Page 1

INSTALLATION

SEALED GAS COOKTOPS

MANUAL

Models: MGC6430 & MGC6536

403 WEST FOURTH STREET, NORTH · NEWTON, IA 50208

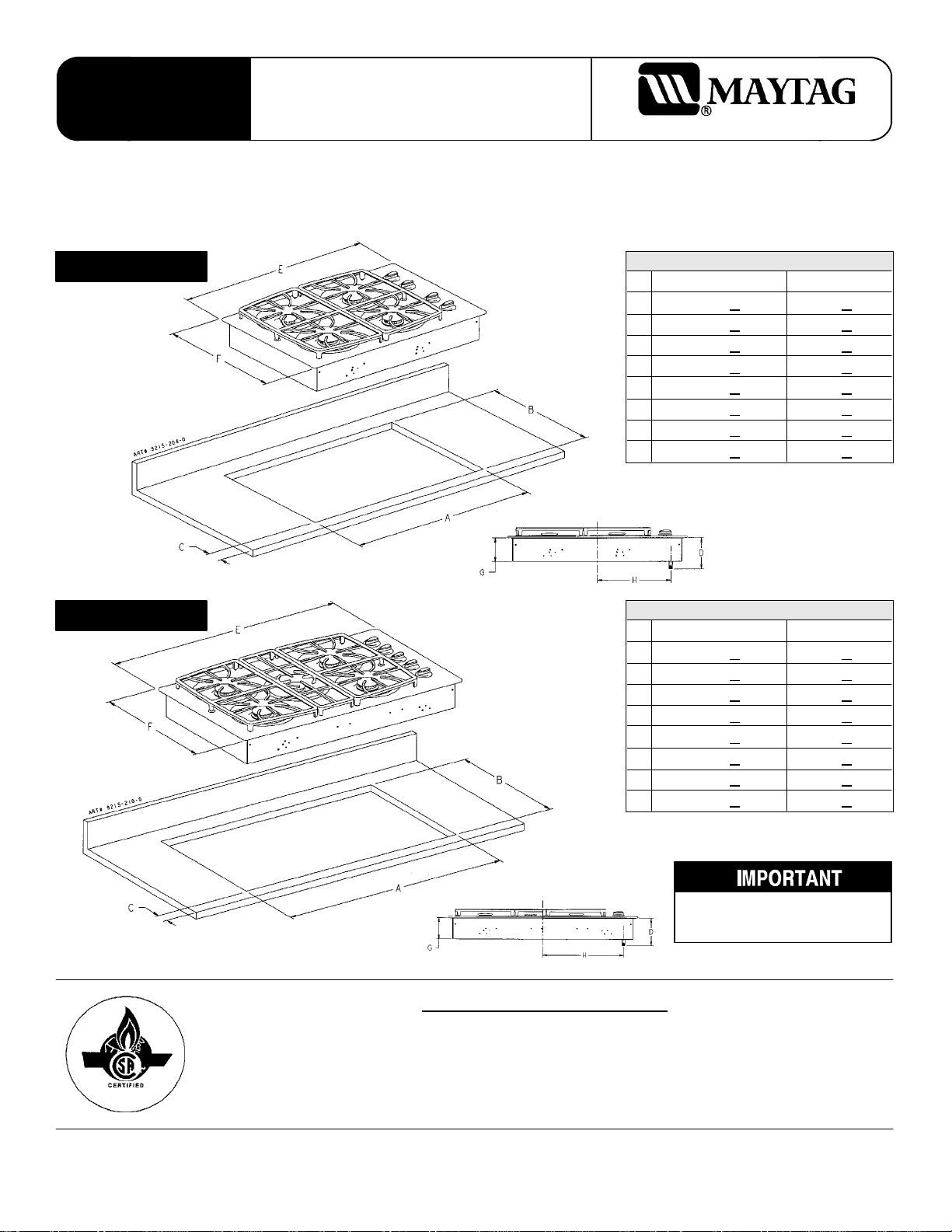

IMPORTANT: Dimensions Shown in Both Inches and Centimeters.

IMPORTANT:

underside of burner box for this information. Do not attempt to convert this appliance for use with a gas other than the type

specified.

30² MODEL

Be sure the appliance being installed is equipped for the gas to be supplied. Refer to serial plate on

DIMENSIONS

inches cm

A281/2 +

B 19 15/16 +

C21/8 +

D51/4 +

E30 +

F211/2 +

G 3 13/16 +

H121/4 +

1/16 72.4 + 0.2

1/16 50.6 + 0.2

1/16 5.4 + 0.2

1/16 13.3 + 0.2

1/16 76.2 + 0.2

1/16 54.6 + 0.2

1/16 9.7 + 0.2

1/16 31.1 + 0.2

36² MODEL

DIMENSIONS

inches cm

A341/2 +

B 19 15/16 +

C21/8 +

D51/4 +

E36 +

F21 +

G 3 13/16 +

H151/4 +

1/16 87.6 + 0.2

1/16 50.6 + 0.2

1/16 5.4 + 0.2

1/16 13.3 + 0.2

1/16 91.4 + 0.2

1/16 53.3 + 0.2

1/16 9.7 + 0.2

1/16 38.7 + 0.2

CUTOUT DIMENSIONS

ARE CRITICAL

SPECIAL WARNING:

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, MAINTENANCE

OR USE OF RANGE CAN RESULT IN SERIOUS INJURY OR PROPERTY DAMAGE.

NOTICE TO INSTALLER: Leave these instructions with the appliance.

NOTICE TO CONSUMER: Retain these instructions for future r eference.

8101P595-60

(05-04-00)

Page 2

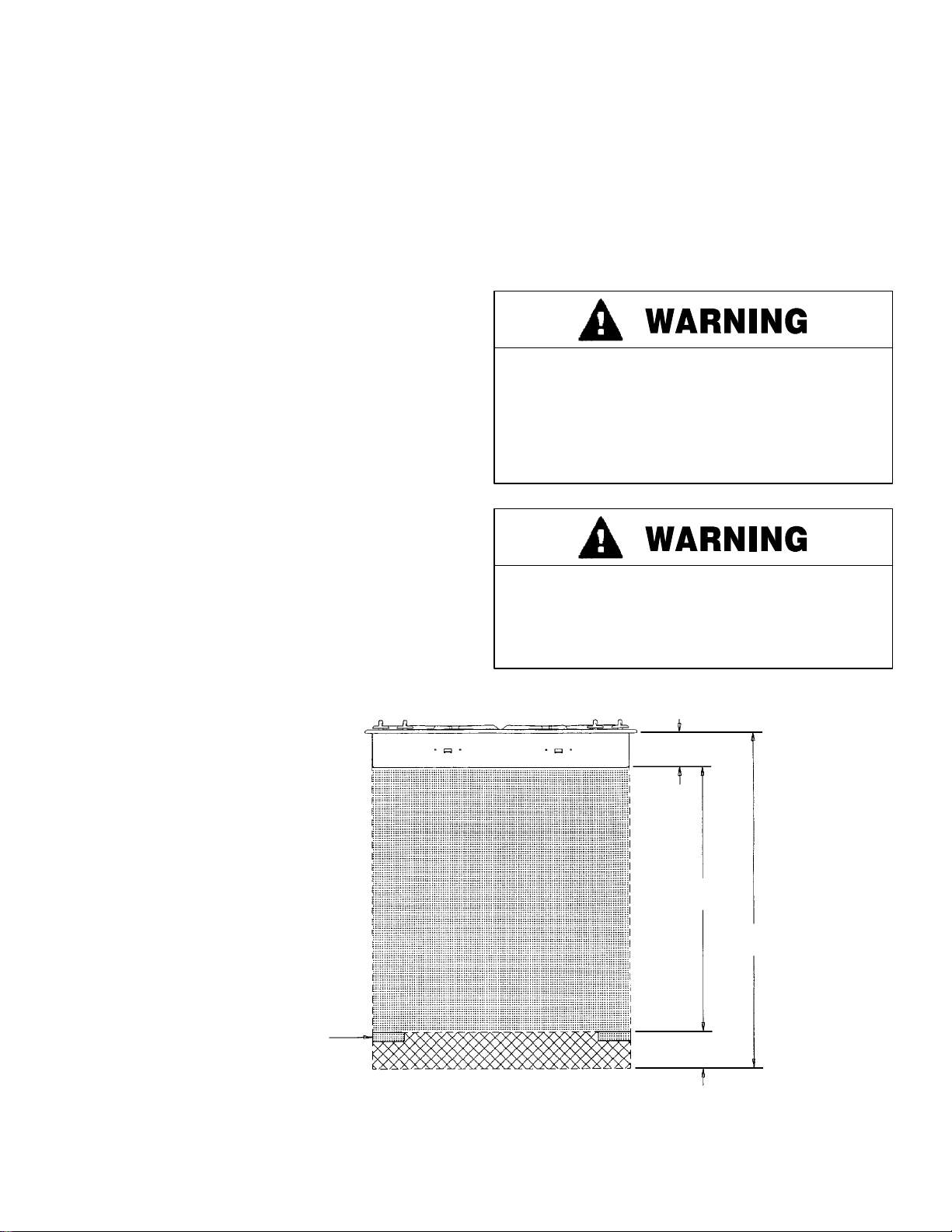

Location Of Your Maytag Appliance

Locate this appliance away from combustible materials

such as window curtains and combustible wall

decorations.

Minimum horizontal clearance between the edge of the

appliance and combustible construction extending from

the cooking surface to 18² (45.72 cm) above the cooking

surface is:

1.0² (2.54 cm) at rear

6² (15.24 cm) at sides

(Dimensions apply to both 30²²²² and 36²²²² wide models).

45.72 cm

1.0²

2.54 cm

18²

Preparation Of Countertop

The countertop cutout must be prepared according to the

illustration on page 1 of these instructions.

CAUTION: Cutout dimensions are critical. Dimensions

must be measured and cut accurately to within +

(.159 cm) to ensure proper fit.

1/16²

Important Preparation Suggestions

1. Chamfer all exposed edges of decorative laminate to

prevent damage from chipping.

2. Radius corners of cutout and file to insure smooth

edges and prevent corner cracking. Recommend

1/4²²²² or 3/8²²²² diameter drill in each corner.

3. Rough edges, inside corners which have not been

rounded and forced fits can contribute to cracking of

the countertop laminate.

4. Countertop must be supported within 3² (7.62 cm) of

cutout.

6²

15.24 cm

FIGURE 1

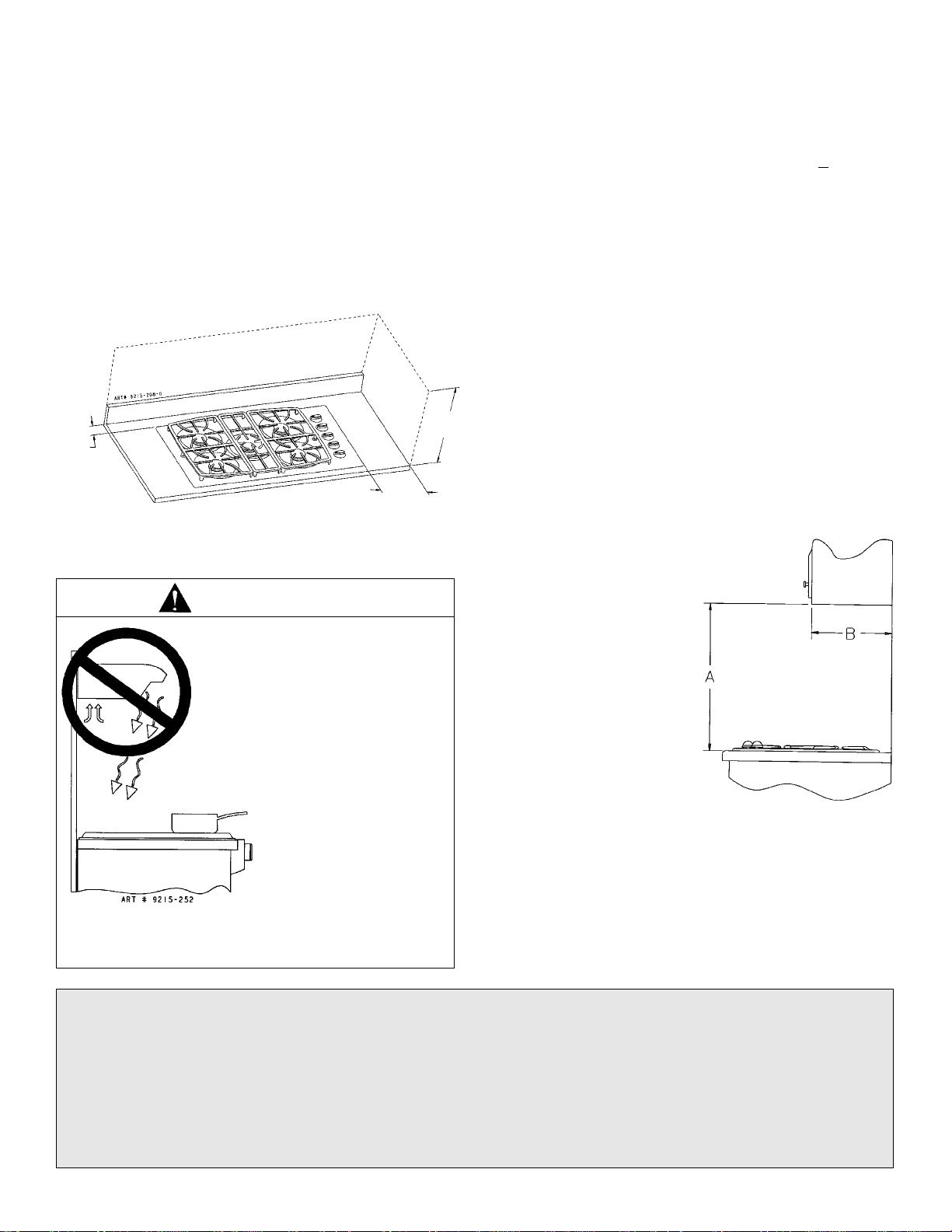

WARNING

THIS PRODUCT SHOULD NOT

BE INSTALLED BELOW A

VENTILATION TYPE HOOD

SYSTEM THAT DIRECTS AIR

IN A DOWNWARD DIRECTION.

(SEE FIGURE)

THESE SYSTEMS MAY CAUSE

IGNITION AND COMBUSTION

PROBLEMS WITH THE GAS

BURNERS RESULTING IN

PERSONAL INJURY AND MAY

AFFECT THE COOKING

PERFORMANCE OF THE UNIT.

NOTE: THE FIGURE MAY NOT ACCURATELY REPRESENT

YOUR RANGE OR COOKTOP; HOWEVER, THIS WARNING

APPLIES TO ALL GAS COOKING PRODUCTS.

Installing Cabinetry Over Your

Maytag Cooktop

A=30² (76.2 cm) minimum

vertical clearance

between cooking surface

and construction above

the appliance. This

clearance may be

reduced to not less than

24 inches (60.96 cm) by

protecting the underside

of the combustible

material or metal cabinet

above the cooking

surface with not less than

1/4 inch (.635 cm)

insulating millboard

covered with sheet metal

not less than 0.0122 inch

thick.

B=13² (33.02 cm) maximum depth of cabinets installed

above cooktop.

Avoid use of cabinets above cooktop for storage space to

eliminate associated potential hazards such as reaching

over open flames.

FIGURE 2

Required Adjustments At Time Of Installation

The installation of this appliance must conform with local codes, or in the absence of local codes, with the latest edition

of the National Fuel Gas Code ANSI Z223.1 USA or current CAN/CGA-B149 INSTALLATION CODE.

V This appliance was manufactured for use with Natural Gas. If LP gas is the fuel of choice, follow the conversion to

LP procedure found in the installation instructions.

V Test all external connections for gas leaks. Never test for gas leaks with an open flame.

V Test all electrical connections.

2

Page 3

Check the cooktop serial plate to see if the cooktop is

approved for installation in mobile homes and/or

recreational park trailers. Serial plate is located on the

bottom of the unit.

All supply piping, except as noted, should use common

National Pipe Thread (N.P.T.). For all pipe connections

use an approved pipe joint compound resistant to the

action of LP gas.

If approved, the following items are applicable:

Mobile Homes

The installation of a range designed for mobile home

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part

3280 [formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24 HUD, (Part 280)] or,

when such standard is not applicable, the Standard for

Manufactured Home Installations, ANSI A225.1/NFPA

501A, or with local codes.

In Canada the range must be installed in accordance with

the current CSA Standard C22.1 - Canadian Electrical

Code Part 1 and Section Z240.4.1 - Installation

Requirements for Gas Burning Appliances in Mobile

Homes (CSA Standard CAN/CSA - Z240MH).

Recreational Park Trailers

The installation of a range designed for recreational park

trailers must conform with state or other codes or, in the

absence of such codes, with the Standard for

Recreational Park Trailers, ANSI A119.5-latest edition.

In Canada the range must be installed in accordance with

CAN/CSA - Z240.6.2 - Electrical Requirements for R.V.’s

(CSA Standard CAN/CSA - Z240 RV Series) and Section

Z240.4.2 - Installation Requirements for Propane

Appliances and Equipment in R.V.’s (CSA Standard

CAN/CSA - Z240 RV Series).

CAUTION: Warranty is void on Maytag equipment

installed other than as recommended by manufacturer.

This appliance is designed for use with the appliance gas

pressure regulator supplied with this appliance. It must be

installed in the gas line ahead of the gas manifold

entrance. It is preset for use with natural gas and must be

converted, as described on pages 8 and 9, for use with

LP gas. (See figures 7 - 12).

This appliance is designed to operate at a pressure of 5

inches of water column (36² models), 4 inches of water

column (30² models) on natural gas or, if converted for

use with LP gas (propane or butane), 10 inches water

column. Make sure this appliance is supplied with and

adjusted for the type of gas for which it is designed.

This appliance was adjusted at the factory for use with

natural gas. If, at any time, this appliance is to be used

with a different type of gas, all of the conversion

adjustments described on pages 8 and 9 must be made

by a qualified service technician before attempting to

operate the cooktop on that gas. Natural gas should be

supplied to the appliance pressure regulator at a line

pressure between 6 and 14 inches of water column or, if

converted for LP gas, between 11 and 14 inches.

Installation Of Appliance

The installation of this appliance must conform with local

codes or, in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1-Latest Edition, or, in

Canada, CAN/CGA-B149 Installation Code, Latest

Edition.

This appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code

ANSI/NFPA No. 70-Latest Edition, or, in Canada, current

CSA Standard C22.1 Canadian Electrical Code, Part 1.

In Th e Commonwealth Of Massachusetts

This product must be installed by a licensed plumber or

gas fitter when installed within the Commonwealth of

Massachusetts.

A “T” handle type manual gas valve must be installed in

the gas supply line to this appliance.

A flexible gas connector, when used, must not exceed a

length of three (3) feet / 36 inches.

If the line pressure supplying the appliance pressure

regulator exceeds 14² water column (any gas), an

external regulator must be installed in the gas line ahead

of the appliance regulator to reduce the pressure to no

more than 14² water column. Failure to do this canresult

in malfunction and damage to the appliance.

Insure this appliance is adjusted for the type of gas

supplied to it and that the gas supply pressure to the

appliance regulator is within the proper pressure range.

S If no other appliance is to be installed in the cabinetry

below this unit, proceed as instructed under paragraph

1, page 4.

S If this unit is to be installed over a Maytag Model

MEW6500 or MEW5500 Series Electric Wall Oven

proceed as instructed under paragraph 2, page 5.

NOTE: In Canada, gas utilization codes prohibit use of

street elbows. Use standard pipe elbows and make

modifications to these instructions as necessary.

3

Page 4

Connecting Appliance To

Gas Supply

A QUALIFIED SERVICE TECHNICIAN OR GAS

APPLIANCE INSTALLER MUST MAKE THE GAS

SUPPLY CONNECTION. Leak testing of the

appliance shall be conducted by the installer

according to the instructions given.

Gas supply piping MUST conform to all local,

municipal and state building codes and local utility

regulations.

1. IF NO OTHER APPLIANCE IS TO BE INSTALLED

BELOW THIS COOKTOP

Join the appliance pressure regulator supplied with this

appliance to the entrance threads of the Gas Manifold.

The appliance regulator is marked with a directional

arrow indicating correct direction of gas flow. Ensure

the appliance regulator is installed with the arrow

pointing toward the gas manifold entrance. Tighten the

appliance regulator to 20 to 30 ft-lbs of torque.

IMPORTANT

IMPORTANT

Applyanon-corrosiveleakdetectionfluidtoalljointsand

fittings in the gas connection between the supply line

shut-off valve and the cooktop. Include gas fittings and

joints in the cooktop if connections were disturbed

during installation. Check for leaks! Bubbles appearing

around fittings and connections will indicate a leak. If a

leak appears, turn off supply line gas shut-off valve,

tighten connections, turn on the supply line gas shut off

valve, and retest for leaks. Never test for gas leaks with

an open flame.

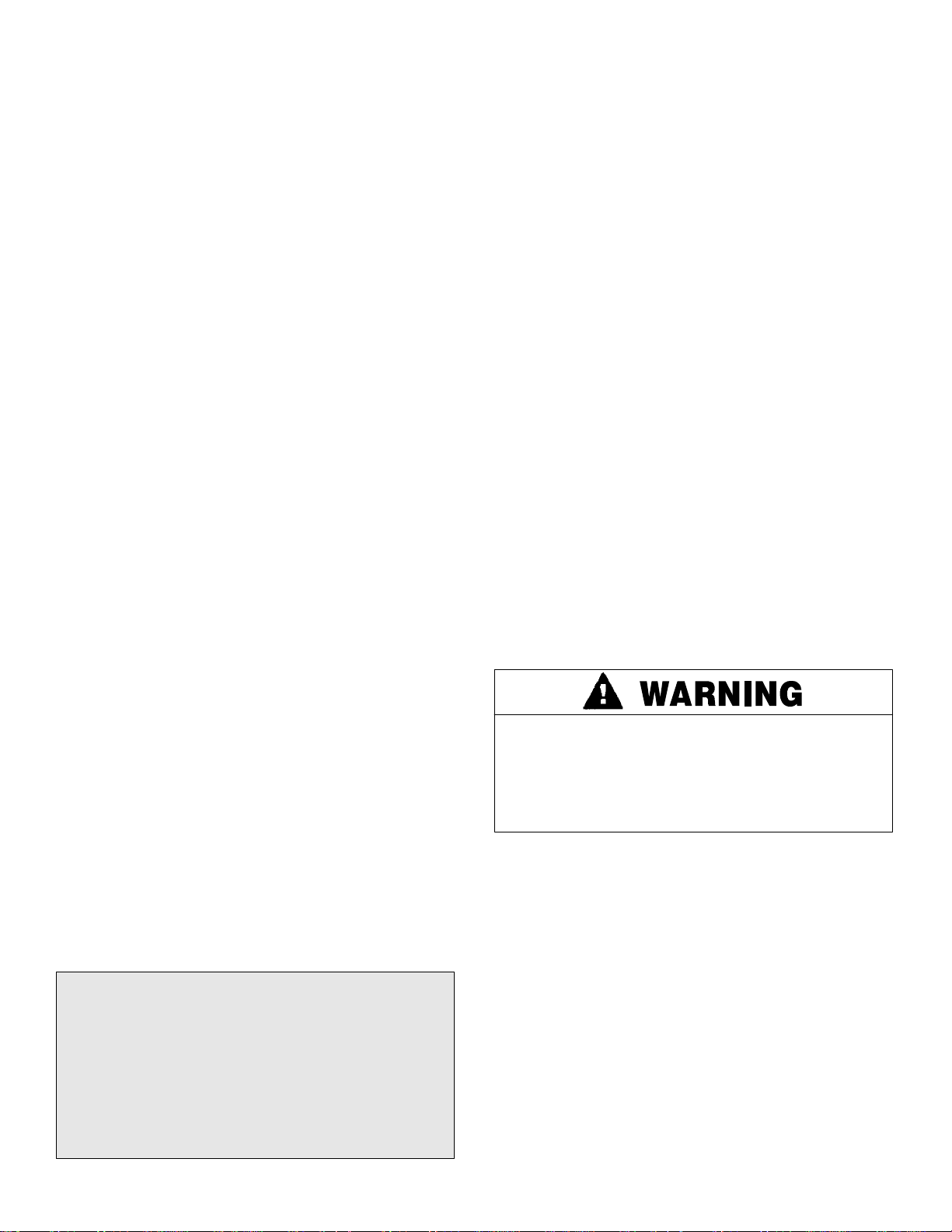

ILLUSTRATIVE GAS SUPPLY PIPING

Never tighten to more than 35 ft-lbs of torque. Always

use an approved pipe joint compound resistant to the

action of LP gas.

Install the appliance in its counter cutout.

Make the gas connection to the inlet of the appliance

pressure regulator with 1/2² NPT male pipe threads.

Install a manual shut-off valve in an accessible location in

the gas line ahead of the appliance pressure regulator

and external to this appliance for the purpose of turning

on or shutting off gas to the appliance.

Make additional pipe connections as necessary ahead of

the shut-off valve to the gas supply source. Assure all

pipe joint connections are gas tight.

WARNING

Gas leaks may occur in your system and result in a

dangerous situation. Gas leaks may not be detected by

smell alone. Gas suppliers recommend you purchaseand

install an UL approved gas detector. Install and use in

accordance with the manufacturer’s instructions.

(3/8² N.P.T.)

ALL SUPPLY SIDE

PIPE JOINTS

1/2² N.P.T.

FIGURE 3

4

Page 5

2. IF THIS UNIT WILL HAVE A MAYTAG MODEL

MEW6500 or MEW5500 SERIES ELECTRIC WALL

OVEN INSTALLED BELOW THIS COOKTOP.

NOTE 1: This appliance and its gas and electrical supply

sources must be installed before the wall oven is installed.

See illustration (Electrical Wiring Information - page 7;

figure 6) for recommended electrical supply source

locations.

NOTE 2: It may be necessary to extend gas supply piping

for this appliance into adjacent under-counter cabinetry

when a wall oven is installed below this appliance.

Joina3/8² NPT pipe elbow (locally available) to the male

threads at the manifold entrance. When joined, ensure

open threads of the elbow face toward the right side of

the appliance. Install the appliance in its counter cutout.

Joina3/8² NPT pipe nipple to the elbow using a pipe

section of sufficient length to extend, horizontally, beyond

the right side of the wall oven. (To accomplish this it may

be necessary to extend the pipe section into adjacent

cabinetry.) Join additional 3/8² NPT elbow(s) and pipe

nipples, as necessary, to accomplish the following:

Join the outlet of the appliance pressure regulator

supplied with this appliance to the male threads of the

newly installed gas supply piping. Install the appliance

regulator in a location which will be accessible beside or

below the wall oven. Insure the appliance regulator is

installed with its directional arrow pointing in the direction

of gas flow. Tighten the appliance regulator to 20 to 30

ft-lbs of torque.

ILLUSTRATIVE GAS SUPPLY PIPING

(WALL OVEN INSTALLED BELOW 30²²²² COOKTOP)

(3/8² N.P.T.)

ALL UNIT SIDE

PIPE JOINTS

3/8² N.P.T.

FIGURE 4

ALL SUPPLY SIDE

PIPE JOINTS

1/2² N.P.T.

IMPORTANT

Never tighten to more than 35 ft-lbs of torque. Always

use an approved pipe joint compound resistant to the

action of LP gas.

Locate and join a manual shut-off valve in an accessible

location in the gas line ahead of the appliance regulator

and external to the appliance for the purpose of turning on

or shutting off gas to the appliance.

Make additional pipe connections as necessary ahead of

the shut-off valve to the gas supply source. Assure all

pipe joint connections are gas tight.

IMPORTANT

Apply a non-corrosive leak detection fluid to all joints and

fittings in the gas connection between the supply line

shut-off valve and the cooktop. Include gas fittings and

joints inthe cooktop if connections were disturbed during

installation. Check for leaks! Bubbles appearing around

fittings and connections will indicate a leak. If a leak

appears, turn off supply line gas shut-off valve, tighten

connections, turn on the supply line gas shut off valve,

andretest for leaks. Never test forgas leaks withanopen

flame.

Note, regarding Figure 4, above:

S For convenience in service a union (not shown: locally

available) should be included in the piping illustrated in

figure 4, in a location most practical for the installation.

Generally, a practical location is in the cabinet below

this appliance, near the manifold entrance, rather than

in an adjoining cabinet.

S If the alternative piping method shown in figure 5 is

selected for the installation, no union is required. (The

flexible appliance connector illustrated provides the

union joints necessary for servicing.) When a dividing

wall is present and a flexible connector is used it is

recommended for convenience, in both installation and

service, the flexible connector, itself, pass through the

dividing wall. Any flexible connector used with this

appliance must satisfy all requirements stated in

the text accompanying figure 5.

5

Page 6

Alternative Piping Methods To

Connect Appliance To Gas Supply

A TRAINED SERVICE TECHNICIAN OR GAS

APPLIANCE INSTALLER MUST MAKE THE GAS

SUPPLY CONNECTION. Leak testing of the

appliance shall be conducted by the installer

according to the instructions given.

Unless prohibited by local codes or ordinances, a new

A.G.A. - Certified, flexible metal appliance connector may

be used to connect this appliance to its gas supply. The

connector must be no more than 5 feet in length. Per

figure 5, use appropriate flare union adapter at each end

of the flexible connector. If a flexible connector is used

assure that both the appliance pressure regulator and

manual shut-off valve are joined solidly to other

permanent hard piping (either gas supply or the appliance

manifold) so as to be physically stationary. See

illustrations below.

CAUTION: Do not attempt to attach the flexible

connector directly to an external pipe thread.

Connection requires flare union adapters.

Pressure Testing

The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 pounds

per square inch (3.5 kPa).

This appliance, as well as its individual shut-off valve,

must be disconnected from the gas supply piping system

during any pressure testing of the system at test

pressures in excess of 1/2 pounds per square inch (3.5

kPa).

When checking appliance regulator function, make certain

pressure of natural gas supply is between 6 and 14

inches of water column or, if converted for LP gas,

between 11 and 14 inches of water column.

ILLUSTRATIVE ALTERNATIVE PIPING

Manifold

Entrance

IMPORTANT

Apply a non-corrosive leak detection fluid to all joints and

fittings in the gas connection between the supply line

shut-off valve and the range. Include gas fittings and

joints in the range if connections were disturbed during

installation. Check for leaks! Bubbles appearing around

fittings and connections will indicate a leak. If a leak

appears, turn off supply line gas shut-off valve, tighten

connections, turn on the supply line gas shut off valve,

andretest for leaks. Never test forgas leaks withanopen

flame.

Appliance Pressure

Regulator, Supplied

(Observe directionality

of Gas Flow)

Flare Union Adaptor

1/2² N.P.T. Flexible

Appliance Connector

(5 ft. max.)

Flare Union Adaptor

Gas Shut-Off Valve

1/2² N.P.T. Pipe

(Stationary Supply Pipe)

Flare Union

Adaptor

3/8² N.P.T. Flexible

Appliance Connector

(5 ft. max.)

Flare Union Adaptor

Appliance Pressure

Regulator, Supplied

(Observe

directionality of Gas

Flow)

1/2² N.P.T. Pipe

Nipple

3/8² N.P.T.

Elbow

Gas Shut-Off Valve

1/2² N.P.T. Pipe

(Stationary Supply

Pipe)

FIGURE 5

6

Page 7

Electrical Wiring Information

This appliance is equipped with a grounded type power

cord. A grounded outlet must be provided. It is

recommended, for convenience, the outlet be located

(with reference to figure 6) as in A or B, below:

A. If no other appliance is to be installed below this

appliance: within either the shaded area or the cross

hatched area shown in figure 6.

B. If a Model MEW6500 or MEW5500 Series Electric Wall

Oven is to be installed below this appliance, either:

1. within the cross hatched area of figure 6, or,

2. within an adjacent cabinet.

If a wall oven is to be installed below this appliance and

the counter units outlet is to be mounted within the cross

hatched area of figure 6:

1. The cabinet’s lower front panel, below the oven, must

be made removable for access to the outlet.

2. A clearance hole for the power cord’s plug (1-1/4² (3.18

cm) dia is recommended) must be provided through the

oven’s floor support shelf and, if necessary, through the

slats supporting the shelf. The clearance hole should

be located as near as practical to the rear of the shelf.

can be located as is convenient in this left wall or in the

corresponding right wall.

In planning any installation, note that the free length of

this appliance’s power cord, extending beyond a point

3-3/4² (9.53 cm) left of the nominal center of the rear wall

of the burner box, when viewed from the front of the unit,

is approximately 46² (117 cm).

User may experience occasional circuit tripping if Ground

Fault Circuit Interrupter (GFCI) outlet or breaker is in use.

Electrical Grounding Instructions

This appliance is equipped with a (three-prong)

grounding plug for your protection against shock

hazard and should be plugged directly into a

properly grounded receptacle. Do not cut or

remove the grounding prong from this plug.

If the outlet is to be mounted in either a left or right

adjacent cabinet, a clearance hole, as described above,

must be provided in the dividing wall between the

cabinets. Figure 4; page 5, illustrates a typical (left side)

dividing wall. The clearance hole (not shown in figure 4)

THIS APPLIANCE MUST BE DISCONNECTED FROM ITS ELECTRICAL SUPPLY

AT THE WALL RECEPTACLE BEFORE

SERVICING THE APPLIANCE.

3 13/16²

9.7 cm

29 3/8²

74.61 cm

37 3/16²

94.46 cm

31/2² (8.89 cm) WIDE

SLATS WHEN A WALL

OVEN IS INSTALLED

BELOW 30² MODEL

4² MAX.

10.16 cm

CABINET BOTTOM

FIGURE 6

7

Page 8

Converting Appliance For Use

With LP Gas

Propane conversion is to be performed by a MAYTAG

AUTHORIZED SERVICER (or other qualified agency) in

accordance with the manufacturer’s instructions and all

codes and requirements of the authority having

jurisdiction. Failure to follow instructions could result in

serious injury or property damage. The qualified agency

performing this work assumes responsibility for this

conversion.

Electrical power and gas must be turned off

prior to conversion.

This appliance was adjusted at the factory for use with

natural gas. To convert it for use with LP gas (propane or

butane), each of the following modifications must be

performed: (A, B, and C)

A. REPLACE ALL ORIFICE SPUDS

Step 1: Remove the grates and burner caps.

Step 2: Remove burner base by removing 2 screws.

(See figure 7).

Step 3: Firmly press 9/32² (or 7mm) nut driver over the

orifice spud (figures 7 and 8) and loosen spud

by turning counter- clockwise. Carefully lift nut

driver out of burner throat. Orifice spud should

be captured in the nut driver. Repeat steps 2 &

3 for each burner.

REMOVAL OF ORIFICE SPUD

Installation Of LP Orifice Spud

0.91

0.64

FIGURE 9

0.91

0.97

0.91

Step 4: Locate the LP orifice spud packet attached to

bottom of appliance. The spuds have small

numbers stamped on the side. This number

codes the orifice diameter and its correct

burner location. Figure 9 and 10 show the

correct LP orifice spud location.

Step 5: Carefully install the orifice spud in the

appropriate burner throat by turning clockwise

to tighten. Tighten to a torque of 15 to 20

inch-lbs.

Step 6: Replace burner base, caps, and grates.

Tighten screws (do not cross thread) to 25-30

in lbs.

Step 7: Save the orifices removed from the appliance

for future use.

FIGURE 7

Orifice

Spud

FIGURE 8

0.91

0.91

0.64

0.97

FIGURE 10

8

Page 9

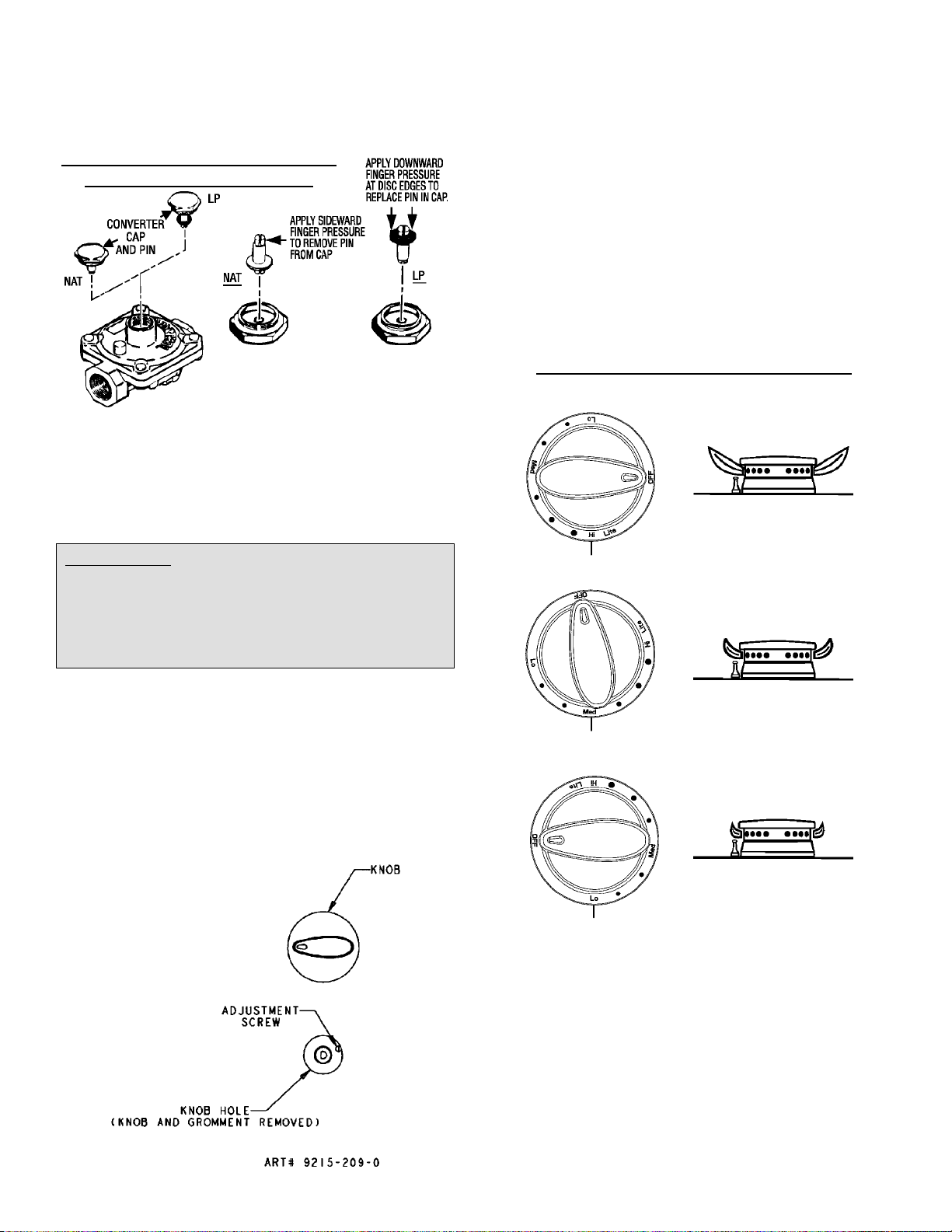

B. INVERT CAP IN APPLIANCE PRESSURE

REGULATOR (See figure 11)

With the appliance installed, the appliance regulator

should be located as shown in figure 3, 4 or 5.

CONVERSION OF APPLIANCE

PRESSURE REGULATOR

FIGURE 11

C. LOW FLAME ADJUSTMENT (See figure 12)

This appliance is shipped from the factory with low and

high flame settings adjusted for use with natural gas.

To set for use with LP proceed as follows:

1. Remove control knob from valve stem.

After adjusting the screw the burner should produce a

stable, steady blue flame of minimum size. The setting

should be checked by turning knob from high to low

several times without extinguishing the flame.

This operation will automatically provide the proper flame

size at medium setting.

After Conversion Steps A, B and C have been completed,

check the appearance of each burner flame at the Hi and

Lo settings against figure 13. If the flames appear too

large or too small, review each step to make sure it was

completed correctly.

FLAME APPEARANCE AT HI AND LO

CAUTION: NEVER USE A METAL BLADE TO

PRY KNOB OFF. IF KNOB CANNOT BE EASILY

REMOVED, TUCK THE FOLDS OF A CLOTH

DISHTOWEL UNDER THE KNOB AND PULLTHE

TOWEL UPWARD WITH STEADY, EVEN PRESSURE.

2. Carefully remove rubber grommet if necessary.

3. Locate the valve adjustment screw. If necessary

align hole in switch cover with adjustment screw.

See figure 12.

4. Insert a slender, thin-blade screwdriver into knob

hole and engage blade with slot in adjusting screw.

5. Turn the adjusting screw clockwise until tight (5-7

in-lbs max.). Do not over tighten.

6. Replace rubber grommet and control knob.

7. Repeat for remaining burners.

FIGURE 13

FIGURE 12

9

Page 10

To Convert Appliance For Use

4 BURNER MODEL (30² WIDE)

With Natural Gas

Electrical power and gas must be turned off

prior to conversion.

If this appliance has been converted for use with LP gas,

each of the following modifications must be performed to

convert the unit back to natural gas.

A. REPLACE ALL ORIFICE SPUDS.

1. Perform Steps 1 and 2 on page 8.

2. Perform Step 3 on page 8.

3. For Step 4: Locate the brass natural gas orifice

spuds that were originally installed in this appliance

before its conversion for use with LP gas. Observe

the number on each of the spuds and note the

correct burner location for each spud as shown in

figures 14 and 15.

Installation Of Natural Gas Orifice Spuds

5 BURNER MODEL (36² WIDE)

1.421.071.55

1.42

1.42

FIGURE 15

4. Complete Steps 5, 6 and 7 on page 8 to complete

the installation of natural gas main spuds in their

correct locations.

5. Save the orifices removed from the appliance for

future use. They will be needed if this appliance is

again converted for use with LP gas.

B. INVERT CAP IN APPLIANCE PRESSURE

REGULATOR. (See figure 11).

1.07

1.61

1.42 1.61

FIGURE 14

With the appliance installed the appliance regulator

should be located as shown in either figure 3, 4 or 5

(pages 4, 5 & 6). Identify the type of appliance

regulator and follow the instructions in the appropriate

illustration.

C. RESET THE VALVES FOR NATURAL GAS

1. Light one burner, and set on low.

2. Remove the knob.

3. Remove the rubber grommets if necessary.

4. Locate the valve adjustment screw. If necessary

align hole in switch cover with adjustment screw.

See figure 12.

5. Insert a slender, thin-blade screwdriver into knob

hole and engage blade with slot in adjusting screw.

6. Starting from the LP position (see #5 on page 9,

under C. LOW FLAME ADJUSTMENT), turn the

screw counter clockwise until the flame stabilizes

and matches the pictured “low” setting on figure 13.

Proper adjustment will produce a stable, steady blue

flame of minimum size. The final adjustment should

be checked by turning the knob from high to low

several times without extinguishing the flame.

After Steps A, B and C have been completed, check

the appearance of each burner’s flame at the Hi and Lo

settings against figure 13. If the flames appear too

large or too small, make sure all steps were completed

correctly.

10

Page 11

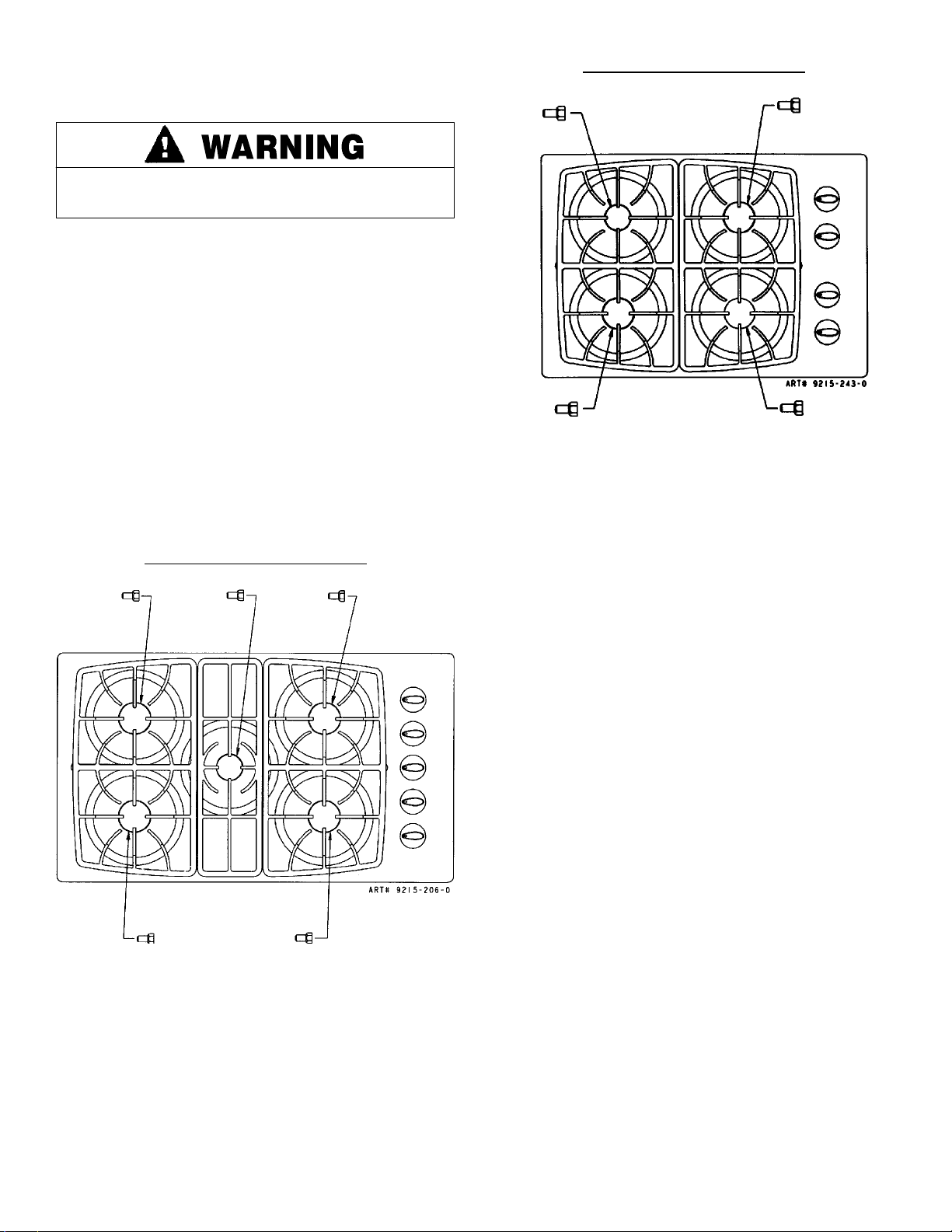

Burner Performance

CAUTION: Never cover control knobs or surrounding

control surface with utensils, towels, or other objects.

Never obstruct free air passage past the control knobs.

The knob openings have been sized to properly control air

entry to the interior of the appliance during operation.

service technician. Some yellow tipping on LP gas is

normal.

Specified input rates are as shown in figures 16 and 17

below.

This appliance has no air shutters. Primary air

adjustments are unnecessary. The burners are designed

to provide optimum aeration for all gases without air

shutters. When operating properly, burners should

produce clearly defined, even blue flames. If the flames

have yellow tips or are hazy and otherwise appear to

have insufficient air, obtain the services of a qualified

5 BURNER MODEL (36²²²² Wide)

High Altitude Notice

The specified gas burner ratings typically apply to

elevations up to 2000 feet. For higher altitudes, the rates

may need to be reduced to achieve satisfactory operation.

A local certified gas servicer will be able to advise if a

reduction is necessary.

4 BURNER MODEL (30²²²² Wide)

FIGURE 16

MAYTAG 36²

INPUT RATES - NATURAL GAS / LP GAS (BTU/HR)

BURNER LOCATION Hi Lo

Right Front 12,500 / 10,500 1300 / 1300

Right Rear 9,200 / 9,100 1300 / 1300

Left Front 9,200 / 9,100 1300 / 1300

Left Rear 10,500 / 9,100 1300 / 1300

Center 5,000 / 4,000 650 / 650

²

²²

FIGURE 17

MAYTAG 30²

INPUT RATES - NATURAL GAS / LP GAS (BTU/HR)

BURNER LOCATION Hi Lo

Right Front 12,500 / 10,500 1300 / 1300

Right Rear 5,000 / 4,000 650 / 650

Left Front 9,200 / 9,100 1300 / 1300

Left Rear 9,200 / 9,100 1300 / 1300

C e n t er -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

²

²²

11

Page 12

MANUAL DE

SUPERFICIES PARA COCINAR

DE GAS SELLADAS

INSTALACIÓN

Modelos: MGC6430 y MGC6536

IMPORTANTE: Las dimensiones aparecen en pulgadas y centímetros.

IMPORTANTE:

la placa de datos que se encuentra en la parte inferior de la caja del quemador para obtener esa información. No trate de

convertir este electrodoméstico para usar otro tipo de gas que el que se especifica.

Asegúresedequeelelectrodoméstico queseinstalaráestéequipadoconelgas quesesurtirá.Consulte

403 WEST FOURTH STREET, NORTH · NEWTON, IA 50208

MODELO de 30”

MODELO de 36”

DIMENSIONES

pulgadas cm

A281/2 +

B 19 15/16 +

C21/8 +

D51/4 +

E30 +

F211/2 +

G 3 13/16 +

H121/4 +

DIMENSIONES

pulgadas cm

A341/2 +

B 19 15/16 +

C21/8 +

D51/4 +

E36 +

F21 +

G 3 13/16 +

H151/4 +

1/16 72,4 + 0,2

1/16 50,6 + 0,2

1/16 5,4 + 0,2

1/16 13,3 + 0,2

1/16 76,2 + 0,2

1/16 54,6 + 0,2

1/16 9,7 + 0,2

1/16 31,1 + 0,2

1/16 87,6 + 0,2

1/16 50,6 + 0,2

1/16 5,4 + 0,2

1/16 13,3 + 0,2

1/16 91,4 + 0,2

1/16 53,3 + 0,2

1/16 9,7 + 0,2

1/16 38,7 + 0,2

IMPORTANTE

LAS DIMENSIONES DE

CORTE DEL HUECO

SON MUY

IMPORTANTES

ADVERTENCIA ESPECIAL:

LA INSTALACIÓN, EL AJUSTE, LA ALTERACIÓN, EL SERVICIO, EL MANTENIMIENTO

O EL USO INCORRECTOS DE LA ESTUFA PUEDEN CAUSAR LESIONES GRAVES O

DAÑOS MATERIALES.

AVISO AL INSTALADOR: Deje estas instrucciones con el electrodoméstico.

AVISO AL CONSUMIDOR: Conserve estas instrucciones para consultarlas en el futuro.

Page 13

Ubicación de su electrodoméstico

Maytag

Coloque este electrodoméstico alejado de materiales

combustibles como cortinas de ventanas y decoraciones

de pared.

El espacio libre horizontal mínimo entre el borde del

electrodoméstico y la construcción combustible que se

extiende de la superficie para cocinar a 18² (45,72 cm)

por encima de la superficie para cocinar es:

1,0² (2,54 cm) por detrás

6² (15,24 cm) a los lados

(Las dimensiones corresponden tanto a los modelos

de 30²²²² como a los de 36²²²² de ancho.)

45,72 cm

1.0²

2,54 cm

6²

FIGURA 1

15,24 cm

ADVERTENCIA

ESTE PRODUCTO NO DEBE

INSTALARSE DEBAJO DE

UNA CAMPANA DE

VENTILACIÓN QUE DIRIJA EL

AIRE EN UNA DIRECCIÓN

HACIA ABAJO.

(VEA LA FIGURA)

ESTOS SISTEMAS DE

VENTILACIÓN PUEDEN

CAUSAR PROBLEMAS DE

IGNICIÓN Y DE

COMBUSTIÓN CON LOS

QUEMADORES A GAS

RESULTANDO EN LESIONES

PERSONALES Y PUEDEN

AFECTAR LA MANERA DE

COCINAR DE LA UNIDAD.

NOTA:ESPOSIBLE QUE LA FIGURANO SEA UNAREPRESENTACIÓN EXACTA DE SU ESTUFAO DE SU SUPERFICIE PARA COCINAR; SIN EMBARGO, ESTA ADVERTENCIA SE APLICA A TODOS

LOS ELECTRODOMÉSTICOS DE COCINA A GAS.

18²

Preparación de la superficie para

cocinar

El recorte de la superficie para cocinar debe prepararse

de acuerdo con la ilustración de la página 1 de estas

instrucciones.

PRECAUCIÓN: Las dimensiones del corte son muy

importantes. Las dimensiones deben medirse y cortarse

con precisión a +

ajuste correcto.

1/16² (0,159 cm) para garantizar un

Sugerencias importantes de

preparación

1. Alise todos los bordes expuestos del laminado

decorativo para evitar que se quiebren.

2. Redondee las esquinas del recorte y límelas para

evitar que se estrellen. Se recomienda una broca

de 1/4²²²² o3/8²²²² de diámetro en cada esquina.

3. Los bordes burdos, las esquinas interiores que no se

han redondeado y los ajustes forzados pueden

contribuir a que se resquebraje el laminado del

mostrador.

4. El mostrador debe estar apoyado a menos de 3²

(7,62 cm) del recorte.

Instalación de gabinetes por encima

de la superficie para cocinar Maytag

A=30² (76,2 cm) de espacio

libre vertical mínimo

entre la superficie para

cocinar y la construcción

que está por encima del

electrodoméstico. Este

espacio puede reducirse

a no menos de 24

pulgadas (60,96 cm) si

se protege el lado inferior

del material combustible

o del gabinete de metal

que está por encima de

la superficie para cocinar

con cuando menos

1/4 pulgadas (0,635 cm)

de un aislante de

partículas de madera con

una hoja metálica de cuando menos 0,0122 pulgadas

de espesor.

B=13² (33,02cm)deprofundidadmáximadelosgabinetes

instalados por encima de la superficie para cocinar.

Evite usar los gabinetes que están por encima de la

superficie para cocinar para almacenar artículos a fin de

eliminar los riesgos potenciales al atravesarse por encima

de la llama para alcanzar algo.

FIGURA 2

Ajustes necesarios al momento de la instalación

La instalación de este electrodoméstico debe estar en conformidad con los códigos locales, o si no existieran los

mismos, con la última edición del Código Nacional de Gas Combustible ANSI Z223.1 USA o el CÓDIGO DE

INSTALACIÓN actual CAN/CGA-B149.

V Este electrodoméstico se fabricó para usarse con gas natural. Si se elige usar gas LP, siga los procedimientos de

conversión LP que se encuentran en las instrucciones de instalación.

V Revise todas las conexiones externas para detectar fugas de gas. Nunca realice pruebas de fugas de gas con una

llama encendida.

V Revise todas las conexiones eléctricas.

2

Page 14

Revise la placa de datos de la superficie para cocinar

para ver si esta última está aprobada para instalarse en

casas móviles y/o en remolques de recreación. La placa

de datos se encuentra localizada en la parte inferior de la

unidad.

Si está aprobada, se aplicarán las siguientes

estipulaciones:

Casas móviles

La instalación de una estufa diseñada para instalarse en

casas móviles debe estar en conformidad con las Normas

de Construcción y Seguridad de casas móviles, Título 24

CFR, Parte 3280 [anteriormente conocida como Normas

Federales para la Construcción y Seguridad de Casas

Móviles, Título 24 HUD, (Parte 280)] o bien, cuando no

corresponden dichas normas, con las Normas para

instalaciones de casas prefabricadas,

ANSI A225.1/NFPA 501A, o con los códigos locales.

En Canadá la estufa debe instalarse de acuerdo con las

Normas actuales CSA C22.1 — Código eléctrico

canadiense Parte 1 y la Sección Z240.4.1 — Requisitos de

instalación para electrodomésticos de gas combustible en

casas móviles (CSA Standard CAN/CSA - Z240MH).

Remolques de recreación

La instalación de una estufa diseñada para remolques de

recreación debe estar en conformidad con los códigos

estatales y demás o, en la ausencia de dichos códigos,

con la última edición de las Normas para remolques de

recreación, ANSI A119.5.

En Canadá la estufa debe instalarse de acuerdo con la

norma CAN/CSA - Z240.6.2 — Requisitos eléctricos para

vehículos de recreación (CSA Standard CAN/CSA - Z240

RV Series) y la Sección Z240.4.2 — Requisitos de

instalación para electrodomésticos y equipo de gas

propano en vehículos de recreación (CSA Standard

CAN/CSA - Z240 RV Series).

Toda la tubería de suministro, excepto cuando se indica,

debe ser de tipo común de rosca NPT (National Pipe

Thread). Use en todas las conexiones de tubería un

compuesto aprobado para uniones de tubería que sea

resistente a la acción del gas LP.

PRECAUCIÓN: La garantía queda anulada en el equipo

Maytag que se instale de manera diferente a la que

recomienda el fabricante.

Este electrodoméstico está diseñado para usarse con el

regulador de presión de gas que se incluye con el mismo.

Debe instalarse en la tubería de gas, antes de la entrada

del múltiple de gas. Está previamente ajustado para

usarse con gas natural y debe convertirse, según se

describe en las páginas 8 y 9, para poder usarse con gas

LP. (Vea las figuras 7 —12).

Este electrodoméstico está diseñado para funcionar a

una presión de 5 pulgadas de columna de agua (en los

modelos de 36”), con 4 pulgadas de columna de agua (en

los modelos de 30”) con gas natural, o bien, si se

convierte para usarse con gas LP (propano o butano),

con 10 pulgadas de columna de agua. Asegúrese de que

este electrodoméstico tenga y esté ajustado para usar el

tipo de gas para el cual se diseñó.

Este electrodoméstico se ajustó de fábrica para usarse

con gas natural. Si, en algún momento, se usará este

aparato con otro tipo de gas, un técnico calificado deberá

hacer todos los ajustes de conversión que se describen

en las páginas 8 y 9 antes de tratar de operar la

superficie para cocinar con ese gas. El gas natural

deberá surtirse al regulador de presión a una presión de

tubería de entre 6 y 14 pulgadas de columna de agua, o

si se convierte a gas LP, a una presión de entre 11 y

14 pulgadas.

ADVERTENCIA

Instalación del electrodoméstico

La instalación de este electrodoméstico debe estar en

conformidad con los códigos locales o, en la ausencia de

códigos locales, con el Código nacional de gas

combustible, ANSI Z223.1 - última edición, o bien, en

Canadá, Código de instalación CAN/CGA-B149, última

edición.

Este electrodoméstico, cuando se instala, debe estar

conectado a tierra eléctricamente de acuerdo con los

códigos locales o, en la ausencia de códigos locales, con

el Código nacional eléctrico ANSI/NFPA No. 70-última

edición, o, en Canadá, con las Normas actuales CSA

C22.1 Código eléctrico canadiense, Parte 1.

En la Commonwealth de Massachusetts

Este producto debe instalarse por un plomero o un

instalador de gas certificado cuando está instalado

dentro de la Commonwealth de Massachusetts.

Debe instalarse en el electrodoméstico una válvula de

gas tipo ”T” manual en la tubería del suministro de gas.

Cuando se utiliza un conector flexible de gas, no debe

exceder una longitud de tres (3) pies o 36 pulgadas

(91,4 cm).

Si la presión de tubería suministrada al regulador de

presión excede las 14 pulgadas de columna de agua (en

cualquiergas), deberá instalarse unregulador externo en

la tubería de gas antes del regulador de presión para

reducir la presión a no más de 14 pulgadas de columna

deagua.Nohacerlo podría causarel mal funcionamiento

y daños al electrodoméstico.

Asegúrese de que este electrodoméstico esté ajustado

para el tipo de gas suministrado y que la presión del

suministro de gas al regulador está dentro de la tasa de

presión adecuada.

S Si no se instalará ningún otro electrodoméstico en los

gabinetes debajo de esta unidad, proceda según se

indica bajo el párrafo 1 de la página 4.

S Si esta unidad se instalará sobre un horno eléctrico de

pared Maytag de la serie MEW6500 o MEW5500

proceda según se indica en el párrafo 2 de la página 5.

NOTA: En Canadá, los códigos de utilización de gas

prohiben el uso de codos de hembra y macho. Use codos

de tubería estándar y haga las modificaciones necesarias

a estas instrucciones.

3

Page 15

Conexión del electrodoméstico

al suministro de gas

LA CONEXIÓN DEL SUMINISTRO DE GAS DEBE

REALIZARLA UN TÉCNICO CALIFICADO O UN

INSTALADOR DE ELECTRODOMÉSTICOS DE GAS.

Las pruebas de fugas de gas debe realizarlas el

instalador de acuerdo con las instrucciones

provistas.

La tubería de suministro de gas DEBE estar en

conformidad con todos los códigos de

construcción locales, municipales y estatales, y

con los reglamentos de servicios públicos locales.

1. SI NO SE INSTALARÁ UN ELECTRODOMÉSTICO

DEBAJO DE ESTA SUPERFICIE PARA COCINAR

Una el regulador de presión que se adjunta con este

electrodoméstico a la rosca de entrada del múltiple de

gas. El regulador está marcado con una flecha

direccional que indica la dirección correcta del flujo de

gas. Asegúrese de que el regulador esté instalado con

la flecha apuntando hacia la entrada del múltiple de

gas. Apriete el regulador a una torsión de 20 a

30 pies-lbs.

IMPORTANTE

Aplique un líquido de detección de fugas que sea

anticorrosivo en todas las uniones y los accesorios de

laconexióndegas entrelaválvulade cierredelatubería

de suministro y la superficie para cocinar. Incluya los

accesorios de gas y las uniones de la superficie para

cocinar si se alteraron las conexiones durante la

instalación. Revise si hay fugas. Si aparecen burbujas

alrededor de los accesorios y las conexiones querrá

decir que hay fugas. Si ocurre esto, cierre la válvula de

cierre de la tubería de suministro de gas, apriete las

conexiones, abra la válvula de cierre de la tubería de

gas, y vuelva a comprobar si hay fugas. Nunca haga

pruebas de fugas de gas utilizando una llama

encendida.

ILUSTRACIÓN DE LA TUBERÍA DE

SUMINISTRO DE GAS

IMPORTANTE

Nunca lo apriete a una torsión mayor de 35 pies-lbs.

Siempre use uncompuesto aprobadopara uniones que

sea resistente a la acción del gas LP.

Instale el electrodoméstico en el recorte del mostrador.

Haga la conexión de gas a la entrada del regulador de

presión con roscas macho de tubería NPT de 1/2².

Instale una válvula de cierre manual en un lugar accesible

en la tubería de gas antes del regulador de presión y en

el exterior de este electrodoméstico con el fin de abrir o

cerrar el gas al electrodoméstico.

Haga las conexiones adicionales de la tubería que sean

necesarias antes de la válvula de cierre a la fuente de

suministro de gas. Asegúrese de que todas las

conexiones de uniones de la tubería estén firmemente

ajustadas.

ADVERTENCIA

Puede ocurrir un escape de gas en su sistema y provocar

una situación peligrosa. Los escapes de gas no pueden

ser detectados por elolor solamente. Los proveedores de

gasrecomiendan que compre e instale undetector degas

aprobadoporellaboratorioUL.Instleloyúselodeacuerdo

con las instrucciones de fabricante.

(SIN NINGÚN ELECTRODOMÉSTICO DEBAJO

DE LA SUPERFICIE PARA COCINAR)

CAJA DEL QUEMADOR

(PARTE POSTERIOR DEL

ELECTRODOMÉSTICO)

ENTRADA AL

MÚLTIPLE

REGULADOR DE

PRESIÓN DEL

ELECTRODOMÉSTICO

TODAS LAS

UNIONES DE

TUBERÍA LATERAL

DE SUMINISTRO

1/2² N.P.T.

CODO

FIGURA 3

(3/8² N.P.T.)

VÁLVULA

MANUAL DE

CIERRE

HACIA LA

ENTRADA

DE GAS

4

Page 16

2. SI SE INSTALARÁ UN HORNO ELÉCTRICO DE

PARED MAYTAG DE LA SERIE MEW6500 O

MEW5500 DEBAJO DE ESTA SUPERFICIE PARA

COCINAR.

NOTA 1: Deberá instalarse este electrodoméstico y sus

fuentes de suministro de gas y eléctrico antes de instalar

el horno de pared. Vea la ilustración (Información de

alambrado eléctrico — en la página 7, figura 6) para

encontrar las ubicaciones recomendadas del suministro

eléctrico.

NOTA 2: Podría ser necesario tener que extender la

tubería de suministro de gas de este electrodoméstico a

los gabinetes inferiores adyacentes cuando se vaya a

instalar un horno de pared debajo del electrodoméstico.

Una un codo de tubería NTP de 3/8² (disponible

localmente) a las roscas macho de la entrada del

múltiple. Una vez unidas, asegúrese de que las roscas

abiertas del codo estén orientadas hacia el lado derecho

del electrodoméstico. Instale el electrodoméstico en el

hueco del mostrador.

Una un niple de tubería NPT de 3/8² al codo usando una

sección de tubería lo suficientemente larga para que se

extienda, horizontalmente, más lejos del lado derecho del

horno de pared. (Para hacer esto, podría ser necesario

tener que extender la sección de la tubería hasta adentro

del gabinete adyacente.) Una los codos adicionales de

tubería NPT de 3/8² y los niples de la tubería, según sea

necesario para lograr lo siguiente:

Una la salida del regulador de presión del

electrodoméstico que se suministra con este

electrodoméstico a las roscas macho de la tubería de

suministro de gas recién instalada. Instale el regulador de

presión en un lugar que sea accesible a un lado o por

debajo del horno de pared. Asegúrese de que el

regulador de presión esté instalado con la flecha de

dirección apuntando en la dirección del flujo del gas.

Apriete el regulador a una torsión de 20 a 30 pies-lbs.

IMPORTANTE

Nunca lo apriete a más de 35 pies-lbs de torsión.

Siempre use un compuesto para juntas de tubería que

esté aprobado y que sea resistente a la acción del gas

LP.

Coloque y fije una válvula manual de cierre en un lugar

accesible en la tubería de gas antes de llegar al regulador

del electrodoméstico y por fuera del mismo para fines de

cierre y apagado del gas al electrodoméstico.

Haga las conexiones adicionales de tubería según sean

necesarias antes de la válvula de cierre a la fuente de

suministro de gas. Asegúrese de que todas las

conexiones de unión de la tubería estén firmemente

ajustadas.

IMPORTANTE

Aplique un líquido de detección de fugas que sea

anticorrosivo en todas las uniones y los accesorios de la

conexión de gas entre la válvula de cierre del suministro

degasylasuperficie paracocinar. Incluyalosaccesorios

y las uniones de gas en la superficie para cocinar si se

alteraron las conexiones durante la instalación. ¡Revise

si existen fugas! Si se forman burbujas alrededor de los

accesorios y las uniones querrá decir que hay fugas. Si

ocurre esto, cierre la válvula de cierre de la tubería de

suministro de gas, apriete todas las conexiones, abra la

válvula de nuevo y vuelva a revisar si hay fugas. Nunca

realice pruebas defuga de gas conuna llama encendida.

ILUSTRACIÓN DE LA TUBERÍA DE SUMINISTRO

DE GAS

(HORNO DE PARED INSTALADO DEBAJO DE UNA

SUPERFICIE PARA COCINAR DE 30²²²²)

CAJA DEL QUEMADOR

(PARTE POSTERIOR DEL

ELECTRODOMÉSTICO)

TODAS LAS

UNIONES DE LA

TUBERÍA DEL

LADO DE UNIDAD

3/8² N.P.T.

ENTRADA AL

MÚLTIPLE

CODO

LA TUBERÍA PASA A TRAVÉS DE

LA PARED DIVISORIA ENTRE

LOS GABINETES ADYACENTES

NIPLES

(las longitudes

necesarias)

REGULADOR

DE PRESIÓN

DEL ELECTRO-

DOMÉSTICO

PERFIL APROXIMADO DE LA

SECCIÓN DEL CORTE

TRANSVERSAL DEL HORNO DE

PARED

VÁLVULA

MANUAL DE

CIERRE

FIGURA 4

(3/8² N.P.T.)

HACIA LA

ENTRADA DE GAS

TODAS LAS

UNIONES DE LA

TUBERÍA DEL

LADO DEL

SUMINISTRO

1/2² N.P.T.

Nota, en referencia a la Figura 4, anterior:

S Para hacer más conveniente el servicio debe incluirse

una unión (no se muestra: está disponible localmente)

en la tubería que se ilustra en la figura 4, en la

ubicación más práctica para la instalación. Por lo

general, una ubicación práctica es el gabinete que se

encuentra debajo de este electrodoméstico, cerca de la

entrada del múltiple, en lugar de usar el gabinete

adyacente.

S Si se selecciona el método alternativo de tubería que

se muestra en la figura 5 para la instalación, no se

requerirá unión. (El conector flexible del

electrodoméstico ilustrado proporciona las uniones

necesarias para darle servicio.) Cuando se tiene una

pared divisoria y se usa un conector flexible se

recomienda que para mayor comodidad, tanto en la

instalación como en el servicio, el conector flexible, en

sí, se pase a través de la pared divisora. El conector

flexible que se use con este electrodoméstico debe

cumplir con todos los requisitos establecidos en el

texto que acompaña a la figura 5.

5

Page 17

Métodos alternativos de tubería

para conectar el electrodoméstico

al suministro de gas

UN TÉCNICO CAPACITADO O UN INSTALADOR DE

ELECTRODOMÉSTICOS DEBE REALIZAR LA

CONEXIÓN DEL SUMINISTRO DE GAS. El

instalador debe realizar las pruebas de fugas del

electrodoméstico de acuerdo con las instrucciones

provistas.

A menos que lo prohiban los códigos o reglamentos

locales, puede usarse un conector metálico flexible

A.G.A. nuevo y certificado para conectar este

electrodoméstico al suministro de gas. El conector no

debe ser más largo de 5 pies. Como en la figura 5, use el

adaptador de unión de expansión adecuado en cada

extremo del conector flexible. Si se usa un conector

flexible asegúrese de que tanto el regulador de presión

como la válvula de cierre manual están firmemente

unidas a otra tubería rígida permanente (ya sea el

suministro de gas o el múltiple del electrodoméstico) para

que esté fijo físicamente. Vea las ilustraciones a

continuación.

Pruebas de presión

El electrodoméstico debe aislarse del sistema de la

tubería de suministro de gas cerrando la válvula de cierre

manual independiente durante las pruebas de presión del

sistema de la tubería de suministro de gas a presiones de

prueba iguales o menores a 1/2 libras por pulgada

cuadrada (3,5 kPa).

Este electrodoméstico, al igual que la válvula de cierre

independiente, deben estar desconectadas del sistema

de la tubería de suministro de gas durante las pruebas de

presión del sistema a presiones por encima de 1/2 libras

por pulgada cuadrada (3,5 kPa).

Cuando revise la función del regulador del

electrodoméstico, asegúrese de qu ela presión del

suministro de gas natural está entre 6 y 14 pulgadas de

columna de agua, o si se convirtió a gas LP, entre 11 y

14 pulgadas de columna de agua.

ILUSTRACIÓN DE LA TUBERÍA ALTERNATIVA

PRECAUCIÓN: No trate de sujetar un

conector flexible directamente en la rosca

externa de la tubería. Las conexionesrequieren

adaptadores de unión de expansión.

IMPORTANTE

Aplique un líquido para la detección de fugas, que sea

anticorrosivo, en todas las uniones y los accesorios dela

conexióndegas entre la válvula de cierredela tuberíade

suministro y la estufa. Incluya todos los accesorios y las

unionesdegasdelaestufa si se alteraron las conexiones

durante la instalación. Revise si hay fugas. Si aparecen

burbujas alrededor de los accesorios y las conexiones

significaráquehayfugas.Siestosucede,cierrelaválvula

de cierre de la tubería de gas, apriete las conexiones,

abra la válvula de cierre de la tubería de gas y vuelva a

revisar las fugas. Nunca revise las fugas de gas con una

llama encendida.

Entrada del

múltiple

Regulador de presión

del electrodoméstico,

incluido (verifique la

dirección del flujo

de gas)

Adaptador de unión

de expansión

Conector flexible de

electrodomésticos

de 1/2² N.P.T. (máx.

5pies)

Adaptador de unión

de expansión

Válvula de cierre de gas

Tubería de 1/2² N.P.T.

(tubería fija de suministro)

Adaptador

de unión de

expansión

Conector flexible de

electrodomésticos

de 3/8² N.P.T. (máx.

5pies)

Adaptador de unión

de expansión

Regulador de presión

del electrodoméstico,

incluido (compruebe

la dirección del flujo

de gas)

Niple de tubería de

1/2² N.P.T.

Codo de

3/8² N.P.T.

SIN ELECTRO-

DOMÉSTICO

MONTADO DEBAJO

DE ESTA SUPERFICIE

PARA COCINAR

CON UN HORNO DE PARED

MONTADO EN LOS

GABINETES QUE ESTÁN

DEBAJO DE ESTA

SUPERFICIE PARA

COCINAR

6

FIGURA 5

Válvuladecierre

de gas

Tubería de 1/2² N.P.T.

(tubería fija de

suministro)

Page 18

Información de alambrado eléctrico

Este electrodoméstico está equipado con un cordón

eléctrico con conexión a tierra. Debe proporcionarse un

tomacorriente conectado a tierra. Se recomienda, por

comodidad, que el tomacorriente se encuentre (con

referencia a la figura 6) como en el punto A o el B que

aparecen a continuación:

A. Si no se instalará otro electrodoméstico debajo de

éste, deberá colocarse dentro del área sombreada o el

área cuadriculada que se muestra en la figura 6.

B. Si se instalará un horno eléctrico de la serie MEW6500

o MEW5500 debajo de este electrodoméstico:

1. debe colocarse dentro del área cuadriculada de la

figura 6, o bien

2. dentro del gabinete adyacente.

Si se instalará un horno de pared debajo de este

electrodoméstico y el tomacorriente de las unidades del

mostrador se montará dentro del área cuadriculada de la

figura 6:

1. El panel delantero inferior del gabinete, debajo del

horno, debe poder quitarse para tener acceso al

tomacorriente.

2. Debe proporcionarse un orificio para el cordón eléctrico

(se recomienda de 1-1/4² (3,18 cm) de diámetro) a

través de la repisa del piso del horno y si fuera

necesario, a través de las tablillas que apoyan la

repisa. El orificio debe estar ubicado tan cerca como

sea posible a la parte posterior de la repisa.

Si el tomacorriente está montado en el gabinete

adyacentealaderechaoalaizquierda,deberá

proporcionarse un orificio como el descrito anteriormente

en la pared divisoria entre los gabinetes. La figura 4 de la

página 5, ilustra una pared divisoria típica (lado

izquierdo). El orificio (que no se muestra en la figura 4)

puede ubicarse según sea conveniente en esta pared

izquierda o en la pared derecha correspondiente.

Al planear cualquier instalación, observe que la longitud

libre del cordón eléctrico de este electrodoméstico,

extendiéndose más allá de 3-3/4² (9,53 cm) a la izquierda

del centro nominal de la pared posterior de la caja del

quemador, al verse de frente la unidad, es

aproximadamente de 46² (117 cm).

El usuario puede experimentar la desconexión ocasional

del circuito si está en uso el interruptor accionado por

corriente de pérdida a tierra del circuito (GFCI).

ADVERTENCIA

Instrucciones eléctricas de conexión

a tierra

Este electrodoméstico está equipado conuna clavija de

conexión a tierra (de tres puntas) para ofrecerle

protección contra descargas eléctricas y debe

conectarse directamenteenunreceptáculoconectadoa

tierra. No corte ni quite la punta de conexión a tierra de

esta clavija.

ADVERTENCIA

ESTE ELECTRODOMÉSTICO DEBE ESTAR

DESCONECTADO DEL SUMINISTRO

ELÉCTRICO DEL RECEPTÁCULO DE LA

PARED ANTES DE DARLE SERVICIO.

TABLILLA DE 3 1/2² (8,89 cm)

DE ANCHO CUANDO SE

INSTALA UN HORNO DE

PARED DEBAJO DE UN

MODELO DE 30²

3 13/16²

9,7 cm

29 3/8²

74,61 cm

37 3/16²

94,46 cm

4² MÁX.

10,16 cm

PARTE INFERIOR DEL GABINETE

FIGURA 6

7

Page 19

Conversión del electrodoméstico

para usarse con gas LP

ADVERTENCIA

La conversión a gas propano debe realizarla un TÉCNICO

AUTORIZADO DE MAYTAG (u otra agencia calificada) de

acuerdo con las instrucciones del fabricante ycon todos los

códigosyrequisitosdelasautoridadescorrespondientes.El

no seguir las instrucciones podría causar lesiones graves y

daños materiales. La agencia calificada que realice el

trabajoasumetoda laresponsabilidadpor dichaconversión.

ADVERTENCIA

La energía eléctrica debe estar desconectada y

la llave del gas debe estar cerrada antes de

realizar la conversión.

Este electrodoméstico está ajustado de fábrica para usarse

con gas natural. Para convertirlo a gas LP (propano o

butano), deben realizarse cada una de las siguientes

modificaciones: (A, B y C)

A. REEMPLACE TODAS LAS COPAS DE ORIFICIO

Paso 1: Quite las parrillas y las tapas de los quemadores.

Paso 2: Retire la base del quemador quitando 2 tornillos.

(Vea la figura 7).

Paso 3: Oprima con firmeza un destornillador de tuercas

de 9/32² (ó 7mm) sobre la copa de orificio

(figuras 7 y 8) y afloje la copa girándola en

sentido contrario al de las manecillas del reloj.

Levante con cuidado el destornillador fuera del

cuello del quemador. La copa de orificio deberá

estar atrapada en el destornillador. Repita los

pasos 2 y 3 en cada quemador.

PARA QUITAR LA COPA DE ORIFICIO

Tapa del

quemador

Instalación de la copa de orificio LP

0,91

0,64

0,91

FIGURA 9

Paso 4: Encuentre el paquete de las copas de orificio

LP que se une al fondo del electrodoméstico.

Las copas tienen pequeños números

estampados en un lado. Estos números

codifican el diámetro y la ubicación correcta

del quemador. Las Figuras 9 y 10 muestran la

ubicación correcta de las copas de orificio LP.

Paso 5: Instale cuidadosamente la copa de orificio en

el cuello del quemador correspondiente

girándola en sentido de las manecillas del

reloj para apretarla. Apriete a una torsión de

15 a 20 pulgadas-lbs.

Paso 6: Coloque de nuevo la base del quemador, la

tapa y las parrillas. Apriete los tornillos (no los

barra) a 25-30 pulgadas-lbs.

Paso 7: Conserve los orificios que quitó del

electrodoméstico para usarlos después.

0,91

0,97

Anillo de

localización

interior

Cabeza del

quemador

Soporte

del orificio

FIGURA 7

Soporte

del orificio

Electrodo

Copa

de

orificio

Destor- nillador

de

tuercas

de7mm

FIGURA 8

0,91

0,91

0,64

0,97

FIGURA 10

8

Page 20

B. INVERSIÓN DE LA TAPA DEL REGULADOR

APL

A

DE PRESIÓN (Vea la figura 11)

Una vez que se instala el electrodoméstico, debe ubicarse el regulador según se indica en la figura 3, 4 ó 5.

CONVERSIÓN DEL

REGULADOR DE PRESIÓN

APLIQUE

TAPA Y PASADOR

CONVERTIDORES

PRESIÓN POR

LOS LADOS CON

LOS DEDOS PARA

QUITAR EL

PASADORDE LA

TAPA

IQUE PRESIÓNHACI

ABAJO CON EL DEDO EN

LOS BORDES DEL DISCO

PARA VOLVER A COLOCAR

EL PASADOR EN LA TAPA.

FIGURA 11

C. AJUSTE DE LA LLAMA BAJA (Vea la figura 12)

Este electrodoméstico se embarca de fábrica con los

ajustes de llama alta y baja listos para usarse con gas

natural. Si desea ajustarlos para usarse con gas LP siga

las instrucciones a continuación:

Después de ajustar el tornillo el quemador debe producir una

llama azul estable, constante del tamaño mínimo. Debe

revisarse el ajuste girando la perilla de alto a bajo varias

veces sin apagar la llama.

Esta operación automáticamente proporcionará el tamaño de

llama adecuado en el ajuste medio.

Después de terminar los pasos A, B y C de conversión,

revise la apariencia de la llama de cada quemador en los

ajustes HI y LO contra los de la figura 13. Si las llamas

parecen estar demasiado grandes o pequeñas, revise cada

paso para asegurar que se realizaron correctamente.

APARIENCIA DE LA LLAMA ALTA (HI)

Y BAJA

(LO)

1. Quite la perilla de control del vástago de la válvula.

PRECAUCIÓN: NUNCA USE UNA HOJA DE METAL

PARA QUITAR LA PERILLA. SI ÉSTA NO PUEDE SACARSE

CON FACILIDAD, INSERTE LOS BORDES DE UNA TOALLA

POR DEBAJO DE LA PERILLA Y TIRE DE LA TOALLA HACIA

ARRIBA CON PRESIÓN UNIFORME Y CONSTANTE.

2. Quite con cuidado la arandela protectora de goma en

caso de necesidad.

3. Encuentre el tornillo de ajuste de la válvula. En caso de

necesidad alinee con cuidado el agujero en la cubierta

del interruptor conel tornillo de ajuste. Vea la figura 12.

4. Inserte un destornillador de hoja delgada y angosta

dentro del orificio de la perilla y coloque el

destornillador en la ranura del tornillo de ajuste.

5. Gire el tornillo de ajuste en el sentido de las manecillas

del reloj hasta que esté bien ajustado

(5-7 pulgadas-lbs máx.). No lo apriete demasiado.

6. Coloque de nuevo la arandela protectora de goma y la

perilla de control.

7. Repita en los quemadores restantes.

PERILLA

FIGURA 13

TORNILLO DE

AJUSTE

(SIN LA PERILLA NI LA ARANDELA PROTECTORA)

ORIFICIO DE LA PERILLA

FIGURA 12

9

Page 21

Para convertir el

electrodoméstico para usarse

con gas natural

ADVERTENCIA

La energía eléctrica debe estar desconectada y

la llave del gas debe estar cerrada antes de

realizar la conversión.

Si este electrodoméstico se convirtió para usarse con gas

LP, deberán realizarse cada una de las siguientes

modificaciones para volver a convertir la unidad para

usarse con gas natural.

A. REEMPLACE TODAS LAS COPAS DE ORIFICIO.

1. Realice los pasos 1 y 2 de la página 8.

2. Realice el paso 3 de la página 8.

3. Para el paso 4: Encuentre las copas de orificio de

gas natural de cobre que estaban instaladas

originalmente en el electrodoméstico antes de

convertirlo para uso de gas LP. Vea el número de

cada una de las copas y fíjese cuál es la ubicación

correcta del quemador para cada copa según se

muestra en las figuras 14 y 15.

Instalación de las copas de orificio de gas

natural

MODELO DE 5 QUEMADORES (DE 36² DE ANCHO)

1,55 1,42

1,07

MODELO DE 4 QUEMADORES (DE 30² DE ANCHO)

1,42

1,42

FIGURA 15

4. Realice los pasos 5, 6 y 7 de la página 8 para

terminar la instalación de las copas principales de

gas natural en sus lugares correctos.

5. Conserve los orificios que quitó del electrodoméstico

para uso futuro. Se necesitarán si este aparato se

convierte de nuevo para usarse con gas LP.

B. INVIERTA LA TAPA DEL REGULADOR DE

PRESIÓN. (Vea la figura 11).

Después de instalar el electrodoméstico, el regulador

debe estar ubicado según se indica en la figura 3, 4 ó 5

(de las páginas 4, 5 y 6). Identifique el tipo de

regulador y siga las instrucciones en la ilustración

correspondiente.

1,07

1,61

1,611,42

FIGURA 14

C. REAJUSTE LAS VÁLVULAS PARA GAS NATURAL

1. Encienda un quemador, y colóquelo en low (bajo).

2. Quite la perilla.

3. Quite las arandelas protectoras de goma en caso de

necesidad.

4. Encuentre el tornillo de ajuste de la válvula. En caso

de necesidad alinee con cuidado el agujero en la

cubierta del interruptor conel tornillo de ajuste. Vea

la figura 12.

5. Inserte un destornillador de hoja delgada y angosta

en el orificio de la perilla y coloque la hoja en la

ranura del tornillo de ajuste.

6. Comenzando en la posición LP (vea el núm. 5 de la

página 9, bajo C, AJUSTE DE LA LLAMA BAJA),

gire el tornillo en contra del sentido de las manecillas

del reloj hasta que la llama se estabilice y se vea

igual a la del dibujo del ajuste “low” de la figura13. El

ajuste correcto producirá una llama azul regular y

uniforme de tamaño mínimo. El ajuste final debe

revisarse girando la perilla de alto a bajo varias

veces sin apagar la llama.

Después de realizar los pasos A, B y C, revise la

apariencia de la llama de cada quemador en el ajuste

Hi y Lo contra la figura 13. Si las llamas parecen estar

demasiado grandes o pequeñas, asegúrese de que

todos los pasos se siguieron correctamente.

10

Page 22

Desempeño de los quemadores

PRECAUCIÓN: Nunca cubra las perillas de control ni

la superficie de control cercana con utensilios, toallas ni

otros objetos. Nunca obstruya el paso libre del aire más

allá de las perillas de control. Los orificios de las perillas

se han ajustado para controlar correctamente la entrada

del aire al interior del electrodoméstico durante el

funcionamiento.

Este electrodoméstico no tiene obturadores de aire. No

son necesarios los ajustes primarios de aire. Los

quemadores están diseñados para proporcionar la

ventilación óptima a todos los tipos de gas sin

obturadores. Cuando funcionan correctamente, los

quemadores deben producir llamas azules, claramente

definidas. Si la llama tiene la punta amarilla o está

borrosa y por otra parte parece no tener suficiente aire,

MODELO DE 5 QUEMADORES

²

(DE 36

² de ancho)

²²

consiga los servicios de un técnico calificado. Algunas

puntas amarillas del gas LP son normales.

Las clasificaciones de entrada específicas se muestran

en las figuras 16 y 17 a continuación.

Aviso de altitud

Las capacidades de funcionamiento especificadas del

quemador de gas por lo general corresponden a

elevaciones de hasta 609.6 metros (2000 pies). Cuando

la altitud es mayor, podría ser necesario reducir las

capacidades de funcionamiento para lograr un

funcionamiento satisfactorio.

Un técnico local, certificado en servicios de gas, podrá

aconsejarle si es necesaria la reducción.

MODELO DE 4 QUEMADORES

²

(DE 30

² de ancho)

²²

FIGURA 16

MAYTAG 36²

UBICACIÓN

DEL QUEMADOR Hi Lo

Delantero derecho 12 500 / 10 500 1 300 /1 300

Posterior derecho 9 200 / 9 100 1 300 /1 300

Delantero izquierdo 9 200 / 9 100 1 300 /1 300

Posterior izquierdo 10 500 / 9 100 1 300 /1 300

Centro 5 000 / 4 000 650 / 650

²

²²

CLASIFICACIÓN DE ENTRADA –

GAS NATURAL / GAS LP (BTU/HR)

FIGURA 17

MAYTAG 30²

UBICACIÓN

DEL QUEMADOR Hi Lo

Delantero derecho 12 500 / 10 500 1 300 /1 300

Posterior derecho 5,000 / 4,000 650 / 650

Delantero izquierdo 9 200 / 9 100 1 300 /1 300

Posterior izquierdo 9,200 / 9,100 1 300 /1 300

C e n t ro -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

11

²

²²

CLASIFICACIÓN DE ENTRADA –

GAS NATURAL / GAS LP (BTU/HR)

Page 23

MANUEL DE

MISE EN SERVICE

PLAQUES DE CUISSON À GAZ

À BRÛLEURS INTÉGRÉS

Modèles : MGC6430 et MGC6536

403 WEST FOURTH STREET,NORTH · NEWTON, IA 50208, ÉTATS- UNIS

IMPORTANT : Dimensions montrées en pouces et en centimètres

IMPORTANT :

signalétique, sous la boîte des brûleurs. Ne pas convertir cet appareil à un type de gaz autre que celui spécifié.

S’assurer quel’appareil correspondau typede gaz fourni. Ces renseignements setrouvent sur la plaque

MODÈLE DE

30 PO (76,2 cm)

MODÈLE DE

36 PO (91,4 cm)

DIMENSIONS

pouces cm

A281/2 +

B 19 15/16 +

C21/8 +

D51/4 +

E30 +

F211/2 +

G 3 13/16 +

H121/4 +

DIMENSIONS

pouces cm

A341/2 +

B 19 15/16 +

C21/8 +

D51/4 +

E36 +

F21 +

G 3 13/16 +

H151/4 +

1/16 72,4 + 0,2

1/16 50,6 + 0,2

1/16 5,4 + 0,2

1/16 13,3 + 0,2

1/16 76,2 + 0,2

1/16 54,6 + 0,2

1/16 9,7 + 0,2

1/16 31,1 + 0,2

1/16 87,6 + 0,2

1/16 50,6 + 0,2

1/16 5,4 + 0,2

1/16 13,3 + 0,2

1/16 91,4 + 0,2

1/16 53,3 + 0,2

1/16 9,7 + 0,2

1/16 38,7 + 0,2

L’EXACTITUDE DES

DIMENSIONS DE LA

DÉCOUPE EST

ESSENTIELLE

AVERTISSEMENT SPÉCIAL :

UNE MAUVAISE RÉALISATION DE LA MISE EN PLACE, DU RÉGLAGE, DE TOUTES

MODIFICATIONS OU RÉPARATIONS OU DE L’ENTRETIEN DE LA CUISINIÈRE OU SON USAGE

INCORRECT PEUVENT ENTRAÎNER DES BLESSURES OU DES DÉGÂTS GRAVES.

À L’INTENTION DE L’INSTALLATEUR : Veuillez laisser ces instructions avec l’appareil.

À L’INTENTION DU CONSOMMATEUR : Veuillez conserver ces instructions pour

référence ultérieure.

Page 24

Emplacement de votre appareil

ménager Maytag

Cet appareil doit être à un emplacement à distance sûre

de tous matériaux combustibles tels que rideaux de

fenêtres et décorations murales susceptibles de prendre

feu.

Le dégagement horizontal minimum entre le bord de

l’appareil et des structures susceptibles de prendre feu

montant jusqu’à une hauteur de 18 po (45,7 cm)

au-dessus de la surface de cuisson est le suivant :

1,0 po (2,54 cm) à l’arrière

6 po (15,2 cm) sur les côtés

(Ces dimensions s’appliquent aux modèles de 30 po

(76,2 cm) et 36 po (91,4 cm) de large.)

45,72 cm

1.0²

2,54 cm

6²

15,24 cm

FIGURE 1

AVERTISSEMENT

CET APPAREIL NE DOIT PAS

ÊTRE INSTALLÉ AU--DESSOUS

D’UNE HOTTE DE VENTILATION

QUI DIRI GE L’AIR DANS UNE

DIRECTION DE HAUT EN BAS.

(VOIR LA FIGURE)

CES SYSTÈMES

D’ÉVACUATION PEUVENT

POSER DES PROBLÈMES

D’ALLUMAGE ET DE

COMBUSTION AVEC DES

BRÛLEURS À GAZ AYANT

POUR RÉSULTAT DES

BLESSURES ET PEUVENT

AFFECTER LA FAÇON DE

CUIRE DE L’APPAREIL.

NOTE: IL EST POSSIBLE QUE LA FIGURE NE SOIT PASUNE REPRÉSENTATION EXACTE DEVOTRE CUISINIÈRE OU DE VOTRE

PLAQUE DECUISSON;POURTANT, CET AVERTISSEMENT S’APPLIQUE À TOUT APPAREIL DE CUISSON À GAZ.

18²

Préparation du comptoir

La découpe dans le comptoir doit être préparée tel que

l’indique l’illustration de la page 1.

ATTENTION : L’exactitude des dimensions de

l’ouverture est essentielle. Pour réaliser correctement la

pose, les dimensions doivent être mesurées avec

précision et la découpe effectuée à 1/16 po (2 mm) près.

Suggestions importantes pour la

préparation

1. Arrondir les angles de tous les rebords du stratifié

décoratif pour éviter qu’ils ne s’écaillent.

2. Arrondir les coins de la découpe et les limer pour

assurer des rebords lisses et éviter que les coins

ne se fendillent. Il est recommandé de percer un

trou de 1/4 ou 3/8 po (6 ou 9 mm) de diamètre dans

chaque coin.

3. Les rebords bruts et les coins intérieurs non arrondis,

ainsi que les endroits où il faut forcer pour permettre la

mise en place de la plaque de cuisson, peuvent

contribuer au fendillement du dessus du comptoir en

stratifié.

4. Le dessus du comptoir doit avoir un support à une

distance maximum de 3 po (7,6 cm) des rebords de la

découpe.

Pose d’armoires au-dessus de votre

plaque de cuisson Maytag

A = 30 po (76,2 cm)

minimum entre la

plaque de cuisson et

tout élément de

construction se trouvant

directement au-dessus

de l’appareil. Ce

dégagement peut être

réduit à un minimum de

24 po (61 cm) si le

dessous du matériau

combustible ou de

l’armoire métallique se

trouvant au-dessus de

la surface de cuisson

est protégé avec du

carton isolant d’un

minimum de 1/4 po

(6,3 mm) recouvert de tôle d’une épaisseur

minimum de 0,0122 po (0,31 mm).

B= 13 po (33,0 cm) maximum de profondeur pour les

armoires se trouvant au-dessus de la plaque de

cuisson.

Éviter l’utilisation d’armoires de rangement au-dessus de

la surface de cuisson pour éliminer les risques potentiels

qui y sont liés, tels que se pencher au-dessus de flammes

pour prendre un article dans l’armoire.

FIGURE 2

Réglages requis lors de la mise en service

La mise en service de cet appareil doit être conforme aux codes locaux ou, en l’absence de tels codes, avec la norme

ANSI Z223.1, dernière édition, du National Fuel Gas Code américain ou du CODE DES INSTALLATIONS B149

CAN/ACG en vigueur.

V Cet appareil est conçu pour fonctionner au gaz naturel. S’il doit être utilisé avec du GPL, suivre la méthode de

conversion au GPL qui se trouve dans les instructions de mise en service.

V Vérifier qu’il n’y a pas de fuite au niveau des raccords externes. Ne jamais vérifier l’absence de fuites à l’aide d’une

flamme.

V Vérifier toutes les connexions électriques.

2

Page 25

Vérifier sur la plaque signalétique de la plaque de cuisson

si elle est homologuée pour la mise en service dans une

maison mobile ou une roulotte de parc. La plaque

signalétique se trouve au fond de l’appareil.

Si la plaque de cuisson est homologuée pour cet usage,

les points suivants s’appliquent :

Maisons mobiles

La mise en service d’une cuisinière prévue pour les

maisons mobiles doit être conforme aux normes

« Manufactured Home Construction and Safety

Standard », titre 24 CFR, partie 3280 (précédemment

« Federal Standard for Mobile Home Construction and

Safety », titre 24 HUD [partie 280]) ou, lorsque ces

normes ne sont pas applicables, les normes « Standard

for Manufactured Home Installations », ANSI

A225.1/NFPA 501A, ou les codes de la construction

locaux.

Au Canada, la mise en service de la cuisinière doit se

faire conformément aux normes CSA C22.1 du code

d’électricité canadien les plus récentes, partie 1 et section

Z240-4.1 relative aux caractéristiques techniques exigées

pour les appareils à gaz utilisés dans les maisons mobiles

(norme CAN/CSA - Z240MH).

Roulottes de parc