Page 1

PROGRAMMING MANUAL

Return to Main Menu

for

MAZATROL MATRIX

(3-D UNIT)

MANUAL No. : H740PB0080E

Serial No. :

Before using this machine and equipment, fully understand the contents of this

manual to ensure proper operation. Should any questions arise, please ask the

nearest Technical Center or Technology Center.

IMPORTANT NOTICE

1. Be sure to observe the safety precautions described in this manual and the contents of the

safety plates on the machine and equipment. Failure may cause serious personal injury or

material damage. Please replace any missing safety plates as soon as possible.

2. No modifications are to be performed that will affect operation safety. If such modifications are

required, please contact the nearest Technical Center or Technology Center.

3. For the purpose of explaining the operation of the machine and equipment, some illustrations

may not include safety features such as covers, doors, etc. Before operation, make sure all

such items are in place.

4. This manual was considered complete and accurate at the time of publication, however, due to

our desire to constantly improve the quality and specification of all our products, it is subject to

change or modification. If you have any questions, please contact the nearest Technical Center

or Technology Center.

5. Always keep this manual near the machinery for immediate use.

6. If a new manual is required, please order from the nearest Technical Center or Technology

Center with the manual No. or the machine name, serial No. and manual name.

Issued by Manual Publication Section, Yamazaki Mazak Corporation, Japan

06. 2006

Page 2

Page 3

SAFETY PRECAUTIONS

Preface

Safety precautions relating to the CNC unit (in the remainder of this manual, referred to simply as

the NC unit) that is provided in this machine are explained below. Not only the persons who

create programs, but also those who operate the machine must thoroughly understand the

contents of this manual to ensure safe operation of the machine.

Read all these safety precautions, even if your NC model does not have the corresponding

functions or optional units and a part of the precautions do not apply.

Rule

1. This section contains the precautions to be observed as to the working methods and states

usually expected. Of course, however, unexpected operations and/or unexpected working

states may take place at the user site.

During daily operation of the machine, therefore, the user must pay extra careful attention to

its own working safety as well as to observe the precautions described bel ow.

2. Although this manual contains as great an amount of information as it can, since it is not

rare for the user to perform the operations that overstep the manufacturer-assumed ones,

not all of “what the user cannot perform” or “what the user must not perform” can be fully

covered in this manual with all such operations taken into consideration beforehand.

It is to be understood, therefore, that functions not clearly written as “executable” are

“inexecutable” functions.

SAFETY PRECAUTIONS

3. The meanings of our safety precautions to DANGER, WARNING, and CAUTION are as

follows:

: Failure to follow these instructions could result in loss of life.

DANGER

: Failure to observe these instructions could result in serious harm to a human

life or body.

WARNING

: Failure to observe these instructions could result in minor injuries or serious

machine damage.

CAUTION

HGENPA0042E

S-1

Page 4

Basics

SAFETY PRECAUTIONS

! After turning power on, keep hands away from the keys, buttons, or switches of the

operating panel until an initial display has been made.

WARNING

! Before proceeding to the next operations, fully check that correct data has been entered

and/or set. If the operator performs operations without being aware of data errors,

unexpected operation of the machine will result.

! Before machining workpieces, perform operational tests and make sure that the machine

operates correctly. No workpieces must be machined without confirmation of normal

operation. Closely check the accuracy of programs by executing override, single-block, and

other functions or by operating the machine at no load. Also, fully utilize tool path check,

Virtual Machining, and other functions, if provided.

! Make sure that the appropriate feed rate and rotational speed are designated for the

particular machining requirements. Always understand that since the maximum usable fee d

rate and rotational speed are determined by the specifications of the tool to be used, those

of the workpiece to be machined, and various other factors, actual capabilities differ from

the machine specifications listed in this manual. If an inappropriate feed rate or rotational

speed is designated, the workpiece or the tool may abruptly move out from the machine.

! Before executing correction functions, fully check that the direction and amount of

correction are correct. Unexpected operation of the machine will result if a correction

function is executed without its thorough understanding.

! Parameters are set to the optimum standard machining conditions prior to shipping of the

machine from the factory. In principle, these settings should not be modified. If it becomes

absolutely necessary to modify the settings, perform modifications only after thoroughly

understanding the functions of the corresponding parameters. Modifications usually affect

any program. Unexpected operation of the machine will result if the settings are modified

without a thorough understanding.

Remarks on the cutting conditions recommended by the NC

! Before using the following cutting conditions:

- Cutting conditions that are the result of the MAZATROL Automatic Cutting Conditions

WARNING

Determination Function

- Cutting conditions suggested by the Machining Navigation Function

- Cutting conditions for tools that are suggested to be used by the Machining Navigation

Function

Confirm that every necessary precaution in regards to safe machine setup has been taken –

especially for workpiece fixturing/clamping and tool setup.

! Confirm that the machine door is securely closed before starting machining.

Failure to confirm safe machine setup may result in serious injury or death.

S-2

Page 5

Programming

WARNING

SAFETY PRECAUTIONS

! Fully check that the settings of the coordinate systems are correct. Even if the designated

program data is correct, errors in the system settings may cause the machine to operate in

unexpected places and the workpiece to abruptly move out from the machine in the event

of contact with the tool.

! During surface velocity hold control, as the current workpiece coordinates of the surface

velocity hold control axes approach zeroes, the spindle speed increases significantly. For

the lathe, the workpiece may even come off if the chucking force decreases. Safety speed

limits must therefore be observed when designating spindle speeds.

! Even after inch/metric system selection, the units of the programs, tool information, or

parameters that have been registered until that time are not converted. Fully check these

data units before operating the machine. If the machine is operated without checks being

performed, even existing correct programs may cause the machine to operate differently

from the way it did before.

! If a program is executed that includes the absolute data commands and relative data

commands taken in the reverse of their original meaning, totally unexpected operation of

the machine will result. Recheck the command scheme before executing programs.

! If an incorrect plane selection command is issued for a machine action such as arc

interpolation or fixed-cycle machining, the tool may collide with the workpiece or part of the

machine since the motions of the control axes assumed and those of actual ones will be

interchanged. (This precaution applies only to NC units provided with EIA functions.)

! The mirror image, if made valid, changes subsequent machine actions significantly. Use

the mirror image function only after thoroughly understanding the above. (This precaution

applies only to NC units provided with EIA functions.)

! If machine coordinate system commands or reference position returning commands are

issued with a correction function remaining made valid, correction may become invalid

temporarily. If this is not thoroughly understood, the machine may appear as if it would

operate against the expectations of the operator. Execute the above commands only after

making the corresponding correction function invalid. (This precaution applies only to NC

units provided with EIA functions.)

! The barrier function performs interference checks based on designated tool data. Enter the

tool information that matches the tools to be actually used. Otherwise, the barrier function

will not work correctly.

! The system of G-code and M-code commands differs, especially for turning, between the

machines of INTEGREX e-Series and the other turning machines.

Issuance of the wrong G-code or M-code command results in totally non-intended machine

operation. Thoroughly understand the system of G-code and M-code commands before

using this system.

Sample program Machines of INTEGREX e-Series Turning machines

S1000M3

S1000M203

The milling spindle rotates at 1000 min–1. The turning spindle rotates at 1000 min–1.

The turning spindle rotates at 1000 min–1. The milling spindle rotates at 1000 min–1.

S-3

Page 6

SAFETY PRECAUTIONS

! For the machines of INTEGREX e-Series, programmed coordinates can be rotated using

an index unit of the MAZATROL program and a G68 command (coordinate rotate command) of the EIA program. However, for example, when the B-axis is rotated through 180

degrees around the Y-axis to implement machining with the turning spindle No. 2, the plus

side of the X-axis in the programmed coordinate system faces downward and if the

program is created ignoring this fact, the resulting movement of the tool to unexpected

positions may incite collisions.

To create the program with the plus side of the X-axis oriented in an upward direction, use

the mirror function of the WPC shift unit or the mirror imaging function of G-code command

(G50.1, G51.1).

! After modifying the tool data specified in the program, be sure to perform the tool path

check function, the Virtual Machining function, and other functions, and confirm that the

program operates properly. The modification of tool data may cause even a field-proven

machining program to change in operational status.

If the user operates the machine without being aware of any changes in program status,

interference with the workpiece could arise from unexpected operation.

For example, if the cutting edge of the tool during the start of automatic operation is present

inside the clearance-including blank (unmachined workpiece) specified in the common unit

of the MAZATROL program, care is required since the tool will directly move from that

position to the approach point because of no obstructions being judged to be present on

this path.

For this reason, before starting automatic operation, make sure that the cutting edge of the

tool during the start of automatic operation is present outside the clearance-including

workpiece specified in the common unit of the MAZATROL program.

CAUTION

! If axis-by-axis independent positioning is selected and simultaneously rapid feed selected

for each axis, movements to the ending point will not usually become linear. Before using

these functions, therefore, make sure that no obstructions are present on the path.

S-4

Page 7

Operations

WARNING

SAFETY PRECAUTIONS

! Single-block, feed hold, and override functions can be made invalid using system variables

#3003 and #3004. Execution of this means the important modification that makes the

corresponding operations invalid. Before using these variables, therefore, give thorough

notification to related persons. Also, the operator must check the settings of the system

variables before starting the above operations.

! If manual intervention during automatic operation, machine locking, the mirror image

function, or other functions are executed, the workpiece coordinate systems will usually be

shifted. When making machine restart after manual intervention, machine locking, the

mirror image function, or other functions, consider the resulting amounts of shift and take

the appropriate measures. If operation is restarted without any appropriate measures being

taken, collision with the tool or workpiece may occur.

! Use the dry run function to check the machine for normal operation at no load. Since the

feed rate at this time becomes a dry run rate different from the program-designated feed

rate, the axes may move at a feed rate higher than the programmed value.

! After operation has been stopped temporarily and insertion, deletion, updating, or other

commands executed for the active program, unexpected operation of the machine may

result if that program is restarted. No such commands should, in principle, be issued fo r the

active program.

CAUTION

! During manual operation, fully check the directions and speeds of axial movement.

! For a machine that requires manual homing, perform manual homing operations after

turning power on. Since the software-controlled stroke limits will remain ineffective until

manual homing is completed, the machine will not stop even if it oversteps the limit area.

As a result, serious machine damage will result.

! Do not designate an incorrect pulse multiplier when performing manual pulse handle feed

operations. If the multiplier is set to 1000 times and the handle operated inadvertently, axial

movement will become faster than that expected.

S-5

Page 8

BEFORE USING THE NC UNIT

BEFORE USING THE NC UNIT

Limited Warranty

The warranty of the manufacturer does not cover any trouble arising if the NC unit is used for its

non-intended purpose. Take notice of this when operating the unit.

Examples of the trouble arising if the NC unit is used for its non-intended purpose are listed

below.

1. Trouble associated with and caused by the use of any commercially available software

products (including user-created ones)

2. Trouble associated with and caused by the use of any Windows operating systems

3. Trouble associated with and caused by the use of any commercially available computer

equipment

Operating Environment

1. Ambient temperature

During machine operation: 0° to 50°C (32° to 122°F)

2. Relative humidity

During machine operation: 10 to 75% (without bedewing)

Note: As humidity increases, insulation deteriorates causing electrical component parts to

deteriorate quickly.

Keeping the Backup Data

Note: Do not attempt to delete or modify the data stored in the following folder.

Recovery Data Storage Folder: D:\MazakBackUp

Although this folder is not used when the NC unit is running normally, it contains important data

that enables the prompt recovery of the machine if it fails.

If this data has been deleted or modified, the NC unit may require a long recovery time. Be sure

not to modify or delete this data.

S-6

E

Page 9

CONTENTS

Page

1 INTRODUCTION.................................................................................. 1-1

2 GENERAL............................................................................................. 2-1

2-1 General...............................................................................................................2-1

2-2 Creation of Curved-Surface Figures...................................................................2-1

2-3 Movement of a Constant Curved Line................................................................2-2

2-4 Changing Conditions of a Curved Line...............................................................2-2

2-5 3-D Machining Units and Types of Curved Surfaces Created............................2-3

3 PROGRAMMING.................................................................................. 3-1

3-1 Program Configuration .......................................................................................3-1

3-2 Before Programming ..........................................................................................3-1

3-3 Programs for 3-D Machining Units......................................................................3-2

3-3-1 Unit definition.......................................................................................................... 3-3

3-3-2 Tool-sequence definition......................................................................................... 3-7

3-3-3 Plane definition.....................................................................................................3-12

3-3-4 Figure definition....................................................................................................3-16

3-3-5 Coordinate transfer............................................................................................... 3-20

3-3-6 Machining area appointment ................................................................................ 3-22

4 PROGRAMMING EXAMPLES ............................................................. 4-1

4-1 ROTATE 1..........................................................................................................4-1

4-2 ROTATE 2..........................................................................................................4-4

4-3 ROTATE 3..........................................................................................................4-6

C-1

Page 10

4-4 ROTATE 4..........................................................................................................4-8

4-5 PARALL. 1........................................................................................................4-10

4-5-1 Tool movement and precautions .......................................................................... 4-12

4-6 PARALL. 2........................................................................................................4-14

4-7 PARALL. 3........................................................................................................4-16

4-8 PARALL. 4........................................................................................................4-18

4-9 NORMAL 1.......................................................................................................4-20

4-9-1 Coordinate axes for defining FL in NORMAL units............................................... 4-22

4-10 NORMAL 2.......................................................................................................4-26

4-11 Ruled Surface...................................................................................................4-28

4-12 ROTATE 1 + Coordinate Transfer....................................................................4-30

4-13 Combination Program (Example 1) ..................................................................4-32

4-14 Combination Program (Example 2) ..................................................................4-35

5 RELATIVE PARAMETERS................................................................... 5-1

C-2

E

Page 11

1 INTRODUCTION

Three-dimensional machining functions are automatic programming functions used for 3dimensional curved-surface machining which presents difficulties for line- or face-machining

programs.

Automatic programming functions in the easy-to-understand MAZATROL language (human

language) enable 3-dimensional curved surfaces to be machined by performing simple

operations.

This Programming Manual describes the programming procedures for machining 3-D curved

surfaces with the MAZATROL MATRIX.

Read through this manual carefully in order to make the most of the 3-D machining functions

available with the MAZATROL MATRIX.

In addition to this manual, reference should also be made to the Programming Manual and the

Operating Manual.

INTRODUCTION 1

1-1

Page 12

1 INTRODUCTION

- NOTE -

1-2

E

Page 13

2 GENERAL

2-1 General

The 3-dimensional machining functions enable 3-dimensional curved surfaces, which are difficult

to machine with line- or face-machining programs, to be handled with relative ease.

Programs with a greater degree of flexibility can be prepared when these functions are used in

conjunction with the line- and face-machining units.

The features of these 3-D machining functions are listed below:

1. Easy-to-understand MAZATROL language

Programming uses the MAZATROL language which allows programs to be created with the

same kind of ease which characterizes ordinary MAZATROL programs. As a result, 3-D

programming, which presented difficulties before, can now be handled with ease.

2. Simple representation of curved surfaces

Wire-frame models that can be defined with figure lines and guide lines are used so that the

3-dimensional curved surfaces can be set as easily as possible. In addition, GL (guide line)

and FL (figure line) figures can be input using methods similar to those for line- or facemachining.

GENERAL 2

3. Creation of wide variety of curved surfaces

A wide variety of complex curved surfaces can be handled by selecting any of the 11 types

of units in accordance with the curved surface to be machined.

4. Automatic determination of tool paths for rough machining and finish machining

Simply by defining the final curved-surface figures, the tool paths for both rough machining

and finish machining can be determined automatically.

5. Outstanding graphic check functions

Not merely the tool path and trace display but also the defined curved-surface figures can

be displayed in wire-frame format, and this makes it easier to understand and check the

defined curved-surface figures.

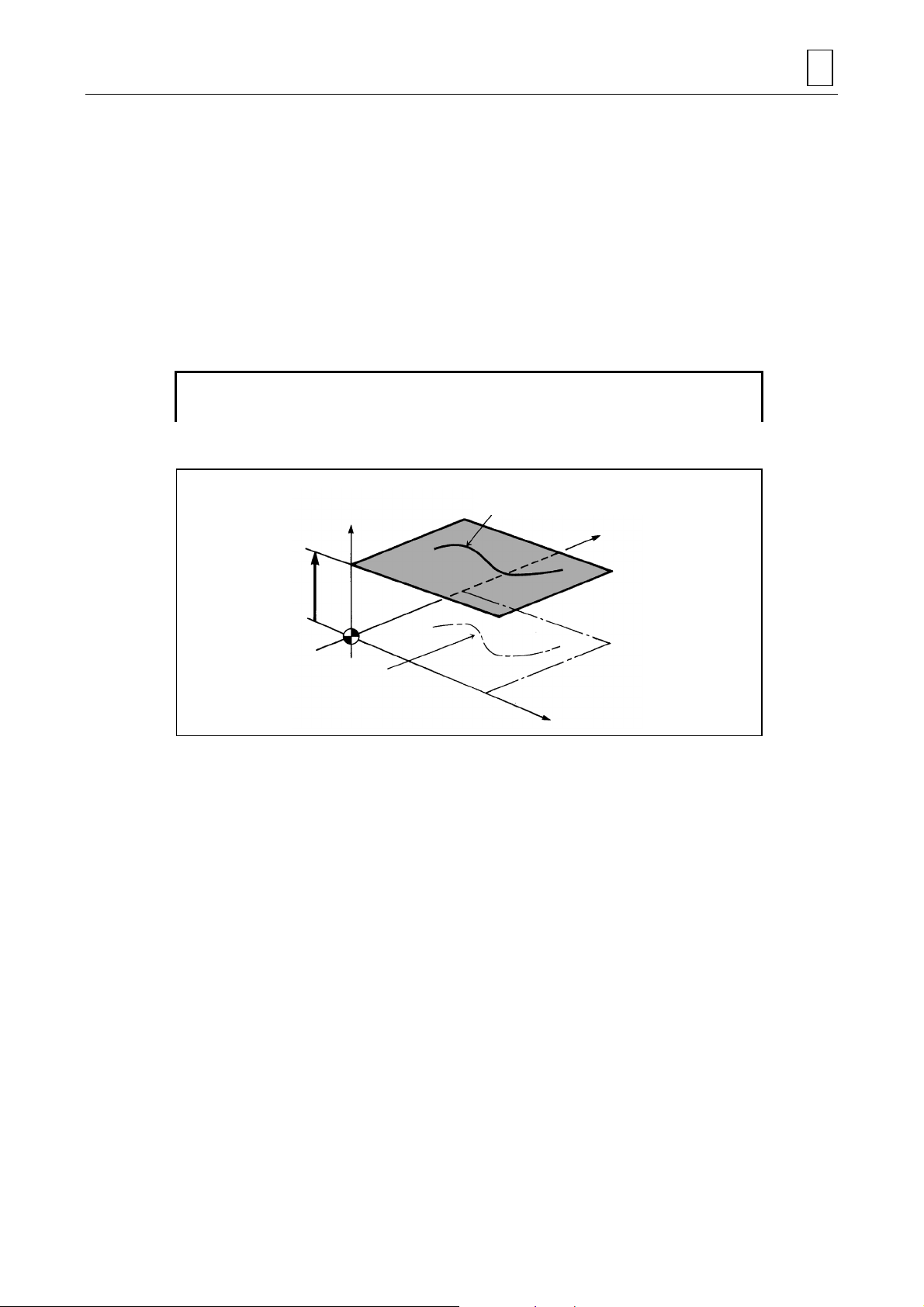

2-2 Creation of Curved-Surface Figures

A curved surface is formed when a curved line on a given plane is moved through 3-dimensional

space.

A variety of curved-surface figures can be created by defining the following conditions.

- Movement of a constant curved line

- Movement of a changing curved line

The curved-surface figures thus defined are then shaped with a 3-D machining unit.

2-1

Page 14

2 GENERAL

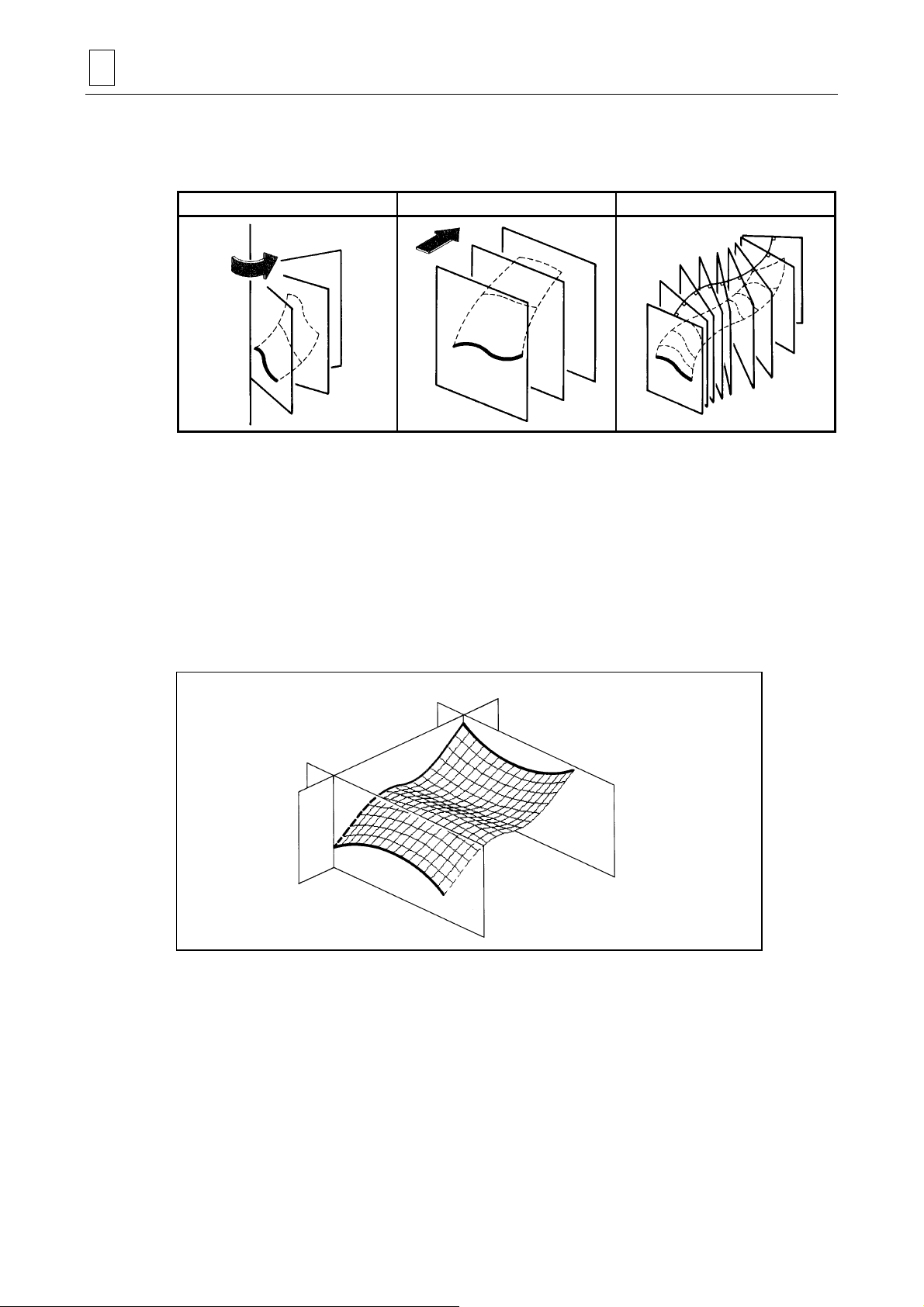

2-3 Movement of a Constant Curved Line

The movement of a curved line through 3-dimentional space is restricted to the following.

Rotation Parallel displacement Normal displacement

Furthermore, a curved-surface figure can be created by smoothly connecting a multiple number

of curved lines on given planes within 3-dimensional space (ruled surface).

2-4 Changing Conditions of a Curved Line

A curved line that is moved through 3-dimensional space is referred to as the FL (figure line).

Usually, one FL is defined as the starting curved line or two FLs are defined as the starting and

ending curved lines. A GL (guide line) which is used to guide the defined FL is also defined.

The desired curved-surface figure is created by moving and changing the starting figure line

(FL1) into the ending figure line (FL2) according to the above conditions and the guid e line (GL).

GL

FL1

FL2

D735P0500

2-2

Page 15

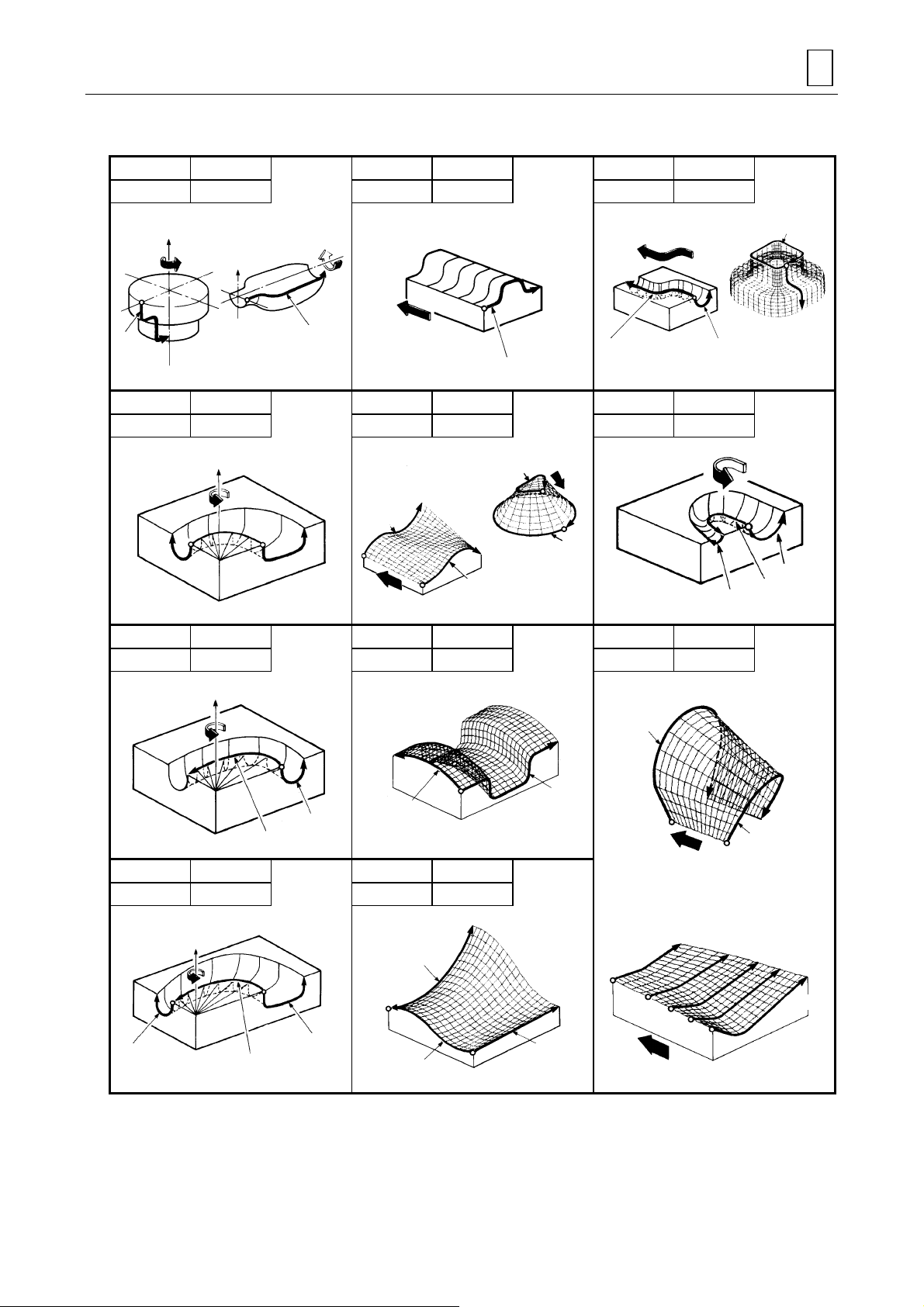

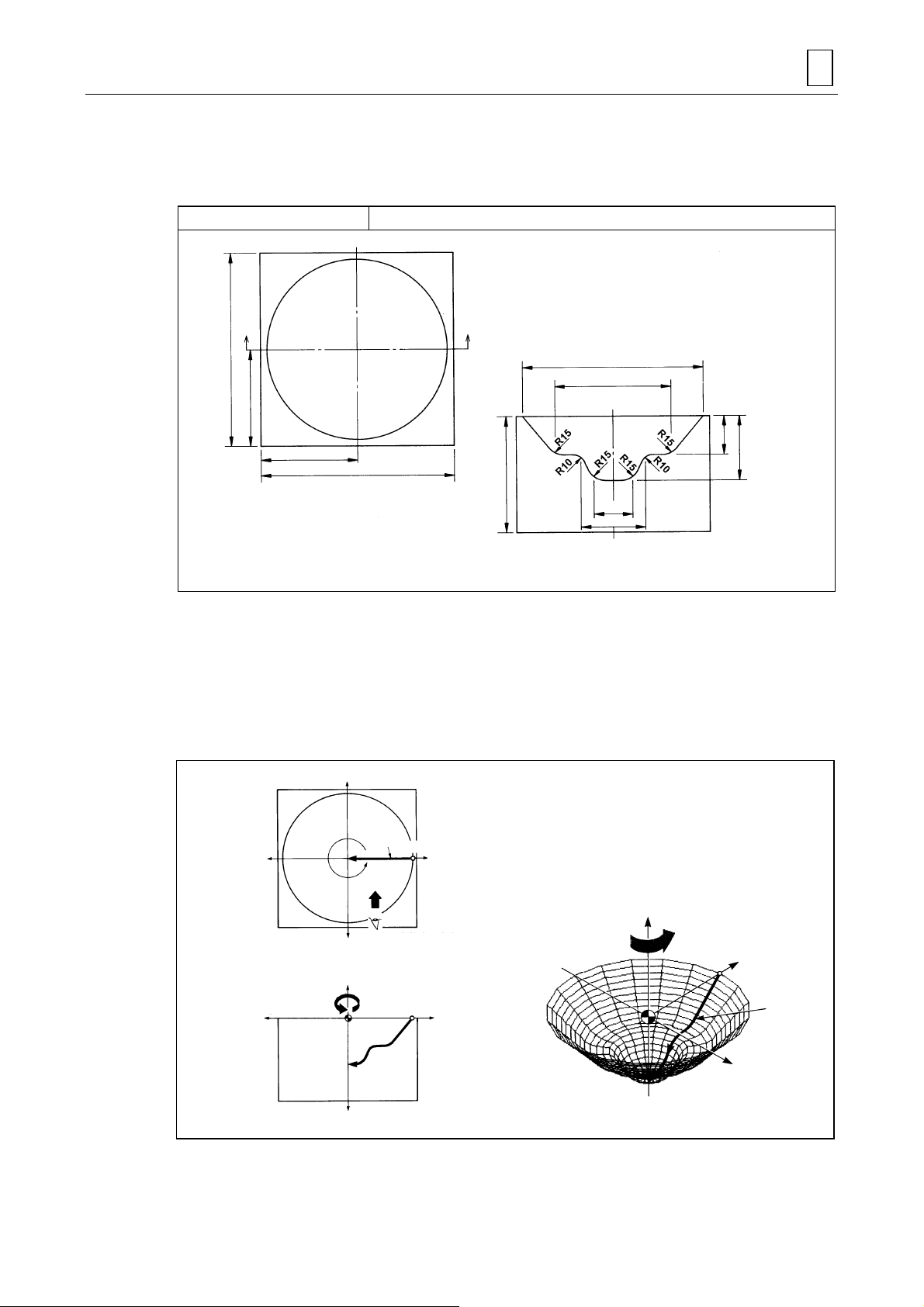

2-5 3-D Machining Units and Types of Curved Surfaces Created

UNIT ROTATE 1 UNIT PARALL.1 UNIT NORMAL 1

GL-FL 0-1 GL-FL 0-1 GL-FL 1-1

GENERAL 2

Z

Z

FL1

UNIT ROTATE 2 UNIT PARALL.2 UNIT NORMAL 2

GL-FL 0-2 GL-FL 0-2 GL-FL 1-2

Z

FL2

UNIT ROTATE 3 UNIT PARALL.3 UNIT RULED-S

GL-FL 1-1 GL-FL 1-1 GL-FL 0-20

FL1

(Applied type)

FL1

GL

FL1

FL1

FL2

FL2

FL1

FL

FL2

GL

FL

FL1

GL

Z

FL1

GL

UNIT ROTATE 4 UNIT PARALL.4

GL-FL 1-2 GL-FL 1-2

Z

FL2

GL

FL1

GL

FL2

GL

FL1

FL1

FL2

FL5

FL4

FL1

FL3

FL2

FL1

2-3

Page 16

2 GENERAL

- NOTE -

2-4

E

Page 17

3 PROGRAMMING

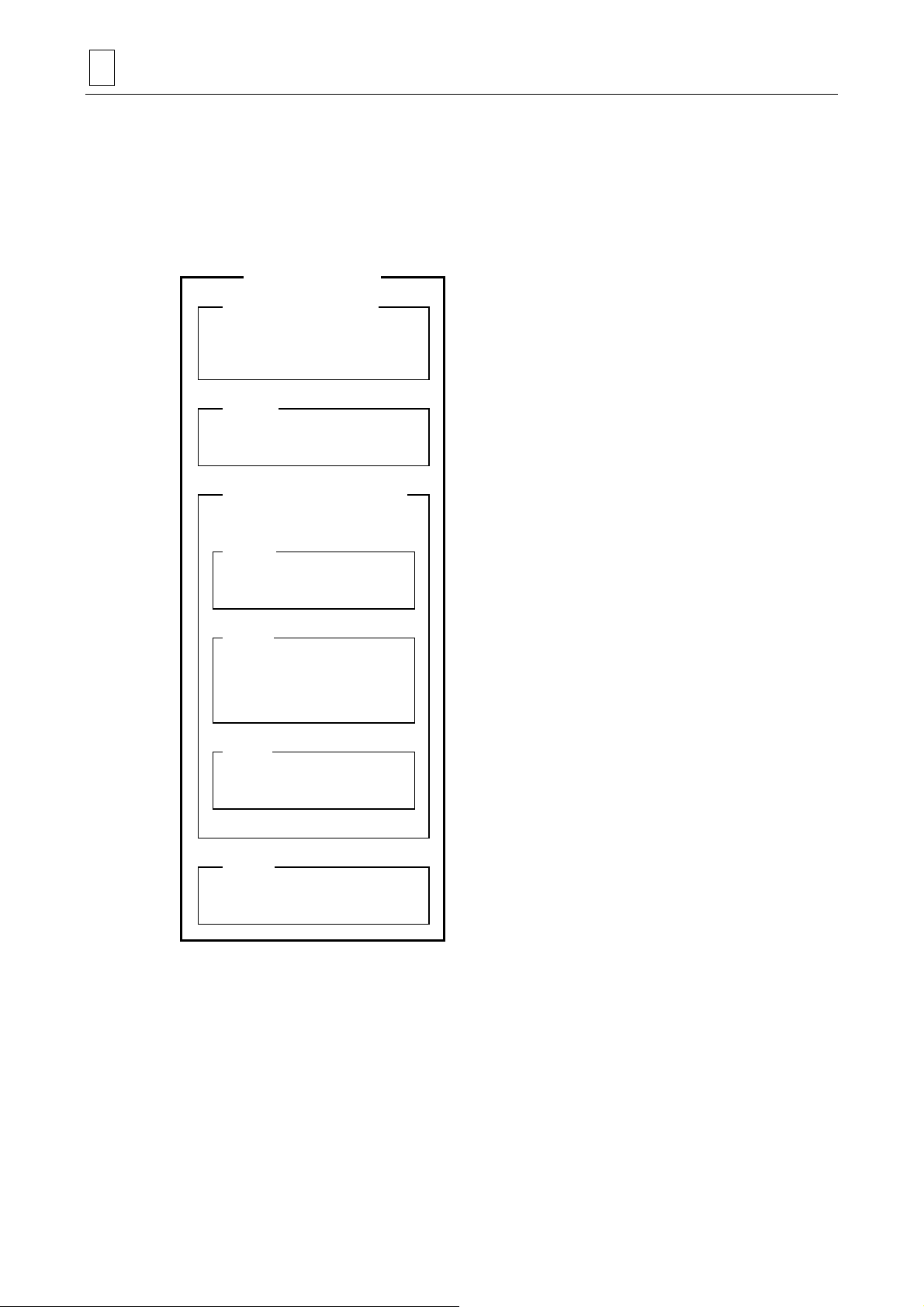

3-1 Program Configuration

The 3-D machining units are handled in exactly the same manner as the point-, line-, and facemachining units. A 3-D program is therefore composed basically of the following 4 program units.

The 3-D machining unit can also be used with the point-, line-, and/or face-machining units.

Program

Common unit

Basic coordinate system unit

Machining unit

- Point-machining unit

- Line-machining unit

- Face-machining unit

- 3-D machining unit

PROGRAMMING 3

..........This unit is always set at the head of all

programs.

..........The basic coordinates of the workpiece zero point

in the machine coordinate system are specified

here.

.......... The machining methods and data relating to the

figures to be machined are specified here.

The 3-D unit can also be specified in addition to

point-, line-, and face-machining units.

By specifying a plurality of machining units, the

workpiece will be machined to the desired shape.

End unit

3-2 Before Programming

Programming is done by following the same pro ce du res as those prescrib ed for point-, line-, and

face-machining.

For details on the methods for creating and editing programs, reference should be made to the

Programming Manual (MAZATROL).

..........This unit is set at the end of all programs.

3-1

Page 18

3 PROGRAMMING

3-3 Programs for 3-D Machining Units

A 3-D machining units consist of unit definition, tool-sequence definition, curved-surface

definition and machining area appointment. The curved-surface definition is subdivided into 3

parts: plane definition (definition of the plane on which curved lines are placed), figure definition

and coordinate transfer.

3D machining unit

UNo. (Unit definition)

SNo.

(Tool-sequence definition)

Curved-surface definition

PLN

(Plane definition)

.......... Select from among the 11 types of units that unit

by which it will be easiest to define the desired

shape.

.......... The tool operating conditions are set with these

data.

.......... The data relating to the machining methods and

shapes of the curved-surfaces are set here.

..........The plane for defining the figure is set here.

FIG

(Figure definition)

TRN

(Coordinate transfer)

CSF

(Machining area appointment)

..........The GL (guide line) and FLs (figure lines) are

input here to create the curved-surface shape for

machining.

..........Data are input here to move or rotate the created

curved surface to any position.

..........The machining area for the created curved

surface is specified here.

3-2

Page 19

3-3-1 Unit definition

The unit definition inputs the data required to automatically determine the tool sequence for 3-D

machining. The tools required for machining are automatically determined by inputting the types

of the units, FL movements/angles, material height, finishing allowance, and cutting processes.

These data are invalid once the tool sequence has been displayed.

UNo. UNIT GL-FL ROT.AXIS DIST/th. MAT-HIGH FIN CUT-PROCESS

[1] [2] [3] [4] [5] [6] [7]

[1] UNIT

Select the menu item in accordance with the machining method.

Input example: [ROTATE 1] → ROTATE 1 unit is set.

[2] GL-FL

The numbers of GLs/FLs used in this unit are displayed.

Display example: 1-1 → One GL and one FL are used.

[3] ROT. AXIS

“Z” is displayed as the rotational axis for GL-FL when one of the [ROTATE 1] through

[ROTATE 4] menu items has been selected for UNIT.

Display example: Z → Denotes that the rotational axis is Z.

PROGRAMMING 3

[4] DIST/th.

Input the values for setting the parallel movement distance of FL or its angle of rotation.

Input example: 30 → 30 mm movement or rotation by 30° in the positive direction

[5] MAT-HIGH

Input a numerical value to set the height of the material from the workpiece zero point.

Input example: 50 → Material height of 50 mm

[6] FIN

Input a numerical value to set the section to be left uncut as a finishing allowance while

rough machining is performed.

Input example: 2 → Finishing allowance of 2 mm

[7] CUT-PROCESS

Select a cutting process and rough machining method from among the menu items.

Input example: [ROUGH R1] → Rough machining only

denotes either items which can be selected from the menu or items for which numerical

values are input.

denotes items which are automatically displayed.

Reference should be made to the following description for details on items [1] through [7].

3-3

Page 20

3 PROGRAMMING

1. UNIT

The unit name selected from the menu is displayed. The following 11 types are available as 3-D

machining units.

Menu 1

Menu 2

ROTATE1ROTATE2ROTATE3ROTATE4PARALLEL1PARALLEL2PARALLEL3PARALLEL4>>>

NORMAL1NORMAL2RULED-S. >>>

2. GL-FL

The number of GLs (guide lines) and FLs (figure lines) is displayed as soon as the unit name

appears.

3. ROT. AXIS

“Z” is displayed as the rotational axis when rotation unit name from among ROTATE 1 through

ROTATE 4 is displayed

4. DIST/th.

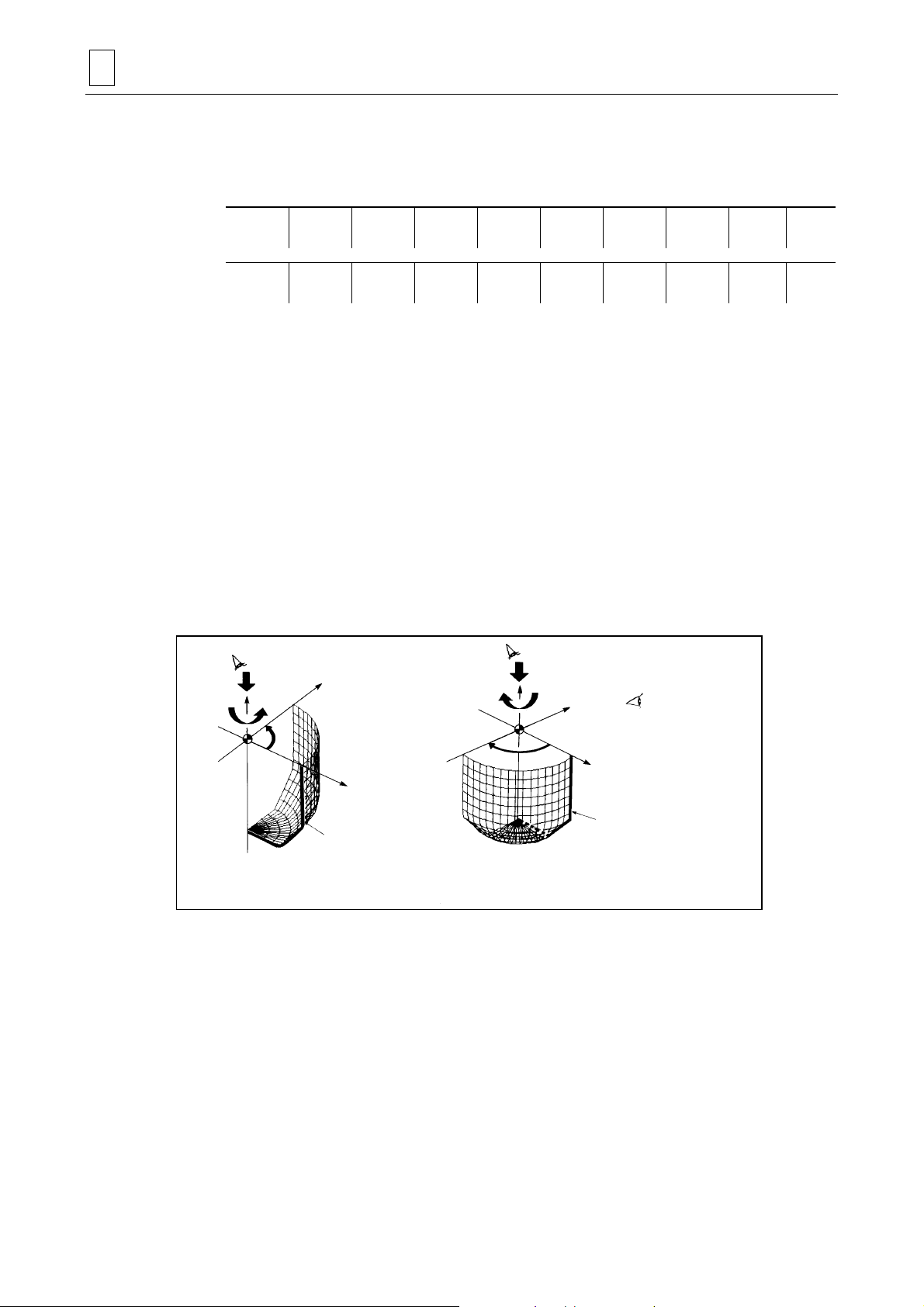

Set the angle through which the FL (figure line) is to be rotated in order to create a curved

surface when ROTATE 1 or ROTATE 2 has been selected. (As seen from the +Z direction, the

selected FL rotates counterclockwise or clockwise if a positive or negative value is entered,

respectively.)

+Z

th

CCW

(th.: positive value)

+Y

FL

+X

+Z

th

CW

(th.: neg at i ve value)

+Y

: Direction in which

the angle is to be

read

+X

FL

D735P0501

3-4

Page 21

PROGRAMMING 3

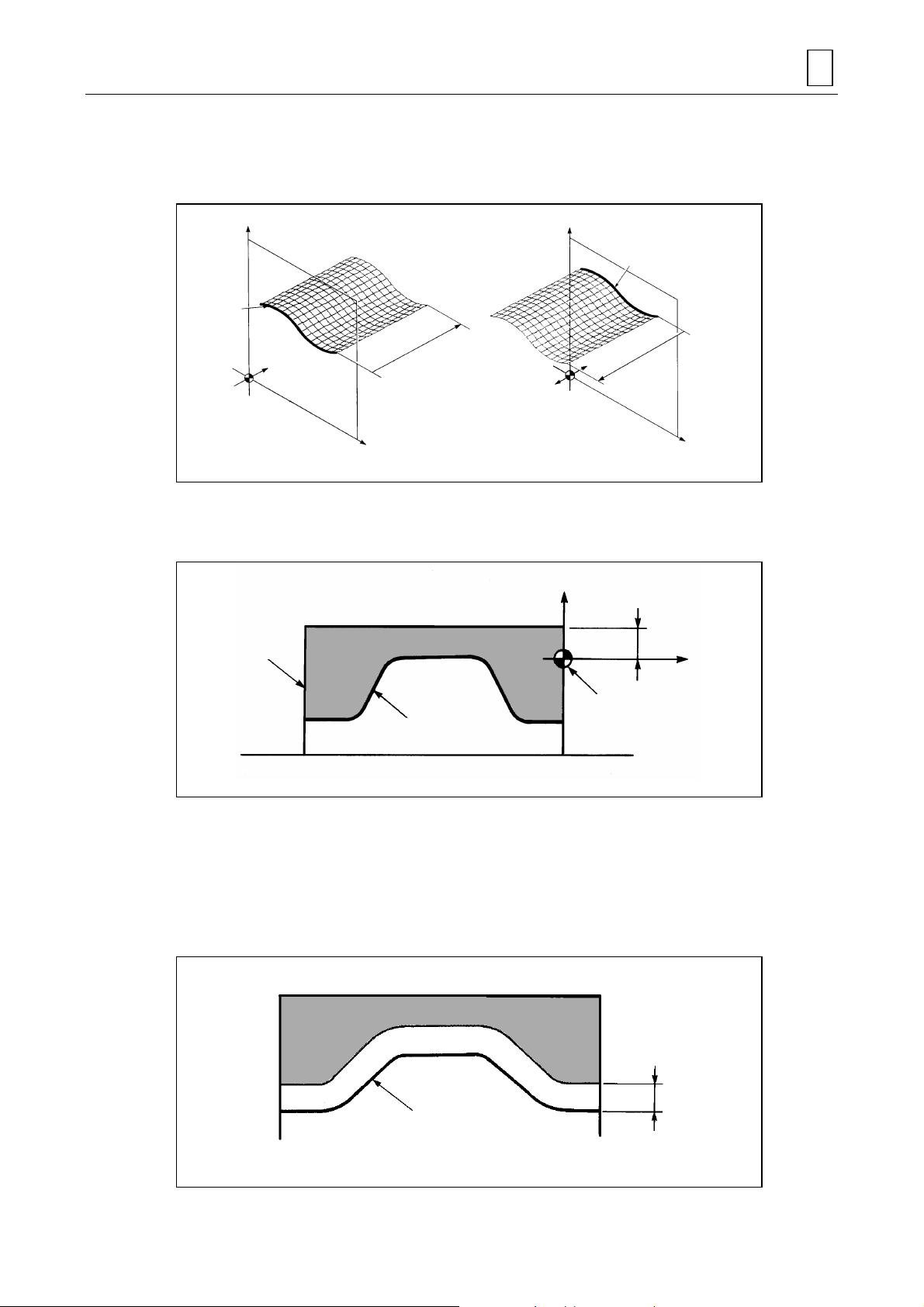

Set the distance through which the FL (figure line) is to be moved in parallel in order to create a

curved surface when either the PARALL. 1 or PARALL. 2 unit has been selected. (The selected

FL moves in parallel in the + (plus) direction if a positive value is entered and in the – (minus)

direction if a negative value is entered.)

+Z+Z

FL

FL

DIST

–Y

Workpiece

zero point

+Y

(Positive value)

–Y

Workpiece

zero point

+Y

(Negative value)

DIST

When a positive

value is set

When a negative

value is set

+X+X

D735P0502

5. MAT-HIGH

Set the height from the workpiece zero point on the Z-axis to the top of the material.

+Z

Material

Curved-surface figure

MAT-HIGH

+X

Workpiece zero point

D735P0503

Note: A negative value cannot be used to set the material height. The workpiece zero point

must therefore be set in the minus direction (in other words, below) from the top of the

material.

6. FIN

Set the finishing allowance for the section to be left uncut by rough machining.

Rough machining

Fini sh machining

Curved-surface figure

3-5

FIN

D735P0504

Page 22

3 PROGRAMMING

7. CUT-PROCESS

Select the cutting process from the following menu as well as whether rough machining is to be

performed at high speed or at normal speed.

The data selected here are used to select the tools in the tool sequence.

(The data become invalid once the tool sequence has been displayed.)

ROUGHR1RGH,FIN1

R1-F2

Menu Cutting process Tool selected

ROUGH R1 Rough machining R1: BAL EMIL

RGH, FIN1 R1-F1 Rough machining → Finishing 1

RGH, FIN2 R1-F2-F3

FINISH 1 F1 Finishing 1 F1: BAL EMIL

FINISH 2 F1-F2 Finishing 1 → Finishing 2

RGH,FIN2

R1-F2-F3

Rough machining → Finishing 1→

Finishing 2

FINISH 1F1FINISH 2

F1-F2

H SPEED

RGH PRC.

R1: BAL EMIL

F2: BAL EMIL

R1: BAL EMIL

F2: BAL EMIL

F3: BAL EMIL

F1: BAL EMIL

F2: BAL EMIL

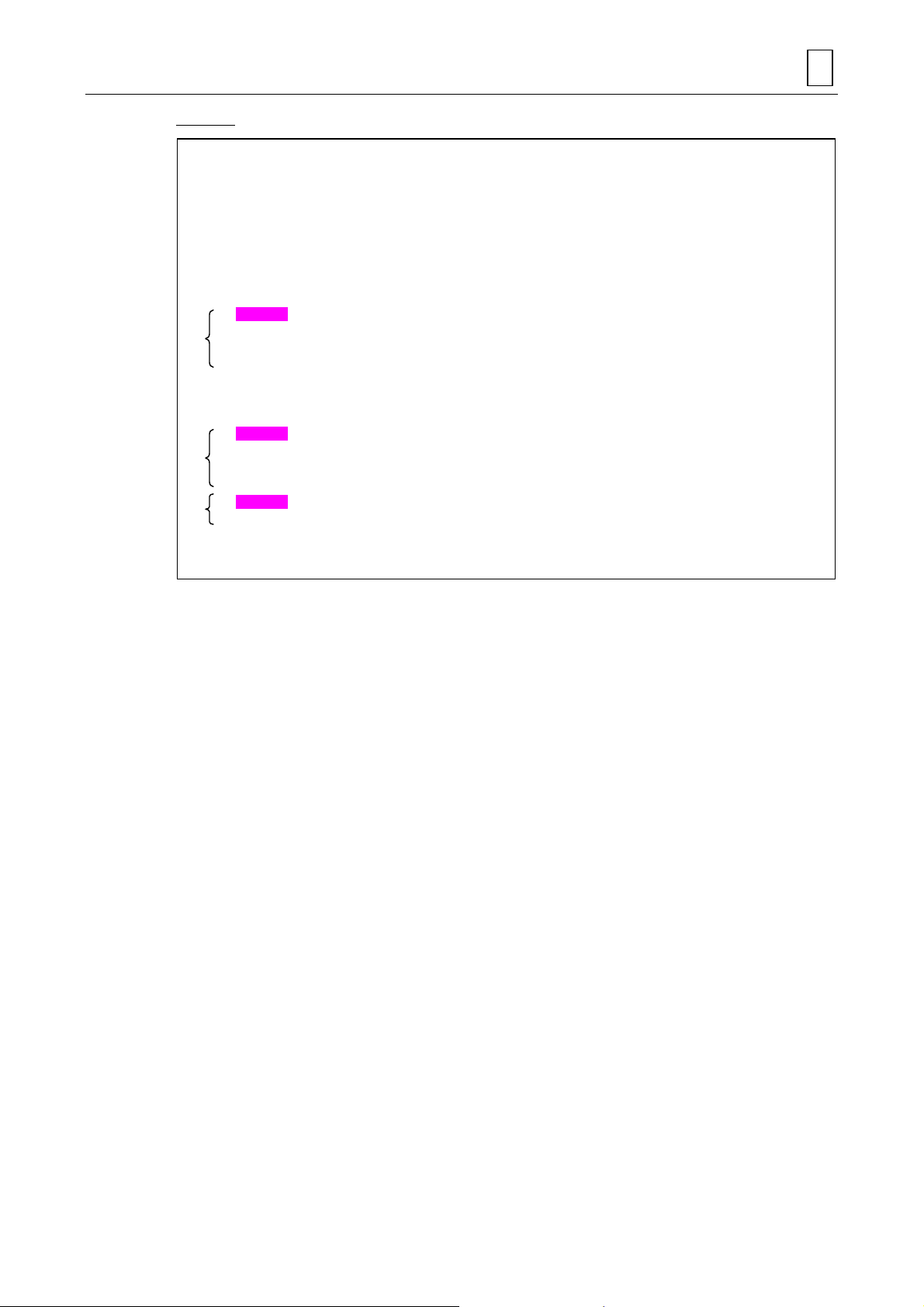

If the rough machining process is selected after reversing the display state of the menu item by

pressing the [H SPEED RGH PRC.] menu key, the rough machining tool in the tool sequence will

be displayed as below:

R1 END MILL

In this case, rough machining will be performed at high speed.

High-speed rough machining can be identified by observing whether or not the tool sequence “R”

appears in red.

High-speed rou gh ma chining

Normal-speed machinin g

D735P0505

3-6

Page 23

3-3-2 Tool-sequence definition

The tools to be used are automatically determined by the unit definition.

A tool is made operational by defining such factors as its normal diameter, approach coordinates,

peripheral speed and feed rate.

SNo. TOOL NOM-φ No. APRCH-X APRCH-Y TYPE DEPTH #T PITCH C-SP FR M M M

[1] [2] [3] [4] [4] [5] [6] [7] [8] [9] [9] [10][10][10]

[1] TOOL

The tool is automatically determined according to the CUT-PROCESS data set during unit

definition.

[2] NOM-φ

Input a numerical value to set the diameter of the tool. Select a suffix from the menu if

necessary.

[3] No.

Input a numerical value to set the operation priority number when the pri ority function for the

same tool is to be used.

PROGRAMMING 3

[4] APRCH-X, APRCH-Y

Input numerical values or press the [AUTO SET] menu key to set the coordinates which the

tool will initially approach.

Input example: [AUTO SET] → “?” is displayed and the values are determined

automatically upon checking the tool path.

[5] TYPE

Select the cutting type from the menu.

Input example: [X BI-DIR] → X-axis bi-directional rough machining

[6] DEPTH

For rough machining, input the numerical value to set the depth for one cutting pass in an

axial direction.

Input example: 5 → Cutting to a depth of 5 mm

For finish machining, input the numerical value to set the amount to be left uncut as the

finishing allowance.

Input example: 2 → 2 mm is left as the finishing allowance.

[7] #T

Input the desired machining error tolerance level for the curved-surface figure using a

number from 1 to 9.

Input example: 1 → Parameter E67 for machining error tolerance level is used.

[8] PITCH

Input a numerical value to set the desired pitch for cutting.

Input example: 10 → Cutting is performed by a pitch of 10 mm.

[9] C-SP, FR

Input numerical values to set the C-SP (peripheral speed) and FR (feed rate).

Input example: C-SP: 500 → Peripheral speed of 500 mm/min

FR: 50 → Feed rate of 50 mm/rev

3-7

Page 24

3 PROGRAMMING

10

]M

[

Reference should be made to the following description for details on items [1] through [

1. TOOL

The tool is automatically selected according to the data set during the cutting process selection

for unit definition.

BAL EMIL (ball-end mill) is used for 3-D machining but END MILL (ordinary end mill) is used for

high-speed rough machining.

2. NOM-φ

Use a value for the tool diameter so that it can be distinguished from the diametrical values of

other tools (0.1 mm). Assign a suffix (identification code A to Z) (except I and O) from the menu

to identify identical tools.

Select from the menu the M-code to be output immediately after the tool has been

automatically changed (ATC).

Input example: [50 AIR BLAST] → Air blasting operation

denotes either items which can be selected from the menu or items for which numerical

values are input.

denotes items which are automatically displayed.

10

].

Note: The tool defined here must be registered on the TOOL FILE display beforehand.

3. No.

Set the operation priority number when the priority function for the same tool is to be used.

1) Operation to be done first (1 to 99)

2) No number

3) Operation to be done later (1 to 99)

(During machining the tools are selected in the order of 1 to 3.)

For further details reference should be made to “PRIORITY FUNCTION FOR THE SAME TOOL”

in the Programming Manual (MAZATROL Programming).

4. APRCH-X, APRCH-Y

Set the coordinates to which the tool is to be approached initially after completing ATC

(automatic tool changing). If the [AUTO SET] menu key is pressed, “?” is displayed and the

coordinates are automatically calculated and set when the tool path is checked.

3-8

Page 25

PROGRAMMING 3

5. TYPE

Select the cutting type from the menu.

For high-speed rough machining

Select one of the following menu items depending on whether the tool is to be fed bi-directionally

or uni-directionally in parallel with the X-axis or Y-axis.

X

BI-DIRYBI-DIRXUNI-DIRYUNI-DIR

X BI-DIR X UNI-DIR

Y BI-DIR Y UNI-DIR

Rapid traverse Cutting feed AP: Approach point

WRK SIZE

DESIGN.

Also select whether high-speed rough machining is to be performed with offset appointment or

workpiece-size appointment. Offset appointment is set when the [WORK SIZE DESIGN.] menu

item is displayed normal; workpiece-size appointment is set when the item is displayed in

reverse form. The display will change alternately each time the menu key is pressed.

Offset appointment Workp i ec e- si ze appoi n tment

E83

Y

X

Z

X

The bold codes represent the parameter addresses.

Material height

E88

E85

Y

X

Z

X

Curved-surface

figure

E86

E87

Material height

D735P0506

Note: Workpiece-size appointment has been provided principally for male figures. It can also

be made effective for female figures by changing the parameters. (Normally, highly

efficient operations can be undertaken through combinations with line- and facemachining.)

3-9

Page 26

3 PROGRAMMING

For cases other than rough machining

Select from the following menu whether bi-directional or uni-directional machining is to be

performed in parallel with or at right angles to the FL (figure line).

6. DEPTH

UNI-DIR

//-1

UNI-DIR

-1

UNI-DIR / /-1 BI-DIR / /-2

UNI-DIR -1 BI-DIR -2

BI-DIR

//-2

BI-DIR

-2

For rough machining

Set the depth to which the workpiece is to be machined per cutting pass in an axial direction.

Example:

DEPTH

Material height

Curved-surface figure

D735P0507

For finish machining

Set the finishing allowance for the section left uncut when machining with finishing tools.

Example:

Material height

Rough machining

FIN

(unit definition)

Fini sh machining 1

Fini sh machining 2

Curved-surface figure

3-10

DEPTH DEPTH

(F2) (F1)

(Remaining allowance)

D735P0508

Page 27

PROGRAMMING 3

T

7. #T

Set the tolerance level of the machining for the curved-surface figure using a number from 1 to 9.

The tolerance levels corresponding to number 1 through 9 have been set in parameters

E75.

Example:

Curved-surface

figure

#

#T

8. PITCH

Set the cutting pitch amount (pick feed).

Example:

PITCH

AP

E67 to

D735P0509

D735P0510

9. C-SP, FR

Set the cutting conditions. An automatic setting function is not available with this setting.

10. M

Set the M-code that is to be output immediately after the tool has been automatically changed

(ATC).

3-11

Page 28

3 PROGRAMMING

3-3-3 Plane definition

In order to define the GL (guide line) and FLs (figure lines) in 3-dimensional space, set the

positional relationship of the plane containing the GL and FLs to the workpiece zero point.

PLN LINE PLANE DISTANCE ROT.-X ROT.-Y ROT.-Z SHIFT-X SHIFT-Y SHIFT-Z

[1] [2] [3] [4] [4] [4] [5] [5] [5]

[1] LINE

The display indicates whether the line to be set is a GL or FL.

Display example: GL → Line to be set is GL.

[2] PLANE

Select from the menu the plane which will serve as the reference for placing the curved

lines.

Input example: X-Y → X-Y plane

[3] DISTANCE

Input a numerical value to set the distance between the plane containing the curved line and

the workpiece zero point.

Input example: 50 → The plane is set 50 mm away from the workpiece zero point.

[4] ROT.-X, ROT.-Y, ROT.-Z

Input a numerical values to set the angle of inclination for the plane containing the curved

line.

Input example: ROT.-X: 30 → +30° rotation around the X-axis

ROT.-Y: 10 → +10° rotation around the Y-axis

ROT.-Z: 0 → No rotation around the Z-axis

Note: The sequence of axes around which the plane rotates is X, Y, and Z.

[5] SHIFT-X, SHIFT-Y, SHIFT-Z

Input a numerical values to set the distance between the plane containing the curved line

and the reference plane.

Input example: SHIFT-X: 50 → Shifting 50 mm in the X-axis positive direction

SHIFT-Y: 20 → Shifting 20 mm in the Y-axis positive direction

SHIFT-Z: 0 → No shifting in the Z-axis direction

Note: The sequence of axes along which the plane moves is X, Y, and Z.

denotes either items which can be selected from the menu or items for which numerical

values are input.

denotes items which are automatically displayed.

3-12

Page 29

PROGRAMMING 3

Y

Reference should be made to the following description for details on items [1] through [5].

The various patterns for plane definition (PLN) which depend on the types of units involved are

summarized in the following table.

GL (guide line) FL (figure line)

Number

of FIGs

ROTATE 1 0 0 — 1 1 X-Z

ROTATE 2 0 0 — 2 1 X-Z

ROTATE 3 1 1 X-Y 1 0 —

ROTATE 4 1 1 X-Y 2 0 —

PARALL. 1 0 0 — 1 1 X-Y, X-Z, Y-Z

PARALL. 2 0 0 — 2 1 X-Y, X-Z, Y-Z

PARALL. 3 1 1 X-Y, X-Z, Y-Z 1 0 X-Y, X-Z, Y-Z

PARALL. 4 1 1 X-Y, X-Z, Y-Z 2 0 X-Y, X-Z, Y-Z

NORMAL 1 1 1 X-Y, X-Z, Y-Z 1 0 —

NORMAL 2 1 1 X-Y, X-Z, Y-Z 2 0 —

RULED-S 0 0 — Max. 20 Max. 20 X-Y, X-Z, Y-Z

Number

of PLNs

Appointed plane

Number

of FIGs

Number of

PLNs

Appointed plane

Note: Several planes are defined for RULED-S. Each time a definition is completed, press

the

[FL DEFINE] menu key and define the next plane.

1. LINE

The GL or FL is displayed depending on the type of unit selected.

This item indicates whether the curved line to be placed on the plane defined here is a GL or FL.

2. PLANE

Appoint an X-Z plane (FL) for ROTATE 1 or ROTATE 2 and an X-Y plane (GL) for ROTATE 3 or

ROTATE 4.

- For the other units in the table, select the corresponding menu item for the plane which will

serve as the reference for placing the curved line. The curved lines are defined on this

reference plane. When the actual curved lines are not present on this plane, designate the

plane by rotation (in [4]) or shifting (in [5]).

- The positional relationship of the planes and the observation points for reading their

coordinates are shown in the figure.

+Z

Y-Z

X-Z

Observation point

when viewing Xplane

+Y

Observation point when

viewing X-Z plane

Workpiece

zero point

X-Y

+X

Observation point

when viewing Y-Z

plane

D735P0511

3-13

Page 30

3 PROGRAMMING

A

g

3. DISTANCE

Set the distance from the plane containing the curved line to the workpiece zero point by e ntering

the coordinate value of the axis passing at right angles through the plane.

PLN LINE PLANE DISTANCE ROT.-X ROT.-Y ROT.-Z SHIFT-X SHIFT-Y SHIFT-Z

Given below is the figure which illustrates this example.

FLX-Z50000000

+Z

Figure difined by

shape sequence

50 (DISTANCE)

+X

+Y

FL

(Figure line shifted in

accordance wi th DISTANCE)

D735P0512

The X-Z plane moves in the Y-axis direction. (In this case, the reference plane moves 50 mm in

the positive direction.)

Note: These distance data have the same significance as those of SHIFT-X, SHIFT-Y and

SHIFT-Z (in [5]). This can be better understood by first setting 0 as the DISTANCE data

and then moving the plane in parallel using the

SHIFT-X/Y/Z.

4. ROT.-X, ROT.-Y, ROT.-Z

Set the angle of inclination of the plane containing the curved line with respect to the base plane

as the angle of rotation around the axis in question. In accordance with this angle, the reference

plane rotates around the designated axis as its center. (Set 0 for an axis around which no

rotation is intended.)

PLN LINE PLANE DISTANCE ROT.-X ROT.-Y ROT.-Z SHIFT-X SHIFT-Y SHIFT-Z

FLX-Y03000000

Given below is the figure which illustrates this example.

+Z

Figure defined with

shape sequence

+X

+Y

FL

(Figure line rotated 30°

according to ROT)

for readin

bservation point

angel

D735P0513

3-14

Page 31

PROGRAMMING 3

In this case, the reference plane rotates 30° counterclockwise (po sitive value) a round the X-axis.

Note 1: The rotational direction around each axis must be designated with a positive value for

counterclockwise rotation when viewed from the positive (+) side of the rotating axis.

For clockwise rotation, set a negative value.

Note 2: If rotational angles are set for a multiple number of axes, the reference plane will rotate

around the axes in the order of X, Y and Z.

5. SHIFT-X, SHIFT-Y, SHIFT-Z

Set the distance between the plane containing the curved line and the reference plane.

The reference plane now moves in parallel with the specified axis. (Set 0 for an axis along which

no movement is intended.)

PLN LINE PLANE DISTANCE ROT.-X ROT.-Y ROT.-Z SHIFT-X SHIFT-Y SHIFT-Z

FLX-Y00000020

Given below is the figure which illustrates this example.

FL

+Z

(Figure line shifted in accordance with SHIFT)

+Y

(Shift amount in

Z-axis direction)

20

Figure defined with

shape sequence

+X

D735P0513

In this case, the reference plane moves 20 mm along the Z-axis in the positive direction.

Note: When the shift amounts are set for a multiple number of axes, the reference plane will

move along in the sequence of the X-, Y- and Z-axes. When both the distance and

rotation data are set in addition to the shift data, the reference plane will move and

rotate in the same order as that displayed (distance, rotation, shift).

3-15

Page 32

3 PROGRAMMING

3-3-4 Figure definition

This defines GL (guide line) and FL (figure line) curved-line figures. The definition method is the

same as that for line- and face-machining. For details, reference should be made to “Shape

sequence data of the line machining and face machining units” in the Programming Manual

(MAZATROL Programming).

<Arbitrary form>

FIG PTN X Y R/th. I J P CNR

<Fixed form>

FIG PTN P1X/CX P1Y/CY P3X/R P3Y CN1 CN2 CN3 CN4

Definitions of arbitrary forms are all handled as open forms. The shape sequence items for the

X-Y plane are always displayed, even if a plane containing a figure is selected as X-Z or Y-Z. The

following table shows the relationship between the reference planes and actual title axes for

sequence data.

Plane Form Actual shape sequence title

X-Y

X-Z

X-Z

Arbitrary form

Fixed form

Arbitrary form

Fixed form

Arbitrary form

Fixed form

FIG PTN X Y R/th I J P CNR

FIG PTN P1X/CX P1Y/CY P3X/R P3Y CN1 CN2 CN3 CN4

FIG PTN X Z R/th I K P CNR

FIG PTN P1X/CX P1Z/CZ P3X/R P3Z CN1 CN2 CN3 CN4

FIG PTN Y Z R/th J K P CNR

FIG PTN P1Y/CY P1Z/CZ P3Y/R P3Z CN1 CN2 CN3 CN4

The number of shapes and the setting sequence differ depending on the type of unit.

Press the [SHAPE END] menu key to complete the setting of a curved-surface shape in a shape

sequence.

When defining a multiple number of curved lines in a single shape sequence, select the

[STARTING POINT] menu item at the head of the figure definition before defining them.

When defining a multiple number of planes and setting the shape sequence in one unit (ruled-

surface), press the [SHAPE END] menu key to complete the setting.

The menu will now change as follows.

[COORDIN. TRANSFER], [FL DEFINE] or [3-D END] can be selected from this menu.

COORDIN.

TRANSFER

FL

DEFINE

3-D

END

Note: When defining an arbitrary form in the figure definition, press the [SHAPE END] menu

key on the arbitrary form menu and then press the [SHAPE END] menu key on the

figure definition menu.

Reference should be made to “3-3-5 Coordinate transfer” for further details on this menu.

3-16

Page 33

PROGRAMMING 3

The tables below show the various sequences for defining a GL (guide line) and FL1 and FL2

(figure lines) in each unit.

ROTATE 1

PLN LINE PLANE

FL X-Z

FIG PTN

LINE

1

2

CW

3

CCW

ROTATE 2

PLN LINE PLANE

FL X-Z

FIG PTN

LINE

1

CW

2

CCW

3

LINE

4

CW

5

CCW

6

ROTATE 3

PLN LINE PLANE

GL X-Y

FIG PTN

LINE

1

CW

2

CCW

3

LINE

4

CW

5

CCW

6

ROTATE 4

PLN LINE PLANE

GL X-Y

FIG PTN

LINE

1

2

CW

3

CCW

LINE

4

CW

5

CCW

6

LINE

7

CW

8

CCW

9

…

…

FL1

…

…

FL1

FL2

…

…

GL

FL1

…

…

GL

FL1

FL2

denotes the starting point of a curved line.

After setting FL1, reverse the menu display by pressing the

[STARTING POINT] menu key and then press the [LINE]

menu key to input the FL2 shape.

After setting GL, reverse the menu display by pressing the

[STARTING POINT] menu key and then press the [LINE]

menu key to input the FL1 shape.

After setting GL, reverse the menu display by pressing the

[STARTING POINT] menu key and then press the [LINE]

menu key to input the FL1 shape.

After setting FL1, reverse the menu display by pressing the

[STARTING POINT] menu key and then press the [LINE]

menu key to input the FL2 shape.

3-17

Page 34

3 PROGRAMMING

PARALL. 1

PLN LINE PLANE …

FL X-Z

FIG PTN …

1

LINE

2

CW

3

CCW

FL1

PARALL. 2

PLN LINE PLANE …

FL X-Z

FIG PTN …

1

LINE

2

CW

3

CCW

4

LINE

5

CW

6

CCW

FL1

FL2

PARALL. 3

PLN LINE PLANE …

GL X-Y

FIG PTN …

1

LINE

2

CW

3

CCW

PLN LINE PLANE …

FL Y-Z

FIG PTN …

4

LINE

5

CW

6

CCW

GL

FL1

PARALL. 4

PLN LINE PLANE …

GL X-Y

FIG PTN …

1

LINE

2

CW

3

CCW

PLN LINE PLANE …

FL Y-Z

FIG PTN …

4

LINE

5

CW

6

CCW

7

LINE

8

CW

9

CCW

GL

FL1

FL2

denotes the starting point of a curved line.

After setting FL1, reverse the menu display by pressing the

[STARTING POINT] menu key and then press the [LINE]

menu key to input the FL2 shape.

After setting GL, press the [SHAPE END] menu key and

then press the

[SHAPE END] menu key on the shape

definition menu and finally select the plane for defining FL.

After setting GL, press the [SHAPE END] menu key and

then press the

[SHAPE END] menu key on the shape

definition menu and finally select the plane for defining FL.

After setting FL1, reverse the menu display by pressing the

[STARTING POINT] menu key and then press the [LINE]

menu key to input the FL2 shape.

3-18

Page 35

PROGRAMMING 3

NORMAL 1

PLN LINE PLANE …

GL X-Y

FIG PTN …

1

LINE

2

CW

3

CCW

4

LINE

5

CW

6

CCW

GL

FL1

NORMAL 2

PLN LINE PLANE …

GL X-Y

FIG PTN …

1

LINE

2

CW

3

CCW

4

LINE

5

CW

6

CCW

7

LINE

8

CW

9

CCW

GL

FL1

FL2

RELED-S

PLN LINE PLANE …

FL X-Y

FIG PTN …

1

LINE

2

CW

3

CCW

PLN LINE PLANE …

FL X-Y

FIG PTN …

1

LINE

2

CW

3

CCW

PLN LINE PLANE …

FL X-Y

FIG PTN …

1

LINE

2

CW

3

CCW

:

:

:

FL1

FL2

FL3

:

:

:

:

denotes the starting point of a curved line.

After setting GL, reverse the menu display by pressing the

[STARTING POINT] menu key and then press the [LINE]

menu key to input the FL1 shape.

After setting GL, reverse the menu display by pressing the

[STARTING POINT] menu key and then press the [LINE]

menu key to input the FL1 shape.

After setting FL1, reverse the menu display by pressing the

[STARTING POINT] menu key and then press the [LINE]

menu key to input the FL2 shape.

After setting FL1, press the [SHAPE END] menu key and

then press the

[SHAPE END] menu key on the figure

definition menu and finally select the plane for defining FL2.

After setting FL2, press the [SHAPE END] menu key and

then press the

[SHAPE END] menu key on the figure

definition menu and finally select the plane for defining FL3.

3-19

Page 36

3 PROGRAMMING

3-3-5 Coordinate transfer

The menu will change as follows upon completion of the figure definition.

COORDIN.

TRANSFER

FL

DEFINE

3-D

END

Press the [COORDIN. TRANSFER] menu key to set the coordinate transfer mode.

Press the

Press the

[FL DEFINE] menu key to define the FL (figure line) for RULED-S.

[3-D END] menu key to move to the next program operation (machining area

appointment).

Coordinate transfer

The curved surfaces (whole figure) created by plane definition and figure definition can be shifted

to any position in 3-dimensional space by using rotation or parallel displacement.

TRN PTN ROT.-X ROT.-Y ROT.-Z SHIFT-X SHIFT-Y SHIFT-Z

SURF-MOVE

[1] [1] [1] [2] [2] [2]

[1] ROT.-X, ROT.-Y, ROT.-Z

Input the numerical values to set the angle through which the created curved surface as a

whole is to be rotated. Input 0 for an axis around which no rotation is intended.

Input example: ROT.-X: 30 → 30° counterclockwise rotation around the X-axis

ROT.-Y: –10 → 10° clockwise rotation around the Y-axis

ROT.-Z: 0 → No rotation around the Z-axis

Note: The sequence of axes around which the curved surface rotates is X, Y, and Z.

[2] SHIFT-X, SHIFT-Y, SHIFT-Z

Input the numerical values to set the distance through which the created curved surface as

a whole is to be shifted. Input 0 for axes for which no movement is intended.

Input example: SHIFT-X: 50 → Shifting 50 mm in the X-axis positive (+) direction

SHIFT-Y: 20 → Shifting 20 mm in the Y-axis positive (+) direction

SHIFT-Z: 0 → No shifting for Z-axis direction

Note: The sequence of axes along which the curved surface moves is X, Y and Z.

denotes items for which numerical values are input.

Reference should be made to the following description for details on items [1] and [2].

1. ROT.-X, ROT.-Y, ROT.-Z

Set the angle of rotation for the axes around which the entire created surface is to be rotated.

(Input 0 for an axis around which no rotation is intended.)

Example:

TRN PTN ROT.-X ROT.-Y ROT.-Z SHIFT-X SHIFT-Y SHIFT-Z

SURF-MOVE 90 0 0 0 0 0

3-20

Page 37

PROGRAMMING 3

Given below is the figure which illustrates this example.

+Z

+Y

°

90

+X

D735P0514

In this case, the curved surface is rotated 90° counterclockwise (positive value) around the Xaxis.

Note 1: The rotational direction around each axis must be designated with a positive value for

counterclockwise rotation when viewed from the positive (+) side of the rotating axis.

For clockwise rotation, set a negative value.

Note 2: If rotational angles are set for a multiple number of axes, the sequence of axes around

which the curved surface rotates is X, Y, and Z.

2. SHIFT-X, SHIFT-Y, SHIFT-Z

Set the distance through which the entire created curved surface is to be shifted along the

particular axis.

(Set 0 for an axis along which no shift is intended.)

Example:

TRN PTN ROT.-X ROT.-Y ROT.-Z SHIFT-X SHIFT-Y SHIFT-Z

SURF-MOVE 0 0 0 0 0 -30

Given below is the figure which illustrates this example.

+Z

+Y

30 mm

+X

D735P0515

In this case, the curved surface is shifted 30 mm in the minus (–) direction along the Z-axis.

Note: When the shift amounts are set for a multiple number of axes, the sequence of axes for

the shift is X, Y, and Z. When both rotation and shift amounts are set, rotation is

performed first (according to the order on the display).

3-21

Page 38

3 PROGRAMMING

3-3-6 Machining area appointment

The machining area for the defined curved surface i s set he re. All data items mu st be left blank if

the entire curved surface is to be set as the machining area.

CSF PTN X-MIN X-MAX Y-MIN Y-MAX Z-MIN Z-MAX IN/OUT

AREA

[1] [1] [1] [1] [2] [2] [3]

[1] X-MIN, X-MAX, Y-MIN, Y-MAX

Input the numerical values to set the machining area in the X-axis and in the Y-axis

directions.

Input example:

X-MIN: 0, X-MAX: 500

→ Machining is performed over an area from 0 to 500 mm in the X-axis direction.

Y-MIN: 0, Y-MAX: 250

→ Machining is performed over an area from 0 to 250 mm in the Y-axis direction.

[2] Z-MIN, Z-MAX

Input the numerical values to set the machining area in the Z-axis direction.

Input example:

Z-MIN: 100, Z-MAX: blank

→ Machining is performed over an area from 100 mm to infinity in the Z-axis direction.

[3] IN/OUT

On the menu select whether machining is to be undertaken inside or outside the area

indicated by MIN and MAX for each axis.

Input example: [IN THE AREA] → Machining is performed over an area between MIN

and MAX.

denotes either items which can be selected from the menu or items for which numerical

values are input.

Reference should be made to the following description for details on items [1] and [2].

3-22

Page 39

1. X-MIN, X-MAX, Y-MIN, Y-MAX (IN/OUT)

X

Set machining areas in the X- and Y-axis directions.

PROGRAMMING 3

Curved-surface figure

Curved-surface figure

+X

: Machining are a

when IN is selected

at IN/OUT

: Machining are a

when OUT is

selected at IN/OUT

+X

D735P0516

Workpiece zero point

Y-MA

Y-MIN

Workpiece zero point

+Y

X-MIN X-MAX

+Y

X-MIN X-MAX

Note 1: If all the data items are left blank, the machining area is treated as infinite. Also, IN is

considered valid for IN/OUT.

X-MAX, Y-MAX → –∞

X-MIN, Y-MIN→ +∞

Note 2: As the machining area is appointed on the basis of pitch, there may be times when an

area smaller than 1 pitch is left uncut.

Note 3: A finishing allowance is added for the roughing tool.

2. Z-MIN, Z-MAX (IN/OUT)

Set the machining area in the Z-axis direction.

: Machining are a

There is no

distinction between

IN and OUT; IN is

always selected.

+X

Z-MAX

Z-MIN

Workpiece

zero point

+Z

Curved-surface figure

Note: If all the data items are left blank, the machining area is treated as infinite.

Z-MIN → –∞

Z-MAX → +∞

D735P0517

3-23

Page 40

3 PROGRAMMING

- NOTE -

3-24

E

Page 41

4 PROGRAMMING EXAMPLES

A’A

A

–

X

–

4-1 ROTATE 1

Programming example 1 ROTATE 1

PROGRAMMING EXAMPLES 4

Unit: mm

150

75

75

150

90

View in direction of A-

140

90

30

50

30

50

’

1) Definition of the plane

Define the FL (figure line) on the X-Z plane containing the workpiece zero point (WPC).

2) Creation of the curved surface

Rotate the X-Z plane (+ side) on which the FL (figure line) has been defined around the Zaxis of the workpiece coordinate system.

Set the rotational angle to 360°.

+Y

D735P0518

–X

360°

rotation

FL

Viewing point for

–Y

defining FL

+Z

–Z

Starting

FL

Starting point

+X

point

+X

4-1

+Y

+Z

Counterclockwise

rotation

+X

FL

Y

D735P0519

Page 42

4 PROGRAMMING EXAMPLES

Y

Program

UNo. UNIT GL-FL ROT.AXIS DIST/th. MAT-HIGH FIN CUT-PROCESS

1 ROTATE 1 0-1 Z 360. 0. 2. R1-F2

[4] [5] [6]

[1] [3]

SNo. TOOL NOM-φ No. APRCH-X APRCH-Y TYPE DEPTH #T PITCH C-SP FR M M M

R1 BAL EMIL 20.A ? ? -1 5. 5 5. 200 0.25

F2 BAL EMIL 20.A ? ? -1 0. 5 5. 250 0.25

[2]

PLN LINE PLANE DISTANCE ROT.-X ROT.-Y ROT.-Z SHIFT-X SHIFT-Y SHIFT-Z

FL X-Z !!!0. !!!

FIG PTN X Y R/th I J P CNR

1 LINE 70. 0.

2 LINE 45. -30. R15.

3 LINE 25. -30. R10.

4 LINE 15. -50. R15.

5 LINE 0. -50.

CSF PTN X-MIN X-MAX Y-MIN Y-MAX Z-MIN Z-MAX IN/OUT

AREA

[1] DIST/th.

This indicates the amount of rotation from the starting plane for machining to the ending

plane of machining.

Incremental angle th

(–360 ≤ th2 ≤360) is to be set.

2

[2] ROT.-Z

The position of the starting plane for machining is to be defined by setting angle th

X-axis.

from the

1

Creatio n of figur e

th

and th2: Angles as seen from

1

plus (+) side of the Z-axis

CW: Clockwise rotation

(negative value)

CCW: Counterclockwise rotation

(positive value)

FL

th

= DIST/th

2

= ROT.-Z

th

1

X

D735P0520

[3] MAT-HIGH

The distance from the workpiece zero point on the Z-axis to the top of the stock material is

to be set.

MAT-HIGH

WPC-Z = 0

D735P0521

4-2

Page 43

PROGRAMMING EXAMPLES 4

[4] TYPE

The type of machining is to be set.

-1 indicates right-angular and uni-directional tool movement (the tool is to be fed at right

angles to the figure line in one direction only).

Tool moves at right

angles to the figure line.

Tool

FL

Tool path

D735P0522

/ /-1 indicates parallel and uni-directional tool movement (the tool is to be fed in parallel with

the figure line in one direction only).

Tool path

Tool

FL

D735P0523

[5] #T

The desired level of tolerance is to be set. (The amount of tolerance is to be set on the

PARAMETER display.)

[6] PITCH

The amount of pick feed is to be set.

The pitch between the tool paths is to be set.

PITCH

PITCH

FL

D735P0524

4-3

Page 44

4 PROGRAMMING EXAMPLES

–

X

g

4-2 ROTATE 2

Programming example 2 ROTATE 2

150

60

60

75 60

Unit: mm

60

75

150

1) Definition of the plane

Define FL1 and FL2 (figure lines) on the X-Z plane containing the workpiece zero point

(WPC).

2) Creation of the curved surface

Rotate the X-Z plane (+ side) around the Z-axis of the workpiece coordinate system so that

FL1 and FL2 can be connected smoothly.

Set the rotational angle to 90°.

+Y

Viewing point for defining FL2

FL2

90° rotation

+Z

FL1

–X

+Z

FL1

Starting

point

FL1

–Y

Viewing point for

FL1

definin

+X

+X

Counterclockwise

rotation

+Y

D735P0525

+X

FL2

–Z

FL2

D735P0526

4-4

Page 45

PROGRAMMING EXAMPLES 4

Program

[1] [4]

UNo. UNIT GL-FL ROT.AXIS DIST/th. MAT-HIGH FIN CUT-PROCESS

1 ROTATE 2 0-2 Z 90. 0. 5. R1-F2-F3

SNo. TOOL NOM-φ No. APRCH-X APRCH-Y TYPE DEPTH #T PITCH C-SP FR M M M

R1 END MILL 10.A ? ? XUN 5. 5 5. 200 0.25

F2 BAL EMIL 20.A ? ? -1 2. 5 5. 200 0.25

F3 BAL EMIL 20.A ? ? -1 0. 2 2. 250 0.25

PLN LINE PLANE DISTANCE ROT.-X ROT.-Y ROT.-Z SHIFT-X SHIFT-Y SHIFT-Z

FL X-Z !!!0 !!!

FIG PTN X Y R/th I J P CNR

1 LINE 40. 0.

[2]

2 CCW 80. 0. 20. ?(60.) ?(0.)

3 LINE 20. 0.

[3]

4 CCW 100. 0. 40. ?(60.) ?(0.)

CSF PTN X-MIN X-MAX Y-MIN Y-MAX Z-MIN Z-MAX IN/OUT

AREA

[1] GL-FL

This indicates the number of GLs (guide lines) and FLs (figure lines) used to define the

curved surfaces.

Two FLs (figure lines) are to be defined with the ROTATE 2 unit.

[2] FIG (FL1)

The first defined figure line becomes the figure line on the starting plane for machining

(FL1).

[3] FIG (FL2)

The second defined figure line becomes the figure line on the ending plane for machining

(FL2).

Press the [STARTING POINT] menu key before defining FL2.

[4] CUT-PROCESS

The high-speed machining mode is to be set.

Press the [H SPEED RGH PRC.] menu key to select the desired cutting process.

4-5

Page 46

4 PROGRAMMING EXAMPLES

–

–

4-3 ROTATE 3

Programming example 3 ROTATE 3

Unit: mm

200

160

80

75

35

50

50

130

200

1) Definition of the plane

Define FL (figure line) on the X-Z plane containing the workpiece zero point (WPC) and

define GL (guide line) on the X-Y plane containing the workpiece zero point.

2) Creation of the curved surface

Define FL on the X-Z plane containing the workpiece zero point. In this case, the zero point

of FL is used as the starting point for GL.

The figure line (FL) defined on the X-Z plane is rotated around the Z-axis of the workpiece

coordinate system along the guide line (GL).

+Y

D735P0527

FL creates the curved surface

when rot at e d along G L.

GL

GL

+Z

FL

+X

D735P0528

X

Starting

–Y

point

Starting point for GL and

+Z

programming zero pont for FL

X

FL

Viewing po in t for

defining FL

FL

+X

+Y

+X

4-6

Page 47

PROGRAMMING EXAMPLES 4

Program

[1]

UNo. UNIT GL-FL ROT.AXIS DIST/th. MAT-HIGH FIN CUT-PROCESS

1 ROTATE 3 1-1 Z ! 40. 5. R1-F2

[4]

SNo. TOOL NOM-φ No. APRCH-X APRCH-Y TYPE DEPTH #T PITCH C-SP FR M M M

R1 END MILL 20.A ? ? XUN 5. 5 5. 200 0.25

F2 BAL EMIL 10.A ? ? -1 0. 2 2. 250 0.25

[5]

PLN LINE PLANE DISTANCE ROT.-X ROT.-Y ROT.-Z SHIFT-X SHIFT-Y SHIFT-Z

GL X-Y 0. 0. 0. 0. 0. 0. 0.

FIG PTN X Y R/th I J P CNR

1 LINE 50. 0.

2 LINE 50. 50. R10.

[2]

3 LINE 0. 80.

5 LINE 0. 0.

6 CCW 10. 10. 10. ? (0.) ?(10.)

[3]

7 CW 70. 10. 30. ?(40.) ?(10.)

8 CCW 80. 0. 10. ?(80.) ?(10.)

CSF PTN X-MIN X-MAX Y-MIN Y-MAX Z-MIN Z-MAX IN/OUT

AREA

[1] GL-FL

This indicates the number of guide lines (GLs) and figure lines (FLs) used to define the

curved surfaces.

One guide line (GL) and one figure line (FL) are defined with the ROTATE 3 unit.

[2] FIG (GL)

The first defined curved line becomes the guide line (GL) on the X-Y plane defined in the

plane definition.

[3] FIG (FL)

The second defined curved line becomes the figure line (FL) o n the X-Z plane containing the

workpiece zero point.

In this case, the program zero point of FL is used as the starting point of GL.

[4] TYPE

“Uni-directional X” is to be set in the workpiece size appointment.

The parameters E85, E86, E87, and E88 are to be set to 0, 70, 0, and 40, respectively, as

the material dimensions.

[5] PLANE

The X-Y plane is to be set for ROTATE 3.

4-7

Page 48

4 PROGRAMMING EXAMPLES

–

X

–

–

Y

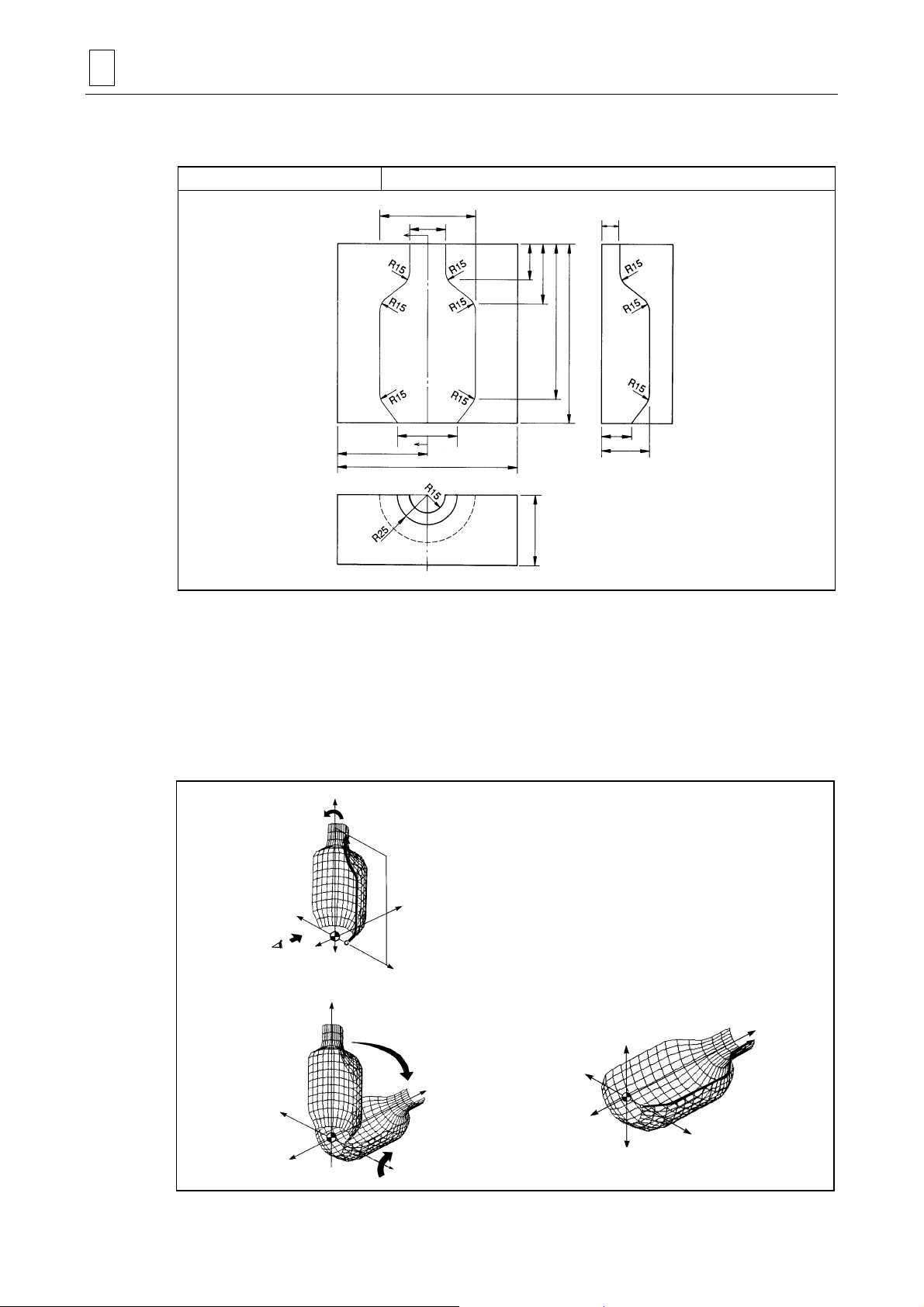

4-4 ROTATE 4

Programming example 4 ROTATE 4

150

150

95

65

110

50

40

30

50

90

130

130

110

90

Unit: mm

1) Definition of the plane

Define FL1 and FL2 (figure lines) on the X-Z plane containing the workpiece zero point

(WPC) and define GL (guide line) on the X-Y plane containing the workpie c e zero point.

D735P0529

2) Creation of the curved surface

The figure line (FL1) defined on the X-Z plane is rotated around the Z-axis of the workpiece

coordinate system along the guide line (GL) with continuou s modifi cation to end smo othly in

the second figure line (FL2).

The starting and ending points of GL must be used as the zero points of FL1 and FL2,

respectively.

+Y

Viewing point for defining FL2

FL2

X

GL

Starting point

for GL

+Z

The starting point for FL1 and FL2 are

the staring and ending points for GL.

FL1

Smooth cr e at ion of a curved

surface from FL1 to FL2

FL1

Viewing point for defining FL1

+X

+X

+Z

GL

+Y

FL2

+X

FL1

FL2

–Z

D735P0530

4-8

Page 49

PROGRAMMING EXAMPLES 4

Program

[1]

UNo. UNIT GL-FL ROT.AXIS DIST/th. MAT-HIGH FIN CUT-PROCESS

1 ROTATE 4 1-2 Z ! 0. 1. R1-F2

SNo. TOOL NOM- φ No. APRCH-X APRCH-Y TYPE DEPTH #T PITCH C-SP FR M M M

R1 BAL EMIL 20.A ? ? -1 5. 5 5. 200 0.25

F2 BAL EMIL 20.A ? ? -1 0. 2 2. 250 0.25

PLN LINE PLANE DISTANCE ROT.-X ROT.-Y ROT.-Z SHIFT-X SHIFT-Y SHIFT-Z

GL X-Y 0. 0. 0. 0. 0. 0. 0.

FIG PTN X Y R/th I J P CNR

1 LINE 90. 0.

2 LINE 50. 40. R10.

[2]

3 LINE 0. 50.

4 LINE 0. 0.

[3]

5 CCW 40. 0. 20. 20. 0.

6 LINE 0. 0.

7 LINE 15. -30. R11.

[4]

8 LINE 30. -30. R11.

9 LINE 60. 0.

CSF PTN X-MIN X-MAX Y-MIN Y-MAX Z-MIN Z-MAX IN/OUT

AREA

[1] GL-FL

This indicates the number of guide lines (GLs) and figure lines (FLs) used to define the

curved surfaces.

One guide line (GL) and two figure lines (FL1 and FL2) are defined with the ROTATE 4 unit.

[2] FIG (GL)

The first defined curved line becomes the guide line (GL) on the X-Y plane defined in the

plane definition.

[3] FIG (FL1)

The second defined curved line becomes the figure line (FL1) on the X-Z plane containing

the workpiece zero point.

In this case, the program zero point of FL1 is used as the starting point of GL.

[4] FIG (FL2)

The third defined curved line becomes the figure line (FL2) on the X-Z plane containing the

workpiece zero point.

In this case, the program zero point of FL2 is used as the ending point of GL.

Note: The two figure lines (FL1 and FL2) are to be defined in the same direction.

4-9

Page 50

4 PROGRAMMING EXAMPLES

X

–

4-5 PARALL. 1

Programming example 5 PARALL. 1

90

60

100

40

110

140

40

60

Unit: mm

1) Definition of the plane

Define the figure line (FL) on the X-Z plane containing the workpiece zero point (WPC).

2) Creation of the curved surface

Create the desired curved surface by shifting in a particular direction the X-Z plane on which

FL has been defined.

The distance traveled by the X-Z plane on which FL has been defined is +100 mm.

D735P0531

+Y

DIST

(100)

+Z

–

–Y

+Z

X

–Z

FL

Viewing poin t fo r defining FL

FL

+X

+X

+X

+Y

FL

D735P0532

4-10

Page 51

PROGRAMMING EXAMPLES 4

Program

[1] [2]

UNo. UNIT GL-FL ROT.AXIS DIST/th. MAT-HIGH FIN CUT-PROCESS

1 PARALL.1 0-1 ! 100. 0. 2. R1-F2

SNo. TOOL NOM-φ No. APRCH-X APRCH-Y TYPE DEPTH #T PITCH C-SP FR M M M

R1 BAL EMIL 20.A ? ? -1 5. 5 5. 200 0.25

F2 BAL EMIL 20.A ? ? -1 0. 2 2. 200 0.25

[3] PLN LINE PLANE DISTANCE ROT.-X ROT.-Y ROT.-Z SHIFT-X SHIFT-Y SHIFT-Z

FL X-Z 0. 0. 0. 0. 0. 0. 0.

FIG PTN X Y R/th I J P CNR

1 LINE 40. 0.

2 LINE 60. -40. R15.

[4]

3 LINE 90. -40. R15.

4 LINE 110. 0.

CSF PTN X-MIN X-MAX Y-MIN Y-MAX Z-MIN Z-MAX IN/OUT

AREA

[1] GL-FL

This indicates the number of guide lines (GLs) and figure lines (FLs) used to define the

curved surfaces.

There is no guide line (GL) with the PARALL. 1 unit and only one figure line (FL) is to be

defined.

[2] DIST/th.

The distance by which the figure line (FL) plane is shifted is to be set.

In this case, FL is shifted 100 mm in the plus (+) direction.

[3] PLN

The machining starting plane containing FL is to be defined.

In this case, DISTANCE, ROT.-X., ROT.-Y, ROT.-Z, SHIFT-X, SHIFT-Y, and SHIFT-Z are

all zero since FL is on the X-Z plane containing the workpiece zero point.

[4] FIG

The figure line (FL) is to be defined.

In this case, since the X-Z plane has been defined in the plane definition, the Y of sequence

items (PTN, X, Y, R/th.) is to be considered Z.

4-11

Page 52

4 PROGRAMMING EXAMPLES

4-5-1 Tool movement and precautions

1. Cutting direction

For uni-directional parallel cutting, machining proceeds from the starting point to the ending point

of the figure line (FL).

For concave shapes

FL

starting point

Tool path

For convex shapes

E59

FL

starting point

E59

FL

Tool path

FL

ending point

FL

ending point

FL

Sectional and top views of tool movement

E59

FL

ending point

FL

FL

Rapid traverse

Cutting feed

FL

starting point

D735P0533

For uni-directional right-angular cutting, machining proceeds from the starting point to the endin g

point of the figure line (FL) and the guide line (GL).

starting point

FL

FL

FL

ending point

ending point

FL

FL

Rapind traverse

Cutting feed

FL