Page 1

INSTALLATION INSTRUCTIONS

27" (68.6 CM) AND 30" (76.2 CM) ELECTRIC BUILT-IN

MICROWAVE/OVEN COMBINATION

INSTRUCTIONS D'INSTALLATION

FOUR CONVENTIONNEL ET FOUR À MICRO-ONDES

ÉLECTRIQUES, COMBINÉS ET ENCASTRÉS

DE 27" (68,6 CM) ET 30" (76,2 CM)

Table of Contents/Table des matières

BUILT-IN MICROWAVE/OVEN COMBINATION SAFETY...........2

INSTALLATION REQUIREMENTS ................................................2

Tools and Parts ............................................................................2

Built-In Microwave/Oven Combination

Location Requirements ................................................................2

Electrical Requirements ...............................................................4

INSTALLATION INSTRUCTIONS ..................................................5

Prepare Built-In Microwave/Oven Combination..........................5

Remove Oven Door(s)..................................................................5

Replace Oven Door(s)..................................................................5

Make Electrical Connection .........................................................6

Install Oven...................................................................................7

Install Warming Drawer Deflector Kit (only for ovens installed

above warming drawers)..............................................................8

Complete Installation ...................................................................9

SÉCURITÉ DU FOUR À MICRO-ONDES ET DU FOUR

CONVENTIONNEL COMBINÉS ET ENCASTRÉS......................10

EXIGENCES D'INSTALLATION ...................................................10

Outils et pièces...........................................................................10

Exigences d'emplacement de l'ensemble four à micro-ondes et

four conventionnel encastrés.....................................................10

Spécifications électriques ..........................................................12

INSTRUCTIONS D'INSTALLATION.............................................13

Préparation de l'ensemble des fours encastrés (micro-ondes/

conventionnel) ............................................................................13

Dépose de la/des porte(s) du four .............................................13

Réinstallation de la/des porte(s) du four ....................................13

Raccordement électrique...........................................................14

Installation du four......................................................................15

Installation de l'ensemble déflecteur du tiroir-réchaud (uniquement

pour les fours installés au-dessus d'un tiroir-réchaud) ...............17

Achever l'installation ..................................................................17

W10696163A

IMPORTANT:

Save for local electrical inspector's use.

IMPORTANT :

À conserver pour consultation par l'inspecteur local des installations électriques.

Page 2

2

BUILT-IN MICROWAVE/OVEN COMBINATION SAFETY

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

■ Phillips screwdriver

■ Measuring tape

■ Drill (for wall cabinet installations)

■ 1" (25 mm) drill bit (for wall cabinet installations)

■ Level

■ Flat-blade screwdriver

Parts needed

■ UL listed or CSA approved conduit connector

■ UL listed wire connectors

■ Warming Drawer Deflector Kit (for ovens installed above a

warming drawer)

Order Part Number W10489566B for white 27" (68.6 cm) kit

Order Part Number W10489564B for black 27" (68.6 cm) kit

Order Part Number W10489568A for stainless steel 27"

(68.6 cm) kit

Order Part Number W10489567B for white 30" (76.2 cm) kit

Order Part Number W10489565B for black 30" (76.2 cm) kit

Order Part Number W10489569A for stainless steel 30"

(76.2 cm) kit

To order, see the “Assistance or Service” section of the Use

and Care Guide.

Parts supplied

■ Four #8–14 x ³⁄₄" screws

■ Bottom vent

■ Two #8–18 x ³⁄₈" screws - bottom vent

■ Four grommets*

Check local codes. Check existing electrical supply. See

“Electrical Requirements.”

It is recommended that all electrical connections be made by a

licensed, qualified electrical installer.

*Grommets are not included with models KEMS309B and

KEMS379B.

Built-In Microwave/Oven Combination

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions provide minimum clearance with oven.

■ Recessed installation area must provide complete enclosure

around the recessed portion of the oven.

■ Grounded electrical supply is required. See “Electrical

Requirements” section.

■ Electrical supply junction box should be located 3" (7.6 cm)

maximum below the support surface when the oven is

installed in a wall cabinet. A 1" (2.5 cm) minimum diameter

hole should have been drilled in the left rear corner of the

support surface to pass the appliance cable through to the

junction box.

■ Oven support surface must be solid, level and flush with

bottom of cabinet cutout. Floor must be able to support a

total weight (microwave and built-in oven) of 208 lbs (95 kg)

for 27" (68.6 cm) models or 249 lbs (113 kg) for 30" (76.2 cm)

models.

IMPORTANT: To avoid damage to your cabinets, check with

your builder or cabinet supplier to make sure that the

materials used will not discolor, delaminate or sustain other

damage. This oven has been designed in accordance with

the requirements of UL and CSA International and complies

with the maximum allowable wood cabinet temperatures of

194°F (90°C).

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

Page 3

3

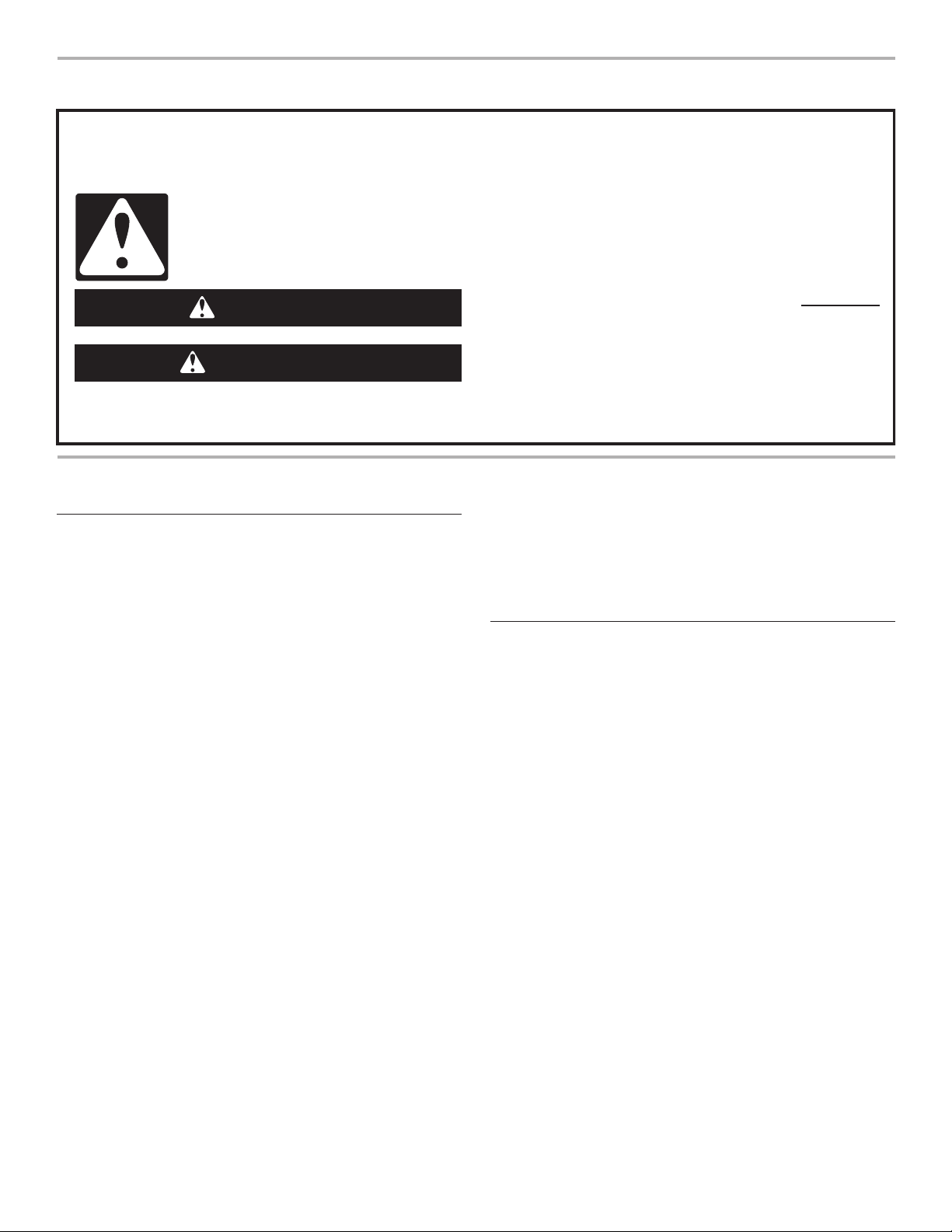

Product Dimensions

27" (68.6 cm) and 30" (76.2 cm) Ovens

Cabinet Dimensions

27" (68.6 cm) and 30" (76.2 cm) Ovens

*NOTE: The cutout height can be between 41" (104.1 cm) and

41½" (105.6 cm) for microwave/oven combination.

27" (68.6 cm) models

A.

42⁹⁄₁₆

" (108.0 cm) overall height

B. 25

⁷⁄₁₆

" (64.6 cm) recessed width

C. 41" (104.1 cm) recessed height

D. 23

¹⁄₄

" (59.1 cm) max. recessed

depth

E. 27" (68.6 cm) overall width

F. 48" (121.9 cm) Flexible conduit

length

measured from the

conduit clamp located at the

rear of the oven. Do not remove

the conduit clamp.

30" (76.2 cm) models

A.

42⁹⁄₁₆

" (108.0 cm) overall height

B. 28

¹⁄₂

" (72.3 cm) recessed width

C. 41" (104.1 cm) recessed height

D. 23

¹⁄₄

" (59.1 cm) max. recessed

depth

E. 30" (76.2 cm) overall width

F. 48" (121.9 cm) Flexible conduit

length

measured from the

conduit clamp located at the

rear of the oven. Do not remove

the conduit clamp.

B

A

C

D

E

F

27" (68.6 cm) models

A. 27" (68.6 cm) min. cabinet

width

B. 1" (2.5 cm) top of cutout to

bottom of upper cabinet door

C. 19

¹⁄₄

" (48.9 cm) bottom of

cutout to floor is

recommended.

4"-19

¹⁄₄

" (10.2-48.9 cm) bottom

of cutout to floor is acceptable.

D. 25

¹⁄₂

" (64.8 cm) cutout width

E. 1

¹⁄₂

" (3.8 cm) min. bottom of

cutout to top of cabinet door

F. 41

⁵⁄₁₆

" (105 cm)* recommended

cutout height

G. 24" (60.7 cm) cutout depth

30" (76.2 cm) models

A. 30" (76.2 cm) min. cabinet

width

B. 1" (2.5 cm) top of cutout to

bottom of upper cabinet door

C. 19

¹⁄₄

" (48.9 cm) bottom of

cutout to floor is

recommended.

4"-19

¹⁄₄

" (10.2-48.9 cm) bottom

of cutout to floor is acceptable.

D. 28

¹⁄₂

" (72.4 cm) cutout width

E. 1

¹⁄₂

" (3.8 cm) min. bottom of

cutout to top of cabinet door

F. 41

⁵⁄₁₆

" (105 cm)* recommended

cutout height

G. 24" (60.7 cm) cutout depth

F

E

A

D

G

B

C

Page 4

4

Electrical Requirements

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path and wire gauge are in accordance with local

codes.

Check with a qualified electrical installer if you are not sure the

oven is properly grounded.

This oven must be connected to a grounded metal, permanent

wiring system.

Be sure that the electrical connection and wire size are adequate

and in conformance with the National Electrical Code, ANSI/

NFPA 70-latest edition or CSA Standards C22.1-94, Canadian

Electrical Code, Part 1 and C22.2 No. O-M91-latest edition, and

all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

Electrical Connection

To properly install your oven, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

■ Oven must be connected to the proper electrical voltage,

amperage, and frequency as specified on the model/serial

number rating plate. See the following illustration.

■

Models rated from 7.3 to 9.6 kW at 240 volts (5.5 to 7.2 kW at

208 volts) require a separate 40-amp circuit. Models rated at

7.2 kW and below at 240 volts (5.4 kW and below at 208 volts)

require a separate 30-amp circuit.

■ A circuit breaker is recommended.

■ Connect directly to the fused disconnect (or circuit breaker

box) through flexible, armored or nonmetallic sheathed,

copper cable (with grounding wire). See “Make Electrical

Connection” section.

■ Flexible conduit from the oven should be connected directly

to the junction box.

■ Do not cut the conduit. The length of conduit provided is for

serviceability of the oven.

■ A UL listed or CSA approved conduit connector must be

provided.

■ If the house has aluminum wiring, follow the procedure

below:

1. Connect a section of solid copper wire to the ends of the

flexible conduit leads.

2. Connect the aluminum wiring to the added section of

copper wire using special connectors and/or tools

designed and UL listed for joining copper to aluminum.

Follow the electrical connector manufacturer's recommended

procedure. Aluminum/copper connection must conform with

local codes and industry accepted wiring practices.

For power requirements, refer to the following table.

*L1 includes both the microwave and the oven, and L2 includes

only the oven. Amperage values noted above are for information

purposes only: The units are rated in watts.

A. Model/serial number plate

A

Model Voltage Amperage

(L1)*

Amperage

(L2)*

Rating

(kW)

MMW9730 120/240

129/208

30

28

15

15

7.2

5.9

WOC54EC0,

WOC95EC0

120/240

120/208

30

28

15

15

7.2

5.9

WOC54EC7 120/240

120/208

30

28

15

15

7.2

5.9

KEMS309 120/240

120/208

33

31

15

15

8.0

6.6

Page 5

5

INSTALLATION INSTRUCTIONS

Prepare Built-In Microwave/Oven

Combination

1. Decide on the final location for the oven. Locate existing

wiring to avoid drilling into or severing wiring during

installation.

2. To avoid floor damage, set the oven onto cardboard prior to

installation. Do not use handle or any portion of the front

frame for lifting.

3. Remember to remove bottom vent from the foam packing on

top of oven.

4. Remove the shipping materials and tape from the oven.

5. Remove the hardware package from inside the bag

containing literature.

6. Remove and set aside racks and other parts from inside the

oven.

7. Move oven and cardboard close to the oven’s final location.

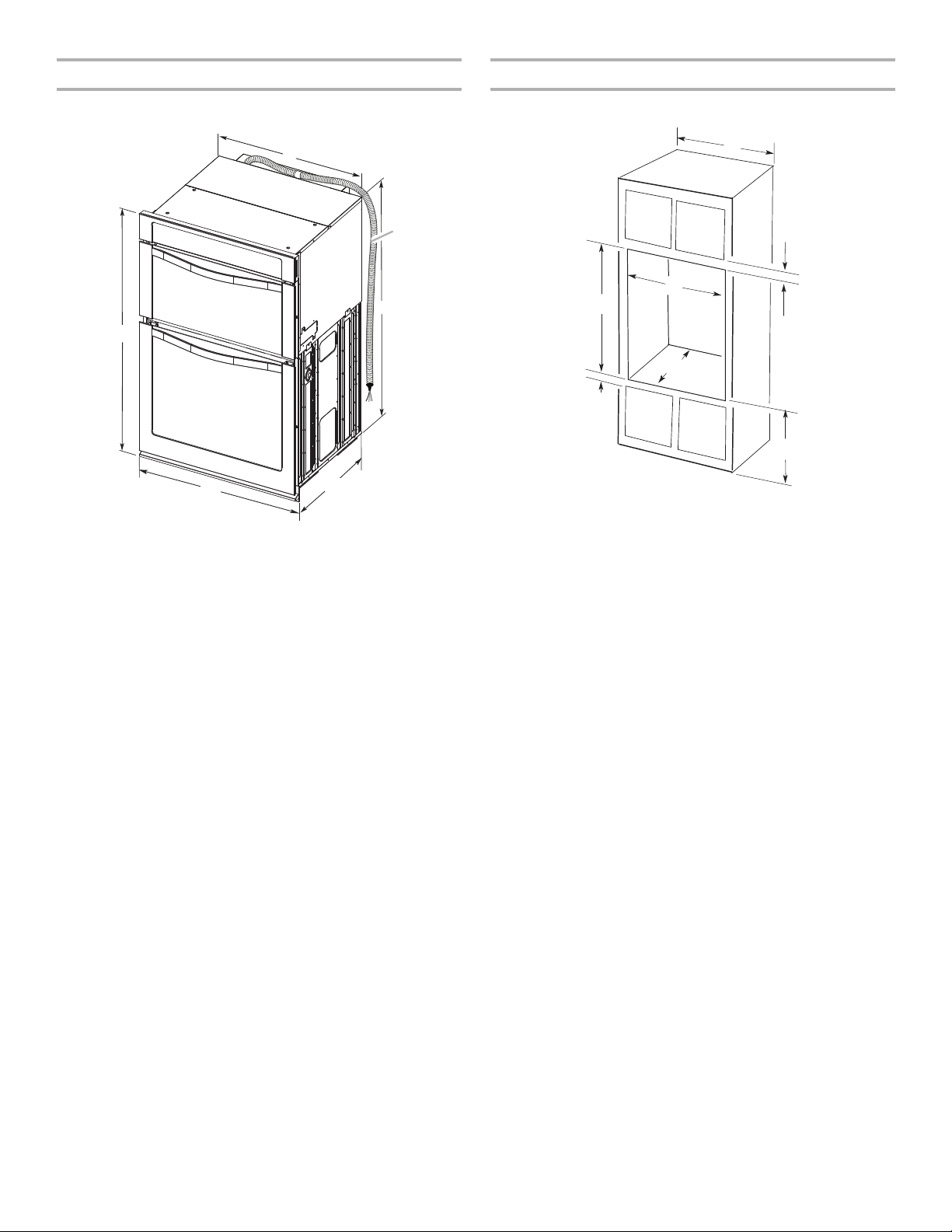

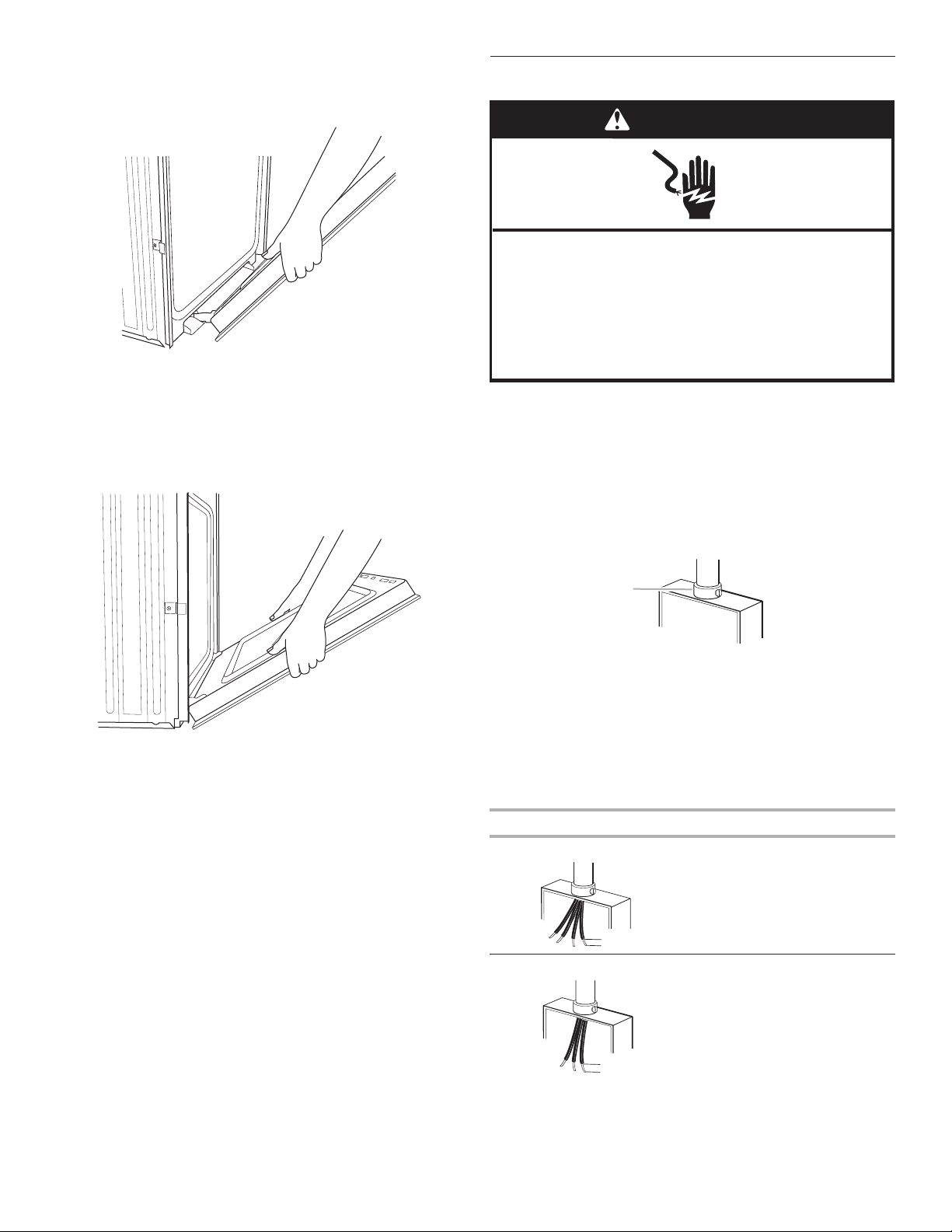

Remove Oven Door(s)

IMPORTANT: Use two hands to remove oven door.

1. Prior to removing the oven door, prepare a surface where you

will place it. This surface should be flat and covered with a

soft blanket, or use the corner posts from your packaging

material.

2. Open the oven door.

3. Locate the oven door hinge locks in both corners of the oven

door, and rotate the hinge locks toward the oven door to the

unlocked position. If the door hinge lock is not rotated fully

(see illustration B), the door will not remove properly.

4. Partially close the door to engage the door latch locks. The

door will stop at this point.

5. Using two hands, grasp the edges of the oven door. Lift and

pull the oven door toward you and remove. You may need to

gently shift door from side to side as you pull.

6. Set the oven door(s) aside on the prepared covered work

surface, with the oven door resting on its handle.

7. To continue with the oven installation, go to the “Positioning

Oven Feet for Multiple Cabinet Cutout Heights” section.

Replace Oven Door(s)

IMPORTANT: Do not replace the oven door(s) until after the oven

has been installed into the cabinet.

1. Using two hands, grasp side edges of door at the midpoint.

Face the oven cavity.

2. Locate the slots on each side of the oven cavity for the door

hinge locks.

A. Oven door hinge lock in

locked position

B. Oven door hinge lock in

unlocked position

WARNING

Excessive Weight Hazard

Use two or more people to move and install oven.

Failure to do so can result in back or other injury.

A

B

A. Slot in the oven cavity for

door hinge lock

A

Page 6

6

3. At a 45° angle, align door hinges with slots in the lower front

of the oven cavity. Slowly insert door, making sure you

maintain the 45° angle. You will know the door is engaged in

the slot when you feel a slight drop.

4. Lower the oven door to the fully open position. If the oven

door does not open to a full 90 degrees, repeat steps 1-3.

5. Locate the oven door hinge locks in the corners of the oven

door, and rotate the hinge locks toward the oven cavity to the

locked position.

See Step 3 (illustration A) in the “Remove Oven Door(s)”

section for proper locked position.

6. Close the oven door.

7. When the hinges are properly installed and the door closed,

there should be an even gap between the door and the

control panel. If one side of the oven door is hanging lower

than the other, the hinge on that side is not properly installed.

Make Electrical Connection

This oven is manufactured with a neutral (white) power supply

wire and a cabinet-connected green (or bare) ground wire twisted

together.

1. Disconnect power.

2. Feed the flexible conduit from the oven through the opening

in the cabinet.

3. Remove junction box cover, if it is present.

4. Install a UL listed or CSA approved conduit connector to the

junction box.

5. Route the flexible conduit from the oven to the junction box

through a UL listed or CSA approved conduit connector.

6. Tighten screws on conduit connector.

7. See “Electrical Connection Options Chart” to complete

installation for your type of electrical connection.

Electrical Connection Options Chart

A. UL listed or CSA approved conduit connector

If your home has: Go to section:

4-wire 4-wire Cable from Home

Power Supply

3-wire 3-wire Cable from Home

Power Supply

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge solid copper wire.

Electrically ground oven.

Failure to follow these instructions can result in death,

fire, or electrical shock.

A

½"

(1.3 cm)

½"

(1.3 cm)

Page 7

7

4-Wire Cable from Home Power Supply

IMPORTANT: Use the 4-wire cable from home power supply in

the U.S. where local codes do not allow grounding through

neutral, New Branch circuit installations (1996 NEC), mobile

homes and recreational vehicles, new construction and in

Canada.

1. Connect the 2 black wires (B) together using a UL listed wire

connector.

2. Connect the 2 red wires (C) together using a UL listed wire

connector.

3. Untwist white wire from green (or bare) ground wire coming

from the oven.

4. Connect the 2 white wires (F) together using a UL listed wire

connector.

5. Connect the green (or bare) ground wire (H) from the oven

cable to the green (or bare) ground wire (in the junction box)

using a UL listed wire connector.

6. Install junction box cover.

3-Wire Cable from Home Power Supply - U.S. Only

IMPORTANT: Use the 3-wire cable from home power supply

where local codes permit a 3-wire connection.

1. Connect the 2 black wires (C) together using a UL listed wire

connector.

2. Connect the 2 white wires (D) and the green (or bare) ground

wire (of the oven cable) using a UL listed wire connector.

3. Connect the 2 red wires (G) together using a UL listed wire

connector.

4. Install junction box cover.

Install Oven

1. Using 2 or more people, lift oven partially into cabinet cutout.

Use the oven opening as an area to grip.

NOTE: Push against seal area of oven front frame when

pushing oven into cabinet. Do not push against the outside

edges.

2. Push against the seal area of the front frame to push the oven

into the cabinet until the back surface of the front frame

touches the front wall of the cabinet.

3. Push the oven completely into the cabinet and center oven

into cabinet cutout.

NOTE: If you have model KEMS379B or KEMS309B, proceed

to Step 6.

4. Insert the grommet into the mounting rail hole using a flat-

blade screwdriver. Insert the screwdriver into the grommet

and turn ¹⁄₄ turn counterclockwise. Make sure the grommet

stays in position.

A. Cable from home power supply

B. Black wires

C. Red wires

D. 4-wire flexible conduit from oven

E. Junction box

F. White wires

G. UL listed wire connectors

H. Green (or bare) ground wires

I. UL listed or CSA approved

conduit connector

A. Cable from home power

supply

B. Junction box

C. Black wires

D. White wires

E. Green (or bare) ground wire

(from oven)

F. 4-wire flexible conduit from

oven

G. Red wires

H. UL listed wire connectors

I. UL listed or CSA approved

conduit connector

A

D

F

H

B

C

E

G

I

B

C

D

E

F

H

G

A

I

Page 8

8

IMPORTANT: If the grommet is not installed, the front frame

will be damaged.

5. Securely fasten oven to cabinet using the #8–14 x ³⁄₄" screws

provided. Insert the screws through hole in the grommet. Do

not overtighten screws.

6. For models KEMS379B and KEMS309B, see the following

instructions.

For all other models, the black front trims can be ordered as

an accessory. Please reference the “Assistance or Service”

section of the Use and Care Guide or contact the dealer from

whom you purchased your built-in oven to order part

numbers W10344482 and W10344483.

■ Remove the tape from black front trims.

■ Securely fasten the oven to the cabinet using the #8-14 x

¾" screws provided.

■ Insert the screws through hole in black trim aligning with

hole in oven frame. Do not overtighten screws.

7. The bottom vent is shipped in the foam packing at the top of

the oven. Install the bottom vent (C) as follows:

■ Align vent tab (B) with oven frame (A) as shown.

■ Using one #8-18 x 3/8" screw (D) on each side of the vent

tab (B), fasten the vent securely to the oven.

8. Replace oven racks.

9. Replace the oven door. See the “Replace Oven Door(s)”

section.

10. Check that door is free to open and close. If it is not, repeat

the removal and installation procedures. See “Prepare Built-In

Microwave/Oven Combination” section.

11. Reconnect power.

12. The display panel will light briefly, and “PF” should appear in

the display.

13. If the display panel does not light, please reference the

“Assistance or Service” section of the Use and Care Guide or

contact the dealer from whom you purchased your oven.

Install Warming Drawer Deflector Kit (only

for ovens installed above warming

drawers)

On combo microwave/oven models installed above a warming

drawer, a warming drawer deflector kit must be installed. See the

“Tools and Parts” section for information on ordering.

Parts Supplied

A. Mounting rail

B. Mounting rail hole

C. Grommet

A. Oven frame

B. Oven frame hole

C. Black trim piece

A

B

C

A

B

C

A. Oven frame

B. Vent tab

C. Bottom vent

D. #8-18 x

³⁄₈

" screws

A. Phillips head screws (4)

only 2 screws for 27" (68.6 cm) size

B. Warming drawer deflector (1)

A

C

D

B

B

A

Page 9

9

Install Deflector Kit

1. Align the deflector (B) with the vent (C) as shown.

2. Using two #8-18 x ¼" screws (A) on each side of the deflector

(B), fasten the deflector securely to the vent.

NOTE: On 27" (68.6 cm) models, only one #8–18 x ¼" screw

is used on each side.

3. Align vent tab (B) with oven frame (A) as shown.

4. Using one #8-18 x ³⁄₈" screw (E) on each side of the vent tab

(B), fasten the vent securely to the oven.

Complete Installation

1. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. For oven use and cleaning, read the Use and Care Guide.

Check Operation of Lower Oven

1. Turn power on.

2. At first use, set up the clock and any other preferences, if

available. For more information, read the Use and Care

Guide.

3. Press BROIL.

4. Set the temperature.

5. Press START.

If oven does not operate, check the following:

■ Household fuse is intact and tight; or circuit breaker has

not tripped.

■ Electrical supply is connected.

■ See “Troubleshooting” section in the Use and Care Guide.

6. When oven has been on for 5 minutes, feel for heat.

If you do not feel heat or if an error message appears in the

display, turn off the oven and contact a qualified technician.

7. Press CANCEL OVEN.

Check Operation of Microwave Oven

1. Fill a microwave-safe container with 1 cup (250 mL) of water

and place container inside microwave oven. Close door

firmly.

2. Press COOK and set microwave oven cook time to

“2:00” minutes.

3. Press START. The interior microwave oven light should be on,

and the remaining cooking time should be displayed.

When display reads “1:00” minute, open microwave oven

door. The microwave should stop cooking. Close door firmly.

The interior microwave oven light should turn off.

4. Press START. Microwave oven should begin cooking, and the

microwave oven interior light should be on.

Let microwave oven complete cooking time. A tone will

sound 4 times at the end of the cooking time, and the

microwave oven will shut off.

5. Open microwave oven door and slowly remove container.

Water in container should be hot.

If you need Assistance or Service:

Please reference the “Assistance or Service” section of the Use

and Care Guide or contact the dealer from whom you purchased

your built-in and microwave ovens.

A. #8–18 x

¹⁄₄

" screws

B. Warming drawer deflector

C. Vent

A. Oven frame

B. Vent tab

C. Oven vent

D. Warming drawer deflector

E. #8–18 x

³⁄₈

" screw

D

B

A

C

B

D

C

A

C

D

B

E

Page 10

10

SÉCURITÉ DU FOUR À MICRO-ONDES ET DU FOUR

CONVENTIONNEL COMBINÉS ET ENCASTRÉS

EXIGENCES D'INSTALLATION

Outils et pièces

Rassembler les outils et pièces nécessaires avant d’entreprendre

l’installation. Lire et observer les instructions fournies avec

chacun des outils de la liste ci-dessous.

Outils nécessaires

■ Tournevis Phillips

■ Mètre ruban

■ Perceuse (pour l’installation dans un placard mural)

■ Foret de 1" (25 mm) (pour installation dans un placard mural)

■ Niveau

■ Tournevis à lame plate

Pièces nécessaires

■ Connecteur de conduit (homologation UL ou CSA)

■ Connecteurs de fils (homologation UL)

■ Ensemble de déflecteur pour tiroir-réchaud (pour les fours

installés par-dessus un tiroir-réchaud)

Commander la pièce W10489566B pour l’ensemble blanc de

27" (68,6 cm)

Commander la pièce W10489564B pour l’ensemble noir de

27" (68,6 cm)

Commander la pièce W10489568A pour l’ensemble en acier

inoxydable de 27" (68,6 cm)

Commander la pièce W10489567B pour l’ensemble blanc de

30" (76,2 cm)

Commander la pièce W10489565B pour l’ensemble noir de

30" (76,2 cm)

Commander la pièce W10489569A pour l’ensemble en acier

inoxydable de 30" (76,2 cm)

Pour commander, voir la section “Assistance ou service” du

Guide d’utilisation et d’entretien.

Pièces fournies

■ Deux vis #8–14 x ³⁄₄"

■ Évent du bas

■ Deux vis n° 8–18 x ³⁄₈" - Évent du bas

■ Quatre œillets*

Consulter les codes locaux. Vérifier l’alimentation électrique

existante. Voir “Spécifications électriques”.

Il est recommandé de faire réaliser tous les raccordements

électriques par un électricien qualifié agréé.

*Les œillets ne sont pas nécessaires et ne sont pas inclus avec

les modèles KEMS309B et KEMS379B.

Exigences d'emplacement de l'ensemble

four à micro-ondes et four conventionnel

encastrés

IMPORTANT : Observer les dispositions de tous les codes et

règlements en vigueur.

■ Respecter les dimensions indiquées pour la cavité

d'installation entre les placards. Ces dimensions prennent en

compte les dégagements de séparation minimaux

nécessaires.

■ L'espace d'installation doit permettre la formation d'une

enceinte complète autour de la partie encastrée du four.

■ Une source d'électricité avec liaison à la terre est nécessaire.

Voir la section “Spécifications électriques”.

Risque possible de décès ou de blessure grave si vous ne

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

AVERTISSEMENT

DANGER

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

Page 11

11

■

Le boîtier de raccordement doit être situé au maximum à

3" (7,6 cm) au-dessous de la surface de support lorsque le

four est installé dans un placard mural. Un trou de diamètre

1" (2,5 cm) ou plus doit avoir été percé dans l'angle arrière

gauche ou droit de la surface de support pour le passage du

câble d'alimentation de l'appareil jusqu'au boîtier de

connexion.

■ La surface de support du four doit être robuste, horizontale et

en affleurement avec le bas de la cavité d’encastrement du

placard. Le plancher doit être capable de supporter un poids

total (four à micro-ondes et four encastré) de 208 lb (95 kg)

pour les modèles de 27" (68,6 cm) ou de 249 lb (113 kg) pour

les modèles de 30" (76,2 cm).

IMPORTANT : Afin d'éviter tout dommage aux placards,

consulter le constructeur de la maison ou le fabricant des

placards afin de déterminer si les matériaux utilisés pourraient

subir un changement de couleur, une déstratification ou d'autres

dommages. Ce four a été conçu conformément aux exigences

des normes UL et CSA International et respecte les températures

maximales autorisées de 194°F (90°C) pour les placards en bois.

Dimensions du produit

Fours de 27" (68,6 cm) et 30" (76,2 cm)

Dimensions du placard

Fours de 27" (68,6 cm) et 30" (76,2 cm)

*REMARQUE : Pour l’ensemble four à micro-ondes/four

traditionnel, la hauteur du placard peut être comprise entre 41"

(104,1 cm) et 41¹⁄₂" (105,6 cm).

Modèles de 27" (68,6 cm)

A. Hauteur hors-tout

42

⁹⁄₁₆

" (108 cm)

B. Largeur d'encastrement

25

⁷⁄₁₆

" (64,6 cm)

C. Hauteur d'encastrement

41" (104,1 cm)

D. Profondeur d'encastrement

23

¹⁄₄

" (59,1 cm) max.

E. Largeur hors-tout

27" (68,6 cm)

F. 48" (121,9 cm) de longueur

de conduit flexible mesuré

depuis la bride de conduit

située à l'arrière du four. Ne

pas retirer la bride de

conduit.

Modèles de 30" (76,2 cm)

A. Hauteur hors-tout

42

⁹⁄₁₆

" (108 cm)

B. Largeur d'encastrement

28¹⁄₂" (72,3 cm)

C. Hauteur d'encastrement

41" (104,1 cm)

D. Profondeur d'encastrement

23

¹⁄₄

" (59,1 cm) max.

E. Largeur hors-tout

30" (76,2 cm)

F. 48" (121,9 cm) de longueur de

conduit flexible mesuré depuis

la bride de conduit située à

l'arrière du four. Ne pas retirer

la bride de conduit.

B

A

C

D

E

F

Modèles de 27" (68,6 cm)

A. Largeur du placard

27" (68,6 cm) min.

B. 1" (2,5 cm) entre le sommet de

l'ouverture et le bas de la porte

du placard supérieur

C. Une hauteur de 19

¹⁄₄

" (48,9 cm)

entre le bas de l'ouverture et le

plancher est recommandée.

Une hauteur de 4" (10,2 cm) à

19

¹⁄₄

" (48,9 cm) entre le bas de

l'ouverture et le plancher est

acceptable.

D. Largeur de l'ouverture

25½" (64,8 cm)

E. 1½" (3,8 cm) min. entre le bas

de l'ouverture et le haut de la

porte du placard

F. Hauteur de l'ouverture

recommandée 41

⁵⁄₁₆

'' (105 cm)*

G. Profondeur de l'ouverture 24"

(60,7 cm)

Modèles de 30" (76,2 cm)

A. Largeur du placard

30" (76,2 cm) min.

B. 1" (2,5 cm) entre le sommet de

l'ouverture et le bas de la porte

du placard supérieur

C. Une hauteur de 19

¹⁄₄

" (48,9 cm)

entre le bas de l'ouverture et le

plancher est recommandée.

Une hauteur de 4" (10,2 cm) à

19

¹⁄₄

" (48,9 cm) entre le bas de

l'ouverture et le plancher est

acceptable.

D. Largeur de l'ouverture

28½" (72,4 cm)

E. 1½" (3,8 cm) min. entre le bas de

l'ouverture et le haut de la porte

du placard

F. Hauteur de l'ouverture

recommandée 41

⁵⁄₁₆

''

(105 cm)*

G. Profondeur de l'ouverture 24"

(60,7 cm)

F

E

A

D

G

B

C

Page 12

12

Spécifications électriques

Si on utilise un conducteur distinct de liaison à la terre lorsque les

codes le permettent, il est recommandé qu'un électricien qualifié

vérifie que la liaison à la terre et le calibre des fils sont conformes

aux codes locaux.

En cas de doute quant à la qualité de la liaison à la terre du four,

consulter un électricien qualifié.

Ce four doit être raccordé à un système permanent, métallique

de câblage relié à la terre.

S'assurer que la connexion électrique et le calibre des fils sont

appropriés et conformes au National Electrical Code, aux normes

ANSI/NFPA 70 - dernière édition, ou aux normes CSA C22.1-94,

au Code canadien de l'électricité, Partie 1 et C22.2 N° O-M91 dernière édition, et à tous les codes et règlements locaux.

Pour obtenir un exemplaire de la norme des codes ci-dessus,

contacter :

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

Raccordement électrique

Pour installer le four correctement, il faut établir le type de

raccords électriques que l'on utilisera et suivre les instructions

indiquées ici.

■ Le four doit être alimenté par une source d'électricité

appropriée (caractéristiques de tension et fréquence

spécifiées sur la plaque signalétique). Voir l'illustration cidessous.

■ Les modèles à 240 volts de 7,3 à 9,6 kW (208 volts de 5,5 à

7,2 kW) doivent être alimentés par un circuit indépendant de

40 A. Les modèles à 240 volts de 7,2 kW ou moins (208 volts

de 5,4 kW ou moins) doivent être alimentés par un circuit

indépendant de 30 A.

■ On recommande d'utiliser un disjoncteur.

■ Raccorder l'appareil directement au tableau de distribution

(fusible ou disjoncteur) par un câble à conducteur de cuivre à

gaine flexible et blindage métallique ou à gaine non

métallique (avec conducteur de liaison à la terre). Voir la

section “Raccordement électrique”.

■ Le câble flexible du four doit être connecté directement au

boîtier de connexion.

■ Ne pas couper le conduit. La longueur du conduit fournie est

destinée à faciliter l'entretien du four.

■ L'installateur doit fournir un connecteur de conduit

(homologation UL ou CSA).

■ Si le domicile est équipé d'un câblage en aluminium, suivre

les instructions suivantes :

1. Connecter une section de câble en cuivre massif aux

extrémités du conduit flexible.

2. Connecter le câblage en aluminium à la section ajoutée

de câblage en cuivre en utilisant des connecteurs et/ou

des outils spécialement conçus et homologués UL pour

fixer le cuivre à l'aluminium.

Appliquer la procédure recommandée par le fabricant des

connecteurs. La connexion aluminium/cuivre doit être

conforme aux codes locaux et aux pratiques de câblage

acceptées par l'industrie.

Pour les conditions d’alimentation électrique, se reporter au

tableau suivant.

*L1 alimente le four à micro-ondes et le four conventionnel, alors

que L2 n'alimente que le four conventionnel. Les valeurs

d'intensité ci-dessus sont fournies à titre indicatif seulement : les

appareils sont caractérisés en watts.

A. Plaque signalétique

A

Modèle Tension Intensité

(L1)*

Intensité

(L2)*

Puissance

nominale

(kW)

MMW9730 120/240

129/2083028

15

15

7,2

5,9

WOC54EC0,

WOC95EC0

120/240

120/2083028

15

15

7,2

5,9

WOC54EC7 120/240

120/2083028

15

15

7,2

5,9

KEMS309 120/240

120/2083331

15

15

8,0

6,6

Page 13

13

INSTRUCTIONS D'INSTALLATION

Préparation de l'ensemble des fours

encastrés (micro-ondes/conventionnel)

1. Choisir l'emplacement final pour l'installation du four. Repérer

le câblage existant pour éviter de le percer ou de

l'endommager lors de l'installation.

2. Pour éviter d'endommager le plancher, placer le four sur une

feuille de carton avant l'installation. Lors des opérations de

levage, ne pas prendre prise sur la poignée ou sur une autre

partie du châssis avant.

3. Ne pas oublier de retirer l'évent inférieur de l'emballage en

mousse du dessus du four.

4. Enlever les matériaux d'emballage et le ruban adhésif du four.

5. Enlever le matériel à l'intérieur du sachet de documentation.

6. Enlever et conserver à part les grilles et autres composants

qu'on trouve à l'intérieur du four.

7. Approcher le four et le carton de l'emplacement final du four.

Dépose de la/des porte(s) du four

IMPORTANT : Retirer la porte du four avec les deux mains.

1. Avant de retirer la porte du four, préparer une surface sur

laquelle on pourra la poser. Cette surface doit être plate et

recouverte d’une couverture douce. On peut aussi utiliser les

cornières de l’emballage.

2. Ouvrir la porte du four.

3. Identifier les loquets de charnière de la porte du four dans les

deux angles de la porte; faire pivoter les loquets de charnière

vers la porte du four jusqu'à la position de déverrouillage. Si

le loquet de charnière de porte n'est pas complètement

tourné (voir illustration B), la porte ne se retirera pas

correctement.

4. Fermer partiellement la porte pour engager les loquets de la

gâche de porte. La porte restera bloquée à cette position.

5. Saisir les bords de la porte du four avec les deux mains.

Soulever et tirer la porte du four vers soi et enlever la porte.

Vous devrez peut-être basculer doucement la porte d'un côté

et de l'autre en la tirant.

6. Conserver la/les porte(s) du four à part sur la surface de

travail couverte en faisant reposer la porte sur sa poignée.

7. Pour continuer l'installation du four, aller à la section

“Positionnement des pieds du four pour des ouvertures

d'encastrement dans le placard”.

Réinstallation de la/des porte(s) du four

IMPORTANT: Ne pas remettre en place la(les) porte(s) du four

avant que le four n'ait été installé dans le placard.

1. Saisir les bords latéraux de la porte par le milieu avec les

deux mains. Se placer face à la cavité du four.

2. Repérer les encoches situées de chaque côté de la cavité du

four pour les loquets de charnière de la porte.

A. Loquet de charnière de

la porte du four en

position de verrouillage

B. Loquet de charnière de la

porte du four en position

de déverrouillage

AVERTISSEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes pour déplacer et

installer le four.

Le non-respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

A

B

A. Encoche située dans la

cavité du four pour le loquet

de charnière de la porte

A

Page 14

14

3. Aligner les charnières de porte dans les encoches situées en

bas/à l’avant de la cavité du four à un angle de 45°. Insérer

doucement la porte tout en veillant à garder un angle de 45°.

Lorsque l'on sent un léger abaissement de la porte, cela

signifie qu'elle est bien positionnée dans l'encoche.

4. Abaisser la porte du four jusqu'à ce qu’elle soit

complètement ouverte. Si la porte du four ne s'ouvre pas

complètement à un angle de 90 degrés, répéter les étapes 1

à 3.

5. Identifier les loquets de charnière de la porte du four dans les

angles de la porte; faire pivoter les loquets de charnière vers

la cavité du four jusqu'à la position de verrouillage.

Voir l'étape 3 (illustration A) dans la section “Dépose de la/

des porte(s) du four” pour une position de verrouillage

correcte.

6. Fermer la porte du four.

7. Une fois les charnières correctement installées et la porte

fermée, il doit y avoir un espace égal entre la porte et le

tableau de commande. Si l'un des côtés de la porte du four

est plus bas que l'autre, la charnière de ce côté-ci n'est pas

correctement installée.

Raccordement électrique

Le câblage d'alimentation de ce four comporte un conducteur

neutre (blanc) et un conducteur vert (ou nu) de liaison à la terre

connecté à la caisse; ces deux conducteurs sont torsadés.

1. Déconnecter la source de courant électrique.

2. Faire passer le conduit de câble flexible depuis le four à

travers l’ouverture dans le placard.

3. Le cas échéant, enlever le couvercle du boîtier de connexion.

4. Installer un connecteur de conduit (homologation UL ou CSA)

sur le boîtier de connexion.

5. Acheminer le conduit de câble flexible depuis le four jusqu'au

boîtier de connexion - utiliser un connecteur de conduit

(homologation UL ou CSA).

6. Serrer les vis sur le connecteur de conduit.

7. Voir “Tableau des options de raccordement électrique” pour

terminer l'installation correspondant à votre type de

raccordement électrique.

Tableau des options de raccordement électrique

A. Connecteur de conduit

(homologation UL ou CSA)

Câblage de la maison : Voir la section :

4 conducteurs Câble à 4 conducteurs depuis

le point de distribution du

domicile

3 conducteurs Câble à 3 conducteurs depuis

le point de distribution du

domicile

AVERTISSEMENT

Risque de choc électrique

Déconnecter la source de courant électrique avant

l'entretien.

Utiliser du fil en cuivre rigide de calibre 8.

Relier le four à la terre.

Le non-respect de ces instructions peut causer un

décès, un incendie ou un choc électrique.

A

½"

(1,3 cm)

½"

(1,3 cm)

Page 15

15

Câble à 4 conducteurs depuis le point de distribution du

domicile

IMPORTANT : Utiliser le câble à 4 conducteurs provenant du

point de distribution du domicile aux États-Unis lorsque les

codes locaux ne permettent pas la mise à la terre par

l'intermédiaire du conducteur neutre, en cas de nouvelle

installation avec alimentation par un circuit secondaire (1996

NEC), dans les résidences mobiles et les véhicules récréatifs,

dans les nouvelles constructions, et au Canada.

1. Connecter ensemble les 2 conducteurs noirs (B) avec un

connecteur de fils (homologation UL).

2. Connecter ensemble les 2 conducteurs rouges (C) avec un

connecteur de fils (homologation UL).

3. Détorsader le conducteur blanc du conducteur vert (ou nu) de

liaison à la terre provenant du four.

4. Connecter ensemble les 2 conducteurs blancs (F) avec un

connecteur de fils (homologation UL).

5. Connecter le conducteur vert (ou nu) de liaison à la terre (H)

du câble du four au conducteur vert (ou nu) de liaison à la

terre dans le boîtier de connexion - utiliser un connecteur de

fils (homologation UL).

6. Installer le couvercle du boîtier de connexion.

Câble à 3 conducteurs depuis le point de distribution du

domicile - É.-U. seulement

IMPORTANT : Utiliser le câble à 3 conducteurs depuis le point

de distribution du domicile lorsque les codes locaux autorisent

un tel raccordement.

1. Connecter ensemble les 2 conducteurs noirs (C) avec un

connecteur de fils (homologation UL).

2. Connecter les 2 conducteurs blancs (D) et le conducteur vert

(ou nu) de liaison à la terre (du câble du four) avec un

connecteur de fils (homologation UL).

3. Connecter ensemble les 2 conducteurs rouges (G) avec un

connecteur de fils (homologation UL).

4. Installer le couvercle du boîtier de connexion.

Installation du four

1. À 2 personnes ou plus, soulever et introduire partiellement le

four dans l’ouverture du placard. Utiliser l’ouverture du four

comme zone de prise.

REMARQUE : Pousser le four pour l’introduire dans le

placard en appuyant sur la zone du joint du four sur le châssis

avant. Ne pas pousser les bords extérieurs.

A. Câble depuis le point de

distribution du domicile

B. Conducteurs noirs

C. Conducteurs rouges

D. Câble flexible à 4 conducteurs

depuis le four

E. Boîtier de connexion

F. Conducteurs blancs

G. Connecteurs de fils

(homologation UL)

H. Conducteurs verts (ou nus) de

liaison à la terre

I. Connecteur de conduit

(homologation UL ou CSA)

A

D

F

H

B

C

E

G

I

A. Câble depuis le point de

distribution du domicile

B. Boîtier de connexion

C. Conducteurs noirs

D. Conducteurs blancs

E. Conducteur vert (ou nu) de

liaison à la terre (depuis le four)

F. Câble flexible à

4 conducteurs depuis le four

G. Conducteurs rouges

H. Connecteurs de fils

(homologation UL)

I. Connecteur de conduit

(homologation UL ou CSA)

B

C

D

E

F

H

G

A

I

Page 16

16

2. Pousser contre la zone du joint du châssis avant pour

introduire le four dans le placard, jusqu'à ce que la surface

arrière du châssis avant soit au contact de la paroi avant du

placard.

3. Pousser complètement le four dans le placard; centrer le four

dans la cavité du placard.

REMARQUE : Si votre modèle est KEMS379B ou

KEMS309B, passer à l’étape 6.

4. Insérer l'œillet dans le trou de la glissière de montage à l’aide

d’un tournevis à lame plate. Insérer le tournevis dans l'œillet

et le tourner de ¹⁄₄ de tour dans le sens antihoraire. Veiller à ce

que l'œillet reste en place.

IMPORTANT : Si l'œillet n'est pas posé, le châssis avant sera

endommagé.

5. Fixer solidement le four au placard à l’aide des vis n° 8–14 x

³⁄₄" fournies. Insérer les vis dans le trou de l'œillet. Ne pas

serrer excessivement les vis.

6. Pour les modèles KEMS379B et KEMS309B, consulter les

instructions suivantes.

Pour tous les autres modèles, les garnitures avant noires

peuvent être commandées comme accessoires. Consulter la

section "Assistance ou service" du Guide d'utilisation et

d'entretien ou contacter le marchand auprès duquel le four

encastré a été acheté, afin de commander les pièces numéro

W10344482 et W10344483.

■ Retirer le ruban adhésif des garnitures avant noires.

■ Fixer solidement le four au placard à l'aide des vis n° 8-14

x ¾" fournies.

■ Insérer les vis dans les trous de la garniture noire en les

alignant avec les trous du châssis du four. Ne pas serrer

excessivement les vis.

7. L'évent inférieur est expédié dans l'emballage en mousse du

dessus du four. Installer l'évent inférieur (C) comme suit :

■ Aligner l'onglet de l'évent (B) avec le châssis du four (A)

comme illustré.

■ Avec une vis #8-18 x 3/8" (D) pour chaque côté du

support de l'évent (B), fixer solidement l'évent au four.

8. Réinstaller les grilles du four.

9. Réinstaller la porte du four. Voir la section “Réinstallation de

la/des porte(s) du four”.

10. Effectuer quelques manœuvres d’ouverture/fermeture de la

porte du four pour en vérifier le bon fonctionnement. Si tel

n’est pas le cas, répéter le processus de dépose et

d’installation de la porte. Voir la section "Préparation de

l’ensemble des fours encastrés (micro-ondes/

conventionnel)”.

11. Reconnecter la source de courant électrique.

12. Le tableau d’affichage s’allume brièvement et “PF” apparaît

sur l'affichage.

13. Si le tableau d'affichage ne s'allume pas, consulter la section

“Assistance ou service” du Guide d'utilisation et d'entretien

ou contacter le marchand qui vous a vendu le four.

A. Glissière de montage

B. Trou de la glissière de montage

C. Œillet

A

B

C

A. Châssis du four

B. Trou du châssis du four

C. Garniture noire

A. Châssis du four

B.Onglet de l'évent

C. Évent inférieur

D. Vis #8-18 x 3/8"

A

B

C

A

C

D

B

Page 17

17

Installation de l'ensemble déflecteur du

tiroir-réchaud (uniquement pour les fours

installés au-dessus d'un tiroir-réchaud)

Sur les modèles de four à micro-ondes/four combiné installés audessus d'un tiroir-réchaud, la pose d'un déflecteur de tiroirréchaud est nécessaire. Voir la section “Outillage et pièces” pour

des renseignements sur le processus de commande.

Pièces fournies

Installation de l'ensemble déflecteur

1. Aligner le déflecteur (B) avec l'évent (C) comme illustré.

2. À l'aide de 2 vis n°8-18 x ¼" (A) de chaque côté du déflecteur

(B), fixer solidement le déflecteur à l'évent.

REMARQUE : Sur les modèles de 27" (68,6 cm), utiliser une

seule vis n°8-18 x ¼" de chaque côté.

3. Aligner le support de l'évent (B) avec le châssis du four (A)

comme illustré.

4. Avec une vis n°8-18 x ³⁄₈" (E) pour chaque côté du support de

l'évent (B), fixer solidement l'évent au four.

Achever l'installation

1. Vérifier que toutes les pièces sont maintenant installées. S'il

reste une pièce, passer en revue les différentes étapes pour

découvrir laquelle aurait été oubliée.

2. Vérifier la présence de tous les outils.

3. Jeter et recycler tous les matériaux d'emballage.

4. Pour l'utilisation et le nettoyage du four, lire le Guide

d'utilisation et d'entretien.

Vérification du fonctionnement du four inférieur

1. Mettre l’appareil sous tension.

2. À la première utilisation, régler l’horloge et toute autre

préférence éventuelle si possible. Consulter le Guide

d'utilisation et d'entretien pour plus de renseignements.

3. Appuyer sur BROIL (cuisson au gril).

4. Régler la température.

5. Appuyer sur START (mise en marche).

Si le four ne fonctionne pas, contrôler ce qui suit :

■ Les fusibles du domicile sont intacts et serrés; ou le

disjoncteur n’est pas déclenché.

■ La prise de courant est correctement alimentée.

■ Voir la section “Dépannage” dans le Guide d’utilisation et

d’entretien.

6. Après que le four a fonctionné pendant 5 minutes, vérifier

qu'il y a émission de chaleur.

Si aucune chaleur n'est ressentie ou si un message d’erreur

apparaît sur l'affichage, éteindre le four et contacter un

technicien qualifié.

7. Appuyer sur CANCEL OVEN (annulation four).

Vérification du fonctionnement du four à micro-ondes

1. Remplir un contenant adapté aux micro-ondes avec 1 tasse

(250 mL) d'eau et placer le contenant dans le four à microondes. Bien fermer la porte.

2. Appuyer sur COOK (cuisson) et régler le four à micro-ondes

pour une durée de cuisson de “2:00” minutes.

A. Vis à tête Phillips (4)

2 vis seulement pour la taille 27" (68,6 cm)

B. Déflecteur du tiroir-réchaud (1)

A. Vis n°8–18 x

¹⁄₄

"

B. Déflecteur du tiroir-réchaud

C. Évent

B

A

D

B

A

C

B

D

C

A. Châssis du four

B. Support de l'évent

C. Évent du four

D. Déflecteur du tiroir-réchaud

E. Vis n°8–18 x

³⁄₈

"

A

C

D

B

E

Page 18

18

3. Appuyer sur START (mise en marche). La lumière intérieure

du four à micro-ondes devrait être allumée et la durée de

cuisson restante devrait s'afficher.

Lorsque l'affichage indique “1:00” minute, ouvrir la porte du

four à micro-ondes. La cuisson par les micro-ondes devrait

cesser. Bien fermer la porte. La lumière intérieure du four à

micro-ondes devrait s'éteindre.

4. Appuyer sur START (mise en marche). Le four à micro-ondes

devrait commencer la cuisson et la lumière intérieure du four

à micro-ondes devrait être allumée.

Laisser le four à micro-ondes terminer la durée de cuisson.

Un signal sonore retentira 4 fois à la fin de la durée de

cuisson et le four à micro-ondes s'éteindra.

5. Ouvrir la porte du four à micro-ondes et retirer lentement le

contenant. L'eau dans le contenant devrait être chaude.

Pour obtenir assistance ou service :

Consulter la section “Assistance ou service” du Guide

d'utilisation et d'entretien ou contacter le marchand chez qui le

four encastré et le four à micro-ondes ont été achetés.

Page 19

19

Notes

Page 20

W10696163A

© 2014.

All rights reserved. Used under license in Canada

Tous droits réservés. Utilisé sous licence au Canada.

4/14

Printed in U.S.A.

Imprimé aux É.-U.

Loading...

Loading...