Page 1

PROGRAMMING MANUAL

for

MAZATROL FUSION 640M

MAZATROL FUSION 640M 5X

MAZATROL FUSION 640M NEXUS

MAZATROL PROGRAMMING

MANUAL No. : H735PG0019E

Serial No. :

Before using this machine and equipment, fully understand the contents of this

manual to ensure proper operation. Should any questions arise, please ask the

nearest Technical/Service Center.

IMPORTANT NOTICE

Be sure to observe the safety precautions described in this manual and the contents of the

1.

safety plates on the machine and equipment. Failure may cause serious personal injury or

material damage. Please replace any missing safety plates as soon as possible.

No modifications are to be performed that will affect operation safety. If such modifications are

2.

required, please contact the nearest Technical/Service Center.

For the purpose of explaining the operation of the machine and equipment, some illustrations

3.

may not include safety features such as covers, doors, etc. Before operation, make sure all

such items are in place.

This manual was considered complete and accu rate at the time of public ation, how ever, due to

4.

our desire to constantly improve the quality and specification of all our products, it is subject to

change or modification. If you have any questions, please contact the nearest Technical/Service

Center.

Always keep this manual near the machinery for immediate use.

5.

If a new manual is required, please order from the nearest Technical/Service Center with the

6.

manual No. or the machine name, serial No. and manual name.

Issued by Manual Publication Section, Yamazaki Mazak Corporation, Japan

03. 2004

Page 2

Page 3

SAFETY PRECAUTIONS

Preface

Safety precautions relating to the CNC unit (in the remainder of this manual, referred to simply as

the NC unit) that is provided in this m achine are explained below. Not only the persons who

create programs, but also those who operate the machine must thoroughly understand the

contents of this manual to ensure safe operation of the machine.

Read all these safety precautions, even if your NC model does not have the corresponding

functions or optional units and a part of the precautions do not apply.

Rule

1. This section cont ains the precautions t o b e obs er ve d as to the working methods and s tates

usually expected. Of course, however, unexpec ted operations and/or un expected working

states may take place at the user site.

During daily operation of the machine, therefore, the user must pay extra careful attention to

its own working safety as well as to observe the precautions described below.

2. Although this manual c ontains as great an amount of information as it can, since it is not

rare for the user to perfor m the operations that ov erstep the manufactur er-assumed ones,

not all of “what the user ca nnot perform” or “what the us er must not perform” c an be fully

covered in this manual with all such operations taken into consideration beforehand.

It is to be understood, therefore, that functions not clearly written as “executable” are

“inexecutable” functions.

SAFETY PRECAUTIONS

3. The meanings of our safety precautions to DANGER, WARNING, and CAUTION are as

follows:

: Failure to follow these instructions could result in loss of life.

DANGER

: Failure to obs erve t hese instructi ons could r esult in ser ious harm to a hum an

life or body.

WARNING

: Failure to obs erve these instructions could result in m inor injuries or serious

machine damage.

CAUTION

HGENPA0029E

S-1

Page 4

Basics

SAFETY PRECAUTIONS

! After turning power on, keep hands away from the keys, buttons, or switches of the

operating panel until an initial display has been made.

WARNING

! Before proceeding to th e next operations, full y check that correct data has b een entered

and/or set. If the operator performs operations without being aware of data errors,

unexpected operation of the machine will result.

! Before machining workpieces, perform operational tests and m ake sure that the machine

operates correctly. No workpieces must be machined without confirmation of normal

operation. Closely check the accuracy of programs by executing override, single-block, and

other functions or b y operating the machine at no load. Also, full y utilize tool path check ,

solid check, and other functions, if provided.

Make sure that the appropriate feed rate and rotational speed are designated for the

!

particular machining requirements. Always understand that since the maximum usable feed

rate and rotational spe ed are det er mined by the specificat ions of the to ol to b e us ed , th os e

of the workpiece to be m achined, and various ot her factors, actual c apabilities diff er from

the machine specif ications listed in this manual. If an inappropriate fee d rate or rotationa l

speed is designated, the workpiece or the tool may abruptly move out from the machine.

! Before executing correction functions, fully check that the direction and amount of

correction are correct. Unexpected operation of the machine will result if a correction

function is executed without its thorough understanding.

Param eters are set to the optim um standard m achining conditi ons prior to sh ipping of the

!

machine from the fac tor y. In princ iple, these settings s houl d not be m odif ied. If it b ecom es

absolutely necessary to modify the settings, perform modifications only after thoroughly

understanding the func tions of the correspondin g parameters . Modifications us ually aff ect

any program. Unexpected oper ation of the machine will resu lt if the settings are modified

without a thorough understanding.

Remarks on the cutting conditions recommended by the NC

! Before using the following cutting conditions:

- Cutting conditions that are the result of the MAZATROL Automatic Cutting Conditions

WARNING

Determination Function

- Cutting conditions sugg es ted b y the Machini ng Na vig atio n Fu nctio n

- Cutting conditions for tools t hat are suggested to be used b y the Machining Navigation

Function

Confirm that every necessary precaution in regards to safe machine setup has been taken –

especially for workpiec e fixt uring /c lamping and tool setup.

! Confirm that the machine door is securely closed before starting machining.

Failure to confirm safe machine setup may result in serious injury or death.

S-2

Page 5

Programming

WARNING

SAFETY PRECAUTIONS

! Full y check that the s ettings of the c oordinate s ystem s are c orrect. Even if th e des ignated

program data is correct, errors i n the s ystem s ettings m a y cause the m ac hine to operate in

unexpected places a nd the work piece to abruptl y m ove out fr om the m achine in the e vent

of contact with the tool.

! During surface velocit y hold control, as the current work piece coordinates of the surf ace

velocity hold contr ol axes appr oach zeroes , the spind le speed inc reases signif icantly. F or

the lathe, the work piece m ay even c om e off if the chuc k ing forc e decreas es. Safety speed

limits must therefore be observed when designating spindle speeds.

! Even after inch/metric system selection, the units of the programs, tool information, or

parameters that have been register ed until that t ime are not c onverted. Full y check these

data units before operating the machine. If the machine is oper ated without checks being

performed, even exis ting correct programs may cause the machine to oper ate differently

from the way it did before.

! If a program is executed that includes the absolute data commands and relative data

commands taken in the r everse of their origin al meaning, totall y unexpected operation of

the machine will result. Recheck the command scheme before executing programs.

! If an incorrect plane selection command is issued for a machine action such as arc

interpolation or fixed-cyc le m ac hini ng, the too l may collide with the work piece or part of the

machine since the m otions of the control axes assum ed and those of actual ones will be

interchanged. (This precaution applies only to NC units provided with EIA functions.)

! The mirror image, if made valid, changes subse quent machine actions si gnificantly. Use

the mirror image f unction only after th oroughly unders tanding the abo ve. (This pr ecaution

applies only to NC units provided with EIA functions.)

If machine coordinate system commands or reference position returning commands are

!

issued with a correction function remaining made valid, correction may become invalid

temporarily. If this is not thoroughly understood, the machine may appear as if it would

operate against the ex pectations of the oper ator. Execute the above com mands only af ter

making the correspondin g correction functio n invalid. (This precaution a pplies only to NC

units provided with EIA functio ns .)

The barrier function performs interference checks based on designated tool data. Enter the

!

tool information that m atches the tools t o be actual ly used. Other wise, the barr ier function

will not work correctly. (This precaution applies only to the M640MT/MT 5X/T/T NEXUS/TN

and M640M Pro/MT Pro.)

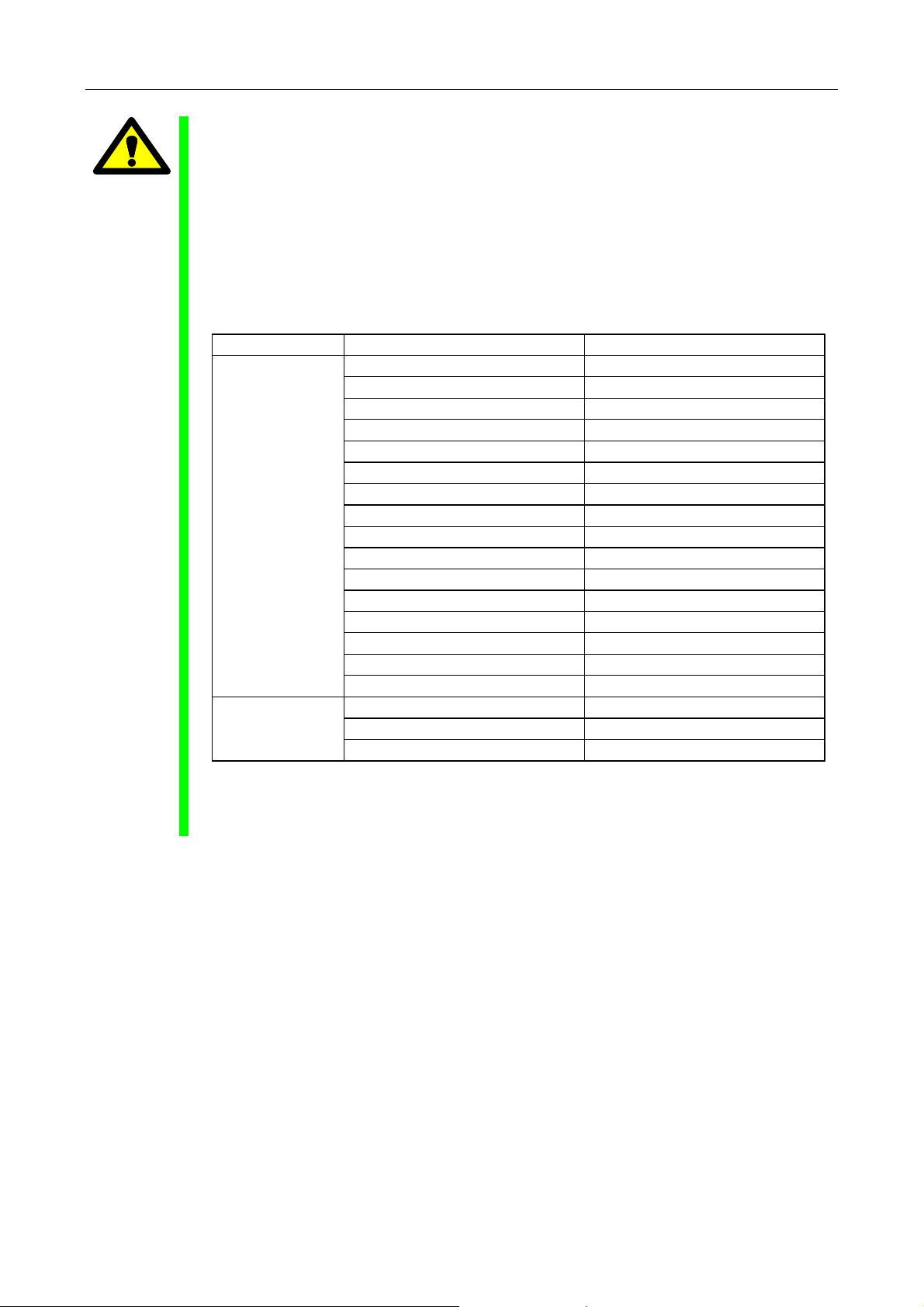

The system of G-code and M-code commands differs between the machines equipped with

!

M640M Pro (e-Series such as the INTGEREX e-410, e-650 and e-1060) and the machines

equipped with M640MT/MT 5X/T/T NEXUS/TN/MT Pro (such as the INTGEREX non eSeries, the SQT Series, the MPX Series and the QTN Series).

Issuance of the wrong G-code or M-code command results in totally non-intended machine

operation. Thoroughly understand the system of G-code and M-code commands before

using this system.

Sample program Machine with M640M Pro

S1000M3

S1000M203

The milling spindle rotates at 1000 min–1. The turning spindle rotates at 1000 min–1.

The turning spindle rotates at 1000 min–1. The milling spindle rotates at 1000 min–1.

S-3

Machine with M640MT/MT 5X/T/

T NEXUS/TN/MT Pro

Page 6

SAFETY PRECAUTIONS

! For the machines equi pped with M640M Pro (e-Ser ies such as the INTGEREX e- 410, e-

650 and e-1060), programmed coordinates can be rotated using an index unit of the

MAZATROL program and a G68 command (coordinate rotate command) of the EIA

program. However, for ex ample, when the B-axis is rota ted through 180 degrees around

the Y-axis to implement machining with the turning spindle No. 2, the plus side of the X-axis

in the programmed coordinate system faces downward and if the program is created

ignoring this fac t, the resulting movement of the tool to unexpected posit ions may incite

collisions.

To create the progr am with the plus sid e of the X - ax is or ie nted in an upward directio n, us e

the mirror function of the WPC shift unit or the mirror imaging function of G-code command

(G50.1, G51.1).

! After modifying the tool data specified in the program, be sure to perform the tool path

check function, the so lid check f unction, an d other f unctions , and conf irm that the program

operates properly. T he m odification of tool dat a ma y cause even a f ield-pro ven m achining

program to change in operational status.

If the user operates the machine without be ing aware of an y changes in program status,

interference with the workpiece could arise from unexpected operation.

For example, if the cutting edge of the tool during the start of automatic operation is present

inside the clearance- i nclu din g blank (unmachined wor kpiece) specified in t he c ommon unit

of the MAZATROL program, care is required since the tool will directly move from that

position to the approac h point because of no obstructions being judged to be pr esent on

this path.

For this reason, before starting automatic operation, make sure that the cutting edge of the

tool during the start of automatic operation is present outside the clearance-including

workpiece specified in the common unit of the MAZATROL program.

S-4

Page 7

CAUTION

SAFETY PRECAUTIONS

! If axis -by-axis independ ent positionin g is selecte d and simultaneous ly rapid f eed selected

for each axis, movem ents to the ending point wi ll not usually bec ome linear. Before using

these functions, therefore, make sure that no obstructions are present on the path.

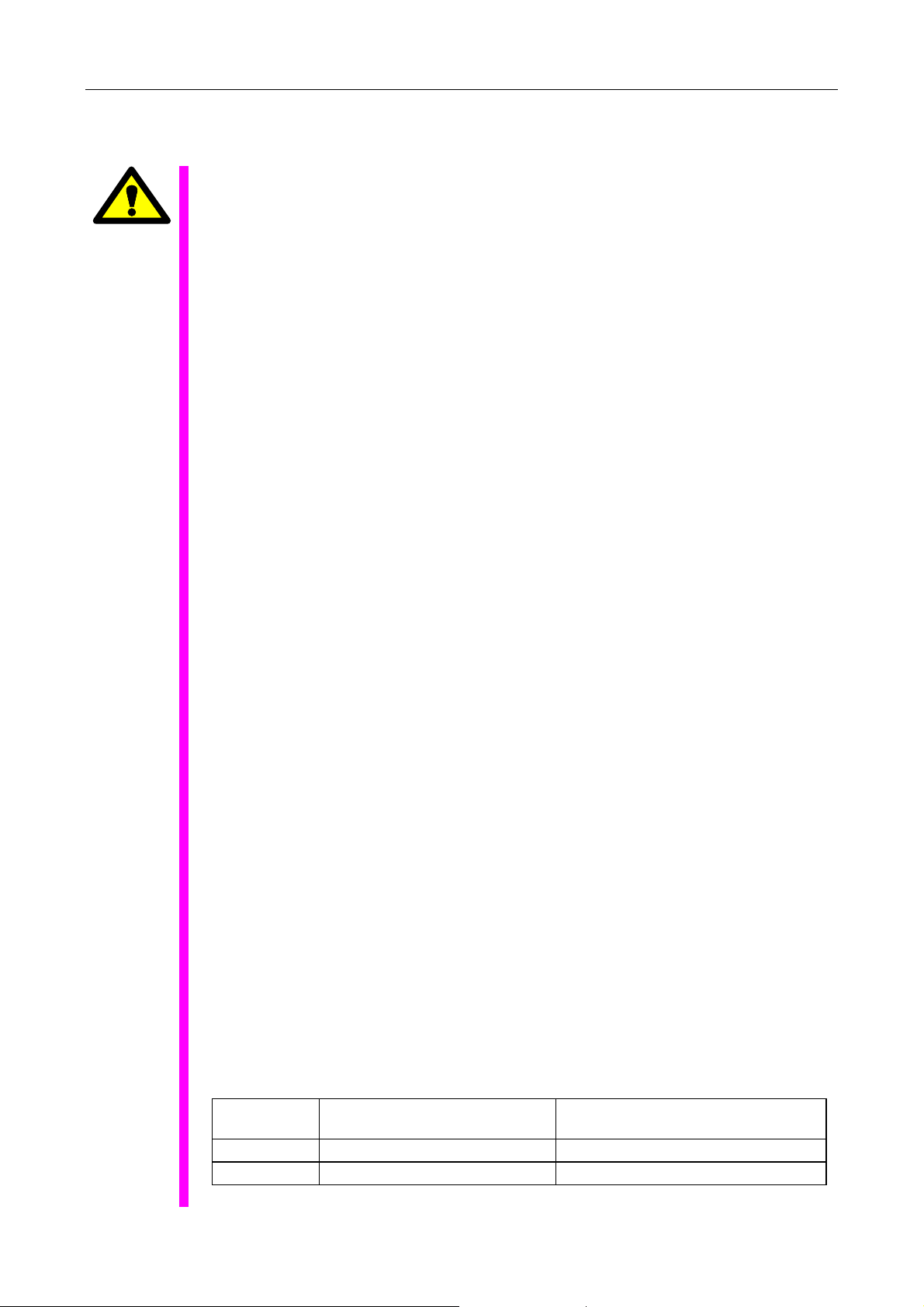

If the machine employs sl iding surface structure, lubr ication may prove to be insuff icient

!

during continuous m icrof eed mac hining ( see Note 1 belo w), an d in the worst cas e, se izure

of the sliding surface could result. For these reasons, the sliding surface needs to be

maintained in a wel l-lubricated con dition during s uch machining by, for exam ple, inserting

an oil-film forming program (see Note 2 below).

List of applicable models and intended axes (Models that employ sliding surface structure)

Classification Machine model Axes with sliding surface structure

Lathes INTEGREX 50Y X-axis, Y-axis, Z-axis

INTEGREX 50YB X-axis, Y-axis, Z-axis

INTEGREX 70Y X-axis, Y-axis, Z-axis

INTEGREX 70YB X-axis, Y-axis, Z-axis

SLANT TURN 450 X-axis, Z-axis

SLANT TURN 50N X-axis, Z-axis

SLANT TURN 60N X-axis, Z-axis

SLANT TURN 80N X-axis, Z-axis

TURNING CENTER M-4N X-axis, Z-axis

TURNING CENTER M-5N X-axis, Z-axis

POWER MASTER X-axis, Z-axis

QUICK TURN 40 X-axis, Z-axis

MEGA TURN series X-axis, Z-axis

SUPER QUADREX 200/250 Z2-axis

SUPER QUICK TURN 200/250MY Y-axis

SUPER QUICK TURN 300MY Y-axis

FJV-35/50/60 Z-axisVertical machining

centers

MTV-515/655/815 Z-axis

V-40/60 Z-axis

For further details and m ore specific examples, refer to the relevant Machine Operating

Manual, Part 4, Section 1-2, “Precautions for Microfeed Machining (Models th at Employ

Sliding Surface Structur e) ”.

Note 1: Cont inuous m ic rofeed machining refers to the oper ation in which t he m ovem ent of the

intended feed axis through strokes shorter than those required for lubrication is

continuously repeated.

Note 2: T he oil-film form ing program refers to a program that creates an oil f ilm on the slidin g

surface by moving the intended machining axis over a long stroke during machining.

S-5

Page 8

Operations

WARNING

SAFETY PRECAUTIONS

! Single-block, feed hold, and override functions can be made invalid using system variables

#3003 and #3004. Execution of this means the important modification that makes the

corresponding operations invalid. Before using these variables, therefore, give thorough

notification to re lated persons. Also, the operator must check the s ettings of the system

variables before starting the above operations.

! If manual intervention during automatic operation, machine locking, the mirror image

function, or other functions ar e execut ed, t he work piece coor dinat e system s will usua ll y be

shifted. When making machine restart after manual intervention, machine locking, the

mirror image f unction, or other functions , consider the resu lting amounts of shift and take

the appropriate measures. If operation is restarted without any appropriate measures being

taken, collision with the tool or workpiece may occur.

! Use the dry run f unction to check the machine for norm al operation at no load . Since the

feed rate at this tim e becomes a dry run r ate different from the program-designated feed

rate, the axes may move at a feed rate higher than the programmed value.

After operation has been stopped temporarily and insertion, deletion, updating, or other

!

commands executed for the active program, unexpected operation of the machine may

result if that program is restarted. No such commands should, in principle, be issued for the

active program.

CAUTION

! During manual operation, fully check the directions and speeds of axial movement.

! For a machine that requires manual homing, perform manual homing operations after

turning power on. Since the software-controlled stroke limits will remain ineffective until

manual homing is completed, the machine will not stop even if it oversteps the limit ar ea.

As a result, serious machine damage will result.

Do not design ate an incorrect puls e multiplier when performing m anual pulse handle f eed

!

operations. If the m ultip lier is se t to 100 t im es and the han dle op erated i nadver tent ly, axia l

movement will become faster than that expected.

S-6

Page 9

OPERATIONAL WARRANTY FOR THE NC UNIT

OPERATIONAL WARRANTY FOR THE NC UNIT

The warranty of the manufacturer does not co ver a n y troub le ar is i ng if the NC un it is used for its

non-intended purpose. Take notice of this when operating the unit.

Examples of the trouble arising if the NC unit is used for its non-intended purpose are listed

below.

1. Trouble associated with and caused by the use of any commercially available software

products (including user-created ones)

2. Trouble associated with and caused by the use of any Windows operating systems

3. Trouble associated with and caused b y the use of any commercially available computer

equipment

Operating Environment

1. Ambient temperature

During machine operation: 5° to 40°C (41° to 104°F)

Note: When power is turne d on, if the therm al s ensor de tects an am bient t em perature und er

5°C, the hard disk warm-up status indic ator lamp will ligh t up and the NC un it will not

start operating at once. After autom atic heating of the hard disk by its int ernal heater,

the lamp will go out and the NC unit will start. It takes about 20 minutes for temperature

to increase from 0 to 5° C in order to avoid condensation due to sudden changes in

temperature.

2. Relative humidity

During machine operation: 30 to 75 % (without bedewing)

Note: As humidity increases, insulation deteriorates causing electrical component parts to

deteriorate quickly.

S-7

Page 10

- NOTE -

OPERATIONAL WARRANTY FOR THE NC UNIT

S-8

E

Page 11

CONSTRUCTION

Introduction

Part 1 MAZATROL PROGRAMMING PROCEDURES

Chapter 1 MAZATROL PROGRAM

Chapter 2 SYSTEM OF COORDINATES

Chapter 3 FUNCTION OF KEYS AND SWITCHES

Chapter 4 PROCEDURE BEFORE PERFORMING THE MACHINING

Part 2 MAZATROL PROGRAM FUNCTIONS

Chapter 1 CALLING UP AND THE END OF THE PROGRAM DISPLAY

Chapter 2 EDITION OF DATA

Chapter 3 WINDOW FUNCTIONS

Chapter 4 PROGRAM CREATION

Chapter 5 PRIORITY FUNCTION FOR THE SAME TOOL

Chapter 6 COORDINATES MEASUREMENT FUNCTION

Appendix

Chapter 7 TPC DATA CREATION

Chapter 8 BACKGROUND PROGRAMMING

Chapter 9 CASE OF APPEARANCE OF ALARM

Chapter 10 THREE-DIGIT G-FORMAT

Appendix 1 LIST OF M CODES

Appendix 2 PROGRAM EXAMPLES

Appendix 3 WHAT TO DO IN SUCH A CASE?

GC-1

Page 12

- NOTE -

GC-2

E

Page 13

Introduction

This manual describes only programming based on the MAZATROL language of the

MAZATROL FUSION 640M system. The description given in this manual assumes that the

readers have already read the relevant Operating Manual and thoroughly understood its

contents.

Programming in the MAZATROL langua ge uses an inter ac ti ve method that allows the system to

be operated in accordance with the messages displayed on the CRT monitor. Thus, even a user

who is to operate the system for the first time can readily create and edit programs.

Carefully read this manual and the Operating Manual to correctly operate the MAZATROL

FUSION 640M system and use its capabilities to their maximum.

H735P0A011E

NOTE:

The MAZATROL FUSIO N 640M controls the m achining center by digital calculat ion, but it is

possible that the m achining cannot be perf ormed because of the process ing of a calculation

error. Before proceed ing with autom atic operat ion therefore, do not fail to ins pect the path of

the tool on the display in order to verify that the machining is being done correctly.

1

Page 14

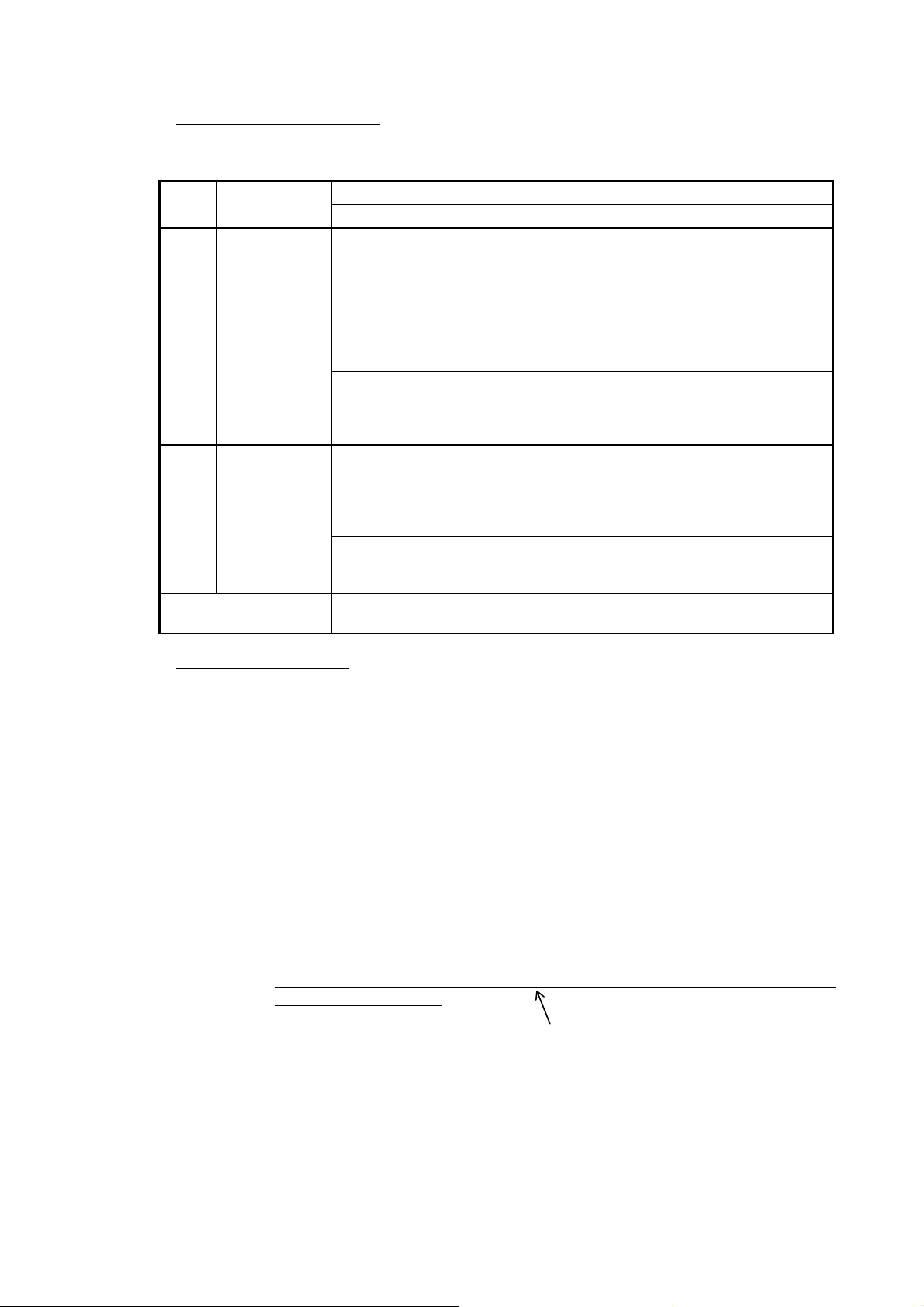

Organization of this manual

The following outlines the organization of this manual:

Part Title

1MAZATROL

PROGRAMMING

PROCEDURES

2MAZATROL

PROGRAM

FUNCTIONS

APPENDIX

Upper row – Directions for using the chapter

Lower row – Contents of the chapter

Those who are going to set up a MAZATROL program for the first time must first read this

part. Actually operate the MAZATROL FUSION 640M system from the beginning as

directed in Chapter 4, “PROCEDURE BEFORE PERFORMING THE MACHINING.” You

will then be able to roughly understand the entire operating procedure from tool

registration to creation of a MAZATROL program. Those who already have an

experience in creating a program using the MAZATROL M-1, M-2, M-32 or MAZATROL

FUSION 640M system will be able to understand the functions and usage of the M640M

system just by directly reading Part 2, “MAZATROL PROGRAM FUNCTIONS.”

The program architecture, coordinates systems, and operation keys are discussed here

as the basic information required for program creation in MAZATROL language. In

addition to the program creation procedures, successive processing procedures up to

machining are described in order after the discussion of the basic information.

Use the functions of the MAZATROL FUSION 640M system only after understanding the

MAZATROL program architecture and program creation procedures described in Part 1.

Also, use this part as a reference whenever required, such as in cases where you have

only a slight idea (or have forgotten) how to use a function, as you create a MAZATROL

program.

How to call up the

details of each function are described here. How to create programs in the background

mode, and how to act in the event of alarms are also discussed.

An M-code list, sample programs, and a Q&A (Questions and Answers) list are

contained. Read this appendix as appropriate.

PROGRAM

display, how to edit data, how to use a function, and

How to use this manual

Next, how to use this manual is briefly described below.

1. In Part 2, “MAZATROL PROGRAM FUNCTIONS,” where the operating procedures for

carrying out the MAZAT RO L la ngu age func t ions are described, the order of s el ect in g menu

items is indicated at “Menu selection.” Use the section as quick reference during menu

selection.

2. In Part 2, “MAZATROL PROGRAM FUNCTIONS,” where the operating procedures are

described, the arrow “!” under the description of each step of the procedure is followed bya

description of the results of the particular operation.

Example:

(1) Press the

! The message

SEARCH

menu key.

SEARCH DATA?

will be displayed and the menu will change to the

following address menu:

The section underlined above denotes the results of the operation.

2

E

Page 15

PART 1

MAZATROL PROGRAMMING

PROCEDURES

Part 1 describes the architecture of MAZATROL programs, coordinate systems,

the keys to be used for programming, and simplified programming procedures.

H735P10017E

Page 16

Page 17

CONTENTS

Page

1 MAZATROL PROGRAM...................................................................... 1-1

2 SYSTEM OF COORDINATES............................................................. 2-1

2-1 Machine Coordinates System............................................................................ 2-1

2-2 Workpiece Coordinates System......................................................................... 2-2

2-3 Machine Coordinates System and Workpiece Coordinates System.................. 2-3

2-4 Basic Coordinates.............................................................................................. 2-3

2-5 Auxiliary Coordinates......................................................................................... 2-4

3 FUNCTION OF KEYS AND SWITCHES..............................................3-1

4 PROCEDURE BEFORE PERFORMING THE MACHINING................4-1

4-1 Diagram of Preparation for the Machining.........................................................4-1

4-2 Part Drawings and Stock Materials.................................................................... 4-3

4-3 Registration of Tools.......................................................................................... 4-5

4-3-1 Calling up the TOOL FILE display .........................................................................4-5

4-3-2 Registration of tools...............................................................................................4-6

4-4 Creation of Simple Programs............................................................................. 4-9

4-4-1 Program structure..................................................................................................4-9

4-4-2 Calling up the PROGRAM display.......................................................................4-10

4-4-3 Assigning workpiece numbers.............................................................................4-11

4-4-4 Creating a program..............................................................................................4-13

4-4-5 Creation of common unit .....................................................................................4-13

4-4-6 Creation of basic coordinates system unit ...........................................................4-15

C-1

Page 18

4-4-7 Face machining unit ............................................................................................4-17

4-4-8 Line machining unit..............................................................................................4-27

4-4-9 Point machining unit (1).......................................................................................4-37

4-4-10 Point machining unit (2).......................................................................................4-46

4-4-11 End unit...............................................................................................................4-53

4-4-12 End of the program..............................................................................................4-54

4-5 Registration of Tools in a Tool Data File.......................................................... 4-56

4-5-1 Pocket numbers and tool numbers......................................................................4-56

4-5-2 TOOL DATA display............................................................................................4-57

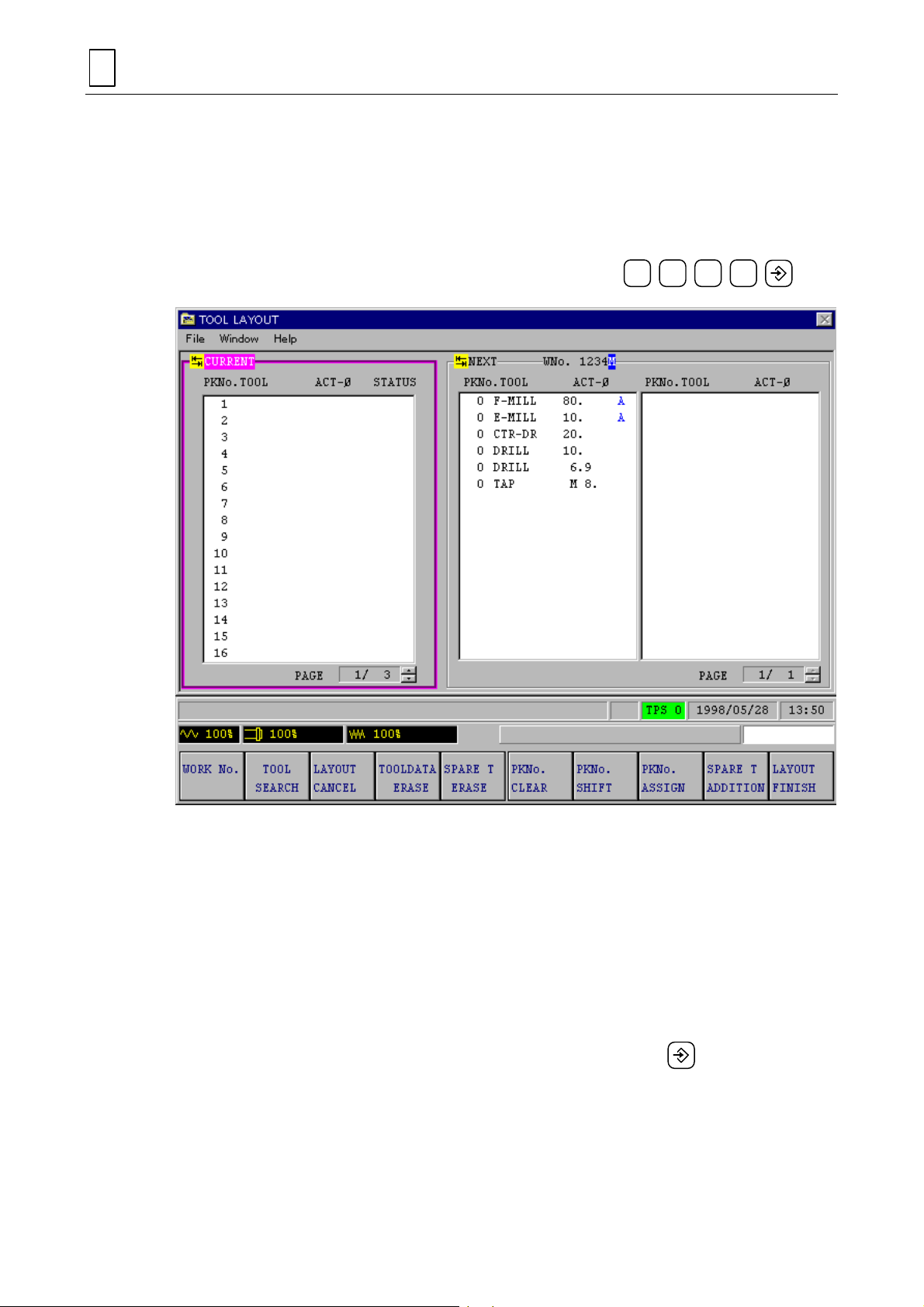

4-5-3 TOOL LAYOUT display .......................................................................................4-59

4-5-4 Registration of tools.............................................................................................4-62

4-6 Check of the Machining Path........................................................................... 4-65

C-2

E

Page 19

1 MAZATROL PROGRAM

The machining MAZ ATROL program of a work piece consists in principle of the following four

units:

1. Common unit

This concerns a un it which is obligatoril y entered in the pr ogram head . It specifies the comm on

data to a program assembly such as the material, the initial point, the machining of several

workpieces, etc.

2. Basic coordinates system unit

Use to specify the value of the coordinates (basic coordinates) of the workpiece zero point in the

machine coordinates system.

3. Machining unit

Use to specify the data concerning the machining method and the machining form.

The machining unit is available in the following three types:

Point machining unit

MAZATROL PROGRAM

1

-Drilling

- RGH CBOR machining

- RGH BCB machining

- Reaming

- Tapping

-Boring

- Back boring

- Circular milling

- Counterbore-tapping

Line machining un i t

- Central linear machining

- Right-hand linear machining

- Left-hand linear m achining

- Outside linear machining

- Inside linear machining

- Right-hand chamfering

- Left-hand chamfering

- Boring of through hole

- Boring o f stepped through hole

- Boring of non-through hole

- Boring o f stepped n on-through hole

Face machining unit

- Face milling

- End milling-top

- End milling-step

- Pocket milling

- Pocket milling-mountain

- Pocket milling-valley

- End milling-slot

- 3-D (option)

H735P1A010E

- Outside chamfering

- Inside chamfering

Moreover, the necessary data are specified in the following two sequences:

Tool sequence ............... Use to specify the data concerning the name of the tool and the

movement of the tool.

Shape sequence ............ Use to specify the data related to the machining dimensions.

1-1

Page 20

1

MAZATROL PROGRAM

4. End unit

Unit created at the end of program.

Also, the following units are entered when necessary.

5. Auxiliary coordinates system unit

Use to specify the auxiliary coordinates system (OFFSET).

6. Special mode unit

There are the following special mode units. It is possible that these units marked with an asterisk

(*) can not be used or executed in certain machine models.

M code............................ Output of M code

Sub-program................... Calling up a sub-program

Pallet changing*.............. Changing of pallet

Indexing*......................... Use to specify the angle of the indexing table.

Process end.................... Delimits the useful scope of the priority function for the same tool.

7. Manual program mode unit

This unit is entered t o establish a program cor responding to the EIA/I SO program using the G

and M codes which permits performing minute movement or a movement other than machining.

8. MMS unit

Automatic measur ement of a basic coordinates s ystem (WPC). MMS unit cann ot be used for

certain machines or will not be performed even if programmed.

1-2

E

Page 21

2 SYSTEM OF COORDINATES

(

)

–Y–

–

(

)

In the preparation of the pr ogram, a system of c oordinates is used for introduci ng th e pos it ion of

the machining and the form of the machining.

The system of coordinat es of the machining cen ter consists of thr ee axes of coordinat es which

each cross the reference zero point at right angles.

An arbitrary point found in this system of coordinates can be defined by the value of the

coordinates in the 3 axes (X, Y and Z).

There are two types of systems of coordinates:

- Machine coordinates system

- Workpiece coordinates system

Z axis

SYSTEM OF COORDINATES

2

X axis

Fig. 2-1 Coordinates system

2-1 Machine Coordinates System

The machine actually m oves in its own system of coordinat es called the machine coordinates

system. A point of reference in this system of coordinates is known as machine zero point.

Generally, the machine coordin ates system has the machining zone on the side of the minus

(negative) direction from the machine zero point.

Note:

The following figure represents the case of vertical machining center.

Machining zone

Machine coordinates system

Axis of X

coordinate

X

+Z

+Y +X

Machine zero point

X0, Y0, Z0

Axis of Z

coordinate

Z

Reference point zero

Y axis

M3P001

Axis of Y

coordinate

Table

NM210-00510

Fig. 2-2 Machine coordinates system

H735P1B010E

2-1

Page 22

2

SYSTEM OF COORDINATES

2-2 Workpiece Coordinates System

If the program is prepared on the bas is of the m achine coordinates system, the entering of the

machining position and of the form of machining is very complex, tedious and inflexible.

Consequently, a temporary reference point is taken in the machine coodinates system for

preparing the program.

The point thus taken is called the workpiece zero point, and the system of coordinates taking this

point as reference is called the workpiece coordinates system.

Example:

Plan of the workpiece

P2

R5

P1

M3P002

100

95

Zero point of

the workpiece

to be taken

60

20

P3

R5

50

φ

5

5

50

M8 tapped holes

(4 places)

10-mm diameter

drilled hole

100

145

150

- When the dim ensions are entered of the configuration on the basis of the ab ove plan of the

workpiece, the bottom left hand corner is taken as the workpiece zero point.

- In this case, the value of the coordinates of the configuration is the following:

Workpiece zero point = ( 0, 0, 0)

P1 = (150, 0, 0)

P2 = (150, 100, 0)

P3 = ( 0, 100, 0)

The adoption of the work piece zero point facilitates the enter ing of the machining dimensions

and therefore the programming.

2-2

Page 23

SYSTEM OF COORDINATES

2-3 Machine Coordinates System and Workpiece Coordinates System

The relationship bet ween the machine coordinates s ystem and workpiece coord inates system

when workpiece has been mounted on the table of a machine is shown below.

Machine coordinates system

Machine coordinates system

Workpiece coordinates system

2

<Model V, double column type> <Model V>

The above relationship may slightly differ according to the type of machine being used.

Note:

Fig. 2-3 Machine coordinates system and workpiece coordinates system

2-4 Basic Coordinates

The machine moves in the machine coordinates system whilst the program is prepared

depending on the workpiece coordinates system.

NM210-00511

<Model H>

NM210-00512

Machine coordinates system

Workpiece coordinates system

NM210-00513

It is necessary therefore to enter in the program, the position relation between the machine

coordinates system and the workpiece coordinates system.

The unit of entry is called the basic coordinates unit.

The basic coordinates are entered as values of the coordinates of the workpiece zero point in the

machine coordinates system.

The unit of the basic coord inates is entered by utilizing the coord inates measurement function

after the workpiece is placed on the machine.

2-3

Page 24

2

(

)

A

SYSTEM OF COORDINATES

Basic

coordinate Z

Basic

coordinate X

Z

−

X

−

+Z

+Y

Fig. 2-4 Basic coordinates

+X

Workpiece zero point

Example of entering of the basic coordinates unit:

Machine zero point

Machine coordinates system

Basic coordinate Y

Y

−

Workpiece coordinates system

NM210-00514

UNo.

1

Basic coordinates unit

No. of basic coordinates

unit

Basic coordinate X

Example: –500

Basic coordinate Y (Exam pl e: –300)

2-5 Auxiliary Coordinates

The auxiliary coordinates are used for offsetting the workpiece zero point to any position in order

to further facilitate the preparation of the program.

The auxiliary coordinates unit (OFFSET) is entered as a value of offsetting in the workpiece zero

point.

UNIT

WPC-0

ADD. WPC X

-500.Y-300.

th

0.

Basic coordinate Z

(Example: –200)

ngle formed by the axes X and Y of the

machine coordinates system and the axes X and

Y of the workpiece coordinates system.

Z

-200.

4

0.

Coordinate or

angle of 4th

axis, if there

is one.

2-4

Page 25

1. Example of entering of auxiliary coordinates

+y

0

R

0

70

Workpiece zero point

In this example, the entering of the position of hole P1 requires a very complicated

calculation.

P2

50

P1

20

30°

SYSTEM OF COORDINATES

+x

0

M3P003

2

P1 = (70 + 50 ×

3

2

, 50 ×

1

)

2

However, the use of auxiliary coordinates permits performing this entering easily.

+y

1

P2

20

P1

R

R

0

70

1

50

Zero point offset in auxil iary

coordinates mode

30°

+x

1

M3P004

As the figure above s hows, positions P1 and P2 ar e entered as follows by off setting the

workpiece zero point to R1.

P1 = (50, 0)

P2 = (50, 20)

In this case, the auxiliary coordinates unit to be programmed is as follows:

UNo.

2

Auxiliary coordinates unit

Offsetting on X axis

UNIT

OFFSET

U (X)

70.

V (Y)

0.

Offsetting on Y axis

D (th)

30.

Offsetting on Z axis

Angle with relation

to workpiece

coordinates system

2-5

W (Z)

0.

Page 26

2

SYSTEM OF COORDINATES

2. Cancellation of auxiliary coordinates

The system of auxiliary coordinates is voided in the following cases:

A. The system of aux iliary coordi nates specif ied in a sub- program is void ed at the t ime of the

return on the main program.

When the main program contains a system of auxiliary coordinates, th e return is made to

this system of auxiliary coordinates.

B. The system of auxiliar y coordinates is voided when a new s ystem of basic coordinates is

introduced. In this case, the state without a system of auxiliary coordinates is assumed.

(When the system of basic coordinates was specified in the sub-program as shown in

Figure 2-5, the retur n to the main program has the effect of voiding the s ystem of auxiliar y

coordinates of the main program.)

Main program

WPC-1

Machining [1]

Subprogram

Machining [2]

WPC is a code that signifies the bas i c coordinates system.

Machining [2] is performed under the coordinates system of WPC-2.

Fig. 2-5 Basic coordinates system after execution of subprogram

Sub program

WPC-2

M3P005

2-6

E

Page 27

3 FUNCTION OF KEYS AND SWITCHES

A MAZATROL program can be c reated usin g onl y the k eys and switches ind icated i n the d otted

portion on the operating panel shown in Fig. 3-1 and Fig. 3-2.

FUNCTION OF KEYS AND SWITCHES

3

H735P1C017E

3-1

Page 28

FUNCTION OF KEYS AND SWITCHES

3

1

3

5

7

6

8

4

2

9

D735P0001

Fig. 3-1 Keys and switches used for creating a MAZATROL program <M640M, M640M-5X> ( portion)

3-2

Page 29

FUNCTION OF KEYS AND SWITCHES

3

1

3

5

7

6

8

4

2

9

D735P0001’

Fig. 3-2 Keys and switches used for creating a MAZATROL program <M640M NEXUS> ( portion)

3-3

Page 30

FUNCTION OF KEYS AND SWITCHES

3

Table 3-1 Functions of keys and switches

No. Name Description

1 Display selector key

2 Menu selector key Press this key to select menu that is displayed on the bottom of the screen.

3 Menu keys

4 Cursor keys

5 Numeric keys

6 Input key Press this key to register keyed-in data in the data display area.

7 Clear key

8 Data cancellation key

9 Page keys

Press this key to select between displays. Depression of this key causes a display

selection menu to be displayed in the menu display area.

A specific key is assigned to each of ten menu data that are displayed in the menu

display area. Press the appropriate key to carry out the operation speci fied by the

particular display or to input the data specified by the particular display.

Press the apropriate key to move the cursor in the desired direction. If a cursor key

is pressed and held down, the cursor will move continuously in the corresponding

direction.

Use these keys to key in the numerics 0 to 9, the minus sign ( – ), and/or the

decimal point ( . ).

Press this key to cancel the data currently being displayed in the data selection

area. This key is also used for erasure of the alarm display.

Press this key to cancel the data that has been displayed in the data display area.

Depression of this key causes the data in the cursor position to be erased.

Press the appropriate key to move the cursor unit by unit. Pressing and holding

down the key will move the cursor unit by unit continuously.

Note: The numbers in the No. column corresponds to those in Fig. 3-1 and 3-2.

3-4

E

Page 31

PROCEDURE BEFORE PERFORMING THE MACHI NING

4 PROCEDURE BEFORE PERFORMING THE MACHINING

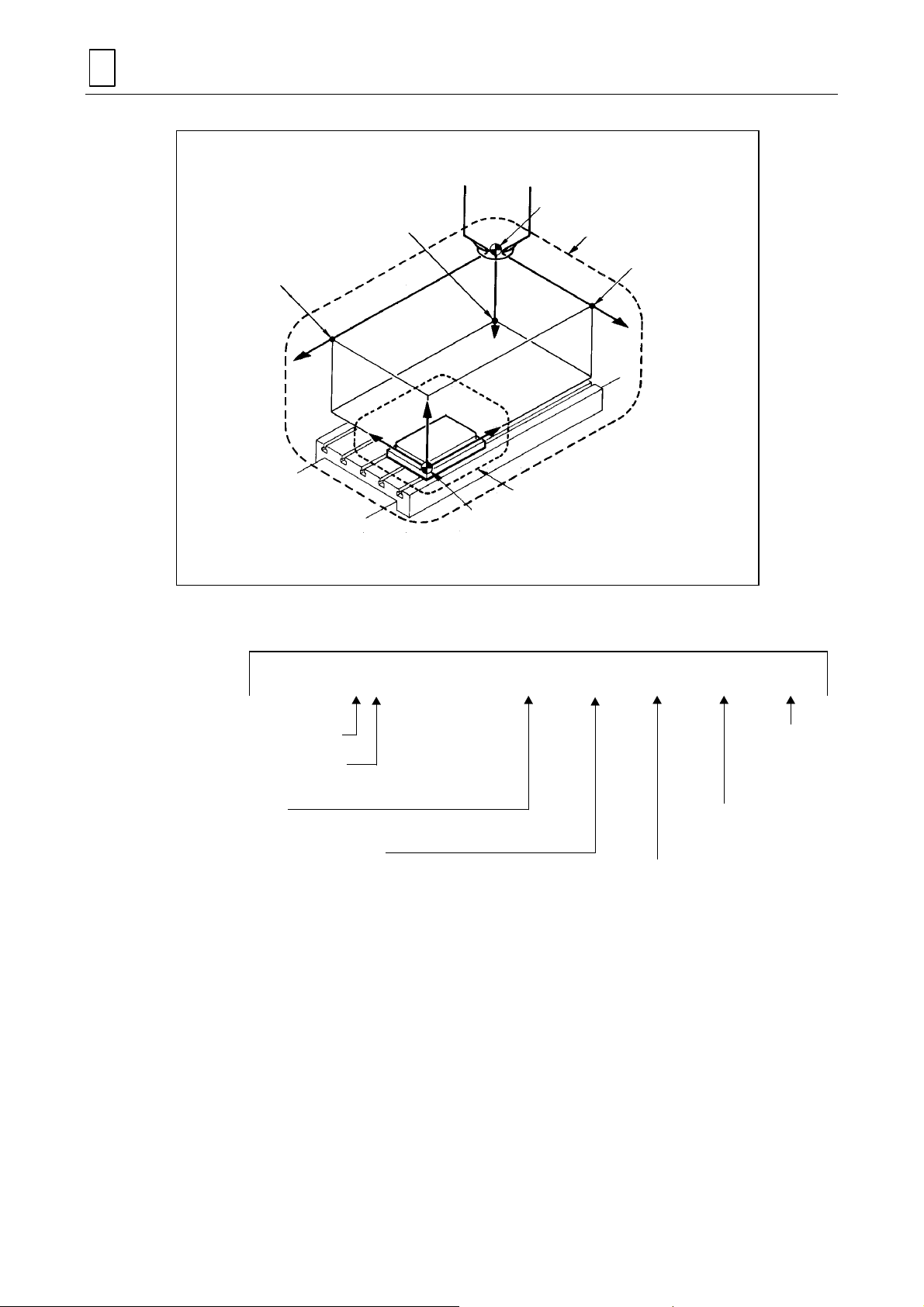

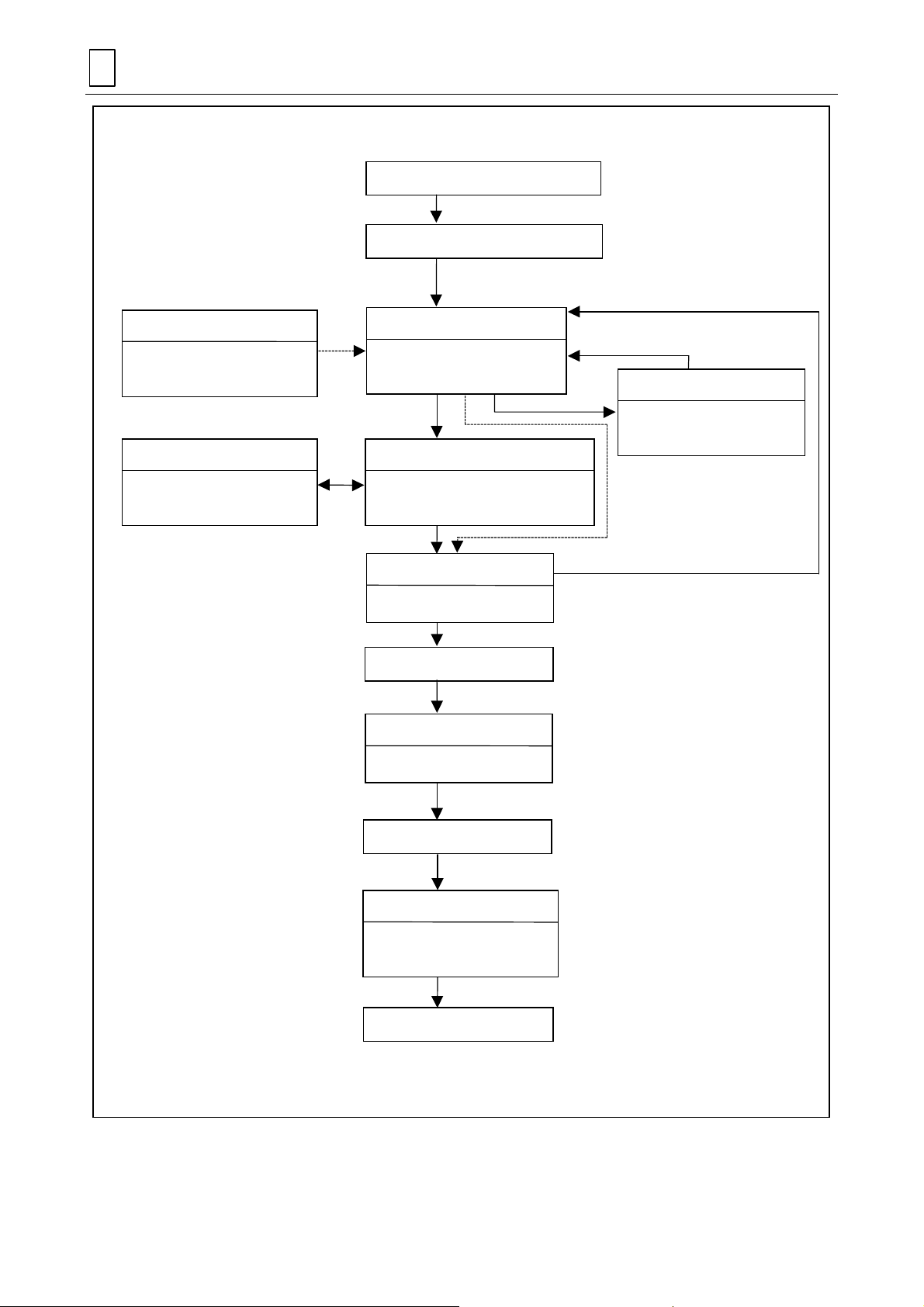

4-1 Diagram of Preparation for the Machining

To machine a workpiec e, it is essential to co ordinate the pr ogramming and th e preparations for

the tool and the workpiece. The f ollowing diagram shows the ge neral procedure to be foll owed

before performing the machining.

4

Note 1:

Note 2:

It is possible to m onitor the path of the tool even if the tool is not recorded in the tool

data. (The path of the tool is laid out by taking the diam eter of the tool = the nominal

diameter and the length of the tool = 0).

Automatic operation c an not be perform ed if the tool used is not recorded in the t ool

data.

H735P1D011E

4-1

Page 32

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

Preparation of part drawings

Reflection of the mounting workpiece

TOOL FILE

Recording of tools available in

the workshop

TOOL DATA

Verification of the tools

mounted on the tool magazine

display

display

PROGRAM

Preparation of machining

program op

TOOL LAYOUT

Recording of a tool to be mounted on

the tool magazine

TOOL PATH CHECK

Verification of path of tool form

Installation of tool

TOOL DATA

Measurement of length of tool

display

display

display

display

SHAPE CHECK

Verification of the programmed

form

display

Installation of workpiece

PROGRAM

Measurement of basic

coordinates

Automatic operation

Fig. 4-1 Procedure before performing the machining

display

4-2

M3P006

Page 33

4-2 Part Drawings and Stock Materials

g

(

)

φ

The following shows the part drawing for which a program is to be created in Section 4-4.

PROCEDURE BEFORE PERFORMING THE MACHI NING

4

R5

50

100 95

60

20

5

5

50

100

145

Fig. 4-2 Part drawing example

M8 tapped holes

(4 places)

10-mm diameter

drilled hole

150

Held by a vise, the part to be machined is shown below.

R5

10

20

Material: Carbon steel

Finish-machinin

surface:

∇, ∇∇

M3P007

NM210-00516

Machining of this part consists of the following four processes:

4-3

Page 34

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

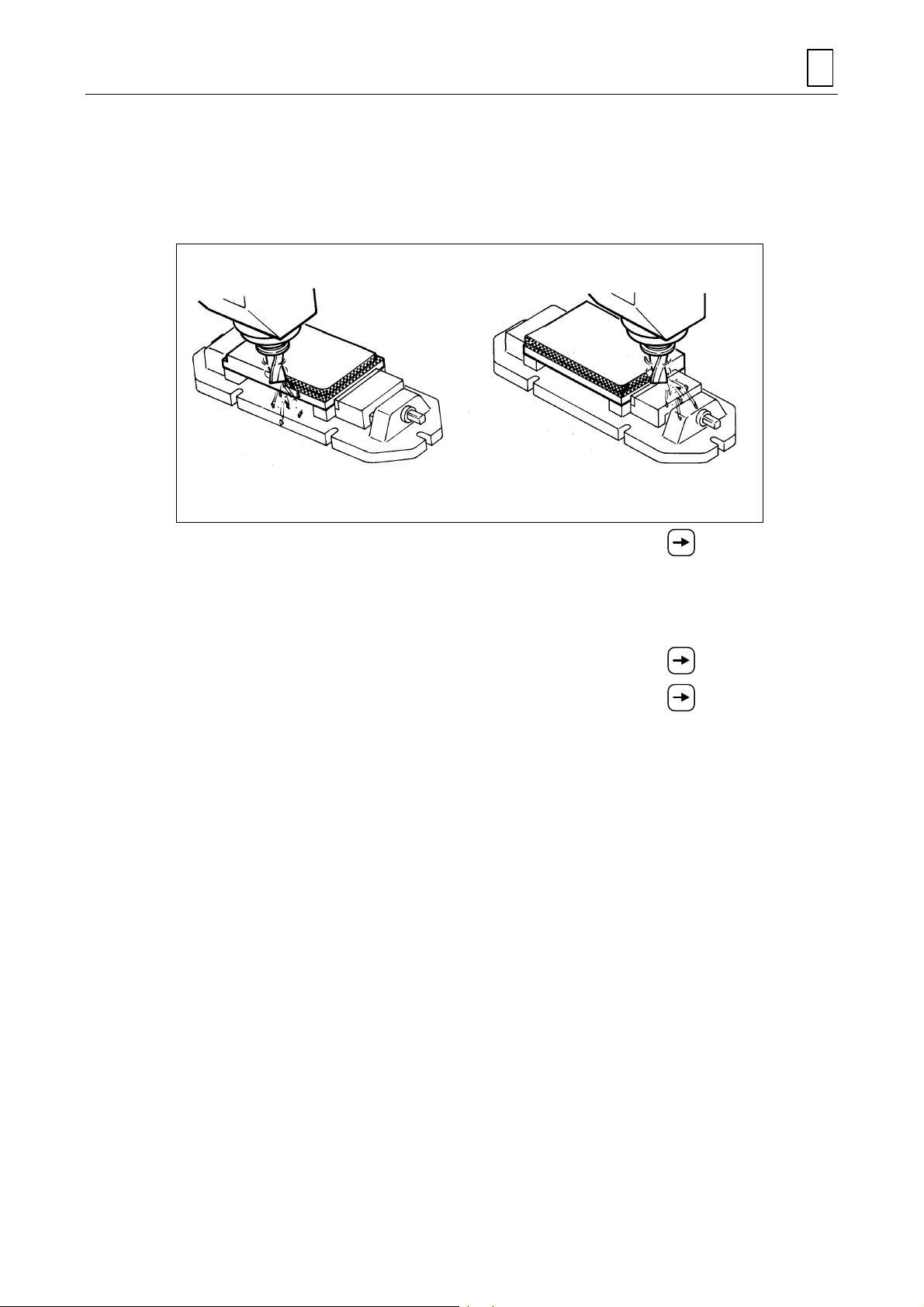

[1] Milling the top face of the workpiece. [2] End-milling the edges of the workpiece.

[3] Drilling a 10-mm diameter through-hole. [4] Drilling four M8 tapped holes.

NM210-00517 NM210-00518

NM210-00519 NM210-00520

4-4

Page 35

4-3 Registration of Tools

First, turn on the power to return the axes to the zero point.

Next, turn the reprogramming switch to the ENABLE position using the key.

Fig. 4-3 Reprogramming switch

PROCEDURE BEFORE PERFORMING THE MACHI NING

Turn

NM210-00521

4

Before creating the program, information on the tools located in the workshop must be registered

in a tool file. Unregistered tools cannot be used for programming or automatic run.

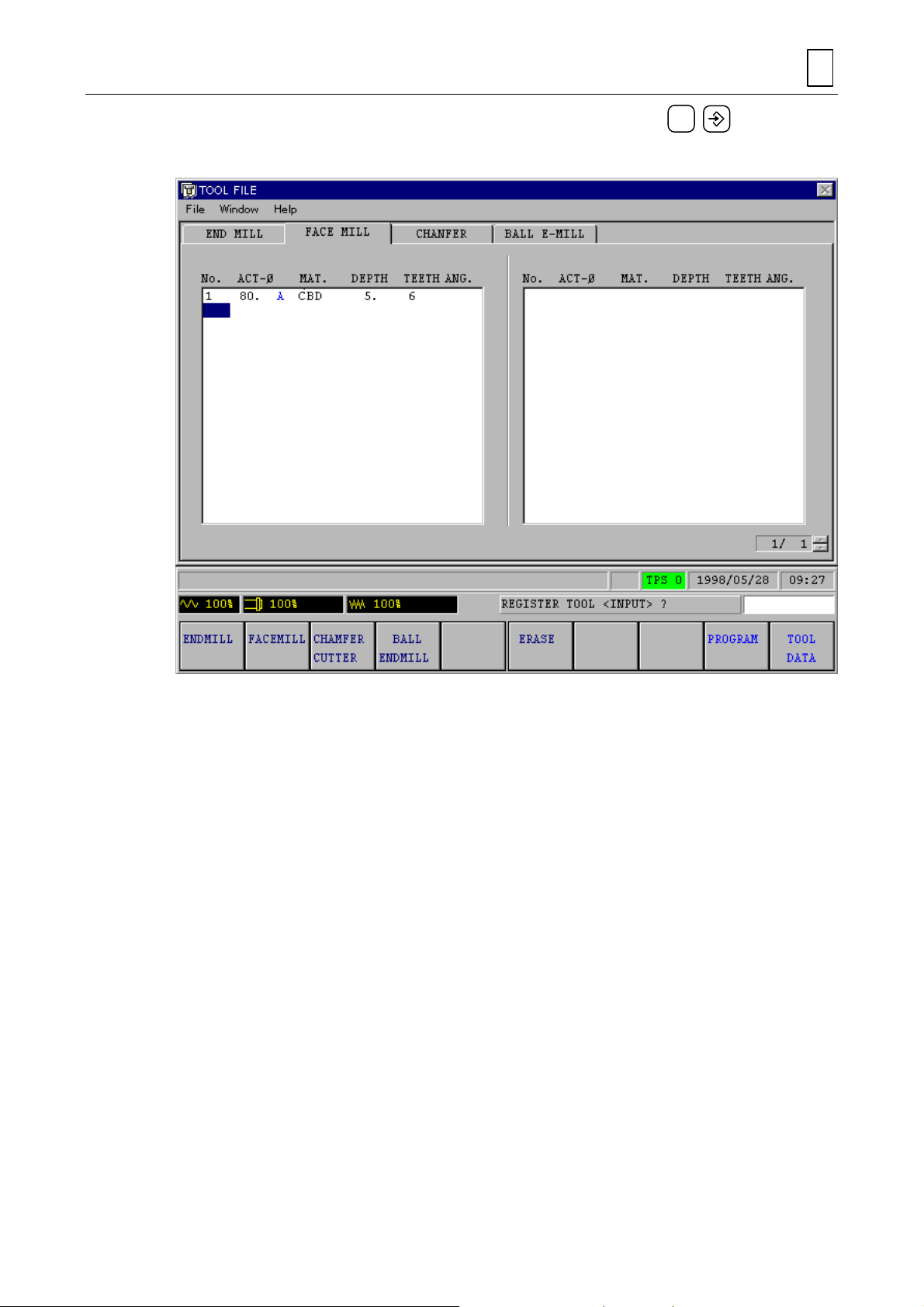

4-3-1 Calling up the TOOL FILE display

Call the

TOOL DATA

TOOL DATA

. Then press the menu key

display by pressing firs tly the disp lay selector k ey and then t he menu k ey

TOOL FILE

to call the following

TOOL FILE

display.

4-5

D735P0002E

Page 36

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

Register tools in the

End mill Face mill Chamfering cutter Ball-end mill

NM210-00522 NM210-00523 NM210-00524 NM210-00525

Tools other than these f our types do not nee d to be registered. T ool selection is automatically

made by the NC unit during programming.

4-3-2 Registration of tools

In this chapter, programming is to be carried out by using the two types of tools shown below.

TOOL FILE

display. The tools to be registered here are as follows:

End mill

Tool material:

Cemented carbide

Number of teeth: 2

30

10

NM210-00522

Fig. 4-4 Registered tools example

Face mill

Tool material:

Cemented carbide

Number of teeth: 6

5

80

NM210-00523

4-6

Page 37

PROCEDURE BEFORE PERFORMING THE MACHI NING

1. Registering the end mill

Using the page keys, search the display for the tool indicated as E-MILL 10. A.

Up to 256 tools can be registered. If the tool is found, this indicates that the tool has been

registered; therefore, proceed to the procedure described in “Registering the face mill.”

4

(1) Press the cursor key

!

The message

display area.

(2) Press the input key

!

The message

(3) Input an approximate tool-diameter value (in this example, input 10 by pressing numeric

1

keys

!

The message

(4) Input a specific code th at identifies the p articular tool ( in this example, input A b y pressing

menu key A).

and

NOMINAL DIAMETER?

0

and then pressing the input key ).

TOOL ID CODE <MENU>?

and position the cursor on an unregistered tool number.

REGISTER TOOL <INPUT>?

to register the tool.

will be displayed.

will then be displayed in the message

will be displayed.

D735P0003E

D735P0004E

!

The message

(5) Select the tool material from the tool material menu. Material names registered in the

CUTTING CONDITION

carbide by pressing menu ke y

!

The message

(6) Input the maximum depth to which the work piece can be cut in the axial directio n by one

cutting operation ( in this example, input 30 by press ing numeric keys

then pressing the input key

!

The message

TOOL MATERIAL <MENU>?

display are disp layed as menu (in this exam ple, select cemented

CARBIDE

MAX DEPTH OF CUT?

).

NUMBER OF TEETH?

).

will be displayed.

4-7

will be displayed.

will be displayed.

3

and

0

and

Page 38

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

(7) Input the number of teeth of the t ool ( in this ex am ple, input 2 b y pressing n um eric ke y

and then pressing the input key ).

!

Registration of the 10-mm diameter end mill will be completed as shown below.

2

2. Registering the face mill

The operations to be carried out are similar to those required for registering the 10-mm diameter

end mill. For brevity of description, the displayed message and key(s) to be pressed are noted to

the right and left respectively as shown below.

(1) Press the menu key

Check if the tool indica ted as 80. A is inc luded in the

the tool is found, then t his indicates th at the t ool has been reg istered. Thus , the oper ations

shown below are not required.

(2) Position the cursor on an unregistered tool number.

REGISTER TOOL <INPUT>?

(3)

NOMINAL DIAMETER?

(4)

TOOL ID CODE <MENU>

(5)

TOOL MATERIAL <MENU>

(6)

MAX DEPTH OF CUT?

(7)

FACE MILL

.................................................................

..................................................................

.

TOOL FILE (FACE MILL)

........................................................

?............................................................

? ........................................................

8 0

A

CARBIDE

5

D735P0005E

display. If

4-8

Page 39

PROCEDURE BEFORE PERFORMING THE MACHI NING

4

NUMBER OF TEETH?

(8)

!

This completes registration of the 80-mm diameter face mill as shown below.

...................................................................

6

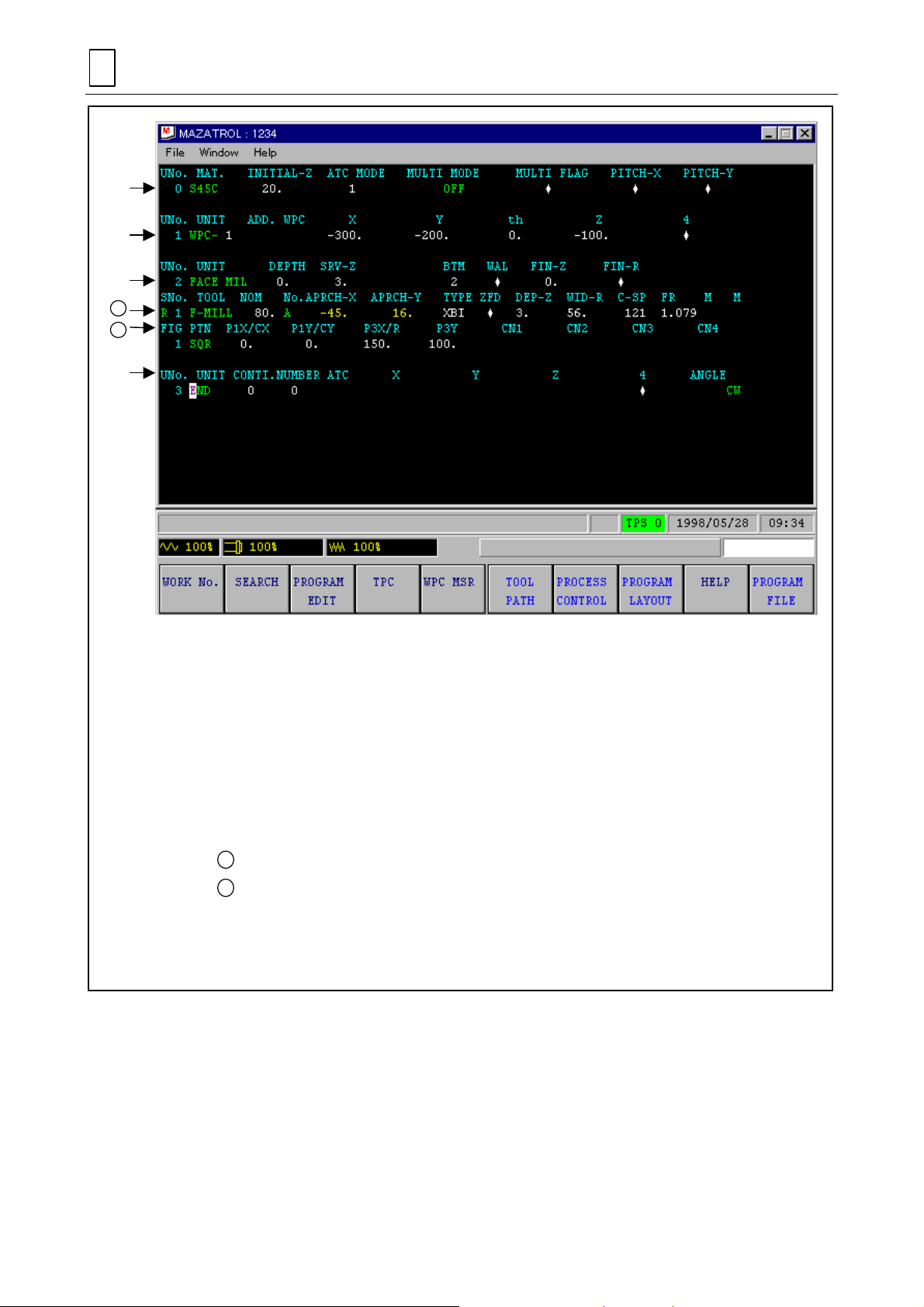

4-4 Creation of Simple Programs

4-4-1 Program structure

The structure of MAZATROL program is described before creating a program. Each MAZATROL

program consists of units. Conversely, a combination of program units forms a program. The

name of each part of a program is described below using part of the program to be created.

D735P0006E

4-9

Page 40

4

A

B

A

B

PROCEDURE BEFORE PERFORMING THE MACHINI NG

[1]

[2]

[3]

[4]

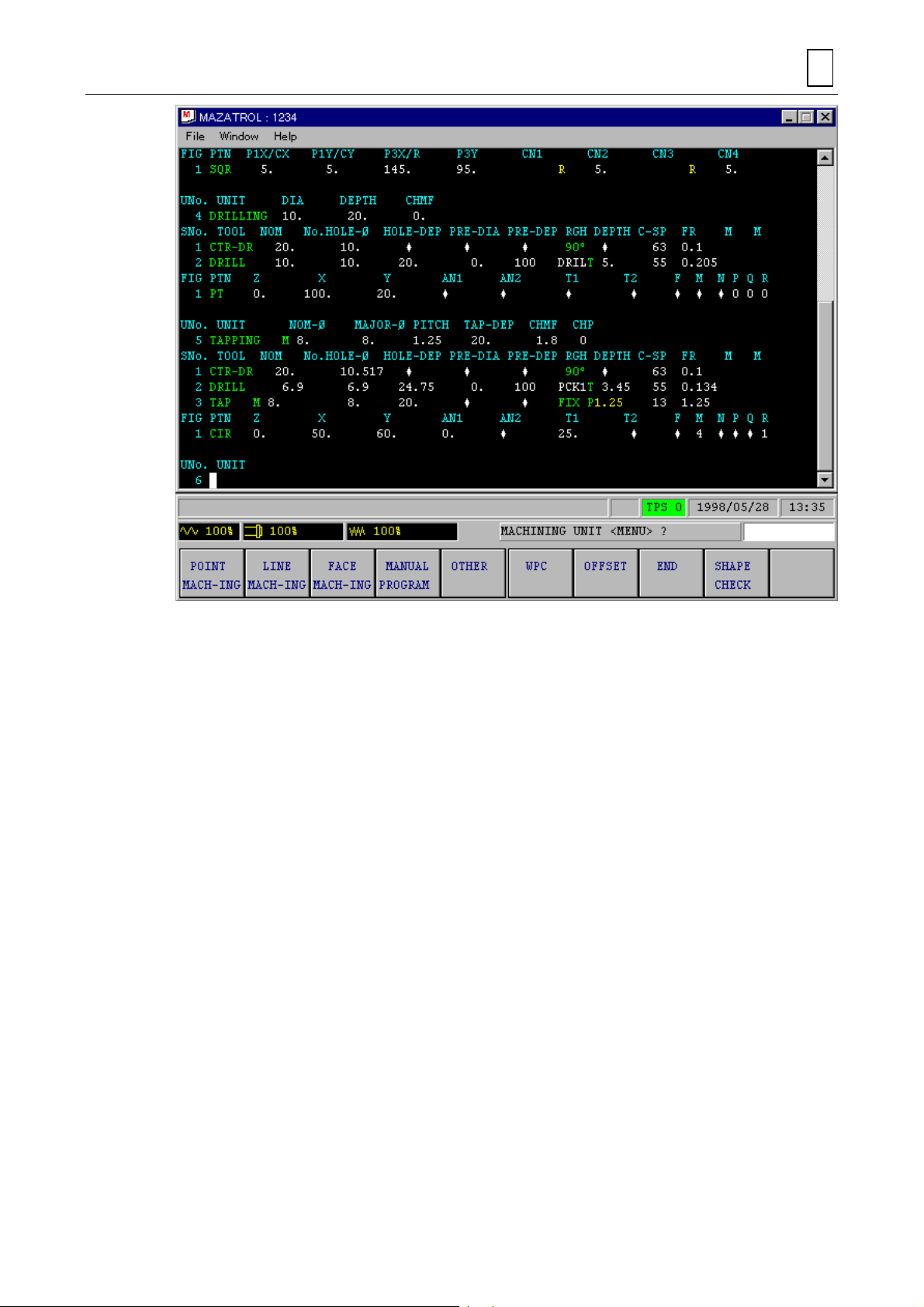

D735P0007E

[1] Common unit

Basic data rel a ted to the en tire prog ra m, su c h as the ma teria l of th e workpiece, is to be

input to this unit.

[2] Basic coordinates system unit

The coordi nat e values of the workpi ece zero poin t in the mach ine coo rdin ates s ystem

are to be input to this unit.

[3] Machining units

Various types of machining units are provided. Data related to selection of a machining

method an d to machining di m e ns ions are to be input to these units.

Tool sequence ................consists of data inputs related to the operation of a tool.

Shape sequence............. consists of data inputs related to the machining shape on

a drawing.

[4] End unit

Denotes the end of a program (i.e., the completion of machining).

Fig. 4-5 Program structure

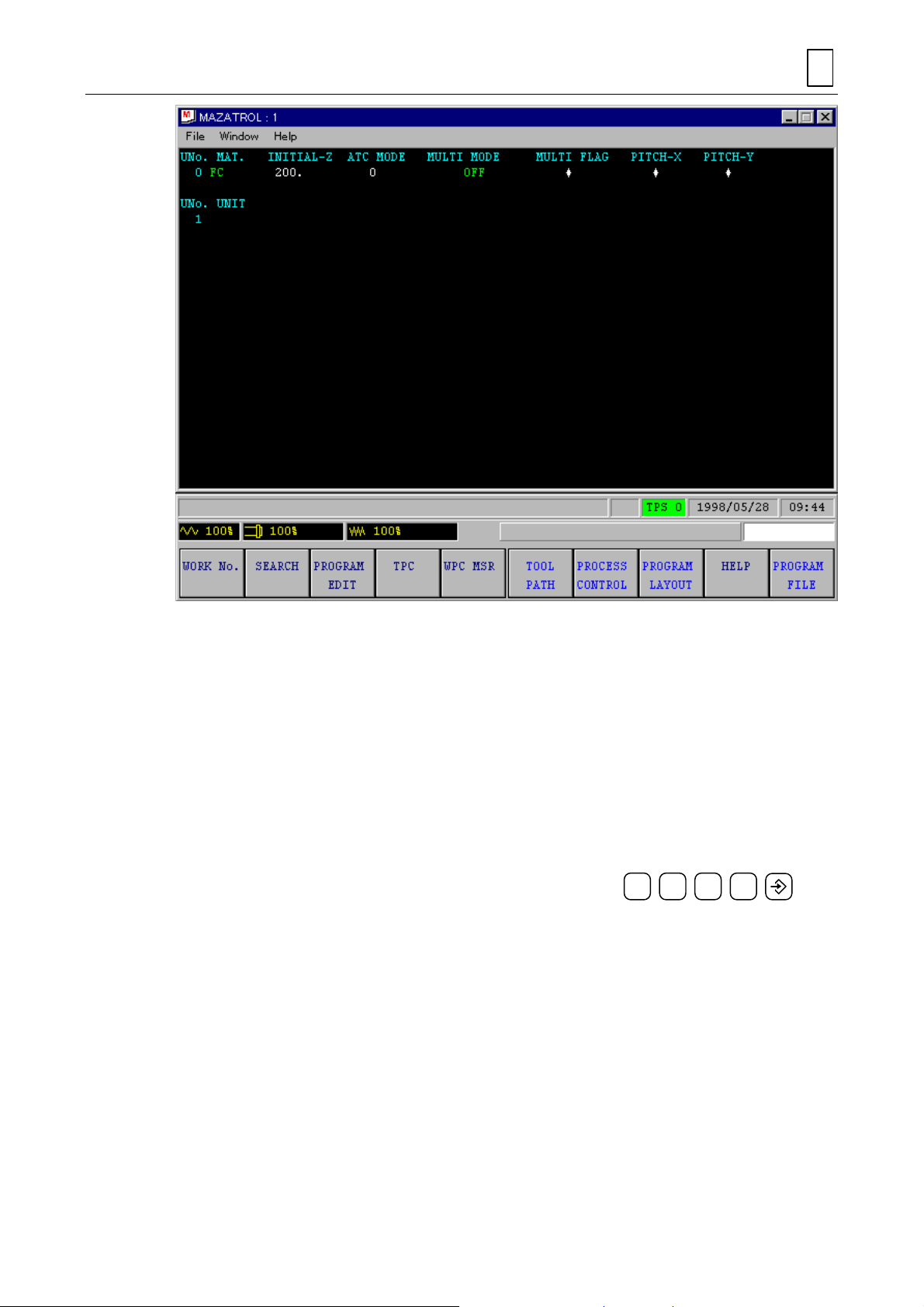

4-4-2 Calling up the PROGRAM display

First, the

FILE

display:

PROGRAM

display is to be presented as previously done when displaying the

TOOL

(1) Press the display selector key.

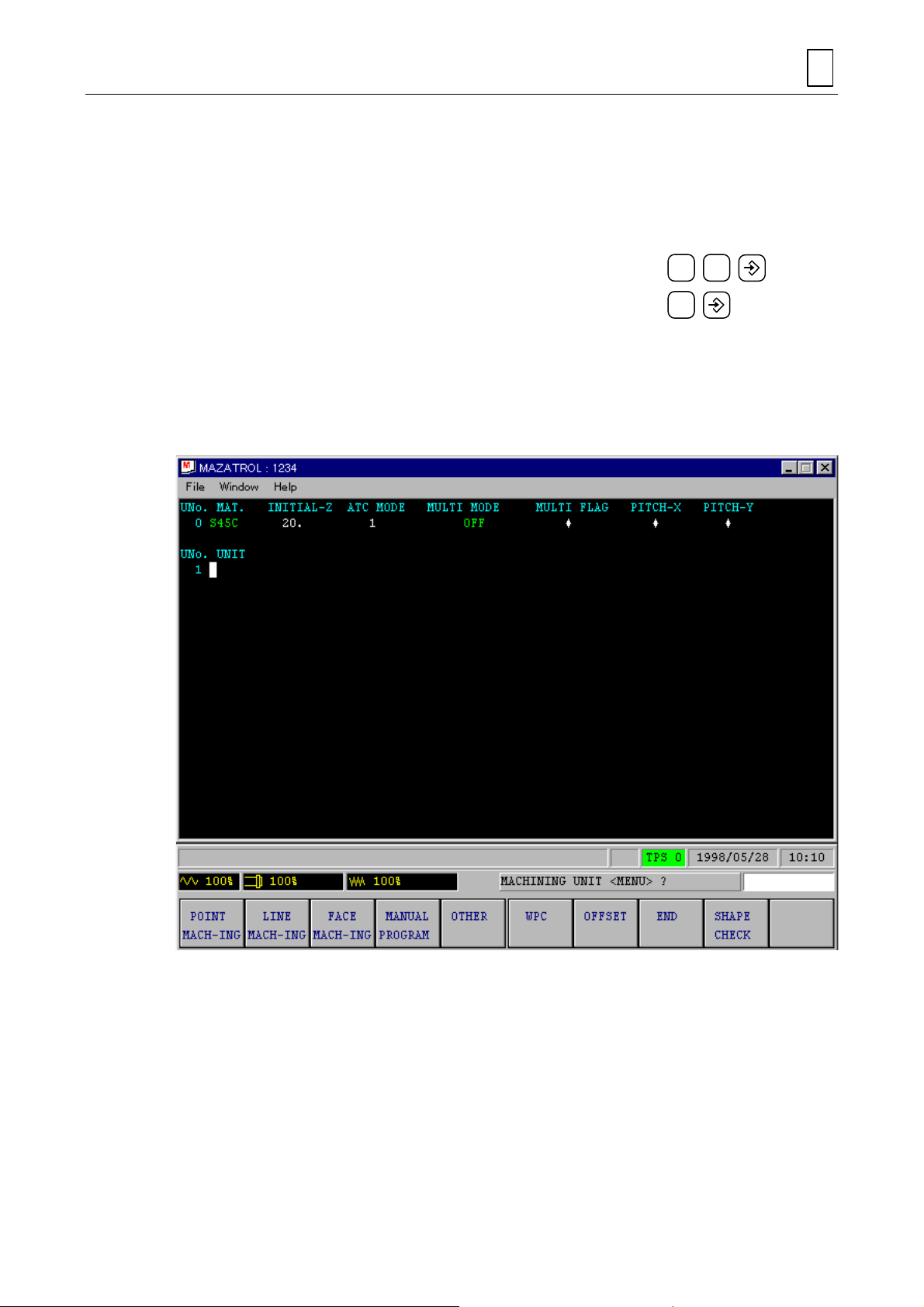

(2) Press the menu key

!

The

PROGRAM

PROGRAM

.

display will be presented then as shown belo w.

4-10

Page 41

PROCEDURE BEFORE PERFORMING THE MACHI NING

4

Note:

The above display status is referred to as the listing mode.

The listing mode is a program-contents check mode.

For details, see Part 2, Section 1-1, “Listing Mode and Creating Mode.”

4-4-3 Assigning workpiece numbers

Number the individual pro grams to be created. T hese numbers identif y the individua l programs

just as part number in a part drawing identif ies the indi vidual parts . These num bers are r eferred

to as workpiece num bers , and the desired number f r om 1 to 9999 999 9 c an be se lec ted for each

program. Here, workpiece No. 1234 is to be set.

(1) Press the menu key

WORK No.

(2)

!

The message

If either one of the t wo displays [1] and [2] sho wn below is displayed inste ad of this

message, then this indicat es that workpiece No. 1 234 has already been used. In that

case, input a different workpiece number.

............................................................................

WORK No.

NEW PROGRAM <MENU>?

1 2 3 4

will be displayed.

D735P0008E

4-11

Page 42

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

[1] MAZATROL program

[2] EIA/ISO program

D735P0009E

4-12

D735P0010E

Page 43

PROCEDURE BEFORE PERFORMING THE MACHI NING

4

Note:

In M640M, two different programs can be created. The program [1] above is referred to

as a MAZATROL program, and the one [2], as an EIA/ISO program.

4-4-4 Creating a program

Let us create a program.

(1) After setting the workpiece number, press the menu key

!

The display shown in Figure 4-6 will be presented. T he program creation will become

possible. This status is referred to as the creating mode.

If the EIA/ISO prog ramming function (optio n) is provided in the s ystem, the following

menu will be displayed.

WORK No. EIA/ISO

PROGRAM

(2) The following display will be presented. The program creation will become possible.

MAZATROL

PROGRAM

MAZATROL PROGRAM

.

Fig. 4-6 PROGRAM display (edit mode)

4-4-5 Creation of common unit

The common unit is the program unit that must be created a t the head position of a pr ogram.

Basic data on the entire program is to be input to this unit.

The help window is described here before the creation of comm on unit. Prior t o input of data to

the unit, full details of the data to inp ut c an be dis p layed on the screen for ease of pr ogramming.

This display is referred to as the help window display. Carry out the following operation to display

the help window display:

D735P0011E

4-13

Page 44

4

p

PROCEDURE BEFORE PERFORMING THE MACHINI NG

(1) Press the menu key

HELP

.

The following help window display will be presented.

D735P0012E

Now, start creating the common unit. The data for the article MAT, INITIAL-Z and ATC

MODE will be specified here.

MAT Specify the material of the workpiece.

INITIAL-Z Specify the initial he ight of the t oo l where it c om es close to th e work piece

for machining purposes (see figure below).

From this level up, the t ool

is kept clear of the workpiec e

or jigs.

Initial point

Workpiece

oint

zero

M3P018

Fig. 4-7 Tool path

4-14

Page 45

PROCEDURE BEFORE PERFORMING THE MACHI NING

ATC MODE Specify the manner in whic h the too l is to be returned to the ATC pos iti on

for tool change.

MULTI MODE Use this function when m ore than one work piece of the sam e type are to

be arranged on the table for successive machining. Do not use this

function here.

4

MATEIRAL <MENU>?

(2)

INITIAL POINT Z (CLEARANCE)?

(3)

ZERO RETURN <Z. X+Y: 0, X+Y+Z: 1>?

(4)

MULTI MODE <MENU>?

(5)

The common unit will be created as shown below.

When the unit is created, the help windo w will be closed and the program wil l a wait dat a i nput to

the next unit.

...................................................................

................................................

.....................................

...............................................................

S45C

2 0

1

MULTI OFF

4-4-6 Creation of basic coordinates system unit

Let us set the basic coordinates (the coordinate values of the workpiece zero point in the

machine coordinate s ystem). This data is to be input using the coor dinates measuring func iton

(refer to Part 2) af ter workpiec e has been m ounted on th e machine. Her e, inpu t the data o n the

assumption that workpiece has been mounted in the position shown below.

4-15

D735P0013E

Page 46

4

)

)

–

PROCEDURE BEFORE PERFORMING THE MACHINI NG

Machine zero point

–200 (Basic coordinate y)

–X

(Basic

coordinate z

Fig. 4-8 Workpiece mounting position

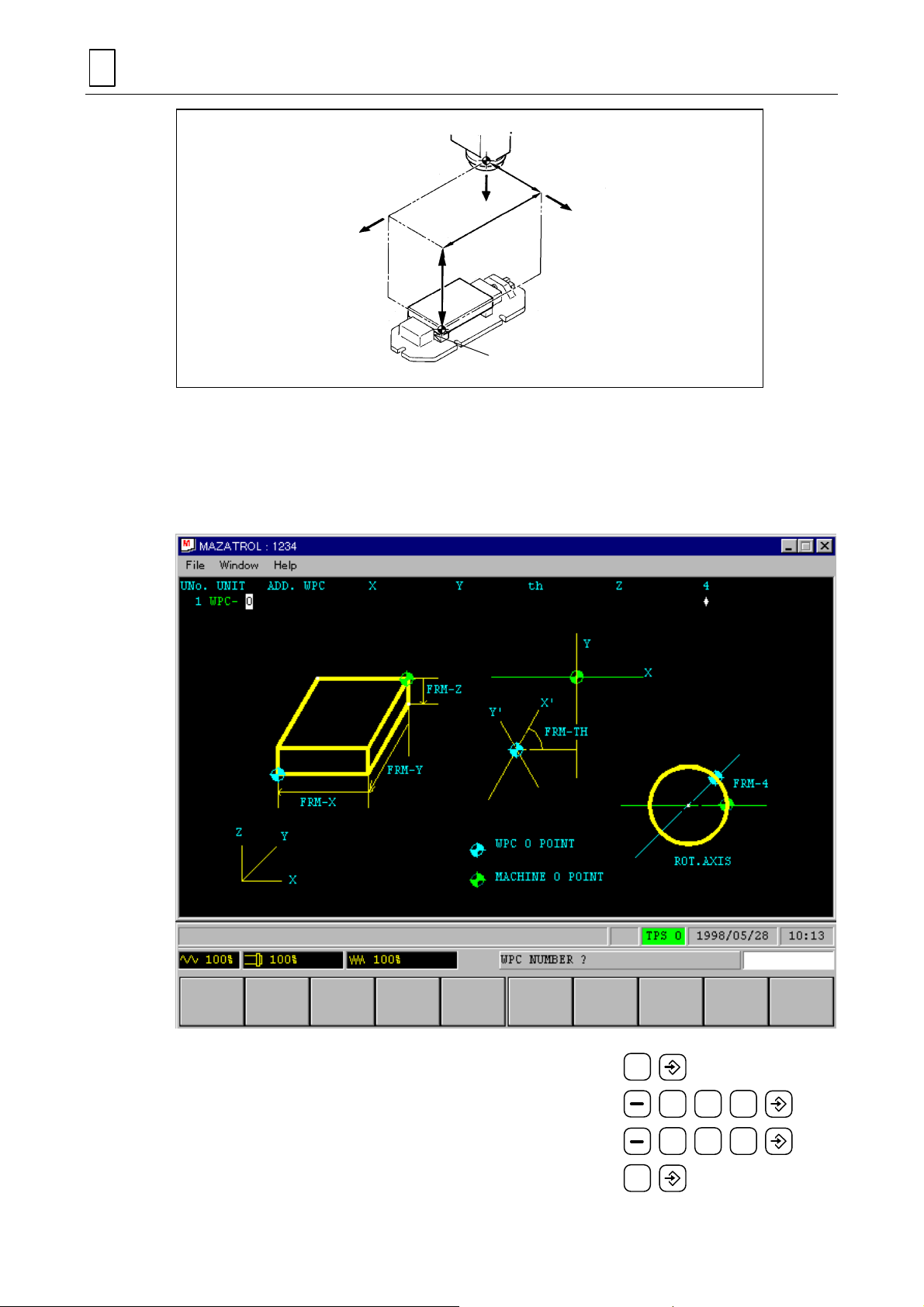

(1) While the message

(2) Press the menu key

!

The following help window will be presented. “WPC” is the abbreviation of the

workpiece coordinates.

–Z

–300

100

(Basic

coordinate x

Workpiece zero point

MACHINING UNIT <MENU>?

HELP

.

–Y

NM210-00526

is displayed, press the menu key

WPC

.

D735P0014E

WPC NUMBER?

(3)

WORKPIECE COORDINATE, WPC-X?

(4)

WORKPIECE COORDINATE, WPC-Y?

(5)

WORKPIECE COORDINATE, WPC-th?

(6)

................................................................... 1

.............................. 3

..............................

............................. 0

0 0

2 0 0

4-16

Page 47

PROCEDURE BEFORE PERFORMING THE MACHI NING

4

WORKPIECE COORDINATE, WPC-Z?

(7)

WORKPIECE COORDINATE, WPC-4?

(8)

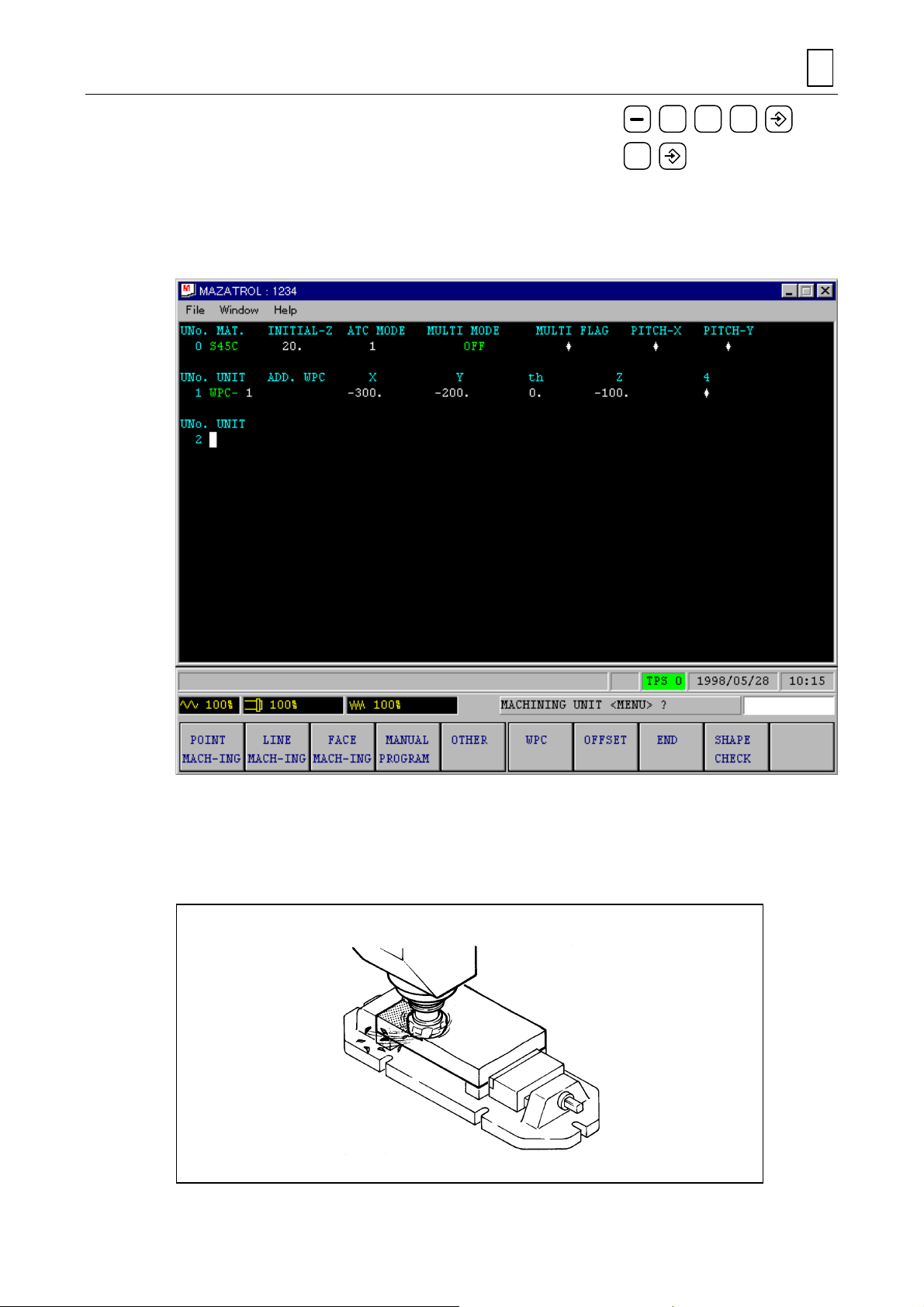

The basic coordinates system unit will be created as shown below.

When the unit is created, the help windo w will be closed and the program wil l a wait dat a i nput to

the next unit.

..............................

...............................

0

1 0 0

4-4-7 Face machining unit

Let us program a unit that mills the top face of a particular material. This machining unit is

referred to as a face milling unit.

D735P0015E

NM210-00517

4-17

Page 48

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

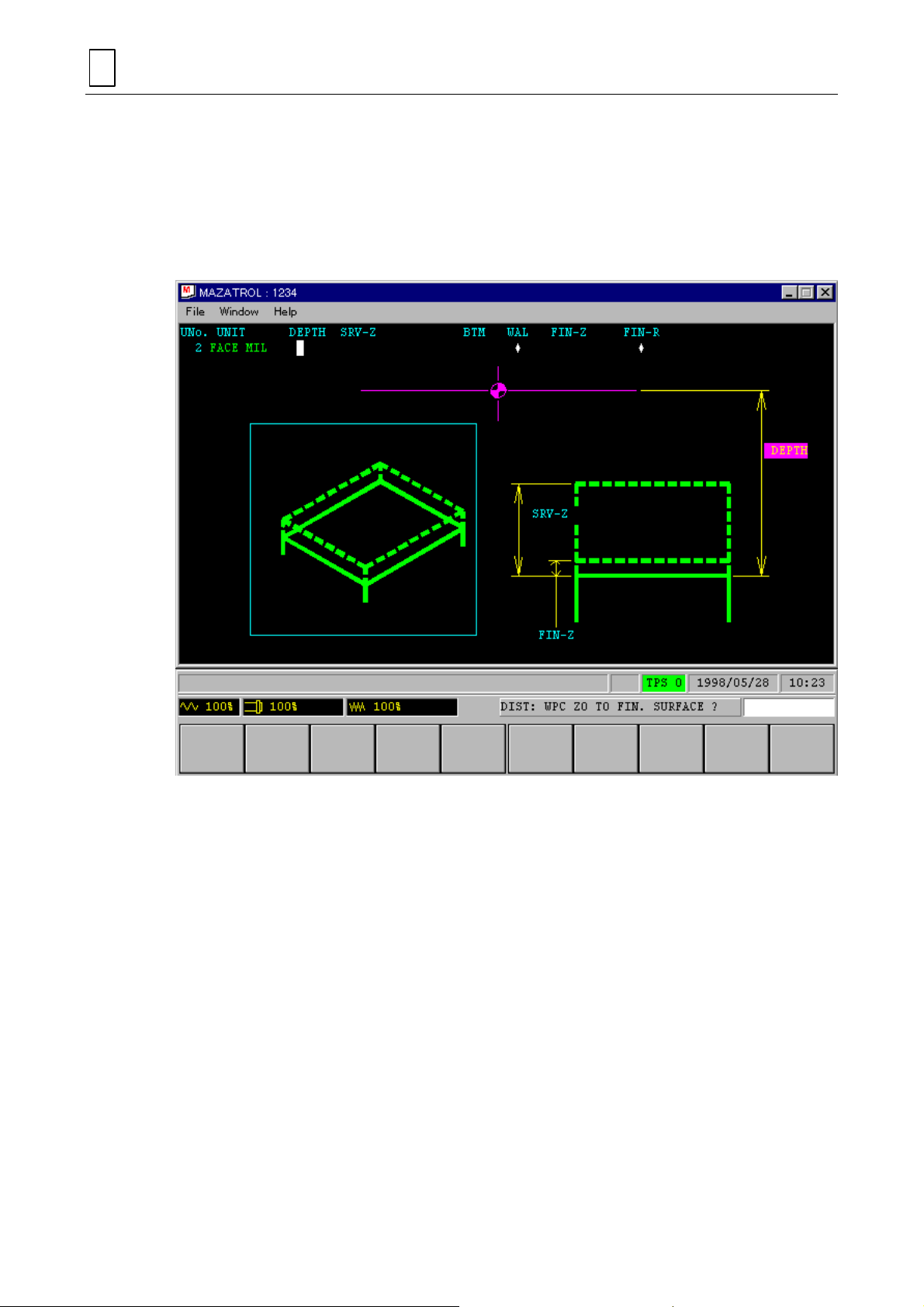

1. Creation of face machining unit

(1) W hile the m ess age

MACH-ING .

MACHINING UNIT <MENU>?

(2)

(3) Press the menu key

!

The following help window is presented.

MACHINING UNIT <MENU>?

........................................................

HELP

.

is displayed, pr ess the m enu key

FACE MIL

FACE

D735P0016E

Now, start creating the fac e machining unit. T he data for the article DEPT H, SRV-Z, BT M,

and FIN-Z will be specified here.

DEPTH ..........Input the distance from the workpiece zero point of the Z axis to the surface to

be finished.

Here, the depth is 0 because the workpiece zero point is on the finishing

surface.

4-18

Page 49

PROCEDURE BEFORE PERFORMING THE MACHI NING

+Z

Workpiece zero point

+XPosition of

WPC-Z = 0

Fig. 4-9 DEPTH and SRV-Z

Chamfering area

Allowance Z

(SRV-Z)

Surface to be

finished

M3P023

SRV-Z .............Input the chamfer ing thick ness of the work piece. An appr oxim ate value ma y

be input because the workpiece surface is not plane.

BTM.................Input an appropriate finishing code that designates the roughness of the

workpiece surface to be finished.

FIN-Z ...............Input the finish milling thickness. This data will be automatically set if the

roughness of the bottom is specified using a finishing code of the menu.

DIST: WPC Z0 TO FIN. SURFACE?

(4)

.............................................

0

4

Z AXIS STOCK REMOVAL?

(5)

BOTTOM FACE ROUGHNESS <MENU>?

(6)

FINISH ALLOWANCE Z?

(7)

.........................................................

..............................................................

...................................

3

!

2

(When the bottom roughness is input, the FIN-Z value will be set automatically. Thus , the

operator can proceed directly to the next data item using the appropriate cursor key.)

A machining unit such as that s ho wn belo w is n o w com p leted . Us ua lly, a tool appropriate f or the

particular tool sequenc e is autom atic ally s elected on t he basis of the data of the m achini ng uni t.

Here, a face mill has been selected.

4-19

Page 50

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

2. Creation of tool sequence

(1) W hile the mes sage

.

(2) Pr ess the menu ke y

that the previously registered tool is included in the display.

!

The following

mill is registered.

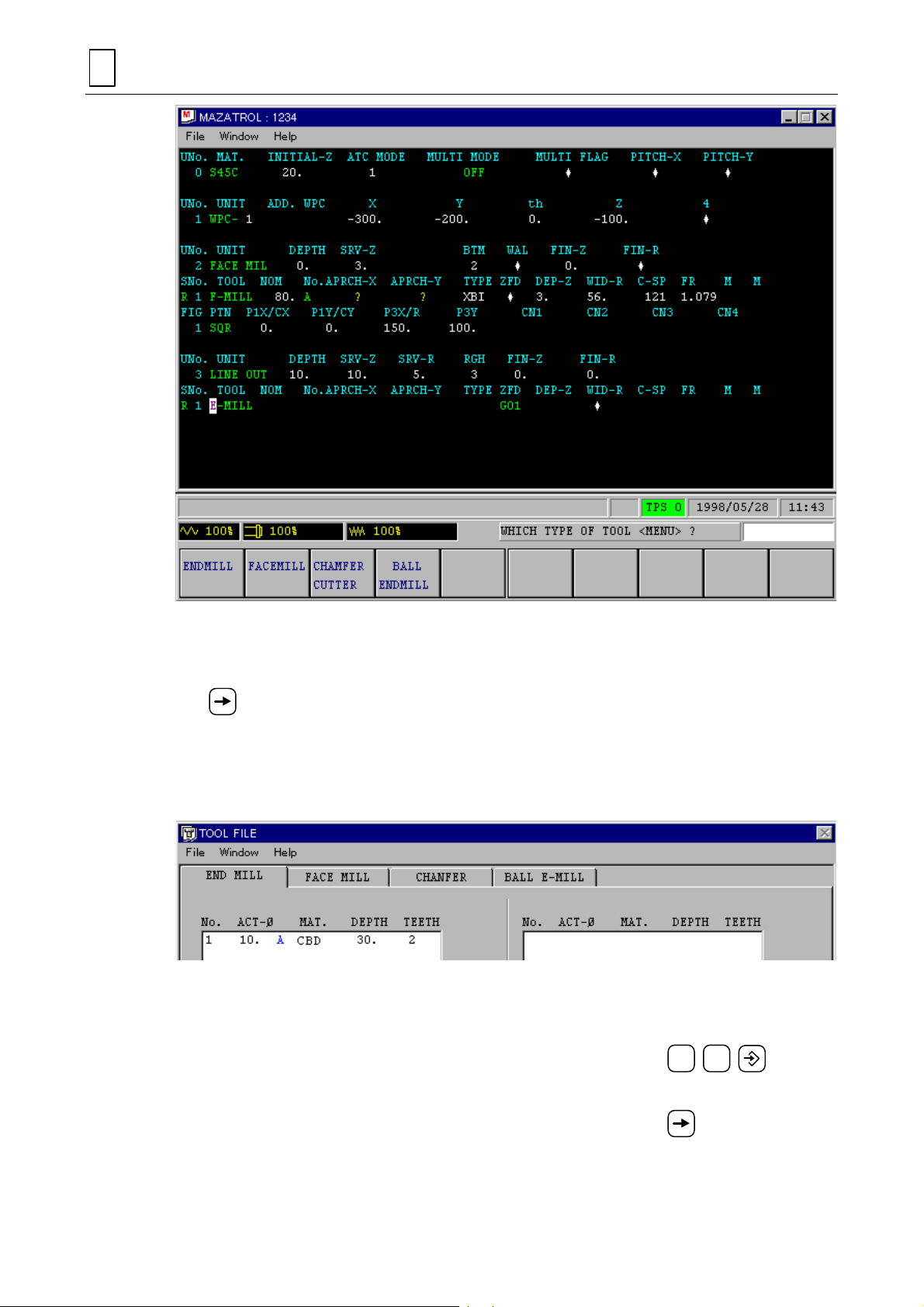

TOOL FILE (FACEMILL)

WHICH TYPE OF TOOL <MENU>?

TOOL FILE

to call the

TOOL FILE

display shows that the 80 mm diameter face

D735P0017E

is displayed, press the curs or key

display on the screen, a nd check

4-20

Page 51

PROCEDURE BEFORE PERFORMING THE MACHI NING

4

(3) Press the menu key

programming.

NOMINAL DIAMETER?

(4)

TOOL FILE CODE

(5)

MACHINING PRIORITY No.?

(6)

(Skip to the next item s inc e the id ent ic al-tool priority function is n o t use d h er e. R efer to Part

2, Chapter 5.)

APPROACH POINT X, AUTO

(7)

APPROACH POINT Y, AUTO

(8)

CUTTING DIRECTION <MENU>?

(9)

The possible directions of cutting are shown below.

PROGRAM

.................................................................

?........................................................................

to return to the

........................................................

<MENU>?

→→→→

<MENU>?

→→→→

.................................................

.................................

.................................

PROGRAM

A

AUTO SET

AUTO SET

X BI-DIR

display and continue

8 0

D735P0018E

4-21

Page 52

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

Cutting feed

Rapid feed

<BI-DIR>

<BI-DIR SHORT>

DEPTH OF CUT?

(10)

WIDTH OF CUT?

(11)

CUTTING SPEED, AUTO

(12)

FEEDRATE, AUTO

(13)

(14)

(15)

M CODE?

M CODE?

.......................................................................

.......................................................................................

<BI-DIRARCSHORT>

...........................................................................

...........................................................................

<MENU>?

→→→→

<MENU>?

→→→→

<UNI-DIR>

........................................

..................................................

M3P026

AUTO SET

AUTO SET

AUTO SET

AUTO SET

A tool sequence such as that s hown below is now completed. F or most of the data items, the

optimal data is set b y depressing the m enu key

AUTO S ET

. The data of the artic le APRCH-X,

APRCH-Y, however, m aintains ? since the necessary dat a is autom atically set u pon com pletion

of the tool path check.

4-22

D735P0019E

Page 53

PROCEDURE BEFORE PERFORMING THE MACHI NING

3. Cutting parameters

The cutting parameters that have been automatically set in procedural step (12) and (13) of

creation of tool sequence above are described here.

The speed at wh ich a too l revolves (circ umfer ential speed) a nd the rat e at which the tool is fed

(feed rate) are referred to as cutting parameters.

Circumferential speed (C-SP):

Speed (m/min) at whic h a tool m oves on th e outer circ umf erence. T he relations hip betwee n the

revolutions per minute and circumferential speed is given by the following equation.

4

Circumferential

speed (m/min)

Feedrate (FR):

The distance (mm /rev) through which workpiece is cut during one revolution of the tool. This

feedrate is called synchronous feedrate.

4. Creation of shape sequence

Tool diameter (mm) × Revolutions per minute (rpm) × 3.14

=

1000

Circumferential speed

Feedrate

NM210-00527

Next, let us program a shape sequence.

Read the machining area from the drawing, and input the coordinate values necessary for the

machining shape. For face milling, the top face of workpiece is to be machined.

Thus, input the dimensions of a shape such as that shown below.

4-23

Page 54

4

g

)

PROCEDURE BEFORE PERFORMING THE MACHINI NG

100

(Y coordinate of

onal point

dia

Start point

150 (X coordinate of diagonal point)

Diagonal point

Corner 2 Corner 3

Corner 1 Corner 4

M3P028

Note:

(1)

(2)

(3)

(4)

(5)

(6)

(7)

The X- and Y-coordinates of the start point are those of the workpiece zero point.

PATTERN OF FIGURE <MENU>?

CORNER 1 COORDINATE X?

CORNER 1 COORDINATE Y?

CORNER 3 COORDINATE X?

CORNER 3 COORDINATE Y?

CORNER 1 CHAMFER?

......................................................

PATTERN OF FIGURE <MENU>?

......................................

............................................

............................................ 0

............................................ 1

............................................ 1

......................................

A shape sequence such as that shown below is now completed.

SQUARE

0

5 0

0 0

SHAPE END

D735P0020E

4-24

Page 55

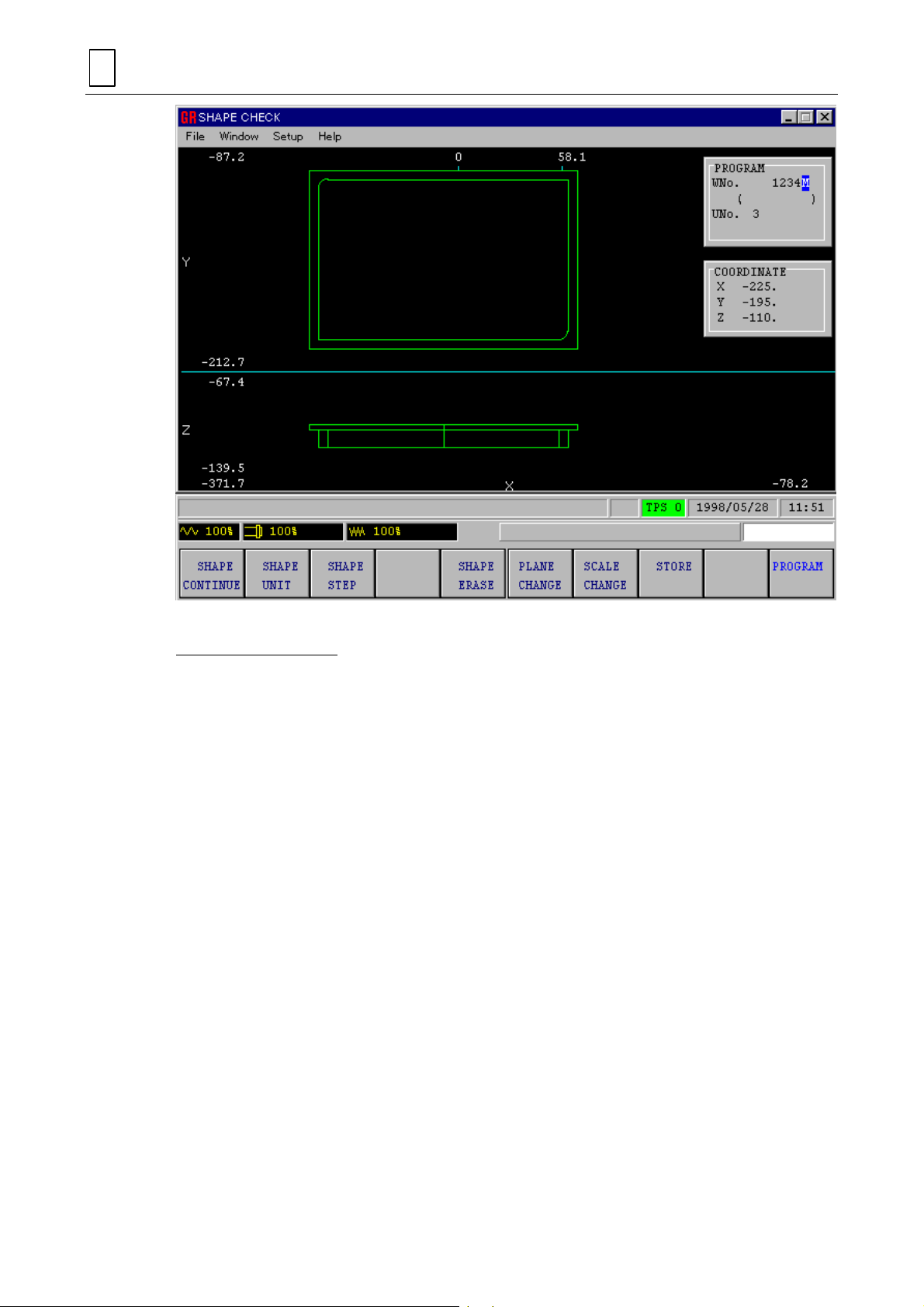

5. Shape check

PROCEDURE BEFORE PERFORMING THE MACHI NING

4

Check the

Of the varioius functions available with the

display of shapes, for erasure of shapes, and for step display of shapes are described here. See

Section 6-3, “SHAPE CHECK Display” of the Operating Manual for details of other functions.

(1) Press the menu key

SHAPE CHECK

!

The following

display to ensure that no errors are included in the inp ut data.

SHAPE CHECK

SHAPE CHECK

SHAPE CHECK

.

display will be displa yed.

display, onl y those for continuous

(2) Press the menu key

!

Shapes will be displayed continuously. The shapes displayed on the screen will be

those of the portions which are chamfered by machining.

SHAPE CONTINUE

4-25

D735P0021E

to display shapes continuously.

Page 56

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

(3) Press the menu key

(4) Repe ated ly press the menu key

the screen.

!

The reverse display state of the menu will be cleared when the final group of shapes is

displayed.

SHAPE ERASE

to erase the shape.

SHAPE STEP

D735P0022E

several times to call shapes step by step on

4-26

Page 57

PROCEDURE BEFORE PERFORMING THE MACHI NING

4

(5) Press the menu key

This completes a face milling unit for use in face machining.

4-4-8 Line machining unit

Let us create a unit that steps the edges of a material by contour machining. This machining unit

is referred to as an outside linear machining.

PROGRAM

to resume the

PROGRAM

D735P0023E

display.

1. Creation of line machining unit

(1) W hile the mess age

MACH-ING

.

MACHINING UNIT <MENU>?

4-27

NM210-00518

is displayed, pr ess the menu key

LINE

Page 58

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

MACHINING UNIT <MENU>?

(2)

(3) Press the menu key

!

The help window will be presented.

HELP

........................................................

.

LINE OUT

D735P0024E

Now, start creating the l ine m achining un it. T he data for the artic le D EPT H, SRV-Z, SR V-R

and RGH will be specified here.

DEPTH............... Input a depth value of 10.

SRV-Z ................Input the wall thickness of the workpiece through which it is to be

chamfered in the Z ax ial direct ion f rom the f ace m ille d surf ace (s ee f igure

below).

SRV-R................ Input the wall thickness of the workpiece through which it is to be

chamfered in the radial direction (see figure below).

4-28

Page 59

z

(

)

A

)

Depth =

Allowance Z

SRV-Z

Fig. 4-10 SRV-Z and SRV-R

PROCEDURE BEFORE PERFORMING THE MACHI NING

x

y

llowance R (SRV-R

M3P034

4

DIST: WPC Z0 TO FIN. SURFACE?

(4)

Z AXIS STOCK REMOVAL?

(5)

X/Y AXIS STOCK REMOVAL?

(6)

.............................................

.........................................................

......................................................

1 0

1 0

5

""

SURFACE ROUGHNESS <MENU>?

(7)

FINISH ALLOWANCE Z?

(8)

FINISH ALLOWANCE R?

(9)

............................................

..............................................................

..............................................................

3

A line machining unit s uch as that shown below is no w completed. This displ ay shows that an

end mill has been automatically selected for the particular tool sequence that is to be

programmed.

4-29

Page 60

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

2. Creation of tool sequence

(1) W hile the mes sage

.

(2) Pr ess the menu ke y

that the previously registered tools ar e inclu ded in the dis play.

!

The following

is registered.

(3) Press the menu key

programming.

NOMINAL DIAMETER?

(4)

TOOL FILE (ENDMILL)

WHICH TYPE OF TOOL <MENU>?

TOOL FILE

PROGRAM

.................................................................

to call the

to return to the

TOOL FILE

display shows that the 10-m m diameter end mill

D735P0025E

is displayed, press the curs or key

display on the screen, a nd check

D735P0026E

PROGRAM

display and continue

1 0

TOOL FILE CODE <MENU>?

(5)

MACHINING PRIORITY No.?

(6)

(Skip to the next article since the priority funct ion for the same tool is not to be used here.

See Part 2, Chapter 5.)

........................................................

........................................................

4-30

A

Page 61

PROCEDURE BEFORE PERFORMING THE MACHI NING

4

APPROACH POINT X, AUTO

(7)

[APPROACH POINT Y, AUTO

(8)

CUTTING DIRECTION <MENU>?

(9)

(Specify the directi on in which the circumf erence is to be cut. The possible d irections of

cutting are clockwise (CW) and counterclockwise (CCW).)

CW

FEEDRATE Z, <MENU>/DATA <INPUT>?

(10)

DEPTH OF CUT?

(11)

...........................................................................

<MENU>?

→→→→

<MENU>?

→→→→

.......................................

..........................

...............................

CCW

...................................

AUTO SET

AUTO SET

CW CUT

NM210-00528

AUTO SET

CUTTING SPEED, AUTO

(12)

FEED RATE, AUTO

(13)

M CODE?

(14)

M CODE?

(15)

A tool sequence such as that shown below is now completed.

.......................................................................................

.......................................................................................

→→→→

<MENU>?

→→→→

<MENU>?

........................................

.................................................

AUTO SET

AUTO SET

4-31

Page 62

4

g

)

PROCEDURE BEFORE PERFORMING THE MACHINI NG

3. Creation of shape sequence

Next, let us program a s hape sequence. For outside linear machining, the edges of a material

are to be machined. Set the dimensions of a shape such as that shown below.

145 (X coordinate of diagonal point)

Corner 2

95

(Y coordinate of

onal point

dia

(Y coordinate

of the start

point)

5

(1) W hile the message

SQUARE

.

R5

Corner 1

5 (X coordinate of the start point)

PATTERN OF FIGURE <MENU>?

Corner 3

R5

Corner 4

M3P037

is displayed, press th e menu key

D735P0027E

CORNER 1 COORDINATE X?

(2)

CORNER 1 COORDINATE Y?

(3)

CORNER 3 COORDINATE X?

(4)

......................................................

......................................................

......................................................

5

5

1 4 5

4-32

Page 63

PROCEDURE BEFORE PERFORMING THE MACHI NING

4

CORNER 3 COORDINATE Y?

(5)

CORNER 1 CHAMFER?

(6)

CORNER 2 CHAMFER?

(7)

CORNER 3 CHAMFER?

(8)

CORNER 4 CHAMFER?

(9)

PATTERN OF FIGURE <MENU>?

(10)

A shape sequence such as that shown below is now completed.

......................................................

................................................................

................................................................

................................................................

................................................................

................................................

9 5

5

5

SHAPE END

4. Shape check

Here, let us call the

(1) Press the menu key

(2) Press the menu key

SHAPE CHECK

SHAPE CHECK

SHAPE CONTINUE

display on the screen.

to call the

.

4-33

SHAPE CHECK

D735P0028E

display.

Page 64

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

D735P0029E

The PLANE CHANGE f unciton is desc ribe d here. The s hape be ing d ispla yed in pr oce dura l step

(2) is that of the workpiece as seen from above. With this function, it becomes possible to display

shapes as seen from the side or from an oblique angle.

The selectable pla ne is one of the f our types sho wn below. It is also possib le to display one of

two plane pairs (either XY-XZ (XY plane and XZ plane) or XY-YZ (XY plane and YZ plane)) at the

same time. See Section 6-3, “SHAPE CHECK Display” of the Operating Manual for the details.

4-34

Page 65

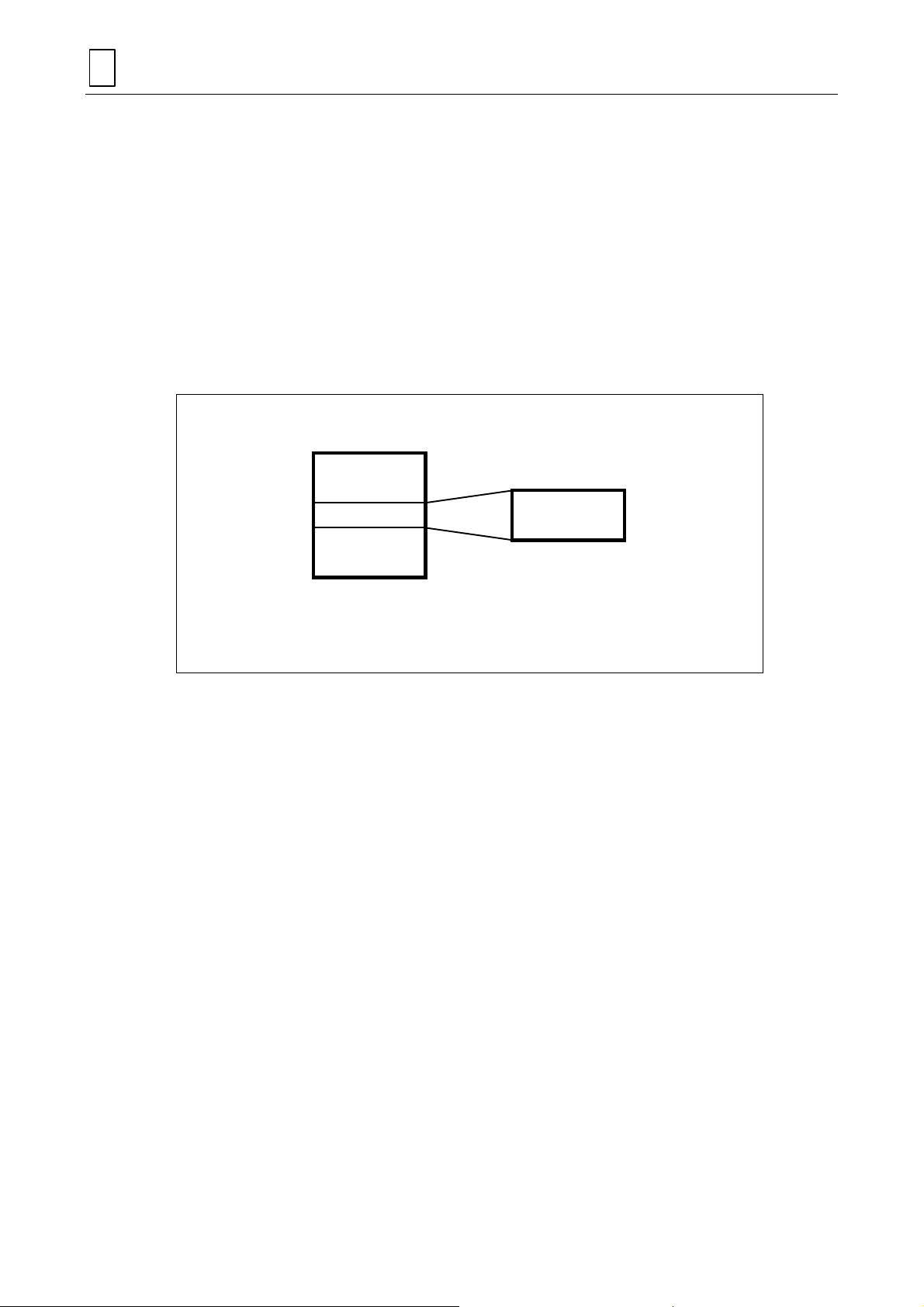

XZ plane

PROCEDURE BEFORE PERFORMING THE MACHI NING

Stereographic

view

XY plane

YZ plane

4

Fig. 4-11 Plane selection

Let us now display shapes of various planes.

XY-XZ plane

(3) Press the menu key

(4) Press the menu key

!

Shapes as seen from above and from the side are selected.

(5) Press the menu key

!

As shown below, a shape as seen from above ( XY plane) a nd a shape as s een from

PLANE CHANGE

XY-XZ

.

SHAPE CONTINUE

the side (XZ plane) are displayed at the same time.

M3P040

.

to display shapes continuously.

4-35

Page 66

4

PROCEDURE BEFORE PERFORMING THE MACHINI NG

Three-dimens ional pla n

(6) Press the menu key

(7) Press the menu key

!

A shape as seen obliquely from above is selected.

(8) Press the menu key

!

The shape will be displayed in stereographic form as shown below.

PLANE CHANGE

3-D

.

SHAPE CONTINUE

.

D735P0030E

to display shapes continuously.

4-36

Page 67

PROCEDURE BEFORE PERFORMING THE MACHI NING

4

(9) Press the menu key

(10) Press the menu key XY to change the display to that of XY plan.

Note:

(11) Press the menu key

This completes an outside linear machining unit.

The selected plane maintains its shape until another plane has been selected.

4-4-9 Point machining unit (1)

Let us create a program unit that is us e d to dr ill a 10- mm diameter through-ho le. This machining

unit is referred to as a drilling unit.

PLANE CHANGE

PROGRAM

. The

.

PROGRAM

D735P0031E