Maytag Services AMV4204AAB, AMV4204AAQ, MMV4205AAB, AMV4204AAW, MMV4205AAW Technical Information

...

Domestic Microwave⎯Technical Information

Over-The-Range Convection Microwave Models

AMV4204AAB/W/Q MMV4205AAB/W/Q/S

• Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or

repair of this unit.

• Refer to Service Manual 16023056 for detailed installation, operating, testing, troubleshooting, and disassembly

instructions.

CAUTION

!

All safety information must be followed as provided in Service Manual 16023056.

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

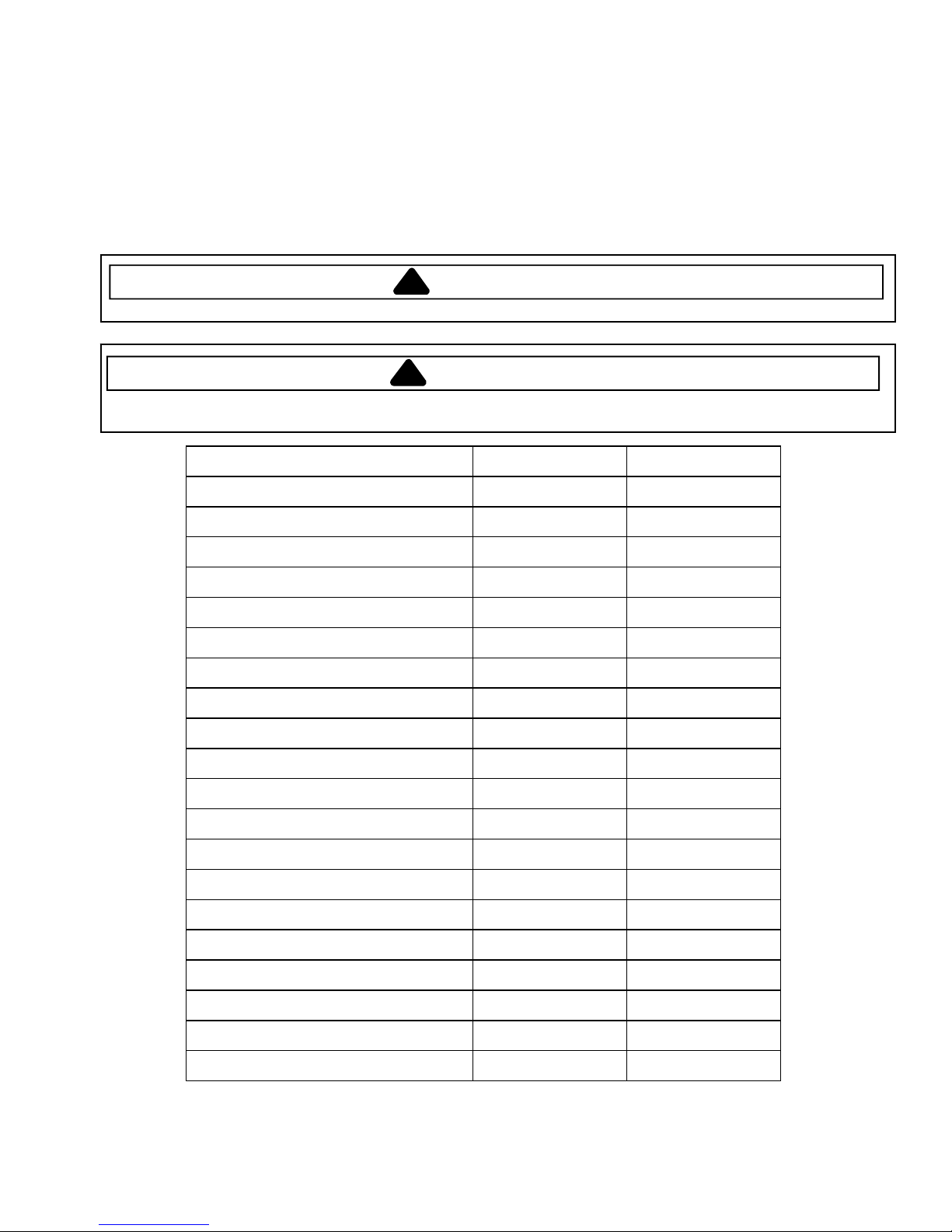

Power Source AMV4204AA* MMV4205AA*

Voltage AC 120 VAC 120 VAC

Amperage 20 A 20 A

Frequency 60 Hz 60 Hz

Single Phase, 3 wire grounded Yes Yes

Power Output

Nominal microwave energy (IEC705) 1150 Watts 1150 Watts

Operating frequency 2450 MHz 2450 MHz

Power Consumption

Microwave, lamp and vent fan 1700 Watts 1700 Watts

Dimensions, Exterior (Cabinet)

Width 29 15/16" 76 cm 29 15/16" 76 cm

Height 16 7/16" 42 cm 16 7/16" 42 cm

WARNING

Depth 15 3/8" 39 cm 15 3/8" 39 cm

Dimensions, Interior (Cavity)

Width 23 1/2" 60 cm 23 1/2" 60 cm

Height 10 3/16 " 26 cm 10 3/16 " 26 cm

Depth 14 1/2" 37 cm 14 1/2" 37 cm

Weight (approx.)

Uncrated 60 lbs 28 kg 60 lbs 28 kg

Crated 68 lbs 30 kg 68 lbs 30 kg

June 2005 16026270

©2005 Maytag Services

1

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

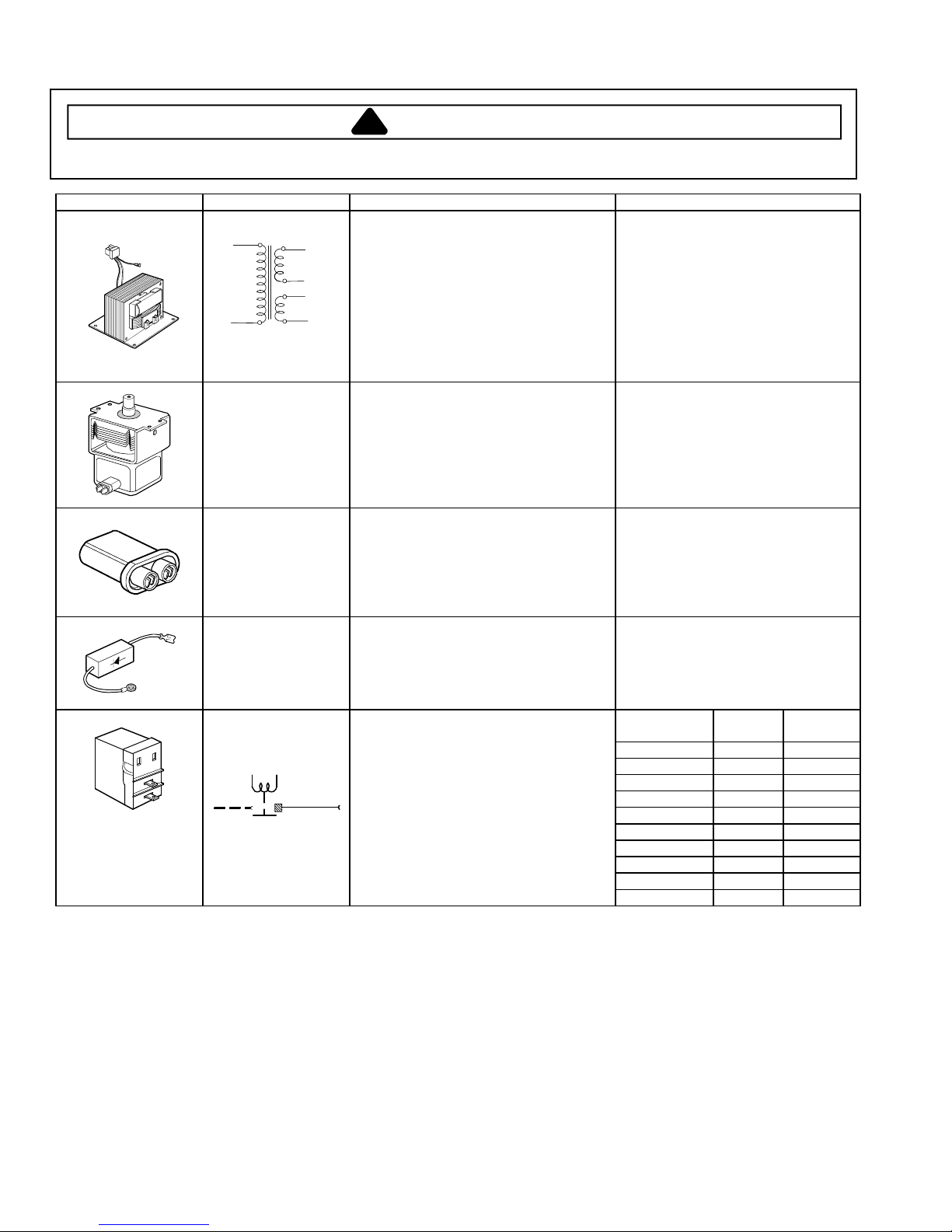

Illustration Component Test Procedure Results

High voltage

transformer

120 V

Primary

0 V

Magnetron

High Voltage

Capacitor

High Voltage Diode

Secondary

Filament

Relay 7

Discharge Capacitor

Disconnect connector and measure

continuity with meter on R x 1 scale:

Secondary ......................................

Filament..........................................

Primary (High & Low)......................

(Measure at room temperature, or 70° F/

22°C)

Measure continuity with meter on “High”

scale: Primary winding to ground ..............

Filament winding to ground .............

Discharge Capacitor

Remove wires from magnetron and

connect ohmmeter to terminals. Also

check between each terminal and ground.

Discharge Capacitor

Remove wires from capacitor terminals

and connect ohmmeter, set on highest

resistance scale to terminals.

Also check between each terminal and

capacitor case.

Discharge Capacitor

Remove diode lead from capacitor and

connect ohmmeter.

Reverse leads for second test.

Disconnect the leads. Place water in the

oven and select power levels 1 through

10. Check continuity between the

terminals of the relays.

Approximately 50-120 Ω

Less than 1 Ω

Less than 1 Ω

Infinite Ω

Infinite Ω

Between Terminals: Less than 1 Ω

Each terminal to ground: Infinite

resistance.

Note: This test is not conclusive. If

oven does not heat and all other

components test good replace the

magnetron and retest.

Between Terminals: Meter should

momentarily indicate several ohms,

then return to infinity. If no deflection

occurs, or if continuous deflection

occurs, replace capacitor.

Terminal to Case: Infinite resistance

Infinite resistance should be measured

in one direction and continuity in the

opposite direction.

NOTE: Ohmmeter must contain a

battery of 6 volts minimum.

Power Level

1 4 sec 18 sec

2 6 sec 16 sec

3 8 sec 14 sec

4 10 sec 12 sec

5 12 sec 10 sec

6 14 sec 8 sec

7 16 sec 6 sec

8 18 sec 4 sec

9 20 sec 2 sec

10 22 sec 0 sec

Cycle On

(Continuity)

Cycle Off

(Open)

16026270 June 2005

©2005 Maytag Services

2

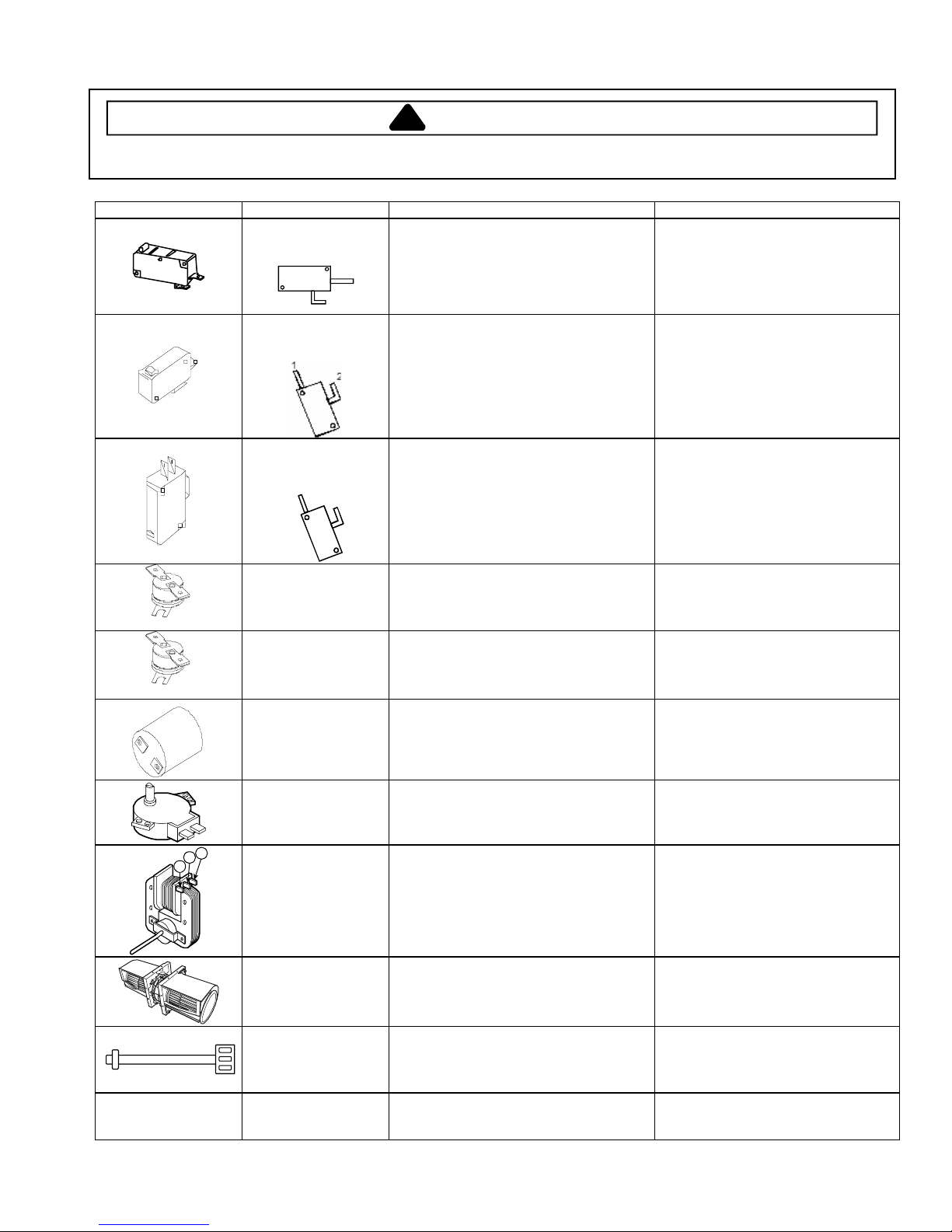

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

Illustration Component Test Procedure Results

Primary Interlock

Switch Test

(Top Switch)

Measure resistance between

terminals 1 and 2:

Door Open...................................................

1

Door Closed.................................................

Open

Continuity

2

Secondary Interlock

Switch Test

(Bottom Switch)

Measure resistance between

terminals 1 and 2:

Door Open...................................................

Door Closed.................................................

Open

Continuity

Interlock Monitor

Switch Test

(Middle Switch)

Magnetron Thermal

Cut-Out (Thermostat)

Oven Thermal CutOut (Thermostat)

Lamp receptacle Test continuity of receptacle terminals......... Indicates continuity if bulb is good and

1

2

Measure resistance between

terminals 1 and 2:

Door Open...................................................

Door Closed.................................................

Disconnect all wires from TCO.

Measure resistance across terminals.

Magnetron TCO ...........................................

Disconnect all wires from TCO.

Measure resistance across terminals.

Oven TCO....................................................

Continuity

Open

Open at 302°F (150°C) and closed at

32°F (0°C)

Open at 230°F (110°C)

Closed at 0°F (32°C)

installed.

Turntable Drive Motor

(Synchronous motor)

A

B

C

Fan motor Remove all wires from motor.

Ventilation Motor Remove all wires

Refer to Parts Manual

for proper power cord

part number.

Thermistor Remove connector from circuit board.

Power cord Measure resistance of wires ........................ Continuity on each wire.

June 2005 16026270

©2005 Maytag Services

Measure voltage across terminals ...............

Measure resistance across terminals...........

Measure resistance .....................................

Measure resistance across terminals...........

Measure resistance across pins 1 & 3.........

3

Approximately 120 VAC

Approximately 2-4 Ω

(All measurements approximate)

Across terminals A & C: 35-50 Ω

Across terminals A & B: 5-15 Ω

Infinite or several, motor is defective.

High Speed: Approximately 49-69 Ω

Low Speed: Approximately 97-117 Ω

Approximately 250-360 KΩ (70°F,

20°C ± 35°F, 2°C)

Verify polarity and grounding.

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

Illustration Component Test Procedure Results

FTP Connector

TOP

Touch Pad/Control

Panel

Model AMV4204A**

1

2

3

4

5

6

7

8

9

10

11

12

13

Removal of Touch

Pad/Control Panel is

required to perform test.

Check for continuity.

When touched: Less than

400

Ω

When not touched: More

than 1 mega

Ω

Pad

1

2

3

4

5

6

7

8

9

0

Popcorn

Baked Potato

Beverage

Cook

Reheat

Poultry

Soften

Melt

Auto Defrost

Time Defrost

Rapid Defrost

Clock

Cook Time

Control Setup

Power Level

Add 30 Sec.

Hold Warm

Stop/Clear

Enter/Start

Custom Program

Kitchen Timer

Light Timer

Vent Hi/Lo/Off

Turntable On/Off

Light Hi/Lo/Off

Trace

8 & 1

8 & 2

8 & 3

8 & 4

8 & 5

8 & 6

8 & 7

13 & 5

13 & 6

13 & 7

11 & 1

9 & 6

9 & 7

11 & 2

11 & 3

10 & 4

10 & 6

10 & 7

11 & 4

11 & 6

11 & 7

12 & 5

9 & 2

12 & 1

13 & 1

11 & 5

12 & 2

13 & 3

13 & 4

9 & 3

12 & 4

9 & 5

10 & 1

12 & 3

10 & 3

Measurement

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

16026270 June 2005

©2005 Maytag Services

4

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

Illustration Component Test Procedure Results

FTP Connector

TOP

Touch Pad/Control

Panel

Model MMV4205A**

1

2

3

4

5

6

7

8

9

10

11

12

13

Removal of Touch

Pad/Control Panel is

required to perform test.

Check for continuity.

When touched: Less than

400

Ω

When not touched: More

than 1 mega

Ω

Pad

1

2

3

4

5

6

7

8

9

0

Popcorn

Baked Potato

Beverage

Cook

Reheat

Poultry

Soften

Melt

Auto Defrost

Time Defrost

Rapid Defrost

Clock

Cook Time

Control Setup

Power Level

Add 30 Sec.

Hold Warm

Stop/Clear

Enter/Start

Custom Program

Kitchen Timer

Light Timer

Vent Hi/Lo/Off

Vent Auto Time Set

Turntable On/Off

Light Hi/Lo/Off

Trace

8 & 1

8 & 2

8 & 3

8 & 4

8 & 5

8 & 6

8 & 7

13 & 5

13 & 6

13 & 7

11 & 1

9 & 6

9 & 7

11 & 2

11 & 3

10 & 4

10 & 6

10 & 7

11 & 4

11 & 6

11 & 7

12 & 5

9 & 2

12 & 1

13 & 1

11 & 5

12 & 2

13 & 3

13 & 4

9 & 3

12 & 4

9 & 5

10 & 1

10 & 5

12 & 3

10 & 3

Measurement

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

Continuity

June 2005 16026270

©2005 Maytag Services

5

Component Testing Procedures

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

WARNING

Power Test (Traditional Test Method)

Test equipment required is Amana power test kit R0157397 (Fahrenheit), or

Menumaster power test kit M95D5 (Celsius).

1. Fill the plastic container to the 1000 ml. line with cool tap water.

2. Using the thermometer; stir the water, measure, and record the water temperature.

Initial water temperature should be approximately 60°F (16°C).

3. Place container on the center of the oven shelf and heat the water for

33 seconds for ovens with more than 1550 watts or 63 seconds for ovens with less than 1550 watts.

NOTE: Use a watch second hand, not the oven timer.

4. Stir the water, measure and record the temperature of the water after heating time is complete.

5. Subtract the starting water temperature (Step 2), from the ending water temperature (Step 4) to obtain the

temperature rise (∆T).

6. See the Traditional Power Test Temperature Chart below.

NOTES: •The IEC-705 test method requires precision measurements and equipment. It is not practical to perform

the IEC test in the field. To convert the traditional power test results to the approximate IEC-705 rating,

take the traditional power test results and add 100 watts per magnetron for the unit being tested.

Example: 1050 ⎯ watts output using the traditional power test

+ 100

1150 ⎯ Approximate IEC-705 results

•Always perform power test three times for accuracy, changing the water after each test is performed.

•Variation or errors in the test procedure will cause a variance in the temperature rise. Additional power

tests should be made if temperature rise appears marginal.

•Low line voltage will cause lower temperature rise.

⎯ watts (1 magnetron X 100 watts)

Traditional Power Test Temperature Chart

SIXTY-THREE (63) SECONDS run time chart for units less than 1550 Watts cooking power

Fahrenheit Celsius

∆T Cooking ∆T Cooking ∆T Cooking ∆T Cooking

(°F) Power Output (°F) Power Output (°C) Power Output (°C) Power Output

16 620 23 891 7 490 15 1050

17 659 24 930 8 560 16 1120

18 697 25 969 9 630 17 1190

19 736 26 1007 10 700 18 1260

20 775 27 1046 11 770 19 1330

21 814 28 1085 12 840 20 1400

22 852 29 1124 13 910 21 1470

14 980 22 1540

16026270 June 2005

©2005 Maytag Services

6

Wiring Diagram and Schematic

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

WH

YL

YL

WH

BK

BN

BK

WH

WH

CAPACITOR

H.V.DIODE

MAGNETRON

BN

RD

H.V.

H.V.

F

FA

AMV4204AAB/W/Q, MMV4205AAB/W/Q/S Schematic Diagram, Series 10

June 2005 16026270

©2005 Maytag Services

7

Wiring Diagram and Schematic

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

WARNING

WARNING

POWER MUST BE DISCONNECTED

BEFORE SERVICING THIS APPLIANCE

AMV4204AAB/W/Q Schematic Diagram, Series 11

16026270 June 2005

©2005 Maytag Services

8

Wiring Diagram and Schematic

!

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

WARNING

WARNING

POWER MUST BE DISCONNECTED

BEFORE SERVICING THIS APPLIANCE

MMV4205AAB/W/Q/S Schematic Diagram, Series 11

June 2005 16026270

©2005 Maytag Services

9

Loading...

Loading...