Page 1

PROGRAMMING MANUAL

Return to Main Menu

for

MAZATROL MATRIX

(For INTEGREX IV)

MAZATROL Program

MANUAL No. : H740PA0031E

Serial No. :

Before using this machine and equipment, fully understand the contents of this

manual to ensure proper operation. Should any questions arise, please ask the

nearest Technical Center or Technology Center.

IMPORTANT NOTICE

1. Be sure to observe the safety precautions described in this manual and the contents of the

safety plates on the machine and equipment. Failure may cause serious personal injury or

material damage. Please replace any missing safety plates as soon as possible.

2. No modifications are to be performed that will affect operation safety. If such modifications are

required, please contact the nearest Technical Center or Technology Center.

3. For the purpose of explaining the operation of the machine and equipment, some illustrations

may not include safety features such as covers, doors, etc. Before operation, make sure all

such items are in place.

4. This manual was considered complete and accurate at the time of publication, however, due to

our desire to constantly improve the quality and specification of all our products, it is subject to

change or modification. If you have any questions, please contact the nearest Technical Center

or Technology Center.

5. Always keep this manual near the machinery for immediate use.

6. If a new manual is required, please order from the nearest Technical Center or Technology

Center with the manual No. or the machine name, serial No. and manual name.

Issued by Manual Publication Section, Yamazaki Mazak Corporation, Japan

10. 2006

Page 2

Page 3

SAFETY PRECAUTIONS

Preface

Safety precautions relating to the CNC unit (in the remainder of this manual, referred to simply as

the NC unit) that is provided in this machine are explained below. Not only the persons who

create programs, but also those who operate the machine must thoroughly understand the

contents of this manual to ensure safe operation of the machine.

Read all these safety precautions, even if your NC model does not have the corresponding

functions or optional units and a part of the precautions do not apply.

Rule

1. This section contains the precautions to be observed as to the working methods and states

usually expected. Of course, however, unexpected operations and/or unexpected working

states may take place at the user site.

During daily operation of the machine, therefore, the user must pay extra careful attention to

its own working safety as well as to observe the precautions described below.

2. Although this manual contains as great an amount of information as it can, since it is not

rare for the user to perform the operations that overstep the manufacturer-assumed ones,

not all of “what the user cannot perform” or “what the user must not perform” can be fully

covered in this manual with all such operations taken into consideration beforehand.

It is to be understood, therefore, that functions not clearly written as “executable” are

“inexecutable” functions.

SAFETY PRECAUTIONS

3. The meanings of our safety precautions to DANGER, WARNING, and CAUTION are as

follows:

: Failure to follow these instructions could result in loss of life.

DANGER

: Failure to observe these instructions could result in serious harm to a human

life or body.

WARNING

: Failure to observe these instructions could result in minor injuries or serious

machine damage.

CAUTION

HGENPA0043E

S-1

Page 4

Basics

SAFETY PRECAUTIONS

! After turning power on, keep hands away from the keys, buttons, or switches of the

operating panel until an initial display has been made.

WARNING

! Before proceeding to the next operations, fully check that correct data has been entered

and/or set. If the operator performs operations without being aware of data errors,

unexpected operation of the machine will result.

! Before machining workpieces, perform operational tests and make sure that the machine

operates correctly. No workpieces must be machined without confirmation of normal

operation. Closely check the accuracy of programs by executing override, single-block, and

other functions or by operating the machine at no load. Also, fully utilize tool path check,

Virtual Machining, and other functions, if provided.

! Make sure that the appropriate feed rate and rotational speed are designated for the

particular machining requirements. Always understand that since the maximum usable fee d

rate and rotational speed are determined by the specifications of the tool to be used, those

of the workpiece to be machined, and various other factors, actual capabilities differ from

the machine specifications listed in this manual. If an inappropriate feed rate or rotational

speed is designated, the workpiece or the tool may abruptly move out from the machine.

! Before executing correction functions, fully check that the direction and amount of

correction are correct. Unexpected operation of the machine will result if a correction

function is executed without its thorough understanding.

! Parameters are set to the optimum standard machining conditions prior to shipping of the

machine from the factory. In principle, these settings should not be modified. If it becomes

absolutely necessary to modify the settings, perform modifications only after thoroughly

understanding the functions of the corresponding parameters. Modifications usually affect

any program. Unexpected operation of the machine will result if the settings are modified

without a thorough understanding.

Remarks on the cutting conditions recommended by the NC

! Before using the following cutting conditions:

- Cutting conditions that are the result of the MAZATROL Automatic Cutting Conditions

WARNING

Determination Function

- Cutting conditions suggested by the Machining Navigation Function

- Cutting conditions for tools that are suggested to be used by the Machining Navigation

Function

Confirm that every necessary precaution in regards to safe machine setup has been taken –

especially for workpiece fixturing/clamping and tool setup.

! Confirm that the machine door is securely closed before starting machining.

Failure to confirm safe machine setup may result in serious injury or death.

S-2

Page 5

Programming

WARNING

SAFETY PRECAUTIONS

! Fully check that the settings of the coordinate systems are correct. Even if the designated

program data is correct, errors in the system settings may cause the machine to operate in

unexpected places and the workpiece to abruptly move out from the machine in the event

of contact with the tool.

! During surface velocity hold control, as the current workpiece coordinates of the surface

velocity hold control axes approach zeroes, the spindle speed increases significantly. For

the lathe, the workpiece may even come off if the chucking force decreases. Safety speed

limits must therefore be observed when designating spindle speeds.

! Even after inch/metric system selection, the units of the programs, tool information, or

parameters that have been registered until that time are not converted. Fully check these

data units before operating the machine. If the machine is operated without checks being

performed, even existing correct programs may cause the machine to operate differently

from the way it did before.

! If a program is executed that includes the absolute data commands and relative data

commands taken in the reverse of their original meaning, totally unexpected operation of

the machine will result. Recheck the command scheme before executing programs.

! If an incorrect plane selection command is issued for a machine action such as arc

interpolation or fixed-cycle machining, the tool may collide with the workpiece or part of the

machine since the motions of the control axes assumed and those of actual ones will be

interchanged. (This precaution applies only to NC units provided with EIA functions.)

! The mirror image, if made valid, changes subsequent machine actions significantly. Use

the mirror image function only after thoroughly understanding the above. (This precaution

applies only to NC units provided with EIA functions.)

! If machine coordinate system commands or reference position returning commands are

issued with a correction function remaining made valid, correction may become invalid

temporarily. If this is not thoroughly understood, the machine may appear as if it would

operate against the expectations of the operator. Execute the above commands only after

making the corresponding correction function invalid. (This precaution applies only to NC

units provided with EIA functions.)

! The barrier function performs interference checks based on designated tool data. Enter the

tool information that matches the tools to be actually used. Otherwise, the barrier function

will not work correctly.

! The system of G-code and M-code commands differs, especially for turning, between the

machines of INTEGREX e-Series and the other turning machines.

Issuance of the wrong G-code or M-code command results in totally non-intended machine

operation. Thoroughly understand the system of G-code and M-code commands before

using this system.

Sample program Machines of INTEGREX e-Series Turning machines

S1000M3

S1000M203

The milling spindle rotates at 1000 min–1. The turning spindle rotates at 1000 min–1.

The turning spindle rotates at 1000 min–1. The milling spindle rotates at 1000 min–1.

S-3

Page 6

SAFETY PRECAUTIONS

! For the machines of INTEGREX e-Series, programmed coordinates can be rotated using

an index unit of the MAZATROL program and a G68 command (coordinate rotate command) of the EIA program. However, for example, when the B-axis is rotated through 180

degrees around the Y-axis to implement machining with the turning spindle No. 2, the plus

side of the X-axis in the programmed coordinate system faces downward and if the

program is created ignoring this fact, the resulting movement of the tool to unexpected

positions may incite collisions.

To create the program with the plus side of the X-axis oriented in an upward direction, use

the mirror function of the WPC shift unit or the mirror imaging function of G-code command

(G50.1, G51.1).

! After modifying the tool data specified in the program, be sure to perform the tool path

check function, the Virtual Machining function, and other functions, and confirm that the

program operates properly. The modification of tool data may cause even a field-proven

machining program to change in operational status.

If the user operates the machine without being aware of any changes in program status,

interference with the workpiece could arise from unexpected operation.

For example, if the cutting edge of the tool during the start of automatic operation is present

inside the clearance-including blank (unmachined workpiece) specified in the common unit

of the MAZATROL program, care is required since the tool will directly move from that

position to the approach point because of no obstructions being judged to be present on

this path.

For this reason, before starting automatic operation, make sure that the cutting edge of the

tool during the start of automatic operation is present outside the clearance-including

workpiece specified in the common unit of the MAZATROL program.

CAUTION

! If axis-by-axis independent positioning is selected and simultaneously rapid feed selected

for each axis, movements to the ending point will not usually become linear. Before using

these functions, therefore, make sure that no obstructions are present on the path.

! Before starting the machining operation, be sure to confirm all contents of the program

obtained by conversion. Imperfections in the program could lead to machine damage and

operator injury.

S-4

Page 7

Operations

WARNING

SAFETY PRECAUTIONS

! Single-block, feed hold, and override functions can be made invalid using system variables

#3003 and #3004. Execution of this means the important modification that makes the

corresponding operations invalid. Before using these variables, therefore, give thorough

notification to related persons. Also, the operator must check the settings of the system

variables before starting the above operations.

! If manual intervention during automatic operation, machine locking, the mirror image

function, or other functions are executed, the workpiece coordinate systems will usually be

shifted. When making machine restart after manual intervention, machine locking, the

mirror image function, or other functions, consider the resulting amounts of shift and take

the appropriate measures. If operation is restarted without any appropriate measures being

taken, collision with the tool or workpiece may occur.

! Use the dry run function to check the machine for normal operation at no load. Since the

feed rate at this time becomes a dry run rate different from the program-designated feed

rate, the axes may move at a feed rate higher than the programmed value.

! After operation has been stopped temporarily and insertion, deletion, updating, or other

commands executed for the active program, unexpected operation of the machine may

result if that program is restarted. No such commands should, in principle, be issued for the

active program.

CAUTION

! During manual operation, fully check the directions and speeds of axial movement.

! For a machine that requires manual homing, perform manual homing operations after

turning power on. Since the software-controlled stroke limits will remain ineffective until

manual homing is completed, the machine will not stop even if it oversteps the limit area.

As a result, serious machine damage will result.

! Do not designate an incorrect pulse multiplier when performing manual pulse handle feed

operations. If the multiplier is set to 1000 times and the handle operated inadvertently, axial

movement will become faster than that expected.

S-5

Page 8

BEFORE USING THE NC UNIT

BEFORE USING THE NC UNIT

Limited Warranty

The warranty of the manufacturer does not cover any trouble arising if the NC unit is used for its

non-intended purpose. Take notice of this when operating the unit.

Examples of the trouble arising if the NC unit is used for its non-intended purpose are listed

below.

1. Trouble associated with and caused by the use of any commercially available software

products (including user-created ones)

2. Trouble associated with and caused by the use of any Windows operating systems

3. Trouble associated with and caused by the use of any commercially available computer

equipment

Operating Environment

1. Ambient temperature

During machine operation: 0° to 50°C (32° to 122°F)

2. Relative humidity

During machine operation: 10 to 75% (without bedewing)

Note: As humidity increases, insulation deteriorates causing electrical component parts to

deteriorate quickly.

Keeping the Backup Data

Note: Do not attempt to delete or modify the data stored in the following folder.

Recovery Data Storage Folder: D:\MazakBackUp

Although this folder is not used when the NC unit is running normally, it contains important data

that enables the prompt recovery of the machine if it fails.

If this data has been deleted or modified, the NC unit may require a long recovery time. Be sure

not to modify or delete this data.

S-6

E

Page 9

CONTENTS

Page

1 MAZATROL PROGRAM CONFIGURATION........................................ 1-1

1-1 Program Configuration .......................................................................................1-1

2 PROGRAM COORDINATE SYSTEM .................................................. 2-1

3 PROGRAM CREATION........................................................................ 3-1

3-1 Procedure for Program Creation ........................................................................3-1

3-2 Common Unit .....................................................................................................3-6

3-2-1 Setting unit data (common data)............................................................................. 3-6

3-3 Materials Shape Unit (MATERIAL).....................................................................3-8

3-3-1 Setting unit data...................................................................................................... 3-8

3-3-2 Setting sequence data............................................................................................ 3-8

3-4 Types of the Milling Unit...................................................................................3-12

3-4-1 Planes to be machined and machining methods.................................................. 3-12

3-5 Point Machining Units.......................................................................................3-15

3-5-1 Types of point machining units.............................................................................3-15

3-5-2 Procedure for selecting point machining unit........................................................ 3-16

3-5-3 Unit data and automatic tool development of the point machining unit ................ 3-17

3-5-4 Automatic tool development for carbide drills....................................................... 3-35

3-5-5 New tapping auto-setting scheme ........................................................................ 3-36

3-5-6 Tool sequence data of the point machining unit...................................................3-41

3-5-7 Tool path of the point machining unit.................................................................... 3-47

3-5-8 Shape sequence data of the point machining unit................................................ 3-96

3-6 Line Machining Units......................................................................................3-116

C-1

Page 10

3-6-1 Types of line machining units ............................................................................. 3-116

3-6-2 Procedure for selecting line machining unit........................................................ 3-117

3-6-3 Unit data, automatic tool development and tool path of the line machining

unit...................................................................................................................... 3-118

3-6-4 Tool sequence data of the line machining unit ................................................... 3-157

3-6-5 Shape sequence data of the line machining unit................................................ 3-160

3-6-6 Precautions in line machining............................................................................. 3-161

3-6-7 Automatic corner override................................................................................... 3-165

3-7 Face Machining Units.....................................................................................3-167

3-7-1 Types of face machining units............................................................................3-167

3-7-2 Procedure for selecting face machining unit....................................................... 3-168

3-7-3 Unit data, automatic tool development and tool path of the face machining

unit...................................................................................................................... 3-169

3-7-4 Tool sequence data of the face machining unit..................................................3-214

3-7-5 Precautions in face machining............................................................................ 3-220

3-7-6 Override in case of the overall width cutting....................................................... 3-230

3-7-7 Shape sequence data of the line/face machining unit........................................3-232

3-8 Turning Units..................................................................................................3-257

3-8-1 Types of turning units ......................................................................................... 3-257

3-8-2 Procedure for selecting turning unit.................................................................... 3-257

3-9 Bar-Materials Machining Unit (BAR)...............................................................3-259

3-9-1 Setting unit data.................................................................................................. 3-259

3-9-2 Setting tool sequence data................................................................................. 3-263

3-9-3 Setting shape sequence data............................................................................. 3-269

3-10 Copy-Machining Unit (CPY) ...........................................................................3-274

C-2

Page 11

3-10-1 Setting unit data.................................................................................................. 3-274

3-10-2 Setting tool sequence data................................................................................. 3-276

3-10-3 Setting shape sequence data............................................................................. 3-278

3-11 Corner-Machining Unit (CORNER).................................................................3-279

3-11-1 Setting unit data.................................................................................................. 3-279

3-11-2 Setting tool sequence data................................................................................. 3-280

3-11-3 Setting shape sequence data............................................................................. 3-282

3-12 Facing Unit (FACING) ....................................................................................3-283

3-12-1 Setting unit data.................................................................................................. 3-283

3-12-2 Setting tool sequence data................................................................................. 3-284

3-12-3 Setting shape sequence data............................................................................. 3-286

3-13 Threading Unit (THREAD)..............................................................................3-288

3-13-1 Setting unit data.................................................................................................. 3-288

3-13-2 Setting tool sequence data................................................................................. 3-291

3-13-3 Setting sequence data........................................................................................ 3-294

3-14 Grooving Unit (T. GROOVE)..........................................................................3-297

3-14-1 Setting unit data.................................................................................................. 3-297

3-14-2 Setting tool sequence data................................................................................. 3-300

3-14-3 Setting shape sequence data............................................................................. 3-304

3-15 Turning Drilling Unit (T. DRILL) ......................................................................3-308

3-15-1 Setting unit data.................................................................................................. 3-308

3-15-2 Setting tool sequence data................................................................................. 3-309

3-15-3 Setting shape sequence data............................................................................. 3-315

3-16 Turning Tapping Unit (T. TAP) .......................................................................3-316

C-3

Page 12

3-16-1 Setting unit data.................................................................................................. 3-316

3-16-2 Setting tool sequence data................................................................................. 3-319

3-16-3 Setting shape sequence data............................................................................. 3-321

3-17 Mill-Turning Unit (MILLTURN)........................................................................3-322

3-17-1 Setting unit data.................................................................................................. 3-322

3-17-2 Setting tool sequence data................................................................................. 3-323

3-17-3 Setting shape sequence data............................................................................. 3-325

3-18 Other Units.....................................................................................................3-326

3-19 Manual Program Machining Unit (MANL PRG)..............................................3-327

3-19-1 Setting unit data.................................................................................................. 3-327

3-19-2 Setting sequence data........................................................................................ 3-329

3-20 M-Code Unit (M-CODE) .................................................................................3-331

3-20-1 Setting unit data (M-code) .................................................................................. 3-331

3-21 Head Selection Unit (HEAD) ..........................................................................3-333

3-21-1 Setting unit data.................................................................................................. 3-333

3-22 Workpiece Transfer Unit (TRANSFER)..........................................................3-334

3-22-1 Setting unit data.................................................................................................. 3-334

3-23 Subprogram Unit (SUB PRO).........................................................................3-338

3-23-1 Setting unit data.................................................................................................. 3-338

3-23-2 Setting sequence data........................................................................................ 3-339

3-24 Add-In MAZATROL Unit.................................................................................3-341

3-24-1 Setting unit data.................................................................................................. 3-341

3-24-2 Setting sequence data........................................................................................ 3-341

3-24-3 Help function on Add-in MAZATROL.................................................................. 3-342

C-4

Page 13

3-25 End Unit (END)...............................................................................................3-346

3-25-1 Setting unit data.................................................................................................. 3-346

3-25-2 Setting sequence data........................................................................................ 3-350

3-26 Simultaneous Machining Unit (SIMULTAN)....................................................3-351

3-26-1 Procedure for calling up the SIMULTAN unit...................................................... 3-351

3-26-2 Setting unit data.................................................................................................. 3-351

3-27 Two-Workpiece Machining Unit (2 WORKPC) ...............................................3-352

3-27-1 Procedure for calling up the 2 WORKPC unit..................................................... 3-352

3-27-2 Setting unit data.................................................................................................. 3-352

3-28 Coordinate Measuring Unit (MMS).................................................................3-353

3-28-1 Procedure for calling up the MMS unit................................................................ 3-353

3-28-2 Setting unit data.................................................................................................. 3-353

3-28-3 Setting sequence data........................................................................................ 3-353

3-28-4 Type of measurement......................................................................................... 3-355

3-29 Workpiece Measuring Unit (WORK MES)......................................................3-358

3-29-1 Procedure for selecting workpiece measuring unit............................................. 3-358

3-29-2 Setting the unit data............................................................................................ 3-358

3-29-3 Setting the sequence data.................................................................................. 3-359

3-29-4 Selection of a measurement type.......................................................................3-360

3-29-5 Offset value and the direction of offset............................................................... 3-369

3-29-6 Offset judgment .................................................................................................. 3-373

3-30 Tool Measuring Unit (TOOL MES)..................................................................3-374

3-30-1 Procedure for selecting tool measuring unit ....................................................... 3-374

3-30-2 Setting the unit data............................................................................................ 3-374

C-5

Page 14

3-30-3 Setting the sequence data.................................................................................. 3-375

3-30-4 Measuring patterns............................................................................................. 3-376

4 PRIORITY FUNCTION FOR THE SAME TOOL................................... 4-1

4-1 Priority Machining Order.....................................................................................4-1

4-2 Priority Machining Zone......................................................................................4-4

4-3 Editing Function and Input Method of Priority Numbers .....................................4-6

4-3-1 Input of priority numbers......................................................................................... 4-6

4-3-2 Assignment of priority numbers .............................................................................. 4-7

4-3-3 Change of priority numbers .................................................................................... 4-8

4-3-4 Deletion of all the priority numbers.........................................................................4-9

4-3-5 How to use the SUB PROG PROC END function .................................................. 4-9

4-4 Relation between the Subprogram Unit and the Priority Machining

Function............................................................................................................4-11

4-5 Relation between the M-Code Unit and the Priority Machining Function..........4-12

5 LOWER-TURRET CONTROL FUNCTIONS ........................................ 5-1

5-1 Machining with the Lower Turret ........................................................................5-1

5-1-1 Independent machining with the lower turret.......................................................... 5-1

5-1-2 Simultaneous machining with the upper and lower turrets ..................................... 5-2

5-1-3 Balanced cutting with the upper and lower turrets.................................................. 5-6

5-1-4 Simultaneous machining of processes 1 and 2, using the upper and lower

turrets (optional)...................................................................................................... 5-7

5-2 Retraction of the Lower Turret..........................................................................5-10

5-3 Other Setup Items............................................................................................5-12

5-3-1 LTUR DIA in common unit.................................................................................... 5-12

C-6

Page 15

6 TPC DATA SETTING ........................................................................... 6-1

6-1 Operating Procedure for Setting TPC (Tool-Path Control) Data.........................6-1

6-2 Description of Each TPC Data Item of Turning Unit and Measurement

Unit.....................................................................................................................6-4

7 PROGRAM EDITING............................................................................ 7-1

7-1 Operating Procedures for Editing Programs.......................................................7-1

7-2 Search................................................................................................................7-2

7-3 Insertion..............................................................................................................7-6

7-4 Deletion............................................................................................................7-10

7-5 Copy.................................................................................................................7-14

8 PROGRAM CREATING/EDITING FUNCTIONS.................................. 8-1

8-1 Help Function.....................................................................................................8-1

8-2 Automatic Crossing-Point Calculation Function..................................................8-2

8-2-1 Automatic crossing-point calculation in the line and face machining units............. 8-2

8-2-2 Automatic crossing-point calculation function in the turning unit............................8-6

8-3 Automatic Cutting-Conditions Setting Function................................................8-15

8-4 Desk Calculator Functions................................................................................8-18

8-5 Tool Data Window............................................................................................8-19

8-6 Tool File Window..............................................................................................8-20

9 SAMPLE PROGRAMS......................................................................... 9-1

10 THREE-DIGIT G-FORMAT................................................................. 10-1

10-1 Outline.............................................................................................................. 10-1

C-7

Page 16

10-2 Detailed Description .........................................................................................10-1

10-3 Three-Digit G-Format of MAZATROL Program................................................10-2

10-4 Various Data Description Using G10..............................................................10-20

C-8

E

Page 17

1 MAZATROL PROGRAM CONFIGURATION

x

1-1 Program Configuration

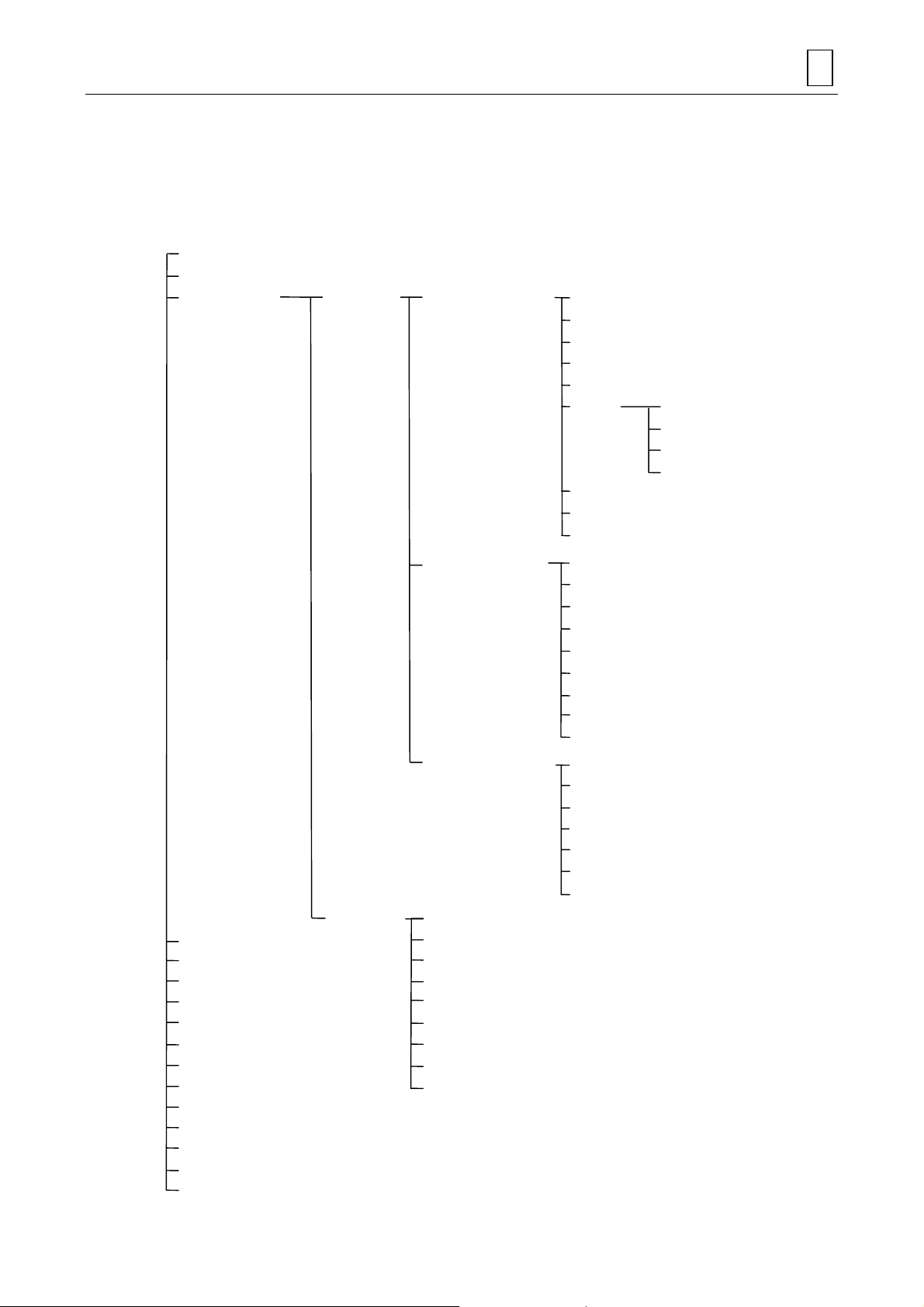

MAZATROL programs are each made up of a set of data referred to as unit. The following types of

units are prepared for this NC equipment:

Common unit

Materials shape unit

Machining unit Milling unit Point mach ining unit Drilling

MAZATROL PROGRAM CONFIGURATION 1

Counterbore machining

Inversed faced hole machining

Reaming

Tapping

Boring Through hole

Non-through hole

Stepped through hole

Stepped non-through hole

Back boring

Circular milling

Counterbore-tapping

Line machining unit Central linear machining

Face machining unit Face milling

Turning unit Bar-materials machining

Manual program machining unit Copy-machining

End unit Corner-machining

M-code unit Facing

Subprogram unit Threading

Coordinate measuring unit Grooving

Workpiece measuring unit Drilling (turning)

Tool measuring unit Tapping (turning)

Head selection unit Mill-turning

Workpiece transfer unit

Process end unit

Simultaneous machining unit

Two-workpiece machining unit

Add-in MAZATROL unit

Right-hand linear machining

Left-hand linear machining

Outside linear machining

Inside linear machining

Right-hand chamfering

Left-hand chamfering

Outside chamfering

Inside chamfering

End milling-top

End milling-step

Pocket milling

Pocket milling-mountain

Pocket milling-valley

End milling slot

E

1-1

Page 18

1 MAZATROL PROGRAM CONFI GURATION

Data to be set in the units listed above is classified into the following four major types:

1. Unit data

The data consists of data on the type of machining and the sections to be machined, etc.

2. Tool sequence data

The tool sequence data consists of tool names and other data relating to the operation of

the tools. This type of data exists for the milling (point, linear, and face machining) and

turning units. For other units, data relating to tools exists with the unit data.

3. Shape sequence data

The data consists mainly of data used to define machining patterns.

4. TPC data (Tool path control data)

TPC data is the auxiliary data to be set on the TPC display. The data consists of tool

path/tool change position adjustment data, M-codes, tool offset numbers, etc. Tool paths

are automatically generated according to the data set on the PROGRAM display and

various parameters. TPC data is intended to eliminate unnecessary paths by changing

thus-generated tool paths on an unit-by-unit basis. Machining itself, therefore, will be

executed even if TPC data is not set.

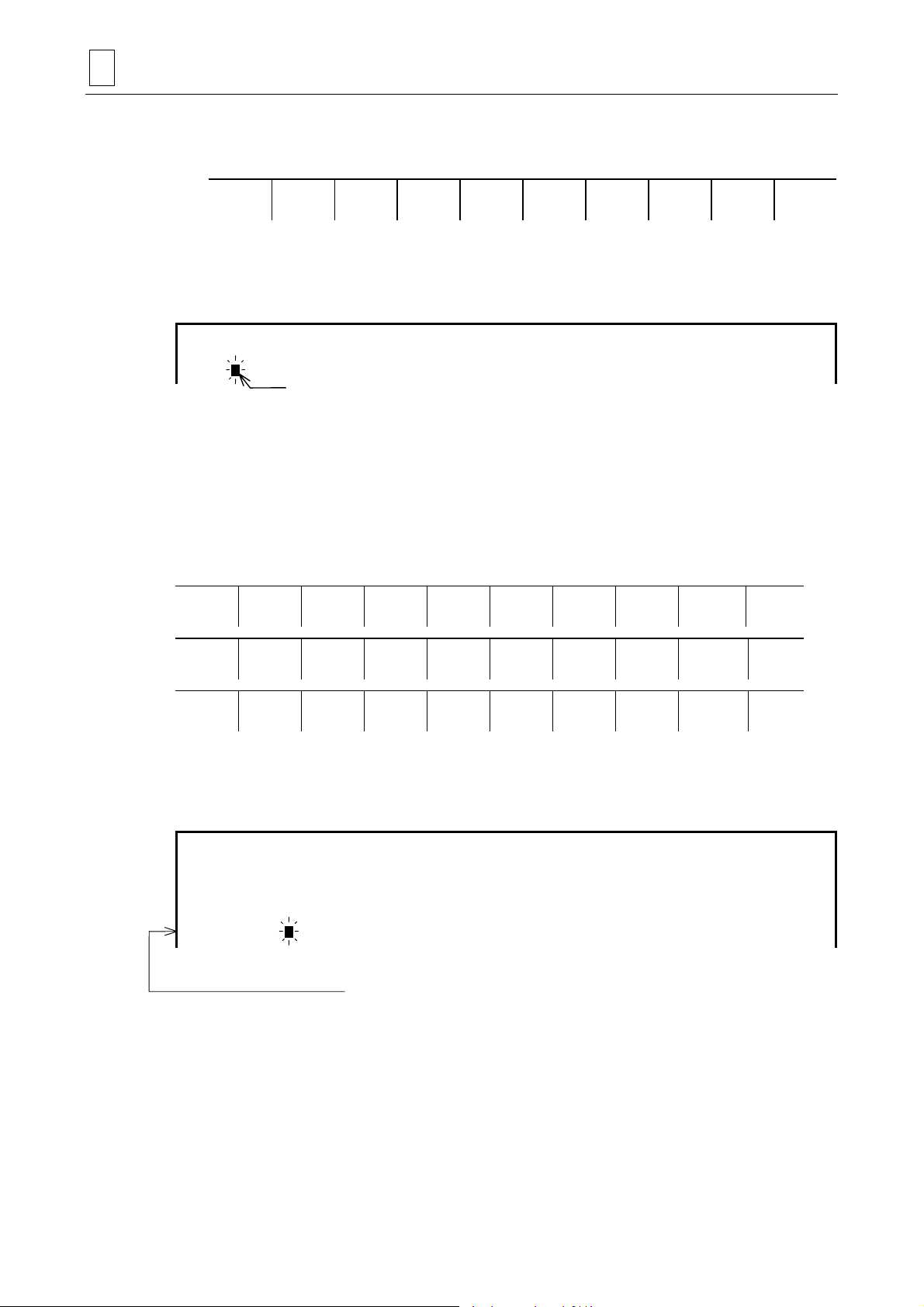

Example: PROGRAM display

UNo. MAT. OD-MAX ID-MIN LENGTH WORK FACE ATC MODE RPM LTUR DIA

A

0 FC 70. 0. 97. 2 0 3000

UNo. UNIT MODE POS-B POS-C DIA DEPTH CHMF

A

1 DRILLING ZC ! ! 10. 20. 0.

SNo.TOOL NOM-φ No. # HOLE-φ HOLE-DEP PRE-DIA PRE-DEP RGH DEPTH C-SP FR M M M

B

1 CTR-DR 12. A 10. !! ! 90. SPOT 25 0.1

2 DRILL 10. 10. 20. 0. 100 DRIL T 5. 63 0.1

FIG PTN SPT-R/x SPT-C/y SPT-Z SPT-Y NUM. ANGLE Q R

C

1 PT 0. 0. 0. 0. ! ! ! 0

UNo. UNIT MODE POS-B POS-C SRV-A SLOT-WID BTM WAL FIN-A FIN-R PAT.

A

2 SLOT ZY ! 90. 10. 20. 4 4 0. 0. 0

SNo. TOOL NOM-φ No. # APRCH-1 APRCH-2 TYPE AFD DEP-A DEP-R C-SP FR M M M

B

F1 END MILL 20. A ? ? CW G01 ! ! 120 0.13

FIG PTN SPT-R Z Y R/th I J P CNR RGH

C

1 LINE 25. 20. 20.

2 LINE ! 20. –20.

A: Unit data

B: Tool sequence data

C: Shape sequence data

Specific details and setting procedures of each data are described in Chapter 3. Here (Chapter

1), you should understand what types of units and data constitute a program.

Note: Specify tools in program by their tool names, nominal diameters and suffixes.

Specify tools in the tool sequence data.

To operate the machine in the automatic operation mode, the tools that have been

specified in the program must be registered on the TOOL DATA display.

1-2

E

Page 19

2 PROGRAM COORDINATE SYSTEM

A

In general, machining dimensions on a drawing are indicated as the distances from a specific

reference point. Likewise, within a program, a machining pattern is defined by setting the

coordinates from a specific reference point. This reference point is referred to as the program

origin and the coordinate system based on the program origin is referred to as the program

coordinate system.

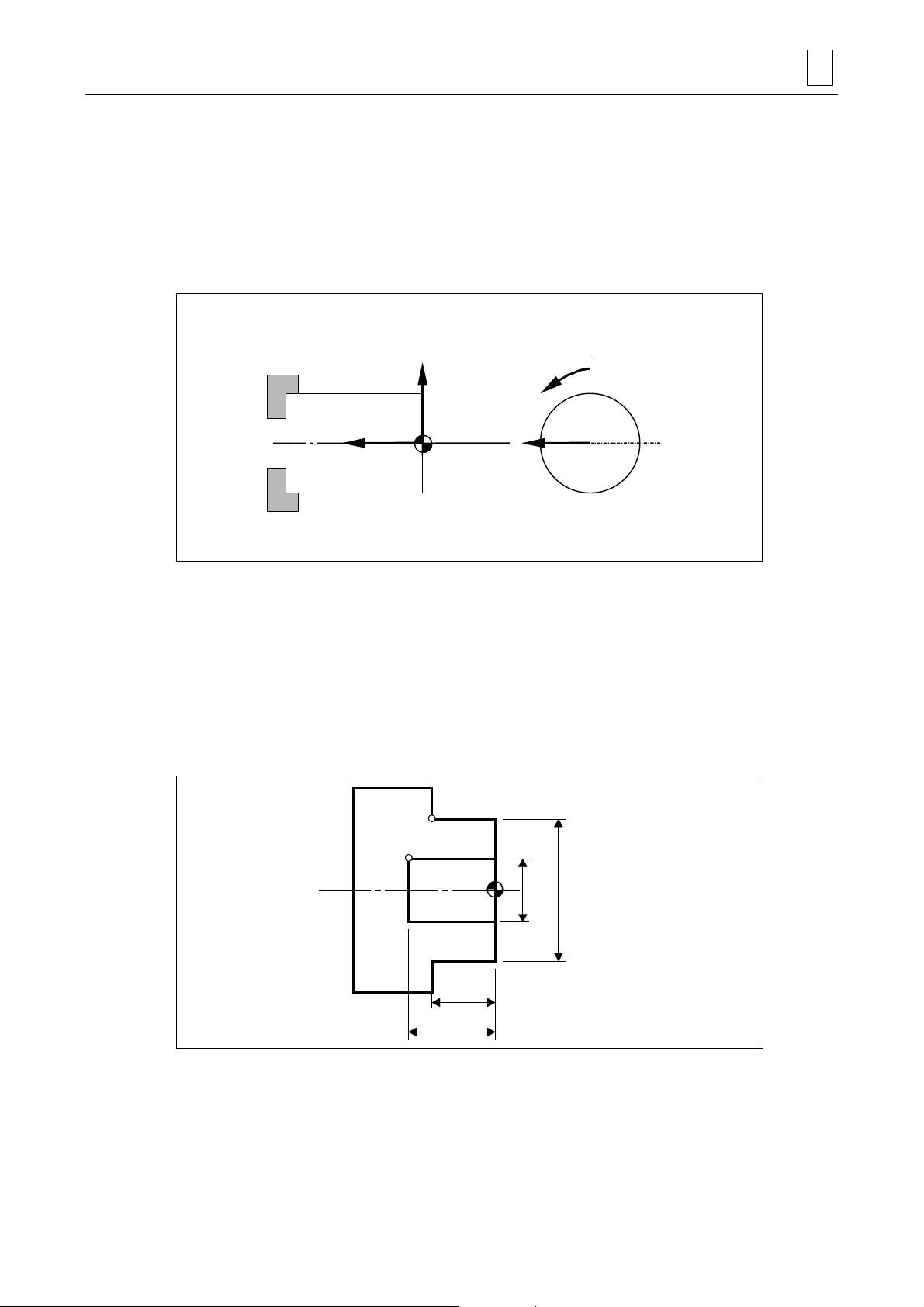

For MAZATROL programs, the following coordinate system is used to define machining patterns:

PROGRAM COORDINATE SYSTEM 2

+X

+Z

Program

origin

Program origin

+C

+Y

T3P001

The program origin of X-Z-coordinates system can be set anywhere on the center line of the

workpiece. Usually, however, the crossing point of the center line of the workpiece and its

finishing edge surface should be taken as the program origin. The program origin of C-axis

(rotational axis) can be set at any position convenient for programming. For MAZATROL

programs, set X-coordinates as diameter data. That is, the workpiece diameter indicated on the

drawing must be set as it is.

Example: For the workpiece shape shown in the diagram below:

The coordinates (x, z) of point A are (50, 20), and the coordinates (x, z) of point B

(20, 30).

B

20φ50

φ

20

30

T3P008

Note 1: For manual program machining units (MANL PRG) and facing units (FACING), the

direction of Z-axis is opposite to the one shown in the diagram above. See the relevant

items in Chapter 3 for further details.

Note 2: Refer to the sections of milling units for details on the C- and Y-axes.

2-1

Page 20

2 PROGRAM COORDINATE SYSTEM

- NOTE -

2-2

E

Page 21

3 PROGRAM CREATION

Both the program data and sequence data within a MAZATROL program must be set on the

PROGRAM display, and TPC data must be set on the TPC display. The TPC display is call ed up

from the PROGRAM display.

This chapter first describes general procedures and precautions related to creating a

MAZATROL program and then describes detailed procedures for setting each type of program

data on a unit-by-unit basis.

3-1 Procedure for Program Creation

(1) Select the PROGRAM display.

- Carry out the following operations to call up the PROGRAM display:

1) Press the display selector key.

! You will then see the follo wing main -display selection me nu in the menu di splay area of

your screen:

PROGRAM CREATION 3

POSITION SET UP

INFO

PROGRAM TOOL

DATA

CUTTING

COND.

PARAM DIANOS DATA

IN/OUT

TOOL

LAYOUT

2) Press the [PROGRAM] m enu key.

! The program last selected will be displayed on the PROGRAM display and the current

menu will change over to this one:

WORK No. FIND PROGRAM BARRIER

INFORM.

WPC MSR TOOL

PATH

PROCESS

CONTROL

PROGRAM

LAYOUT

HELP PROGRAM

(2) Press the [WORK No.] menu key.

! The display of [WORK No.] becomes highlighted and the work-Nos. listing window will

be displayed.

* The work-Nos. listing window refers to a window that displays a list of work numbers of the

programs that have already been registered in the NC equipment.

(3) Set the work number of the creating program.

- A “work number” refers to a number assigned to each program to distinguish one program

from another. A combination of up to 32 alphanumeric characters: 0 to 9 and A to Z,

including the symbols “_”, “.”, “+” and “–”, can be used for a work number.

Note 1: If a work number is composed of figures alone, it should be a natural number

between 1 and 99999999.

DISPLAY

MAP

FILE

Note 2: A program name should not begin with a dot (.).

- If a work number already registered in the NC unit is set, that program will be displayed on

the screen. To create a new MAZATROL program, therefore, you must set a work number

not used in other programs.

You can check the work-Nos. listing window or the PROGRAM FILE display to see which

work numbers are not yet used

3-1

Page 22

3 PROGRAM CREATION

- If you set a work number not used for the programs that have been registered in the NC

unit, the current menu will change over to this one:

WORK No. EIA/ISO

* The EIA/ISO programming function is optional.

(4) Press the [MAZATROL PROGRAM] menu key.

! The following line will be displayed on the screen:

UNo. MAT. OD-MAX ID-MIN LENGTH WORK FACE ATC MODE RPM LTUR DIA

0

This line denotes the common unit.

(5) Set data in each item of the common unit.

- See Section 3-2, “Common Unit” for details of the data to be set.

- Each time you set data, the cursor moves to the next item automatically.

- When you set data in the last item of the common unit, the cursor will move to the starting

position of the next line and then the following menu A will be displayed, and pressing the

[ >>> ] menu key changes A → B → C → A → B → C in order.

*

PROGRAM

Cursor

MAZATROL

PROGRAM

POINT

MACH-ING

SELECT

HEAD

LINE

MACH-ING

TRANSFER

WORKPICE

FACE

MACH-ING

PROCESS

END

TURNING MANUAL

PROGRAM

M

M CODE

SUB

PROGRAM

WPC MSR WORKPICE

MEASURE

END SHAPE

CHECK

TOOL

MEASURE

SIMUL. 2 WORKPC

WORKPIECE

SHAPE

MODE

(6) From the menus A, B and C, select a unit that is to follow the common unit.

! The unit data line of the selected unit will be displayed in the screen.

Example: If you have selected the bar-materials machining unit (BAR):

UNo. MAT. OD-MAX ID-MIN LENGTH WORK FACE ATC MOCE RPM LTUR DIA

0 CBN STL 100. 0. 100. 2. 0 3000 120.

UNo. UNIT PART POS-B CPT-X CPT-Z FIN-X FIN-Z

1 BAR

↑

Cursor

This line will be displayed.

If you have selected a unit that consists of only unit data (e. g. M-code unit):

>>>

>>>

>>>

A

"""

B

"""

C

"""

(7) Set data in each item on the unit data line.

- See the relevant part of this section for further detail of the data to be set.

- Each time you set data, the cursor moves to the next item automatically.

- When you set data in the last item, the cursor will move to the beginning of the next line

(unit data line).

3-2

Page 23

PROGRAM CREATION 3

If you have selected a unit that consists of unit data, tool sequence data, and shape

sequence data of only one line (e. g. corner-machining unit):

(7)-1 Set data in each item on the unit data line.

- See the relevant part of this section for further detail of the data to be set.

- Each time you set data, the cursor moves to the next item automatically.

- When you set data in the last item, the cursor will move to the beginning of the next line

(tool sequence data line).

(7)-2 Set data in each item on the tool sequence data line.

- See the relevant part of this section for further details of the data to be set.

- Each time you set data, the cursor moves to the next item automatically.

- When you set data in the last item, the cursor will move to the beginning of the next line

(shape sequence data line).

(7)-3 Set data in each item on the shape sequence data line.

- See the relevant part of this section for further details of the data to be set.

- Each time you set data, the cursor moves to the next item automatically.

- When you set data in the last item, the cursor will move to the beginning of the next line

(unit data line).

If you have selected a unit that consists of unit data, tool sequence data, and shape

sequence data of multiple lines (e. g. bar-materials machining unit):

(7)-1 Set data in each item on the unit data line.

- See the relevant part of this section for further details of the data to be set.

- Each time you set data, the cursor moves to the next item automatically.

- When you set data in the last item, the cursor will move to the beginning of the next line

(tool sequence data line).

(7)-2 Set data in each item on the tool sequence data line.

- See the relevant part of this section for further details of the data to be set.

- Each time you set data, the cursor moves to the next item automatically.

- When you set data in the last item, the cursor will move to the beginning of the next line

(shape sequence data line).

(7)-3 Set data in each item on the shape sequence data line.

- See the relevant part of this section for further details of the data to be set.

- Each time you set data, the cursor moves to the next item automatically.

(7)-4 After you have set the entire shape sequence data, press the [SHAPE END] menu key.

- The line that immediately succeeds the last shape sequence data line will be displayed as

a unit data line.

- For a unit that permits you to set more than one line of shape sequence data, you cannot

select the next unit unless you carry out this operation (pressing the [SHAPED END]

menu key).

3-3

Page 24

3 PROGRAM CREATION

If you have selected a unit that consists of unit data, tool sequence data of multiple lines

and shape sequence data of multiple lines (e. g. drilling unit):

(7)-1 Set data in each item on the unit data line.

- See the relevant part of this section for further details of the data to be set.

- Each time you set data, the cursor moves to the next item automatically.

- When you set data in the last item, the tool sequence data is made automatically and the

cursor will move to the beginning of the tool sequence data line.

(7)-2 Set data in each item on the tool sequence data line.

- See the relevant part of this section for further details of the data to be set.

- Each time you set data, the cursor moves to the next item automatically.

(7)-3 After you have set the entire tool sequence data, set data in each item on the shape

sequence data line.

- See the relevant part of this section for further details of the data to be set.

- Each time you set data, the cursor moves to the next item automatically.

(7)-4 After you have set the entire shape sequence data, press the [SHAPE END] menu key.

- The line that immediately succeeds the last shape sequence data line will be displayed as

a unit data line.

- For a unit that permits you to set more than one line of shape sequence data, you cannot

select the next unit unless you carry out this operation (pressing the [SHAPED END]

menu key).

(8) Select the units required for the intended machining operation by repeating steps (6) and (7)

above (including steps (7)-1, (7)-2, (7)-3 and (7)-4), and then set data in each of the items

displayed on the screen.

- A selectable unit differs according to the type of product to be machined. Select a unit in

the most suitable order in accordance with your machining drawing, unit sheet, etc.

After unit selection, the program can be generated just by setting data as guided by

messages.

(9) Set the end unit at the end of the program.

- Press the [END] menu key.

- Without the end unit, the program will not be regarded as a complete one. Therefore, you

must set the end unit at the last line of the program.

(10) Set data in each item of the end unit.

- See the section “End Unit (END)” for details of the data to be set.

Note 1: One MAZATROL program can contain a maximum of 1000 units, including the

common unit and the end unit. For units that allow you to set multiple lines of sequence

data, up to a maximum of 200 lines of shape sequence data can be regi ste red per unit.

Note 2: The shape data that you have set can be checked for errors by calling up the SHAPE

CHECK display while you are creating the program. See the Operating Manual for

details.

3-4

Page 25

Note 3: For the following units, TPC data can be set as required:

Turning

- BAR unit

- CPY unit

- CORNER unit

- FACING unit

- THREAD unit

- T. GROOVE unit

- T. DRILL unit

- T. TAP unit

- MILLTURN unit

Other units

- MMS unit

- WORK MES unit

- TOOL MES unit

- TRANSFER unit

Milling

- DRILLING unit

- RGH CBOR unit

- RGH BCB unit

- REAMING unit

- TAPPING unit

- BK-CBORE unit

- CIRC MIL unit

- CBOR-TAP unit

- BORE T1 unit

- BORE S1 unit,

- BORE T2 unit

- BORE S2 unit

- LINE CTR unit

- LINE RGT unit

- LINE LFT unit

- LINE OUT unit

- LINE IN unit

- CHMF RGT unit

- CHMF LFT unit,

- CHMF OUT unit

- CHMF IN unit

- FCE MILL unit

- TOP EMIL unit

- STEP unit

- POCKET unit

- PCKT MT unit

- PCKT VLY unit

- SLOT unit

PROGRAM CREATION 3

See “TPC DATA SETTING” for further details of the data to be set.

3-5

Page 26

3 PROGRAM CREATION

[4]

3-2 Common Unit

The common unit is the first to be placed in a MAZATROL program, and always takes unit

number 0.

Data that is set in this unit is referred to as common data, which becomes the base data for the

entire program. When creating a MAZATROL program, therefore, you must first set data in this

unit.

3-2-1 Setting unit data (common data)

UNo. MAT. OD-MAX ID-MIN LENGTH WORK FACE ATC MODE RPM LOW TURR

0 [1] [2] [3] [4] [5] [6] [7] [8]

[1] MAT

The following menu will be displayed when the cursor is placed at this item:

CST IRN DUCT IRN CBN STL ALY STL STNLESS ALUMINUM L.C.STL AL CAST

From the menu, select the materials type of the workpiece to be machined.

If the workpiece to be machined is of a materials type other than those listed above, pre-register

that materials type on the CUTTING CONDITION - PERCENTAGE display. See the Operating

Manual for details.

The data of this item is referred to by the system during automatic setting of cutting conditions.

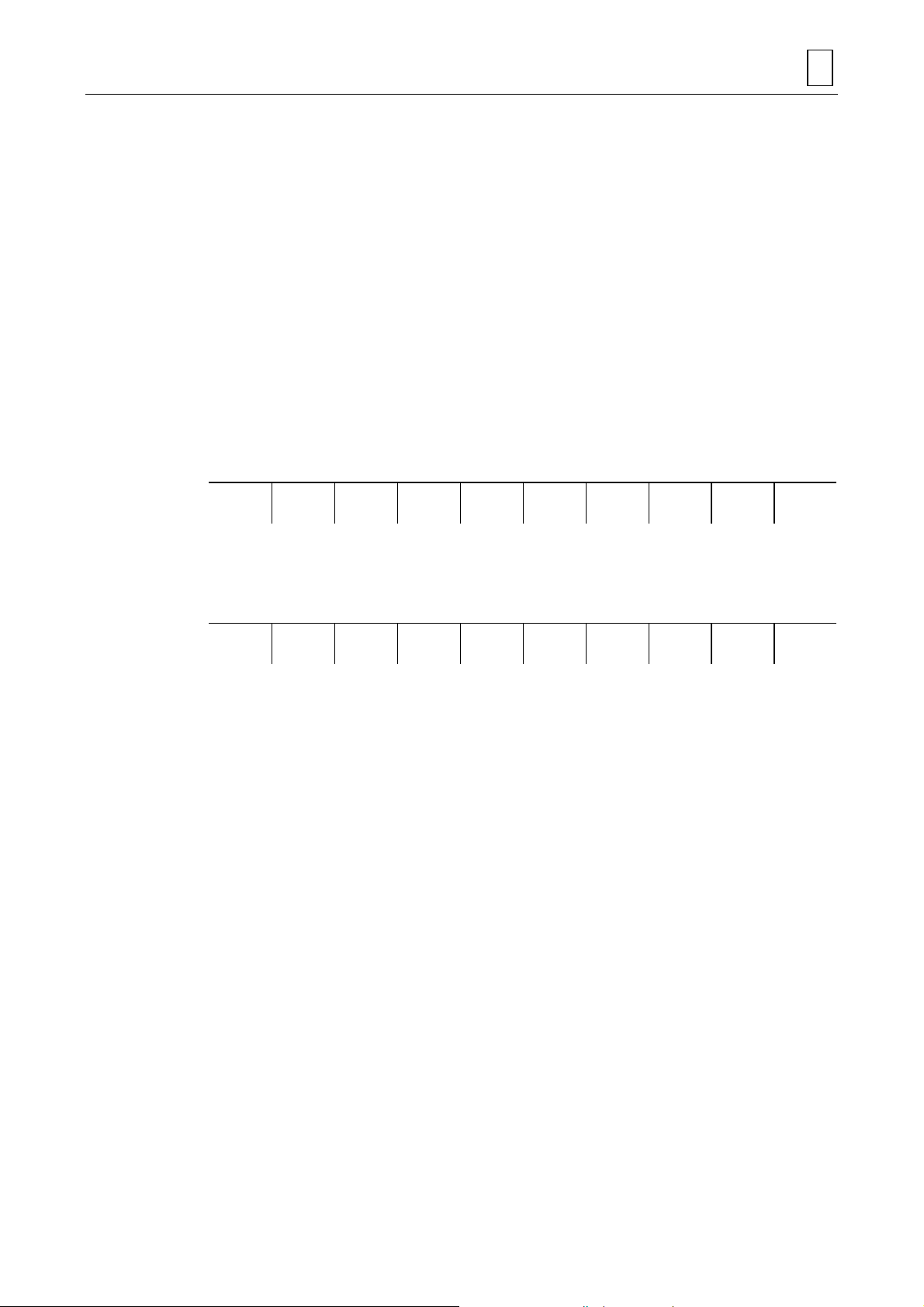

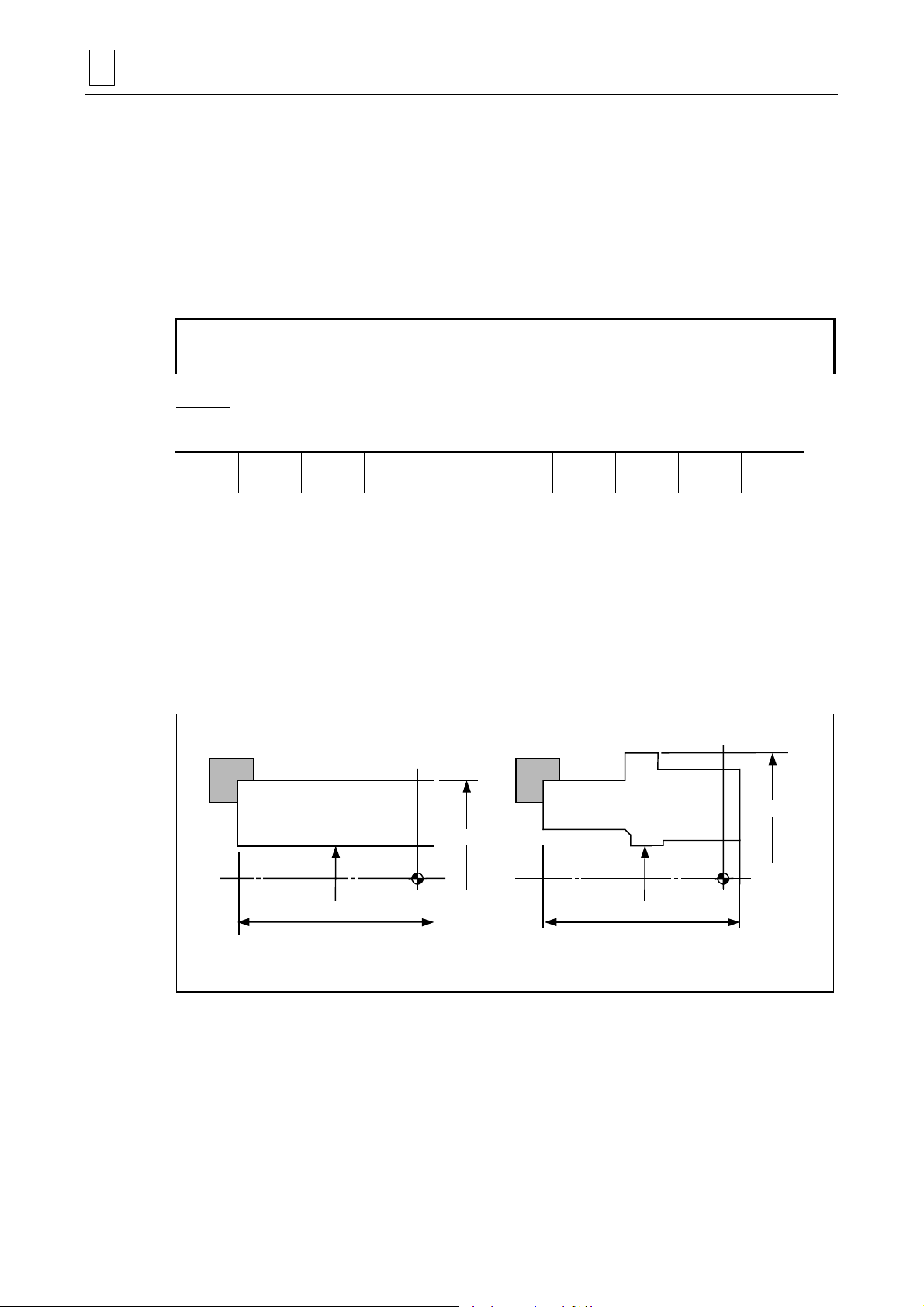

[2] OD-MAX, [3] ID-MIN, [4] LENGTH

Set the maximum outside diameter, minimum inside diameter, and maximum length, respectively,

of the workpiece.

[2] OD-MAX

[2] OD-MAX

Program

origin

T4P017

[3] ID-MIN

[4] LENGTH

Round bar materials

Program

origin

[3] ID-MIN

LENGTH

Molded materials

- Set the workpiece length, including the edge protrusion (edge section to be cut), in item [4].

3-6

Page 27

PROGRAM CREATION 3

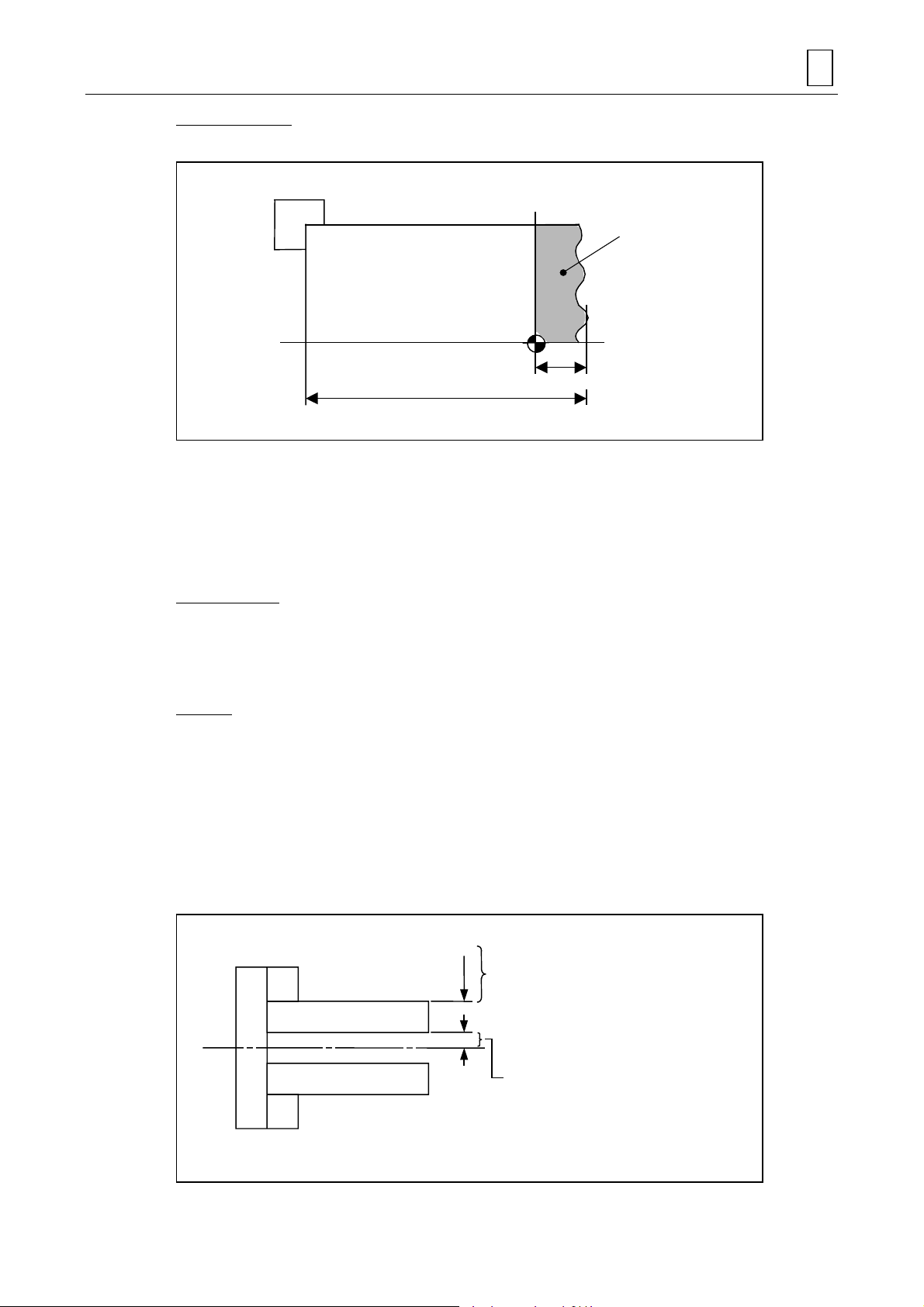

[5] WORK FACE

Set the length of the workpiece edge protrusion in the Z-axis direction.

Protrusion

Program origin

[4] LENGTH

[5] WORK FACE

T4P019

- The workpiece edge protrusion refers to a section to be cut during a facing unit (FACING

FACE).

For units other than facing units, the protrusion is not regarded as part of the workpiece.

Therefore, if the workpiece edge is to be cut (that is, if a value other than 0 is set for this item),

an facing unit must be selected before selecting a unit involving other machining operations.

Either 0 or a plus value must always be set for this item.

[6] ATC MODE

Specify how to retract the axes before ATC.

- Enter 0 to move the axes one by one from the machining end point to the ATC position.

- Enter 1 to move the axes all together from the machining end point to the ATC position.

[7] RPM

If the maximum spindle speed is to be limited, set that maximum value. Data does not need be

set if the spindle speed is permitted to reach the maximum value provided for in the

specifications.

This data has no relation to the milling axial velocity.

Note: For an X-axial tool-tip position over OD-MAX or under ID-MIN (both specified in the

common unit), constant cutting speed control will opportunely be relieved by the

constant spindle speed control for extra-workpiece area and the spindle will rotate at

the speed calculated for the position of OD-MAX or ID-MIN.

The spindle speed for this area is downwards

limited to the value c al culated for OD-MAX.

OD-MAX

ID-MIN

The spindle speed for this area is upwards

limited to the value c al culated for ID-MIN.

* Constant surface speed control is cancelled for extra-workpiece

area in order to reduce the machining time.

3-7

Page 28

3 PROGRAM CREATION

[8] LOW TURR

For a machine equipped with upper and lower turrets, enter a safe outside -diameter value for the

lower turret. See Chapter 5, “LOWER-TURRET CONTROL FUNCTIONS”, for further details.

3-3 Materials Shape Unit (MATERIAL)

The shapes of cast materials or forged materials cannot be defined using the common unit alone.

To machine such molded materials, the materials shape unit must be selected following the

common unit and the shape data of the materials to be machined must be set.

Only the outside-diameter shape and inside-diameter shape of the intended workpiece can be

defined using the materials shape unit. This unit of base data, therefore, has no relation to units

of machining on the front and back faces, since the tool path for such units are created merely on

the basis of the settings in the common unit.

This unit need not be set for round-bar materials.

Press the [WORKPICE SHAPE] menu key to select the materials sha pe unit.

3-3-1 Setting unit data

UNo. UNIT

∗ MATERIAL [1]

[1] UNIT

The following menu will be displayed when the cursor is placed at this item.

OUT IN

- Select [OUT] to define the outside-diameter shape of the workpiece.

- Select [IN] to define the inside-diameter shape of the workpiece.

Both OUT and IN can be defined using a maximum of 25 sequences.

You must first select [OUT], however, when defining both the outside-diameter and insidediameter shapes of a workpiece. That is, after selecting the materials shape unit a s both units No.

1 and No. 2, define the outside-diameter shape using unit No. 1 and then define the insidediameter shape using unit No. 2.

3-3-2 Setting sequence data

UNo. UNIT

∗ MATERIAL ∗∗∗

FIG PTN SPT-X SPT-Z FPT-X FPT-Z RADIUS

1 [1] [2] [3] [4] [5] [6]

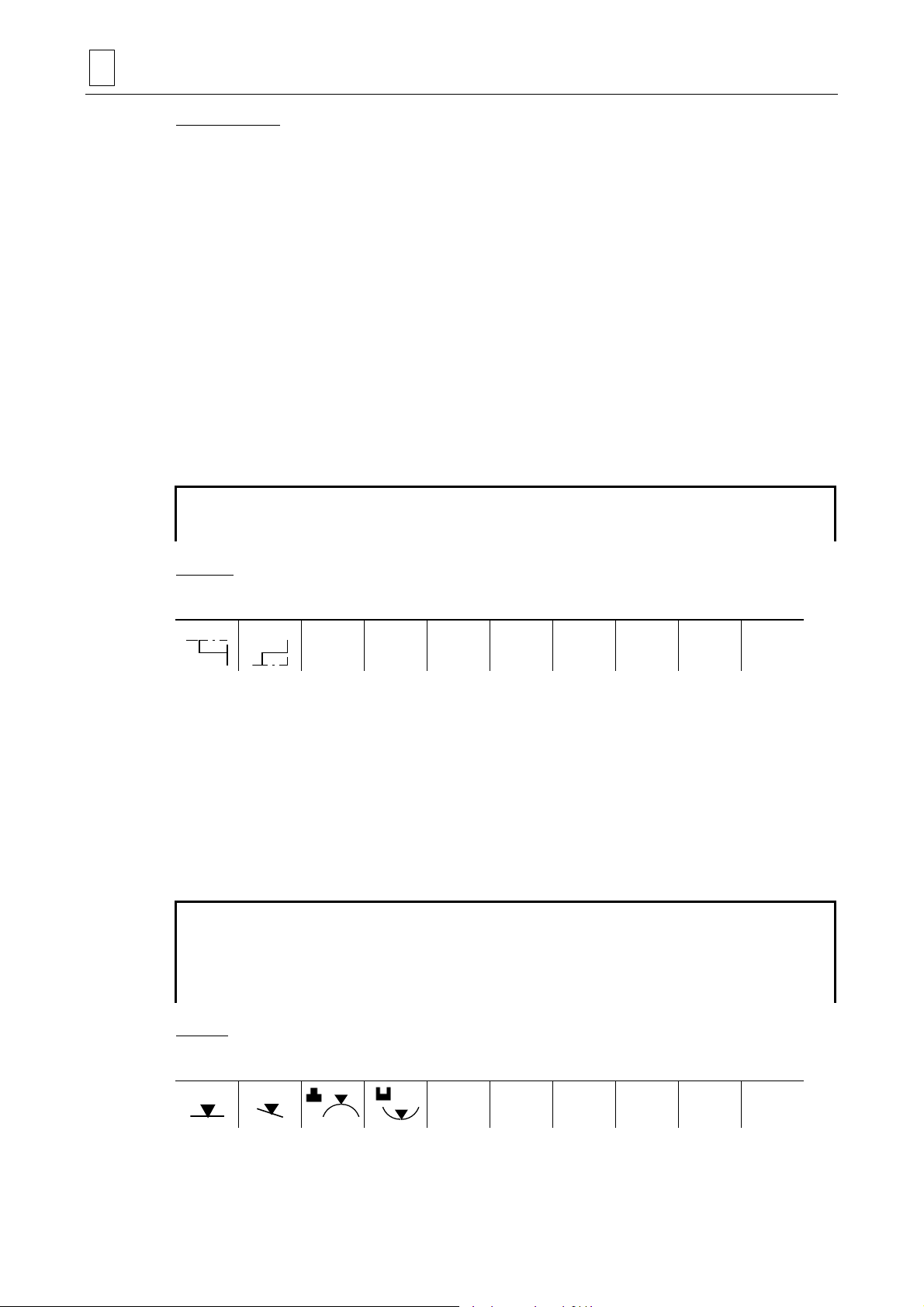

[1] PTN

The following menu will be displayed when the cursor is placed at this item.

LIN TPR SHAPE

Select the type of shape from the above menu.

3-8

END

Page 29

The data of the displayed menu denote the following shapes:

PROGRAM CREATION 3

LIN : Line parallel to the center line of the workpiece

TPR : Line not parallel to the center line of the workpiece (Taper line)

: Convex arc

:Concave arc

Outer diameter

shape

Inner diameter

shape

TPR

LIN

Material shape

T4P021

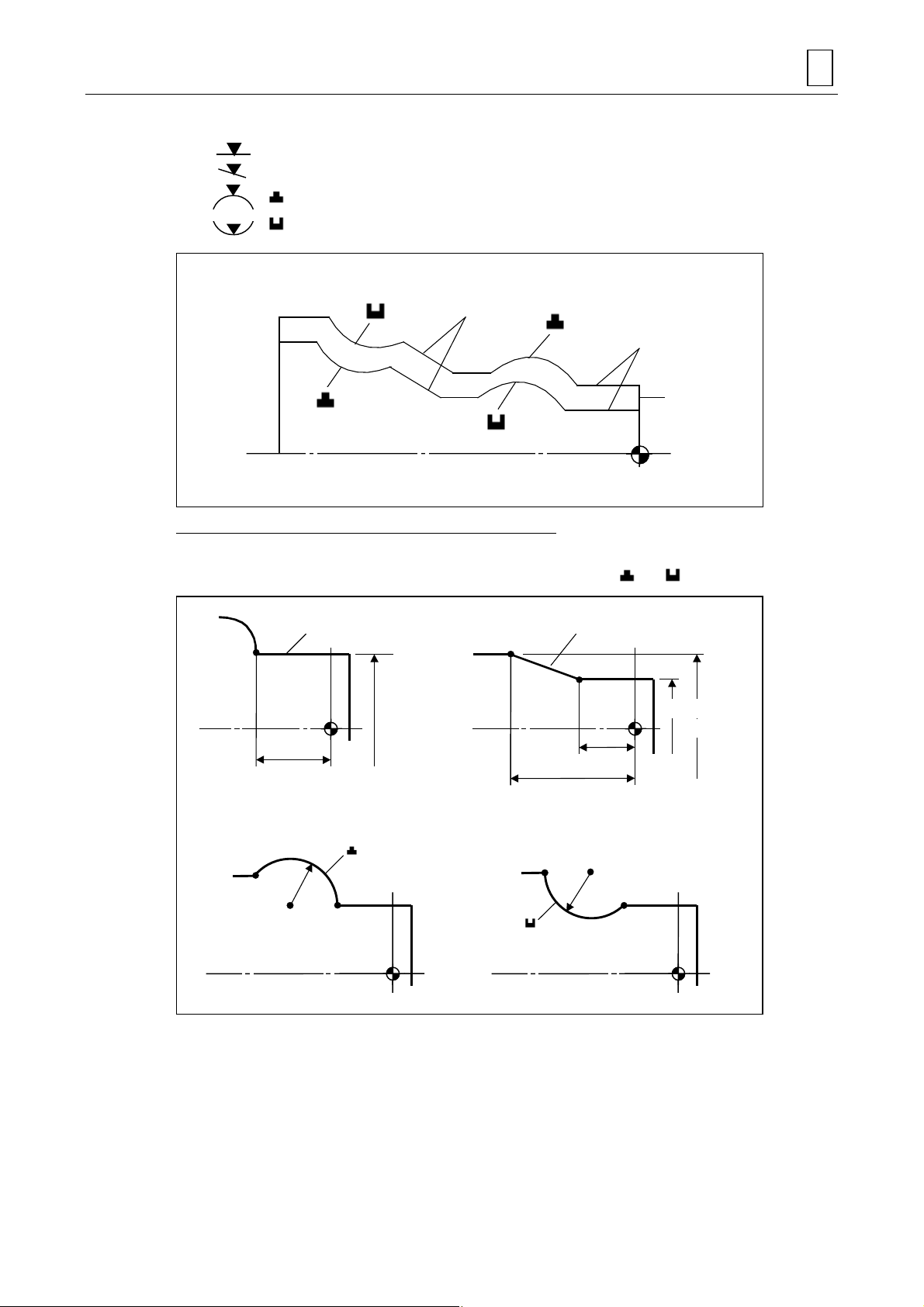

[2] SPT-X, [3] SPT-Z, [4] FPT-X, [5] FPT-Z, [6] RADIUS

Set the coordinates of the intended start point and end point of the shape you selected for item

[1]. Also set the radius of the desired circle if you have selected

or .

LIN

End

point

[4] FPT-X

[5] FPT-Z

End

point

[6] RADIUS

Start

point

End

point

TPR

Start point

[2] SPT-X

[4] FPT-X

[3] SPT-Z

[5] FPT-Z

End

point

[6] RADIUS

Start

point

T4P023

- If you have selected [LIN] for item [1] above, it is good enough just to designate only the

coordinates of the end point (FPT-X and -Z). This is because the NC unit will then form

automatically two orthogonal lines between the end point of the immediately preceding shape

(or the program origin for an LIN as the first shape) and that end point.

3-9

Page 30

3 PROGRAM CREATION

End point

Note 1: The Z-coordinates of any points located to the right of the program origin must be set

Start point

(The coordinates do not need to be set. )

End point of imm edi at el y preceding shape

T4P022

with a minus sign.

Plus data Minus data

T4P024

Note 2: If the start point of a shape is present in the same position as that of the end point of

the immediately preceding shape, those coordinates can be automatically set by

pressing the [NEXT] menu key.

UNo. UNIT

1 MATERIAL OUT

FIG PTN SPT-X SPT-Z FPT-X FPT-Z RADIUS

1

2

LIN

TPR

##20. 30. #

Cursor

#

Pressing the [NEXT] menu key with the cursor at the position shown above sets the

following data automatically:

UNo. UNIT

1 MATERIAL OUT

FIG PTN SPT-X SPT-Z FPT-X FPT-Z RADIUS

1

2

LIN

TPR

#

20.#30.

20. 30. #

#

These values are set automatically.

You can use this function also for BAR and CPY units.

3-10

Page 31

PROGRAM CREATION 3

Note 1: Although a maximum of 200 lines of shape sequence data can be set in one materials

shape unit or turning unit, the maximum usable number of shape sequence data lines

may be less than 200 when corner R/C is defined for a complex shape. In that case,

alarm 723 EXCEEDS NUMBER OF SHAPES will be displayed, even before the

maximum usable number of shape sequence data lines is reached.

Note 2: If the maximum usable number of shape sequence data lines is exceeded, alarm 723

EXCEEDS NUMBER OF SHAPES will be displayed during tool path checking, shape

checking, shape drawing, or automatic operation.

3-11

Page 32

3 PROGRAM CREATION

3-4 Types of the Milling Unit

The milling unit is available in the following three types :

- Point machining unit ...... used for drilling of holes (Section 3-5)

- Line machining unit ........ used for a contour machining (Section 3-6)

- Face machining unit ...... used for machining an area and machining form (Section 3-7)

Each milling unit includes tool sequence and shape sequence.

3-4-1 Planes to be machined and machining methods

Data items for setting the plane to be machined and for setting the machining method exist in all

point, linear, and face machining unit data. These data items are displayed as MODE, POS-B,

and POS-C.

Specify the desired face and method under the MODE, POS-B, and POS-C columns.

UNo. UNIT MODE POS-B POS-C DIA DEPTH CHMF

DRILLING

[1] MODE

[1] [2] [3]

Select the machining method.

Mode Description

Cylindrical sides can be machined into the desired shape as specified in the Z-C coordinate

system.

(C-axial machining)

ZC

Edges can be machined into the desired shape as specified in the R-C or X-Y coordinate system.

(C-axial machining)

XC

C

C

If C-axis function for No. 2 spindle is

Note:

available, the line machining can be

executed on the No. 2 spindle as well.

C

XC

Rear plane can be machined into the desired shape as specified in the R-C or X-Y coordinate

system.

(C-axial machining)

C

Note: The line machining is possible only if

the machine has C-axis function for

No. 2 spindle.

3-12

Page 33

Mode Description

Plane of cylinder can be machined into the desired shape as specified in the Z-Y coordinate

system.

(Y-axial machining)

PROGRAM CREATION 3

ZY

XY

XY

Z

Y

Edges can be machined into the desired shape as specified in the X-Y or R-C coordinate system.

(Y-axial machining)

X

Y

Rear plane can be machined into the desired shape as specified in the X-Y or R-C coordinate

system.

(Y-axial machining)

X

Y

/C

/C

/Y

Holes can be machined on an oblique plane at the desired oblique positioning angle as specified

in the B-axial direction. (C-axial machining)

This mode cannot be selected for the line or plane machining units.

C

The tool approaches from the edge side.

Holes can be machined on an oblique plane at the desired oblique positioning angle as specified

in the B-axial direction. (C-axial machining)

This mode cannot be selected for the line or plane machining units.

C

The tool approaches from the rear side.

Holes can be machined on an oblique plane at the desired oblique positioning angle as specified

in the B-axial direction. (Y-axial machining)

The tool approaches from the edge side.

3-13

Page 34

3 PROGRAM CREATION

Mode Description

/Y

The XC , XY , /C , /Y mode can be selected for a machine model capable of back

machining.

Holes can be machined on an oblique plane at the desired oblique positioning angle as specified

in the B-axial direction. (Y-axial machining)

The tool approaches from the rear side.

Note: For the line machining unit, the /C or /C

/C or /C

Precautions for milling with the lower turret

1. The machine operates in single-workpiece independent machining mo de.

2. The machine operates only in point-machining mode.

Drilling, inverse faced hole machining, reaming, tapping, and boring (see Note 2 below) are

possible (see Note 1 below).

Counterbore machining, back boring, circular milling, or counterbore-tapping i s impossible.

3. It is possible to use ZC, XC, or XC

It is not possible to use /C, /C

4. The machine does not operate in line- or face-machining mode.

5. The lower turret cannot be used for the M-MANUAL unit that operates the Y-axis.

6. Simultaneous machining with the milling tools mounted in the upper and lower turrets is

impossible.

Note 1: Machining that requires Y-axis operation results in an alarm (for chamfering cycle 2).

Note 2: Boring cycle 1 and 2 cannot be used (an alarm occurs for lower-turret milling spindle

orientation).

mode cannot be selected for a face machining unit.

mode. (See Note 1.)

, ZY, XY, XY , /Y, or /Y mode.

mode cannot be selected. The ZC, XC, XC ,

[2] POS-B

When machining an oblique plane, specify angle B of the oblique plane with respect to a

reference angle of 0 degrees of the edge.

This data item will become valid when the /C, /Y, /C

having a B-axis.

[3] POS-C

Specify the position of the C-axis.

This data item will become valid when the ZY, XY, XY

3-14

, /Y mode is selected for a machine model

, /Y, /Y mode is selected.

Page 35

3-5 Point Machining Units

The point machining unit serves to determine the data concerning the machining method and

machining form for the drilling of holes.

The unit includes the tool sequence determining the tool data used and the shape sequence

determining the data concerning the machining dimensions on the drawing.

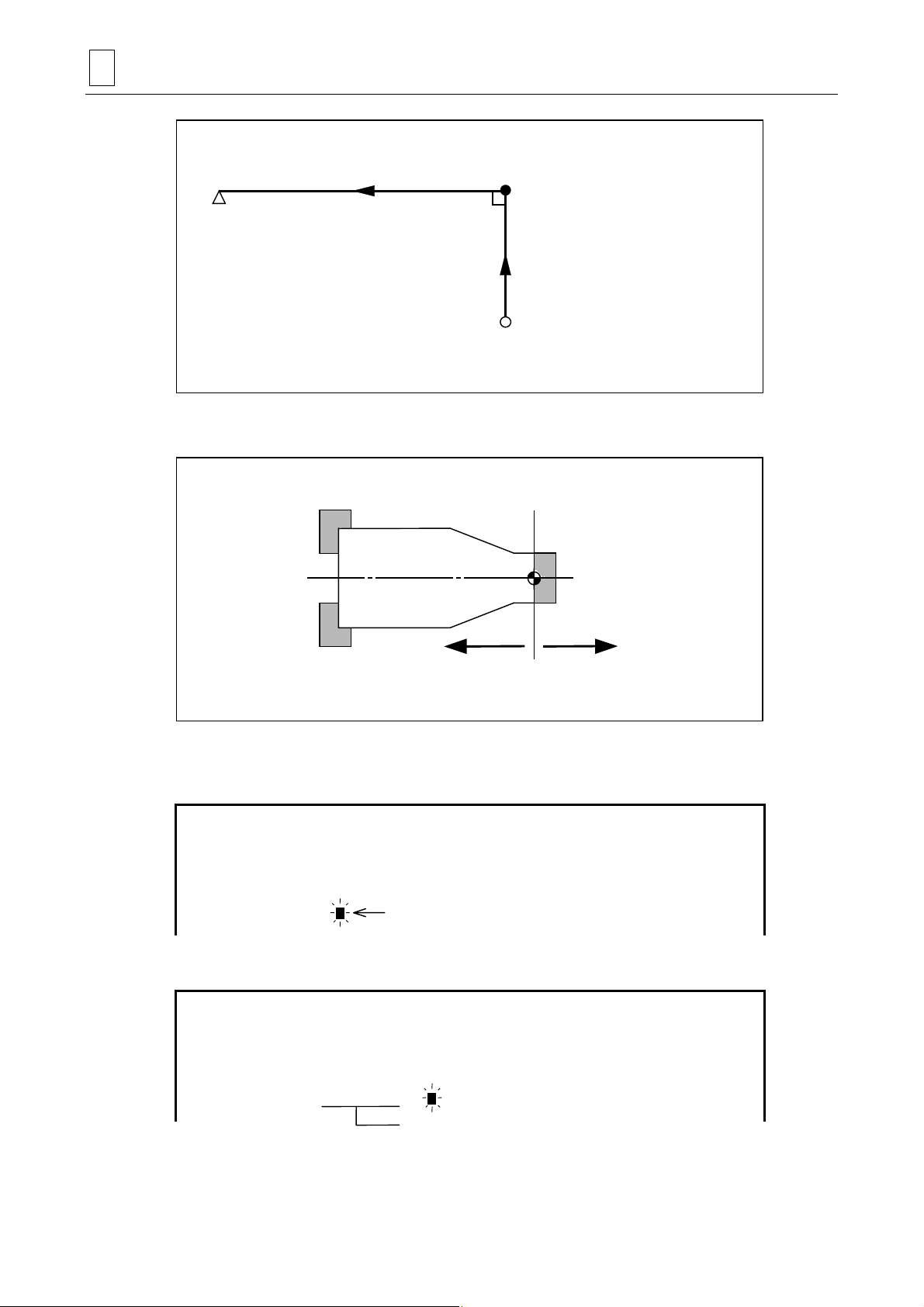

3-5-1 Types of point machining units

As shown below 12 types of point machining units are available:

PROGRAM CREATION 3

1. Drilling 2. Counterbore machining

NM210-00532

5. Tapping 6-(1) Boring of through hole

NM210-00533 NM210-00534 NM210-00535

3. Inversed faced hole

machining

6 (2) Boring of non-

through hole

4. Reaming

6 (3) Boring of stepped

through hole

NM210-00536

6-(4) Boring of stepped

non-through hole

NM210-00540 NM210-00541 NM210-00542 NM210-00543

Fig. 3-1 Types of point machining units

NM210-00537

7. Back boring 8. Circular milling 9. Counterbore-tapping

NM210-00538

NM210-00539

3-15

Page 36

3 PROGRAM CREATION

3-5-2 Procedure for selecting point machining unit

(1) Press the menu selector key (key located at the right of the menu keys) to display the

following menu.

POINT

MACH-ING

LINE

MACH-ING

FACE

MACH-ING

TURNING MANUAL

PROGRAM

END SHAPE

CHECK

>>>

(2) Presse the [POINT MACH-ING] menu key.

! The following unit menu will be displayed.

DRILLING RGH CBOR RGH BCB REAMING TAPPING BORING BK CBOR CIRC MIL CBOR TAP HI SPD.

DRL.USE

(3) Press the appropriate menu key of the desired machining unit.

- When the [BORING] menu key is pressed, the menu of the four following machining subunits is displayed.

BORING BORING BORING BORING

Remark: For the function of the [HI SPD. DRL. USE] menu key, refer to the Subsection 3-5-4,

“Automatic tool development for cemented carbide drills”.

3-16

Page 37

PROGRAM CREATION 3

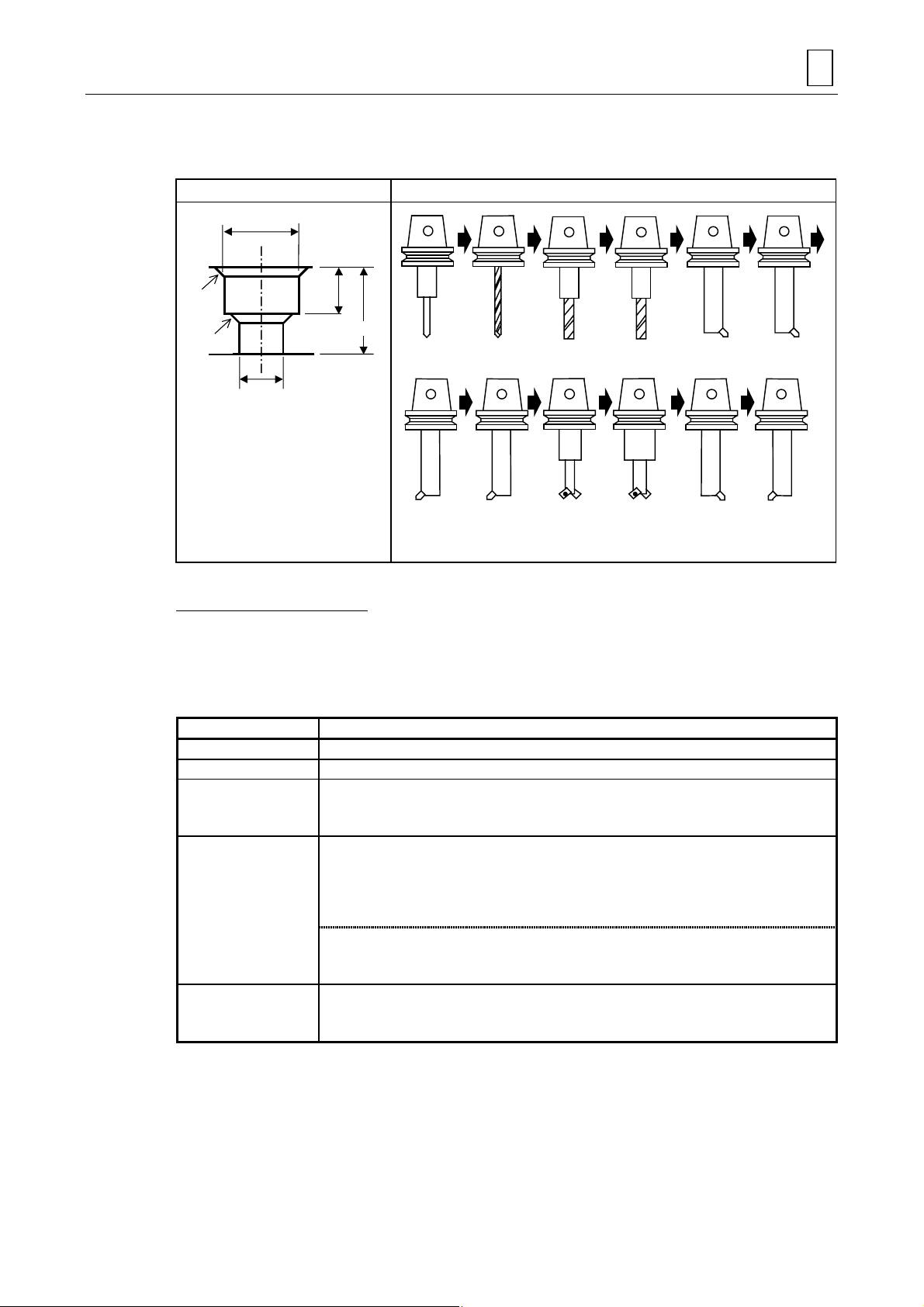

3-5-3 Unit data and automatic tool development of the point machining unit

1. Drilling unit (DRILLING)

Select this drilling unit for machining of a hole with a drill.

DRILLING unit Tool sequence

DIA

CHMF

DEPTH

Centering drill

M3P085 D740PA030

The tools in parentheses ( ) are developed or not developed depending on the particular case.

Drill (Drill) (Drill)

(Chamfering cutter)

Automatic tool development

The tools are automatically developed according to different patterns on the basis of the data

entered in the unit. The machining is executed on the basis of the tool sequence data and the

unit data are not used for the machining. If the data developed are inappropriate for the

machining, edit by modifying the data or deleting the tool.

Tool Development patterns

Centering drill Development is always executed.

A maximum of three tools are developed depending on the diameter of the hole.

0

Drill

Chamfering cutter

< DIA ≤ D8: Development of one tool

D8 < DIA ≤ D9: Development of two tools

D9 < DIA ≤ D10: Development of three tools

Development is not executed in the following cases:

DIA + (CHMF × 2) ≤ D2 – D4

CHMF = 0

The bold codes represent parameter addresses.

Note: In the following cases the alarm 416 AUTO PROCESS IMPOSSIBLE will be displayed.

- DEPTH < CHMF

- DIA = 0

- D10 < DIA

3-17

Page 38

3 PROGRAM CREATION

2. Counterbore machining unit (RGH CBOR)

This unit is selected for machining a hole with a counterbore (faced hole).

RGH CBOR unit Tool sequence

CB-DIA

CB-DEP

CHAMF

DIA

The tools in parentheses ( ) are developed or not developed depending on the particular case.

DEPTH

Centering drill Drill (Drill) (Drill) End mill (Chamfering

cutter)

M3P087 D740PA031

Automatic tool development

The tools are automatically developed according to different patterns on the basis of the data

entered in the unit. The machining is executed on the basis of the tool sequence data and the

unit data are not used for the machining. If the data developed are inappropriate for the

machining, edit by modifying the data or deleting the tool.

Tool Development patterns

Centering drill Development is always executed.

A maximum of three tools are developed depending on the diameter of the hole.

0 < DIA

Drill

End mill Development is always executed.

Development is not executed in the following casses:

Chamfering cutter

≤ D8: Development of one tool

D8 < DIA ≤ D9: Development of two tools

D9 < DIA ≤ D10: Development of three tools

CHMF = 0

DIA + (DEPTH × 2)

≥ CB-DIA + (CHMF × 2) < D13

The bold codes represent parameter addresses.

Note: In the following cases the alarm 416 AUTO PROCESS IMPOSSIBLE will be displayed.

- CB-DIA < DIA

- DEPTH < CB-DEP

- DEPTH < CHMF

3-18

Page 39

3. Inversed faced hole machining unit (RGH BCB)

This unit is selected for machining a hole with an inversed faced hole.

RGH BCB unit Tool sequence

DIA

PROGRAM CREATION 3

CHMF

CB-DIA

DEPTH

CB-DEP

M3P089 D740PA032

The tools in parentheses ( ) are developed or not developed depending on the particular case.

Centering drill Drill (Drill) Back facing(Drill) (Chamfering

cutter)

Automatic tool development

The tools are automatically developed according to different patterns on the basis of the data

entered in the unit. The machining is executed on the basis of the tool sequence data and the

unit data are not used for the machining. If the data developed are inappropriate for the

machining, edit by modifying the data or deleting the tool.

Tool Development patterns

Centering drill Development is always executed.

A maximum of three tools are developed depending on the diameter of the hole.

0 < DIA

Drill

Development is not executed in the following cases:

Chamfering cutter

Back facing tool Development is always executed.

≤ D8: Development of one tool

D8 < DIA ≤ D9: Development of two tools

D9 < DIA ≤ D10: Development of three tools

DIA + (CHMF × 2)

CHMF = 0

≤ D2 – D4

The bold codes represent parameter addresses.

Note: In the following cases the alarm 416 AUTO PROCESS IMPOSSIBLE will be displayed.

- CB-DIA < DIA

- DEPTH < CB-DEP

- DEPTH < CHMF

3-19

Page 40

3 PROGRAM CREATION

4. Reaming unit (REAMING)

Select this unit for performing finish machining with reamer.

In reaming, the content of the tool sequence to be set is different according to the preceding

process.

A. Case of preceding process = drilling

REAMING unit Tool sequence

DIA

CHMF

DEPTH

Centering drill

M3P091 D740PA033

The tools in parentheses ( ) are developed or not developed depending on the particular case.

Drill

(Drill) (Drill)

(Chamfering cutter)

Reamer

Automatic tool development

The tools are automatically developed according to different patterns on the basis of the data

entered in the unit. The ma chining is executed on th e basis of the tool sequenc e data and the

unit data are not used for the machining. If the data developed are inappropriate for the

machining, edit by modifying the data or deleting the tool.

Tool Development patterns

Centering drill Development is always executed.

A maximum of three tools are developed depending on the diameter of the hole.

Drill

Chamfering cutter

Reamer Development is always executed.

0 < DIA –

D8 < DIA – D35 ≤ D9: Development of two tools

D9 < DIA – D35 ≤ D10: Development of three tools

Development is not executed in the following cases:

DIA + (CHMF × 2)

CHMF = 0

D35 ≤ D8: Development of one tool

≤ D2 – D4

The bold codes represent parameter addresses.

Note: In the following case the alarm 416 AUTO PROCESS IMPOSSIBLE will be displayed.

- DEPTH < CHMF

3-20

Page 41

B. Case of preceding process = boring

REAMING unit Tool sequence

DIA

PROGRAM CREATION 3

CHMF

DEPTH

Centering drill

(Chamfering

cutter)

M3P093 D740PA034

The tools in parentheses ( ) are developed or not developed depending on the particular case.

Drill

Reamer

(Drill) (Drill)

Boring

Automatic tool development

The tools are automatically developed according to different patterns on the basis of the data

entered in the unit. The machining is executed on the basis of the tool sequence data and the

unit data are not used for the machining. If the data developed are inappropriate for the

machining, edit by modifying the data or deleting the tool.

Tool Development patterns

Centering drill Development is always executed.

A maximum of three tools are developed depending on the diameter of the hole.

Drill

Boring tool Development is always executed.

Chamfering cutter

Reamer Development is always executed.

0 < DIA –

D8 < DIA – D36 ≤ D9: Development of two tools

D9 < DIA – D36 ≤ D10: Development of three tools

Development is not executed in the following cases:

DIA + (CHMF × 2) ≤ D2 – D4

CHMF = 0

D36 ≤ D8: Development of one tool

The bold codes represent the parameter addresses.

Note: In the following case the alarm 416 AUTO PROCESS IMPOSSIBLE will be displayed.

- DEPTH < CHMF

3-21

Page 42

3 PROGRAM CREATION

C. Case of preceding process = end mill

REAMING unit Tool sequence

DIA

CHMF

DEPTH

Centering drill Drill (Drill) (Drill) End mill

End mill

M3P095 D740PA035

The tools in parentheses ( ) are developed or not developed depending on the particular case.

(Chamfering

cutter)

Reamer

Automatic tool development