RovaEarth

USER MANUAL

COMMERCIAL ICE MAKER

Models CIM-480F, CIM-720F, CIM-960F

TABLE OF CONTENTS

2

3

4

6

8

10

11

12

BEFORE STARTING

PART NUMBERS

INSTALLATION

HOW TO USE

TROUBLESHOOTING

MAINTENANCE

SPECIFICATIONS

WARRANT Y

1

BEFORE STARTING

PART NUMBERS

• To prevent any internal damage or malfunctions, keep

refrigeration unit upright during transportation and

installation. Keep the unit upright for 24 hours before

beginning use.

• Inspect the unit before installing. Do not use unit with

any visible damage or warranty may be waived. Report any shipping damage to the manufacturer immediately for replacement.

• It is recommended that the unit not be used with an

extension cord. If the user proceeds with an extension cord, be sure that the exension cord has a cable

thickness of at least 0.75mm and has a rated voltage of 6A/250V or above. This equipment must be

grounded.

• Do not use the unit outdoors. Keep away from direct

sunlight.

• Keep the unit on a level surface. Do not place the unit

on carpet or other fabric materials. Do not cover power cord or keep near exposed liquid.

• Do not use any liquid other than water in this unit.

• Do not use flammable liquids to clean the unit.

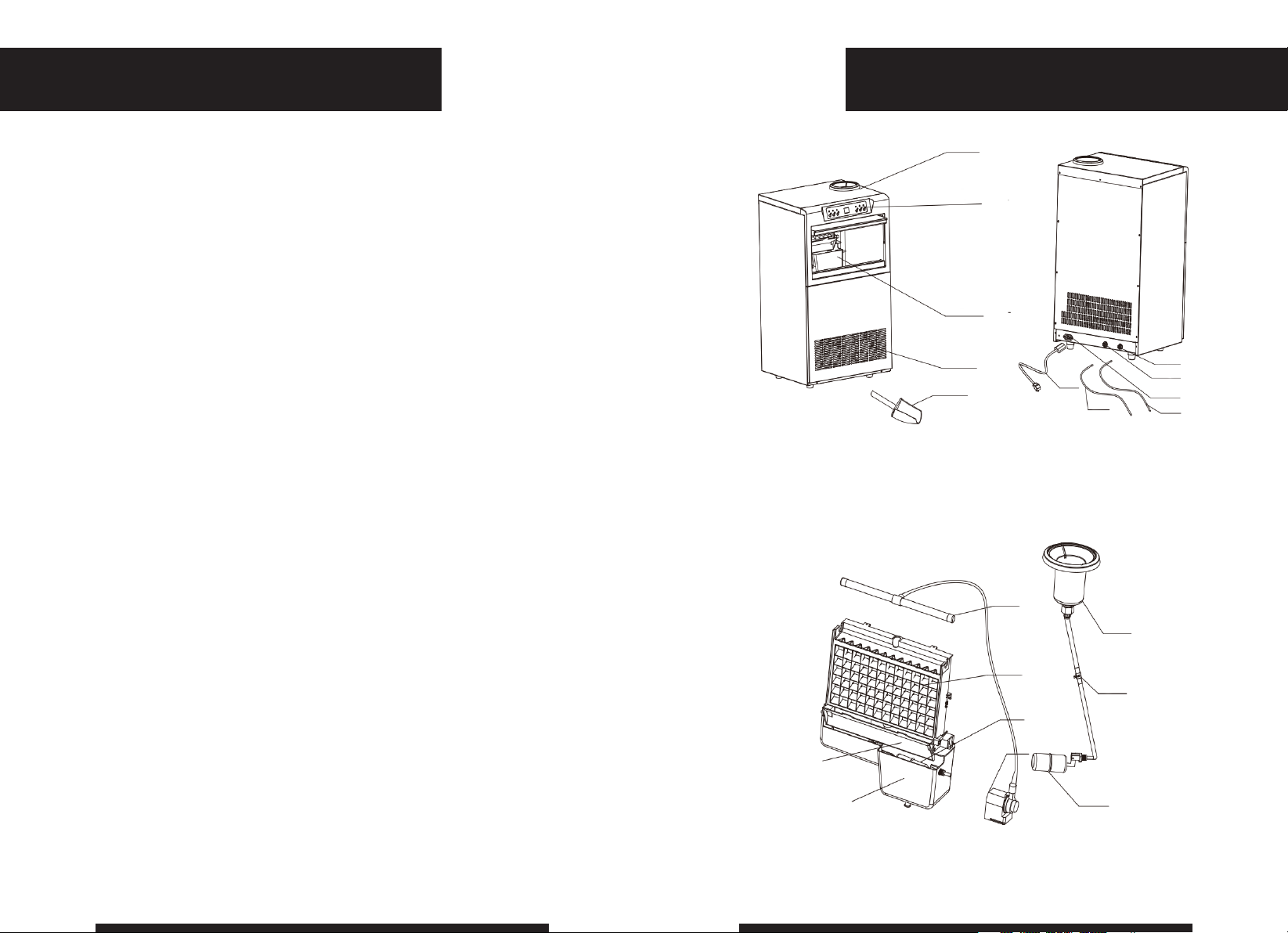

EXTERIOR

. TOP COVER

. CONTROL PANEL

. WATER BASIN

. COOLING FAN

INTERIOR

1

2

3

4

5

. ICE SCOOP

. DRAIN VALVE

. WATER INLET

. POWER SOCKET

1

6

7

11

10

. DRAIN PIPE

. WATER INLET PIPE

. POWER CORD

7

8

9

• Do not use any third-party equipment to modify the

unit other than those recommended by the manufacturer.

• Dispose of flammable gas of refrigerant and blowing

agent acording to local regulations.

8

9

. DISTRIBUTIVE PIPE

. ICECUBE TRAY

. LEVEL CONTROLLER

. WATER PUMP

. WATER PLUG

. WATER VALVE

2

6

3

4

5

. BOTTLE HOLDER

. RETAINING FLAP

. WATE R TA N K

2 3

INSTALLATION

BOT TLED WATER

INSTALLATION

WATER LINE

INSTALLATION

WATER LINE

INLET PIPE

VA LV E

WATER FILTER

FILTER HOLDER

UNIT WATER

INLET PIPE

DRAIN PIPE

DRAIN PIPE

1. Tilt the unit slightly to install the four feet.

2. Place the bottled water into the holder.

3. Open the valve inside of the unit.

4. Place the drain pipe accordingly.

5. Wait 24 hours before plugging in the unit.

1. Tilt the unit slightly to install the four feet.

2. Mount the water filter holder.

3. Connect the water line inlet pipe to the water source.

4. Connect the unit water inlet pipe to the water inlet.

5. Place the drain pipe accordingly.

6. Wait 24 hours before plugging in the unit.

4 5

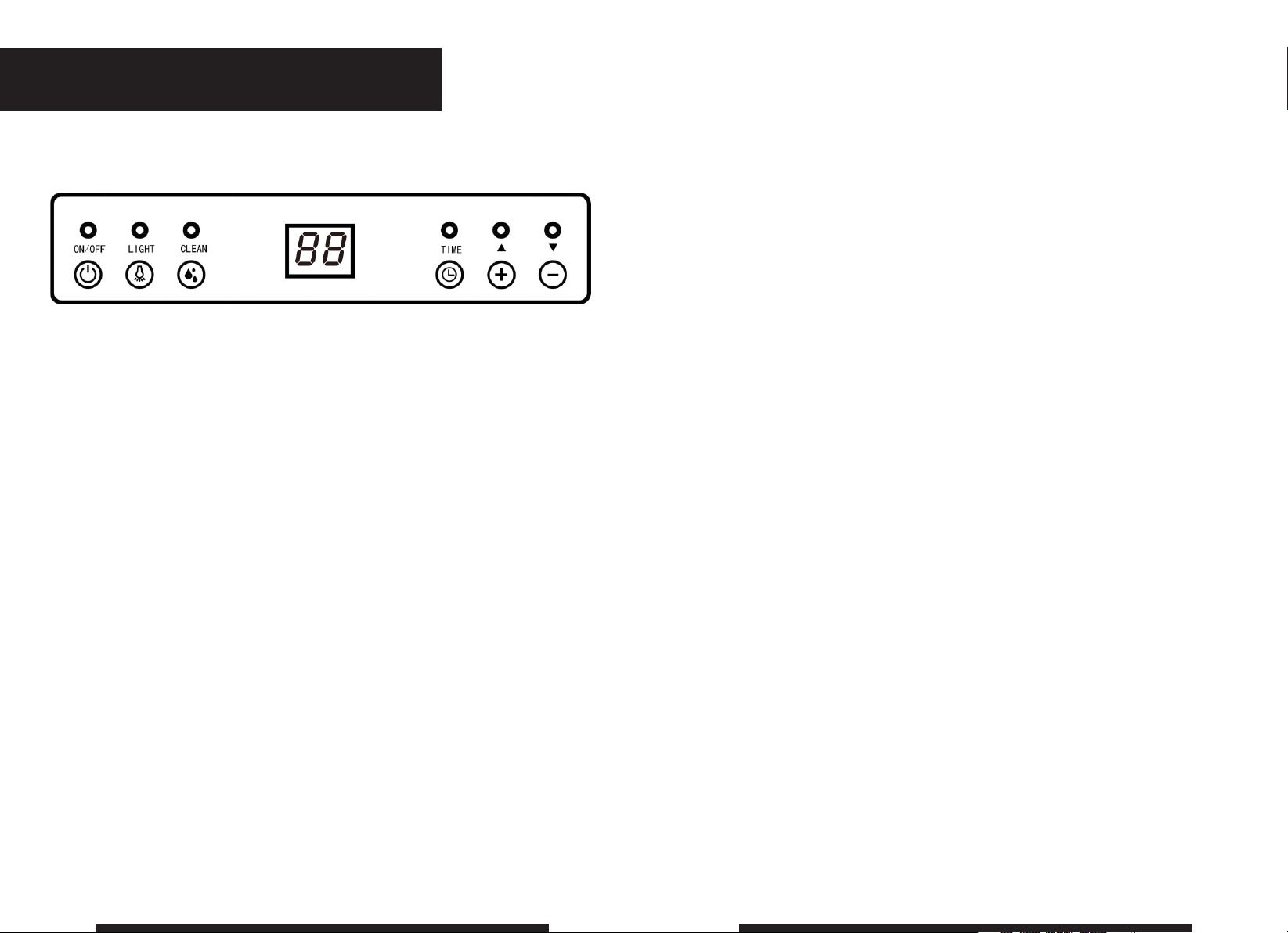

HOW TO USE

• Once a start/stop timer has been set, the indicator

light will turn green.

TURNING THE LIGHT ON/OFF

• Press the light button to turn on the interior lighting.

The green indicator light will appear and the interior

lights will be present. Press the button again to turn

the lights off.

POWERING ON

• Connect the water source and plug the unit in to

the power source. The indicator light will turn green.

Press the power button to turn on.

• If a red light appears and the LED screen displays

00, the water source is not properly connected. Make

sure that the valve has been opened inside of the unit.

SELECTING ICE SIZE

• Once the water tank has been filled, the red indicator

light will turn off. The LED screen will display numbers counting from 00 to 59, indicating the warm-up

time in seconds.

• After the first minute of warm-up, select the preferred

ice size, the smallest being -9 and largest +9.

SETTING THE START/STOP TIMER

To set a start time while the unit is off, press the timer

button. Use the +/- buttons to select the number of

hours that the unit will begin function, up to 24 hours.

To set a stop time while the unit is running, press

the timer button. Use the +/- buttons to select the

number of hours that the unit will remain on, up to 24

hours.

DEICING MODE

• If the unit senses a blockage in the ice pallet, the red

indicator light will flash red. The LED screen will then

display 00, and the water pump and fan will stop running.

• After de-icing is completed, the unit will automatically resume icemaking.

• To force de-icing while unit is in use, hold the clean

button until the indicator flashes red. The LED screen

will then display 00, and the water pump and fan will

stop running.

• After de-icing is completed, the unit will automatically resume icemaking.

CLEANING MODE

• To turn on cleaning mode while the unit is in standby,

press the clean button. The indicator light will turn

green.

• Once the unit door has been open for 10 minutes, it

will automatically shut off cleaning mode and resume

standby mode.

6 7

TROUBLESHOOTING

ERROR CAUSE SOLUTION

E1, E2

E3, E4

Temperature probe experiencing an open circuit

Ice is too thick or thin,

causing a de-icing failure

Water retaining flap failure

or magnetic sensor failure

Refrigerant leak After the unit has been on for 10

Compressor not running Check to see if the fan is blowing

Check the connection of the insert.

Use +/- to change the ice size

accordingly.

Hold the clean button force de-icing,

then press down on the retaining flap

to simulate the de-icing process. If the

the unit does not resume icemaking,

the part may need replacement.

minutes, check the water basin to see

whether it is cold. If the water is not

cold, add coolant to the unit.

warm air and the compressor is running (recognizable by a low buzz). If

the compressor is not running or the

fan is blowing cold air, the part may

need replacement.

ERROR CAUSE SOLUTION

Unit has stopped

working and the +

indicator is red

Water is overflowing

from the water basin

The basin is full of

water but the +

indicator is red

Unit is cycling, but

no ice is produced

No water or not enough

water

The water valve is not tightened or the water source is

not connected correctly

The float control is stuck De-ice the unit and make

The refrigerant is leaking or

there’s a malfunction with

the cooling system

Check the water supply or

refill the water supply.

If the water source is a

water line, close the interior

valve. Check the external

source conections.

sure that the float can move

as needed.

Add coolant to the unit. If

the unit is still malfunctioning, replace the refrigeration

pipeline.

Fan not turning Check to see if there is air blowing

Water pump not working Press the clean button to prompt a

from the back of the unit. If there is no

air, check the circuit connection. If the

fan still does not work, the part may

need replacement.

start/stop of the water pump. Also

check the circuit connection of the

pump. If the pump is not working, the

part may need a replacement.

8 9

MAINTENANCE

SPECIFICATIONS

• Clean the unit thoroughly before use and every 360

hours to maintain proper function and cleanliness.

• Unplug the unit before cleaning.

• To clean the unit before use:

1. Remove the ice scoop. Soak a soft cloth with en-

vironmental protection deterent diluted with warm

water. Wipe the machine and accessories with the

detergent-soaked cloth.

2. Rinse the ice scoop with room temperature drink-

ing water. Connect the drain on the back of the

unit to drain any residual fluid.

3. Wipe the outside of the unit a soft cloth and envi-

ronmental protection detergent diluted with room

temperature water.

4. Dry the inside and outside of the unit with a dry

soft cloth.

• If the unit has not been used for more 96 hours, close

the water supply and drain residual fluid from the water basin to maintain cleanliness. Wipe with a soft

cloth before restarting use.

MODEL CIM-480F CIM-720F CIM-960F

RATED VOLTAGE

RATED FREQUENCY

RATED CURRENT

REFRIGERANT

HIGH SIDE PRESSURE

LOW SIDE PRESSURE

INSULATION

BLOWING GAS

115V 115V 115V

60Hz 60Hz 60Hz

2.1 49 A 3.012A 4.380A

R290 /

1.69oz

275psig 275psig 275psig

130psig 130psig 130psig

C5H

10

R290 /

2.29oz

C5H

10

R290 /

3.1oz

C5H

10

10 11

WARRANT Y

• When receiving the unit, check for damage from

transportation.

• Any damage seen should be immediately reported to

the manufacturer via Amazon. Please be sure to provide photos of the damage to the item and any damage to the exterior packaging. A new machine will

only be reissued if photos of the damage are provided. For all damaged units a prepaid return label will

be provided in order to ship the item back to the manufacturer’s facility.

• To request a return, contact the manufacturer via

Amazon and provide a reason for the request.

• This product has a limited warranty in which manufacturer defects and shipping damage is covered.

• The warranty does not cover the following:

• Normal wear-and-tear

• Damage caused by non-compliance with manual

• Inappropriate point source connections

• Partial or complete removal of components

• Modification of the unit using unauthorized

third-party equipment or tools

Please contact our 24/7 customer service line at

909-479-7844 for further assistance.

12

Loading...

Loading...