Maytag SDG3606AWW, SDG5401AWW, SDG4606AWW, SDG5701AWQ, SDG2606AWW Installation Instructions

...Page 1

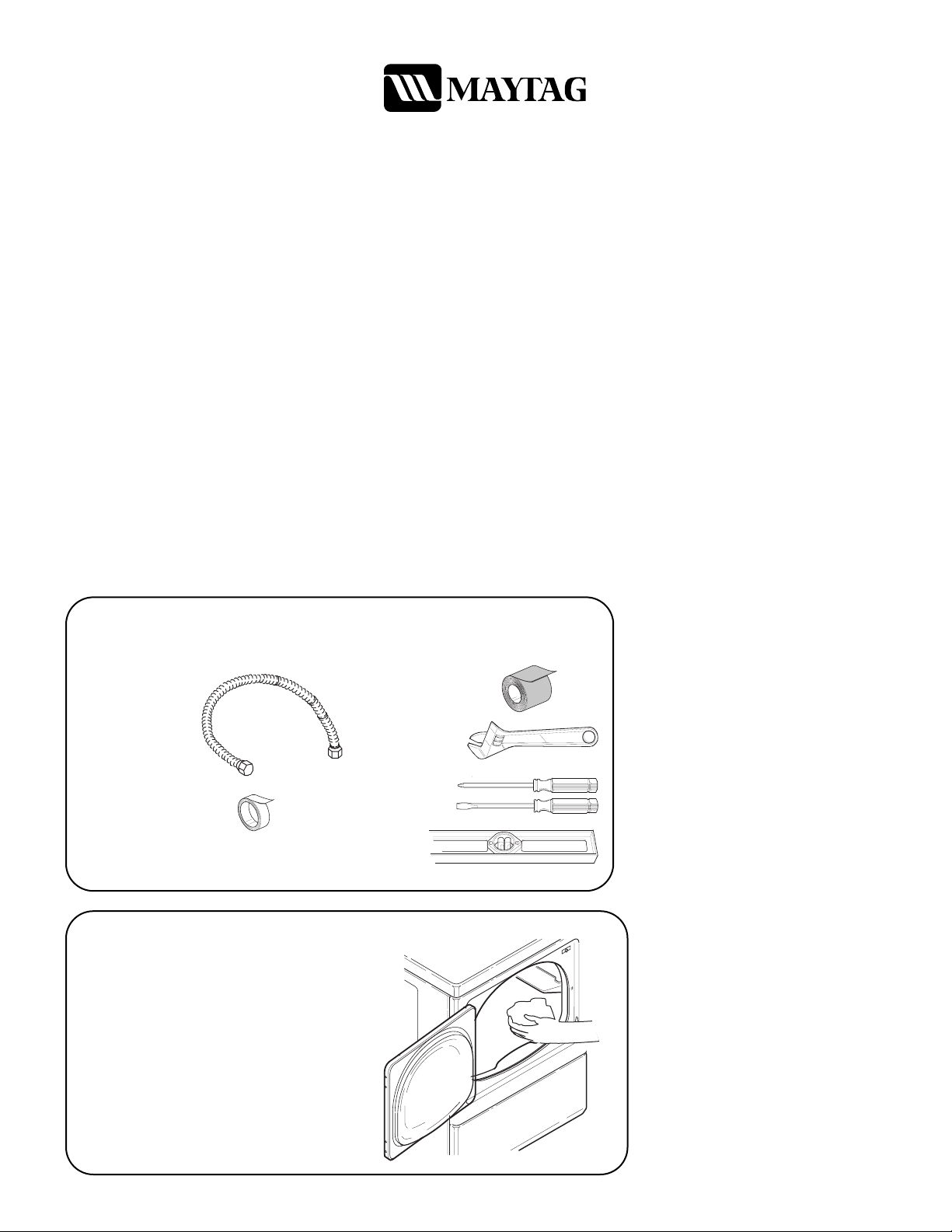

Stainless Steel

or Hard Pipe

Gas Connector

Teflon Tape or

Joint Compound

Duct Tape

Wrench

Screw

Drivers

Level

Installation

Instructions

Gas Dryer

Keep instructions for future reference.

Be sure manual stays with dryer.

1

REMOVE PARTS

AND CLEAN

DRYER DRUM

Wipe drum with clean rag and soap

diluted in warm water to remove

any oil used in manufacturing. Make

a paste of laundry detergent and

clean drum if necessary.

To reverse the direction that the

door opens, see the User’s Guide.

®

Optional Kits

Kits are available at extra cost

through your Maytag dealer or

Maytag Customer Assistance at

1-800-688-9900 USA

1-800-688-2002 Canada

1-800-688-2080 TTY USA Only

Directional Exhaust Kit

DK1 Sales Accessory (Directional

Exhaust Kit #528P3).

Flexible Metal Vent Kit

Exhausting the dryer in hard-toreach locations can be accomplished by installing Kit # 521P3.

Manufactured (Mobile) Home

Installation Kit

Manufactured home anchor Kit

#526P3.

Propane Gas Conversion Kit

LPK1 Sales Accessory

(L.P./ Propane Kit # 649P3).

Questions?

See the User’s Guide or

call Maytag Appliances

Sales Company

1-800-688-9900 USA

1-800-688-2002

Canada

1-800-688-2080

TTY USA Only

You'll Need a Few Things Before You Begin

Part No. 40136401 Printed in U.S.A. 11/01

Page 2

2

2

CONNECT DRYER

TO EXHAUST

SYSTEM

Secure all joints with clamps or duct

tape. DO NOT use sheet metal

screws or other fastening means

which extend into the duct to attach

exhaust pipe joints. They could

catch lint and reduce the efficiency

of the exhaust system.

IMPORTANT: Keep exhaust duct

as short as possible.

Be sure old ducts are clean before

installing your new dryer.

To prevent backdraft when dryer is

not in operation, outer end of

exhaust pipe must have a weather

hood with hinged dampers (obtain

locally).

Weather hood should be installed at

least 12" (30.5 cm) above the

ground. Higher clearances may be

necessary in areas where heavy

snowfall can occur.

No extra system length consideration is necessary when exhausting

through the roof. Use MAXIMUM

EXHAUST LENGTH table to calculate system length. Use a roof cap

that provides air flow equal to

weather hood.

Exhaust Directions

Dryer can be exhausted to the outdoors through the back, right, or

bottom of the dryer. Gas dryers

cannot be vented out the left side

because of the burner housing.

Dryer is shipped from factory ready

for rear exhaust. No kits required.

To exhaust dryer through sides or

bottom, install a DK1 Sales

Accessory (Directional Exhaust Kit

528P3). Available as optional equipment at extra cost.

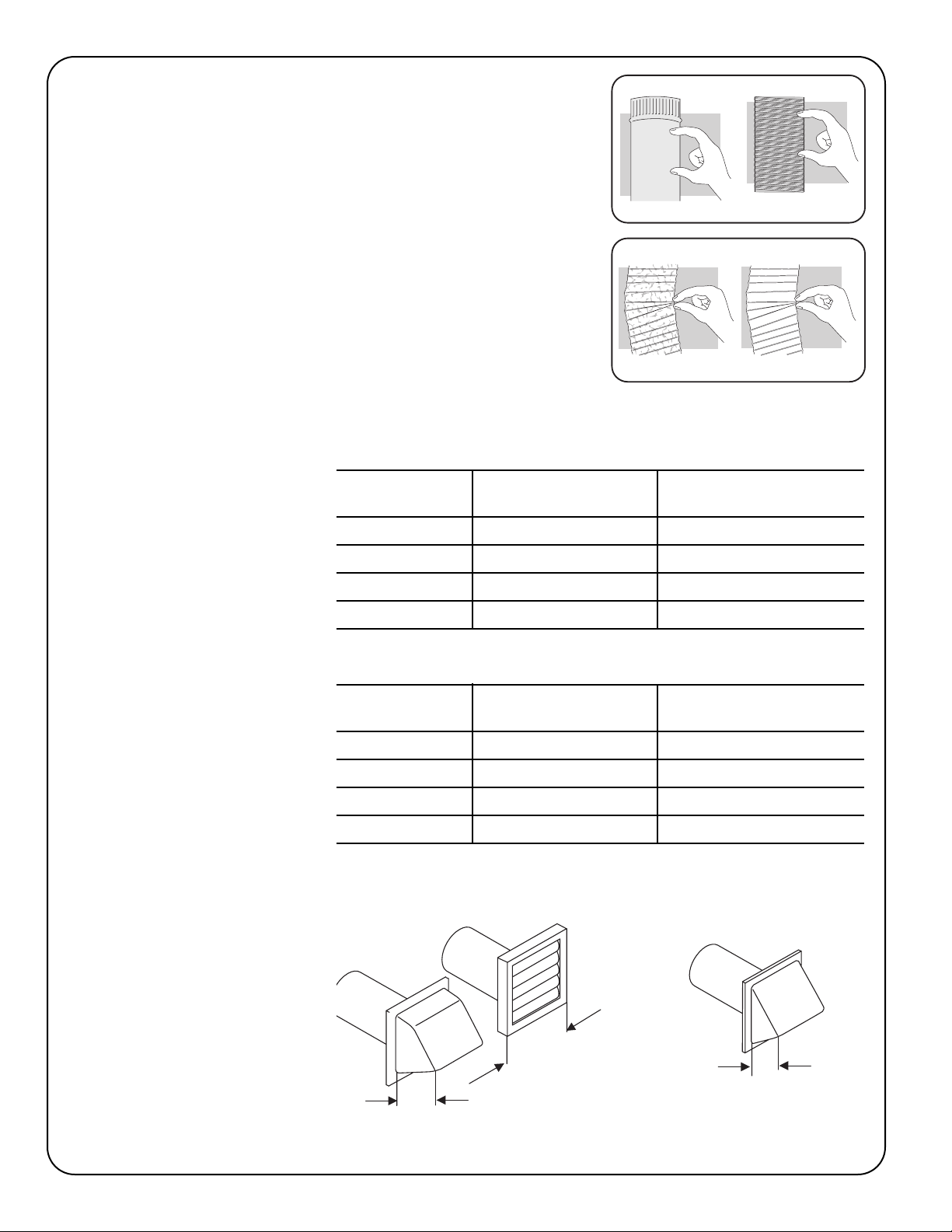

Exhaust System Materials

Exhaust duct must be four inches

(10.2 cm) in diameter without

obstructions. Rigid metal duct is

recommended. Non-combustible

semirigid flexible metal duct is

acceptable.

DO NOT use plastic pipe, foil pipe,

or flexible plastic pipe, because it

contributes to poor drying performance and collects lint, which can

lead to a fire hazard. To identify

flexible foil or plastic duct, pinch the

coils of the duct between your fingers. If the coils can be brought

together, do not use the duct.

Flexible Foil

Maximum Exhaust Length

Rigid Metal Duct

Number of Weather Hood Weather Hood

90° Elbows 4-inch Opening 2

1

⁄2-inch Opening

0 44 feet (13.4 m) 34 feet (10.4 m)

1 34 feet (10.4 m) 26 feet (7.9 m)

2 26 feet (7.9 m) 20 feet (6.1 m)

3 20 feet (6.1 m) 14 feet (4.3 m)

Flexible Metal Duct

Number of Weather Hood Weather Hood

90° Elbows 4-inch Opening 2

1

⁄2-inch Opening

0 24 feet (7.3 m) 20 feet (6.1 m)

1 20 feet (6.1 m) 16 feet (4.9 m)

2 16 feet (4.9 m) 12 feet (3.7 m)

3 12 feet (3.7 m) 8 feet (2.4 m)

4" (10,16 cm)

4" (10,16 cm)

2-1/2" (6,35 cm)

Recommended Weather Hood

Recommended for

Short Runs Only

Rigid Metal Semirigid Metal

Use

Do Not Use

Plastic

Page 3

3

3

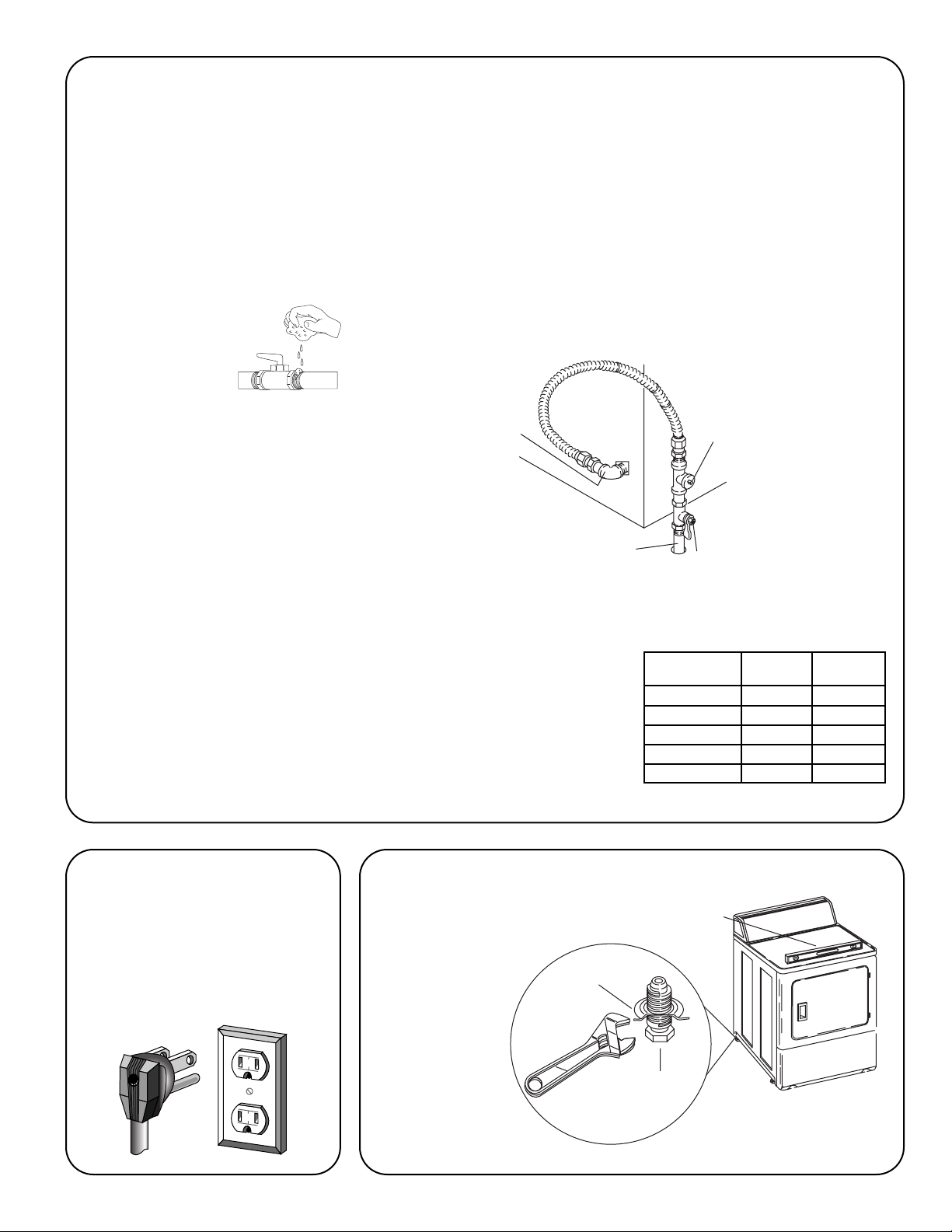

CONNECT GAS

SUPPLY

L.P./Propane

DO NOT connect dryer to

L.P./Propane gas service without

converting the gas valve. An LPK1

Sales Accessory L.P./Propane Gas

Conversion Kit 649P3 must be

installed.

Test for Gas Leaks

After final gas connection is made,

turn on manual gas

valve and test all

connections in gas supply piping for

gas leaks. Leak testing of the appliance shall be conducted according

to the manufacturer’s instructions.

1. Place soap suds on connections.

2. If bubbles appear, a leak is present. Shut off gas supply valve.

3. Tighten joint if leak is at factory

fitting.

• If leak is not at factory fitting,

unscrew, apply more joint

compound, and tighten to correct leak.

4. Retest connection for leak after

tightening or adding joint

compound.

• Retest any connections that

were disturbed.

Connect gas supply to dryer using a

new stainless steel flexible connector or hard pipe (check local codes)

according to illustration. Test for

leaks and check burner flame after

gas supply is connected. See

Checking Burner Flame section on

back page.

• Dryer must be connected to type

of gas as shown on nameplate

located in the door recess.

For proper operation at altitudes

above 2,500 feet

The natural gas valve spud orifice

size must be reduced to ensure

complete combustion. See table.

• Use pipe joint compound insoluble on LP (propane) Gas, or

Teflon tape, on all pipe threads.

• Purge air and sediment from gas

supply line before connecting it to

the dryer. Before tightening the

connection, purge remaining air

from gas line to dryer until odor of

gas is detected. This step is

required to prevent gas valve

contamination.

4

CONNECT

POWER CORD

TO ELECTRICITY

See Installation Requirements

section. Plug dryer into 3-prong

grounded outlet only.

5

POSITION AND

LEVEL DRYER

Place dryer in position,

adjust all legs (4)

until dryer is level

side to side and

front to back.

Dryer

Base

Level

Leveling

Leg

Use new stainless steel flexible connector

only if allowed by local codes (use Design A.G.A. certified connector)

3/8" NPT gas

connection

1/8" NPT pipe plug

(for checking inlet

gas pressure)

Install equipment

shut-off valve

within 6' (1,8 m)

of dryer.

Black iron pipe

Shorter than 20' (6,1 m) - use 3/8" pipe

Longer than 20' (6,1 m) - use 1/2" pipe

Altitude Orfice Part

Ft. (M) Size # Number

3000 (915) 43 503778

6000 (1830) 44 58719

8000 (2440) 45 503779

9000 (2740) 46 503780

10000 (3050) 47 503781

Page 4

4

Important Safety Information

About Ground Wires

In the event of an electrical short

circuit, a ground wire reduces the

risk of electric shock by providing

an escape wire for the electric

current.

Standard accepted color coding for

ground wires is green or green

with a yellow stripe.

Grounding wires and wires colored

like grounding wires are NOT to be

used as current carrying conductors.

WARNING

• Observe all local codes and

ordinances.

• Disconnect electrical power to

unit before servicing.

• Ground appliance properly.

• Check with a qualified electrician

if you are not sure this appliance

is properly grounded.

• DO NOT ground to gas line.

• DO NOT ground to cold water

pipe if pipe is interrupted by

plastic, non-metallic gaskets or

other insulating (non-conducting)

materials.

• DO NOT modify plug on power

cord. If plug does not fit electrical outlet, have proper outlet

installed by qualified electrician.

• DO NOT have a fuse in the neutral or ground circuit. A fuse in

the neutral or ground circuit

could result in an electrical

shock.

• DO NOT use an extension cord

with this appliance.

• DO NOT use an adapter plug

with this appliance.

• DO NOT pinch power cord.

To avoid risk of personal injury or death due to electrical shock:

WARNING

To avoid death, personal injury or property damage, from fire or explosion, information in this manual must be followed exactly:

• Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone in your

building.

– Immediately call your gas supplier from a neighbor’s phone. Follow

the gas supplier’s instructions.

– If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

Grounding Instructions

Dryer must be grounded. Dryer is equipped with a cord having a grounding

conductor and a 3-prong grounding plug. The three-prong grounding plug on

the power cord should be plugged directly into a polarized three-slot grounded

receptacle rated 110/120V AC (alternating current) 15 Amps.

Save These Instructions

WARNING

To reduce the risk of fire, the

dryer MUST be exhausted to

the outdoors. DO NOT exhaust

dryer air into a window well,

gas vent, chimney or enclosed,

unventilated area, such as an

attic, wall, ceiling, crawl space

under a building or concealed

space of a building.

WARNING

To reduce the risk of fire, DO

NOT use plastic pipe, foil pipe,

or flexible plastic pipe to exhaust

the dryer. Never install flexible

duct in concealed spaces, such

as a wall or ceiling.

WARNING

To reduce the risk of fire, electric shock, serious injury or

death, all wiring and grounding

must conform with the latest

edition of the National Electric

Code, ANSI/NFPA 70, or the

Canadian Electrical Code,

CSA C22.1, and such local

regulations as might apply. It is

the customer’s responsibility to

have the wiring and fuses

checked by a qualified electrician to make sure your home

has adequate electrical power

to operate the dryer.

Page 5

5

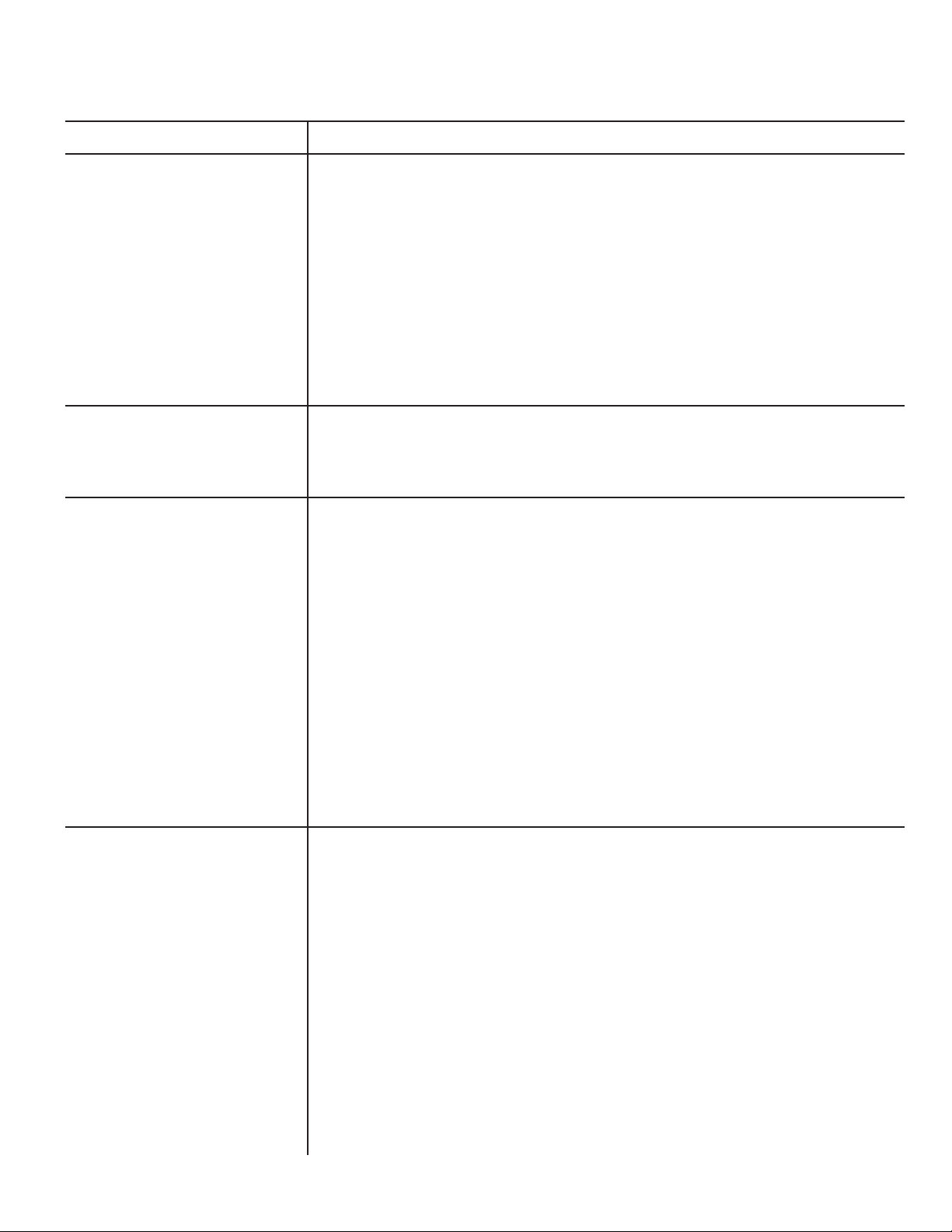

Consider

Location

Description

Use dimensions shown in manual to determine space needed for installation.

Place dryer on a solid floor in an area with an adequate air supply. A closet door

must have a supply air vent of 80 sq. in. (517 sq. cm) minimum.

No other fuel burning appliance should be installed in the same closet with the dryer.

Dryer must not be installed or stored in an area where it will be exposed to water

and/or weather.

Manufactured (mobile) home installation must conform to the Manufactured

Home Construction and Safety Standards, Title 24 CFR, Part 32-80 or Standard

CAN/CSA-Z240 MH.

Gas dryers must be permanently attached to the floor at the time of installation.

Order No. 526P3 Dryer Installation Kit for a manufactured (mobile) home installation.

Dryer requires 120 volt, 15 amp, 60 Hz power supply and 3-prong grounding plug.

Power cord is approximately 69" long. Do not operate other appliances on the same

circuit when this appliance is operating. Refer to serial plate for specific requirements. Wiring diagram is located in control hood.

Electrical Requirements

Natural Gas Pressure, 1000 Btu/ ft3(37.3 MJ/m3), service must be supplied at 6.5 +

1.5 inch water column pressure. L.P. (propane) Gas Pressure, 2,500 Btu/ ft3(93.1

MJ/m3), service must be supplied at 10 + 1.5 inch water column pressure.

NOTE: The dryer and its appliance main gas valve must be disconnected from the

gas supply piping system during any pressure testing of that system at test pressures

in excess of 1/2 psi (3.45 kPa). Dryer must be isolated from the gas supply piping

system by closing the equipment shut-off valve during any pressure testing of the gas

supply piping system at test pressures equal to or less than 1/2 psi (3,45 kPa).

When connecting to a gas line, an equipment shutoff valve must be installed within

6' (1.8 m) of the dryer. An 1/8" N.P.T. pipe plug must be installed.

The gas service to a gas dryer must conform with the local codes and ordances or in

the absence of local codes and ordinances, with the latest edition of the National

Fuel Gas Code ANSIZ223.1/NFPA 54 or the CAN/CGA-B149, National Gas

Installation Code. LPK1 Sales Accessory (L.P./Propane Gas Conversion Kit 649P3)

must be installed. DO NOT connect dryer to L.P./Propane Gas Service without

converting the gas valve.

Gas

Use rigid or semi-rigid duct and exhaust the dryer to the outside by the shortest

route possible. Failure to exhaust dryer properly will void warranty.

• Dryer exhaust duct must be secured to the mobile home structure. Dryer exhaust

MUST NOT terminate under the mobile home.

• Exhaust duct must not be connected to any other duct, vent or chimney.

• Venting materials are not supplied with the dryer (obtain locally). Do not use plastic or thin foil flexible ducting.

• Static pressure in the dryer’s exhaust duct should be no greater than .6 inches (1.5

cm). Check with dryer running and no load. This can be measured with a manometer placed on the exhaust duct approximately two feet (61 cm) from the dryer.

For the best exhaust system:

• Locate dryer so exhaust duct is as short as possible.

• Verify old ducts are cleaned before installing new dryer.

• Use 4 inch (10.2 cm) diameter rigid or flexible metal duct.

• Use duct tape on all joints.

• Use as few elbows as possible.

Exhaust

Installation Requirements

Before You Install…

Page 6

6

Installation Checks and Adjustments

*With leveling legs turned fully into base

23.5"

(59,7 cm)

7.7"

(19,6 cm)

4.0"

(10,2 cm)

4.0"

(10,2 cm)

28"

(71,1 cm)

.4"

(1,1 cm)

15.4"

(39,1 cm)

26.9"

(68,3 cm)

*36" (91,4 cm)

*43" (109,2 cm)

2.8"

(7 cm)

2.3"

(6 cm)

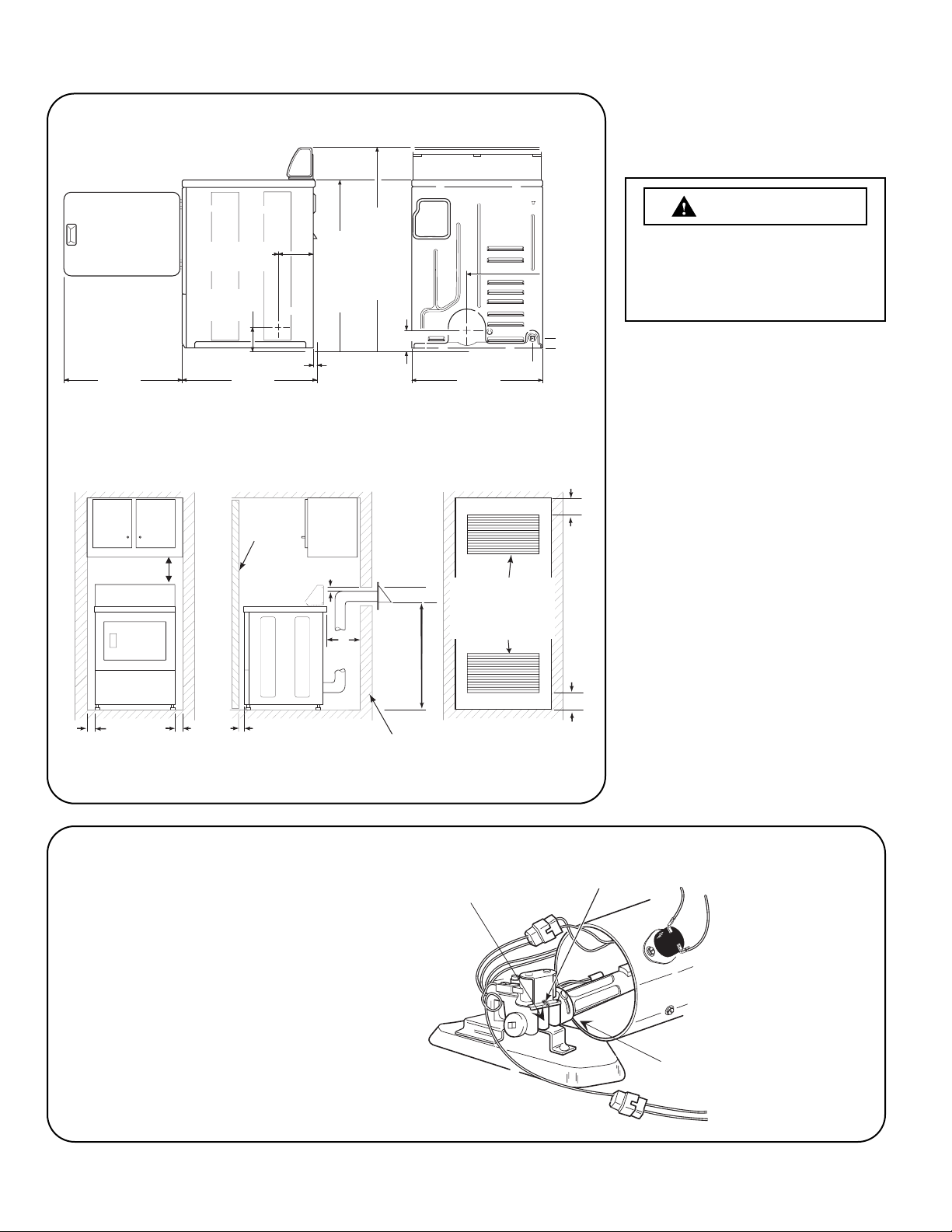

Checking Burner Flame

To view the burner flame, remove the

lower front panel of the dryer.

Adjusting Air Flow to Burner

1. Loosen air shutter lock screw.

2. Turn air shutter to left to get a

luminous yellow-tipped flame,

turn it back slowly to the right to

obtain a steady, soft blue flame.

3. After air shutter is adjusted for

proper flame, tighten air shutter

lock screw securely.

After the dryer has operated for

approximately three minutes,

exhaust air or exhaust pipe should

be warm.

Appliance main

gas valve

Air shutter

lockscrew

Air

shutter

View of burner

with front access

panel removed

WARNING

To prevent personal injury or

property damage, front panel

must be in place during normal

operation.

Close the loading door, start the

dryer in a heat setting (refer to User’s

Guide) The dryer will start, ignitor will

glow red, and main burner will ignite.

IMPORTANT: If all air is not purged

out of gas line, gas ignitor may go

off before gas is ignited. If this

happens, after approximately two

minutes ignitor will again attempt

gas ignition.

After the dryer has operated for

approximately 5 minutes, observe

burner flame through lower front

panel. Adjust air shutter to obtain a

soft, uniform blue flame. (A lazy,

yellow tipped flame indicates lack of

air. A harsh, roaring, very blue flame

indicates too much air.)

FRONT VIEW

(w/o Closet Door)

SIDE VIEW FRONT VIEW

(Closet Door)

Centered air

openings minimum

40 sq. in.

(260 sq. cm) each

Closet

Door

Outer wall of

enclosure

3" (7,6 cm)

3" (7,6 cm)

2" (5,1 cm)

2" (5,1 cm)

0"

(0 cm)

0" (0 cm)0" (0 cm)

12"

(30,5 cm)

Min.

12"

(30,5 cm)

Page 7

7

Conduit de

raccordement

à la canalisation

de gaz – acier

inoxydable, ou

tuyauterie rigide.

Ruban de téflon

ou composé

d’étanchéité des

jointures

Ruban adhésif

Clé à

molette

Tournevis

Niveau

Instructions

d’installation

Sécheuse à gaz

Conserver ces instructions comme références.

Veiller à laisser le manuel avec la sécheuse

1

RETIRER LES PIÈCES ET

NETTOYER LE TAMBOUR

DE LA SÉCHEUSE

Essuyer la surface du tambour avec un chiffon

propre et une solution d’eau tiède et de savon

(dilué) pour éliminer tout résidu d’huile de la

fabrication. Si nécessaire, on peut utiliser une

pâte constituée de détergent de buanderie

pour nettoyer le tambour.

Pour inverser le sens d’ouverture de la porte,

voir le guide de l’utilisateur.

®

Ensembles facultatifs

Ensembles disponibles contre facturation additionnelle; consulter le détaillant Maytag ou le service à la clientèle

de Maytag au

1-800-688-9900 É.-U.

1-800-688-2002 Canada

1-800-688-2080 É.-U. (seulement avec

ATS)

Ensemble pour évacuation directionnelle

Accessoires DK1 (ensemble pour

évacuation directionnelle n° 528P3).

Ensemble d’évacuation en conduit

métallique flexible

Pour le circuit d’évacuation de la

sécheuse, dans une configuration

d’accès difficile – utiliser l’ensemble

n° 521P3.

Ensemble d’installation pour résidence

mobile

Ensemble d’ancrage pour résidence

mobile n° 526P3.

Ensemble de conversion GPL/propane

Ensemble d’accessoires LPK1

(Ensemble GPL/propane n° 649P3).

Avez-vous des questions ?

Consultez le guide de l’utili-

sateur ou contactez Maytag

Appliances Sales Company au

1-800-688-9900 (États-Unis),

1-800-688-2002 (Canada),

1-800-688-2080

(É.-U. seulement avec ATS)

Matériel nécessaire

Page 8

8

2

RACCORDER LA

SÉCHEUSE AU CIRCUIT

D’ÉVACUATION

Pour assujettir les sections adjacentes du circuit d’évacuation, utiliser des brides ou du

ruban adhésif pour conduits. NE PAS utiliser

des vis à tôle ou autres articles qui

dépasseraient à l’intérieur du conduit, et qui

pourraient retenir des peluches; une accumulation de tels débris réduirait l’efficacité du

circuit d’évacuation.

IMPORTANT : Minimiser la longueur du circuit d’évacuation.

Vérifier la propreté du circuit d’évacuation

existant avant d’installer la sécheuse neuve.

Pour éviter un reflux d’air lorsque la

sécheuse ne fonctionne pas, il faut qu’une

bouche d’évacuation avec clapet de fermeture, protégée des intempéries, soit installée

à l’extrémité du circuit d’évacuation (obtenir

cet article localement).

Installer la bouche d’évacuation à au moins

30 cm (12 po) au-dessus du sol. Une distance de séparation plus élevée peut être

nécessaire dans une région exposée à d’importantes chutes de neige.

La configuration d’évacuation à travers le toit

n’a pas d’effet particulier sur la longueur du

circuit d’évacuation. Voir LA LONGUEUR

MAXIMUM indiquée dans le tableau pour la

détermination de la longueur du circuit

d’évacuation. Installer une mitre qui

permettra un débit d’air égal à celui que

produirait une bouche d’évacuation protégée

contre les intempéries.

Directions d’évacuation

L’air humide de la sécheuse peut être évacué par l’arrière, par la droite ou par le bas

de la sécheuse. Il n’est pas possible

d’évacuer l’air humide de la sécheuse par

le côté gauche, où se trouve le logement

du brûleur.

La sécheuse est configurée à l’usine pour

l’évacuation par l’arrière. Aucun ensemble de

pièces additionnel n’est nécessaire dans ce

cas.

Pour l’évacuation par le côté ou par le bas,

installer l’ensemble accessoire DK1

(ensemble pour évacuation directionnelle

n° 528P3), disponible à raison d’un coût supplémentaire, comme équipement facultatif.

Matériaux du circuit d’évacuation

Utiliser du conduit sans obstruction, de

10,2 cm (4 po) de diamètre. On recommande

l’emploi de conduit métallique. L’emploi de

conduit métallique flexible semi-rigide, non

combustible, est acceptable.

NE PAS utiliser du conduit en plastique, conduit en feuille métallique mince ou conduit en

plastique flexible; ces produits favorisent

l’accumulation de peluches, ce qui réduit la

performance de séchage et entraîne un

risque d’incendie. Pour identifier un conduit

en plastique ou conduit flexible en feuille

mince, pincer entre les doigts des spires de

l’armature; s’il est possible de rapprocher des

spires adjacentes, ne pas utiliser ce type de

conduit.

Conduit métallique

rigide

Conduit métallique

semi-rigide

Conduit

mince flexible

Conduit

en plastique

Longueur maximale du circuit d’évacuation

Conduit métallique rigide

Nombre de Bouche d’évacuation 10,2 cm (4 po) Bouche d’évacuation 6,35 cm (2-1/2 po)

coudes à 90° protégée contre les intempéries protégée contre les intempéries

0 44 pieds (13,4 m) 34 pieds (10,4 m)

1 34 pieds (10,4 m) 26 pieds (7,9 m)

2 26 pieds (7,9 m) 20 pieds (6,1 m)

3 20 pieds (6,1 m) 14 pieds (4,3 m)

Conduit métallique flexible

Nombre de Bouche d’évacuation 10,2 cm (4 po) Bouche d’évacuation 6,35 cm (2-1/2 po)

coudes à 90° protégée contre les intempéries protégée contre les intempéries

0 24 pieds (7,3 m) 20 pieds (6,1 m)

1 20 pieds (6,1 m) 16 pieds (4,9 m)

2 16 pieds (4,9 m) 12 pieds (3,7 m)

3 12 pieds (3,7 m) 8 pieds (2,4 m)

10,16 cm

(4 po)

10,16 cm

(4 po)

6,35 cm

(2-1/2 po)

Bouche d’évacuation

recommandée

(protection contre les intempéries)

Produit recommandé

seulement pour un circuit

de longueur réduite

Produits acceptables

Produits non acceptables

Page 9

9

3

RACCORDER

À LA CANALISATION

DE GAZ

Propane

NE PAS raccorder la sécheuse à une source

de gaz de pétrole liquéfié (GPL)/propane si le

dispositif d’alimentation n’a pas fait l’objet de

la conversion nécessaire. On doit installer les

composants de l’ensemble accessoire LPK1

– ensemble de conversion «propane» 649P3.

Rechercher les fuites

Après le raccordement de

l’appareil à la canalisation

de gaz, ouvrir le robinet

d’arrêt manuel et

effectuer une inspection de recherche des

fuites au niveau de chaque jointure du circuit

de gaz, selon la méthode recommandée par

le fabricant de l’appareil.

1. Appliquer une solution savonneuse sur

les connexions.

2. Si on peut observer la formation de

bulles, il y a une fuite. Fermer immédiatement le robinet d’arrêt de la canalisation.

3. Pour une fuite au niveau du raccord

installé à l’usine, resserrer le raccord.

• Pour une fuite au niveau d’une autre

jointure, dévisser le raccord, appliquer

une plus grande quantité de composé

d’étanchéité, et resserrer.

4. Effectuer de nouveau une recherche des

fuites après un resserrage ou l’addition

de composé d’étanchéité.

• Effectuer une recherche des fuites sur

toute connexion qui a été perturbée.

Utiliser un conduit de raccordement flexible

ou un tuyau rigide (consulter le code local)

pour raccorder la sécheuse à la canalisation

de gaz; voir l’illustration. Après le raccordement, effectuer une inspection de recherche

des fuites, et examiner la flamme du brûleur.

Voir la section Examen de la flamme du

brûleur, en dernière page.

• Il faut que la sécheuse soit alimentée par

le gaz identifié sur la plaque signalétique

(zone en retrait de la porte).

• Pour assurer l’étanchéité sur chaque jointure de tuyauterie, utiliser du ruban de

Pour un fonctionnement correct à une

altitude supérieure à 762 m (2 500 pi)

Pour garantir une combustion complète du

gaz, on doit réduire la taille du gicleur utilisé

pour l’alimentation au gaz naturel. Voir le

tableau.

téflon ou un composé d’étanchéité résistant à l’action du GPL/propane.

• Avant de raccorder la sécheuse à la

canalisation de gaz, éliminer tout sédiment

et résidu d’air dans la canalisation de gaz.

Avant le serrage final des raccords, purger

tout résidu d’air dans le conduit de raccordement installé entre la sécheuse et la

canalisation de gaz, jusqu’à ce qu’une

odeur de gaz soit perceptible. Cette étape

est nécessaire pour la prévention de la

contamination de la vanne d’alimentation

en gaz.

4

RACCORDER

À LA SOURCE

D’ÉLECTRICITÉ

Voir les spécifications à la section

Caractéristiques de l’installation.

Brancher la sécheuse seulement sur une

prise de courant à trois alvéoles, reliée

à la terre.

Altitude Taille du Pièce

pi (m) gicleur n° n°

3000 (915) 43 503778

6000 (1830) 44 58719

8000 (2440) 45 503779

9000 (2740) 46 503780

10000 (3050) 47 503781

5

METTRE

EN PLACE

ET DE NIVEAU

Placer la sécheuse à son

emplacement d’installation; régler la hauteur

des pieds (4) pour

établir un bon aplomb

(transversalement et

avant/arrière).

Base

de la

Sécheuse

Niveau

Pied de mise

à niveau

Tuyauterie d’acier

Moins de 6 m (20 pi) – tuyau de 0,95 cm (3/8 po)

Plus de 6 m (20 pi) – tuyau de 1,27 cm (1/2 po)

Utiliser un conduit neuf de raccordement flexible en acier inoxydable

seulement si le code local le permet (utiliser alors un conduit de

raccordement dont la conception est homologuée par l’A.G.A).

Raccord avec bouchon

Raccord 0,95 cm

(3/8 po) NPT

à filetage 0,32 cm

(1/8 po) NPT

(pour l’installation

d’un manomètre)

Installer un robinet

d’arrêt à moins de

1,8 m (6 pi) de la

sécheuse

Page 10

10

Sécurité – Information Importante

Conducteurs de liaison à la terre

Advenant qu’un court-circuit électrique se

produise, un conducteur de liaison à la terre

réduit le risque de choc électrique; il constitue un itinéraire de transmission du

courant électrique entre l’appareil et la terre.

La couleur de codage standard de l’isolant du

conducteur de liaison à la terre est vert, ou

vert avec un liséré jaune.

NE JAMAIS utiliser pour la transmission d’un

courant électrique un conducteur normalement employé pour la liaison à la terre (ou

de la même couleur).

AVERTISSEMENT

• Respecter toutes les prescriptions

des codes et règlements locaux.

• Interrompre l’alimentation électrique de

l’appareil avant d’entreprendre toute

intervention.

• Relier correctement l’appareil à la terre.

• Consulter un électricien qualifié en cas

d’incertitude quant à la qualité de la liaison à la terre de l’appareil.

• NE PAS utiliser la canalisation de gaz

pour la liaison à la terre.

• NE PAS utiliser une canalisation d’eau

froide pour la liaison à la terre si la

tuyauterie renferme des matériaux

isolants ou non conducteurs (joints en

plastique ou non métalliques, ou section

de tuyauterie non métallique).

• NE JAMAIS modifier la configuration de la

fiche de branchement. S’il n’est pas possible de brancher la fiche sur la prise de

courant, faire installer une prise de courant

adéquate par un électricien qualifié.

• NE PAS installer un fusible dans le circuit du conducteur neutre ou le circuit de

liaison à la terre; ceci entraînerait un

risque de choc électrique.

• NE PAS utiliser un câble de rallonge

pour l’alimentation de cet appareil.

• NE PAS utiliser une fiche d’adaptation

pour l’alimentation de cet appareil.

• NE PAS coincer le cordon d’alimentation.

Pour éviter un choc électrique susceptible de provoquer des blessures graves ou

mortelles :

Pour leur sécurité, les utilisateurs doivent se conformer aux instructions de ce guide pour

minimiser les risques d’incendie ou explosion et pour éviter dommages matériels, dommages corporels ou accident mortel.

• Ne jamais remiser ou utiliser de l’essence ou un autre produit liquide ou gazeux inflammable au voisinage de cet appareil ou de tout autre appareil.

• QUE FAIRE SI L’ON SENT UNE ODEUR DE GAZ

– Ne mettre aucun appareil en marche.

– Ne pas toucher à un interrupteur électrique ; n’utiliser aucun téléphone de l’immeuble.

– Se rendre chez un voisin et téléphoner immédiatement à la compagnie de gaz. Suivre

les directives données par le préposé de la compagnie de gaz.

– S’il est impossible de joindre la compagnie de gaz, téléphoner au service des

incendies.

• L’installation et les réparations doivent être confiées à un installateur compétent, à une

entreprise de service ou à la compagnie de gaz.

Instructions de Liaison à la Terre

Il faut que la sécheuse soit électriquement reliée à la terre. La sécheuse est dotée d’un cordon

d’alimentation comportant un conducteur de liaison à la terre et une fiche de branchement à trois

broches (pour liaison à la terre). On doit brancher la fiche du cordon d’alimentation directement sur

une prise de courant polarisée à trois alvéoles (avec liaison à la terre) conçue pour l’utilisation

dans un circuit 110/120 V CA 15 A.

Conserver ces instructions

AVERTISSEMENT

Pour réduire le risque d’incendie, IL

FAUT que l’air humide généré par la

sécheuse soit évacué à l’extérieur. NE

PAS placer l’extrémité du circuit d’évacuation dans un puits de fenêtre, cheminée

d’appareil à gaz, cheminée, ou zone fermée et non ventilée comme grenier,

cavité murale ou de plafond, espace

sanitaire sous un bâtiment, ou espace

dissimulé d’un bâtiment.

Pour minimiser le risque d’incendie, NE

PAS utiliser pour le circuit d’évacuation du

conduit en plastique, conduit en feuille

mince, ou conduit en plastique flexible. Ne

jamais installer un conduit flexible dans un

espace dissimulé, comme cavité murale

ou cavité de plafond.

Pour minimiser les risques d’incendie,

choc électrique, ou blessure grave ou

mortelle, on doit veiller à ce que tout le

câblage électrique et la liaison à la terre

satisfassent aux critères de l’édition la

plus récente de la norme ANSI/NFPA 70

des États-Unis, ou de la norme CSA

C22.1 (code canadien de l’électricité),

ou de tout autre code ou règlement local

applicable. C’est au propriétaire de l’appareil qu’incombe la responsabilité de

faire inspecter le câblage électrique et

les fusibles par un électricien compétent,

qui pourra vérifier que l’installation électrique de la résidence permet le fonctionnement adéquat de la sécheuse.

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

Page 11

11

Facteurs à considérer

Emplacement d’installation

Description

Pour déterminer l’espace nécessaire pour l’installation, voir les dimensions mentionnées dans le manuel.

Placer la sécheuse sur un sol ferme, en un endroit jouissant d’une alimentation en air adéquate. Dans le

cas de l’installation dans une armoire, il faut que la porte de l’armoire comporte une ouverture d’entrée

d’air d’au moins 517 cm2(80 po2).

Aucun autre appareil alimenté par un combustible ne devrait être installé dans la même armoire que la sécheuse.

Ne pas installer ou remiser la sécheuse en un endroit où elle serait exposée à de l’eau ou aux intempéries.

Dans le cas de l’installation dans une résidence mobile, on doit satisfaire aux prescriptions de la

norme CAN/CSA-Z240 MH (au Canada), ou de la norme Manufactured Home Construction and Safety

Standards (aux États-Unis).

La sécheuse à gaz doit être fixée à demeure sur le plancher lors de l’installation. Pour l’installation dans

une résidence mobile, commander l’ensemble d’installation de sécheuse n° 526P3.

Pour l’utilisation de la sécheuse, on doit disposer d’une prise de courant à trois alvéoles (reliée à la terre)

120 V 15 A 60 Hz. La longueur du cordon d’alimentation est d’environ 175 cm (69 po). Veiller à ce que le circuit de

la prise de courant n’alimente aucun autre appareil lorsque la sécheuse fonctionne. La plaque signalétique indique

les besoins spécifiques de l’appareil. On trouve un schéma de câblage sous le haut du tableau de commande.

Alimentation électrique

La sécheuse doit être alimentée en gaz naturel (capacité thermique de 37,3 MJ/m

3

[1 000 BTU/pi3]), sous

une pression de 16,5 + 3,8 cm (6,5 + 1,5 po) (colonne d’eau), ou bien en propane (capacité thermique de

93,1 MJ/m3[2 500 BTU/pi3]), sous une pression de 25,4 + 3,8 cm (10 + 1,5 po) (colonne d’eau).

REMARQUE : Pour tout test de pressurisation de la canalisation de gaz à une pression relative supérieure à

3,5 kPa (1/2 lb/po2), on doit déconnecter la sécheuse et la vanne d’alimentation en gaz de la canalisation de gaz.

Pour tout test de pressurisation de la canalisation de gaz à une pression relative égale ou inférieure à

3,5 kPa (1/2 lb/po2), on doit isoler la sécheuse et la vanne d’alimentation en gaz de la canalisation de gaz

par fermeture du robinet d'arrêt manuel.

Dans le cas du raccordement de l’appareil à une canalisation de gaz, on doit installer un robinet d’arrêt à

moins de 1,8 m (6 pi) de la sécheuse. On doit également incorporer dans la canalisation un raccord

fermé par un bouchon à filetage 0,32 cm (1/8 po) NPT.

La canalisation de gaz qui alimente la sécheuse doit être conforme aux prescriptions des codes et règlements locaux; en l’absence de code ou règlement local, elle doit satisfaire aux prescriptions de l’édition la

plus récente de la norme ANSI Z223.1/NFPA 54 (National Fuel Gas Code – aux États-Unis) ou de la

norme CAN/ACG-B149 (Code national d’installation des appareils à gaz – au Canada). Dans le cas de

l’alimentation de la sécheuse au propane, on doit installer l’ensemble accessoire LPK1 – ensemble de

conversion GPL/propane n° 649P3. NE PAS raccorder la sécheuse à une source de GPL/propane sans

avoir effectué l’opération de conversion nécessaire.

Gaz

Utiliser du conduit rigide ou semi-rigide pour réaliser le circuit d’évacuation entre la sécheuse et l’extérieur; choisir l’itinéraire le plus court possible. La garantie ne pourra être honorée si un circuit d’évacuation adéquat n’est pas associé à la sécheuse.

• Le circuit d’évacuation de la sécheuse doit être solidement fixé à la structure de la résidence mobile.

L’extrémité d’évacuation du circuit d’évacuation NE DOIT PAS se trouver sous la résidence mobile.

• Le circuit d’évacuation de la sécheuse ne doit pas être connecté à un autre conduit, à une cheminée,

ou à un conduit de ventilation.

• Les matériaux du circuit d’évacuation ne sont pas fournis avec la sécheuse (acquisition locale). Ne pas

utiliser du conduit mince ou du conduit en plastique.

• La pression statique dans le circuit d’évacuation de la sécheuse ne doit pas être supérieure à 1,5 cm

(0,6 po) (colonne d’eau). Mesurer la pression statique alors que la sécheuse fonctionne, à vide; utiliser

pour cela un manomètre installé sur le conduit d’évacuation à environ 60 cm (2 pi) de la sécheuse.

Pour optimiser l’efficacité du circuit d’évacuation :

• Choisir un emplacement d’installation permettant l’emploi du circuit d’évacuation le plus court possible.

• Veiller à nettoyer tout vieux conduit avant d’installer la sécheuse neuve.

• Utiliser du conduit métallique flexible ou rigide de 10,2 cm (4 po).

• Assurer l’étanchéité de chaque jointure avec du ruban adhésif pour conduits.

• Minimiser le nombre de coudes à 90° dans le circuit d’évacuation.

Évacuation

Caractéristiques de L’installation

Avant D’entreprendre L’installation…

Page 12

12

Contrôles et Réglages

*Avec pieds de mise à niveau complètement vissés dans la base

23,5 po

(59,7 cm)

7,7 po

(19,6 cm)

4,0 po

(10,2 cm)

28 po

(71,1 cm)

0,4 po

(1,1 cm)

15,4 po

(39,1 cm)

26,9 po

(68,3 cm)

*36 po (91,4 cm)

*43 po (109,2 cm)

2,8 po

(7 cm)

2,3 po

(6 cm)

4,0 po

(10,2 cm)

Examen de la flamme du brûleur

Pour examiner la flamme du brûleur, ôter le

panneau avant inférieur de la sécheuse.

Réglage du débit d’air d’alimentation du brûleur

1. Desserrer la vis de blocage de la virole d’admission d’air.

2. Faire tourner la virole vers la gauche pour

obtenir une flamme lumineuse à pointe jaune;

faire tourner lentement la virole vers la droite

pour obtenir une flamme bleue et ferme.

3. Après avoir établi une flamme de configuration

appropriée, bien resserrer la vis de blocage de

la virole.

Après environ trois minutes de fonctionnement de

la sécheuse, le conduit de séchage devrait être

chaud.

Vanne d’alimentation

en gaz de l’appareil

Vis de blocage de la

virole d’admission d’air

Virole

d’admission

d’air

Vue du

brûleur –

panneau

avant ôté

Pour éviter tout risque de blessure ou

de dommages matériels, on doit laisser

le panneau avant en place durant le

fonctionnement normal.

Fermer la porte de chargement; faire fonctionner la sécheuse, avec chauffage (voir le guide

de l’utilisateur). La sécheuse doit se mettre en

marche; le dispositif d’allumage devient incandescent, et le brûleur principal s’allume.

IMPORTANT : Si on n’a pas totalement

purgé l’air de la canalisation de gaz, l’incandescence du dispositif d’allumage peut

cesser avant l’inflammation du gaz. Si ceci

se produit, le dispositif d’allumage fera une

autre tentative après environ deux minutes.

Après que la sécheuse a fonctionné pendant

5 minutes environ, observer la flamme du

brûleur à travers l’ouverture du panneau avant

inférieur. Ajuster la position de la virole

d’admission d’air pour obtenir une flamme

bleue uniforme, et de forme nette. Une flamme

vacillante, avec des teintes jaunes, correspond

à une carence d’air. Une flamme très bleue qui

émet un grondement correspond à un excès

d’air.

AVERTISSEMENT

VUE AVANT

(sans porte d’armoire)

VUE LATÉRALE VUE AVANT

(porte d’armoire)

Ouvertures centrées,

d’au moins

260 cm2

(40 po2)

chacune

Porte

d’armoire

Cloison externe

de l’enceinte

7,6 cm (3 po)

7,6 cm (3 po)

5,1 cm

(2 po)

5,1 cm (2 po)

0 cm

(0 po)

0 cm

(0 po)

0 cm

(0 po)

30,5 cm

Min.

(12 po)

30,5 cm

(12 po)

Page 13

13

Conector del

Gas de Acero

Inoxidable o

Tubería Dura

Cinta Teflón o

Compuesto para

Juntas

Cinta para

Conductos

Llave

Destornilladores

Nivel

Instrucciones

de Instalación

Secadora a Gas

Conserve las instrucciones para referencia futura.

Asegúrese de que el manual se mantenga

junto con la secadora.

1

RETIRO DE PIEZAS

Y LIMPIEZA DEL

TAMBOR

Limpie el tambor con un paño limpio y

jabón diluido en agua tibia para extraer

cualquier aceite usado en la fabricación.

Haga una pasta con detergente de lavar

ropa y limpie el tambor si es necesario.

Para invertir la dirección en que se abre

la puerta, vea la Guía del Usuario.

®

Kits Opcionales

Los kits están disponibles a un costo adicional a través del distribuidor Maytag o

del Departamento de Ayuda a los

Consumidores (Maytag Customer

Assistance) llamando al

1-800-688-9900 EE.UU.

1-800-688-2002 Canadá

1-800-688-2080 Personas con problemas

auditivos o del habla – EE.UU. solamente

Kit de Evacuación Direccional

Accesorio de Venta DK1 (Kit de

Evacuación Direccional #528P3).

Kit de Evacuación de Metal Flexible

Para facilitar la instalación de un sistema

de evacuación en lugares difíciles de

alcanzar utilice el Kit #521P3.

Kit de Instalación para Casas

Prefabricadas (Móviles)

Anclaje para casas prefabricadas

Kit #256P3.

Kit de Conversión a Gas Propano

Accesorio de Venta LPK1

(Kit de Conversión a P.L./Gas Propano

#649P3).

¿Preguntas?

Consulte la Guía del Usuario o

llame a 'Maytag Appliances

Sales Company'

1-800-688-9900 EE.UU.

1-800-688-2002 Canadá

1-800-688-2080 Personas

con problemas auditivos

o del habla EE.UU. solamente

Antes de comenzar necesitará los siguientes artículos:

Page 14

14

2

CONEXION DE LA

SECADORA AL

SISTEMA DE

EVACUACION

Asegure todas las juntas con abrazaderas o

cinta para conductos. NO use tornillos para

chapas de metal ni ningún otro método de

sujeción que se extienda hacia el interior del

conducto para unir las juntas del conducto

de evacuación. Los tornillos pueden atrapar

pelusas y reducir la eficacia del sistema de

evacuación.

IMPORTANTE: Mantenga el conducto de

evacuación tan corto como sea posible.

Asegúrese de que los conductos de evacuación antiguos estén limpios antes de instalar su nueva secadora.

A fin de evitar contracorriente cuando la

secadora no está en funcionamiento, se

debe instalar una caperuza exterior con reguladores abisagrados (obtener localmente)

en el extremo exterior del conducto de evacuación.

Las caperuzas exteriores deben instalarse

por lo menos a 12" (30,5 cm) sobre el suelo.

Puede que sea necesario instalarlas a mayor

distancia en las áreas donde pueden ocurrir

nevadas fuertes.

No es necesario alargar el sistema cuando la

evacuación se realiza a través del techo.

Use la tabla sobre el LARGO MAXIMO DEL

CONDUCTO DE EVACUACION para calcular el largo del sistema de evacuación. Use

una caperuza de techo que proporcione flujo

de aire igual que la caperuza exterior.

Direcciones del Conducto de Evacuación

La secadora puede ser evacuada al exterior

a través de la parte trasera, del lado derecho

o por la parte inferior de la secadora. Las

secadoras a gas no pueden ser evacuadas por el lado izquierdo debido a la

caja del quemador.

La secadora es enviada desde la fábrica lista

para evacuación por la parte trasera. No se

necesitan kits especiales.

Para evacuar la secadora a través de los

costados o por la parte inferior, instale el

Accesorio de Venta DK1 (Kit de Evacuación

Direccional 528P3). Disponible como equipo

opcional a un costo adicional.

Materiales del Sistema de Evacuación

Los conductos de evacuación deben ser de

cuatro pulgadas (10,2 cm) de diámetro sin

obstrucciones. Se recomiendan los conductos de metal rígido. Los conductos de metal

flexible semirígido no combustible son aceptables.

NO use tubos de plástico, tubos de papel

metálico ni tubos de plástico flexible porque

contribuyen a un rendimiento deficiente del

secado y acumulan pelusas, lo cual puede

conducir a un riesgo de incendio. Para identificar el conducto de papel metálico flexible

o el conducto de plástico, apriete las espiras

entre sus dedos. Si las espiras pueden juntarse, no use el conducto.

Plastico

Papel Metálico

Flexible

Metal Rígido

Metal Semirígido

Largo Máximo del Conducto de Evacuación

Conducto de Metal Rígido

Número de Caperuza Exterior con Caperuza Exterior con

Codos de 90° Abertura de 4 pulgadas Abertura de 2-1/2 pulgadas

0 44 pies (13,4 m) 34 pies (10,4 m)

1 34 pies (10,4 m) 26 pies (7,9 m)

2 26 pies (7,9 m) 20 pies (6,1 m)

3 20 pies (6,1 m) 14 pies (4,3 m)

Conducto de Metal Flexible

Número de Caperuza Exterior con Caperuza Exterior con

Codos de 90° Abertura de 4 pulgadas Abertura de 2-1/2 pulgadas

0 24 pies (7,3 m) 20 pies (6,1 m)

1 20 pies (6,1 m) 16 pies (4,9 m)

2 16 pies (4,9 m) 12 pies (3,7 m)

3 12 pies (3,7 m) 8 pies (2,4 m)

(4")

10,16 cm

(4")

10,16 cm

(2-1/2")

6,35 cm

Caperuza Exterior Recomendada

Recomendada para instalaciones

Cortas Solamente

Use

No Use

Page 15

15

5

UBICACION Y

NIVELACION DE

LA SECADORA

Coloque la secadora en el

lugar definitivo, ajuste los

(4) tornillos niveladores

hasta que la secadora

quede nivelada de

lado a lado y de

adelante hacia atrás.

3

CONEXION DEL

SUMINISTRO DE

GAS

P.L./Gas Propano

NO conecte la secadora al servicio de P.L./

Gas Propano sin antes modificar la válvula

del gas. Se debe instalar un Accesorio de

Venta LPK1 consistente en un Kit # 649P3

de Conversión a P.L./Gas Propano.

Verifique si hay escapes de gas

Después de que se haga

la última conexión del

gas, gire la válvula

manual del gas y pruebe

todas las conexiones en

la tubería de suministro

del gas para verificar si hay escapes. La

comprobación de escapes en el artefacto

debe ser realizada de acuerdo con las

instrucciones del fabricante.

1. Coloque espuma de jabón en las

conexiones.

2. Si aparecen burbujas, existe un escape.

Cierre la válvula de suministro del gas.

3. Apriete la junta si el escape está en un

accesorio de fábrica.

• Si el escape no está en un accesorio

de fábrica, destornille, aplique más

compuesto para juntas y apriete para

corregir la junta.

4. Vuelva a probar la conexión para verificar

si hay escape después de apretar o agregar compuesto para juntas.

• Vuelva a probar todas las conexiones

que fueron perturbadas.

Conecte el suministro de gas a la secadora

usando un conector flexible de acero inoxidable o una tubería dura (verifique los códigos

locales) de acuerdo con la ilustración.

Verifique si hay escapes y verifique además

la llama del quemador después de que haya

conectado el suministro de gas. Ver la

sección 'Verificación de la Llama del

Quemador' en la última página.

• La secadora debe ser conectada al tipo de

gas que se indica en la placa de datos

ubicada en el rebajo de la puerta.

Para funcionamiento apropiado en altitudes sobre 2,500 pies (762m)

Se debe reducir el tamaño de la tobera del

mechero de la válvula de gas natural para

asegurar una combustión completa. Ver la

tabla.

• Use compuesto para juntas de tubos que

no sea soluble en Propano Líquido o Gas

Propano o cinta Teflón en todas las roscas

de la tubería.

• Purgue el aire y sedimentos de la tubería

de suministro del gas antes de conectarla

a la secadora. Antes de apretar la

conexión, purgue el aire restante de la

tubería del gas a la secadora hasta que se

perciba olor a gas. Este paso es requerido

para evitar contaminación de la válvula

del gas.

4

ENCHUFE EL

CORDON ELECTRICO EN EL

TOMACORRIENTE

Ver la sección 'Requerimientos de la

Instalación'. Enchufe la secadora en un

tomacorriente puesto a tierra de 3

tomas solamente.

Base

de la

Secadora

Nivel

Tornillo

Nivelador

Use un conector nuevo flexible de acero inoxidable

solamente si lo permiten los códigos locales

(use el conector certificado por la A.G.A.)

Conexión del gas

de 3/8" (9,5 mm)

NPT

Ta p ón de tubería de 1/8"

(3,2 mm) NPT (para verificar

la presión de entrada del gas)

Instalar la válvula de cierre del

equipo dentro de 6' (1,8 m) de

la secadora

Tubería de hierro negra

Más corta que 20' (6,1 m) - use tubería de 3/8" (9,5 mm

Más larga que 20' (6,1 m) - use tubería de 1/2" (12,7 mm)

Altitud # del Tamaño de Número del

Pies (m) la Tobera Repuesto

3000 (915) 43 503778

6000 (1830) 44 58719

8000 (2440) 45 503779

9000 (2740) 46 503780

10000 (3050) 47 503781

Page 16

16

Información Importante sobre Seguridad

Alambres de Puesta a Tierra

En caso de un cortocircuito eléctrico, el

alambre de puesta a tierra reduce el riesgo

de sufrir un choque eléctrico permitiendo que

la corriente eléctrica escape a través del

alambre.

El código de color estándar aceptado para

los alambres de puesta a tierra es verde o

verde con una franja amarilla.

Los alambres de puesta a tierra y los

alambres de color similares a los de puesta

a tierra NO deben ser usados como

con

ductores portadores de corriente

eléctrica.

ADVERTENCIA

• Observe todos los c digos y

reglamentos locales.

• Desenchufe la secadora antes de

cualquier reparación.

• Ponga a tierra la secadora de manera

correcta.

• Consulte con un electricista calificado si

no está seguro de que este aparato esté

debidamente puesto a tierra.

• NO ponga a tierra en una tubería de

gas.

• NO ponga a tierra en una tubería de

agua fría si la tubería contiene empaquetaduras plásticas, no metálicas u

otros materiales aisladores (no

conductores).

• NO modifique el enchufe del cordón

eléctrico. Si el enchufe no calza en el

tomacorriente eléctrico, haga instalar un

tomacorriente apropiado por un electricista calificado.

• NO coloque un fusible en el circuito neutro o de puesta a tierra. Un fusible en el

circuito neutro o de puesta a tierra

puede ocasionar un choque eléctrico.

• NO use un adaptador con este electrodoméstico.

• NO use un cordón de extensión con este

artefacto.

• NO apriete el cordón eléctrico.

A fin de reducir el riesgo de lesión personal o mortal debido a un choque eléctrico:

A fin de evitar una lesión personal o mortal o daños materiales, debido a un incendio o

explosión, se debe seguir estrictamente la información contenida en este manual:

• No almacene ni utilice gasolina u otros vapores y líquidos inflamables en la proximidad

de éste o de cualquier otro artefacto.

• QUE DEBE HACER SI PERCIBE OLOR A GAS

– NO trate de encender ningún artefacto eléctrico.

– NO toque ningún interruptor eléctrico; NO use ningún teléfono en su edificio.

– Llame inmediatamente a su proveedor de gas desde el teléfono de un vecino. Siga

las instrucciones del proveedor de gas.

– Si no logra comunicarse con su proveedor de gas, llame al departamento de

bomberos.

• La instalación y el servicio de mantenimiento debe realizarlo un instalador calificado, la

agencia de servicios o el proveedor de gas.

Instrucciones para la Puesta a Tierra

La secadora debe ser puesta a tierra. La secadora está equipada con un cordón que tiene un

conductor de puesta a tierra y un enchufe con puesta a tierra de 3 clavijas. El enchufe con puesta

a tierra de 3 clavijas del cordón eléctrico debe ser enchufado directamente en un tomacorriente

polarizado puesto a tierra de 3 tomas para 110/120 V CA (corriente alterna) 15 amperes.

Conserve Estas Instrucciones

ADVERTENCIA

A fin de reducir el riesgo de incendio,

la secadora DEBE ser evacuada al

exterior. NO evacue el aire de la

secadora en el espacio que rodea una

ventana, en un conducto de evacuación de gas, chimenea o en un

área cerrada sin ventilación, tal como

un ático, pared, techo, sótano entre el

primer piso y el terreno natural de un

edificio o espacio oculto de un edificio.

A fin de reducir el riesgo de incendio,

NO use tubería de plástico, tubería de

papel metálico o tubería de plástico

flexible para el conducto de evacuación de la secadora. Nunca instale

conducto flexible en espacios ocultos,

tales como una pared o techo.

A fin de reducir el riesgo de incendio,

choque eléctrico, lesión grave o mortal, todo el cableado y puesta a tierra

debe estar de acuerdo con la última

edición del Código Eléctrico Nacional,

ANSI/NFPA 70 o con el Código

Eléctrico Canadiense, CSA C22.1 y

con todos los reglamentos locales

aplicables. Es responsabilidad del

cliente hacer revisar el cableado y los

fusibles por un electricista calificado

para asegurarse de que su hogar

tiene la energía eléctrica adecuada

para hacer funcionar la secadora.

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

Page 17

17

Requerimientos

Ubicación

Descripción

Use las dimensiones indicadas en el manual para determinar el espacio necesario para la instalación.

Coloque la secadora sobre suelo firme en un lugar con suministro de aire adecuado. La puerta de un

closet debe tener por lo menos un respiradero de aire de 80 pulg

2

(517 cm2).

No debe instalarse ningún otro artefacto que queme combustible en el mismo closet con la secadora.

La secadora no debe ser instalada o guardada en un lugar donde estará expuesta al agua y/o a las

inclemencias del tiempo.

La instalación en casas prefabricadas (móviles) debe ser de acuerdo con las Normas de Seguridad y

Construcción de Casas Prefabricadas, Título 24 CFR, Parte 32-80 o la Norma CAN/CSA-Z240 MH.

Las secadoras a gas deben ser permanentemente aseguradas al piso en el momento de la instalación.

Solicite el Kit de Instalación de Secadora No. 526P3 para una instalación en una casa prefabricada

(móvil).

La secadora requiere un suministro eléctrico de 120 voltios, 15 amp., 60 Hz y un enchufe con puesta a

tierra de 3 clavijas. El cordón eléctrico es de 69" (175 cm) de largo. No haga funcionar otros electrodomésticos en el mismo circuito cuando la secadora esté funcionando. Consulte la placa de serie para los requerimientos específicos. El diagrama del cableado se encuentra en el interior de la tapa del protector trasero.

Requerimientos Eléctricos

Con alimentación a gas natural, capacidad térmica de 1000 Btu/pies

3

(37,3 MJ/m3), el suministro debe ser

a una presión de 6,5 + 1,5 pulgadas (columna de agua).

Con alimentación a gas propano líquido, capacidad térmica de 2.500 Btu/pies

3

(93,1 MJ/m3), el sumi-

nistro debe ser a una presión de 10 + 1,5 pulgadas (columna de agua).

NOTA: La secadora y su válvula de gas principal deben desconectarse de la tubería de suministro del

gas durante cualquier prueba de la presión de la tubería cuando se utilicen presiones de prueba que

sobrepasen 1/2 libra/pulg2(3,45 kPa). La secadora debe ser aislada de la tubería de suministro del gas

cerrando la válvula de cierre del equipo durante cualquier prueba de la presión de la tubería de suministro del gas a presiones de prueba iguales o inferiores a 1/2 libra/pulg

2

(3,45 kPa).

Cuando se conecta a una tubería de gas, se debe instalar una válvula de cierre del equipo a una distancia de 6' (1,8 m) de la secadora. Se debe instalar en la tubería un tapón de 1/8" NPT.

El suministro de gas de una secadora a gas debe cumplir con todos los códigos y reglamentos locales o

en ausencia de los códigos y reglamentos, con la última edición del Código Nacional de Gas Combustible

ANSI Z223.1/NFPA 54 o el Código Nacional de Instalación de Gas CAN/CGA-B149. Se debe instalar el

Accesorio de Venta LPK1 (Kit 649P3 de Conversión a Propano Líquido/Gas Propano). NO conecte la

secadora a propano líquido/gas propano sin antes haber convertido la válvula del gas.

Gas

Use conducto rígido o semirígido y evacue la secadora al exterior mediante la ruta más corta posible. Si

el sistema de evacuación de la secadora no es apropiado, la garantía queda inválida.

• El conducto de evacuación de la secadora debe estar asegurado a la estructura de la casa móvil. El

conducto de evacuación NO DEBE terminar debajo de la casa móvil.

• El conducto de evacuación no debe estar conectado a ningún otro conducto, respiradero o chimenea.

• Los materiales de la ventilación no son suministrados con la secadora (obtener localmente). No use

conducto flexible de plástico o papel metálico delgado.

• La presión estática en el conducto de evacuación de la secadora no debe ser superior a 0,6 pulgadas

(1,5 cm). Verifique con la secadora funcionando y sin carga. Esto puede ser medido con un manómetro

colocado en el conducto de evacuación aproximadamente a dos pies (61 cm) de la secadora.

Para el mejor sistema de evacuación:

• Ubique la secadora de modo que el conducto de evacuación sea tan corto como sea posible.

• Verifique que los conductos antiguos estén limpios antes de instalar la nueva secadora.

• Use un conducto rígido o de metal flexible de 4 pulgadas (10,2 cm) de diámetro.

• Use cinta para conductos en todas las juntas.

• Use la menor cantidad de codos que sea posible.

Evacuación

Requerimientos de Instalación

Antes de la instalación.....

Page 18

18

Ajustes y Verificación de la Instalación

*Con los tornillos niveladores girados totalmente hacia el interior de la base

23,5"

(59,7 cm)

7,7"

(19,6 cm)

4,0"

(10,2 cm)

28"

(71,1 cm)

0,4"

(1,1 cm)

15,4"

(39,1 cm)

26,9"

(68,3 cm)

*36" (91,4 cm)

*43" (109,2 cm)

2,8"

(7 cm)

2,3"

(6 cm)

4,0"

(10,2 cm)

Verificación de la Llama del Quemador

Para ver la llama del quemador, retire el panel

inferior delantero de la secadora

Ajuste del Flujo de Aire al Quemador

1. Afloje el tornillo de seguridad del obturador del

aire.

2. Gire el obturador del aire a la izquierda para

obtener una llama de punta amarilla luminosa,

gírelo lentamente a la derecha para obtener una

llama constante azul clara.

3. Después de ajustar el obturador de aire para

obtener la llama apropiada, apriete firmemente el

tornillo de seguridad del obturador del aire.

Después de que la secadora ha funcionado durante

aproximadamente tres minutos, el aire de evacuación

o el conducto de evacuación debe estar tibio.

Válvula de gas

principal

del artefacto

Tornillo de seguridad

del obturador de aire

Obturador

del aire

Vista del quemador

sin el panel de

acceso delantero

ADVERTENCIA

Para evitar una lesión personal o daños

materiales, el panel delantero debe

estar colocado en su lugar durante el

funcionamiento normal de la secadora.

Cierre la puerta de carga de la secadora,

ponga en marcha la secadora en un ajuste de

calor (consulte la Guía del Usuario). La

secadora comenzará a funcionar, el encendedor se enrojecerá y el quemador principal se

encenderá.

IMPORTANTE: Si no se ha purgado todo el

aire de la tubería del gas, el encendedor del

gas se apagará antes de que el gas se

encienda. Si esto sucede, después de

aproximadamente dos minutos el encendedor tratará nuevamente de encender el gas.

Después de que la secadora haya funcionado

durante aproximadamente 5 minutos , observe

la llama del quemador a través del panel inferior delantero. Ajuste el obturador del aire para

obtener una llama suave uniforme de color

azul. (una llama de punta amarilla indica falta

de aire. Una llama fuerte, ruidosa muy azul

indica demasiado aire.)

VISTA DE FRENTE

(sin la puerta del closet)

VISTA LATERAL VISTA DE FRENTE

(Puerta del Closet)

Las aberturas

centradas del aire

deben ser por lo menos

de 40 pulg.2 (260 cm2)

cada una

Puerta

del

Closet

Pared exterior

del recinto

3" (7,6 cm)

3" (7,6 cm)

2" (5,1 cm)

2" (5,1 cm)

0"

(0 cm)

0" (0 cm)0" (0 cm)

12"

(30,5 cm)

12"

(30,5 cm)

Mín.

Page 19

19

Notes

Page 20

Part No. 40136401 Printed in U.S.A. 11/01

MAYTAG • 403 West Fourth Street North • P.O. Box 39 • Newton, Iowa 50208

Loading...

Loading...