Maytag MHW2000AWA, MHW2000AWW, MUG2000AXA, MUE2000AYA, MUG2000AWW Installation Instructions

...Page 1

NIAYI'AG STACKED WASHER/DRYER

_,o INSTALLATION INSTRUCTIONS

The installation, including a proper exhaust system, is the responsibility of the owner.

LEAVE THESEINSTRUCTIONSWITHTHEOWNER

PrintedinU.S.A. 6 2708140-0498

Page 2

Read this before you start...

• Teflontape or pipejoint • Level

compound (gas) • Screwdriver (standard)

• Cutting knife • Ducttape

• Pipe wrench(gas) • Crescentwrench

TOOLS needed for installation

• Ratchet • 3/8" deepwell socket

___,(_)_1 • 5/16" socket (electric- U.S.only)

• 5/16" nutdriver

Electric Washer/Dryer Only Gas Washer/Dryer Only

ITEMS PROVIDED 0

Makesure you have everythingnecessaryfor proper installation.

1. GROUNDEDELECTRICALOUTLET isrequired. SeeElectrical Requirementsstartingon page 6.

2. POWERCORDSfor electricdryers (except Canada).

3. GASLINES (if a gasdryer) mustmeet Nationaland LocalCodes.

4. EXHAUSTSYSTEM- use rigid metal or flexible metalexhaust ducting. See Exhaust Requirementsin

this section.

5. UTILITIESSHUT OFFS (electric,gas andwater) mustbe accessibleafterinstallation.

NOTE: Dryerdoor reversalinstructionsare on page 23 items 58 and 59.

27"

I, 69.9 cm • I

27V2"

Location Location

of Canadian of Canadian

terminal terminal

block

_5/16" _cationo yer terminal I,

2.4 block on electric models _' ___ L- 3/4"

Gas Manifold (except Canadian)

Connection on gas moaeJs _,'_

395/32" .95 cm

washer drain hose valve connections 69.9 cm

washer water I 27_/2"

block

(electric 1 _8,:_,._

models) .v _,.,} Dryer

and power supply cord _ I-tl.9 cm

711/2" 2.9 cm

81.6 cm

3/8"rain. Washer

Page 1

/

--,. . 1_18"

Page 3

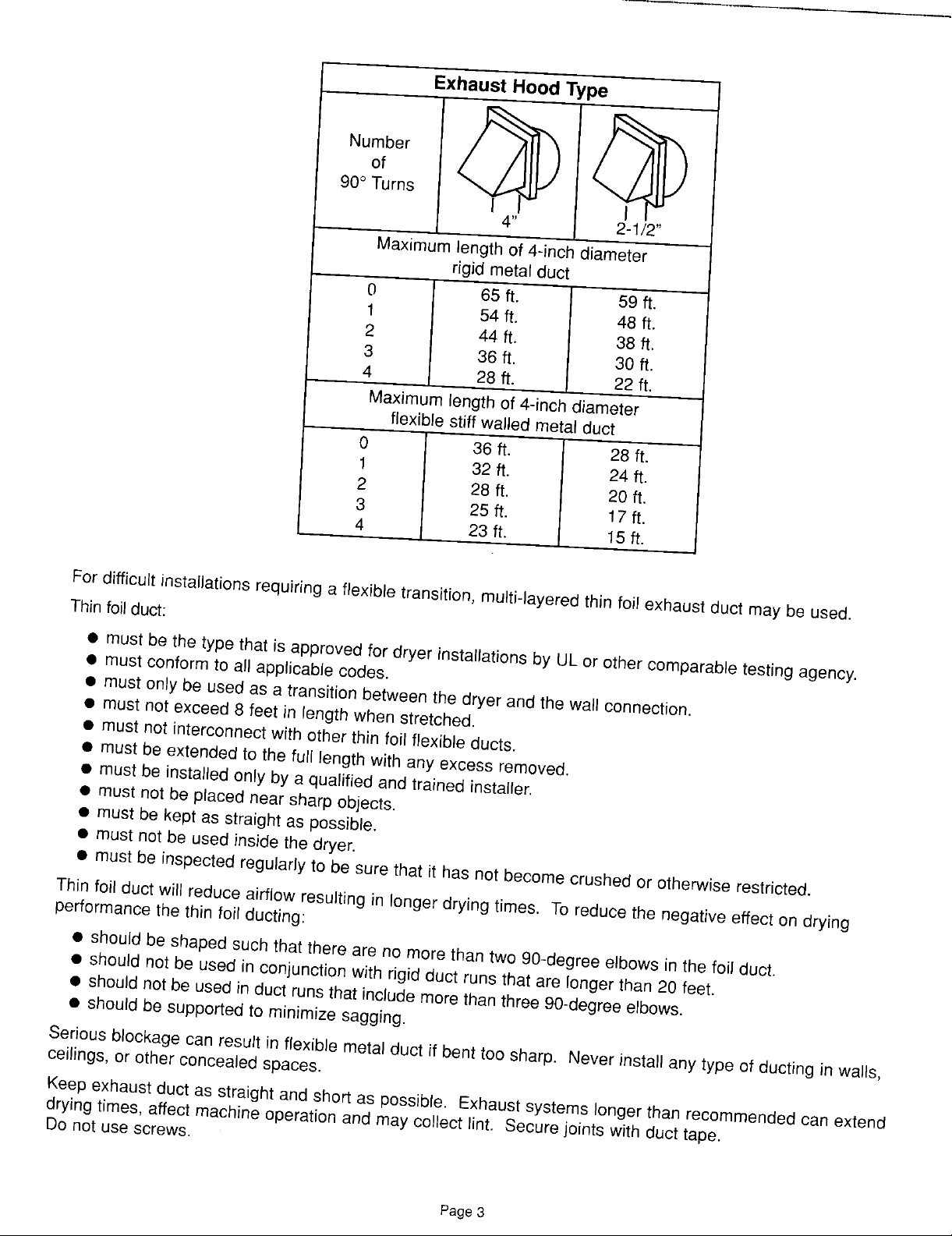

Exhaust Hood Type

90° Turns

4" 2-1/2"

Maximumlength of 4-inchdiameter

rigid metal duct

0 65 ft. 59 ft.

1 54 ft. 48 ft.

2 44 ft. 38 ft,

3 36 ft. 30 ft.

4 28 ft. 22 ft.

Maximumlengthof 4-inchdiameter

flexiblestiff wailedmetal duct

0 36 ft. 28 ft.

1 32ft. 24ft.

2 28ft. 20ft.

3 25 ft. 17ft.

4 23ft. 15ft.

Fordifficultinstallationsrequiringa flexibletransition, multi-layeredthin foil exhaust ductmay be used.

Thinfoil duct:

• must be the type that isapproved fordryer installationsby ULor other comparabletesting agency.

• must conformto allapplicablecodes.

• must only be used as atransition betweenthe dryer and the wallconnection.

• must not exceed8 feet in length when stretched.

• must not interconnectwith otherthin foil flexibleducts.

• must be extendedto the full lengthwith any excessremoved.

• must be installedonly by a qualified and trained installer,

• must not be placed near sharpobjects.

• must be kept as straightas possible.

• must not be used inside the dryer.

• must be inspectedregularlyto be surethat it has not becomecrushedor otherwiserestricted.

Thinfoil ductwill reduce airflow resultingin longer dryingtimes. To reducethe negativeeffecton drying

performancethe thin foilducting:

• shouldbe shaped such that thereare no morethan two 90-degree elbows in the foil duct.

• shouldnot be usedin conjunctionwith rigid duct runsthat are longer than 20 feet.

• shouldnot be usedin duct runsthat includemorethanthree90-degreeelbows.

• shouldbe supportedto minimizesagging.

Seriousblockagecan resultin flexible metal ductif benttoo sharp. Neverinstall anytype of ducting in walls,

ceilings,or otherconcealedspaces.

Keepexhaustduct as straight andshort as possible. Exhaust systemslonger than recommendedcanextend

dryingtimes,affectmachine operationand may collect lint. Securejoints with ducttape.

Donot use screws.

Page 3

Page 4

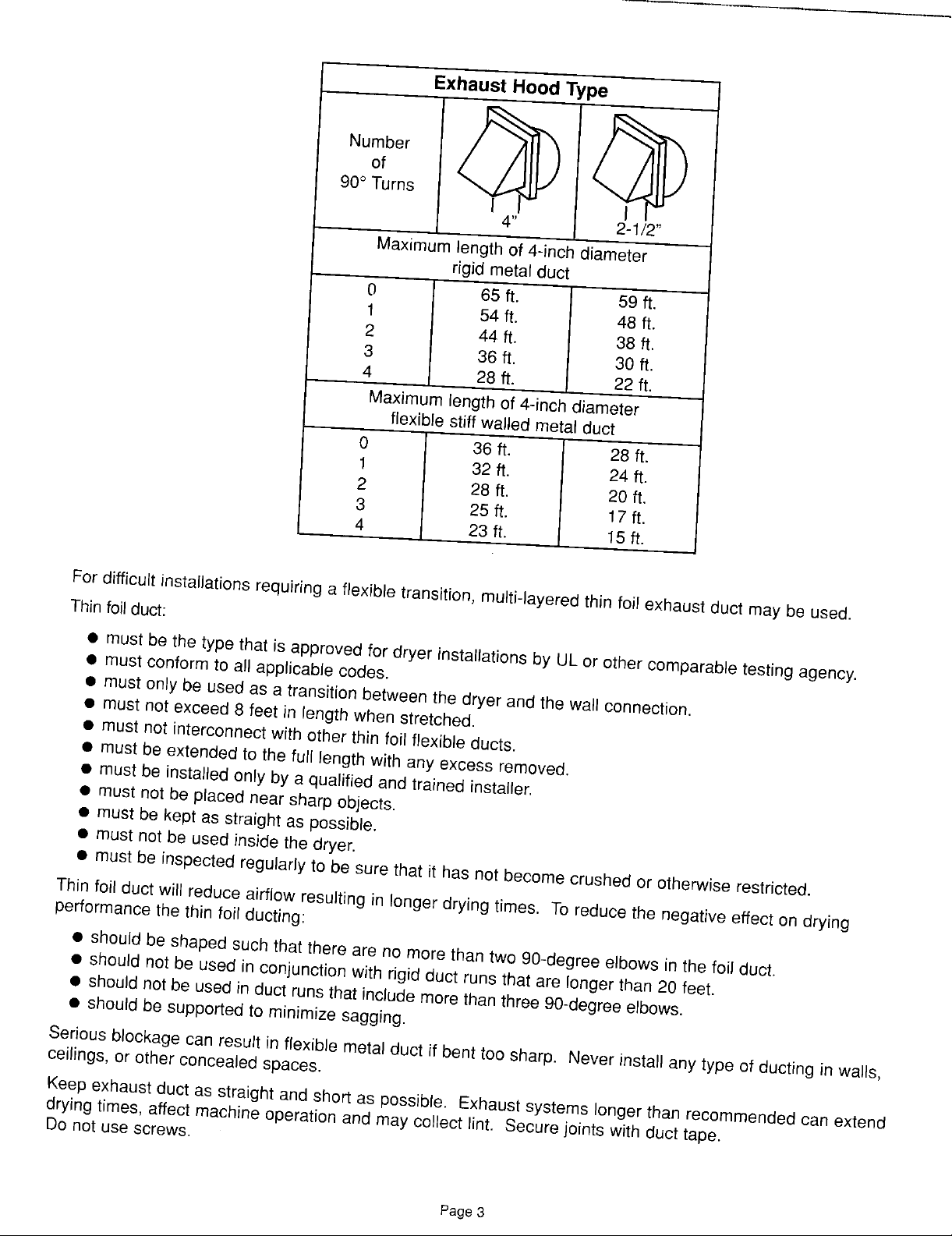

Exhaust Hood Type

90° Turns

4" 2-1/2"

Maximumlength of 4-inchdiameter

rigid metal duct

0 65 ft. 59 ft.

1 54 ft. 48 ft.

2 44 ft. 38 ft,

3 36 ft. 30 ft.

4 28 ft. 22 ft.

Maximumlengthof 4-inchdiameter

flexiblestiff wailedmetal duct

0 36 ft. 28 ft.

1 32ft. 24ft.

2 28ft. 20ft.

3 25 ft. 17ft.

4 23ft. 15ft.

Fordifficultinstallationsrequiringa flexibletransition, multi-layeredthin foil exhaust ductmay be used.

Thinfoil duct:

• must be the type that isapproved fordryer installationsby ULor other comparabletesting agency.

• must conformto allapplicablecodes.

• must only be used as atransition betweenthe dryer and the wallconnection.

• must not exceed8 feet in length when stretched.

• must not interconnectwith otherthin foil flexibleducts.

• must be extendedto the full lengthwith any excessremoved.

• must be installedonly by a qualified and trained installer,

• must not be placed near sharpobjects.

• must be kept as straightas possible.

• must not be used inside the dryer.

• must be inspectedregularlyto be surethat it has not becomecrushedor otherwiserestricted.

Thinfoil ductwill reduce airflow resultingin longer dryingtimes. To reducethe negativeeffecton drying

performancethe thin foilducting:

• shouldbe shaped such that thereare no morethan two 90-degree elbows in the foil duct.

• shouldnot be usedin conjunctionwith rigid duct runsthat are longer than 20 feet.

• shouldnot be usedin duct runsthat includemorethanthree90-degreeelbows.

• shouldbe supportedto minimizesagging.

Seriousblockagecan resultin flexible metal ductif benttoo sharp. Neverinstall anytype of ducting in walls,

ceilings,or otherconcealedspaces.

Keepexhaustduct as straight andshort as possible. Exhaust systemslonger than recommendedcanextend

dryingtimes,affectmachine operationand may collect lint. Securejoints with ducttape.

Donot use screws.

Page 3

Page 5

DONOT exhaustdryer into any wall, ceiling, crawl spaceor a concealedspace of a building,gas vent,

or any other common ductor chimney. This could createa fire hazardfrom lint expelled by the dryer.

The exhaustductshould end withan exhaust hoodwith a swingout damperto prevent backdraftsand entry

of wildlife. NEVER use an exhausthood with a magneticdamper. The hood should haveat least 12inches

of clearance betweenthe bottom of the hood andthe groundor otherobstruction. The hoodopeningshould

pointdown. NEVERinstall a screenoverthe exhaustoutlet.

Whenpossible,do notexhaust the dryer directly intoa windowwell in orderto avoid lint build-up. Do not

exhaustundera houseorporch.

If exhaustductworkmust run through an unheated area,the duct shouldbe insulated and slope slightlydown

towardsthe exhaust hoodto reducecondensationand lint build-up.

If an existingexhaust system is to be used withyour dryer(s)you must be sure:

• The exhaustsystem meetsall local,state and national codes.

• That plasticflexibleduct is not used.

• To completelyinspect and cleanall lint accumulatingfrom the interiorof the duct.

• The ductis not kinkedor crushed.

• The exhaust hooddamperopens andcloses freely.

Inspectand cleanthe interiorof the exhaust system at leasttwice a year. Disconnectelectricservice priorto

cleaning. Check gas line on gasdryers anytimethe dryer is moved.

Frequentlycheckto be sure the exhausthooddamper opensand closes freely.

WASHER REQUIREMENTS

Waterpressureof 20to 120 p.s.i,is requiredto correctlyfill the washerto the proper levels.

DRAIN FACILITY

Recommendedheightof the stand pipe is 36 inches. Ifthe stand pipe is less than 36 incheshigh,the drain

hoseshould be routedthroughthe clip to raise the hoseto the properheight. Standpipe must be large

enoughto acceptthe outsidediameterof the drain hose.

Without the 36 inches high elevation, water may run out of the washer prematurely. Shouldthe washer

fill and drain atthe sametime could indicatethat the drain hosehas notbeen elevatedto the properheight.

Thedrain hose is attachedat the factory.

FLOORING

For bestperformancethe washer must be installedon a solidly constructedfloor. Wood floors may needto

be reinforcedto minimizevibration and/or unbalancedloadsituations. Carpeting and softtile surfacesare

contributingfactorsin vibration and/ortendency for awasher to moveslightly during the spin cycle. Never

installthe washer on a platform or weak supportedstructure.

LOCATION CONSIDERATIONS

It is recommendedthewasher never be installedin areaswhere water may freeze sincethe washer will

always maintainsome water in the watervalve, pumpand hose areas. This can cause damage to belts,

pump, hosesand other components. Operatingtemperatureshould be above60°F.

Page4

Page 6

GAS REQUIREMENTS

Useonly Naturalor LP (liquidpropane) gases.

THE INSTALLATIONMUSTCONFORMWITHLOCALCODES,OR IN THEABSENCEOF LOCALCODES,

WITHTHE NATIONALFUELGAS CODEANSI/Z223.1, LATESTREVISION(FORTHE UNITEDSTATES),

OR WITHTHE CAN/CGA-B149INSTALLATIONCODES(FOR CANADA).

A gas dryer is equippedwith a burner orifice for operation on NATURALgas. If the dryer is to be operated

on LPgas, it mustbe convertedfor safe and proper performanceand mustbe converted by a

qualifiedservice technician. Conversionkits from NATURALto LP,or LP to NATURALareavailable

through your localdealer (seeAccessories). If other conversionsarerequired,check with the localgas utility

for specific informationconcerningconversionrequirements.

Eachdryerwill provide an input of 22,000 B.T.U.per hour.

A 1/2inchgassupply lineis recommendedandmust be reducedto connectto the 3/8 inchgas line onthe

dryer.

The internal gas shut-off isaccessedby removingthe access panel on the dryer. The shut-offis positioned

for easy accessnear the gasvalve.

The NationalFuelGas Code requiresthat an accessible,approvedmanual gas shut offvalve be installed

within 6feet of the dryer.

Additionally,a 1/8 inch N.P.T.(NationalPipeThread) pluggedtapping, accessiblefor test gaugeconnection,

mustbe installedimmediatelyupstreamof the gas supplyconnectionto the dryer.

Thedryermustbe disconnectedfromthegassupply pipingsystemduringanypressuretestingofthesystem.

DO NOT re-useold flexible metalgas line. Flexiblegas line mustbe design certifiedby AmericanGas

Association(CGAin Canada). NOTE: Any pipejoint compoundused must be resistantto the actionof any

liquefiedpetroleumgas.

NOTE: Asa courtesy,most local gas utilitieswill inspect a gas applianceinstallation.

GAS IGNITION -

Thedryeruse anautomaticignitionsystemto ignitethe burner. There is no constant burning pilot.

GROUNDING

• Improperconnectionof the equipment-groundingconductorcan resultin a risk of

electricalshock. Checkwith a qualifiedelectricianor servicemanifyou arein

• Do not modifythe plug providedwith the appliance- ifit will not fitthe outlet,

havea properoutletinstalledbya qualifiedelectrician.

• Toprevent unnecessaryriskof fire, electricalshock or personalinjury,all wiring

and groundingmust be done in accordancewith the NationalElectricalCode

I 1_0 I doubtas to whetherthe applianceis properlygrounded.

the personalresponsibilityand obligation of the applianceowner to provideadequateelectrical services

forthis appliance.

• All gasinstallationsmustbe done in accordancewith the NationalFuelGas CodeANSI/Z223.1-Latest

Revision(forthe U.S.) orthe CAN/CGA-B149InstallationCodes-LatestRevision(forCanada) and local

codesand ordinances.

ANSI/NFPA,No.70-Latest Revision(for U.S.)or the CanadianElectricalcode

CSAC22.1-LatestRevision (for Canada)and localcodes and ordinances. It is

Page 5

Page 7

ELECTRICAL REQUIREMENTS WARNING- TOprevent

unnecessaryrisk of fire,

NOTE: Wiring diagram is located inside the access panel, electricalshock or

personalinjury,all wiring

Export models (not U.S. or Canada): and grounding must be

See Additional Instructionsfor Export Modelson the following done in accordance

pages, with local codes, with

the National Electrical Code,

GROUNDING ANSl/NFPA(for the United States)

or the Canadian Electrical Code

Eachdryer must be grounded. In the eventof malfunctionor CSAC22.1 (for Canada).

breakdown,the ground will reducethe risk of electricalshock by

providing a pathof leastresistancefor electricalcurrent.

Eachapplianceisequippedwitha cordhavinganequipment-grounding

conductoranda groundingplug. Theplug mustbe pluggedintoan

appropriateoutletthatis properlyinstalledandgroundedinaccordance

withall localcodesandordinances.

Do notmodifythe plugprovidedwith theappliance- if it will not fit the

GAS MODELS _

outlet,have a properoutlet installedby a qualified electrician.

If a separateground is requiredby local codes,anaccessorygroundwire and ground clamp isavailable. Con-

nectgroundwireto backof unitwiththecabinetgroundscrew and washertheground screwand washerar

foundinthe partspackage. Secureotherend of groundwire to a suitableexternalgroundconnection. The

wire maybe securedwith the clampto a groundedCOLDmetalwater pipe. NEVER CONNECTGROUND

WIRETO PLASTICPLUMBINGLINES,GAS LINESOR HOTWATERPIPES.

ELECTRIC MODELS

If a powercordis notused andtheelectricdryer isto be perma-

nentlywired,thedryer must beconnectedto a groundedmetal, WARNING: Improper

permanentwiringsystem;oran equipmentgroundingconductor connectionof the

mustbe run withthe circuitconductorsandconnectedto the equipmentgrounding

equipmentgroundingterminal, conductorcan result in

U.S.Electricmodelsareshippedwith a groundstrap connected

fromthe neutralterminalblockpostto theframeof eachdryer. If Checkwith a qualified

localcodesprohibitstheuse ofthe groundstrap,the dryer mustbe electricianor servicemanif youare in

groundedinaccordancewith localcodes, doubt asto whether the applianceis

properlygrounded.

Eachelectricdryermustbe connectedto a groundedmetal,

permanentwiringsystem;oran equipmentgroundingconductor

mustbe runwith the circuitconductorsandconnectedtothe

equipmentgroundingterminal.

a riskof electric shock.

ELECTRICALCONNECTIONS

BEFOREOPERATINGOR TESTING,follow all groundinginstructionsin GroundingSectionabove.

An individualbranch (or separate)circuit servingonly thisappliance is recommended. DO NOT USEAN

EXTENSIONCORD.

GAS MODELS - U.S. and Canada

A 120volt,60 HzAC,approvedelectricalsupply,witha 15amperefuse orcircuitbreakerisrequired.

Page 6

Page 8

ELECTRIC MODELS - U.S. and Canada

A 120/240volt, 60 HzAC approvedelectricalservice fusedthrougha 30amperefuseor circuitbreakeronboth

sidesofthe lineis requiredforthe dryeranda 120volt60 HzACapprovedelectricalsupplywith a 15ampere

fuseor circuitbreakerforthe washer.

Ifa powercord is used,the cord should be pluggedinto a 30 ampere receptacle.

U.S. ELECTRIC MODELS

The power cord is NOTprovidedwith U.S. electric model dryers.

IMPORTANT: Whenpermittedby localcodes, the dryerelectrical supply may be connectedby meansof a

newpowersupply cord kit, markedfor usewith clothesdryer, that is U.L.listed, ratedat 120/240volts

minimum,30 ampereswith three No. 10copperwire conductorsterminatedwith closedloop terminals,

open-endspade lugs with turnedup ends orwith tinned leads.

Donot reuse a power supplycordfrom an olddryer. The powercord electric supplywiring mustbe retained

at the dryercabinet with a suitable ULlisted strain relief.

Ifthe dryer is to be installedin an area where local codesdo not permitgroundingthrough neutral, onlya 4

conductorpower cord, ratedand terminatedas above,may be used.

120/208Volt Electrical Systems:

A U.S.electricwasher/dryermustbe convertedif it is to operateon a 120/208volt electricalsystem. A heating

elementconversionkitis availableforthe dryer along with a transformerforthe washer (seeAccessories).

CANADIAN ELECTRIC MODELS

All Canadian models are shipped with the power cord attached.

It is not permissible to convert a dryer in Canada to 208 volts,

Additional Instructions for Export Models

(not U.S. or Canada)

Contactthe distributorthat sold the appliance or: Maytag International,8700W. Bryn MawrAvenue,Chicago,

IllinoisUSA 60631,773-714-0100, for informationon product,shippingdamage,replacementpartsand

accessories.

Maytagmodels manufacturedfor operationon 60 HzAC are not designedfor useon 50 HzAC

electricalservice and conversionof the productfrom 60to 50 Hz operationis not recommended. For

additionalinformationon 50 Hz products,contact Maytag International.

The electricservice requirementscan befound on the data labellocated onthe front of the dryer behindthe

door.

EXPORT ELECTRIC MODELS

Exportelectricmodelsare manufacturedfor operationon either 230/240volt, 50 Hzor 220 volt, 60 Hz

approvedelectricservice. A two-wireapprovedelectricalservicewith a30 amperefuse or circuit breakeris

required. The dryer must be properlygroundedwith a groundwire.

IMPORTANT:When permitted by local codes,the dryer electricalsupply maybe connectedby meansof a

newpowersupply cord kit, markedfor use with clothes dryers, that is agencylisted, ratedat 240 volts

minimum,30 ampereswith two No. 10copper wire conductorsterminatedwith closedloop terminals,

open-endspade lugs with turnedup ends orwith tinned leads.

Donot reuse a power supplycordfrom an old dryer. The powercord or electricsupplywiring must be

retainedat the dryer cabinetwith a suitable agencylisted strain relief.

Page7

Page 9

ADDITIONALINFORMATION

REPLACEMENT PARTS AND ACCESSORIES

Ifthe dryer requiresreplacementpartsor accessories,contactyour local Maytagdealer fromwhom you

purchasedyourapplianceor:

MaytagCustomerService

240 EdwardsStreet, S.E.

Cleveland,Tennessee 37311

Phone615-472-3333,for informationon the nearestauthorizedMaytag PartsDistributor.

EXPORT MODELS

Contactthe CommercialDistributorfromwhom you purchasedyour applianceor:

MaytagInternational

8700 W. BrynMawrAvenue

Chicago, Illinois,USA 60631

Phone312-714-0100,for informationon the nearestauthorizedMaytagParts Distributor.

Page 8

Page 10

To install...

1•Carefullyremoveany packagingmaterialsfrom the outsideof the

washer. Set asidetwo cornerpostsfor installation. IMPORTANT:

Noticethat the hoses and powercord aretied upwith a shipping

strap. Thestrap should not be cut or removed until the machine

is readyto be installed.

Figure 1

2. Laytwo cornerposts behindthe washer and _ ___ -•

gentlytip the washerover on to itsback. 4L_____j..jiI if///

3. Usinga screwdriver,pry off the crate bottom

wire retainers(2) and removethe cratebottom

fromthe washer.

Figure2 Figure3

4. Locatetwo 1/2inch hexshippingbolts on bottomof

metalbase. Removeboth bolts, freeingthe tub and Shipping __

suspension. DONOTBEALARMEDas the lastbolt Bolts

restingagainstthe back of the washer.

is removed,the tub will jumpto a positionwhere it is _

5. Loosenthe four adjustablewasherlegs and lock nuts. Install

vinyl feetfound in installationpackage. Feetcan be more _--'---

easily installedwhen immersedin hotwater beforeinstalling.

Carefullyraise the washer backto an upright position.

6. At the installationsite, locatethe metal bucklesattachedto

the shippingstraps at backof washer. Carefullycut away

strapsnear both buckles,completely removingboth

bucklesfrom the washer.

Figure6 Figure7 removed.

Figure4 __'_

Pull loose straps

from backof washer

oneat a time until

all straps have been

Insertinlet hose screensin the ends of the hot and cold inlethoses. Screensare foundin the

miscellaneouspartspackage. Domedsurface is to facethe valve.

Page9

Page 11

7, Open the washerdoor 90degrees. Removethe tape holding the accesscover. (Seefigure 8.)

Removethe accesscover by slidingforward. DO NOT pull up. (Seefigure 9.)

Figure8 Figure9

8, Open the AccessoryCartonand removethe access panel. Discardshipping materials. Gas dryers

includea gas pipe assemblyin the carton. (Seefigures 10& 11.)

Figure 10 Figure11

For Gas Dryers: Removered and bluethreadprotectors fromgas pipe. Knockout square hole in rear of

supportand insert gas pipe throughhole. (See figures 12a-d.) Allow pipe to rest on inside

of support. (See figure 13.) Makesurevalve is closed. (Seefigure 13a.)

Page 10

Page 12

Figure 12a Figure 12b

Figure12c Figure12d

Figure13 Figure13a

Page 11

Page 13

9. For nonalcove installations, utilities and

venting can be connected after units are

stacked.

For alcove installations:

Securetheexhaustbrackettothe rearofthe

washerwith screwsprovided.

(Seefigures14,15& 16.)

Unsnaphosesfromplastic hosecaddy,leaving

caddyattachedto thebackofthe cabinet.

Connectfillhosestofaucets(hotwaterhoseis

the left hoseas youstandfacingthe front ofthe

washer). Insertthe drainhosein thestandpipe

recommendedheightof 36 inches,minimumof

24inches. Note: Ifdrainhoseisnotsecurein

thestandpipe, usea portionofthe shipping

strapto securethedrainhoseto thestand pipe. Figure 14

Makesurethatdrainhoseis securedto the hose

caddyafter installation.Fillhosesarenot to

besecuredtocaddy. Turnonwaterand checkfor leaks.

Moveunitintoposition,levelandtightenthe levelinglocknutsonthe legs. Securetheventpipeto the

exhaustbracket. (See figure 16.) MAKINGSUREFIRSTTHATOUTLETISNOTENERGIZED,plug

washerintooutlet.

Figure15 Figure 16

Page 12

Page 14

For gasdryers applyjoint compoundor about 1-1/2 wraps of Teflontape _ 1

over threadedconnectionon the end of the gas pipe. (See figure 17.)

An elbow is recommended,for additionaldepth, pointing downto allow

the unit to be locatedfurther back into the alcove. (Seefigure 18.)

Note: Pipejoint compoundmust be resistantto the action of anyliquefied

petroleumgas.

Add additionalfittingto connectthe 3/8 inch gaspipe to a female threaded

end of a 3/4 inchflexibleconnector makingsure the connectionis tight. Figure 17

(See figure 19.)

Makesuretheshutoffvalveon theendof thegas pipe is closedandconnectto the gassupply.

Opengas servicevalve and check all gassupply connectionsfrom servicevalveto shutoffvalve for

leaksusinga soap solution, DONOT use an openflame to checkfor

gas leaks. Ifbubbles occur,tightenthe connections and recheck.

NOTE: Asa courtesy,manylocal gas utilitieswill inspect a gas applianceinstallation. Check with your

local utility to see if this serviceis providedin your area.

NOTE: The minimumpermissiblegas (naturalor mixed)supplypressure forpurposesof input

adjustmentis 4.5 inchesof water.

1

Figure18 Figure 19

1 0, Laythe dryer on itsside using 2 of the

cardboardcornerpoststo protectthe side of

the cabinet. (See figure20.) Remove

protectivefilm from the control panel, and using

a 5/16 inch nut driver,removethe shipping

bolts (3) securingthe wood shippingbaseto

the bottom of the upperdryer.

Figure20

Page 13

Page 15

11, For gas dryers:

Removeyellowthread protectorfrom union. (See figure21.)

Positionthe dryerupright in front of the washer,with the rear of the dryer facingthe washer. To prevent

damageto floors do notslide the dryeron the floor!

NOTE: Forgasdryer alcove installation,plug powercord for dryer intoan outlet MAKINGSURE FIRST

THATOUTLETIS NOTENERGIZEDpriorto liftingdryer ontowasher.

Holdingthe baseto support bracket,removethe 2 #10 hexhead screwsand basesupport brackets

(notehowthe bracketsare inserted)located at the front of the dryer base,markedwith orange labels.

(See figures22 &23.) NOTE: Bracketsand screwswill be used later.

A protectiveconduit (plastic)is provided for the powercord. Installthe conduit overthe power cord.

The conduitis slit to facilitate installation. (See figure24.)

Yellow

Thread

Protector Hex Base

Head

Screw Bracket

Figure21 Figure22

Base

Su

Bracket

Figure23 Figure24

Page 14

Page 16

TO MAKE ELECTRICALCONNECTIONFOR U.S.DRYERS

Reviewelectricalrequirementsonpage 6 of theseinstructions.

12, For electricdryers: I

CONNECTION. The dryer frame is groundedto the neutralconductor

at the terminalblock. A 4-WIRE SYSTEMCONNECTIONis required

IMPORTANT- All U.S. modelsare producedfor a 3-WIRESYSTEM /®l _er_ I®

for new or remodeledconstruction,mobile homes, or if local codesdo

notpermit groundingthroughneutral. If the 4-wiresystem is used, _ _ |

the dryerframecannot be groundedto the neutralconductorat the / O

terminalblock. Referto the followinginstructionsfor 3- and 4-WIRE ,Figure 25

SYSTEMCONNECTIONS.

Removethe terminalblock coverplate. (See figure25.) I i

B

I

A protectiveconduit(plastic)is providedforthe powercord. Cutthe

conduitsothat it isapproximately18 inchesshorterthanthe power

cordandthreadthe power cordthroughthe conduit. (Seefigures26 &

27.)

Insertthe power cord with a U.L.listed strain reliefthroughthe hole Figure26

providedinthe cabinetnearthe terminal block. Note, a strain relief

must be used.

3-WIRE SYSTEM CONNECTIONS

Do not loosenthe nutsalready installedonthe terminal block. Be

sure they are tight. Usea 3/8 inch deep nut driver.

Ifthe powercord hasterminals,placethe terminals overthe existing

nutsonthe posts. The neutral (whiteor center wire on power cord) Figure27

conductormustalways be connectedto the center (silvercolored)

postofthe terminal block. 3-Wire System with

Cord Attached

Securein placeusingthe nuts providedin the parts oackage. If the ,__,,_Power

powercord does not haveterminals, use the cuppedwashers ahead

of the nuts. Ground

Besure the terminal blocknuts aretight. Secure the power cord in

position. Tightenthe strain reliefscrew(s) in order to clamp the strain

reliefto the cord. (See figure28.)

Replacethe terminalblock cover. Neutral

BEFOREOPERATINGOR TESTING,followthe grounding directions

on page 5. Strain

4-WIRE SYSTEM CONNECTIONS relief

Removetheground strapscrew fromthe terminal block support. Fold Figure28

the groundstrap over so bothends of the ground strap are attached

to the centerterminalblock post. 4-Wire System with

Connectthe neutral (white)conductorof the cord to the center (silver) Power Supply Attached

postof the terminal block. Connectthe grounding (green)wire of the

cord to the terminalblock supportusingthe groundstrap screw. -- ° Folded

Connectthe redand black wires of the cord to the outer posts ofthe Neutral _ _.'_'_ Ground

terminalblock. Post ----. __/ StrapBe surethe terminal blocknuts are ontight. Securethe power cord in

positiOn.reliefto theTightencord,the(seeStrainfigurerelief29.)screw(s)in order to clamp the strain •///__ /e NeutralReplacethe terminalblock cover. Strain

WARNING: If convertingfrom 4-wireelectricalsystemsto 3-wire,the o _ Relief

groundstrap mustbe reconnectedto terminalblock supportto ground (_ 4''/

thedryer frameto the neutral conductor. Figure29

Page 15

Page 17

2-WIRE AND GROUND SYSTEM CONNECTIONS

Removetheterminalblockcoverplate.

Insertthepowercordwithanagencylistedstrainrelief (" _

throughtheholeprovidedinthe cabinetneartheterminal _ o

block. Note,a strainreliefmustbe used. __

Donotloosenthenutsalreadyinstalledonthe terminal Neutral

block. Besuretheyaretight. Use a 3/8 inchdeepwell Post" Power

socket. Ground

supportusingthe groundscrew. (Seefigure 30.)

Ifthe powercord has terminals, placethe terminals over

Securethe powercord groundwiretothe terminal block _;Je ,Wire

the existing nuts on the posts. The neutralwire in power

cord mustbe connectedto the center (silvercolored Power

postofthe terminal block. Neutral o f-_ _. • and

Securein placeusing the nutsprovidedin the parts ("Ah JF"/- strain

usethe cuppedwashersahead of the nuts.

package. If the powercord does nothave terminals f relief

Be surethe terminal blocknuts aretight. Securethe Figure30

powercord in position. Tightenthe strainrelief screw(s)

in ordertoclampthestrainreliefto the cord.

2-Wire and Ground System

o o Cord

cord

Replacethe terminalblock cover.

BEFOREOPERATINGOR TESTING,be surethe machineis properlygrounded.

EXPORT GAS MODELS

Exportgas modelsare manufacturedfor operationon either 230/240 volt, 50 Hz or 220volt, 60 HzAC

approvedelectricalservicewith a 15amperefuse or circuitbreaker.

Exportgas models havebeen manufacturedfor use with natural gashaving a higher heatingvalue of approxi-

mately 1025 BTUpercubic foot. Conversionto LPgas with a higherheating value of approximately2500

BTU per cubicfoot must be performedby a qualified servicetechnician. A conversionkitis available.

For electric dryers in alcove installation:

MAKINGSURE FIRST THAT OUTLET IS NOT ENERGIZED,plugpowercordfor dryerintoan outletpriorto

liftingdryer ontowasher.

13.Makesurethat the exhaustseal is in placeand evenwith the end of the exhaustpipe.

(Seefigures31 & 32.)

Figure31 Figure32 Figure33

Makesurefront tabs are not bent, use screwdriverto straightentabs if bent. (See figure33.)

Page 16

Page 18

1 4, Two people,one on each side,grasp andliftthe dryeronto the washer(seefigure 34),takingcare not to

bendthe tabs locatedtowardsthe front of the washer. Slide the upperdryertowardthe rear makingsure

that theguidesfall betweenthe railson the supportof the washer. (Seefigure35.)

WARNING: Makesure POWERIS NOT SUPPLIEDTO OUTLETduringinstallation.

Whenplacing the dryeronto the washer, makesure the POWERCORDIS NOTPINCHEDbetween

the washer andthe dryer or betweenthe exhaust pipeand bracket. If the dryercannot be pushedall

the way back, check to see if the power cord is being pinchedbetween the back ofthe dryer and the

exhaust bracket.

Makesure that SHUT-OFFFOR UTILITIES(electric,gas and water) WILL BEACCESSIBLEafter the

applianceis installed.

Figure34 Figure35

15.Checkto make sure the tabson the washer are engagedin slots atthe front ofthe base ofthe dryer.

(See figures36 & 37 - somecomponents removedfor clarity.)

Front Right

Dryer

Base

O

Figure36 Figure37

Rotateforward to check engagement.

Page 17

Page 19

16.Insert the base to support brackets (removed in step 11) on both sides the upper base and secure with

the screws also removed in step 12. (See figures 38 & 39.)

.... " _" o ppL'u--or"

\\\

\\

Dryer _\_ -\

Base - _

"/ Tab /_

...., _; Screw

,\

Figure 38 Figure 39

17.Raise gas pipe with shut off valve up and secure to gas valve union• (See figure 40.) Tighten fitting

with a crescent wrench being careful not to over tighten. (See figure 41.)

Do not apply teflon tape or pipe sealing compound to the threads of the shut off valve. This is a

brass expansion sleeve fitting.

Figure 40 Figure 41

Page18

Page 20

18.Openthe gas shut offvalve inside the upperdryer (see figures 42 & 43), and check the union

connectionto the gas valve for leaksusinga soap solution,DO NOTuse an open flame to check for

gas leaks. If bubblesoccur,tighten the connectionsand recheck. Makesure notto let solutiondrip

into anyelectricalconnectoror component.

NOTE: As a courtesy,manylocal gas utilitieswill inspect a gas applianceinstallation. Checkwith your

local utilityto seeif this service is provided inyour area.

NOTE: The minimumpermissiblegas (naturalor mixed)supplypressure for purposesof input

adjustmentis 4.5 inchesof water.

Figure42 Figure43

19.Removewire harnessesand plastic clips from base (see figure44) andconnect each harnessto the

connectorin the washer makingsure lockingtabs areengaged, and harness is tucked out ofthe wayof

the dispenser. (Seefigures45 & 46.)

Figure45

7 ii_iii

Figure44

L

Figure 46

Page 19

Page 21

20, Removethe accesscover screw (see figure47),alongwith the orangelabel onthe accesscover. Make

sure emergencydoor releaseisaccessibleafteraccesscover isinstalled (Seefigures48 & 49.)

m

Figure47 Figure48

Figure49

21• Secure the accesscoverto the baseof the _"

upperdryer using a ratchetandthe #10 hex

head accesscover screw removedin step 20.

(See figure50.) NOTE: Apply rearward

pressureon the accesscover while applying

finaltorque to screw.

Figure50

Page 20

Page 22

22.Rotateaccesspanel intoposition, and securewith whiteor almondscrewssuppliedin the

miscellaneousparts package. (Seefigure 51.) Removeprotective filmfrom fasciaand tape from

edgesof control panel. (Seefigure 52.)

23.Removewasherand dryer timer knobsfrom miscellaneouspartspackage and insert them on the

respectiveshafts. NOTE: Timershafts are differentbetweenthe washerand dryer. (See figure53.)

.....

!

Figure51

Figure53

Figure52

24. For nonalcove installations (where there is access to the rearof the appliance):

Plug in powercordforthewasherand dryer.

Removethe 2 outerscrewsinthe backofthe cabinetclosesttothesides(see figure54) andsecure

the securitybrackets(2) to the uppercabinet. NOTE: Slottedholeis orienteddown. (See figure55.)

Do nottightenuntilthe nextstep iscompleted.

CabinetScrew Cabinet

Screw

Figure54 Figure55

Page 21

Page 23

Securethe other ends ofthe security brackets(2) to the support using #10 hex headscrews providedin

the miscellaneouspartspackage. (See figure 56.)

i

Figure56

Ifappliancehas notbeen leveled, moveit into position,check itwith a level and makethe necessary

adjustmentsto the levelinglegs. Once level,tighten the levelingleg lockingnuts with a wrench.

Connectthe exhaustducts to ductwork by insertingthe elbowwhile holdingontothe exhaust seal.

(Seefigure 57.)

Figure57

25. Removethe tape and cardboardprotectionfor the door on the lowerdryer.

Page 22

Page 24

26.Directions for reversingthe dryer door:

1. Removethe hinge holecovers and screws. Movethe door catchcover tothe oppositeside.

2. While supportingthe door, remove4 screws inthe hingesthat secure the hingesto the cabinet and

setthe door down.

3. Movethe following partsto the oppositeside of the door: 2 hinges and 4 hinge screws,4 door

screws,door strikeand screw,inner door cover plateand screw.

4. Attachthe doorto the oppositeside of the cabinet usingthe 2 countersunk hinge screws.

(Seefigure 58.)

5. Replacethe hingehole coversto the opposite side.

.-" .... "-. _ ' Door

/" _', _" _ %-- Screws

" "", str,ka

I I 1

t _,, Cover Coy ,

x _+ --uoor

• .---22-222222-222J _ Screws

'_,, _/[/Figure58 "

Door Catch Counter Sunk Screw

27.Directionsfor reversingthe washerdoor:

1. Swingdoor fully openand support it while removingfour hingescrews (whichhold hingesto door

assembly).

2. Setdoor asideandtransferfourcolormatcheddoorscrewstothe oppositeside ofthe doorassembly.

3. Removeonescrew holding top hinge to cabinet and one screw holdingtop hingecover to cabinet

(oppositeside).

4. Removehinge and bracketfrom cabinet by movingthem upand down to a positionwherethey are

released.

5. Installhinge and bracketin swappedlocationsand drivescrewsto attachthem securelyto the cabi-

net.

6. Comparetop hingeandtop bracketto bottom hingeand bottom bracketfor correctassemblyposi-

tion.

7. Repeatprocedures4 through 6 for bottomhingeto cabinetand bottom bracketto cabinet.

8. Supportdoor infully open position on hingeside and drive four screwsto secure attachhingesto

doorassembly.

9. Closedoor andcheck to see that clotheswasher operatesproperly.

// / / '/"_" Door

f _1 7it Hole I ng

I t I_t Covers

Counter Sunk Screw_,

Screws

Figure59

,,,,!,\_...... +++

"-_.!,\.,..___ _ _ .. / _ _ _ "_+ _' _ Screws

Page 23

Door

Page 25

INSTALLATION ACCESSORIES FINAL INSTALLATION CHECK LIST

i •Vent hood- 4" (10.16cm)opening- 059129 _ Instructionand InstallationKit havebeen

'_ •Aluminumpipe - 4" x 24" (10.16cmx 60.96cm) removedfrom dryer.

_ - 059130 [] Shippingboltsandstrapshavebeenremoved.

! , _ •Aluminumelbow- 4" (10.16cm)- 059131 [] Assurethatthedryer isslidback and is

,_ •Aluminumwindowplate - 15"x 20" (38.10cmx securedtothe washer.

50.80cm)-4" (10.16cm)hole- 059134 [] Vinyl feet havebeen installed.

i •Flexiblealuminumvent duct - 4" (10.16cm) [] Washer/dryeris levelwith all legs firmly on

ii diameter- 38" (81.28cm)length stretches to the floor,with the lock nutstightenedagainst

' 8' (2.44cm) 304353 the base.

! • Clampfor flexible aluminumduct - 304630 _ Drainhose is properlylocated into drain

_: •Exhaustduct kit for base or left sideexhausting facility,snapped into drain hosestrap and is

....ii - 33001881 nbt kinked.

•Rectangularventkits - 059144 [] Gas Models- gas is turned on,there are no

i, • Backdraft damper4"- 059146 gas leaks.

n

i! • NATURALto LPconversionkit [] Water is turned on and checked for leaks at

i - LPto NATURALconversionkit- 33001287 C]

30619_

faucet andwater valve connections.

Washerfills properly on all temperature

•Anchorbracket kit - 303740 selections.

_i • Heatingelementconversionkit, _ Exhaustduct work is hookedup andjoints

i_ 208v.,- 308590 (NOT FOR CANADA) taped.

ll •Groundingwire - 311155 [] Use rigidor stiffwalled flexible metalvent

!t •Ground clamp- 301548 material.

i! • Powercords - 240v, 30A [] Plasticflexibleduct is NOTused.

I_ 4' - 3-wire- 33001780 [] Washer and dryer areplugged into electrical

5' - 3-wire- 33001822 outlet and areproperly grounded.

6'- 3-wire - 33001823 [] Testfor properoperationby runningthe

10'- 3-wire- 33001838 washerthrougha complete cycle.

4' - 4-wire- 33001781

6'- 4-wire - 33001824 1. SelectCotton/Sturdy,Hot/Coldand Max

Extract. Makesure the Extra Rinse

6'-4-wire- 33001825 option is not selected.

2. Setthe timerintothe Heavy-Normal-Light

washband andpresstheStart/Stopbutton.

3. Verifythe washer isfilling fromthe hot

watervalve.

4. Verifythe washerstops filling.

5. PushStart/Stopto stop washer.

6. Set the timer intothe Final Rinse

incrementand pressthe Start/Stop

buttonto restart the washer.

7. Verifythe washer is filing fromthe cold

watervalve.

8. Verifythe washer stopsfilling.

9. Wait 30 seconds for the timerto advance

itself one increment intoSpin.

10. Verifythe washerspins. This will take

several minutesas the door needsto lock

and distributethe load. _-

11. Pullonthe doorto makesure it haslocked.

12. Resetthe washerto start position.

[] Dryer runs, heats,shuts off.

Page 24

Loading...

Loading...