Maytag MLE20PDBGW1, MLG20PDBGW1, MLG20PDBGW2, MLG20PDBGW3, MLE20PNBGW1 Installation Guide

...

I

STALLATI

I

COMMERCIAL STACKED

WASHER/DRYER

GAS OR ELECTRIC

CTI

I CTI

/

LAVE-LING E/SECH E-LING E SUPERPOSES

_, USAGE COMMERCIAL

A GAZ OU I_LECTRIGUE

INSTRUCCIONES

LAVADORA/SECADORA COMERCIALES

APILADAS A GAS O ELECTRICAS

MLE20PD

MLG20PD

MLE20PN

I I

I I E

LAVATRICE/ASCI UGATRICE

COMMERCIALE A COLONNA

A GAS O ELETTRICA

W10335466C www.maytagcommerciallaundry.com

TABLE OF CONTENTS

(Australia and New Zealand Installations)

Page

Stacked Washer/Dryer Safety ..................................................................3

Stacked Washer/Dryer Disposal .............................................................6

Tools & Parts .....................................................................................................7

Alternate Parts and Accessories .............................................................8

Dimensions/Clearances .............................................................................9

Stacked Washer/Gas Dryer Installation Requirements .......... 10

Stacked Washer/Electric Dryer

Installation Requirements .......................................................................13

Dryer Venting Requirements .................................................................15

Dryer Gas Supply Requirements .........................................................17

Installing Stacked Washer/Dryer .........................................................18

Washer Drain System ................................................................................21

Leveling .............................................................................................................22

Complete Installation .................................................................................23

Reversing Dryer Door Swing ..................................................................24

Stacked Washer/Dryer Maintenance Instructions ......................26

If You Need Assistance .............................................................................27

Technical Specifications - Gas Dryer ................................................28

Electronic Control Setup Instructions ...............................................29

Warranty ...........................................................................................................35

iNDICE

Pagina

Seguridad de la lavadora/secadora apiladas .................................71

EliminaciSn de la lavadora/secadora apiladas ..............................74

Herramientas y piezas .................................................................................75

Piezas y accesorios adicionales ...........................................................76

Dimensiones y espacios libres ..............................................................77

Requisitos de instalaci6n de la lavadora/secadora

a gas apiladas .................................................................................................78

Requisitos de instalaci6n de la lavadora/

secadora el_ctricas apiladas ..................................................................81

Requisitos de ventilaciSn de la secadora ........................................83

Requisitos del suministro de gas de la secadora .......................86

InstalaciSn de la lavadora/secadora apiladas ................................87

Sistema de desag_ie de la lavadora .....................................................90

Nivelaci6n ...........................................................................................................91

Complete la instalaciSn .............................................................................92

C6mo invertir el cierre de la puerta de la secadora ....................93

Instrucciones de mantenimiento

de la lavadora/secadora apiladas .........................................................95

Si necesita ayuda ...........................................................................................96

Especificaciones t_cnicas - secadora a gas .................................97

Instrucciones de programaci6n del control electr6nico ...........98

Garant_a ...........................................................................................................105

TABLE DES MATII_RES

Page

S_curit_ du lave-linge/seche-linge superposes ...........................36

I_limination du lave-linge/seche-linge superposes .....................39

Outils et pieces ..............................................................................................40

Pieces suppl_mentaires et accessoires ...........................................41

Dimensions/Distances de d_gagement ...........................................42

E×igences d'installation pour

le lave-linge/seche-linge a gaz superposes ...................................43

E×igences d'installation pour le lave-linge/seche-linge

_lectriques superposes ............................................................................46

E×igences concernant I'_vacuation du seche-linge ....................48

Specifications de ralimentation en gaz du seche-linge ...........51

Installation du lave-linge/seche-linge superposes ....................52

Syst_me d'_vacuation du lave-linge ....................................................55

Nivellement .......................................................................................................56

Achever rinstallation ....................................................................................57

Inversion du sens d'ouverture de la porte du seche-linge ......58

Instructions d'entretien du lave-linge/

seche-Iinge superposes ...........................................................................60

Si vous avez besoin d'assistance .........................................................61

Fiche technique - seche-linge a gaz ..................................................62

Instructions de r_glage du tableau

de commande _lectronique .....................................................................63

Garantie ..............................................................................................................70

INDICE

Pagina

Sicurezza della lavatrice/asciugatrice impilati ...........................106

L'eliminazione della lavatrice/asciugatrice impilati ..................109

Attrezzi e componenti .............................................................................110

Parti ed accessori alternati ....................................................................111

Dimensioni/spazi ......................................................................................112

Requisiti delrinstallazione della lavatrice/asciugatrice

a gas impilati ...............................................................................................113

Requisiti delrinstallazione della lavatrice/asciugatrice

elettrica impilat ...........................................................................................116

Requisiti di scarico dell'asciugatrice ..............................................118

Requisiti di alimentazione del gas dell'asciugatrice ..............120

Installazione della lavatrice/asciugatrice impilati .....................121

Sistema dello scolD della lavatrice ..................................................124

Livellamento .................................................................................................125

Completamento delrinstallazione ...................................................126

Inversione della rotazione di apertura delrasciugatrice ...... 127

Istruzioni di manutenzione della lavatrice/

asciugatdce impilat ....................................................................................12g

Se avete bisogno dell'assistenza .....................................................130

Dati tecnici - asciugatrice a gas .......................................................131

Configurazione dei controlli elettronici .........................................132

Garanzia .........................................................................................................139

STACKED WASHER/DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions,

You can be killed or seriously injured if you don't follow

instructions,

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

WARNING - ofFi,o..

= Clothes dryer installation must be performed by a qualified installer.

- install the clothes dryer according to the manufacturer's instructions and local codes.

- Do not install a clothes dryer with flexible plastic venting materials or flexible metal

(foil type) duct. if flexible metal duct is installed, it must be of a specific type identified

by the appliance manufacturer as suitable for use with clothes dryers. Flexible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire.

- To reduce the risk of severe injury or death, follow all installation instructions.

- Save these instructions.

It is recommended that the owner post, in a prominent location, instructions for the customer's use in the event the customer

smells gas. This information should be obtained from your gas supplier.

m Post the following warning in a prominent location.

FOR YOU RSAFETY

1. DO NOT USE OR STORE PETROL OR OTHER FLAMMABLE MATERIALS IN THIS APPLIANCE OR NEAR THIS APPLIANCE.

2. DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

3. DO NOT MODIFY THIS APPLIANCE.

3

STACKED WASHER/DRYER SAFETY

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

- Do not store or use petrol or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO iF YOU SMELL GAS:

= Do not try to light any appliance.

®Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building, or area of all occupants.

o Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

= if you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

4

STACKED WASHER/DRYER SAFETY

iMPORTANT SAFETY iNSTRUCTiONS

WAR N ING: To reduce the risk of fire, electric shock, or injury to persons when using the washer/dryer, follow basic precautions,

including the following:

[] Read all instructions before using the washer/dryer.

[] This dryer is intended only for drying clothes and textiles

that have been washed in water. Do not use for any other

purpose.

[] WARNING: If you smell gas, do not use the dryer or any

electrical equipment nearby. Warn other people to clear the

area. Contact the dryer owner immediately.

[] Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

[]

If it is unavoidable that fabrics that contain vegetable or

cooking oil or that have been contaminated by hair care

products be placed in a tumble dryer, they should first be

washed in hot water with extra detergent - this will reduce,

but not eliminate the hazard.

[] Do not wash or dry articles that have been previously

cleaned in, washed in, soaked in, or spotted with petrol,

dry-cleaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite or

explode.

[] Items that have been soiled with substances such

as acetone, alcohol, petrol, kerosene, spot removers,

turpentine, waxes, and wax removers should be washed

in hot water with extra detergent before being dried in

the dryer.

[] Do not add gasoline, dry-cleaning solvents, or other

flammable, or explosive substances to the wash water.

These substances give off vapors that could ignite or

explode.

[] Do not dry unwashed items in the dryer.

[] Do not use this dryer if industrial chemicals have been used

for cleaning. The possible presence of residual quantities

of aggressive or decomposed chemicals in the load may

produce damage to the dryer and harmful fumes.

[] Do not allow children to play on or in the washer/dryer.

Close supervision of children is necessary when the

washer/dryer is used near children.

[] This dryer is not intended for use by persons (including

children) with reduced physical, sensory, or mental

capabilities, or lack of experience or knowledge, unless they

have been given supervision or instruction concerning use

of the dryer by a person responsible for their safety.

[] Before the washer/dryer is removed from service

or discarded, remove the doors to the washer/dryer

compartments.

[] Do not reach into the washer/dryer if the tub, agitator

or drum is moving.

[] Do not open door while dryer is in operation. It will stop.

[] When loading or re-loading the dryer, avoid touching hot

metal parts of the drum (burn risk).

SAVE THESE iNSTRUCTiONS

[] If drum rotation is blocked due to trapped textiles,

disconnect the dryer from the electrical supply before gently

removing the blockage.

[] If the dryer is not heating, or appears to be defective or

damaged, do not use it. Contact the owner.

[] Do not install or store the washer/dryer where it will be

exposed to the weather.

[] Do not tamper with controls.

[] Clean dryer lint screen before or after each load.

[] Do not use this dryer without the lint screen in place.

[] Under certain conditions, hydrogen gas may be produced

in a hot water system that has not been used for 2 weeks

or more. HYDROGEN GAS IS EXPLOSIVE. If the hot water

system has not been used for such a period, before using

the washer, turn on all hot water faucets and let the water

flow from each for several minutes. This will release any

accumulated hydrogen gas. As the gas is flammable, do not

smoke or use an open flame during this time.

[] Do not repair or replace any part of the washer/dryer or

attempt any servicing unless specifically recommended

in this Use and Care Guide or in published user-repair

instructions that you understand and have the skills to

carry out.

[] Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

[] Do not use heat to dry articles containing foam rubber

or similarly textured rubber-like materials.

[] The final part of a tumble dryer cycle occurs without heat

(cool-down cycle) to ensure that the articles are left at a

temperature that ensures that the items will not be damaged.

[] WARNING: Never stop a tumble dryer before the end

of the drying cycle unless all items are quickly removed and

spread out so that the heat is dissipated. (Avoids risk of

spontaneous combustion).

[] In case of electrical supply failure, remove the load quickly

and spread it out to avoid risk of spontaneous combustion.

[] Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

[] The fresh air ventilation openings into the room and into

the dryer must not be blocked or sealed.

[] Emergency stop control: The mains plug should be removed

in an emergency.

[] The interior of the dryer and dryer exhaust vent should be

cleaned periodically by qualified service personnel.

[] See "Electrical Requirements" section of the Installation

Instructions booklet for grounding instructions.

5

STACKED WASHER/DRYER DISPOSAL

This appliance is marked according to the European directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE).

By ensuring this product is disposed of correctly, you will help avoid potential negative consequences for the environment and

human health, which could otherwise be caused by inappropriate waste handling of this product.

The symbol on the product, or on the documents accompanying the product, indicates that this appliance may not be treated

as household waste. Instead it shall be handed over to the applicable collection point for the recycling of electrical and

electronic equipment.

Disposal must be carried out in accordance with local environmental regulations for waste disposal.

For more detailed information about treatment, recovery and recycling of this product, please contact your local city office, your

household waste disposal service or the shop where you purchased the product.

MODEL NOM ENCLATU RE:

MLE - Maytag Electric

MLG - Maytag Gas

20 - Model Type Number

PD - Electronic Control - Coin Drop Enabled

PN - Electronic Control - Non-Pay

"M, ol

EU - DECLARATION OF CONFORMITY

CE - DECLARATION DE CONFORMITE

w_ BAUKNE(HT HAUSGERATE GmbH, D-73614 Schorndorf

_p_*ntingWHIRLPOOL EUROPE S.r.1 1-21025 COMERIO

declare under our sole responsibility that the product

(?ommercial stacked pail" MAYTAG MLE 20PD

washer/dwer MAYTAG MLE 20PN

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

EN 60335-1:2002+Al+A2+A1 l+A12+A13+A14+A15

EN 60335-2-7:2010

EN 60335-2-11:2010

EN 62233:2008

EN 61770:1999+A1:2004+A2:2006

EN ISO 10472-1:2008

EN ISO 10472-2:2008

EN ISO 14121-1:2007

EN 55014-1:2006+A1:2009

EN 55014-2:1997+Al:2001+A2:2008

EN 61000-3-2:2006+Al:2009+A2:2009

EN 61000-3-11:2000

following the provisions of Directive(s):

2006/42/EC MACHINERY DIRECTIVE

2004/108/EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

2011/65/E[ ROHS DIRECTIVE

2002/96/EC WEEE DIRECTIVE

SchorndorL 28.02.2012

Place and date:

iepresemed by

Micael Zirondi Karl-Dieter Klingenstein

Director PDC FC EMEA Product Approval

GPO, Schorndorf

"W ol

EU - DECLARATION OF CONFORMITY

CE - DECLARATION DE CONFORMITE

w_ BAUKNE(HT HAUSGERATE GmbH, D-73614 Schorndorf

_*p_*_*ntin_WHIRLPOOL EUROPE S.r.1 1-21025 COMERIO

declare under our sole responsibility that the product

Commercial gas dryer MAYTAG MLG 20PD

to which this declaration relates is in confornfity with the following standard(s) or other

normative document(s)

EN 60335-1:2002+Al+A2+All+A12+A13 (+A14+A15 only electrical part)

EN 60335-2-11:2010

EN 60335-2-102:2006+A1

EN 62233:2008

EN 12752-1:1999

EN ISO 10472-1:2008

EN ISO 10472-4:2008

EN ISO 14121-1:2007

EN 55014-1:2006+A1:2009

EN 55014-2:1997+Al:2001+A2:2008

EN 61000-3-2:2006+Al:2009+A2:2009

EN 61000-3-11:2000

following the provisions of Directive(s):

2006/42/EC MACHINERY DIRECTIVE

2009/142/EC E[ ROPEAN GAS APPLIANCE DIRECTIVE

2004/108/EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

2011/65/E[ ROHS DIRECTIVE

2002/96/EC WEEE DIRECTIVE

Schorndor£ 19.04.2012

Place and date:

iepresemed by

Micael Zirondi Karl-Dieter Klingenstein

Director PDC FC EMEA Product Approval

GPO, Schorndorf

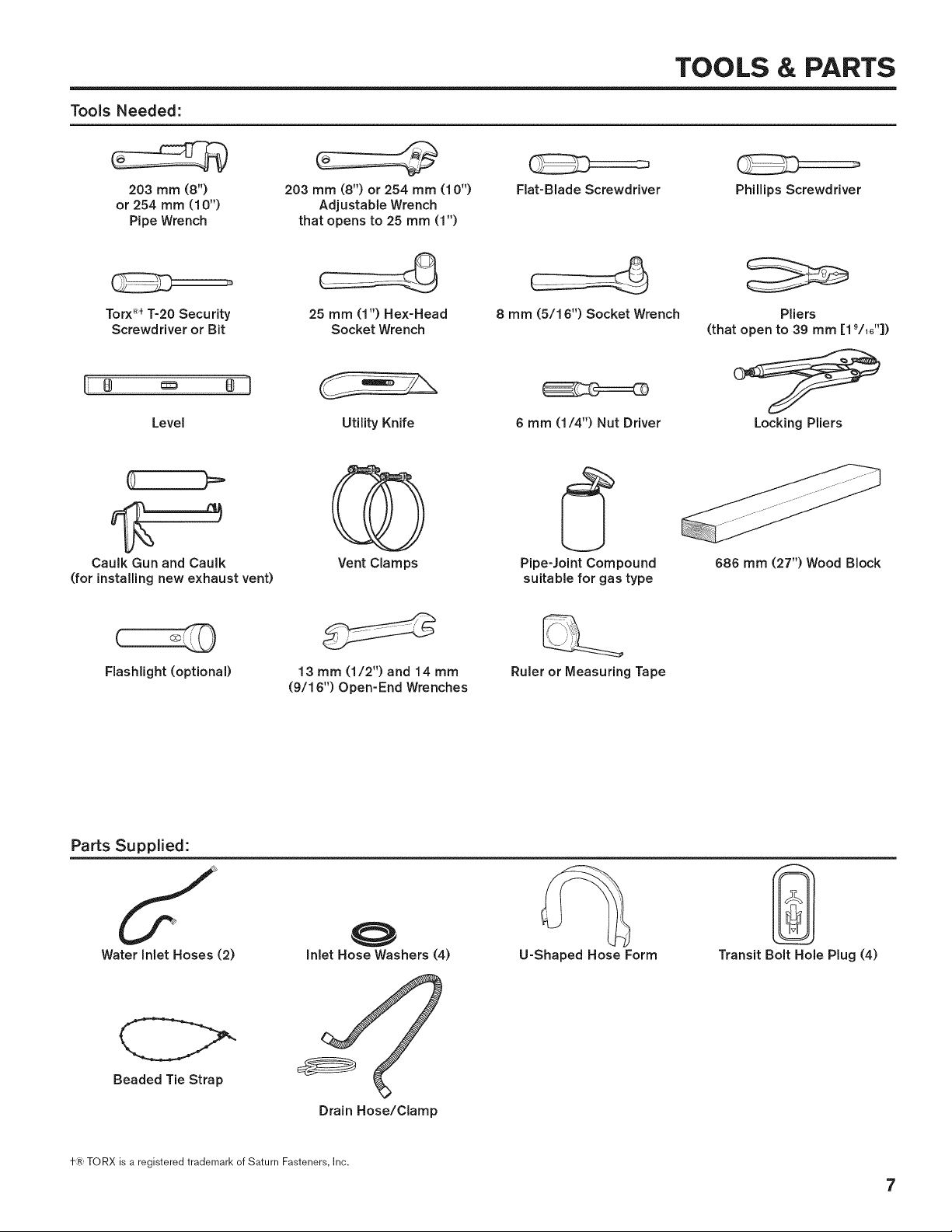

Tools Needed:

TOOLS & PARTS

203 mm (8")

or 254 mm (10")

Pipe Wrench

Torx _ T-20 Security

Screwdriver or Bit

Level

Caulk Gun and Caulk Vent Clamps Pipe-Joint Compound

(for installing new exhaust vent) suitable for gas type

203 mm (8") or 254 mm (10")

Adj ustable Wrench

that opens to 25 mm (1")

25 mm (1") Hex-Head

Socket Wrench

Utility Knife

Fiat-Blade Screwdriver

8 mm (5/16") Socket Wrench

6 mm (1/4") Nut Driver

Phillips Screwdriver

Pliers

(that open to 39 mm [19/16"])

Locking Pliers

686 mm (27") Wood Block

Flashlight (optional)

Parts Supplied:

Water Inlet Hoses (2)

Beaded Tie Strap

13 mm (1/2") and 14 mm

(9/16") Open-End Wrenches

Inlet Hose Washers (4)

Drain Hose/Clamp

Ruler or Measuring Tape

U-Shaped Hose Form Transit Bolt Hole Plug (4)

t-_:' TORX is a registered trademark of Saturn Fasteners, Inc.

7

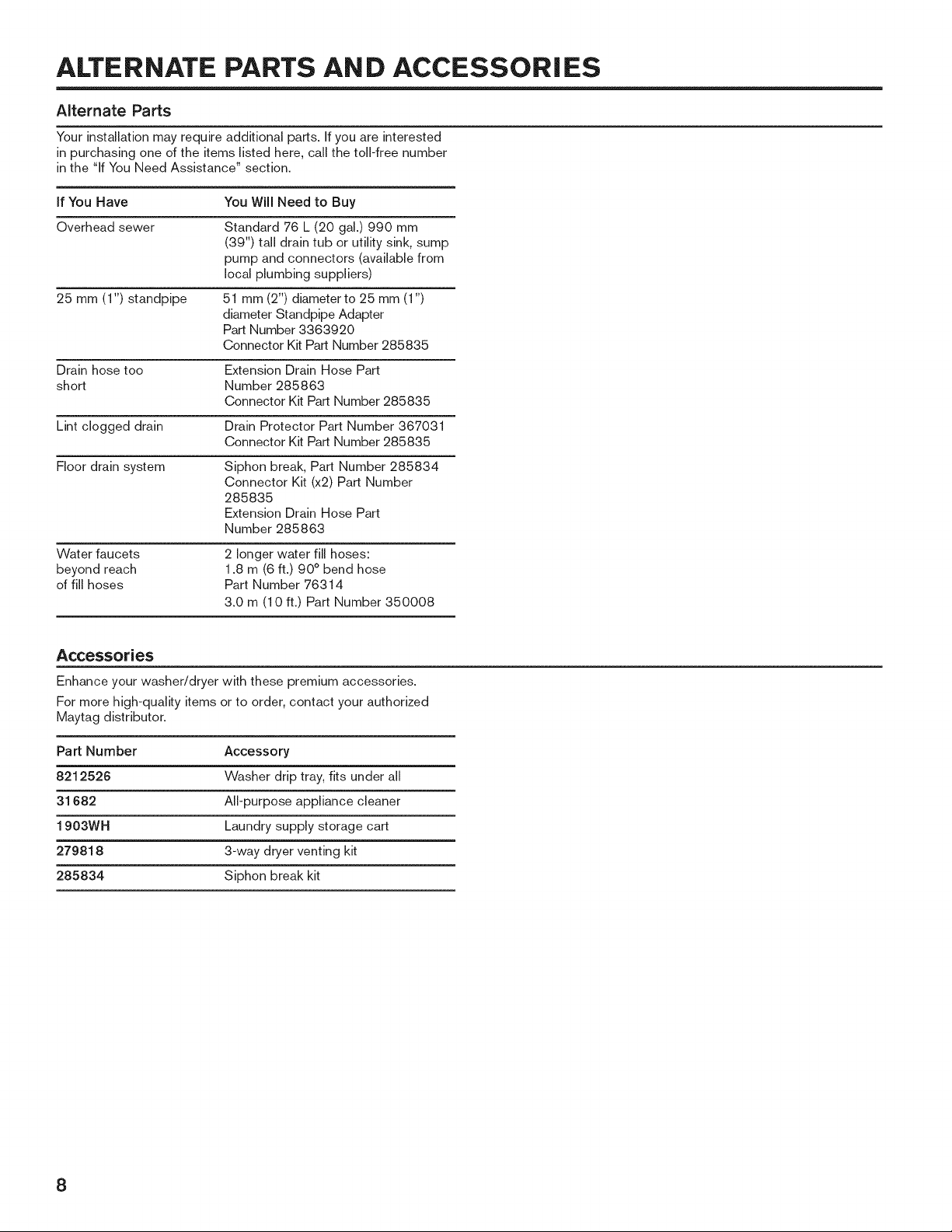

ALTERNATE PARTS AND ACCESSORIES

Alternate Parts

Your installation may require additional parts. If you are interested

in purchasing one of the items listed here, call the toIFfree number

in the "If You Need Assistance" section.

If You Have You Will Need to Buy

Overhead sewer Standard 76 L (20 gal.) 990 mm

(39") tall drain tub or utility sink, sump

pump and connectors (available from

local plumbing suppliers)

25 mm (1") standpipe 51 mm (2") diameter to 25 mm (1 ")

diameter Standpipe Adapter

Part Number 3363920

Connector Kit Part Number 285835

Drain hose too Extension Drain Hose Part

short Number 285863

Connector Kit Part Number 285835

Lint clogged drain Drain Protector Part Number 367031

Floor drain system Siphon break, Part Number 285834

Water faucets

beyond reach

of fill hoses

Connector Kit Part Number 285835

Connector Kit (x2) Part Number

285835

Extension Drain Hose Part

Number 285863

2 longer water fill hoses:

1.8 m (6 ft.) 90 ° bend hose

Part Number 76314

3.0 m (10 ft.) Part Number 350008

Accessories

Enhance your washer/dryer with these premium accessories.

For more high-quality items or to order, contact your authorized

Maytag distributor.

Part Number Accessory

8212526 Washer drip tray, fits under all

31682 AIFpurpose appliance cleaner

1903WH Laundry supply storage cart

279818 3-way dryer venting kit

285834 Siphon break kit

8

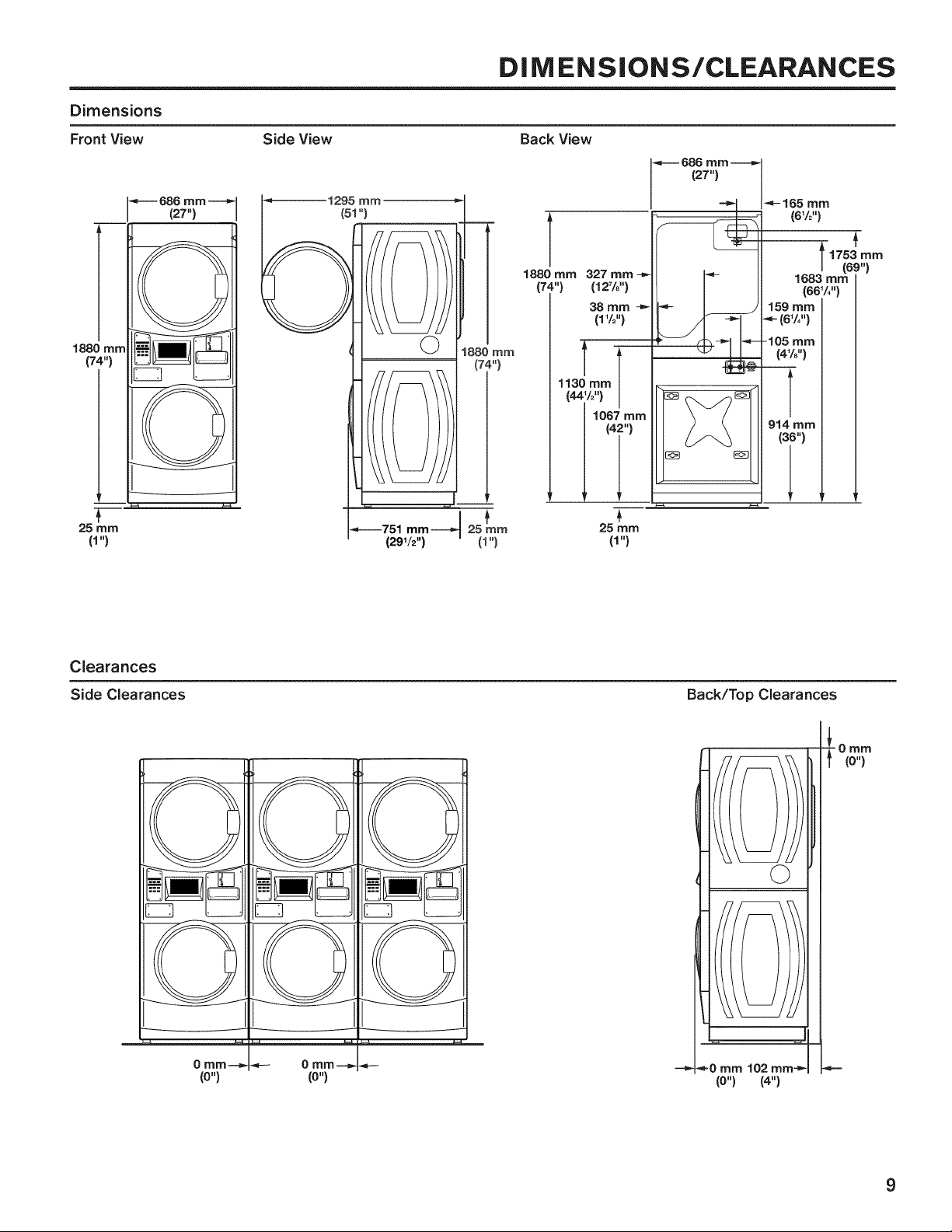

DiM ENS iONS/CLEARANCES

Dimensions

Front View Side View Back View

--,---686 mm ---_

(27")

I c51"! ___

l

1880 mm 327 mm --_

(7 .") (12%")

1880 mm

(74")

38 mm -_

{1v2")

-,,--- 686 mm---_

(27")

-,,,- 165 mm

(6V_")

Cs61/.,,)

159 mm

(6%")

-105 mm

(4'/_")

914 mrn

(36"}

25 mm

--_ H

(1")

Clearances

Side Clearances

4----751 mm---_ 25 rnm

(291/2'') (1")

25 mm

(1 ")

Back/Top Clearances

0 mm ---_

CO")

.,--- 0 mm ---_

CO")

9

STACKED WASHER/GAS DRYER iNSTALLATiON REQUIREMENTS

(Australia and New Zealand = for full details of installation requirements refer to AS/NZS 5601.1 = Gas Installations)

Stacked Washer/Gas Dryer Location

Stacked washer/gas dryer installation clearances

[] The location must be large enough to allow the washer and dryer

doors to be fully opened.

[] Additional spacing should be considered for ease of installation

and servicing. The doors open more than 180 °. The washer door

is not reversible.

[] Additional clearances might be required for wall, door, and floor

moldings.

Explosion Hazard

Keep flammable materials and vapors, such as petrol,

away from dryer,

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

Selecting the proper location for your washer/dryer improves

performance and minimizes noise and possible washer "walk"

Your washer/dryer can be installed in a basement, laundry room,

or recessed area. See "Drain System:'

Companion appliance location requirements should also be

considered.

IMPORTANT: Do not install or store the washer/dryer where it will

be exposed to the weather. Do not store or operate the washer/

dryer in temperatures at or below 0°C (32°F). Some water can

remain in the washer and can cause damage in low temperatures.

Proper installation is your responsibility.

You will need:

[] A water heater set to deliver 49°C (1 20°F) water to the washer.

[] A grounded electrical outlet located within 1.8 m (6 ft.) of

where the power cord is attached to the back of the washer.

See "Electrical Requirements_'

[] Hot and cold water faucets located within 1.2 m (4 ft.)

of the hot and cold water fill valves, and water pressure

of 137.9-689.6 kPa (20-100 psi).

[] A level floor with a maximum slope of 25 mm (1 ") under

entire washer/dryer. Installing the washer/dryer on soft floor

surfaces, such as carpets or surfaces with foam backing, is not

recommended.

[] A sturdy and solid floor to support the washer/dryer with a total

weight (water and load) of 204 kg (450 Ibs).

[] A floor drain under the bulkhead. Prefabricated bulkheads with

electrical outlets, water inlet lines, and drain facilities should be

used only where local codes permit.

[] Additional spacing of 25 mm (1") on all sides of the washer/dryer

is recommended to reduce noise transfer.

[] Companion appliance spacing should also be considered.

When installing a gas dryer:

IMPORTANT: Observe all governing codes and ordinances.

[] Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

NOTE: For installation in Australia and New Zealand, install

dryer in accordance with AS/NZS 5601.1 and local governance

codes.

[] Make sure that lower edges of the cabinet, plus the back and

bottom sides of the washer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

"Recessed Area and Closet Installation Instructions" below for

minimum spacing requirements.

[] Do not install on carpet.

Recessed Area and Closet Installation Instructions

This washer/dryer may be installed in a recessed area or closet.

This washer/dryer must not be installed behind a Iockable door,

a sliding door, or a door with a hinge on the opposite side to that

of the washer/dryer. For recessed area and closet installations,

minimum clearances can be found on the warning label on the rear

of the dryer or in "Dimensions/Clearances_'

The installation spacing is in millimeters and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes

and ordinances.

If closet door is installed, the minimum unobstructed air opening in

the top and bottom is required. Louvered doors with equivalent air

openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same closet

as the washer/dryer.

NOTE: For installation in Australia and New Zealand, refer to

AS/NZS 5601.1 for ventilation requirements.

10

i'ii

310 cm 2

(48 in.2)

t

Front

View

155 cm 2

(24 in.2)

q--

©

Closet

door

t

76 mm

(3")

76 ram

{3")

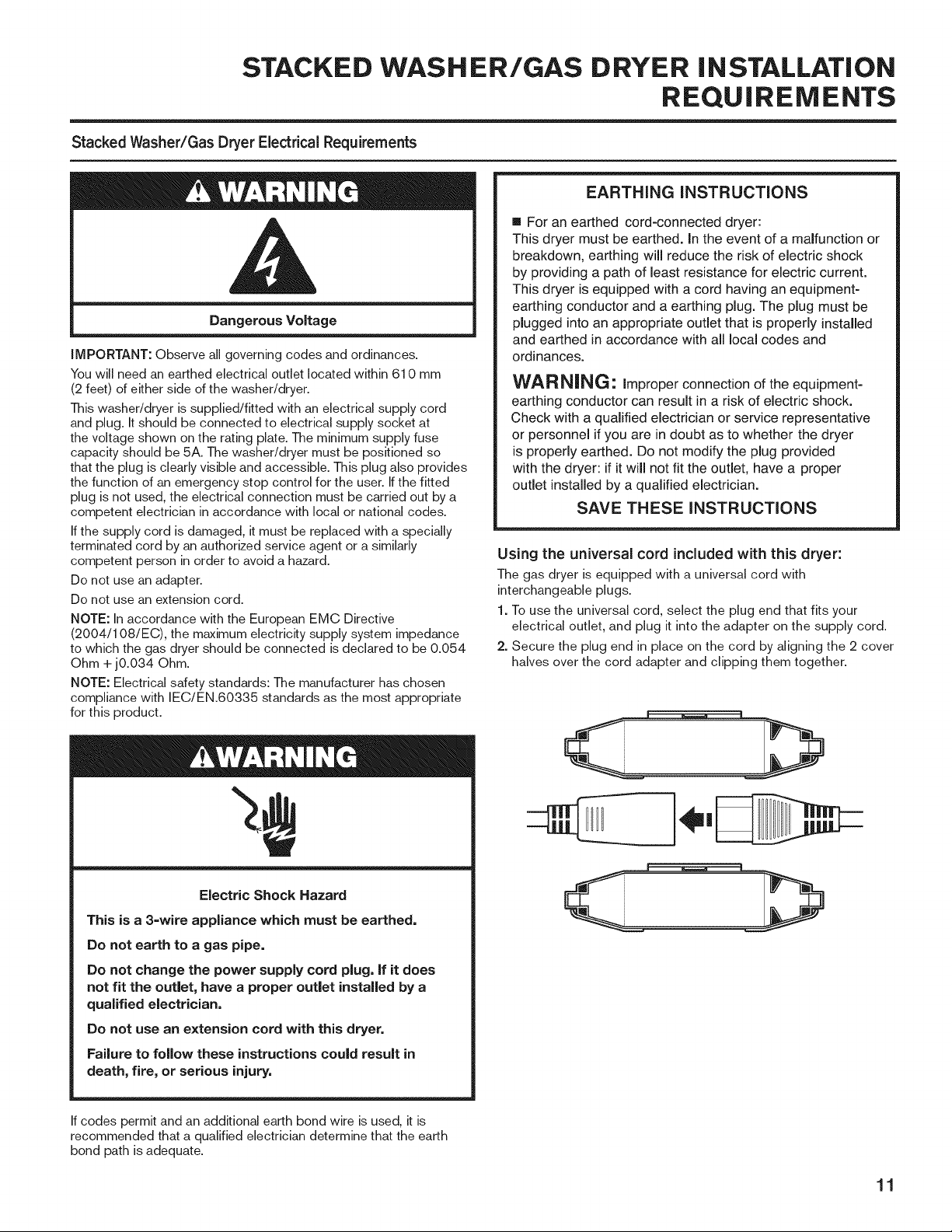

STACKED WASHER/GAS DRYER iNSTALLATiON

Stacked Washer/Gas Dryer Electrical Requirements

Dangerous Voltage

IMPORTANT: Observe all governing codes and ordinances.

You will need an earthed electrical outlet located within 610 mm

(2 feet) of either side of the washer/dryer.

This washer/dryer is supplied/fitted with an electrical supply cord

and plug. It should be connected to electrical supply socket at

the voltage shown on the rating plate. The minimum supply fuse

capacity should be 5A. The washer/dryer must be positioned so

that the plug is dearly visible and accessible. This plug also provides

the function of an emergency stop control for the user. If the fitted

plug is not used, the electrical connection must be carried out by a

competent electrician in accordance with local or national codes.

If the supply cord is damaged, it must be replaced with a specially

terminated cord by an authorized service agent or a similarly

competent person in order to avoid a hazard.

Do not use an adapter.

Do not use an extension cord.

NOTE: In accordance with the European EMC Directive

(2004/108/EC), the maximum electricity supply system impedance

to which the gas dryer should be connected is declared to be 0.054

Ohm + j0.034 Ohm.

NOTE: Electrical safety standards: The manufacturer has chosen

compliance with IEC/EN.60335 standards as the most appropriate

for this product.

REQUIREMENTS

EARTHING INSTRUCTIONS

m For an earthed cord-connected dryer:

This dryer must be earthed. In the event of a malfunction or

breakdown, earthing will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

earthing conductor and a earthing plug. The plug must be

plugged into an appropriate outlet that is properly installed

and earthed in accordance with all local codes and

ordinances.

WARNING" Improper connection of the equipment-

earthing conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer

is properly earthed. Do not modify the plug provided

with the dryer: if it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Using the universal cord included with this dryer:

The gas dryer is equipped with a universal cord with

interchangeable plugs.

1. To use the universal cord, select the plug end that fits your

electrical outlet, and plug it into the adapter on the supply cord.

2. Secure the plug end in place on the cord by aligning the 2 cover

halves over the cord adapter and clipping them together.

Electric Shock Hazard

This is a 3-wire appliance which must be earthed.

Do not earth to a gas pipe.

Do not change the power supply cord plug. if it does

not fit the outlet, have a proper outlet installed by a

qualified electrician.

Do not use an extension cord with this dryer.

Failure to follow these instructions could result in

death, fire, or serious injury.

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond path is adequate.

11

STACKED WASHER/GAS DRYER iNSTALLATiON

REQUIREMENTS

Stacked Washer/Gas Dryer Gas Supply Requirements

Supply line requirements:

Provide a rigid gas supply line to the washer/dryer location. It

should be minimum 12.5 mm (1/2") ID. When acceptable to the

gas supplier and local codes, 10 mm (3/8") ID rigid supply line

may be used for lengths under 6.1 m (20'). Pipe-joint compounds

resistant to the action of L.R gas must be used.

NOTE: For installation in Australia and New Zealand, refer to

AS/NZS 5601 for pipe sizing details. All piping is to be in

Explosion Hazard

Connect this dryer to a regulated gas supply. Supply

pressure must be in accordance with the Technical

Specifications.

Install a shut=off valve.

Securely tighten aft gas connections.

if connected to LP, have a qualified person make sure

gas pressure is correct.

Failure to do so can result in death, explosion, or fire.

IM PORTANT: Observe all governing codes and ordinances.

In Australia and New Zealand, refer to AS/NZS 5601.1 - Gas

Installations.

Gas Supply

Before installation, check that the local gas distribution conditions,

nature of gas and pressure, and the adjustment of the appliance

are compatible. Burner information will be found on the model/

serial rating plate in the door recess of the dryer. If this information

does not agree with the type of gas available, see your dealer.

Natural Gas:

This dryer is factory adjusted for use with NATURAL GAS (G20),

and no further adjustment should be required at installation.

L.P.Gas:

This dryer is also certified for use with L.R (propane or butane)

gases with appropriate conversion. No attempt shall be made to

convert the appliance from the gas specified on the model/serial

rating plate for use with a different gas without consulting the

serving gas supplier.

Conversion must be done by a competent service technician. Gas

conversion kit (European Country), part number W10233219,

is available for purchase from your dealer. Gas conversion kit

(Australia), part number W10315369, is available for purchase

from your dealer. Full instructions are supplied with the kit.

Natural gas (France/Belgium):

This dryer is also certified for France/Belgium for use with G20/

G25 gases (20 mbar/25 mbar) with appropriate conversion.

No attempt should be made to convert this appliance from the

gas specified on the gas rating label for use with a different gas

without consulting the serving gas supplier. Gas conversion must

be done by a qualified gas service technician. Conversion kit, part

number (W10181947) is available for purchase from your dealer.

Full instructions are supplied with the kit.

accordance with AS/NZS 5601.1 - Gas Installations.

Gas connection to the dryer itself should be made by means

of a flexible gas hose suitable for the appliance and gas category

in accordance with national installation regulations. If in doubt,

contact the gas supplier. It should be minimum 10 mm (3/8") ID.

A means of restraint should be used between the washer/dryer

and the wall to avoid straining of the rigid gas supply when the

washer/dryer is moved. An appropriate length of chain and a wall

hook is recommended.

The dryer gas inlet connection is a 3/8" NPT thread. An adapter is

supplied for conversion to standard ISO.228-1 thread (3/8" BSP).

Check for leaks by using an approved noncorrosive leak-detection

solution. Bubbles will show a leak. Correct any leak found. A

pressure measurement tapping is provided on the gas valve within

the dryer, accessible after removal of the lower front panel.

The dryer must be disconnected from the gas supply piping

system during any pressure testing of that system.

12

STACKED WASHER/ELECTRIC DRYER iNSTALLATiON

Stacked Washer/Electric Dryer Location

Explosion Hazard

Keep flammable materials and vapors, such as petrol,

away from dryer.

Do not instafl in a garage.

Failure to do so can result in death, explosion, or fire.

NOTE: In Australia and New Zealand, refer to AS/NZS 5601.1 -

Gas Installations.

Selecting the proper location for your washer/dryer improves

performance and minimizes noise and possible washer "walk_'

Your washer/dryer can be installed in a basement, laundry room, or

recessed area. See "Drain System_'

Companion appliance location requirements should also be

considered.

iMPORTANT: Do not install or store the washer/dryer where it will

be exposed to the weather. Do not store or operate the washer/

dryer in temperatures at or below 0°C (32°F). Some water can

remain in the washer and can cause damage in low temperatures.

Proper installation is your responsibility.

YOU will need:

A water heater set to deliver 49°C (1 20°F) water to the washer.

In A grounded electrical outlet located within 1.8 m (6 ft.) of

where the power cord is attached to the back of the washer.

See "Electrical Requirements:'

m Hot and cold water faucets located within 1.2 m (4 ft.)

of the hot and cold water fill valves, and water pressure

of 137.9-689.6 kPa (20-100 psi).

In A level floor with a maximum slope of 25 mm (1") under

entire washer/dryer. Installing the washer/dryer on soft floor

surfaces, such as carpets or surfaces with foam backing, is not

recommended.

In A sturdy and solid floor to support the washer/dryer with a total

weight (water and load) of 204 kg (450 Ibs).

In A floor drain under the bulkhead. Prefabricated bulkheads with

electrical outlets, water inlet lines, and drain facilities should be

used only where local codes permit.

REQUIREMENTS

Stacked washer/electric dryer installation clearances

in The location must be large enough to allow the washer

and dryer doors to be fully opened.

In Additional spacing should be considered for ease of installation

and servicing. The doors open more than 180 °. The washer door

is not reversible.

i Additional clearances might be required for wail, door, and floor

moldings.

m Additional spacing of 25 mm (1 ") on ai[ sides of the washer/dryer

is recommended to reduce noise transfer.

In Companion appliance spacing should also be considered.

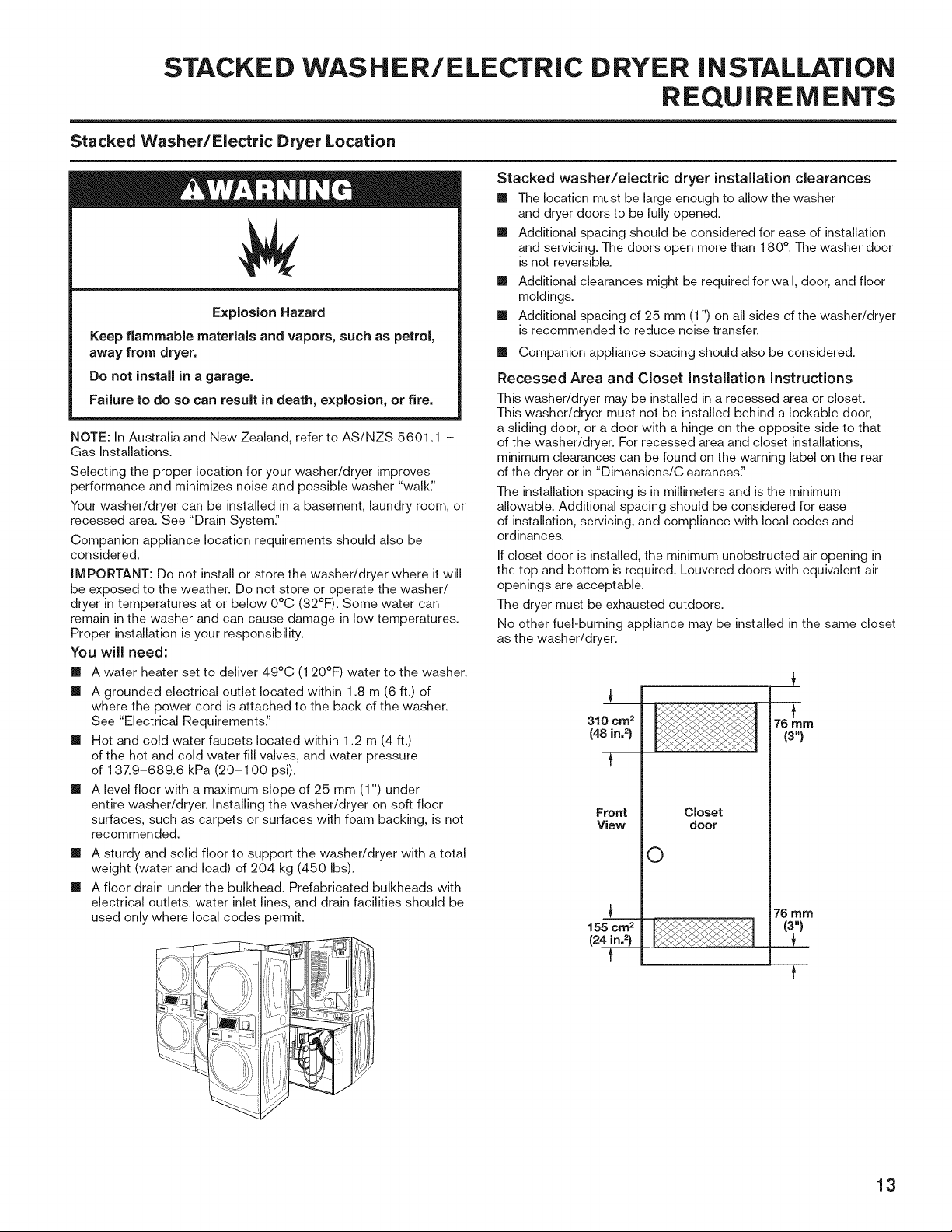

Recessed Area and Closet Installation Instructions

This washer/dryer may be installed in a recessed area or closet.

This washer/dryer must not be installed behind a Iockable door,

a sliding door, or a door with a hinge on the opposite side to that

of the washer/dryer. For recessed area and closet installations,

minimum clearances can be found on the warning label on the rear

of the dryer or in "Dimensions/Clearances_'

The installation spacing is in millimeters and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes and

ordinances.

If closet door is installed, the minimum unobstructed air opening in

the top and bottom is required. Louvered doors with equivalent air

openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same closet

as the washer/dryer.

310 cm2

{48 in,2)

q---

Front

View

155 cm2

(24 in. 2}

q---

Closet

door

©

76 ml

(3"}

76 mi

(3")

'-¸¸

13

STACKED WASHER/ELECTRIC DRYER iNSTALLATiON

REQUIREMENTS

Stacked Washer/Electric Dryer Electrical

Requirements

Dangerous Voltage

This washer/dryer is supplied without an electric cord and plug. It

must be connected by a competent electrician to a single-phase

electricity supply at the voltage shown on the dataplate, using

a suitable fixed wiring installation in accordance with local and

national wiring regulations.

A 3-wire circular cord of minimum conductor size 2.5 mm 2

cross-section area should be used.

m A 30A supply fuse should be used, and a switch having

a contact separation in both poles that provides full

disconnection under over-voltage category III conditions must

be incorporated into the fixed wiring in accordance with local

wiring regulations. The washer/dryer should be positioned

so that the disconnection switch is clearly visible and easily

accessible to the user. This disconnection switch also provides

the function of an emergency stop control for the user.

m A cord clamp bush is provided on the washer/dryer, and

should be tightened on completion of wiring. The electrical

mains terminals are located behind the small rear access panel

(terminal block cover), and connections should be made in

accordance with the terminal markings. Remember to replace

the terminal access panel (terminal block cover).

NOTE: In accordance with the European EMC Directive

(2004/108/EC), the maximum electrical supply system impedance

to which the electric dryer should be connected is declared to be

0.054 Ohm + j0.034 Ohm.

NOTE: Electrical safety standards: The manufacturer has

chosen compliance with IEC/EN.60335 standards as the most

appropriate for this product.

Electric Shock Hazard

This is 3=wire appliance which must be earthed.

Do not earth to a gas pipe.

Failure to follow these instructions could resu|t in

death, fire, or serious injury.

If codes permit and an additional earth bond wire is used, it is

recommended that a qualified electrician determine that the earth

bond path is adequate.

Recommended Earthing Method

It is your responsibility to contact a qualified electrical installer

to ensure that the electrical installation is adequate and in

conformance with all local codes and ordinances.

14

DRYER VENTING REQUIREMENTS

Fire Hazard

Use a heavy metal vent,

Do not use a plastic vent,

Do not use a metal foil vent,

Failure to follow these instructions can result in death

or fire,

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IM PORTANT: Observe all governing codes and ordinances.

In Australia and New Zealand, refer to AS/NZS 5601.1 - Gas

Installations.

[]

Following these venting requirements will minimise ducfing air

noise.

[]

Adequate ventilation has to be provided to avoid the backflow

of gases into the room from appliances burning other fuels,

including open fires (i.e. available airflow into the room should

match airflow out from the room).

[] Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or flexible metal vent shall be used for

exhausting.

[] Do not use an exhaust hood with a magnetic latch.

(4")

t 02 mm (4") Heavy, Metal Exhaust Vent

[] Only a 4" (102 mm) heavy, metal exhaust vent and clamps may

be used.

[] Do not use plastic or metal foil vent.

Rigid metal vent:

[] Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

[] Must be fully extended and supported in final dryer location.

[] Remove excess to avoid sagging and kinking that may result in

reduced airflow and poor performance.

[] Do not install in enclosed walls, ceilings, or floors.

[] The total length should not exceed 73/4ft. (2.4 m).

[] An exhaust hood should cap the vent to keep rodents and

insects from entering the building.

NOTE: If using an existing vent system, clean lint from entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace plastic or metal foil vents with rigid metal or flexible

metal vents. Review "Vent System Chart" and if necessary, modify

existing vent system to achieve best drying performance.

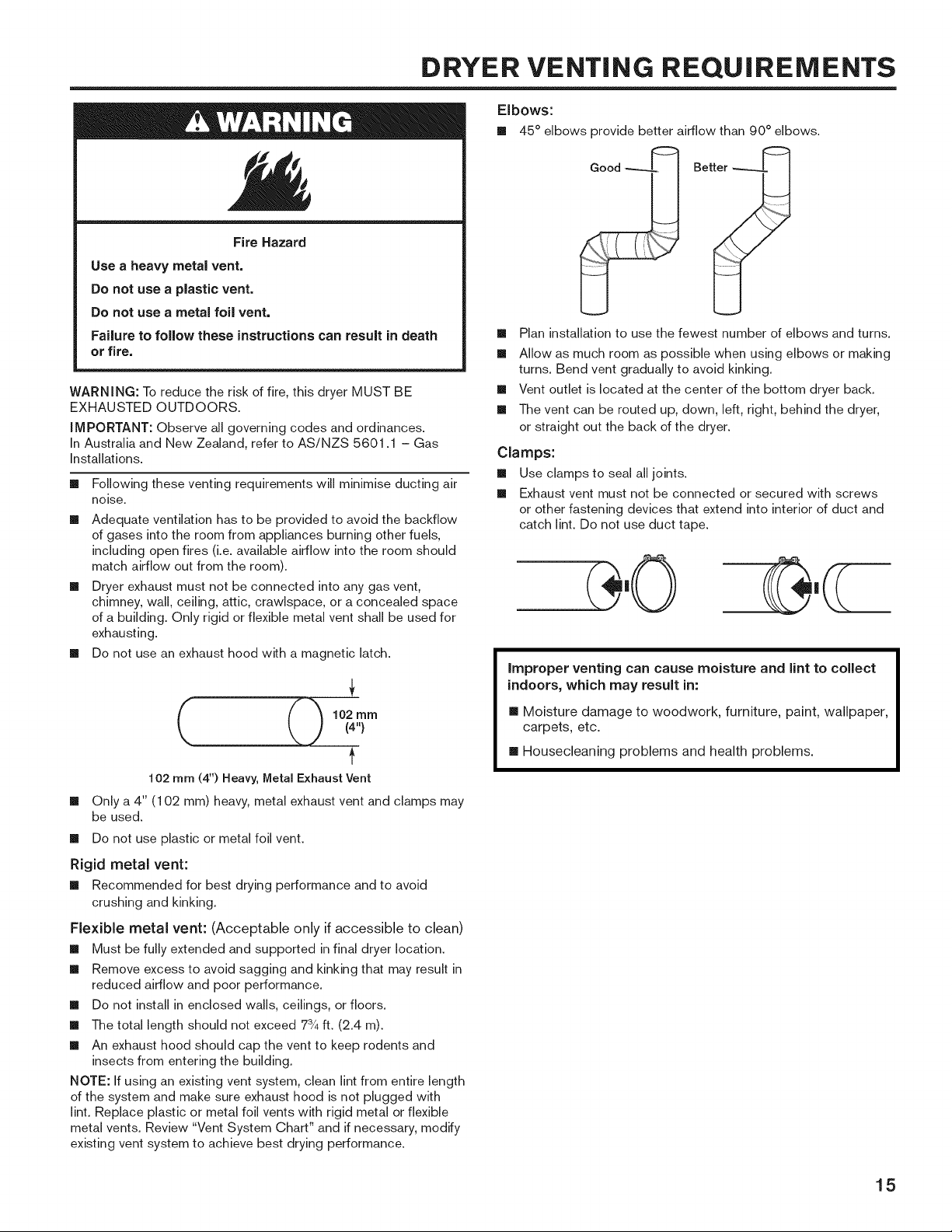

Elbows:

[] 45 ° elbows provide better airflow than 90 ° elbows.

Bet

[] Plan installation to use the fewest number of elbows and turns.

[] Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

[] Vent outlet is located at the center of the bottom dryer back.

[] The vent can be routed up, down, left, right, behind the dryer,

or straight out the back of the dryer.

Clamps:

[] Use clamps to seal all joints.

[] Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct and

catch lint. Do not use duct tape.

improper venting can cause moisture and lint to collect

indoors, which may result in:

[] Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

[] Housecleaning problems and health problems.

15

DRYER VENTING REQUIREMENTS

(in Australia and New Zealand, refer to AS/NZS 5601.1 = Gas Installations)

Vent Hoods

102 mm (4") Diameter Exhaust Hoods

Box Hood Louvered Hood Angled Hood

Vent System Length

Maximum Vent Length/Vent Connection

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood.

Vent System Chart (Rigid Metal Vent)

No. of

90°Turns

0

1

2

3

4

Box and Angled

Louvered Hood Hood

39.6 m (130 ft.) 39.3 m (129 ft.)

38.1 m (125 ft.) 36.3 m (119 ft.)

35.1 m. (115 ft) 33.2 m (109 ft.)

32.3 m (106 ft.) 30.5 m (100 ft.)

29.9 m (98 ft.) 28.0 m (92 ft.)

Exhaust hood must be at least 305 mm (1 2") from the ground or

any object that may be in the path of the exhaust (such as flowers,

rocks, bushes, or snow).

3. Tighten hose clamp with Phillips screwdriver.

\

For vent systems not covered by the vent specification chart, see

your parts distributor.

Provision must be made for enough air for combustion and

ventilation. (Check governing codes and ordinances.) See

"Recessed Area and Closet Installation Instructions" in the

"Stacked Washer/Gas Dryer Location" and "Stacked Washer/

Electric Dryer Location" sections.

A 102 mm (4") outlet hood is preferred. However, a 64 mm

(21/2'') outlet exhaust hood may be used. A 64 mm (21/2'') outlet

creates greater back pressure than other hood types. For

permanent installation, a stationary vent system is required.

Connect Vent

1. If connecting to existing vent, make sure the vent is clean.

2. Using a 102 mm (4") clamp, connect vent to exhaust outlet in

dryer. Vent Collar

NOTE: Do not remove vent collar.

4. Make sure the vent is secured to exhaust hood with a 102 mm

(4") clamp.

5. Move dryer into final position. Do not crush or kink vent. Make

sure dryer is level.

16

DRYER VENTING REQUIREMENTS

(in Australia and New Zealand, refer to AS/NZS 5601.1 = Gas installations)

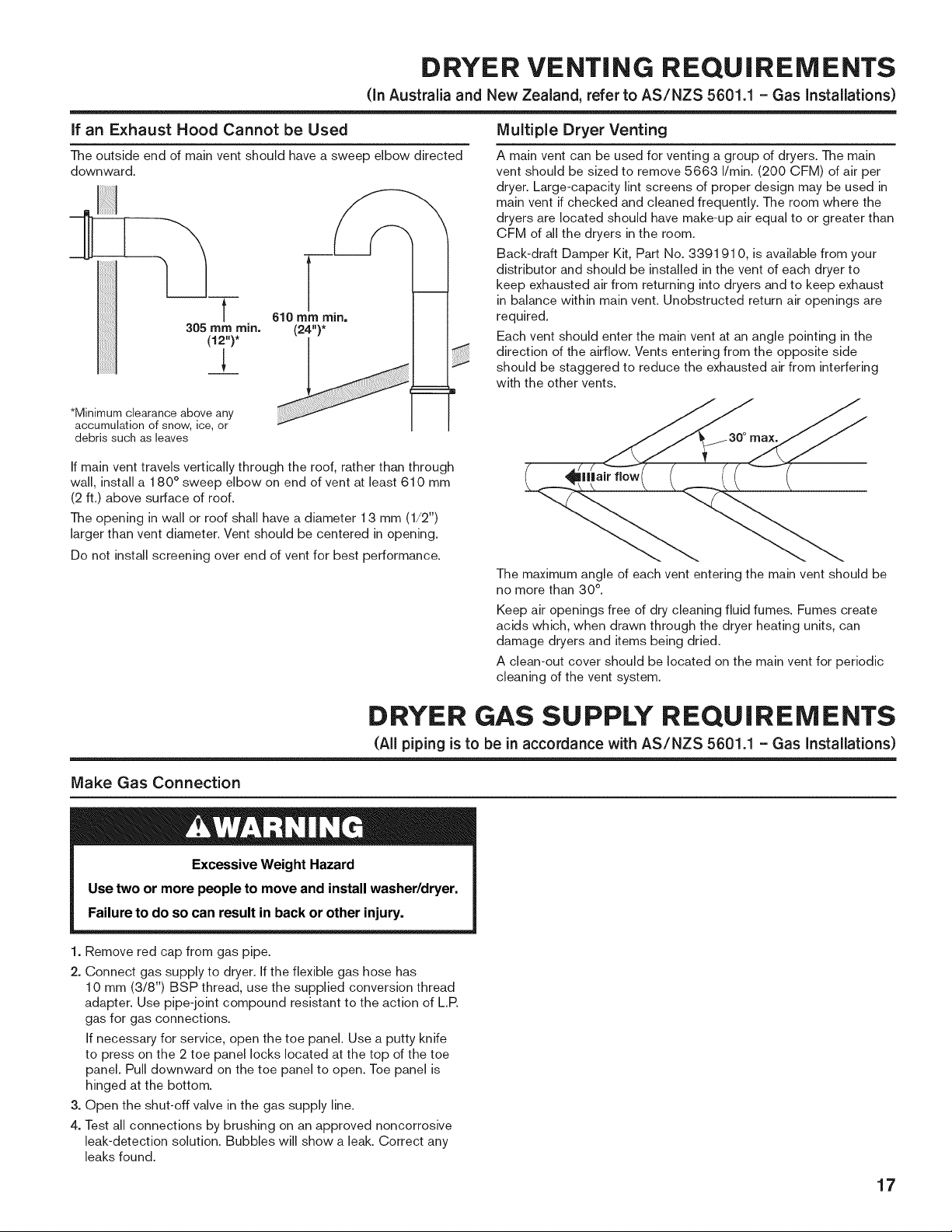

if an Exhaust Hood Cannot be Used

The outside end of main vent should have a sweep elbow directed

downward.

t

305 mm rain,

(12")*

*Minimum clearance above any

accumulation of snow, ice, or

debris such as leaves

If main vent travels vertically through the roof, rather than through

wall, install a 180 ° sweep elbow on end of vent at least 610 mm

(2 ft.) above surface of roof.

The opening in wall or roof shall have a diameter 13 mm (1/2")

larger than vent diameter. Vent should be centered in opening.

Do not install screening over end of vent for best performance.

610 ram rain.

(24")*

Multiple Dryer Venting

A main vent can be used for venting a group of dryers. The main

vent should be sized to remove 5663 I/min. (200 CFM) of air per

dryer. Large-capacity lint screens of proper design may be used in

main vent if checked and cleaned frequently. The room where the

dryers are located should have make-up air equal to or greater than

CFM of all the dryers in the room.

Back-draft Damper Kit, Part No. 3391910, is available from your

distributor and should be installed in the vent of each dryer to

keep exhausted air from returning into dryers and to keep exhaust

in balance within main vent. Unobstructed return air openings are

required.

Each vent should enter the main vent at an angle pointing in the

direction of the airflow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

The maximum angle of each vent entering the main vent should be

no more than 30 °.

Keep air openings free of dry cleaning fluid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and items being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

DRYER GAS SUPPLY REQUIREMENTS

(All piping is to be in accordance with AS/NZS 5601.1 = Gas Installations)

Make Gas Connection

Excessive Weight Hazard

Use two or more people to move and install washer/dryer.

Failure to do so can result in back or other injury.

1. Remove red cap from gas pipe.

2. Connect gas supply to dryer. If the flexible gas hose has

10 mm (3/8") BSP thread, use the supplied conversion thread

adapter. Use pipe-joint compound resistant to the action of L.R

gas for gas connections.

If necessary for service, open the toe panel. Use a putty knife

to press on the 2 toe panel locks located at the top of the toe

panel. Pull downward on the toe panel to open. Toe panel is

hinged at the bottom.

3. Open the shut-off valve in the gas supply line.

4. Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leaks found.

17

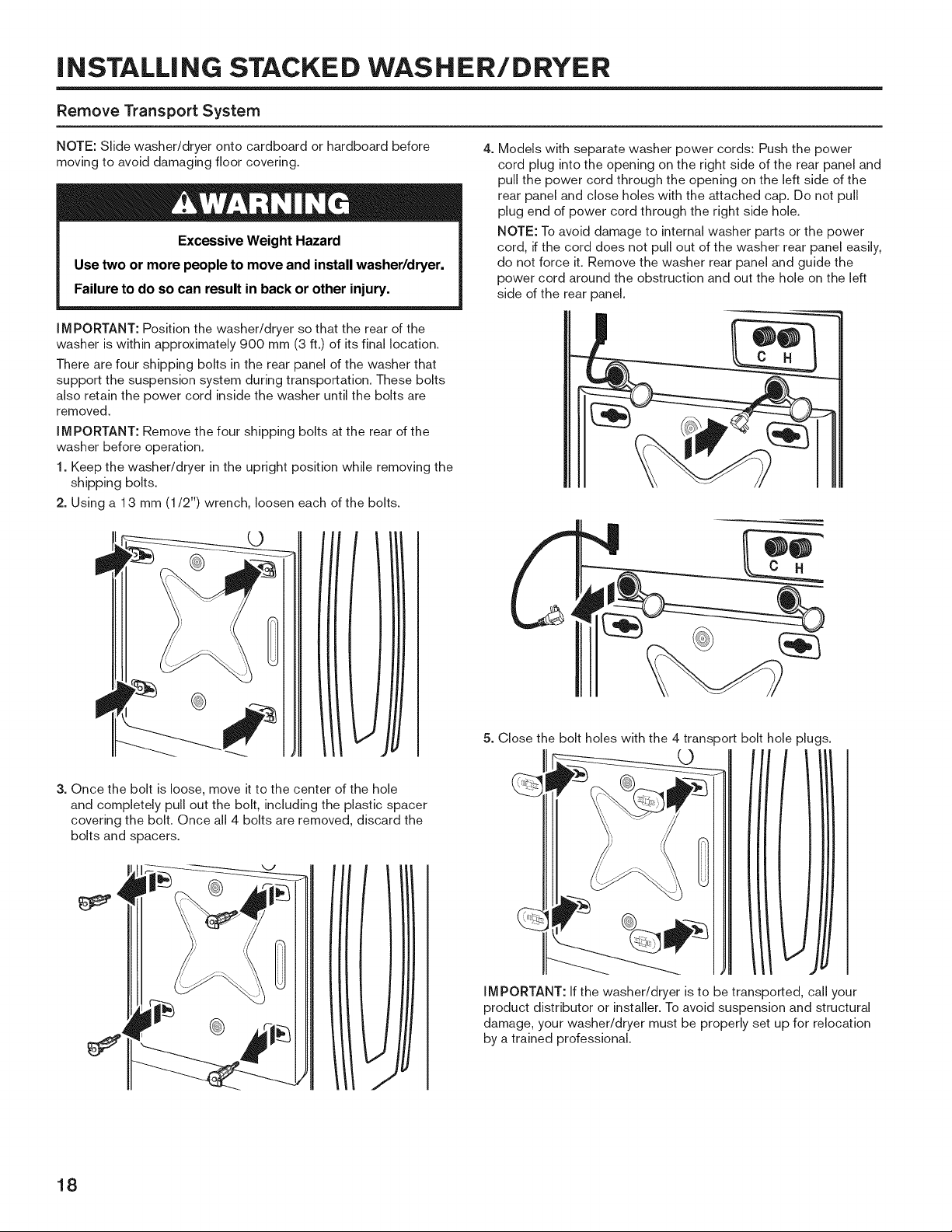

iNSTALLiNG STACKED WASHER/DRYER

Remove Transport System

NOTE: Slide washer/dryer onto cardboard or hardboard before

moving to avoid damaging floor covering.

Excessive Weight Hazard

Use two or more people to move and install washer/dryer.

Failure to do so can result in back or other injury.

IM PORTANT: Position the washer/dryer so that the rear of the

washer is within approximately 900 mm (3 ft.) of its final location.

There are four shipping bolts in the rear panel of the washer that

support the suspension system during transportation. These bolts

also retain the power cord inside the washer until the bolts are

removed.

iMPORTANT: Remove the four shipping bolts at the rear of the

washer before operation.

1. Keep the washer/dryer in the upright position while removing the

shipping bolts.

2. Using a 13 mm (1/2") wrench, loosen each of the bolts.

4. Models with separate washer power cords: Push the power

cord plug into the opening on the right side of the rear panel and

pull the power cord through the opening on the left side of the

rear panel and close holes with the attached cap. Do not pull

plug end of power cord through the right side hole.

NOTE: To avoid damage to internal washer parts or the power

cord, if the cord does not pull out of the washer rear panel easily,

do not force it. Remove the washer rear panel and guide the

power cord around the obstruction and out the hole on the left

side of the rear panel.

C H

3. Once the bolt is loose, move it to the center of the hole

and completely pull out the bolt, including the plastic spacer

covering the bolt. Once all 4 bolts are removed, discard the

bolts and spacers.

18

5. Close the bolt holes with the 4 transport bolt hole plugs.

IMPORTANT: If the washer/dryer is to be transported, call your

product distributor or installer. To avoid suspension and structural

damage, your washer/dryer must be properly set up for relocation

by a trained professional.

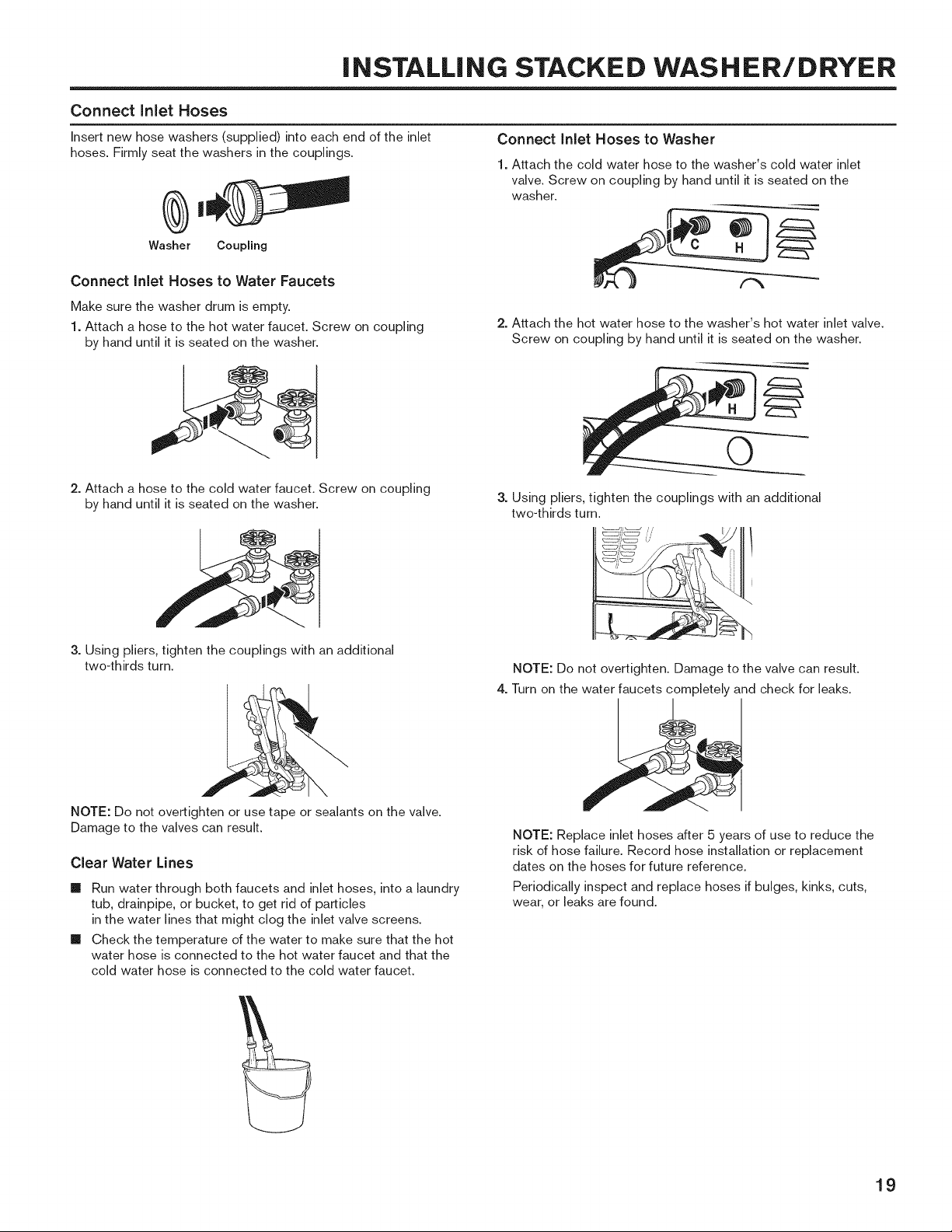

Connect Inlet Hoses

iNSTALLiNG STACKED WASHER/DRYER

Insert new hose washers (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

Washer Coupling

Connect Inlet Hoses to Water Faucets

Make sure the washer drum is empty.

1. Attach a hose to the hot water faucet. Screw on coupling

by hand until it is seated on the washer.

2. Attach a hose to the cold water faucet. Screw on coupling

by hand until it is seated on the washer.

Connect Inlet Hoses to Washer

1. Attach the cold water hose to the washer's cold water inlet

valve. Screw on coupling by hand until it is seated on the

washer.

2. Attach the hot water hose to the washer's hot water inlet valve.

Screw on coupling by hand until it is seated on the washer.

0

3. Using pliers, tighten the couplings with an additional

two-thirds turn.

3. Using pliers, tighten the couplings with an additional

two-thirds turn.

NOTE: Do not overtighten or use tape or sealants on the valve.

Damage to the valves can result.

Clear Water Lines

In Run water through both faucets and inlet hoses, into a laundry

tub, drainpipe, or bucket, to get rid of particles

in the water lines that might clog the inlet valve screens.

II Check the temperature of the water to make sure that the hot

water hose is connected to the hot water faucet and that the

cold water hose is connected to the cold water faucet.

NOTE: Do not overtighten. Damage to the valve can result.

4. Turn on the water faucets completely and check for leaks.

NOTE: Replace inlet hoses after 5 years of use to reduce the

risk of hose failure. Record hose installation or replacement

dates on the hoses for future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

19

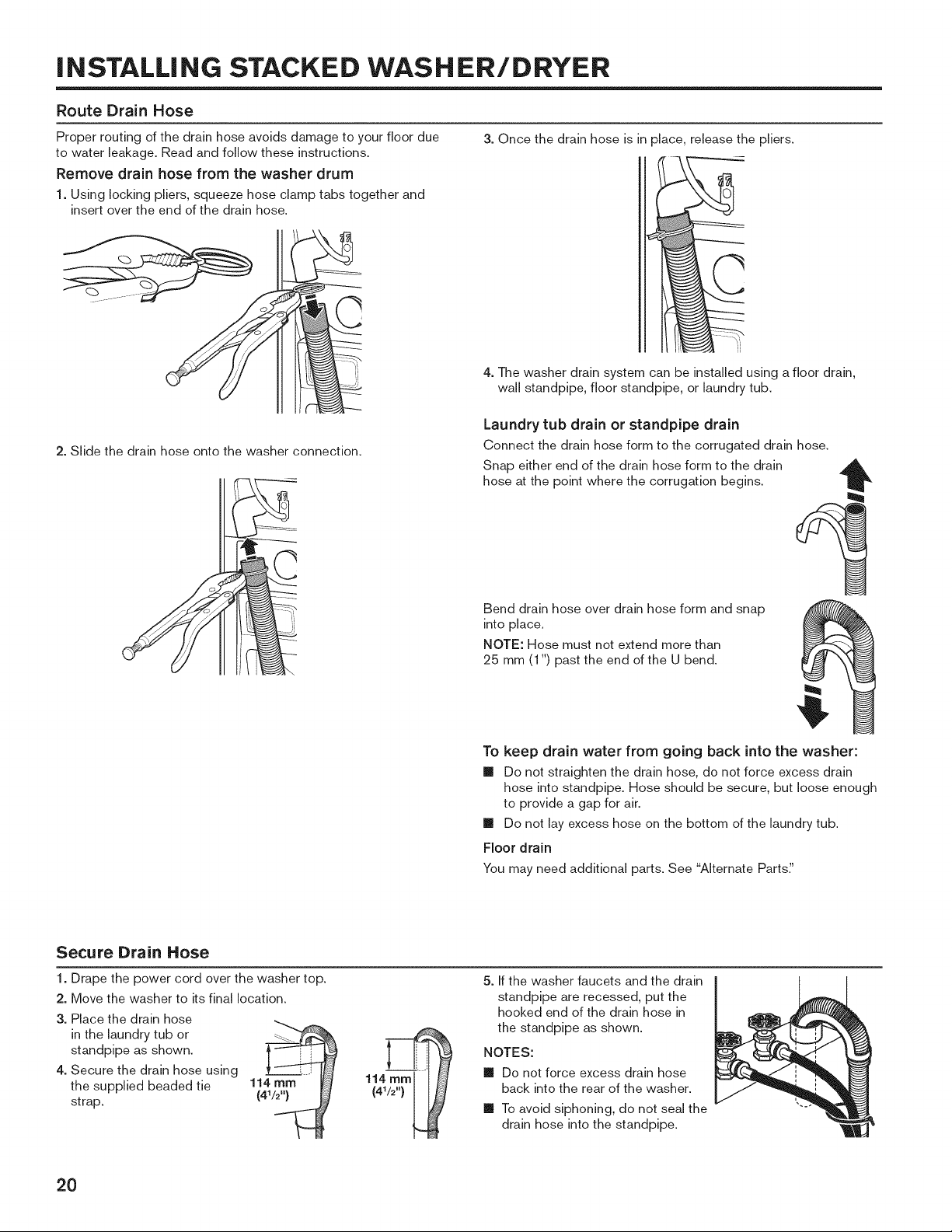

iNSTALLiNG STACKED WASHER/DRYER

Route Drain Hose

Proper routing of the drain hose avoids damage to your floor due

to water leakage. Read and follow these instructions.

Remove drain hose from the washer drum

1. Using locking pliers, squeeze hose clamp tabs together and

insert over the end of the drain hose.

2. Slide the drain hose onto the washer connection.

3. Once the drain hose is in place, release the pliers.

C

4. The washer drain system can be installed using a floor drain,

wall standpipe, floor standpipe, or laundry tub.

Laundry tub drain or standpipe drain

Connect the drain hose form to the corrugated drain hose.

Snap either end of the drain hose form to the drain

hose at the point where the corrugation begins.

Secure Drain Hose

1. Drape the power cord over the washer top.

2. Move the washer to its final location.

3. Place the drain hose

in the laundry tub or _--_.. ;

standpipe as shown.

4. Secure the drain hose using

the supplied beaded tie 114 mm

strap. (4t/2"}

(41/2")

Bend drain hose over drain hose form and snap

into place.

NOTE: Hose must not extend more than

25 mm (1 ") past the end of the U bend.

To keep drain water from going back into the washer:

m Do not straighten the drain hose, do not force excess drain

hose into standpipe. Hose should be secure, but loose enough

to provide a gap for air.

m Do not lay excess hose on the bottom of the laundry tub.

Floor drain

You may need additional parts. See "Alternate Parts_'

5. If the washer faucets and the drain

standpipe are recessed, put the

hooked end of the drain hose in

the standpipe as shown.

NOTES:

m Do not force excess drain hose

back into the rear of the washer.

m To avoid siphoning, do not seal the

drain hose into the standpipe.

2O

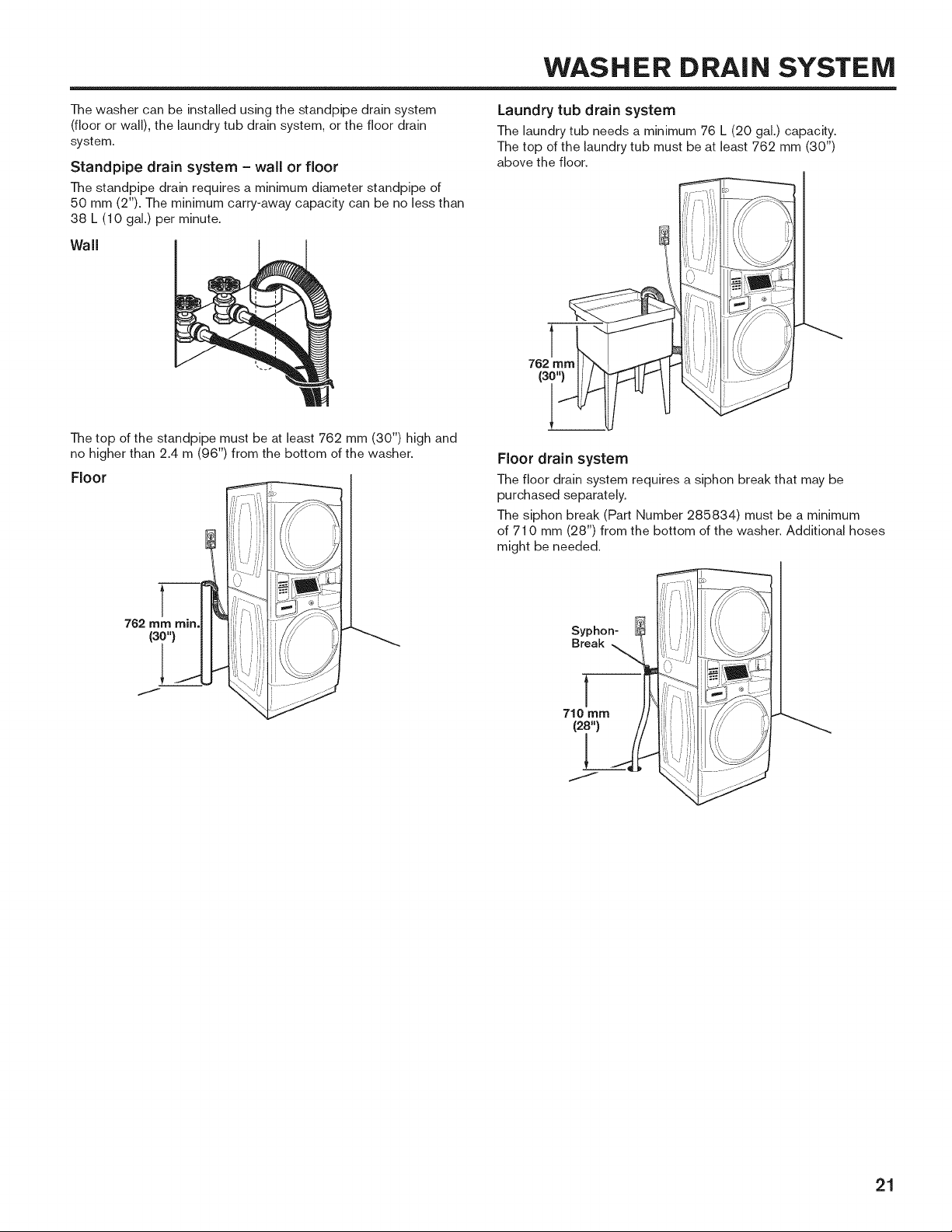

WASHER DRAIN SYSTEM

The washer can be installed using the standpipe drain system

(floor or wall), the laundry tub drain system, or the floor drain

system.

Standpipe drain system - wall or floor

The standpipe drain requires a minimum diameter standpipe of

50 mm (2"). The minimum carry-away capacity can be no less than

38 L (10 gal.) per minute.

Wall

The top of the standpipe must be at least 762 mm (30") high and

no higher than 2.4 m (96") from the bottom of the washer.

Floor

Laundry tub drain system

The laundry tub needs a minimum 76 L (20 gal.) capacity.

The top of the laundry tub must be at least 762 mm (30")

above the floor.

762 mm

(30")

Floor drain system

The floor drain system requires a siphon break that may be

purchased separately.

The siphon break (Part Number 285834) must be a minimum

of 710 mm (28") from the bottom of the washer. Additional hoses

might be needed.

1

762 mm rain.

(30")

Syphon-

Break,_

1

710 mm

21

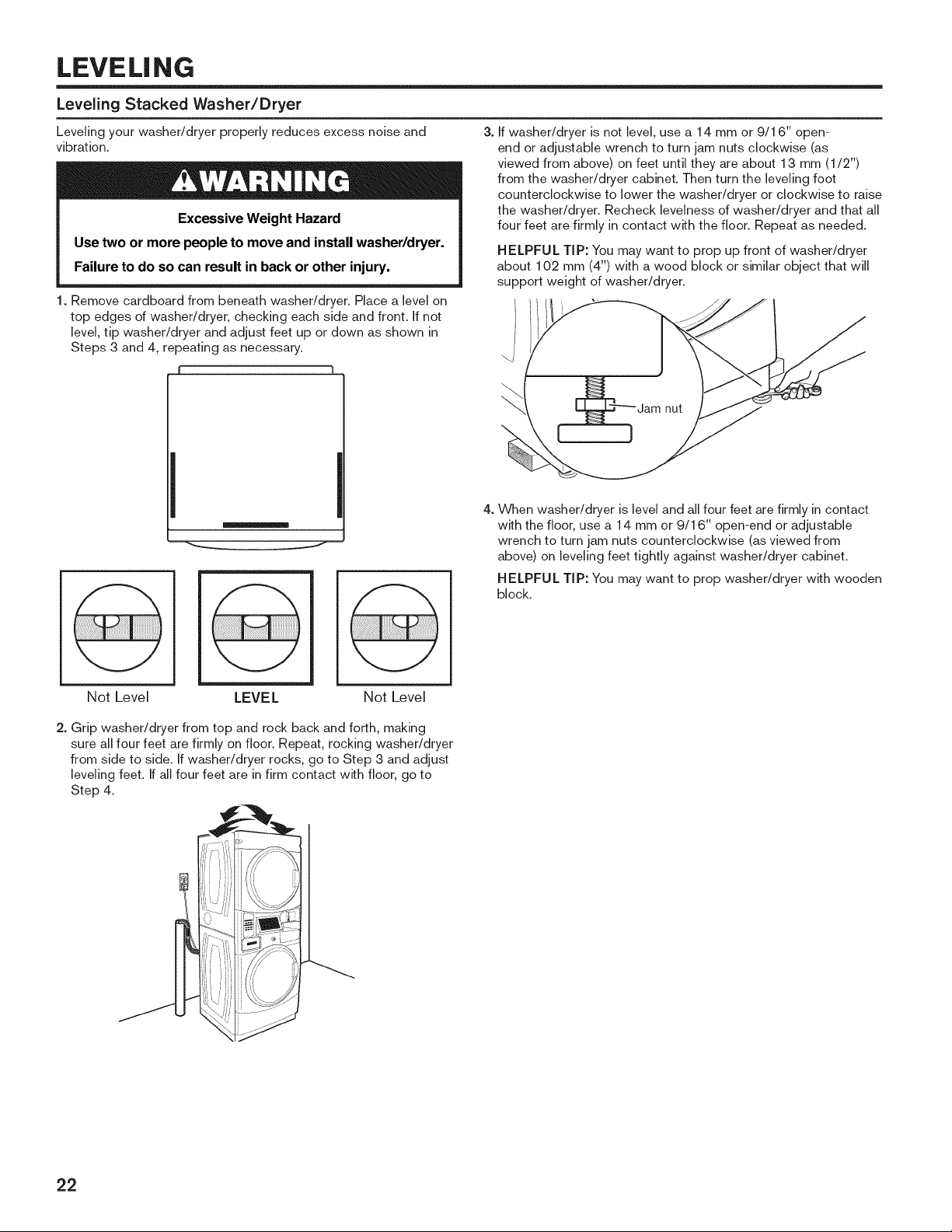

LEVELING

Leveling Stacked Washer/Dryer

Leveling your washer/dryer properly reduces excess noise and

vibration.

Excessive Weight Hazard

Use two or more people to move and install washer/dryer.

Failure to do so can result in back or other injury.

1. Remove cardboard from beneath washer/dryer. Place a level on

top edges of washer/dryer, checking each side and front. If not

level, tip washer/dryer and adjust feet up or down as shown in

Steps 3 and 4, repeating as necessary.

jm

3. If washer/dryer is not level, use a 14 mm or 9/16" open-

end or adjustable wrench to turn jam nuts clockwise (as

viewed from above) on feet until they are about 13 mm (1/2")

from the washer/dryer cabinet. Then turn the leveling foot

counterclockwise to lower the washer/dryer or clockwise to raise

the washer/dryer. Recheck levelness of washer/dryer and that all

four feet are firmly in contact with the floor. Repeat as needed.

HELPFUL TiP: You may want to prop up front of washer/dryer

about 102 mm (4") with a wood block or similar object that will

support weight of washer/dryer.

4. When washer/dryer is level and all four feet are firmly in contact

with the floor, use a 14 mm or 9/16" open-end or adjustable

wrench to turn jam nuts counterclockwise (as viewed from

above) on leveling feet tightly against washer/dryer cabinet.

HELPFUL TiP: You may want to prop washer/dryer with wooden

block.

Not Level LEVEL Not Level

2. Grip washer/dryer from top and rock back and forth, making

sure all four feet are firmly on floor. Repeat, rocking washer/dryer

from side to side. If washer/dryer rocks, go to Step 3 and adjust

leveling feet. If all four feet are in firm contact with floor, go to

Step 4.

22

COM PLETE iNSTALLATiON

1. Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended grounding

method. See "Electrical Requirements"

2. Check that all parts are now installed. If there is an extra part,

go back through the steps.

3. Check that you have all of your tools.

4. Dispose of/recycle all packaging materials.

5. Check that the water faucets are on.

6. Check for leaks around faucets and inlet hoses.

Electric Shock Hazard

This washer/dryer must be earthed.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electric shock.

8. To test and to clean your washer, measure 1/2 the detergent

manufacturer's recommended amount of High Efficiency (H E)

detergent for a medium-size load. Pour the detergent into the

detergent dispenser. Select any cycle and allow the washer to

complete one whole cycle.

9. Check dryer operation. Using a full heat cycle, let the dryer run

for at least five minutes. Dryer will stop when time is

used up.

NOTE: Dryer door must be closed for dryer to operate. When door

is open, dryer stops, but timer continues to run. To restart dryer,

dose door and push cycle button.

If the burner does not ignite and you can feel no heat inside

the dryer, shut off dryer for five minutes. Check that all supply

valve controls are in "ON" position and that the electrical cord is

plugged in. Repeat five-minute test.

7, Plug into a grounded outlet, or connect power.

23

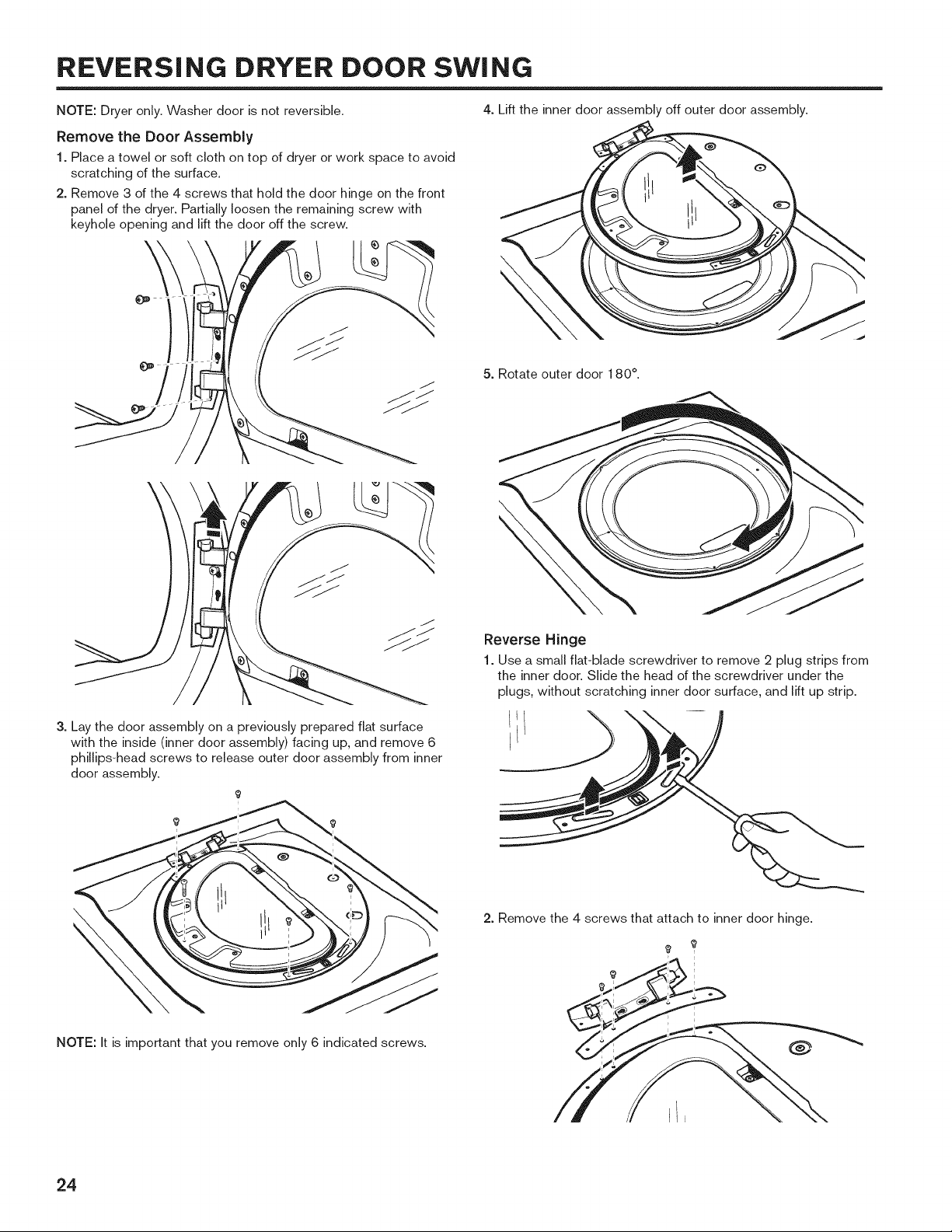

REVERSING DRYER DOOR SWING

NOTE: Dryer only. Washer door is not reversible.

Remove the Door Assembly

1. Place a towel or soft cloth on top of dryer or work space to avoid

scratching of the surface.

2. Remove 3 of the 4 screws that hold the door hinge on the front

panel of the dryer. Partially loosen the remaining screw with

keyhole opening and lift the door off the screw.

\

4. Lift the inner door assembly off outer door assembly.

5. Rotate outer door 180 °.

3. Lay the door assembly on a previously prepared flat surface

with the inside (inner door assembly) facing up, and remove 6

phillips-head screws to release outer door assembly from inner

door assembly.

NOTE: It is important that you remove only 6 indicated screws.

Reverse Hinge

1. Use a small flat-blade screwdriver to remove 2 plug strips from

the inner door. Slide the head of the screwdriver under the

plugs, without scratching inner door surface, and liftup strip.

2. Remove the 4 screws that attach to inner door hinge.

24

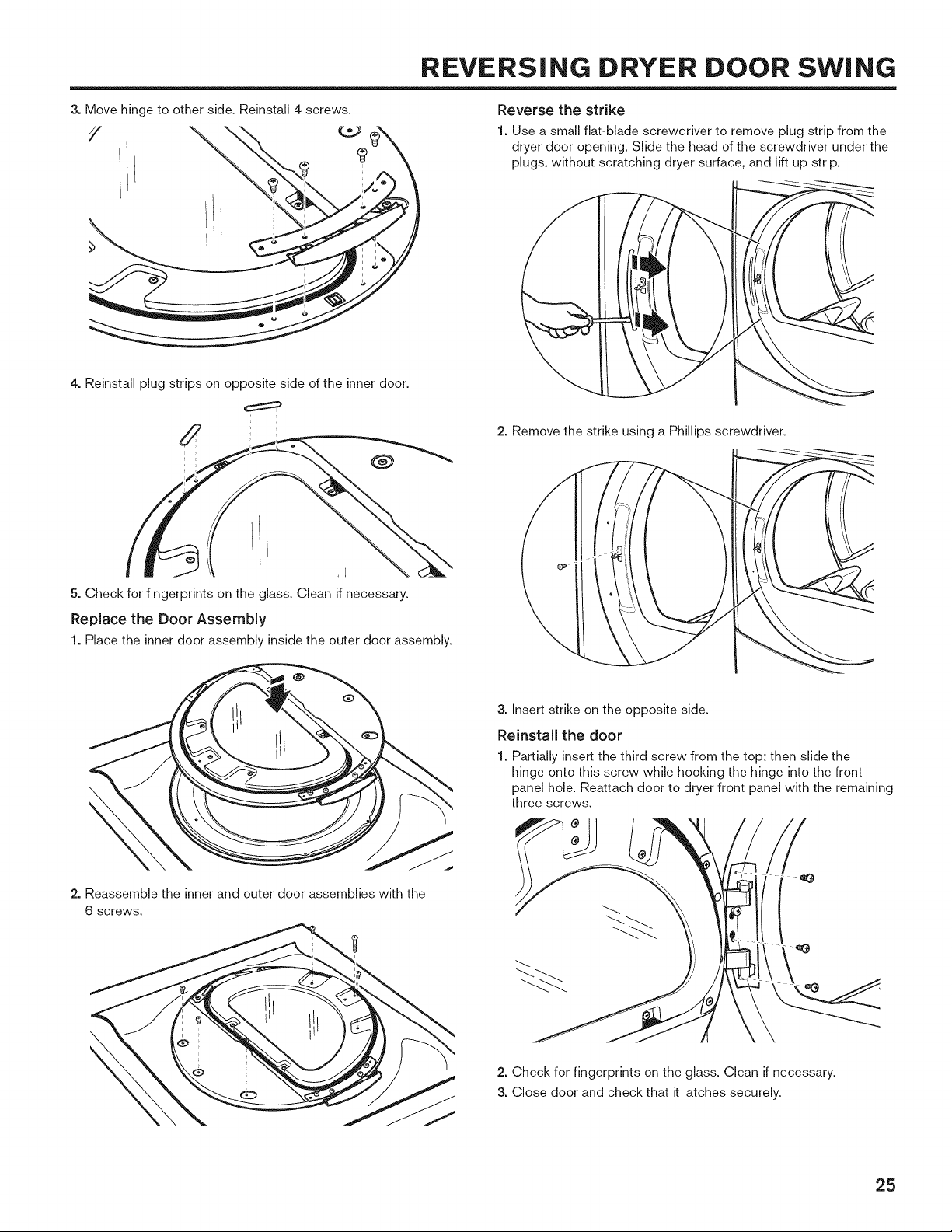

REVERSING DRYER DOOR SWING

3. Move hinge to other side. Reinstall 4 screws.

4. Reinstall plug strips on opposite side of the inner door.

I

,I

5. Check for fingerprints on the glass. Clean if necessary.

Replace the Door Assembly

1. Place the inner door assembly inside the outer door assembly.

Reverse the strike

1. Use a small flat-blade screwdriver to remove plug strip from the

dryer door opening. Slide the head of the screwdriver under the

plugs, without scratching dryer surface, and lift up strip.

2. Remove the strike using a Phillips screwdriver.

2. Reassemble the inner and outer door assemblies with the

6 screws.

3. Insert strike on the opposite side.

Reinstall the door

1. Partially insert the third screw from the top; then slide the

hinge onto this screw while hooking the hinge into the front

panel hole. Reattach door to dryer front panel with the remaining

three screws.

2. Check for fingerprints on the glass. Clean if necessary.

3. Close door and check that it latches securely.

25

STACKEDWASHER/DRYER MAINTENANCEINSTRUCTIONS

Washer

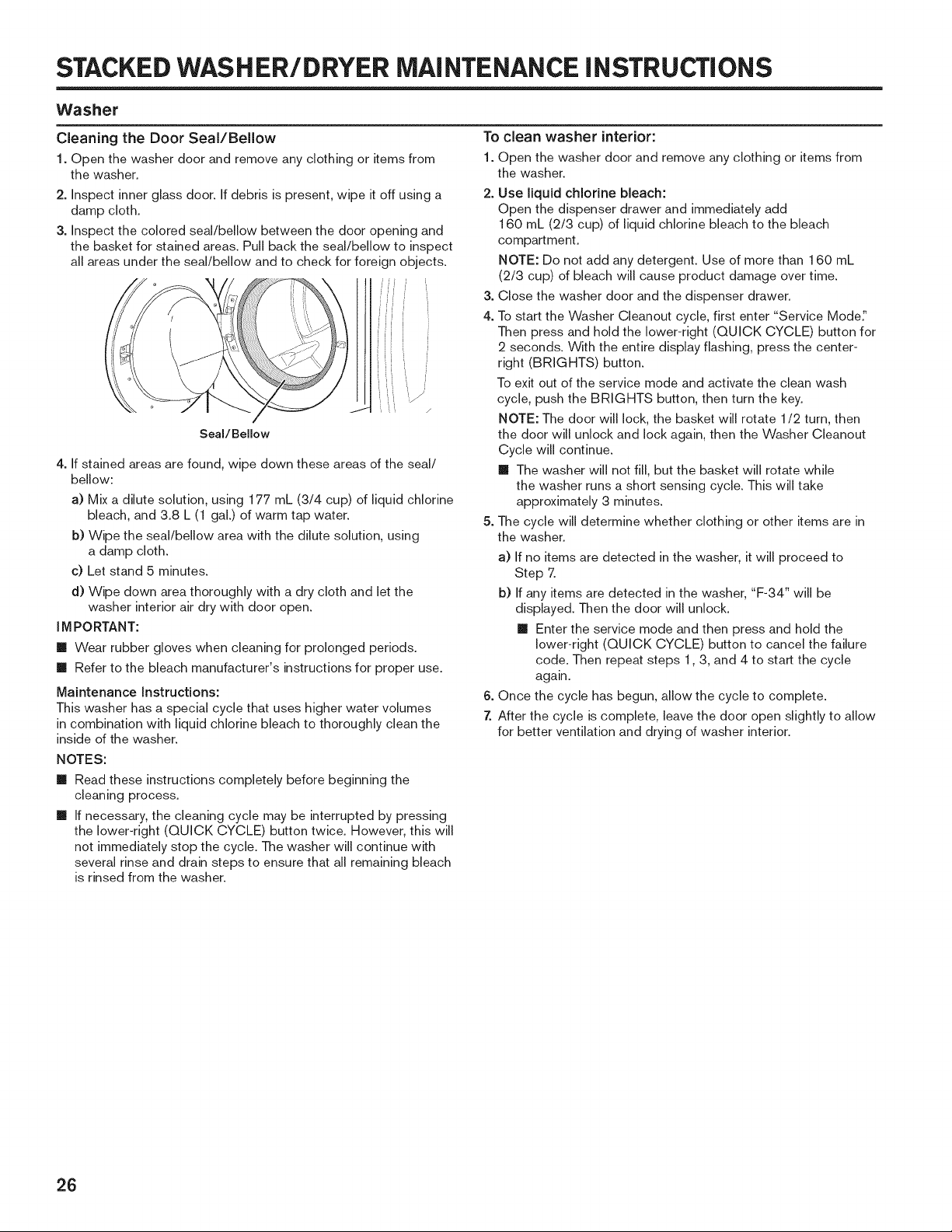

Cleaning the Door Seal/Bellow To clean washer interior:

1. Open the washer door and remove any clothing or items from

the washer.

2. Inspect inner glass door. If debris is present, wipe it off using a

damp cloth.

3. Inspect the colored seal/bellow between the door opening and

the basket for stained areas. Pull back the seal/bellow to inspect

all areas under the seal/bellow and to check for foreign objects.

J

Seal/Bellow

4. If stained areas are found, wipe down these areas of the seal/

bellow:

a) Mix a dilute solution, using 177 mL (3/4 cup) of liquid chlorine

bleach, and 3.8 L (1 gal.) of warm tap water.

b) Wipe the seal/bellow area with the dilute solution, using

a damp cloth.

c) Let stand 5 minutes.

d) Wipe down area thoroughly with a dry cloth and let the

washer interior air dry with door open.

IM PORTANT:

m Wear rubber gloves when cleaning for prolonged periods.

m Refer to the bleach manufacturer's instructions for proper use.

Maintenance Instructions:

This washer has a special cycle that uses higher water volumes

in combination with Jiquid chlorine bleach to thoroughly dean the

inside of the washer.

NOTES:

m Read these instructions completely before beginning the

cleaning process.

m If necessary, the cleaning cycle may be interrupted by pressing

the lower-right (QUICK CYCLE) button twice. However, this will

not immediately stop the cycle. The washer will continue with

several rinse and drain steps to ensure that all remaining bleach

is rinsed from the washer.

1. Open the washer door and remove any clothing or items from

the washer.

2. Use liquid chlorine bleach:

Open the dispenser drawer and immediately add

160 mL (2/3 cup) of liquid chlorine bleach to the bleach

compartment.

NOTE: Do not add any detergent. Use of more than 160 mL

(2/3 cup) of bleach will cause product damage over time.

3. Close the washer door and the dispenser drawer.

4. To start the Washer Cleanout cycle, first enter "Service Mode_'

Then press and hold the lower-right (QUICK CYCLE) button for

2 seconds. With the entire display flashing, press the center-

right (BRIGHTS) button.

To exit out of the service mode and activate the dean wash

cycle, push the BRIGHTS button, then turn the key.

NOTE: The door will lock, the basket will rotate 1/2 turn, then

the door will unlock and lock again, then the Washer Cleanout

Cycle will continue.

The washer will not fill, but the basket will rotate while

the washer runs a short sensing cycle. This will take

approximately 3 minutes.

5. The cycle will determine whether clothing or other items are in

the washer.

a) If no items are detected in the washer, it will proceed to

Step 7.

b) If any items are detected in the washer, "F-34" will be

displayed. Then the door will unlock.

m Enter the service mode and then press and hold the

lower-right (QUICK CYCLE) button to cancel the failure

code. Then repeat steps 1,3, and 4 to start the cycle

again.

6. Once the cycle has begun, allow the cycle to complete.

7. After the cycle is complete, leave the door open slightly to allow

for better ventilation and drying of washer interior.

26

STACKEDWASHER/DRYER MAINTENANCE iNSTRUCTiONS

Washer

Always do the following to maintain washer freshness:

m Use only HE High Efficiency detergent.

m Leave the door slightly open after each cycle to allow for better

ventilation and drying of washer interior.

m Clean the washer monthly using the Washer Maintenance

Procedure, using 160 mL (2/3 cup) of liquid chlorine bleach.

m If the procedure does not sufficiently improve the washer

freshness, please evaluate your installation and usage

conditions for other causes.

Cleaning the exterior

Use a soft damp cloth or sponge to wipe up any spills.

Occasionally wipe the outside of your washer to keep it looking

new. Use mild soap and water. Do not use abrasive products.

Cleaning the dispenser drawer

The dispenser drawer is removable for easy cleaning.

1. Unlock the dispenser drawer for removal by inserting a flat-blade

screwdriver into the catch release. Remove the dispenser drawer.

2. Remove the inserts (the siphon from the softener and bleach

compartments).

3. Wash the parts under running water.

NOTE: Do not wash components in the dishwasher.

4. Replace the inserts and return the dispenser to the drawer.

Water inlet hoses

Replace the inlet hoses after 5 years of use to reduce the risk of

hose failure. Periodically inspect and replace inlet hoses if bulges,

kinks, cuts, wear, or leaks are found.

When replacing your inlet hoses, record the date of replacement.

Dryer

Maintenance instructions:

* Clean lint screen before and after each cycle.

* Removing accumulated lint:

From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done

by a qualified person.

From the exhaust vent:

Lint should be removed every 2 years, or more often,

depending on dryer usage.

* Keep area around dryer clear and free from combustible

materials, gasoline and other flammable vapors and liquids.

* Keep dryer area clear and free from items that would obstruct

the flow of combustion and ventilation air.

If dryer does not operate, check the following:

, Electrical supply is connected.

* Circuit breaker is not tripped or house fuse is not blown.

, Door is closed. Listen closely to hear the door switch activate.

* Cycle selection button has been pushed firmly.

* For gas dryers, check that gas supply shut-off valves are set in

open position.

If you need help, contact the dealer from whom you purchased the

appliance, or a Maytag designated service company. When calling,

please know the purchase date and the complete model and serial

number of your appliance. This information will help us to better

respond to your request.

IF YOU NEED ASSISTANCE

Accessories

Enhance your washer/dryer with these premium accessories.

For more high-quality items or to order, contact your authorized

Maytag distributor.

Part Number Accessory

8212526 Washer drip trays; fits under all

31682 All-purpose appliance cleaner

1903WH Laundry supply storage cart

Whirlpool Corporation, Benton Harbor, Michigan 49022, U.S.A.

Manufacturer site: Whirlpool Mexico S.A. de C.V.,

Antigua Carretera a Roma Km 9, Col.

El Milagro, Apodaca, Nuevo Leon, C.R 66634, Mexico.

EU representative: Maytag UK Ltd, Redhill, RH1 lAX, UK

BAUKNECHT HAUSERGRATE Gmb H, D-73614 Schomdorf

27

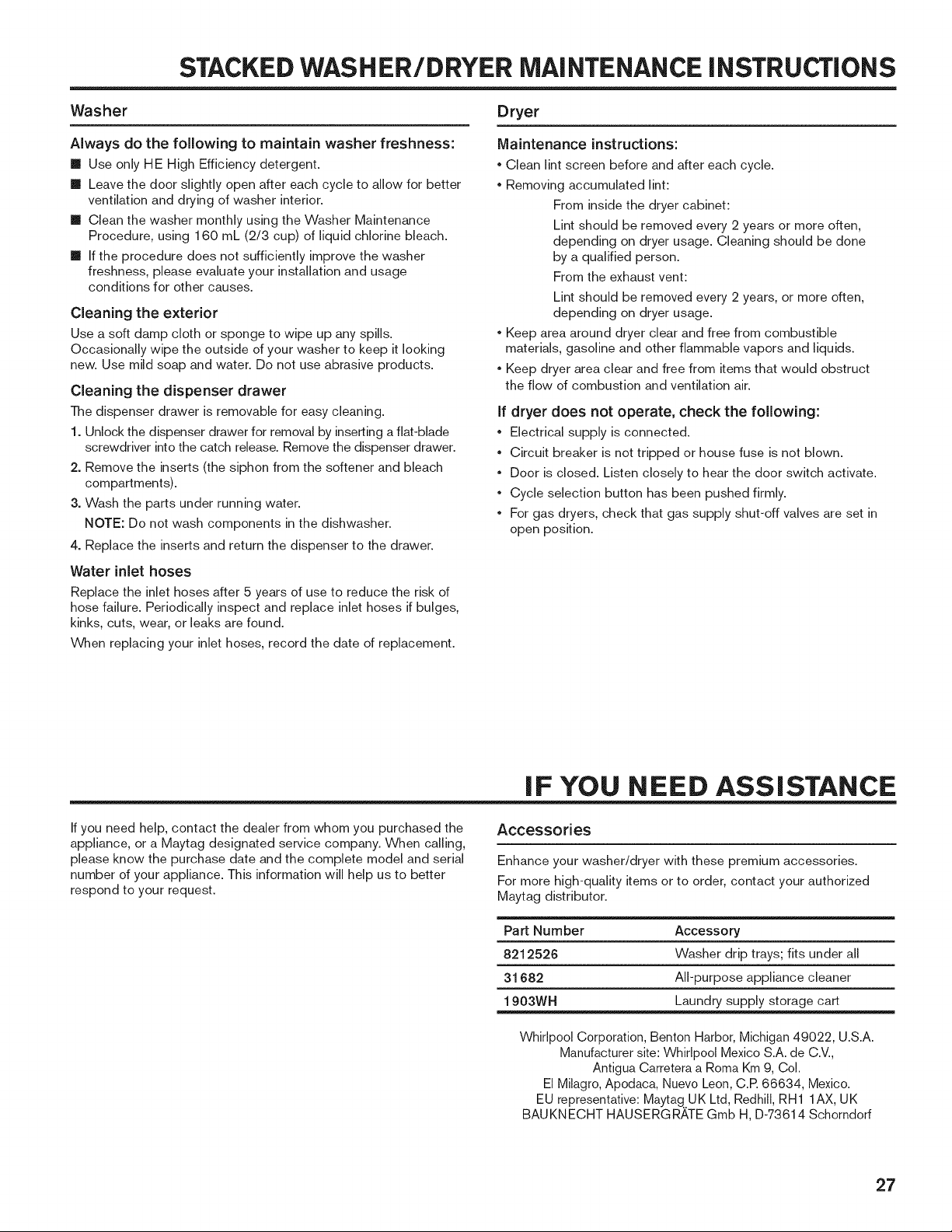

TECHNICALSPECiFiCATIONS - GAS DRYER

220=240V-50Hz lph 3A max. IP24 Clothes capacity: 9.0 kg max. Sound pressure level, Lpa: 58 dBA

(uncertainty, Kpa: +/-10 dBA)Total mass: 68 kg max.

European Country:

European Gas Category:

Gas Flow Rate:

Supply Pressure (G20)

Factory Adjusted Pressure:

European Country:

European Gas Category:

Butane Supply Pressure (G30):

Adjusted Pressure:

Propane Supply Pressure (G31):

Adjusted Pressure:

European Country: FR, BE

European Gas Category: _2E+

Supply Pressure (G20): 20 mbar

Supply Pressure (G25): 25 mbar

Adjusted Pressure: N/A

CH, CZ, CY, ES, GB, GR, HR,

IE, IT, PT, SI, SK, TR

112H3+

0.562703 m3/hr

20 mbar

7.4 mbar

CH, CZ, CY, ES, GB, GR, HR,

IE, IT, PT, SI, SK, TR

112H3+

28-30 mbar

N/A

37 mbar

N/A

CY, CZ, DK, EE, FI, GR, HU, IT, NO,

RO, SE, SK, TR

112H3B/P

0.562703 M3/HR

20 mbar

7.4 mbar

CY, CZ, DK, EE, FI, GR, HU, IT, NO,

RO, SE, SK, TR

112H3B/P

30 mbar

N/A

30 mbar

N/A

Country:

Supply Pressure (G20):

Adjusted Pressure (Test Point Pressure):

Nominal Hourly Gas Consumption:

Country:

Propane Supply Pressure:

Adjusted Pressure:

Nominal Hourly Gas Consumption:

NOTE: Conversion kit: From Natural Gas to LP Gas - Europe: Whirlpool Part No. W10233219.

Conversion kit: From Natural Gas to LP Gas - Australia: Whirlpool Part No. W10315369.

Conversion kit: From Natural Gas to Natural Gas - France/Belgium: Whirlpool Part No. W10181947.

Manufacturer: Whirlpool Corporation, Benton Harbor, Michigan 49022, U.S.A.

Manufacturing Site: Whirlpool Corporation, 1300 Marion=Agosta Rd., Marion, OH, 43302, U.S.A.

EU Representatives: Maytag UK Ltd., 2 St. Annes Blvd., Redhill, RH1 lAX, UK

& Bauknecht Hausgerb.te GmbH, D-73614 Schorndorf, Germany

AS, NZS

minimum 1.13 kPa

0.74 kPa

21.1 MJ/h

AS, NZS

2.75 kPa

2.75 kPa

23 MJ/h

28

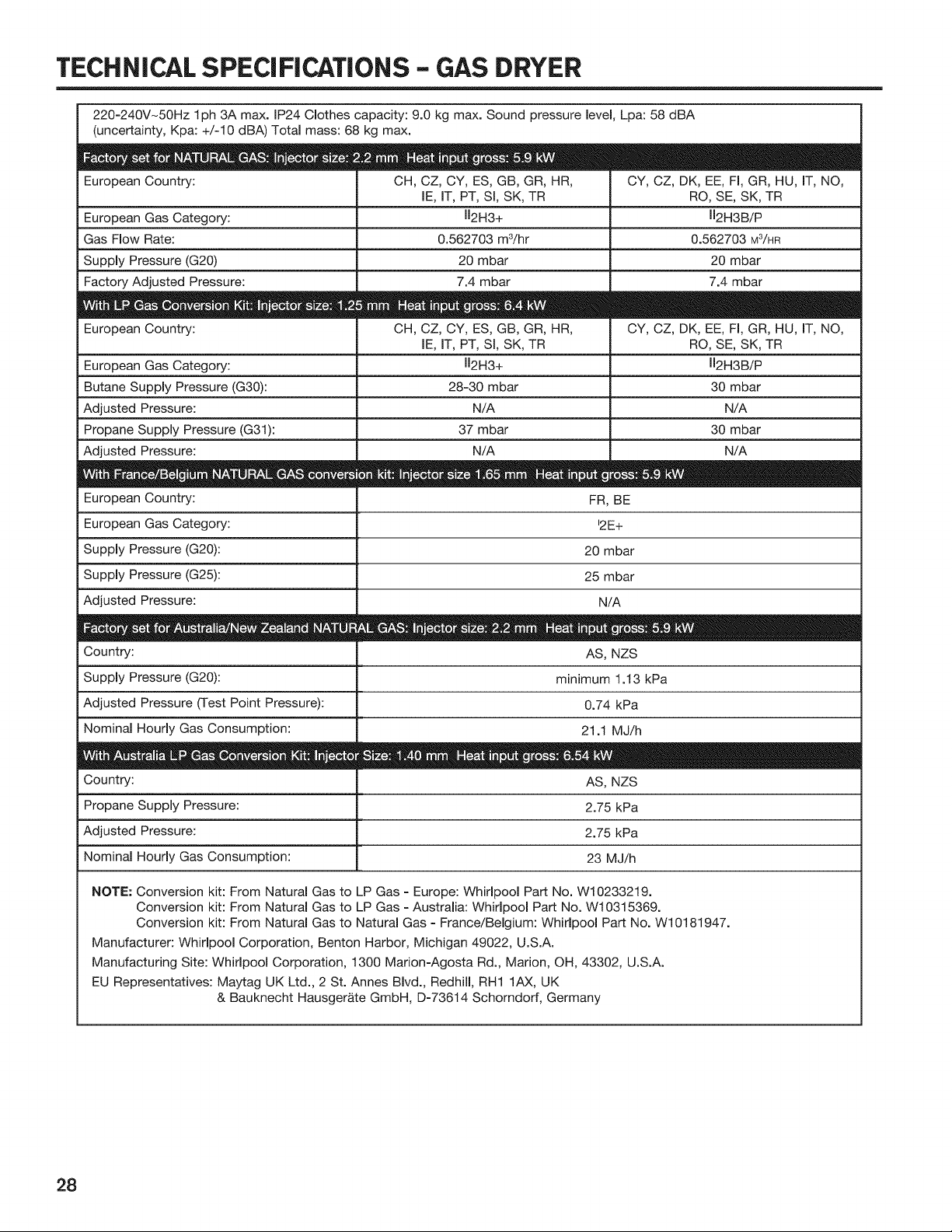

ELECTRONIC CONTROL SETUP iNSTRUCTiONS

Washer Control

NOTE: After the washer/dryer has been installed and plugged

in, the display will show "0 MINUTES" on the washer and dryer

portions of the display. After the washer and dryer doors have

been opened and closed, the display will show the price for each

machine. On washer/dryers set for free cycles, the display sections

will flash "SELECT CYCLE'

1. PD Models: Insert coins until "SELECT CYCLE" flashes on the

display portion of the washer or dryer that is to be run.

PN Models: A debit card is required rather than coins.

Generation 1 or 2 debit card systems may be used; but

when the Generation 2 debit system is used, the controls

will automatically be set to Enhanced Debit mode (J. Ed). In

Enhanced Debit mode, the card balance will also display when

a debit card is inserted into the reader.

2. Door must be closed on the desired washer/dryer before cycle

selection is made.

3. Press the fabric setting button for the washer/dryer cycle

desired. After the cycle is started, the time will display and

count down.

4. If a cycle is interrupted by opening the door or power loss,

"RESELECT CYCLE" will flash in the display. To restart the

washer/dryer, close door and reselect desired cycle.

NOTE: When set for free vend operation an ongoing dryer cycle

will cancel if the door is opened.

Dryer Control

General Washer/Dryer User Information

SCROWNG "OUT OF ORDER" MESSAGE, FOLLOWED BY A

FAILU RE OR DIAGNOSTIC CODE, SHOWING IN DISPLAY - This

condition indicates the washer/dryer is inoperative. Diagnostic

codes being displayed on the upper portion of the display pertain

to the dryer section, and diagnostic codes displayed on the lower

portion of the display apply to the washer section. Diagnostic

codes displayed on both the upper and lower portions of the

display pertain to the control system of both the washer and dryer.

"0 MINUTES" SHOWING IN DISPLAY - This indicates the cycle

is complete and the washer/dryer cannot be operated. Coins

dropped or debit inputs during this condition will be stored in

escrow but cannot be used until normal operation is restored by

opening and closing the door. If a door switch has failed, causing

"0 MINUTES" to remain in the display after the door is opened

and closed, it must be replaced before normal operation can be

restored.

COLD START (Initial first use) - Washer/dryer is programmed at

the factory as follows:

Washer 11 -minute wash period

1.75 wash price (PD models)

0.00 wash price (PN models)

3 rinses (extra rinse not enabled)

Dryer 5 minutes per coin for PD models

45 minutes dry time for PN models

1.50 dry price (fixed cycle with top off - PD

Models)

0.00 dry price (fixed cycle - PN Models)

29

ELECTRONIC CONTROL SETUP iNSTRUCTiONS

WARM START (after power failure) - A few seconds after power

is restored, if a cycle was in progress at the time of the power

failure, "RESELECT CYCLE" will flash in the display, indicating

the need for a key press to restart washer or dryer.

WASHER DOOR LOCK - Prior to beginning a cycle, there is a

door lock routine of Iock/unlock/relock, then cycle begins. The

door will remain locked until the end of a cycle or approximately

2 minutes after a power interruption.

PRICING - After the door is opened and then closed following

the completion of a cycle, the display indicates the cycle price

(unless set for free operation, where the display will flash "SELECT

CYCLE"). As coins are dropped or debit inputs arrive, the display

will change to lead the user through the initiation of a cycle.

There are four (4) types of dryer pdcing:

Fixed "Vend" Pricing

A dryer setup for "Fixed Cycle" operation can only accept

additional time accumulated by increments equal to the length of a

complete dry cycle. A maximum of 99 minutes may be purchased;

no additional credit is given for coins dropped with 99 minutes in

the display.

Accumulator Pricing

If the price is set to one coin 1, then accumulator pricing is

in effect. Cycle time can be purchased one coin at a time

(PD models) up to the maximum time of 99 minutes.

Fixed Cycle With Top Off Pdcing

A dryer set to offer "Top Off" capability will allow time to be added

to an existing dry cycle in increments equal to the number of

minutes of dry time per coin (coin 1), up to 99 minutes, regardless

of the cost required to start the dryer. No credit is given for coins