Page 1

Gas Dryer Installation Instructions

Canadian Electric Dryer Installation Instructions

Instructions pour l'installation de la s6eheuse a gaz

p

(E.-U. et Canada) et 61eetrique (Canada uniquement)

Table of Contents

DRYER SAFETY ................................................................ 2

iNSTALLATiON REQUIREMENTS .................................... 4

Tools and Parts .................................................................... 4

Location Requirements ...................................................... 5

Electric Dryer Power Hookup-Canada Only ..................... 6

Gas Dryer Power Hookup ................................................... 7

iNSTALL LEVELING LEGS .......................................................... 8

VENTING ...................................................................................... 9

Venting Requirements ......................................................... 9

Plan Vent System ............................................................... 10

Install Vent System ............................................................ 12

MAKE GAS CONNECTION ....................................................... 12

CONNECT iNLET HOSES ......................................................... 12

CONNECT VENT ....................................................................... 14

LEVEL DRYER ........................................................................... 14

COMPLETE iNSTALLATiON CHECKLIST ............................... 15

REVERSE DOOR SWING .......................................................... 15

TROUBLESHOOTING ............................................................... 17

INSTALLATION NOTES

Date of purchase:

Date of installation:

Installer:

Model number:

Serial number:

Table des matibres

SECURIT¢: DE LA S¢:CHEUSE ........................................ 18

EXIGENCES D'INSTALLATION ....................................... 20

Outillage et pi_ces ............................................................. 20

Exigences d'emplacement ................................................ 21

Raccordement de la s6cheuse

_lectrique - Canada seulement ........................................ 22

Raccordement d'une s_cheuse _ gaz .............................. 23

iNSTALLATiON DES PIEDS DE NIVELLEMENT ...................... 25

L' EVACUATION .......................................................................... 25

Exigences concernant I'evacuation ................................. 25

Planification du syst_me d'_vacuation ............................ 26

installation du syst_me d'_vacuation ............................... 28

RACCORDEMENT AU GAZ ....................................................... 29

RACCORDEMENT DES TUYAUX D'ALIMENTATION .............. 29

RACCORDEMENT DU CONDUIT D'ISVACUATION ................. 31

RLeGLAGE DE L'APLOMB DE LA SISCHEUSE ......................... 31

LISTE DE VleRIFICATION

POUR iNSTALLATiON TERMINleE ............................................ 32

iNVERSiON DU SENS D'OUVERTURE DE LA PORTE ............ 32

DLePANNAGE .............................................................................. 34

NOTES CONCERNANT L'INSTALLATION

Date d'achat :

Date d'installation :

Installateur :

Num6ro de module :

Num_ro de s6rie :

Para obtener acceso al "lnstrucciones de instalaci6n" en espa_ol, o para obtener informaci6n adicional acerca

de su producto, visite:

www.whirlpool.com

Tenga listo su nOmero de modelo completo. Puede encontrar el nOmero de modelo y de serie dentro de la cavidad

superior de la puerta.

W10388777A

W10388779A=SP

Page 2

DRYER S_ETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

WARNING - ...i.. ofFi,o..

- Clothes dryer installation must be performed by a qualified installer.

- install the clothes dryer according to the manufacturer's instructions and local codes,

= Do not install a clothes dryer with fle×ible plastic venting materials or flexible metal

(foil type) duct. if fle×ible metal duct is installed, it must be of a specific type identified

by the appliance manufacturer as suitable for use with clothes dryers, Fle×ible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire.

= To reduce the risk of severe injury or death, follow all installation instructions.

= Save these instructions.

When discarding or storing your old clothes dryer, remove the door.

2

Page 3

WARNING: For your safety, the information in this manual must be followed to minimize 1

the risk of fire or explosion, or to prevent property damage, personal injury, or death. 1

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO iF YOU SMELL GAS:

o Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

®Clear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

= if you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

iMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSi Z223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22.1.

in the State of Massachusetts, the following installation instructions apply:

[] Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

[] if using a ball valve, it shall be a T-handle type.

[] A flexible gas connector, when used, must not exceed 3 feet.

Page 4

IN$ LATION REQUIREMENTS

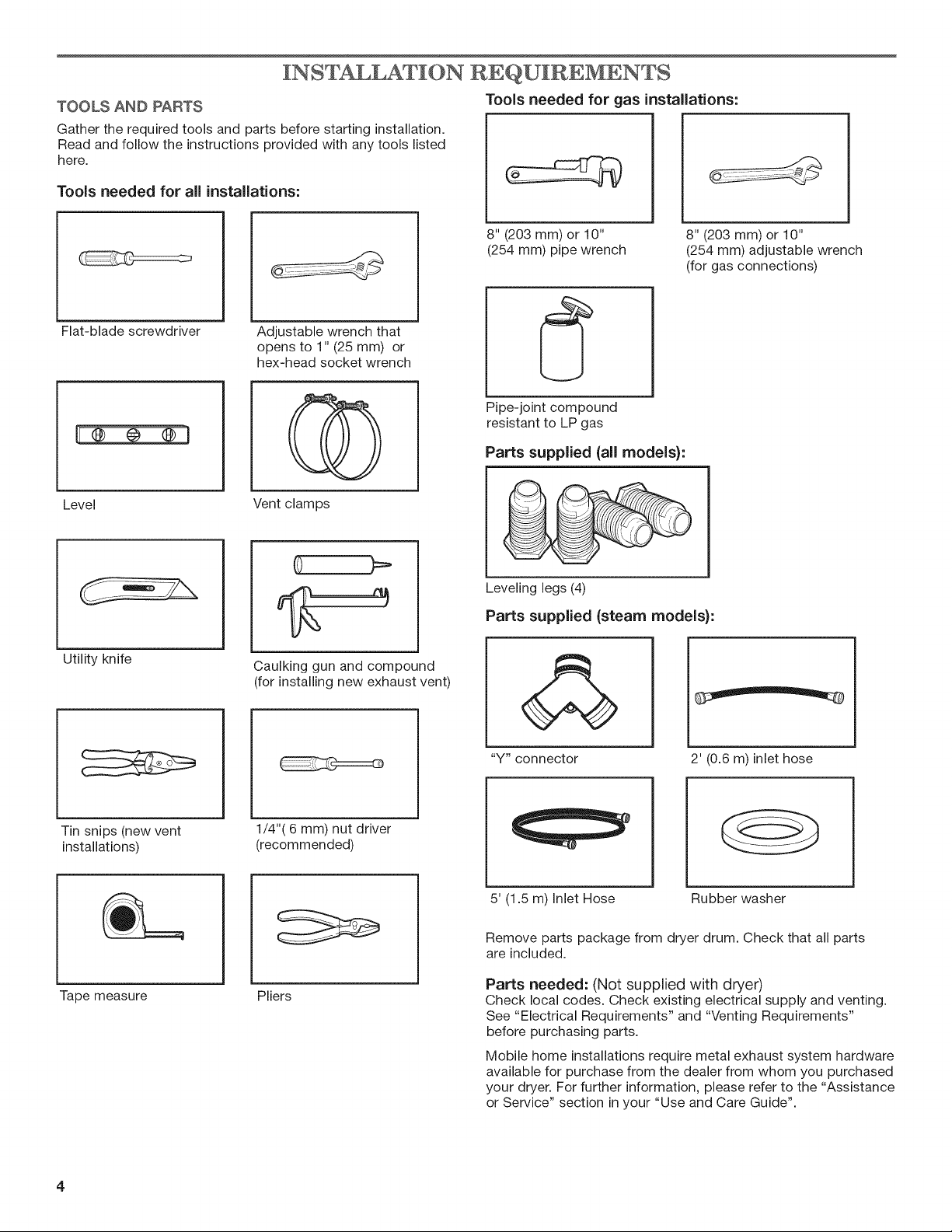

TOOLS AND PARTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed for all installations:

Tools needed for gas installations:

Flat-blade screwdriver

Level

Utility knife

Adjustable wrench that

opens to 1" (25 mm) or

hex-head socket wrench

Vent clamps

Caulking gun and compound

(for installing new exhaust vent)

8" (203 mm) or 10"

(254 mm) pipe wrench

Pipe-joint compound

resistant to LP gas

Parts supplied {all models):

Leveling legs (4)

Parts supplied (steam models):

8" (203 mm) or 10"

(254 mm) adjustable wrench

(for gas connections)

Tin snips (new vent

installations)

Tape measure Pliers

1/4"( 6 mm) nut driver

(recommended)

4

"Y" connector

5' (1.5 m) Inlet Hose

Remove parts package from dwer drum. Check that all parts

are included.

Parts needed: (Not supplied with dwer)

Check local codes. Check existing electrical supply and venting.

See "Electrical Requirements" and "Venting Requirements"

before purchasing parts.

Mobile home installations require metal exhaust system hardware

available for purchase from the dealer from whom you purchased

your dryer. For further information, please refer to the "Assistance

or Service" section in your "Use and Care Guide".

2' (0.6 m) inlet hose

Rubber washer

Page 5

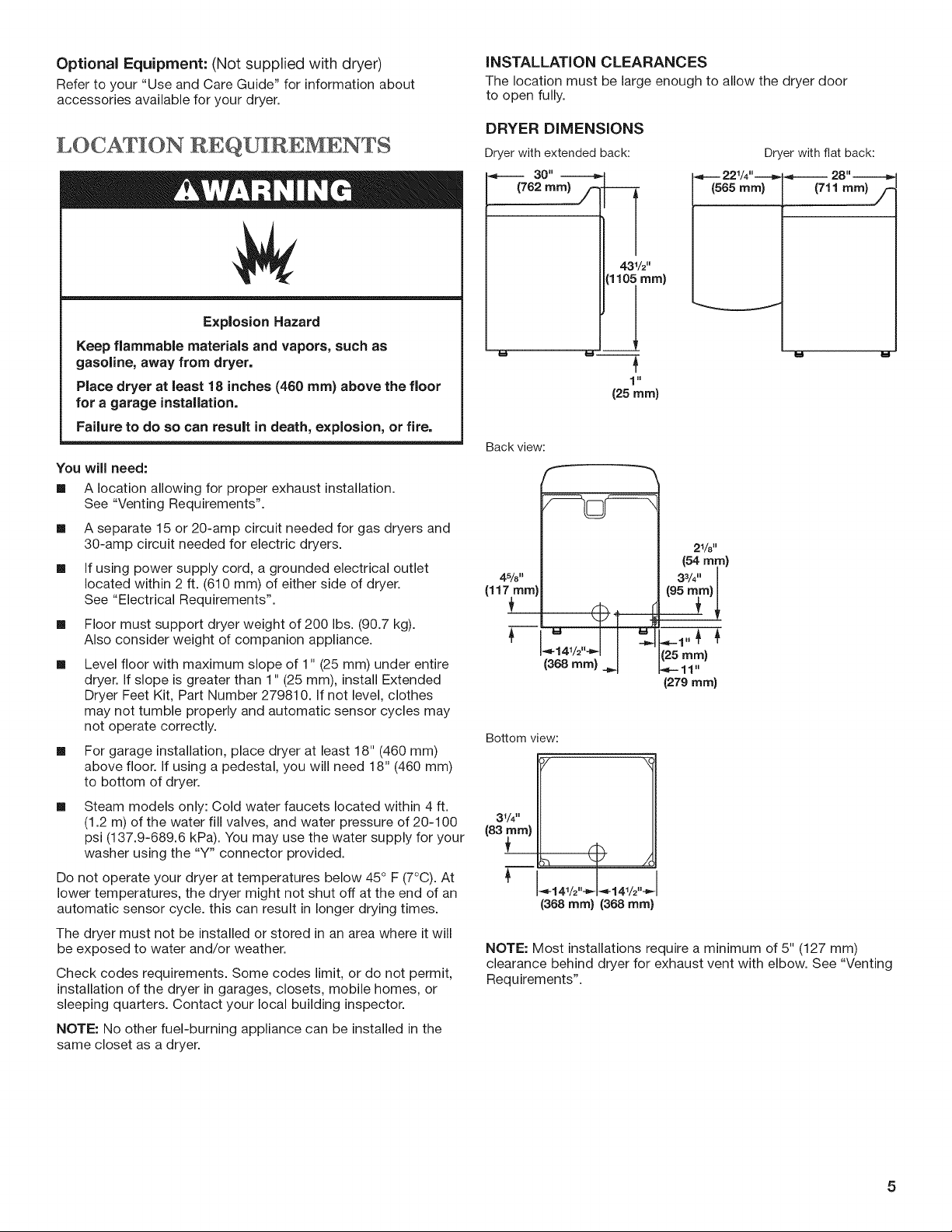

Optional Equipment: (Not supplied with dryer)

Refer to your "Use and Care Guide" for information about

accessories available for your dryer.

LOCATION REQUIREMENWS

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer,

Place dryer at least 18 inches (460 ram) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

You will need:

[] A location allowing for proper exhaust installation.

See "Venting Requirements".

[] A separate 15 or 20-amp circuit needed for gas dryers and

30-amp circuit needed for electric dryers.

[] If using power supply cord, a grounded electrical outlet

located within 2 ft. (610 mm) of either side of dryer.

See "Electrical Requirements".

[] Floor must support dryer weight of 200 Ibs. (90.7 kg).

Also consider weight of companion appliance.

[]

Level floor with maximum slope of 1" (25 mm) under entire

dryer. If slope is greater than 1" (25 mm), install Extended

Dryer Feet Kit, Part Number 279810. If not level, clothes

may not tumble properly and automatic sensor cycles may

not operate correctly.

[] For garage installation, place dryer at least 18" (460 mm)

above floor. If using a pedestal, you will need 18" (460 mm)

to bottom of dryer.

[]

Steam models only: Cold water faucets located within 4 ft.

(1.2 m) of the water fill valves, and water pressure of 20-100

psi (137.9-689.6 kPa). You may use the water supply for your

washer using the "Y" connector provided.

Do not operate your dryer at temperatures below 45° F (7°C). At

lower temperatures, the dryer might not shut off at the end of an

automatic sensor cycle, this can result in longer drying times.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Check codes requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

NOTE: No other fuel-burning appliance can be installed in the

same closet as a dryer.

INSTALLATION CLEARANCES

The location must be large enough to allow the dryer door

to open fully.

DRYER DIMENSIONS

Dryerwithextended back:

30"

1110i ram}

-,,,,F---221/4"-............_

(565 ram)

431/2''

Dryer with flat back:

,.P----- 28"

"------7

"1u

(25 ram)

Back view:

21/8"

(54,turn)

33/, I

125mm)

(279 ram}

Bottom view:

31/4"

_"1 41/2 '''_ _"1 41/2 '''t="

(368 ram¿(368 ram)

NOTE: Most installations require a minimum of 5" (127 mm)

clearance behind dryer for exhaust vent with elbow. See "Venting

Requirements".

Page 6

Spacingfor recessedareaor closet installation

All dimensions show recommended spacing allowed, with tested

spacing of 0" (0 mm) clearance on sides and rear.

[] Additional spacing should be considered for ease of

installation and servicing.

[] Additional clearances might be required for wall, door, and

floor moldings.

[] Additional spacing should be considered on all sides of the

dryer to reduce noise transfer.

[]

For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilitation openings are

acceptable.

[] Companion appliance spacing should also be considered.

14" max,

(356 rnrn)I

(76

n

(76

(127 ram)

ELECTRIC DR R

FOWER HOOKUFo ONLY

ELECTRICAL REQUIREMENTS

Electrical Shock Hazard

Plug into a grounded 4 prong outlet.

Failure to do so can result in death or electrical shock.

it is your responsibility:

[] Tocontact aqualified electrical installer.

[]

To be sure that the electrical connection is adequate and in

conformance with Canadian Electrical Code, C22.1-1atest

edition and all local codes. A copy of above codes standard

may be obtained from: Canadian Standards Association,

178 Rexdale Blvd., Toronto, ON M9W 1R3 CANADA.

[]

To supply the required 4 wire, single phase, 120/240 volt,

60 Hz, AC only electrical supply on a separate 30-amp

circuit, fused on both sides of the line. A time-delay fuse or

circuit breaker is recommended. Connect to an individual

branch circuit.

[]

This dryer is equipped with a CSA International Certified

Power Cord intended to be plugged into a standard 14-30R

wall receptacle. The cord is 5 ft. (1.52 m) long. Be sure wall

receptacle is within reach of dryer's final location.

(25turn}

Mobile home =Additional installation requirements:

This dryer is suitable for mobile home installations.

The installation must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR,

Part 3280 (formerly the Federal Standard for Mobile home

construction and Safety, Title 24, HUD Part 280) or Standard

CAN/CSA-Z240 MH.

Mobile home installations require:

All dryers:

[] Metal exhaust system hardware, available for purchase

from your dealer. For further information, see "Assistance

or Service" section in your "Use and Care Guide".

[]

Special provisions must be made in mobile homes to

introduce outside air into dryer. Openings (such as a

nearby window) should be at least twice as large as

dryer exhaust opening.

For gas dryers mobile home installations:

[] Mobile Home Installation Hold-down Kit Part Number

346764 is available to order. For further information, see

"Assistance or Service" section in your "Use and Care

Guide".

4-wire receptacle (14-30R)

If using a replacement power supply cord, it is recommended that

you use Power Supply Cord Replacement Part Number 9831317.

For further information, please reference service numbers located

in "Assistance or Service" section of your "Use and Care Guide".

6

Page 7

GROUNDING iNSTRUCTiONS

GROUNDING INSTRUCTIONS

m For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

GAS DR R POWER HOOKUP

ELECTRICAL REQUIREMENTS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

GAS SUPPLY REQUIREMENTS

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

[]

120 Volt, 60 Hz, AC only, 15- or 20- amp fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is also recommended that a separate

circuit serving only this dryer be provided.

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut=off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (330 ram) water

column,

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

GAS TYPE

Natural Gas:

This dryer is equipped for use with Natural gas. It is design-

certified by CSA International for LP (propane or butane) gases

with appropriate conversion.

[]

Your dryer must have the correct burner for the type of gas

in your home. Burner information is located on the rating

plate in the door well of your dryer. If this information does

not agree with the type of gas available, contact your dealer

or call the phone numbers referenced in the "Assistance or

Service" section of your "Use and Care Guide".

Page 8

LP Gas Conversion:

IMPORTANT: Conversion must be made by a qualified

technician.

No attempt shall be made to convert the dryer from the gas

specified on the model/serial rating plate for use with a different

gas without consulting your gas company.

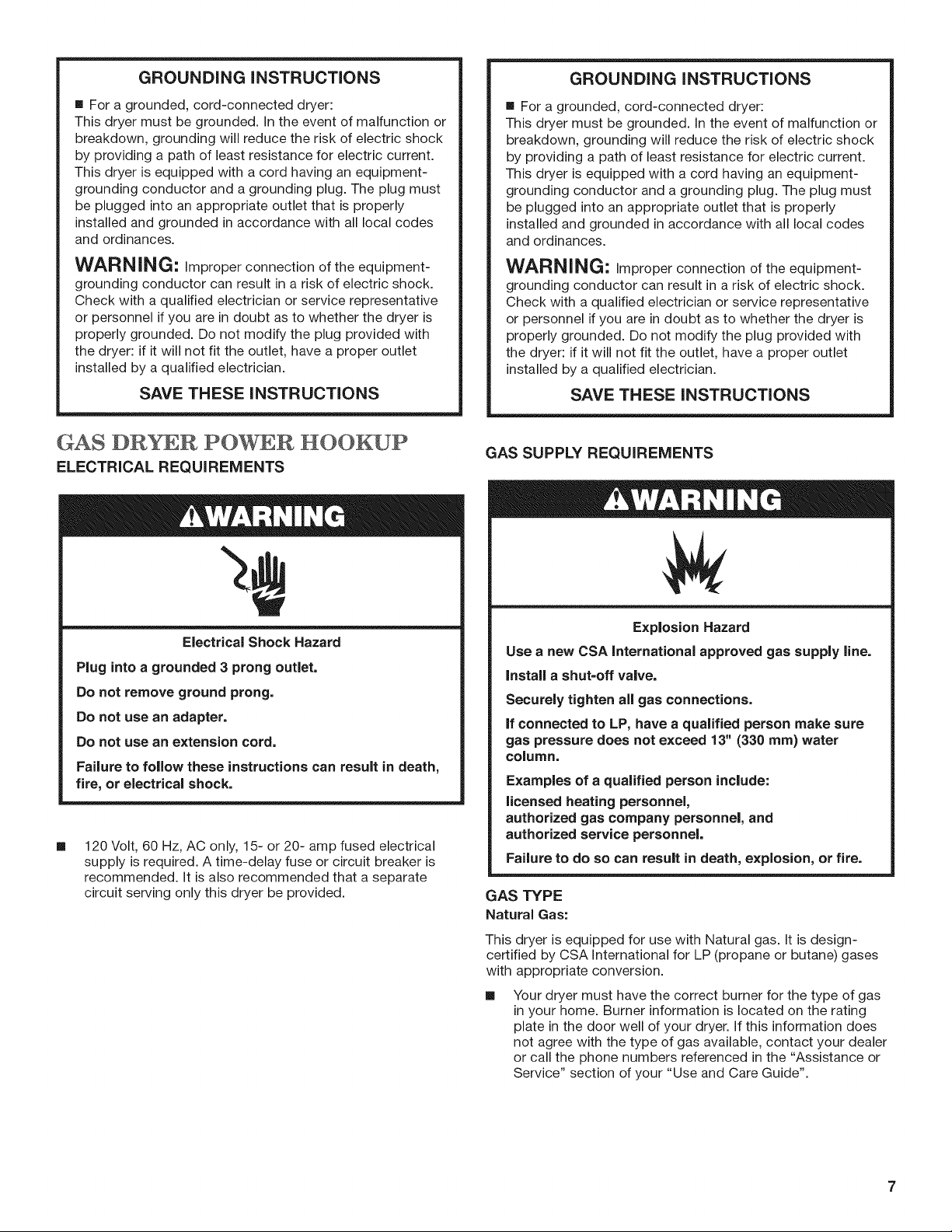

GAS SUPPLY LiNE

[] Must include 1/8" NPT minimum plugged tapping accessible

for test gauge connection, immediately upstream of the gas

connection to the dryer.

E

B

A. 3/8" flexible gas connector

B.3/8" pipe to flare adapter fitting

C. 1/8" NPT minimum plugged tapping

D. 1/2" NPT gas supply line

E.Gasshutoff valve.

[] 1/2" IPS pipe is recommended.

[] 3/8" approved aluminum or copper tubing is acceptable for

lengths under 20 ft. (6.1 m) if local codes and gas supplier

permit.

[] If you are using Natural gas, do not use copper tubing.

[] Lengths over 20 ft. (6.1 m) should use larger tubing and

a different size adapter fitting.

[] If your dryer has been converted to use LP gas, 3/8" LP

compatible copper tubing can be used. If the total length of

the supply line is more than 20 ft. (6.1 m), use larger pipe.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not use TEFLON®ttape.

[] Must include shut-off valve

In the U.S.A.:

An individual manual shut-off valve must be installed within

six (6) ft. (1.8 m) of the dryer in accordance with the National

Fuel Gas Code, ANSI Z223.1. The location should be easy to

reach for opening and closing.

In Canada:

An individual manual shut-off valve must be installed in

accordance with the B149.1, Natural Gas and Propane

Installation Code. It is recommended that an individual

manual shutoff valve be installed within six (6)ft. (1.8 m) of

the dryer. The location should be easy to reach for opening

and closing.

BURNER iNPUT REQUIREMENTS

Elevations above 10,000 ft. (3,048 m):

[] When installed above 10,000 ft. (3,048 m) a 4% reduction

of the burner Btu rating shown on the model/serial number

plate is required for each 1,000 ft. (305 m) increase in

elevation.

Gas supply pressure testing

[] The dryer must be disconnected from the gas supply piping

system during pressure testing at pressures greater than

1/2 psi.

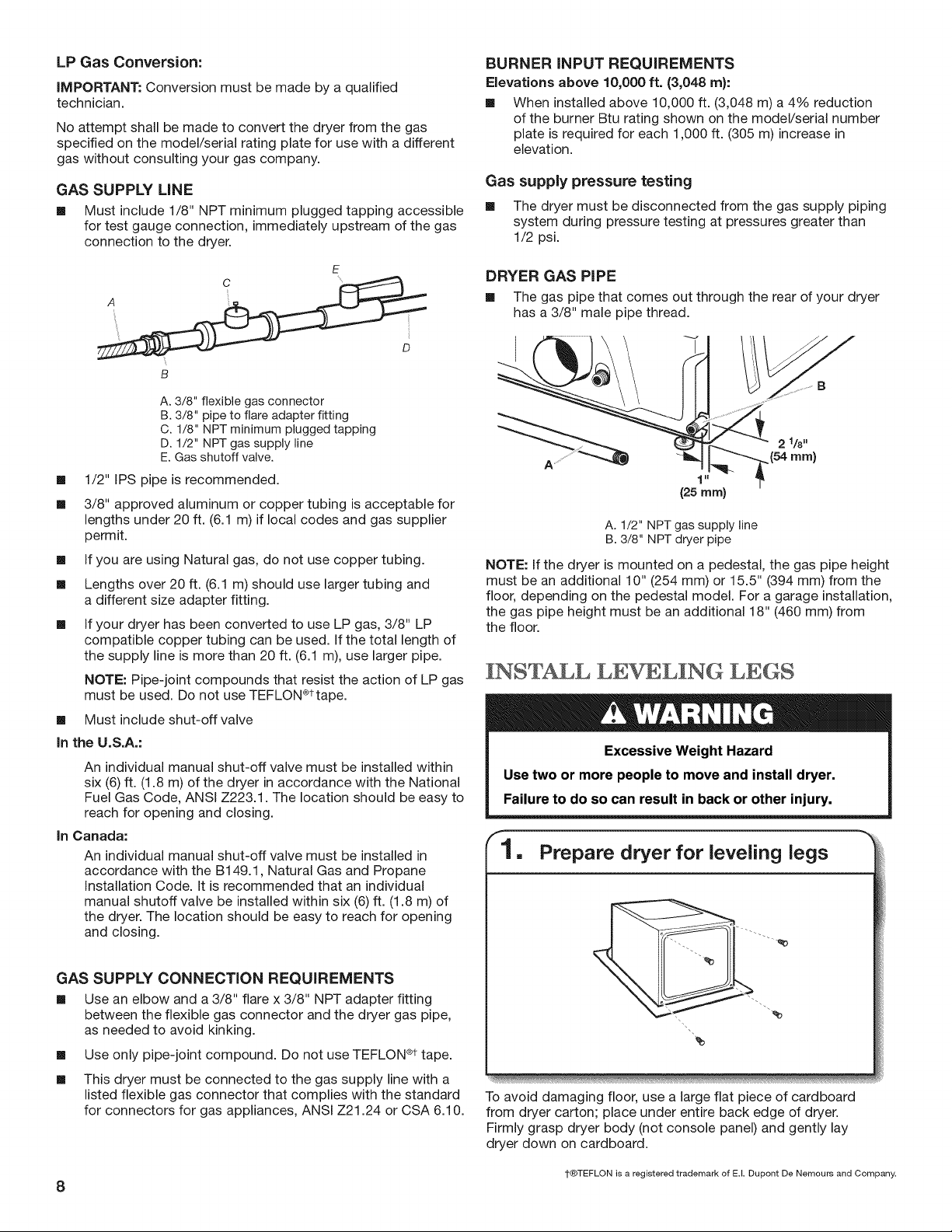

DRYER GAS PiPE

[] The gas pipe that comes out through the rear of your dryer

has a 3/8" male pipe thread.

I

2 1/8"

1,,_(54 ram)

(25 ram)

A. 1/2" NPT gas supply line

B. 3/8" NPT dryer pipe

NOTE: If the dryer is mounted on a pedestal, the gas pipe height

must be an additional 10" (254 mm) or 15.5" (394 mm) from the

floor, depending on the pedestal model. For a garage installation,

the gas pipe height must be an additional 18" (460 mm) from

the floor.

INSTALL LE¥ LING LEGS

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Prepare dryer for leveling legs

GAS SUPPLY CONNECTION REQUIREMENTS

[] Use an elbow and a 3/8" flare x 3/8" NPT adapter fitting

between the flexible gas connector and the dryer gas pipe,

as needed to avoid kinking.

[] Use only pipe-joint compound. Do not use TEFLON ®ttape.

[] This dryer must be connected to the gas supply line with a

listed flexible gas connector that complies with the standard

for connectors for gas appliances, ANSI Z21.24 or CSA 6.10.

8

To avoid damaging floor, use a large flat piece of cardboard

from dryer carton; place under entire back edge of dryer.

Firmly grasp dryer body (not console panel) and gently lay

dryer down on cardboard.

1®TEFLON is a registered trademark of E.I. Dupont De Nemours and Company.

Page 9

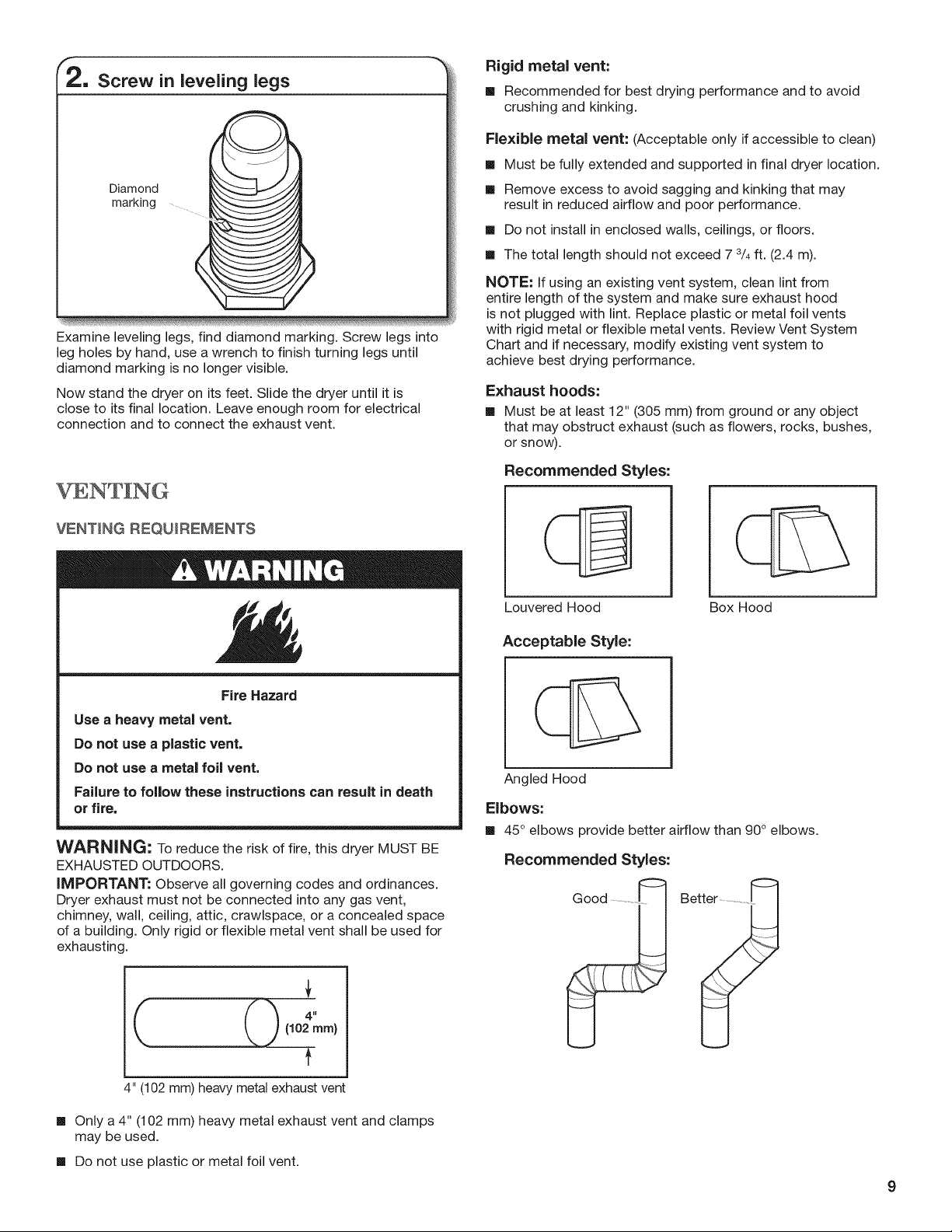

Screw in leveling legs

Diamond

marking

( )

Examine leveling legs, find diamond marking. Screw legs into

leg holes by hand, use a wrench to finish turning legs until

diamond marking is no longer visible.

Now stand the dryer on its feet. Slide the dryer until it is

close to its final location. Leave enough room for electrical

connection and to connect the exhaust vent.

¥ NTING

Rigid metal vent:

[] Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

[]

Must be fully extended and supported in final dryer location.

[]

Remove excess to avoid sagging and kinking that may

result in reduced airflow and poor performance.

[] Do not install in enclosed walls, ceilings, or floors.

[] The total length should not exceed 7 3/4ft. (2.4 m).

NOTE: If using an existing vent system, clean lint from

entire length of the system and make sure exhaust hood

is not plugged with lint. Replace plastic or metal foil vents

with rigid metal or flexible metal vents. Review Vent System

Chart and if necessary, modify existing vent system to

achieve best drying performance.

Exhaust hoods:

[] Must be at least 12" (305 mm) from ground or any object

that may obstruct exhaust (such asflowers, rocks, bushes,

or snow).

Recommended Styles:

VENTING REQUIREMENTS

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent,

Do not use a metal foil vent,

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or flexible metal vent shall be used for

exhausting.

Louvered Hood

Box Hood

Acceptable Style:

Angled Hood

Elbows:

[] 45° elbows provide better airflow than 90° elbows.

Recommended Styles:

...........................Be

(102 ram)

4"

t

4" (102 mm) heavy metal exhaust vent

[]

Only a 4" (102 mm) heaw metal exhaust vent and clamps

may be used.

[]

Do not use plastic or metal foil vent.

Page 10

Clamps:

[] Useclampstosealalljoints.

[] Exhaustventmustnotbeconnectedorsecuredwithscrews

orotherfasteningdevicesthatextend into interior of duct

and catch lint. Do not use duct tape.

improper venting can cause moisture and lint to collect

indoors, which may result in:

[] Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

[] Housecleaning problems and health problems.

Vent products can be purchased from your dealer. For more

information, see "Assistance or Service" section in your "Use

and Care Guide".

Optional exhaust installations:

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent,

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

[] Exhaust Cover Kit (to cover unused exhaust holes):

Part Number W10186596 - all models

[] Bottom Exhaust Kit- Part Number 8212503

PLAN SYSTEM

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

B

A

H

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

E. Clamps

R Rigid metal or flexible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

If you prefer, dryer may be converted to exhaust through

the bottom. You must contact your local dealer to have dryer

converted.

A

A. Standard rear offset exhaust installation

B. Bottom exhaust installation

B

10

Page 11

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best

for your installation. Two close-clearance installations are shown.

Refer to the manufacturer's instructions.

A B

A. Over-the-top installation

(also available with one offset elbow)

B. Periscope installation

NOTE: The following kits for close clearance alternate

installations are available for purchase. Contact your local dealer.

[]

Over-the-Top installation:

Part Number 4396028

[]

Periscope installation (For use with dryer vent to wall vent

mismatch):

Part Number 4396037 - 0" (0 mm) to 18" (460 mm) mismatch

Part Number 4396011 - 18" (460 mm) to 29" (737 mm)

mismatch

Part Number 4396014 - 29" (737 mm) to 50" (1270 mm)

mismatch

Determine vent path:

[] Select route that will provide straightest and most direct

path outdoors.

[] Plan installation to use fewest number of elbows and turns.

[] When using elbows or making turns, allow as much room

as possible.

[] Bend vent gradually to avoid kinking.

[] Use as few 90° turns as possible.

Determine vent length and elbows needed for best

drying performance:

[] Use following Vent System Chart to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specified

in Vent System Chart. Exhaust systems longer than those

specified will:

[] Shorten life of dryer.

[] Reduce performance, resulting in longer drying times

and increased energy usage.

The Vent System Charts provide venting requirements that

will help achieve best drying performance.

Whirlpool Vent System Chart

Number of Type Box/Iouvered Angled

90 ° elbows of vent hoods hoods

Special provisions for mobile homes:

Exhaust vent must be securely fastened to a noncombustible

portion of mobile home and must not terminate beneath the

mobile home. Terminate exhaust vent outside.

/_

Mobile Home Exhaustinstallation

Rigid metal 64 ft. (20 m) 58 ft. (17.7 m)

Rigid metal 54 ft. (16.5 m) 48 ft. (14.6 m)

Rigid metal 44 ft. (13.4 m) 38 ft. (11.6 m)

3 Rigid metal 35 ft. (10.7 m) 29 ft. (8.8 m)

4 Rigid metal 27 ft. (8.2 m) 21 ft. (6.4 m)

Maytag Vent System Chart

Number of Type Box/Iouvered Angled

90 ° elbows of vent hoods hoods

0 Rigid metal 100 ft. (30.5 m) 94 ft. (28.7 m)

1 Rigid metal 90 ft. (27.4 m) 84 ft. (25.6 m)

2 Rigid metal 80 ft. (24.4 m) 74 ft. (22.6 m)

3 Rigid metal 71 ft. (21.6 m) 65 ft. (19.8 m)

4 Rigid metal 63 ft. (19.2 m) 57 ft. (17.4 m)

NOTE: Bottom exhaust installations have a 90 °turn inside the

dryer. To determine maximum exhaust length, add one 90 ° turn

to the charts.

11

Page 12

INSTALL ¥_NT SYSTEM

2. Plan pipe fitting connection

1, install exhaust hood

_] _ 12" rain.

Install exhaust hood and use caulking compound to seal

exterior wall opening around exhaust hood.

_305 ram)

2. Connect vent to exhaust hood

I

I

A combination of pipe fittings must be used to connect dryer

to existing gas line. A recommended connection is shown.

Your connection may be different, according to supply line

type, size, and location.

3. Open shut-off valve

CIosed_

Open valve

Vent must fit over the exhaust hood. Secure vent to exhaust

hood with 4" (102 mm) clamp. Run vent to dryer location

using straightest path possible. Avoid 90° turns. Use clamps

to seal all joints. Do not use duct tape, screws, or other

fastening devices that extend into interior of vent to secure

vent, because they can catch lint.

r__ GAS CONNECTION

Flared L__ _ Non-flared

malefitting __ _

Remove red cap from gas pipe. Using a wrench to tighten,

connect gas supply to dryer. Use pipe-joint compound

on threads of all non-flared male fittings. If flexible metal

tubing is used, be sure there are no kinks.

NOTE: For LP gas connections, you must use pipe-joint

compound resistant to action of LP gas. Do not use

TEFLON ®t tape.

Open shut-off valve in supply line; valve is open when handle

is parallel to gas pipe. Then, test all connections by brushing

on an approved noncorrosive leak-detection solution.

Bubbles will show a leak. Correct any leaks found.

CONNECT INLET HOSES

For non-steam models, skip to "Connect Vent" on page 14.

The dryer must be connected to the cold water faucet using

the new inlet hoses. Do not use old hoses.

f1. urn cold water off, remove and

replace rubber washer

®

®

®

Turn cold water faucet off and remove washer inlet hose.

Check and see if rubber washer is in the "Y" connector.

Remove old rubber washer from inlet hose and replace with

new rubber washer provided.

12

1®TEFLON is a registered trademark of E.I. Dupont De Nemours and Company.

Page 13

Attach short hose and

"Y" connector

If space permits, attach the brass female end of the "Y"

connector to the cold water faucet. See figure A.

If "Y" connector cannot be attached directly to the cold water

faucet, the short hose must be used. See figure B. Attach

short hose to cold water faucet. Screw on coupling by hand

until it is seated on faucet. Then attach "Y" connector to

brass male end of the short hose. Screw on coupling by hand

until it is seated on connector.

valve and tighten coupling

Attach other end of long hose

to fill valve at bottom of dryer

back panel. Screw on coupling

by hand until it is seated on fill

valve connector. Using pliers,

tighten the couplings an additional

two-thirds turn.

NOTE: Do not overtighten. Damage

to the coupling can result.

Using pliers, tighten the couplings with additional

two-thirds turn.

NOTE: Do not overtighten. Damage to the coupling can result.

connector and tighten couplings

Turn on cold water faucet

Check that the water faucets are turned on.

Check for leaks

One end of the long hose has a wire mesh strainer inside the

coupling. Attach this end to the "Y" connector. Attach washer

cold inlet hose to other side of "Y" connector. Screw on

coupling by hand until it is seated on connector. Using pliers,

tighten the couplings an additional two-thirds turn.

NOTE: Do not overtighten. Damage to the coupling can result.

Check for leaks around "Y" connector, faucets, and hoses.

13

Page 14

CONNECT _NT

LEVEL DR_R

, Connect vent to exhaust outlet

Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure vent is

clean. Dryer vent must fit over dryer exhaust outlet and inside

exhaust hood. Check that vent is secured to exhaust hood

with a 4" (102 mm) clamp.

2, Move dryer to final location

1, Level Dryer

Place

level _

Place

level

Check levelness of dryer from side to side. Repeat from

front to back.

NOTE: The dryer must be level for the moisture sensing

system to operate correctly.

Move dryer to final location. Avoid crushing or kinking vent.

After dryer is in place, remove cardboard from under dryer.

Not Level LEVEL Not Level

2, Adjust leveling legs

If dryer is not level, prop up using a wood block, use wrench

to adjust legs up or down, and check again for levelness. Once

legs are level, make sure all four legs are snug against the floor.

14

Page 15

COMPLETE INSTAL ION

[_ Check that all parts are now installed. If there is an extra

part, go back through steps to see what was skipped.

[_ Check that you have all of your tools.

[_ Dispose of/recycle all packaging materials.

[_ Be sure the water faucets are on.

[_ Check for leaks around "Y" connector, faucets, and hoses.

[_ Check dryer's final location. Be sure vent is not crushed

or kinked.

[_ Check that dryer is level. See "Level Dryer".

[_ Remove film on console and any tape remaining on dryer.

[_ Wipe dryer drum interior thoroughly with a damp cloth to

remove any dust.

[_ Read "Dryer Use" in your "Use and Care Guide".

[_ If you live in a hard water area, use of a water softener is

recommended to control the buildup of scale through the

water system in the dryer. Over time, the buildup of lime

scale may clog different parts of the water system, which will

reduce product performance. Excessive scale buildup may

lead to the need for certain part replacement or repair.

RE RSE DOOR SWING

You can change your door swing from a right-side opening

to a left-side opening, if desired.

1. Place a towel or soft cloth on top of dryer or work space

to avoid damaging the surface.

Remove the door assembly

1. Open the dryer door.

2. Remove the bottom screw (B) from each of the two hinges

that attach dryer door to front panel of dryer.

3. Loosen the top screw (A)from each of the two hinges

in Step 2.

A

B

Electric Models:

[_ Plug into a grounded outlet.

Gas Models:

[_ Check that gas supply is on.

[_ Check for leaks.

All Models:

[_ Select a Timed Dry heated cycle, and start dryer. Do not

select Air Only Temperature setting.

If dryer will not start, check the following:

* Controls are set in a running or "On" position.

* Start button has been pushed firmly.

* Dryer is plugged into an outlet and/or electrical supply is

connected.

* Household fuse is intact and tight, or circuit breaker has

not tripped.

* Dryer door is closed.

This dryer automatically runs an installation diagnostic routine

at the start of its first cycle.

NOTE: You may notice an odor when dryer is first heated. This

odor is common when heating element is first used. The odor will

go away.

.A

B

4. Remove the dryer door and the hinges by lifting upward

on the door. Lay the door on a flat, covered surface, with

the inside of the door facing up. Remove remaining two

loose screws from dryer front panel.

5. Remove the 4 plastic plugs (A) located outside the dryer

door opening.

6. Install 4 plastic plugs (A) into screw holes in the dryer left

where the hinges were removed in Step 4.

15

Page 16

Reverse the strike

1. Remove the door strike (A) from the dryer door opening.

2. Remove the cosmetic screw (B) opposite the door strike (A).

A

A. Door strike

B. Cosmetic screw

3, Reinstall the door strike and cosmetic screw on the opposite

side of dryer door opening from where they were removed.

NOTE: Door strike and plugs must be on the same side

of the dryer door opening.

4, Install the two hinges to the front panel of the dryer using

4 screws. Use the non-slotted side to attach the hinge

to the front panel.

5, Install screws in top hinge holes in the door. Do not tighten

screws. Leave approximately 1/4" (5 mm) of screw exposed.

6, Hang door by placing screw heads into top slotted holes of

hinges and slide door down. Align bottom screw holes in hinge

and door. Install two bottom screws. Tighten all hinge screws.

Reinstall the door

1. Remove the 4 screws and two hinges from the dryer door.

j.........

I

2, Replace the 4 screws in the same holes

3, Remove the 4 screws from the opposite side of the door.

i

, 1

7, Close door to engage door strike.

16

Page 17

TROUBLESHOOTING

DRYER OPERATION

Dryer will not run

[] Has a household fuse blown, or has a circuit breaker

tripped?

There may be two household fuses or circuit breakers

for the dryer. Check that both fuses are intact and tight,

or that both circuit breakers have not tripped. Replace

the fuse or reset the circuit breaker. If the problem

continues, call an electrician.

[]

Is the correct power supply available?

Electric dryers require a 240-volt power supply. Check

with a qualified electrician.

[]

Was a regular fuse used?

Use a time-delay fuse.

No heat

[] Has a household fuse blown, or has a circuit breaker

tripped?

The drum may be turning, but you may not have heat.

Elelctric dryers use two household fuses or circuit breakers.

Replace the fuse or reset the circuit breaker. If the problem

continues, call an electrician.

Dryer displaying code message

[] "PF" (power failure}, check the following:

Was the drying cycle interrupted by a power failure?

Press and hold START/PAUSE to restart the dryer.

Try the following:

Check to see if a household fuse has blown or circuit breaker

has tripped. Electric dryers use two household fuses or

breakers. Replace the fuse or reset the circuit breaker.

Confirm the power cord is properly installed.

Select a Timed Dry heated cycle, and restart the dryer.

If the message persists, consult a qualified electrician.

[]

"F" Variable (F1E1, F2E2, F3E1, F3E2, FTE1, F3E6, F3ET}

service codes:

Call for service.

DRYER RESULTS

Clothes are not drying satisfactorily, drying times are

too long, or load is too hot

[] Is the lint screen clogged with lint?

Lint screen shold be cleaned before each load.

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

Is the exhaust vent or outside exhaust hood clogged with

lint, restricting air movement?

Run the dryer for 5-10 minutes. Hold your hand under

the outside exhaust hood to check air movement. If you

do not feel air movement, clean exhaust system of lint or

replace exhaust vent with heavy metal or flexible vent. See

"Installation Instructions'.

[]

Are fabric softener sheets blocking the grille?

Use only one fabric softener sheet, and use it only once.

[]

Is the exhaust vent the correct length?

Check that the exhaust vent is not too long or has too

many turns. Long venting will increase drying times. See

"Installation Instructions".

[]

Is the exhaust vent diameter the correct size?

Use 4" (102 mm) diameter vent material.

[]

is the dryer located in a room with temperature below

45°F (7°C}?

Proper operation of dryer cycles requires temperatures

above 45°F (7°C).

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (460 ram) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

Is the dryer located in a closet?

Closet doors must have ventilation openings at the top and

bottom of the door. The front of the dryer requires a minimum

of 1" (25 mm) of airspace, and, for most installations, the

rear of the dryer requires 5" (127 mm). See "Installation

Instructions'.

17

Page 18

p p p

$ECURITE DE LA $ECHEUSE

Votre s_curit_ et celle des autres est tr_s irnportante.

Nous donnons de nombreux messages de securit6 importants dans ce manuel et sur votre appareil m6nager. Assurez-vous de

toujours lire tousles messages de s6curit6 et de vous y conformer.

Voici le symbole d'alerte de s_curit&

Ce symbole d'alerte de s6curit6 vous signale les dangers potentiels de d6c_s et de blessures graves & vous

et & d'autres.

Tous les messages de securit6 suivront le symbole d'alerte de s6curit6 et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient :

Risque possible de d_c_s ou de blessure grave si vous ne

suivez pas imm_diaternent les instructions.

Risque possible de d_c_s ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de s6curit6 vous diront quel est le danger potentiel et vous disent comment r6duire le risque de blessure et

ce qui peut se produire en cas de non=respect des instructions.

AVERT|SSEMENT d,i.oo°dio,,

m

L'installation de la s6cheuse a linge dolt _tre effectu6e par un installateur qualifi_.

m

Installer la s_cheuse conforrn_rnent aux instructions du fabricant et aux codes Iocaux,

m

Ne pas installer de s_cheuse a linge avec des mat_riau× d'_vacuation en plastique

souple ou un conduit m6tallique souple (de type papier d'aluminium). Si un conduit

m_tallique souple est installS, celui-ci doit 6tre d'un type sp6cifique identifi6 par le

fabricant de I'appareil et convenir & une utilisation avec les s6cheuses a linge. Les

mat6riaux d'6vacuation soupies sont connus pour s'affaisser, 6tre facilement _cras6s

et bloquer la charpie, Ces situations obstrueront le d6bit d'air de la s6cheuse _ linge et

augmenteront le risque d'incendie,

Pour r_duire le risque de blessure grave ou de d_c_s, suivre routes

les instructions d'installation.

Conserver ces instructions.

Pour mettre I'ancienne s6cheuse au rebut ou pour la remiser, enlever la porte.

18

Page 19

AVERTISSEMENT : Pour votre s6curit6, les renseignements dans ce manuel doivent

_tre observ6s pour r6duire au minimum les risques d'incendie ou d'e×plosion ou pour

_viter des dommages au produit, des blessures ou un d6c_s.

- Ne pas entreposer ou utiliser de I'essence ou d'autres vapeurs ou liquides

inflammables a proximit_ de cet appareil ou de tout autre appareil _lectrom_nager.

- QUE FAIRE DANS LE CAS D'UNE ODEUR DE GAZ :

• Ne pas tenter d'allumer un appareil.

= Ne pas toucher a un commutateur 61ectrique; ne pas utiliser le t616phone se trouvant

sur les lieu×.

® l_vacuer tous les gens de la piece, de 1'6difice ou du quarrier.

®Appeler imm6diatement le foumisseur de gaz d'un t_16phone voisin. Suivre ses

instructions.

= A d6faut de joindre votre fournisseur de gaz, appeler les pompiers.

- L'installation et I'entretien doivent _tre effectu6s par un installateur qualifi_, une

agence de service ou le fournisseur de gaz.

AVERTISSEMENT : L'odorat ne permet pas toujours la detection d'une fuite de gaz.

Les distributeurs de gaz recommandent I'emploi d'un detecteur de gaz (homologation UL ou CSA).

Pour d'autre information, contacter le fournisseur de gaz local.

En cas de d6tection d'une fuite de gaz, ex6cuter les instructions "Que faire dans le cas d'une odeur de gaz".

iMPORTANT : L'installation du gaz doit se conformer aux codes Iocaux, ou en I'absence de codes Iocaux, au code canadien

d'installation Bt49.1 du gaz naturel ou du propane.

La secheuse doit _tre 61ectriquement reli6e &la terre conformement aux codes Iocaux, ou en I'absence de codes Iocaux, au Code

canadien de I'electricit6, CSA C22.1.

Dans I'#tat du Massachusetts, les instructions d'installation suivantes sont applicables :

[] Les travaux d'installation et r6paration doivent 6tre ex6cut6s par un plombier ou tuyauteur qualifi6 ou licenci6, ou par le

personnel qualifi6 d'une entreprise licenci6e par I'Etat du Massachusetts.

[] Si une vanne & boisseau sph6rique est utilis6e, elle dolt comporter une manette "T".

[] Si un conduit de raccordement flexible est utilise, sa Iongueur ne doit pas depasser 3 pi.

19

Page 20

EXIGNNCNS D IN$ LATION

OUTILLAGE ET PIECES

Rassembler les outils et composants n6cessaires avant

d'entreprendre I'installation. Lire et observer les instructions

fournies avec chacun des outils de la liste ci-dessous.

Outils n6cessaires _ toutes les installations :

Tournevis & lame plate

Niveau

Cl6 b,molette avec ouverture

jusqu'a 1" (25 mm) ou cl6

douille hexagonale

Brides de conduit

Outils n6cessaires pour les installations _ gaz :

CI6 a tuyau de 8" (203 mm)

ou 10" (254 mm)

Compos6 d'6tanch6it6 des

raccords filet6s - r6sistant

au gaz propane

CI6 a mollette de 8" (203 mm)

ou 10" (254 mm)

(pour le raccordement au gaz)

Pi_ces fournies (tous les modules) :

Couteau utilitaire

Cisaille de ferblantier

(pour I'installation d'un

nouveau conduit)

Metre-ruban

20

Pistolet a calfeutrage et

compos6 de calfeutrage

(pour I'installation d'un

nouveau conduit

d'6vacuation)

Tourne-6crou de 1/4"

(6 mm) (recommand6)

Pince

Pieds de nivellement (4)

Pi_ces fournies (modUles _ vapeur) :

Tuyau d'alimentation

de 2' (0,6 m)

Tuyau d'alimentation

de 5' (1,5 m)

Retirer le sachet de pieces du tambour de la s6cheuse. V6rifier

que toutes les pieces sont pr6sentes.

Pi_ces n6cessaires : (Non fourni avec la secheuse)

Consulter les codes Iocaux. V6rifier I'alimentation 61ectrique et le

circuit d'6vacuation existants. Voir "Installations 61ectriques" et

"Exigences concernant 1'6vacuation" avant d'acheter les pieces.

Les installations pour maison mobile n6cessitent un

systeme d'6vacuation en m6tal disponible chez le revendeur

aupres duquel vous avez achet6 votre s6cheuse. Pour plus

d'informations, voir la section "Assistance ou service" dans le

"Guide d'utilisation et d'entretien".

Rondelle en caoutchouc

Page 21

Mat6rielfacultatif: (Non fourni avec Ja secheuse)

Consulter le "Guide d'utilisation et d'entretien" pour plus

d'informations sur les accessoires disponibles qui conviennent

&votre s6cheuse.

EXIGENCES D'EMPLACEMENT

Risque d'expJosion

Garder les matibres et les vapeurs inflammables, telle

que I'essence, loin de la s6cheuse.

Placer la s6cheuse au moins 460 mm (18 po) au=dessus

du plancher pour une instal|ation darts un garage.

Le non=respect de ces instructions peut causer

un d6c_s, une explosion ou un incendie.

II vous faudra :

[]

Un emplacement permettant une 6vacuation appropri6e.

Voir "Exigences concernant 1'6vacuation".

[]

Un circuit distinct de 15 ou 20 A est requis pour les

s6cheuses & gaz et un circuit distinct de 30 A est requis

pour les s6cheuses 61ectriques.

[]

Si on utilise un cordon d'alimentation, une prise 61ectrique

reli6e &la terre situ6e & 2 pi (61 cm) maximum d'un des

c6t6s de la s6cheuse. Voir "Sp6cifications 61ectriques".

[]

Le plancher dolt pouvoir soutenir le poids de la s6cheuse

de 200 Ib (90,7 kg). Tenir 6galement compte du poids des

appareils voisins.

[]

Un plancher de niveau avec une pente maximale de 1"

(25 mm) sous I'ensemble de la s6cheuse. Si I'inclinaison

est sup6rieure & 1" 25 ram, installer I'ensemble de

pieds d'extension de la s6cheuse, piece no 279810. Si

la s6cheuse n'est pas de niveau, le linge peut ne pas

culbuter convenablement et les programmes de d6tection

automatiques peuvent ne pas fonctionner correctement.

[]

For garage installation, place dryer at least 18" (460 mm)

above floor. If using a pedestal, you will need 18" (460 mm)

to bottom of dryer.

[]

Modeles vapeur uniquement : Des robinets d'eau froide

situ6s & 4 pi (1,2 m) maximum des valves de remplissage,

et une pression d'eau de 20 & 100 psi (137,9 &689,6 kPa).

On peut utiliser I'alimentation en eau de la laveuse & I'aide

du raccord en "Y" fourni.

Ne pas faire fonctionner la s6cheuse & des temp6ratures

inf6rieures & 45°F (7°C). A des temp6ratures inf6rieures, la

s6cheuse risque de ne pas s'arr6ter & la fin d'un programme de

d6tection automatique. Ceci peut prolonger la dur6e du s6chage.

La s6cheuse ne dolt pas 6tre install6e ou remis6e dans un endroit

oQ elle sera expos6e a I'eau et/ou aux intemp6ries.

V6rifier les sp6cifications des codes. Certains codes limitent ou

n'autorisent pas I'installation des s6cheuses dans un garage,

un placard, une maison mobile ou une chambre & coucher.

Communiquer avec I'inspecteur des bfitiments local.

REMARQUE • Aucun autre appareil consommant un combustible

ne dolt 6tre install6 dans le m6me placard.

DISTANCES DE Df==GAGEMENTA RESPECTER POUR

L'INSTALLATION

Uemplacement dolt 6tre assezgrand pour permettre d'ouvrir

completement laporte de las6cheuse.

DIMENSIONS DE LA SECHEUSE

S6cheuseavec pattie

arri_re prolong6e :

30"

{762m_)f

___1105 mm)

Back view:

431/2"

"1"

(25 ram)

(565 ram)

21/8 n

(51,ram)

a /4 J

S6cheuse avec partie

arri_re plate :

221/4"--_

28"

,,5

t t

(25ram)

-,_--11"

(279 ram)

Bottom view:

7 ',,

31/4"

(83 _nm)

-"_'14V2"'""_'14V2"'="

(368 mm) 1368ram)

REMARQUE • La plupart des installations requierent un espace

minimum de 5" (127 mm) derriere la s6cheuse pour le conduit

d'6vacuation avec coude. Voir "Exigences concernant

1'6vacuation'.

21

Page 22

Espacementpouruneinstallation darts

un encastrement ou dans un placard

Toutes les dimensions indiquent le d6gagement autoris6, avec

un d6gagement test6 de 0" (0 mm) de chaque c6t6 et a I'arriere.

[] Pr6voir davantage d'espace pour faciliter I'installation

et I'entretien.

[]

Un espace suppl6mentaire peut 6tre requis pour les

moulures de porte et de plancher et pour les plinthes.

[]

Un espace suppl6mentaire dolt 6tre envisag6 de tous les

c6t6s de la s6cheuse afin de r6duire le transfert de bruit.

[]

Pour installation dans un placard avec porte, on dolt pr6voir

des ouvertures minimums d'entr6e d'air en haut et en bas

de la porte. Des portes a claire-vole offrant des ouvertures

6quivalentes de passage de I'air sont acceptables.

[]

IIfaut aussi prendre en compte I'espace requis entre les

appareils voisins.

14" max.

(356 rnm)

a

(76

i.\ .........

a

(76

(127 ram}

(25ram}

(25 ram)

installation darts une r_sidence mobile = Exigences

suppl_mentaires :

Cette s6cheuse peut _tre install6e dans une r6sidence mobile.

L'installation dolt se conformer aux criteres de la Manufactured

Home Construction and Safety Standard, Titre 24 CFR, partie

3280 (anciennement Federal Standard for Mobile Home

Construction and Safety, Titre 24 HUD, partie 280) ou de la

Norme CAN/CSA-Z240MH.

Autres crit_res _ respecter pour une installation

en r_sidence mobile :

"routes les s_cheuses :

[] Un systeme d'6vacuation en m6tal est disponible & I'achat

chez votre revendeur. Pour plus d'informations, voir la

section "Assistance ou service" dans le "Guide d'utilisation

et d'entretien".

[]

IIfaut prendre des dispositions sp6ciales dans les r6sidences

mobiles pour I'apport d'air de I'ext@ieur dans la s6cheuse.

Les ouvertures (telle qu'une fen_tre a proximit6) devraient

6tre au moins deux fois plus grandes que I'ouverture de

d6charge de la s6cheuse.

Pour les installations en r_sidence mobile avec s_cheuse

gaz :

[] II est possible de commander un ensemble d'ancrage au sol

pour installation en r6sidence mobile, piece num@o 346764.

Pour plus d'informations, voir la section "Assistance ou

service" dans le "Guide d'utilisation et d'entretien".

RACCORDES{ENT DE LA

SECHEUSE NLECTRIQUE o

UNIQUEMENT

SPC:ClFICATIONS €:LECTRIQUES

Risque de choc 61ectrique

Brancher sur une prise &4 alv_oles reli6e & la terre.

Le non=respect de cette instruction peut causer

un d_c_s ou un choc _lectrJque.

C'est _ I'utilisateur qu'incombe la responsabilit6 de :

[]

Contacter un 61ectricien qualifi6.

[]

S'assurer que le raccordement 61ectrique est ad6quat

et conforme a la derniere 6dition du Canadian Electrical

Code, C22.1, eta tous les codes et reglements Iocaux

en vigueur. Pour obtenir un exemplaire des normes

des codes ci-dessus, contacter : Canadian Standards

Association, 178 Rexdale Blvd., Toronto, ON M9W 1R3

CANADA.

[]

L'appareil dolt 6tre aliment6 uniquement par un circuit

monophas6 de 120/240 V, CA uniquement, 60 Hz a 4 ills,

sur un circuit s6par6 de 30 amperes, prot6g6 par fusible

aux deux extr6mit6s de la ligne. On recommande d'utiliser

un fusible ou un disjoncteur temporis6. On recommande

6galement que cet appareil soit aliment6 par un circuit

ind6pendant.

[]

Cette s6cheuse est 6quip6e d'un cordon 61ectrique

homologu6 par la CSA International & introduire dans

une prise murale standard 14-30R. Le cordon mesure

5 pi (1,52 m). Veiller a ce que la prise murale se trouve

proximit6 de I'emplacement d6finitif de la s6cheuse.

Prise murale _ 4 ills (14-30R)

En cas d'utilisation d'un cordon de rechange, il est recommand6

d'utiliser le cordon d'alimentation de rechange - piece num@o

9831317.

Pour plus d'informations, consulter les num@os de d6pannage

dans la section "Assistance ou service" du "Guide d'utilisation

et d'entretien".

22

Page 23

iNSTRUCTiONS DE LiAiSON A LA TERRE

[] Pour une s6cheuse reli6e & la terre et connect6e par

un cordon :

Cette s6cheuse dolt _tre reli6e _,la terre. En cas de mauvais

fonctionnement ou de panne, la liaison _,la terre r6duira le

risque de choc 61ectrique en offrant au courant 61ectrique un

acheminement d'6vacuation de moindre r6sistance. Cette

s6cheuse est aliment6e par un cordon 61ectrique comportant

un conducteur reli6 #,la terre et une fiche de branchement

munie d'une broche de liaison &la terre. La fiche dolt _tre

branch6e sur une prise appropri6e qui est bien install6e et

reli6e _,la terre conform6ment &tousles codes et reglements

Iocaux.

AVERTISSEMENT " Le raccordement incorrect de

cet appareil au conducteur de liaison & la terre peut susciter

un risque de choc 61ectrique. En cas de doute quant #, la

qualit6 de liaison #, la terre de la s6cheuse, consulter un

61ectricien ou un technicien ou un personnel qualifi& Ne pas

modifier la fiche de branchement fournie avec la s6cheuse;

si la fiche ne correspond pas _,la configuration de la prise de

courant, demander & un 61ectricien qualifi6 d'installer une

prise de courant appropri6e.

CONSERVEZ CES INSTRUCTIONS

INSTRUCTIONS DE LIAISON A LA TERRE

[] Pour une s6cheuse reli6e & la terre et connect6e par

un cordon :

Cette s6cheuse dolt _tre reli6e _,la terre. En cas de mauvais

fonctionnement ou de panne, la liaison #,la terre r6duira le

risque de choc 61ectrique en offrant au courant electrique un

acheminement d'6vacuation de moindre r6sistance. Cette

s6cheuse est aliment6e par un cordon 61ectrique comportant

un conducteur reli6 #,la terre et une fiche de branchement

munie d'une broche de liaison & la terre. La fiche dolt _tre

branch6e sur une prise appropri6e qui est bien install6e et

reli6e _,laterre conform6ment & tousles codes et reglements

Iocaux.

AVERTISSEMENT " Le raccordement incorrect de

cet appareil au conducteur de liaison & la terre peut susciter

un risque de choc 61ectrique. En cas de doute quant _, la

qualit6 de liaison & la terre de la s6cheuse, consulter un

61ectricien ou un technicien ou un personnel qualifi& Ne pas

modifier la fiche de branchement fournie avec la s6cheuse;

si la fiche ne correspond pas _,la configuration de la prise de

courant, demander & un 61ectricien qualifi6 d'installer une

prise de courant appropri6e.

CONSERVEZ CES INSTRUCTIONS

RACCOgDEMENT LECTRXQUE

DE LA SECHEUSE A

SPECIFICATIONS €:LECTRIQUES

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

[]

Une source d'alimentation de 120 V, 60 Hz, CA

uniquement, de 15 ou 20 amperes et prot6g6e

par fusible est n6cessaire. On recommande d'utiliser

un fusible ou un disjoncteur temporis& II est 6galement

recommand6 de raccorder I'appareil sur un circuit distinct

exclusif &cet appareil.

SPI_CIFICATIONS DE L'ALIMENTATION EN GAZ

Risque d'explosion

Utiliser une canalisation neuve d'arriv_e de gaz

approuv_e par CSA International.

Installer un robinet d'arr_t.

Bien serrer chaque organe de connexion de la

canaiisation de gaz.

En cas de connexion au gaz propane, demander & une

personne qualifiee de s'assurer que la pression de gaz

ne d_passe pas 330 ram (13 po) de la colonne d'eau.

Par personne quaHfi6e, on comprend :

le personnel autorise de chauffage,

le personnel autoris_ d'une compagnie de gaz, et

le personnel d'entretien autoris&

Le non=respect de ces instructions peut causer

un d6c_s, un explosion ou un incendie.

23

Page 24

TYPE DE GAZ

GBz natureJ :

Cette s6cheuse est 6quip6e pour une alimentation au gaz naturel.

Sa conception est homologu6e par CSA International pour

I'alimentation au gaz de p6trole liqu6fi6 (propane ou butane),

avec conversion appropri6e.

[]

Cette s6cheuse dolt 6tre 6quip6e du brQleur convenable,

correspondant au gaz sp6cifique qui alimente I'habitation.

Uinformation sur le brQleur se trouve sur la plaque

signal6tique dans le Iogement de la porte de la s6cheuse.

Si ces renseignements ne correspondent pas au type de

gaz disponible, contacter votre revendeur ou composer les

num6ros de t616phone indiqu6s dans la section "Assistance

ou service" de votre "Guide d'utilisation et d'entretien".

Conversion pour I'alimentation au propane :

iMPORTANT : Un technicien qualifi6 dolt effectuer la conversion.

Ne pas entreprendre de convertir la s6cheuse dans le cas d'une

utilisation avec un gaz diff6rent de celui indiqu6 sur la plaque

signal6tique sans d'abord consulter la compagnie de gaz.

CANALISATION DE GAZ

[] La canalisation dolt comprendre un connecteur obtur6

(filetage NPT de 1/8" ou plus) accessible pour le

raccordement de I'instrument de mesure imm6diatement en

amont de la connexion d'alimentation en gaz de la s6cheuse.

E

B

A. Raccord flexible de gaz de 3/8"

B. Adaptateur entre le conduit et le joint

conique de 3/8"

C. Connecteur obtur6 (filetage NPT

de 1/8" ou plus)

D. Canalisation d'alimentation en gaz

(filetage NPT de 1/2")

E. Robinet d'arr_t du gaz

[]

On recommande un tuyau IPS de 1/2".

[]

Pour les Iongueurs inf6rieures a 20 pi (6,1 m), on peut

utiliser des tuyaux approuv6s en aluminium ou en cuivre

de 3/8" dans la mesure oQ les codes Iocaux et le fournisseur

de gaz I'autorisent.

Aux letats-Unis :

Un robinet d'arr6t individuel manuel dolt 6tre install6 & six

(6) pieds (1,8 m) maximum de la s6cheuse conform6ment

au Code National d'alimentation au gaz, ANSI Z223.1.

Uemplacement dolt 6tre facile a atteindre pour ouvrir et

fermer la s6cheuse.

Au Canada :

Un robinet d'arr6t individuel dolt 6tre install6 conform6ment

au Code B149.1 relatif & I'installation du gaz naturel et du

propane. II est recommand6 d'installer un robinet d'arr6t

individuel manuel & six (6) pieds (1,8 m) maximum de la

s6cheuse. L'emplacement dolt 6tre facilement accessible

pour les manceuvres d'ouverture et de fermeture.

SPI_CIFICATIONS DU RACCORDEMENT

DE L'AMMENTATION EN GAZ

[] Utiliser un coude et un adaptateur NPT de 3/8" x 3/8"

entre le raccord de gaz flexible et la conduite de gaz de la

s6cheuse, tel que n6cessaire pour 6viter le pincement.

[]

Utiliser uniquement un compos6 d'6tanch6it6 des

tuyauteries. Ne pas utiliser de ruban adh6sif TEFLON%

[]

On dolt raccorder la s6cheuse & la conduite d'alimentation

en gaz & I'aide d'un raccord de gaz flexible homologu6 qui

respecte les normes applicables aux raccords utilis6s avec

des appareils m6nagers a gaz, ANSI Z21.24 ou CSA 6.10.

SPI_CIFICATIONS DE L'AUMENTATION DU BROLEUR

Altitudes sup6rieures _ 10 000 pieds (3 048 m) :

[] Si la s6cheuse dolt 6tre utilis6e & une altitude sup6rieure

& 10 000 pi (3 048 m), on dolt r6duire le d6bit thermique

du brOleur indiqu6 sur la plaque signal6tique de 4% pour

chaque tranche de 1 000 pi (305 m) d'augmentation de

I'altitude.

f=preuve sous pression de I'alimentation en gaz

[] La s6cheuse dolt 6tre d6connect6e du systeme de

canalisations d'alimentation en gaz Iors de tout test de

pression a des pressions plus 61ev6es que 1/2Ib/po 2.

CANALISATION DE GAZ DE LA SECHEUSE

[] La canalisation d'arriv6e de gaz sortant depuis I'arriere de la

s6cheuse est dot6e d'un filetage m&le de 3/8".

I

[]

Pour le gaz naturel, ne pas utiliser de conduits en cuivre.

[]

Pour les Iongueurs sup6rieures a 20 pi (6,1 m), on peut

utiliser des tuyaux plus gros et un adaptateur de calibre

diff6rent.

[]

Si la s6cheuse a 6t6 convertie pour une utilisation au

propane, on peut utiliser un tuyau en cuivre pour propane

compatible de 3/8". Si la Iongueur totale de la canalisation

d'alimentation en gaz est sup6rieure a 20 pi (6,1 m), utiliser

un conduit de taille sup6rieure.

REMARQUE : On dolt utiliser un compos6 d'6tanch6it6

des tuyauteries r6sistant a I'action du gaz propane. Ne pas

utiliser de ruban adh6sif TEFLON ®t.

[] Robinet d'arr6t n6cessaire.

1-®Teflon est une marque depos6e de E.I. Du Pont De Nemours et Compagnie.

24

2 1/8""

1,,_(54 ram)

125ram)

A. Canalisation d'alimentation en gaz (filetage NPT de 1/2")

B. Conduit NPT de las6cheuse de 3/8"

REMARQUE : Si la s6cheuse est mont6e sur un pi6destal,

pr6voir 10" (254 mm) ou 15,5" (394 mm) de plus &partir du sol

pour la hauteur de la canalisation d'arriv6e de gaz, en fonction

du modele de pi6destal. Pour une installation dans un garage,

pr6voir 18" (460 mm) de plus & partir du sol pour la hauteur de

la canalisation d'arriv6e de gaz.

Page 25

INSTALLATION DES FINDS DE

NI LLEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes pour d_placer et

installer la s_cheuse,

Le non=respect de cette instruction peut causer

une blessure au dos ou d'autre blessure,

Pr6parer la s cheuse pour

ies pieds de nivellement

Afin d'6viter d'endommager le plancher, utiliser un grand

morceau de carton plat extraJt de la boTte d'emballage

de la s6cheuse et le placer sous toute la partie arri_re

de la s6cheuse. Saisir fermement le corps de la s6cheuse

(et non pas le panneau de la console) puis reposer

la s6cheuse sur le carton avec precaution.

EXIGENCES CONCERNANT L'EVACUATION

Risque d'incendie

Utiliser un conduit d'_vacuation en rn_tal Iourd.

Ne pas utiliser un conduit d'_vacuation en plastique,

Ne pas utJliser un conduit d'_vacuation en feuJlle

de rn_tal.

Le non=respect de ces instructions peut causer

un d_c_s ou un incendie.

AVERTISSEMENT : Pour r6duire le risque d'incendie,

ce s_che-linge dolt EVACUER L'AIR A L'EXTERIEUR.

iMPORTANT : Respecter les dispositions de tousles codes

et r_glements en vigueur. Le conduit d'6vacuation de la

s6cheuse ne dolt pas _tre raccord6 & une 6vacuation de gaz,

une chemin6e, un mur, un plafond, un grenier, un vide sanitaire

ou un vide de construction. Seul un conduit d'6vacuation

m6tallique rigide ou souple dolt etre utilis6 pour le systeme

d'6vacuation.

4 ml

(102ram)

2, Visser les pieds de nivellement

Rep_re

en forme

de Iosange

Examiner les pieds de nivellement pour trouver le rep_re

en forme de Iosange. Visser manuellement les pieds dans

les trous pour pieds de nivellement et utiliser une cl6 pour

terminer le vissage, jusqu'a ce que le rep_re en forme

de Iosange ne soit plus visible.

A pr6sent, redresser la s6cheuse et la placer sur ses

pieds. Faire glisser la s6cheuse jusqu'& ce qu'elle se trouve

proximit6 de son emplacement final. Laisser suffisamment

d'espace pour pouvoir r6aliser le raccordement 61ectrique

et raccorder le conduit d'6vacuation.

t

Conduit d'6vacuation m6tallique robuste

de 4 pouces (102 ram)

[] On peut utiliser un conduit d'6vacuation m6tallique robuste

de 4 pouces (102 mm).

[] Ne pas utiliser de conduit de plastique ou de m6tal tr_s mince.

Conduit rn6tallique rigide :

[] Recommand6 pour une performance de s6chage id6ale afin

d'6viter tout 6crasement ou deformation.

25

Page 26

Conduit m6tallique flexible : (Acceptable uniquement

si son acces reste facile pour le nettoyage)

[] Dolt 6tre entierement d6ploy6 et soutenu & I'emplacement

d'installation final de la s6cheuse.

[]

Enlever tout exces de conduit flexible pour 6viter tout

affaissement et d6formation susceptible de r6duire

la capacit6 d'6vacuation et le rendement.

[]

Ne pas installer le conduit m6tallique flexible dans des cavit6s

ferm6es de tour, plafonds ou planchers.

[] La Iongueur totale ne dolt pas d6passer 7 3/4pi (2.4 m).

REMARQUE : Lors de I'utilisation d'un systeme d'6vacuation

existant, nettoyer et 61iminer la charpie sur toute la Iongueur du

systeme, et veiller & ce que le clapet d'6vacuation ne soit pas

obstru6 par de la charpie. Remplacer tout conduit de plastique

ou en aluminium par un conduit m6tallique rigide ou souple.

Consulter & nouveau le tableau des systemes d'6vacuations et

modifier le systeme d'6vacuation existant au besoin pour obtenir

un meilleur s6chage.

Clapets d'_vacuation :

[] Dolt se trouver & au moins 12" (305 mm) du plancher ou

de tout objet susceptible d'obstruer I'ouverture d'6vacuation

(tels des fleurs, des pierres, des buissons ou de la neige).

Styles recommand_s

Brides de serrage :

[] Utiliser des brides pour sceller tousles joints.

[]

Le conduit d'6vacuation ne dolt pas 6tre raccord6 ou fix6 avec

des vis ou tout autre dispositif de serrage qui se prolongerait

& I'int&ieur du conduit et retiendrait la charpie. Ne pas utiliser

de ruban adh6sif pour conduit.

Une mauvaise _vacuation de Pair peut causer de

I'humidit_ et une accumulation de charpie _ I'int_rieur de

la maison, ce qui peut provoquer :

[] Dommages par I'humidit6 aux boiseries, meubles, peinture,

papier-peint, tapis, etc.

[] Problemes de nettoyage dans la maison et problemes

de sant&

Le mat6riel d'6vacuation peut 6tre achet6 aupres de votre

revendeur. Pour plus d'informations, voir la section "Assistance

ou service" du "Guide d'utilisation et d'entretien".

Clapet &persiennes

Clapet de type boite

Style acceptable :

Clapet inclin6

Coudes :

[] Les coudes a 45° permettent une meilleure circulation de I'air

que les coudes &90°.

Styles recommand_s :

Bon ........._ Meill

PLANIFICATION DU SYSTNME

installations d'_vacuation recommand_es

Les installations typiques consistent a acheminer le conduit

d'6vacuation & I'arriere de la s6cheuse. D'autres installations

sont possibles.

B

A

H

A. S6cheuse

B. Raccord coud6

C. Mur

D. Clapet d'6vacuation

E. Brides

R Conduit d'6vacuation m6tallique rigide

ou souple

G. Longueur de conduit d'6vacuation

n6cessaire pour le raccordement des

coudes

H. Bouche de d6charge

26

d

Page 27

Installations d'_vacuation facultatives :

Risque d'incendie

Utiliser un conduit d'_vacuation en mdtal Iourd.

Ne pas utiliser un conduit d'_vacuation en plastique.

Ne pas utiliser un conduit d'_vacuation en feuille

de rn_taL

Le non=respect de ces instructions peut causer

un d_c_s ou un incendie.

[]

Trousse d'obturation pour 6vacuation (pour couvrir les trous

d'6vacuation inutilis6s) " Piece num@o W10186596 -- Tous

les modeles

[] Trousse d'6vacuation par le bas -- Piece num@o 8212503

/_

Autres installations avec d_gagement r6duit

II existe de nombreux systemes d'6vacuation. Choisir le systeme

qui convient le mieux a votre installation. Deux installations

d6gagement r6duit sont illustr6es. Voir les instructions du

fabricant.

A B

A. Installationau-dessus de la s6cheuse

(6galementdisponible avec un coude d6cal6)

B. Installation de p@iscope

REMARQUE : On peut acheter les trousses suivantes pour

les installations oQ le d6gagement est r6duit. Contacter votre

marchand local.

[]

Installation au-dessus de la s6cheuse " Piece num@o

4396028

[]

Installation avec p@iscope (Pour utilisation en cas

de non-concordance de la bouche de d6charge

de la s6cheuse avec la bouche d'6vacuation murale) :

Piece num@o 4396037 -- Non-concordance de 0"

(0 mm) a 18" (460 mm)

Piece num@o 4396011 -- Non-concordance de 18"

(460 mm) a 29" (737 mm)

Piece num@o 4396014 -- Non-concordance de 29"

(737 mm) a 50" (1270 mm)

Si vous pr6f@ez, la s6cheuse peut _tre convertie pour 6vacuer

par le bas. Contactez votre revendeur local pour convertir la

s6cheuse.

A B

A. Installationavec acheminement standard

du conduit d'6vacuation par I'arri_re

B. Installation avec 6vacuation par le bas

Dispositions sp6ciales pour les installations

en r6sidence mobile :

Le systeme d'6vacuation dolt 6tre solidement fix6 &une section

non combustible de la structure de la r6sidence mobile et ne dolt

passe terminer en dessous de la r6sidence mobile. Acheminer

le conduit d'6vacuation vers I'ext@ieur.

Installation du syst_me d'6vacuation en r6sidence mobile

D_terminer I'itin_raire d'acheminement du conduit :

[] Choisir I'itin6raire d'acheminement vers I'ext@ieur qui sera

le plus direct et le plus rectiligne.

[] Planifier I'installation de fagon & introduire un nombre minimal

de coudes et de changements de direction.

[] Si des coudes ou changements de direction sont utilis6s,

pr6voir autant d'espace que possible.

[] Plier le conduit graduellement pour 6viter de le d6former.

[] Utiliser le moins possible de changements de direction a 90 °.

27

Page 28

D_terminer la Iongueur du conduit et le nombre

de coudes n_cessaires pour une performance

optimale de s_chage.

[] Utiliser le tableau des syst_mes d'6vacuation suivant

pour d6terminer le type de mat6riel d'6vacuation et les

combinaisons de hotte acceptables.

RENIARQUE : Ne pas utiliser de conduits de Iongueur sup6rieure

la valeur sp6cifi6e dans le tableau des syst_mes d'6vacuation.

Si la Iongueur du circuit est sup6rieure a la valeur sp6cifi6e dans

le tableau, on observera :

[] Un cycle de vie r6duit de la s6cheuse.

[] Une r6duction du rendement, avec temps de s6chage plus

longs et une plus grande consommation d'6nergie.

Le tableau des systemes d'6vacuation fournit les sp6cifications

d'6vacuation qui vous aideront a obtenir une performance

de s6chage id6ale.

Tableau des syst mes d' vacuation

Whirlpool

Nombre Type de Clapets Clapets

de coudes conduit d'_vacuation d'_vacuation

90° d'_vacuation de type inclines

boite ou

persiennes

0 M_tallique 64 pi (20 m) 58 pi (17,7 m)

rigide

INSTALLATION DU SYSTEME

D'EVAC ION

Installer le clapet d'6vacuation

L- 12" rnin.

12" rain.

Lors de I'installation du clapet d'6vacuation, calfeutrer le c6t6

ext6rieur de I'ouverture murale autour du clapet d'6vacuation.

f

2, Raccorder le conduit

au clapet

1 M_tallique 54 pi (16,5 m) 48 pi (14,6 m)

2 M_tallique 44 pi (13,4 m) 38 pi (11,6 m)

3 M_tallique 35 pi (10,7 m) 29 pi (8,8 m)

4 M_tallique 27 pi (8,2 m) 21 pi (6,4 m)

rigide

rigide

rigide

rigide

Tableau des syst rnes d' vacuation

Maytag

Nombre Type de Clapets

de coudes conduit d'_vacuation

90° d'_vacuation inclines

0 M_tallique 94 pi (28,7 m)

rigide

1 M_tallique 84 pi (25,6 m)

rigide

2 M_tallique 74 pi (22,6 m)

rigide

3 M_tallique 65 pi (9,8 m)

rigide

Clapets

d'_vacuation

de type

boite ou

persiennes

100 pi (30,5 m)

90 pi (27,4 m)

80 pi (24,4 m)

71 pi (21,6 m)

Le conduit dolt _tre ins6r6 par dessus le clapet d'6vacuation.

Fixer ensemble le conduit et le clapet avec une bride de 4"

(102 mm). Acheminer le conduit jusqu'a I'emplacement de

la s6cheuse en utilisant le chemin le plus rectiligne possible.

Eviter les changements de direction & 90°. Utiliser des brides

pour sceller tousles joints. Ne pas utiliser de ruban adh_sif

pour conduit, de vis ou autres dispositifs de fixation qui se

prolongeraient a I'int6rieur du conduit pour fixer le conduit

d'6vacuation; ceux-ci pourraient retenir la charpie.

4 57 pi (17,4 m)

i{

REMARQUE Les installations d'6vacuation par le bas

comportent un changement de direction a 90° & I'int6rieur