Page 1

DRYER INSTALLATION INSTRUCTIONS

27" Wide Models

Gas (U.S.A. and Canada) & Electric (Canada Only)

INSTRUCTIONS D’INSTALLATION DE LA SÉCHEUSE

Modèles de 27 de largeur

"

À gaz (É.-U. et Canada) et Électrique (Canada uniquement)

Para obtener acceso al manual de uso y cuidado en español, o para obtener información

adicional acerca de su producto, visite: www.maytag.com

Tenga listo su número de modelo completo. Puede encontrar el número de modelo

y de serie dentro de la cavidad superior de la puerta.

Table of Contents

DRYER SAFETY ............................................................... 2

INSTALLATION REQUIREMENTS ................................... 5

Tools and Parts ................................................................... 5

LOCATION REQUIREMENTS .................................................... 6

ELECTRIC DRYER POWER HOOKUP – CANADA ONLY ........ 8

Electrical Requirements .................................................... 8

GAS DRYER ELECTRICAL REQUIREMENTS ......................... 9

INSTALL LEVELING LEGS ......................................................... 9

GAS SUPPLY REQUIREMENTS .............................................. 10

VENTING ................................................................................... 11

Venting Requirements ...................................................... 11

Plan Vent System .............................................................. 12

Venting Kits ....................................................................... 13

Install Vent System ........................................................... 14

Make Gas Connection ..................................................... 14

Connect Vent .................................................................... 15

LEVEL DRYER .......................................................................... 15

COMPLETE INSTALLATION CHECKLIST .............................. 16

REVERSE DOOR SWING (OPTIONAL) ................................... 16

TROUBLESHOOTING .............................................................. 18

SÉCURITÉ DE LA SÉCHEUSE ...................................... 19

EXIGENCES D’INSTALLATION ..................................... 22

Outillage et pièces ........................................................... 22

EXIGENCES D’EMPLACEMENT ............................................. 23

RACCORDEMENT À L’ALIMENTATION ÉLECTRIQUE

DE LA SÉCHEUSE ÉLECTRIQUE – CANADA SEULEMENT .. 25

Spécications électriques ............................................... 25

SPÉCIFICATIONS ÉLECTRIQUES

DE LA SÉCHEUSE À GAZ ....................................................... 26

INSTALLATION DES PIEDS DE NIVELLEMENT .................... 26

RACCORDEMENT D’UNE SÉCHEUSE À GAZ ...................... 26

SPÉCIFICATIONS DE L’ALIMENTATION EN GAZ ................. 26

L’ÉVACUATION......................................................................... 28

Exigences concernant l’évacuation ............................... 28

Planication du système d’évacuation .......................... 29

Trousses d’évacuation ..................................................... 30

Installation du circuit d’évacuation ................................ 31

Raccordement au gaz ...................................................... 32

Raccordement du conduit d’évacuation ........................ 33

RÉGLAGE DE L’APLOMB DE LA SÉCHEUSE........................ 33

ACHEVER L’INSTALLATION – LISTE DE VÉRIFICATION ...... 34

INVERSION DU SENS DE L’OUVERTURE

DE LA PORTE

DÉPANNAGE ............................................................................ 36

Table des matières

(FACULTATIF)

................................................... 34

INSTALLATION NOTES

Date of purchase: ________________________________

Date of installation: _______________________________

Installer: _______________________________________

Model number: __________________________________

Serial number: ___________________________________

NOTES CONCERNANT L’INSTALLATION

Date d’achat: ____________________________________

Date d’installation: ________________________________

Installateur: _____________________________________

Numéro de modèle: _______________________________

Numéro de série: _________________________________

W11407407A

W11407408-SP

Page 2

DRYER SAFETY

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, Part 1, CSA C22.1.

2

Page 3

In the State of Massachusetts, the following installation instructions apply:

■ Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gas fitter qualified or licensed by

the State of Massachusetts.

■ Acceptable Shut-off Devices: Gas Cocks and Ball Valves installed for use shall be listed.

■ A flexible gas connector, when used, must not exceed 4 feet (121.9 cm).

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death, or property

damage.

–

Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this

or any other appliance.

–

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Clear the room, building, or area of all occupants.

•

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

•

instructions.

If you cannot reach your gas supplier, call the re department.

•

–

Installation and service must be performed by a qualied installer, service agency, or

the gas supplier.

3

Page 4

Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to a

chemical reaction that could cause a load to catch re.

To reduce the risk of re due to contaminated loads, the

nal part of a tumble dryer cycle occurs without heat

(cool down period). Avoid stopping a tumble dryer before

the end of the drying cycle unless all items are quickly

removed and spread out so that the heat is dissipated.

See Installation Instructions for grounding instructions.

4

Page 5

INSTALLATION REQUIREMENTS

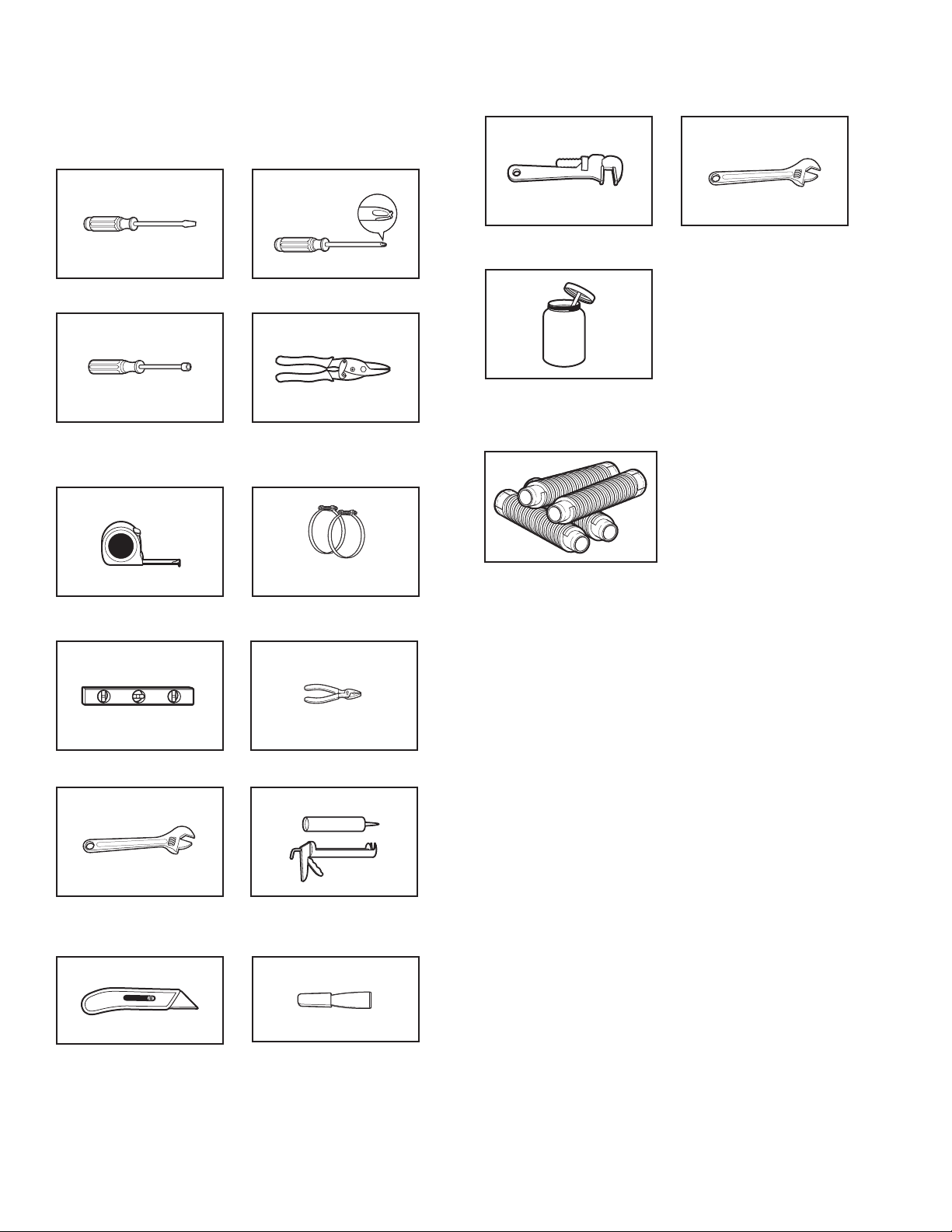

Tools and Parts

Gather the required tools and parts before starting installation.

Tools needed for all installations:

Flat-blade screwdriver

1/4" (6 mm) nut

driver or socket wrench

(recommended)

#2 Phillips screwdriver

Tin snips (new vent

installations)

Tools needed for gas installations:

8" (203 mm) or 10"

(254 mm) pipe wrench

Pipe-joint compound

resistant to propane gas

8" (203 mm) or 10"

(254 mm) adjustable

wrench (for gas

connections)

Parts supplied:

Tape measure

Level

Adjustable wrench that

opens to 1" (25 mm) or

hex-head socket wrench

Vent clamps

Pliers

Caulking gun and

compound (for installing

new exhaust vent)

Leveling legs (4)

Parts package is located in dryer drum. Check that all parts

are included.

Parts needed:

Check local codes. Check existing electrical supply and venting.

See “Electrical Requirements” and “Venting Requirements”

before purchasing parts.

Check code requirements. Some codes limit, or do not permit,

installing dryer in garages, closets, mobile homes, or sleeping

quarters. Contact your local building inspector.

Optional Equipment (Not supplied with dryer):

Refer to your Use and Care Guide for information

about accessories available for your dryer.

Utility knife

Putty knife

5

Page 6

LOCATION REQUIREMENTS

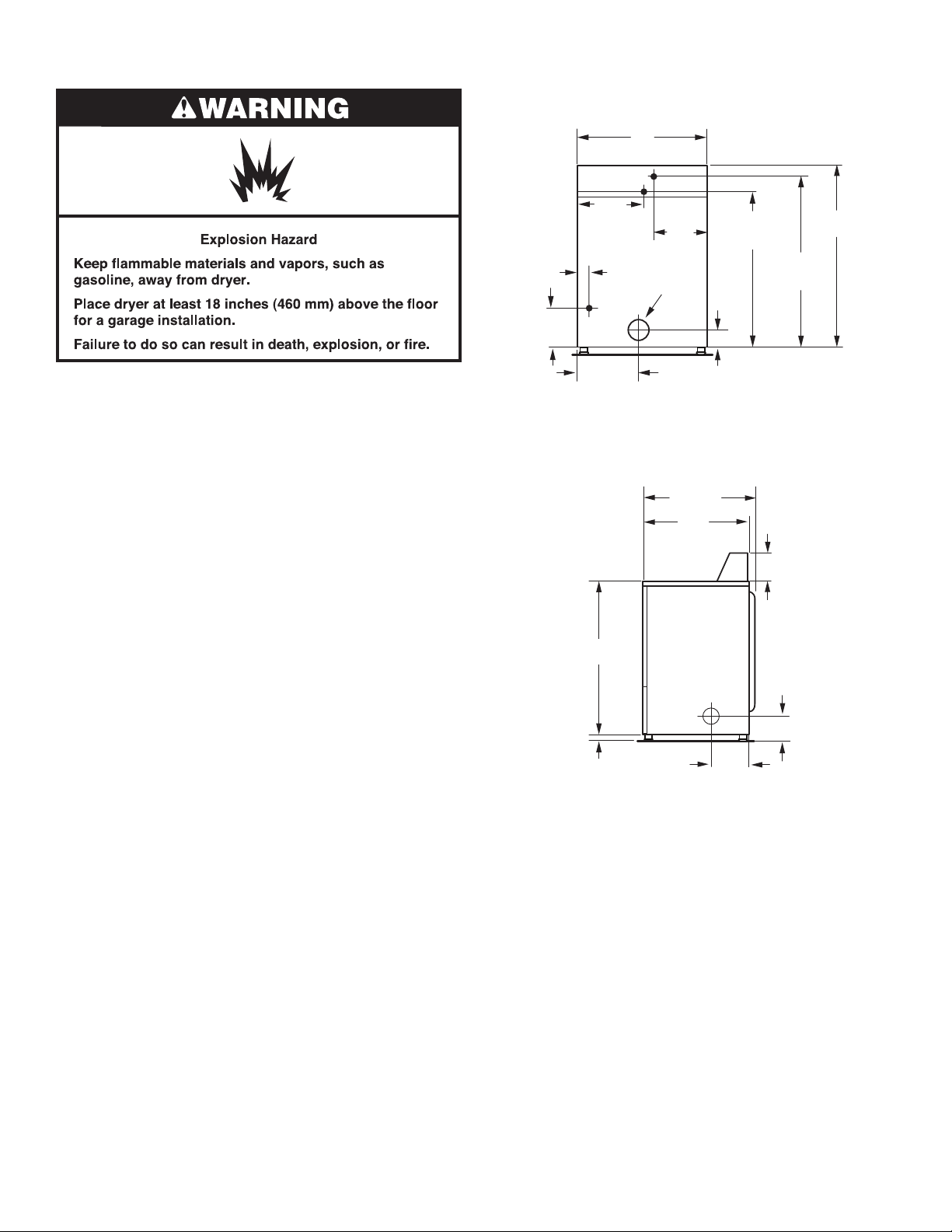

Dryer Dimensions

131/2"

(343 mm)

11/2"

(38 mm)

27"

(686 mm)

Electric

(102 mm)

Back View

103/4

"

(273 mm)

4" dia

36"

(914 mm)

(electric models)

371/2"

(953 mm)

(gas models)

41"

(1042 mm)

You will need:

■ A location allowing for proper exhaust installation.

See “Venting Requirements.”

■ A separate 30 A circuit for electric dryers.

■ A separate 15 A or 20 A circuit for gas dryers.

■ If you are using power supply cord, a grounded electrical

outlet located within 2 ft. (610 mm) of either side of dryer.

See “Electrical Requirements.”

■ A sturdy oor to support dryer and a total weight (dryer

and load) of 200 lbs. (90.7 kg). The combined weight of a

companion appliance should also be considered.

■ Level oor with maximum slope of 1" (25 mm) under entire

dryer. If slope is greater than 1" (25 mm), install Extended

Dryer Feet Kit, Part Number 279810. If not level, clothes

may not tumble properly and automatic sensor cycles may

not operate correctly.

Do not operate your dryer at temperatures below 45°F (7°C).

At lower temperatures, the dryer might not shut off at the end

of an automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

NOTE: No other fuel-burning appliance can be installed in the

same closet as a dryer.

Installation clearances:

The location must be large enough to allow the dryer door to

open fully.

Most installations require a minimum 5½" (140 mm) clearance

behind the dryer for the exhaust vent with elbow. See “Venting

Requirements.”

/2"

Gas

1

13

/2"

(343 mm)

31/4"

(83 mm)

1

5

(140 mm)

Side View

291/4"

(743 mm)

26"

(660 mm)

1

8

/4"

(210 mm)

35"

(889 mm)

31/4"

(83 mm)

1

/2"

7

(191 mm)

1"

(25 mm)

Most installations require a minimum 5½" (140 mm) clearance

behind the dryer for the exhaust vent with elbow. See “Venting

Requirements.”

6

Page 7

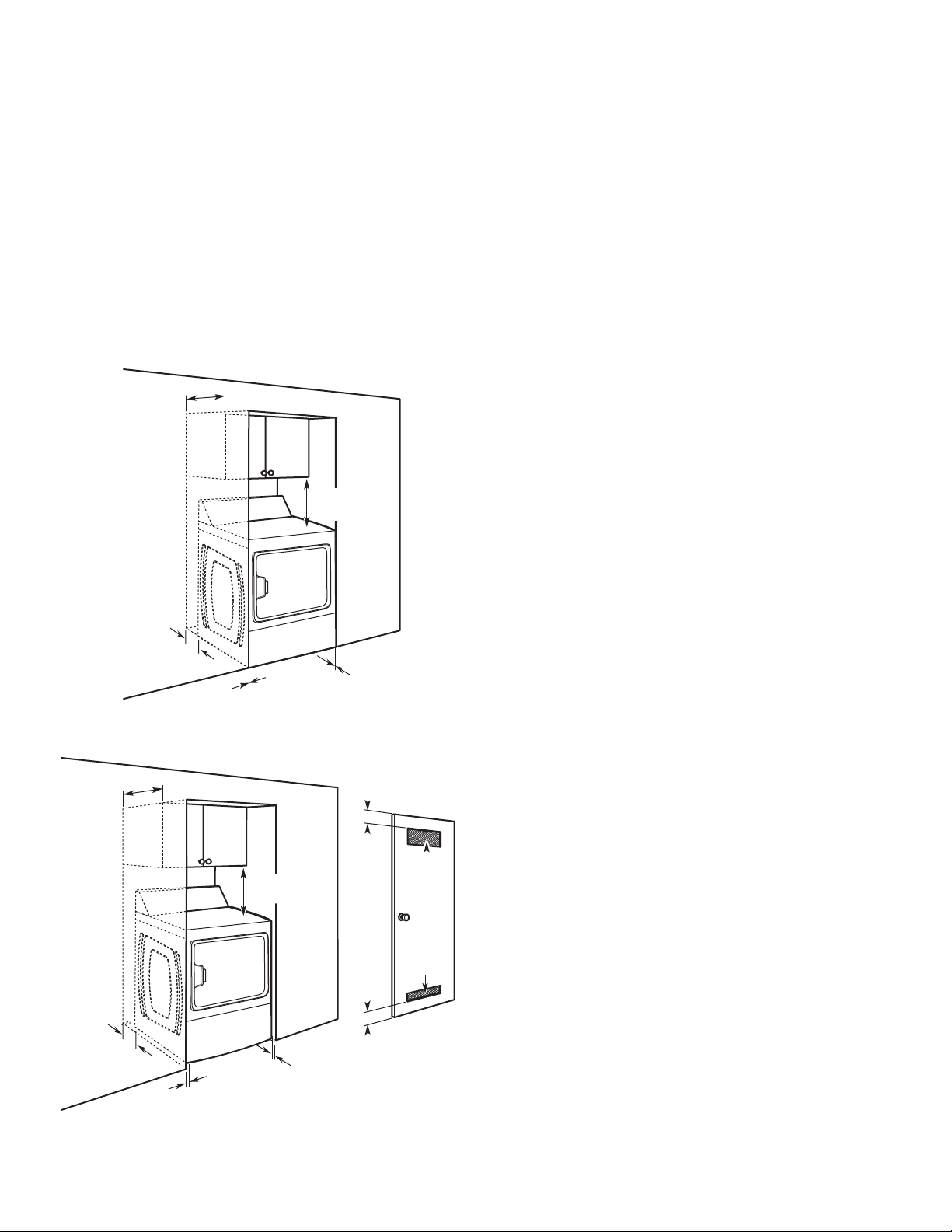

Minimum spacing for recessed area

or closet installation

The dimensions shown following are for the minimum spacing

allowed.

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances might be required for wall, door,

and oor moldings.

■ Additional spacing of 1" (25 mm) on all sides of the dryer

is recommended to reduce noise transfer.

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings

are acceptable.

■ Companion appliance spacing should also be considered.

Minimum Required Spacing

Recessed Area Installation

14" max

(356 mm)

15"

(381 mm)

Mobile home – Additional installation requirements

This dryer is suitable for mobile home installations. The

installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280) or the Canadian

Manufactured Home Standard CAN/CSA-Z240 MH.

■ Metal exhaust system hardware, which is available

for purchase. For further information, please reference the

“Assistance or Service” section of the Use and Care Guide.

■ Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such

as a nearby window) should be at least twice as large

as the dryer exhaust opening.

0"

(0 mm)

0"

(0 mm)

Closet Installation

14" max

(356 mm)

(381 mm)

0"

(0 mm)

0"

(0 mm)

Additional spacing recommended

15"

(25 mm)

1"

0"

(0 mm)

3"

(76 mm)

3"

(76 mm)

2

48 in

(310 cm2)

2

24 in

(155 cm2)

7

Page 8

ELECTRIC DRYER POWER

HOOKUP – CANADA ONLY

Electrical Requirements

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

It is your responsibility:

■ To contact a qualied electrical installer.

■ To be sure that the electrical connection is adequate

and in conformance with the Canadian Electrical Code,

C22.1 – latest edition and all local codes. A copy of the

above codes standard may be obtained from: Canadian

Standards Association, 178 Rexdale Blvd., Toronto, ON

M9W 1R3 CANADA.

■ To supply the required 4-wire, single phase, 120 V/240 V,

60 Hz., AC-only electrical supply on a separate 30 A circuit,

fused on both sides of the line. A time-delay fuse

or circuit breaker is recommended. Connect to an individual

branch circuit.

■ This dryer is equipped with a UL Listed and/or CSA

International Certied Power Cord intended to be plugged

into a standard 14-30R wall receptacle. The cord is 5 ft.

(1.52 m) in length. Be sure wall receptacle is within reach

of dryer’s nal location.

WARNING:

grounding conductor can result in a risk of electric shock.

Check with a qualied electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not t the outlet, have a proper outlet

installed by a qualied electrician.

Improper connection of the equipment-

SAVE THESE INSTRUCTIONS

4-wire receptacle (14-30R)

■ Do not use an extension cord.

If using a replacement power supply cord, it is recommended

that you use Power Supply Cord Replacement Part Number

8579325. For further information, please reference the

“Assistance or Service” section of the Use and Care Guide.

8

Page 9

GAS DRYER ELECTRICAL

REQUIREMENTS

■ 120 V, 60 Hz., AC-only, 15 A or 20 A fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is also recommended that a separate

circuit serving only this dryer be provided.

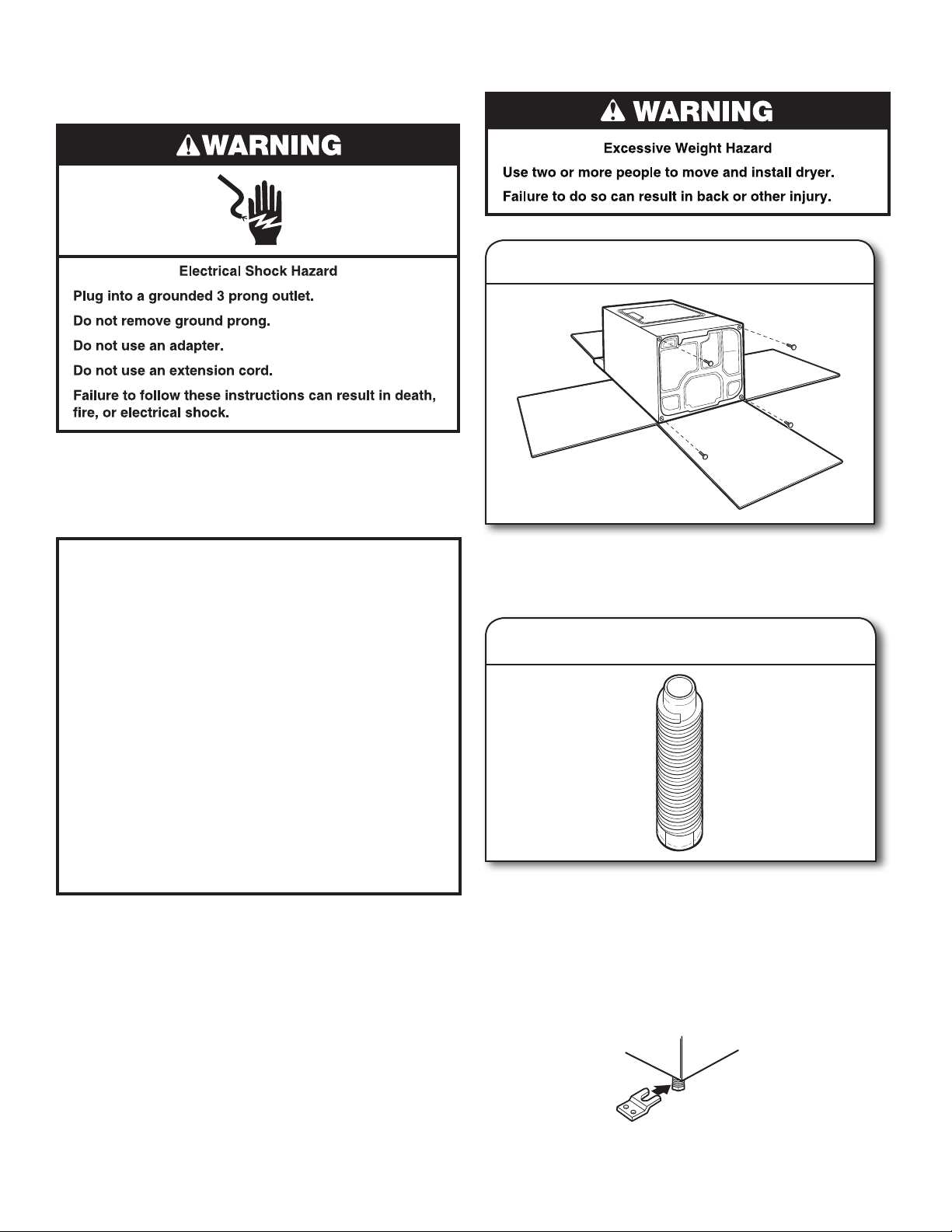

INSTALL LEVELING LEGS

1. Prepare dryer for leveling legs

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualied electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not t the outlet, have a proper outlet

installed by a qualied electrician.

SAVE THESE INSTRUCTIONS

To avoid damaging oor, use a large at piece of cardboard

from dryer carton; place under entire back edge of dryer.

Firmly grasp dryer body (not console panel) and gently lay

dryer down on cardboard.

2. Screw in leveling legs

Using a wrench and tape measure, screw legs into leg holes

until bottom of foot is approximately 1½" (38 mm) from

bottom of dryer.

Now stand the dryer on its legs. Slide the dryer until it is

close to its nal location. Leave enough room for electrical

connection and to connect the exhaust vent.

For mobile home use

Gas dryers must be securely fastened to the oor.

Mobile home installations require a Mobile Home Installation

Hold-down Kit. For ordering information, please reference the

Use and Care Guide.

9

Page 10

GAS SUPPLY REQUIREMENTS

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 13" (330 mm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

GAS SUPPLY LINE

■ 1/2" NPT pipe is recommended.

■ 3/8" approved tubing is acceptable for lengths under

20 ft. (6.1 m) if local codes and gas supplier permit.

■ Must include 1/8" NPT minimum plugged tapping accessible

for test gauge connection, immediately upstream of the gas

connection to the dryer (see illustration).

■ Must include a shut-off valve.

In the U.S.A.:

An individual manual shut-off valve must be installed within

six (6) feet (1.8 m) of the dryer in accordance with the National

Fuel Gas Code, ANSI Z223.1.

In Canada:

An individual manual shut-off valve must be installed in

accordance with the B149.1, Natural Gas and Propane

Installation Code. It is recommended that an individual

manual shut-off valve be installed within six (6) feet (1.8 m)

of the dryer.

The shut-off valve location should be easy to reach for opening

and closing.

E

C

A

GAS TYPE

Natural gas:

This dryer is equipped for use with natural gas. It is certied

by UL for use with propane gas with appropriate conversion.

■ Your dryer must have the correct burner for the type of gas

in your home. Burner information is located on the rating

plate in the door well of your dryer. If this information does

not agree with the type of gas available, please reference the

“Assistance or Service” section of the Use and Care Guide.

Propane gas conversion:

IMPORTANT: Conversion must be made by a qualied

technician.

No attempt shall be made to convert the dryer from the gas

specied on the model/serial rating plate for use with a different

gas without consulting the serving gas supplier.

IMPORTANT: The gas installation must conform with local codes,

or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the Canadian Natural Gas and

Propane Installation Code, CSA B149.1.

D

B

A. 3/8" exible gas connector

B. 3/8" pipe to are adapter tting

C. 1/8" NPT minimum plugged tapping

D. 1/2" NPT gas supply line

E. Gas shut-off valve

GAS SUPPLY CONNECTION REQUIREMENTS

There are many methods by which your gas dryer can be

connected to the gas supply. Listed here are some guidelines

for two different methods of connection.

This dryer must be connected to the gas supply line with

a listed exible gas connector that complies with the standard

for connectors for gas appliances, ANSI Z21.24 or CSA 6.10.

Option 1 (Recommended Method)

Flexible stainless steel gas connector:

■ If local codes permit, use a new exible stainless steel gas

connector (Design Certied by the American Gas Association

or CSA International) to connect your dryer to the rigid gas

supply line. Use an elbow and a 3/8" are x 3/8" NPT adapter

tting between the stainless steel gas connector and the dryer

gas pipe, as needed to prevent kinking.

10

†®TEFLON is a registered trademark of Chemours.

Page 11

Option 2 (Alternate Method)

Approved aluminum or copper tubing:

■ Lengths over 20 ft. (6.1 m) can use 3/8" approved tubing

(if codes and gas supplier permit).

■ If you are using natural gas, do not use copper tubing.

■ 3/8" are x 3/8" NPT adapter tting between dryer pipe

and 3/8" approved tubing.

■ Lengths over 20 ft. (6.1 m) should use larger tubing and

a different size adapter tting.

■ If your dryer has been converted to use propane gas,

3/8" propane compatible copper tubing can be used.

If the total length of the supply line is more than 20 ft.

(6.1 m), use larger pipe.

NOTE: Pipe joint compounds that resist the action of

propane gas must be used. Do not use TEFLON®† tape.

DRYER GAS PIPE

■ The gas pipe that comes out through the rear of your dryer

has a 3/8" male pipe thread.

VENTING

Venting Requirements

1

1

/2"

(38 mm)

A

*5 3/4"

(146 mm)

A. 3/8" NPT dryer pipe

BURNER INPUT REQUIREMENTS

Elevations up to 10,000 ft. (3,048 m):

■ The design of this dryer is certied by CSA International for

use at altitudes up to 10,000 ft. (3,048 m) above sea level at

the B.T.U. rating indicated on the model/serial number plate.

Burner input adjustments are not required when the dryer is

operated up to this elevation.

Elevations above 10,000 ft. (3,048 m):

■ When installed above 10,000 ft. (3,048 m), a 4% reduction

of the burner B.T.U. rating shown on the model/serial

number plate is required for each 1,000 ft. (305 m)

increase in elevation.

Gas supply pressure testing

■ The dryer must be disconnected from the gas supply piping

system during pressure testing at pressures greater than

1/2 psi.

WARNING: To reduce the risk of re, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or exible metal vent shall be used

for exhausting.

4"

(102 mm)

4" (102 mm) heavy metal exhaust vent

■ Only a 4" (102 mm) heavy metal exhaust vent and clamps

may be used.

■ Do not use plastic or metal foil vent.

Rigid metal vent:

■ Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

■ Must be fully extended and supported in nal dryer location.

■ Remove excess to avoid sagging and kinking that may result

in reduced airow and poor performance.

■ Do not install in enclosed walls, ceilings, or oors.

■ The total length should not exceed 7

NOTE: If using an existing vent system, clean lint from

entire length of the system and make sure exhaust hood is

not plugged with lint. Replace plastic or metal foil vents with

rigid metal or exible metal vents. Review “Vent System Chart”

and, if necessary, modify existing vent system to achieve best

drying performance.

3

/4 ft. (2.4 m).

11

Page 12

Exhaust hoods:

I

■ Must be at least 12" (305 mm) from ground or any object

that may obstruct exhaust (such as owers, rocks, bushes,

or snow).

Recommended Styles:

Louvered hood Box hood

Acceptable Style:

Plan Vent System

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

B

C

D

E

A

F

G

B

H

Angled hood

Elbows:

■ 45° elbows provide better airow than 90° elbows.

Good

Better

Clamps:

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct

and catch lint. Do not use duct tape.

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

E. Clamps

F. Rigid metal or exible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

I. Optional side exhaust outlet

Optional exhaust installations:

Exhaust can be converted out the right side, left side, or through

the bottom (4-way vent kit). Each kit includes step-by-step

instructions. For ordering information, see “Venting Kits.”

See “Venting Kits” for more information.

12

A B C

A. Standard rear offset exhaust installation

B. Left or right side exhaust installation

C. Bottom exhaust installation

Page 13

Alternate installations for close clearances

Venting systems come in many varieties. Select the best type

for your installation. Two close-clearance installations are shown.

Refer to the manufacturer’s instructions.

Over-The-Top installation (also available with one offset elbow)

Periscope installation

NOTE: The following kits for close clearance alternate

installations are available for purchase.

Special provisions for mobile home installations:

The exhaust vent must be securely fastened to a noncombustible

portion of the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

Determine vent path:

■ Select route that will provide straightest and most direct

path outdoors.

■ Plan installation to use fewest number of elbows and turns.

■ When using elbows or making turns, allow as much room

as possible.

■ Bend vent gradually to avoid kinking.

■ Use as few 90° turns as possible.

Venting Kits

For more information, call 1-800-344-1274

in the U.S. (1-800-688-2002 in Canada) or visit us

at www.maytagreplacementparts.com.

Part Number Descriptions

8171587RP 0"–5" Metal vent periscope

4396037RP 0"–18" Metal vent periscope

4396011RP 18"–29" Metal vent periscope

4396014 29"–50" Metal vent periscope

4392892 In-wall metal DuraVent™ periscope

W10186596 4-way vent kit – universal grey

4396028 Sure Connect™ venting kit

(over-the-top installation)

4396009RP 5' Universal connect vent, exible dryer venting

4396010RP 6' SecureConnect™ vent, exible dryer venting

4396013RB Dryer vent installer’s kit

4396033RP 5' exible dryer venting with clamps

4396727RP 8' exible dryer venting with clamps

4396004 Dryer offset elbow

4396005 Wall offset elbow

4396006RW DuraSafe™ close elbow

4396007RW Through-the-wall vent cap

4396008RP 4" steel dryer venting clamps – 2 pack

8212662 Flush mounting louvered vent hood, 4"

Determine vent length and elbows needed for best

drying performance:

■ Use following Vent System Chart to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specied

in Vent System Chart. Exhaust systems longer than those

specied will:

■ Shorten life of dryer.

■ Reduce performance, resulting in longer drying times

and increased energy usage.

The Vent System Chart provides venting requirements that

will help achieve best drying performance.

Vent System Chart

Number of

90° turns

or elbows

0 Rigid metal

1

2

3

4

Type

of vent

Rigid metal

Rigid metal

Rigid metal

Rigid metal

Box/louvered

hoods

64 ft. (20 m)

54 ft. (16.5 m)

44 ft. (13.4 m)

35 ft. (10.7 m)

27 ft. (8.2 m)

Angled

hoods

58 ft. (17.7 m)

48 ft. (14.6 m)

38 ft. (11.6 m)

29 ft. (8.8 m)

21 ft. (6.4 m)

NOTE: Side and bottom exhaust installations have a 90º turn

inside the dryer. To determine maximum exhaust length, add

one 90º turn to the chart.

13

Page 14

A

B

C

D

A

B

Install Vent System

12" min.

(305 mm)

12" min.

(305 mm)

Make Gas Connection

1. Install exhaust hood

Install exhaust hood and use caulking compound to seal

exterior wall opening around exhaust hood.

2. Connect vent to exhaust hood

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 13" (330 mm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

1. Connect gas supply to dryer

Vent must t over the exhaust hood. Secure vent to exhaust

hood with 4" (102 mm) clamp. Run vent to dryer location

using straightest path possible. Avoid 90° turns. Use clamps

to seal all joints. Do not use duct tape, screws, or other

fastening devices that extend into interior of vent to secure

vent, because they can catch lint.

Non-ared

male tting

Flared

male tting

Remove red cap from gas pipe. Using a wrench to tighten,

connect gas supply to dryer. Use pipe-joint compound

on threads of all non-ared male ttings. If exible metal

tubing is used, be sure there are no kinks.

NOTE: For propane gas connections, you must use pipe-joint

compound resistant to action of propane gas. Do not use

TEFLON®† tape.

2. Plan pipe tting connection

14

A. 3/8" exible gas connector

B. 3/8" dryer pipe

A combination of pipe ttings must be used to connect dryer

to existing gas line. A recommended connection is shown.

Your connection may be different, according to supply line

type, size, and location.

C. 3/8" to 3/8" pipe elbow

D. 3/8" pipe-to-are adapter tting

Page 15

3. Open shut-off valve

LEVEL DRYER

Closed valve

A

Open valve

B

Open shut-off valve in supply line; valve is open when handle

is parallel to gas pipe. Then, test all connections by brushing

on an approved noncorrosive leak-detection solution.

Bubbles will show a leak. Correct any leaks found.

Connect Vent

1. Connect vent to exhaust outlet

1. Level dryer

Check levelness of dryer from side to side. Repeat from

front to back.

NOTE: The dryer must be level for the moisture sensing

system to operate correctly.

Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure vent is

clean. Dryer vent must t over dryer exhaust outlet and inside

exhaust hood. Check that vent is secured to exhaust hood

with a 4" (102 mm) clamp.

2. Move dryer to nal location

Not Level LEVEL Not Level

2. Tighten and adjust leveling legs

If dryer is not level or the same height as the washer, prop up

using a wood block. Use wrench to adjust legs up or down,

and check again for levelness. Once dryer is level, make sure

all four legs are snug against the oor before tightening them.

Move dryer to nal location. Avoid crushing or kinking vent.

After dryer is in place, remove corner posts and cardboard

from under the dryer.

15

Page 16

COMPLETE INSTALLATION

CHECKLIST

Check that all parts are now installed. If there is an extra

q

part, go back through steps to see what was skipped.

Check that you have all of your tools.

q

Dispose of/recycle all packaging materials.

q

Check dryer’s nal location. Be sure vent is not crushed

q

or kinked.

Check that dryer is level. See “Level Dryer.”

q

Remove lm on console and any tape remaining on dryer.

q

Wipe dryer drum interior thoroughly with a damp cloth to

q

remove any dust.

Read “Dryer Use” in your Use and Care Guide.

q

Set the dryer on a full heat cycle (not an air cycle)

q

for 20 minutes and start the dryer.

If the dryer will not start, check the following:

■ Gas dryer is plugged into a grounded 3-prong

outlet. Electric dryer is plugged into a grounded

4-prong outlet.

■ Electrical supply is connected.

■ Household fuse is intact and tight, or circuit breaker

has not tripped.

■ Dryer door is closed.

When the dryer has been running for 5 minutes, open the

q

dryer door and feel for heat. If you feel heat, cancel cycle

and close the door.

If you do not feel heat, turn the dryer off and check

the following:

Gas Dryers:

■ If the gas supply line shut-off valve is closed, open it,

then repeat the 5-minute test as outlined above.

■ If the gas supply line shut-off valve is open, contact

a qualied technician.

Electric Dryers:

■ There may be two household fuses or circuit breakers

for the dryer. Check that both fuses are intact and

tight, or that both circuit breakers have not tripped.

If there is still no heat, contact a qualied technician.

NOTE: You may notice an odor when the dryer is rst heated.

This odor is common when the heating element is rst used.

The odor will go away.

REVERSE DOOR SWING

(OPTIONAL)

NOTE: Magnetized screwdriver is helpful.

27" Wide Model Side-Swing Door

1. Place towel on dryer

Place towel on top of dryer to avoid damaging the surface.

2. Remove bottom screws

Open dryer door. Remove bottom screws from dryer cabinet

side of hinges. Loosen (do not remove) top screws from dryer

cabinet side of hinges.

3. Lift door off top screws

16

Lift door until top screws in dryer cabinet are in large part of

hinge slot. Pull door forward off screws. Set door (handle side

up) on top of dryer. Remove top screws from dryer cabinet.

Page 17

4. Remove screws from hinges

7. Flip door over

Flip door over so handle side is down.

Remove screws attaching hinges to door.

5. Remove screws from door

Remove screws at top, bottom, and side of door (ve

screws). Keep door screws separate from hinge screws as

they are different sizes. Holding door over towel on dryer,

grasp sides of outer door and lift to separate it from inner

door.

NOTE: Do not pry apart with putty knife or screwdriver.

Do not pull on door seal or plastic door catches.

6. Rotate outer door

8. Attach door hinges

Rotate outer door 180º and set it back down on inner door.

Be certain to keep cardboard spacer centered between

doors. Reattach outer door panel to inner door panel so

handle is on the side where hinges were just removed.

Insert ve door screws.

Reattach door hinges to dryer door so that the larger hole

is at the bottom of the hinge.

9. Remove and transfer plugs

Remove the four screws that attach two plugs on the left side.

Transfer plugs to opposite side using the same four screws.

17

Page 18

10. Insert screws in hinge holes

on dryer cabinet

NOTE: Two people may be needed to reinstall door.

Insert screws into the bottom holes on left side of dryer cabinet.

Tighten screws halfway. Position door so large end of door

hinge slot is over screws. Slide door up so screws are in bottom

of slots. Tighten screws. Insert and tighten top screws in hinges.

11. Check door strike alignment

TROUBLESHOOTING

See the Use and Care Guide or visit our website and reference

“Frequently Asked Questions” to possibly avoid the cost of

a service call.

Close door and check that door strike aligns with door catch.

If it is needed, slide door catch left or right within slot to adjust

alignment.

18

Page 19

SÉCURITÉ DE LA SÉCHEUSE

19

Page 20

IMPORTANT : L'installation du gaz doit se conformer aux codes locaux, ou en l'absence de codes locaux, au code d'installation

du gaz naturel ou du propane, CSA B149.1.

La sécheuse doit être électriquement reliée à la terre conformément aux codes locaux, ou en l'absence de codes locaux, au Code

canadien de l'électricité, partie 1, CSA C22.1.

Dans l’État du Massachusetts, les instructions d’installation suivantes sont applicables :

■ Les travaux d’installation et réparation doivent être exécutés par un plombier ou tuyauteur qualifié ou licencié, ou par le

personnel qualifié d’une entreprise licenciée par l’État du Massachusetts.

■ Remplacer par des dispositifs de fermeture acceptables : Les robinets de gaz et robinets à bille installés pour l'utilisation

devraient être indiqués.

■ Si un conduit de raccordement flexible est utilisé, sa longueur ne doit pas dépasser 4 pi (121,9 cm).

AVERTISSEMENT :

’

RISQUE D

INCENDIE OU D’EXPLOSION

Le non-respect des avertissements de sécurité peut causer des dommages à la propriété,

des blessures graves, voire la mort.

– Ne pas entreposer ou utiliser de l’essence ou d’autres vapeurs ou liquides inammables

à proximité de cet appareil ou de tout autre appareil électroménager.

– QUE FAIRE DANS LE CAS D’UNE ODEUR DE GAZ :

Ne pas tenter d’allumer un appareil.

•

Ne pas toucher à un commutateur électrique; ne pas utiliser le téléphone se trouvant

•

sur les lieux.

Évacuer tous les gens de la pièce, de l’édice ou du quartier.

•

Appeler immédiatement le fournisseur de gaz d’un téléphone voisin. Suivre ses

•

instructions.

À défaut de joindre votre fournisseur de gaz, appeler les pompiers.

•

– L’installation et l’entretien doivent être effectués par un installateur qualié, une agence

de service ou le fournisseur de gaz.

20

Page 21

Consulter les instructions d’installation pour savoir

comment effectuer la mise à la terre.

21

Page 22

EXIGENCES D’INSTALLATION

Outillage et pièces

Rassembler les outils et composants nécessaires avant

d’entreprendre l’installation.

Outils nécessaires pour toutes les installations :

Tournevis à lame plate Tournevis Phillips n° 2

Tourne-écrou de 1/4"

(6 mm) (recommandé)

Mètre-ruban

Cisaille de ferblantier

(pour l’installation d’un

nouveau conduit)

Brides de serrage pour

conduit d’évacuation

Couteau utilitaire

Couteau à mastic

Outils nécessaires aux installations au gaz :

Clé à tuyau de 8"

(203 mm) ou 10" (254 mm)

Composé d’étanchéité

des raccords letés –

résistant au gaz propane

Clé à molette de 8"

(203 mm) ou 10" (254 mm)

(pour le raccordement au gaz)

Pièces fournies

Niveau

Clé à molette avec

ouverture jusqu’à

1" (25 mm) ou clé à

douille à tête hexagonale

22

Pince

Pistolet à calfeutrage et

composé de calfeutrage

(pour l’installation d’un

nouveau conduit d’évacuation)

Pieds de nivellement (4)

Le sachet de pièces se trouve dans le tambour de la sécheuse.

Vérier que toutes les pièces sont présentes.

Pièces nécessaires :

Consulter les codes locaux. Vérier l’alimentation électrique et

le circuit d’évacuation existants. Voir “Spécications électriques”

et “Exigences concernant l’évacuation” avant d’acheter

les pièces.

Vérier les exigences des codes. Certains codes limitent ou

n’autorisent pas l’installation des sécheuses dans un garage,

un placard, une maison mobile ou une chambre à coucher.

Contacter l’inspecteur en bâtiment local.

Équipement facultatif (Non fourni avec la sécheuse) :

Se référer au Guide d’utilisation et d’entretien pour des

renseignements sur les accessoires disponibles pour

la sécheuse.

Page 23

EXIGENCES D’EMPLACEMENT

Dimensions de la sécheuse

Vue arrière

27"

(686 mm)

Electric

131/2"

(343 mm)

103/4

11/2"

(38 mm)

(273 mm)

4" dia

(102 mm)

36"

(914 mm)

"

(electric models)

(1042 mm)

371/2"

(953 mm)

(gas models)

41"

Il vous faudra :

■ Un emplacement permettant une évacuation appropriée.

Voir “Exigences concernant l’évacuation.”

■ Un circuit distinct de 30 A pour les sécheuses électriques.

■ Un circuit distinct de 15 A ou 20 A pour les sécheuses

à gaz.

■ Si on utilise un cordon d’alimentation, une prise électrique

avec liaison à la terre située à moins de 2 pi (610 mm) de

l’un des côtés de la sécheuse. Voir “Spécications électriques.”

■ Un plancher robuste capable de supporter le poids de

la sécheuse (sécheuse et charge) de 200 lb. (90,7 kg).

Il faut aussi prendre en compte le poids combiné d’un

appareil ménager voisin.

■ Un plancher de niveau ayant une pente maximale de

1" (25 mm) sous l’ensemble de la sécheuse. Si la pente

est supérieure à 1" (25 mm), installer un ensemble de

pieds d’extension pour sécheuse, pièce n° 279810. Si

la sécheuse n’est pas d’aplomb, le linge peut ne pas

culbuter convenablement, et les programmes automatiques

de détection peuvent ne pas fonctionner correctement.

Ne pas faire fonctionner la sécheuse à une température inférieure

à 45 °F (7 °C). À des températures inférieures, la sécheuse risque

de ne plus s’arrêter à la n d’un programme automatique. Les

temps de séchage risquent alors d’augmenter.

La sécheuse ne doit pas être installée ou remisée dans un endroit

où elle sera exposée à l’eau et/ou aux intempéries.

Vérier les règlements locaux. Certains codes limitent ou

n’autorisent pas l’installation des sécheuses dans un garage,

un placard, une maison mobile ou une chambre à coucher.

Communiquer avec l’inspecteur des bâtiments local.

REMARQUE : Aucun autre appareil consommant un combustible

ne doit être installé dans le même placard que la sécheuse.

/2"

Gas

1

13

/2"

(343 mm)

31/4"

(83 mm)

1

5

(140 mm)

Vue latérale

291/4"

(743 mm)

26"

(660 mm)

1

8

/4"

(210 mm)

35"

(889 mm)

31/4"

(83 mm)

1

/2"

7

(191 mm)

1"

(25 mm)

La plupart des installations requièrent un espace minimum de

5½" (140 mm) derrière la sécheuse pour le conduit d’évacuation

avec coude. Voir “Exigences concernant l’évacuation.”

Espacements d’installation :

L’emplacement doit être assez grand pour permettre d’ouvrir

complètement la porte de la sécheuse.

La plupart des installations requièrent un espace minimum de

5½" (140 mm) derrière la sécheuse pour le conduit d’évacuation

avec coude. Voir “Exigences concernant l’évacuation.”

23

Page 24

Espacement pour une installation

dans un encastrement ou dans un placard

Les dimensions correspondent à l’espacement minimum permis.

■ Prévoir davantage d’espace pour faciliter l’installation

et l’entretien.

■ Un espace supplémentaire peut être requis pour les moulures

de porte et de plancher et pour les plinthes.

■ Un espace supplémentaire de 1" (25 mm) doit être envisagé

de tous les côtés de la sécheuse an de réduire le transfert

de bruit.

■ Pour une installation dans un placard avec porte, on doit

prévoir des ouvertures minimums d’entrée d’air en haut

et en bas de la porte. Les portes à claire-voie offrant

des ouvertures équivalentes de passage de l’air sont

acceptables.

■ Il faut aussi prendre en compte l’espace requis entre

les appareils voisins.

Espacement minimal requis

Installation dans un encastrement

14" max

(356 mm)

Installation dans une maison mobile –

exigences supplémentaires

Cette sécheuse peut être installée dans une maison mobile.

L’installation doit satisfaire aux critères du Manufactured Home

Construction and Safety Standard, Titre 24 CFR, Partie 3280

(anciennement Federal Standard for Mobile Home Construction

and Safety, Titre 24, HUD Partie 280) ou du Canadian

Manufactured Home Standard CAN/CSA-Z240 MH.

■ Un matériel d’évacuation métallique, disponible à l’achat.

Pour plus d’informations, consulter la section “Assistance

ou service” dans le Guide d’utilisation et d’entretien.

■ Il faut prendre des dispositions spéciales dans les maisons

mobiles pour l’apport d’air de l’extérieur dans la sécheuse.

L’ouverture (telle qu’une fenêtre à proximité) devrait être au

moins deux fois plus grande que l’ouverture de décharge

de la sécheuse.

14" max

(356 mm)

15"

(381 mm)

0"

(0 mm)

0"

(0 mm)

(0 mm)

Installation dans un placard

(76 mm)

15"

(381 mm)

(76 mm)

0"

3"

3"

2

48 po

(310 cm2)

24 po

(155 cm2)

2

0"

(0 mm)

0"

(0 mm)

1"

(25 mm)

Un espace supplémentaire est recommandé

24

Page 25

RACCORDEMENT À L’ALIMENTATION ÉLECTRIQUE

DE LA SÉCHEUSE ÉLECTRIQUE – CANADA SEULEMENT

Spécications électriques

C’est à l’utilisateur qu’incombe la responsabilité de :

■ Contacter un électricien qualié.

■ S’assurer que le raccordement électrique est adéquat

et conforme au Code canadien de l’électricité, C22.1 –

dernière édition, et à tous les codes locaux en vigueur.

Pour obtenir un exemplaire des normes des codes ci-dessus,

contacter : Canadian Standards Association, 178 Rexdale

Blvd., Toronto, ON M9W 1R3 CANADA.

■ L’appareil doit être alimenté uniquement par un circuit

monophasé de 120 V/240 V CA seulement, 60 Hz à 4 ls,

sur un circuit séparé de 30 A, fusionné aux deux extrémités

de la ligne. On recommande d’utiliser un fusible

ou un disjoncteur temporisé. On recommande également

que cet appareil soit alimenté par un circuit indépendant.

■ Cette sécheuse est équipée d’un cordon d’alimentation

homologué UL et/ou par la CSA International à introduire

dans une prise murale standard 14-30R. Le cordon mesure

5 pi (1,52 m). Veiller à ce que la prise murale se trouve

à proximité de l’emplacement dénitif de la sécheuse.

INSTRUCTIONS DE LIAISON À LA TERRE

Pour une sécheuse reliée à la terre et connectée par

un cordon :

Cette sécheuse doit être reliée à la terre. En cas de mauvais

fonctionnement ou de panne, la liaison à la terre réduira le

risque de choc électrique en offrant au courant électrique un

acheminement d'évacuation de moindre résistance. Cette

sécheuse est alimentée par un cordon électrique comportant

un conducteur relié à la terre et une che de branchement

munie d'une broche de liaison à la terre. La che doit être

branchée sur une prise appropriée qui est bien installée et

reliée à la terre conformément à tous les codes et règlements

locaux.

AVERTISSEMENT :

cet appareil au conducteur de liaison à la terre peut susciter

un risque de choc électrique. En cas de doute quant à la

qualité de liaison à la terre de la sécheuse, consulter un

électricien ou un technicien ou un personnel qualié. Ne pas

modier la che de branchement fournie avec la sécheuse;

si la che ne correspond pas à la conguration de la prise de

courant, demander à un électricien qualié d'installer une

prise de courant appropriée.

Le raccordement incorrect de

CONSERVEZ CES INSTRUCTIONS

Prise murale à 4 ls (14-30R)

■ Ne pas utiliser de câble de rallonge.

En cas d’utilisation d’un cordon d’alimentation de rechange,

il est conseillé d’utiliser le cordon d’alimentation de rechange –

pièce numéro 8579325. Pour plus d’information, consulter

la section “Assistance ou service” dans le Guide d’utilisation

et d’entretien.

25

Page 26

SPÉCIFICATIONS ÉLECTRIQUES

DE LA SÉCHEUSE À GAZ

■ L’appareil doit être alimenté par un circuit de 120 V, CA

seulement, 60 Hz, 15 A ou 20 A, protégé par un fusible.

On recommande l’emploi d’un fusible ou d’un disjoncteur

temporisé. Il est recommandé de raccorder l’appareil sur

un circuit distinct exclusif à cet appareil.

INSTALLATION DES PIEDS

DE NIVELLEMENT

1. Préparer la sécheuse pour les pieds

de nivellement

INSTRUCTIONS DE LIAISON À LA TERRE

Pour une sécheuse reliée à la terre et connectée par

un cordon :

Cette sécheuse doit être reliée à la terre. En cas de mauvais

fonctionnement ou de panne, la liaison à la terre réduira le

risque de choc électrique en offrant au courant électrique un

acheminement d'évacuation de moindre résistance. Cette

sécheuse est alimentée par un cordon électrique comportant

un conducteur relié à la terre et une che de branchement

munie d'une broche de liaison à la terre. La che doit être

branchée sur une prise appropriée qui est bien installée et

reliée à la terre conformément à tous les codes et règlements

locaux.

AVERTISSEMENT : Le raccordement incorrect de

cet appareil au conducteur de liaison à la terre peut susciter

un risque de choc électrique. En cas de doute quant à la

qualité de liaison à la terre de la sécheuse, consulter un

électricien ou un technicien ou un personnel qualié. Ne pas

modier la che de branchement fournie avec la sécheuse;

si la che ne correspond pas à la conguration de la prise de

courant, demander à un électricien qualié d'installer une

prise de courant appropriée.

CONSERVEZ CES INSTRUCTIONS

Pour ne pas endommager le plancher, utiliser un grand

morceau de carton découpé dans l’emballage de la sécheuse;

le placer sous tout le bord arrière de la sécheuse. Saisir

fermement la sécheuse par la caisse (non par le panneau

de commande) et incliner soigneusement la sécheuse

sur le carton.

2. Visser dans les pieds de nivellement

À l’aide d’une clé et d’un mètre-ruban, visser les pieds

dans les trous pour pieds de nivellement jusqu’à ce que

le bas de chaque pied se trouve à environ 1½" (38 mm)

du bas de la sécheuse.

À présent, redresser la sécheuse et la placer sur ses pieds.

Faire glisser la sécheuse jusqu’à ce qu’elle se trouve à

proximité de son emplacement nal. Laisser sufsamment

d’espace pour le branchement électrique et pour connecter

le conduit d’évacuation.

26

Page 27

B

Pour utilisation en maison mobile

Les sécheuses à gaz doivent être solidement xées

au plancher.

Les installations en maison mobile nécessitent un ensemble

d’ancrage au sol pour installation en maison mobile. Pour le

processus de commande, consulter le Guide d’utilisation et

d’entretien.

SPÉCIFICATIONS DE

L’ALIMENTATION EN GAZ

AVERTISSEMENT

Risque d'explosion

Utiliser une canalisation neuve d'arrivée de gaz

approuvée par CSA International.

Installer un robinet d'arrêt.

Bien serrer chaque organe de connexion de la

canalisation de gaz.

En cas de connexion au gaz propane, demander à une

personne qualifiée de s’assurer que la pression de gaz

ne dépasse pas 330 mm (13 po) de la colonne d’eau.

Par personne qualifiée, on comprend :

le personnel autorisé de chauffage,

le personnel autorisé d’une compagnie de gaz, et

le personnel d’entretien autorisé.

Le non-respect de ces instructions peut causer

un décès, un explosion ou un incendie.

TYPE DE GAZ

Gaz naturel :

Cette sécheuse est équipée pour une alimentation au gaz naturel.

Elle est homologuée par UL pour l’alimentation au gaz propane,

avec conversion appropriée.

■ Cette sécheuse doit être équipée du brûleur convenable,

correspondant au gaz spécique qui alimente l’habitation.

L’information sur le brûleur se trouve sur la plaque

signalétique dans le logement de la porte de la sécheuse.

Si ces renseignements ne correspondent pas au type de gaz

disponible, composer les numéros de téléphone indiqués

dans la section “Assistance ou service” du Guide d’utilisation

et d’entretien.

Conversion pour l’alimentation au propane :

IMPORTANT : Un technicien qualié doit effectuer la conversion.

Ne pas entreprendre de convertir la sécheuse pour l’utilisation

d’un gaz différent de celui indiqué sur la plaque signalétique

sans d’abord consulter la compagnie de gaz.

IMPORTANT : L’installation au gaz doit être conforme aux codes

locaux, ou en l’absence de codes locaux, au Code National

d’alimentation au gaz, à la norme ANSI Z223.1/NFPA 54 ou au

Code canadien des installations au gaz naturel et au propane,

CSA-B149.1.

CANALISATION DE GAZ

■ Un tuyau IPS de 1/2" est recommandé.

■ Pour les longueurs inférieures à 20 pi (6,1 m), on peut utiliser

des tuyaux approuvés de 3/8" dans la mesure où les codes

locaux et le fournisseur de gaz l’autorisent.

■ La canalisation doit comprendre un connecteur obturé

(letage NPT de 1/8" ou plus) accessible pour le

raccordement de l’instrument de mesure immédiatement en

amont de la connexion d’alimentation en gaz de la sécheuse

(voir l’illustration).

■ La canalisation doit comprendre un robinet d’arrêt.

Aux États-Unis :

Un robinet d’arrêt individuel manuel doit être installé à

six (6) pi (1,8 m) maximum de la sécheuse, conformément

au Code national d’alimentation au gaz, ANSI Z223.1.

Au Canada :

Un robinet d’arrêt individuel manuel doit être installé

conformément à la norme B149.1 du Code des installations

au gaz naturel ou propane. On recommande que le robinet

d’arrét manuel individuel soit installé à 6 pi (1,8 m) maximum

de la sécheuse.

Le robinet d’arrêt doit être facilement accessible pour l’ouverture

et la fermeture.

C

A

A. Connecteur de gaz exible de 3/8"

B. Adaptateur de tuyau au joint conique de 3/8"

C. Connecteur obturé (letage NPT de 1/8" ou plus)

D. Canalisation de gaz (NPT de 1/2")

E. Robinet d’arrêt du gaz

E

D

EXIGENCES CONCERNANT

LE RACCORDEMENT AU GAZ

Cette sécheuse à gaz peut être raccordée au gaz de nombreuses

façons différentes. Voir ci-dessous quelques directives pour deux

méthodes de raccordement différentes.

Cette sécheuse doit être raccordée à la canalisation d’alimentation

en gaz à l’aide d’un connecteur de gaz exible homologué qui

respecte les normes applicables aux connecteurs utilisés avec

des appareils ménagers à gaz, ANSI Z21.24 ou CSA 6.10.

Option 1 (méthode recommandée)

Raccord à gaz en acier inoxydable souple :

■ Si les codes locaux le permettent, utiliser un raccord neuf

en acier inoxydable souple (conception homologuée par

l’American Gas Association ou par CSA International) pour

raccorder la sécheuse à la canalisation rigide d’alimentation

en gaz. Selon le besoin, utiliser un coude et un adaptateur

de 3/8" x tuyau NPT de 3/8" entre le raccord de gaz exible

et la canalisation de gaz de la sécheuse, pour éviter toute

déformation.

27

Page 28

Option 2 (méthode alternative)

Conduit d’aluminium ou de cuivre approuvé :

■ Pour les longueurs supérieures à 20 pi (6,1 m), on peut

utiliser des conduits approuvés de 3/8" (si les codes et

le fournisseur de gaz le permettent).

■ Pour le gaz naturel, ne pas utiliser de conduits en cuivre.

■ Adaptateur de 3/8" x tuyau NPT de 3/8" entre le conduit

de la sécheuse et le tuyau approuvé de 3/8."

■ Pour les longueurs supérieures à 20 pi (6,1 m), on doit utiliser

des tuyaux plus gros et un adaptateur de calibre différent.

■ Si la sécheuse a été convertie pour une utilisation de gaz

propane, on peut utiliser un tuyau en cuivre compatible

au propane de 3/8." Si la longueur totale de la canalisation

d’alimentation en gaz est supérieure à 20 pi (6,1 m), utiliser

un conduit de taille supérieure.

REMARQUE : On doit utiliser un composé d’étanchéité

des tuyauteries résistant à l’action du gaz propane. Ne pas

utiliser de ruban adhésif TEFLON.

®†

CANALISATION D’ARRIVÉE DE GAZ

DE LA SÉCHEUSE

■ La canalisation d’arrivée de gaz sortant à l’arrière

de la sécheuse est dotée d’un letage mâle de 3/8."

1

1

/2"

(38 mm)

A

*5 3/4"

(146 mm)

A. Conduit NPT de la sécheuse de 3/8"

CARACTÉRISTIQUES D’ALIMENTATION DU BRÛLEUR

Altitudes inférieures ou égales à 10 000 pi (3 048 m) :

■ La conception de cette sécheuse a été homologuée par

CSA International pour une utilisation jusqu’à une altitude

de 10 000 pieds (3 048 m) au-dessus du niveau de la mer

pour le débit thermique indiqué sur la plaque signalétique.

Aucun réglage du brûleur n’est nécessaire lorsque la

sécheuse est utilisée à une altitude inférieure à cette valeur

maximale.

Altitudes supérieures à 10 000 pieds (3 048 m) :

■ Si la sécheuse doit être utilisée à une altitude supérieure

à 10 000 pieds (3 048 m), on doit réduire de 4 % le débit

thermique du brûleur indiqué sur la plaque signalétique

pour chaque tranche de 1 000 pieds (305 m) d’augmentation

de l’altitude.

Épreuve sous pression de l’alimentation en gaz

■ La sécheuse doit être déconnectée du système de

canalisations d’alimentation en gaz lors de tout test

de pression à des pressions plus élevées que 1/2 lb/po².

†®TEFLON est une marque déposée de Chemours.

28

L’ÉVACUATION

Exigences concernant l’évacuation

AVERTISSEMENT : Pour réduire le risque d’incendie,

cette sécheuse doit ÉVACUER L’AIR À L’EXTÉRIEUR.

IMPORTANT : Respecter les dispositions de tous les codes

et règlements en vigueur. Le conduit d’évacuation de la sécheuse

ne doit pas être connecté à une évacuation de gaz, une

cheminée, un mur, un plafond, un grenier, un vide sanitaire ou un

vide de construction. Seul un conduit en métal exible ou rigide

doit être utilisé pour l’évacuation.

4"

(102 mm)

Conduit d’évacuation en métal lourd de 4" (102 mm)

■ Utiliser un conduit d’évacuation en métal lourd de

4" (102 mm) et des brides de serrage.

■ Ne pas utiliser de conduit de plastique ou en aluminium.

Conduit métallique rigide :

■ Recommandé pour une meilleure performance de séchage

et pour réduire les risques d’écrasement et de déformation.

Conduit métallique exible : (Acceptable uniquement

si accessible pour le nettoyage)

■ Doit être complètement déployé et supporté dans

l’emplacement nal de la sécheuse.

■ Enlever tout excès de conduit pour éviter tout affaissement

et déformation susceptible de réduire la capacité d’évacuation

et le rendement.

■ Ne pas installer le conduit dans les cavités fermées des murs,

plafonds ou planchers.

■ La longueur totale ne doit pas excéder 7

REMARQUE : Lors de l’utilisation d’un système de décharge

existant, nettoyer et éliminer la charpie sur toute la longueur

du système et veiller à ce que le clapet d’évacuation ne soit

pas obstrué par une accumulation de charpie. Remplacer

tout conduit de plastique ou d’aluminium par un conduit

métallique rigide ou exible. Examiner le “Tableau des systèmes

d’évacuation” et, au besoin, apporter les modications

nécessaires au système d’évacuation pour atteindre le meilleur

rendement de séchage.

3

/4 pi (2,4 m).

Page 29

Clapets de décharge :

■ Doit se situer à au moins 12" (305 mm) au-dessus du

sol ou de tout objet susceptible d’obstruer l’évacuation

(par exemple eurs, roches, arbustes ou neige).

Styles recommandés :

Clapet à persiennes Clapet de type boîte

Style acceptable :

Planication du système d’évacuation

Installations d’évacuation recommandées

Les installations typiques consistent à acheminer le conduit

d’évacuation à l’arrière de la sécheuse. D’autres installations

sont possibles.

B

C

D

E

A

F

G

B

Clapet incliné

Coudes :

■ Les coudes à 45° permettent une meilleure circulation

de l’air que les coudes à 90.°

Bon

Meilleur

Brides de serrage :

■ Utiliser des brides de serrages pour sceller toutes

les jointures.

■ Le conduit d’évacuation ne doit pas être connecté ou xé

avec des vis ou avec tout autre dispositif de serrage qui se

prolonge à l’intérieur du conduit et où la charpie risque de

s’accrocher. Ne pas utiliser de ruban adhésif pour conduit.

H

A. Sécheuse

B. Coude

C. Mur

D. Clapet de décharge

E. Brides

I

F. Conduit métallique rigide ou souple

G. Longueur de conduit nécessaire

pour raccorder les coudes

H.Bouche de décharge

I. Sortie d’évacuation latérale facultative

Installations d’évacuation facultatives :

L’évacuation peut être convertie pour évacuer par le côté droit,

le côté gauche ou par le bas (ensemble d’évacuation 4 voies).

Chaque ensemble comporte des instructions étape par étape.

Pour les renseignements sur la manière de commander, voir

“Trousses d’évacuation.”

Pour plus de renseignements voir “Trousses d’évacuation.”

A B C

A. Installation avec acheminement standard du conduit

d’évacuation par l’arrière

B. Installation avec évacuation par la gauche ou par

la droite

C. Installation avec évacuation par le bas

29

Page 30

Installations alternées pour dégagements étroits

Il existe de nombreux systèmes d’évacuation. Choisir le

type le mieux adapté à votre installation. Sur l’illustration :

deux installations avec dégagement réduit. Se rapporter

aux instructions du fabricant.

Installation au-dessus de la sécheuse

(également disponible avec un coude décalé)

Installation de périscope

REMARQUE : Les trousses suivantes pour les installations

alternées à dégagements étroits sont disponible à l’achat.

Trousses d’évacuation

Pour plus de renseignements, contacter 1-800-688-2002, ou

visiter notre site Web www.maytagreplacementparts.com.

Numéro

de pièces Descriptions

8171587RP Périscope d’évacuation métallique de 0" à 5"

4396037RP Périscope d’évacuation métallique de 0" à 18"

4396011RP Périscope d’évacuation métallique de 18" à 29"

4396014 Périscope d’évacuation métallique de 29" à 50"

4392892 Périscope DuraVent™ métallique mural

W10186596 Trousse d’évacuation à 4 directions –

gris universel

4396028 Trousse d’évacuation Sure Connect™

(installation par le dessus)

4396009RP Conduit raccordement universel de 5,' conduit

d’évacuation souple pour sécheuse

4396010RP Conduit SecureConnect™ de 6,' conduit

d’évacuation souple pour sécheuse

4396013RB Trousse d’installation du conduit de sécheuse

4396033RP Conduit d’évacuation souple pour sécheuse

de 5' avec brides

4396727RP Conduit d’évacuation souple pour sécheuse

de 8' avec brides

4396004 Coude décalé pour sécheuse

4396005 Coude décalé pour mur

4396006RW Coude serré DuraSafe™

4396007RW Clapet de conduit d’évacuation à travers le mur

4396008RP Brides d’évacuation en acier de 4"

pour sécheuse – lot de 2

8212662 Clapet d’évacuation à persiennes de 4"

pour montage en affleurement

30

Page 31

Dispositions spéciales pour les maisons mobiles :

12" min.

(305 mm)

12" min.

(305 mm)

Le système d’évacuation doit être solidement xé à une section

non combustible de la structure de la maison mobile et ne doit

pas se terminer en dessous de celle-ci. Acheminer le conduit

d’évacuation vers l’extérieur.

Le Tableau des systèmes d’évacuation fournit les spécications

d’évacuation qui vous aideront à atteindre la meilleure

performance de séchage.

Tableau des systèmes d’évacuation

Déterminer l’itinéraire d’acheminement du conduit :

■ Choisir l’itinéraire d’acheminement vers l’extérieur qui sera

le plus direct et le plus rectiligne.

■ Planier l’installation pour introduire le nombre minimal

de coudes et de changements de direction.

■ Si des coudes ou changements de direction sont utilisés,

prévoir autant d’espace que possible.

■ Plier le conduit graduellement pour éviter de le déformer.

■ Utiliser le moins possible de changements de direction

à 90.°

Déterminer la longueur du conduit et les coudes

nécessaires pour un séchage optimal :

■ Utiliser le Tableau des systèmes d’évacuation ci-dessous

pour déterminer le type de composants et les combinaisons

acceptables.

REMARQUE : Ne pas utiliser un conduit de longueur

supérieure à la valeur spéciée dans le Tableau des

systèmes d’évacuation. Si la longueur du circuit est

supérieure à la valeur spéciée dans le tableau, on

observera :

■ Une réduction de la longévité de la sécheuse.

■ Une réduction du rendement, avec temps de séchage

plus longs et une plus grande consommation d’énergie.

Nombre de

coudes à 90°

0

1

2

3

4

REMARQUE : Les installations d’évacuation par le côté

ou par le bas comportent un changement de direction à 90º

à l’intérieur de la sécheuse. Pour établir la longueur maximale

du conduit, ajouter un changement de direction à 90º

au tableau.

Type de

conduit

d’évacuation

Métallique

rigide

Métallique

rigide

Métallique

rigide

Métallique

rigide

Métallique

rigide

Clapets de

type boîte/à

persiennes

64 pi (20 m)

54 pi (16,5 m)

44 pi (13,4 m)

35 pi (10,7 m)

27 pi (8,2 m)

Clapets

inclinés

58 pi (17,7 m)

48 pi (14,6 m)

38 pi (11,6 m)

29 pi (8,8 m)

21 pi (6,4 m)

Installation du circuit d’évacuation

1. Installer le clapet d’évacuation

Installer un clapet d’évacuation et calfeutrer l’ouverture

murale à l’extérieur autour du clapet d’évacuation.

31

Page 32

2. Raccorder le conduit

A

B

C

D

A

B

d’évacuation au clapet

1. Raccorder l’alimentation en gaz

à la sécheuse

Le conduit doit se trouver par dessus le clapet d’évacuation.

Fixer ensemble le conduit et le clapet avec une bride de

4" (102 mm). Acheminer le conduit d’évacuation jusqu’à

l’emplacement de la sécheuse, utiliser l’itinéraire le plus

rectiligne possible. Éviter les changements de direction à 90º.

Utiliser des brides de serrage pour sceller toutes les jointures.

Ne pas utiliser de ruban adhésif pour conduit, de vis ou autres

dispositifs de xation qui se prolongeraient à l’intérieur du

conduit pour sécuriser l’évacuation, car la charpie pourrait

s’y accrocher.

Raccordement au gaz

AVERTISSEMENT

Raccord mâle

conique

Retirer le capuchon rouge de la canalisation de gaz. À l’aide

d’une clé pour serrer, raccorder l’alimentation en gaz à la

sécheuse. Utiliser un composé d’étanchéité des tuyauteries sur

tous les letages des raccords mâles non coniques. Si on utilise

un conduit métallique souple, veiller à ce qu’il ne soit pas pincé.

REMARQUE : Pour les raccordements au gaz propane,

on doit utiliser un composé d’étanchéité résistant à l’action

du gaz propane. Ne pas utiliser de ruban adhésif TEFLON®†.

Raccord mâle

non conique

2. Préparer la connexion

des raccords de tuyauterie

Risque d'explosion

Utiliser une canalisation neuve d'arrivée de gaz

approuvée par CSA International.

Installer un robinet d'arrêt.

Bien serrer chaque organe de connexion de la

canalisation de gaz.

En cas de connexion au gaz propane, demander à une

personne qualifiée de s’assurer que la pression de gaz

ne dépasse pas 330 mm (13 po) de la colonne d’eau.

Par personne qualifiée, on comprend :

le personnel autorisé de chauffage,

le personnel autorisé d’une compagnie de gaz, et

le personnel d’entretien autorisé.

Le non-respect de ces instructions peut causer

un décès, un explosion ou un incendie.

32

A. Raccord exible de gaz

de 3/8"

B. Conduit de la sécheuse

de 3/8"

On doit utiliser une combinaison de raccords de tuyauterie

pour raccorder la sécheuse à l’alimentation en gaz existante.

L’illustration présente un raccordement recommandé.

Le raccordement peut varier selon le type, la taille et

l’emplacement de la canalisation d’alimentation.

C. Coude de 3/8" par 3/8"

D. Adaptateur entre le conduit

et le joint conique de 3/8"

3. Ouvrir le robinet d’arrêt du gaz

Robinet fermé

Ouvrir le robinet d’arrêt de la canalisation d’alimentation;

le robinet est ouvert lorsque la manette est parallèle à la

canalisation de gaz. Vérier ensuite tous les raccordements

en les badigeonnant d’une solution de détection des fuites

non corrosive approuvée. L’apparition de bulles indique

la présence d’une fuite. Réparer toute fuite éventuelle.

A

Robinet

B

ouvert

Page 33

Raccordement du conduit

d’évacuation

RÉGLAGE DE L’APLOMB

DE LA SÉCHEUSE

1. Raccorder le conduit d’évacuation

à la bouche d’évacuation

À l’aide d’une bride de serrage de 4" (102 mm), relier

le conduit d’évacuation à la bouche d’évacuation de la

sécheuse. Si on utilise le conduit d’évacuation existant,

s’assurer qu’il est propre. Le conduit d’évacuation de la

sécheuse doit être xé par-dessus la bouche d’évacuation

de la sécheuse, et à l’intérieur du clapet d’évacuation. Vérier

que le conduit d’évacuation est xé au clapet d’évacuation

à l’aide d’une bride de serrage de 4" (102 mm).

2. Déplacer la sécheuse à son

emplacement nal

1. Régler l’aplomb de la sécheuse

Vérier l’aplomb de la sécheuse d’un côté à l’autre. Répéter

l’opération de l’avant vers l’arrière.

REMARQUE : La sécheuse doit être d’aplomb pour que

le système de détection d’humidité fonctionne correctement.

Pas d’aplomb D’APLOMB Pas d’aplomb

Placer la sécheuse à son emplacement nal. Éviter d’écraser

ou de déformer le conduit d’évacuation. Une fois que la

sécheuse est à son emplacement dénitif, ôter les cornières

et le carton du dessous de la sécheuse.

2. Serrer et ajuster les pieds

de nivellement

Si la sécheuse n’est pas d’aplomb, la soulever à l’aide d’une

cale en bois. Utiliser une clé pour ajuster les pieds vers le haut

ou vers le bas, et vérier à nouveau si elle est d’aplomb. Une

fois que la sécheuse est d’aplomb, s’assurer que les quatre

pieds sont solidement appuyés contre le plancher avant de

les serrer.

33

Page 34

ACHEVER L’INSTALLATION –

LISTE DE VÉRIFICATION

Vérier que toutes les pièces sont maintenant installées.

q

S’il reste une pièce, passer en revue les différentes étapes

pour découvrir laquelle aurait été oubliée.

Vérier la présence de tous les outils.

q

Éliminer/recycler les matériaux d’emballage.

q

Vérier l’emplacement dénitif de la sécheuse. S’assurer

q

que le conduit d’évacuation n’est pas écrasé ou déformé.

Vérier que la sécheuse est d’aplomb. Voir “Réglage de

q

l’aplomb de la sécheuse.”

Retirer la pellicule sur le panneau de commande et tout ruban

q

adhésif resté sur la sécheuse.

Essuyer soigneusement l’intérieur du tambour de la sécheuse

q

avec un chiffon humide pour éliminer toute trace de

poussière.

Lire la section “Utilisation de la sécheuse” dans le Guide

q

d’utilisation et d’entretien.

Régler la sécheuse pour un programme de séchage complet

q

(pas le programme de séchage à l’air) de 20 minutes et mettre

la sécheuse en marche.

Si la sécheuse ne démarre pas, vérier ce qui suit :

■ La sécheuse à gaz est branchée sur une prise à trois

alvéoles reliée à la terre. La sécheuse électrique est

branchée sur une prise à quatre alvéoles reliée à la terre.

■ La prise de courant est correctement alimentée.

■ Les fusibles du domicile sont intacts et serrés;

le disjoncteur n’est pas déclenché.

■ La porte de la sécheuse est fermée.

Après 5 minutes de fonctionnement, ouvrir la porte de la

q

sécheuse et déterminer si l’on détecte de la chaleur. Si de la

chaleur est détectée, annuler le programme et fermer la porte.

Si vous ne sentez aucune chaleur, éteindre la sécheuse

et vérier ce qui suit :

Sécheuses à gaz :

■ Si le robinet d’arrêt de la canalisation de gaz est fermé,

l’ouvrir, puis répéter le test de 5 minutes décrit ci-dessus.

■ Si le robinet d’arrêt de la canalisation de gaz est ouvert,

contacter un technicien qualié.

Sécheuses électriques :

■ Il peut y avoir deux fusibles ou disjoncteurs domestiques

pour la sécheuse. Vérier que les deux fusibles sont

intacts et bien en place ou que les deux disjoncteurs ne

se sont pas déclenchés. S’il n’y a toujours pas de chaleur,

contacter un technicien qualié.

REMARQUE : Il est possible que la sécheuse dégage une

odeur lors du chauffage initial. Cette odeur est normale lorsque

l’élément chauffant est utilisé pour la première fois. L’odeur

disparaîtra.

INVERSION DU SENS DE

L’OUVERTURE DE LA PORTE

(FACULTATIF)

REMARQUE : Un tournevis aimanté serait utile.

Porte à ouverture latérale, modèle de 27"

1. Placer une serviette sur la sécheuse

Placer une serviette sur le dessus de la sécheuse pour éviter

d’endommager la surface.

2. Ôter les vis inférieures

Ouvrir la porte de la sécheuse. Ôter les vis inférieures de la

portion des charnières attachée à la caisse de la sécheuse.

Desserrer (ne pas retirer) les vis supérieures de la portion

des charnières attachée à la caisse de la sécheuse.

3. Soulever la porte pour la dégager

des vis supérieures

34

Soulever la porte jusqu’à ce que les vis supérieures situées

dans la caisse de la sécheuse se trouvent dans la partie

évasée de l’encoche de charnière. Tirer la porte vers l’avant

pour la dégager des vis. Placer la porte (côté poignée vers

le haut) sur la sécheuse. Retirer les vis supérieures de la

caisse de la sécheuse.

Page 35

4. Ôter les vis des charnières

7. Retourner la porte

Retourner la porte de façon à ce que la poignée soit orientée

vers le bas.

Retirer les vis xant les charnières à la porte.

5. Ôter les vis du panneau de porte

Retirer les vis du sommet, du bas et du côté de la porte

(six vis). Conserver séparément les vis de porte et les vis

de charnière, car elles sont de tailles différentes. Tout en

maintenant la porte sur la serviette et sur la sécheuse, saisir

les côtés de la porte externe et la soulever pour la séparer

de la porte interne.

REMARQUE : Ne pas utiliser de couteau à mastic ou de

tournevis pour séparer les portes. Ne pas tirer sur le joint