REAR END PANEL

End Of Sie

4

2

6

5

5

5

5

15

5

5

5

4

2

6

5

B3E0980B095

09–80B–51

Page 73

BODY STRUCTURE [PANEL REPLACEMENT]

REAR END PANEL INSTALLATION

4SD

C3U098070750B02

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

6

7

1

3

5

REAR END PANEL

5

15

6

7

1

3

B3E0980B096

09–80B–52

Page 74

BODY STRUCTURE [PANEL REPLACEMENT]

5HB

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

2

REAR END PANEL

4

2

6

5

5

5

5

5

4

2

6

5

09–80B

End Of Sie

5

15

5

B3E0980B097

09–80B–53

Page 75

BODY STRUCTURE [PANEL REPLACEMENT]

REAR FENDER RAIN RAIL AND CORNER PLATE REMOVAL

4SD

1. Remove the rear fender rain rail and corner plate.

Note

• When removing the rear fender rain rail and the corner plate separately, drill the 3 locations indicated by

(A).

2

3

3

2

C3U098070440B01

REAR FENDER RAIN RAIL

1

CORNER PLATE

(A)3

B3E0980B098

09–80B–54

Page 76

BODY STRUCTURE [PANEL REPLACEMENT]

5HB

1. Remove the rear fender rain rail and corner plate.

Note

• When removing the rear fender rain rail and the corner plate separately, drill the 8 locations indicated by

(A).

CUT-AND-JOIN LOCATION

110mm {4.33 in}

40mm {1.57 in}

6

(A)4

REAR CUT LOCATION

REAR FENDER RAIN RAIL

CORNER PLATE

09–80B

End Of Sie

(A)4

1

B3E0980B099

09–80B–55

Page 77

BODY STRUCTURE [PANEL REPLACEMENT]

REAR FENDER RAIN RAIL AND CORNER PLATE INSTALLATION

C3U098070440B02

4SD

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

Note

• When replacing the rear fender rain rail and corner plate separately, weld the 3 locations indicated by (A).

2

3

3

2

REAR FENDER RAIN RAIL

1

CORNER PLATE

(A)3

B3E0980B100

09–80B–56

Page 78

BODY STRUCTURE [PANEL REPLACEMENT]

5HB

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

Note

• When replacing the rear fender rain rail and corner plate separately, weld the 8 locations indicated by (A).

CUT-AND-JOIN LOCATION

110mm {4.33 in}

REAR FENDER RAIN RAIL

6

CORNER PLATE

09–80B

End Of Sie

(A)4

(A)4

1

B3E0980B101

09–80B–57

Page 79

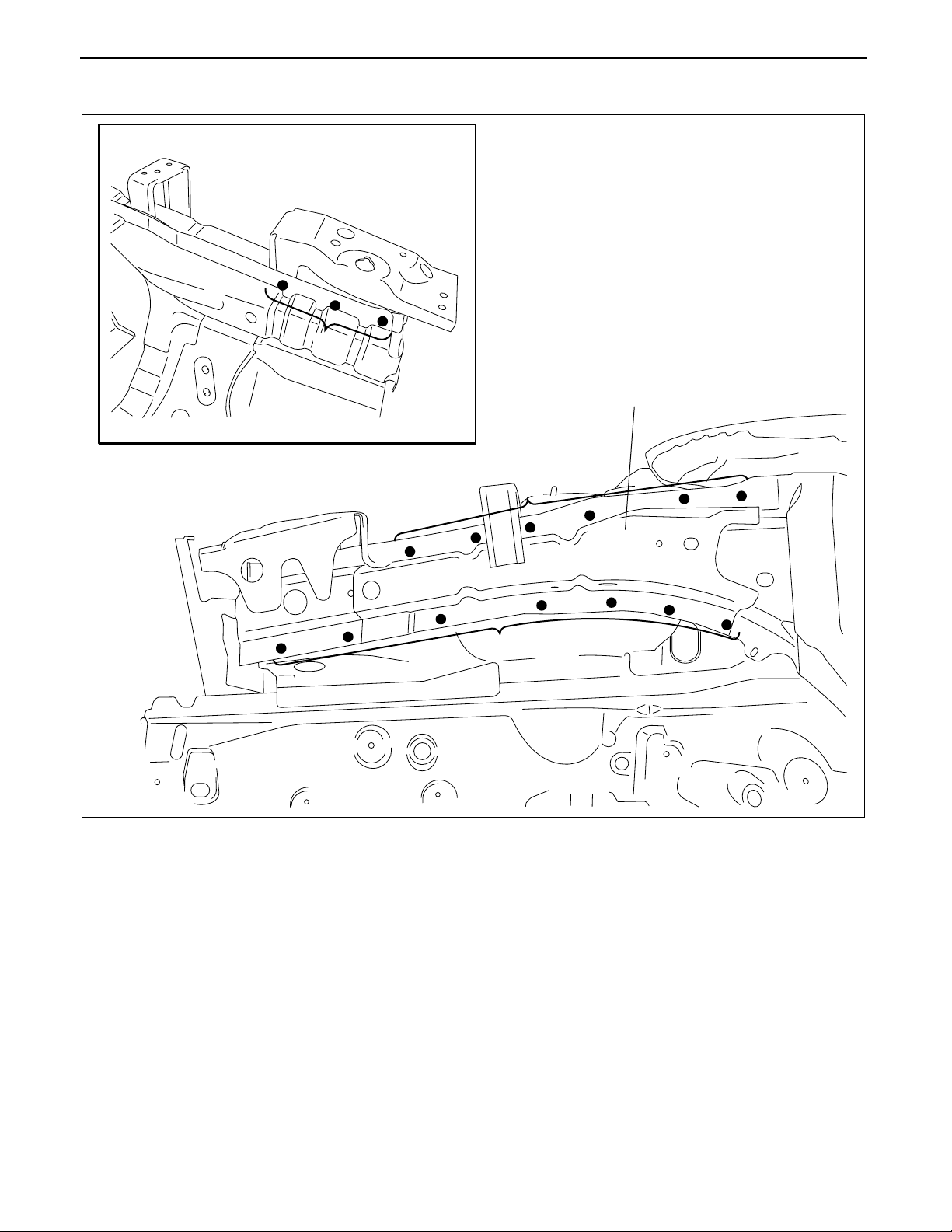

BODY STRUCTURE [PANEL REPLACEMENT]

REAR FLOOR PAN REMOVAL

1. Rough cut area (A).

Caution

•••• When rough cutting area (A), cut 20mm {0.79 in} away from the flange (towards rear) at the rear of

the lower anchor.

2. Remove the rear floor pan.

(A) ROUGH CUT LOCATION

FOR REAR FLOOR PAN

REAR FLOOR PAN

LOWER ANCHOR

20mm

{0.79 in}

CROSSMEMBER No.4

A-A

(A) ROUGH CUT LOCATION

FOR REAR FLOOR PAN

A

A

C3U098053750B01

4

6

8

5

3

13

8

REAR FLOOR PAN

4

6

8

13

5

3

B3E0980B102

09–80B–58

Page 80

BODY STRUCTURE [PANEL REPLACEMENT]

2

3

09–80B

End Of Sie

B3E0980B103

09–80B–59

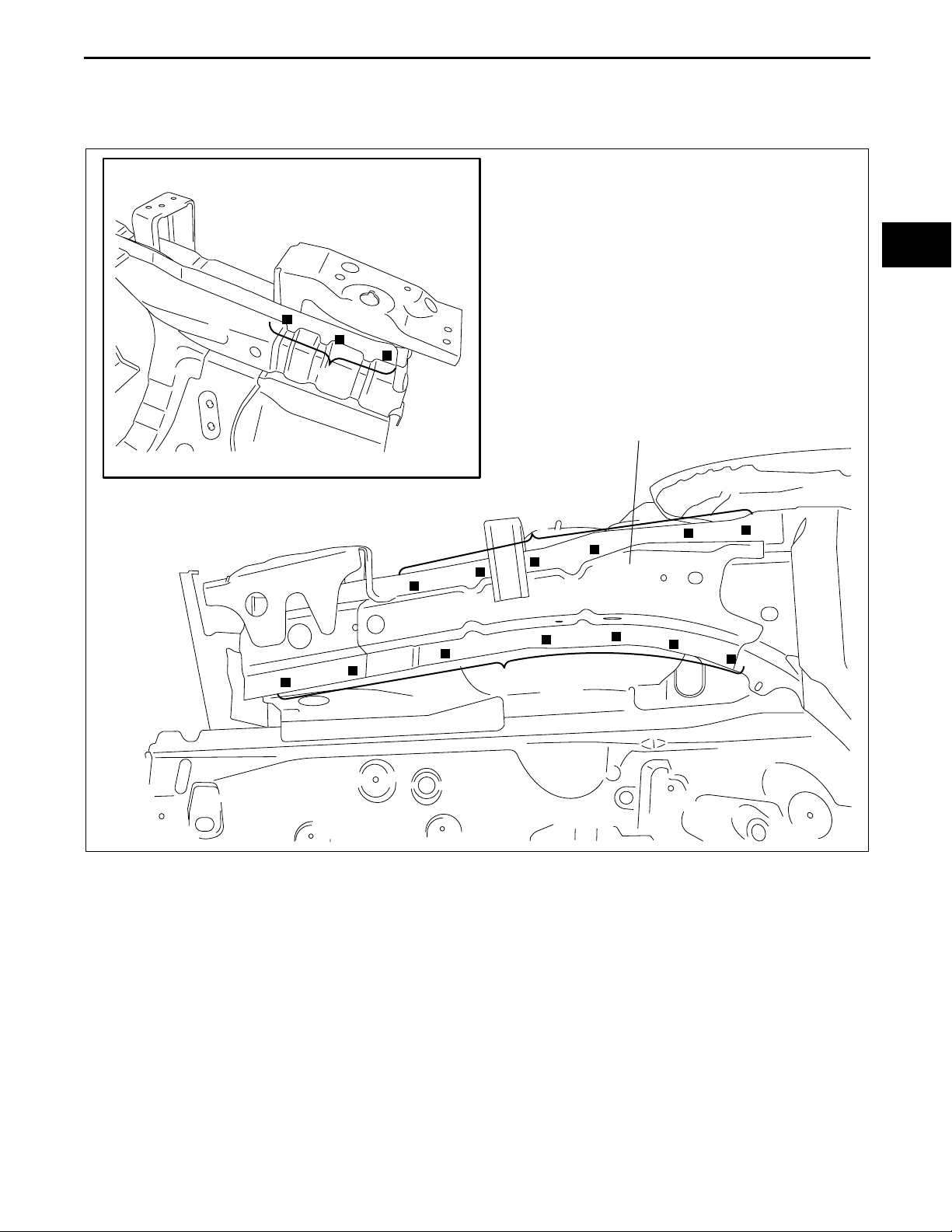

Page 81

BODY STRUCTURE [PANEL REPLACEMENT]

REAR FLOOR PAN INSTALLATION

C3U098053750B02

1. To prepare for installation, cut area (A) on the new rear floor pan, drill the 20 locations indicated by (B) and then

remove the lower anchor.

Caution

•••• When rough cutting area (A), cut 30 mm {1.18 in} away from the flange (towards front) at the rear of

the lower anchor.

(A) ROUGH CUT LOCATION

FOR REAR FLOOR PAN

LOWER ANCHOR

30mm

{1.18 in}

A-A

REAR FLOOR PAN

NEW REAR FLOOR PAN

(A) ROUGH CUT LOCATION

FOR REAR FLOOR PAN

CROSSMEMBER No.4

A

(B)5 (B)5 (B)5

A

(B)5

B3E0980B104

2. Drill the 11 locations indicated by (A).

3. Separate the lower anchor where joined using a chisel or similar tool and bend upwards to facilitate installation.

(C)3

EXISTING REAR FLOOR PAN

(C)3 (C)2(C)3

LOWER ANCHOR

09–80B–60

B3E0980B105

Page 82

BODY STRUCTURE [PANEL REPLACEMENT]

4. Apply spot sealer to the areas where both the overlapping ends of the new and existing parts will be welded.

Adhere the sections to be welded, and plug weld in 18 locations indicated by (D). Fillet weld along the seams of

the lower anchor, and new and existing parts at the locations indicated by (E).

Note

• Create a flange with flanging seal where new and existing parts are joined.

5. Weld the remaining weld locations and install the rear floor pan.

(E) FILLET WELDIMG

LOWER ANCHOR

EXISTING PARTS

NEW PARTS

CROSSMEMBER No.4

B-B

8

5

09–80B

B

(D)3

(D)2

4

6

13

(D)3 (D)3 (D)2

8

(D)3

B

4

6

8

13

5

(D)2

End Of Sie

3

REAR FLOOR PAN

2

3

3

B3E0980B106

09–80B–61

Page 83

BODY STRUCTURE [PANEL REPLACEMENT]

REAR SIDE FRAME (PARTIAL CUTTING) REMOVAL

1. Rough cut and remove the damaged part of the rear side frame.

50mm

{1.97 in}

C3U098053810B01

200mm {7.87 in}

CUT-AND-JOIN LOCATION

End Of Sie

ROUGH CUT LOCATION

B3E0980B107

09–80B–62

Page 84

BODY STRUCTURE [PANEL REPLACEMENT]

REAR SIDE FRAME (PARTIAL CUTTING) INSTALLATION

C3U098053810B02

1. Cut the new and existing parts at the cut-and-join location, and bevel the parts.

2. To cut-and-join the new part, cut at the locations indicated in the figure below and bevel the cut-and-join

locations of the new parts.

3. When installing the new parts, trial-fit new and existing parts, and then measure and adjust the body to conform

with standard dimensions.

4. After temporarily installing new parts, make sure the related parts fit properly.

Caution

•••• The cut-and-join area indicates the maximum size range of the installation position.

200mm {7.87 in}

09–80B

End Of Sie

CUT-AND-JOIN LOCATION

B3E0980B108

09–80B–63

Page 85

BODY STRUCTURE [PANEL REPLACEMENT]

ROOF PANEL REMOVAL

4SD

1. Remove the roof panel.

17

C3U098070600B01

WITH SUNROOF:19

WITHOUT SUNROOF:20

13

WITH SUNROOF:19

WITHOUT SUNROOF:20

B3E0980B109

09–80B–64

Page 86

5HB

1. Remove the roof panel.

BODY STRUCTURE [PANEL REPLACEMENT]

1

17

4

09–80B

3

28

15

End Of Sie

28

B3E0980B110

09–80B–65

Page 87

BODY STRUCTURE [PANEL REPLACEMENT]

ROOF PANEL INSTALLATION

C3U098070600B02

4SD

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

WITH SUNROOF:19

WITHOUT SUNROOF:20

17

13

WITH SUNROOF:19

WITHOUT SUNROOF:20

B3E0980B111

09–80B–66

Page 88

BODY STRUCTURE [PANEL REPLACEMENT]

5HB

1. When installing new parts, measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

3. After temporarily installing new parts, make sure the related parts fit properly.

17

28

1

4

3

15

09–80B

End Of Sie

28

B3E0980B112

09–80B–67

Page 89

BODY STRUCTURE [WATER-PROOF AND RUST PREVENTIVE]

09–80C BODY STRUCTURE [WATER-PROOF AND RUST

PREVENTIVE]

BODY SEALING . . . . . . . . . . . . . . . . . . . 09–80C–2

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80C–2

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80C–5

UNDER COATING. . . . . . . . . . . . . . . . . . 09–80C–8

CHIPPING-RESISTANT COATING. . . . . 09–80C–9

End of Toc

With Side Step Molding . . . . . . . . . . . . . 09–80C–9

Without Side Step Molding . . . . . . . . . . 09–80C–9

RUST PREVENTIVE TREATMENT . . . . .09–80C–10

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80C–10

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80C–11

09–80C

09–80C–1

Page 90

BODY STRUCTURE [WATER-PROOF AND RUST PREVENTIVE]

BODY SEALING

Sealant is applied to the parts where the panels meet and to the hemmed parts of the door panel and hood panel

to provide water proofing and rust proofing.

4SD

C3U098007000B02

09–80C–2

B3U0980B032

Page 91

BODY STRUCTURE [WATER-PROOF AND RUST PREVENTIVE]

09–80C

B3U0980B033

09–80C–3

Page 92

BODY STRUCTURE [WATER-PROOF AND RUST PREVENTIVE]

HOOD

DOOR

TRUNK LID

09–80C–4

B3U0980B034

Page 93

5HB

BODY STRUCTURE [WATER-PROOF AND RUST PREVENTIVE]

09–80C

B3U0980B035

09–80C–5

Page 94

BODY STRUCTURE [WATER-PROOF AND RUST PREVENTIVE]

09–80C–6

B3U0980B033

Page 95

HOOD

DOOR

BODY STRUCTURE [WATER-PROOF AND RUST PREVENTIVE]

09–80C

End Of Sie

LIFTGATE

B3U0980B037

09–80C–7

Page 96

BODY STRUCTURE [WATER-PROOF AND RUST PREVENTIVE]

UNDER COATING

The shaded areas indicated under body locations that are undercoated to prevent noise and rusting.

C3U098007000B03

End Of Sie

B3U0980B038

09–80C–8

Page 97

BODY STRUCTURE [WATER-PROOF AND RUST PREVENTIVE]

CHIPPING-RESISTANT COATING

The coating locations are indicated by the shaded areas.

With Side Step Molding

C3U098007000B04

09–80C

A

A

OVER SPRAY ALLOWED

Without Side Step Molding

OVER SPRAY ALLOWED

URETHANE PAINT

A-A

B3E0980B039

A

A

End Of Sie

URETHANE PAINT

A-A

B3U0980B046

09–80C–9

Page 98

BODY STRUCTURE [WATER-PROOF AND RUST PREVENTIVE]

RUST PREVENTIVE TREATMENT

4SD

HOOD

DOOR

C3U098007000B05

TRUNK LID

B3U0980B040

09–80C–10

Page 99

5HB

BODY STRUCTURE [WATER-PROOF AND RUST PREVENTIVE]

HOOD

09–80C

DOOR

End Of Sie

LIFTGATE

B3U0980B045

09–80C–11

Page 100

BODY STRUCTURE [DIMENSIONS]

09–80D BODY STRUCTURE [DIMENSIONS]

UNDERBODY FLAT-PLANE

DIMENSIONS . . . . . . . . . . . . . . . . . . . . 09–80D–2

UNDERBODY STRAIGHT-LINE

DIMENSIONS . . . . . . . . . . . . . . . . . . . . 09–80D–3

FRONT BODY STRAIGHT-LINE

DIMENSIONS (1) . . . . . . . . . . . . . . . . . . 09–80D–4

FRONT BODY STRAIGHT-LINE

DIMENSIONS (2) . . . . . . . . . . . . . . . . . . 09–80D–5

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80D–5

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80D–6

FRONT BODY STRAIGHT-LINE

DIMENSIONS (3) . . . . . . . . . . . . . . . . . . 09–80D–7

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80D–7

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80D–8

End of Toc

CABIN SIDE FRAME STRAIGHT-LINE

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . 09–80D–9

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80D–9

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80D–10

ROOM STRAIGHT-LINE

DIMENSIONS (1) . . . . . . . . . . . . . . . . . . 09–80D–11

ROOM STRAIGHT-LINE

DIMENSIONS (2) . . . . . . . . . . . . . . . . . . 09–80D–12

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80D–12

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80D–13

REAR BODY STRAIGHT-LINE

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . 09–80D–14

4SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80D–14

5HB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09–80D–15

09–80D

09–80D–1

Loading...

Loading...