Maytag NDG6800AWW, NDE6800AYW Installation Instructions

Printed in USA ©2005 Maytag Corporation 2204560

Automatic

Dryer

Sécheuse automatique/Secadora automática

Installation Instructions/Instructions d’installation/Instrucciones de Instalación.

Features vary by model.

Les caractéristiques et le style

varient selon le modèle.

Las características y los estilos

varían según el modelo.

Automatic Dryer

1 1/2"

(3.81 cm)

2

7

"

(

6

8.5

cm

)

1

3

1/2

"

(34.3 cm

)

3

1/4

"

(8.3 cm

)

2 7

/16

"

(

6

.

2

cm

)

43

1/4

" min.

(109.

9

cm)

3

6

1/4

" min.

(

9

2

cm)

2

7

1/2"

(

69

.

9

cm)

22 1/4

"

(56.

5

cm)

3 5/8”

(9.2 cm)

3 7/16”

(8.7 cm)

6 13/16”

(17.3 cm)

1 1/2" min.

(3.81 cm)

Important to Installer

• PLEASE READ THE FOLLOWING INSTRUCTIONS CAREFULLY BEFORE STARTING TO INSTALL THE

DRYER. THESE INSTRUCTIONS SHOULD BE RETAINED FOR FUTURE REFERENCE.

• REMOVE THE DOOR FROM ALL DISCARDED APPLIANCES TO AVOID THE DANGER OF A CHILD

SUFFOCATING.

• PROPER INSTALLATION IS THE RESPONSIBILITY OF THE OWNER.

• SERVICE CALLS PERFORMED AS A RESULT OF POOR SET-UP, ADJUSTMENT AND CONNECTION

ARE THE RESPONSIBILITY OF THE INSTALLER.

REQUIREMENTS

GENERAL

Make sure you have everything necessary for proper installation.

1. GROUNDED ELECTRICAL OUTLET is required. See Electric Requirements.

2. POWER CORD for electric dryers (except Canada).

3. GAS LINES (if a gas dryer) must meet National and Local Codes.

4. EXHAUST SYSTEM – must be rigid metal or flexible stiff walled metal exhaust ducting. See Exhaust Requirements.

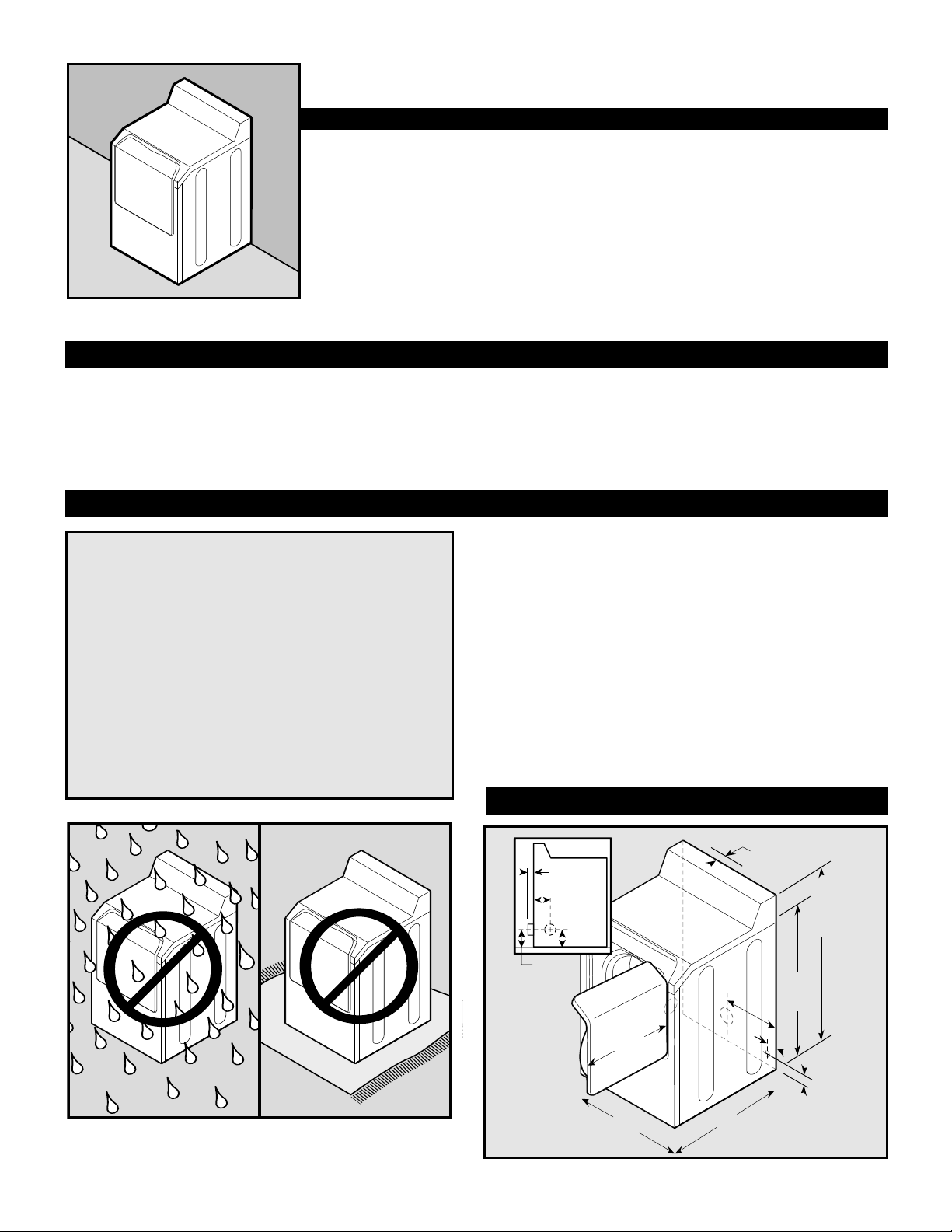

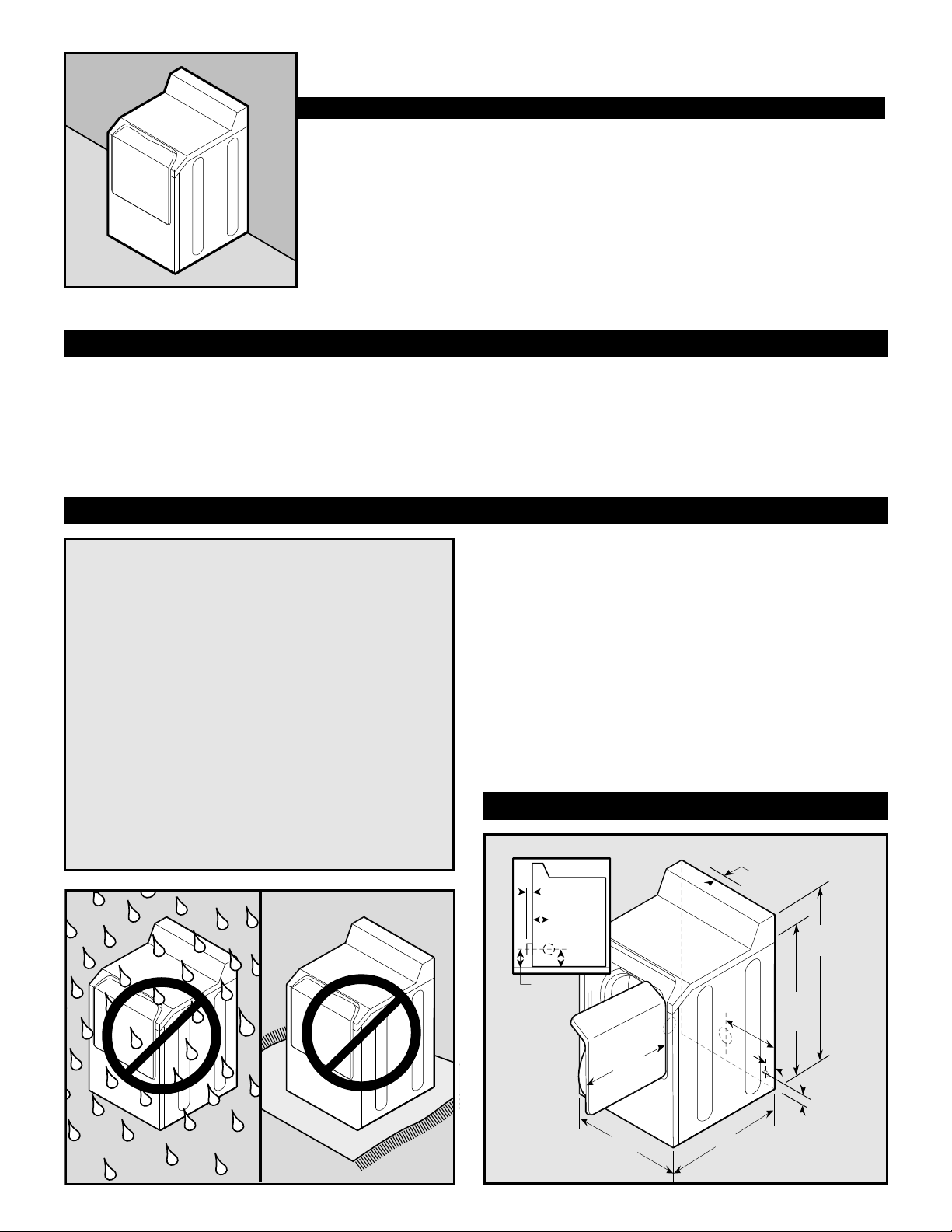

LOCATION CONSIDERATIONS

Instructions

CAUTION

THE DRYER MUST NOT BE INSTALLED OR STORED

IN AN AREA WHERE IT WILL BE EXPOSED TO

WATER AND/OR WEATHER. THE DRYER AREA IS TO

BE KEPT CLEAR AND FREE FROM COMBUSTIBLE

MATERIALS, GASOLINE AND OTHER FLAMMABLE

VAPORS AND LIQUIDS. A DRYER PRODUCES

COMBUSTIBLE LINT. THE AREA AROUND THE

DRYER SHOULD BE KEPT FREE OF LINT.

The dryer should be located to permit adequa

te room in front for

loading the dryer, and sufficient room behind the dryer for the

exhaust system.

yer is factory-ready for rear exhaust.

This dr

To exhaust out the

bottom or left side, use the accessory exhaust kit #12001453

(see Accessories). Instructions are included with the kit.

It is important to make sure the room has adequate make-up air.

The area where the dryer is located must not obstruct the flow of

combustion or ventilating air.

On gas dryers, adequate clearance as noted on the data plate must

be maintained to insure adequa

tion of the dryer.

opera

te air for combustion and proper

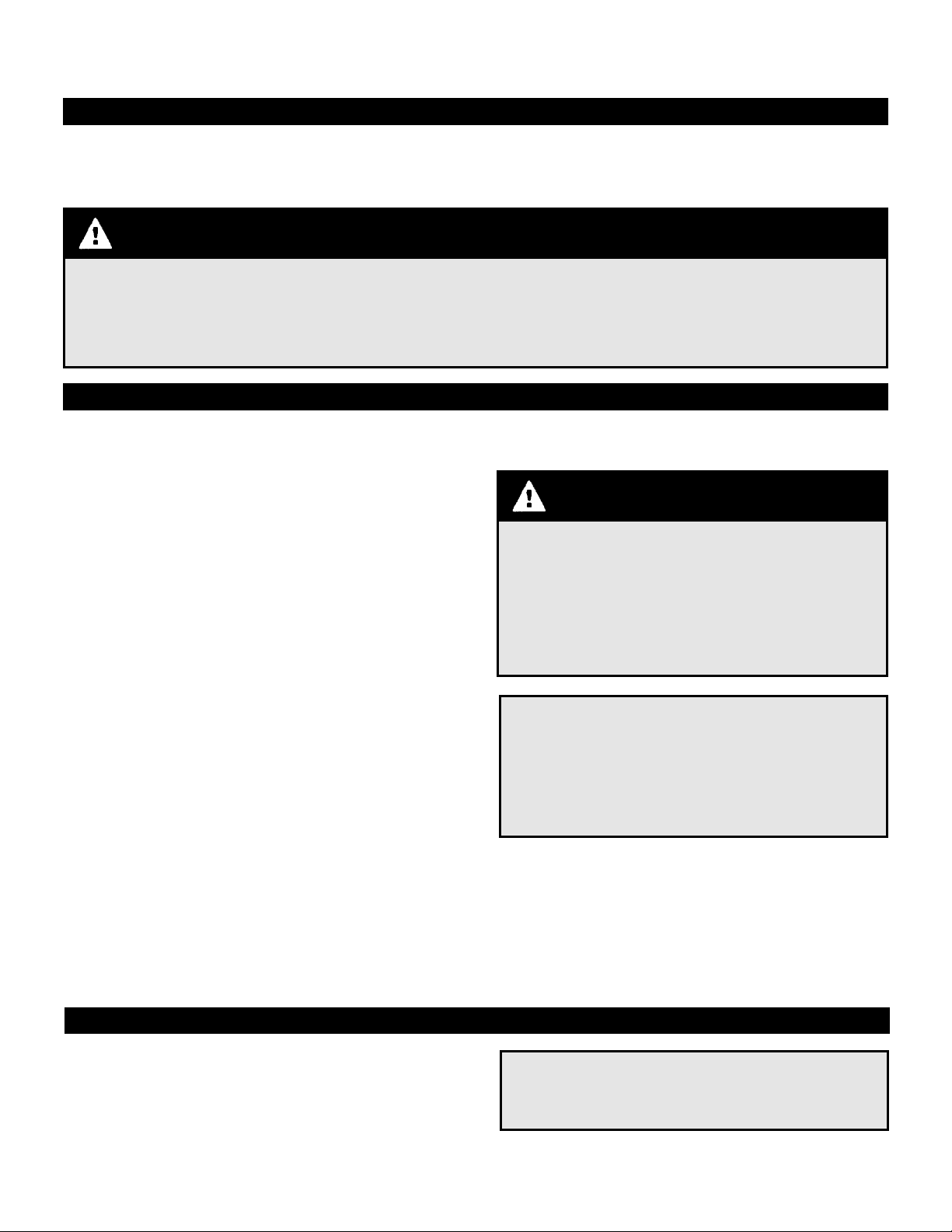

DRYER DIMENSIONS

2

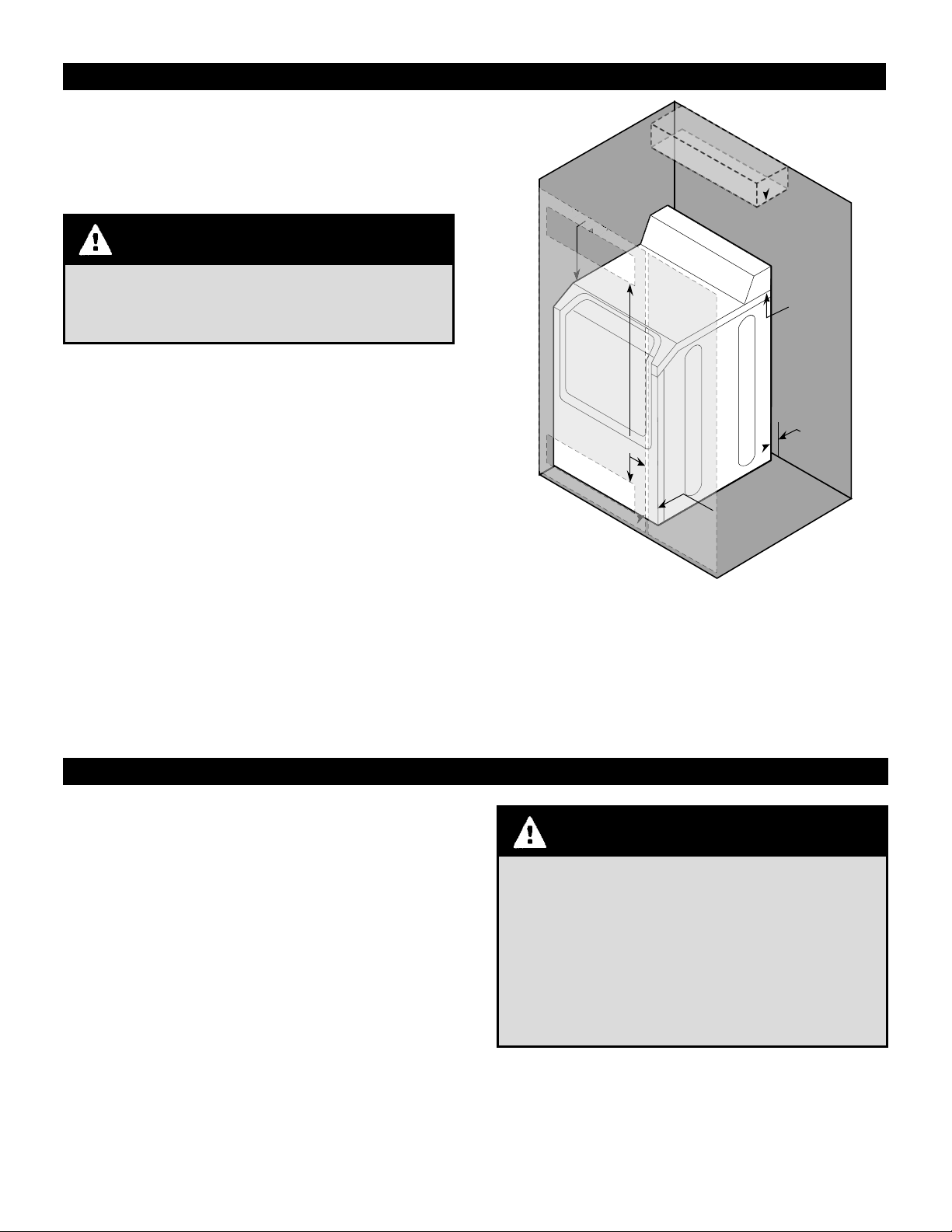

MOBILE HOME INSTALLATION

The installation of the dryer in mobile homes must conform

to the Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 32-80 {formerly the Federal

Standard for Mobile Home Construction and Safety, Title 24,

HUD (part 280), 1975} (for the United States), or CSA

Standards Z240 (for Canada).

When installing a dryer in a mobile home, provisions for

anchoring the dryer to the floor must be made. An anchor

bracket kit #12002643 is available with instructions (see

Accessories). Locate in an area that has adequate make up

unobstructed opening is required.

All mobile home installations must be exhausted to the

to the mobile home structure, using materials that will not

support combustion. The exhaust duct may not terminate

beneath the mobile home.

W A R N I N G

THE DRYER MUST BE EXHAUSTED TO THE

OUTSIDE TO REDUCE THE RISK OF FIRE WHEN

INSTALLED.

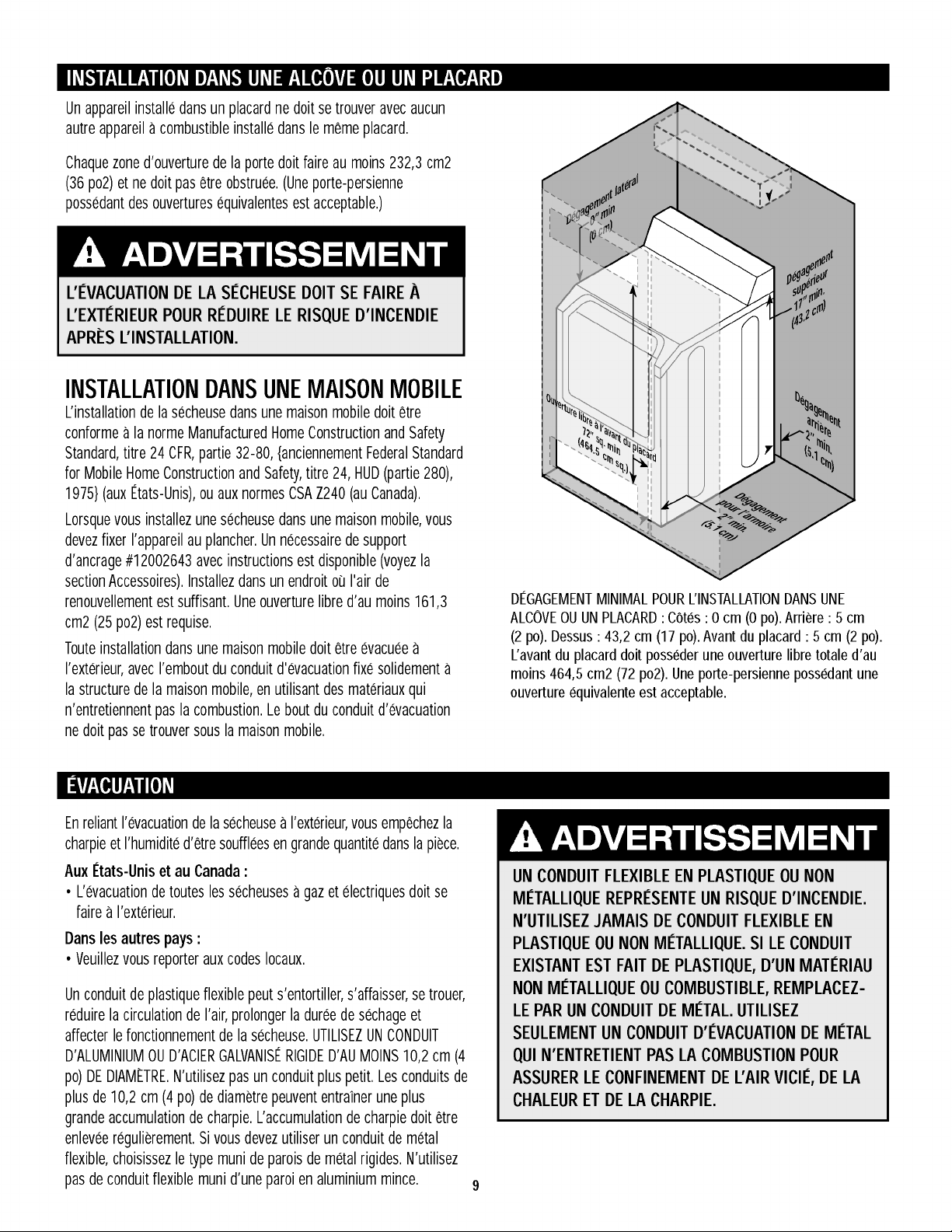

ALCOVE OR CLOSET INSTALLATION

An appliance installed in a closet shall have no other fuel-burning

appliance installed in the same closet.

Each opening area in the door must have a minimum of 36 square

inches. These openings must not be obstructed. (Louvered door

with equivalent air openings is acceptable.)

EXHAUST

Exhausting the dryer to the outside will prevent large amounts of

lint and moisture from being blown into the room.

In the United States and Canada:

• All gas and electric dryers must be exhausted to the outside.

Outside the U.S. and Canada:

• Refer to local codes.

Plastic flexible duct can kink,

sag, be punctured, reduce air flow,

extend drying times and affect dryer operation. USE A MINIMUM

OF 4-INCH (10.2 cm) DIAMETER RIGID ALUMINUM OR RIGID

GALVANIZED STEEL DUCT. Do not use smaller duct. Ducts larger

than 4 inches (10.2 cm) in diameter can result in increased lint

accumulation. Lint accumulation should be cleaned regularly. If

flexible metal duct must be used, use the type with a stiff sheet

metal wall. Do not use flexible duct with a thin foil wall. Serious

blockage can result if flexible metal duct is bent too sharp.

W A R N I N G

PLASTIC OR NONMETAL FLEXIBLE DUCT

PRESENTS A POTENTIAL FIRE HAZARD. NEVER

USE PLASTIC OR NONMETAL FLEXIBLE DUCT. IF

YOUR EXISTING DUCTWORK IS PLASTIC,

NONMETAL OR COMBUSTIBLE, REPLACE IT WITH

METAL. USE ONLY METAL EXHAUST DUCT THAT

WILL NOT SUPPORT COMBUSTION TO INSURE THE

CONTAINMENT OF EXHAUST AIR, HEAT AND LINT.

Sid

e

Clea

r

a

nc

e

0

” m

i

n

(

0

c

m

)

Bac

k

Cle

a

ra

nc

e

2”

mi

n.

(5

.

1

c

m)

T

o

p

C

l

earance

1

7

”

m

i

n.

(

4

3

.

2

c

m

)

C

l

os

et Clearan

ce

2

”

mi

n

.

(

5

.

1 c

m

)

Sid

e

Clea

r

a

nc

e

0

” m

i

n

cm)

cm)

i

n

e

Clea

r

a

nc

e

C

lo

s

et

Front Air

O

p

ening

72

"

s

q

.

m

i

n

(4

6

4

.

5

cm s

q.

)

MINIMUM CLEARANCES FOR CLOSET AND ALCOVE

INSTALLATIONS: Sides – 0 in. Rear – 2 in. Top – 17 in. Closet

Front – 2 in. The closet front must have a total unobstructed

air opening of 72 sq. in. minimum. A louvered door with

equivalent air opening is acceptable.

3

air. A minimum of 25 square inches (161.3 cm sq.) of

outside with the exhaust duct termination securely fastened

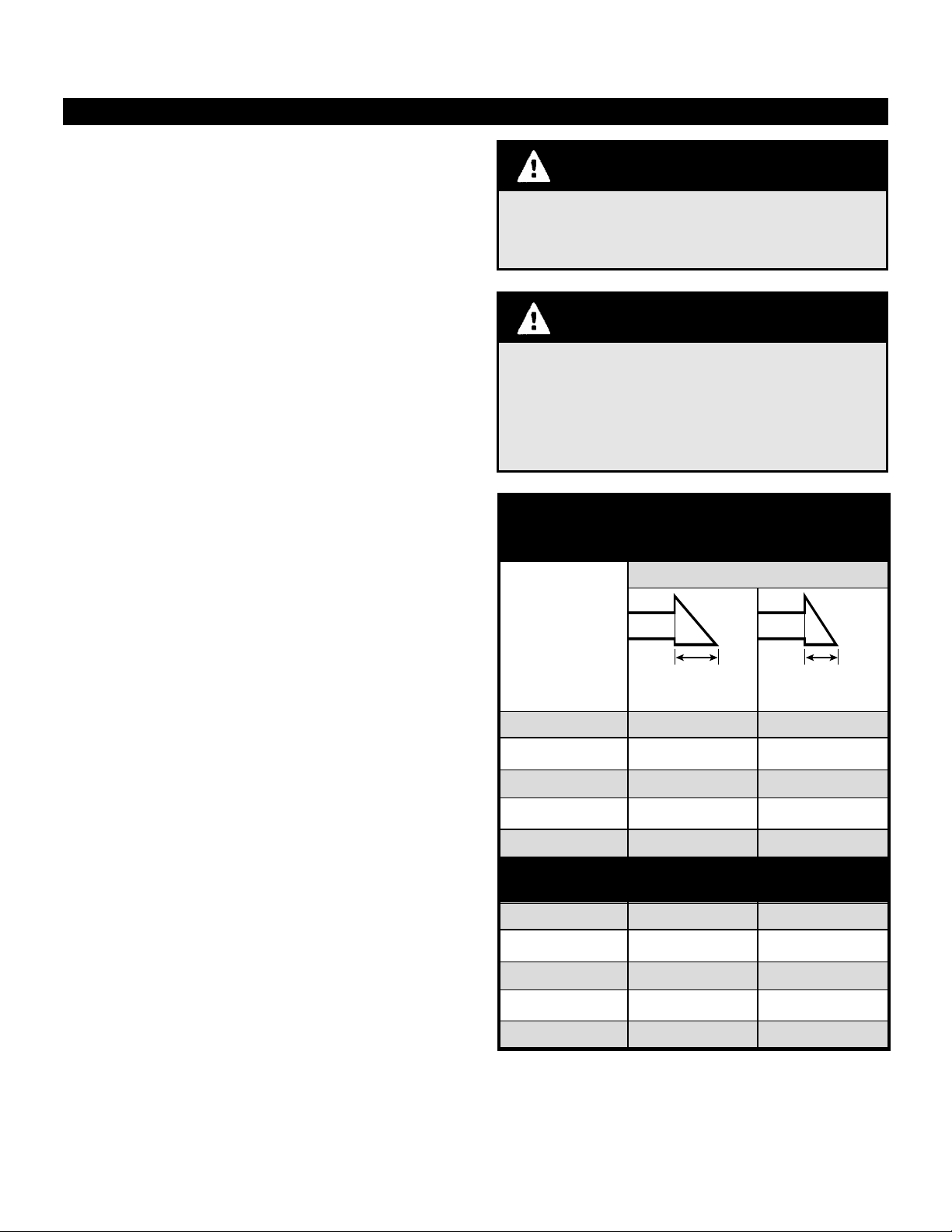

EXHAUST CONTINUED

VENT HOOD TENT

0

100 Feet (30.5m)

59 Feet (18.0m)

1

80 Feet (24.4m)

48 Feet (14.6m)

2

65 Feet (19.8m)

38 Feet (11.6m)

3

50 Feet (15.2m)

30 Feet (9.1m)

4

35 Feet (10.7m)

22 Feet (6.7m)

4" (10.2cm)

Opening

2

1/2

" (6.4cm)

Opening

LENGTH OF VENT

Maximum Length of 4" Rigid Duct

Number of 90˚

turns separated by

at least 4'

(121.9cm) of

straight run.

0

36 Feet (11.0m)

28 Feet (8.5m)

1

32 Feet (9.8m)

24 Feet (7.3m)

2

28 Feet (8.5m)

20 Feet (6.1m)

3

25 Feet (7.6m)

17 Feet (5.2m)

4

23 Feet (7.0m)

15 Feet (4.6m)

4" (10.2cm) Opening/

Ouverture/Cavidad

2

1/2

" (6.4cm) Opening/

Ouverture/Cavidad

Maximum Length of 4" Diameter Flexible stiff walled metal duct

Never install any type of flexible duct in walls, ceilings or other

concealed spaces. Keep exhaust duct as straight and short as

possible. Exhaust systems longer than recommended can extend

drying times, affect machine operation and may collect lint. Secure

joints with duct tape. Do not use screws.

The exhaust duct should end with an exhaust hood with a swing

out damper to prevent backdrafts and entry of wildlife. Never use

an exhaust hood with a magnetic damper. The hood should have at

least 12 inches (30.5 cm) of clearance between the bottom of the

hood and the ground or other obstruction. The hood opening should

point down. Never install a screen over the exhaust outlet.

When possible,

in order to avoid lint build-up. Do not exhaust under a house or

porch.

If exhaust ductwork must run through an unhea

should be insulated and slope slightly down towards the exhaust

hood to reduce condensation and lint build-up.

If an existing exhaust system is to be used with your new dryer,

you must be sure:

• The exhaust system meets all local, state and national codes.

• That plastic flexible duct is not used.

To completely inspect and clean all lint accumulation from the

•

interior of the duct.

• The duct is not kinked or crushed.

• The exhaust hood damper opens and closes freely.

The static pressure in any exhaust system must not exceed 0.92

inches of wa

with the dryer running with a manometer at the point where the

exhaust duct connects to the dryer.A no heat setting should be

used. The dryer tumbler should be empty and the lint filter clean

Inspect and clean the interior or the exhaust system at least once a

year. Disconnect electrical service prior to cleaning. Check the gas

line on gas dr

be sure the exhaust hood damper opens and c

do not exhaust the dryer directly into a window well

ter column,

yers an

or be less than 0.

ytime the dr

yer is moved.

ted area,

the duct

This can be measured

requently check to

F

loses freely

.

WARNING

THE DRYER MUST BE EXHAUSTED TO THE

OUTSIDE TO REDUCE THE RISK OF FIRE WHEN

INSTALLED.

WARNING

DO NOT EXHAUST DRYER INTO ANY WALL,

CEILING, CRAWL SPACE, CONCEALED SPACE OF A

BUILDING, GAS VENT, OR ANY OTHER COMMON

DUCT OR CHIMNEY. THIS COULD CREATE A FIRE

HAZARD FROM LINT EXPELLED BY THE DRYER.

4

GAS REQUIREMENTS

Use only Natural or LP (liquid propane) gases.

CAUTION

THE INSTALLATION MUST CONFORM WITH LOCAL

CODES, OR IN THE ABSENCE OF LOCAL CODES,

WITH THE NATIONAL FUEL GAS CODE

ANSI/Z223.1, LATEST REVISION (FOR THE UNITED

STATES), OR WITH THE CAN/CGA-B149

INSTALLATION CODES (FOR CANADA).

A 1/2”(1.27 cm) gas supply line is recommended and must be

reduced to connect to the 3/8”(1.0 cm) gas line on the dryer.

The National Fuel Gas Code requires that an accessible, approved

manual gas shut off valve be installed within 6 feet of the dryer.

A 1/8”(.3 cm) N.P.T.(National Pipe Thread) plugged tapping,

accessible for test gauge connection, must be installed

immedia

The dryer must be disconnected from the gas supply piping

system during any pressure testing of the system.

tely upstream of the gas supply connection to the dryer.

Gas dryers are equipped with a burner orifice for operation on

NATURAL gas.

CAUTION

IF THE DRYER IS TO BE OPERATED ON LP (LIQUID

PROPANE) GAS, IT MUST BE CONVERTED FOR

SAFE AND PROPER PERFORMANCE AND MUST BE

CONVERTED BY A QUALIFIED SERVICE

TECHNICIAN.

Conversion kits from NATURAL to LP, or LP to NATURAL are

available through your local Maytag dealer (see Accessories). If

other conversions are required, check with the local gas utility for

specific information concerning conversion requirements.

CAUTION

GAS DRYERS INSTALLED IN RESIDENTIAL

GARAGES MUST BE ELEVATED 18 INCHES (46 CM)

ABOVE THE FLOOR.

CAUTION

DO NOT RE-USE OLD FLEXIBLE METAL GAS LINE.

FLEXIBLE GAS LINE MUST BE DESIGN CERTIFIED

BY AMERICAN GAS ASSOCIATION (CGA IN

CANADA).

GAS IGNITION

This dryer uses an automatic ignition system to ignite the burner.

There is no constant burning pilot.

TION

COMMONWEAL

INSTRUCTIONS

This gas dryer must be installed by a licensed plumber or gas

fitter.

A “T”handle manual gas valve must be installed in the gas

supply line to this gas dryer.

If a flexible gas connector is used to install this gas dr

connector must have a maximum length of 3 feet.(36 inches)

TH OF MASSACHUSETTS INST

ALLA

yer, the

TE:Any pipe joint compound used must be resistant to the

NO

action of any liquefied petroleum gas.

NOTE: As a courtesy, most local gas utilities will inspect a gas

appliance installation.

WARNING

GAS LEAKS MAY OCCUR IN YOUR SYSTEM AND

RESULT IN A DANGEROUS SITUATION. GAS LEAKS

MAY NOT BE DETECTED BY SMELL ALONE. GAS

SUPPLIERS RECOMMEND YOU PURCHASE AND

INSTALL A UL APPROVED GAS DETECTOR.

INSTALL AND USE IN ACCORDANCE WITH THE

MANUF

ACTURER’S INSTRUCTIONS.

5

ELECTRICAL REQUIREMENTS

NOTE: Wiring diagram is located inside the control console.

Export models (not U.S. or Canada): See Additional Instructions for Export Models.

WARNING

TO PREVENT UNNECESSARY RISK OF FIRE, ELECTRICAL SHOCK OR PERSONAL INJURY, ALL WIRING AND

GROUNDING MUST BE DONE IN ACCORDANCE WITH LOCAL CODES, OR IN THE ABSENCE OF LOCAL CODES,

WITH THE NATIONAL ELECTRICAL CODE, ANSI/NFPA, NO. 70-LASTEST REVISION (FOR THE UNITED STATES) OR

THE CANADIAN ELECTRICAL CODE CSA C22.1 (FOR CANADA).

GROUNDING

This dryer must be grounded. In the event of malfunction or breakdown, the ground will reduce the risk of electrical shock by providing a

path of least resistance for electrical current.

GAS MODELS

This appliance is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must be

plugged into an appropria

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided with the appliance – if it will not

fit the outlet,

electrician.

If a separate ground is required by local codes, a grounding kit

art No.12001875) is available.

(P

ground screw and washer. Connect ground wire to back of unit

with the cabinet ground screw and washer. Secure other end of

ground wire to a suitable external ground connection. The wire

may be secured with the c

pipe.

have a proper outlet installed by a qualified

te outlet that is properly installed and

It contains ground wire, clamp,

lamp to a grounded COLD metal wa

ter

IMPROPER CONNECTION OF THE EQUIPMENT

GROUNDING CONDUCTOR CAN RESULT IN A RISK

OF ELECTRIC SHOCK. CHECK WITH A QUALIFIED

ELECTRICIAN OR SERVICEMAN IF YOU ARE IN

DOUBT AS TO WHETHER THE APPLIANCE IS

PROPERLY GROUNDED.

CAUTION

NEVER CONNECT GROUND WIRE TO PLASTIC

PLUMBING LINES, GAS LINES OR HOT WATER

PIPES.

WARNING

ELECTRIC MODELS

U.S.electric models are shipped with a ground strap connected from the neutral terminal block post to the frame of the dryer. If local codes

prohibit the use of the ground strap, the dryer must be grounded in accordance with local codes.

If a power cord is not used and the electric dryer is to be permanently wired, the dryer must be connected to a grounded metal, permanent

wiring system; or an equipment grounding conductor must be run with the circuit conductors and connected to the equipment grounding

terminal.

ELECTRICAL CONNECTIONS

w all grounding instructions in

BEFORE OPERA

Grounding Section.

only this appliance is recommended.

TING OR

TESTING,

An individual branch (or separate) circuit serving

follo

CAUTION

NEVER USE AN EXTENSION CORD.

6

ELECTRICAL CONNECTIONS CONTINUED

GAS MODELS – U.S. and Canada

A 120 volt, 60 Hz AC, approved electrical service, with a 15 ampere fuse or circuit breaker is required.

ELECTRIC MODELS – U.S. Only

Most U.S. dryers, as manufactured, require a 120/240 volt, 60 Hz AC approved electrical service. Some require 120/208 volt, 60 Hz approved

electrical service. The electric service requirements can be found on the data label located on the front behind the door. A 30 ampere fuse or

circuit breaker on both sides of the line is required.

A 120/240 volt U.S. electric dryer must be converted if it is to operate on a 120/208 volt electrical system. A heating element conversion kit

is available.

If a power cord is used, the cord should be plugged into a 30 ampere receptacle.

The power cord is NOT provided with U.S. electric model dryers.

IMPORTANT:When permitted by local codes, the dryer electrical supply may be connected by means of a new power supply cord kit, marked

for use with clothes dryer, that is U.L. listed, rated at 120/240 volts minimum, 30 amperes with three No. 10 copper wire conductors

terminated with closed loop terminals, open end spade lugs with turned up ends or with tinned leads.

Do not reuse a power supply cord from an old dryer. The power cord electric supply wiring must be retained at the dryer cabinet with a

suitable UL listed strain relief.

If the dryer is installed in a mobile home, recreational vehicle, a new branch circuit or an area where local codes do not permit grounding

through neutral, only a 4 conductor power cord, rated and terminated as above may be used.

ELECTRIC MODELS – Canada Only

A 120/240 volt, 60 Hz AC approved electrical service fused through a 30 ampere fuse or circuit breaker on both sides of the line is required.

All Canadian models are shipped with the power cord attached. The power cord should be plugged into a 30 ampere receptacle.

NOTE: It is not permissible to convert a dryer in Canada to 208 volts.

REPLACEMENT PARTS AND ACCESSORIES

If your dryer requires replacement parts or accessories, contact the dealer from whom you purchased your dryer or contact:

Maytag Customer Service

Box 2370

Cleveland, Tennessee 37320-2370

phone 1-800-688-9900 in the USA 1-800-688-9902 in Canada

arts Distributor

for informa

ADDITIONAL INFORMATION FOR INTERNATIONAL USE (not U.S. or Canada)

Maytag dryer models manufactured for operation on 60 Hz AC are not designed for use on 50 Hz AC electrical service and conversion of the

product from 60 to 50 Hz opera

Maytag International

1475 East Woodfield Road

Schaumburg, Illinois USA 60173

phone 847-273-3100

tion on the nearest authorized Mayta

tion is not recommended.

g P

.

or additional informa

F

tion on 50 Hz products,

contact Maytag International.

The electric ser

vice requirements can be found on the da

ta label loca

ted on the front of the dryer behind the door.

7

Sécheuse automatique

1 1/2"

(3.81 cm)

2

7

"

(

6

8.5

cm

)

1

3

1/2

"

(34.3 cm

)

3

1/4

"

(8.3 cm

)

2 7

/16

"

(

6

.

2

cm

)

43

1/4

" min.

(109.

9

cm)

3

6

1/4

" min.

(

9

2

cm)

2

7

1/2"

(

69

.

9

cm)

22 1/4

"

(56.

5

cm)

3 5/8”

(9.2 cm)

3 7/16”

(8.7 cm)

6 13/16”

(17.3 cm)

1 1/2" min.

(3.81 cm)

Instructions

Message important pour l’installateur

• VEUILLEZ LIRE ATTENTIVEMENT LES INSTRUCTIONS SUIVANTES AVANT DE DÉBUTER

L’INSTALLATION DE LA SÉCHEUSE. CES INSTRUCTIONS DOIVENT ÊTRE CONSERVÉES POUR VOUS

Y REPORTER ULTÉRIEUREMENT.

• ENLEVEZ LA PORTE DE TOUT APPAREIL MIS AU REBUT POUR ÉVITER LE RISQUE D’ASPHYXIE CHEZ

LES ENFANTS.

• LA RESPONSABILITÉ D’UNE INSTALLATION CORRECTE DE L’APPAREIL INCOMBE AU PROPRIÉTAIRE.

• L’INSTALLATEUR EST RESPONSABLE DES RÉPARATIONS EFFECTUÉES EN RAISON D’UNE MAUVAISE

EXIGENCES

GÉNÉRAL

Assurez-vous d’avoir tous les accessoires nécessaires pour effectuer l’installation.

1. UNE PRISE MISE À LA TERRE est requise.Voyez les exigences électriques.

2. UN CORDON D’ALIMENTATION pour sécheuses électriques (sauf au Canada).

3. LES CONDUITES DE GAZ (pour une sécheuse à gaz) doivent être conformes aux codes nationaux et locaux.

4. LE SYSTÈME D’ÉVACUATION – doit être un conduit d’évacuation fait de métal rigide ou de métal flexible à parois rigides. Voyez les exigences

d’évacuation.

EMPLACEMENT

INSTALLATION, D’UN RÉGLAGE ERRONÉ OU D’UN RACCORDEMENT INAPPROPRIÉ.

A TTENTION

LA SÉCHEUSE NE DOIT PAS ÊTRE INSTALLÉE OU

ENTREPOSÉE DANS UN ENDROIT OÙ ELLE PEUT

ÊTRE EXPOSÉE À L’HUMIDITÉ OU AUX

INTEMPÉRIES. L’EMPLACEMENT DE LA SÉCHEUSE

DOIT ÊTRE LIBRE DE TOUT COMBUSTIBLE,

ESSENCE ET AUTRES VAPEURS OU LIQUIDES

INFLAMMABLES. LA SÉCHEUSE PRODUIT DE LA

CHARPIE COMBUSTIBLE. ASSUREZ-VOUS QU’IL

N’Y A PAS DE CHARPIE SUR LES SURFACES

AVOISINANT LA SÉCHEUSE.

La sécheuse doit être installée de manière à disposer d’un espace suffisant

à l’avant, pour le chargement, et à l’arrière, pour le système d’évacuation.

Cette sécheuse est préparée à l’usine pour recevoir un conduit

d’évacuation à l’arrière. Pour installer un conduit d’évacuation au bas ou

sur le côté gauche, utilisez le nécessaire d'évacuation #12001453 (voyez la

section Accessoires). Des instructions sont comprises avec le nécessaire.

Il est important de s’assurer que la pièce possède de l’air de

renouvellement en quantité suffisante. L’endroit où la sécheuse est située

ne doit pas obstruer la circulation de l’air de combustion ou de ventilation.

Pour les sécheuses à gaz, le dégagement approprié indiqué sur la plaque

signalétique doit être respecté afin d’assurer une quantité suffisante d’air

de combustion, ainsi que le bon fonctionnement de la sécheuse.

DIMENSIONS DE LA SÉCHEUSE

8

Loading...

Loading...