Page 1

Form No. C/08/03 Part No.111541.001 h t t p : / / w w w . m a y t a g . c o m Litho U.S.A.

©2003 Maytag Appliance Sales Co.

TOP MOUNT REFRIGERATOR TM-1

Installer: Please leave this manual with

this appliance.

Consumer: Please read and keep this

manual for future reference.Keep sales receipt and/or cancelled check as proof of

purchase.

If you have questions, write us (include

your model number and phone number) or

call:

Maytag Services

SM

Attn: CAIR®Center

P.O. Box 2370

Cleveland, TN 37320-2370

1-800-688-9900 U.S.A.

1-800-688-2002 Canada

1-800-688-2080 (U.S.A.TTY for

hearing or speech impaired)

(Mon.-Fri., 8 a.m.-8 p.m.Eastern Time)

Internet: http://www.maytag.com

For service information, see page 15.

In our continuing effort to improve

the quality and performance of our

appliances, it may be necessary to

make changes to the appliance

without revising this guide.

R

Page 2

1

IMPORTANT SAFETY INSTRUCTIONS

➢

When using your appliance,

always follo w basic precautions.

➢ Use the refrigerator only for its intend-

ed purpose.

➢ To prevent possibility of hazard due to

electrical shock, never plug the refrigerator into a receptacle which has not

been grounded adequately and in

accordance with the local and national

electrical codes. See warning and

the grounding instructions that follow.

➢ Unplug the refrigerator before clean-

ing or replacing a light bulb.

➢ In case of po wer f ailure , minimiz e door

openings. If the power failure is of a

long duration, protect the food by placing blocks of dry ice on top of the

packages or check with a local frozen

foods locker about temporary storage.

Frozen foods which have thaw ed completely should not be refrozen.

➢ Any electrical service cord that

becomes frayed or damaged should

be immediately repaired or replaced.

Never unplug your appliance by

pulling on the power cord.

➢ Your refrigerator should not be operat-

ed in the presence of explosive fumes .

➢ Children should not climb, hang or

stand on the shelves of this refrigerator.

IMPORTANT: Child entrapment and suffocation are not problems of the past.

Junked or abandoned refrigerators are still

dangerous…even if they will sit for “just a

➢ This appliance is designed to

operate on a normal 115 volt, 15

amp, 60 cycle line. There should

be a separate, grounded circuit

serving this appliance only. Do

not use an extension cord. Do

not use any device that will alter

the electrical performance of this

appliance.

This appliance is equipped with a threepronged grounding plug for your protection against possible electrical shock hazards. It must be plugged into a grounding

receptacle. Where a standard two-prong

wall receptacle is encountered, it is the

personal responsibility and obligation of

the customer to have it replaced with a

properly grounded three-prong wall

receptacle. Do not under any circumstances, cut or remove the third (ground)

prong from the power cord.Do not use an

adapter plug.

Save These Instructions For Future Reference

What You Need to Know

About Safety

Instructions

Warning and Important Safety Instructions appearing in this manual are not

meant to cover all possible conditions

and situations that may occur. Common

sense, caution and care must be exercised when installing, maintaining or

operating this appliance.

Always contact your dealer, distributor,

service agent or manufacturer about

problems or conditions you do not understand.

RECOGNIZE SAFETY

SYMBOLS,WORDS,

LABELS

few days.” If you are getting rid of your old

refrigerator, please follow the instructions

below to help prevent accidents.

➢ Take off the doors.

➢ Leave the

shelves in

place so

that children may

not easily

climb inside.

POWER SUPPLY CORD

WITH 3-PRONG

GROUNDING PLUG

GROUNDING TYPE

WALL RECEPTACLE

DANGER – Immediate hazards which

WILL result in severe personal injury

or death.

DANGER

WARNING – Hazards or unsafe prac-

tices which COULD result in severe

personal injury or death.

WARNING

CAUTION – Hazards or unsafe prac-

tices which COULD result in minor

personal injury or product or proper ty

damage.

CAUTION

WARNING

WARNING

POWER SUPPLY CORD

WITH 3-PRONG

GROUNDING PLUG

GROUNDING TYPE

WALL RECEPTACLE

Page 3

2

safety

INSTALLATION

For further assistance, call 1-800-688-9900 U.S.A., 1-800-688-2002 Canada or www.maytag.com

Leveling

To enhance appearance and maintain

performance, the refrigerator should be

level.Depending on the model, the refrigerator can be leveled in one of two ways.

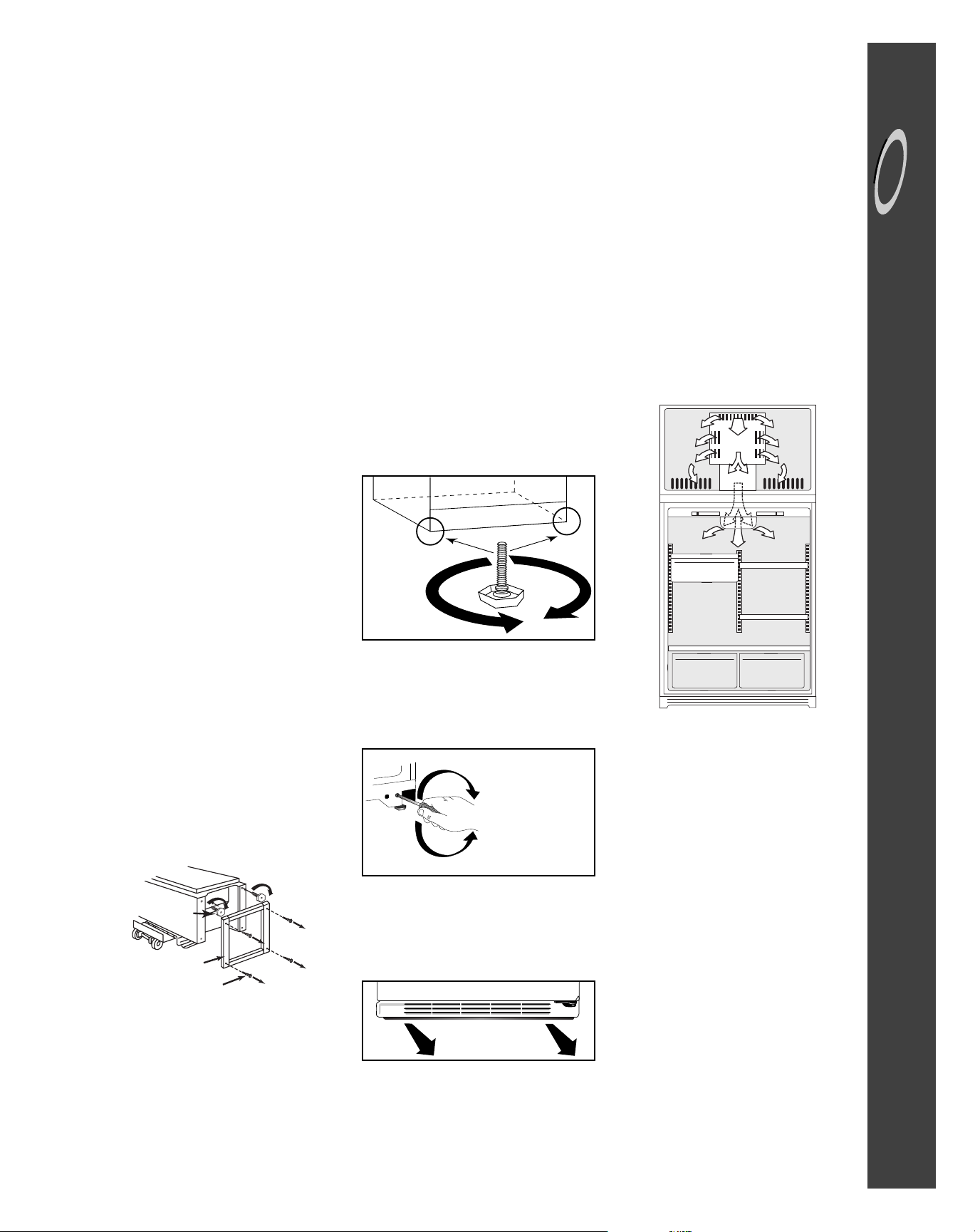

➢ All refrigerator models have leveling

screws at the base of the cabinet

beneath each front corner. Levelers

can be adjusted by turning in or out as

required. If the floor is not level and it

is necessary to raise the rear of the

cabinet, use a piece of plywood or

other shim material. To lock the cabinet into place, turn down both leveling

screws.(See figure 1.)

TURN COUNTER-

CLOCKWISE TO

LOWER CABINET

CORNER

TURN CLOCKWISE

TO RAISE CABINET

CORNER

➢ Some refrigerator models have

adjustable wheels and can be leveled

by removing the base grille* and

adjusting the wheels with a

1

⁄4" socket

or screwdriver. (See figure 2.)

*To remove the base grille, grasp both

ends and pull straight out. To replace,

align the spring clips with the round

openings in the cabinet and push each

end in until the grille locks into place.

➢ For best results, after leveling the

cabinet, open and close the doors,

then relevel.

Figure 1

Figure 2

Location

➢ Allow for a free flow of air through the

front base grille.

➢ Install the refrigerator where the room

temperature will not go below 55° F.

With temperatures below 55° F, the

refrigerator will not run frequently

enough to maintain proper temperature in the freezer.

➢ Allow a minimum

1

⁄2" clearance on the

sides, top and back for ease of installation. If refrigerator is placed with the

door hinge side against a wall, you

may want to allow additional space or

reverse the door swing (see page 4)

so the door can be opened wider.

➢ Use caution when installing the unit on

vinyl or hardwood floors so as not to

mark or otherwise damage the flooring. A piece of plywood, a rug or other

material should be used to protect the

floor while positioning the unit.

➢ Refrigerator should remain upright for

at least 30 minutes before plugging in.

Uncrate

➢ Remove and retain levelers attached

to crate base.

➢ Remove and discard crate base and

screws.

➢ Using slip joint pliers, install levelers

all the way into holes located in the

front corners of the cabinet.

Your new refrigerator was packed carefully for shipment. Remove and discard

shelf packing clips (if used) located just

above each shelf where they hook onto

the frame. To remove plastic clips wiggle

the clips sideways and pull straight out.

Ensure proper

air circulation

In order to ensure proper temperatures,

you need to permit air flow between the

refrigerator and freezer sections. As

shown in the illustration.

DO NOT block any of these vents with

food packages. If the vents are blocked,

airflow will be prevented and temperature

and moisture problems may occur.

IMPORTANT: Do not remove foam insulation from the vents located in the ceiling

of the fresh food compartment.

T

O

T

O

L

O

W

E

R

R

A

I

S

E

Levelers

Crate

Base

Screws

Page 4

3

INSTALLATION,CONT.

Door Adjustment

(IF NEEDED)

• Retighten screws after making

adjustments.

* Refer to installation instructions for

more information.

Door should be level when the cabinet is

level.

• The freezer door is too high.

•Both doors are too high.

•Both doors are too low.

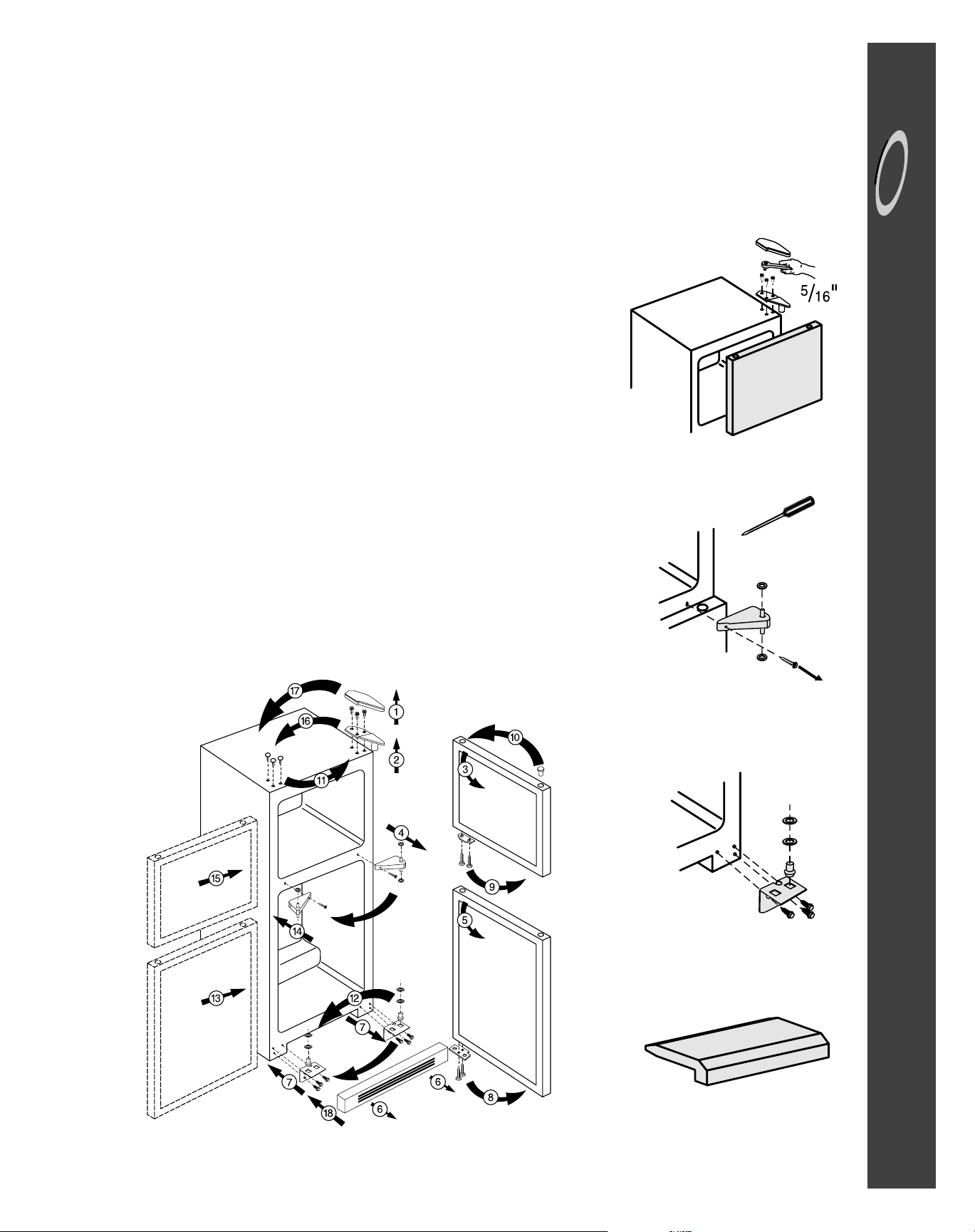

Top-Mount Handle

TOP MOUNT HANDLE INSTALLATION INSTRUCTIONS

TOP OF FREEZER DOOR

ALIGN HANDLE OVER SCREW HOLES.

FIRST INSTALL THE "A" SCREWS TO

SECURE HANDLE, FOLLOWED BY THE

"B" SCREWS.

DO NOT OVER TIGHTEN.

NO. 2 PHILLIPS

SCREW DRIVER

IS REQUIRED

FOR

INSTALLATION.

A

A

B

B

NOTE: ALL HANDLE TIE DOWN

SCREW HOLES AT THE TOP AND

BOTTOM OF THE DOORS ARE SIZED

FOR SELF THREADING SCREWS.

DO

NOT

DRILL THEM TO A LARGER SIZE.

REFRIGERATOR DOOR HANDLE WITHOUT EXTENSION TRIM

ALIGN HANDLE OVER SCREW

HOLES. FIRST INSTALL THE "A"

SCREW TO SECURE HANDLE,

FOLLOWED BY THE "B" SCREW.

DO NOT OVER TIGHTEN.

NO. 2 PHILLIPS

SCREW DRIVER

IS REQUIRED

FOR

INSTALLATION.

INSTALL SCREW IN

HANDLE HOLE.

DO

NOT OVER TIGHTEN.

SNAP EXTENSION INTO

PLACE AT THE BOTTOM

OF THE HANDLE.

A

B

REFRIGERATOR DOOR HANDLE WITH EXTENSION TRIM

NO. 2 PHILLIPS SCREW DRIVER IS

REQUIRED FOR INSTALLATION.

ALIGN HANDLE OVER SCREW

HOLES. FIRST INSTALL THE "A"

SCREW TO SECURE HANDLE,

FOLLOWED BY THE "B" SCREW.

DO NOT OVER TIGHTEN.

INSTALL SCREW IN HANDLE

HOLE.

DO NOT OVER TIGHTEN.

SLIDE HANDLE

EXTENSION OVER

BRACKET AT

BOTTOM OF

DOOR.

SNAP TOP OF EXTENSION

INTO PLACE AT THE

BOTTOM OF THE

HANDLE.

ON CERTAIN MODELS

REMOVE BACKING

FROM TAPE.

AFTER

STEP 5

APPLY

PRESSURE.

A

B

Page 5

4

installation

Reversing Doors

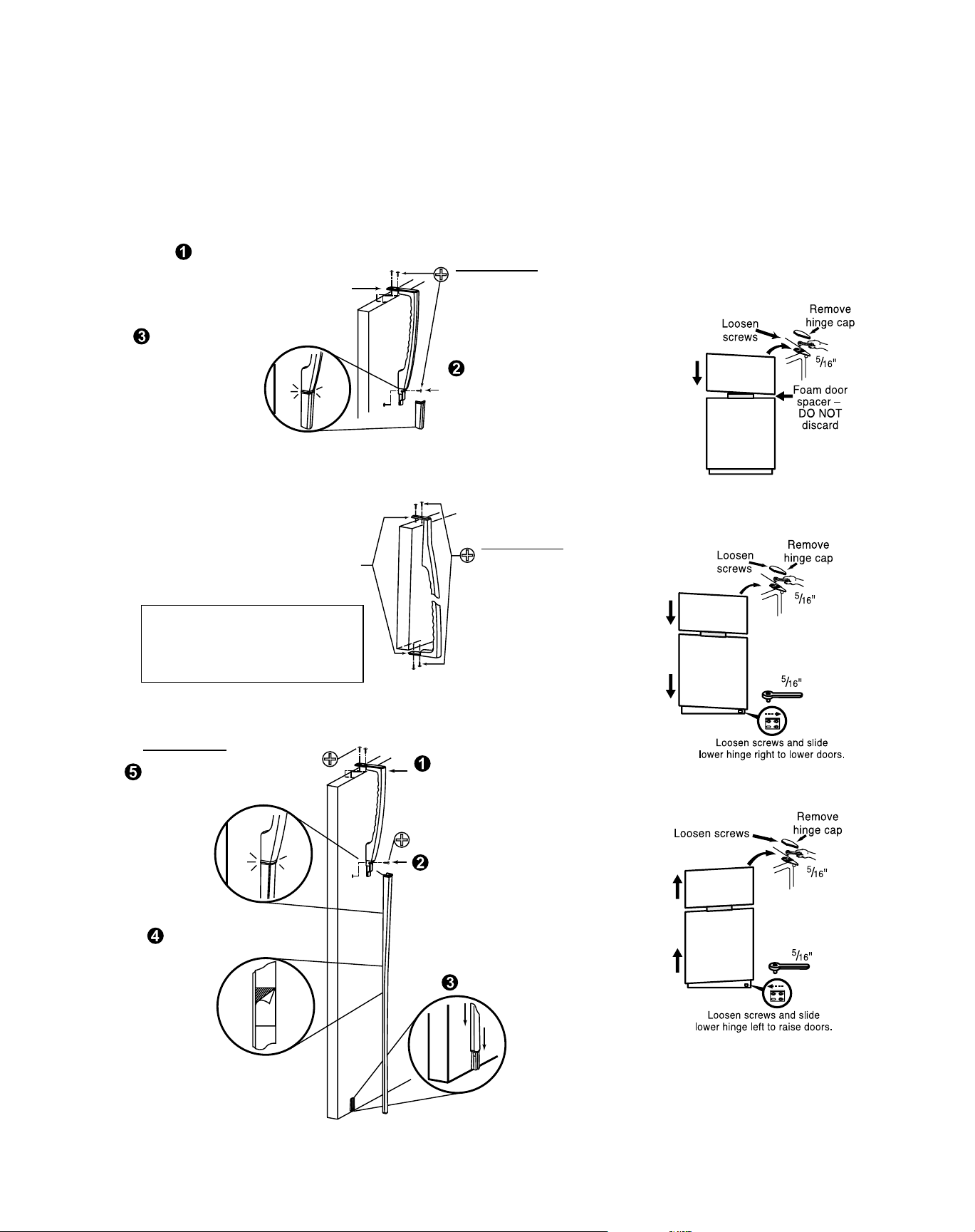

Tools Required: Phillips screwdriver,

5/16" socket and ratchet, putty knife or

5/16" end wrench.

1. Remove the hinge cap and set aside.

2. Remove screws and hinge with a

5/16" socket wrench and set aside.

3. Carefully lift and remove freezer door.

4. Remove screw and hinge arm from

top of the refrigerator door.

5. Carefully lift and remove refrigerator

door.

6. Remove grille cover and set aside.

7. Remove hinge plate from lower corner of refrigerator and secure it on the

opposite side.

8. Remove the plate from the underside

of the refrigerator door and secure it

on the opposite side.

9. Remove the plate from the underside

of the freezer door and secure it on

the opposite side.

10. Remove the plug buttons from tops of

freezer and refrigerator doors and

replace them on the opposite side.

11. Remove screw hole plugs from top of

cabinet and replace on the opposite

side.

12. Remove washers and stem from the

inside of the hinge plate and place

them on the outside of the hinge

plate.

13. Carefully replace refr igerator door on

the hinge plate in lower corner.

14. Slide the hinge arm into place and

secure with screw.

15. Carefully place freezer door on top of

hinge arm use foam door spacer to

set gap.*

16. Slide top hinge into place on freezer

door and secure screws with 5/16"

wrench.

17. Snap hinge cap securely in place.

18. Replace grille cover.

Remember to plug in your refrigerator

and reset the controls to the appropriate

setting(s).

Removing Doors

(IF NEEDED)

Rest door on a non-scratching surface.

A. Remove left screw.

B. Open door and lift. Rest door on a

non-scratching surface.

Tools

Remove hinge plate assembly. Rest door

on a non-scratching surface.

Do not discard the foam door spacer.

Doors may settle with use.

*

For further assistance, call 1-800-688-9900 U.S.A., 1-800-688-2002 Canada or www.maytag.com

Page 6

5

TEMPERATURE CONTROLS

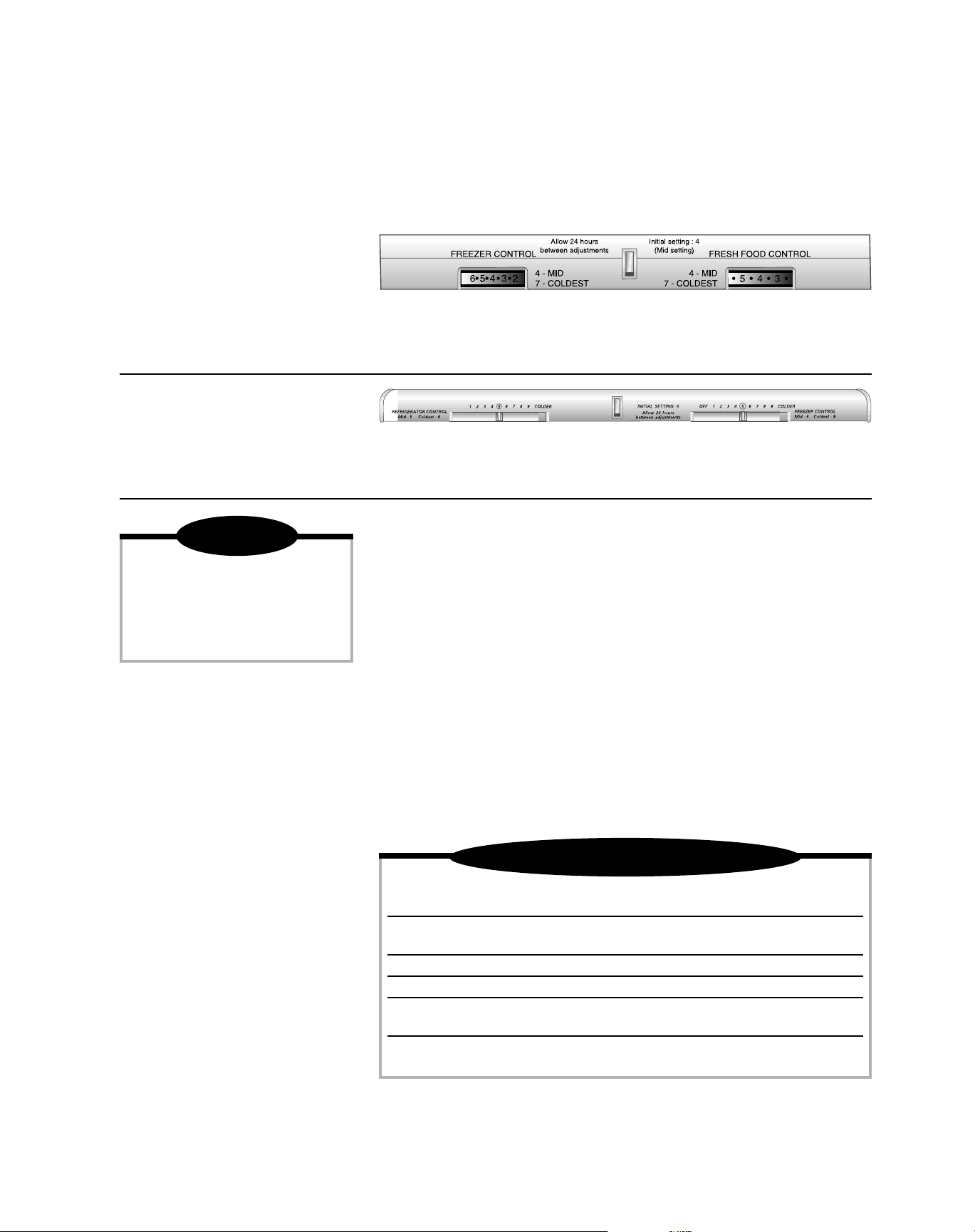

Depending on the model, the style of the controls will vary. The controls are located at the top of the fresh food compartment.

Dial controls

TEMPERATURE CONTROL GUIDE

Fresh Food Compartment Adjust fresh food control to next higher setting.

too Warm

Fresh Food Compartment Adjust fresh food control to next lower setting.

too Cold

Freezer too Warm Adjust freezer control to next higher setting.

Freezer too Cold Adjust freezer control to next lower setting.

Turn Refrigerator Off Set fresh food control to OFF or 0.

(Dial Controls)

Turn Refrigerator Off Slide the freezer control to OFF.

(Slide Controls)

NOTE: Turning the control to OFF or 0 stops cooling in BOTH compartments. It does

not shut off power to the refrigerator.

Slide controls

➢ The freezer control has settings from 1

(warmest) to 7 (coldest). Initially set

this control on 4.

➢ The refrigerator control has settings

from 1 (warmest) to 9 (coldest).

Initially set this control on 5.

➢ The freezer control has settings from 1

(warmest) to 9 (coldest). Initially set

this control on 5.

NOTE

❚ Your refrigerator will run continu-

ously for several hours when you

first start it. This is normal.

❚ Let the refrigerator run at least 8-12

hours before adding food.

Adjusting the controls

➢ 24 hours after adding food, you may

decide that one or both compartments

should be colder or warmer. If so,

adjust the control(s) as indicated in the

table below.

➢ Except when starting the refr igerator,

do not change either control more

than one number at a time.

➢ Allow 24 hours for temperatures to

stabilize before resetting.

➢ Changing either control will have

some effect on the temperature of the

other compartment.

Wa rm cabinet surfaces

At times, the front of the refrigerator cabinet may be warm to the touch. This is a

normal occurrence that helps prevent

moisture from condensing on the cabinet.

This condition will be more noticeable

when you first start the refrigerator, during hot weather and after excessive or

lengthy door openings.

➢ The fresh food control has settings

from 1 (warmest) to 7 (coldest).

Initially set this control on 4.

INITIAL SETTINGS

INITIAL SETTINGS

Page 7

6

ice service

ICE SERVICE

Some models are automatic ice maker

ready. The number of the appropriate ice

maker kit needed for installation into

these models appears on the data plate.

The kit contains installation instructions

and water connection instructions.

Other models have a factory installed ice

maker. Connect the ice maker to the

water supply as instructed in the separate

instructions furnished with the refrigerator.Proper water flow and a level refrig-

erator is essential for optimal ice

maker performance.

After your refrigerator has been connected to the water supply, move the sensor

arm into the down position.The ice maker

will fill with water when the freezer reaches the proper temperature.

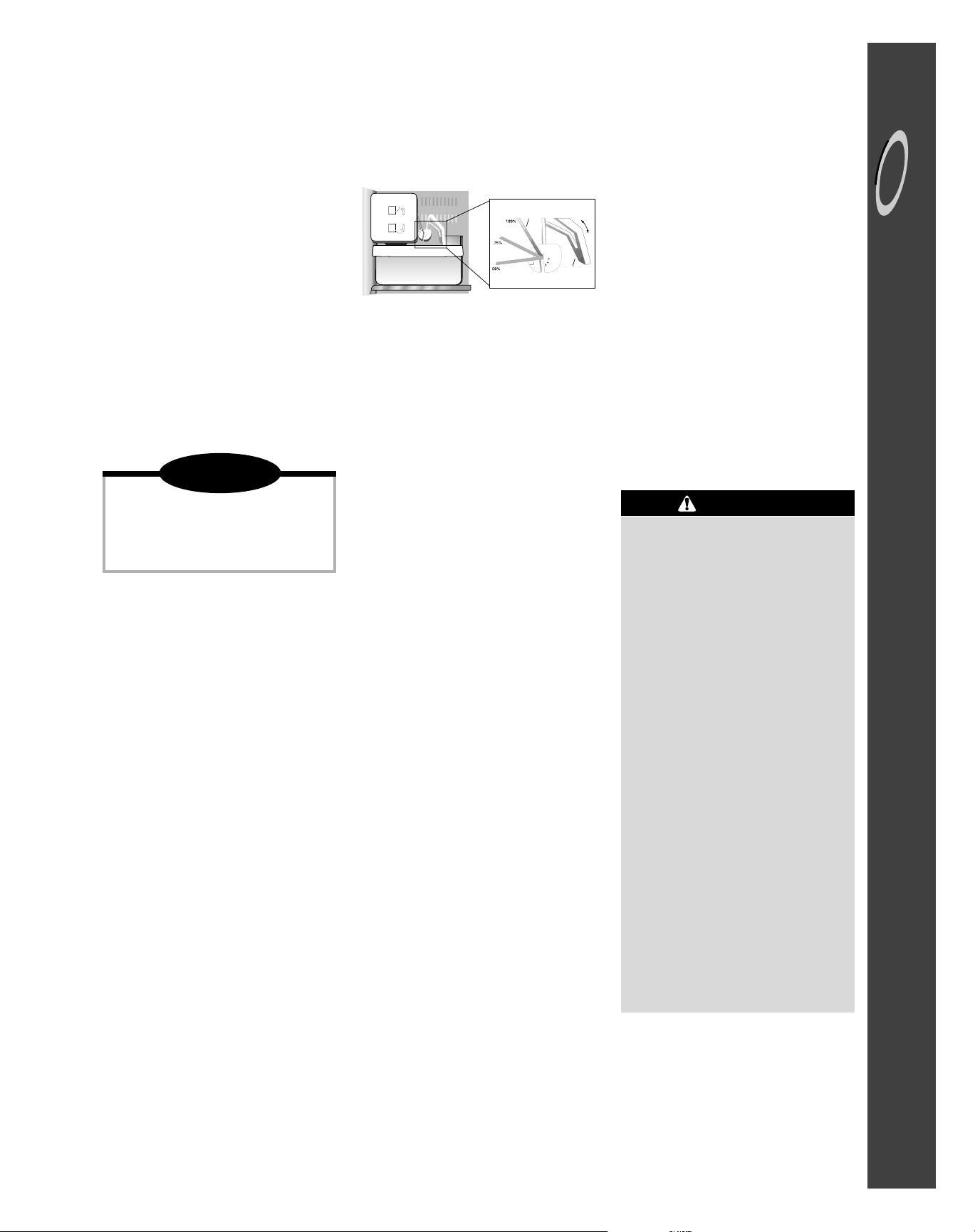

Some ice makers are equipped with an

adjustable sensor arm that allows you to

adjust the amount of ice in your ice storage

tray for times when less ice is needed.

NOTE

❚ Energy rating guides that are post-

ed on the refrigerator at the time of

purchase do not include optional

ice maker energy usage.

To adjust the amount of ice produced:

(select models) Rotate the wire lever arm

to provide the desired level of ice production. The 100% setting provides maximum ice production.

➢ It may be 8 to 12 hours before the ice

maker furnishes any usable ice cubes.

The first one or two batches will probably contain undersized and irregular

cubes because of air in the supply

line.

➢ The initial batch may also contain

impurities from the new water supply

piping. Therefore, all cubes from the

first two or three batches should be

discarded.

➢ When the ice cubes are ejected it is

normal for several cubes to be joined

together at the ends. They can easily

be broken apart. The ice maker will

continue to make ice until the supply

of ice cubes raises the sensor arm,

shutting the ice maker off.

➢ Certain sounds may accompany the

various cycles of the ice maker. The

motor may have a slight hum, the

cubes will rattle as they fall into an

empty storage pan and the water

valve may click or “buzz” occasionally.

➢ If the ice is not used frequently, the ice

cubes will become cloudy, shrink, stick

together and taste stale.Empty the ice

storage bin periodically and wash it in

lukewarm water. Be sure to dry the bin

before replacing it.

ON

OFF

ON

OFF

1

0

0

%

7

5

%

I

C

E

L

E

V

E

L

5

0

%

I

C

E

L

E

V

E

L

5

0

%

7

5

%

1

0

0

%

1

0

0

%

7

5

%

I

C

E

L

E

V

E

L

5

0

%

I

C

E

L

E

V

E

L

5

0

%

7

5

%

1

0

0

%

Wire Lever

Arm

Sensor

Arm

➢ To r em o v e the ice bin, pull it forward,

away from the ice maker.To avoid the

ice maker dumping ice while the bin is

removed, turn the ice maker off by lifting the sensor arm.

➢ To replace the ice bin, reverse the

above procedure. Turn the ice maker

on by lowering the sensor arm.

➢ Beverage and foods should not be

placed in the ice storage bin for quick

chilling. These items can block the

sensor arm, causing the ice maker to

malfunction.

➢ Tu rn off (arm up) the ice maker when

the water supply is to be shut off for

several hours.

Ice Cube Trays

Some models are equipped with ice cube

trays.To release the ice cubes from a tray,

hold the tray upside down and twist both

ends.

The ice bin (select models) either slides

into rails under an ice cube tray rack or

stacks on top of the ice cube trays.

Automatic Ice Maker

(optional)

FOR Y OUR SAFETY

Do not place fingers or hands on

the automatic ice making mechanism while the refrigerator is

plugged in. This will help protect

you from possible injury. It will also

prevent interference with moving

parts of the ejector mechanism and

the heating element that releases

the cubes.

Under certain rare circumstances,

ice cubes may be discolored,

usually appearing with a greenbluish hue. The cause of this

unusual discoloration can be a

combination of factors such as certain characteristics of local waters,

household plumbing and the accumulation of copper salts in an inactive water supply line which feeds

the ice maker.

Continued consumption of such

discolored ice cubes may be injurious

to health. If such discoloration is

observed, discard the ice cubes

and contact your dealer to purchase and install a water line filter.

For further assistance, call 1-800-688-9900 U.S.A., 1-800-688-2002 Canada or www.maytag.com

WARNING

Page 8

7

LOOKING INSIDE

Shelves

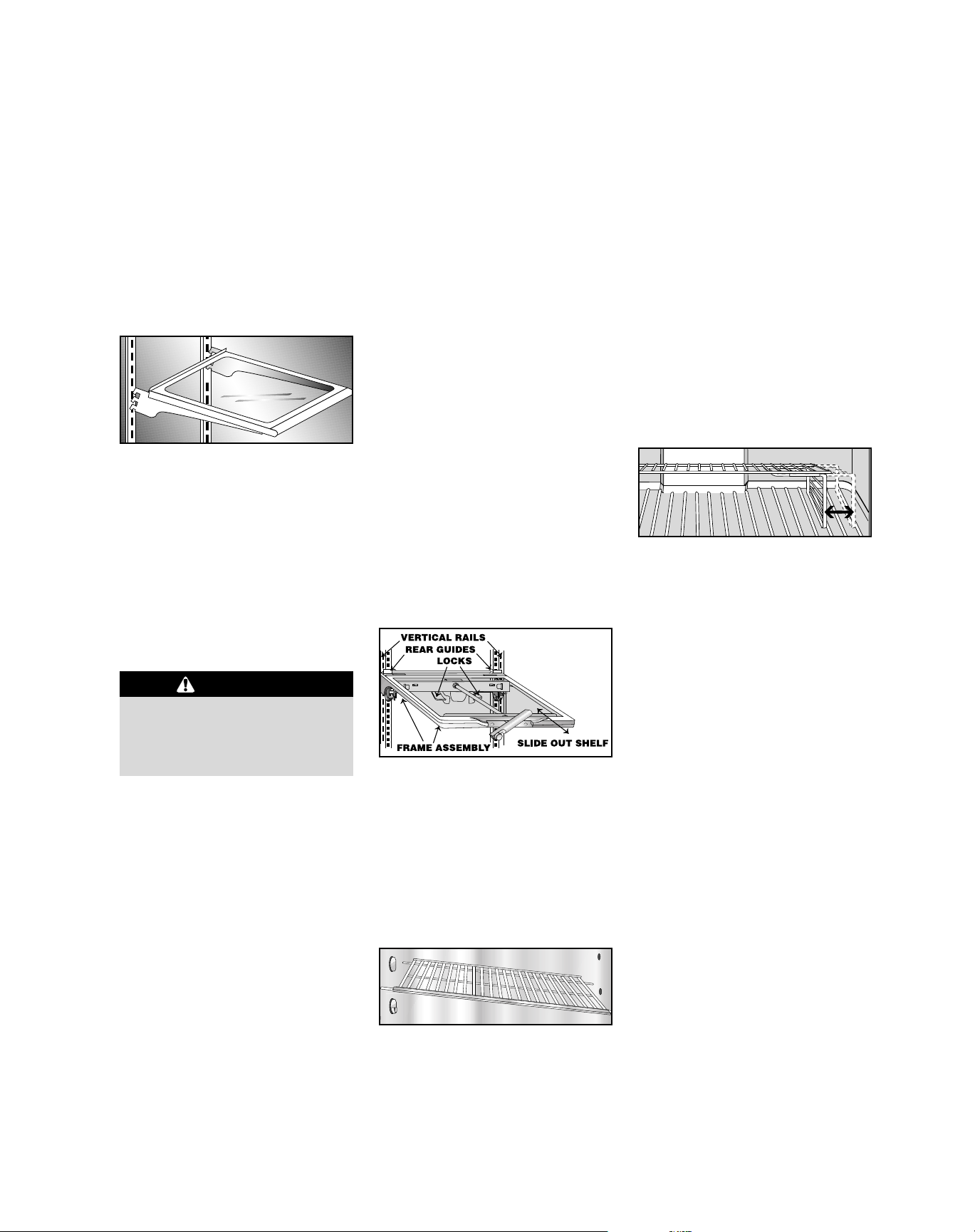

Your refrigerator has either SpillCatcher™ or Tempered Glass Shelves.

The Spill-Catcher™ shelves have a spill

retainer edge which allows for easier

clean up, and some are equipped with

the Easy Glide slide out feature.

To slide out (select models), grasp the

front of the shelf and pull forward.Push in

the shelf to return to the original position.

To remove a shelf, slightly lift up the rear

of the shelf and pull the shelf straight out

To lock the shelf into another position, tilt

up the front edge of the shelf. Inser t the

hooks into the desired frame openings

and let the shelf settle into place, being

sure the shelf is securely locked at the

rear.

➢

Never attempt to adjust a shelf

that is loaded with food (except

in the case of the Elevator

TM

Shelf).

ELEVATOR™ SHELF

(select models)

The fresh food compartment may also be

equipped with an Elevator™ Shelf. This

shelf has a spill retainer edge for easy

cleanup. It also has the convenient slide

out feature that allows easy access to

items stored at the rear of the shelf.

This shelf can be adjusted up or down

without having to be unloaded of its contents. To adjust an Elevator™ Shelf, pull

out the knob on the crank handle. Rotate

the crank clockwise to raise the height of

the shelf, and counterclockwise to lower

the height of the shelf.

To remove the Elevator™ shelf for occasional cleaning, completely unload the

shelf and pull the shelf forward.When the

shelf stops, press up on the tabs located

underneath its outside edges, then continue pulling forward, clear of the frame.

To reinstall, align the shelf to the frame

and push it all the way back.(There is no

need to depress the tabs for reinstallation).

In ordinary use, the Elevator™ shelf with

the frame assembly does NOT require

removal.Though unlikely, and not recommended, the correct removal procedure

is as follows:

Unload the shelf completely, raise the

shelf to its highest possible position.

While supporting the shelf and frame

from the front, press both locks inward.

Lift slightly and tilt the frame assembly to

allow the rear guides to clear the vertical

rails.

To reinstall, tilt the frame assembly while

depressing both locks, reposition the rear

guide behind the vertical rails. When the

shelf is level, release the locks allowing

the shelf to latch in the correct position.

ADJUSTABLE FREEZER

SHELF (select models)

To remove the shelf, lift the left end up

about 3 inches; pull the right end bars out

of the side wall cups.To replace the shelf,

reposition the removable support plugs

on the left side wall to the desired level

and reverse the removal procedure.

EXPANDABLE-WIDTH

FREEZER SHELF

(select models)

The shelf adjusts sideways to open up a

full-height space for tall packages, such

as pizza. The leg on the right side of the

shelf slides to make this adjustment.

The shelf can also adjust to two heights.

To adjust the shelf height, remove the

shelf from the freezer.Slide the leg out of

the channels and reinsert the leg in the

alternate height position. Return the shelf

to the freezer, inserting the left end into

the liner cups.

DOOR STORAGE

Pick-Off Door Bins (select models) are

roomy enough to handle gallon-plus

sized containers.They are adjustable and

can be easily removed.

To remove, lift the bin front up until it

clears the retainers on the door liner then

pull the bin straight out

To replace, reverse the above procedure.

Other models are constructed with

durable, Fixed Door Shelves with the

gallon-plus storage capacity.

Some refrigerator and freezer door

shelves have Keepers to secure bottles

and other containers in place when the

door is being opened or closed. The

keepers are easily adjusted by sliding

from side to side.

The Tall Bottle Retainer (select models)

is designed to prevent tall bottles from tipping forward. It is easily adjusted by sliding from side to side.

WARNING

Other models have a partial width freezer

shelf. This shelf is positioned on the left

side of the freezer compartment by

mounting into the left side wall.

Page 9

8

looking inside

RACKS

The Multi-Can Rack (select models)

suspends from one of the spill-proof

refrigerator shelves. It hooks over the

wires found in the framework under the

shelf. The sloped design allows for cans

to roll forward as one is removed. (This

rack cannot be positioned under an

Elevator™ shelf.)

The Multi-Use Rack (select models)

provides a place for horizontally storing

wine.The rack also can hold canned beverages or an egg carton.

Position the rack to rest on the left hand

side of a refrigerator shelf (this rack cannot be positioned on an Elevator™ shelf).

Special Storage Areas

Your refrigerator has either a Snack

Center Drawer or an Adjusti-Temp™

Drawer.

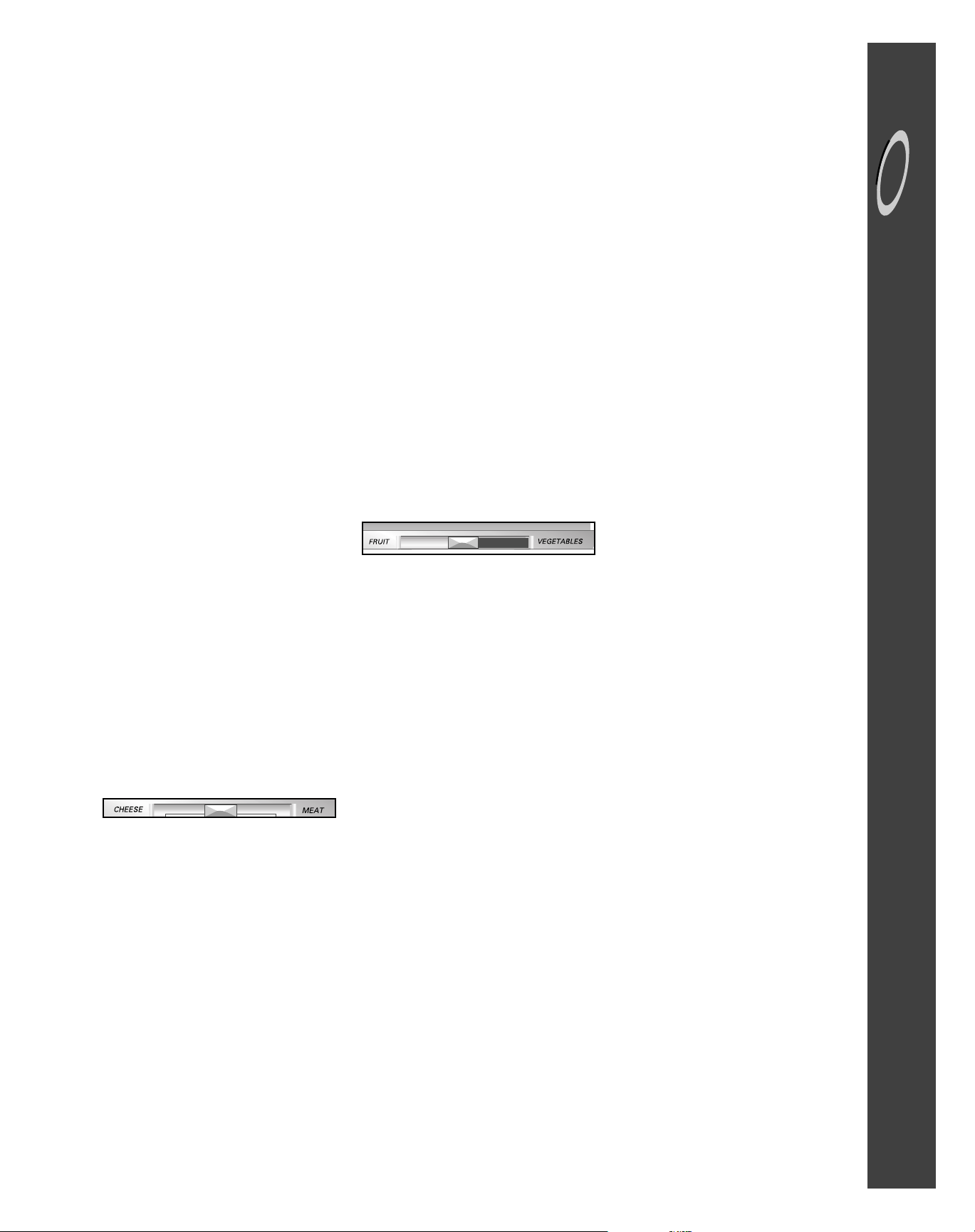

For models with the Adjusti-Temp™

Drawer, a control is located on the shelf

front above the drawer. Simply slide the

control knob left or right to adjust the internal temperature of the drawer.

➢ For cheese storage, slide the control

to the left. To achieve a lower temperature within the drawer when storing

fresh meat, poultry or fish, slide the

control to the right.

To replace the drawer, reverse the above

procedure.

This drawer can be positioned as desired

on either the left or right side of the refrigerator cabinet.

For best results, keep this drawer closed

tightly.

The Crispers provide storage for fruit

and vegetables.There is a humidity control located on the crisper shelf above

each of the crisper drawers.

➢ For fruit storage, slide the crisper con-

trol to the left to provide lower humidity conditions in the drawer.

➢ For vegetable storage, slide the crisper

control to the right to provide higher

humidity conditions in the drawer.

To remove a crisper drawer for cleaning:

➢ pull out the crisper until it stops

➢ tilt the drawer front up and pull it out

To replace a crisper drawer:

➢ align the drawer in the tracks

➢ lift the drawer front and slide in

For best results, keep the crispers tightly

closed.

To remove the Crisper Top:

➢ lift the front edge of the shelf

➢ pull the shelf straight out

To replace the Crisper Top:

➢ set the rear bars on the support

➢ push the shelf back until the front edge

can be lowered into place

Your refrigerator may come equipped

with an Egg Cradle (style may vary). It

can be removed to be washed or carried

to a work area.

To use the Dairy Compartment, raise

the cover.The dairy compartment may be

equipped with a Keeper to secure food

items in place.If your model has the dairy

keeper , simply slide it from side to side for

desired placement.

In some models, the dairy compartment

can be removed.

The Slide Out Freezer Basket (select

models) is found in the main freezer compartment. It is a convenient storage area,

providing easy access to items stored in

the rear of the freezer. Slide the basket

out to reach or store frozen foods.

To remove the basket:

➢ pull the basket until it stops

➢ lift and pull the basket out

To replace the basket, reverse the

removal procedure.

The Drop Down Freezer Basket (select

models) is found on the lower shelf of the

freezer door.This area provides space for

frozen food items that tend to shift or slide

(such as bagged vegetables).

The Snack Center drawer does not have

an adjustable temperature capability.

To remove the Snack Center Drawer or

Adjusti-Temp Drawer for cleaning:

➢ pull the drawer out until it stops

➢ lift the drawer up slightly and pull it out

For further assistance, call 1-800-688-9900 U.S.A., 1-800-688-2002 Canada or www.maytag.com

Page 10

9

FOOD STORAGE TIPS

Fresh Food Storage

➢ The fresh food compartment of a

refrigerator should be kept between

34° F and 40° F with an optimum temperature of 37° F. To check the temperature, place an appliance thermometer in a glass of water and place

in the center of the refrigerator.Check

after 24 hours. If the temperature is

above 40° F adjust the controls as

explained on page 5.

➢ Avoid overcrowding the refrigerator

shelves.This reduces the circulation of

air around the food and results in

uneven cooling.

FRUITS AND VEGETABLES

➢ Storage in the crisper drawers traps

moisture to help preserve the fruit and

vegetable quality for longer time periods. (Refer to page 8).

➢ Sort fr uits and vegetables before stor-

age and use bruised or soft items first.

Discard those showing signs of decay.

➢ Always wrap odorous foods such as

onions and cabbage so the odor does

not transfer to other foods.

➢ While vegetables need a certain

amount of moisture to remain fresh,

too much moisture can shorten storage times (especially leafy vegetables). Drain vegetables well before

storing.

MEAT AND CHEESE

➢ Raw meat and poultry should be

wrapped securely so leakage and

contamination of other foods or surfaces does not occur.

➢ Occasionally mold will develop on the

surface of hard cheeses (Swiss,

Cheddar, Parmesan). Cut off at least

an inch around and below the moldy

area. Keep your knife or instrument

out of the mold itself. The remaining

cheese will be safe and flav orful to eat.

Do NOT try to save individual cheese

slices, soft cheese, cottage cheese,

cream, sour cream or yogurt when

mold appears.

DAIRY FOOD

➢ Most dairy foods such as milk, yogurt,

sour cream and cottage cheese have

freshness dates on their cartons for

appropriate length of storage. Store

these foods in the original carton and

refrigerate immediately after purchasing and after each use.

Frozen Food Storage

➢ The freezer compartment of a refriger-

ator should be kept at approximately

0° F. To check the temperature, place

an appliance thermometer between

the frozen packages and check after

24 hours. If the temperature is above

0˚ F, adjust the control as described on

page 5.

➢ A freezer operates more efficiently

when it is at least two-thirds full.

PACKAGING FOODS FOR

FREEZING

➢ To minimize dehydration and quality

deterioration use aluminum foil, freezer wrap, freezer bags or airtight containers. Force as much air out of the

packages as possible and be sure

they are tightly sealed.Tr apped air can

cause the food to dry out, change

color and develop an off-flavor (freezer burn).

➢ Overwrap fresh meats and poultry

with suitable freezer wrap prior to

freezing.

➢ Do not refreeze meat that has com-

pletely thawed.

LO ADING THE FREEZER

➢ Avoid adding too much warm food to

the freezer at one time.This overloads

the freezer, slows the rate of freezing

and can raise the temperature of

frozen foods.

➢ Leave space between the packages so

cold air can circulate freely, allowing

food to freeze as quickly as possible.

➢ Avoid storing hard-to-freeze foods

such as ice cream and orange juice on

the freezer door shelves.These foods

are best stored in the freezer interior

where the temperature varies less with

door openings.

Refer to the Food Storage Chart on

page 10 for approximate storage

times.

Page 11

10

food storage tips

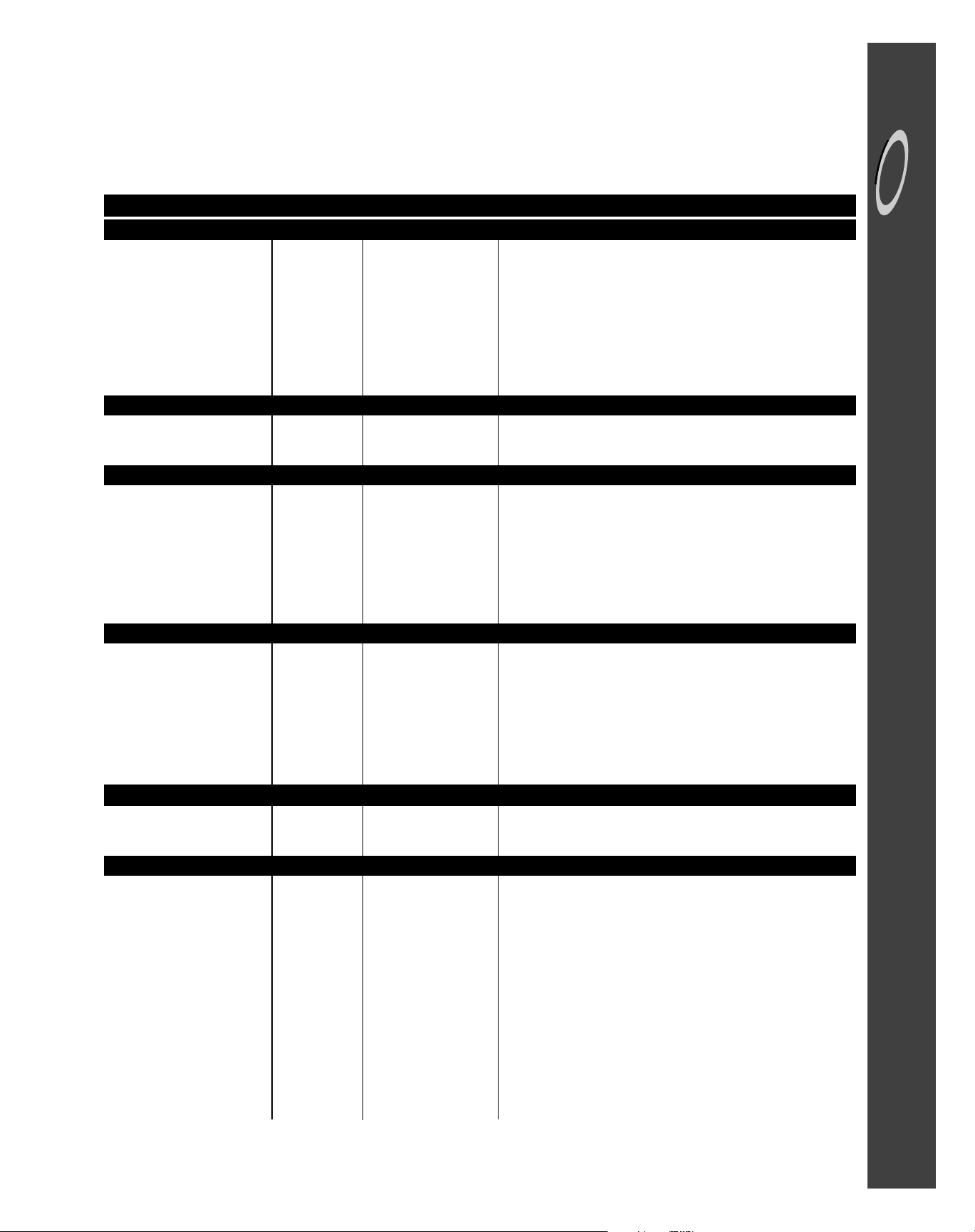

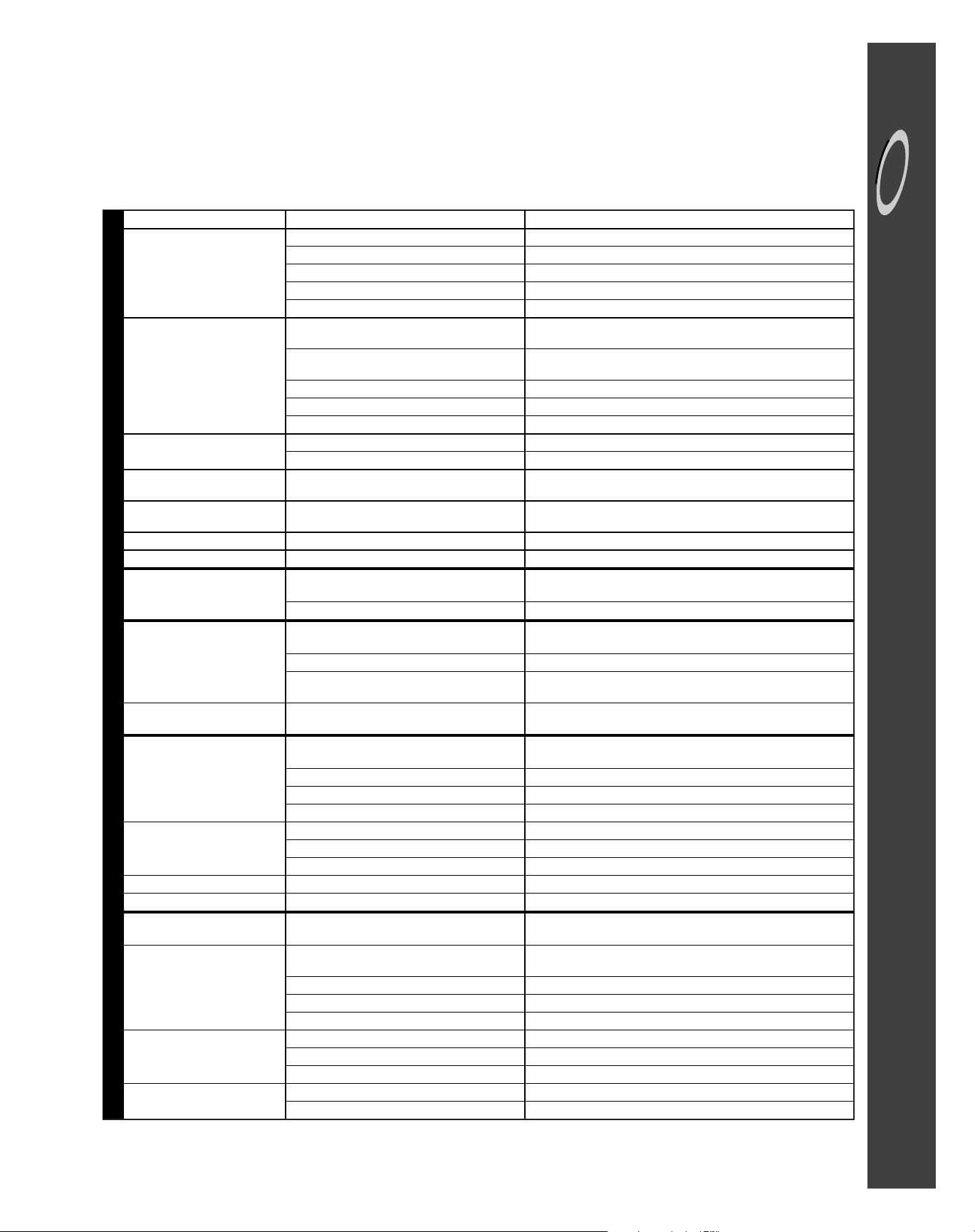

FOOD STORAGE CHART

(Storage times are approximate and ma y v ary depending on type of packaging, storage temperature , and the quality of the f ood when

purchased.)

Foods

Butter

Milk & cream

Cream cheese, cheese

spread & cheese food

Cottage cheese

Sour cream

Hard cheese (Swiss,

Cheddar & Parmesan)

Eggs in the shell

Leftover yolks or whites

Apples

Bananas

Pears, plums, avocados

Berries, cherries, apricots

Grapes

Citrus fruits

Pineapples, cut

Asparagus

Brussels sprouts, broccoli, cau-

liflower, green peas, lima

beans, onions, peppers

Cabbage, celery

Carrots, parsnips, beets, &

turnips

Lettuce

Chicken and Turkey, whole

Chicken and Turkey, pieces

Fish

Bacon

Beef or lamb, ground

Beef or lamb, roast & steak

Ham, fully cooked, whole

half

slices

Luncheon meat

Pork, roast

Pork, chops

Sausage, ground

Sausage, smoked

Veal

Frankfurters

Refrigerator

1 month

1 week

1-2 weeks

3-5 days

10 days

1-2 months

3 weeks

2-4 days

1 month

2-4 days

3-4 days

2-3 days

3-5 days

1-2 weeks

2-3 days

1-2 days

3-5 days

1-2 weeks

7-10 days

7-10 days

1-2 days

1-2 days

1-2 days

7 days

1-2 days

3-5 days

7 days

5 days

3 days

3-5 days

3-5 days

3-5 days

1-2 days

7 days

3-5 days

7 days

Freezer

6-9 months

Not recommended

Not recommended

Not recommended

4-6 months

May become crumbly

Not recommended

9-12 months

8 months (cooked)

6 months (whole/peeled)

Not recommended

6 months

1 month (whole)

Not recommended

6-12 months

8-10 months

8-10 months

Not recommended

8-10 months

Not recommended

12 months

9 months

2-6 months

1 month

3-4 months

6-9 months

1-2 months

1-2 months

1-2 months

1-2 months

4-6 months

4 months

1-2 months

1-2 months

4-6 months

1 month

Storage Tips

Wrap tightly or cover.

Check carton date. Close tightly. Don’t retur n unused por tions

to original container.Don’t freeze cream unless whipped.

Wrap tightly.

Store in original carton. Check carton date.

Wrap tightly. Cut off any mold.

Refrigerate small ends down.

For each cup of yolks to be frozen, add 1 tsp.sugar for use in

sweet, or 1 tsp. salt for non-sweet dishes.

May also store unripe or hard apples at 60-70° F.

Ripen at room temperature before refrigerating.Bananas and avo-

cados darken when refrigerated.

May also store at 60-70° F. If refrigerated, store uncovered.

Will not ripen after purchase. Use quickly.

Do not wash before refrigerating.Store in crisper.

Wrap odorous foods.Leave peas in pods.

Wrap odorous foods & refrigerate in crisper.

Remove tops.Wrap odorous foods and refrigerate in the crisper.

Keep in original packaging for refrigeration. Place in the Meat and

Cheese Drawer.When freezing longer than 2 weeks, overwrap with

freezer wrap.

Fresh meats can be kept in original packaging for refrigeration.

Place in the Meat and Cheese Drawer.When freezing longer than

2 weeks, overwrap with freezer wrap.

Unopened, vacuum-packed luncheon meat may be kept up to 2

weeks in the Meat and Cheese Drawer.

Processed meats should be tightly wrapped and stored in the Meat

and Cheese Drawer.

EGGS

FRUITS

DAIRY PRODUCTS

Sources: United States Department of Agriculture; Food Marketing Institute; Cooperative Extension Service, Iowa State University

VEGETABLES

MEATS

POULTRY & FISH

Page 12

11

STORING THE REFRIGERATOR

Vacat i ons

If you will be gone for a month or less,

leave the controls at the usual settings.

During longer absences:

1. Remove all food.

2. Shut off the ice maker (if installed) and

the valve where you tapped into the

water line to supply the refrigerator.

3. Disconnect the refrigerator from the

electrical outlet.

4. Clean and dry the refrigerator

thoroughly.

5. Leave the doors open to prevent

odors.

Moving

When moving, follow steps 1–4 under

Vacations. In addition, remove and carefully pack any items that are easily

removable. Ship the refrigerator in an

upright position with the doors taped

shut.

CARE AND CLEANING

Refer to the chart on the following page for

specific refrigerator cleaning guidelines.

➢

Disconnect the power cord

before cleaning.

➢

Disconnect the power cord

before replacing light bulb(s).

Wear gloves as protection

against broken glass.

CLEANING UNDER THE

REFRIGERATOR

Your refrigerator can be rolled out for cleaning the floor underneath. Raise the leveling

screws if engaged (see page 2). Pull the

refrigerator straight out from the wall.

REPLACING A

LIGHT BULB

Always use a standard 40 or 60 watt

appliance bulb.

Refrigerator

There are two light bulbs located under

the top of the refrigerator compartment,

on either side of the Dual Cool™ control

housing.

➢ Carefully grasp the lightbulb by reach-

ing behind the bulb cover.

➢ Unscrew the light bulb and replace.

Freezer

The freezer light (select models) is located on the back wall, near the upper right

corner.

To remove the bulb cover:

➢ Grasp the top and bottom of the bulb

cover.Press in the areas of the attachment tabs, applying enough pressure

to unhook the tabs. At the same time,

pivot the cover down and remove.

➢ Unscrew the lightbulb and replace.

➢ Replace the bulb cover by pivoting it

back into place and snapping the tabs

into the appropriate slots.

NO CLEAN™

COMMERCIAL-DUTY

CONDENSER

A clean condenser means more efficient

refrigerator operation. Thanks to the

unique design of the No Clean™ condenser there is no longer a need for routine condenser cleaning in normal home

usage surroundings.

Some operating environments may be

particularly dusty or greasy.In these situations, the condenser can be periodically

cleaned to insure maximum efficiency.

No Defrosting

Your refrigerator is designed to defrost

automatically.

Energy Saving Tips

➢ Locate the refrigerator away from heat

producing appliances such as the

range or dishwasher, heat vents and

direct sunlight.

➢ Level the refrigerator and do not block

ventilation around the front grille.

➢ Keep the freezer full to near capacity

so less cold air will escape during door

openings. When the freezer is less

than two-thirds full, place milk cartons

half full of water in the freezer.

➢ Let hot dishes cool slightly before put-

ting into the refrigerator or freezer.

➢ Cover liquids.

➢ Wipe moisture from the outside of

containers before placing them into

the refrigerator.

➢ Avoid opening the doors too often.

CAUTION

CAUTION

NOTE

❚ During the automatic defrost cycle,

you may notice a red glow/reflection in the vents on the back wall of

the freezer compartment and you

may hear the sound of water

droplets coming into contact with

the defrost heater. This is normal

during the defrost cycle.

Page 13

12

Part

Cleaning Agents

Mild detergent and warm

water

Mild liquid sprays

Vacuum cleaner attachment

Cleaning brush

(Part No.20001017)

available from your dealer.

Mild detergent and warm

water

Mild liquid sprays

Mild detergent and warm

water

Mild liquid sprays

Light cleaning: mild

detergent and water or a

solution of white vinegar

and water

Moderate soil: Bon Ami*

Discolorations: Cameo

Stainless Steel Cleaner*

Tips and Precautions

Remove the base grille by grasping the ends and pulling straight out.

To replace, align the clips with the round openings in the cabinet and

push each end in until the base grille snaps into place.

No need for cleaning unless environment is particularly greasy, dusty

or there is significant pet traffic in the home (see page 11).

Dry with a clean, soft cloth.

Do not wipe the refrigerator with a soiled dishwashing cloth or wet

towel.These may leave residue that can scratch and weaken the

paint. Do not use scouring pads, powdered cleansers, bleach or

cleaners containing bleach.These products can scratch and erode

the paint finish.

Do not wax plastic or vinyl parts.

Use a soft cloth or sponge.

Always wipe with the grain of the stainless steel.

Do not use chlorine bleach or a cleaning product that contains chlo-

rine bleach.

After cleaning, rinse and dry.To retore luster and remove streaks fol-

low with Stainless Steel Magic Spray* (Part No. 20000008).

Refrigerator Exterior

Refrigerator & Freezer Interior

Base grille

Condenser

Door handles

Door gasket

Glass shelves

Interior and door liner

Drawers, bins,

egg cradle, etc.

Painted metal surfaces:

Cabinet, doors

Stainless steel doors

(select models)

Refrigerator Cleaning Chart

Baking soda and warm

water

Mild detergent and warm

water

Mild detergent and warm

water

Glass cleaner

Mild liquid sprays

Mild detergent and warm

water

Baking soda and warm

water

Mild detergent and warm

water

Use 1-2 tablespoons baking soda per quart of water.Be sure to

wring out excess water from sponge or cloth when cleaning

around controls, lights, or electrical parts.

Allow the glass to warm up to room temperature before

immersing in warm water. Never use hot water.

See above for baking soda solution.

DO NOT use abrasive cleaners, concentrated detergents, bleaches, cleaning waxes, solvents or polish cleaners to clean the refrigerator interior.

Dry thoroughly. DO NOT wash in automatic dishwasher.

* Brand names are the trademarks of the respective manufacturer

➢

Disconnect the power cord before c leaning.Do not touch refrigerated surfaces with wet or damp hands. Damp objects

stick to cold metal surfaces. Before cleaning the freezer, allow it to warm up. Allow glass shelves to warm up before

immersing in warm water.

For further assistance, call 1-800-688-9900 U.S.A., 1-800-688-2002 Canada or www.maytag.com

care & cleaning

CAUTION

Page 14

13

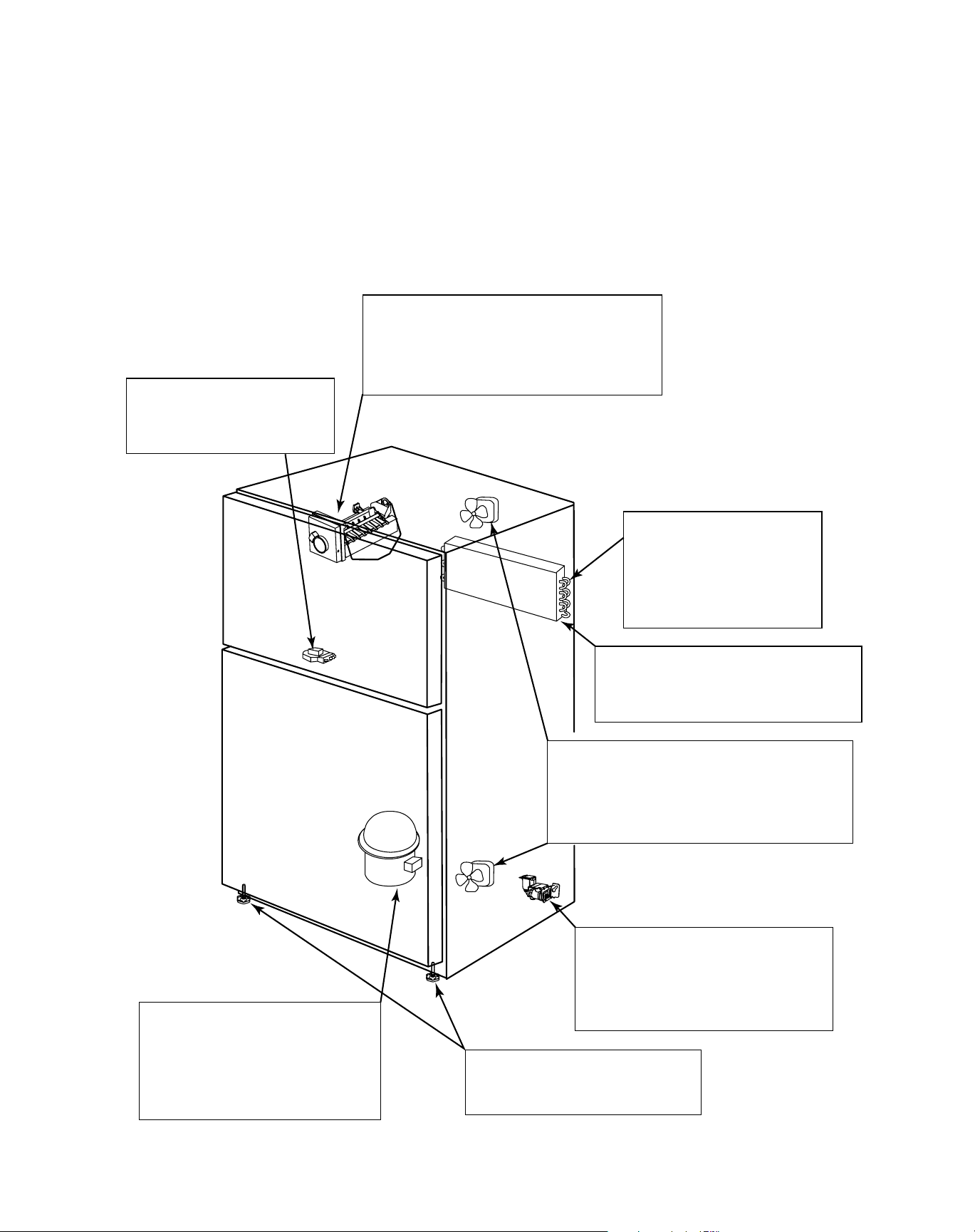

NORMAL OPERATING SOUNDS

Improvements in refrigeration design may produce sounds in your new refrigerator that are different or were not present in an older

model.These improvements were made to create a refrigerator that is better at preserving food, is more energy efficient, and is quieter

overall. Because new units run quieter, sounds may be detected that were present in older units, but were masked by higher sound

levels. Many of these sounds are normal. Please note that the surfaces adjacent to a refrigerator, such as hard walls, floors and

cabinetry may make these sounds seem ev en louder .The following are some of the normal sounds that may be noticed in a new refrigerator.

DEFROST TIMER: Frost-free

refrigerators have a defrost timer

that will generate a clicking

sound when it cycles the unit into

and out of defrost cycle.

ICE MAKER: (if equipped) The ice maker will

occasionally generate a rattling sound when the

ice cubes are ready to drop down into the ice

bin. Also, the motor that ejects the ice from its

tray prior to dropping the ice may also be

detectable. These are normal sounds necessary

for making ice.

FREEZER COMPARTMENT

CONTRACTION AND EXPANSION: A popping sound

may occur in the freezer when

the unit starts up due to

contraction or expansion of

the materials in the freezer

area.

REFRIGERANT FLOW: The flow of the

refrigerant in your refrigerator may cause a

gurgling or rattling sound when the unit is

running or just after the unit cycles off. The

refrigerant is still flowing in the tubing.

AIRFLOW SOUNDS: Both the freezer evaporator

fan and the condenser fan at the bottom of the

cabinet will create airflow sounds. The evaporator

fan is circulating the cold air throughout the

refrigerator and freezer compartments. The

condenser fan is removing the heat generated

when the unit is cooled.

WATER VALVE (if equipped): A buzzing

sound may be detected in the back of the

unit when the ice dispenser calls for the

water valve to open to fill the ice maker

tray. Following the ejection of the ice,

there may be some water dripping

sounds when the trays are being filled.

CABINET LEVELING: An unlevel

cabinet may cause rattling or vibrating

noises. This can be fixed by adjusting

the wheels or levelers properly.

COMPRESSOR: In order for a new

refrigerator to run more efficiently, the

refrigeration system may run longer to

keep food at the desired temperatures

for freshness. That new, high

efficiency compressor may run longer

and generate sounds such as a higher

pitched hum or pulsation.

Page 15

14

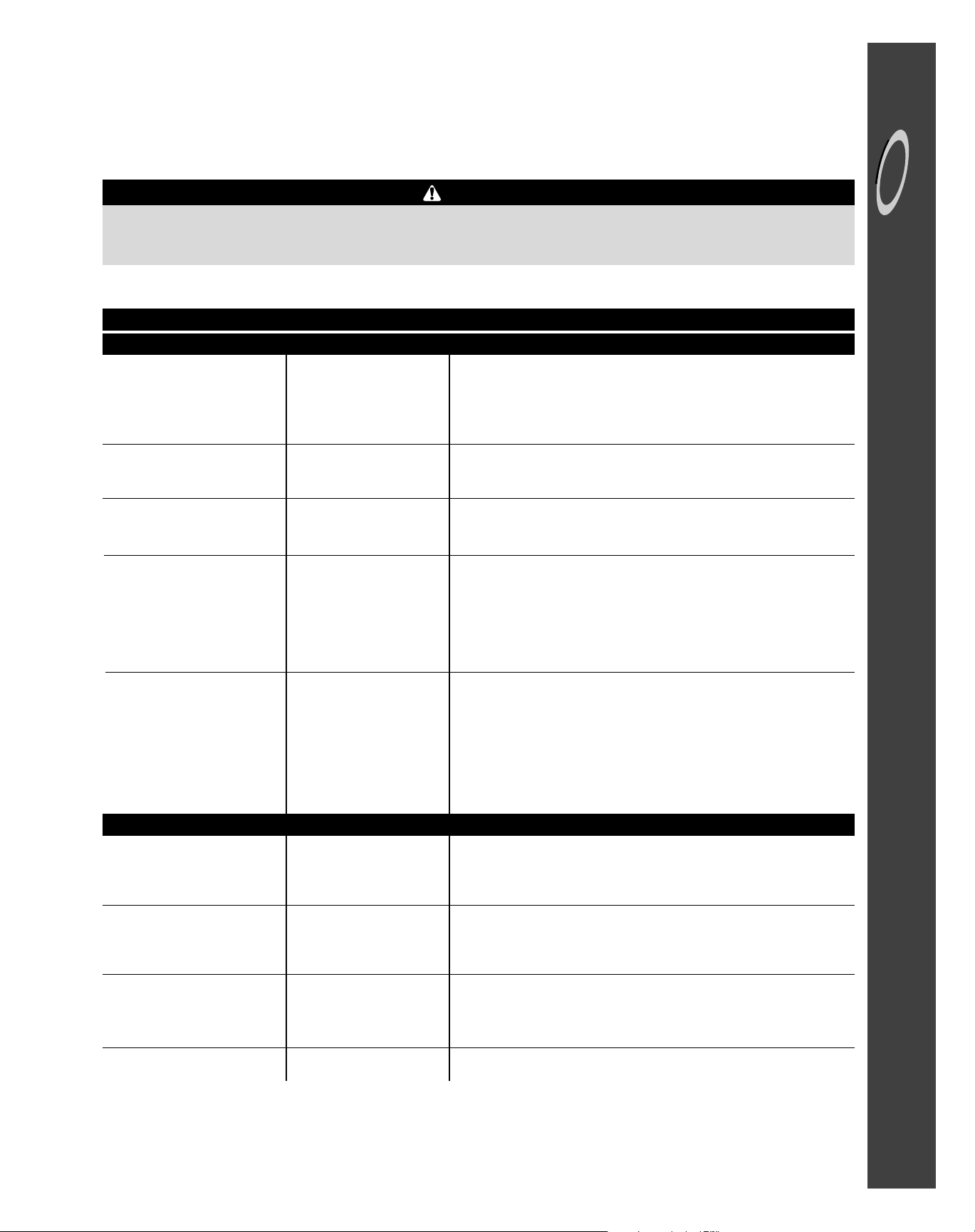

BEFORE YOU CALL FOR SERVICE

before you call

PROBLEM POSSIBLE CAUSES WHAT TO DO

Won’t run Power cord not plugged in. Push plug into outlet.

No power to outlet. Replace fuse, reset circuit breaker.

Freezer control set to OFF position. Set freezer control (see page 5).

Refrigerator is in automatic defrost. Wait 25 minutes for defrost cycle to end.

Room temperature less than 55° F. Relocate unit to proper climate (see installation on page 2).

Runs too long, Today’s refrigerators start and stop more

too frequently often to maintain even temperatures.

Normal at startup for new or recently Wait 24 hours to completely cool down

installed units. (see temperature controls on page 5).

Prolonged or frequent door openings. This is normal.Minimize door openings.

Door not sealing. Check to see if something is preventing door from closing.

Base grille blocked. Unblock to allow warm air to exit unit.

Light not working Bulb burned out. Unplug refrigerator and change bulb (see page 11).

No power to unit. Check to see if power cord is completely plugged in.

Visible glow in Appearance of a red glow or reflection is

freezer vents normal during the defrost cycle.

War m air from This is normal air flow for condenser

cabinet bottom circulation.

Cabinet vibrates Cabinet not level.Weak floor. Level cabinet (see page 2.)

Odor in cabinet Odor producing foods not covered. Cover or wrap odorous foods tightly. Clean cabinet.

Noise, sounds and Normal noise. See Normal Operating Sounds page 13.

vibrations

Cabinet not level. Level cabinet (see page 2).

Freezer, refrigerator Control set too warm. Adjust temperature control (see page 5).

too warm (soft ice cream) Prolonged door openings. Minimize door openings.

Room temperature less than 55° F. Unit will not run often enough to maintain proper temperatures.

Products with high sugar content may

not harden completely when frozen.

Freezer, refrigerator Control set too cold. Adjust temperature control (see page 5).

too cold (food freezing)

Automatic icemaker Sensor ar m in up position. Adjust sensor arm down to ON position.

not working

Cabinet not level. Level unit (see page 2).

Water supply not connected or restricted. Connect water supply, or clear obstr uctions.

Freezer too warm. Adjust freezer temperature control (see page 5).

Ice cubes have Old cubes. Discard; ice cubes may absorb odors which affect taste.

odor/taste

Bad water quality. Contact local water treatment company.

Food transmits odor/taste to ice. Wrap foods tightly.

Ice cubes sticking in tray Residue from minerals in the water. Wipe trays with vinegar-soaked cloth until clean.

Ice cubes evaporating Limited use of ice. Dump old ice cubes.

Moisture on cabinet Not unusual during periods of high humidity.

surface between doors

Moisture on inside cabinet Hot humid weather. Normal.

walls or in crisper

Frequent or prolonged door openings. Minimize door openings.

Door not closed properly. Check to see if something is preventing door from closing.

Food not wrapped properly. Wrap or cover all foods tightly.

Foods dry out Crisper not tightly closed. Close crisper all the way.

Temperature controls set too cold. Adjust temperature controls (see page 5).

Packages not wrapped or sealed properly. Wrap or cover all foods tightly.

Excessive moisture in Food not wrapped properly. Wrap or cover all foods tightly.

crisper

Hot, humid weather. Minimize door openings.

Review this chart of troubleshooting tips first…you may not need to call for service at all.

GENERAL OPERATION

NOISE

TEMPERATURE

ICEMOISTURE

For further assistance, call 1-800-688-9900 U.S.A., 1-800-688-2002 Canada or www.maytag.com

Page 16

15

MAYTAG • 403 West Fourth Street North • P.O. Box 39 • Newton, Iowa 50208

Maytag Warranty What is Not Covered By These Warranties:

1. Conditions and damages resulting from any of the following:

a. Improper installation, delivery, or maintenance.

b. Any repair, modification, alteration, or adjustment not authorized by the

manufacturer or an authorized servicer.

c. Misuse, abuse, accidents, or unreasonable use.

d. Incorrect electric current, voltage, or supply.

e. Improper setting of any control.

2. Warranties are void if the original serial numbers have been removed,

altered, or cannot be readily determined.

3. Light bulbs.

4. Products purchased for commercial or industrial use.

5. The cost of service or service call to:

a. Correct installation errors.

b. Instruct the user on the proper use of the product.

c. Transpor t the appliance to the ser vicer.

6. Consequential or incidental damages sustained by any person as a result

of any breach of these warranties.Some states do not allow the exclusion

or limitation of consequential or incidental damages, so the above exclusion may not apply.

To purchase accessories or replacement parts not covered by your

product warranty:

Please have your model and serial numbers ready and call our parts

specialists at 1-877-232-6771 U.S.A.or 1-800-688-8408 Canada from

7 a.m. to 7 p.m. central time Monday through Friday.

If You Need Service

❚ Call the dealer from whom your appliance was purchased or call Maytag

ServicesSM, Maytag Customer Assistance at 1-800-688-9900, USA or

1-800-688-2002 Canada to locate an authorized servicer.

❚ Be sure to retain proof of purchase to verify warranty status. Refer to

WARRANTY for further information on owner’s responsibilities for warranty service.

❚ If the dealer or service company cannot resolve the problem, write to

Maytag ServicesSM, Attn: CAIR®Center, P.O. Box 2370, Cleveland, TN

37320-2370, or call 1-800-688-9900 U.S.A. or 1-800-688-2002 Canada.

U.S. customers using TTY for deaf, hearing impaired or speech impaired,

call 1-800-688-2080.

NOTE: When wr iting or calling about a service problem, please include

the following information:

a.Your name, address and telephone number;

b. Model number and serial number ;

c. Name and address of your dealer or servicer;

d. A clear description of the problem you are having;

e. Proof of purchase (sales receipt).

❚ User’s guides, service manuals and parts information are available from

Maytag ServicesSM, Maytag Customer Assistance.

Full One Year Warranty

For one (1) year from the date of original retail

purchase, any part that fails in normal home

use will be repaired or replaced free of charge.

Ice Maker - When purchased with the refrigerator and installed by the dealer the ice maker

will be considered part of the refrigerator for

warranty purposes.

Limited Warranty - Major Refrigeration

Components

Second Through Fifth Year - After the first

year from the date of original retail purchase,

through the end of the fifth year, Maytag

Services

SM

will repair or replace, at its option,

free of charge for parts and labor only, any part

of the sealed refrigeration system (consisting

of the compressor, evaporator, condenser,

drier and connecting tubing) and the cabinet

liner (exclusive of the door liner) which fail in

normal home use. All other costs, including

mileage, transportation, trip charge and diagnostic charge, if required, shall be the responsibility of the owner.

Limited Warranty - Other Parts

Second Y ear - Parts other than major refriger-

ation components which fail in normal home

use during the second year following the date

of original retail purchase will be repaired or

provided free of charge for the part itself, with

the owner paying all other costs, including

labor, mileage, transportation, trip charge and

diagnostic charge, if required.

Please note: The full warranty and the limited

warranties apply when the refrigerator is located in the United States or Canada.

Refrigerators located elsewhere are covered

by the limited warranties only including parts

that fail during the first year.

Limitations of Liability

The warrantor shall not be liable for any incidental or consequential damages, including

food loss. Some states do not allow the exclusion or limitation of consequential damages, so

the above limitation or exclusion may not apply

to you.

The specific warranties expressed above are

the ONLY warranties provided by the manuf ac-

turer. These warranties give you specific

legal rights, and you may also ha v e other rights

which vary from state to state.

Page 17

RÉFRIGÉRATEUR À COMPARTIMENTS SUPERPOSÉS TM-1

R

Form No. A/01/01 Part No. 8113P291-60 h t t p : / / w w w . m a y t a g . c o m 7400???? Litho U.S.A .

Installateur : Veuillez laisser ce guide

avec l’appareil.

Consommateur : Veuillez lire et conserver ce guide pour consultation ultérieure.

Conservez la facture d’achat ou le chèque

annulé comme preuve d’achat.

Si vous av ez des questions, v euillez écrire

ou nous appeler (en incluant le numéro de

modèle et votre numéro de téléphone) à :

Maytag Services

SM

Attn: CAIR®Center

P.O. Box 2370

Cleveland, TN 37320-2370

É.-U.1-800-688-9900

Canada 1-800-688-2002

Les clients des É.-U.utilisant un ATS

(pour handicap d’audition ou d’élocution)

doivent composer le 1-800-688-2080.

(Du lundi au vendredi de 8 h à 20 h,

heure de l’Est)

Internet : http://www.maytag.com

Pour des informations sur le service

après-vente, voir page 31.

Dans le cadre de nos pratiques

d’amélioration constante de la qualité

de nos appareils, des modifications

peuvent être introduites sur les

appareils sans que cela donne lieu à

une révision de ce guide.

Page 1 7

Pages 18-20

Page 2 1

Page 2 2

Pages 23-24

Pages 25-26

Page 2 7

Pages 27-28

Page 2 9

Page 3 0

Page 3 1

Page 3 2

Numéro de modèle

Numéro de série

Date de l’achat

bruits normaux

conseils pour la conservation des aliments

intérieur du réfrigérateur

production de glace

réglage des les températures

installation

remisage du réfrigérateur

sécurité

entretien et nettoyage

avant d'appeler

garantie

guía del usuario

Page 18

17

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

➢

Utiliser le réfrigérateur uniquement pour

son application prévue.

➢

Pour é viter un risque de choc électrique, ne

jamais brancher le réfrigérateur sur une

prise de courant qui n’a pas été adéquatement reliée à la terre, conformément aux

prescriptions des codes national et local

des installations électriques. Voir

ci-dessous l’avertissement et les instructions de liaison à la terre.

➢

Débrancher le réfrigérateur avant de le nettoyer ou de remplacer une ampoule.

➢

En cas de panne d’électricité, éviter d’ouvrir les portes. Si l’interruption de l’alimentation se prolonge, placer des blocs de

glace carbonique par-dessus les paquets

pour protéger les aliments plus longtemps,

ou contacter un entrepôt frigorifique local

pour organiser un stockage temporaire.Ne

pas recongeler des aliments surgelés qui

ont été complètement décongelés.

➢

Réparer ou remplacer tout cordon d’alimentation électrique qui a été endommagé

ou détérioré. Ne jamais tirer sur le cordon

pour débrancher l’appareil.

➢

Ne pas faire fonctionner le réfrigérateur en

présence de fumée explosive.

➢

Ne jamais laisser un enfant se tenir sur,

grimper sur, ou se suspendre à une

clayette de ce réfrigérateur.

IMPORTANT : Les r isques d’enfermement et

d’étouffement d’un enfant dans un réfrigérateur n’ont pas disparu. Un réfrigérateur abandonné demeure dangereux...même s’il ne

reste ainsi accessible que pendant quelques

Cet appareil est doté d’une fiche de branchement à 3 broches (pour liaison à la terre), ce

qui assure une protection adéquate contre les

risques de chocs électriques.On doit brancher

l’appareil uniquement sur une prise de courant

reliée à la terre. Si la prise de courant

disponible ne comporte que deux alvéoles,

c’est au client qu’incombent la responsabilité

et l’obligation personnelle de la faire remplacer

par une prise de courant à 3 alvéoles convenablement reliée à la terre. On ne doit

jamais, quelles que soient les circonstances,

couper ou arracher la troisième broche (liaison

à la terre) de la fiche de branchement. Ne

jamais utiliser une fiche d’adaptation.

CONSERVER CES INSTRUCTIONS COMME RÉFÉRENCES

CE QUE VOUS DEVEZ

SAVOIR SUR LES

INSTRUCTIONS DE

SÉCURITÉ

Les instructions de sécurité impor tantes et les

avertissements paraissant dans ce guide ne

sont pas destinés à couvrir toutes les situations et conditions éventuelles qui peuvent se

présenter.Il faut faire preuve de bon sens et de

prudence lors de l’installation, de l’entretien ou

de l’utilisation de l’appareil.

Prenez toujours contact avec votre revendeur,

distributeur, agent de service ou fabricant, au

sujet de problèmes ou conditions que vous ne

comprenez pas.

RECONNAISSEZ LES

ÉTIQUETTES, PHRASES

OU SYMBOLES SUR LA

SÉCURITÉ

jours. Lorsqu’on se débarrasse d’un vieux

réfrigérateur, il faut appliquer les instructions

ci-dessous pour éviter tout accident.

➢

Démonter les portes.

➢

Laisser les

clayettes en

place pour

qu’un

enfant ne

puisse pas

facilement

s’introduire

dans le réfrigérateur.

➢

Suivre toujours les précautions de

base lors de l’utilisation de cet

appareil.

➢

Cet appareil est conçu pour être

alimenté à partir du réseau normal

de 115 V/60 Hz, 15 A. L’appareil

devrait être alimenté par un circuit

indépendant. Ne pas utiliser un câble

de rallonge. Ne jamais utiliser un dispositif susceptible de dégrader la

performance électrique de cet

appareil.

CORDON D’ALIMENTATION

AVEC FICHE DE BRANCHEMENT

À 3 BROCHES

PRISE DE COURANT

MURALE RELIÉE

À LA TERRE

DANGER – risques immédiats qui

RÉSULTERONT en de graves blessures

ou même la mort.

DANGER

AVERTISSEMENT – r isques ou pratiques

non sûres, qui POURRAIENT résulter en

de graves blessures ou même la mort.

AVERTISSEMENT

ATTENTION – risques ou pratiques non

sûres qui POURRAIENT résulter en

blessures mineures, dommages du produit

ou dégâts matériels.

ATTENTION

AVERTISSEMENT

AVERTISSEMENT

POWER SUPPLY CORD

WITH 3-PRONG

GROUNDING PLUG

Page 19

18

sécurité

INSTALLATION

Pour toute aide supplémentaire, composez le 1-800-688-9900 aux É.-U., le 1-800-688-2002 au Canada, ou consultez www.maytag.com

Établissement de la

bonne circulation de

l’air

Pour assurer le maintien des températures

appropriées, il est nécessaire que la circulation de l’air se fasse correctement entre les

compartiments de réfrigération et de congélation, comme l’indique l’illustration.

NE bloquer aucun de ces évents avec des

aliments. S’ils étaient bloqués, la circulation

de l’air serait entravée, ce qui entraînerait des

problèmes de température et d’humidité.

Emplacement

d’installation

➢ Veiller à ce que l’air puisse circuler libre-

ment à travers la grille de plinthe avant.

➢ Installer le réfrigérateur à un endroit où la

température ambiante ne baissera pas audessous de 13 °C (55 °F). Lorsque la

température ambiante est inférieure à

13 °C (55 °F), le réfrigérateur ne fonctionne

pas assez fréquemment pour le maintien

de la température adéquate dans le compartiment de congélation.

➢ Prévoir un espace libre d’au moins 1,5 cm

(

1

⁄2 po) sur les côtés, au sommet et à

l’arrière pour faciliter l’installation. Si le côté

comportant les charnières de porte est

contre un mur, il est désirable qu’il y ait un

espace libre plus important de ce côté pour

pouvoir ouvrir complètement les portes ou

inverser leur sens d’ouverture (page 20).

➢ Dans le cas d’un plancher en vinyle ou en

bois, travailler prudemment lors de l’installation pour éviter de laisser des marques

sur le plancher ou de l’endommager.

Utiliser une plaque de contreplaqué ou un

morceau de tapis ou d’un autre matériau

pour protéger le sol lors du positionnement

de l’appareil.

➢ Le réfrigérateur doit rester vertical pendant

au moins 30 minutes avant d’être branché.

Deballage

➢ Retirer et conserver les dispositifs de mise

à niveau fixés à la base de déménagement.

➢ Retirer et jeter la base de déménagement

et les vis.

➢ À l’aide d’une pince à joint coulissant,

installer les dispositifs de mise à niveau

dans les trous situés aux angles avant de

la caisse.

Aplomb du réfrigérateur

Pour optimiser l’esthétique et la performance

du réfrigérateur, il faut le placer d’aplomb.

Selon le modèle, le réfrigérateur peut être mis

d’aplomb de deux façons.

➢ Tous les modèles de réfr igérateur ont des

vis de mise à niveau à la base de la caisse,

sous chacun des coins avant. Ces pieds

peuvent être ajustés en les tournant dans

un sens ou l’autre, au besoin.Si le plancher

n’est pas de niveau et qu’il soit nécessaire

de relever l’arrière de la caisse, utiliser un

morceau de contreplaqué ou autre matériau de calage.Pour immobiliser la caisse en

place, faire descendre les deux vis de mise

à niveau (voir fig.1).

ROTATION ANTIHORAIRE

POUR BAISSER LE COIN

DE LA CAISSE

ROTATION HORAIRE

POUR SOULEVER LE

COIN DE LA CAISSE

➢ Les modèles de réfrigérateur qui com-

portent des roulettes réglables peuvent

être mis à niveau en retirant la grille de

plinthe* et en réglant ces roulettes à l’aide

d’un tournevis ou d’une douille de

1

⁄4 pouce

(voir fig. 2).

*Pour retirer la grille de plinthe, saisir les

deux extrémités et tirer en ligne droite.Pour

la réinstaller, aligner les attaches avec les

ouvertures rondes dans la caisse et pousser sur chaque extrémité pour l’emboîtement.

➢ Pour de meilleurs résultats, après avoir mis

la caisse à niveau, ouvrir et fermer les

portes et remettre à niveau.

Figure 1

Figure 2

IMPORTANT : Ne pas enlever l’isolant en

mousse des évents situés dans le plafond du

compartiment d’aliments frais.

Ce réfrigérateur a fait l’objet d’un emballage

soigné. Enlever et jeter les agrafes éventuellement utilisées pour l’immobilisation des

clayettes (juste au-dessus de chaque

clayette -- accrochage sur le châssis). Pour

enlever les agrafes de plastique, faire bouger

les agrafes latéralement et tirer en ligne droite.

P

O

U

R

S

P

O

U

R

B

A

I

S

S

E

R

L

A

C

A

I

S

S

E

O

U

L

E

V

E

R

L

A

C

A

I

S

S

E

Dispositifs

de mise à

niveau

Base de

déménagement

Vis

Page 20

19

INSTALLATION,SUITE

RÉGLAGE DE LA PORTE

(AU BESOIN)

•Resserrer les vis après avoir fini les

réglages.

* Se repor ter aux instructions d’installa-

tion pour obtenir plus d’informations.

La porte doit être de niveau lorsque la

caisse l’est.

• La porte du congélateur est trop

haute.

•Les deux portes sont trop hautes.

•Les deux portes sont trop basses.

POIGNÉE MONTÉE SUR LE DESSUS

Page 21

20

installation

INVERSION DU SENS

DES PORTES

Outils nécessaires : tour nevis Phillips, clé à

rochet et douille de 5/16 po (8 mm), couteau à

mastic ou clé ouverte de 5/16 po (8 mm).

1. Retirer le couvre-char nière et le mettre de

côté.

2. Retirer les vis et la charnière avec une clé

à douille de 5/16 po (8 mm) et les mettre

de côté.

3. Soulever doucement la porte du congélateur et la retirer.

4. Enlever la vis et le bras de charnière du

dessus de la porte du réfrigérateur.

5. Soulever doucement la porte du réfrigérateur et la retirer.

6. Retirer le protecteur de grille et le mettre

de côté.

7. Retirer la plaque de charnière du coin

inférieur du réfrigérateur et l’installer de

l’autre côté.

8. Retirer la plaque du dessous de la por te

du réfrigérateur et l’installer de l’autre

côté.

9. Retirer la plaque du dessous de la por te

du congélateur et l’installer de l’autre côté.

10. Retirer les boutons sur le dessus des

portes de réfrigérateur et de congélateur

et les réinstaller de l’autre côté.

11. Retirer les bouchons des trous de vis du

dessus de la caisse et les réinstaller de

l’autre côté.

12. Retirer les rondelles et l’axe de l’intérieur

de la plaque de charnière et les installer à

l’extérieur de la plaque de charnière.

13. Réinstaller soigneusement la porte du

réfrigérateur sur la plaque de charnière au

coin inférieur.

14. Coulisser le bras de char nière en place et

le fixer avec une vis.

15. Installer soigneusement la porte du congélateur sur le dessus du bras de

charnière en se servant de la cale

d’espacement pour maintenir l’intervalle.*

16. Coulisser la charnière supérieure en place

sur la porte du congélateur et fixer les vis à

l’aide d’une clé de 5/16 po (8 mm).

17. Bien enclencher en place le couvrecharnière.

18. Remettre le protecteur de grille.

Ne pas oublier de rebrancher le réfrigérateur et

de réenclencher les commandes au réglage

voulu.

DÉPOSE DES PORTES

(AU BESOIN)

po

Poser la por te sur une surface non rugueuse.

A. Retirer la vis gauche.

B. Ouvrir la porte et la soulever. Poser la

porte sur une surface non rugueuse.

Outils

Retirer l’ensemble de plaque de charnière.

Poser la por te sur une surface non rugueuse.

Ne pas jeter la cale d’espacement en mousse

de la porte. Les por tes peuvent se stabiliser à

l’usage.

*

Pour toute aide supplémentaire, composez le 1-800-688-9900 aux É.-U., le

1-800-688-2002 au Canada, ou consultez www.maytag.com

Page 22

21

Surfaces de la caisse

chaudes

Occasionnellement, la face avant de la caisse

du réfrigérateur peut être chaude au toucher.Il

s’agit d’un effet normal qui empêche la condensation d’humidité sur la caisse. Ceci se

remarque particulièrement lors de la mise en

marche initiale du réfrigérateur, par temps

chaud ou après une période prolongée ou

excessive des portes.

RÉGLAGE DE LES TEMPÉRATURES

GUIDE POUR LE RÉGLAGE DE LA TEMPÉRATURE

Compartiment «réfrigération»

trop chaud

Compartiment «réfrigération»

trop froid

Compartiment «congélation»

trop chaud

Compartiment «congélation»

trop froid

Mettre le réfrigérateur à l’arrêt

(Commandes rotatives)

Mettre le réfrigérateur à l’arrêt

(Commandes à curseur)

Faire tour ner le bouton «réfrigérateur» jusqu’au chiffre

supérieur (1 unité)

Faire tour ner le bouton «réfrigérateur» jusqu’au chiffre

inférieur (1 unité).

Faire tour ner le bouton «congélateur» jusqu’au chiffre

supérieur (1 unité).

Faire tour ner le bouton «congélateur» jusqu’au chiffre

inférieur (1 unité)

Placer la commande «réfrigérateur» à la position

d’arrêt «OFF».

Mettre le curseur sur «OFF» (ARRÊT)

REMARQUE : Lorsqu’on place le bouton de commande «réfrigérateur» à la position d’arrêt

«OFF», le refroidissement cesse dans les DEUX compartiments. L’alimentation de l’appareil n’est

pas interrompue.

INITIAL DES COMMANDES

REMARQUE

❚ Lors de la mise en marche initiale, le com-

presseur du réfrigérateur fonctionnera pendant plusieurs heures.Ceci est normal.

❚ Laisser le réfrigérateur fonctionner pen-

dant au moins 8 à 12 heures avant d’y

placer des aliments.

Réglage fin des

commandes

➢ 24 heures après l’addition d’aliments, il est

possible de décider s’il convient d’ajuster la

température dans l’un ou l’autre ou les

deux compartiments. Dans ce cas, modifier

la position du ou des boutons de commande, selon les indications du tableau

ci-dessous.

➢ Sauf lors de la mise en marche initiale du

réfrigérateur, ne pas changer la position du

bouton de commande de plus d’une unité à

la fois.

Le style des commandes varient selon le modèle. Les commandes sont emplacer à curseur à la partie supérieure du compar timent réfrigérateur.

Commandes rotatives

Commandes à curseur

➢ La commande qui agit sur le compartiment

de réfrigération comporte une graduation

de 1 (température maximale) à 9 (température minimale). Sélectionner initialement la

valeur 5 pour cette commande.

➢ La commande qui agit sur le compartiment

de congélation comporte une graduation

de 1 (température maximale) à 9 (température minimale). Sélectionner initialement la

valeur 5 pour cette commande.

INITIAL DES COMMANDES

➢ La commande qui agit sur le compartiment

de réfrigération comporte une graduation

de 1 (température maximale) à 7 (température minimale). Sélectionner initialement la

valeur 4 pour cette commande.

➢ La commande qui agit sur le compartiment

de congélation comporte une graduation

de 1 (température maximale) à 7 (température minimale). Sélectionner initialement la

valeur 4 pour cette commande.

➢ Laisser les températures se stabiliser pen-

dant 24 heures avant de modifier les

réglages.

➢ Une modification du réglage de l’un ou

l’autre des boutons de commande entraîne

une modification de la température dans

l’autre compartiment.

Page 23

22

production de glace

PRODUCTION DE GLACE

Certains modèles sont prêts pour une installation de machine à glaçons automatique. Le

numéro du nécessaire de machine à glaçons

approprié pour l’installation sur ces modèles

apparaît sur la plaque signalétique. Le nécessaire comprend les instructions d’installation et

de raccordement de l’eau.

D’autres modèles ont une machine à glaçons

installée à l’usine. Raccorder la machine à

glaçons à la canalisation d’eau comme il est

indiqué dans les instructions fournies à part

avec le réfrigérateur. Une bonne circulation

d’eau et la mise à niveau du réfrigérateur

sont essentielles à des performances optimales de la machine à glaçons.

Après le raccordement du réfrigérateur à l’alimentation d’eau, abaisser le bras de détection.

La machine à glaçons se remplit d’eau dès

que la température adéquate est établie avec

le congélateur.

Certaines machines à glaçons sont dotées

d’un bras de détection réglable, qui permet de

choisir la quantité de glaçons dans le moule à

glaçons pour les fois où une quantité inférieure

de glaçons est nécessaire.

Pourrégler la quantité de glaçons produits :

(certains modèles) Tourner le levier métallique

pour produire la quantité désirée de glaçons.

Le réglage 100% assure une production

maximale.

➢ Il faut attendre 8 à 12 heures avant que la

machine à glaçons produise des glaçons

utilisables.Le premier ou les deux premiers

lots seront probablement constitués de

glaçons de petite taille et irréguliers, du fait

de la présence d’air dans la canalisation.

➢ Le premier lot peut également contenir des

impuretés présentes dans la nouvelle canalisation d’eau.Par conséquent, jeter tous les

glaçons des deux ou trois premiers lots.

➢ Lors de l’éjection des glaçons, il est normal

que plusieurs glaçons soient collés ensemble aux extrémités. Il est facile de les

séparer. La machine à glaçons continuera

à produire des glaçons jusqu’à ce que

l’accumulation de glaçons relève le bras de

détection, ce qui arrête la machine à

glaçons.

➢ Certains sons peuvent accompagner les

diverses phases de la production de

glaçons : léger bourdonnement du moteur,

chute de glaçons dans le bac à glaçons

vide et déclic de l’électrovanne ou, de

temps à autre, bourdonnement.

➢ Si la consommation de glaçons est faible,

les glaçons accumulés vont prendre un

aspect trouble, se contracter , coller ensemb le

et prendre un goût.Vider périodiquement le

bac pour le laver à l’eau tiède.Veiller à bien

le sécher avant de le réinstaller.

➢ Pour retirer le bac à glaçons, le tirer vers

l’avant puis l’enlever de la machine à

glaçons. Pour empêcher que la machine à

glaçons ne produise des glaçons alors que

le bac est enlevé, arrêter la machine à

glaçons en relevant le bras de détection.

ON

OFF

ON

OFF

1

0

0

%

7

5

%

I

C

E

L

E

V

E

L

5

0

%

I

C

E

L

E

V

E

L

5

0

%

7

5

%

1

0

0

%

1

0

0

%

7

5

%

I

C

E

L

E

V

E

L

5

0

%

I

C

E

L

E

V

E

L

5

0

%

7

5

%

1

0

0

%

Levier

métallique

Bras de

détection

➢ Pour remettre le bac à glaçons en place,