Page 1

16023083

Page 2

16023083

Page 3

INTRODUCTION

The information presented in this manual is printed in a loose format and is divided into

sections relating to a general group of components and/or service procedures. Each

section is further subdivided to describe a particular component or service procedure.

Anything of a unique nature concerning these models has been detailed and labeled as

such in the manual.

The subdividing of the subject matter, plus the loose leaf form will facilitate the updating of the manual as new or revised components are added or new models are introduced.

Each page of the manual will be identified in the lower right-hand corner, and as new or

revised pages are published, the manual can easily be updated by following the file

instructions on the cover letter of the supplement.

The service manual is a valuable tool and care should be taken to keep it up to date by

prompt and proper filing of subsequent pages as they are used.

MODELS COVERED IN THIS MANUAL

DLW231*

PAV2300*

PAV3300*

PAV5000*

PAV5157*

PAV5158*

PAV1000AW*

PAV2000AW*

PAVT344*

HAV2460*

PAVT244*

PAVT234*

HAV2360*

MAV2200*

HAV2557*

HAV2558*

HAV3460*

PAVT444*

HAV4657*

16023083

INTRODUCTION i

© 1996 Maytag Corporation

Page 4

16023083

© 1996 Maytag Corporation

INTRODUCTION

ii

Page 5

CONTENTS

SECTION 1. INSTALLATION ...............................................................1-1

PRE-INSTALLATION REQUIREMENT ..........................................................................1-1

Water Supply Requirements ..................................................................................1-1

Drain Requirements ................................................................................................1-1

Electrical Requirements ..........................................................................................1-2

INSTALLATION PROCEDURE......................................................................................1-2

SECTION 2. OUTLINE OF MECHANICAL OPERATION...................2-1

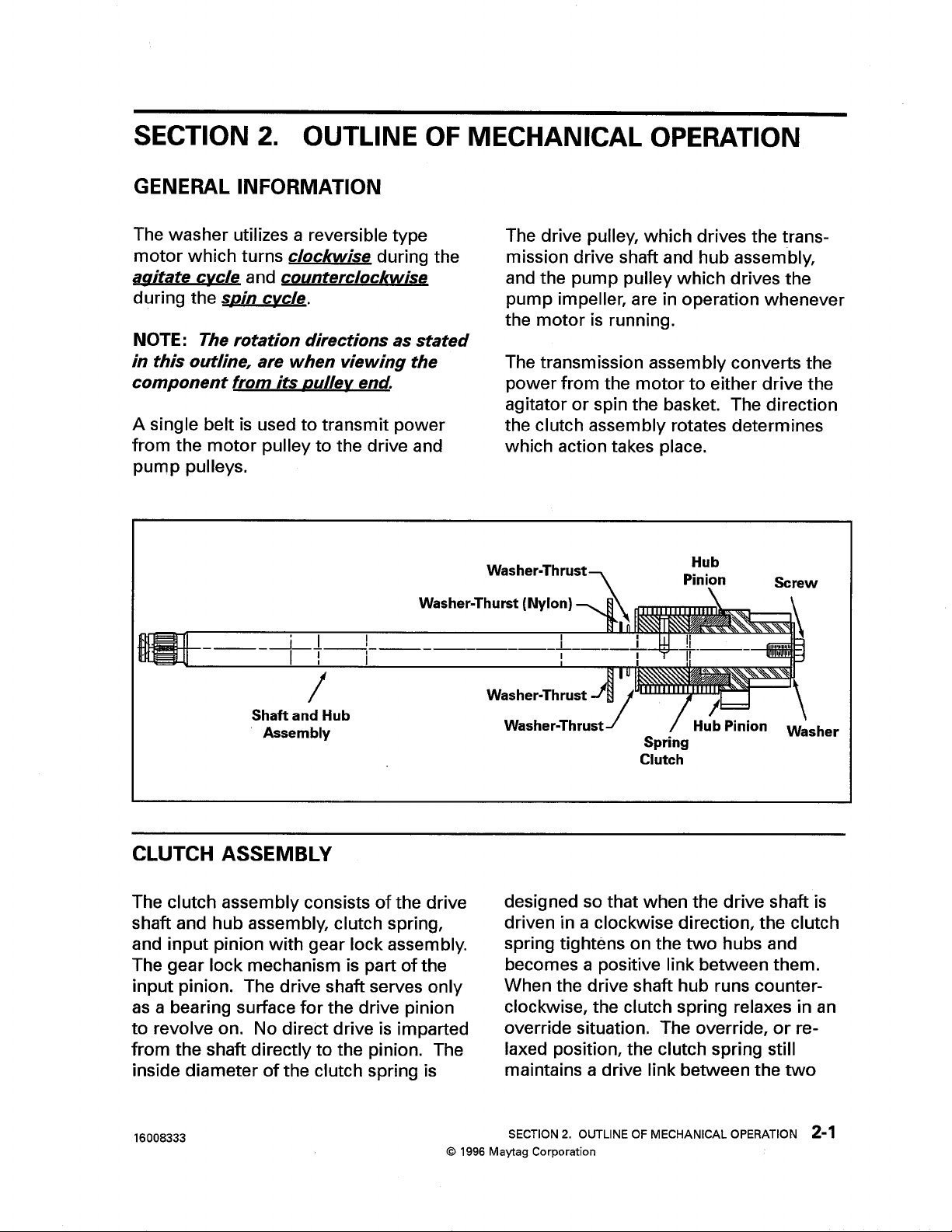

CLUTCH ASSEMBLY...................................................................................................2-1

AGITATION ..................................................................................................................2-2

SPIN .............................................................................................................................2-2

SECTION 3. CABINET ASSEMBLY COMPONENTS ......................... 3-1

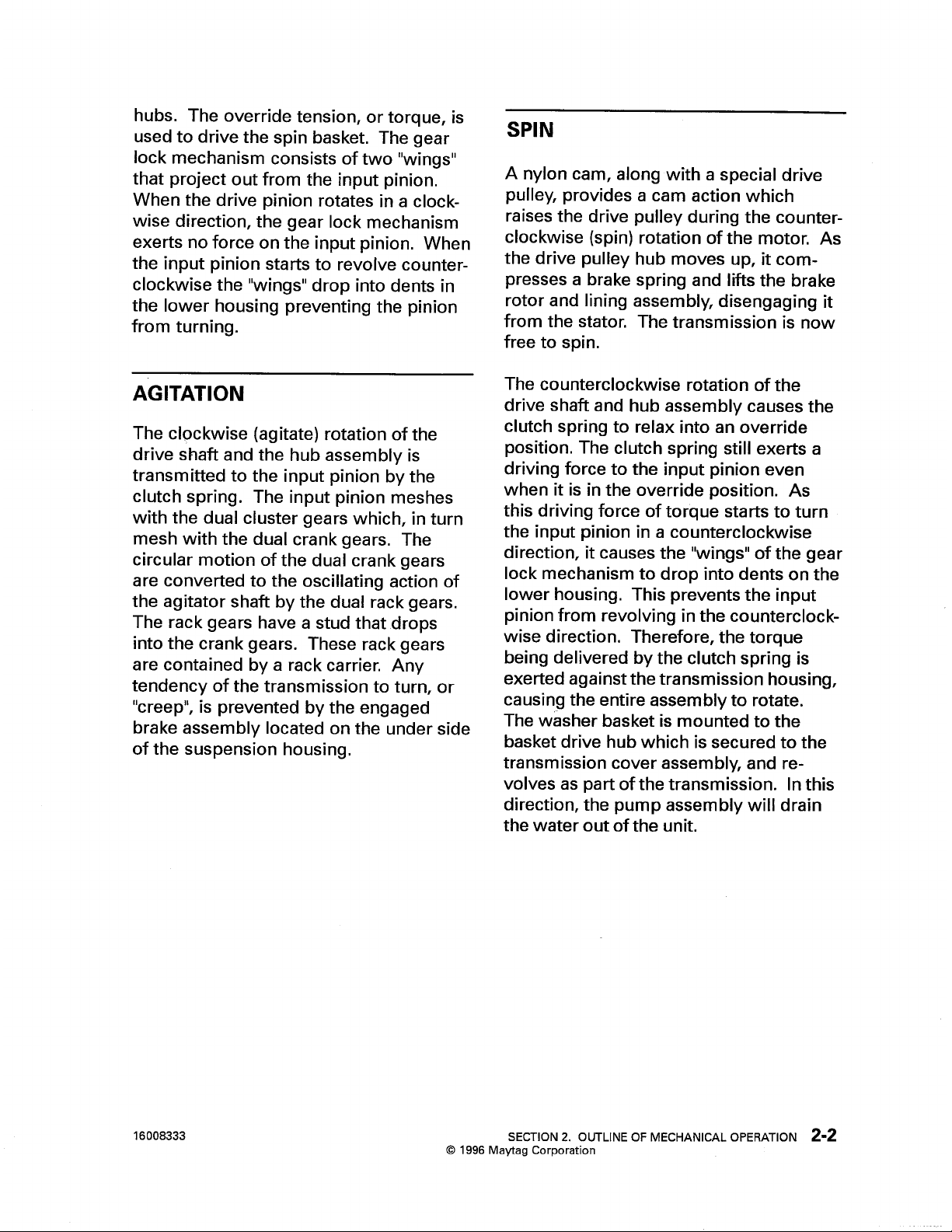

CABINET BODY ASSEMBLY ......................................................................................3-1

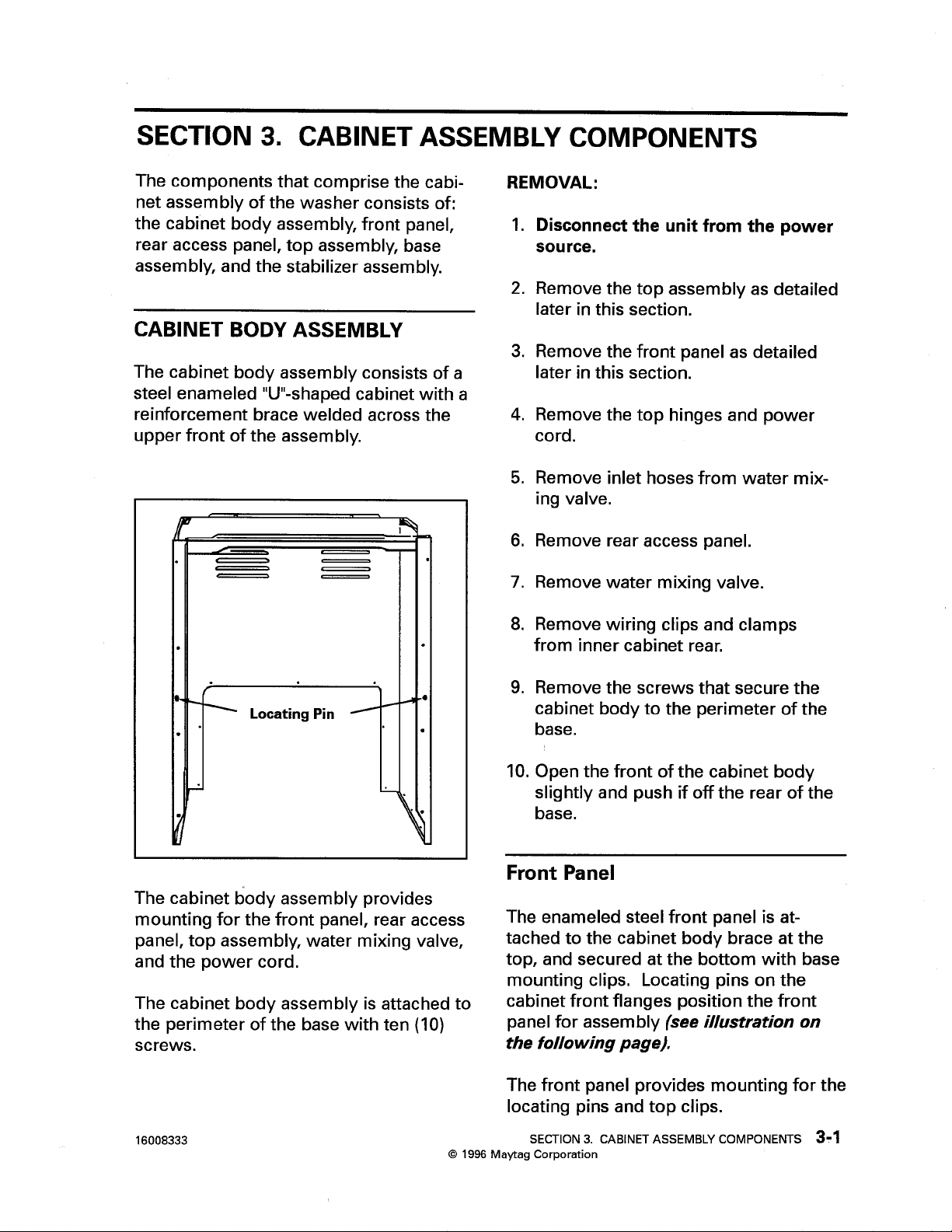

Front Panel .............................................................................................................3-1

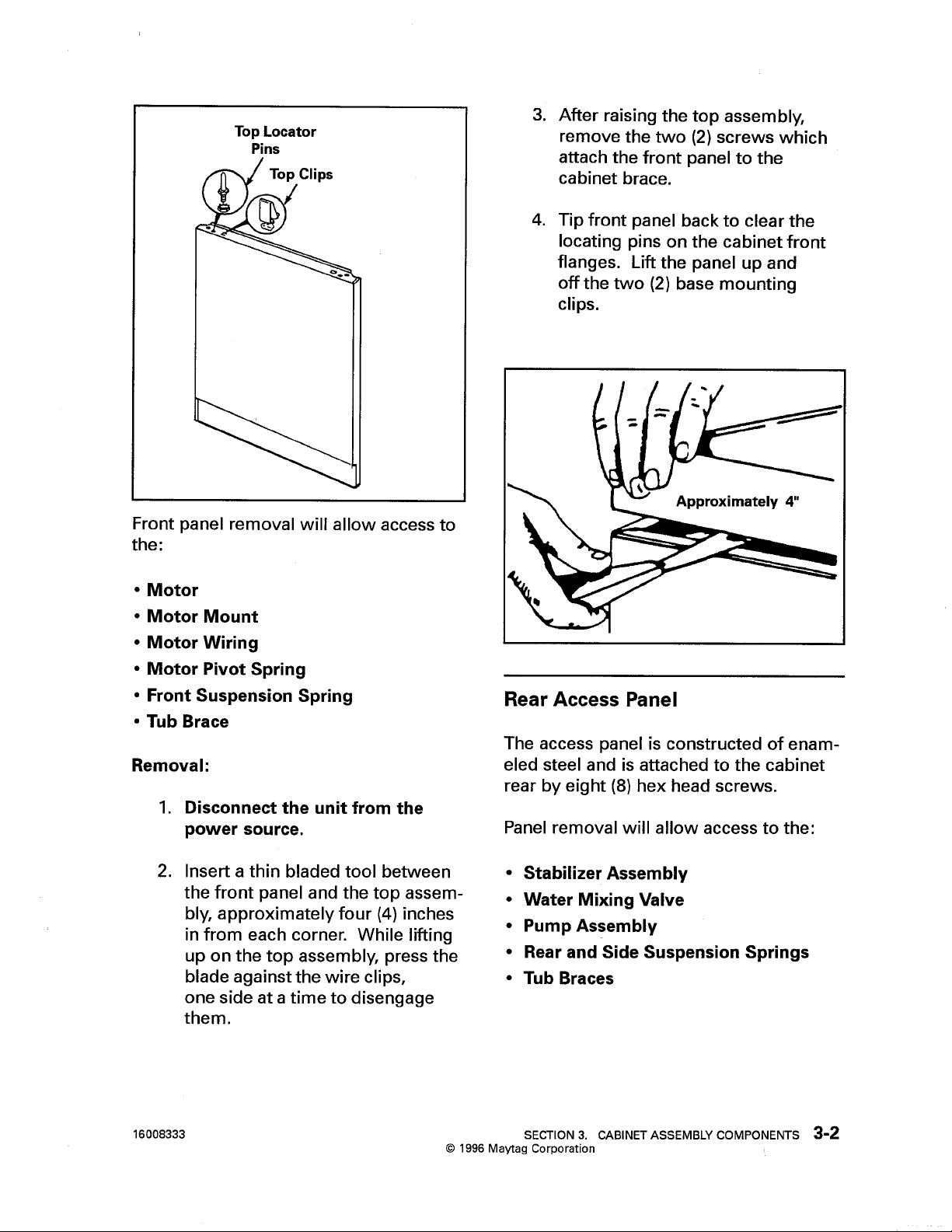

Rear Access Panel .................................................................................................3-2

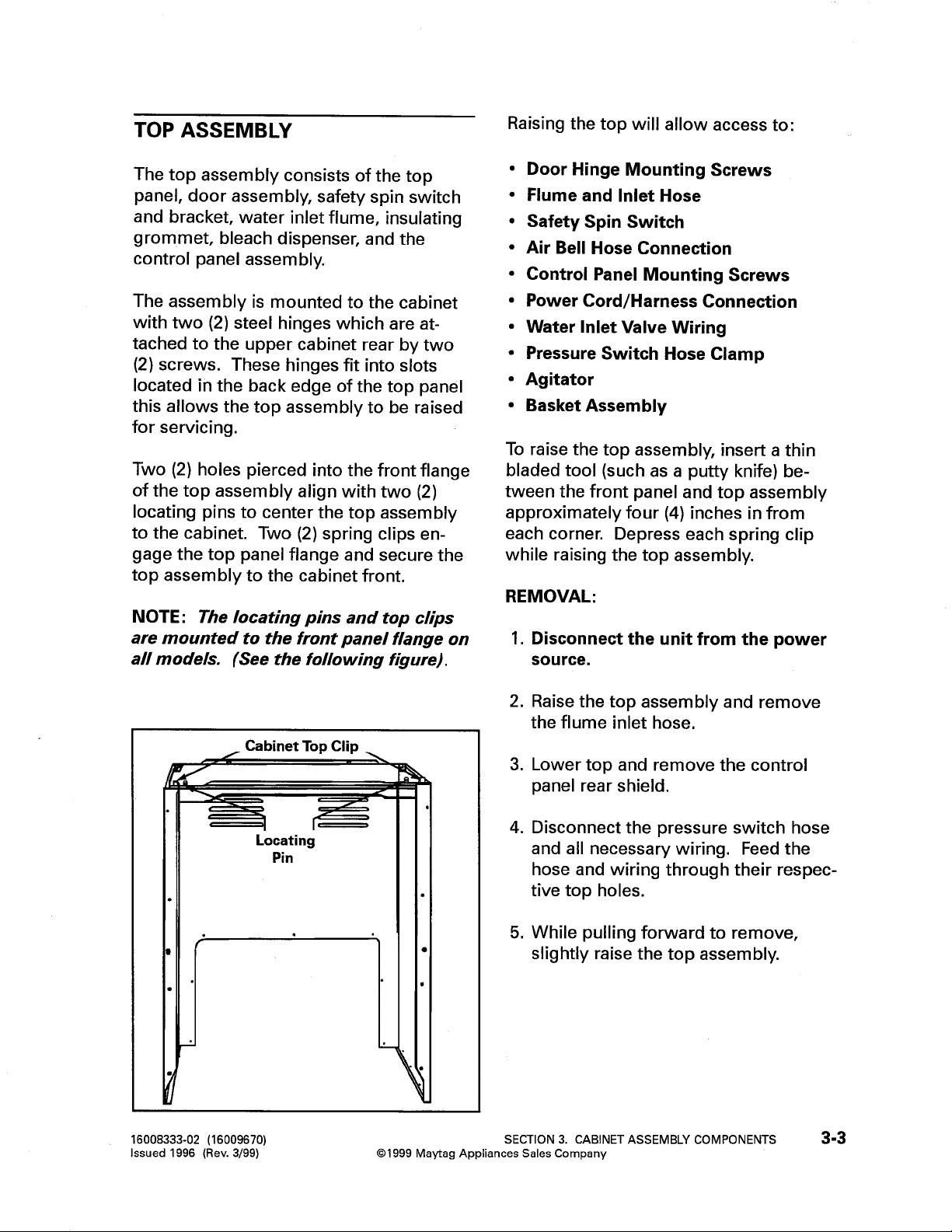

TOP ASSEMBLY..........................................................................................................3-3

DOOR ASSEMBLY ......................................................................................................3-4

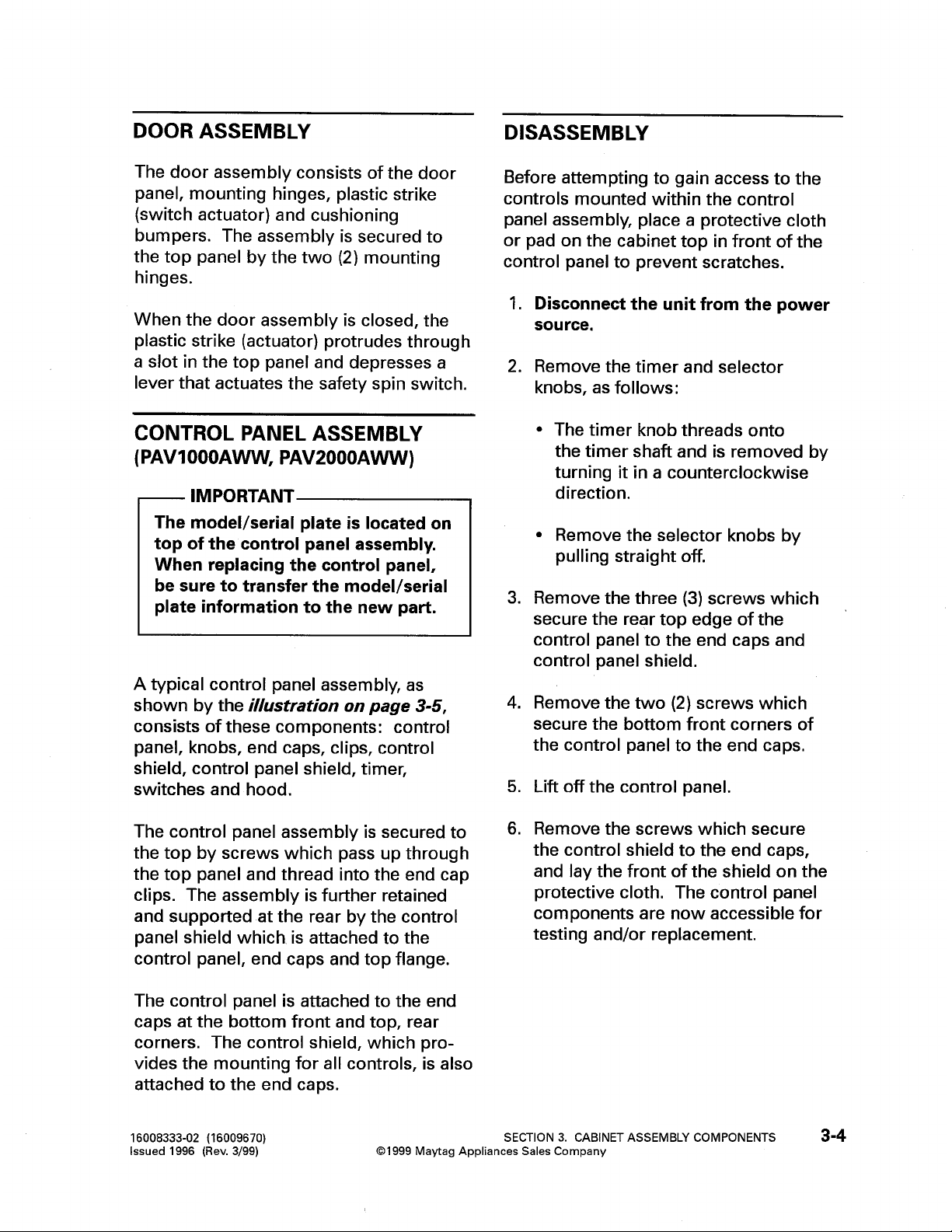

CONTROL PANEL ASSEMBLY (PAV1000AWW, PAV2000AWW) ............................3-4

Disassembly...........................................................................................................3-4

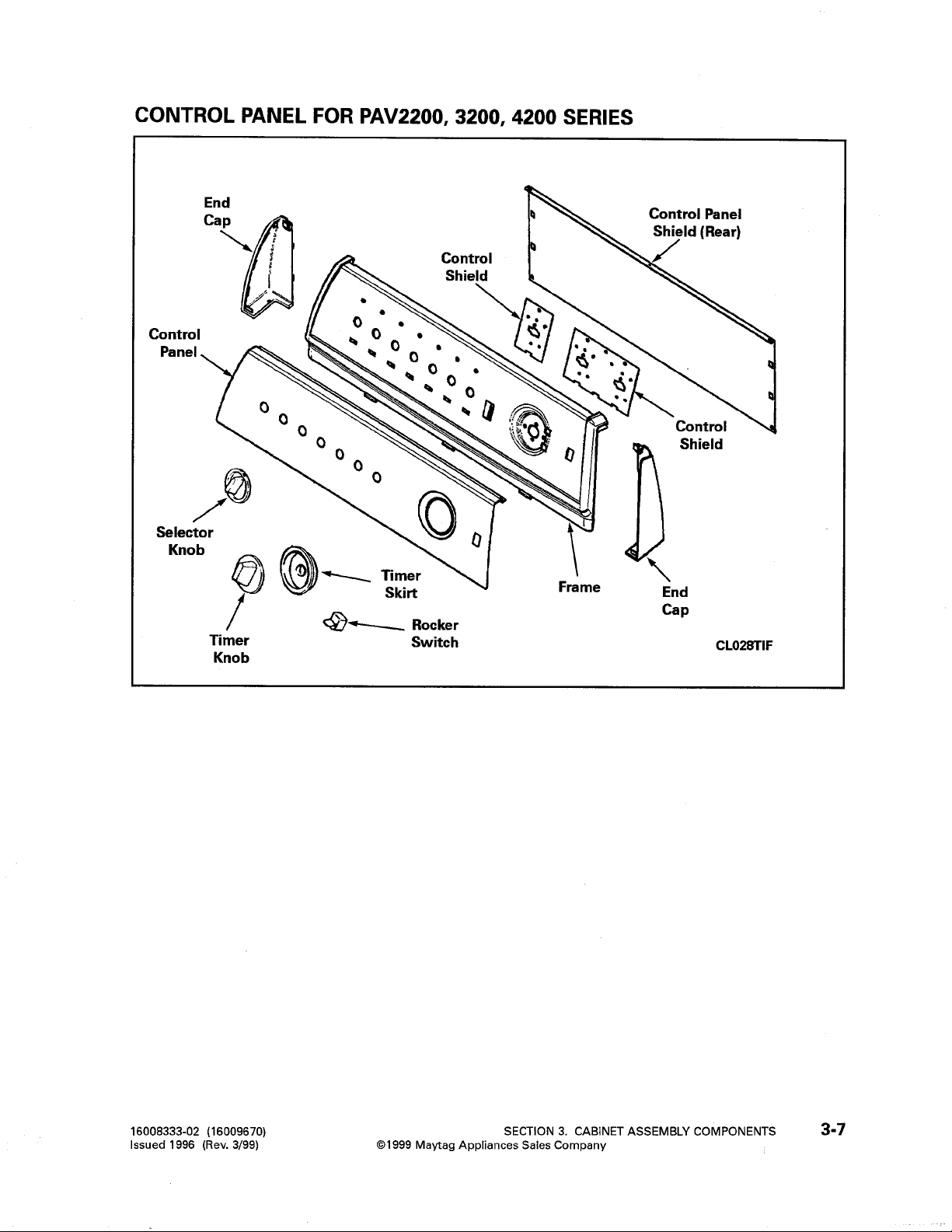

CONTROL PANEL ASSEMBLY (PAV2200, 3200, 4200).............................................3-6

Disassembly...........................................................................................................3-6

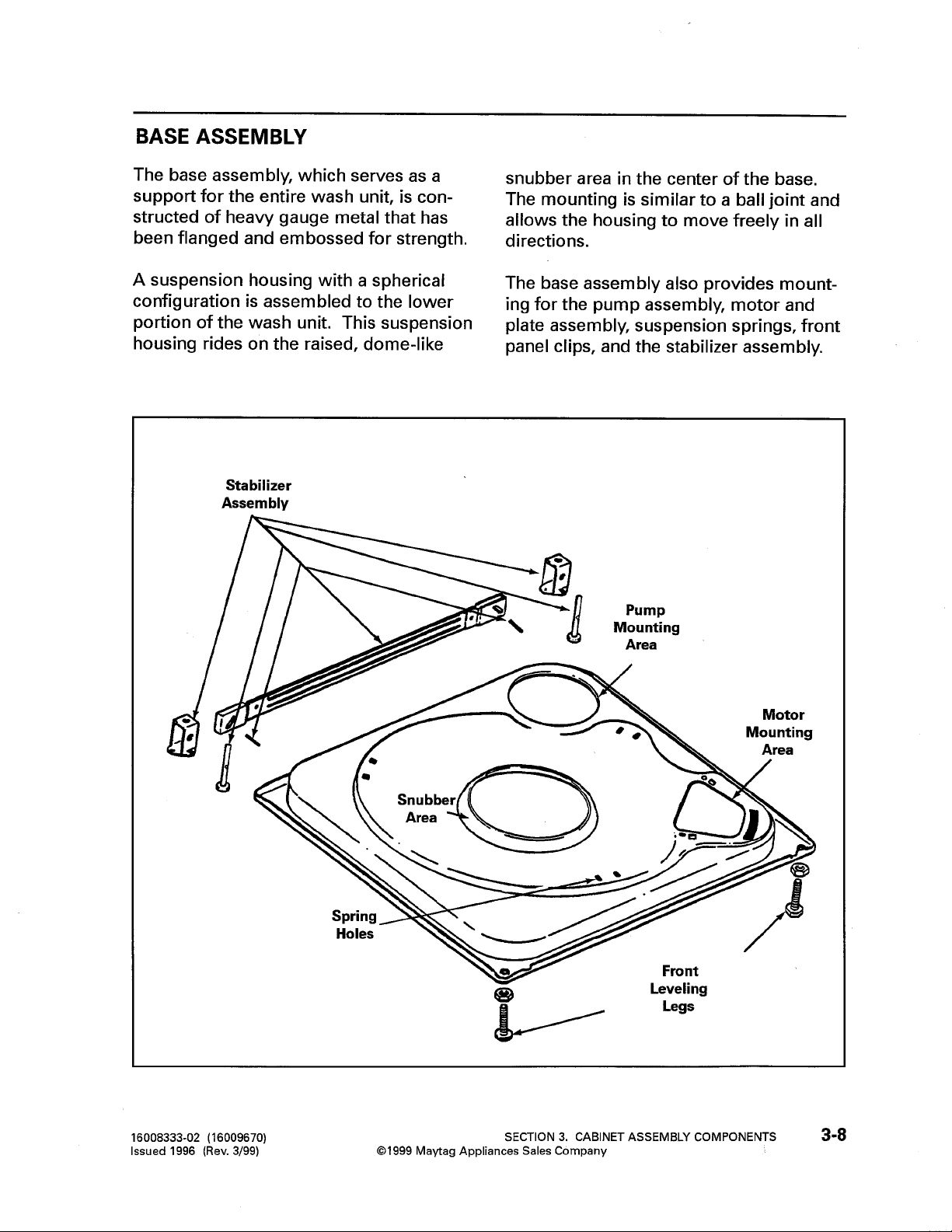

BASE ASSEMBLY .......................................................................................................3-8

STABILIZER ASSEMBLY.............................................................................................3-9

SECTION 4. WATER RELATED COMPONENTS ................................4-1

WATER MIXING VALVE ..............................................................................................4-2

WATER INLET FLUME..................................................................................................4-3

AIR BELL ......................................................................................................................4-3

HOSES.........................................................................................................................4-3

TUB TOP ......................................................................................................................4-4

AGITATOR (PAV1000AWW, PAV2000AWW) ............................................................ 4-4

AGITATOR (PAV2200, 3200, 4200).............................................................................4-5

SPIN BASKET ..............................................................................................................4-5

OUTER TUB ASSEMBLY.............................................................................................4-6

PUMP ASSEMBLY .......................................................................................................4-7

SECTION 5. SUSPENSION SYSTEM (PAV1000AWW, PAV2000AWW) ... 5-1

SUSPENSION SYSTEM (PAV2200, 3200, 4200)........................................................5-2

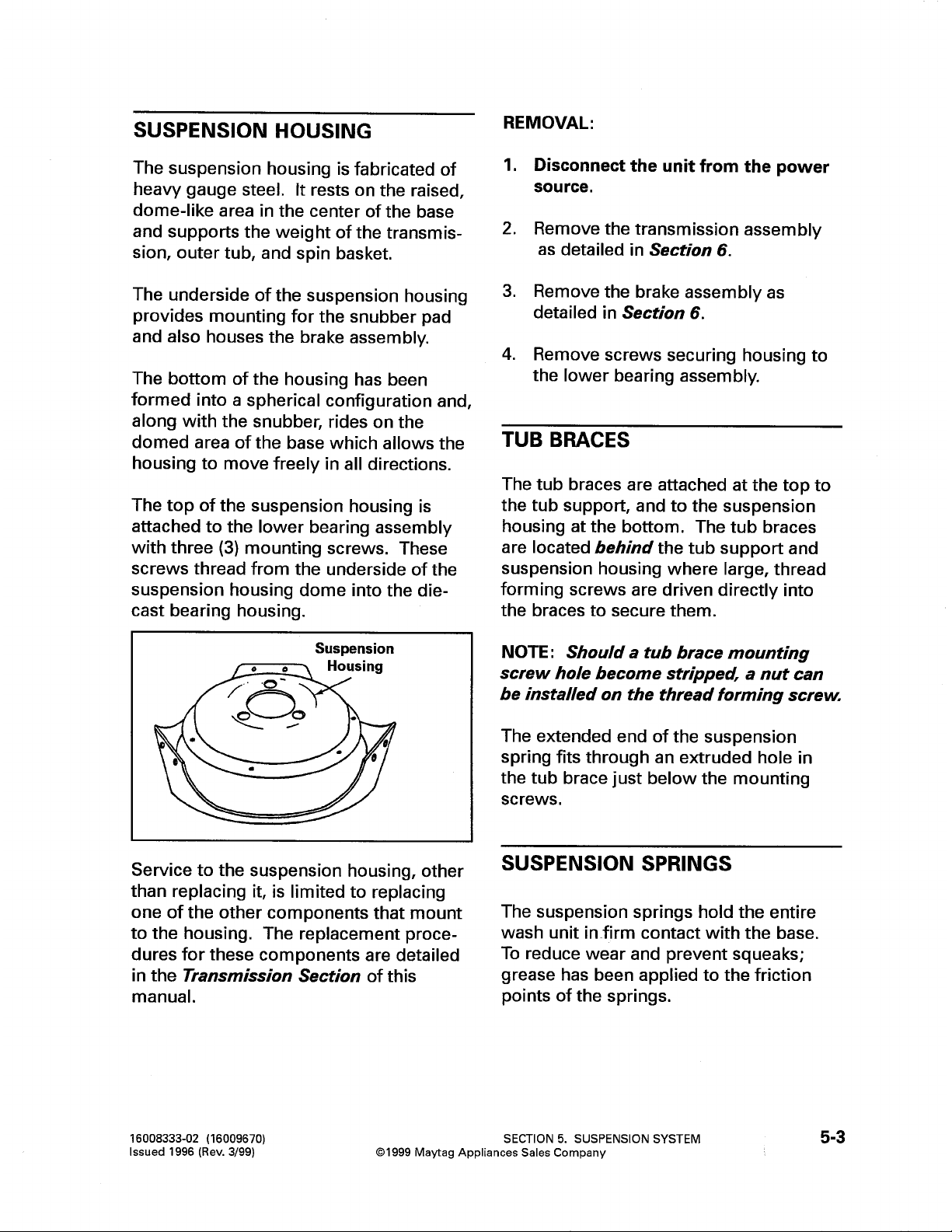

SUSPENSION HOUSING.............................................................................................5-3

TUB BRACES...............................................................................................................5-3

SUSPENSION SPRINGS..............................................................................................5-3

16023083

© 1996 Maytag Corporation

CONTENTS

iii

Page 6

SECTION 6. TRANSMISSION AND RELATED COMPONENTS ........ 6-1

CENTER POST ASSEMBLY ........................................................................................6-2

BEARING AND SEAL HOUSING ..................................................................................6-2

TUB SEAL ....................................................................................................................6-3

SPIN BEARING.............................................................................................................6-4

DRIVE PULLEY AND CAMS ........................................................................................6-5

BRAKE ASSEMBL Y .....................................................................................................6-8

TRANSMISSION HOUSING ASSEMBL Y.....................................................................6-10

Oil Seal Replacement ............................................................................................ 6-11

LOWER BEARING ASSEMBL Y .................................................................................. 6-11

DIAGNOSING TRANSMISSION PROBLEMS .............................................................6-13

SECTION 7. ELECTRICAL COMPONENTS AND TESTING .............. 7-1

TIMER...........................................................................................................................7-1

TIMER SEQUENCE CHART .........................................................................................7-2

MOTOR ........................................................................................................................7-3

MOTOR SWITCH ........................................................................................................7-3

MOTOR MOUNTING ....................................................................................................7-6

MOTOR CIRCUIT TESTING .........................................................................................7-7

Overload Protector ................................................................................................7-7

Motor Switch...........................................................................................................7-8

Motor ......................................................................................................................7-8

WATER MIXING VALVE ..............................................................................................7-8

WATER LEVEL SWITCH..............................................................................................7-9

SELECTOR SWITCHES.............................................................................................7-11

SAFETY SPIN SWITCH .............................................................................................7-11

SECTION 8. SCHEMATIC DIAGRAM...................................................8-1

SECTION 9. TROUBLESHOOTING ......................................................9-1

16023083

© 1996 Maytag Corporation CONTENTS iv

Page 7

SAFETY NOTES

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SER VICING TO AVOID

POSSIBLE EXPOSURE TO EXCESSIVE DANGER AND ELECTRICAL SHOCK:

1. Disconnect electrical supply before servicing machine.

2. If electricity is required for a test:

(A) First, disconnect electrical supply;

(B) Second, make any connections or adjustments required for the test;

(C) Third, connect electrical supply;

(D) Fourth, perform the test. If service is required, disconnect electrical

supply before servicing machine.

3. Please use caution when servicing the machine with the front panel

removed because there is danger of injury due to potential contact

with spinning transmission.

4. Please use caution when servicing the machine with the front panel

removed because there is danger of injury due to contact with a

potential "pinch point" between the turned up edge of the transmission

cover and the tub support flange.

16023083

© 1996 Maytag Corporation

SAFETY NOTES v

Page 8

16023083

© 1996 Maytag Corporation

SAFETY NOTES vi

Page 9

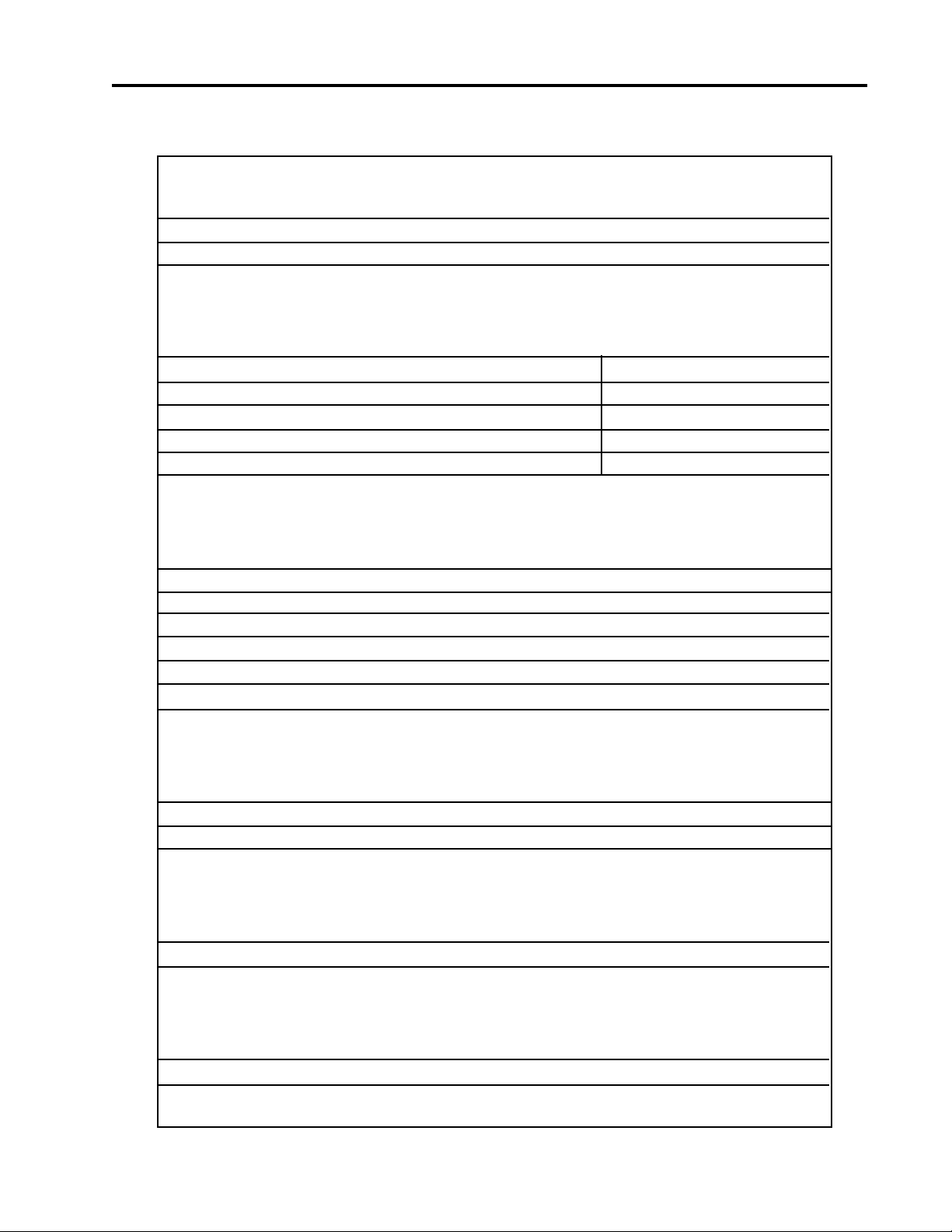

SPECIFICATIONS

Shipping - 185 pounds approximately

Operating - 160 pounds approximately

Width 27"

Depth 27"

Height to top of cabinet 35 3/4"

Height to top of control panel 44"

Height with door open 53 1/2"

W ASHER WEIGHT

DIMENSIONS

FINISH

Cabinet Top - powdered paint

Clothes Door - powdered paint

Outer Tub - constructed entirely of polypropylene

Basket - polypropylene

Cabinet - baked enamel

Base and other finished parts - baked primer

DRAIN HEIGHT

32 inch minimum

60 inch minimum

MOTOR

3/4 H.P., reversible, 115 volt, 60 cycle A.C.

TRANSMISSION

16023083

Rack and pinion type, incorporating reduction gears

SPECIFICATIONS Vii

© 1996 Maytag Corporation

Page 10

Setting Gallons *Depth *Basket

Inches Perforations

Mini 10.5 6" 3 1/2"

Medium 14.1 8 1/2" 5"

High 19.5 11" 7"

Super 23.3 13 1/2" 9 1/4"

*Allowable variations are plus or minus 1/2 inch.

AGITATOR SPEED

Regular Cycle 90 Oscillations per minute

Slow (Delicate) Cycle 60 Oscillations per minute

SPIN SPEED

Regular Cycle 625 R.P.M.

Slow (Fine Wash) Cycle 416 R.P.M.

TABLE 0-1. AMPERAGE CHART

WATER

CYCLE LEVEL *AMPS

Agitate-Regular Full Tub 10.4

Agitate-Slow Full Tub 7.6

Agitate-Regular Dry Tub 7.5

Spin-Regular Dry Tub 10.2

Spin-Slow Dry Tub 7.6

Pump Out-Regular Full Tub 10.8

Pump Out-Slow Full Tub 8.0

T ABLE 0-2. RESIST ANCE CHART

*RESISTANCE

COMPONENTS (OHMS)

Timer Motor 2360

Mixing Valve

Cold Solenoid 853

Hot Solenoid 867

Drive Motor

High Speed 1.3

Low Speed 2.3

Start 3.1

TABLE 0-2. RESISTANCE CHART

*WATTAGE

CYCLE RANGE

Agitate-Regular

Full Tub 610-640 / 670 (MAX.)

Agitate-Slow

Full Tub 370-400 / 420 (MAX.)

Agitate-Regular

Dry Tub 460-470 / 480 (MAX.)

Agitate-Slow

Dry Tub 350-360 / 370 (MAX.)

Pump Out-Regular 760

Pump Out-Slow 510

Spin-Regular

Full Tub 460

Spin-Slow

Full Tub 340

* These will vary with washer load and line voltage.

16023083

* These values can vary slightly .

SPECIFICATIONS viii

© 1996 Maytag Corporation

Page 11

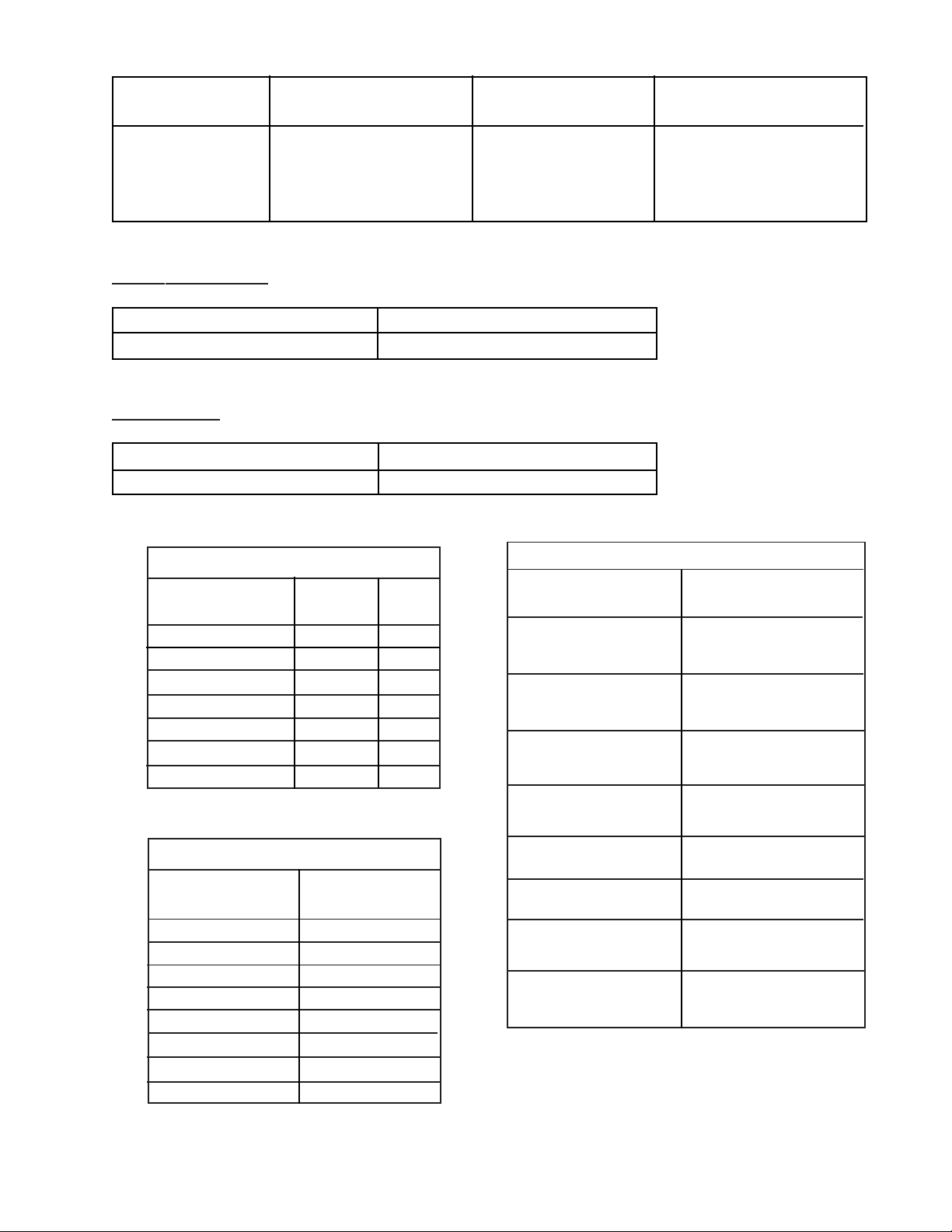

SPECIAL TOOLS

All special tools are manufactured by Robinaire with the exception of the 35-2442 Brake Removal T ool

and 35-2968 Spanner W rench - Basket Hub. These tools are privately manufactured for and stocked

by Maytag Customer Service.

NOTE: The tools listed below can be ordered from any authorized Maytag Customer Service parts

distributor.

Transmission Seal Tool, Part Number 14242

Spring Tool Kit, Part Number 21001138

Brake Removal Tool, Part Number 35-2442

Spanner Wrench-Basket Hub, Part Number 35-2968

Motor Test Cord, Part Number 038183

16023083

SPECIAL TOOLS ix

© 1996 Maytag Corporation

Page 12

16023083

© 1996 Maytag Corporation

SPECIAL TOOLS x

Page 13

16023083

Page 14

16023083

Page 15

16023083

Page 16

16023083

Page 17

16023083

Page 18

16023083

Page 19

16023083

Page 20

16023083

Page 21

16023083

Page 22

16023083

Page 23

16023083

Page 24

16023083

Page 25

16023083

Page 26

16023083

Page 27

16023083

Page 28

16023083

Page 29

16023083

Page 30

16023083

Page 31

16023083

Page 32

16023083

Page 33

16023083

Page 34

16023083

Page 35

16023083

Page 36

16023083

Page 37

16023083

Page 38

16023083

Page 39

16023083

Page 40

16023083

Page 41

16023083

Page 42

16023083

Page 43

SECTION 6. TRANSMISSION AND RELATED

COMPONENTS

This section will detail the servicing procedures on the transmission assembly which

has splines formed on the agitator drive shaft. An "O" ring is installed on the shaft just

above the center post to provide a center post seal when the agitator is installed.

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-1

Page 44

CENTER POST ASSEMBLY

REMOVAL:

The center post assembly consists of a

plastic center post. A nylon agitator

bearing slips over the lower portion on

the center post body.

The center post assembly is secured to

the basket hub assembly by the spin

basket, and to the agitator shaft. A

small rubber gasket is installed in a

groove on the bottom flange of the center

post, and a foam gasket is placed

between the bottom of the spin basket

and the basket hub assembly.

The center post can be removed after

removing the spin basket, and the agitator shaft "O" ring.

BEARING AND SEAL HOUSING

1. Disconnect the unit from the power

source.

2. Remove the agitator , spin basket,

tub assembly , and center post.

3. Remove the Seal nut with 2202898 and

35-2968

4. Remove the basket hub assembly

by turning it in a counterclockwise direction, using tool number

35-2968.

5. Remove the suspension springs to

prevent damage to the tub braces

and unbolt the tub braces from the

tub support.

6. T o remove, lift up on the bearing

and seal housing with tub support

attached.

The die-cast bearing and seal housing

slips over a machined area on the lower

drive tube. The basket hub assembly

threads downward over the drive tube

and secures the bearing and seal housing.

The spin bearing and the tub seal are

installed in a cavity in the center of the

housing. The sheet metal tub support is

attached to the under side of the housing

with three (3) mounting screws. The

spin bearing has been pressed into the

underside of the housing cavity and is

secured by the tub support.

The center of the tub assembly mounts to

the upper flange of the housing with a tub

gasket and a tub seal installed between.

The bottom of the tub sits on, and is

attached to, the tub support.

7. T o disassemble tub support from

housing, remove mounting screws

from underside.

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-2

Page 45

TUB SEAL

There are 2 Tub Seal designs, the original

Face Seal and the new Triple Lip Seal

introduced at series 17.

Face Seal

The tub Face Seal consists of the seal face

and seal body .

NOTE: All parts of the seal must be

replaced if either of the sealing surfaces

are damaged.

The seal face fits into a recess in the underside of the basket hub assembly . Also, the

seal body installs in the cavity on the top side

of the bearing and seal housing. The spin

bearing is located in a cavity on the underside of the bearing and seal housing.

Seal

Face

Seal

Body

Each of the two (2) sealing parts, the seal

face and the seal body , have sealing faces

which are brought into contact with one

another when the basket hub assembly is

threaded down on the drive tube. The

springs in the seal body exert pressure to

keep the sealing faces in contact.

Triple Lip Seal

Triple Lip Tub Seal

Assembly used with the

21001867 Hi-T orque

Transmission Assembly .

NOTE: Sealing surface

are on the O.D. of the

aluminum spinner hub

with no seal in the hub

cavity.

NOTE: The Triple Lip Seal and Bearing is only used with the High Torque Dual Drive

transmission. The 21001867 High Torque service transmission will include a T riple Lip Seal and

Bearing for proper matching of parts. The High Torque transmission will have An “HT” next to the date

code for field identification purposes. Do not use 21001868 Seal kit on older transmissions not de

signed to operate at higher torque levels. Always refer to Parts Pro or Microfiche for proper p arts

ordering. The 21001868 Triple Lip Seal kit will include a sticker to be placed on the Outer Tub of the

washer to identify the washer has been modified with a High Torque Transmission and Triple Lip Seal

kit.

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-3

Page 46

TUB SEAL REPLACEMENT:

Should the tub seal begin to leak or develop

excess seal drag, it must be replaced. The

service replacement seal includes all the

parts necessary to replace the entire seal.

Be sure to replace all parts of the seal even if

only one part is found to be damaged.

TRIPLE LIP SEAL

1. Apply center seal grease (056016) to

Seal Nut and T riple Lip Seal before

installing.

Seal Nut (056016) grease

NOTE: If the tub seal is being replaced

because it has begun to leak, the spin

bearing is probably defective also and

should be replaced. To replace the spin

bearing, the bearing and seal housing

must be removed as previously described. This also allows access to the

tub seal for removal and replacement

(refer to steps 2 and 3 below when installing).

Removal and replacement of the tub seal

can ONL Y be accomplished as follows:

1. Follow steps 1 through 3 for the

face seal

NOTE: For Triple Lip Seal special instuction,

see next column

FACE SEAL

2. Before installing the new seal, coat

the mounting recess of the housings

with silicone grease (part number

203959). This will allow the seal

body and seal face to slip into position.

NOTE: MAKE SURE NO GREASE

COMES IN CONTACT WITH THE

MATING SURFACES OF THE SEAL.

3. Make sure both seal mating surfaces

are free of foreign matter, then clean

both surfaces with an alcohol satu-

rated cloth.

NOTE: Do not use any agent other than

alcohol to clean the mating surface. Do

not use any lubricant other than Silicone

Grease, part number 203959.

Triple Lip Seal (056016) grease

SPIN BEARING

The spin bearing is installed in a cavity on

the underside of the bearing and seal

housing. It is also press fitted and bottoms out on the cavity shoulder. It is

further secured in place by the inner

diameter of the tub support.

SPIN BEARING REPLACEMENT :

1. Disconnect the unit from the power

source.

2. Remove the bearing and seal housing and the tub support as previously described.

3. Remove the seal body from the

housing cavity.

4. Press the spin bearing out of

the cavity from the opposite side of

the housing.

5. When installing the replacement

bearing into the housing cavity, be

sure to press against the outer race

of the bearing to avoid damage to

the bearing shield and causing premature failure.

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-4

Page 47

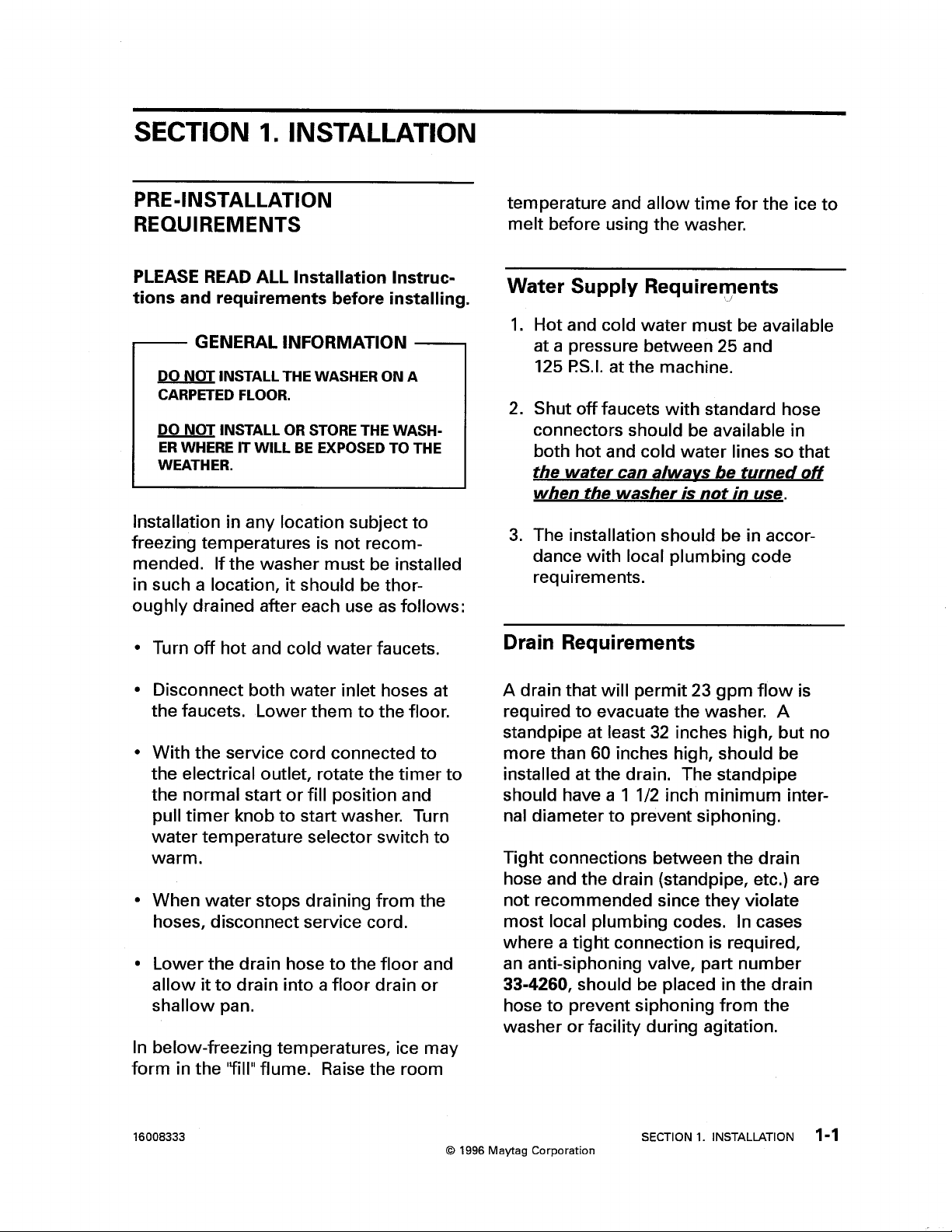

DRIVE PULLEY AND CAMS

OPERA TION:

The drive pulley and cam is located below

the brake assembly on the drive shaft.

Models are equipped with a plastic drive

pulley which has the upper cam molded

onto the bottom of the hub. The purpose

of the pulley and cam arrangement is to

drive the clutch assembly during the

agitate and spin cycle, and to disengage

the brake assembly during the spin cycle.

The drive pulley slips over the drive shaft

and rests against a series of washers, a

thrust bearing, and a large washer type

spacer. The spacer locates against the

bottom of the brake rotor and lining

assembly. (See the illustration on

page 6-6.)

The lower cam slips over the end of the

drive shaft where splines formed in the

cam engage with mating splines on the

drive shaft end. This imparts a direct

drive from the cam to the drive shaft.

A shoulder molded on the bottom of the

pulley hub engages "dogs" formed on the

sides of the lower cam, and will drive it

and the drive shaft in either direction.

When the drive pulley rotates CLOCK-

WISE, the upper and lower cams are

designed to nest together which allows

the drive pulley to remain in position on

the drive shaft. The break remains engaged and the drive pulley will turn the

lower cam and drive the shaft to cause

the transmission

to agitate.

When the drive pulley rotates COUNTER-

CLOCKWISE, the upper cam and pulley

ride up the lower cam approximately 3/16

of an inch before the driving shoulders on

the pulley hub engage the "dogs" on the

lower cam.

This causes the top of the pulley hub to

push against the spacer which compresses the brake spring and lifts the

brake rotor and lining assembly off the

brake stator. The brake is disengaged

and the pulley will turn the lower cam

and drive shaft to cause the transmission

to spin.

A washer and retaining ring secure the

pulley and cam on the drive shaft. A

plastic dust cap snaps to the underside

of the pulley to keep the cam surfaces

clean.

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-5

Page 48

Original Thrust Washer Design

Spacer

Brake

Stator

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-6

Page 49

REMOVAL:

1. Disconnect the unit from the power

source.

2. Tip the unit over and remove the

drive belt.

3. Remove the dust cap from the under

side of pulley.

4. Remove retaining ring and washer

from end of drive shaft.

5. Firmly pull lower cam off the drive

shaft splines, then slide the other

parts off the shaft. This will also

allow access to the brake assembly

for removal.

REASSEMBLY:

the brake starts to release and the

transmission begins to turn.

(See following figure).

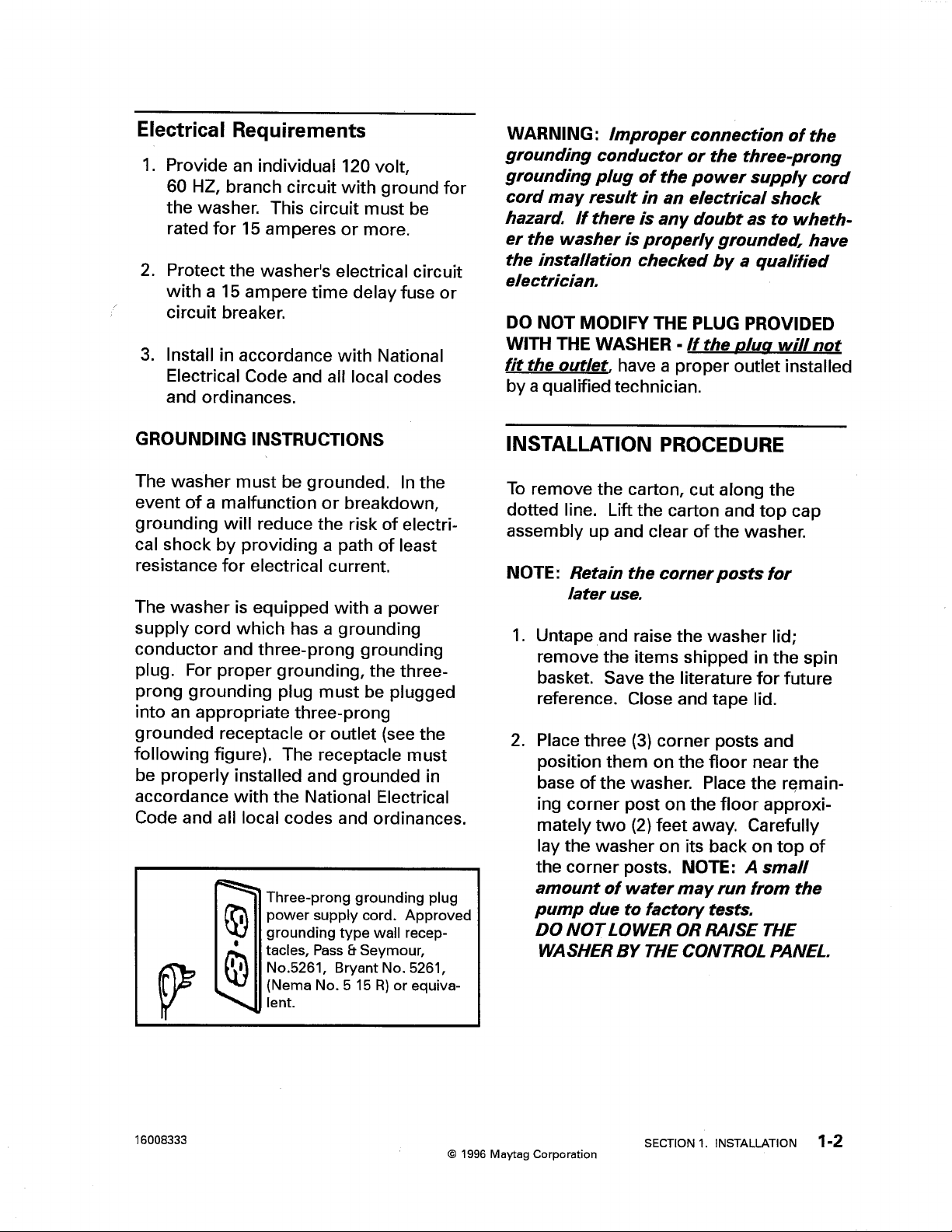

2. Counting the reference marks on the

lower cam from right to left, the

pulley hub shoulder should be positioned between reference marks 9

and 3, with 6 being the median.

(Shown in the following figure).

After reassembling the components on

the drive shaft, it will probably be necessary to pull down on the shaft to take the

end play out of it before the thrust washer

and retaining ring can be reinstalled.

NOTE:

Each time the cams are reas-

sembled on the drive shaft, the point in

the cam rise where the brake disengages

the stator should be checked and adjusted as necessary.

Reference marks have been molded

around the bottom outer edge of the

lower cam as an aid in checking the point

of brake disengagement (see following

figure). Each mark, from right to left,

represents approximately .010 of an inch

cam rise.

T o Check Brake Disengagement:

1. Manually rotate the drive pulley in a

slow counterclockwise direction until

If the position of the pulley hub shoulder

is not within these parameters and the

brake has started disengaging,

adjust-

ment is required.

T o Adjust Brake Disengagement:

1. If the position of the pulley hub

shoulder is

less than 3 reference

marks, remove the standard (.062

thickness) thrust washer and replace

it with a thinner (.032 thickness)

thrust washer (part number 35-2132).

Recheck disengagement.

2. If the position of the pulley hub

shoulder is

more than 9 reference

marks, add a 35-2132 thrust washer

(.032) to the standard thrust washer

and recheck disengagement.

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-7

Page 50

BRAKE ASSEMBL Y

The brake assembly is located inside the

domed area of the suspension housing

and consists of the following components: brake spring retainer, brake

spring, rotor and lining assembly, and

the brake stator.

2. Remove the drive pulley and cam

components as previously described.

3. Using brake removal tool number

35-2442, proceed as follows:

• Pull out and remove "U" retainer

from tool.

The brake assembly, as well as the snubber, is held in position by the brake stator

which is secured to the underside of the

suspension housing by six (6) mounting

screws.

Spring pressure forces the rotor and

lining assembly down on the brake stator

and prevents the transmission from

turning during agitation.

As stated previously, the drive pulley and

cams provide a cam action which raises

the drive pulley during the counterclockwise (spin) direction of the motor. When

the drive pulley hub travels upward, it

compresses the brake spring and moves

the rotor and lining assembly up the drive

tube disengaging it from the stator. The

transmission is now free to spin.

Splines in the brake rotor hub mesh with

splines on the drive tube end to provide

positive vertical movement for the rotor

and lining assembly. The splines are

greased for ease of movement.

• Slip the splined end of the drive

shaft into hole located in the tool

inner plunger.

• Looking at the side of the tool,

align slots on tool barrel and holes

in tool plunger between splines

and chamfered shoulder of shaft.

• Slip "U" retainer through tool slots

and holes capturing the drive

shaft behind the chamfered shoulder.

NOTE: Be sure "U" retainer is

completely through both sides of

tool.

• Tighten tool nut to compress

brake spring

until transmission

turns freely.

• Remove the six (6) screws which

secure the brake stator and snubber to the underside of the suspension housing.

CAUTION

The brake assembly has a compres sive spring force of approximately

200 pounds. See the following in structions for disassembly.

DISASSEMBLY:

1. Disconnect the unit from the power

source.

16023083

© 2004 Maytag Services

• Loosen tool nut

until the brake

spring reaches its free length.

• Remove "U" retainer from tool and

remove tool from drive shaft.

• Remove brake components.

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

6-8

Page 51

Min Pull ey H ub

Reference

Max Pulley Hub

Reference

Reference Cam

Arrow

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-9

Page 52

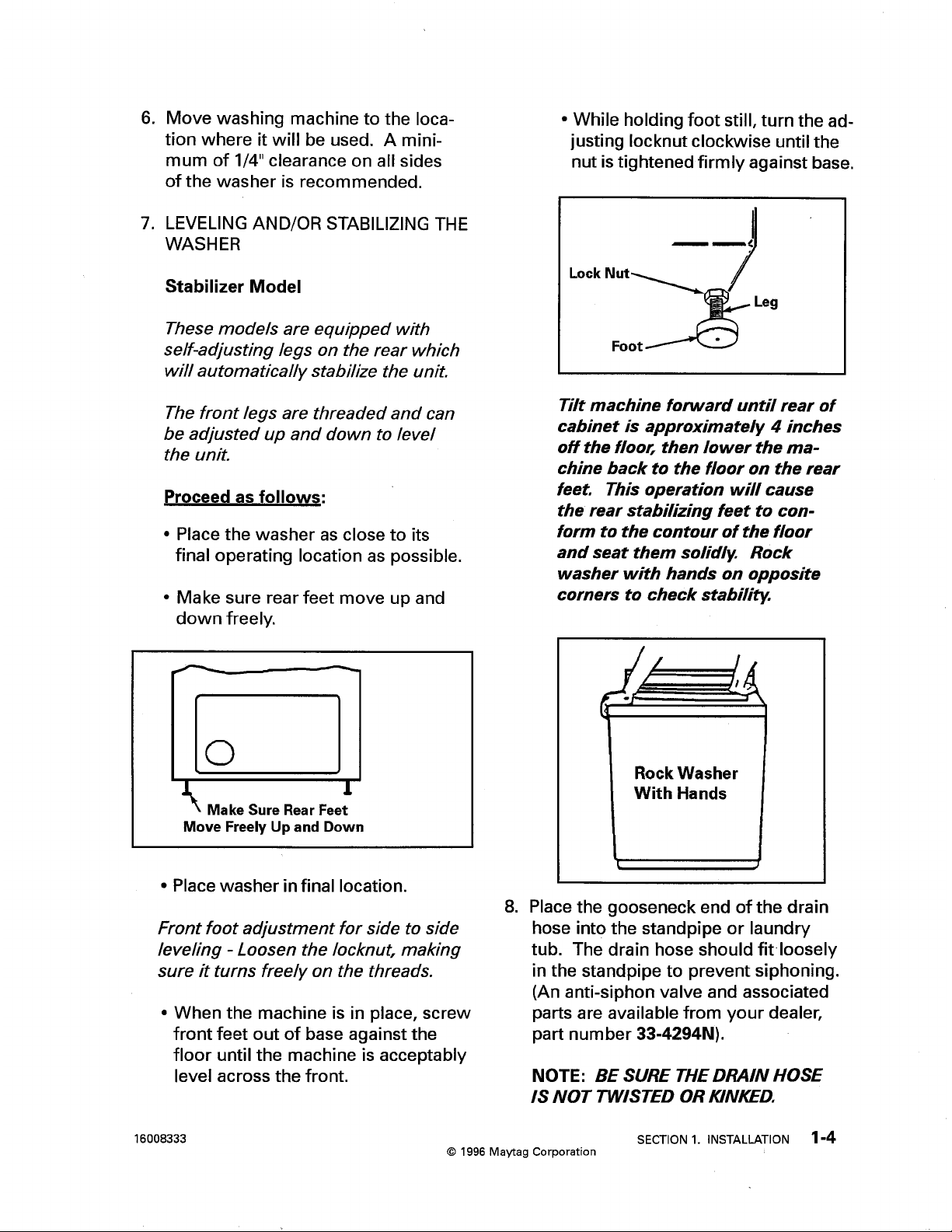

Rack Gear

Carrier

Transmission

Cover

Rack

Gear

Agitator

Shaft

Cluster

Gear

Output

Pinion

Drive

T ube

Input

Shaft

Lower

Seal

Crank

Gear

Transmission

Housing

Bearing

Housing

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-10

Page 53

TRANSMISSION HOUSING

ASSEMBLY

The die-cast aluminum transmission

housing has four studs pressed into its

upper region. The studs provide mounting for the two crank and two cluster

gears. The top cover is threaded into the

lower housing. A sealant is used on the

threads as a gasket material. A steel

drive tube with a splined end is pressed

into the bottom of the transmission housing. A sleeve bearing is installed in the

lower I. D. of the drive tube. Another

bearing is pressed into the lower housing

above the drive tube. These bearings

provide a path for the drive shaft to ride

in. An oil seal is installed in the bottom of

the drive tube. The oil seal can be replaced as a separate part.

5. Remove the cone-shaped end from

the seal protector tool and slide the

tool, drive washer, and new seal over

the drive shaft up to the seal cavity.

6. Slide the transmission seal driver

(tool number 14242) over the drive

shaft until it makes contact with the

drive washer. Use the impact sleeve

of the tool to "tap" the seal into the

end of the drive tube.

LOWER BEARING ASSEMBL Y

The lower bearing assembly consists of a

ball type bearing which has been installed

in an aluminum die-cast housing. The

transmission assembly must be removed

from the washer cabinet before the lower

bearing assembly can be replaced.

Oil Seal Replacement:

The oil seal is located in the spline end of

the drive tube. The seal can be replaced

without removing or disassembling the

transmission, as outlined below:

1. Disconnect the unit from the power

source.

2. Remove the brake assembly to

access the seal.

3. Use a thin, flat bladed screwdriver to

carefully pry the old seal out.

4. Place the drive washer (tool number

14242) and the new seal over

the seal protector.

The lower bearing assembly provides

lateral support for the drive tube and

shaft against the tension of the drive belt.

The top of the suspension housing

is attached to the underside of the lower

bearing assembly.

REPLACEMENT:

IMPORTANT

Because the lower bearing assembly

has been pressed onto the drive tube

under approximately 1,000 pounds of

pressure, a puller must be used to

remove it. However, the puller

forcing screw

must not be used on

the end of the drive shaft or the

clutch assembly could be damaged.

Instead, a simple pipe and cap as sembly can be made to slip over the

drive shaft, with end clearance, and

rest against the end of the drive tube.

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-11

Page 54

The puller forcing screw is used on the

end of the pipe cap which directs the

forward thrust of the puller to the bottom

of the drive tube.

REMOVAL:

1. Disconnect the unit from the power

source.

5. Slip the pipe and cap assembly over

the drive shaft and up against the

drive tube.

6. Using a puller with at least a 3 1/2

inch spread and sufficient reach to

encompass the pipe and cap assembly, remove the lower bearing assembly.

2. Remove the transmission from the

washer cabinet.

3. Remove the cams, drive pulley, and

brake assembly.

4. Remove the three (3) screws which

secure the suspension housing to

the lower bearing assembly.

NOTE: When installing the new lower

bearing assembly, be sure to drive

against the

inner race only to avoid

damaging the bearing shield which

could cause premature failure.

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-12

Page 55

DIAGNOSING TRANSMISSION PROBLEMS

Listed below are most of the service

complaints which would normally be

caused by a malfunctioning component

of the transmission assembly.

Oil Leaks

Oil leaks can be caused by faulty seals,

gaskets, or a loose fitting stud.

Slow Spin Speed

Slow spin speed can be caused by a

binding tub seal and/or bearing, brake

rotor assembly not disengaging properly,

a slipping clutch spring, or an off balance

clothes load. The test that follows can be

used to isolate the problem.

The torque available to drive the spin

basket is determined by the amount of

drag or resistance presented by the tub

seal and spin bearing, deducted from the

input torque imparted to the transmission

housing assembly by the clutch assembly.

The Following Torque Tests Will Allow a

Problem in the

Spin Drive Train to be

Pinpointed:

NOTE: Before starting these tests, the

washer should be operated in the agitation cycle with hot water for about two

(2) minutes, and then for two (2) minutes in a spin cycle. This warms up the

transmission oil and the spin drive train

components.

TORQUE TESTING:

A quick test of the efficiency of the spin

operation components can be made by

placing a 3 1/2 pound weight, such as a

bag of sand, in the washer basket and

starting the machine in the spring cycle.

If the basket appears to reach full spin

with the weight, the machine components are performing as intended. If the

basket does not attain full spin speed, the

torque test procedures as outlined in the

following paragraphs should be performed to determine the problem.

Available T orque

Place a 1/2 inch socket and torque

wrench on the agitator retaining bolt.

Depress the safety spin switch to allow

the washer to operate in the spin cycle,

then while reading the torque allow the

wrench to turn slowly (about 6 R.P.M.)

through a complete 360 degree cycle.

The reading should be between 18 and

25 inch pounds throughout the complete

360 degree rotation of the wrench.

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-13

Page 56

If the torque readings are within these

limits, the washer is performing properly

and any slow spin complaints can be

assumed to have been the result of offbalance loads.

If the torque reading exceeds 25 inch

pounds, the input torque outlined later

should be checked to determine the

cause. Probable causes are that the drive

shaft is binding in the transmission housing (drive tube) sleeve bearings, or that

the clutch spring is binding on the drive

shaft hub.

If the available torque reading is less than

20 pounds, follow the procedure for

testing the drag torque.

Drag T orque

Position the washer so the drive pulley

can be accessed, and remove the drive

belt. While holding the transmission to

keep it from turning, manually rotate the

drive pulley counterclockwise

until the

brake stays disengaged. Make certain

the drive pulley hub shoulder has rotated

fully against the cams in the spin driving

position to ensure the complete disengagement of the brake. Release the

transmission so it is free to turn.

Place a 1/2 inch socket and torque

wrench on the agitator retaining bolt.

Slowly rotate the wrench 360 degrees at

approximately 6 R.P.M. and read the

torque. If the torque reading is over 4

inch pounds, remove the brake stator (as

detailed earlier in this section) and recheck the drag torque.

If the reading is still over 4 inch pounds,

the tub seal and/or spin bearing is binding and should be replaced.

If the

18 inch pounds and the

available torque reading is below

drag torque

reading is not over 4 inch pounds, follow

the procedure for checking the clutch

assembly as to its input torque.

Input T orque

NOTE: It will be observed that the

readings used to check the input torque

are slightly lower than the readings used

to check the available torque. The reason for this is when the brake is disengaged, as in checking the available

torque, the compressed brake spring

exerts a downward force on the bottom

of the clutch hub and thrust washers.

This keeps the clutch spring from slipping quite as readily as in checking the

input torque where the brake is engaged

and the downward force on the clutch

hub is minimized.

To check the input torque, remove the

drive pulley and position the washer so

the scale on the torque wrench can be

read when it is placed on the input (drive)

shaft. Attach the torque wrench adapter

firmly to the shaft, place the wrench in

the adapter and slowly rotate the wrench

in a counterclockwise direction. A properly operating clutch assembly will have a

torque reading between 17 and 20 inch

pounds.

If the input torque is less than 17 inch

pounds, the clutch assembly is defective

and must be repaired or replaced.

If the torque reading is now under 4 inch

pounds, the brake is binding and should

be repaired.

16023083

© 2004 Maytag Services

If the input torque exceeds 20 inch

pounds, remove the clutch assembly

from the transmission. Secure the drive

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

6-14

Page 57

pinion in a vise using two (2) small blocks

of wood to prevent damage to the gear

teeth, and repeat the input torque check.

NOTE: If the "O" ring is to be reused, be

extremely careful not to damage it during the removal.

If the torque reading is between 17 and

20 inch pounds, the drive shaft is binding

in the sleeve bearings.

If the torque reading still exceeds 20 inch

pounds, the clutch assembly is defective

and must be repaired or replaced.

TRANSMISSION REMOVAL:

The transmission assembly can be removed from the washer cabinet after

removing the drive belt, spin basket,

outer tub and the suspension springs.

NOTE: Be sure to dust the base dome

lightly with cornstarch before installing

the transmission.

CAUTION

Once the agitator has been removed,

the center post slips off the shaft.

Therefore, do not attempt to handle

the drive train by the center post after

the agitator has been removed. In stead, after removing the agitator

and the agitator shaft "O" ring, slip

the center post off the shaft and

handle the drive train by the shaft.

Remove the center post, "O" ring and

agitator once the drive train is back in

place.

The transmission assembly, when removed as described, will have the related

components assembled to it. These

related components should be examined

carefully before reinstalling.

IMPORTANT

When installing the transmission, it is

necessary that the tub be located on

the tub support a certain way if all the

mounting holes are to be properly

aligned. This should be done before

attempting to mount the tub to the

bearing and seal housing.

To assist in correctly positioning the tub, a

small indentation has been formed on the

tub support just above one of the tub

brace mounting areas. This is the left

front tub brace.

When the tub is in proper position and

ready to be mounted to the tub support,

the large tub cover lock (on the side of

the tub) should be located directly above

the indentation and tub brace.

(See the illustration on page 6-14.)

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-15

Page 58

Large T ub

Cover Lock

Alignment

Indentation

Tub

Left Front

T ub Brace

TUB TO TUB SUPPORT ALIGNMENT

Tub Support

16023083

SECTION 6. TRANSMISSION AND RELATED COMPONENTS

© 2004 Maytag Services

6-16

Page 59

16023083

Page 60

16023083

Page 61

16023083

Page 62

16023083

Page 63

16023083

Page 64

16023083

Page 65

16023083

Page 66

16023083

Page 67

16023083

Page 68

16023083

Page 69

16023083

Page 70

16023083

Page 71

16023083

Page 72

16023083

Page 73

16023083

Page 74

16023083

Page 75

16023083

Page 76

© 1996 M

aytag

C

orporation

SECTION 2. WIRING INFORMATION

16023083

DLW231

P

C

O

SWITCH FUNCTION

A

S

M

T

0

U

ADVANCE-EX.RINSE

T

AGITATE SELECT

2

B

SPRAY RINSE

WASH FILL

T

4

B

RINSE FILL

SPIN DIRECTION

T

6

B

AGITATE DIRECTION

T

AGITATE DIRECTION

B

8

SPIN DIRECTION

T

B

T

TM P/SW BYPASS

10

B

MOTOR CONTROL NORM

T

TM P/SW BYPASS

12

B

MOTOR CONTROL-SLOW

T

BUZZER

B

14

INTERVAL NUMBER

16008333

DEGREES

TERM.

10

IDENT.

26-17

28-26

28-15TM

70-71

70-72

7-32

7-8

9-32

9-8

15TM-27

15TM-63

15TM-27

15TM-62

15TM-81

203040 50 60 70 80 90 100

1 2 3 4 5 6 7 8910 11 121314

WASH-REGULAR

TO CHANGE TIMER POSITION PUSH KNOB IN AND TURN CLOCKWISE (ALL TIMER CONTACTS WILL OPEN)

SWITCH AND TIMER SEQUENCE

P

A

U

S

SPIN

E

FILL

AGIT

RINSE

110

120 130 140

18 192021 22 23 24 25 26 27 282930 31 32

15 16 17

P

A

U

S

SPIN

E

OFF

AGIT

P

A

U

S

SPIN

E

EX-RINSE

150 160 170 180

33 34

SPIN

OFF

200 210

190

35 36 373839 40 41 42 43

P

A

U

S

E

SPIN

220 230 240 250 260

A

P

G

A

I

U

FILL

T

S

RINSE

E

44 454647 48 49 50 51

FAST FILL

SPIN

AGIT

WASH-PERM. PRESS

OFF

SECTION 8. CIRCUIT REVIEW 8-6

270

290 300

280

52 53

54 55

P

A

P

U

A

S

U

E

SLOW

S

E

SPIN

320

310

330 340 350

56 57 58 59 60 61 62 63 64 65 66

S

P

R

A

Y

FILL

RINSE

P

A

U

AGIT

S

SPIN

E

OFF

WASH

Page 77

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-7

DLW231

16008333

Page 78

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-8

PAV2300

P

C

O

SWITCH FUNCTION

A

S

M

T

U

0

AGITATE SELECT

T

2

B

SPRAY RINSE

WASH FILL

T

B

4

RINSE FILL

T

SPIN DIRECTION

6

B

AGITATE DIRECTION

AGITATE DIRECTION

T

B

8

SPIN DIRECTION

T

B

TM P/SW BYPASS

T

10

B

MOTOR CONTROL NORMAL

T

TM P/SW BYPASS

B

12

MOTOR CONTROL-SLOW 15TM-62

T

B

14

INTERVAL NUMBER

DEGREES

TERM.

IDENT.

28-26

28-15TM

70-71

70-72

7-32

7-8

9-32

9-8

15TM-27

15TM-63

15TM-27

1 2 3 4 5 678 9

16008333

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300 310 320 330 340 35010

WASH-REGULAR

TO CHANGE TIMER POSITION PUSH KNOB I

SWITCH AND TIMER SEQUENCE

10

1112131415

P

A

U

S

E

SPIN

P

A

U

AGIT

FILL

S

E

RINSE

20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 4847 605958575655545352515049

16

17 18 19

SPIN OFF

N AND TURN CLOCKWISE (ALL TIMER CONTACTS WILL OPEN)

P

A

U

S

NORM. SPD.

SLOW SPD.

E

WASH-PERM. PRESS

WASH-GENTLE

FILL AGIT

RINSE

P

A

U

S

E

SPIN

OFF

P

A

U

S

E

SPIN

S

P

P

R

A

A

U

Y

S

E

SPIN

FILL AGIT

RINSE

P

A

U

S

SPIN

E

WASH

OFF

Page 79

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-9

PAV2300

16008333

Page 80

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-10

PAV3200

P

C

A

O

SWITCH FUNCTION

M

S

U

LINE SWITCH/PUSH OFF

0

L

WASH FILL

U

1

L

RINSE FILL

SPRAY RINSE

U

4

L

AGITATE SELECT

TM. P. SW. BYPASS SPIN

U

6

L

MOTOR CONTROL AGITATE

SPIN DIRECTION

U

9

L

AGITATE DIRECTION

U

8

L

MOTOR CONTROL SPIN

U

AGITATE DIRECTION

13

L

SPIN DIRECTION

ADVANCE TO WASH

U

14

L

MTR. CONT. SOAK SPIN

U

L

TERM.

IDENT.

26-12

70-71

70-72

28-15TM

28-26

15TM-27

15TM-63

7-32

7-8

15TM-62

9-32

9-8

26-16

26-17

20

WASH

5

10

105

P

A

8 4

U

S

E

16 12

MINUTES

REGULAR CYCLE

SPIN

SWITCH AND TIMER SEQUENCE

N AND TURN CLOCKWISETO CHANGE TIMER POSITION PUSH KNOB I

15

15

F

S

I

P

R

L

L

A

Y

RINSE

P

A

U

S

E

20

20

SPIN

25

STEP INCREMENTS

3025

30

A

G

I

T

A

T

E

G

G

G

A

A

A

I

I

I

U

U

U

T

T

T

S

S

S

A

A

A

E

E

E

T

T

T

E

E

E

A

A

P

P

P

A

WASH

SHORT CYCLE

P

A

U

S

E

35

35

F

P

I

R

L

LYA

R

I

N

S

E

SPIN

40

P

A

U

S

E

SPIN

45

A

G

I

T

A

T

E

A

G

I

T

A

T

E

AS

G

I

T

A

SOAK E

T

E

SOAK CYCLE

ADVANCE TO WASH

55

50

5540 45

SOAK

60

6550

60P65

A

G

A

I

U

T

S

A

TESPIN

P

A

U

S

E

16008333

Page 81

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-11

PAV3200

16008333

Page 82

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-12

PAV3300

P

C

O

A

S

M

T

0

U

T

2

B

T

4

B

T

6

B

T

8

B

T

10

B

T

TM P/SW BYPASS S

12

B

T

14

B

T

B

SWITCH FUNCTION

ADVANCE-WASH

ADVANCE-2ND RINSE

AGITATE SELECT

SPRAY RINSE

WASH SELECT

RINSE SELECT

SPIN DIRECTION

AGITATE DIRECTION

AGITATE DIRECTION

SPIN DIRECTION

SPIN SOAK

MOTOR CONTROL SPIN

MOTOR CONTROL-AGIT

BUZZER

TERM.

IDENT.

28-15TM

70-71

70-72

15TM-69

15TM-62

15TM-27

15TM-63

15TM-81

INTERVAL NUMBER

28-26

7-32

26-16

26-17

7-8

9-32

9-8

16008333

SWITCH AND TIMER SEQUENCE

DEGREES

1 2 3

WASH-REGULAR

30

10

20

40 50 60 70 80 90 100

4 567 8910 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 41 42 43 444546 484749 50 51 52 5453 55 56 57 58 59 60 61 62 63 64 65 66

P

A

U

S

SPIN

E

FILL AGIT

RINSE

P

A

U

S

SPIN

E

TO CHANGE TIMER POSITION PUSH KNOB I

N AND TURN CLOCKWISE (ALL TIMER CONTACTS WILL OPEN)

110

AGIT

EXTRA RINSE

OFF

120 130 140

P

A

U

S

E

SPIN

150 160 170 180

WASH-PERM. PRESSOFF

200 210

190

38 39 40

S

P

P

R

A

A

U

FILL

Y

S

SPIN

RINSE

E

220 230 240 250 260

A

P

G

A

I

U

T

S

SPIN

E

OFF

270

290 300

280

AGIT

SOAK - ADVANCE TO WASH

310

A A

G

I

T

320

G

I

T E

330 340 350

P

A

U

S

SPIN

67

PAUSE

Page 83

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-13

PAV3300

16008333

Page 84

© 1996 M

aytag

C

orporation

WIRING INFORMATION

SWITCH

35-6345 "B"

10

12

14

16023083

SECTION 8. CIRCUIT REVIEW 8-14

PAV5000

DOOR SW.

N.O.

ADVANCE TO

RINSE SWITCH

EMPTY

SPEED SELECTOR SWITCH

WASH SPEEDS

POSITION CIRCUIT

N-S

S-N

S-S

YELLOW-RED

FULL

1

2

3

WATER

LEVEL

SWITCH

64-66 67-66

64-66 67-65

64-65 67-66

64-65 67-65

TAN

LT. BLUE

TAN

LT. BLUE

GRAY

BUZZER

LT. BLUE

ORANGE

POSITION

H-C

W-C

C-C

ATCW-W

ATCW-C

ATCC-C

REDBLK

TIMER

KNOB-PUSH OFF

16

12

17

28

15

27

15

15

81

TIMER

MOTOR

8

8

7O

CIRCUIT

17-19-16, 18-43

17-16-19-20, 18-43

17-16-20, 18-43

17-18-19-20

17-20-19, 18-43

17-20, 18-43

CONNECTION

LINE VOLTAGE

SERVICE CORD

DIAGRAM

GND.

P

5

3

4

GRAY

GRAY

PINK

20

2O

GRN

MOTOR

6PM

4PM

START

WATER

VALVE

GND

2

WHITE

21

COLD

HOT

1

W

H

I

T

E

21

26

W

H

I

T

E

63

69

62

WH-PUR

YEL-BLK

WH-BRN

32

7

32

9

64

67

SELECTOR

YELLOW

RED

65

66

SPEED

SWITCH

YELLOW

BLUE

GRN-BLK

* CAPACITOR

WHITE-YELLOW

WHITE-RED

17

71

WHITE-RED

72

43

WHITE

16

19

1

20

18

RED

PINK

3

6

8

7

11

4

10

WHITE-YEL.

WHITE-BLUE

PURPLE

PURPLE

WATER

TEMPERATURE

TEMPERATURE

CONTROL

P

C

O

SWITCH FUNCTION

A

S

M

T

0

U

ADVANCE-2ND RINSE

T

AGITATE SELECT

2

B

SPRAY RINSE

T

WASH SELECT

4

B

RINSE SELECT

T

SPIN DIRECTION

6

B

AGITATE DIRECTION

T

AGITATE DIRECTION

8

B

SPIN DIRECTION

T

SPIN SOAK

B

MOTOR CONTROL SPIN

TM P/SW BYPASS S

T

B

MOTOR CONTROL-AGIT

T

BUZZER

B

T

B

INTERVAL NUMBER

TERM.

IDENT.

26-16

26-17

28-26

28-15TM

70-71

70-72

7-32

9-32

15TM-69

15TM-62

15TM-27

15TM-63

15TM-81

7-8

9-8

DEGREES

1 2 3 456

WASH-REGULAR

16008333

TO CHANGE TIMER POSITION PUSH KNOB IN AND TURN CLOCKWISE (ALL TIMER CONTACTS WILL OPEN)

10

203040 50 60 70 80 90 100

7 8

11 12 13

9 10

P

A

U

S

E

SPIN

14 15 16 17 18 19 20 212223 24 25 26

P

A

AGIT

U

FILL

S

RINSE

E

SWITCH AND TIMER SEQUENCE

SPIN

110

AGIT

OFF

120 130 140

P

A

U

S

E

EXTRA RINSE

SPIN

150 160 170 180

27 28

29 303132 33 343536 37 41 42 43 44 45 46 4847 49

WASH-PERM. PRESSOFF

200 210

190

S

P

P

R

A

A

U

Y

S

E

SPIN

220 230 240 250 260

40

38 39

A

P

G

A

I

U

FILL

T

S

SPIN

RINSE

E

OFF

AGIT

SOAK - ADVANCE TO WASH

270

290 300

280

50 51 52 5453 55 56 57 58

A

G

I

T

310

59 60

320

330 340 350

61 62 63 64 65 66

P

A

A

U

G

S

I

SPIN

E

T

67

PAUSE

Page 85

© 1996 M

aytag

C

orporation

WIRING INFORMATION

L1

16023083

SECTION 8. CIRCUIT REVIEW 8-15

PAV5000

WASH FILL

HOT WATER

WASH FILL

COLD WATER

MOTOR AGIT.

FAST

MOTOR AGIT.

SLOW

MOTOR START

AGITATE

MOTOR START

SPIN

MOTOR SPIN

FAST

MOTOR SPIN

SLOW

T.M.

AGITATE

T.M.

SPIN

T.M. ADVANCE

TO RINSE

BUZZER

SPEED

SW.

WH-BRN

WH-BRN

WH-BRN

WATER

TEMP. SW.

WATER

TEMP. SW.

66

LINE VOLTAGE

PINK

1917

WH.-YEL.

17 20

SPEED

SW.

YELLOW

66

SPEED

SW.

65

YEL

32 9

SPEED

SW.

67 65

67 66

67 65

LT.-BLUE

TIMER ADVANCE

RINSE SWITCH

TEMP. CONT. BOARD

9

TIMER

32

YEL

410

3

YELLOW

GRN-BLK

BLU.

TIMER

32

YEL.

GRN-BLK

LT.-BLUE

TAN

TEMP. CONT. BOARD

TIMER

SPEED

SW.

SPEED

SW.

PINK

PURPLE

7

RED

TIMER

SPEED

SW.

TIMER

TIMER

HOT

W.S.

22

COLD

W.S.

20

START-MOTOR

2

START-MOTOR

4

YELLOW

32

GRN-BLK

65

15

15

15 P P

21

21

WHITE

WHITE

3

5

4

2

3

TIMER

TIMER

MOTOR

MOTOR

RED

BLU.

MOTOR

MOTOR

8

8

7 8

9 8

TM

TM

TM

BUZ

WHT-YEL

WHT-YEL

1

1

TIMER

TIMER

1

1

TIMER

8

TIMER

8

TIMER

8

TIMER

8

WHTYEL

WHTYEL

WHTYEL

WHTYEL

WHTYEL

WHTYEL

B

L

TIMER

12

B

L

TIMER TIMER

K

12

B

L

TIMER TIMER TIMER

K

12

B

L

TIMER TIMER TIMER

K

12

B

L

TIMER TIMER TIMER

K

12

B

L

TIMER

K

12

B

L

TIMER

K

12

B

L

TIMER

K

12 26 P P

B

L

TIMER TIMER

K

12

B

L

TIMER

K

12

B

L

TIMER

TIMER

K

12 26

12

TIMER

26

28 3 P P26 1 15 63 64

DOOR

SWITCH

BRN.

26

DOOR

SWITCH

BRN.

26 P P

DOOR

SWITCH

BRN.

26

DOOR

SWITCH

BRN. BRN.

26

TIMER TIMER

12 17

DOOR

SWITCH

BRN.

WATER

LEVEL

GRAY

28 1 2

GRAY

28 2 P P26 1 70

GRAY

28 3

GRAY

28 3

WATER

LEVEL

GRAY

BRN.

BRN.

BRN.

GRAY

28 3

BRN.

ORANGE

WATER

LEVEL

ORANGE

WATER

LEVEL

LT.BLUE WH.-PUR. WH.

1 15

WATER

LEVEL

LT.BLUE WH.-PUR. WH.

1 15

LT.BLU

TIMER

27 15

TIMER

15

27

TIMER

27 15

WATER

LEVEL

1

TIMER

27 15

TIMER

15

27

LADDER WIRING DIAGRAM

TIMER

WH.-RED

70 71 P P

TIMER

WH.-RED

71

63 64

63 64

WH.-PUR.

TIMER

15

62

TIMER

62

15

TIMER

15 62

YEL-RED

TIMER

81

15

MP

MP

MP

P P26

MP

P P26

MP

MP

P P

MP

MP

MP

P P

MP

P P

MP

MP

P P

N

WH.

WH.

WH.

WH.

WH.

WH.

WH.

WH.

WH.

WH.

GRAY

10

17

YEL-RED

LT-BLU

LT-BLU

72

WH-BLU71WH-RED

ORANGE

WHITE-

WHITE WHITE

WHITE

RD-BLK

62

WH-BRN

LT-BLU

63

15 TM

WH-PUR

FRONT TIMER PLATE

= NOT USED.

8

16

26

32

32

69

27

81

GRAY

7

RED

6

BOARD

WHITE/RED, D/STRIPE

4

5 11

16

RD-BLK

26

BRN

71

WH-RED ORANGE72WH-BLU

32

YEL

32

YEL

69

YEL-BLK

27

BRN

81

TAN

PINK9WHITE/YELLOW, D/STRIPE

TEMPERATURE CONTROL

12

RD-BLK

BLK

28

GRAY

BRN

70

7

YEL

RED

9

BLUE

YEL

YEL-BLK

BRN

LT-BLU

TAN

PINK3VIOLET

HARNESS PLUG

CONNECTOR END

12

BLK

28

GRAY

70

7

RED

9

BLUE

RD-BLK

LT-BLU

15 TM

LT-BLU

2

WHITE

CLOSED UP

4

17

YEL-RED

LT-BLU

LT-BLU

WHITEYELLOWYELLOW

WHITE

62

WH-BRN

63

WH-PUR

* CAPACITOR USED WITH ALTERNATE

CAPACITOR START MOTOR.

BLK

PUR

WHT

YEL

4P MAIN

RED

6P MAIN

ORANGE

BLUE

PROT

RED

4

5

GREEN-BLACK

P

WHITE

G

GREEN

2

BLUE

3

YELLOW

1

WHITE-YELLOW

V

RUN

G

START

SCHEMATIC

EMERSON

V

1

3

2

P

5

4

AUX

16008333

Page 86

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-16

PAV5157, PAV5158

C

P

SWITCH FUNCTION

A

O

S

M

ADVANCE-WASH

0

ADVANCE-2ND RINSE

U

T

AGITATE SELECT

2

SPRAY RINSE

B

T

WASH SELECT

4

B

RINSE SELECT

T

SPIN DIRECTION

6

B

AGITATE DIRECTION

T

AGITATE DIRECTION

8

B

SPIN DIRECTION

T

SPIN SOAK

10

B

MOTOR CONTROL SPIN

TM P/SW BYPASS S

T

12

B

MOTOR CONTROL-AGIT

T

BUZZER

14

B

T

B

*120 SECONDS

PER INTERVAL

26-16T

26-17

28-26

28-15TM

70-72

7-32

9-32

15TM-69

15TM-62

15TM-27

15TM-63

15TM-81

* INTERVAL NUMBER

TERM.

IDENT.

70-71

7-8

9-8

16008333

DEGREES

1 2 3 4 5 6 7 8910 11 12 13

TO CHANGE TIMER POSITION PUSH KNOB IN AND TURN CLOCKWISE (ALL TIMER CONTACTS WILL OPEN)

20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300 310 320 330 340 35010

P

A

U

FILL AGIT

S

SPIN

E

RINSE

SWITCH AND TIMER SEQUENCE

18 19 20 21 22

14 151617

P

A

U

S

E

SPIN OFF

23 24

P

A

U

S

AGIT

E

EXTRA RINSE

25 26 27 28 29 30 31 32 33 34 35 36

P

A

SPIN

WASH-PERM. PRESSOFF

U

S

E

39 40

37 414243 44 45 46 48

38

S

A

P

P

G

R

A

I

A

U

FILL

Y

T

S

RINSEWASH-REGULAR

SPIN

SPIN

E

49 50 51 52 5453 55 56 57 58 59 60 61 62 63 64 65 66 67

47

AGIT

OFF

A

G

I

T

SOAK - ADVANCE TO WASH

P

A

A

G

U

I

S

SPIN

T E

PAUSE

Page 87

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-17

PAV5157, PAV5158

16008333

Page 88

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-18

PAVT344

16008333

Page 89

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-19

PAVT344

16008333

Page 90

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-20

HAV2460

16008333

Page 91

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-21

HAV2460

16008333

Page 92

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-22

PAVT244

16008333

Page 93

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-23

PAVT244

16008333

Page 94

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-24

PAVT234, HAV2360, MAV2200

16008333

Page 95

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-25

PAVT234, HAV2360, MAV2200

16008333

Page 96

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-26

HAV2557/2558

16008333

Page 97

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-27

HAV2557/2558

16008333

Page 98

© 1996 M

aytag

C

orporation

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-28

HAV3460

16008333

Page 99

© 1996 M

aytag

C

orporation

WIRING INFORMATION

SECTION 8. CIRCUIT REVIEW 8-29

HAV3460

16008333

Page 100

WIRING INFORMATION

16023083

SECTION 8. CIRCUIT REVIEW 8-30

PAVT444, HAV4657

16008333

© 1996 Maytag Corporation

Loading...

Loading...