Maytag Services MDE5500A, MDE6800A Service Manual

27" Domestic Dryer

⎯⎯

⎯Technical Information

⎯⎯

MDE5500A*, MDE6800A*

• Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or

repair of this unit.

• Refer to Service Manual 160231 10 for detailed installation, operating, testing, troubleshooting, and disassembly

instructions.

CAUTION

!

All safety information must be followed as provided in Service Manual 160231 10.

!

T o avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless

testing requires power.

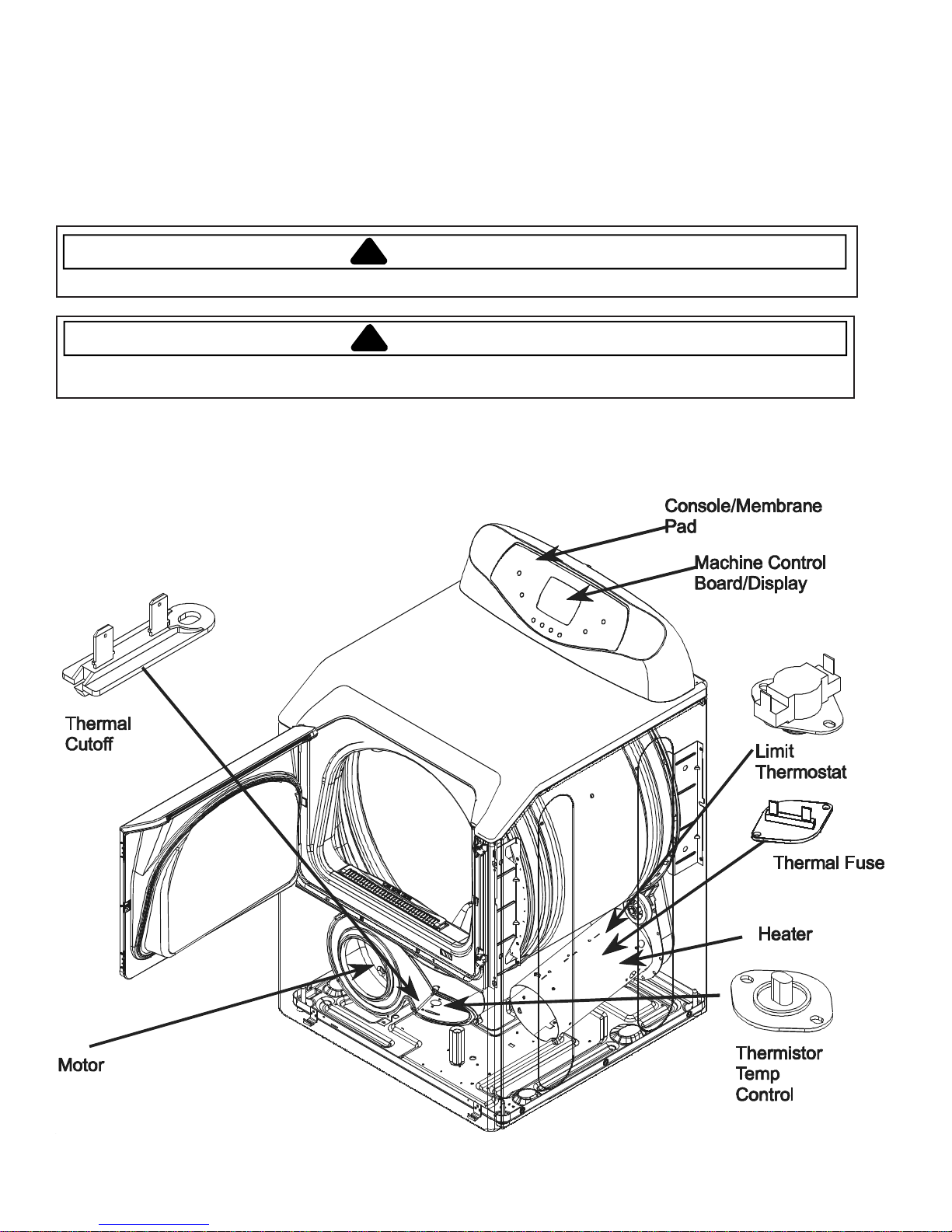

Maytag LED Electric Dryer

WARNING

September 2006 1 16027056

©2006 Maytag Services

Troubleshooting Procedures

g

!

WARNING

T o avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless

testing requires power.

Maytag Dryer MDE6800A, MDE5500B

• Due to po ssibility of per sonal injury or property damage, always contact an authorized technician for servicing

or repair of this unit.

Will Not Run

Will not start or run:

• All wires are hooked up to their corresponding

terminals.

• Dryer is plugged in.

• Blown fuse or circuit breaker.

• Door switch functional...door closed.

• Start/Pause switch functional.

• Control Board operational.

• Drive motor functional.

• Blown thermal fuse.

Motor ru ns/ tumbler will no t t urn:

• Belt off or broken/damaged.

• Idler tension spring too weak or stretched.

• Idler pulley jammed or stuck.

Runs a few minutes and then stops:

• Lint buildup around drive motor.

• Low voltage present.

• Blower impeller blocked in blower

housing.

• Drive motor - start switch contacts stuck closed.

Blows fuses or trips circuit breaker:

• The amperage readings are at 240 volts. One line

will be 24 amps and the other line will be 21 amps .

The neutral line will be at 3 amps. If the above

amperages are present, then the house wiring,

fuse box or circuit breaker should be suspect.

• Shorted heating element to housing.

• Incorrect wiring or a wire shorting to ground.

• Drive motor winding shorting to ground.

Will Not Dry

Will not heat (motor runs):

• Open heating element.

• Hi-Limit trips easily or is open.

• Regulating thermostat trips easily or is open.

• Membrane switch open.

• Drive motor centrifugal start switch not allowing

voltage to gas valve or heating element.

Improper drying/clothes wrinkled/ rough

texture/long dry time:

• Lint filter is not clean.

• Restriction in exhaust.

• Outside exhaust hood damper door stuck closed.

• Exhaust too long, too many elbows, flex ductwork

installed.

• Poor makeup air available for the dryer.

• Incorrect tumbler speed. Tumbler belt slipping.

• Blower impeller bound; check for foreign material

in blower area.

• Customer overloading dryer.

• Check clothing labels for fabric content and cycle

selected.

• Clothes too wet due to insufficient spin out by

washer.

Will Not Shu t Off

Short in Sensor Circuit.

Check Membrane Pad.

Check Electronic Control Board.

Troubleshooting the electronic

control cir c uit:

• Check for m iswiring of the electrical connector at

the electronic control board.

• Does not shut off, then the problem is in the

electronic control unit. Disconnect the sensor wire

from the sensor bar. If the dryer runs for about 20

minutes, then shuts down or the timer advances,

then the electronic control unit is good and the

problem lies in the sensor bar.

• Check sensor for continuity. If found, replace

sensor bar or clean with alcohol. Some fabric

softener sheets w ill coat the sensor bars.

Noisy and/Or Vibration

• Thumping Check for loose tumbler baffle, rear

tumbler roller(s) worn or misaligned, out-of-round

tumbler or high weld seam on tumbler.

• Ticking Check for loose wire harness or object

caught in blower wheel area.

• Scraping Check for front or rear bulkhead felt seal

out of position or worn tumbler front bearings.

• Roaring Check for blower wheel rubbing on blower

housing or bad motor bearings.

• Popping or squealing sound. Check for a sticky

or frayed belt.

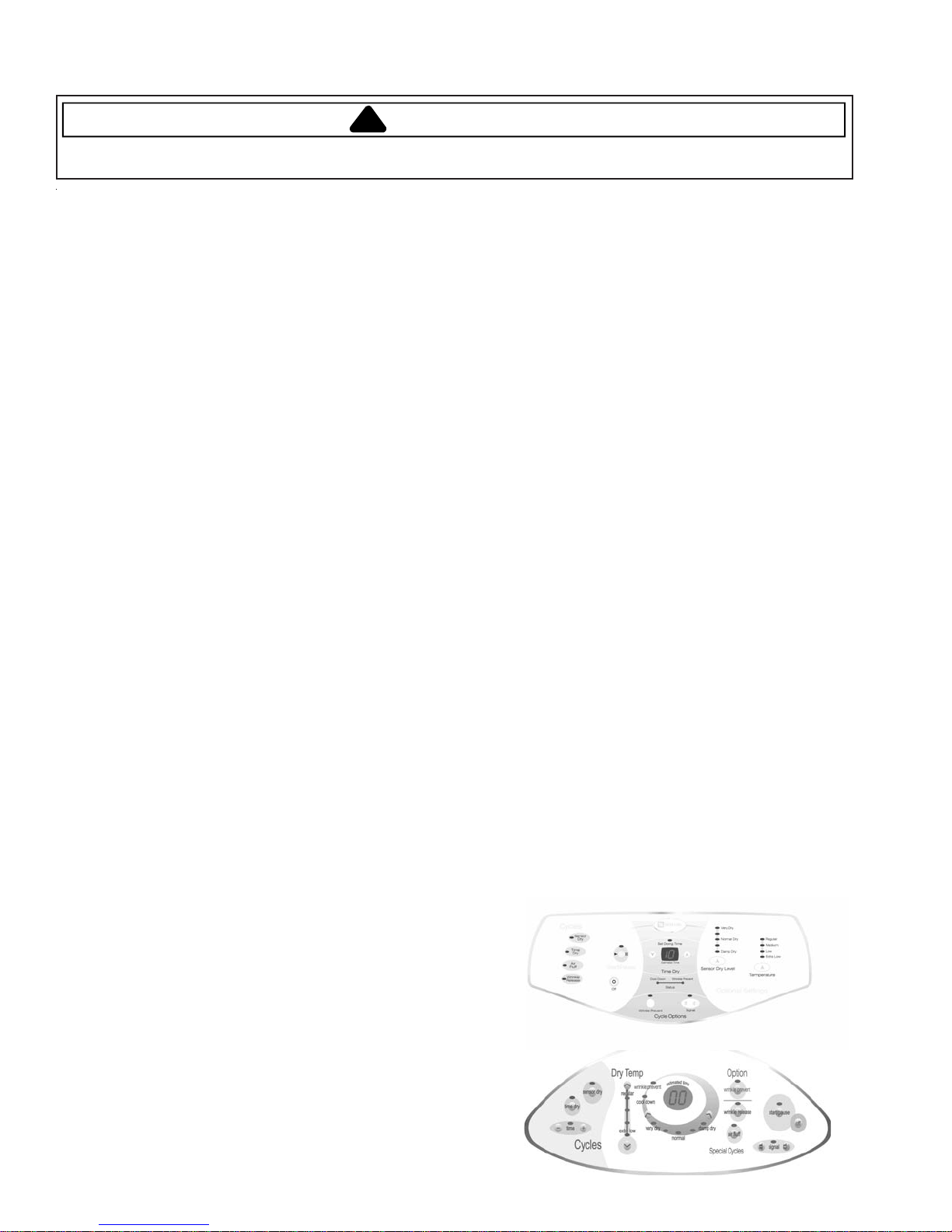

Control Configuration

This Trouble Shooting guide illustrates how the

software works with the 13 and 15 key membrane

switches. The section on Accessing Diagnostic Codes

includes instruction for use with older control boards.

13 Key Membrane

15 Key Membrane

16027056 2 September 2006

©2006 Maytag Services

Troubleshooting Procedures

T o avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless

testing requires power.

Service Mode

This mo de provides Service Personnel the ability to

verify the operation of the dryer.

The Service Mode can be implemen ted in the middle of

any dry cycle. While in the Ser v ice Mode, the

Technician ca n start special diagnostic t ests such as a

System Check Mode, Membra ne Pad Check, Display

Software versio n number and display diagnostic/help

code listings.

and

Time (^)

- 13

- 13 Key Membrane.

- 15 Key

Test/Function

Display list of

diagnostic codes.

To sequence thru

the diagnostic

and help codes.

Display revision

number

View current

cycle temperature

in Celsius

Start or pause

cycle running but

remain in

diagnostic mode.

Enter Service Mode:

Press

Air Fluff

or

Air Fluff

keys for 3 sec onds, or until a beep is heard . The

machine will now be in Se rvice Mode and “d” will be

displayed.

Exit Service Mode

Press the OFF key to exit Service Mode or repeat the

Air Fluff and Time (+) sequence.

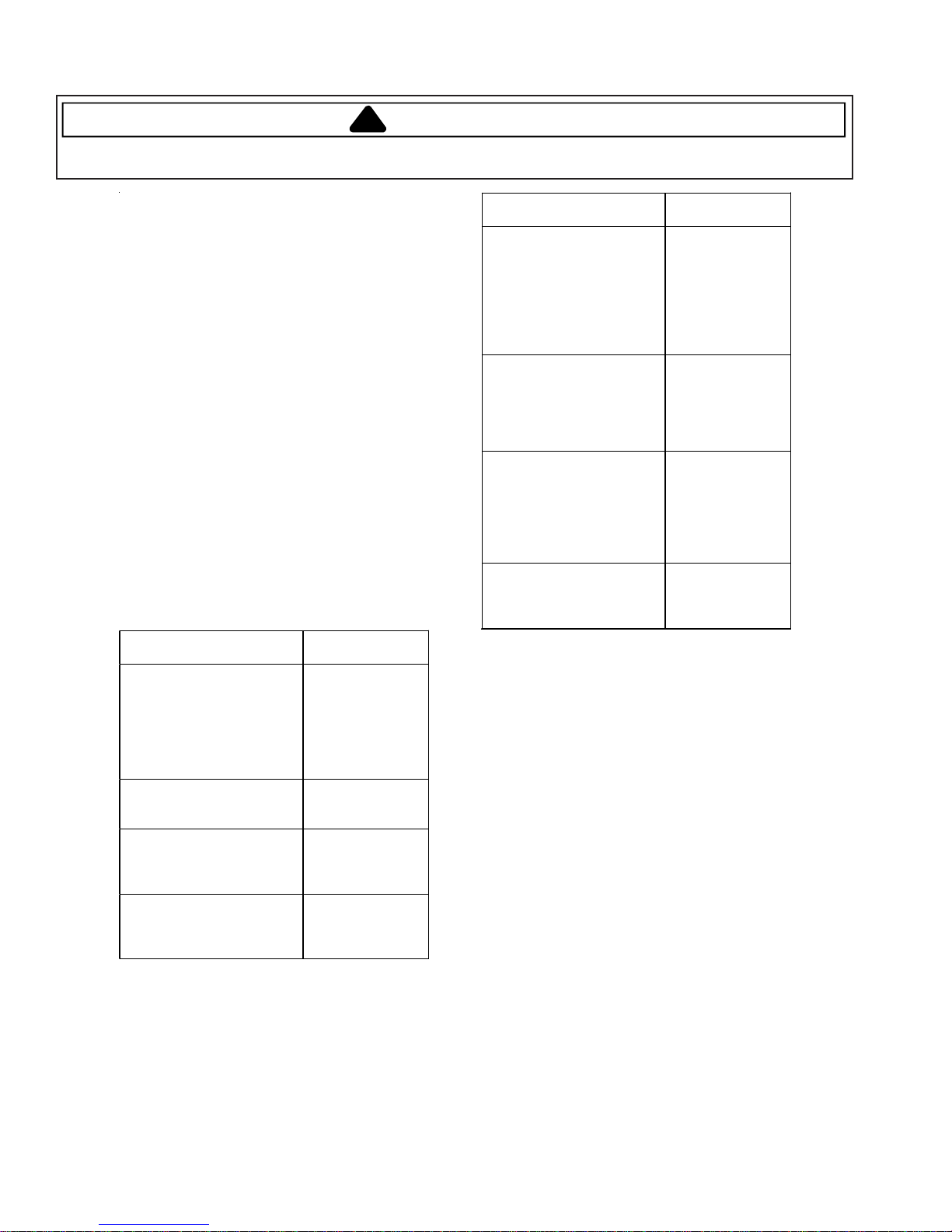

Diagnostic Tests

The following ta ble lists the various tests available while

in the Service Mode, which can be accessed by

pressing the following keys:

Key Press Special

Wrinkle release

Then press

Temperature (^) - 13 Key

or

Dry Temp (^) - 15 Key

Time (v) - 13 Key

or

Time (-) - 15 Key

Sensor Dry Level (^)

Key

or

Very Dry (<) - 15 Key

Start/Pause

System Check Mode

While in Service Mode, pressing the

Air Fluff and Signal (+) - 13 Ke y Membrane

or

Air Fluff and Signal (+) - 15 Ke y Membrane

keys for 3 sec onds, will put the dryer into the System

Check m ode and "SC" will display. The following table

lists the various functions based on the keys being

pressed.

System Check Mode Table

and

Time (+)

September 2006 3 16027056

©2006 Maytag Services

!

Membrane.

WARNING

Key Pressed: Function

Sensor Dry

Start/Pause

Temperature (^)

or

Dry Temp (^)

Sensor Dry Level (^) - 13

Key

or

Very Dry (<) - 15 Key

Performed

Enable sensor

dry circuit (sense

dry LED) when

short circui t is

detected acros s

the sensor bars

the normal dr y

LED will turn on.

Cycles the motor

relay on/off.

When the motor

is running the

start/pause LED

is on.

- 13 Key

- 15 Key

Membrane Pad Check

The membrane check turns all the embedded LED’s on.

All the LED’s can the n be toggled off by pressing t he

key associated with the LED.

While in

Air Fluff and Sensor Dry - 13 Key

or

Air Fluff and Sensor Dry - 15 Key

keys for 2 sec onds, will start a Memb rane Pad Switch

Test. To exit the test at any point, pres s the same keys

again for 2 seconds or press the OFF key to exit

Service Mode.

System Check

If motor is

running, cycles

the heater/gas

valve on/off.

When the heater

is regular temp

LED is on.

View current

cycle temperature

in Celsius.

Mode, pressing the

Loading...

Loading...