Page 1

Installation

A

B

Location

• Do not install refrigerator near oven, radiator or

other heat source. If not possible, shield refrigerator

with cabinet material.

•

Do not install where temperature falls below 55° F

(13° C) or rises above 110° F (43° C). Malfunction

may occur at this temperature.

Refrigerator is designed for indoor household

•

application only.

Measuring the Opening

When installing your refrigerator, allow

1

and

⁄2” space behind machine compartment cover

ated in the rear) for proper air circulation. If the

(loc

refrigerator is placed with the door hinge side against

a wall, you may want to allow additional space so the

door can be opened wider

Subflooring or floor coverings (i.e. carpet, tile, wood

floors, rugs) may make your opening smaller than

anticipated.

Some clearance may be gained by using the leveling

procedure under

Important: If refrigerator is to be installed into a

recess where the top of the refrigerator is completely

covered, use dimensions from floor to top of hinge c

to verify proper clearance.

Leveling.

.

1

⁄2” space at top

ap

Door and Hinge Removal

Some installations require door removal to get

refrigerator to final location.

WARNING

To avoid severe personal injury or death,

observe the following:

• Disconnect power to refrigerator before removing

doors. Connect power only after replacing doors.

• Green ground wire must be attached to top hinge

while performing door removal and replacement.

• Tape decorative panels (select models) securely

into place

To avoid property damage, observe the following:

• Protect vinyl or other flooring with cardboard, rugs

or other protective material prior to moving

refrigerator.

Do not adjust refrigerator to be any shorter than

•

1

68

⁄2” tall (minus hinge and cap). Doing so may

damage underside components.

1.

Unplug power cord from power source.

Remove toe grille (see page 4).

2.

• Open both doors 180°, or as wide as possible.

before removing door handles.

CAUTION

Transporting Your Refrigerator

• NEVER transport refrigerator on its side. If an

upright position is not possible, lay refrigerator on it

back. Allow refrigerator to sit upright for

approximately 30 minutes

assure oil returns to the compressor. Plugging

refrigerator in immediately may cause damage to

s.

internal par

• Use an appliance dolly when moving refrigerator.

A

W

AL

back–NEV

• Protect outside finish of refrigerator during transport

by wrapping cabinet in blankets or inserting padding

between the refrigerator and dolly.

• Secure refrigerator to dolly firmly with straps or

bungee cords. T

possible.

restraints may dent or damage outside finish.

3

t

S

Y

truck refrigerator from it

ER

from it

hread straps through handle

Do not over-tighten. Over-tightening

before plugging it in to

s side or

s front.

s when

Note: For refrigerators in operation, shut off water

before removing water line from the door.

o Disconnect the Water Line:

s

T

• Push in white collar (A) and hold.

Pull the door-side tube from the connector

•

To Reconnect the Water Line:

• Firmly push tube

lines on the tube as a guide for full insertion.

• If tube end is damaged, cut off

reconnecting.

• If leaking occurs, reconnect the line.

5

⁄8” into the connector. Use

5

⁄8” before

(B).

Page 2

Installation

A

B

A

B

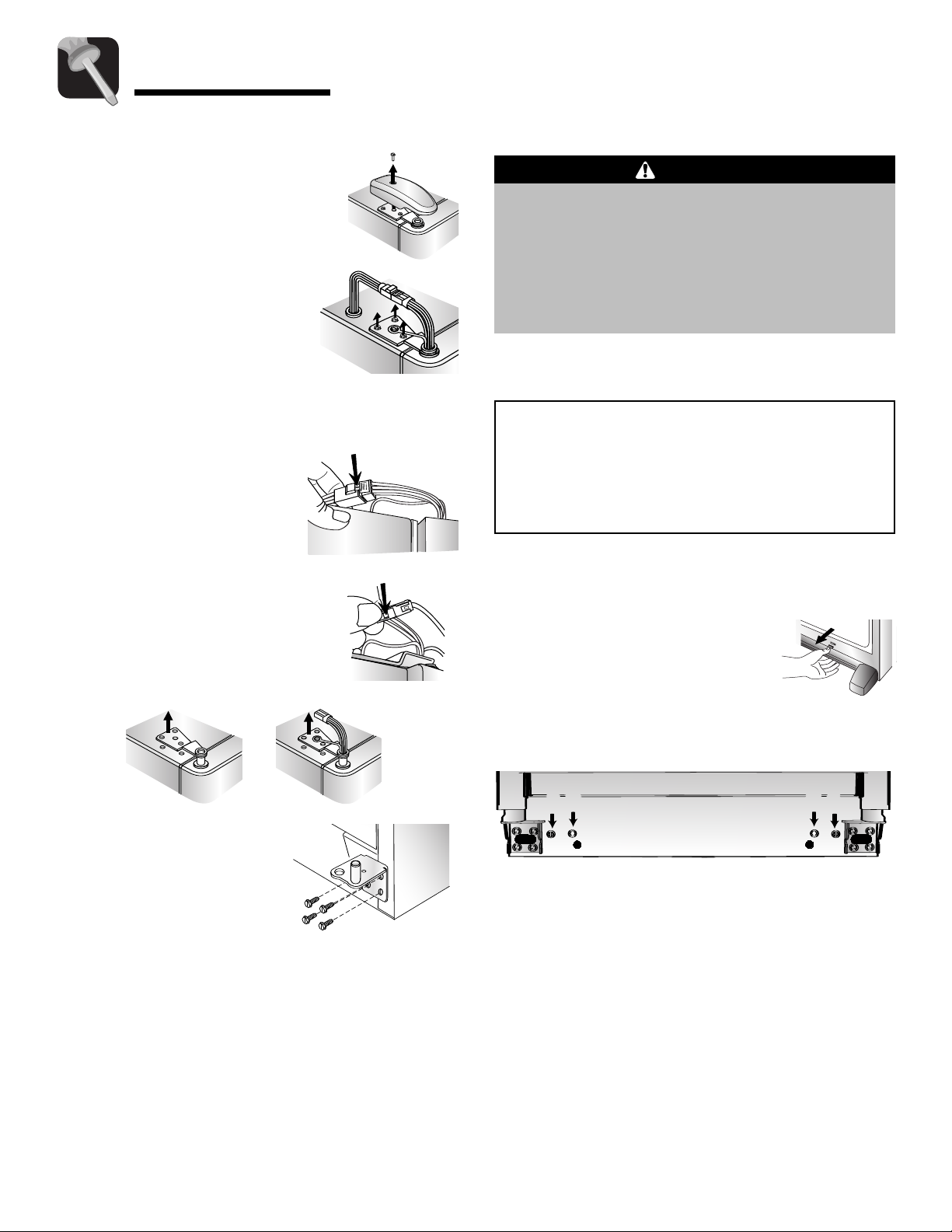

3. Close doors.

4. Remove top hinge covers by

removing Phillips screws.

5. Unscrew

top hinges.

For water dispensing

models only:

• Do not remove screw

connecting green ground

wire.

For ice and water dispensing models only:

6.

Detach main wire connector harness and red wire

harness.

• To detach main wire

harness, use a flat blade

tool or fingernail to press

junction point between two

connectors to release.

• To detach red wire harness,

pre

connector to release.

5

⁄1

” hex head screws from

6

ss tab on underside of

Leveling

CAUTION

To protect personal property and refrigerator

from damage, observe the following:

• Protect vinyl or other flooring with cardboard, rugs,

or other protective material.

•

Do not use power tools when performing leveling

procedure.

To enhance the appearance and maintain performance,

the refrigerator should be level.

Notes:

• Complete any required door reversal, panel

installation and/or a water supply connection

before leveling.

• Some models only have adjustment screws

Materials Needed:

3

•

⁄8” hex head driver

• Carpenter’s level

1. Remove toe grille.

(A).

7. Remove top hinges along with

doors.

Remove bottom hinge

8.

with a

3

⁄8” hex head driver

s

.

Replacing the Doors

• To replace the doors, follow the steps in Door and

Hinge Removal in reverse order.

Important: If water line tube end is damaged, cut off

5

⁄8” before reconnecting.

• Grasp firmly and pull outward

to unclip.

Using hex head driver

2.

screws

to lower the front of the refrigerator

3. Select models also have rear adjustment screws

(B). Using the hex head driver, turn each of these

adjustment screws (B) to raise or lower the rear of

the refrigerator

Using the c

4.

refrigerator is

back of refrigerator and that the refrigerator is level

from side to side.

5. If required, correct rocking of refrigerator by

turning rear adjustment screw

rocking corner

following:

(A) clockwise to raise and counterclockwise

.

arpenter’s level, make sure front of

1

⁄4” (6 mm) or 1⁄2 bubble higher than

. If doors are uneven, do the

, turn front adjustment

.

clockwise to raise

Cont.

4

Page 3

Installation

• Determine which

door needs to be

raised.

• Turn front roller

adjustment screw

(A) clockwise to

raise front corner of

door.

• If one refrigerator door has reached the limit of

its adjustment range and doors are still not level,

raise or lower the opposite door by turning roller

adjustment screw

• Check with level to verify

proper door closure.

If refrigerator is aligned and stable, replace toe

•

grille.

• Align the toe grille mounting clips with the lower

cabinet slot

• Push the toe grille firmly until it snaps into place.

s.

clockwise or counterclockwise.

1

⁄4” tilt to the back for

Connecting the Water Supply

(select models)

WARNING

To reduce the risk of injury or death, f

basic precautions, including the following:

• Read all instructions before installing ice maker.

• Do not attempt installation if instructions are not

understood or if they are beyond personal skill

level.

Observe all local codes and ordinances.

•

• Do not service ice maker unless specifically

recommended in Use & Care Guide or published

user-repair instructions.

• Disconnect power to refrigerator before installing

ice maker

• Water damage due to an improper water

connection may c

up spills or leakage immediately!

.

ause mold/mildew growth. Clean

ollow

CAUTION

To avoid property damage or possible injury,

follow basic precautions, including the

following:

• Consult a plumber to connect

tubing

compliance with local codes and ordinances.

• Confirm water pressure to water valve is between

35 and 100 pounds per square inch, 20 pounds

per square inch without filter.

•

Do not use a self-piercing, or

Both reduce water flow and can become clogged

over time, and may cause leaks if repair is

attempted.

• Tighten nuts by hand to prevent cross threading.

Finish tightening nuts with pliers and wrenches.

Do not over-tighten.

• Wait two to three hours before placing refrigerator

into final position to check and correct any water

leaks. Recheck for leaks after 24 hours.

• Verify the copper tubing under the sleeve is

smooth and free from defects.

old sleeve.

Materials Needed:

1

•

⁄4” outer diameter flexible copper tubing

• Shut-off valve (require

water supply line before valve att

• Adjustable wrench (2)

1

•

⁄4” hex nut driver

to household plumbing to assure

s a

1

⁄4” O.D. copper

3

⁄16” saddle valve.

Do not reuse an

1

⁄4” hole to be drilled into

achment)

Notes:

• Use copper tubing only for installation. Plastic is

less durable and can cause damage.

• Add 8’ to tubing length needed to reach water

supply for creation of service loop.

1. Create service loop with

copper tubing (minimum 2’

diameter). Avoid kinks in the

copper tubing when

bending the service loop.

not use plastic tubing.

Do

2’ diameter

minimum

Remove plastic c

2.

inlet port.

5

ap from water valve

Page 4

Installation

3. Place brass nut (A) and sleeve (B)

on copper tube end as illustrated.

Reminder: Do not use an old

sleeve. The nut and sleeve are

provided in the Use and Care

packet.

4. Place end of copper tubing into

water valve inlet port. Shape

tubing slightly.

that tubing feeds straight into inlet

port.

5. Slide brass nut over sleeve and

screw nut into inlet port.

Place adjustable wrench on nut

(1) att

and maintain position.

Using second adjustable wrench

turn the lower nut

counterclockwise and fully

tighten while holding the upper

nut in place.

ached to plastic waterline

Do not kink – so

(2)

Plastic Handle with Extensions

Attach Extensions to Handle:

1. Align handle and extension as shown.

B

A

B

A

1

2

2. Place extension in handle opening.

3. Apply slight pressure

to both sides of the

extension piece.

4. Slide extension until it

stops on inside edge

of handle.

To Install:

1. The handles are to be oriented as shown.

2. Align door handle with the door studs.

3. Ensure the large hole in the mounting clip is

positioned

down on both ends of the handle.

Important: Do not over-tighten. Cross threading

may occur

6. Pull on tubing to confirm

connection is secure.

Connect tubing to frame

with water tubing clamp

and turn on water supply.

Check for leaks and correct

if nece

observe the water supply

connection for two to three

hours prior to moving the

refrigerator to its permanent

location.

7. Monitor water connection for 24 hours. Correct

leaks, if nece

.

ary. Continue to

ss

.

ary

ss

(C)

Handle Installation

If not installed, the handle is located in the interior of

the fre

refrigerator. Remove and discard handle packaging

and tape.

sh food section or attached to the back of your

C

Door

Stud

4. Rotate the handle so that the

handle is flat against the door

5. Grasp the handle firmly and slide

down.

.

Handle de

Please reference the appropriate instructions for your

model.

sign varie

s from refrigerator to refrigerator.

Cont.

6

Page 5

Installation

To Remove:

1. Grasp the lower part of the handle firmly,

slide up, lift and remove from the

surface.

Wide-by-Side™ Handles

Materials Needed:

• Gloves to protect hands

• Plastic door handle removal card (or

thick plastic card), retain the card

• Flat blade screwdriver

To Install:

1. Align fresh food handle with trim

retainer and door clip.

2. Make sure the tabs of the handle clip

are

below the t

3. Rotate the handle so that the handle

is flat against the door (see page 6).

4. The tab on the lower part of the

handle will align with the hole in the

handle c

Slide handle

5.

abs of the door clip.

ap.

upward until it clicks.

1

⁄32”

To Install:

1. Release top door trim by

removing Phillips screws from

top of fresh food door, retaining

screws for later use.

2. Align notches on back of handle

with retaining clips on doors. Insert

clips into notches and slide handle

down until it contacts bottom trim.

3. Replace top door trim and Phillips screws.

4. Repeat instructions 1-3 to install other handle.

Door Clip

WARNING

To avoid possible injury and damage to property,

tape decorative panels (select models) securely into

place before removing door handles.

To Remove:

1. Release top door trim by removing

Phillips screws from top of fresh food

door, retaining screws for later use.

2. Grasp handle firmly with both hands.

Slide handle

approximately

upward

3

⁄4” to release.

6. Snap top of handle into trim retainer clip.

7. Repeat for freezer handle.

To Remov

1. Protect the area above the handle trim with tape.

Insert the tip of a flat blade screwdriver between

the handle trim and door panel. Carefully pry the

trim away from the door panel.

2. Pull trim free from the trim retainer.

3. Insert door removal card (or

between the handle and door panel (approximately

1

Grasp the handle firmly and pull

4.

downward to remove.

5. Repeat for freezer handle.

e:

1

⁄32” thick plastic card)

1

).

⁄2”

Full-Length Aluminum

Handles

Materials Needed:

Repeat instructions 1-2 to

3.

remove other handle.

To Reinstall:

1. Repeat in reverse order.

Metal Handle

Materials Needed:

3

•

⁄32” Allen wrench

s to protect hands

Glove

•

Note: Metal handles can scratch doors.

o Remove:

T

Loosen set screws in handle using

•

wrench.

• Repeat the procedure on all screws.

To Replace:

• Align handle with the mounting posts.

• Apply upward pressure to the handle and hold.

3

⁄32” Allen

• Phillips screwdriver

7

• Fully tighten all set screws to secure handle in

place.

Loading...

Loading...