Page 1

PROGRAMMING MANUAL

Return to Library

for

MAZATROL MATRIX

(for Machining Centers)

EIA/ISO Program

MANUAL No. : H740PB0041E

Serial No. :

Before using this machine and equipment, fully understand the contents of this

manual to ensure proper operation. Should any questions arise, please ask the

nearest Technical Center or Technology Center.

IMPORTANT NOTICE

1. Be sure to observe the safety precautions described in this manual and the contents of the

safety plates on the machine and equipment. Failure may cause serious personal injury or

material damage. Please replace any missing safety plates as soon as possible.

2. No modifications are to be performed that will affect operation safety. If such modifications are

required, please contact the nearest Technical Center or Technology Center.

3. For the purpose of explaining the operation of the machine and equipment, some illustrations

may not include safety features such as covers, doors, etc. Before operation, make sure all

such items are in place.

4. This manual was considered complete and accurate at the time of publication, however, due to

our desire to constantly improve the quality and specification of all our products, it is subject to

change or modification. If you have any questions, please contact the nearest Technical Center

or Technology Center.

5. Always keep this manual near the machinery for immediate use.

6. If a new manual is required, please order from the nearest Technical Center or Technology

Center with the manual No. or the machine name, serial No. and manual name.

Issued by Manual Publication Section, Yamazaki Mazak Corporation, Japan

11. 2006

Page 2

Page 3

SAFETY PRECAUTIONS

Preface

Safety precautions relating to the CNC unit (in the remainder of this manual, referred to simply as

the NC unit) that is provided in this machine are explained below. Not only the persons who

create programs, but also those who operate the machine must thoroughly understand the

contents of this manual to ensure safe operation of the machine.

Read all these safety precautions, even if your NC model does not have the corresponding

functions or optional units and a part of the precautions do not apply.

Rule

1. This section contains the precautions to be observed as to the working methods and states

usually expected. Of course, however, unexpected operations and/or unexpected working

states may take place at the user site.

During daily operation of the machine, therefore, the user must pay extra careful attention to

its own working safety as well as to observe the precautions described below.

2. Although this manual contains as great an amount of information as it can, since it is not

rare for the user to perform the operations that overstep the manufacturer-assumed ones,

not all of “what the user cannot perform” or “what the user must not perform” can be fully

covered in this manual with all such operations taken into consideration beforehand.

It is to be understood, therefore, that functions not clearly written as “executable” are

“inexecutable” functions.

SAFETY PRECAUTIONS

3. The meanings of our safety precautions to DANGER, WARNING, and CAUTION are as

follows:

: Failure to follow these instructions could result in loss of life.

DANGER

: Failure to observe these instructions could result in serious harm to a human

life or body.

WARNING

: Failure to observe these instructions could result in minor injuries or serious

machine damage.

CAUTION

HGENPA0043E

S-1

Page 4

Basics

SAFETY PRECAUTIONS

! After turning power on, keep hands away from the keys, buttons, or switches of the

operating panel until an initial display has been made.

WARNING

! Before proceeding to the next operations, fully check that correct data has been entered

and/or set. If the operator performs operations without being aware of data errors,

unexpected operation of the machine will result.

! Before machining workpieces, perform operational tests and make sure that the machine

operates correctly. No workpieces must be machined without confirmation of normal

operation. Closely check the accuracy of programs by executing override, single-block, and

other functions or by operating the machine at no load. Also, fully utilize tool path check,

Virtual Machining, and other functions, if provided.

! Make sure that the appropriate feed rate and rotational speed are designated for the

particular machining requirements. Always understand that since the maximum usable fee d

rate and rotational speed are determined by the specifications of the tool to be used, those

of the workpiece to be machined, and various other factors, actual capabilities differ from

the machine specifications listed in this manual. If an inappropriate feed rate or rotational

speed is designated, the workpiece or the tool may abruptly move out from the machine.

! Before executing correction functions, fully check that the direction and amount of

correction are correct. Unexpected operation of the machine will result if a correction

function is executed without its thorough understanding.

! Parameters are set to the optimum standard machining conditions prior to shipping of the

machine from the factory. In principle, these settings should not be modified. If it becomes

absolutely necessary to modify the settings, perform modifications only after thoroughly

understanding the functions of the corresponding parameters. Modifications usually affect

any program. Unexpected operation of the machine will result if the settings are modified

without a thorough understanding.

Remarks on the cutting conditions recommended by the NC

! Before using the following cutting conditions:

- Cutting conditions that are the result of the MAZATROL Automatic Cutting Conditions

WARNING

Determination Function

- Cutting conditions suggested by the Machining Navigation Function

- Cutting conditions for tools that are suggested to be used by the Machining Navigation

Function

Confirm that every necessary precaution in regards to safe machine setup has been taken –

especially for workpiece fixturing/clamping and tool setup.

! Confirm that the machine door is securely closed before starting machining.

Failure to confirm safe machine setup may result in serious injury or death.

S-2

Page 5

Programming

WARNING

SAFETY PRECAUTIONS

! Fully check that the settings of the coordinate systems are correct. Even if the designated

program data is correct, errors in the system settings may cause the machine to operate in

unexpected places and the workpiece to abruptly move out from the machine in the event

of contact with the tool.

! During surface velocity hold control, as the current workpiece coordinates of the surface

velocity hold control axes approach zeroes, the spindle speed increases significantly. For

the lathe, the workpiece may even come off if the chucking force decreases. Safety speed

limits must therefore be observed when designating spindle speeds.

! Even after inch/metric system selection, the units of the programs, tool information, or

parameters that have been registered until that time are not converted. Fully check these

data units before operating the machine. If the machine is operated without checks being

performed, even existing correct programs may cause the machine to operate differently

from the way it did before.

! If a program is executed that includes the absolute data commands and relative data

commands taken in the reverse of their original meaning, totally unexpected operation of

the machine will result. Recheck the command scheme before executing programs.

! If an incorrect plane selection command is issued for a machine action such as arc

interpolation or fixed-cycle machining, the tool may collide with the workpiece or part of the

machine since the motions of the control axes assumed and those of actual ones will be

interchanged. (This precaution applies only to NC units provided with EIA functions.)

! The mirror image, if made valid, changes subsequent machine actions significantly. Use

the mirror image function only after thoroughly understanding the above. (This precaution

applies only to NC units provided with EIA functions.)

! If machine coordinate system commands or reference position returning commands are

issued with a correction function remaining made valid, correction may become invalid

temporarily. If this is not thoroughly understood, the machine may appear as if it would

operate against the expectations of the operator. Execute the above commands only after

making the corresponding correction function invalid. (This precaution applies only to NC

units provided with EIA functions.)

! The barrier function performs interference checks based on designated tool data. Enter the

tool information that matches the tools to be actually used. Otherwise, the barrier function

will not work correctly.

! The system of G-code and M-code commands differs, especially for turning, between the

machines of INTEGREX e-Series and the other turning machines.

Issuance of the wrong G-code or M-code command results in totally non-intended machine

operation. Thoroughly understand the system of G-code and M-code commands before

using this system.

Sample program Machines of INTEGREX e-Series Turning machines

S1000M3

S1000M203

The milling spindle rotates at 1000 min–1. The turning spindle rotates at 1000 min–1.

The turning spindle rotates at 1000 min–1. The milling spindle rotates at 1000 min–1.

S-3

Page 6

SAFETY PRECAUTIONS

! For the machines of INTEGREX e-Series, programmed coordinates can be rotated using

an index unit of the MAZATROL program and a G68 command (coordinate rotate command) of the EIA program. However, for example, when the B-axis is rotated through 180

degrees around the Y-axis to implement machining with the turning spindle No. 2, the plus

side of the X-axis in the programmed coordinate system faces downward and if the

program is created ignoring this fact, the resulting movement of the tool to unexpected

positions may incite collisions.

To create the program with the plus side of the X-axis oriented in an upward direction, use

the mirror function of the WPC shift unit or the mirror imaging function of G-code command

(G50.1, G51.1).

! After modifying the tool data specified in the program, be sure to perform the tool path

check function, the Virtual Machining function, and other functions, and confirm that the

program operates properly. The modification of tool data may cause even a field-proven

machining program to change in operational status.

If the user operates the machine without being aware of any changes in program status,

interference with the workpiece could arise from unexpected operation.

For example, if the cutting edge of the tool during the start of automatic operation is present

inside the clearance-including blank (unmachined workpiece) specified in the common unit

of the MAZATROL program, care is required since the tool will directly move from that

position to the approach point because of no obstructions being judged to be present on

this path.

For this reason, before starting automatic operation, make sure that the cutting edge of the

tool during the start of automatic operation is present outside the clearance-including

workpiece specified in the common unit of the MAZATROL program.

CAUTION

! If axis-by-axis independent positioning is selected and simultaneously rapid feed selected

for each axis, movements to the ending point will not usually become linear. Before using

these functions, therefore, make sure that no obstructions are present on the path.

! Before starting the machining operation, be sure to confirm all contents of the program

obtained by conversion. Imperfections in the program could lead to machine damage and

operator injury.

S-4

Page 7

Operations

WARNING

SAFETY PRECAUTIONS

! Single-block, feed hold, and override functions can be made invalid using system variables

#3003 and #3004. Execution of this means the important modification that makes the

corresponding operations invalid. Before using these variables, therefore, give thorough

notification to related persons. Also, the operator must check the settings of the system

variables before starting the above operations.

! If manual intervention during automatic operation, machine locking, the mirror image

function, or other functions are executed, the workpiece coordinate systems will usually be

shifted. When making machine restart after manual intervention, machine locking, the

mirror image function, or other functions, consider the resulting amounts of shift and take

the appropriate measures. If operation is restarted without any appropriate measures being

taken, collision with the tool or workpiece may occur.

! Use the dry run function to check the machine for normal operation at no load. Since the

feed rate at this time becomes a dry run rate different from the program-designated feed

rate, the axes may move at a feed rate higher than the programmed value.

! After operation has been stopped temporarily and insertion, deletion, updating, or other

commands executed for the active program, unexpected operation of the machine may

result if that program is restarted. No such commands should, in principle, be issued for the

active program.

CAUTION

! During manual operation, fully check the directions and speeds of axial movement.

! For a machine that requires manual homing, perform manual homing operations after

turning power on. Since the software-controlled stroke limits will remain ineffective until

manual homing is completed, the machine will not stop even if it oversteps the limit area.

As a result, serious machine damage will result.

! Do not designate an incorrect pulse multiplier when performing manual pulse handle feed

operations. If the multiplier is set to 1000 times and the handle operated inadvertently, axial

movement will become faster than that expected.

S-5

Page 8

BEFORE USING THE NC UNIT

BEFORE USING THE NC UNIT

Limited Warranty

The warranty of the manufacturer does not cover any trouble arising if the NC unit is used for its

non-intended purpose. Take notice of this when operating the unit.

Examples of the trouble arising if the NC unit is used for its non-intended purpose are listed

below.

1. Trouble associated with and caused by the use of any commercially available software

products (including user-created ones)

2. Trouble associated with and caused by the use of any Windows operating systems

3. Trouble associated with and caused by the use of any commercially available computer

equipment

Operating Environment

1. Ambient temperature

During machine operation: 0° to 50°C (32° to 122°F)

2. Relative humidity

During machine operation: 10 to 75% (without bedewing)

Note: As humidity increases, insulation deteriorates causing electrical component parts to

deteriorate quickly.

Keeping the Backup Data

Note: Do not attempt to delete or modify the data stored in the following folder.

Recovery Data Storage Folder: D:\MazakBackUp

Although this folder is not used when the NC unit is running normally, it contains important data

that enables the prompt recovery of the machine if it fails.

If this data has been deleted or modified, the NC unit may require a long recovery time. Be sure

not to modify or delete this data.

S-6

E

Page 9

CONTENTS

Page

1 CONTROLLED AXES........................................................................... 1-1

1-1 Coordinate Words and Controlled Axes ............................................................. 1-1

2 UNITS OF PROGRAM DATA INPUT................................................... 2-1

2-1 Units of Program Data Input...............................................................................2-1

2-2 Units of Data Setting...........................................................................................2-1

2-3 Ten-Fold Program Data......................................................................................2-1

3 DATA FORMATS.................................................................................. 3-1

3-1 Tape Codes........................................................................................................3-1

3-2 Program Formats ...............................................................................................3-5

3-3 Tape Data Storage Format................................................................................. 3-6

3-4 Optional Block Skip ............................................................................................3-6

3-5 Program Number, Sequence Number and Block Number: O, N ........................3-7

3-6 Parity-H/V...........................................................................................................3-8

3-7 List of G-Codes ................................................................................................3-10

4 BUFFER REGISTERS.......................................................................... 4-1

4-1 Input Buffer.........................................................................................................4-1

4-2 Preread Buffer.................................................................................................... 4-2

5 POSITION PROGRAMMING................................................................ 5-1

5-1 Dimensional Data Input Method.........................................................................5-1

5-1-1 Absolute/Incremental data input: G90/G91............................................................. 5-1

C-1

Page 10

5-2 Inch/Metric Selection: G20/G21..........................................................................5-3

5-3 Decimal Point Input ............................................................................................5-4

6 INTERPOLATION FUNCTIONS........................................................... 6-1

6-1 Positioning (Rapid Feed): G00...........................................................................6-1

6-2 One-Way Positioning: G60.................................................................................6-4

6-3 Linear Interpolation: G01....................................................................................6-5

6-4 Circular Interpolation: G02, G03.........................................................................6-6

6-5 Radius Designated Circular Interpolation: G02, G03..........................................6-9

6-6 Spiral Interpolation: G2.1, G3.1 (Option)..........................................................6-11

6-7 Plane Selection: G17, G18, G19......................................................................6-19

6-7-1 Outline .................................................................................................................. 6-19

6-7-2 Plane selection methods....................................................................................... 6-19

6-8 Virtual-Axis Interpolation: G07..........................................................................6-21

6-9 Spline Interpolation: G06.1 (Option).................................................................6-22

6-10 NURBS Interpolation: G06.2 (Option)...............................................................6-33

6-11 Cylindrical Interpolation: G07.1 ........................................................................6-40

6-12 Helical Interpolation: G02, G03 ........................................................................6-49

7 FEED FUNCTIONS.............................................................................. 7-1

7-1 Rapid Traverse Rates.........................................................................................7-1

7-2 Cutting Feed Rates.............................................................................................7-1

7-3 Asynchronous/Synchronous Feed: G94/G95.....................................................7-1

7-4 Selecting a Feed Rate and Effects on Each Control Axis...................................7-3

C-2

Page 11

7-5 Automatic Acceleration/Deceleration..................................................................7-6

7-6 Speed Clamp......................................................................................................7-7

7-7 Exact-Stop Check: G09......................................................................................7-7

7-8 Exact-Stop Check Mode: G61..........................................................................7-10

7-9 Automatic Corner Override: G62...................................................................... 7-10

7-10 Tapping Mode: G63 ..........................................................................................7-15

7-11 Cutting Mode: G64 ...........................................................................................7-15

7-12 Geometry Compensation/Accuracy Coefficient: G61.1/,K................................7-16

7-12-1 Geometry compensation function: G61.1.............................................................7-16

7-12-2 Accuracy coefficient (,K)....................................................................................... 7-17

7-13 Inverse Time Feed: G93 (Option).....................................................................7-18

8 DWELL FUNCTIONS ........................................................................... 8-1

8-1 Dwell Command in Time: (G94) G04..................................................................8-1

8-2 Dwell Command in Number of Revolutions: (G95) G04.....................................8-2

9 MISCELLANEOUS FUNCTIONS......................................................... 9-1

9-1 Miscellaneous Functions (M3-Digit)....................................................................9-1

9-2 No. 2 Miscellaneous Functions (A8/B8/C8-Digit)................................................9-2

10 SPINDLE FUNCTIONS ...................................................................... 10-1

10-1 Spindle Function (S5-Digit Analog)...................................................................10-1

10-2 Spindle Clamp Speed Setting: G92..................................................................10-1

11 TOOL FUNCTIONS............................................................................ 11-1

11-1 Tool Function (4-Digit T-Code).........................................................................11-1

C-3

Page 12

11-2 Tool Function (8-Digit T-Code).........................................................................11-1

12 TOOL OFFSET FUNCTIONS............................................................. 12-1

12-1 Tool Offset........................................................................................................12-1

12-2 Tool Length Offset/Cancellation: G43, G44, or T-Code/G49............................12-5

12-3 Tool Position Offset: G45 to G48......................................................................12-7

12-4 Tool Diameter Offset Function: G40, G41, G42 .............................................12-13

12-4-1 Overview............................................................................................................. 12-13

12-4-2 Tool diameter offsetting...................................................................................... 12-13

12-4-3 Tool diameter offsetting operation using other commands................................. 12-22

12-4-4 Corner movement............................................................................................... 12-29

12-4-5 Interruptions during tool diameter offsetting ....................................................... 12-29

12-4-6 General precautions on tool diameter offsetting................................................. 12-31

12-4-7 Offset number updating during the offset mode ................................................. 12-32

12-4-8 Excessive cutting due to tool diameter offsetting................................................ 12-34

12-4-9 Interference check.............................................................................................. 12-36

12-5 Three-Dimensional Tool Diameter Offsetting (Option)....................................12-43

12-5-1 Function description............................................................................................ 12-43

12-5-2 Programming methods ....................................................................................... 12-44

12-5-3 Correlationships to other functions..................................................................... 12-48

12-5-4 Miscellaneous notes on three-dimensional tool diameter offsetting................... 12-48

12-6 Programmed Data Setting: G10.....................................................................12-49

12-7 Tool Offsetting Based on MAZATROL Tool Data...........................................12-57

12-7-1 Selection parameters.......................................................................................... 12-57

12-7-2 Tool length offsetting .......................................................................................... 12-58

C-4

Page 13

12-7-3 Tool diameter offsetting...................................................................................... 12-59

12-7-4 Tool data update (during automatic operation)................................................... 12-60

12-8 Shaping Function (Option)..............................................................................12-61

12-8-1 Overview............................................................................................................. 12-61

12-8-2 Programming format........................................................................................... 12-62

12-8-3 Detailed description............................................................................................ 12-62

12-8-4 Remarks ............................................................................................................. 12-69

12-8-5 Compatibility with the other functions.................................................................12-70

12-8-6 Sample program.................................................................................................12-71

13 PROGRAM SUPPORT FUNCTIONS................................................. 13-1

13-1 Hole Machining Pattern Cycles: G34.1/G35/G36/G37.1...................................13-1

13-1-1 Overview............................................................................................................... 13-1

13-1-2 Holes on a circle: G34.1 ....................................................................................... 13-2

13-1-3 Holes on a line: G35............................................................................................. 13-3

13-1-4 Holes on an arc: G36............................................................................................ 13-4

13-1-5 Holes on a grid: G37.1.......................................................................................... 13-5

13-2 Fixed Cycles.....................................................................................................13-7

13-2-1 Outline .................................................................................................................. 13-7

13-2-2 Fixed-cycle machining data format....................................................................... 13-8

13-2-3 G71.1 (Chamfering cutter CW)........................................................................... 13-11

13-2-4 G72.1 (Chamfering cutter CCW) ........................................................................ 13-12

13-2-5 G73 (High-speed deep-hole drilling)................................................................... 13-13

13-2-6 G74 (Reverse tapping) ....................................................................................... 13-14

13-2-7 G75 (Boring).......................................................................................................13-15

C-5

Page 14

13-2-8 G76 (Boring).......................................................................................................13-16

13-2-9 G77 (Back spot facing)....................................................................................... 13-17

13-2-10 G78 (Boring) ....................................................................................................... 13-18

13-2-11 G79 (Boring) ....................................................................................................... 13-19

13-2-12 G81 (Spot drilling)............................................................................................... 13-19

13-2-13 G82 (Drilling)....................................................................................................... 13-20

13-2-14 G83 (Deep-hole drilling)...................................................................................... 13-21

13-2-15 G84 (Tapping)..................................................................................................... 13-22

13-2-16 G85 (Reaming) ................................................................................................... 13-23

13-2-17 G86 (Boring) ....................................................................................................... 13-23

13-2-18 G87 (Back boring)............................................................................................... 13-24

13-2-19 G88 (Boring) ....................................................................................................... 13-25

13-2-20 G89 (Boring) ....................................................................................................... 13-25

13-2-21 Synchronous tapping (Option)............................................................................ 13-26

13-3 Initial Point and R-Point Level Return: G98 and G99 .....................................13-30

13-4 Scaling ON/OFF: G51/G50.............................................................................13-31

13-5 Mirror Image ON/OFF: G51.1/G50.1..............................................................13-44

13-6 Subprogram Control: M98, M99 .....................................................................13-45

13-7 End Processing: M02, M30, M998, M999.......................................................13-52

13-8 Linear Angle Commands................................................................................13-53

13-9 Macro Call Function: G65, G66, G66.1, G67..................................................13-54

13-9-1 User macros ....................................................................................................... 13-54

13-9-2 Macro call instructions........................................................................................ 13-55

13-9-3 Variables............................................................................................................. 13-64

C-6

Page 15

13-9-4 Types of variables............................................................................................... 13-66

13-9-5 Arithmetic operation commands.........................................................................13-84

13-9-6 Control commands.............................................................................................. 13-88

13-9-7 External output commands (Output via RS-232C).............................................. 13-92

13-9-8 External output command (Output onto the hard disk)....................................... 13-94

13-9-9 Precautions......................................................................................................... 13-96

13-9-10 Specific examples of programming using user macros ...................................... 13-98

13-10 Geometric Commads (Option)......................................................................13-102

13-11 Corner Chamfering and Corner Rounding Commands.................................13-103

13-11-1 Corner chamfering ( , C_)................................................................................. 13-103

13-11-2 Corner rounding ( ,R_)...................................................................................... 13-105

14 COORDINATE SYSTEM SETTING FUNCTIONS.............................. 14-1

14-1 Fundamental Machine Coordinate System, Workpiece Coordinate

Systems, and Local Coordinate Systems.........................................................14-1

14-2 Machine Zero Point and Second, Third, and Fourth Reference Points.............14-2

14-3 Fundamental Machine Coordinate System Selection: G53..............................14-3

14-4 Coordinate System Setting: G92......................................................................14-4

14-5 Automatic Coordinate System Setting..............................................................14-5

14-6 Reference Point Return: G28, G29 ..................................................................14-6

14-7 Second, Third, or Fourth Reference Point Return: G30....................................14-8

14-8 Reference Point Check Command: G27 ........................................................14-10

14-9 Workpiece Coordinate System Setting and Selection: (G92) G54 to G59......14-11

14-10 Additional Workpiece Coordinate System Setting and Selection: G54.1........14-16

C-7

Page 16

14-11 Local Coordinate System Setting: G52...........................................................14-22

14-12 Reading/Writing of MAZATROL Program Basic Coordinates.........................14-27

14-12-1 Calling a macroprogram (for data writing) .......................................................... 14-27

14-12-2 Data reading ....................................................................................................... 14-27

14-12-3 Rewriting............................................................................................................. 14-28

14-13 Workpiece Coordinate System Rotation.........................................................14-29

14-14 Three-Dimensional Coordinate Conversion: G68...........................................14-42

15 MEASUREMENT SUPPORT FUNCTIONS........................................ 15-1

15-1 Skip Function: G31...........................................................................................15-1

15-1-1 Function description.............................................................................................. 15-1

15-2 Skip Coordinate Reading..................................................................................15-2

15-3 Amount of coasting in the execution of a G31 block.........................................15-3

15-4 Skip coordinate reading error...........................................................................15-4

15-5 Multi-Step Skip: G31.1, G31.2, G31.3, G04 .....................................................15-5

16 PROTECTIVE FUNCTIONS............................................................... 16-1

16-1 Pre-move Stroke Check ON/OFF: G22/G23 ....................................................16-1

17 THREADING: G33 (Option)................................................................ 17-1

17-1 Equal-Lead Threading......................................................................................17-1

17-2 Continuous Threading......................................................................................17-4

17-3 Inch Threading .................................................................................................17-4

18 DYNAMIC OFFSETTING: M173, M174 (Option) ............................... 18-1

C-8

Page 17

19 HIGH-SPEED SMOOTHING CONTROL FUNCTION (OPTION)....... 19-1

19-1 Programming Format........................................................................................19-2

19-2 Commands Available in the High-Speed Smoothing Control Mode .................19-2

19-3 Additional Functions in the High-Speed Smoothing Control Mode...................19-3

19-4 Related Parameters..........................................................................................19-4

19-5 Remarks...........................................................................................................19-4

19-6 Related Alarms.................................................................................................19-4

20 FUNCTION FOR SELECTING THE CUTTING CONDITIONS........... 20-1

21 TORNADO TAPPING (G130)............................................................. 21-1

22 HIGH-SPEED MACHINING MODE FEATURE (OPTION)................. 22-1

23 AUTOMATIC TOOL LENGTH MEASUREMENT: G37 (OPTION) ..... 23-1

24 DYNAMIC OFFSETTING II: G54.2P0, G54.2P1 - G54.2P8

(OPTION)............................................................................................ 24-1

25 EIA/ISO PROGRAM DISPLAY........................................................... 25-1

25-1 Procedures for Constructing an EIA/ISO Program ...........................................25-1

25-2 Editing Function of EIA/ISO PROGRAM Display..............................................25-2

25-2-1 General................................................................................................................. 25-2

25-2-2 Operation procedure............................................................................................. 25-2

25-3 Macro-Instruction Input.....................................................................................25-8

25-4 Division of Display (Split Screen)......................................................................25-9

25-5 Editing Programs Stored in External Memory Areas ......................................25-12

C-9

Page 18

- NOTE -

C-10

E

Page 19

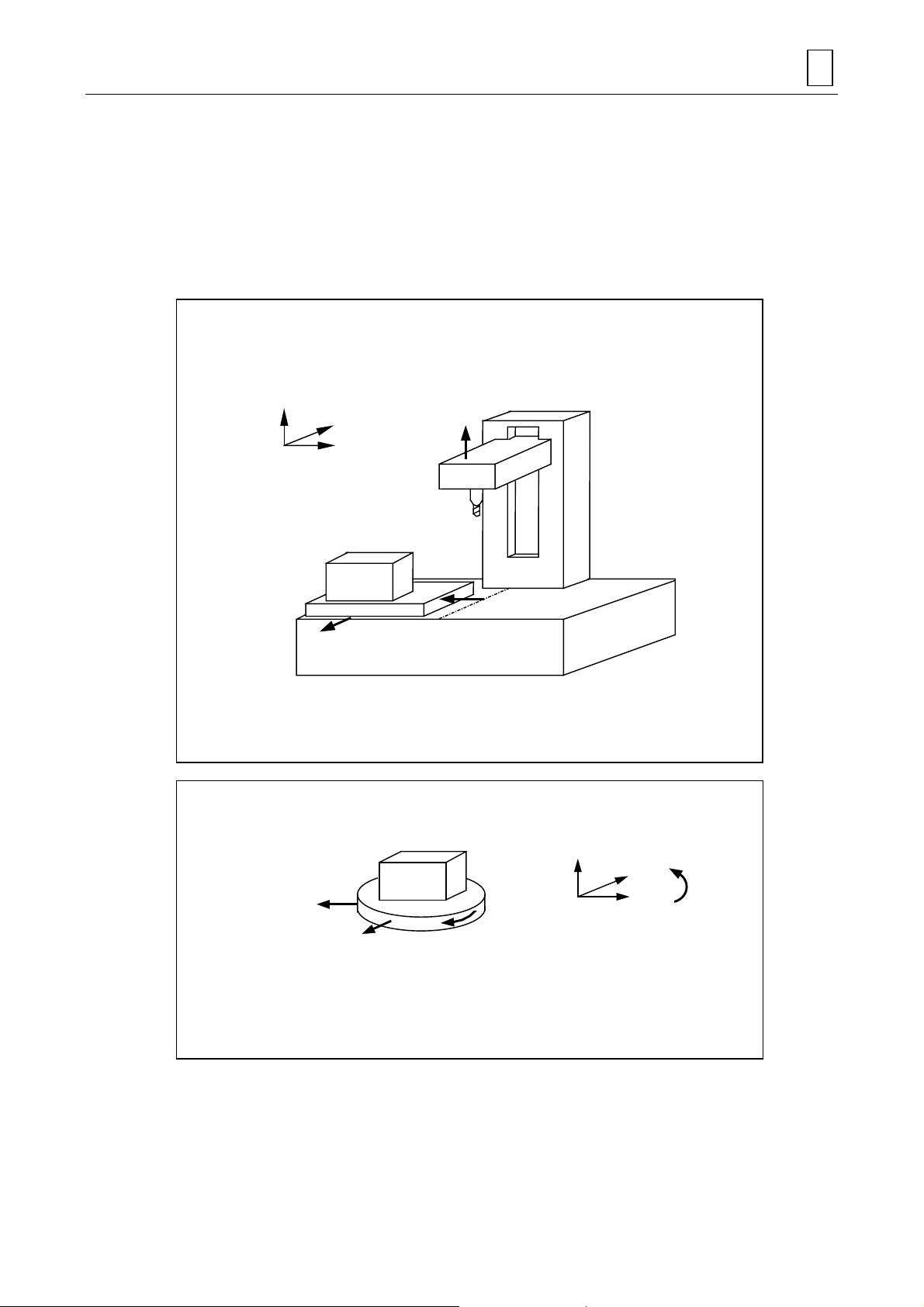

1 CONTROLLED AXES

1-1 Coordinate Words and Controlled Axes

Under standard specifications, there are three-dimensional controlled axes. With an added

feature and a special option, the machine can control up to a maximum of six axes, including the

three fundamental axes. The direction of machining can be designated using a predetermined

coordinate word consisting of an alphabetic character.

For X-Y table

CONTROLLED AXES 1

+Z

+Y

+X

Program coordinates

Workpiece

X-Y table

+Y

For X-Y table and turntable

+Z

Table moving directions

+X

Bed

MEP001

+X

Table moving directions

+Y

Workpiece

Workpiece

+C

Table turning

direction

1-1

+Z

+Y

+X

Program coordinates

+C

MEP002

Page 20

1 CONTROLLED AXES

- NOTE -

1-2

E

Page 21

2 UNITS OF PROGRAM DATA INPUT

2-1 Units of Program Data Input

The movements on coordinate axes are to be commanded in the MDI mode or machining

program. The movement data are expressed in millimeters, inches or degrees.

2-2 Units of Data Setting

Various data commonly used for control axes, such as offsetting data, must be set for the

machine to perform an operation as desired.

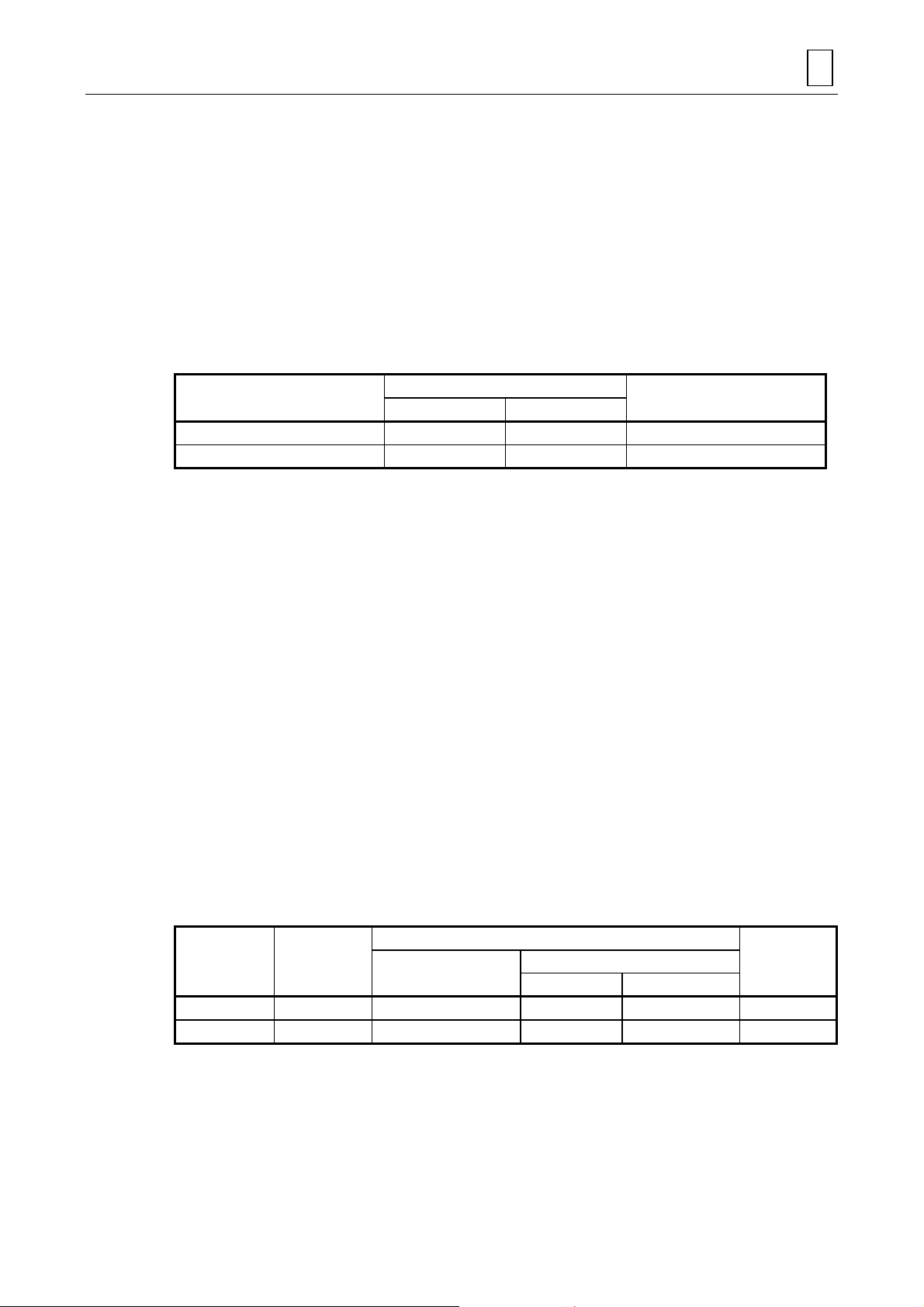

The units of data setting and those of program data input are listed below.

UNITS OF PROGRAM DATA INPUT 2

Units of program data input 0.0001 mm 0.00001 in. 0.0001 deg

Units of data setting 0.0001 mm 0.00001 in. 0.0001 deg

Note 1: Inch/metric selection can be freely made using either bit 4 of parameter F91 (“0” for

metric, “1” for inches; validated through power-off and -on) or G-code command s (G20,

G21).

Selection using the G-code commands is valid only for program data input.

Variables and offsetting data (such as tool offsetting data) should therefore be set

beforehand using the appropriate unit (inch or metric) for the particular machining

requirements.

Note 2: Metric data and inch data cannot be used at the same time.

2-3 Ten-Fold Program Data

Using a predetermined parameter, machining program data can be processed as set in units of

one micron. There may be cases that a machining program which has been set in units of one

micron is to be used with a numerical control unit based on 0.1 micron increment s. In such cases,

use of this parameter allows the machine to perform the required machining operations without

rewriting the program.

Use bit 0 of user parameter F91 for this purpose.

All types of coordinate data (axis movement data) not provided with the decimal point will be

multiplied by a factor of 10. This does not apply, indeed, to preset tool-offsetting data designated

with addresses H and D.

Linear axis

Metric system Inch system

Rotational axis

Linear axis

Rotational axis

Program

command

X1 (Y1 / Z1)

B1

Moving distance when program commands are executed

NC (A) for which the

program was prepared

1 micron 0.1 micron 1 micron Applicable

0.001° 0.0001° 0.001° Applicable

Bit 0 of F91 = 0 Bit 0 of F91 = 1

MAZATROL (B)Controlled axis

2-1

Program

applicability

(A) → (B)

Page 22

2 UNITS OF PROGRAM DATA INPUT

- NOTE -

2-2

E

Page 23

3 DATA FORMATS

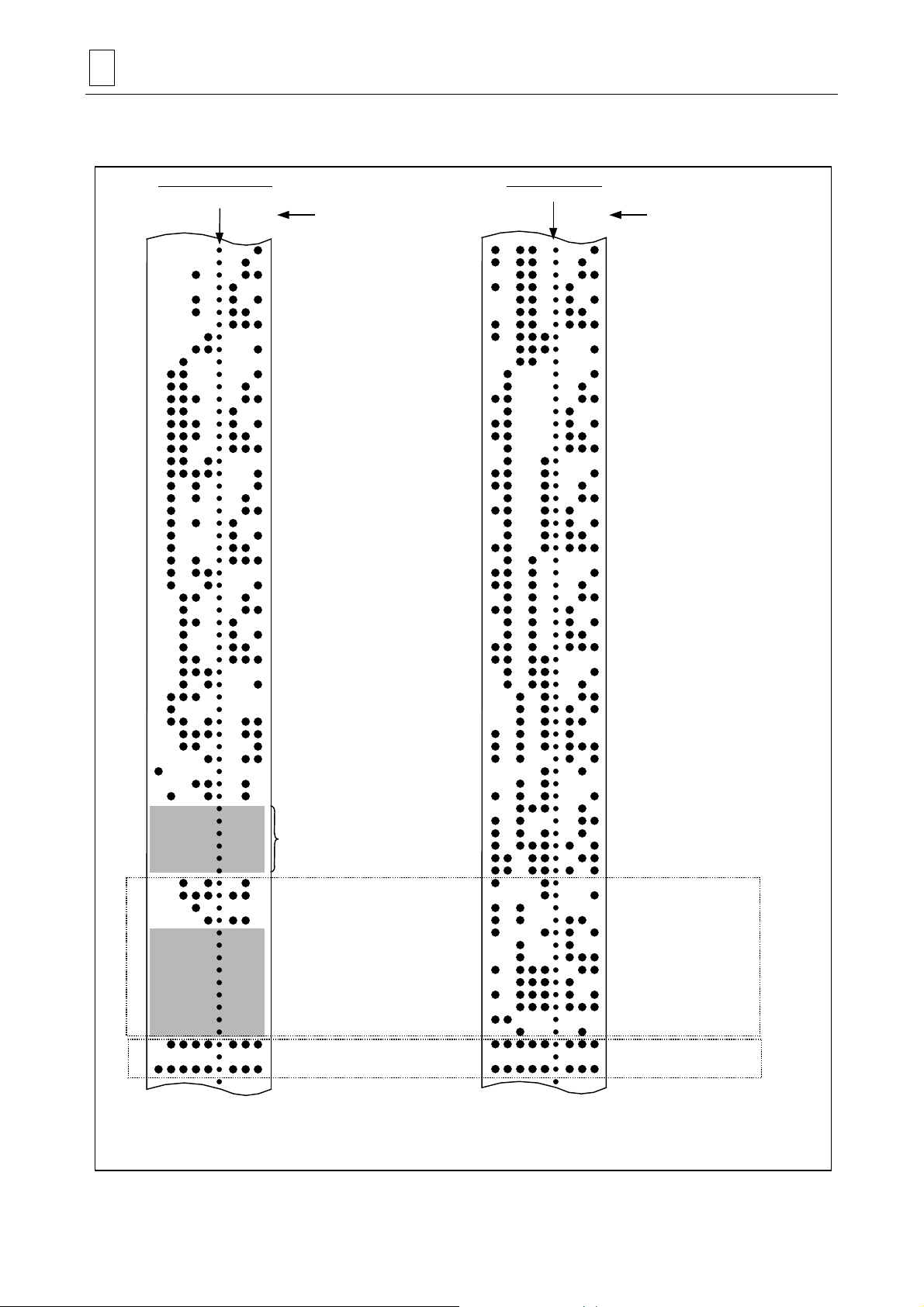

3-1 Tape Codes

This numerical control unit (in the remainder of this manual, referred to as the NC unit) uses

command information that consists of letters of the alphabet (A, B, C .... Z), numerics (0, 1, 2 ....

9), and signs (+, –, /, and so on). These alphanumerics and signs are referred to collectively as

characters. On paper tape, these characters are represented as a combination of a maximum of

eight punched holes.

Such a representation is referred to as a code.

The NC unit uses either the EIA codes (RS-244-A) or the ISO codes (R-840).

Note 1: Codes not included in the tape codes shown in Fig. 3-1 will result in an error when they

are read.

Note 2: Of all codes specified as the ISO codes but not specified as the EIA codes, only the

following codes can be designated using the data I/O (Tape) parameters TAP9 to

TAP14:

[ Bracket Open

] Bracket Close

# Sharp

∗ Asterisk

= Equal sign

:Colon

However, you cannot designate codes that overlap existing ones or that result in parity

error.

DATA FORMATS 3

Note 3: EIA/ISO code identification is made automatically according to the first EOB/LF code

appearing after the NC unit has been reset. (EOB: End Of Block, LF: Line Feed)

1. Significant information area (LABEL SKIP function)

During tape-based automatic operation, data storage into the memory, or data searching, the NC

unit will ignore the entire information up to the first EOB code (;) in the tape when the unit is

turned on or reset. That is, significant information in a tape refers to the information contained in

the interval from the time a character or numeric code appears, following the first EOB code (;)

after the NC unit has been reset, until a reset command is given.

2. Control Out, Control In

The entire information in the area from Control Out “(” to Control In “)” will be ignored in regard to

machine control, while they will surely be displayed on the data display unit. Thus, this area can

be used to contain information, such as the name and number of the command tape, that is not

directly related to control.

During tape storage, however, the information in this area will also be stored. The NC unit will

enter the Control In status when power is turned on.

3-1

Page 24

3 DATA FORMATS

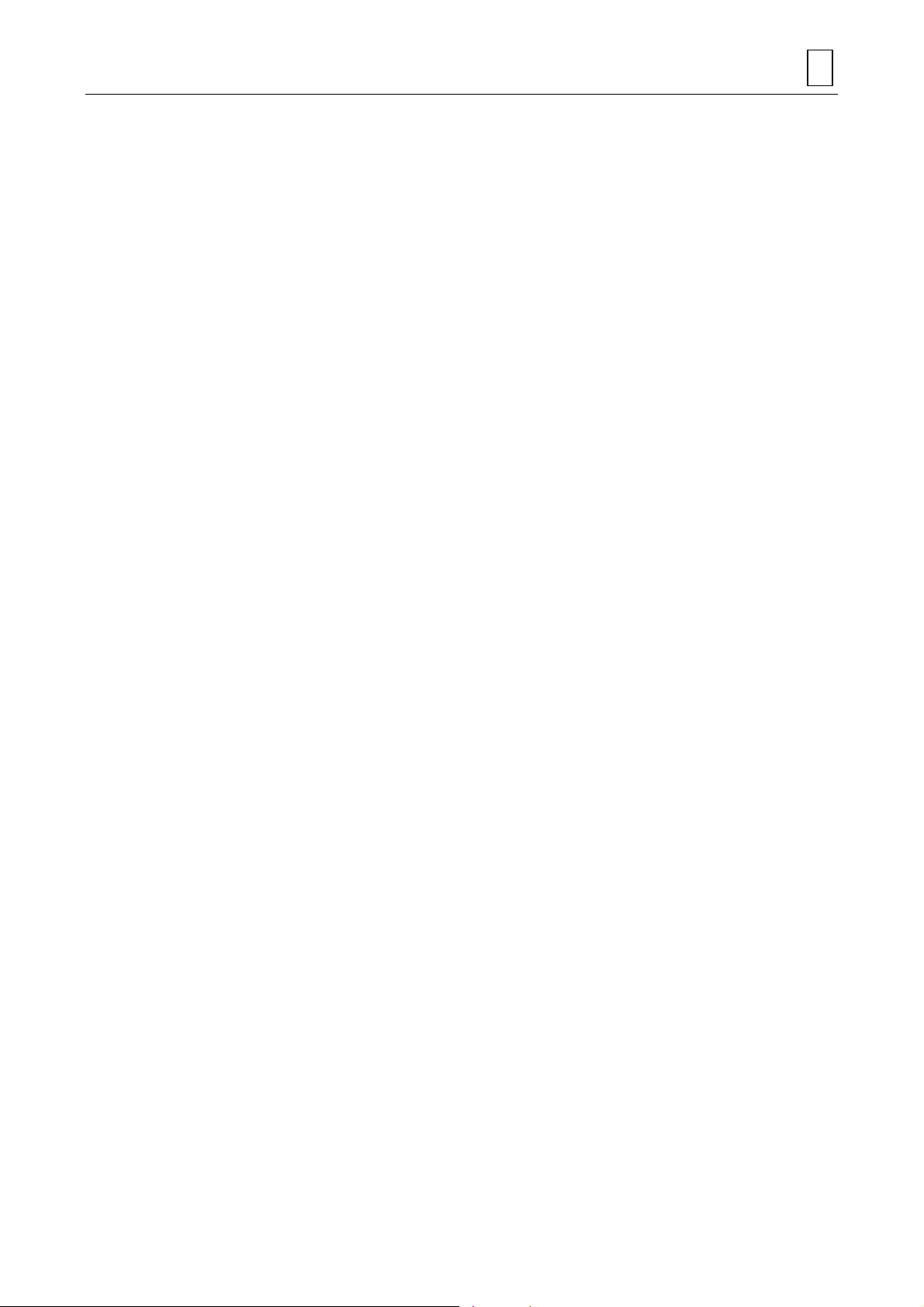

Example of EIA Code

Control InControl Out

CON

E

U

P R 1 10

O

L

B

Name of tape is printed out

CON

E

1 1 1 1

U

O

L

B

Name of tape is punched in captital letters.

N

D

E

L

D

U

E

L

L

N

R R R O

U

L

R

N

U

.ONMARGO

L

N

UL1

/R

C

E

O

I

B

D

N

N

N

1

1 1

E

L

2DE

U

L

L

E

U

U

O

L

LCI

B

MEP003

Example of ISO Code

E

C

C

OBG0 X–8500 0 640 C U T T E R

R

R

Operator information is printed out.

Control Out

0 0 0

0 0 0G0 X 500 0 40 C U T T E R

YR

(

The information at this portion is ignored

and nothing is executed.

S

S

E T U R N )–

E T U R NR

P

P

Control In

E

O

B

3. EOR code (%)

In general, the EOR (End Of Record) code is punched at both ends of a tape and has the

following functions:

- To stop rewinding (only when a rewinding device is provided)

- To start rewinding during tape data search (only when a rewinding device is provided)

- To terminate the storage of tape data.

MEP004

3-2

Page 25

DATA FORMATS 3

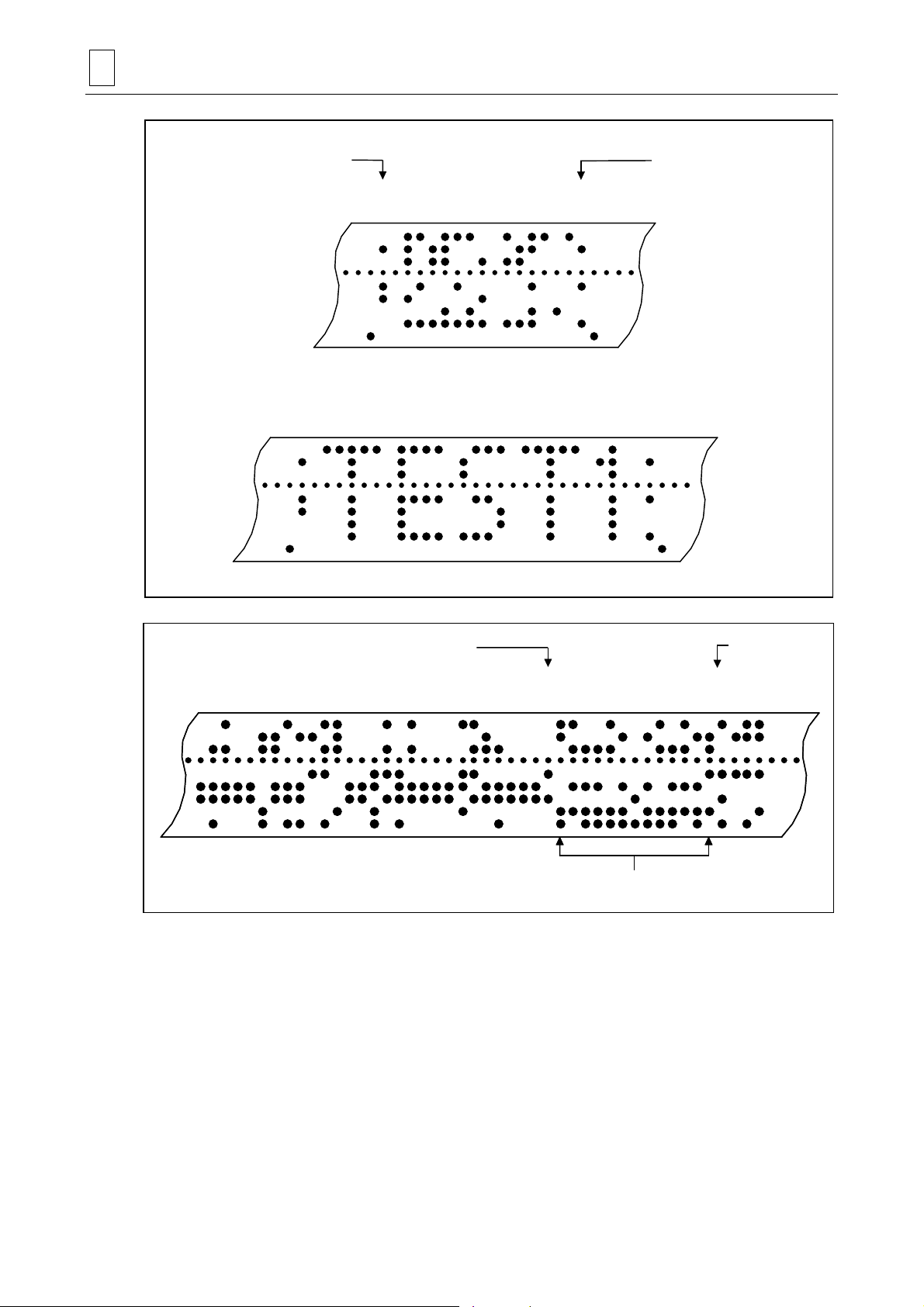

4. Tape creation method for tape operation (Only when a rewinding device is used)

;

10 cm

2m First block Last block 2m

!!!!!!!!!

!!!!!!!!!

; ;

!!!!!!!!!

;

10 cm %%

TEP005

The two meters of dummy at both ends and the EOR (%) at the head are not required when a

rewinding device is not used.

3-3

Page 26

3 DATA FORMATS

A

A

A

A

EIA/ISO identification is made automatically by detecting whether EOB or LF initially appears

after the NC unit has been reset.

EIA code (RS-244-A)

Feed holes

87654 321

Channel number

1

2

3

4

5

6

7

8

9

0

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

+

–

.

,

/

EOR (End of Record)

EOB (End of Block) or CR

CO (2+4+5)

CI (2+4+7)

Definable in parameters

BS (Back Space)

TAB

SP (Space)

&

DEL (Delete)

S (All Space=Feed)*

M (All Mark=EOB+DEL)*

ISO code (R-840)

Feed holes

87654 321

Channel number

1

2

3

4

5

6

7

8

9

0

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

+

–

.

,

/

%

LF (Line Feed) or NL

( (Control Out)

) (Control In)

:

#

?

=

[

]

BS (Back Space)

HT (Horizontal Tab)

SP (Space)

&

CR (Carriage Return)

$

' (Apostrophe)

;

<

>

?

@

"

DEL (Delete)

NULL

DEL (Delete)

[1]

[2]

* The codes asterisked above are not EIA codes,

but may be used for the convenience’s sake.

Fig. 3-1 Tape codes

LF or NL acts as EOB and %

acts as EOR.

MEP006

3-4

Page 27

Codes in section [1] will only be stored as tape data when they are present in a comment section,

A

and ignored elsewhere in the significant information area.

Codes in section [2] are non-operative and will always be ignored (but undergo the parity-V

check).

A dotted area indicates that the EIA Standard provides no corresponding codes.

3-2 Program Formats

A format predetermined for assigning control information to the NC unit is referred to as a

program format. The program format used for our NC unit is word address format.

1. Words and addresses

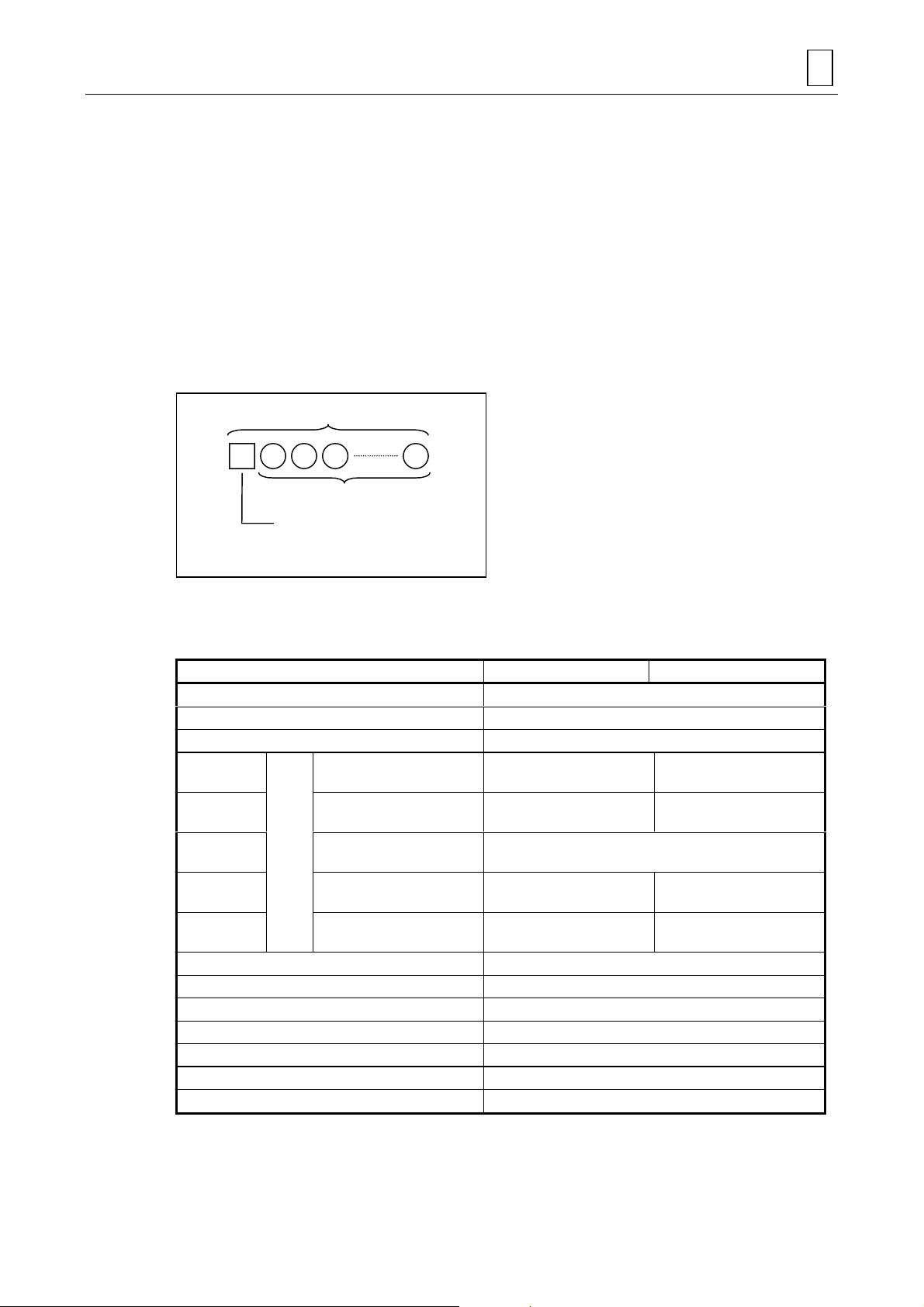

A word is a set of characters arranged as shown below, and information is pro ce ssed in words.

DATA FORMATS 3

Word

Numeral

lphabet (address)

Word configuration

The alphabetic character at the beginning of a word is referred to as an address, which defines

the meaning of its succeeding numeric information.

Table 3-1 Type and format of words

Item Metric command Inch command

Program No. O8

Sequence No. N5

Preparatory function

Moving axis

Auxiliary axis

Dwell

Feed

Fixed cycle

Tool offset

Miscellaneous function M3 × 4

Spindle function S5

Tool function

No. 2 miscellaneous function B8, A8 or C8

Subprogram

Variables number #5

Input

unit

0.0001 mm (deg.),

0.00001 in.

0.0001 mm (deg.),

0.00001 in.

0.001 mm (rev),

0.0001 in.

0.0001 mm (deg.),

0.00001 in.

0.0001 mm (deg.),

0.00001 in.

X+54 Y+54 Z+54 α+54 X+45 Y+45 Z+45 α+45

I+54 J+54 K+54 I+45 J+45 K+45

F54 (per minute)

F33 (per revolution)

R+54 Q54 P8 L4 R+45 Q45 P8 L4

G3 or G21

X54 P8 U54

F45 (per minute)

F24 (per revolution)

H3 or D3

T4 or T8

P8 H5 L4

3-5

Page 28

3 DATA FORMATS

1. Code O8 here indicates that program number can be set as an unsigned integer of eight

digits following O, and for X+54, “+” indicates that the value can be signed (negative) and

the two-digit number (54) indicates that the decimal point can be used and that five digits

before and four after the decimal point are effective (5 + 4 = 9 digits are effective for a

designation without decimal point).

2. The alpha sign (

rotational axis.

3. The number of digits in the words is checked by the maximum number of digits in the

addresses.

4. When data with decimal point is used for address for which decimal input is not available,

decimal figures will be ignored.

5. If the number of integral digits exceeds the specified format, an alarm will result.

6. If the number of decimal digits exceed the specified format, the excess will be rounded.

2. Blocks

A block, unit of instruction, contains a number of words which constitute information necessary

for the NC machine to perform an operation. The end of each block must be indicated by an EOB

(End Of Block) code.

3. Programs

A number of blocks form one program.

4. Program end

M02, M30, M99, M998, M999 or % is used as program end code.

α) denotes additional axis address. +44 will be used when α is specified for

3-3 Tape Data Storage Format

As with tape operation, tape data to be stored into the memory can be either of ISO or EIA code.

The first EOB code read in after resetting is used by the NC unit for automatic identification of the

code system ISO or EIA.

The area of tape data to be stored into the memeory is, if the NC unit has been reset, from the

character immediately succeeding the first EOB code the EOR code, and in all other cases, from

the current tape position to the EOR code. Usually, therefore, start tape data storage operation

after resetting the NC unit.

3-4 Optional Block Skip

1. Function and purpose

Optional block skip is a function that selectively ignores that specific block within a machining

program which begins with the slash code “/”.

Any block beginning with “/” will be ignored if the [BLOCK SKIP] menu function is set to ON, or

will be executed if the menu function is set to OFF.

For example, if all blocks are to be executed for a type of parts but specific blocks are not to be

executed for another type, then different parts can be machined using one and the same

program that contains the “/” code at the beginning of the specific blocks.

3-6

Page 29

2. Operating notes

1. Blocks that have already been read into the pre-read buffer cannot be skipped.

2. This function is valid even during sequence number search.

3. During tape data storage (input) or output, all blocks, including those having a “/” code, are

in- or outputted, irrespective of the status of the [BLOCK SKIP] menu function.

3-5 Program Number, Sequence Number and Block Number: O, N

Program numbers, sequence numbers, and block numbers are used to monitor the execution

status of a machining program or to call a machining program or a specific process within a

machining program.

Program numbers are assigned to command blocks as required. A program number must be set

using the letter O (address) and a numeric of a maximum of eight digits that follow O.

Sequence numbers identify command blocks forming a machining program. A sequence number

must be set using the letter N (address) and a numeric of a maximum of five digits that follow N.

Block numbers are counted automatically within the NC unit, and reset to 0 each time a program

number or a sequence number is read. These numbers will be counted up by one if the block to

be read does not have an assigned program number or sequence number.

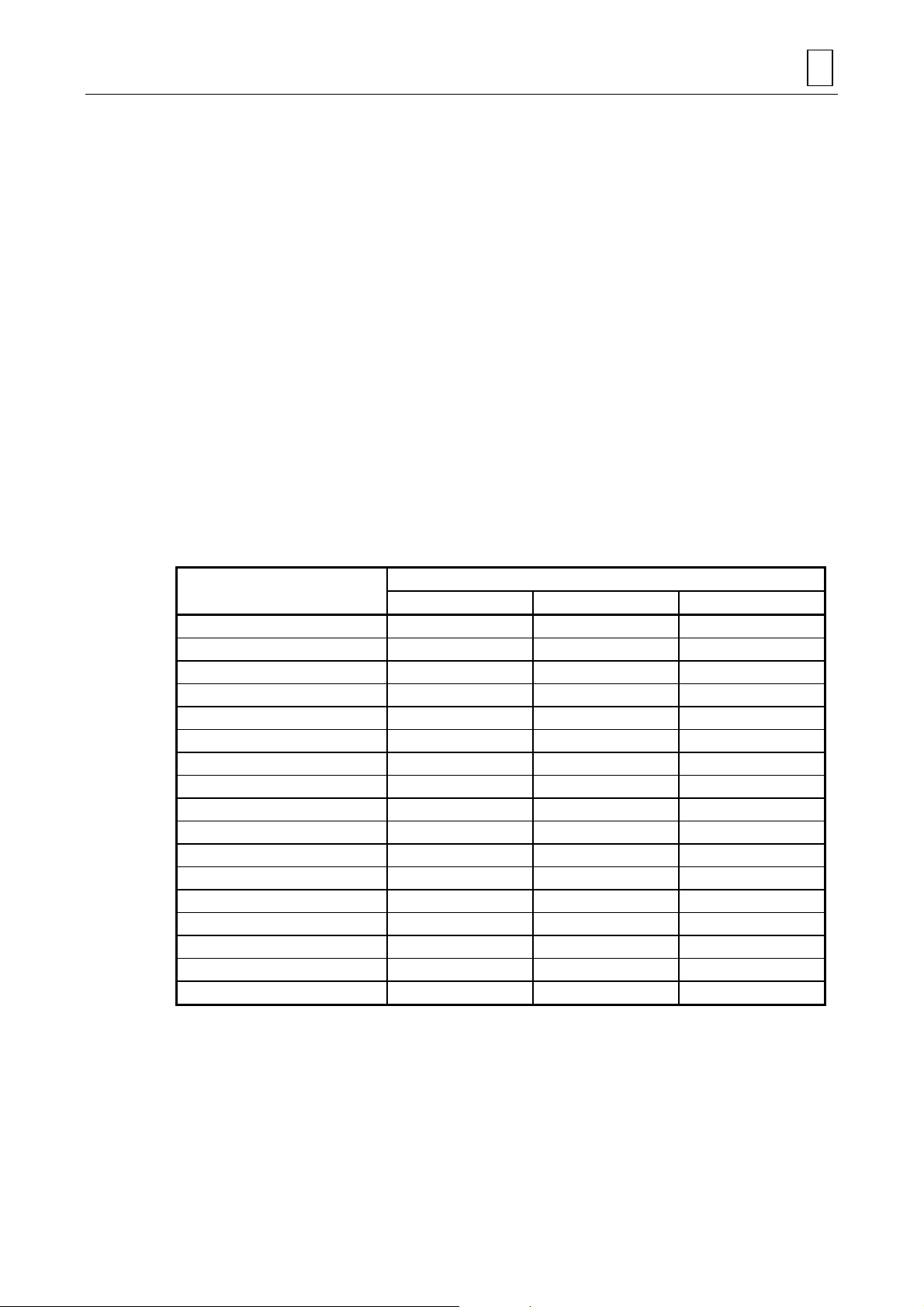

All blocks of a machining program, therefore, can be uniquely defined by combining program

number, sequence number, and block number as shown in the table below.

DATA FORMATS 3

NC input machining program

O1234 (DEMO. PROG)

G92X0Y0

G90G51X–150. P0.75

N100G00X–50. Y–25.

N110G01X250. F300

Y–225.

X–50.

Y–25.

N120G51Y–125. P0.5

N130G00X–100. Y–75.

N140G01X–200.

Y–175.

X–100.

Y–75.

N150G00G50X0Y0

N160M02

%

NC monitor display

Program No. Sequence No. Block No.

1234 0 0

1234 0 1

1234 0 2

1234 100 0

1234 110 0

1234 110 1

1234 110 2

1234 110 3

1234 120 0

1234 130 0

1234 140 0

1234 140 1

1234 140 2

1234 140 3

1234 150 0

1234 160 0

3-7

Page 30

3 DATA FORMATS

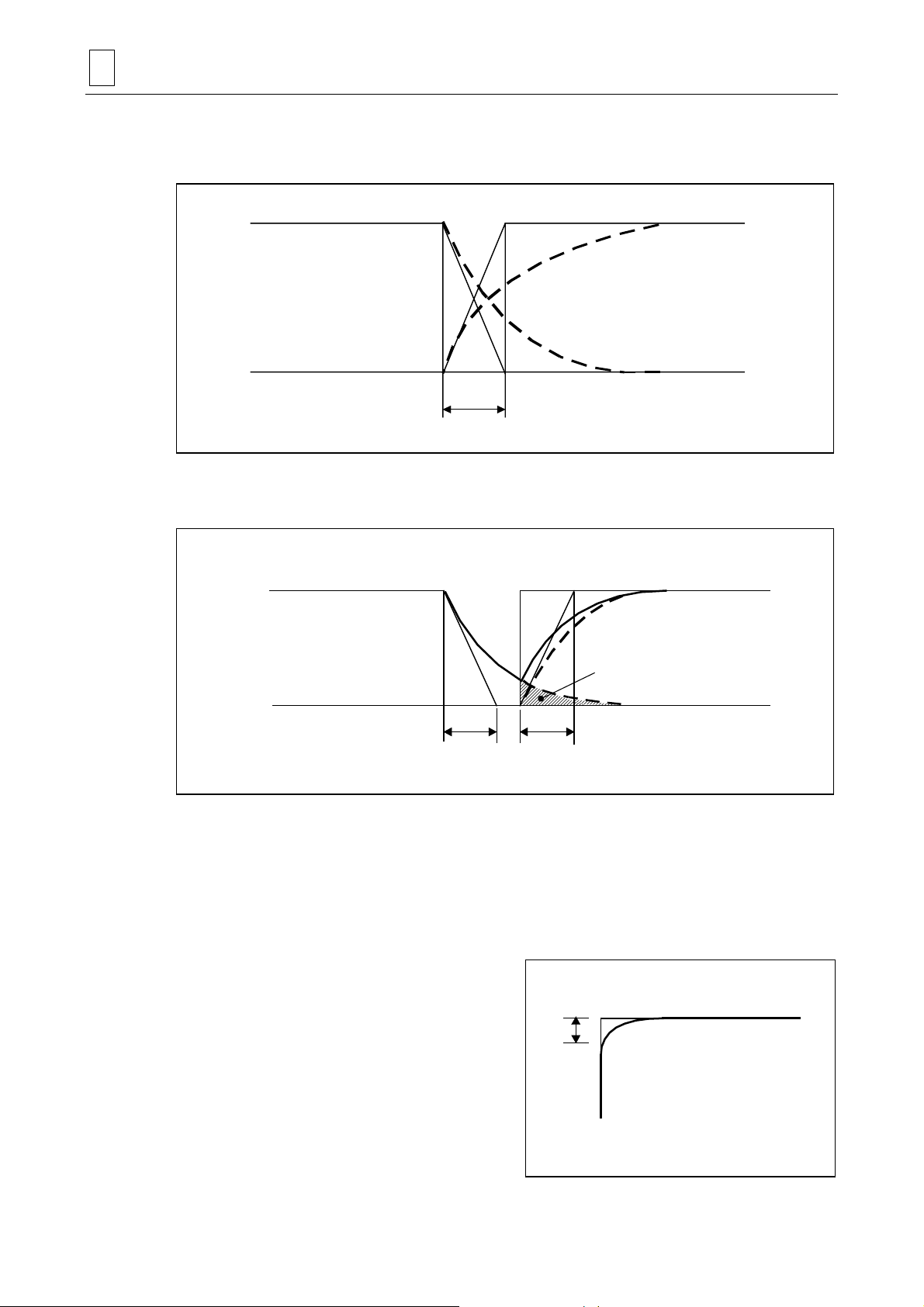

3-6 Parity-H/V

One method of checking if the tape is correctly created is by parity checks. Parity checks are

performed to check a tape for errors in punched codes, that is, for punching errors. There are two

types of parity checks: parity-H and parity-V.

1. Parity-H check

Parity-H checks are intended to check the quantity of punched holes which form one character,

and performed during tape operation, tape loading, and sequence-number searching.

A parity-H error occurs in the following cases:

- ISO Codes

If a code with an odd number of punched holes is present in the significant information area.

- EIA Codes

If a code with an even number of punched holes is present in the significant information area or

if non-punched holes (sprockets only) are present after a significant code in one block.

Example 1: Parity-H error (for EIA codes)

This character leads to a Parity-H error.

One block

This non-punched character will result in a Parity-H

error.

These non-punched characters will

not result in a Parity-H error.

If a parity-H error occurs, the tape will stop at the position next to the error code.

MEP007

3-8

Page 31

DATA FORMATS 3

2. Parity-V check

Parity-V checks will be performed during tape operation, tape loading, or sequence-number

searching, if parity-V check item on the PARAMETER display is set to ON. Parity-V during

memory operation, however, will not be checked.

A parity-V error occurs in the following case:

If an odd number of codes are present in the significant information area from the first significant

code in the vertical direction to the EOB code (;), that is, if an odd number of characters are

present in one block.

In the event of a parity-V error, the tape stops at a code next to the EOB (;).

Example 2: An example of parity-V error

1234567

This block leads to a Parity-V error.

MEP009

Note 1: During a parity-V check, some types of code are not counted as characters. See Fig.

3-1, “Tape codes” for further details.

Note 2: Space codes in the area from the first EOB code to the first address code or slash code

“/” are not subjected to counting for parity-V check.

3-9

Page 32

3 DATA FORMATS

3-7 List of G-Codes

G functions are described in the list below.

Positioning

Linear interpolation

Circular interpolation (CW) G02 01

Circular interpolation (CCW) G03 01

Spiral interpolation (CW) G02.1 01

Spiral interpolation (CCW) G03.1 01

Dwell G04 00

High-speed machining mode G05 00

Fine spline interpolation G06.1 01

NURBS interpolation G06.2 01

Virtual-axis interpolation G07 00

Cylindrical interpolation G07.1 00

Exact-stop check G09 00

Data setting mode ON G10 00

Command address OFF G10.1 00

Data setting mode OFF G11 00

X-Y plane selection

Z-X plane selection

Y-Z plane selection

Inch command

Metric command

Pre-move stroke check ON G22 04

Pre-move stroke check OFF ▲G23 04

Reference point check G27 00

Reference point return G28 00

Return from reference point G29 00

Return to 2nd, 3rd and 4th reference points G30 00

Skip function G31 00

Multi-step skip 1 G31.1 00

Multi-step skip 2 G31.2 00

Multi-step skip 3 G31.3 00

Thread cutting (straight, taper) G33 01

Variable lead thread cutting G34 01

Hole machining pattern cycle (on a circle) G34.1 00

Hole machining pattern cycle (on a line) G35 00

Hole machining pattern cycle (on an arc) G36 00

Hole machining pattern cycle (on a grid) G37.1 00

Automatic tool length measurement G37 00

Vector selection for tool radius compensation G38 00

Corner arc for tool radius compensation G39 00

Tool radius compensation OFF ▲G40 07

Tool radius compensation (left) G41 07

3-D tool radius compensation (left) G41.2 07

Tool radius compensation (right) G42 07

3-D tool radius compensation (right) G42.2 07

Tool length offset (+) G43 08

Function G-code Group

■G00

■G01

■G17

■G18

■G19

■G20

■G21

01

01

02

02

02

06

06

3-10

Page 33

Function G-code Group

Tool tip point control (Type 1) ON G43.4 08

Tool tip point control (Type 2) ON G43.5 08

Tool length offset (–) G44 08

Tool position offset, extension G45 00

Tool position offset, reduction G46 00

Tool position offset, double extension G47 00

Tool position offset, double reduction G48 00

Tool position offset OFF ▲G49 08

Scaling OFF ▲G50 11

Scaling ON G51 11

Mirror image OFF ▲G50.1 19

Mirror image ON G51.1 19

Local coordinate system setting G52 00

Machine coordinate system selection G53 00

Selection of workpiece coordinate system 1 ▲G54 12

Selection of workpiece coordinate system 2 G55 12

Selection of workpiece coordinate system 3 G56 12

Selection of workpiece coordinate system 4 G57 12

Selection of workpiece coordinate system 5 G58 12

Selection of workpiece coordinate system 6 G59 12

Additional workpiece coordinate systems G54.1 12

Selection of fixture offset G54.2 23

One-way positioning G60 00

Exact stop mode G61 13

High-accuracy mode (Geometry compensation) G61.1 13

Automatic corner override G62 13

Tapping mode G63 13

Cutting mode ▲G64 13

User macro single call G65 00

User macro modal call A G66 14

User macro modal call B G66.1 14

User macro modal call OFF ▲G67 14

Programmed coordinate rotation ON G68 16

Programmed coordinate rotation OFF G69 16

3-D coordinate conversion ON G68 16

3-D coordinate conversion OFF ▲G69 16

Fixed cycle (Chamfering cutter 1, CW) G71.1 09

Fixed cycle (Chamfering cutter 2, CCW) G72.1 09

Fixed cycle (High-speed deep-hole drilling) G73 09

Fixed cycle (Reverse tapping) G74 09

Fixed cycle (Boring 1) G75 09

Fixed cycle (Boring 2) G76 09

Fixed cycle (Back spot facing) G77 09

Fixed cycle (Boring 3) G78 09

Fixed cycle (Boring 4) G79 09

Fixed cycle OFF ▲G80 09

Fixed cycle (Spot drilling) G81 09

Fixed cycle (Drilling) G82 09

Fixed cycle (Deep-hole drilling) G83 09

DATA FORMATS 3

3-11

Page 34

3 DATA FORMATS

Fixed cycle (Tapping) G84 09

Fixed cycle (Synchronous tapping) G84.2 09

Fixed cycle (Synchronous reverse tapping) G84.3 09

Fixed cycle (Reaming) G85 09

Fixed cycle (Boring 5) G86 09

Fixed cycle (Back boring) G87 09

Fixed cycle (Boring 6) G88 09

Fixed cycle (Boring 7) G89 09

Absolute data input

Incremental data input

Coordinate system setting/Spindle clamp speed setting G92 00

Workpiece coordinate system rotation G92.5 00

Inverse time feed G93 05

Feed per minute (asynchronous)

Feed per revolution (synchronous)

Initial point level return in fixed cycles ▲G98 10

R-point level return in fixed cycles G99 10

Measurement macro, workpiece/coordinate measurement G136

Compensation macro G137

Function G-code Group

■G90

■G91

■G94

■G95

03

03

05

05

Notes:

1. The codes marked with ▲ are selected in each group when the power is turned ON or

executing reset for initializing modal.

2. The codes marked with " are able to be selected by a parameter as an initial modal which is

to become valid when the power is turned ON or executing reset for initializing modal.

Changeover of inch/metric system, however, can be made valid only by turning the power

ON.

3. G-codes of group 00 are those which are not modal, and they are valid only for commanded

blocks.

4. If a G-code not given in the G-code list is commanded, an alarm is displayed. And if a Gcode without corresponding option is commanded, an alarm is displayed (808 MIS-SET G

CODE).

5. If G-codes belong to different groups each other, any G-code can be commanded in the

same block. The G-codes are then processed in order of increasing group number. If two or

more G-codes belonging to the same group are commanded in the same block, a G-code

commanded last is valid.

3-12

E

Page 35

4 BUFFER REGISTERS

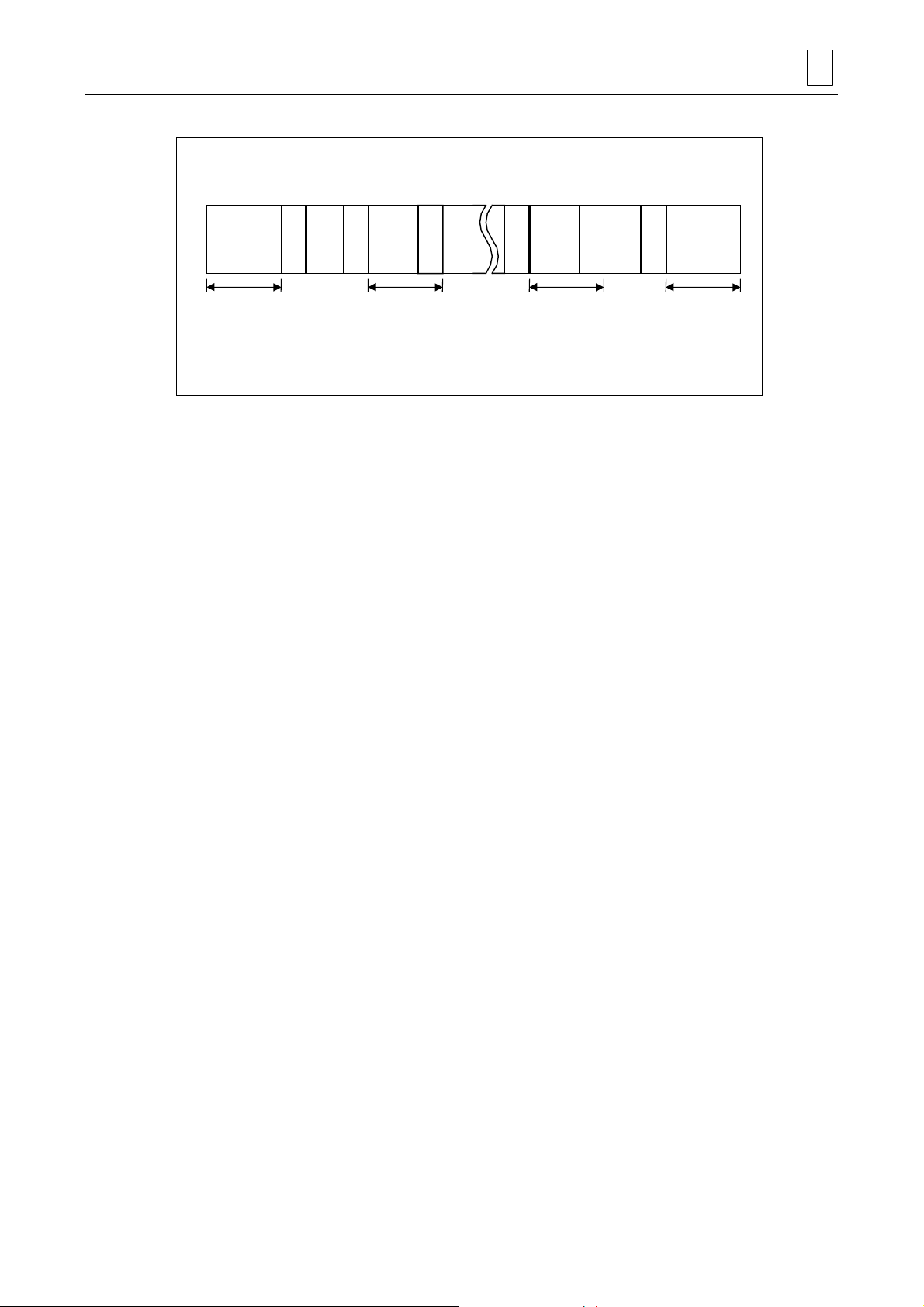

4-1 Input Buffer

1. Overview

During tape operation or RS-232C operation, when the preread buffer becomes empty, the

contents of the input buffer will be immediately shifted into the pre-read buffer and, following this,

if the memory capacity of the input buffer diminuishes to 248 × 4 characters or less, next data (up

to 248 characters) will be preread from the tape and then stored into the input buffer.

The input buffer makes block-to-block connections smooth by eliminating any operational delays

due to the tape-reading time of the tape reader.

These favorable results of prereading, however, will be obtained only if the execution time of the

block is longer than the tape-reading time of the next block.

BUFFER REGISTERS 4

Tape

Keyboard

Input buffer

Memory

Mode

selection

Preread

buffer 5

Buffer 4

Buffer 3

Buffer 2

Buffer 1

Note:

One block of data is stored in one buffer.

2. Detailed description

- The memory capacity of the input buffer is 248 × 5 characters (including the EOB code).

- The contents of the input buffer register are updated in 248-character units.

Arithmetic

operation

process

TEP010

- Only the significant codes in the significant information area are read into the buffer.

- Codes, including “(” and “)”, that exist between Control Out and Control In, are read into the

input buffer. Even if optional block skip is valid, codes from / to EOB will also be read into the

input buffer.

- The contents of the buffer are cleared by a reset command.

4-1

Page 36

4 BUFFER REGISTERS

4-2 Preread Buffer

1. Overview

During automatic operation, one block of data is usually preread to ensure smooth analysis of

the program. During tool radius compensation, however, maximal five blocks of data are prere ad

to calculate crossing point or to check the interference.

In the high-speed machining mode (G05P2), moreover, up to 8 blocks of data are preread, and in

the mode of high-speed smoothing control up to 24 blocks of data are stored with the currently

executed block in the middle (i. e. 12 blocks being preread).

2. Detailed description

- One block of data is stored into the prepared buffer.

- Only the significant codes in the significant information area are read into the pre-read buffer.

- Codes existing between Control Out and Control In are not read into the pre-read buffer. If

optional block skip is valid, codes from / to EOB will not also be read into the pre-read buffer.

- The contents of the buffer are cleared by a reset command.

- If the single block operation mode is selected during continuous operation, processing will stop

after pre-reading the next block data.

4-2

E

Page 37

5 POSITION PROGRAMMING

5-1 Dimensional Data Input Method

5-1-1 Absolute/Incremental data input: G90/G91

1. Function and purpose

Setting of G90 or G91 allows succeeding dimensional data to be processed as absolute data or

incremental data.

Setting of arc radius (with address R) or arc center position (with addresses I, J, K) for circular

interpolation, however, must always refer to incremental data input, irrespective of preceding

G90 command.

2. Programming format

POSITION PROGRAMMING 5

G90 (or G91) Xx

Yy1 Zz1 αα1 (α : Additional axis)

1

where G90: Absolute data input

G91: Incremental data input

3. Detailed description

1. In the absolute data mode, axis movement will be performed to the program-designated

position within the workpiece coordinate system, irrespective of the current position.

N1 G90G00X0 Y0

In the incremental data mode, axis movement will be performed through the programdesignated distance as relative data with respect to the current position.

N2 G91G01X200. Y50. F100

N2 G90G01X200. Y50. F100

Y

200.

Tool

100.

N1

N2

100. 200. 300.

W

X

MEP011

Commands for a movement from the origin of the workpiece coordinate system are given

with the same

values, irrespective of whether the absolute data mode or the incremental

data mode is used.

5-1

Page 38

5 POSITION PROGRAMMING

2. The last G90 or G91 command works as a modal one for the following blocks.

(G90) N3 X100. Y100.

This block will perform a movement to the position of X = 100 and Y = 100 in the workpiece

coordinate system.

(G91) N3 X-100. Y50.

This block will perform a movement of –100 on the X-axis and +50 on the Y-axis, and thus

result in a movement to the position of X = 100 and Y = 100.

Y

200.

100.

100. 200. 300.

W

N3

X

MEP012

3. Multiple G90 or G91 commands can be set in one block, and thus only a specific address

can be set as absolute data or incremental data.

N4 G90X300. G91Y100.

In this example, dimensional data X300 preceded by G90 will be processed as an absolute

data input, and Y100 preceded by G91 as an incremental data input. Therefore, this block

will result in a movement to the position of X = 300 and Y = 200 (100 + 100) in the workpiece

coordinate system.

Y

200.

N4

100.

X

W

100. 200.

300.

MEP013

Moreover, G91 (incremental data input mode) will work for the succeeding blocks.

4. Either the absolute data mode or the incremental data mode can be freely selected as initial

mode by setting the bit 2 of user parameter F93.

5. Even in the MDI (Manual Data Input) mode, G90 and G91 will also be handled as modal

commands.

5-2

Page 39

5-2 Inch/Metric Selection: G20/G21

1. Function and purpose

Inch command/metric command selection is possible with G-code commands.

2. Programming format

G20: Inch command selection

G21: Metric command selection

3. Detailed description

1. Changeover between G20 and G21 is effective only for linear axes; it is meaningless for

rotational axes.

Example: Preset unit of data input and G20/G21 (for decimal-point input type Ι)

POSITION PROGRAMMING 5

Axis Example

X

Y

Z

B

X100

Y100

Z100

B100

Initial Inch (parameter) OFF Initial Inch (parameter) ON

G21 G20 G21 G20

0.0100 mm 0.0254 mm 0.00039 inches 0.00100 inches

0.0100 mm 0.0254 mm 0.00039 inches 0.00100 inches

0.0100 mm 0.0254 mm 0.00039 inches 0.00100 inches

0.0100 deg 0.0100 deg 0.0100 deg 0.0100 deg

2. To perform G20/G21 changeover in a program, you must first convert variables, parameters,

and offsetting data (such as tool length/tool position/tool diameter offsetting data) according

to the unit of data input for the desired system (inch or metric) a nd then set all these types of

data either on each data setting display or using the programmed parameter input function.

Example: If Initial inch selection is OFF and offsetting data is 0.05 mm, the offsetting data

must be converted to 0.002 (0.05 ÷ 25.4 ≈ 0.002) before changing the G21

mode over to the G20 mode.

3. In principle, G20/G21 selection should be done before machining. If you want this

changeover to be performed in the middle of the program, temporarily stop the program by

an M00 command after G20 or G21 and convert the offsetting data as required.

Example: G21 G92 Xx

Yy1 Zz

1

1

MM

MM

MM

G20 G92 Xx

Yy2 Zz

2

2

M00 → Convert offsetting data here.

M

F10 → Set an F (Feed rate) command anew.

Note: Do not fail to give an F command appropriate to the new unit system after

changeover between G20 and G21. Otherwise, axis movements would be

performed using the last F value before the changeover, without any conversion,

on the basis of the new unit system.

4. Whether G20 or G21 is to be selected upon switching-on can be specified by the bit 4 of

user parameter F91 (Initial Inch parameter).

5-3

Page 40

5 POSITION PROGRAMMING

5-3 Decimal Point Input

1. Function and purpose

The decimal point can be used to determin the units digit (mm or inch) of dimensional data or

feed rate.

2. Programming format

!!!!!.!!!! Metric system

!!!!.!!!!! Inch system

3. Detailed description

1. Decimal-point commands are valid only for the distance, angle, time, speed, and scaling

factor (only after G51) that have been set in the machining program.

2. As listed in the table below, the meaning of command data without the decimal point differs

between decimal-point input types Ι and ΙΙ according to the type of command unit system.

Command Command unit × 10 Type Ι Type ΙΙ

X1

OFF 0.0001 (mm, inches, deg) 1.0000 (mm, inches, deg)

ON 0.0010 (mm, inches, deg) 1.0000 (mm, inches, deg)

3. Decimal-point commands are only valid for addresses X, Y, Z, U, V, W, A, B, C, I, J, K, E, F,

P, Q and R, where address P only refers to a scaling factor.

4. The number of effective digits for each type of decimal-point command is as follows:

Move command

(Linear)

Integral part Decimal part Integral part Decimal part Integral part Decimal part Integral part Decimal part

mm 0. - 99999. .0000 - .9999 0. - 99999. .0000 - .9999 0. - 200000. .0000 - .9999 0. - 99999. .000 - .999

inch 0. - 9999.

.00000 .99999

Move command

(Rotational)

0. - 99999.

(359.)

Feed rate Dwell

.0000 - .9999 0. - 20000.

.00000 .99999

0. - 99999. .000 - .999

5. Decimal-point commands are also valid for definition of variables data used in subprograms.

6. For data which can be, but is not specified with the decimal point, either the minimum

program data input unit or mm (or in.) unit can be selected using bit 5 of parameter F91.

7. A decimal-point command issued for an address which does not accept the decimal point

will be processed as data that consists of an integral part only. That is, all decimal digits will

be ignored. Addresses that do not accept the decimal point are D, H, L, M, N, O, S and T. All

types of variables command data are handled as the data having the decimal point.

5-4

Page 41

4. Sample programs

A. Sample programs for addresses accepting the decimal point

POSITION PROGRAMMING 5

Command category

Program example

G0X123.45

(With the decimal point always given

as the millimeter point)

G0X12345

#111=123 #112=5.55

X#111 Y#112

#113=#111+#112 (ADD)

#114=#111–#112 (SUBTRACT)

#115=#111#112 (MULTIPLY)

#116=#111/#112

#117=#112/#111 (DIVIDE)

For 1 = 1 µ For 1 = 0.1 µ 1 = 1 mm

X123.450 mm X123.450 mm X123.450 mm

X12.345 mm* X1.2345 mm** X12345.000 mm***

X123.000 mm

Y5.550 mm

#113 = 128.550

#114 = 117.450

#115 = 682.650

#116 = 22.162

#117 = 0.045

* The least significant digit is given in 1 micron.

** The least significant digit is given in 0.1 micron.

*** The least significant digit is given in 1 mm.

5-5

Page 42

5 POSITION PROGRAMMING

B. Validity of decimal point for each address

Decimal

Address

A

B

C

D Invalid

E Valid Valid

F Valid Feed rate Valid

G Valid Preparatory function code

H

I

J

K

L Invalid

M Invalid Miscellaneous function code

point

command

Valid Coordinate position data Invalid Dwell time

Invalid

Valid Linear angle data Invalid Number of helical pitches

Valid Coordinate position data Invalid Offset amount (in G10)

Invalid

Valid Coordinate position data Valid

Invalid

Valid Corner chamfering amount

Invalid

Invalid

Valid Coordinate of arc center U Valid Coordinate position data

Valid

Valid Coordinate of arc center W Valid Coordinate position data

Valid

Valid Coordinate of arc center

Valid

Valid Knot for NURBS curve Z Valid Coordinate position data

Rotary table

Miscellaneous function code

Rotary table

Miscellaneous function code

Rotary table

Miscellaneous function code

Offset number (tool position,

tool length and tool diameter)

Offset number (tool postion,

tool length and tool diameter)

Intra-subprogram sequence

number

Vector component for

tool diameter offset

Vector component for

tool diameter offset

Vector component for

tool diamater offset

Fixed cycle/subprogram

repetition

Application Remarks Address

P

Q

R

S Invalid Spindle function code

T Invalid Tool function code

V Valid Coordinate position data

X

Y Valid Coordinate position data

Decimal

point

command

Valid Subprogram call number

Valid Scaling factor

Invalid Rank for NURBS curve

Cutting depth for

deep-hole drilling cycle

Valid Shift amount for back boring

Valid Shift amount for fine boring