Page 1

INSTALLATION INSTRUCTIONS AND OWNER’S MANUAL

W10706417B

Counter Depth Side by Side Refrigerator

IMPORTANT: INSTALLATION REQUIRES 2 OR MORE PEOPLE.

Do Not Throw Away — Additional important safety information included.

INSTRUCCIONES DE INSTALACIÓN

Y MANUAL DEL PROPIETARIO

Refrigerador de dos puertas con profundidad de mostrador

IMPORTANTE: LA INSTALACIÓN REQUIERE DE 2 O MÁS PERSONAS.

No tirar — Se incluye información adicional importante.

INSTRUCTIONS D’INSTALLATION ET MANUEL D’UTILISATION

Réfrigérateur côte à côte à profondeur de comptoir

IMPORTANT : L’INSTALLATION NÉCESSITE L’INTERVENTION DE 2 PERSONNES OU PLUS.

Ne pas jeter — Autres consignes de sécurité importantes ci-jointes.

Table of Contents / Índice / Table des matières

REFRIGERATOR SAFETY............................... 2

Proper Disposal of Your Old Refrigerator..... 2

INSTALLATION REQUIREMENTS ................. 3

Tools and Parts............................................. 3

Product Dimensions...................................... 3

Location Requirements................................. 5

Electrical Requirements................................ 5

Water Supply Requirements......................... 6

INSTALLATION INSTRUCTIONS ................... 6

Unpack the Refrigerator.....

Connect Water Supply.................................. 7

Complete the Installation.............................. 8

Leveling and Door Closing............................ 9

Door Alignment ............................................. 9

FILTERS AND ACCESSORIES ....................... 9

Install Air Filter............................................... 9

Install Produce Preserver............................ 10

Changing the Water Filter........................... 11

REFRIGERATOR CARE................................. 12

Cleaning ...................................................... 12

Lights........................................................... 12

Vacation and Moving Care ......................... 14

PROBLEM SOLVER....................................... 15

WATER FI

PERFORMANCE DATA SHEET.................... 20

LTER CERTIFICATIONS.............. 19

........................... 6

SEGURIDAD DEL REFRIGERADOR............ 22

Cómo deshacerse adecuadamente

de su refrigerador viejo ............................... 23

REQUISITOS DE INSTALACIÓN.................. 23

Piezas y herramientas................................. 23

Medidas del producto................................. 23

Requisitos de ubicación.............................. 25

Requisitos eléctricos................................... 26

Requisitos del suministro de agua.............. 26

INSTRUCCIONES DE INSTALACIÓN.......... 27

Desempaque el refrigerador ....................... 27

Conexión del suministro de agua ............... 27

Complete la instalación .............................. 29

Nivelación y cierre de la puerta................... 29

Alineamiento de la puert

FILTROS Y ACCESORIOS ............................ 30

Instalación del filtro de aire......................... 30

Instalación del preservador

de alimentos frescos................................... 31

Cómo cambiar el filtro de agua .................. 32

CUIDADO DE SU REFRIGERADOR............. 33

Limpieza ...................................................... 33

Luces........................................................... 33

Cuidado durante las

vacaciones y mudanzas.............................. 35

SOLUCIÓN DE PROBLEMAS....................... 36

HOJA DE DATOS DEL RENDIMIENTO ....... 42

a ........................... 30

SÉCURITÉ DU RÉFRIGÉRATEUR................ 43

Mise au rebut appropriée

de votre vieux réfrigérateur......................... 44

EXIGENCES D’INSTALLATION.....

Outillage et pièces....................................... 44

Dimensions du produit................................ 44

Exigences d'emplacement ......................... 46

Spécifications électriques........................... 47

Spécifications de l’alimentation en eau...... 47

INSTRUCTIONS D’INSTALLATION.............. 48

Déballage du réfrigérateur .......................... 48

Raccordement de la canalisation d'eau ..... 48

Achever l’installation................................... 50

Nivellement et fermeture de la porte .......... 50

Alignement des portes................................ 51

FILTRES ET ACCESSOIRES......................... 51

Installation du filtre à air.............................. 51

Installation du sachet de

conservation pour produits frais................. 52

Changer le filtre à eau

ENTRETIEN DU RÉFRIGÉRATEUR ............. 54

Nettoyage.................................................... 54

Lampes........................................................ 54

Entretien avant les vacances

ou lors d’un déménagement....................... 56

RÉSOLUTION DE PROBLÈMES................... 57

FEUILLE DE DONNÉES

SUR LA PERFORMANCE.............................. 63

................................. 53

............... 44

Page 2

REFRIGERATOR SAFETY

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

To reduce the risk of fire, electric shock, or injury when using your refrigerator, follow these basic precautions:

SAVE THESE INSTRUCTIONS

■ Plug into a grounded 3 prong outlet.

■ Do not remove ground prong.

■ Do not use an adapter.

■ Do not use an extension cord.

■ Disconnect power before servicing.

■ Replace all parts and panels before operating.

■ Remove doors from your old refrigerator.

■ Use nonflammable cleaner.

■ Keep flammable materials and vapors, such as gasoline,

away from refrigerator.

■ Use two or more people to move and install refrigerator.

■ Disconnect power before installing ice maker (on ice maker

kit ready models only).

■ Use a sturdy glass when dispensing ice (on some models).

■ Do not hit the refrigerator glass doors (on some models).

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

WARNING

Suffocation Hazard

Remove doors from your old refrigerator.

Failure to do so can result in death or brain damage.

Important information to know about disposal of

refrigerants:

Dispose of refrigerator in accordance with Federal and Local

regulations. Refrigerants must be evacuated by a licensed,

EPA certified refrigerant technician in accordance with

established procedures.

Proper Disposal of Your Old Refrigerator

IMPORTANT: Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigerators are still dangerous,

even if they will sit for “just a few days.” If you are getting rid of

your old refrigerator, please follow these instructions to help

prevent accidents.

Before You Throw Away Your Old Refrigerator or Freezer:

■ Take off the doors.

■ Leave the shelves in place so that children may not easily

2

climb inside.

Page 3

INSTALLATION REQUIREMENTS

A

C

35¹⁄₂"

(90.0 cm)

23⁷⁄₈"

(60.4 cm)

15³⁄₈"

(38.9 cm)

20"

(50.8 cm)

B

⁵⁄₈"

(1.6 cm)

35³⁄₄"

(90.8 cm)

A

3

¹⁄₄"

(8.2 cm)

Tools and Parts

IMPORTANT:

■ Observe all governing codes and ordinances.

■ Installer: Leave Installation Instructions with homeowner.

■ Homeowner: Keep Installation Instructions for future reference

and for the local electrical inspector’s use.

■ Keep cardboard shipping piece or plywood under refrigerator

until it is installed in the operating position.

■ Comply with installation specifications and dimensions.

■ Remove any moldings or decorative panels from kitchen

cabinets that would not allow access to the refrigerator for

service.

■ Contact a qualified electrical installer.

TOOLS NEEDED (on some models):

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

■ Cordless drill

■ ¹⁄₄" Nut driver

and drill bit

■ Flat-blade

screwdriver

PARTS NEEDED (on some models):

■ Your refrigerator dealer has a kit available with a ¹⁄₄" (6.35 mm)

saddle-type shutoff valve, a union, and copper tubing.

■ Or you can purchase a ¹⁄₄" (6.35 mm) copper tubing with

shutoff valve and a ¹⁄₄" (6.35 mm) compression fitting

(coupling).

■ Depending on water line connections, you may also need a ¹⁄₄"

(6.35 mm) nut and ¹⁄₄" (6.35 mm) ferrule.

■ ⁵⁄₁₆" or adjustable wrench

■ ⁷⁄₁₆" and ¹⁄₂" Open-end wrenches

■ Two adjustable wrenches

■ ³⁄₈" and ¹⁄₂" Socket wrenches

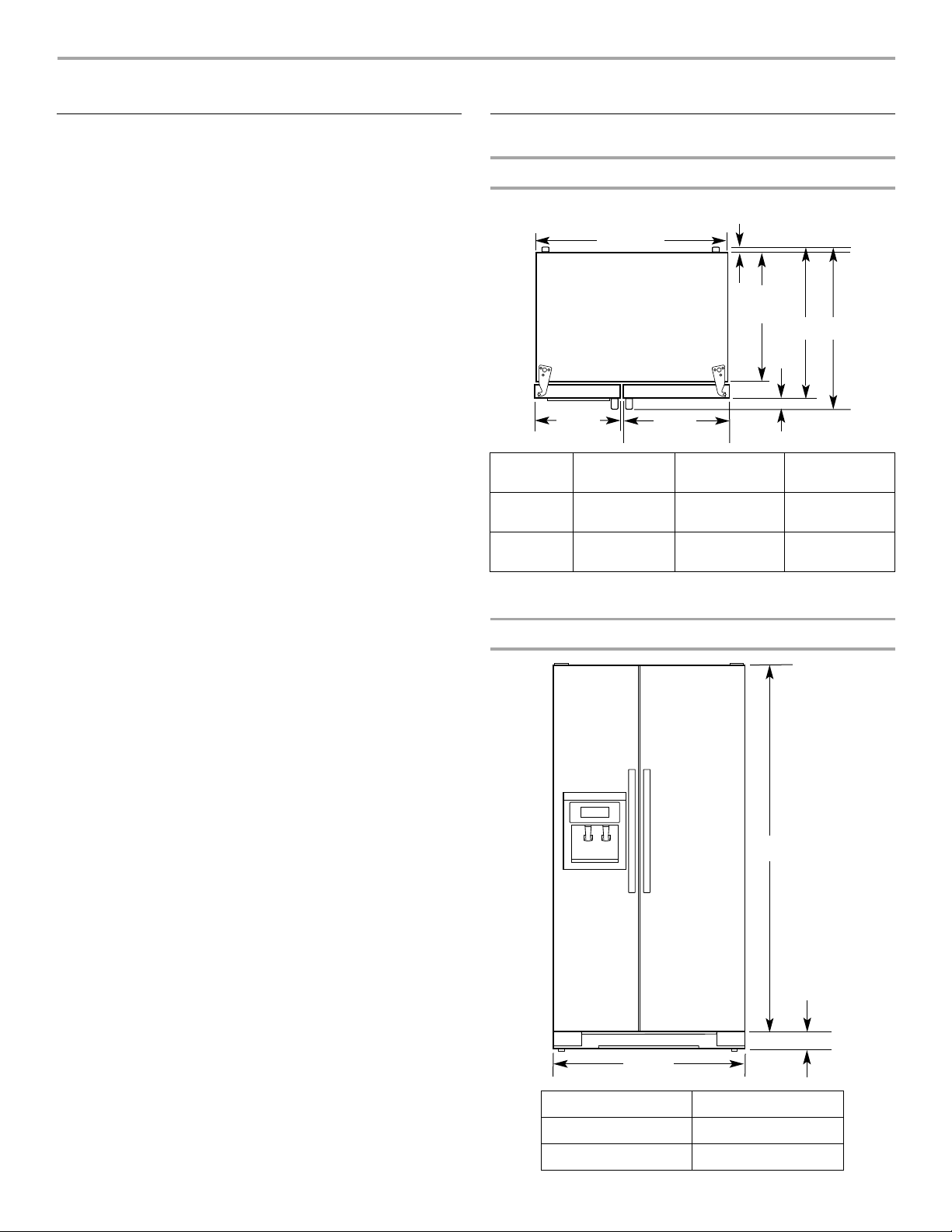

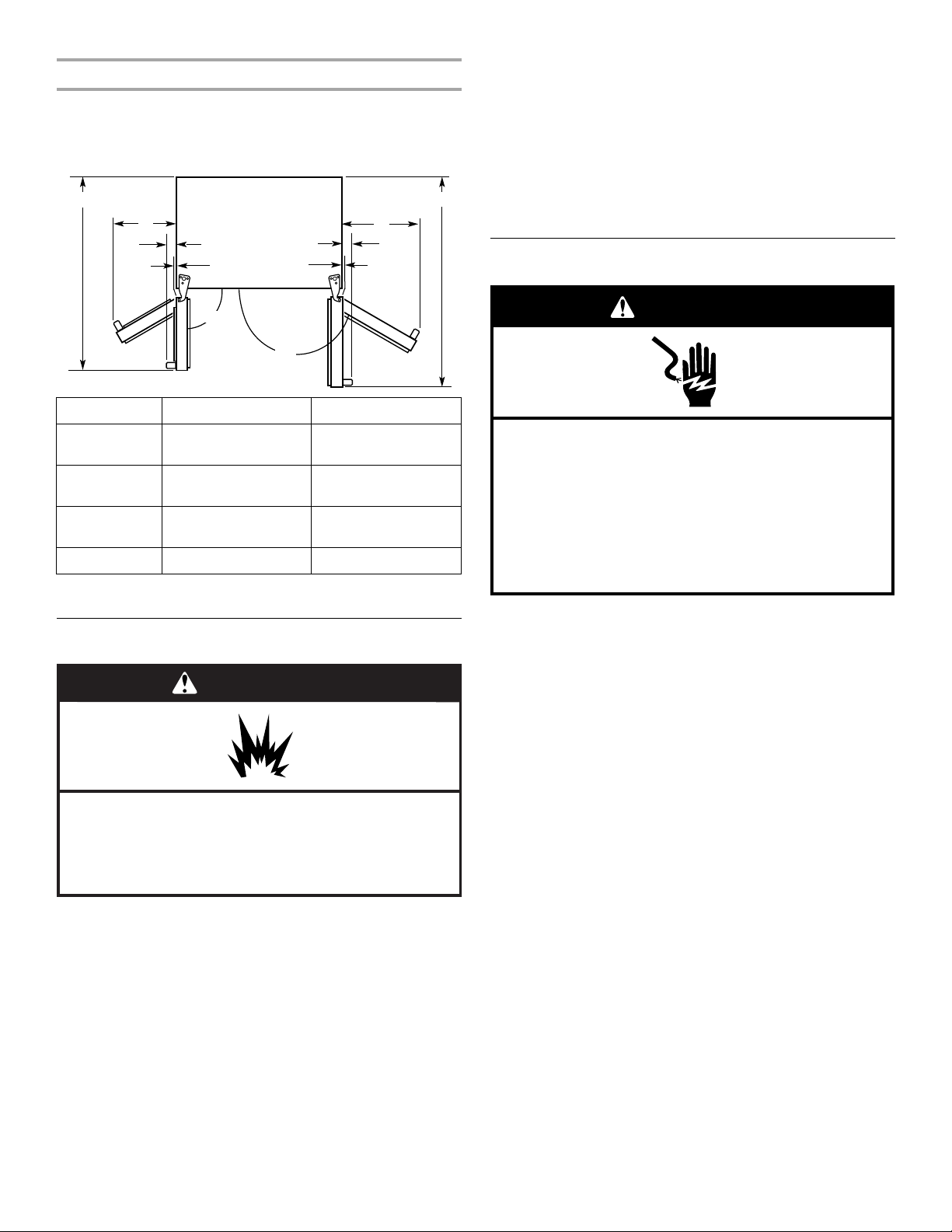

Product Dimensions

Top View

Door

Style

Flat 27¹⁄₂"

Curved 28⁵⁄₈"

*Dimension may vary based on style of door handle.

The depth for the largest available handle is listed.

Front View

Depth

A

(69.8 cm)

(72.5 cm)

Depth

B

2⁵⁄₈"(6.5cm)

maximum*

2⁵⁄₈"

(6.5 cm)

30" (76.3 cm)

Depth

C

maximum*

31¹⁄₈"

(79.1 cm)

Model Size Height A

69" 65³⁄₄" (166.9 cm)

72" 68¹⁄₈" (172.9 cm)

3

Page 4

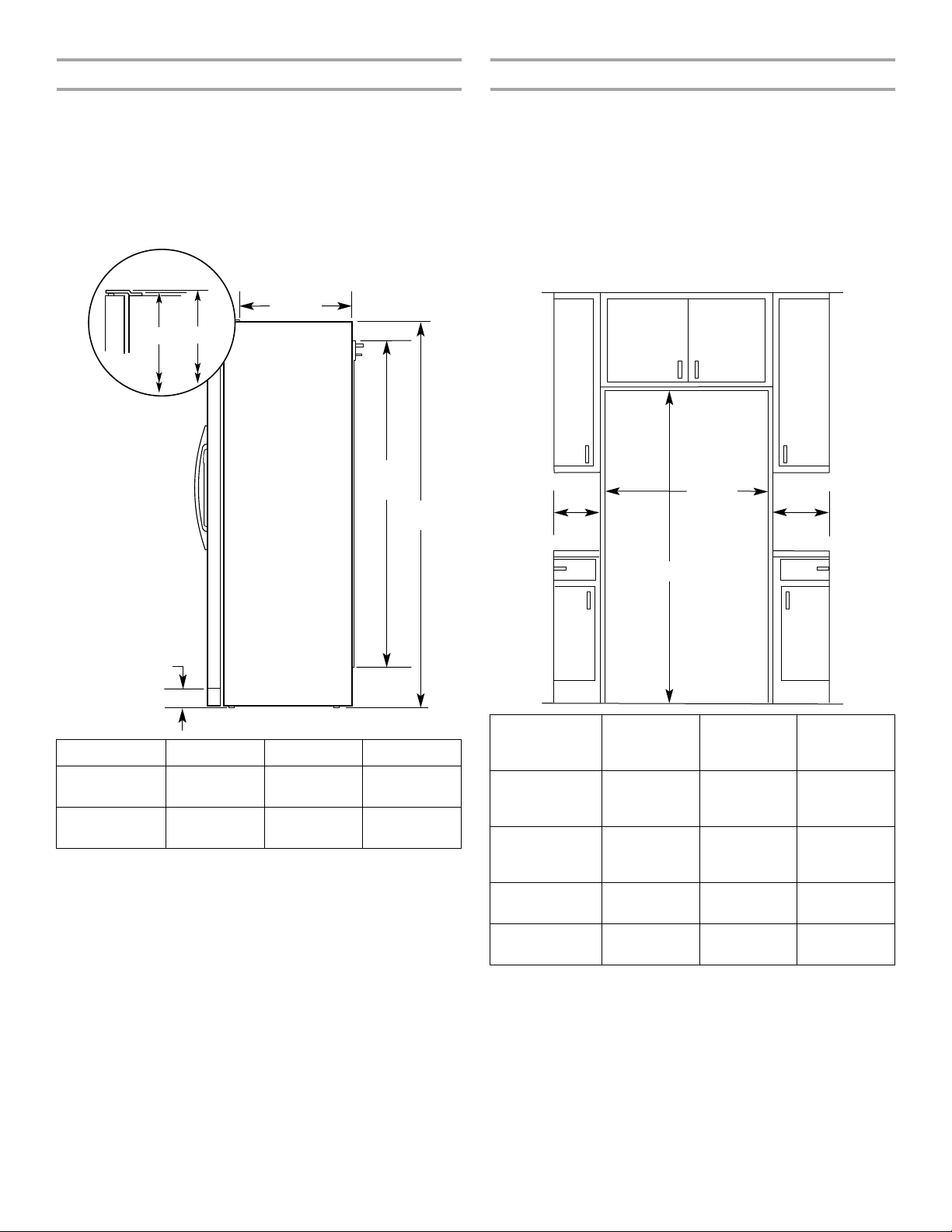

Side View

21³⁄₄"

(55.1 cm)

61¹⁄₄"

(155.6 cm)

3¹⁄₄" (8.2 cm)

C

A

B

36"

(91.4 cm)

B

C

A

Opening Dimensions

■ Height dimensions are shown with the leveling legs extended

to the minimum height of ¹⁄₄" (6.35 mm) below the refrigerator.

NOTE: When leveling legs are fully extended to 1" (25 mm)

below the refrigerator, add ³⁄₄" (19 mm) to the height

dimensions.

■ The power cord is 61¹⁄₄" (155.6 cm) long.

■ The water line attached to the back of the refrigerator is 78"

(198.1 cm) long.

■ Height dimensions are shown with the leveling legs extended

to the minimum height of ¹⁄₄" (6.35 mm) below the refrigerator.

NOTE: When leveling legs are fully extended to 1" (25 mm)

below the refrigerator, add ³⁄₄" (19 mm) to the height

dimensions.

■ In the following graphic, “A” represents the opening height

required for standard cabinets. For full-overlay cabinet doors

with a trim kit, add ¹⁄₈" (0.3 cm).

■ In the following graphic, “B” represents the distance needed

to fully open the freezer door and “C” represents the distance

needed to fully open the refrigerator door.

Model Size Height A Height B Height C

69" 68⁷⁄₈"

(174.8 cm)

72" 71¹⁄₄"

(180.8 cm)

(174.9 cm)

(180.9 cm)

68⁷⁄₈"

71¹⁄₄"

68¹⁄₂"

(174.2 cm)

71"

(180.2 cm)

Model Size

and

Height

A

Width

B

Door Style

69"

Flat

69"

(175.3 cm)

13⁵⁄₈"

(34.5 cm)

maximum*

72"

Flat

72"

(182.9 cm)

13⁵⁄₈"

(34.5 cm)

maximum*

69"

Curved

72"

Curved

69"

(175.3 cm)

72"

(182.9 cm)

13³⁄₄"

(34.9 cm)

13³⁄₄"

(34.9 cm)

*Dimension may vary based on style of door handle.

The width for the largest available handle is listed.

Width

C

18¹⁄₈"

(46.0 cm)

maximum*

18¹⁄₈"

(46.0 cm)

maximum*

18³⁄₈"

(46.4 cm)

18³⁄₈"

(46.4 cm)

4

Page 5

Door Swing Dimensions

A

41

¹⁄₄" (104.5 cm)

C

D

B

45⁷⁄₈" (116.4 cm)

90˚

165˚

C

D

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from refrigerator.

Failure to do so can result in death, explosion, or fire.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

WARNING

■ Location must permit doors to open to a minimum of 165°.

■ In the following graphic, “A” represents the distance needed

to fully open the freezer door and “B” represents the distance

needed to fully open the refrigerator door.

Dimension Flat Doors Curved Doors

■ Location should permit doors to open fully. See “Product

Dimensions.”

■ This refrigerator is intended for use in a location where the

temperature ranges from a minimum of 55°F (13°C) to a

maximum of 110°F (43°C). The preferred room temperature

range for optimum performance, which reduces electricity

usage and provides superior cooling, is between 60°F (15°C)

and 90°F (32°C). It is recommended that you do not install the

refrigerator near a heat source, such as an oven or radiator.

■ Floor must support refrigerator weight (more than 600 lbs

[272 kg]) and contents.

Electrical Requirements

A 13⁵⁄₈" (34.5 cm)

13³⁄₄" (34.9 cm)

maximum*

B 18¹⁄₈" (46.0 cm)

18³⁄₈" (46.4 cm)

maximum*

C 2³⁄₄" (6.7 cm)

3³⁄₄" (9.4 cm)

maximum*

D ¹⁄₈" (0.2 cm) 1¹⁄₄" (2.9 cm)

*Dimension may vary based on style of door handle.

The width for the largest available handle is listed.

Location Requirements

Before you move your refrigerator into its final location, it is

important to make sure you have the proper electrical connection.

Recommended Grounding Method

A 115 volt, 60 Hz, AC only, 15- or 20-amp fused, grounded

electrical supply is required. It is recommended that a separate

circuit serving only your refrigerator be provided. Use an outlet

that cannot be turned off by a switch. Do not use an

extension cord.

NOTE: Before performing any type of installation or cleaning, or

removing a light bulb, turn cooling off or turn the control

(Thermostat, Refrigerator or Freezer Control depending on the

model) to OFF, and then disconnect the refrigerator from the

electrical source. When you are finished, reconnect the

refrigerator to the electrical source and turn cooling on or reset the

control (Thermostat, Refrigerator or Freezer Control depending on

the model) to the desired setting. See “Using the Controls” in the

User Instructions, User Guide, or Use & Care Guide.

NOTES:

■ The refrigerator can be installed into a recessed opening, at

the end of cabinets or as a freestanding refrigerator.

■ If you are installing the refrigerator to fit flush with the front of

the base cabinets, all shoe moulding and baseboards must be

removed from the rear of the refrigerator opening. Allow for

1" (2.54 cm) of space behind the refrigerator.

5

Page 6

Water Supply Requirements

WARNING

Excessive Weight Hazard

Use two or more people to move and install

refrigerator.

Failure to do so can result in back or other injury.

When Moving Your Refrigerator:

Your refrigerator is heavy. When moving the refrigerator for

cleaning or service, be sure to cover the floor with

cardboard or hardboard to avoid floor damage. Always pull

the refrigerator straight out when moving it. Do not wiggle or

“walk” the refrigerator when trying to move it, as floor

damage could occur.

Important information to know about glass shelves

and covers:

Do not clean glass shelves or covers with warm water when

they are cold. Shelves and covers may break if exposed to

sudden temperature changes or impact, such as bumping.

Tempered glass is designed to shatter into many small,

pebble-size pieces. This is normal. Glass shelves and covers

are heavy. Use both hands when removing them to avoid

dropping.

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

TOOLS NEEDED:

■ Flat-blade screwdriver

■ ⁷⁄₁₆" and ¹⁄₂" open-end or

two adjustable wrenches

NOTE: Your refrigerator dealer has a kit available with a ¹⁄₄"

(6.35 mm) saddle-type shutoff valve, a union, and copper tubing.

Before purchasing, make sure a saddle-type valve complies with

your local plumbing codes. Do not use a piercing-type or ³⁄₁₆"

(4.76 mm) saddle valve which reduces water flow and clogs more

easily.

IMPORTANT:

■ All installations must meet local plumbing code requirements.

■ Use copper tubing and check for leaks. Install copper tubing

only in areas where the household temperatures will remain

above freezing.

Water Pressure

A cold water supply with water pressure of between 30 and

120 psi (207 and 827 kPa) is required to operate the water

dispenser and ice maker. If you have questions about your water

pressure, call a licensed, qualified plumber.

■ If your refrigerator has a water dispenser: After installation is

complete, use the water dispenser to check the water

pressure.

■ With the water filter removed, dispense 1 cup (237 mL) of

water. If 1 cup of water is dispensed in 8 seconds or less,

the water pressure to the refrigerator meets the minimum

requirement.

■ If it takes longer than 8 seconds to dispense 1 cup of

water, the water pressure to the refrigerator is lower than

recommended. See “Problem Solver” for suggestions.

Reverse Osmosis Water Supply

IMPORTANT: The pressure of the water supply coming out of a

reverse osmosis system going to the water inlet valve of the

refrigerator needs to be between 30 and 120 psi (207 and

827 kPa).

If a reverse osmosis water filtration system is connected to your

cold water supply, the water pressure to the reverse osmosis

system needs to be a minimum of 40 to 60 psi (276 to 414 kPa).

If the water pressure to the reverse osmosis system is less than

40 to 60 psi (276 to 414 kPa):

■ Check to see whether the sediment filter in the reverse

osmosis system is blocked. Replace the filter if necessary.

■ Allow the storage tank on the reverse osmosis system to refill

after heavy usage.

■ If your refrigerator has a water filter, it may further reduce the

water pressure when used in conjunction with a reverse

osmosis system. Remove the water filter. See “Water Filtration

System” in the User Instructions, User Guide, or Use & Care

Guide.

If you have questions about your water pressure, call a licensed,

qualified plumber.

■ ¹⁄₄" nut driver

■ ¹⁄₄" drill bit

■ Cordless drill

INSTALLATION INSTRUCTIONS

Unpack the Refrigerator

Remove the Packaging

Dispose of/recycle all packaging materials. Do not use sharp

instruments, rubbing alcohol, flammable fluids, or abrasive

cleaners to remove tape or glue. These products can damage the

surface of your refrigerator.

IMPORTANT:

■ Use ¹⁄₂" socket wrench to remove skids (socket extension is

recommended).

■ All four leveling legs must contact the floor to support and

stabilize the full weight of the refrigerator.

Clean Before Using

After you remove all of the package materials, clean the inside of

your refrigerator before using it. See the cleaning instructions.

6

Page 7

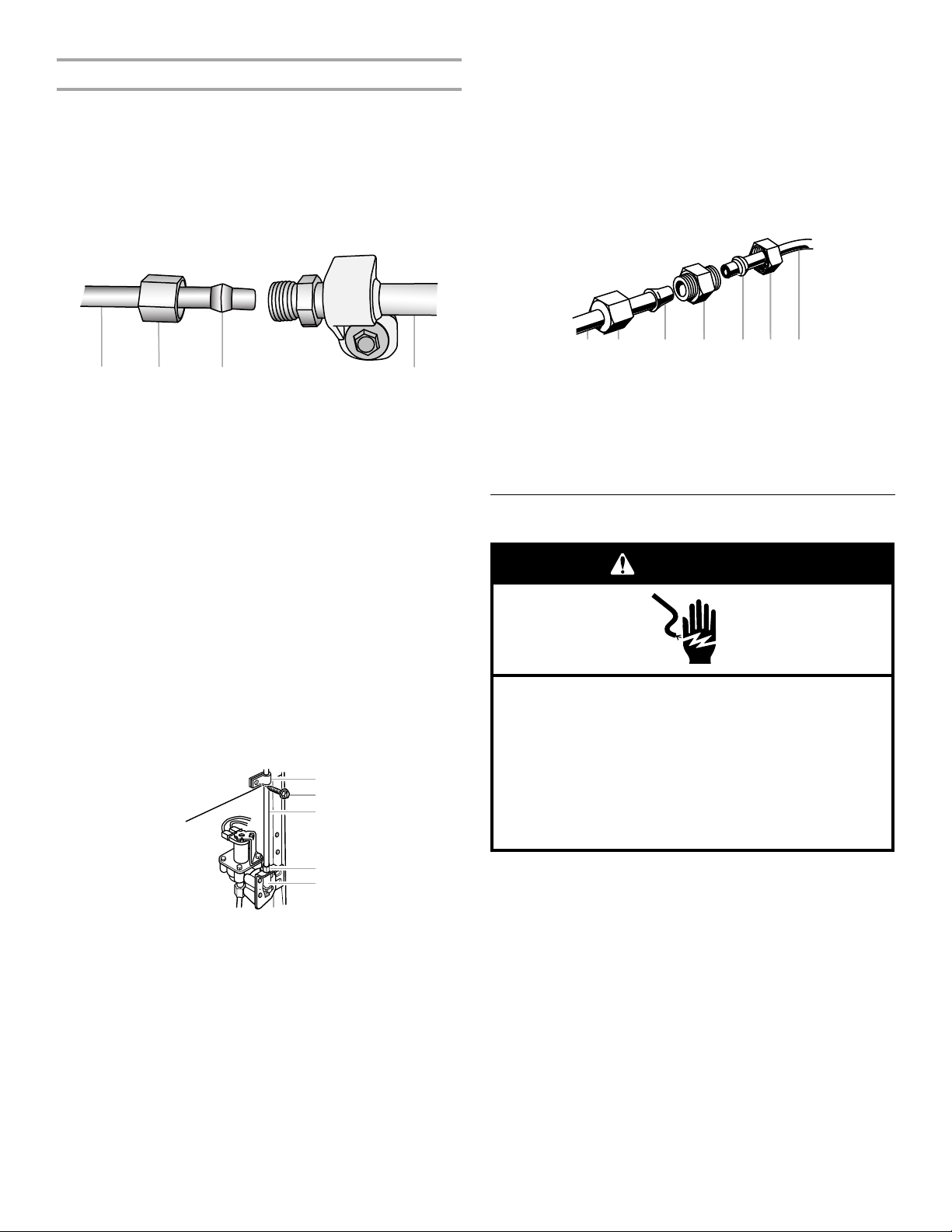

Connect Water Supply

A

B

D

C

B CA

A

B

C

DEF

G

Read all directions before you begin.

IMPORTANT:

Plumbing shall be installed in accordance with the

International Plumbing Code and any local codes and

ordinances.

The gray water tubing on the back of the refrigerator (which is

used to connect to the household water line) is a PEX

(cross-linked polyethylene) tube. Copper and PEX tubing

connections from the household water line to the refrigerator

are acceptable, and will help avoid off-taste or odor in your ice

or water. Check for leaks.

If PEX tubing is used instead of copper, we recommend the

following Whirlpool Part Numbers:

W10505928RP (7 ft [2.14 m] jacketed PEX),

8212547RP (5 ft [1.52 m] PEX), or

W10267701RP (25 ft [7.62 m] PEX).

Install tubing only in areas where temperatures will remain

above freezing.

TOOLS NEEDED:

Gather the required tools and parts before starting installation.

Flat-blade screwdriver

⁷⁄₁₆" and ¹⁄₂" open-end wrenches or two adjustable wrenches

¹⁄₄" nut driver

Connect to Water Line

IMPORTANT: If you turn the refrigerator on before the water line is

connected, turn the ice maker OFF.

Style 1 (Recommended)

1. Unplug refrigerator or disconnect power.

2. Turn OFF main water supply. Turn ON nearest faucet long

enough to clear line of water.

3. Use a quarter-turn shutoff valve or the equivalent, served by a

¹⁄₂" copper household supply line.

NOTE: To allow sufficient water flow to the refrigerator, a

minimum ¹⁄₂" size copper household supply line is

recommended.

Slip compression sleeve and compression nut onto

copper tubing as shown. Insert end of tubing into outlet

end squarely as far as it will go. Screw compression nut

onto outlet end with adjustable wrench. Do not

overtighten.

A. Compression sleeve

B. Compression nut

C. Copper tubing

5. Place the free end of the tubing into a container or sink, and

turn on main water supply to flush out tubing until water is

clear. Turn off shutoff valve on the water pipe.

NOTE: Always drain the water line before making the final

connection to the inlet of the water valve to avoid possible

water valve malfunction.

6. Bend the copper tubing to meet the water line inlet, which is

located on the back of the refrigerator cabinet as shown.

Leave a coil of copper tubing to allow the refrigerator

to be

pulled out of the cabinet or away from the wall for service.

Style 2

1. Unplug refrigerator or disconnect power.

2. Turn OFF main water supply. Turn ON nearest faucet long

enough to clear line of water.

3. Locate a

pipe near the refrigerator.

IMPORTANT:

4. Determine the length of copper tubing you need. Measure

from the connection on the lower rear corner of refrigerator to

the water pipe. Add 7 ft (2.1 m) to allow for cleaning. Use ¹⁄₄"

(6.35 mm) O.D. (outside diameter) copper tubing. Be sure both

ends of copper tubing are cut square.

5. Using a cordless drill, drill a ¹⁄₄" (6.35 mm) hole in the cold

water pipe you have selected.

¹⁄₂" (1.27 cm) to 1¹⁄₄" (3.18 cm) vertical cold water

Make sure it is a cold water pipe.

Horizontal pipe will work, but drill on the top side of the

pipe, not the bottom. This will help keep water away from

the drill and normal sediment from collecting in the valve.

A. Cold water pipe

B. Pipe clamp

C. Copper tubing

D. Compression nut

E. Compression sleeve

F. Shutoff valve

G. Packing nut

6. Fasten the shutoff valve to the cold water pipe with the pipe

A. Bulb

B. Nut

C. Copper tubing (to refrigerator)

D. Household supply line (½" minimum)

4. Now you are ready to connect the copper tubing to the shutoff

valve. Use ¹⁄₄" (6.35

mm) OD soft copper tubing to connect the

shutoff valve and the refrigerator.

Ensure that you have the proper length needed for the job.

Be sure both ends of the copper tubing are cut square.

clamp. Be sure the outlet end is solidly in the ¹⁄₄" (6.35 mm)

drilled hole in the water pipe and that the washer is under the

pipe clamp. Tighten the packing nut. Tighten the pipe clamp

screws slowly and evenly so the washer makes a watertight

seal. Do not overtighten, or you may crush the copper tubing.

7. Slip the compression sleeve and compression nut on the

copper tubing as shown. Insert the end of the tubing into the

outlet end squarely as far as it will go. Screw the compression

nut onto outlet end with adjustable wrench. Do not

overtighten.

8. Place the free end of the tubing in a container or sink, and turn

ON the main water supply. Flush the tubing until water is clear.

Turn OFF the shutoff valve on the

water pipe. Coil the copper

tubing.

7

Page 8

Connect to Refrigerator

D

A B C

A

C

B

D

E

A B C D E F G

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

WARNING

Style 1

1. Unplug refrigerator or disconnect power.

2. Remove and discard the short, black plastic part from the end

of the water line inlet.

3. Thread the nut onto the end of the tubing. Tighten the nut by

hand. Then tighten it with a wrench two more turns. Do not

overtighten.

NOTE: To avoid rattling, be sure the copper tubing does not

touch the cabinet’s side wall or other parts inside the cabinet.

Style 3

1. Unplug refrigerator or disconnect power.

2. Remove and discard the black nylon plug from the gray water

tube on the rear of the refrigerator.

3. If the gray water tube supplied with the refrigerator is not long

enough, a ¹⁄₄" x ¹⁄₄" (6.35 mm x 6.35 mm) coupling is needed in

order to connect the water tubing to an existing household

water line. Thread the provided nut onto the coupling on the

end of the copper tubing.

NOTE: Tighten the nut by hand. Then tighten it with a wrench

two more turns. Do not overtighten.

A. Household water line

B. Nut (purchased)

4. Install the water supply tube clamp around the water supply

line to reduce strain on the coupling.

5. Turn shutoff valve ON.

6. Check for leaks. Tighten any connections (including

connections at the valve) or nuts that leak.

C. Ferrule (purchased)

D. Refrigerator water tubing

Style 2

1. Unplug refrigerator or disconnect power.

2. Remove and discard the plastic part that is attached to the

inlet of the water valve.

3. Attach the copper tube to the valve inlet using a compression

nut and sleeve as shown. Tighten the compression nut. Do not

overtighten.

4. Use the tube clamp on the back of the refrigerator to secure

the tubing to the refrigerator as shown. This will help avoid

damage to the tubing when the refrigerator is pushed back

against the wall.

5. Turn shutoff valve ON.

6. Check for leaks. Tighten any connections (including

connections at the valve) or nuts that leak.

A. Refrigerator water tubing

B. Nut (provided)

C. Bulb

D. Coupling (purchased)

4. Turn shutoff valve ON.

5. Check for leaks. Tighten any nuts or connections (including

connections at the valve) that leak.

E. Ferrule (purchased)

F. Nut (purchased)

G. Household water line

Complete the Installation

A. Tube clamp

B. Tube clamp screw

C. Copper tubing

7. On some models, the ice maker is equipped with a built-in

water strainer. If your water conditions require a second water

strainer, install it in the ¹⁄₄" (6.35 mm) water line at either tube

connection. Obtain a water strainer from your nearest

appliance dealer.

8

D. Compression nut

E. Valve inlet

1. Plug into a grounded 3 prong outlet.

2. Wait a few minutes. Check that the compressor is operating

properly and that all lights are working.

NOTE: If the refrigerator does not operate, check that the

circuit breaker is not tripped or that the household fuse has

not blown.

3. Flush the water system. See “Water and Ice Dispensers” in the

User Instructions or User Guide.

NOTE: Allow 24 hours to produce the first batch of ice. Allow

72 hours to completely fill ice container.

IMPORTANT: If construction will continue after refrigerator has

been installed, unplug refrigerator or disconnect power.

Page 9

Leveling and Door Closing

A

B

C

Raise

Lower

A

Raise

Lower

Your refrigerator has two adjustable front feet — one on the right

and one on the left. In most cases, the refrigerator should be

steady when both feet are touching the floor. If your refrigerator

seems unsteady or if you want the doors to close more easily,

adjust the refrigerator's tilt using the instructions below:

1. Move the refrigerator into its final location. Open both doors

to 90°. Remove the base grille by removing the two screws,

then pulling out on the outside corners.

NOTE: The doors must only be opened to 90°. If they are

opened all the way, the base grille will not come off.

2. The two leveling feet are located on the brackets on each side

of the product.

Door Alignment

A refrigerator that is not level from side-to-side may appear to

have doors that are not properly aligned. If the doors appear this

way, use the instructions in the previous section to check the

leveling.

The doors are designed to be slightly different heights when the

refrigerator is empty, in order to account for the weight of food

that will be placed on the doors. If the doors are still not aligned

after checking the leveling and loading the refrigerator with food,

follow the steps below to adjust the door alignment.

1. If necessary, open both doors to 90° and remove the base

grille.

2. Locate the alignment screw on the bottom hinge of the

refrigerator door.

A. Bottom hinge

B. Leveler bracket

C. Leveling foot

NOTE: Having someone push against the top of the refrigerator

takes some weight off the leveling feet. This makes it easier to

make adjustments.

3. Use a ¹⁄₄" open-ended or adjustable wrench to adjust the

leveling feet. Turn the leveling foot to the left to raise that side

of the product, or turn it to the right to lower that side of the

product.

NOTE: Both leveling feet should be snug against the floor, and

the rollers should not touch the floor. This keeps the

refrigerator from rolling forward when opening the doors.

4. Open both doors again and check that they close as easily as

you like. If not, tilt the refrigerator slightly more to the rear by

turning the leveling feet to the left. It may take several more

turns, and you should turn both leveling feet the same

amount.

5. Use a bubble level to check the leveling of the refrigerator.

NOTE: Whenever you need to move the refrigerator, turn the

leveling feet to the right until they are no longer touching the

ground. This will allow the refrigerator to roll more easily.

A. Alignment screw

3. Use a ⁵⁄₁₆" open-ended or adjustable wrench to turn the screw.

To raise the refrigerator door, turn the screw to the right. To

lower the door, turn the screw to the left.

4. Check that the doors are even at the top. If necessary,

continue to turn the alignment screw until the doors are

aligned.

5. Open both doors to 90°. Replace the base grille.

FILTERS AND ACCESSORIES

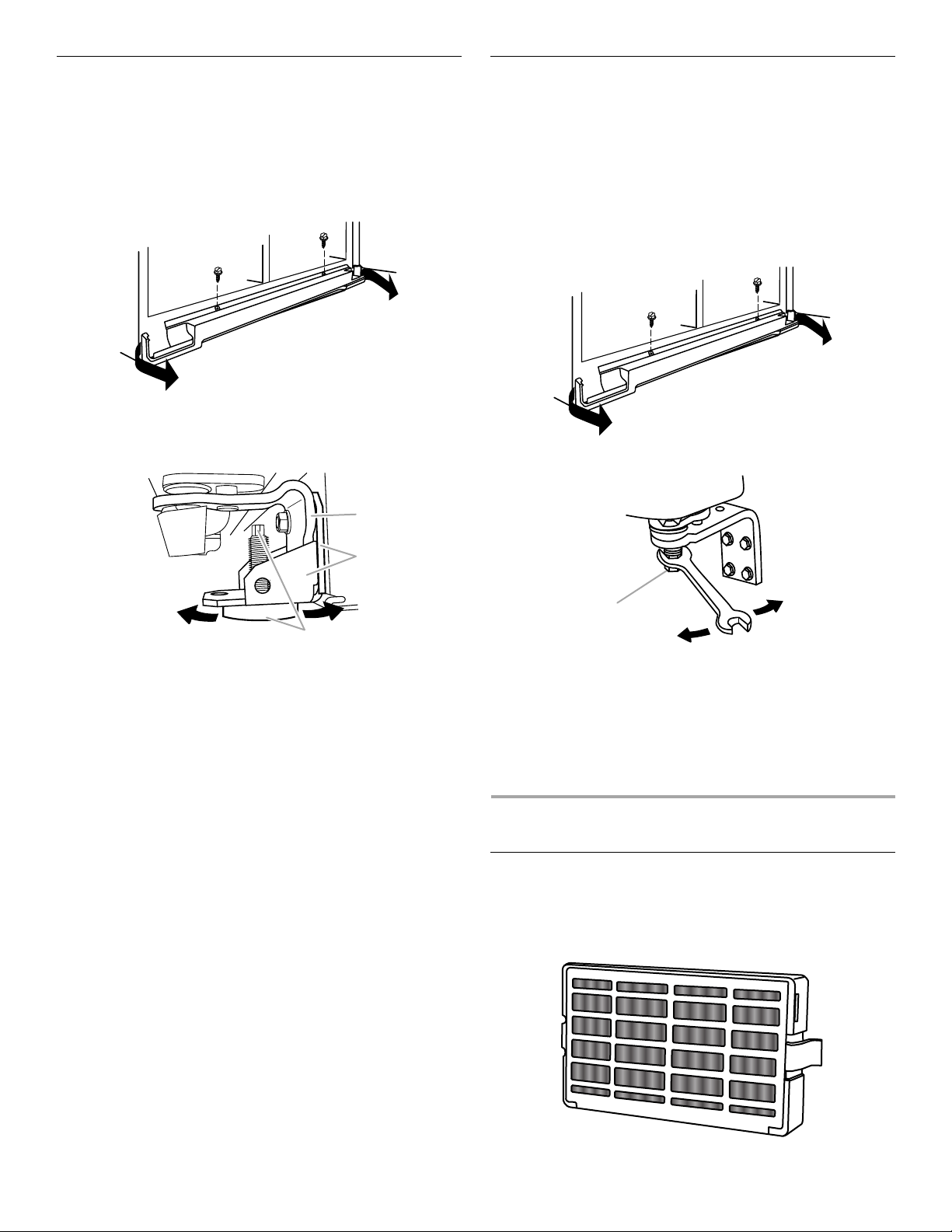

Install Air Filter

(on some models)

On some models, your refrigerator's accessory packet includes

an air filter, which must be installed prior to use. On some models,

the air filter is already installed at the factory.

The air filter reduces the buildup of odors. This helps to maintain a

cleaner environment inside the refrigerator.

9

Page 10

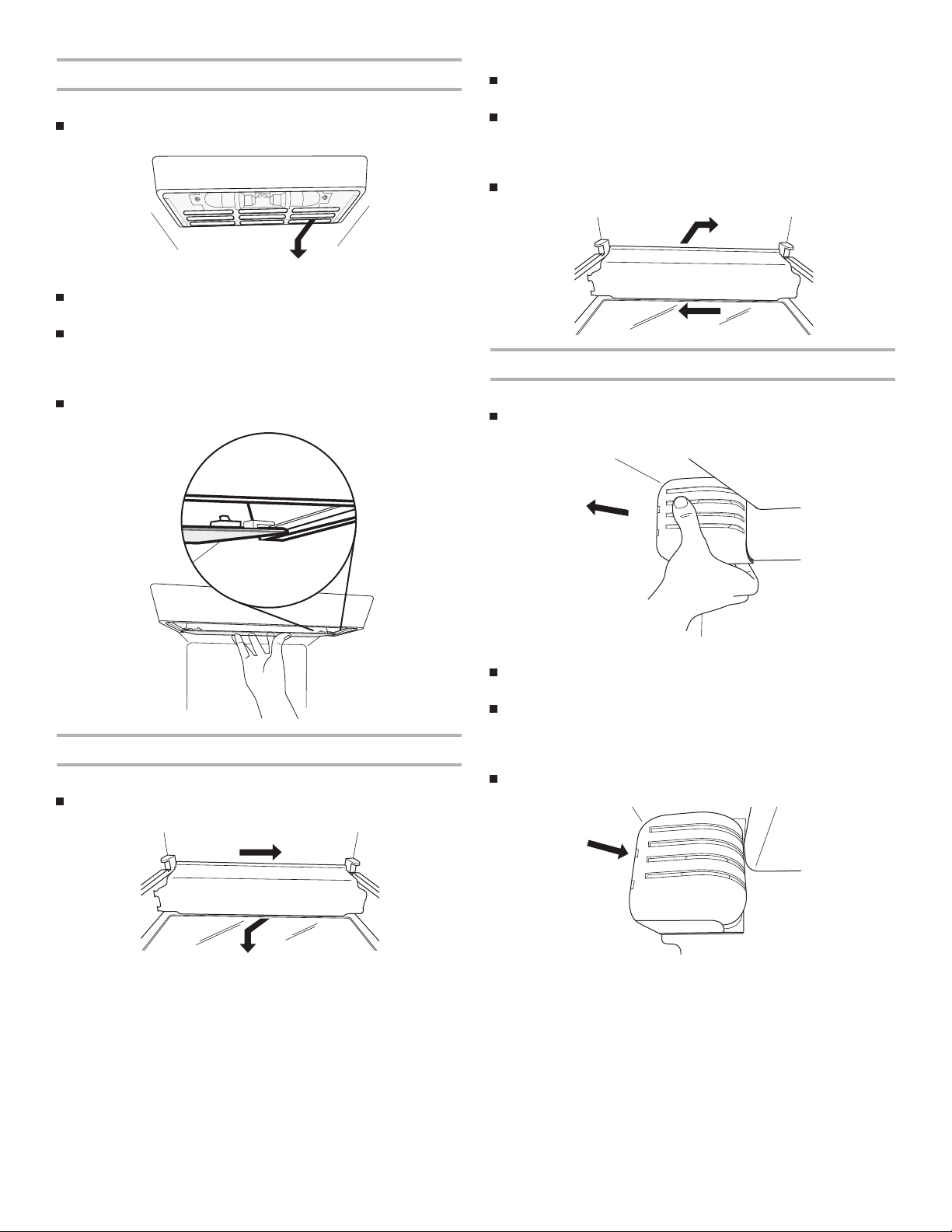

Installing the Air Filter (on some models)

Replacing the Air Filter

The filter should be installed behind the vented door, which is

located (depending on your model) along either the rear or left

interior wall near the top of the refrigerator compartment.

1. Remove the air filter from its packaging.

2. Lift open the vented door.

3. Snap the filter into place.

4. Close the vented door.

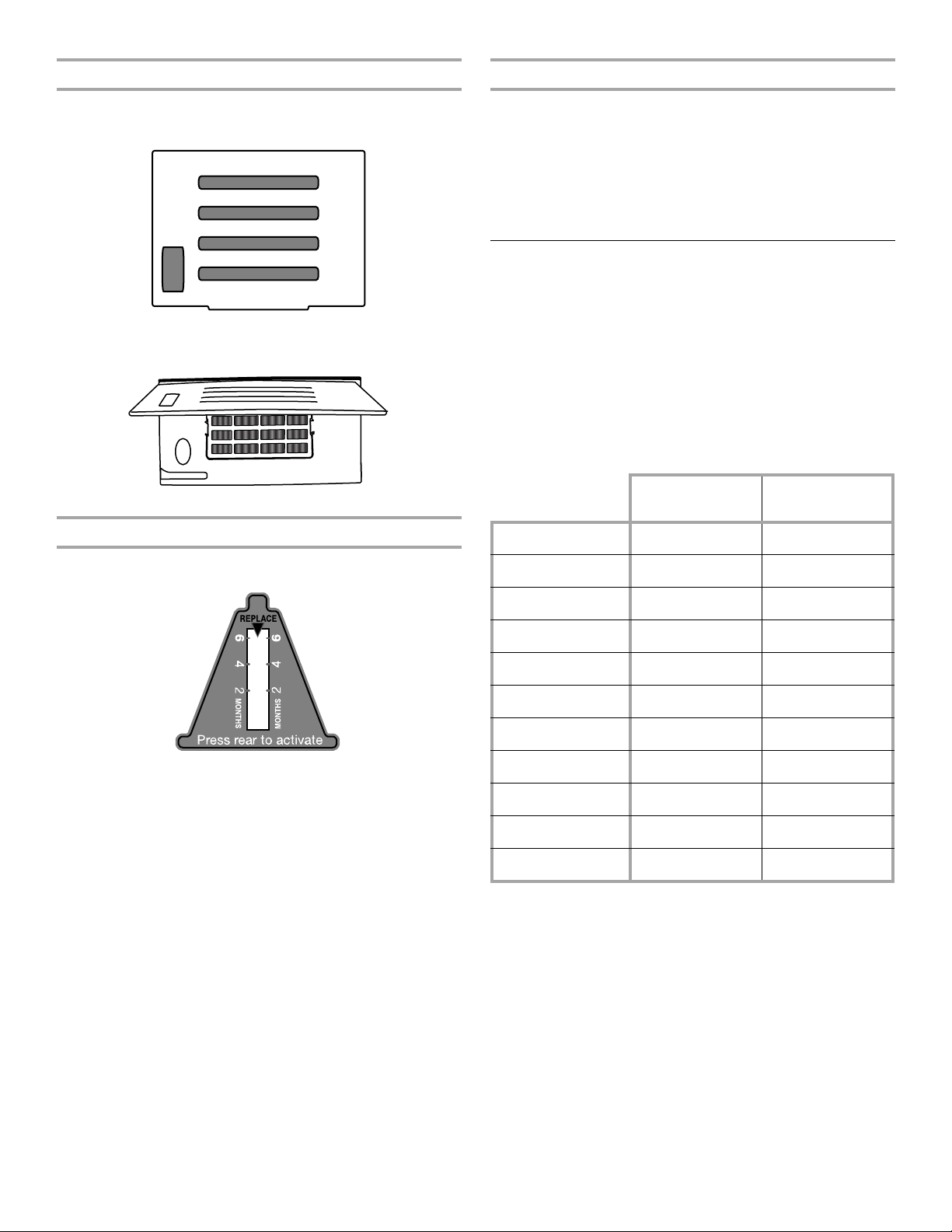

Installing the Filter Status Indicator (on some models)

The disposable air filter should be replaced every 6 months, when

the status indicator has completely changed from white to red.

To order a replacement air filter, see “Accessories” in the User

Instructions or User Guide.

1. Remove the old air filter by squeezing in on the side tabs.

2. Remove the old status indicator.

3. Install the new air filter and status indicator using the

instructions in the previous sections.

Install Produce Preserver

(on some models)

On some models, your refrigerator's accessory packet includes a

Produce Preserver, which should be installed prior to use. On

some models, the Produce Preserver is already installed at the

factory.

The Produce Preserver absorbs ethylene, allowing the ripening

process of many produce items to slow down. As a result, certain

produce items will stay fresh longer.

Ethylene production and sensitivity varies depending on the type

of fruit or vegetable. To preserve freshness, it is best to separate

produce with sensitivity to ethylene from fruits that produce

moderate to high amounts of ethylene.

Sensitivity to

Ethylene

Apples High Very High

Ethylene

Production

The filter comes with a status indicator, which should be activated

and installed at the same time the air filter is installed.

1. Place the indicator face-down on a firm, flat surface.

2. Apply pressure to the bubble on the back of the indicator, until

the bubble pops to activate the indicator.

3. Lift open the vented air filter door. On some models, there are

notches behind the door.

4. On models with notches:

■ Slide the indicator down into the notches, facing outward.

NOTE: The indicator will not easily slide into the notches

if the rear bubble has not been popped.

■ Close the air filter door, and check that the indicator is

visible through the rectangular hole in the door.

On models without notches:

■ Store the indicator in a visible place you will easily

remember - either inside the refrigerator, or elsewhere in

your kitchen or home.

Asparagus Med. Very Low

Berries Low Low

Broccoli High Very Low

Cantaloupe Med. High

Carrots Low Very Low

Citrus Fruit Med. Very Low

Grapes Low Very Low

Lettuce High Very Low

Pears High Very High

Spinach High Very Low

10

Page 11

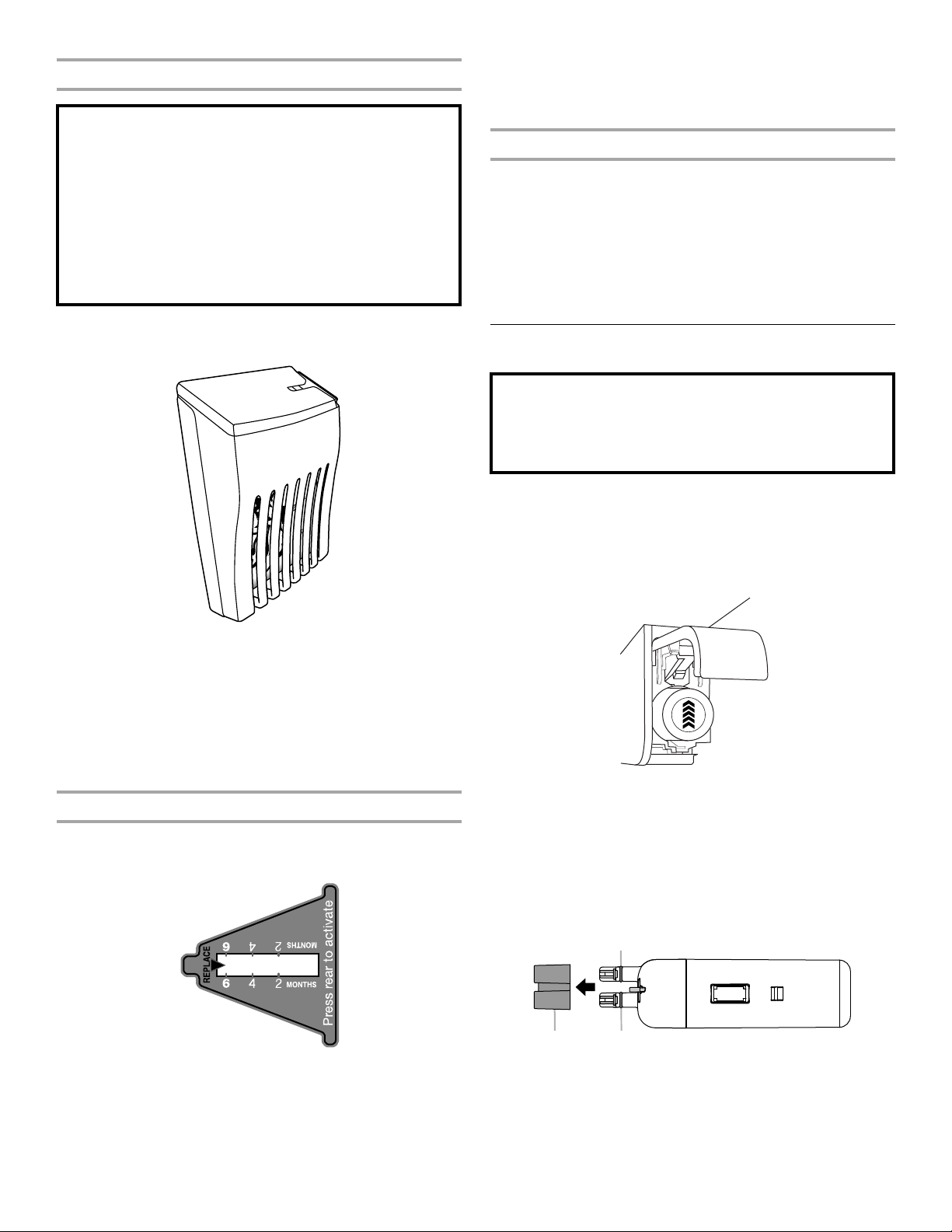

Installing the Produce Preserver (on some models)

CAUTION: IRRITANT

MAY IRRITATE EYES AND SKIN. DANGEROUS FUMES

FORM WHEN MIXED WITH OTHER PRODUCTS.

Do not mix with cleaning products containing ammonia,

bleach or acids. Do not get in eyes, on skin or clothing. Do

not breathe dust. Keep out of reach of children.

FIRST AID TREATMENT: Contains potassium

permanganate. If swallowed, call a Poison Control Center or

doctor immediately. Do not induce vomiting. If in eyes, rinse

with water for 15 minutes. If on skin, rinse with water.

CAUTION

IR

R

IT

A

N

T

Read cautions on back.

ATTENTION

IR

R

ITA

N

T

Lisez des prudences sur le revers.

Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before

or after the system. Systems certified for cyst reduction

may be used on disinfected waters that may contain

filterable cysts.

B

B

A

The Produce Preserver pouches should be installed in their

housing, which is located along an interior side wall of the crisper

or convertible drawer.

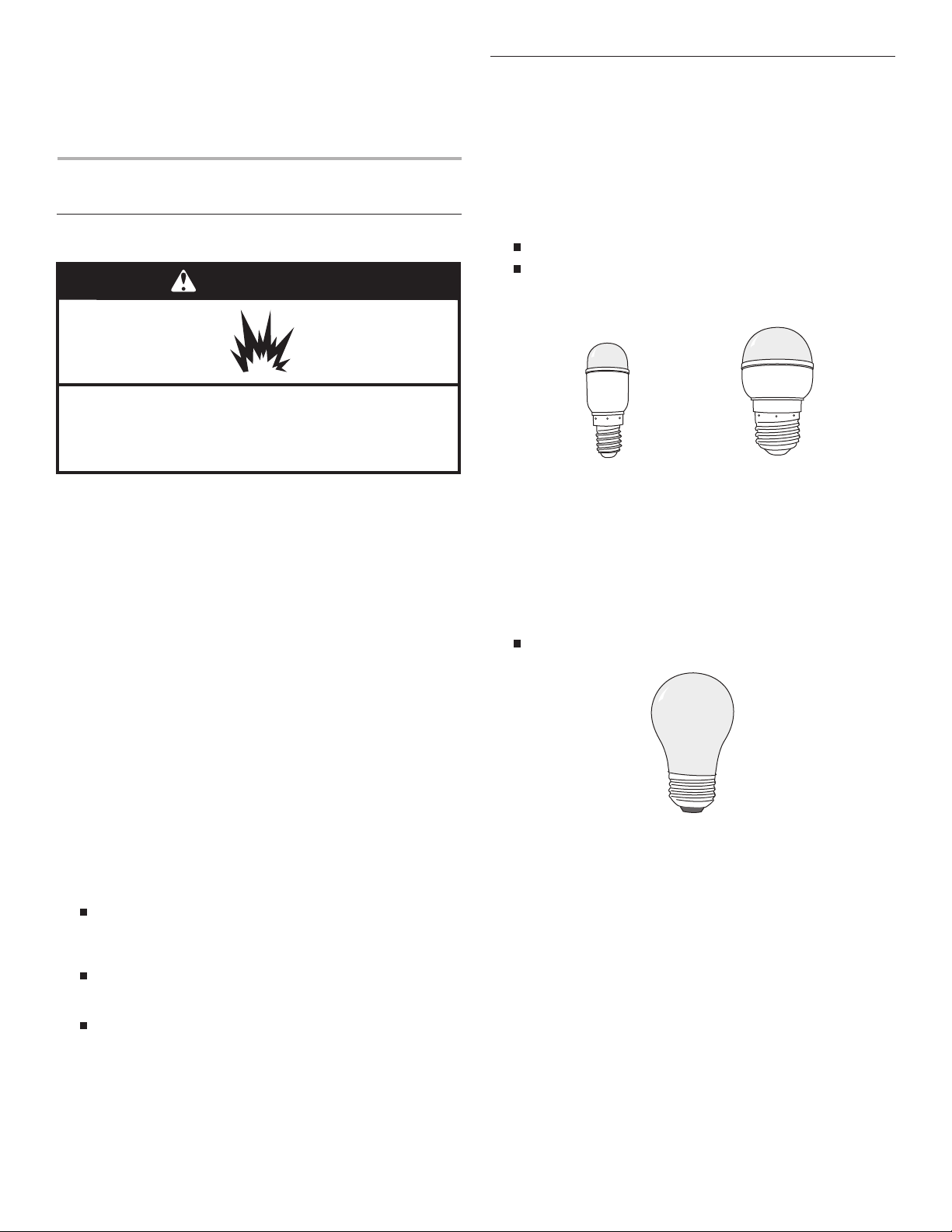

5. Slide the cap closed, and check that the indicator is visible

through the rectangular hole in the cap.

NOTE: The cap will not easily close if the indicator’s rear

bubble has not been popped.

Replacing the Produce Preserver (on some models)

The disposable pouches should be replaced every 6 months,

when the status indicator has completely changed from white to

red.

To order replacements, see “Accessories” in the User Instructions

or User Guide.

1. Remove the old pouches from the Produce Preserver housing.

2. Remove the old status indicator.

3. Install the new pouches and status indicator using the

instructions in the previous sections.

Changing the Water Filter

The water filter status light will help you know when to change

your water filter. See “Water Filtration System” in the User

Instructions or User Guide.

NOTE: If water flow to your water dispenser or ice maker

decreases noticeably, change the filter sooner. The filter should be

replaced at least every 6 months, depending on your water quality

and usage.

NOTE: For best performance, always use two pouches.

1. Remove the Produce Preserver pouches from their packaging.

2. Lift up on the housing in order to remove it from its mounting

tab along the wall.

3. Open the housing by pulling up and out on the back of the top

of the housing.

4. Place both pouches inside the housing, then snap the housing

back together.

5. Place the housing back on the mounting tab along the wall.

Installing the Status Indicator (on some models)

The Produce Preserver comes with a status indicator, which

should be activated and installed at the same time the pouch is

installed.

1. Place the indicator face-down on a firm, flat surface.

2. Apply pressure to the bubble on the back of the indicator, until

3. Slide open the cap on the Produce Preserver housing.

4. Place the indicator in the top of the housing, facing outward.

the bubble pops to activate the indicator.

1. Locate the water filter in the top-right corner of the refrigerator

compartment.

2. Lift open the filter cover door. The filter will be released and

then be ejected as the door is opened.

3. When the door is completely open, pull the filter straight out.

NOTE: There may be some water in the filter. Some spilling

may occur. Use a towel to wipe up any spills.

4. Take the new filter out of its packaging and remove the cap.

Be sure the O-rings are still in place after the cap is removed.

A. Cap B. O-rings

5. With the arrow pointing up, align the new filter with the filter

housing and slide it into place. The filter cover door will

automatically begin to close as the new filter is inserted.

11

Page 12

6. Close the filter cover door completely in order to snap the filter

into place. You may need to press hard.

7. After changing the filter, reset the filter status light. See “Water

Filtration System” in the User Instructions or User Guide.

8. Flush the water system. See “Water and Ice Dispensers” in the

User Instructions or User Guide.

REFRIGERATOR CARE

Cleaning

WARNING

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

Both the refrigerator and freezer sections defrost automatically.

However, clean both sections about once a month to avoid

buildup of odors. Wipe up spills immediately.

IMPORTANT: Because air circulates between both sections, any

odors formed in one section will transfer to the other. You must

thoroughly clean both sections to eliminate odors. To avoid odor

transfer and drying out of food, wrap or cover foods tightly.

To Clean Your Refrigerator:

NOTE: Do not use abrasive or harsh cleaners such as window

sprays, scouring cleansers, flammable fluids, cleaning waxes,

concentrated detergents, bleaches or cleansers containing

petroleum products on plastic parts, interior and door liners or

gaskets. Do not use paper towels, scouring pads, or other harsh

cleaning tools.

1. Unplug

2. Hand wash, rinse, and dry removable parts and interior

surfaces thoroughly. Use a clean sponge or soft cloth and a

mild detergent in warm water.

3. Wash stainless steel and painted metal exteriors with a clean

sponge or soft cloth and a mild detergent in warm water.

4. There is no need for routine condenser cleaning in normal

home operating environments. If the environment is

particularly greasy or dusty, or there is significant pet traffic in

the home, the condenser should be cleaned ev

3 months to ensure maximum efficiency.

If you need to clean the condenser:

5. Plug in refrigerator or reconnect power.

refrigerator or disconnect power.

ery 2 to

Remove the base grille. See the “Door Removal”

instructions, either in the User Instructions or the

Installation Instructions and Owner’s Manual, or in the

separate instruction sheet provided with your refrigerator.

Use a vacuum cleaner with a soft brush to clean the grille,

the open areas behind the grille and the front surface area

of the condenser.

Replace the base grille when finished.

Lights

IMPORTANT: The refrigerator and freezer compartments, air

tower and dispenser lights are LEDs that cannot be changed

by yourself. To order replacement LED lightings, call Whirlpool

service. In the U.S.A., call 1-800-253-1301. In Canada,

call 1-800-807-6777.

Light Styles:

The dispenser lights are mini LEDs that cannot be changed.

The interior lights vary by model.

Some models have mini LEDs that cannot be changed.

Some models have full-size LED bulbs that can be

changed. To order replacement LED bulbs, call

1-800-253-1301 (U.S.A.) or 1-800-807-6777 (Canada).

Whirlpool

Part Number

W10574850A

(2.0 watts)

NOTE: Some LED replacement bulbs are not

recommended for wet/damp environments. The

refrigerator and freezer compartments are considered to

be wet/damp environments. If using a brand of LED bulb

other than the recommended Whirlpool LED bulb, read

and follow all instructions on the replacement bulb’s

packaging before installing it.

Some models have incandescent 40-watt bulbs that can

be changed.

NOTE: Not all replacement bulbs will fit your refrigerator.

Do not use an incandescent bulb in excess of 40 watts.

To Change a Light Bulb:

1. Unplug refrigerator or disconnect power.

2. Remove the light shield as explained in the following

sections.

NOTE: To clean the light shield, wash it with warm water and

liquid detergent. Before reinstalling, thoroughly rin

the shield.

3. Replace the burned-out light bulb, as explained in the

following sections.

4. Reinstall the light shield, as explained in the following

sections.

5. Plug in refr

igerator or reconnect power.

Whirlpool

Part Number

W10565137A

(3.6 watts)

se and dry

12

Page 13

Refrigerator Compartment - Upper Lights

Light Shield Removal:

Slide the light shield toward the rear of the refrigerator and

remove it from the light housing.

Replacement Bulb:

If the burned-out light is a full-size LED bulb, replace it with

Whirlpool part number W10574850A (a 2.0 watt LED bulb).

If the burned-out light is an incandescent bulb, replace it with

an incandescent appliance bulb of the same size, shape and

wattage (40-watt maximum).

Light Shield Reinstallation:

Align the light shield in the grooves at the bottom edge of the

light housing, then slide it forward until it snaps into place.

Replacement Bulb:

If the burned-out light is a full-size LED bulb, replace it with

Whirlpool part number W10565137A (a 3.6 watt LED bulb).

If the burned-out light is an incandescent bulb, replace it with

an incandescent appliance bulb of the same size, shape and

wattage (40-watt maximum).

Light Shield Reinstallation:

Place the right end of the light shield into the wall slots, then

snap the left end into its wall slots.

Freezer Compartment - Upper Light

Light Shield Removal:

Gently squeeze the front and the bottom-rear edge of the light

shield to release the tabs from the wall slots, then pull the light

shield forward.

Refrigerator Compartment - Lower Lights

Light Shield Removal:

Slide the light shield to the right to remove the left end from

the wall slots; then, pull the right end out of its wall slots.

Replacement Bulb:

If the burned-out light is a full-size LED bulb, replace it with

Whirlpool part number W10565137A (a 3.6 watt LED bulb).

If the burned-out light is an incandescent bulb, replace it with

an incandescent appliance bulb of the same size, shape and

wattage (40-watt maximum).

Light Shield Reinstallation:

Align the light shield in its proper position, and snap the tabs

into the wall slots.

13

Page 14

Freezer Compartment - Lower Light

Light Shield Removal:

■ Slide the light shield to the left to remove the right end from

the wall slots, then pull the left end out of its wall slots.

Replacement Bulb:

■ If the burned-out light is a full-size LED bulb, replace it with

Whirlpool part number W10565137A (a 3.6 watt LED bulb).

■ If the burned-out light is an incandescent bulb, replace it with

an incandescent appliance bulb of the same size, shape and

wattage (40-watt maximum).

Light Shield Reinstallation:

■ Place the left end of the light shield into the wall slots, then

snap the right end into its wall slots.

Vacation and Moving Care

Vacations

If You Choose to Leave Refrigerator On While You Are Away:

1. Use up any perishables and freeze other items.

2. If your refrigerator has an automatic ice maker and is

connected to the household water supply, turn off the water

supply to the refrigerator. Property damage can occur if the

water supply is not turned off.

3. If you have an automatic ice maker, turn off the ice maker.

NOTE: Depending on your model, raise the wire shutoff arm to

OFF (up) position or press the switch to OFF (right).

4. Empty the ice bin.

If You Choose to Turn Refrigerator Off Before You Leave:

1. Remove all food from the refrigerator.

2. If your refrigerator has an automatic ice maker:

■ Turn off the water supply to the ice maker at least one day

ahead of time.

■ When the last load of ice drops, raise the wire shutoff arm

to the OFF (up) position or move the switch to the OFF

(right) setting.

3. Depending on the model, turn the Refrigerator Control to OFF

or turn cooling off. See “Using the Controls” in the User

Instructions, User Guide, or Use & Care Guide.

4. Clean, wipe, and dry thoroughly.

5. Tape rubber or wood blocks to the tops of both doors to prop

them open far enough for air to get in. This stops odor and

mold from building up.

Moving

When you are moving your refrigerator to a new home, follow

these steps to prepare it for the move.

1. If your refrigerator has an automatic ice maker:

■ Turn off the water supply to the ice maker at least one day

ahead of time.

■ Disconnect the water line from the back of the refrigerator.

■ When the last load of ice drops, raise the wire shutoff arm

to the OFF (up) position or move the switch to the OFF

(right) setting.

2. Remove all food from the refrigerator and pack all frozen food

in dry ice.

3. Empty the ice bin.

4. Depending on the model, turn the Refrigerator Control to OFF

or turn cooling off. See “Using the Controls” in the User

Instructions, User Guide, or Use & Care Guide.

5. Unplug refrigerator.

6. Clean, wipe, and dry thoroughly.

7. Take out all removable parts, wrap them well, and tape them

together so they don’t shift and rattle during the move.

8. Depending on the model, raise the front of the refrigerator so it

rolls more easily OR screw in the leveling legs so they don't

scrape the floor. See “Adjust the Doors” or “Door Removal,

Leveling and Alignment.”

9. Tape the doors closed and tape the power cord to the back of

the refrigerator.

When you get to your new home, put everything back and refer to

the Installation Instructions for preparation instructions. Also, if

your refrigerator has an automatic ice maker, remember to

reconnect the water supply to the refrigerator.

14

Page 15

PROBLEM SOLVER

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

WARNING

First try the solutions suggested here or visit our website to possibly avoid the cost of a service call.

GENERAL OPERATION Possible Causes and/or Recommended Solutions

Refrigerator

will not operate

■ Not connected to an electrical supply - Plug the power cord into a grounded 3 prong outlet.

Do not use an extension cord.

■ No power to the electrical outlet - Plug in a lamp to see if the outlet is working.

■ Household fuse has blown or circuit breaker has tripped - Replace the fuse or reset the circuit

breaker. If the problem continues, contact a licensed electrician.

■ Control or cooling is not turned on - Turn on the refrigerator control, or turn cooling on. See “Using

the Controls” in the User Instructions or User Guide.

■ New installation - Following installation, allow 24 hours for the refrigerator and freezer to cool

completely.

NOTE: Adjusting the temperature control(s) to the coldest setting will not cool either compartment

(refrigerator or freezer) more quickly.

Motor seems to

run too much

■ Your new refrigerator has an energy-efficient motor - The refrigerator may run longer than you’re

used to, because the compressor and fans operate at lower speeds that are more energy-efficient.

This is normal.

NOTE: Your refrigerator may run even longer if the room is warm, a large load of food is added, the

doors are opened often, or if a door has been left open.

Refrigerator

seems noisy

The compressor in your new refrigerator regulates temperature more efficiently and uses less energy

than older models. During various stages of operation, you may hear normal operating sounds that are

unfamiliar.

The following noises are normal:

■ Buzzing/Clicking - Heard when the water valve opens and closes to dispense water or fill the ice

maker. If the refrigerator is connected to a water line, this is normal. If the refrigerator is not

connected to a water line, turn off the ice maker.

■ Cracking/Crashing - Heard when ice is ejected from the ice maker mold.

■ Popping - Heard when the inside walls contract/expand, especially during initial cooldown.

■ Pulsating/Whirring - Heard when the fans/compressor adjust to optimize performance during

normal operation.

■ Rattling - Heard when water passes through the water line, or due to the flow of refrigerant. Rattling

may also come from items placed on top of the refrigerator.

■ Water running or gurgling - Heard when ice melts during the defrost cycle and water runs into the

drain pan.

■ Sizzling - Heard when water drips onto the heater during the defrost cycle.

15

Page 16

GENERAL OPERATION Possible Causes and/or Recommended Solutions

Temperature

is too warm

■ New installation - Following installation, allow 24 hours for the refrigerator and freezer to cool

completely.

NOTE: Adjusting the temperature control(s) to the coldest setting will not cool either compartment

(refrigerator or freezer) more quickly.

■ Doors are opened often or not closed completely - This allows warm air to enter the refrigerator.

Minimize door openings, keep the doors fully closed, and make sure both doors are properly sealed.

■ Air vents are blocked - Remove items that are immediately in front of the vents.

■ Large amount of warm food recently added - Allow several hours for the refrigerator to return to

its normal temperature.

■ Controls are not set correctly for the surrounding conditions - Adjust the controls to a colder

setting. Check the temperature again in 24 hours.

Temperature is too cold ■ Controls are not set correctly for the surrounding conditions - Adjust the controls to a warmer

setting. Check the temperature again in 24 hours.

■ Top refrigerator shelf is colder than lower shelves - On some models, air from the freezer enters

the refrigerator compartment through vents near the top refrigerator shelf. As a result, the top shelf

can be slightly colder than lower shelves.

■ Air vents are blocked - Remove items that are immediately in front of the vents.

Interior moisture buildup NOTE: Some moisture buildup is normal. Clean with a soft dry cloth.

■ Room is humid - A humid environment contributes to moisture buildup. Use the refrigerator only in

an indoor location, with as little humidity as possible.

■ Doors are opened often or not closed completely - This allows humid air to enter the refrigerator.

Minimize door openings, keep the doors fully closed, and make sure both doors are properly sealed.

Interior lights

do not work

■ Doors have been open for an extended period of time - Close the doors to reset the lights.

■ Light bulb is loose in the socket or has burned out - On models with incandescent or full-size LED

interior light bulbs, tighten or replace the bulb. See “Lights.”

NOTE: On models with mini LED lights, call for assistance or service if the interior lights do not illuminate

when either door is opened. See the Warranty in the User Instructions or User Guide for contact

information.

Dispenser lights

do not work

(on some models)

■ Dispenser light is turned off - On some models, if the dispenser light is set to OFF, the light will turn

on only when a dispenser pad/lever is pressed. If you want the dispenser light to stay on

continuously, select a different setting. See “Water and Ice Dispensers” in the User Instructions or

User Guide.

■ Dispenser light is set to AUTO or NIGHT LIGHT - On some models, if the dispenser light is set to

AUTO or NIGHT LIGHT, make sure the dispenser light sensor is not blocked. See “Water and Ice

Dispensers” in the User Instructions or User Guide.

NOTE: On models with mini LED lights, call for assistance or service if the dispenser lights do not

operate correctly. See the Warranty in the User Instructions or User Guide for contact information.

16

Page 17

DOORS AND LEVELING Possible Causes and/or Recommended Solutions

WARNING

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

Cut Hazard

Use a sturdy glass when dispensing ice.

Failure to do so can result in cuts.

WARNING

Doors are difficult to open ■ Gaskets are dirty or sticky - Clean the gaskets and contact surfaces with mild soap and warm

water. Rinse and dry with a soft cloth.

Doors will not

close completely

■ Door is blocked open - Move food packages away from the door. Make sure all bins and

shelves are in their correct positions. Make sure all packaging materials have been removed.

Doors appear to be uneven ■ Doors need to be aligned, or refrigerator needs to be leveled - See the leveling and door

alignment instructions.

Refrigerator rocks

and is not stable

■ Refrigerator is not level - To stabilize the refrigerator, remove the base grille and lower the

leveling feet until they touch the floor. See the leveling and door alignment instructions.

ICE AND WATER Possible Causes and/or Recommended Solutions

Ice maker is not

producing ice,

not producing

enough ice,

or producing

small/hollow ice

■ Refrigerator is not connected to a water supply, or the water supply shutoff valve is not fully

turned on - Connect the refrigerator to a water supply and make sure the water shutoff valve is

fully open.

■ Kink in the water source line - A kink in the water line can reduce water flow, resulting in decreased ice

production, small ice cubes, and/or hollow or irregularly-shaped ice. Straighten the water line.

■ Ice maker is not turned on - Turn on the ice maker. See “Ice Maker and Storage Bin” in the User

Instructions or User Guide.

■ New installation - After connecting the refrigerator to a water source, flush the water system.

(See “Water and Ice Dispensers” in the User Instructions or User Guide.) Wait 24 hours for ice

production to begin. Wait 72 hours for full ice production. Discard the first three batches of ice produced.

■ Large amount of ice was recently removed - Allow sufficient time for the ice maker to produce

more ice.

■ Ice is jammed in the ice maker ejector arm (on some models) - Remove ice from the ejector arm

using a plastic utensil.

■ Inadequate water pressure - Verify that the household has adequate water pressure. See “Water

Supply Requirements.”

■ Water filter is installed incorrectly - Make sure the filter is properly installed. See “Water Filtration

System” in the User Instructions or User Guide.

■ A reverse osmosis water filtration system is connected to your cold water supply - This can

decrease water pressure. See “Water Supply Requirements.”

NOTE: If questions remain regarding water pressure, contact a licensed, qualified plumber.

17

Page 18

ICE AND WATER Possible Causes and/or Recommended Solutions

Ice dispenser

will not operate

properly

Ice or water has an

off-taste, odor,

or gray color

Doors not closed completely - Make sure both doors are firmly closed. (On some models, only the

freezer door must be closed in order to operate the dispenser.)

New installation - After connecting the refrigerator to a water source, flush the water system.

(See “Water and Ice Dispensers” in the User Instructions or User Guide.) Wait 24 hours for ice

production to begin. Wait 72 hours for full ice production. Discard the first three batches of ice produced.

Ice maker is not turned on, or ice bin is not installed correctly - Turn on the ice maker and make sure

the ice storage bin is firmly in position. See “Ice Maker and Storage Bin” in the User Instructions or User

Guide.

Ice is clogged or frozen together in the ice storage bin, or ice is blocking the ice delivery

chute - Remove or separate the clogged ice, using a plastic utensil if necessary. Clean the ice delivery

chute and the bottom of the ice storage bin using a warm damp cloth; then, dry both thoroughly. To avoid

clogging and to maintain a fresh supply of ice, empty the storage bin and clean both the storage bin and

the delivery chute every 2 weeks.

Wrong ice has been added to the storage bin - Use only ice cubes produced by the current ice maker.

Dispenser is locked - Unlock the dispenser. See “Water and Ice Dispensers” in the User Instructions or

User Guide.

Ice dispenser jams while dispensing crushed ice - For models with the ice storage bin on the door,

temporarily switch from crushed ice to cubed ice to clear the jam.

Dispenser pad/lever has been pressed too long - Ice will automatically stop dispensing. Wait a few

minutes for the dispenser to reset, then resume dispensing. Take large amounts of ice directly from the

ice bin, not through the dispenser.

Water pressure to the home is not at or above 30 psi (207 kPa) - The water pressure to the home

affects the flow from the dispenser. See “Water Supply Requirements.”

Water filter is clogged or incorrectly installed - Replace filter or reinstall it correctly. See “Water

Filtration System” in the User Instructions or User Guide.

New plumbing connections - New plumbing connections can result in off-flavored or discolored ice or

water. This problem should go away over time.

Ice has been stored too long - Discard the ice and wash the ice bin. Allow 24 hours for the ice maker to

produce new ice.

Odor has transferred from food - Use airtight moisture-proof packaging to store food.

Use of non-recommended water supply line - Odors and tastes can transfer from certain materials

used in non-recommended water supply lines. Use only a recommended water supply line. See “Water

Supply Requirements.”

There are minerals (such as sulfur) in the water - A water filter may need to be installed in order to

remove the minerals.

Water filter was recently installed or replaced - Gray or dark discoloration in ice or water indicates

that the water filtration system needs additional flushing. See “Water and Ice Dispensers” in the User

Instructions or User Guide.

Water dispenser

will not operate

properly

18

Doors not closed completely - Make sure both doors are firmly closed. (On some models, only the

freezer door must be closed in order to operate the dispenser.)

Refrigerator is not connected to a water supply, or the water supply shutoff valve is not

turned on - Connect the refrigerator to a water supply and make sure the water shutoff valve is

fully open.

Kink in the water source line - A kink in the water line can reduce water flow to the dispenser.

Straighten the water line.

Water pressure to the home is not at or above 30 psi (207 kPa) - The water pressure to the home

affects the flow from the dispenser. See “Water Supply Requirements.”

New installation - After connecting the refrigerator to a water source, flush the water system.

See “Water and Ice Dispensers” in the User Instructions or User Guide.

Dispenser is locked - Unlock the dispenser. See “Water and Ice Dispensers” in the User Instructions or

User Guide.

Water filter is clogged or incorrectly installed - Replace filter or reinstall it correctly. See “Water

Filtration System” in the User Instructions or User Guide.

A reverse osmosis water filtration system is connected to your cold water supply - This can

decrease water pressure. See “Water Supply Requirements.”

NOTE: If questions remain regarding water pressure, contact a licensed, qualified plumber.

Page 19

ICE AND WATER Possible Causes and/or Recommended Solutions

Water is leaking or

dripping from the

dispenser

Water is leaking

from the back of the

refrigerator

Water from the

dispenser is

not cool enough

(on some models)

NOTE: After dispensing, a few additional drops of water are normal.

■ Glass was not held under the dispenser long enough - Hold the glass under the dispenser for

2 to 3 seconds after releasing the dispenser pad/lever.

■ New installation, or water filter was recently installed or replaced - Air in the water lines causes the

water dispenser to drip. Flush the water system to remove the air in the water lines. See “Water and Ice

Dispensers” in the User Instructions or User Guide.

■ Residual ice in the dispenser chute is melting - Make sure the ice chute is free of ice shavings or

pieces.

■ Water line connections are not fully tightened - Make sure all connections are firmly tightened. See

“Connect Water Supply.”

NOTE: Water from the dispenser is chilled to 50°F (10°C).

■ New installation - Allow 24 hours after installation for the water supply to cool completely.

■ Recently dispensed a large amount of water - Allow 24 hours for the new water supply to cool

completely.

■ Water has not been recently dispensed - The first glass of water may not be cool. Discard the first

glass of water dispensed.

■ Refrigerator is not connected to a cold water pipe - Make sure the refrigerator is connected to a cold

water pipe. See “Water Supply Requirements.”

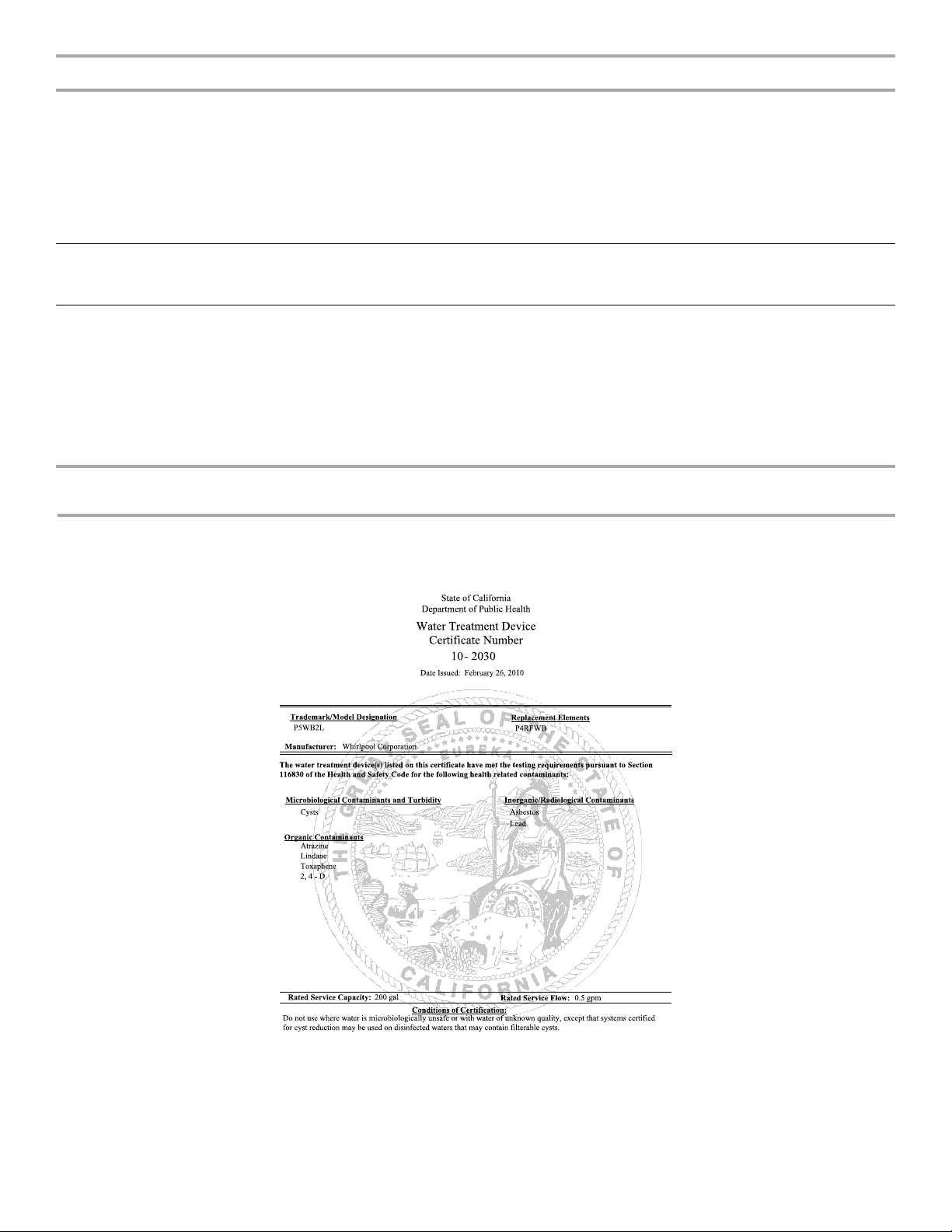

WATER FILTER CERTIFICATIONS

19

Page 20

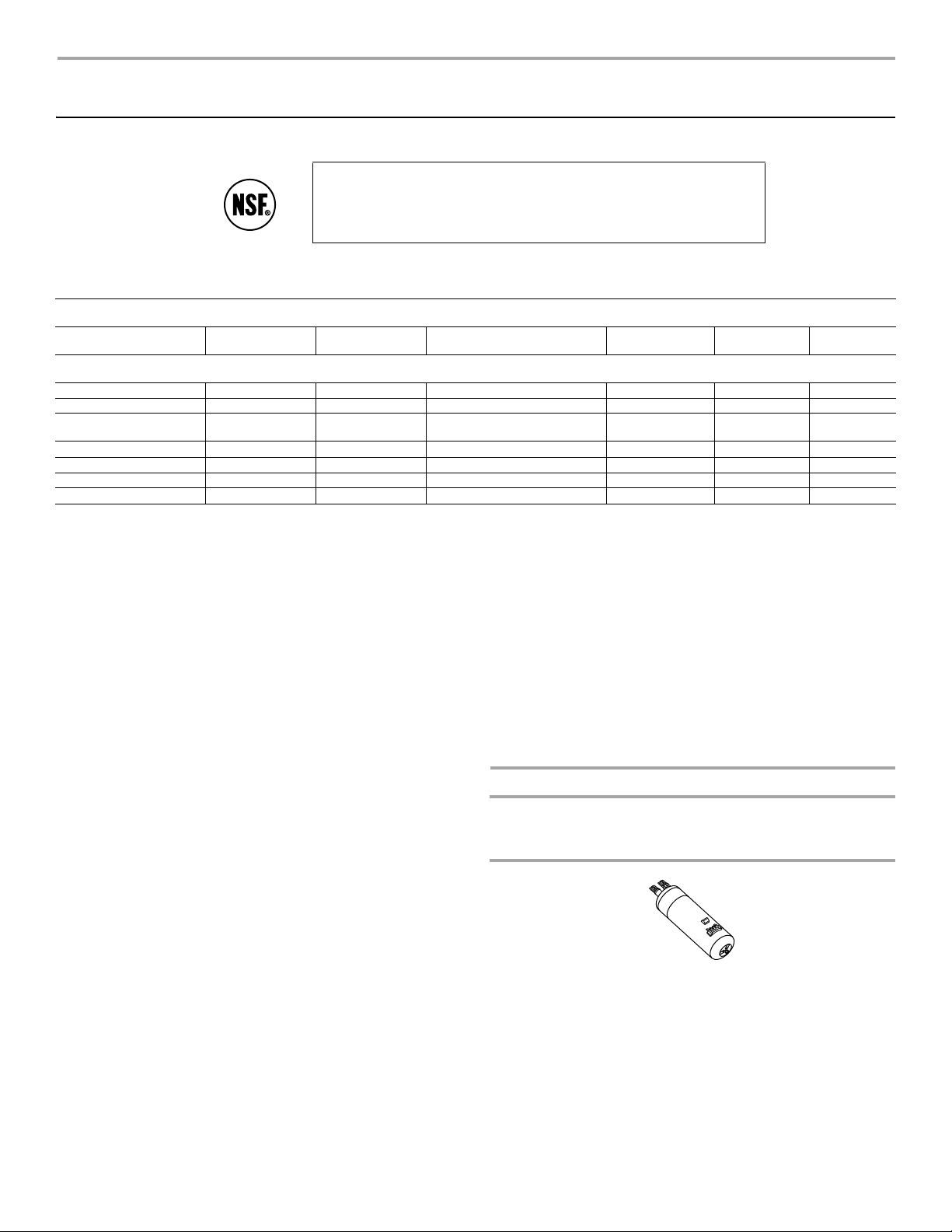

PERFORMANCE DATA SHEET

*

**

†

††

Class I particle size: >0.5 to <1 um

Test requirement is at least 100,000 particles/mL of AC Fine Test Dust.

Based on the use of Cryptosporidium parvum oocysts

Fibers greater than 10 um in length

® NSF is a registered trademark of NSF International.

Water Filtration System

Model P5WB2L/P4RFWB Capacity 200 Gallons (757 Liters)

System tested and certified by NSF International against NSF/ANSI

Standard 42 for the reduction of Chlorine Taste and Odor, and Particulate

Class I*; and against NSF/ANSI Standard 53 for the reduction of Live

Cysts, Asbestos, Lead, Lindane, Toxaphene, Atrazine, and 2,4 - D.

This system has been tested according to NSF/ANSI Standards 42 and 53 for the reduction of the substances listed below.

The concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to

the permissible limit for water leaving the system, as specified in NSF/ANSI Standards 42 and 53.

Substance Reduction

Aesthetic Effects

Chlorine Taste/Odor

Particulate Class I

Contaminant

Reduction

Live Cysts

Asbestos 99% 87 MFL 10

Lead: @ pH 6.5

Lead: @ pH 8.5

Lindane 0.0002 mg/L 0.0019 mg/L 0.002 mg/L ± 10% 0.00002 mg/L 98.9 99

Toxaphene 0.003 mg/L 0.014 mg/L 0.015 mg/L ± 10% 0.001 mg/L 93 93

Atrazine 0.003 mg/L 0.0094 mg/L 0.009 mg/L ± 10% 0.0005 mg/L 94.5 94.7

2,4 - D 0.07 mg/L 0.220 mg/L 0.210 mg/L ± 10% 0.028 mg/L 87.5 96.1

*

†

Test Parameters: pH = 7.5 ± 0.5 unless otherwise noted. Flow = 0.5 gpm (1.9 Lpm). Pressure = 60 psig (413.7 kPa).

Temp. = 68°F to 71.6°F (20°C to 22°C). Rated service capacity = 200 gallons (757 liters).

NSF Reduction

Requirements

50% reduction

85% reduction

NSF Reduction

Requirements

99.95% 160,000/L 50,000/L min. 54/L

0.010 mg/L

0.010 mg/L

Average

Influent

2.0 mg/L

7,300,000 #/mL

Average

Influent

0.160 mg/L

0.140 mg/L

Influent Challenge

Concentration

2.0 mg/L ± 10%

At least 10,000 particles/mL

Influent Challenge

Concentration

7

to 108 fibers/L

0.15 mg/L ± 10%

0.15 mg/L ± 10%

††

Maximum

Effluent

0.20 mg/L

75,000 #/mL

Maximum

Effluent

0.17 MFL 99 99

0.001 mg/L

0.005 mg/L

Minimum %

Reduction

97

**

99

Minimum %

†

Reduction

99.97 99.99

99.4

98.6

Average %

Reduction

97.2

99.4

Average %

Reduction

99.4

98.6

■ It is important that operational, maintenance, and filter

replacement requirements be carried out for the product to

perform as advertised. Property damage can occur if all

instructions are not followed.

■ Use replacement filter P4RFWB, part #W10295370A.

2014 suggested retail price of $39.99 U.S.A./$49.99 Canada.

Prices are subject to change without notice.

Style 1 – When the water filter status display changes from

“GOOD” to “ORDER,” order a new filter. When the filter

indicator reads “REPLACE,” it is recommended that you

replace the filter.

Style 2 – When the filter indicator changes from green to

yellow, order a new filter. When the indicator changes from

yellow to red, it is recommended that you replace the filter.

Style 3 – When the filter indicator reads 10%, order a new

filter. When the indicator reads 0%, it is recommended that

you replace the filter.

Style 4 – Press FILTER to check the status of your water filter.

If the filter indicator light is yellow, order a new filter. If the filter

indicator light is red, it is recommended that you replace the

filter.

■ After changing the water filter, flush the water system. See

“Water and Ice Dispensers” or “Water Dispenser” in the User

Instructions or User Guide.

■ These contaminants are not necessarily in your water supply.

While testing was performed under standard laboratory

conditions, actual performance may vary.

■ The product is for cold water use only.

■ The water system must be installed in compliance with state

and local laws and regulations.

■ Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after

the system. Systems certified for cyst reduction may be used

on disinfected waters that may contain filterable cysts.

■ Refer to the “Warranty” section (in the User Instructions or

User Guide) for the Manufacturer’s name, address and

telephone number.

■ Refer to the “Warranty” section (in the User Instructions or

User Guide) for the Manufacturer’s limited warranty.

Application Guidelines/Water Supply Parameters

Water Supply

Water Pressure

Water Temperature

Service Flow Rate

City or Well

30 - 120 psi (207 - 827 kPa)

33° - 100°F (0.6° - 37.8°C)

0.5 gpm (1.9 Lpm) @ 60 psi

20

Page 21

Notes

21

Page 22

INSTRUCCIONES DE INSTALACIÓN

Si no sigue las instrucciones de inmediato, usted puede

morir o sufrir una lesión grave.

Si no sigue las instrucciones, usted puede morir o sufrir

una lesión grave.

Todos los mensajes de seguridad le dirán el peligro potencial, le dirán cómo reducir las posibilidades de sufrir una lesión y lo que

puede suceder si no se siguen las instrucciones.

Su seguridad y la seguridad de los demás es muy importante.

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su electrodoméstico. Lea y obedezca siempre

todos los mensajes de seguridad.

ADVERTENCIA

PELIGRO

Este es el símbolo de advertencia de seguridad.

Este símbolo le llama la atención sobre peligros potenciales que pueden ocasionar la muerte o una lesión a

usted y a los demás.

Todos los mensajes de seguridad irán a continuación del símbolo de advertencia de seguridad y de la palabra

“PELIGRO” o “ADVERTENCIA”. Estas palabras significan:

Para reducir el riesgo de incendio, choque eléctrico, o lesiones personales al usar su refrigerador siga

estas precauciones básicas:

ADVERTENCIA:

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

CONSERVAR ESTAS INSTRUCCIONES

■ Conecte a un contacto de pared de conexión a tierra de

3 terminales.

■ No use un adaptador.

■ No quite la terminal de conexión a tierra.

■ No use un cable eléctrico de extensión.

■ Desconecte el suministro de energía antes de darle servicio.

■ Vuelva a colocar todos los componentes y paneles antes de

hacerlo funcionar.

■ Remueva las puertas de su refrigerador viejo.

■ Use un limpiador no inflamable.

■ Mantenga los materiales y vapores inflamables, tales como

gasolina, alejados del refrigerador.

■ Use dos o más personas para mover e instalar el

refrigerador.

■ Desconecte el suministro de energía antes de instalar la

fábrica de hielo (en aquellos modelos que incluyen el juego

de instalación de la fábrica de hielo).

■ Use un vaso resistente para recibir hielo del despachador

(en algunos modelos).

■ No golpee las puertas de vidrio del refrigerador (en algunos

modelos).

Advertencias de la Proposición 65 del estado de California:

ADVERTENCIA: Este producto contiene una o más sustancias químicas identificadas por el estado de California como

causantes de cáncer.

ADVERTENCIA: Este producto contiene una o más sustancias químicas identificadas por el estado de California como

causantes de defectos congénitos o algún otro tipo de daños en la función reproductora.

YMANUALDELPROPIETARIO

Refrigerador de dos puertas con profundidad de mostrador

SEGURIDAD DEL REFRIGERADOR

22

Page 23

Cómo deshacerse adecuadamente de

ADVERTENCIA

Peligro de Asfixia

Remueva las puertas de su refrigerador viejo.

No seguir esta instrucción puede ocasionar la muerte

o daño al cerebro.

Información importante para saber acerca del desecho

de refrigerantes:

Deshágase del refrigerador siguiendo los reglamentos

federales y locales. Los refrigerantes deberán ser evacuados

por un técnico certificado en refrigeración por EPA (Agencia

de protección del medioambiente) según los procedimientos

establecidos.

A

C

35¹⁄₂"

(90,0 cm)

23⁷⁄₈"

(60,4 cm)

15³⁄₈"

(38,9 cm)

20"

(50,8 cm)

B

⁵⁄₈"

(1,6 cm)

su refrigerador viejo

IMPORTANTE: El atrapamiento y asfixia de niños no es un

problema del pasado. Los refrigeradores tirados y abandonados

son un peligro, aún si van a quedar ahí “por unos pocos días”.

Si Ud. está por deshacerse de su refrigerador viejo, por favor siga

las instrucciones que se dan a continuación para prevenir

accidentes.

Antes de tirar su viejo refrigerador o congelador:

■ Saque las puertas.

■ Deje los estantes en su lugar para que los niños no puedan

meterse con facilidad.

REQUISITOS DE INSTALACIÓN

Piezas y herramientas

IMPORTANTE:

■ Observe todos los códigos y reglamentos aplicables.

■ Instalador: Deje las instrucciones de instalación con el

propietario.

■ Propietario: Guarde las instrucciones de instalación para

referencia futura y para que puedan ser usadas por el

inspector eléctrico local.

■ Mantenga un tramo de cartón de empaque o de madera

contrachapada debajo del refrigerador hasta que lo instale en

su ubicación final.

■ Cumpla con las especificaciones y medidas de instalación.

■ Saque todas las molduras o paneles decorativos de los

armarios de la cocina que impidan el acceso al refrigerador

para darle servicio.

■ Contacte a un instalador electricista calificado.

HERRAMIENTAS NECESARIAS (en algunos modelos):

Reúna las herramientas y piezas necesarias antes de comenzar la

instalación. Lea y siga las instrucciones provistas con cualquiera

de las herramientas enlistadas aquí.

■ Taladro inalámbrico

■ Llave para tuercas

de ¹⁄₄"y broca

■ Destornillador de

hoja plana

PIEZAS NECESARIAS (en algunos modelos):

■ El distribuidor de su refrigerador tiene un juego disponible de

válvula de cierre tipo montura de ¼" (6,35 mm), una unión y

tubería de cobre.

■ O usted puede comprar una tubería de cobre de ¼" (6,35 mm)

con válvula de cierre y un accesorio de compresión

(acoplamiento) de ¼" (6,35 mm).

■ Llave de ⁵⁄₁₆" o llave ajustable