Page 1

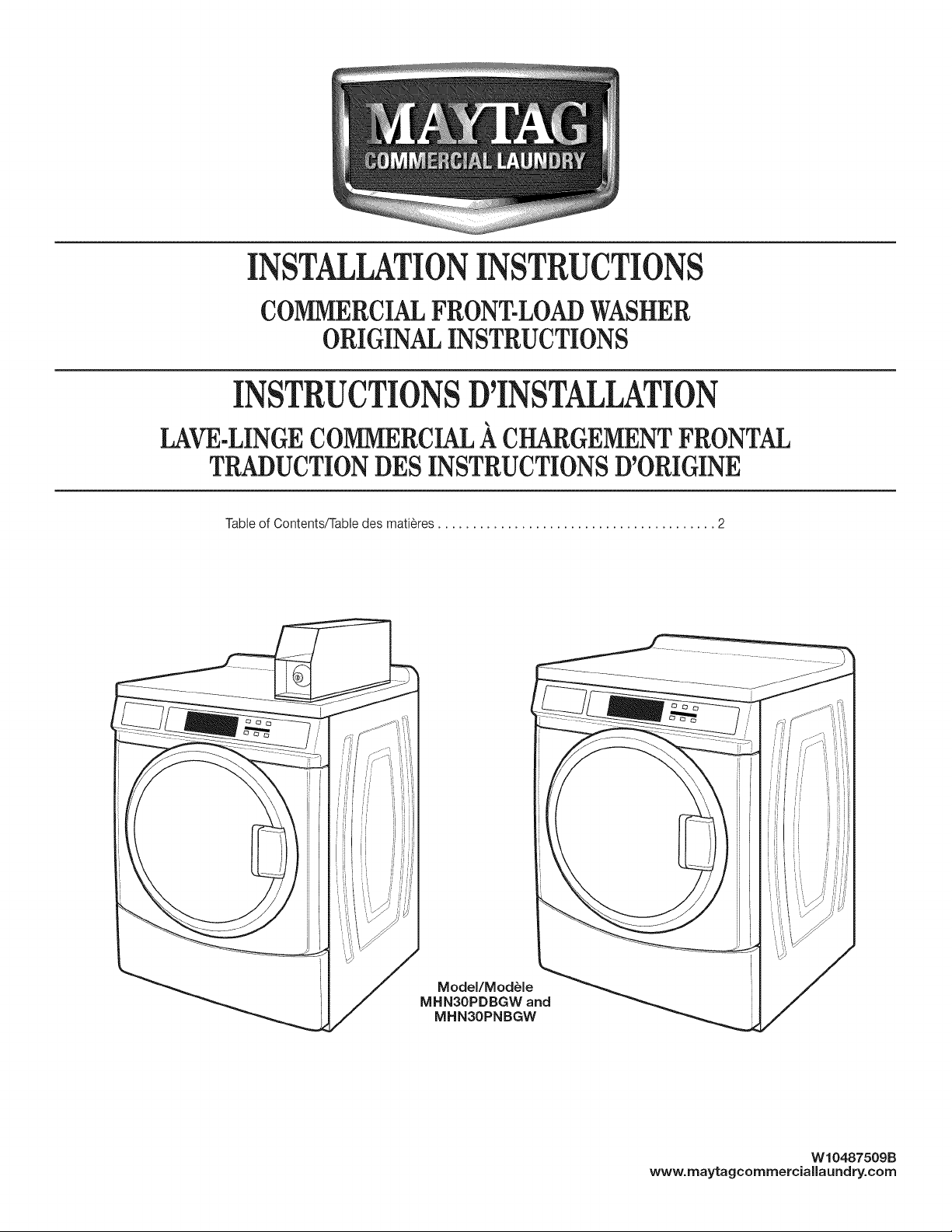

INSTALLATIONINSTRUCTIONS

COMMERCIALFRONT-LOADWASHER

ORIGINALINSTRUCTIONS

INSTRUCTIONSD'INSTALLATION

LAVE.LINGECOMMERCIALACHARGEMENTFRONTAL

TRAI)UCTIONDESINSTRUCTIONSD'ORIGINE

Table of Contents/Table des mati_res ........................................ 2

Model/ModUle

MHN30PDBGW and

MHN30PNBGW

WlO487509B

www.maytagcommercialaundry.com

Page 2

TABLEOFCONTENTS

WASHER SAFETY ................................................................................... 2

WASHER DISPOSAL ............................................................................... 3

iNSTALLATiON REQUIREMENTS .......................................................... 4

Tools and Parts ..................................................................................... 4

Options ................................................................................................. 4

Location Requirements ........................................................................ 5

Drain System ........................................................................................ 5

Electrical Requirements ........................................................................ 6

INSTALLATION INSTRUCTIONS ............................................................ 7

Remove Transport System ................................................................... 7

Power Cord Installation ........................................................................ 7

Connect the Inlet Hoses ....................................................................... 8

Connect the Drain Hose ....................................................................... 8

Secure the Drain Hose ......................................................................... 9

Level the Washer .................................................................................. 9

Payment System Set-up .................................................................... 10

Installing Pad Strips ........................................................................... 10

Complete Installation .......................................................................... 10

USER & SET-UP INSTRUCTIONS ........................................................ 11

General User Information ................................................................... 11

Control Set-up Procedures ................................................................ 11

Set-up Codes ..................................................................................... 12

Washer Diagnostic Modes ................................................................. 15

WASHER CARE ..................................................................................... 16

Cleaning Your Washer ........................................................................ 16

Water Inlet Hoses ............................................................................... 16

ASSISTANCE OR SERVICE .................................................................. 17

Accessories ........................................................................................ 17

WARRANTY ........................................................................................... 17

DECLARTION OF CONFORMITY ......................................................... 18

TABLEDESMATIERES

SECURIT_: DU LAVE-LINGE ................................................................. 19

MISE AU REBUT DU LAVE-LINGE ...................................................... 20

EXIGENCES D'INSTALLATION ............................................................ 20

Outillage et pi_ces .............................................................................. 20

Options ............................................................................................... 21

Exigences d'emplacement ................................................................. 21

Syst_me de vidange ........................................................................... 22

Sp6cifications 61ectriques .................................................................. 22

INSTRUCTIONS D'INSTALLATION ...................................................... 23

D6pose du syst_me de transport ....................................................... 23

Installation du cordon d'alimentation ................................................. 23

Raccordement des tuyaux d'alimentation .......................................... 24

Raccordement du tuyau de vidange .................................................. 25

Immobilisation du tuyau de vidange .................................................. 25

R6glage de I'aplomb du lave-linge ..................................................... 26

Param6trage du syst_me de paiement .............................................. 26

Installation des bandes de protection ................................................ 26

Achever I'installation .......................................................................... 27

INSTRUCTIONS DE CONFIGURATION ............................................... 28

Informations g6n6rales pour I'utilisateur ............................................ 28

Proc6dures de r6glage des syst_mes de commande ........................ 28

Codes de param6trage ...................................................................... 29

Mode de diagnostic du lave-linge ...................................................... 32

ENTRETIEN DU LAVE-LINGE .............................................................. 34

Nettoyage du lave-linge .................................................................... 34

Tuyaux d'arriv6e d'eau ....................................................................... 35

ASSISTANCE OU SERVICE .................................................................. 35

Accessoires ........................................................................................ 35

GARANTIE .................................................................. Couverture arri_re

WASHERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

2

Page 3

iMPORTANT SAFETY iNSTRUCTiONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the washer, follow basic precautions,

including the following:

m=Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been used

for 2 weeks or more. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system has not been

used for such a period, before using the washing

machine, turn on all hot water faucets and let the water

flow from each for several minutes. This will release

any accumulated hydrogen gas. As the gas is

flammable, do not smoke or use an open flame during

this time.

[] Before the washer is removed from service or discarded,

remove the door or lid.

[] Do not install or store the washer where it will be exposed to

the weather.

[] Do not repair or replace any part of the washer or attempt any

servicing unless specifically recommended in this manual or in

published user-repair instructions that you understand and

have the skills to carry out.

[] See "Electrical Requirements" for earthing instructions.

SAVE THESEINSTRUCTIONS

WASHERDISPOSAL

This appliance is marked according to the European directive 2002/96/EC on Waste Electrical and Electronic Equipment

(WEEE).

By ensuring this product is disposed of correctly, you will help avoid potential negative consequences for the environment and

human health, which could otherwise be caused by inappropriate waste handling of this product.

The symbol on the product, or on the documents accompanying the product, indicates that this appliance may not be treated

as household waste. Instead it shall be handed over to the applicable collection point for the recycling of electrical and

electronic equipment.

Disposal must be carried out in accordance with local environmental regulations for waste disposal.

For more detailed information about treatment, recovery and recycling of this product, please contact your local city office, your

household waste disposal service or the shop where you purchased the product.

Model Nornenclature

MHN - Maytag

30 - Model Type Number

PN - Electronic Control - Non-Pay

PD - Electronic Control - Coin Drop enabled

3

Page 4

INSTALLATIONREQUIREMENTS

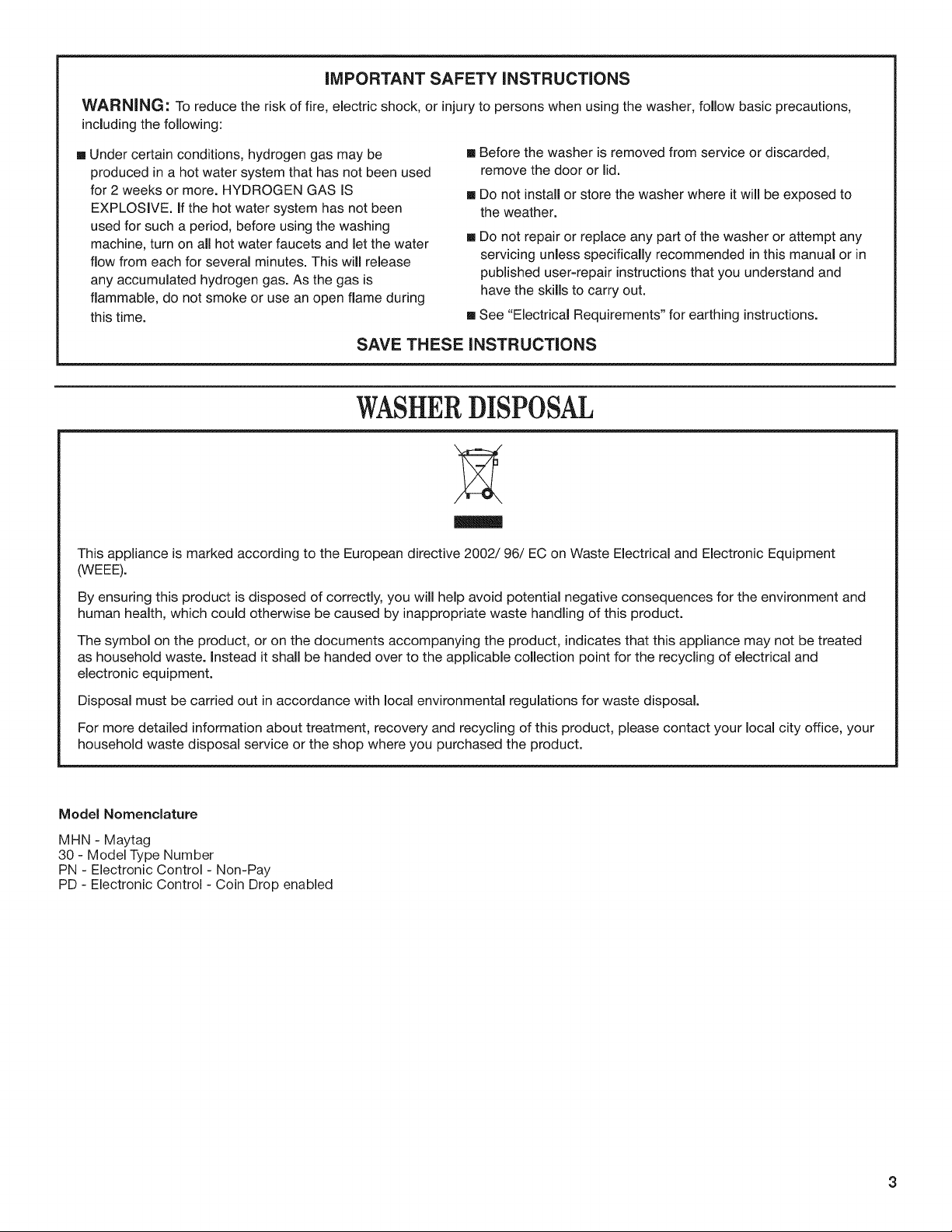

Gather the required tools and parts before starting installation.

The parts supplied are in the washer drum.

Tools needed for connecting the water inlet hoses

[] Pliers (that open to [] Flashlight (optional)

39.5 mm [1%6"])

Tools needed for installation

[] Open end wrenches [] Level

1/2" and 9/16"

[] Torx®l- T-20 Security [] Ruler or measuring tape

screwdriver

[] 1/4" nut driver

Parts supplied

[] Wood block

c

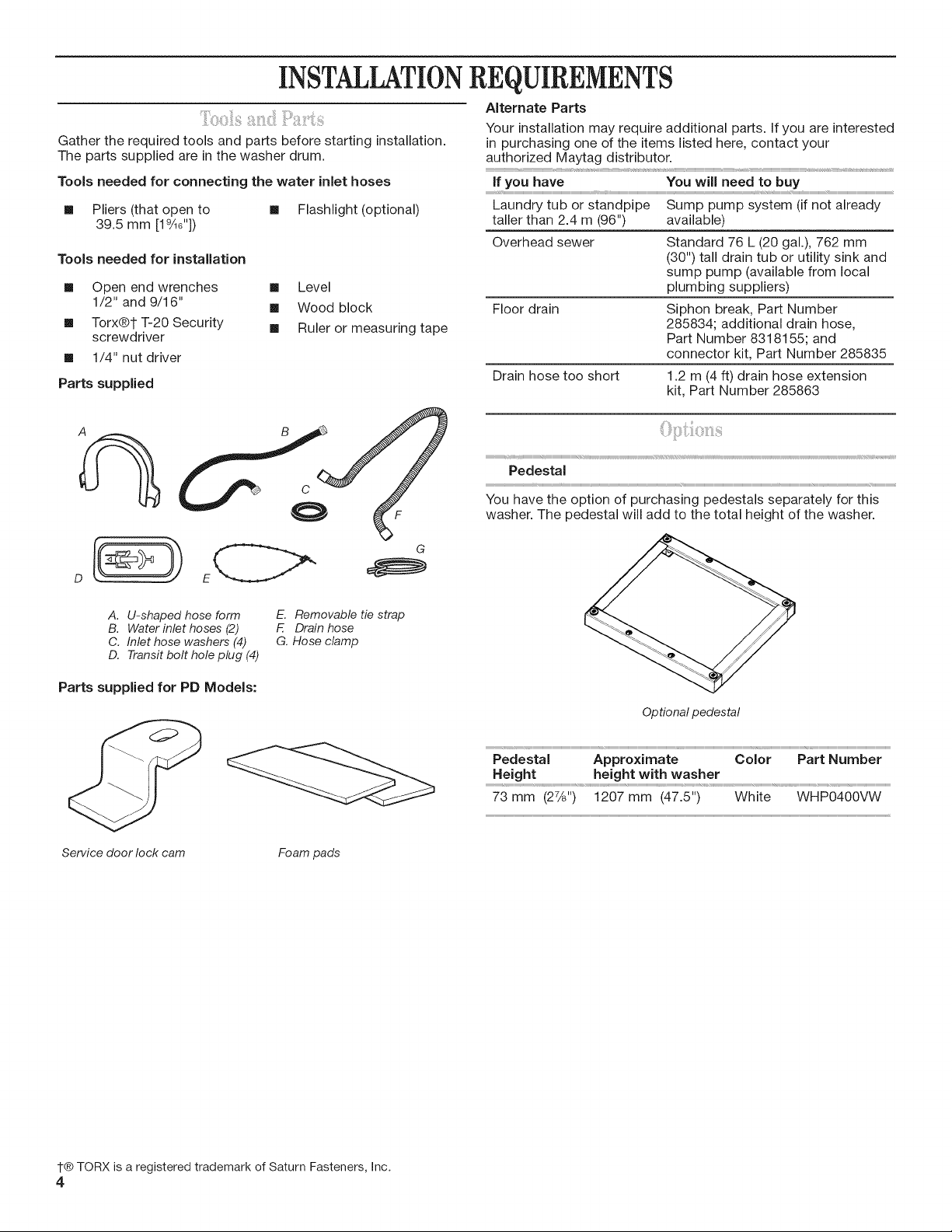

Alternate Parts

Your installation may require additional parts. If you are interested

in purchasing one of the items listed here, contact your

authorized Maytag distributor.

If you have You will need to buy

Laundry tub or standpipe Sump pump system (if not already

taller than 2.4 m (96") available)

Overhead sewer

Floor drain

Drain hose too short 1.2 m (4 ft) drain hose extension

You have the option of purchasing pedestals separately for this

washer. The pedestal will add to the total height of the washer.

t t _t

Standard 76 L (20 gal.), 762 mm

(30") tall drain tub or utility sink and

sump pump (available from local

plumbing suppliers)

Siphon break, Part Number

285834; additional drain hose,

Part Number 8318155; and

connector kit, Part Number 285835

kit, Part Number 285863

Pedestal

D

A. U-shaped hose form

B. Water inlet hoses (2)

C. Inlet hose washers (4)

D. Transit bolt hole plug (4)

Parts supplied for PD Models:

Service door lock cam

E

E. Removable tie strap

F. Drain hose

G. Hose clamp

Foam pads

G

Optionalpedestal

Pedestal Approximate Color

Height height with washer

73 mm (2%") 1207 mm (47.5") White

Part Number

WHP0400VW

1® TORX isa registered trademark of Saturn Fasteners, Inc.

4

Page 5

3!¸,0 czii!/i;i 0s i!!ii_0qil_;_i!iliii_i¸_ii!!_s_:iii_ii!!_ii:i_;i_iii;5

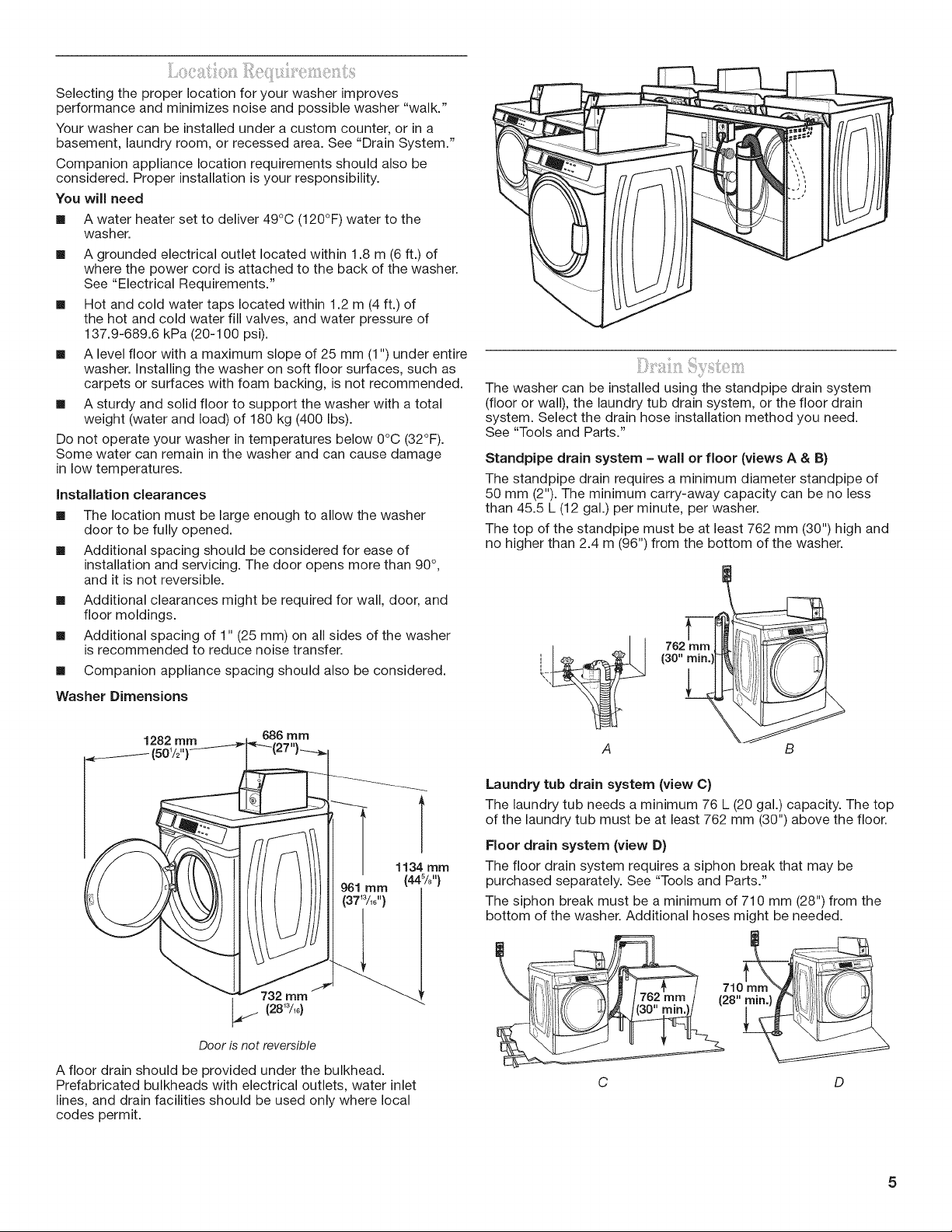

Selecting the proper location for your washer improves

performance and minimizes noise and possible washer "walk."

Your washer can be installed under a custom counter, or in a

basement, laundry room, or recessed area. See "Drain System."

Companion appliance location requirements should also be

considered. Proper installation is your responsibility.

You will need

[] A water heater set to deliver 49°C (120°F) water to the

washer.

[] A grounded electrical outlet located within 1.8 m (6 ft.) of

where the power cord is attached to the back of the washer.

See "Electrical Requirements."

[] Hot and cold water taps located within 1.2 m (4 ft.) of

the hot and cold water fill valves, and water pressure of

137.9-689.6 kPa (20-100 psi).

[] A level floor with a maximum slope of 25 mm (1") under entire

washer. Installing the washer on soft floor surfaces, such as

carpets or surfaces with foam backing, is not recommended.

[] A sturdy and solid floor to support the washer with a total

weight (water and load) of 180 kg (400 Ibs).

Do not operate your washer in temperatures below 0°C (32°F).

Some water can remain in the washer and can cause damage

in low temperatures.

Installation clearances

[] The location must be large enough to allow the washer

door to be fully opened.

[] Additional spacing should be considered for ease of

installation and servicing. The door opens more than 90°,

and it is not reversible.

[] Additional clearances might be required for wall, door, and

floor moldings.

[] Additional spacing of 1" (25 mm) on all sides of the washer

is recommended to reduce noise transfer.

[]

Companion appliance spacing should also be considered.

Washer Dimensions

The washer can be installed using the standpipe drain system

(floor or wall), the laundry tub drain system, or the floor drain

system. Select the drain hose installation method you need.

See "Tools and Parts."

Standpipe drain system - wall or floor (views A & B)

The standpipe drain requires a minimum diameter standpipe of

50 mm (2"). The minimum carry-away capacity can be no less

than 45.5 L (12 gal.) per minute, per washer.

The top of the standpipe must be at least 762 mm (30") high and

no higher than 2.4 m (96") from the bottom of the washer.

1282 mm

686 mm

1134 mrn

_ (28,3/,0}

Door is not reversible

A floor drain should be provided under the bulkhead.

Prefabricated bulkheads with electrical outlets, water inlet

lines, and drain facilities should be used only where local

codes permit.

(44%")

A B

Laundry tub drain system (view C)

The laundry tub needs a minimum 76 L (20 gal.) capacity. The top

of the laundry tub must be at least 762 mm (30") above the floor.

Floor drain system (view D)

The floor drain system requires a siphon break that may be

purchased separately. See "Tools and Parts."

The siphon break must be a minimum of 710 mm (28") from the

bottom of the washer. Additional hoses might be needed.

__ 71o_

C D

5

Page 6

Dangerous Voltage

Electric Shock Hazard

Plug into an earthed socket outlet.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electric shock.

EARTHING iNSTRUCTiONS

This washer must be earthed. In the event of a malfunction

or breakdown, earthing will reduce the risk of electric

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-earthing conductor and an earthing plug. The

plug must be plugged into an appropriate outlet that is

properly installed and earthed in accordance with all local

codes and ordinances.

WARNING: Improper connection of the equipment-

earthing conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are in

doubt as to whether the appliance is properly earthed.

Do not modify the plug provided with the appliance - if it will

not fit the outlet, have a proper outlet installed by a qualified

electrician.

NOTE: Electrical safety standards: The manufacturer has

chosen compliance with EC/EN.60335 standards as the most

appropriate for this product.

[] Sound Pressure Level, Lpa: 58 dbA (uncertainty,

Kpa: +/-3.6 dbA)

[] A 220-240V, 50 Hz., fused electrical supply is required. A

time-delay 10-16A fuse or circuit breaker is recommended.

[] This washer is equipped with a power supply cord having

a 3 prong earthed plug.

[] To minimize possible shock hazard, the cord must be

plugged into a mating, 3 prong, grounding-type outlet,

grounded in accordance with local codes and ordinances.

If a mating outlet is not available, it is the personal

responsibility and obligation of the customer to have the

properly grounded outlet installed by a qualified electrician.

[] If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

earth path is adequate.

[] If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent, or a qualified person to

avoid a hazard.

[] Do not earth to a gas pipe.

[] Check with a qualified electrician if you are not sure the

washer is properly earthed.

[] Do not have a fuse in the neutral or earth circuit.

6

Page 7

INSTALLATIONINSTRUCTIONS

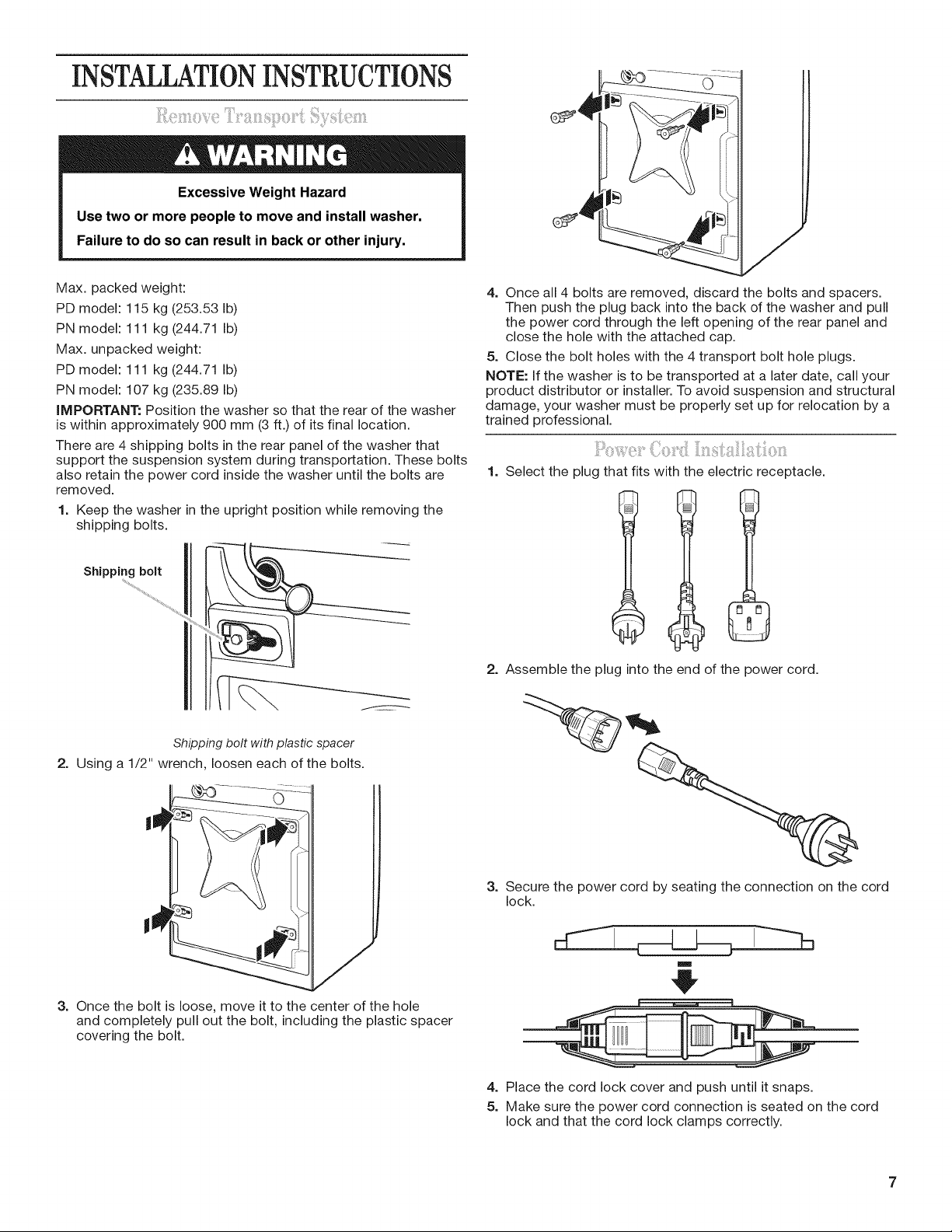

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

Max. packed weight:

PD model: 115 kg (253.53 Ib)

PN model: 111 kg (244.71 Ib)

Max. unpacked weight:

PD model: 111 kg (244.71 Ib)

PN model: 107 kg (235.89 Ib)

iMPORTANT: Position the washer so that the rear of the washer

is within approximately 900 mm (3ft.) of its final location.

There are 4 shipping bolts in the rear panel of the washer that

support the suspension system during transportation. These bolts

also retain the power cord inside the washer until the bolts are

removed.

1. Keep the washer in the upright position while removing the

shipping bolts.

Shipping bolt

4. Once all 4 bolts are removed, discard the bolts and spacers.

Then push the plug back into the back of the washer and pull

the power cord through the left opening of the rear panel and

close the hole with the attached cap.

5. Close the bolt holes with the 4 transport bolt hole plugs.

NOTE: If the washer is to be transported at a later date, call your

product distributor or installer. To avoid suspension and structural

damage, your washer must be properly set up for relocation by a

trained professional.

1. Select the plug that fits with the electric receptacle.

2. Assemble the plug into the end of the power cord.

Shipping bolt with plastic spacer

2. Using a 1/2" wrench, loosen each of the bolts.

3. Once the bolt is loose, move it to the center of the hole

and completely pull out the bolt, including the plastic spacer

covering the bolt.

3. Secure the power cord by seating the connection on the cord

lock.

m

4. Place the cord lock cover and push until it snaps.

5. Make sure the power cord connection is seated on the cord

lock and that the cord lock clamps correctly.

7

Page 8

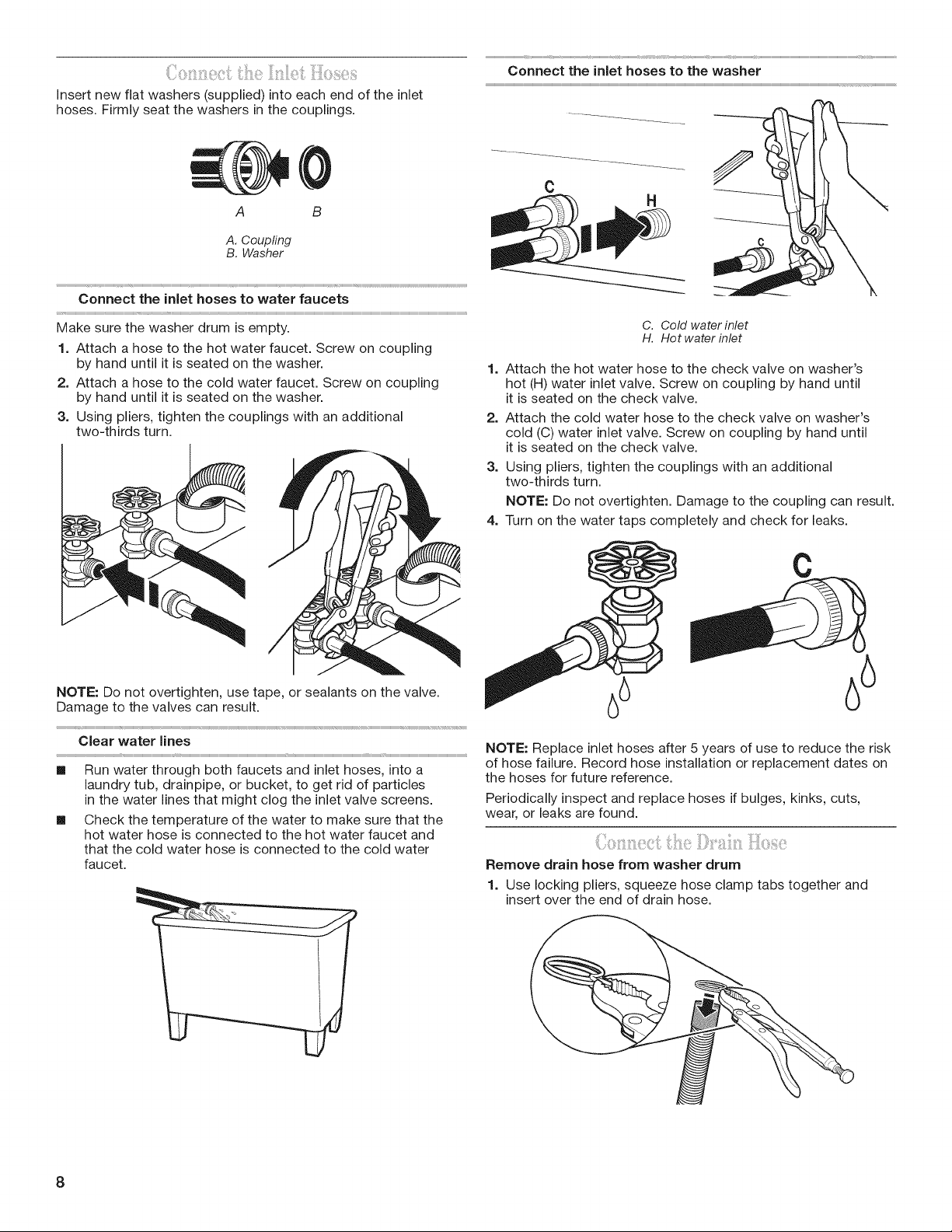

insert new flat washers (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

A B

A. Coupling

B. Washer

Connect the inlet hoses to the washer

r_

C

Connect the inlet hoses to water faucets

r; ......................................................................................;; r

Make sure the washer drum is empty.

1. Attach a hose to the hot water faucet. Screw on coupling

by hand until it is seated on the washer.

2. Attach a hose to the cold water faucet. Screw on coupling

by hand until it is seated on the washer.

3. Using pliers, tighten the couplings with an additional

two-thirds turn.

NOTE: Do not overtighten, use tape, or sealants on the valve.

Damage to the valves can result.

Clear water Hnes

r r r

[] Run water through both faucets and inlet hoses, into a

laundry tub, drainpipe, or bucket, to get rid of particles

in the water lines that might clog the inlet valve screens.

[] Check the temperature of the water to make sure that the

hot water hose is connected to the hot water faucet and

that the cold water hose is connected to the cold water

faucet.

C. Cold water inlet

H. Hot water inlet

Attach the hot water hose to the check valve on washer's

hot (H) water inlet valve. Screw on coupling by hand until

it is seated on the check valve.

2_

Attach the cold water hose to the check valve on washer's

cold (C)water inlet valve. Screw on coupling by hand until

it is seated on the check valve.

3_

Using pliers, tighten the couplings with an additional

two-thirds turn.

NOTE: Do not overtighten. Damage to the coupling can result.

4_

Turn on the water taps completely and check for leaks.

C

NOTE: Replace inlet hoses after 5 years of use to reduce the risk

of hose failure. Record hose installation or replacement dates on

the hoses for future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

Remove drain hose from washer drum

1. Use locking pliers, squeeze hose clamp tabs together and

insert over the end of drain hose.

8

Page 9

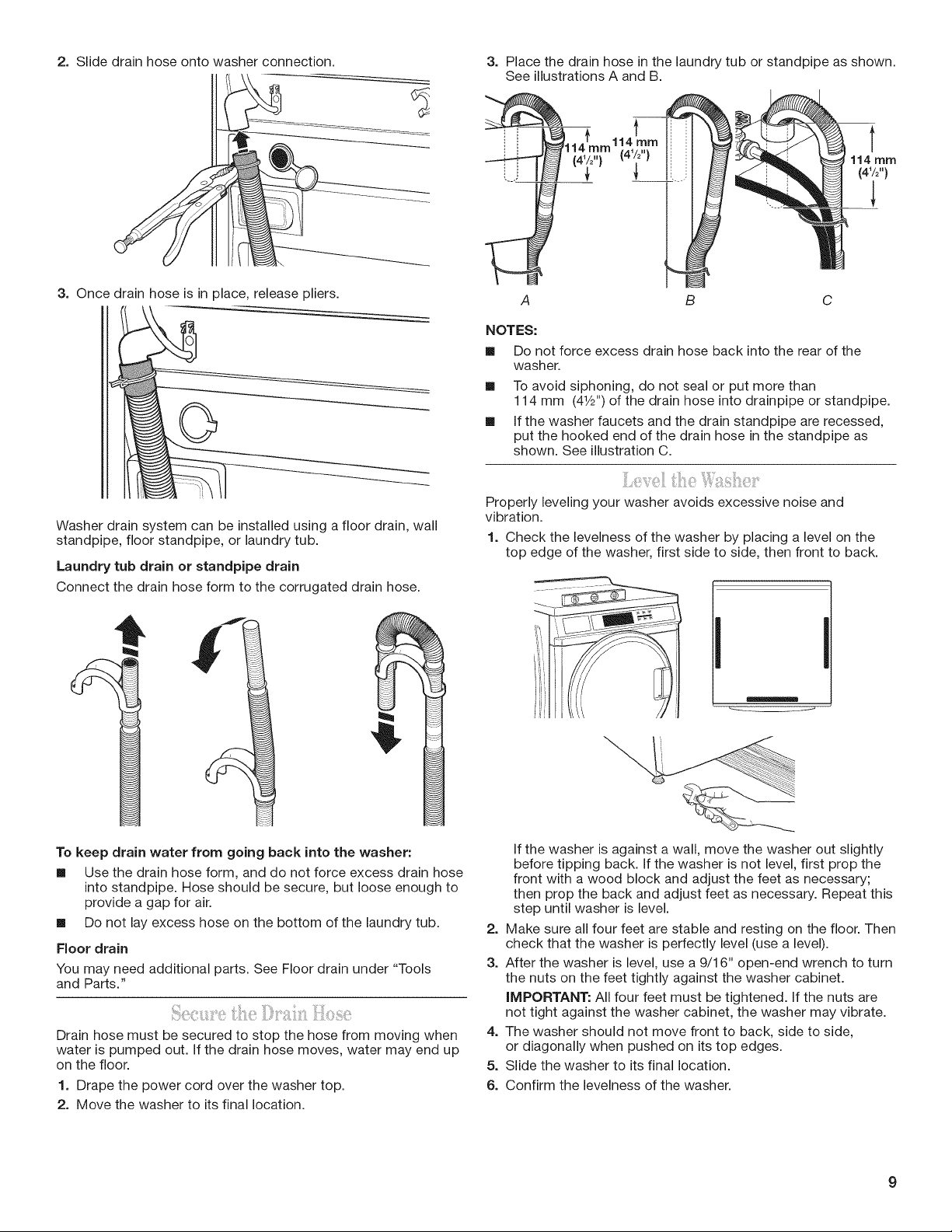

2. Slide drain hose onto washer connection.

3. Place the drain hose in the laundry tub or standpipe as shown.

See illustrations A and B.

t

114 mm

L_.JIN {

(4v_")

4

3. Once drain hose is in place, release pliers.

Washer drain system can be installed using a floor drain, wall

standpipe, floor standpipe, or laundry tub.

Laundry tub drain or standpipe drain

Connect the drain hose form to the corrugated drain hose.

A B C

NOTES:

[] Do not force excess drain hose back into the rear of the

washer.

[] To avoid siphoning, do not seal or put more than

114 mm (41/2'') of the drain hose into drainpipe or standpipe.

[] If the washer faucets and the drain standpipe are recessed,

put the hooked end of the drain hose in the standpipe as

shown. See illustration C.

Properly leveling your washer avoids excessive noise and

vibration.

1. Check the levelness of the washer by placing a level on the

top edge of the washer, first side to side, then front to back.

To keep drain water from going back into the washer:

[] Use the drain hose form, and do not force excess drain hose

into standpipe. Hose should be secure, but loose enough to

provide a gap for air.

[] Do not lay excess hose on the bottom of the laundry tub.

Floor drain

You may need additional parts. See Floor drain under "Tools

and Parts."

Drain hose must be secured to stop the hose from moving when

water is pumped out. If the drain hose moves, water may end up

on the floor.

1. Drape the power cord over the washer top.

2. Move the washer to its final location.

If the washer is against a wall, move the washer out slightly

before tipping back. If the washer is not level, first prop the

front with a wood block and adjust the feet as necessary;

then prop the back and adjust feet as necessary. Repeat this

step until washer is level.

2=

Make sure all four feet are stable and resting on the floor. Then

check that the washer is perfectly level (use a level).

3.

After the washer is level, use a 9/1 6" open-end wrench to turn

the nuts on the feet tightly against the washer cabinet.

IMPORTANT: All four feet must be tightened. If the nuts are

not tight against the washer cabinet, the washer may vibrate.

4=

The washer should not move front to back, side to side,

or diagonally when pushed on its top edges.

5.

Slide the washer to its final location.

6.

Confirm the levelness of the washer.

9

Page 10

PD Model Washer is coin payment ready and allows the use of

two different sizes of coins if a dual drop is installed. To set-up

the washer for coin payment, acquire a coin drop mechanism

with the appropriate coin sensors. Connect coin sensors to the

coin slot 1 and 2, respectively.

iiiiiii ::ii !ii i ii: i!j iiiiiiiiii!iii :i !iiiii:¸

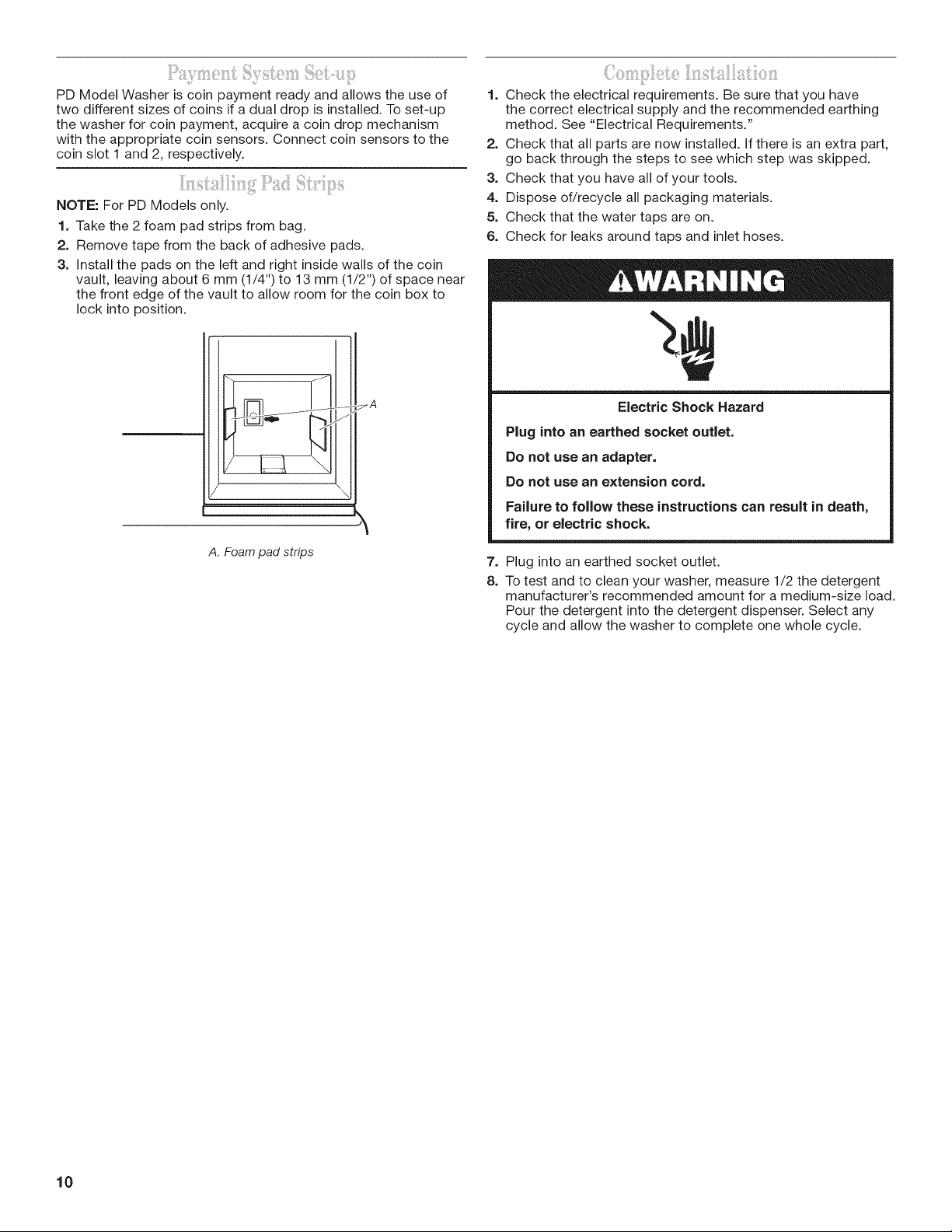

NOTE: For PD Models only.

1. Take the 2 foam pad strips from bag.

2. Remove tape from the back of adhesive pads.

3. Install the pads on the left and right inside walls of the coin

vault, leaving about 6 mm (1/4") to 13 mm (1/2") of space near

the front edge of the vault to allow room for the coin box to

lock into position.

1. Check the electrical requirements. Be sure that you have

the correct electrical supply and the recommended earthing

method. See "Electrical Requirements."

2. Check that all parts are now installed, if there is an extra part,

go back through the steps to see which step was skipped.

3. Check that you have all of your tools.

4. Dispose of/recycle all packaging materials.

5. Check that the water taps are on.

6. Check for leaks around taps and inlet hoses.

Electric Shock Hazard

Plug into an earthed socket outlet.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electric shock.

A. Foam pad strips

7.

Plug into an earthed socket outlet.

8.

To test and to clean your washer, measure 1/2 the detergent

manufacturer's recommended amount for a medium-size load.

Pour the detergent into the detergent dispenser. Select any

cycle and allow the washer to complete one whole cycle.

10

Page 11

USER&SET.UPINSTRUCTIONS

WHITES COLORS BRIGHTS

PENN. DELICATES QUICK

PRESS AND KNITS CYCLE

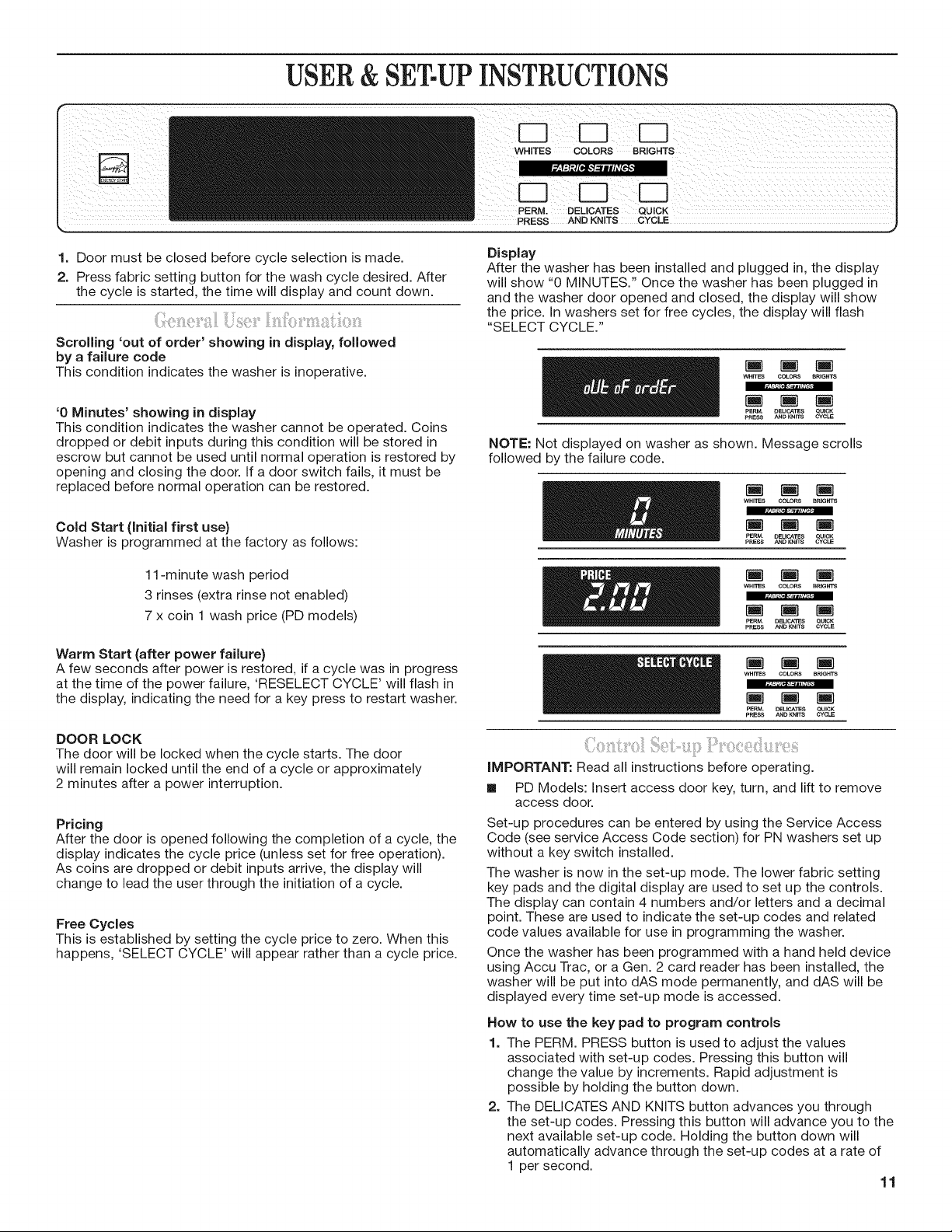

1. Door must be closed before cycle selection is made.

2. Press fabric setting button for the wash cycle desired. After

the cycle is started, the time will display and count down.

Scrolling 'out of order' showing in display, followed

by a failure code

This condition indicates the washer is inoperative.

'0 Minutes' showing in display

This condition indicates the washer cannot be operated. Coins

dropped or debit inputs during this condition will be stored in

escrow but cannot be used until normal operation is restored by

opening and closing the door. If a door switch fails, it must be

replaced before normal operation can be restored.

Cold Start (Initial first use)

Washer is programmed at the factory as follows:

11-minute wash period

3 rinses (extra rinse not enabled)

7 x coin 1 wash price (PD models)

Warm Start (after power failure)

A few seconds after power is restored, if a cycle was in progress

at the time of the power failure, 'RESELECT CYCLE' will flash in

the display, indicating the need for a key press to restart washer.

DOOR LOCK

The door will be locked when the cycle starts. The door

will remain locked until the end of a cycle or approximately

2 minutes after a power interruption.

Pricing

After the door is opened following the completion of a cycle, the

display indicates the cycle price (unless set for free operation).

As coins are dropped or debit inputs arrive, the display will

change to lead the user through the initiation of a cycle.

Free Cycles

This is established by setting the cycle price to zero. When this

happens, 'SELECT CYCLE' will appear rather than a cycle price.

Display

After the washer has been installed and plugged in, the display

will show "0 MINUTES." Once the washer has been plugged in

and the washer door opened and closed, the display will show

the price. In washers set for free cycles, the display will flash

"SELECT CYCLE."

WHITES COLORS BRIGHTS

PERM. DELICA33E8 QUICK

PRESS AND F3MITS CYCLE

NOTE: Not displayed on washer as shown. Message scrolls

followed by the failure code.

WHI_8 COLORS BPJGHTS

_ N rm

PERM. DELICATES QUICK

PRESS ANDKNrrs CYCLE

WHl'rl_s COLORS BRIGFn'8

pERM. DELICA'rE8 QUICK

pRESS AND KNITS CYCLE

WHITES COLORS BRIGHTS

i i !

-- PRESS AND KNITS CYCLE

PERM. DELICATES QUICK

IMPORTANT: Read all instructions before operating.

[] PD Models: insert access door key, turn, and lift to remove

access door.

Set-up procedures can be entered by using the Service Access

Code (see service Access Code section) for PN washers set up

without a key switch installed.

The washer is now in the set-up mode. The lower fabric setting

key pads and the digital display are used to set up the controls.

The display can contain 4 numbers and/or letters and a decimal

point. These are used to indicate the set-up codes and related

code values available for use in programming the washer.

Once the washer has been programmed with a hand held device

using Accu Trac, or a Gen. 2 card reader has been installed, the

washer will be put into dAS mode permanently, and dAS will be

displayed every time set-up mode is accessed.

How to use the key pad to program controls

1. The PERM. PRESS button is used to adjust the values

associated with set-up codes. Pressing this button will

change the value by increments. Rapid adjustment is

possible by holding the button down.

2. The DELICATES AND KNITS button advances you through

the set-up codes. Pressing this button will advance you to the

next available set-up code. Holding the button down will

automatically advance through the set-up codes at a rate of

1 per second.

11

Page 12

3.TheQUICKCYCLEbuttonisusedtoselectordeselect

options.

StartOperatingSet-up

NOTE:Priortooperation,apaymentsystemoranOPLkitmust

beinstalledonPDmodels,aspartoftheset-up.

Beforeproceeding,itisworthnotingthat,despiteallofthe

optionsavailable,anownercansimplychoosetouncrateanew

commercialwasher,hookitup,plugitin,andhaveawasher

thatoperates.Washersarepresetatthefactoryforan11-minute

washperiodand3rinses(noextrarinse).

[] TheDELICATESANDKNITSbuttonwilladvanceyoufrom

codetocode.

[] ThePERM.PRESSbuttonwillchangethecodevalue.

[] TheQUICKCYCLEbuttonwillselectordeselectoptions.

FORPNMODELS:Theset-upcodesarethesameasforthe

"PD"modelexceptwherenoted.

Theset-upcodeisindicatedbytheoneortwoleft-hand

characters.Theset-upcodevalueisindicatedbythetwo

orthreeright-handcharacters.Thefirstcodeshownineach

sectionistheFactoryDefaultsetting.

CODE EXPLANATION

6 07 REGULAR CYCLE PRICE (Factory Default)

6 07 Represents the number of coins (Coin 1) needed

to start the washer; may adjust from 0-39. (See

VALUE OF COIN 1.) Advance from 0-39 by

pressing PERM. PRESS button. Factory default

of 7xcoinl.

With coin slide activation, this code represents

the number of push-in actuations of a coin slide

to start the washer.

6 01 setting would represent one coin slide

actuation.

NOTE: For coin slide activation, replacement of

the meter case is necessary.

6 00 PN MODELS ONLY: Factory default for 0 coins.

--> Press the DELICATES AND KNITS button once

to advance to next code.

7 11 WASH LENGTH

7 11 This is the number of minutes for WASH. Washer

comes from the factory preset with 11 minutes.

Choose from 9-17 minutes by pressing the PERM

PRESS button.

--> Press the DELICATES AND KNITS button once to

advance to next code.

NOTE: This option does not apply to QUICK

CYCLE.

8 00 ADDITIONAL RINSE OPTION

This option is either SELECTED 'ON' or NOT

SELECTED 'OFF'.

8 00 Not Selected 'OFF'.

Ar Selected 'ON'. Cannot be combined with the

Super Cycle rinse option.

Press the QUICK CYCLE button once for this

selection.

--> Press the DELICATES AND KNITS button once

to advance to next code.

12

CODE EXPLANAT{ON

9 00 CYCLE COUNTER OPTION

This option is either SELECTED 'ON' or NOT

SELECTED 'OFF'.

9 00 Not Selected 'OFF'.

9 0C Selected 'ON' and not able to be deselected.

Press the QUICK CYCLE button 3 consecutive

times to select 'ON'. Once selected 'ON' it cannot

be deselected.

--> Press the DELICATES AND KNITS button once to

i t

1. 00 MONEY COUNTER OPTION

1. 00 Not Selected 'OFF'.

1. 0C Selected 'ON'.

1. CO Selected 'ON' and not able to be deselected.

2. 00 SPECIAL PRICING OPTIONS

2. 00 Not Selected 'OFF', and next available code will

2. SP Selected 'ON'. Press the QUICK CYCLE button

if SPECIAL PRiCiNG OPTION is selected, there is access

to codes '3.XX' through '9.XX'.

--> Press the DELICATES AND KNITS button once to

....................................................i

5. 00 TIME-OF-DAY CLOCK, MINUTES

5. 00 This is the TIME-OF-DAY CLOCK, minute setting;

6. 00 TIME-OF-DAY CLOCK, HOURS

............................................, r r r r i r

6. 00 This is the TIME-OF-DAY CLOCK, hour setting;

advance to next code.

This option is either SELECTED 'ON' or NOT

SELECTED 'OFF'.

Press the QUICK CYCLE button 3 consecutive

times to select 'ON' and 3 consecutive times to

remove (Not Selected 'OFF'.) Counter resets by

going from 'OFF' to 'ON'.

--> Press the DELICATES AND KNITS button once

to advance to next code.

To select 'ON' and not able to be deselected,

first select 'ON', then within 2 seconds, press

the QUICK CYCLE twice, PERM PRESS once,

and exit the set-up mode.

This option is either SELECTED 'ON' or NOT

SELECTED 'OFF'.

be A.00.

once for this selection.

advance to next code.

PN MODELS ONLY: Factory default of 0 coins.

--> Press the DELICATES AND KNITS button once

to advance to next code.

select 0-59 minutes by pressing the PERM.

PRESS button.

--> Press the DELICATES AND KNITS button once

to advance to next code.

NOTE: Uses the 24 hr. clock

select 0-23 hours by pressing the PERM. PRESS

button.

-->

Press the DELICATES AND KNITS button once

to advance to next code.

Page 13

CODE EXPLANATION

7.7.00 SPEC{AL PRICE START HOUR

NOTE: Uses the 24 hr. clock

00 This is the start hour; 0-23 hours. Select START

HOUR by pressing the PERM. PRESS button.

-> Press the DEL{CATES AND KN{TS button once

to advance to next code.

8. 00 SPECIAL PRICE STOP HOUR

NOTE: Uses the 24 hr. clock

r

8. 00 This is the stop hour; 0-23 hours. Select STOP

HOUR by pressing the PERM. PRESS button.

--> Press the DELICATES AND KNITS button once

to advance to next code.

9. 10 SPECIAL PR{CE DAY

r r r rr r r r r r r r r r

r r r r r r r

9. 10 This represents the day of the week and whether

special pricing is selected for that day. A number

followed by '0' indicates no selection that

particular day (9.10). A number followed by an 'S'

indicates selected for that day (9.1S). To change

the value of '0' and 'S', use the QUICK CYCLE

button.

Days of the week (1-7) are selected by pressing

the PERM. PRESS button.

When exiting set-up code '9', the display must

show current day of week:

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1 = Sunday 1S

20 Day 2 = Monday 2S

30 Day 3 = Tuesday 3S

40 Day 4 = Wednesday 4S

50 Day 5 = Thursday 5S

60 Day 6 = Friday 6S

70 Day 7 = Saturday 7S

--> Press the DELICATES AND KNITS button once

...............................................r r; r; ; r r r; ; r

to advance to next code.

A. 00 VAULT VIEWING OPTION

This option is either SELECTED 'ON' or NOT

SELECTED 'OFF'.

A. 00 Not Selected 'OFF'. E. 00 Not Selected 'OFF'.

A. SC Selected 'ON'. Press the QUICK CYCLE button

once for this selection. When selected, the money

and/or cycle counts will be viewable (if counting is

selected) when the coin box is removed.

--> Press the DELICATES AND KNITS button once

to advance to next code.

b. 05 VALUE OFCOIN 1

b. 05 This represents the value of coin 1 in the quantity

of 5% increments of the larger coin value. 5 x

5%=25%.

By pressing the PERM. PRESS button, there

is the option of 1-199 for the quantity of 5%

increments.

With coin slide activation, this represents the total

vend price.

NOTE: For coin slide activation, replacement of

the meter case is necessary.

-->

Press the DELICATES AND KNITS button once

to advance to next code.

C. 20 VALUE OF COIN 2

C. 20 This represents the value of coin 2 in the quantity

of 5% increments of the larger coin value. 20 x

5%=100%.

By pressing the PERM. PRESS button, there

is the option of 1-199 for the quantity of 5%

increments.

C. 05

PN MODELS: This represents the value of coin

2 in the quantity of 5% increments of the larger

coin value. Factory default = 5 x 5% of the larger

coin value.

Press the DELICATES AND KNITS button once

to advance to next code.

d. 00 COIN SLIDE OPTION

This option is either SELECTED 'ON' or NOT

SELECTED 'OFF'.

r; r r; r; i r; .......................................; r; r; r r

d. 00 Not Selected 'OFF'. Used with coin drop or card

readers.

Selected 'ON'. Press the QUICK CYCLE button

3 consecutive times for this selection.

NOTE: This option needs to be set to "00" unless

the meter case has been changed to accept a

coined slide device.

d. CS When coin slide mode is selected 'On', set b.

equal to value of vend price. Set set-up code

6 (regular cycle price) and set-up code 3 (special

cycle price) to number of slide pushes. If washer

is set up as "CS" and a coin drop is installed, it

will not register coins.

NOTE: For coin slide activation, replacement of

the meter case is necessary.

--> Press the DEL{CATES AND KNITS button once

to advance to next code.

r r r r; r r; r

E. 00 ADD COINS OPTION

This option is either SELECTED 'ON' or NOT

SELECTED 'OFF'. This option causes the

customer display to show the number of coins

(coin 1) to enter, rather than the amount.

E. AC Selected 'ON'. Press the QUICK CYCLE button

3 consecutive times for this selection.

--> Press the DELICATES AND KNITS button once

to advance to next code.

R 00 ENHANCED PRICING OPTION

R 00 Not Selected 'OFF'.

F. CP Cycle-Based pricing enabled. This option allows

configuration of different prices for cold, warm,

and hot water cycles.

F. Su Super Cycle pricing enabled. This option allows

customers to upgrade cycles by depositing

extra money. Set-up codes "H." and "h." will be

displayed only when this option is enabled. Press

the QUICK CYCLE button once for this selection.

Press the DELICATES AND KNITS button once

--> to advance to next code.

r

13

Page 14

CODE EXPLANATION

H. 01 SUPER CYCLE UPGRADE PRICE

(Skipped unless super cycle pricing is enabled.)

H. 01 This represents the number of coin 1 required to

upgrade a base cycle to a super cycle. Advance

from 0-39 by pressing the PERM. PRESS keypad.

-e Press the DELICATES AND KNITS button once

to advance to next code.

h. 01 SUPER CYCLE TYPE

(Skipped unless Super Cycle pricing is enabled.)

h. 01 This represents the Super Cycle upgrade option.

Press the PERM. PRESS button to step through

upgrade options 1-3 as follows:

01 - enhanced wash, extra 3 minutes of wash

tumble in addition to the programmed wash time.

02 - extra rinse for all cycles.

03 - both 01 and 02.

--> Press the DELICATES AND KNITS button once

............................................... t

J. Cd COIN/DEBIT OPTION

...............................................i

to advance to next code.

J. Cd Both coin & debit selected. Press the QUICK

CYCLE button 3 consecutive times to change this

section.

J. C_ Coins selected, debit disabled. Press the QUICK

CYCLE button 3 consecutive times to change this

selection.

J. _d Debit card selected, coins disabled. This is the

factory default for PN models. Press the QUICK

CYCLE button 3 consecutive times to change this

selection.

J. Ed Enhanced Debit is self-selected when a

Generation 2 card reader is installed in the

washer. The Ed option cannot be manually

selected or deselected.

--> Press the DELICATES AND KNITS button once

to advance to next code.

L. 00 PRICE SUPPRESSION OPTION

This option causes the customer display to show

'ADD' or 'AVAILABLE' rather than the amount of

money to add. (Used mainly in debit installations.)

L. 00 Not Selected 'OFR'

L. PS Selected 'ON.' Press the QUICK CYCLE button

once for this selection.

--> Press the DELICATES AND KNITS button once

to advance to next code.

n. CE CLEAR ESCROW OPTION

When selected, money held in escrow for

30 minutes without further escrow or cycle

activity will be cleared.

00 Not Selected 'OFF'.

CE Selected 'ON'. Press the QUICK CYCLE button

once for this selection.

--> Press the DELICATES AND KNITS button once

to advance to next code.

CODE EXPLANATION

r. 800 TOPSPiN SPEED RPM

r. 800 This can be selected from the following spin

speeds: 600 rpm, 750 rpm, 800 rpm, 1000

(displays as 999) rpm. Step between speeds by

pressing the PERM. PRESS button. Factory

pre-set for 800 rpm.

-e Press the DELICATES AND KNITS button once

to advance to next code.

U. 00 PENNY INCREMENT OFFSET

U. 00 This option is not supported for European Models

and the value must be set to 00.

-e Press the DELICATES AND KNITS button once

to advance to next code.

A1. 00 PREWASH LENGTH

Choose 0 to disable the prewash or select

between 2 and 7 minutes by pressing the PERM.

PRESS button.

--> Press the DELICATES AND KNITS button once

to advance to next code.

A2. 03 FINAL SPiN LENGTH

A2. 03 This is the number of minutes of final high speed

spin. Choose from 3-8 minutes by pressing the

PERM. PRESS button.

--> Press the DELICATES AND KNITS button once

to advance to next code.

If cycle counter (9 0C) is selected, the following is true:

1 00 Number of cycles in HUNDREDS. 1 02 = 200

2 00 Number of cycles in ONES. 2 2`5 = 25

TOTAL CYCLES = 225

This is 'VIEW ONLY' and cannot be cleared.

--> Press the DELICATES AND KNITS button once to

advance to next code.

If money counter (1.0C or 1.00) is selected, the following

is true:

3 00 Currency amount in HUNDREDS.

4 00 Currency amount in ONES.

5 00 Currency amount in HUNDREDTHS.

301=100.00

4 68 = 68.00

5 7,5 = 00.75

TOTAL = 168.75

END OF SET-UP PROCEDURES

EXIT FROM SET=UP MODE

[] PD Models: Reinstall access door.

[] PN MODELS WiTH PROGRAMMING SWITCH:

Turn key clockwise and remove.

[] PN MODELS WITHOUT PROGRAMMING SWITCH:

Set-up mode can be exited by using procedures from the

Service Access Code section.

14

Page 15

,¸ !ii! i,iiiiiiiiio :! ::! ii

To enter the "Washer Diagnostic Mode," first enter "Start

Operating Set-up." Then press and hold the QUICK CYCLE

button for 1 second while in set-up code 6, anytime a diagnostic

code is present, or while dAS displays if operating with Maytag

Data Acquisition set-up.

On entry to diagnostic mode the entire display will flash, a

cycle in process is canceled, money in escrow is cleared, and

diagnostic codes are cleared, if a diagnostic code persists,

it must be corrected before the following cycle options are

permitted.

There are five possible ways to initiate cycle activity from

diagnostic mode as follows:

1. Washer Cleanout cycle - With the entire display flashing, this

cycle is started by pressing the BRIGHTS button.

Use the Washer Cleanout cycle once a month to keep the

inside of your washer fresh and clean. This cycle uses

a higher water level. Use with liquid chlorine bleach to

thoroughly clean the inside of the washer. This cycle should

not be interrupted.

IMPORTANT: Do not place garments or other items in the

washer during the Washer Cleanout cycle. Use this cycle with

an empty wash drum.

2. Cycle Credit - With the entire display flashing, a cycle may

be credited by pressing the PERM. PRESS button (CC will

display). When the service mode is exited, "SELECT CYCLE"

will be displayed unless the end-of-cycle door opening is

required.

3. Manual Overview Test - With the entire display flashing, this

cycle is started by pressing the WHITES button. This cycle

provides more typical full length fills, tumbles, drains, and

actuator dispenser movement, allowing for a more thorough

analysis of the washer operation, including pressure switch

behavior.

4. Quick Spin Cycle - With the entire display flashing, this

cycle is started by pressing the COLORS button. This cycle

provides a method to quickly drain and spin (remove water

from the washer) if desired.

5. Quick Overview Test - With the entire display flashing, this

cycle is started by pressing the DELICATES AND KNITS

button. This cycle provides a quick verification that the cold

and hot water valves, dispensers, and pump motor are

working, as well as actuator dispenser movement. It also

includes door lock, drain, and spin operations.

Pressing the QUICK CYCLE button will exit diagnostic mode

and cancel a diagnostic cycle in process.

DIAGNOSTIC CODES

If one of the following has occurred, the appropriate diagnostic

code will be in the display.

d5 Blocked coin 1 or coin drop control circuit failure (coin

recognition and price display disabled while blockage

persists).

PN Models Only: Set-up mode J. should be set

to d to eliminate coin related diagnostic codes.

d9 Low voltage detected for 8 seconds.

d13 Blocked coin 2 or coin drop control circuit failure (coin

recognition and price display disabled while blockage

persists).

F20 Slow Fill. The washer will not detect water input for 4 min.

Pressure switch failure or no water inlet. This code is

reported as d8 on d7.

F22 The door is not able to lock. Door lock error or someone

trying to start the washer, by pressing the door switch

with the finger. This code is reported as dl 7 on Accu Trac.

(For any other codes, check supplied Technical Sheet)

SERVICE ACCESS CODE

This code can be entered to access service mode without

removing the console. It only functions on washers set up for

0 vend price without any Special Pricing set-up, and the Coin/

Debit Option must be set to "J. d". If the washer is not in failure

mode, the door must be opened to proceed. Service Access

Code contains 6 steps and some are timed. Using only the three

bottom buttons (numbered 1,2, and 3 from left to right):

1. Press 2 for longer than 2 seconds but less than 10 seconds.

2. Press 1 & 3 together for 2 seconds, then release.

Displays S 3.

3. Press 1 & 2 together, then release. Displays S 4.

4. Press 2 & 3 together, then release. Displays S 5.

5. Press 2, then release. Display shows "codE".

6. Wait at least 2 seconds, but not more than 15 seconds, then

press in succession: 3, 2, 1, 3.

NOTE: If the Service Access Code procedure is not completed

properly, as noted above, there is a 15 second delay before it can

be attempted again.

There are 3 options to exit from the Service Mode:

1. From Set-up Code 8, press key #1 for 4 seconds.

2. Wait 2 minutes without touching any buttons (without

diagnostic modes running).

3. Power down the washer, then reapply power.

WASHER HELP MODE

This mode is entered by pressing the PERM. PRESS button while

in special pricing option mode 2.XX (or while dAS displays if

operating with Maytag Data Acquisition set-up).

In help mode, other display symbols and elements are mapped to

reflect the state of various inputs and outputs as follows:

Display Symbol Description

Wash Water sensed at wash level.

* Low voltage present (below about

90 VAC).

° (Circle above digit) Door closed

DOOR LOCKED Door sensed locked.

COLD Cold water relay on.

HOT Hot water relay on.

OR Door unlock.

AVAILABLE Drain pump ON.

NOTE: A Technical Sheet is supplied taped to inside of lower

front panel, which includes fault codes and a machine schematic

diagram.

15

Page 16

WASHER CARE

Ciiiii ii! iJ :/i i:iiiil;¸ '¸

Cleaning the Door Seal/Bellow

1. Open the washer door and remove any clothing or items from

the washer.

2. Inspect the colored seal/bellow between the door opening

and the drum for stained areas. Pull back the seal/bellow

to inspect all areas under the seal/bellow and to check for

foreign objects.

A

A. Seal/Bellow

3. If stained areas are found, wipe down these areas of the seal/

bellow, using the procedure that follows.

a} Mix a dilute solution, using 177 mL (3/4 cup) of liquid

chlorine bleach, and 3.8 L (1 gal. ) of warm tap water.

b} Wipe the seal/bellow area with the dilute solution,

using a damp cloth.

c} Let stand 5 minutes.

d} Wipe down area thoroughly with a dry cloth and let the

washer interior air dry with door open.

IMPORTANT:

[] Wear rubber gloves when cleaning for prolonged periods.

[] Refer to the bleach manufacturer's instructions for proper use.

Washer Maintenance Procedure

This washer has a special cycle that uses higher water volumes

in combination with liquid chlorine bleach to thoroughly clean

the inside of the washer.

NOTES:

[]

Read these instructions completely before beginning the

cleaning process.

[]

If necessary, the cleaning cycle may be interrupted by

pressing the QUICK CYCLE button twice. However, this

will not immediately stop the cycle. The washer will

continue with several rinse and drain steps to ensure that

all remaining bleach is rinsed from the washer.

Begin procedure

1. Open the washer door and remove any clothing or items from

the washer.

2, Use liquid chlorine bleach:

Open the dispenser drawer and immediately add

160 mL (2/3 cup) of liquid chlorine bleach to the bleach

compartment.

NOTE: Do not add any detergent to this cycle. Use of more

than 160 mL (2/3 cup) of bleach will cause product damage

over time.

3. Close the washer door and the dispenser drawer.

4. To start the Clean Washer cycle, first enter "Start Operating

Set-up." Then press and hold QUICK CYCLE for

1 second. With the entire display flashing, press BRIGHTS.

NOTE: The drum will rotate, then the door will unlock, lock

again, and then the cycle will continue.

[] The washer will not fill, but the drum will rotate while

the washer runs a short sensing cycle. This will take

approximately 3 minutes.

5. The cycle will determine whether clothing or other items are

in the washer.

a} If no items are detected in the washer, it will proceed

to Step 7.

b} If any items are detected in the washer, "rL" or "F-34"

will be displayed. Then the door will unlock.

[] Press QUICK CYCLE to cancel the failure code. Then

repeat steps 1, 3, and 4 to start the cycle again.

6. Once the cycle has begun, allow the cycle to complete.

7. After the cycle is complete, leave the door open slightly,

to allow for better ventilation and drying of washer interior.

Always do the following to maintain washer freshness

[] Use only "HE" High Efficiency detergent.

[] Leave the door slightly open after each cycle to allow

for better ventilation and drying of washer interior.

[] Clean the washer monthly using the Washer Maintenance

Procedure, and 160 mL (2/3 cup) of liquid chlorine bleach.

[] if the procedure does not sufficiently improve the machine

freshness, please evaluate your installation and usage

conditions for other causes.

Cleaning the exterior

;r r; r i r ............ r

Use a soft damp cloth or sponge to wipe up any spills.

Occasionally wipe the outside of your washer to keep it looking

new. Use mild soap and water. Do not use abrasive products.

................................................................r ;; ;

Cleaning the dispenser drawer

r r

The dispenser drawer is removable for easy cleaning.

1. Unlock the dispenser drawer by pressing the Release Lever.

Remove the drawer.

2. Remove the inserts (the siphon from the softener and bleach

compartments).

3. Wash the parts under running water.

NOTE: Do not wash components in the dishwasher.

4. Replace the inserts and return the dispenser to the drawer.

Replace water inlet hoses after 5 years of use to reduce the risk

of hose failure. Periodically inspect and replace water inlet hoses

if bulges, kinks, cuts, wear, or leaks are found.

When replacing your water inlet hoses, mark the date of

replacement on the label with a permanent marker.

16

Page 17

ASSISTANCEORSERVICE

If you need help, contact the dealer from whom you purchased

the appliance, or a Maytag designated service company. When

calling, please know the purchase date and the complete model

and serial number of your appliance. This information will help us

to better respond to your request.

MAYTAG ® COMMERCIAL SINGLE-LOAD AND VENDED

MULTI-LOAD WASHER & DRYER

WARRANTY

LIMITED WARRANTY ON PARTS

For the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the

instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter "Maytag") will pay for factory

specified parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date

is required to obtain service under this warranty.

Enhance your washer with these premium accessories.

For more high-quality items or to order, contact your authorized

Maytag distributor.

Part Number Accessory

8212526 Washer drip trays, fits under all

31682 All purpose appliance cleaner

1903WH Laundry supply storage cart

Manufacturer site: Whirlpool Mexico S.A. de C.V.,Antigua Carretera a Roma Km 9, Col.

Whirlpool Corporation, Benton Harbor, Michigan 49022, USA.

El Milagro, Apodaca, Nuevo Leon, C.R 66634, Mexico.

EU representative: Maytag UK Ltd, Redhill, RH1 lAX, UK

BAUKNECHT HAUSERGR)i,TEGrab H, D-73614 Schorndorf

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood, acts of

God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not approved

by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

10. Repairs made by a non-Whirlpool authorized service technician.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATIONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THiS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FORA PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LiMiTATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

if you need service, please contact your authorized Maytag ® Commercial Laundry distributor. To locate your authorized Maytag ®

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

3/1o

For written correspondence:

Maytag ® Commercial Laundry Service Department

2000 M-63 North

Benton Harbor, Michigan 49022 USA

17

Page 18

Whir ®

EU- DECLARATION OF CONFORMITY

CE - DECLARATION DE CONFORMITE

WE (nolts): BAUKNECHT HAUSGERA_TE GmbH, D-73614 Schorndorf

representing (repr&'entant): WHIRLPOOL EUROPE S.r.1 I-21025 COMERIO

declare under our sole responsibility that the product

d_c/arons solts notre propre res]_onsabilit_ ctlte /e prodltit

washing machines

(machine ?4 laver le linge) :

Whirlpool

Maytag

Maytag

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

altctltel se r_f_re cette d_claration est col_fbrme altx normes sltivantes olt alttres docltments normatif_'

EN 60335-1:2002+Al+A2+All+A12+A13+A14+A15

EN 60335-2-7:2010

EN 62233:2008

EN 61770:1999+Al:2004+A2:2006

EN ISO 10472-1:2008

EN ISO 10472-2:2008

EN ISO 12100-1:2010

EN 55014-1:2006+A1:2009

EN 55014-2:1997+Al:2001+A2:2008

EN 61000-3-2:2006+Al:2009+A2:2009

EN 61000-3-3:2008

3LCHW9100YQ

MHN30PN

MHN30PD

following the provisions of Directive(s):

sltivant les pr_visions des' Directives:

2006/42/EC MACHINERY DIRECTIVE

2004/108/EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

2011/65/EU ROHS DIRECTIVE

2002/96/EC WEEE DIRECTIVE

represented by

Schorndorf, 01.06.2012 Micael Zirondi

Place and date: Director PDC FC EMEA

lieu et date

Name and siNlal_ue of a_uthorised person

_llz et sigllamre de la persolllle autorisde

18

Karl-Dieter Klingenstein

Product Approval

GPO, Schorndorf

Page 19

P P

SECURITEDULAVE-LINGE

Votre s_curit_ et celle des autres est tr_s importante.

Nous donnons de nombreux messages de securit6 importants dans ce manuel et sur votre appareil menager. Assurez-vous de

toujours lire tousles messages de s6curit6 et de vous y conformer.

Voici le symbole d'alerte de securit6.

Ce symbole d'alerte de s6curit6 vous signale les dangers potentiels de d6c_s et de blessures graves & vous

et & d'autres.

Tousles messages de s6curit_ suivront le symbole d'alerte de s6curit6 et le mot "DANGER" ou

"AVERTISSEMENT'. Ces mots signifient :

Risque possible de d_c_s ou de blessure grave si vous ne

suivez pas imm6diatement les instructions.

Risque possible de d_c_s ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de s6curit6 vous diront quel est le danger potentiel et vous disent comment r_duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

llVIPORTANTES iNSTRUCTiONS DE SECURITE

AVERTISSEMENT : Pour r6duire les risques d'incendie, de choc electrique ou de blessures Iors de I'utilisation de la

laveuse, suivre les pr6cautions fondamentales dont les suivantes :

[] Dans certaines conditions, de I'hydrog_ne gazeux

peut se former dans un circuit d'eau chaude qui n'a

pas _t6 utilis6 pendant 2 semaines ou plus. LE GAZ

HYDROGC:NE EST EXPLOSIBLE. Si le circuit d'eau

chaude n'a pas 6t6 utilis6 pendant une telle p6riode,

avant d'utiliser la laveuse, ouvrir tousles robinets

d'eau chaude et laisser I'eau s'6couler pendant

plusieurs minutes par chaque robinet. Ceci

permettra I'evacuation de I'hydrog_ne gazeux

accumul6. Comme ce gaz est inflammable, ne pas

fumer ou utiliser une flamme nue au cours de cette

p6riode.

[] Avant de mettre la laveuse au rebut ou hors de service,

enlever la porte ou le couvercle.

[] Ne pas installer ou remiser cette laveuse & un endroit ot_elle

serait expos6e aux intemperies.

[] Ne pas r6parer ou remplacer un composant quelconque de

la laveuse, ni entreprendre une op6ration de service, si ce

n'est specifiquement recommand6 dans ce manuel ou dans

un manuel d'instructions de reparations destine h I'utilisateur;

il est alors essentiel que la personne concernee comprenne

ces instructions et soit competente pour les ex_cuter.

[] Voir "Specifications electriques" pour les instructions de

liaison a la terre.

CONSERVEZ CES iNSTRUCTiONS

19

Page 20

MISEAUREBUT DU LAVE.LINGE

Le marquage de rappareil est conforme h la directive europ6enne 2002/96/EC sur les 6quipements 61ectroniques et

dlectriques, pour gestion des d6chets.

En veillant & 1'61imination correcte de ce produit, vous 6viterez d'dventuelles consdquences n6fastes pour I'environnement et la

sant6 humaine qui peuvent _tre associ6es au traitement inapproprid de ce produit Iorsqu'il a 6t6 mis au rebut.

Le symbole figurant sur le produit ou dans les documents qui accompagnent le produit indique que cet appareil ne dolt pas 6tre

trait6 comme d6chet m6nager; on dolt plut6t le remettre hun centre de collecte spdcialis6 pour le recyclage des 6quipements

61ectriques et 61ectroniques.

L'61imination de ce produit apres mise au rebut dolt _tre effectuee conformement aux prescriptions de la reglementation locale

de protection de I'environnement.

Pour I'information detaill6e concernant le traitement, le recyclage et la recup6ration de ce produit, contacter la municipalite

locale, le service d'61imination des ddchets m_nagers, ou le commergant qui a vendu le produit.

Nomenclature des modules

MHN - Maytag 30 - Numdro de type de modele

PN - Module de commande dlectronique sans paiement

PD - Module de commande dlectronique avec chute de piece activd

EXIGENCESD'INSTALLATION

Rassembler les outils et pieces ndcessaires avant de commencer

I'installation. Les pieces fournies se trouvent dans le tambour du

lave-linge.

Outils n_cessaires au raccordement des tuyaux d'arriv_e

d_eau

[] Pince (ouverture jusqu'& [] Lampe de poche

39,5 mm [19/16"]) (facultative)

Outils ndcessaires _ I'installation

[] Clds plates de 1/2" et [] Niveau

9/16"

[] Tournevis de sdcuritd [] Regle ou metre ruban

Torx_l -I--20

[] Tourne-dcrou de 1/4"

[] Cale en bois

Pi_ces fournies

A B

c

A. Bride de retenue pour tuyau de vidange (en forme de U)

B. Tuyaux d'arrivee d'eau (2)

C. Rondelles pour tuyau d'arrivee d'eau (4)

D. Bouchons pour les trous des boulons de transport (4)

E. Attache de fixation amovible

F. Tuyau de vidange

G. Bride de tuyau

Pi_ces fournies pour les modules PD :

1® TORXest une marque d6pos6e de Saturn Fasteners,Inc.

20

Came de verrouillage de

la porte de service

Bandes de protection

Page 21

Autrespi_ces

IIsepeutqueI'installationn6cessitedespiecessuppl6mentaires.

PouracheterI'undesarticlesindiqu6sici,contacterle

distributeuraupresduquellelave-lingea6t6achet&

Si VOUS avez

Evier de buanderie ou

tuyau rigide de rejet &

1'6gout plus haut que

2,4 m (96")

Ftgout sur61ev6

Ftgout au plancher

Tuyau de vidange trop

court

Pi_destal

Vous avez la possibilit6 d'acheter des pi6destaux s6par6ment

pour ce lave-linge. Le pi6destal augmentera la hauteur totale du

lave-linge.

Vous devrez acheter

Systeme de pompe de puisard

(si non d6j& disponible)

Ftvier de vidange standard de

76 L (20 gal.) de 762 mm (30") de

hauteur ou 6vier utilitaire et pompe

de puisard (disponibles chez votre

fournisseur local d'articles de

plomberie)

Brise-siphon, piece n° 285834;

tuyau de vidange additionnel,

piece n° 8318155; et ensemble

de connexion, piece n° 285835

Trousse de rallonge du tuyau de

vidange de 1,2 m (4 pi), piece n°

285863

IIvous faudra

[] Un chauffe-eau configur_ pour fournir de I'eau

49°C (120°F) au lave-linge.

[] Une prise _lectrique reli_e a la terre situ_e a moins de

1,8 m (6 pi) du cordon d'alimentation _lectrique fix_

I'arriere du lave-linge. Voir "Specifications _lectriques".

[] Des robinets d'eau chaude et d'eau froide situ_s a moins

de 1,2 m (4 pi) des robinets d'admission d'eau chaude

et d'eau froide et une pression d'eau de 137,9-689,6 kPa

(20-1 O0 Ib/po2).

[] Un plancher de niveau ayant une pente maximale de

25 mm (1") sous I'ensemble du lave-linge. Uinstallation

du lave-linge sur des surfaces de sol molles, telles que

tapis ou surfaces avec sous-couche en mousse n'est pas

recommand_e.

[] Un plancher robuste et solide capable de soutenir le poids

total du lave-linge (eau et charge) de 180 kg (400 Ibs).

Ne pas faire fonctionner le lave-linge & des temperatures

inf_rieures & 0°C (32°F). Une quantit_ d'eau peut demeurer

dans le lave-linge et causer des dommages & des temperatures

basses.

D_gagements de s_paration _ respecter

[] L'emplacement dolt _tre assez grand pour permettre

d'ouvrir completement la porte du lave-linge.

[] Pr_voir davantage d'espace pour faciliter I'installation

et I'entretien. La porte s'ouvre & plus de 90° et n'est pas

r_versible.

[] Un espace suppl_mentaire peut _tre requis pour les

moulures de porte et de plancher et pour les plinthes.

[] Un espace suppl_mentaire de 25 mm (1") de tous les c6t_s

du lave-linge est recommand_ pour r_duire le transfert

du bruit.

[]

IIfaut aussi prendre en compte I'espace requis entre

les appareils voisins.

Dimensions du lave-linge

Piedestal facultatif

Hauteur du Hauteur Couleur Num_ro de

pi_destal approximative module

avec laveqinge

73 mm (27/8 ") 1207 mm (47,5") Blanc WHPO4OOVW

Le choix d'un emplacement appropri_ pour le lave-linge en

am_liore le rendement et r_duit au minimum le bruit et le

"d_placement" possible du lave-linge.

Le lave-linge peut _,tre install_ sous un comptoir personnalis_,

dans un sous-sol, une salle de buanderie ou un encastrement.

Voir "Systeme de vidange".

IIfaut aussi prendre en compte les exigences d'emplacement des

appareils voisins. C'est a I'utilisateur qu'incombe la responsabilit_

de r_aliser une installation correcte.

1282 686 mm

1134 mm

(44%")

{37'_/,e"}

La porte n'est pas reversible.

Un systeme de vidange au plancher doit _tre install_ sous la

cloison. Des cloisons pr_-fabriqu_es avec prises de courant,

canalisations d'arriv_e d'eau, et am_nagements pour installation

de vidange ne doivent _tre install_s que Ifl off les codes Iocaux

I'autorisent.

21

Page 22

Le lave-linge peut 6tre install6 en utilisant le systeme de rejet

1'6gout (au plancher ou mural), le systeme de vidange de

1'6vier de buanderie, ou le systeme de vidange au plancher.

S61ectionner la m6thode d'installation du tuyau de vidange

selon les besoins. Voir "Outillage et pieces".

Syst_me de vJdange avec tuyau de rejet a 1'6gout - mural

ou au plancher (vues Aet B)

Le systeme de rejet & 1'6gout n6cessite un tuyau rigide d'un

diametre minimum de 50 mm (2"). La capacit6 minimale

d'acheminement ne dolt pas 6tre inf@ieure & 45.5 L (12 gal.)

par minute et par lave-linge.

Le sommet du tuyau rigide de rejet &1'6gout dolt 6tre au moins

& 762 mm (30") de hauteur et au maximum &2,4 m (96") de la

base du lave-linge.

Syst_me de vidange au plancher (vue D)

Le systeme de vidange au plancher n6cessite un brise-siphon

qui peut 6tre achet6 s6par6ment. Voir "Outillage et pieces".

Le brise-siphon dolt 6tre au moins a 710 mm (28") de la base

du lave-linge. Des tuyaux suppl6mentaires peuvent 6tre requis.

C D

Tension E_lectrique Dangereuse

762

(30"

A

B

Syst_me de vidange avec 6vier de buanderie (vue C)

L'6vier de buanderie dolt avoir une capacit6 minimale de

76 L (20 gal.). La partie sup6rieure de 1'6vier de buanderie

dolt 6tre a au moins 762 mm (30") au-dessus du plancher.

Risque de choc 61ectrique

Brancher sur une prise reli6e _ la terre.

Ne pas utJliser un adaptateur,

Ne pas utJliser un c_ble de rallonge,

Le non=respect de ces instructions peut causer

un d6c_s, un incendie ou un choc 61ectrique.

[]

Une alimentation 61ectrique de 220-240V, 50 Hz, prot6g6e

par un fusible est requise. On recommande d'utiliser un

fusible temporis6 de 10 & 16 A ou un disjoncteur temporis6.

[]

Ce lave-linge comporte un cordon d'alimentation 61ectrique

pour liaison & la terre.

[]

Pour minimiser les risques de choc 61ectrique, on dolt

brancher le cordon sur une prise de courant de configuration

correspondante reli6e a la terre et install6e conform6ment

aux codes et reglements Iocaux. Si une prise de courant de

configuration correspondante n'est pas disponible, le client

a la responsabilit6 et I'obligation de faire installer par un

61ectricien qualifi6 une prise de courant correctement reli6e

la terre.

[]

Si les codes le permettent et si on utilise un conducteur

distinct de liaison & la terre, il est recommand6 qu'un

61ectricien qualifi6 v@ifie la qualit6 de la liaison a la terre.

22

Page 23

[]

Si le cordon d'alimentation est endommag6, il dolt 6tre

remplac6 par le fabricant, son agent de service ou toute

autre personne qualifi6e afin d'6viter tout danger.

[]

Ne pas utiliser une tuyauterie de gaz pour le raccordement

& la terre.

[] En cas de doute quant & la qualit6 de la liaison & la terre

du lave-linge, consulter un 61ectricien qualifi6.

[] Ne pas installer un fusible dans le conducteur neutre ou

le conducteur de liaison & la terre.

On trouve sur le panneau arriere du lave-linge 4 boulons

d'exp6dition qui soutiennent le systeme de suspension durant le

transport. Ces boulons retiennent aussi le cordon d'alimentation

61ectrique a I'int6rieur du lave-linge jusqu'a ce que les boulons

soient retir6s.

1. Laisser le lave-linge en position verticale pendant que I'on 6te

les boulons d'exp6dition.

Boulon !

INSTRUCTIONS DE LIAISON A LA TERRE

Ce lave-linge dolt 6tre reli6 a la terre. En cas d'anomalie de

fonctionnement ou de panne, la liaison a la terre r6duira le

risque de choc electrique en offrant au courant 61ectrique

un itin6raire d'6vacuation de moindre r6sistance. Ce

lave-linge est aliment6 par un cordon 61ectrique comportant

un conducteur reli6 a la terre et une fiche de branchement

munie d'une broche de liaison a la terre. La fiche dolt 6tre

branch6e sur une prise de courant appropri6e qui est bien

install6e et reli6e a la terre conform6ment a tous les codes

et reglements Iocaux.

AVERTISSEMENT : Le raccordement incorrect de cet

appareil au conducteur de liaison h la terre peut susciter un

risque de choc 61ectrique. En cas de doute quant h la

qualit6 de la liaison h la terre de I'appareil, consulter un

61ectricien ou technicien d'entretien qualifie.

Ne pas modifier la fiche de branchement fournie avec

I'appareil - si la fiche ne correspond pas a la configuration

de la prise de courant, demander a un 61ectricien qualifi6

d'installer une prise de courant convenable.

REMAROUE : Normes de s6curit6 61ectriques : Pour ce produit,

le fabricant a estim6 que la mise en conformit6 aux normes

IEC/EN.60335 6tait la plus appropri6e.

[] Niveau d'6mission sonore, Lpa : 58 dbA (uncertainty,

Kpa: +/-3.6 dbA)

INSTRUCTIONSD'INSTALLATION

Risque du poids excessif

Utiliser deux ou plus de personnes pour d6placer et

installer la laveuse.

Le non-respect de cette instruction peut causer une

blessure au dos ou d'autre blessure,

d'exp6dition I

Boulon d'expedition avec cale d'espacement en plastique

2. Au moyen d'une cl6 de 1/2", desserrer chacun des boulons.

3. Une fois le boulon dessert6, le d6placer au centre du

trou et retirer completement le boulon, y compris la cale

d'espacement en plastique couvrant le boulon.

4. Une fois que les 4 boulons ont 6t6 retir6s, jeter les boulons et

les cales d'espacement. Enfoncer ensuite la prise au dos du

lave-linge, tirer le cordon d'alimentation a travers I'ouverture

gauche du panneau arriere et boucher le trou avec le bouchon

fourni.

5. Obturer les trous des boulons avec les 4 bouchons

d'obturation des boulons de transport.

REMARQUE : Si le lave-linge dolt 6tre transport6 & une date

ult6rieure, appeler le distributeur ou I'installateur du produit. Pour

6viter des dommages concernant la suspension et la structure,

votre lave-linge dolt 6tre correctement mont6 pour r6installation

ult6rieure par un technicien certifi6.

1. S61ectionner la prise qui correspond a la prise 61ectrique

murale.

Poids max. avec emballage :

Modele PD: 115 kg (253,53 Ib)

Modele PN : 111 kg (244,71 Ib)

Poids max. sans emballage :

Modele PD : 111 kg (244,71 Ib)

Modele PN : 107 kg (235, 89 Ib)

iMPORTANT : Positionner le lave-linge de sorte que I'arriere du

lave-linge soit & environ 900 mm (3 pi) de son emplacement final.

2. Fixer la prise a I'extr6mit6 du cordon d'alimentation.

23

Page 24

3. Fixer le cordon d'alimentation en immobilisant le raccord sur

le dispositif de blocage du cordon.

m

4. Installer le couvercle du dispositif de blocage du cordon

et appuyer jusqu'& ce qu'il s'emboite.

5. S'assurer que le raccord du cordon d'alimentation est

immobilis6 sur le dispositif de blocage du cordon et que

le serrage du dispositif de blocage est correct.

Ins6rer les rondelles plates neuves (fournies) dans chaque

extr6mit6 des tuyaux d'arriv6e d'eau. Ins6rer fermement les

rondelles dans les raccords.

A B

REMARQUE : Ne pas serrer excessivement ou utiliser du ruban

adh6sif ou un calfeutrant sur la valve. Les valves risquent d'6tre

endommag6es.

Purger les canalisations d'eau

[] Laisser s'6couler I'eau des deux robinets et des tuyaux

d'alimentation dans un 6vier de buanderie, un tuyau rigide

de rejet a 1'6gout ou un seau, pour 61iminer les particules se

trouvant dans les canalisations d'eau qui pourraient obstruer

les tamis de la valve d'arriv6e d'eau.

[] V6rifier la temp6rature de I'eau pour s'assurer que le tuyau

d'eau chaude est connect6 au robinet d'eau chaude et que

le tuyau d'eau froide est connect6 au robinet d'eau froide.

A. Raccord

B. Rondelle

Connecter les tuyaux d'arrJv6e d'eau aux robinets d'eau

S'assurer que le tambour du lave-linge est vide.

1. Fixer un tuyau au robinet d'eau chaude. Visser completement