Page 1

)

$

I

j

MAZATROL

.1

M32

PARAMETERS

l

i

i

;*>

I

l

Page 2

1

.

.

.

.

.

.

.

$

.

I.

'

»

*

I

•

•

'

*r

I

•r

-

*

.

.

.

*

.

.

;

••

.

A*

a

.

*

I

»

i

«

i

-

.

Page 3

Introduction

describes

text

This

MAZATROL

possibilities

advisable

is

It

Notes:

prohibited

is

1.

It

manual.

This

the

In

which

our

service

manual

case

was

2.

3.

M-32.

of

the

to

consult

where

prepared

center.

meaning

the

Read

this

MAZATROL

the

Operating

to

partially

will

be

subject

you

find

with

and

list

carefully

M-32.

completely

or

to

doubtful

a

careful

setting

manual

change

attention,

in

without

point,

of

various

order

required.

as

transcribe,

notice.

error

an

please

make

to

reproduce

or

omission

send

parameters

the

best

or

in

your

suggestions

Mazak

used

for

of

use

modify

this

this

manual

to

the

the

&

;•

Documents

Standard

Operating

•

Programming

•

Parameter

•

Alarm

•

Option

Programming

•

Programming

•

Programming

•

CPU-LINK

•

Operating

•

Operating

•

accompany

that

manual

manual

(This

list

list

manual

manual

manual

communication

manual

manual

the

for

MAZATROL

for

MAZATROL

Text)

for

MAZATROL

for

3-D

for

five-surface

for

for

software

MAZATROL

MAZATROL

product

M-32

processing

preparation

CAM32-A

EDITOR

M-32

EIA/ISO

M-32

machining

system

procedure

I

3-

1

Page 4

’

•t

I

•(

.

.

••

&

y

V

.

r

*

.

/

J

J

•

*

»

-

i

.

.

•

;

••

!

I

*

i

*

%

'

*

.

••

-

Page 5

Mazak

Preliminary

Parameters,

data

the

Parameters

meaning:

Cutting

(1)

Cutting

the

(2)

User

The

input/output

(3)

Machine

Constants

are

See

4-8

up

the

Format

parameter

Each

parameters

Unit

of

Name

|

Setting

Classification

Classification

Address

!

remarks

which

necessary

be

can

condition

condition

cutting

conditions

parameters

needed

data

eta

parameters

related

registered.

PARAMETER

displays

19

parameter

of

table

Characters

lower

Program

range

Conditions

to

refer

cutting

for

broadly

constants

parameters

parameters

(circumferential

point-,

for

registered.

are

to

the

display

for

used

tables

is

written

left

of

Display

type

operations,

divided

line-,

servo

of

the

display

in

displayed

the

screen

title

specific

into

are

the

face-machining

and

motors

Operating

the

following

the

the

at

VI

to

possess

following

the

constants

and

speed

spindle

and

setting

and

NC

the

a

that

feed

motors,

Manual

of

format:

Valid

M:

Valid

E:

Description

machines

very

important

types

three

used

are

during

rate)

data,

constants

machine

the

for

parameter

for

MAZATROL

for

EIA/ISO

and

equipment

meaning.

according

to

automatically

program

related

status

procudure

data.

program

to

creation.

to

data

for

calling

program

and

their

*

set

data

eta

1

i

data

Allowable

displayed

L

M/

/

Parameter

displayed

screen

i

name

on

the

Units

of

rH

range

(j-)

of

data

PoKTio

ir

/ÿ*

Conditions

changed

becomes

a?

**

O*SLY

P

parameter

valid

&

under

which

a

Details

parameter

or

meaning

of

the

3

-1-/9

Page 6

Mazak

Precautions:

Details

©

presence/absence

equipment,

parameter

The

©

power

Before

©

is

the

details

If

©

your

MAZAK

When

©

the

If

©

parameter

that

In

may

result.

against

parameters.

In

addition

©

(Programmable

Manual

accompanying

the

of

etc.

panel

making

to

one

the

of

changing

particular

memory

case,

To

separate

the

to

details

for

parameters

Therefore,

list

shipment

at

changes

be

changed.

parameter

service

details

machine

errors

prevent

the

Logic

the

option(s),

of

an

supplied

is

of

tp,.details

center

of

a

is

run

will

will

occur

this,

parameter

parameters

Controller),

of

PLC-related

electric

may

not

do

in

the

machines.

the

to

be

changed

before

parameter,

not

used

down.

the

in

first

check

list

listed

are

wiring

differ

production

the

use

the

form

parameter,

a

of

making

maintain

for

a

(Battery

parameters

the

and

then

in

also

parameters

diagram.

according

parameters

data

of

careful

Be

cannot

the

time,

long

alarm)

existing

make

document,

this

available;

to

time

sheets

make-

clearly

be

changes.

records

then

and

thus

details

the

refer

and

machine

the

of

the

of

external

within

the

not

to

lose

sure

that

understood,

the

old

of

battery

the

machine

parameters

of

the

necessary

those

to

the

Machine

PLC

the

NC

machines

machines.

NC

the

the

and

to

malfunctions

changes

related

Parameter

used,

the

and

heavy-duty

list.

parameter

contact

new

data.

protect

the

closely

to

the

to

PLC

Operating

List

Jf

if

2

3-

Page 7

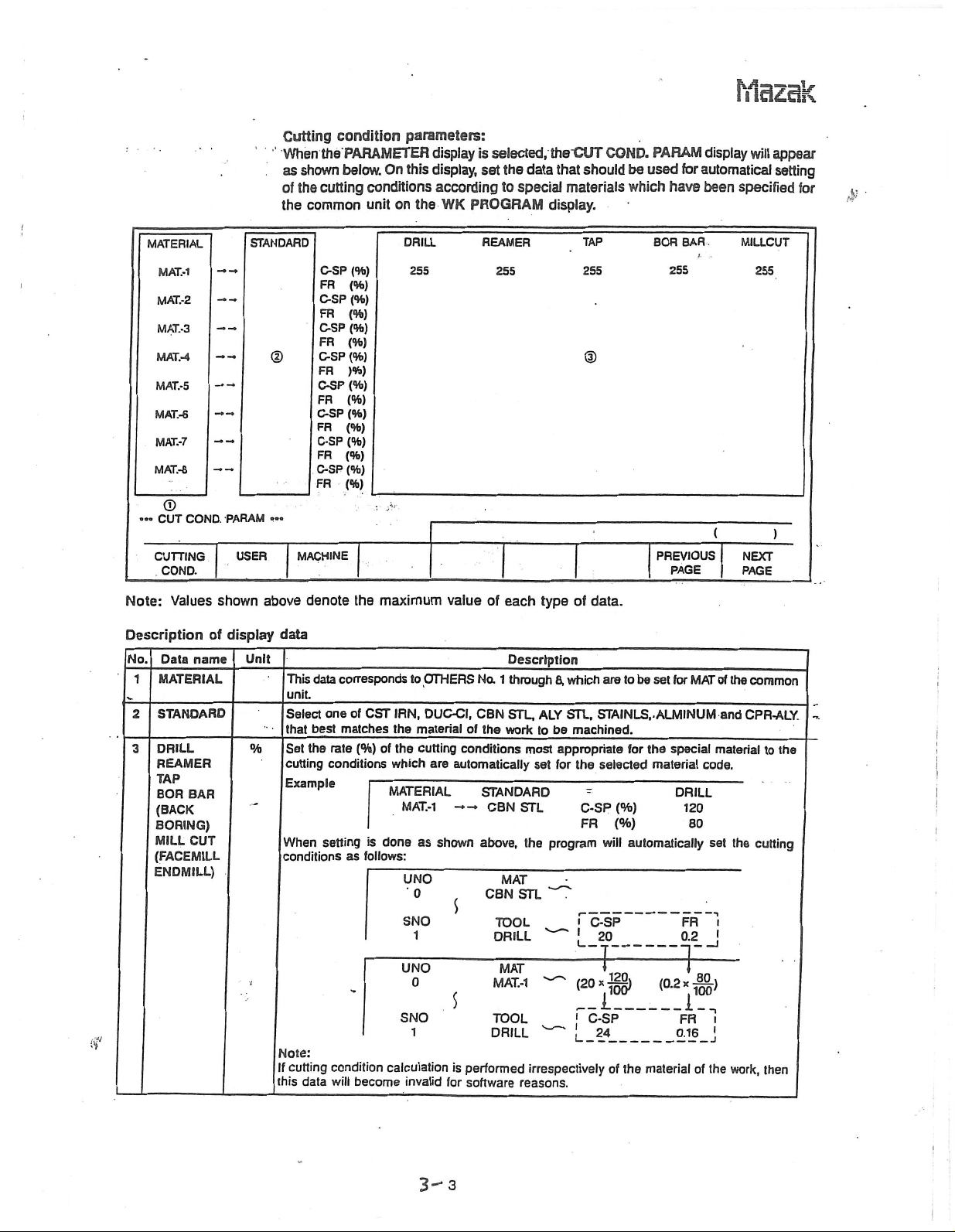

Mazak

MATERIAL

MAT.-1

MAT.-2

MAT.-3

MAT.-4

MAT.-5

MAT.-6

MAT.-7

MAT.-8

©

...

CUT

CUTTING

COND.

COND.

STANDARD

PARAM

USER

Cutting

When

as

of

the

©

•••

condition

PARAMETER

the

below.

shown

cutting

the

common

C-SP

FR

C-SP

FR

C-SP

FR

C-SP

FR

C-SP

FR

C-SP

FR

C-SP

FR

C-SP

(%)

FR

MACHINE

conditions

unit

<%)

(%)

(%)

(%)

(%)

(%)

(%)

)%)

(%)

(%)

(%)

(%)

(%)

(%)

(%)

parameters:

CQND.

should

materials

TAP

255

PARAM

be used

which

BOR

for

have

BAR

255

display

automatical

been

data

special

theÿCUT

that

display.

display

this

On

display,

according

on

WK

the

DRILL

255 255

selected,

is

the

set

to

PROGRAM

REAMER

255

©

;.V

PREVIOUS

PAGE

(

will

appear

setting

specified

MILLCUT

)

NEXT

PAGE

for

4*

'

Note:

Values

Description

Data

No.

MATERIAL

1

STANDARD

2

3

DRILL

REAMER

TAP

BOR

(BACK

BORING)

MILL

(FACEMILL

ENDMILL)

name

BAR

CUT

shown

of

display

Unit

%

above

data

This

unit.

Select

that

Set

cutting

Example

When

conditions

Note:

If

this

denote

data

best

the

cutting

data

the

corresponds

one

of

matches

(%)

rate

conditions

setting

as

condition

will

become

maximum

IRN,

CST

the

of

the

which

MATERIAL

is

done

follows:

SNO

calculation

to

OTHERS

DUC-CI,

material

cutting

are

MAT.-1

as

UNO

0

SNO

1

UNO

0

1

invalid

value

No.

CBN

of

the

conditions

automatically

STANDARD

--

above,

shown

5

5

performed

is

for

software

of

each

Description

1

through

STL,

work

CBN

MAT

CBN

TOOL

DRILL

MAT

MAT.-1

TOOL

DRILL

type

8,

which

STL,

ALY

to

be

appropriate

most

for

set

STL

program

the

STL

irrespectively

reasons.

of

data.

are

to

set

for

be

MAT

STAINLS.-ALMINUM

machined.

special

the

for

the

selected

material

DRILL

(%)

C-SP

FR

r

C-SP

1

(%)

automatically

will

20

120

80

FR

0.2

f-

(20*j§§)

C-SP

'

L_24

of

(0.2

the

materialofthe

xJJ,

FR

0.16

of

and

material

code.

set

i

1

i

1

the

common

CPR-ALY.

to

the

cutting

work,

then

the

3-3

Page 8

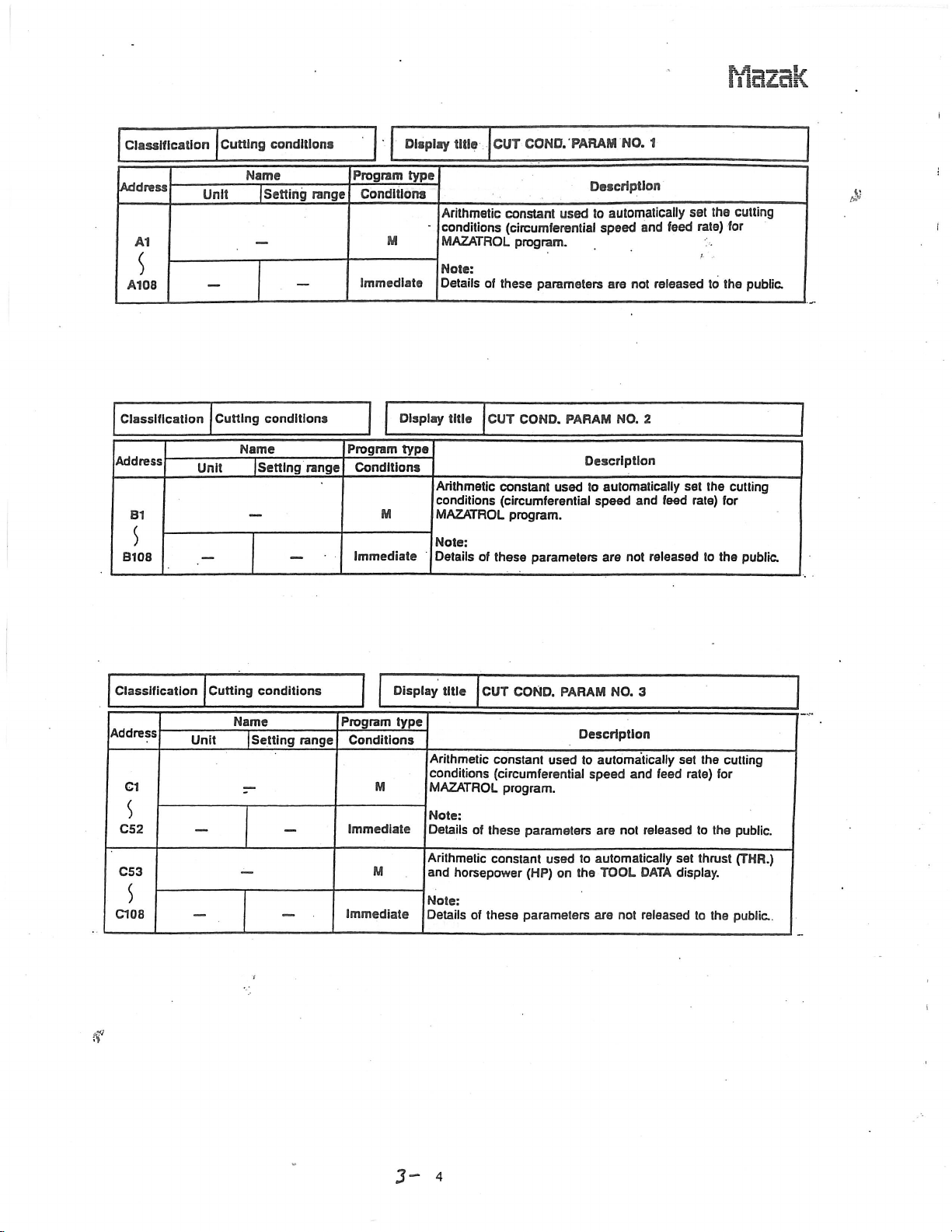

Classification

Cutting

conditions

Display

title

CUT

COND.

PARAM

NO.

IViSZik

1

Address

A1

5

A108

Classification

Address

B1

5

B108

Unit

Unit

Cutting

Name

Name

|

Setting

conditions

[Setting

range

range

Program

Conditions

M

Immediate

Program

Conditions

M

Immediate

type

Display

type

Arithmetic

conditions

MAZATROL

Note:

Details

of

these

title

CUT

Arithmetic

conditions

constant

(circumferential

MAZATROL

Note:

Details

of

these

constant

(circumferential

program.

parameters

COND.

used

used

PARAM

program.

parameters

Description

automatically

to

speed

are

not

NO.

Description

automatically

to

speed

are

not

and

released

2

and

released

feed

feed

set

set

rate)

rate)

to

the

to

the

for

the

cutting

for

the

cutting

public.

&

public.

Classification

Address

C1

s

C52

C53

$

C108

(f

Unit

Cutting

Name

conditions

[Setting

range

Program

Conditions

M

Immediate

M

Immediate

Display

type

Arithmetic

conditions

MAZATROL

Note:

Details

Arithmetic

and

Note:

Details

title

of

horsepower

of

CUT

COND.

constant

(circumferential

program.

parameters

these

constant

(HP)

parameters

these

PARAM

used

used

on

NO.

Description

automatically

to

speed

not

are

automatically

to

TOOL

the

are

not

3

set

rate)

feed

and

releasedtothe

set

DATA

display.

released

the

thrust

to

the

cutting

for

public.

(THR.)

public.

3-

4

Page 9

Mazak

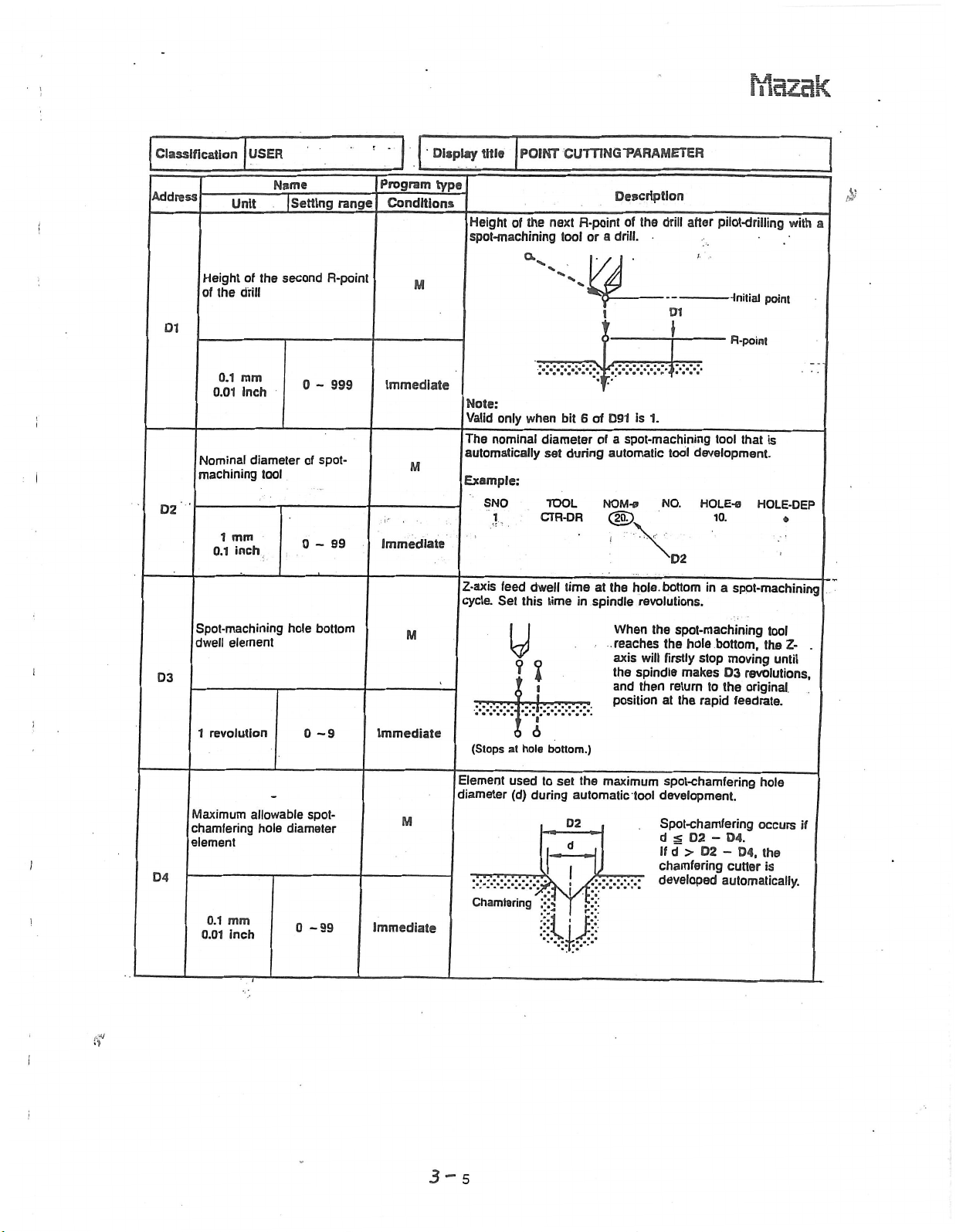

Classification

Address

Height

of

D1

Nominal

machining

D2

the

0.1

0.01

1

0.1

Unit

of

drill

mm

Inch

mm

inch

USER

Name

the

second

diameter

tool

[Setting

0

-

spot¬

of

0-99

range

R-point

999

Program

Conditions

M

immediate

M

Immediate

Display

type

Height

spot-machining

Note:

Valid

The

automatically

Example:

Z-axis

cycle.

title

only

nominal

SNO

h

feed

Set

POINT

of

when

.

this

CUTTINGTARAMETER

Description

of

R-point

next

the

tool

.

or

6

a

i

drill.

r

r-

of

D91

6

bit

spot-machining

during

of

a

automatic

NOM-a

(20)ÿ

diameter

set

TOOL

CTR-DR

‘

dwell

timeatthe

time

in

hole,

spindle

drill

the

D1

.v.v

is

1.

tool

NO.

D2

bottom

revolutions.

after

pilot-drilling

b

--Initial

R-point

tool

development.

HOLE-e

10.

a

in

spot-machining

point

that

is

HOLE-DEP

*

with

'

$

a

Spot-machining

element

dwell

D3

:

i

D4

revolution

1

Maximum

chamfering

element

hole

allowable

hole

diameter

bottom

-9

0

spot-

M

Immediate

M

(Stops

Element

diameter

y

n

i

;

6

hole

at

to

used

(d)

during

Itiii

bottom.)

set

automatic

D2

.

the

When

reaches

axis

will

spindle

the

and

then

position

maximum

tool

!vf

the

spot-machining

the

hole

bottom,

stop

firstly

return

the

at

spot-chamfering

development.

Spot-chamfering

d

£

d

If

chamfering

developed

makes

rapid

D2

D2

>

to

-

moving

D3

the

D4.

-

cutter

automatically.

tool

the

revolutions,

original

feedrate.

hole

occurs

the

D4.

is

until

Z-

.

if

Ctiamls.ingkÿyÿy

mm

0.1

0.01

inch

0-99

Immediate

i

3-5

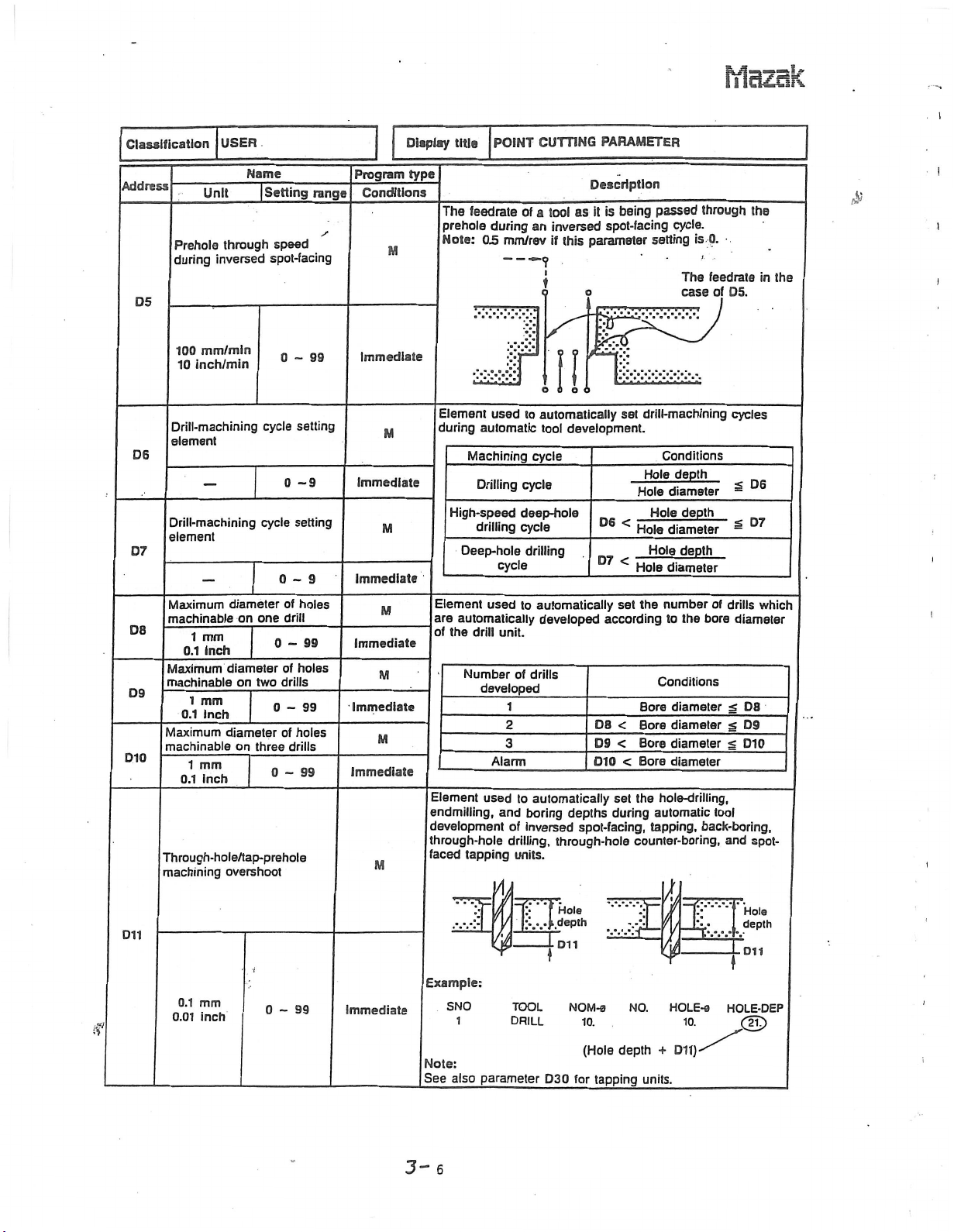

Page 10

hitiZdk

Classification

Address

Unit

Prehole

during

D5

mm/mln

100

inch/min

10

Drill-machining

element

D6

Drill-machining

element

D7

Maximum

machinable

08

D9

D10

1

mm

inch

0.1

Maximum

machinable

mm

1

inch

0.1

Maximum

machinable

1

mm

inch

0.1

Through-hole/tapprehole

machining

USER

Name

|

Setting

through

inversed

diameterofholes

diameter

overshoot

speed

spot-facing

0-99

cycle

0

cycle

0-9

diameterofholes

one

on

drill

0-99

on

two

drills

0-99

of

on

three

drills

0-99

range

setting

-9

setting

holes

s

Program

Conditions

M

Immediate

M

Immediate

M

Immediate

M

Immediate

M

Immediate

M

Immediate

M

Display

type

Element

during

Element

are

of

Element

endmilling,

development

through-hole

faced

tills

The

feedrate

prehole

Note:

during

03

automatic

Machining

Drilling

High-speed

drilling

Deep-hole

used

automatically

the

drill

Number

developed

used

tapping

CUTTING

POINT

of

tool

a

an

mm/rev

I

fin

©

cycle

unit.

of

1

2

3

and

of

drilling,

units.

to

cycle

deep-hole

cycle

to

to

inversed

automatically

tool

cycle

drilling

automatically

developed

drills

automatically

boring

used

Alarm

Description

as

it

inversed

parameter

this

if

o

o o

development.

D@

D7

D8

D9

D10

depths

spot-facing,

through-hole

PARAMETER

passed

being

is

spot-facing

.vX

set

<

<

set

according

<

<

<

set

during

cycle.

setting

drill-machining

Conditions

depth

Hole

Hole

diameter

Hole

diameter

Hole

Hole

Hole

diameter

the

number

to

Conditions

diameter

Bore

Bore

diameter

diameter

Bore

diameter

Bore

hole-drilling,

the

automatic

tapping,

counter-boring,

through

is

0.

The

feedrate

case

of

depth

depth

of

the

bore

back-boring,

05.

drills

g

g

g

tool

and

the

in

cycles

<

D6

s

D7

which

diameter

D8

D9

Dio

spot¬

the

£

I

i

i

!

I

h

;.....}.depth

D11

/

\

Example:

0.1

0.01

mm

inch

0-99

Immediate

if

3-

Note:

See

6

SNO

1

also

TOOL

DRILL

parameter

D30

SCOT:

D11

NOM-0

10.

for

(Hole

tapping

NO.

depth

units.

HOLE-0

Dll)

+

10.

Hols

depth

011

HOLE-DEP

£f£>

i

Page 11

hlciZdk

Classification

Address

Unit

USER

Name

[Setting

Program

range

Display

type

Conditions

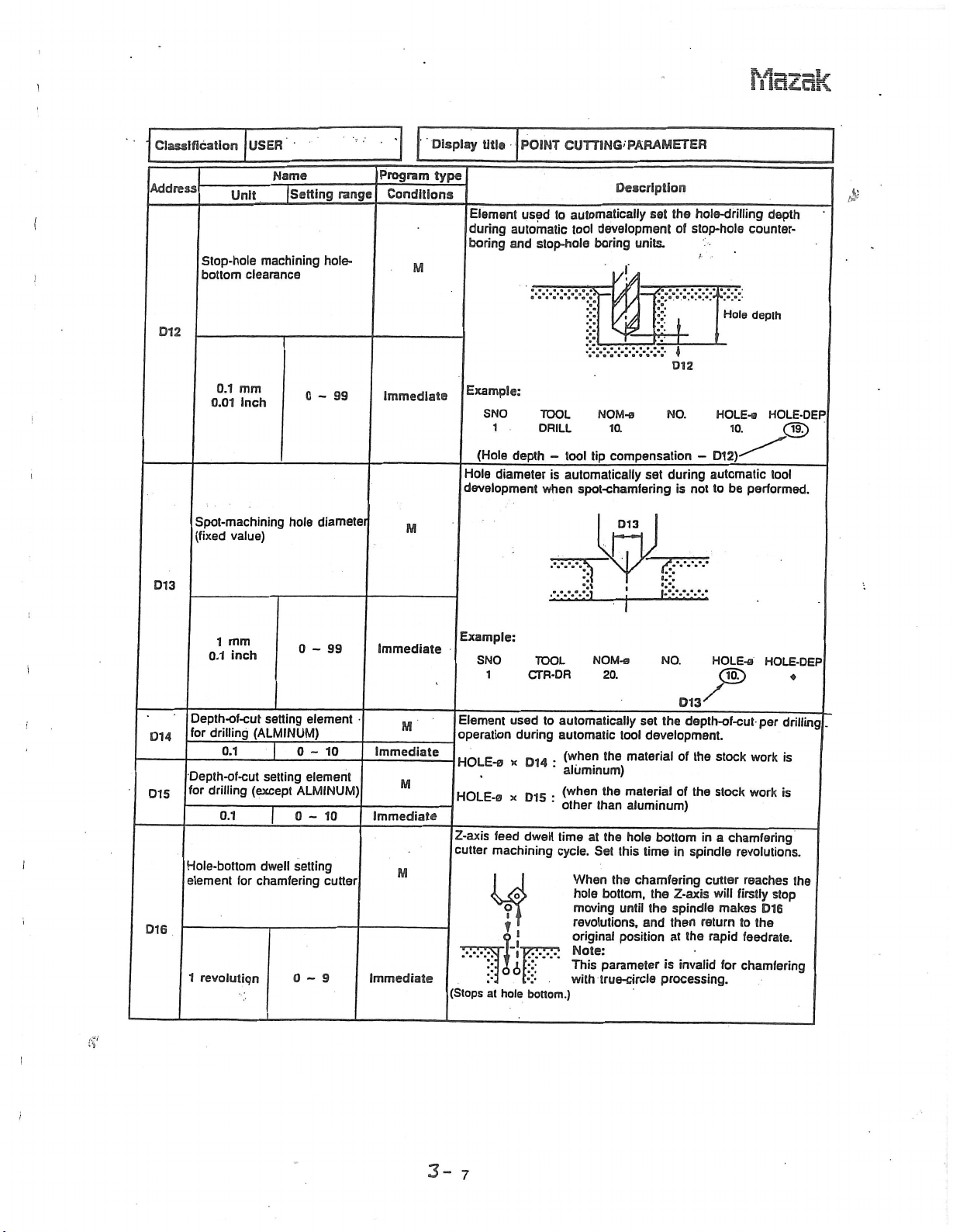

Element

during

boring

Stop-hole

!

bottom

machining

clearance

hole-

M

title

POINT

used

automatic

stop-hole

and

CUTTING'

automatically

to

development

tool

boring

PARAMETER

Description

the

set

of

units.

f

/:

hole-drilling

stop-hole

£

depth

counter-

%

Hole

depth

D12

;ÿ

«

D12

mm

0.1

inch

0.01

i

Spot-machining

(fixed

value)

hole

0-99

diameter

Immediate

M

D13

I

mm

0.1

1

inch

0-99

Immediate

Example:

SNO

1

(Hole

depth

Hole

diameter

development

Example:

SNO

1

TOOL

DRILL

-

is

when

TOOL

CTR-DR

NOM-a

10.

compensation-D12)

tip

tool

automatically

spot-chamfering

NOM-s

20.

set

NO.

during

I:-':

I

NO.

is

automatic

to

not

HOLE-0

HOLE-o

10.

performed.

be

HOLE-DEP

<3E>

tool

HOLE-DEP

o

D13

Depth-of-cut

drilling

for

D14

Depth-of-cut

for

D15

I

drilling

Hole-bottom

element

D16

1

revolution

I

i

0.1

0.1

for

setting

setting

|

dwell

element

0-10

element

ALMINUM)

0-10

setting

0-9

(ALMINUM)

(except

chamfering

cutter

M

Immediate

M

Immediate

M

Immediate

Element

operation

HOLE-s

HOLE-a

Z-axis

cutter

(Stops

used

during

x

x

feed

machining

i

.1

I

K\-

at

hole

to

014

D15

dwell

7?

bottom.)

automatically

automatic

,he

(when

•

‘

aluminum)

,he

(whan

•

other

than

timeatthe

cycle.

Set

When

bottom,

hole

moving

revolutions,

original

Note:

parameter

This

with

true-circle

set

tool

material

material

aluminum)

hole

this

chamfering

the

until

and

position

depth-of-cut-

the

development.

of

the

of

the

bottom

spindle

time

in

the

Z-axis

spindle

the

then

return

the

at

is

invalid

processing.

stock

stock

a

in

cutter

will

rapid

makes

for

per

work

work

chamfering

revolutions.

reaches

firstly

stop

D1G

to

the

feedrate.

chamfering

drilling

is

is

the

3-

7

Page 12

Mazak

Classification

Address

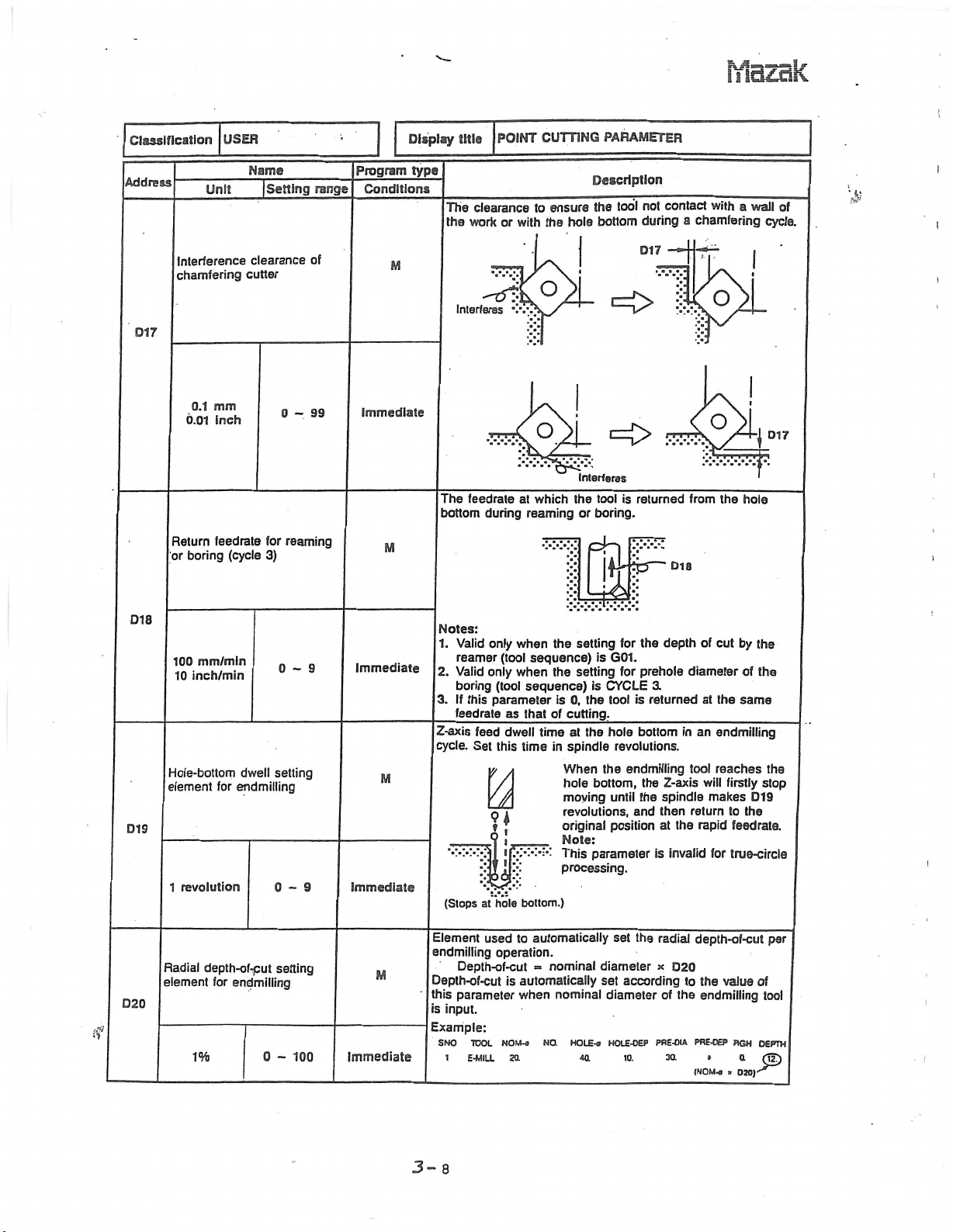

Interference

chamfering

D17

Return

dr

0.1

0.01

boring

USER

Unit

mm

inch

feedrate

(cycle

Name

|

Setting

clearance

cutter

for

3)

0

-

reaming

range

of

99

Program

Conditions

M

Immediate

M

Display

type

The

bottom

title

The

the

work

Interferes

feedrate

POINT

clearance

or

v.

during

CUTTING

to

with

o

at

which

reaming

ensure

hole

the

s

v

Interferes

the

or

PARAMETER

Description

contact

not

tool

the

bottom

during

017

=£>

returned

is

tool

boring.

=171

\vfc

;•

a

K

from

Dia

with

a

chamfering

o

:::

the

wall

hole

cycle.

D17

j

of

D18

mm/mln

D19

D20

100

inch/min

10

Hole-bottom

element

revolution

1

Radial

depth-of-put

element

for

dwell

for

endmilling

endmilling

0-9

setting

0-9

setting

Immediate

M

Immediate

M

(f

1%

0

100

-

Immediate

Notes:

Valid

1.

only

reamer

2.

3.

Z-axis

cycle.

Valid

boring

If

this

feedrate

feed

Set

only

V

(l

Y.v.‘

(Stops

at

Element

endmilling

Depth-of-cut

this

is

Example:

SNO

used

Depth-of-cut

parameter

input.

TOOL

1

E-MILL

when

(tool

when

(tool

sequence)

parameter

as

that

dwell

this

time

V,

•i

bottom.)

hole

to

operation.

automatically

is

when

NOM-a

setting

the

sequence)

setting

the

0,

is

the

cutting.

of

at

time

the

spindle

in

When

hole

moving

revolutions,

original

Note:

This

processing.

automatically

nominal

=

nominal

NO.

HOLE

4a

for

G01.

is

for

CYCLE

is

tool

_

hole

revolutions.

endmilling

the

bottom,

until

position

parameter

set

diameter

according

set

diameter

-a

HOLE-OEP

10.

the

prehole

3.

is

returned

bottom

the

the

and

the

depth

Z-axis

spindle

then

the

at

invalid

is

radial

x

D20

the

of

PRE-OIA

3a

of

cut

diameter

the

at

an

in

endmilling

tool

reaches

will

makes

return

rapid

for

depth-of-cut

to

the

endmiiling

PHE-OEP

(NOM««

by

the

of

the

same

firstly

D19

to

the

feedrate.

true-circle

of

value

HGH

DEPTH

Q

»

020)*ÿ

the

stop

per

tool

®

3-8

Page 13

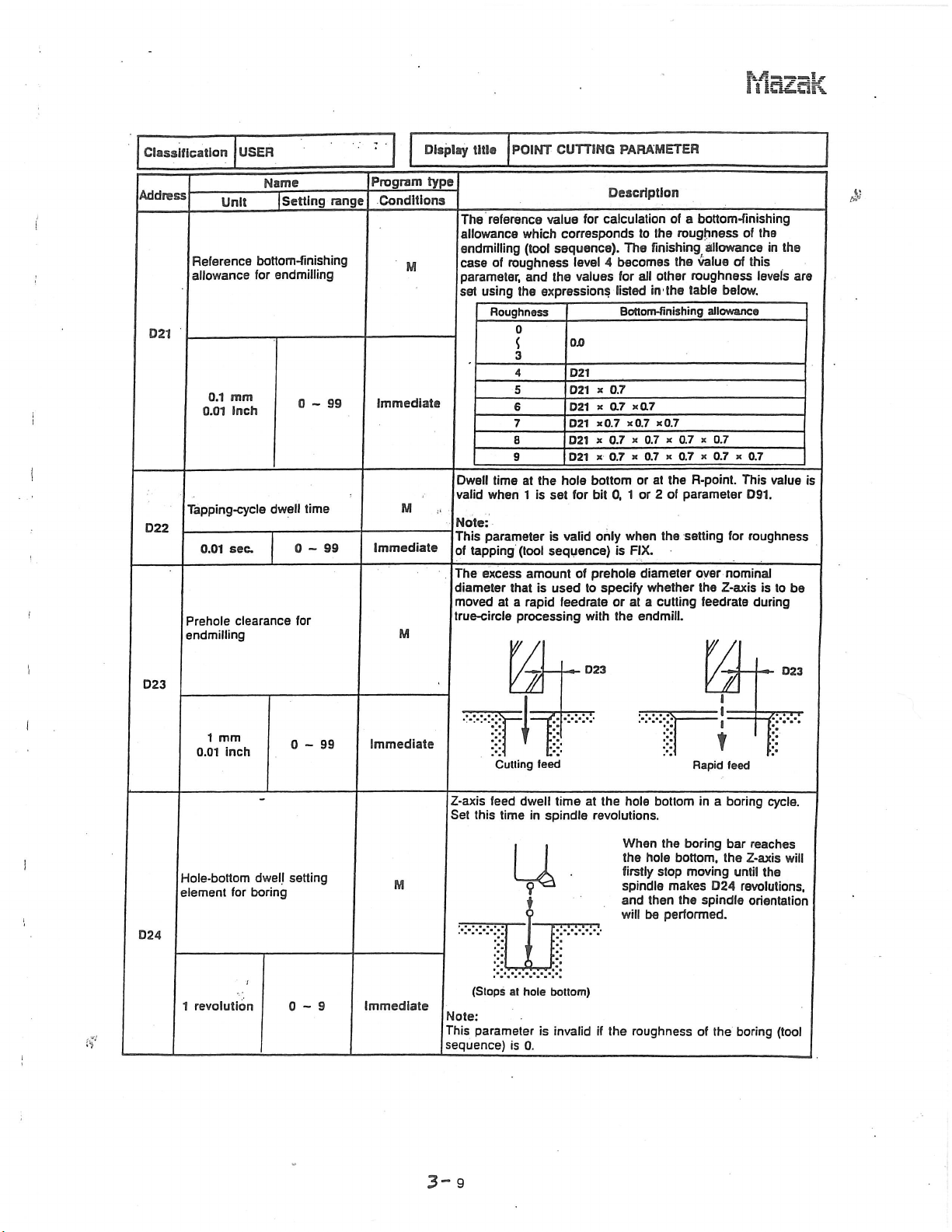

Classification

USER

Display

title

POINT

CUTTING

Mazak

PARAMETER

M

M

M

type

reference

The

allowance

endmilling

of

case

parameter,

using

set

Roughness

Dwell

time

valid

when

Note:

parameter

This

tapping

of

The

excess

diameter

moved

at

true-circle

Culling

value

which

(tool

roughness

and

expressions

the

0

4

5

6

7

8

9

the

at

1

set

is

is

(tool

sequence)

amount

is

that

rapid

a

processing

w

£

V

feed

for

corresponds

sequence).

level

values

the

OJD

D21

D21

*

*0.7

021

bottom

hole

bit

for

only

valid

prehole

of

to

used

feedrate

with

Description

calculation

to

The

becomes

4

all

for

listed

Bottom-finishing

»

0.7

*a7

ar

K

0.7

x

0.7x0.7

x

x

0.7

or

0,

or

1

when

FIX.

is

diameter

specify

or

at

endmill.

the

of

the

finishing

other

the

in1

KQ.7

x

x

0.7

at

the

2

of

the

whether

cutting

a

bottom-finishing

a

roughness

allowance

value

the

roughness

table

below.

allowance

x

0.7

0.7

x

0.7

0.7

R-point.

parameter

setting

for

over

nominal

the

Z-axis

feedrate

r

A

a

?

Rapid

feed

of

this

of

levels

x

0.7

This

D91.

roughness

during

the

is

I

in

value

to

$

the

are

is

be

D23

Address

Reference

!

allowance

Unit

bottom-finishing

for

Name

|

Setting

endmiiiing

range

Program

Conditions

D21

mm

D22

D23

0.1

inch

0.01

Tapping-cycle

sec.

0.01

0.01

1

clearance

mm

inch

Prehole

endmilling

dwell

0-99

time

0-99

for

0-99

Immediate

Immediate

Immediate

Z-axis

feed

dwell

Set

this

time

setting

Hole-bottom

element

for

dwell

boring

U

y.

3“

(Stops

Note:

parameter

This

sequence)

9

1

revolution

0-9

Immediate

if

spindle

in

u

at

hole

is

is

0.

timeatthe

:::

bottom)

invalidifthe

hole

revolutions.

When

the

firstly

spindle

and

will

roughness

hole

then

be

bottom

boring

the

bottom,

stop

moving

makes

the

performed.

in

a

D24

spindle

of

the

boring

bar

reaches

the

Z-axis

until

revolutions,

orientation

boring

cycle.

will

the

(tool

Page 14

Mazak

i

Classification

Address

Boring-bar

D25

Boring

bottom

D26

0.1

0.01

USER

Unit

mm

inch

back-boring

or

return

Name

[Setting

tip

relief

0-99

range

hole-

Program

Conditions

M

Immediate

M

Display

type

title

The

kept

Notes:

Valid

1.

boring

For

2.

of

The

same

hole

::j:

'

POINT

amount

clear

During

only

(tool

the

bit

3

distance

feedrate

bottom.

!

of

X

relief

and

S:

CUTTING

of

relief

the

hole

boring

when

sequence)

direction

4

bit

boring

the

as

that

provided

wall

setting

the

114.

of

existing

PARAMETER

Description

for

spindle

after

for

CYCLE

is

tool

of

the

back-boring

or

after

'

!

f

the

the

:::

1.

tip,

the

"

tip

of

a

orientation.

!*

.

During

prehole

see

the

is

tool

tool

has

026

boring

H+—

-

CvX

-

B

0

B

returning

diameter

description

returned

reached

L-Kd

bar

D2S

!$

I

,

|

»

to

of

the

at

the

the

ZT77-

be

!

$

i

the

at

D28

original

tool

@

the

of

of

70%

of

the

to

complete

positioned

Returned

rapid

feedrate.

boring

the

original

value

boring

at

at

(tool

before

(tool

chip

a

the

a

i

D27

Q.1

mm

inch

0.01

Bottom-finishing

boring

0-99

amount

of

Immediate

M

Has

©

hole

Note:

Not

valid

sequence)

Invalid

The

distance

feedrate

reached

bottom.

to

if

is

finish

the

1.

the

the

setting

_

boring

the

©

hole

v.;.y-

Returned

same

the

for

bar

bottom.

feedrate.

roughness

is

fed

I

-fCyy.o

il

at

in

I

D2S

The

feedrate

hole

0.1

0.01

mm

Inch

0-99

immediate

(f

D29

Chip

removal

1

sec.

time

0-99

M

Immediate

the

Note:

Not

valid

sequence)

The

time

removal

hole

bottom.

is

bottom

if

the

is

1.

required

operation

reduced

is

reached.

setting

for

after

to

70%

for

the

chip

a

the

tool

of

roughness

removal

has

the

been

Page 15

Mazsk

Classification

Address

Number

threads

Tapper

tap

1

Unit

thread

USER

Name

incomplete

of

tapping

in

elongation

|Setting

cycle

0-9

amount

range

of

Program

Conditions

M

Immediate

M

Display

type

Set

title

Element

during

Example:

SNO

1

Hole

f

Excess

during

this

POINT

used

automatic

depth

amount

a

tapping

value

R-point

CUTTING

automatically

to

tool

TOOL

DRILL

D11

-f

of

tool

cycle.

spindle

in

-f

PARAMETER

Description

development

;

X

%-

fp

NOM-a

10.

(D30

+

return

due

revolutions.

«

set

:::

pitch)

the

hole-drilling

for

tapping

j

Hole

-

D30

,

NO.

l

elongation

to

D31

depth

K

Pitch

HOLE-e

10.

Pitch

*

depths

unit.

HOLE-DEP

of

the

&

19?

tapper

revolution

1

0-9

Immediate

SI

Number

until

beginsintapping

revolution

1

Back-boring

D33

!

0.1

0.01

D34

of

spindle

mm

inch

spindle

CCW

tool

revolutions

rotation

_

cycle

0-99

tip

relief

0-99

M

Immediate

M

Immediate

The

has

spindle

rotation.

The

kept

the

prehole

©

Note:

For

the

bit

3

Invalid

number

rotated

CCW

amount

clear

During

relief

and

bit

inertial

of

clockwise

rotation

relief

of

the

of

in

the

back-boring

direction

4

of

prehole

oriented

I

114.

turns

during

command

provided

walls

state

iii

the

of

in

the

tool

tapping

time

to

for

a

as

of

tip,

it

cycle

output

from

the

start

back-boring

being

is

spindle.

the

k

!

0

0

During

©

see

the

that

the

of

of

spindle

tool

passed

-=>-

-i

r.-.v.1

.

\\

m,

passage

description

spindle

a

CCW

tip

to

through

D33

of

be

i

3-

11

Page 16

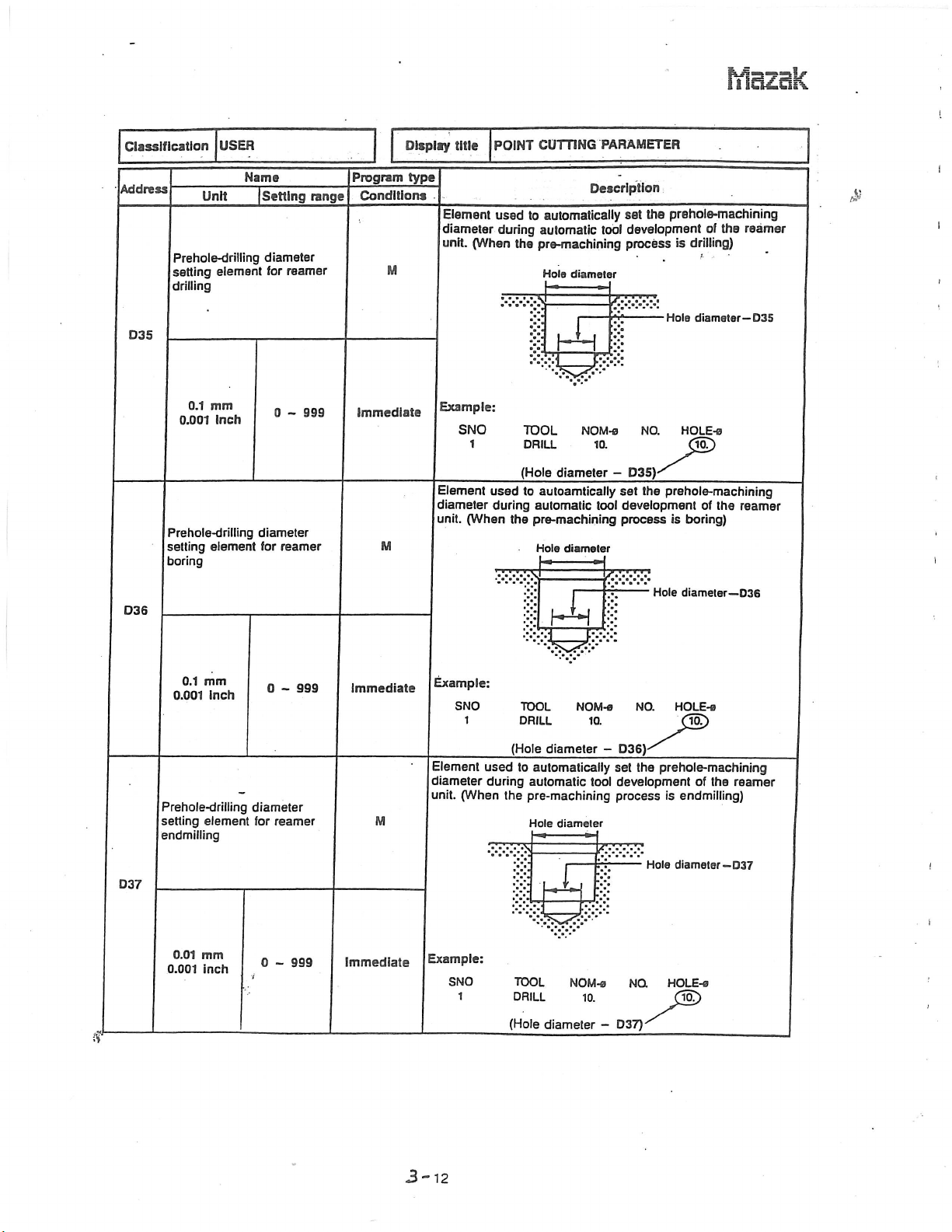

Mazak

i

Classification

Address

Prehole-driliing

setting

drilling

D35

0.001

Prehole-drilling

setting

boring

D36

0.1

USER

Unit

element

mm

Inch

element

Name

|

Setting

diameter

for

diameter

for

reamer

0

-

reamer

range

999

Program

Conditions

M

Immediate

M

Display

type

diameter

title

Element

diameter

(When

unit.

Example:

SNO

1

Element

(When

unit.

POINT

used

during

the

used

during

the

CUTTING

automatically

to

automatic

pre-machining

Hole

diameter

TOOL

DRILL

(Hole

diameter

autoamtically

to

automatic

pre-machining

Hole

diameter

Li

PARAMETER

Description

tool

rrÿ

JL_j

•••

NOM-o

10.

-

set

development

tool

process

prehole-machining

the

set

development

process

D35)

is

Hole

NO.

the

prehole-machining

is

Hole

of

the

drilling)

b

diameter—

HOLE-®

10.

of

the

boring)

diameter—

reamer

D35

reamer

D36

i

D37

mm

0.1

inch

0.001

Prehole-drilling

setting

element

endmilling

0.01

mm

0.001

inch

0

-

diameter

reamer

for

0

-

999

999

Immediate

M

Immediate

Example:

SNO

1

Element

diameter

(When

unit.

Example:

SNO

1

used

during

the

TOOL

DRILL

(Hole

diameter

to

automatically

automatic

pre-machining

Hole

diameter

£

H

4S

TOOL

DRILL

(Hole

diameter

NOM-s

H

r*;

NOM-0

10.

10.

-

set

tool

X

-

NO.

D36)-

the

prehole-machining

development

process

D37)

NQ

is

Hole

HOLE-®

HOLE-e

10.

of

the

endmilling)

diameter—

10.

reamer

037

!

i

3-12

Page 17

Md£ok

Display

type

Conditions

M

0.01

0.001

Unit

element

mm

inch

USER

Name

|

Setting

diameter

for

0

boring

999

-

Program

range

or

Immediate

Classification

Address

)

i

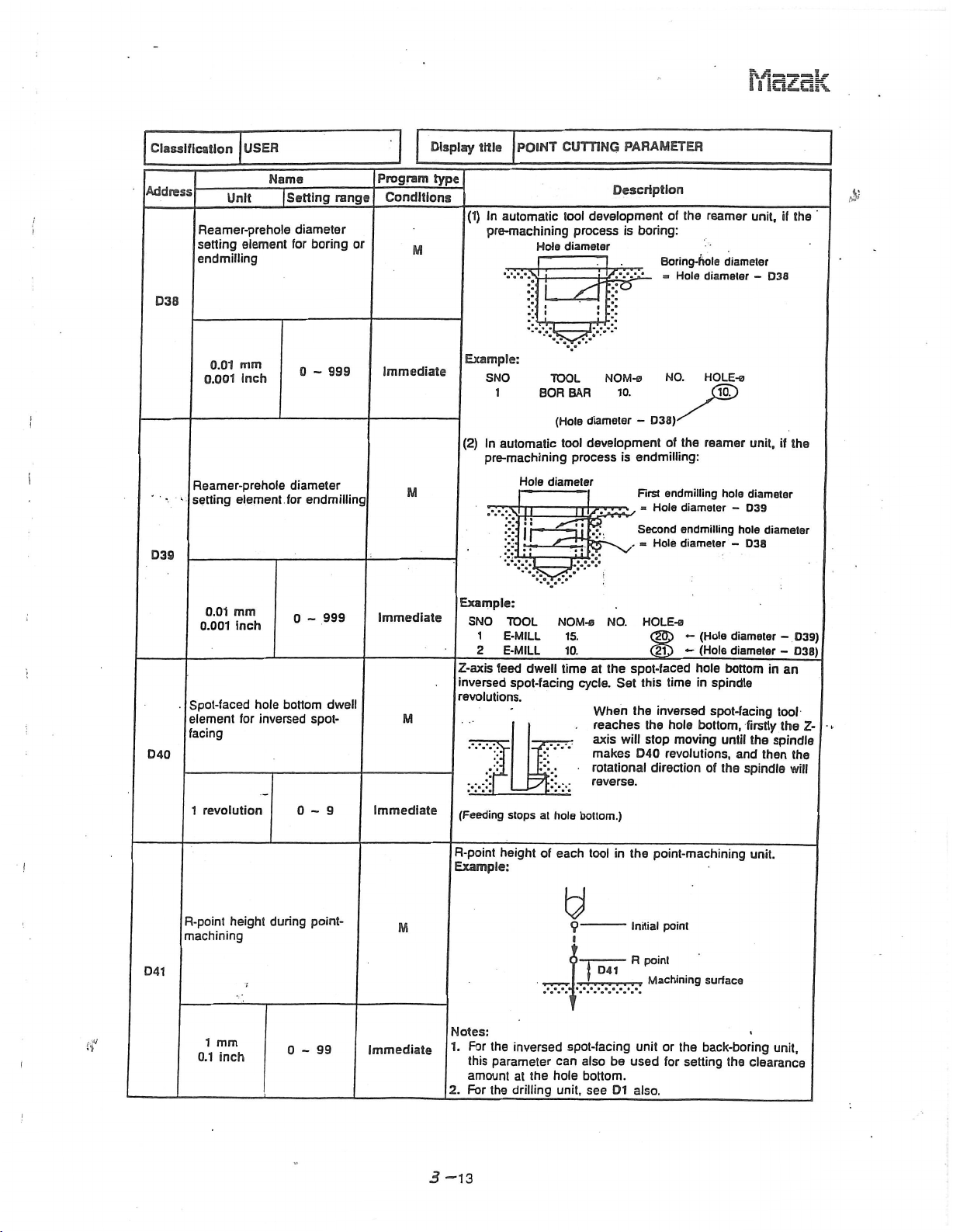

Reamer-prehole

setting

endmilling

D3S

I

D39

Reamer-prehole

setting

element

diameter

endmilling

for

M

title

In

(1)

automatic

pre-machining

Example:

SNO

1

(2)

In

automatic

pre-machining

i

CUTTING

POINT

tool

process

diameter

Hole

I

TOOL

BAR

BOR

(Hole

tool

process

Hole

diameter

mz

PARAMETER

Description

development

diameter

development

l/y.-AL

c

:

NOM-0

10.

boring:

is

-

endmilling:

is

First

Second

«

Soring-hola

-

D38)-

»

Hole

Hole

the

of

Hole

NO.

the

of

endmilling

diameter

endmilling

diameter

reamer

diameter

diameter

HOLE-e

10.

reamer

hole

-

-

unit,

-

unit,

diameter

D39

hole

D38

if

D38

if

the

diameter

$

the

mm

0.01

0.001

inch

999

0

-

immediate

:>

Spot-faced

D40

D41

element

facing

revolution

1

R-point

machining

1

0.1

!

t?

i

mm

inch

for

height

hole

inversed

during

bottom

0-9

0-99

dwell

spot¬

point¬

M

Immediate

M

Immediate

Example:

SNO

TOOL

1

E-MILL

2

E-MILL

Z-axis

feed

inversed

revolutions.

dwell

spot-facing

JUT

For

the

this

parameter

amount

For

the

stops

height

inversed

at

drilling

the

at

hole

of

hole

(Feeding

R-point

Example:

Notes:

1.

2.

NOM-s

15.

10.

at

time

cycle.

bottom.)

tool

each

Q

?

9

spot-facing

can

also

bottom.

unit,

see

NO.

spot-faced

the

Set

When

reaches

axis

will

makes

rotational

reverse.

the

in

D41

be

D1

HOLE-0

ap

>

<

&0

-

this

time

the

inversed

the

hole

stop

moving

revolutions,

D40

direction

point-machining

point

Initial

point

R

Machining

or

unit

the

for

_

setting

used

also.

(Hole

-

(Hole

hole

spindle

in

spot-facing

bottom,

until

of

the

surface

back-boring

diameter

diameter

bottom

firstly

the

and

spindle

the

clearance

unit.

in

tool

spindle

then

unit,

-

-

an

the

D39)

038)

Z-

the

will

3

-13

Page 18

Mazak

Classification

Address

D42

D46

Reamer-prehole

overshoot

D47

0.01

0.001

D48

D90

Unit

mm

inch

USER

Name

|

Setting

machining

Display

Program

range

999

0

-

Conditions

Immediate

type

Invalid

Element

endmilling

the

M

Example:

Invalid

title

reamer

•y.\\

SNO

1

POINT

used

and

unit.

For

drilling

TOOL

DRILL

automatically

to

boring

(Hole

CUTTING

during

Hole

D47

NOM-fl

10.

depth

Description

depth

PARAMETER

set

hole

the

automatic

For

endmilling

NO.

HOLE-a

D47)

+

depth

tool

development

•!•!

!

10.

of

drilling,

depth

|Hole

D47

or

boring

HOLE-DEP

-(S)

I

£

l

of

i

D91

Bit

Binary

digits

eight

M

Immediate

L

_

_

_

_

I

I?

L.M04

dwelled

tapping

_

The

output

tapping

The

returned

tapping

The

during

(endmilling).

__The

true-circle

(chamfering).

.The

as

Execution,

(1:

is

tool

tool

finishing

tool

R-point

D1.

output

at

cycle.

at

cycle.

dwells

cycle.

true-circle

a

path

after

hole

the

dwells

after

the

hole

after

R-point

to

the

tool

is

shortened

processing

height

0:

No

the

bottom

M04

bottom

it

path

processing

cycle

of

the

execution)

tool

has

during

has

during

has

been

during

is

shortened

during

drill

is

been

a

cycle

set

a

a

i

a

if

I

3-

14

Page 19

Mazak

Classification

Address

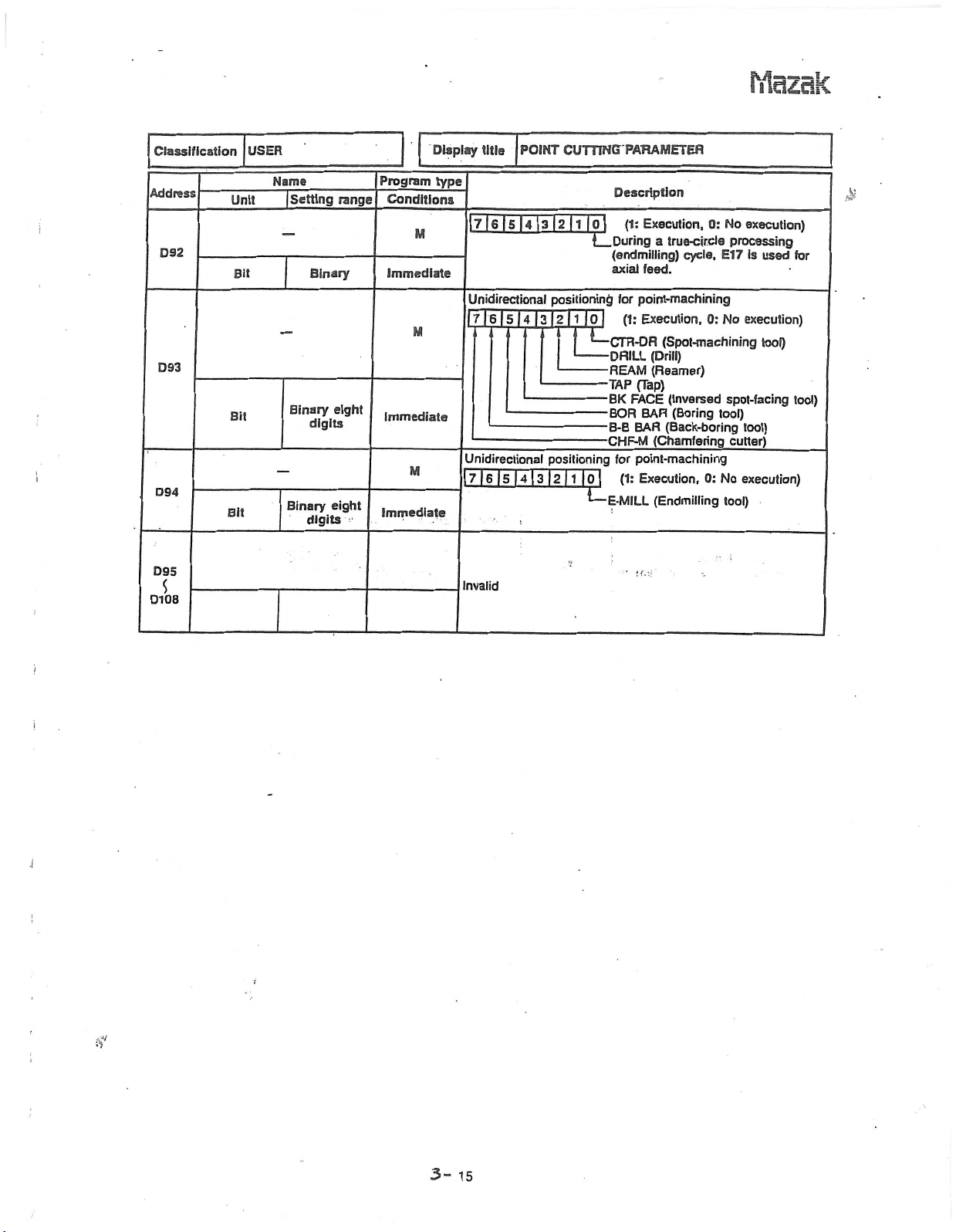

D92

D94

D

95

D108

Unit

Bit

Bit

Bit

USER

Name

|

Setting

Binary

Binary

Binary

digits

digits

range

eight

eight

Program

Conditions

M

Immediate

M

Immediate

M

Immediate

Display

type

|7|6|5l4|3|2|l

Unidirectional

|7|6|5|4|3|2|1

Unidirectional

7

Invalid

title

|6|5|4

POINT

positioning

|2

[3

CUTTING

|0|

L_

positioning

|ol

*

f

—

1

-

|0~l

M

PARAMETER

Description

Execution,

(1:

During

a

(endmilling)

feed.

axial

point-machining

for

Execution,

(1:

Cm

DRILL

REAM

TAP

BK

BOR

B-B

CHF-M

for

E-MILL

(Spot-machining

-DR

(Drill)

(Reamer)

(Tap)

FACE

BAR

(Back-boring

BAR

(Chamfering

point-machining

Execution,

(1:

(Endmilling

'*

r.

:.i

i

0:

true-cir.cle

cycle,

0:

(Inversed

(Boring

0:

No

execution)

processing

is

E17

used

No

execution)

tool)

spot-facing

tool)

tool)

cutter)

No

execution)

tool)

•;

£

for

tool)

!

J

3-

15

Page 20

ffidZik

i

Classification

Address

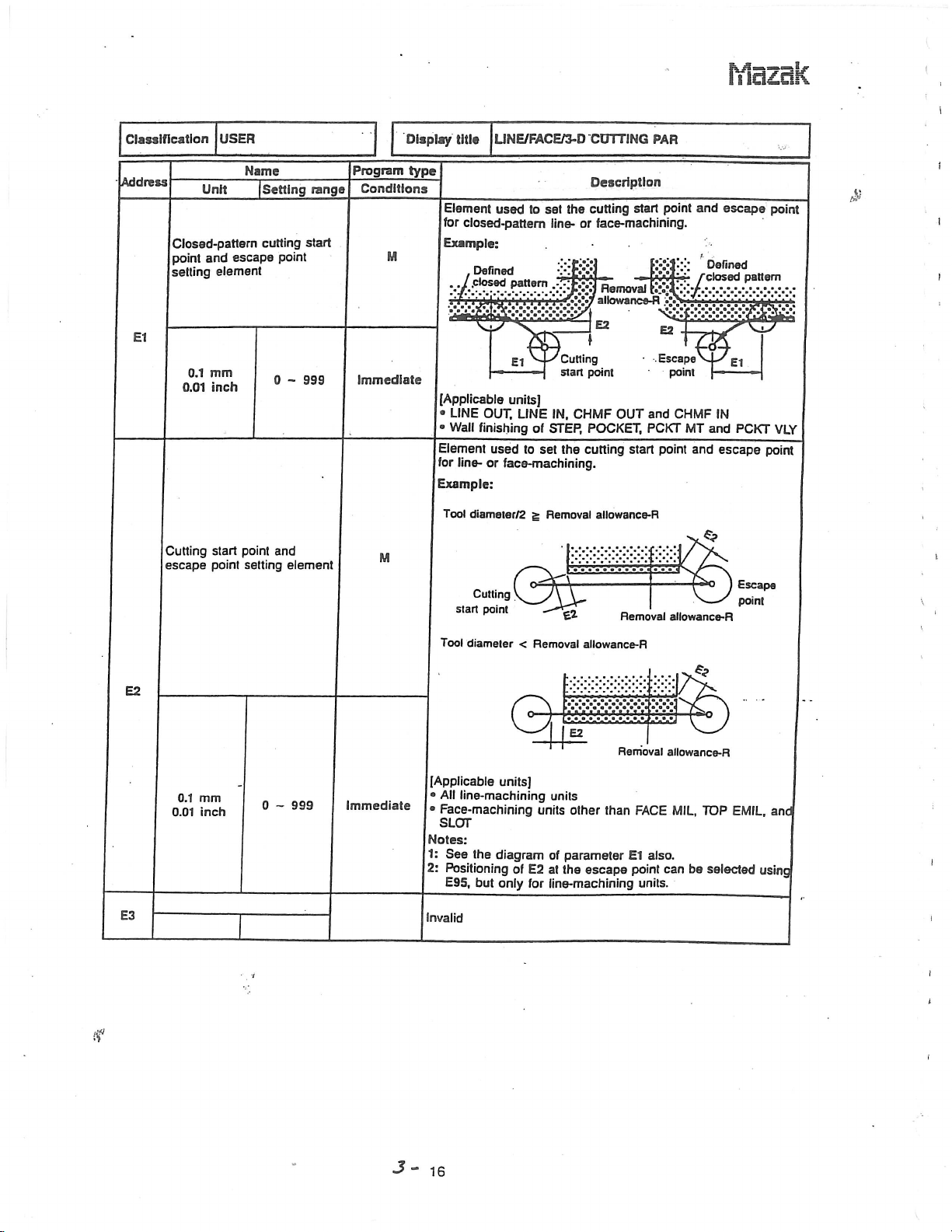

Closed-pattern

point

setting

El

0.01

Cutting

escape

0.1

Unit

and

element

mm

inch

start

point

USER

escape

point

Name

|Setting

cutting

setting

point

0

-

and

element

range

start

999

Program

Conditions

M

Immediate

M

Display

type

[Applicable

Element

for

Example:

title

Element

for

closed-pattern

Example:

>MM

LINE

•

OUT.

8

Wall

finishing

line-

Tool

diameter/2

Cutting

point

start

Tool

diameter

LSNE/FACE/3-D

set

to

used

the

line-

sfsi

LINE

of

to

g

Cutting

start

IN,

STEP,

set

the

Removal

E1

units]

used

or

face-machining.

eg

£2

Removal

<

CUTTING

Description

cutting

face-machining.

or

•

»

point

CHMF

OUT

POCKET,

cutting

allowance-R

Removal

allowance-R

start

start

PAH

point

.Escape

point

CHMF

and

PCKT

point

allowance-R

and

MT

and

escape

w-

IN

and

escape

El

PCKT

Escape

point

point

VLY

point

i

£

i

l

3?

E2

0.1

0.01

mm

inch

Removal

[Applicable

®

0

999

~

immediate

All

Face-machining

•

units]

line-machining

units

units

other

than

SLOT

FACE

allowance-R

MIL,

TOP

EMIL,

and

Notes:

1:

See

the

E3

2:

Positioning

E9S,

Invalid

but

diagram

of

only

parameter

of

the

at

E2

line-machining

for

escape

E1

point

also.

units.

can

be

selected

using

i

i

*

if

J

“

16

Page 21

Mazak

Classification"

Address

Reference

radial

in

E4

0.1

0.01

E5

Reference

axial

in

USER

Unit

direction

mm

inch

direction

Name

|Setting

allowance

allowance

of

when

have

R

of

below.

OO

E4

x

E4

x

E4

x

E4

x

E4

x

E4

CUTTING

Description

each

roughness

the

been

the

in

parameter,

this

are

calculated

0.7

x

0.7

x

0.7

x

0.7

0,7

X

Display

Program

range

of

0

999

-

Conditions

finish

Immediate

type

M

title

LINE/FACE/3-0

The

reference

automatically

face-machining

The

finish

becomes

other

listed

allowance

the

roughness

in

the

Roughness

0

1

3

4

S

6

7

8

9

table

value

set

units

value

levels

PAR

Finish

allowance

levels

set.

roughness

of

case

and

using

Finish

allowance

0.7

x

0.7

0.7

0.7x0.7x0.7

0,7

X

X

0.7

0.7

the

the

x

R

which

the

of

level

values

expressions

R

0.7

line-

for

is

or

4

all

Invalid

of

finish

The

reference

automatically

face-machining

The

finish

M

becomes

other

listed

allowance

the

roughness

in

the

table

value

set

units

value

of

when

of.

levels

below.

have

Z

this

in

are

each

roughness.

the

been

the

parameter,

calculated

finish

case

allowance

set.

of

levels

roughness

and

the

using

the

Z

which

of

the

level

values

expressions

line-

for

is

or

4

all

E6

E7

0.1

0.01

mm

inch

Roughness

0

5

3

4

5

999

0

-

immediate

6

7

8

9

0.0

E6

E6

E6

E6

EG

E6

x

x

x

x

X

invalid

Finish

0.7

0.7x0.7

0.7x0.7x0.7

x

x

0.7

0.7

0.7

X

0.7

0.7

X

0.7x0.7

allowance

x

0.7

Z

x

0.7

I

tf

I

3-

17

Page 22

frlazak

Classification

Address

Radial

of

E8

Allowance

start

E9

0.01

USER

Unit

interference

chamfering

0.1

mm

inch

0.01

position

0.1

mm

Inch

Name

Setting

cutter

axial-cutting

of

0

clearance

0

-

999

-

range

999

Program

Conditions

M

Immediate

M

Immediate

Display

type

work

Example:

title

The

amount

chamfering

Interferes

Element

axial

direction

ing

tool

has

a

at

UNE/FACE/3-D

of

clearance

with

cutter

/

Interference

used

rapid

to

is

been

distance

set

the

be

to

moved

feedrate.

YA

t

'.•.T.,.w.vX,.v,

CUTTING

Description

that

hole

the

position

started

from

Initial

ES

PAR

ensures

walls

<>

which

in

the

after

initial

the

point

Removal

no

during

the

line-

point

allowance

interference

E8

ilr

mo

or

of

the

face-machining.

I

cutting

feed

face-machin¬

toward

Z

in

the

&

i

.

I

t

i

l

E10

E11

Depth-of-cut-R

element

setting

Endmilling-top,

relief)

10%

Axial

interference

of

chamfering

0.1

mm

inch

0.01

automatic

(Face

Endmilling-

0-9

clearance

cutter

5-40

milling,

M

Immediate

M

Immediate

Element

Radial

SNO

HI

sequence

tool

TOOL

F-MILL

amount

the

Example:

The

chamfering

Interference

to

used

depth-of-cut

NOM-o

1CX1A

of

clearance

automatically

cutter

o

depth

in

NO.

with

FACE

=

APBCHJt

? ?

the

Interferes

set

MIL,

TOP

Nominal

that

hole

diameter

APRCH-Y

ensures

bottom

U=£>

the

10

TYPE

Nominal

radial

EMIL

XSI

diamotcf

no

interference

during

depth-of-cut

or

STEP

E10

><

ZFD

DEM

u

E10

10

chamfering.

oBo

a

o

a'i

of

unit.

W1D-H

TO

I.

(he

of

i

Ell

tKi'

i

i

l

J

if

1

3-18

Page 23

Classification

USER

Mazak

.ÿ

i

'

Display

UNE/FACE/3-D

title

CUTTING

PAH

Address

E12

E13

E14

Unit

interference

Radial

milling

face

of

mm

0.1

inch

0.01

path

Tool

endmilling-top

10%

Depth-of-cut-R

setting

element

milling.

Pocket

milling-hollow)

Pocket

10%

path

Tool

face

(reciprocating

setting

milling

Name

|

Setting

unit

setting

unit

automatic

(Pocket

milling-relief,

element

unit

short)

clearance

0

-

element

1

-

0-9

range

999

9

for

for

Program

Conditions

M

Immediate

M

Immediate

M

Immediate

M

type

The

the

Example:

Element

endmilling-top

Example:

Tool

Element

the

Example:

SNO

m

Element

figure

Example:

amount

tool

and

Escape

o-

o-

Cutting

start

point

used

diameter

used

sequence

tool

depth-of-cut

Radial

TOOL

NOWLo

ZOA

EMILL

used

for

reciprocating-short

clearance

of

figure

the

point

E12

to

set

unit.

E3

x

-

10

automatically

to

in

NO.

APRCH-X

to

set

the

Description

that

during

-

L

path

tool

the

O

POCKET.

Nominal

»

APHCH-Y-

?

path

tool

machining

ensures

face

Defined

internal

Defined

the

set

PCKT

7

external

no

milling.

figure

E12

t

Tool

radial

MT

diameter

10

TYPE

cw

Nomina]

with

contact

to

the

diameter

figure

depth-of-cut

or

PCKT

x

ZFD

GOT

die

roefof

10

to

the

face

-i

figure

E14

OEP-Z

n

E14

defined

milling

between

x

VLY

-WIOÿ

ia

for

_

Etg

10

of

unit.

1?

unit.

&

’

Tool

-

©

diameler

E1S

x

-

10

E15

o

i

10%

9

1

-

immediate

3-

Tool

19

diameter

x

10

Defined

7

figure

Page 24

Mazak

Classification

Address

Peripheral-cutting

override

unit

E16

Axial-cutting

E17

USER

Unit

endmilling-relief

for

feedrate

Name

Setting

I

feedrate

1

-

override

range

20

Program

Conditions

M

Immediate

M

Display

type

Override

endmilling-relief

the

Note:

Valid

Example:

Tool

feedrate

Override

face-machining

moved

Notes:

1.

2.

Example:

title

LINE/FACE/3-D

valueofihe

work.

only

when

sequence

x

value

to

the

Valid

only

Feed

overriding

unit

bit

E16

of

unit

machining

when

idle-cutting

is

of

0

feedrate

the

(excluding

ZFD

is

invalid

u

i

CUTTING

Description

moved

be

to

E91

is

H

at

face

surface

sequence

tool

of

when

feedrate

and

1

which

in

this

PAR

around

bit

milling

an

axial

parameter

7

figure

the

is

which

at

the

is

0.

Tool

feed

tool

of

unit)

is

direction.

G01.

outer

a

to

is

tool

of

form

sequence

rate

or

line-

be

0.

.

.

&

of

I

i

l

i

i

Pocket-machining

width

E18

10%

override

10%

0-9

across-the-

0-9

Immediate

M

Immediate

Tool

sequence,

_

.

w

leedrale

Override

which

equal.

E17

.

*

10

valueofthe

the

pocket-machining

.

£1

Note:

Across-the-width

is

0.

[Applicable

Rough-machining

STEP

units]

tool

overriding

POCKET,

of

diameter

radial

Tool

not

is

PCKT

E9

8

(across-the-width)

depth-of-cut

sequence

valid

MT,

when

PCKT

feedrate

this

Removal

allowance

*

Machining

"•

surface

becomes

parameter

VLY

and

Z

to

g

_

Ei

x

10

i

3“

20

Page 25

Ftick.dk

i

Classification

Address

E19

E20

Wall-cutting

figure

E21

0.01

0.1

Unit

mm

inch

USER

Name

|

Setting

overlap

Program

range

in

closed

0

999

-

Immediate

Display

Conditions

M

i

of

Override

corner

value

overriding

automatic

/

M

type

title

Invalid

The

amount

in

closed-pattern

Example:

Escape

[Applicable

OUT,

LINE

°

Wall

hnishing

•

SLOT

Override

machining

Example:

Tool

LINE/FACE/3-D

overlap

of

point

units)

LINE

of

valueofautomatic

sequence

teed

rate

line-

Defined

IN,

STEP,

or

CHMF

E22

100

CUTTING

Description

of

the

face-machining.

closed

PAR

wall-cutting

pattern

:SE2?5»SS®,

OUT

comer

and

PCKT

overriding

POCKET,

'

!ÿ

-

start

9

jCutting

CHMF

MT,

and

IN

PCKT

in

line-

Tool

feed

end

point

start

VLY

or

sequence

rate

areas

and

face-

E22

Note:

1%

Effective

(upper

corner

E23

I

Effective

(lower

corner

E24

tf

removal

limit)

overriding

1%

removal

limit)

overriding

1%

of

automatic

of

automatic

0-99

allowance

99

1

-

allowance

99

1

-

Immediate

M

Immediate

M

Immediate

Automatic

is

0.

[Applicable

RGT,

LINE

PCKT

MT

The

range

The

automatic

following

[Removal

line-

Tool

diameter

allowance]

Removal

Machining

Line-roughmachining

Face-roughmachining

corner

units]

LINE

and

of

removal

corner

or

E24

x

x

100

allowance

PCKT

overriding

LFT,

face-machining

<

=

is

OUT,

LINE

VLY

allowances

overriding

Removal

allowance

invalid

LINE

(upper

becomes

conditions

<

-

(Radial

(Radial

-

(Radial

when

IN,

and

Tool

diameter

f

Removal

removal

this

parameter

STEP,

POCKET.

lower

valid

when

are

met:

E23

*

100

allowance

allowance)

allowance)

finish

depth-of-cut)

limits).

the

J-

21

Page 26

Classification

USER

Display

LINE/FACE/3-0

title

CUTTING

Mazak

i

PAR

Address

E25

E26

$

£54

Effective

automatic

of

overriding

3-D

cutting-feed

Axial

Unit

r

angle

Name

|Settlng

(upper

corner

1

overriding

range

limit)

Program

Conditions

type

shape

The

The

automatic

following

line-

Shape

angle

corner

face-machining

or

angle

range

g

Description

(upper

overriding

E25

angle

Shape

limit).

becomes

conditions

valid

are

when

met:

the

£

I

\

w

179

-

Immediate

M

Invalid

Feed

overriding

a

3-D

unit.

Example:

for

cutting

Tool

a

work

sequence

rate

feed

an

in

axial

jss.

direction

y

10

using

iH

E55

E56

10%

3-D

Inversion

surface

check

pattern

of

-9

0

curved-

1

0,

Immediate

M

Immediate

High-speed

Note:

overriding

Feed

The

parameter

message

pattern

becomes

0:

No

1:

Alarm

Example:

The

curved

pattern

points

Note:

parameter

This

processing.

is

to

be

points

in

impossible).

alarm

surface

in

is

rough

is

invalid

used

displayed

the

the

invalid

processing

to

select

-Z

defined

of

a

-Z

during

Depth-o(-cut

when

whether

if

the

direction

direction.

Finish

parameter

this

or

curved

(normally,

high-speed

S5

processing

an

not

surface

processing

rough

is

0,

alarm

of

I

a

defined

ES9

I

i

i

i

3-22

Page 27

r£.S

<?M*

P

X

<5-

A\

<v

6

<

o?

/

x

$

VN

X

QJD

c>ÿ

/

‘

Mazak

v—

"XMo-0

CUTTING

to

select

accordance

is

no?

strictly

is

invalid

is

time

becomes

select

to

according

a

of

made

position

the

started

toward

E59

;.j

high-speed

_

(cutting)

to

Description

defined

the

the

type

Element

axial

from

Example:

Material

The

of

curved

Example:

Mis'

L1NE/FACE/3-0

parameter

The

performed

be

pitch

data

The

0:

The

1:

Notes:

This

1.

processing.

The

2.

to

1.

parameter

The

diameter

for

the

0:

Diameter

1:

Diameter

Example:

Diameter

direction

the

in

setting.

pitch

pitch

setting

parameter

operation

compensation

curved

surface

compensation

compensation

compensation

used

to

istobe

point

initial

y

i

s

height

i

$*x*F:**m

Normal-speed

rough

processing

finish

surface.

EGO

processing

with

the

3-D

normal

used

strict

setting

used

set

Work

or

respect

Display

Conditions

M

Immediate

M

M

M

0.1

0.01

USER

Unit

check

position

mm

inch

cutting

Name

|

Setting

of

compensation

axial-cutting

of

0

allowance

cutting

0,

0,

1

999

-

Program

range

1

Immediate

Immediate

Classification

Address

3-D

Severity

pitch

E57

3-D

Tool-diameter

ESS

3-D

Allowance

start

E59

i

3-D

Normal

E60

whether

strictly

observed.

during

long

-whether

made

not

made

Diameter

in

after

work

defined

PAR

or

with

the

observed.

high-speed

if

this

or

to

tool

pattern.

compensation

which

the

tool

a

at

Finish

allowance

pattern

;

I

'

not

processing

tool-sequence

rough

parameter

not

3-D

data

is

the

cutting

has

been

rapid

feedrate.

u

!

processing

in

the

of

EGO

tool-

to

be

n

a

•

not

feed

moved

pattern

direction

the

is

is

set

made

made

in

IE59

£

to

0.1

0.01

mm

inch

999

0

-

Immediate

3-

23

yy

Page 28

Mazak

i

Classification

Address

E61

3-D

Search

cutting

E62

3-D

Pattern

segments

E63

3-D

Pattern

segments

E64

3-D

Radial

area

ESS

0.01

3-D

Axial

area

E66

0.01

3-D

Search

cutting

0.1

0.01

0.1

0.01

check

0.1

cutting

check

mm

0.1

inch

USER

Unit

length

mm

inch

length

mm

Inch

display

display

cutting

mm

inch

Name

|

for

division

(FL

direction)

division

(GL

direction)

allowance

allowance

0

Setting

parallel

for

0

-

right-angle

0

-

0

-

0

-

0

-

999

-

999

999

for

999

S99

999

range

for

Program

Conditions

M

Immediate

M

immediate

M

immediate

M

immediate

M

Immediate

M

Immediate

Display

type

Note:

This

pattern,

from

machined.

The

which

Example:

title

The

length

nest

approximation

Depending

ESI

is

BSZ

is

The

number

curved

surface

surface

Example:

GL

or

parameter

and

the

allowance

has

E66

I

slM'

L1ME/FACE/3-D'

line

short

of

a

point

tool-sequence

on

the

applicable

applicable.

pattern

normal

thus

actual

been

segments

of

is

on

E64

to

is

the

pattern

of

cutting

set

to

the

FL

used

using

for

for

be

PATH

for

pattern

of

?

%

v

I

I

I

I

f

£

il

"

I

CUTTING

Description

segment

tool-path

.for

II-Z-,

or

/A1

_|-1

or

into

which

divided

CHECK

display

displayed

the

curved

work

a

area

the

PAR

which

determines

creation.

selected:

method

or

.

_J-2.

the

defined

display

for

of

along

check

of

display.

E63

a

curved-surface

may

slightly

the

function.

to

wall

surface

u

I

I

I

UJ

rsp

—

ESS

the

be

of

w

Max.

pattern

curved-

FL

differ

the

area

the

ES6

4*

%

1

s

of

a

j

3-24

Page 29

ffidzak

Classification

Address

3-D

Processing

E67

E75

0.01

0.001

3-D

Entire-width

E76

Unit

mm

inch

USER

error