Page 1

AUTOMATIC DRYER INSTALLATION INSTRUCTIONS

MISE EN SERVICE SI_CHEUSE AUTOMATIQUE

INSTRUCCIONES DE INSTALACION DE LA SECADORA AUTOMATICA

The installation, including a proper exhaust system,

is the responsibility of the owner.

La responsabilit_ de la mise en service, y compris le syst_me

d'_vacuation qui convient, revient au propri_taire.

Es responsabilidad del propietario la instalaci6n correcta,

incluso la del sistema de escape.

LEAVE THESE INSTRUCTIONS WITH THE OWNER

REMETTRE CES INSTRUCTIONS AU PROPRIF: TAIRE

DEJE ESTAS INSTRUCCIONES CON EL PROPIETARIO

Printed in U.S.A., Printed in U.S.A.. Impreso en los Estados Unidos. Stampato negli Stati Uniti 6 3901250

Page 2

Read this before you start...

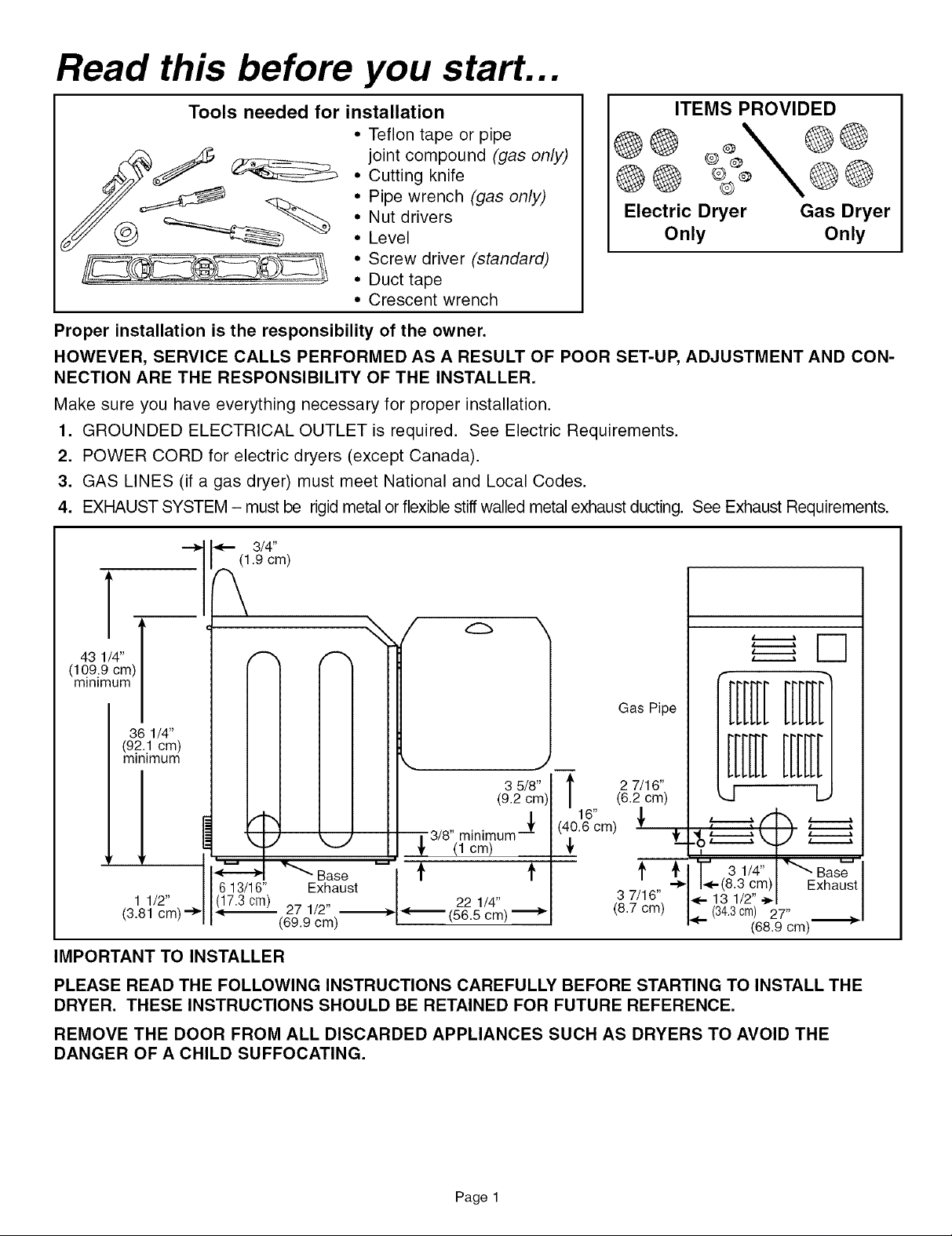

Tools needed for installation

• Teflon tape or pipe

joint compound (gas only)

• Cutting knife

• Pipe wrench (gas only)

• Nut drivers

• Level

• Screw driver (standard)

• Duct tape

° Crescent wrench

Proper installation is the responsibility of the owner.

HOWEVER, SERVICE CALLS PERFORMED AS A RESULT OF POOR SET-UP, ADJUSTMENT AND CON-

NECTION ARE THE RESPONSIBILITY OF THE INSTALLER.

Make sure you have everything necessary for proper installation.

1. GROUNDED ELECTRICAL OUTLET is required. See Electric Requirements.

2. POWER CORD for electric dryers (except Canada).

3. GAS LINES (if a gas dryer) must meet National and Local Codes.

4. EXHAUST SYSTEM - must be rigid metal or flexible stiff walled metal exhaust ducting. See Exhaust Requirements.

3/4"

(1.9 cm)

@@

@

Electric Dryer

ITEMS PROVIDED

Only

@@

@

Gas Dryer

Only

36 1/4"

(9,2,1cm)

minimum

1

1 1/2"

(3.81 cm)

IMPORTANT TO INSTALLER

PLEASE READ THE FOLLOWING INSTRUCTIONS CAREFULLY BEFORE STARTING TO INSTALL THE

DRYER. THESE INSTRUCTIONS SHOULD BE RETAINED FOR FUTURE REFERENCE.

REMOVE THE DOOR FROM ALL DISCARDED APPLIANCES SUCH AS DRYERS TO AVOID THE

DANGER OF A CHILD SUFFOCATING.

Page 1

Page 3

LOCATION CONSIDERATIONS

The dryer should be located to permit adequate room in front for loading the dryer, and sufficient room behind

the dryer for the exhaust system.

This dryer is factory-ready for rear exhaust. To exhaust out the bottom or left side, use the accessory exhaust

kit (see Accessories). Instructions are included with the kit.

It is important to make sure the room has adequate make-up air. The area where the dryer is located must not

obstruct the flow of combustion or ventilating air.

On gas dryers, adequate clearance as noted on the data plate must be maintained to insure adequate air for

combustion and proper operation of the dryer.

THE DRYER MUST NOT BE INSTALLED OR STORED IN AN AREA WHERE IT WILL BE EXPOSED TO

WATER AND/OR WEATHER. THE DRYER AREA IS TO BE KEPT CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS. A DRYER

PRODUCES COMBUSTIBLE LINT. THE AREAAROUND THE DRYER SHOULD BE KEPT FREE OF LINT.

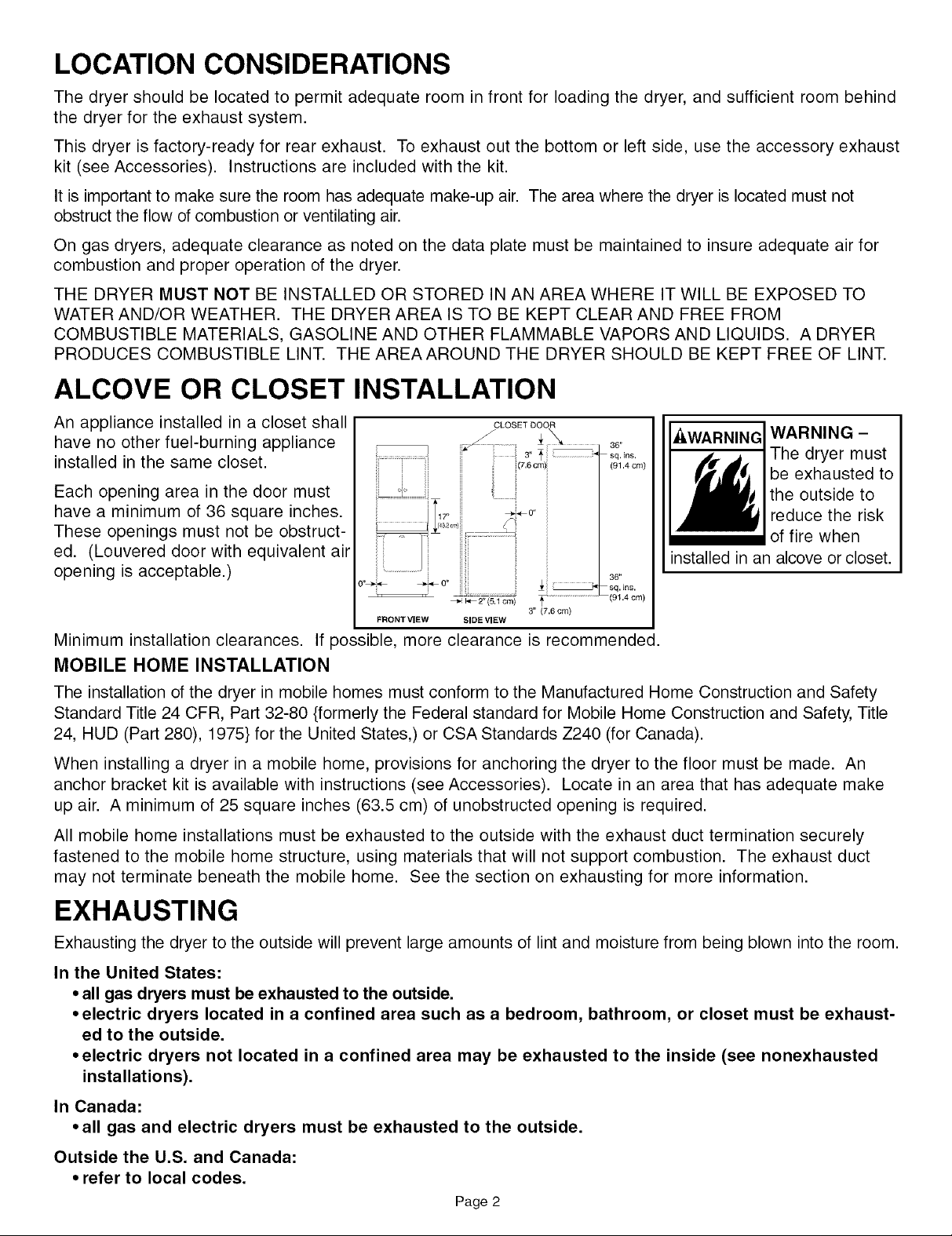

ALCOVE OR CLOSET INSTALLATION

An appliance installed in a closet shall

have no other fuel-burning appliance

installed in the same closet.

Each opening area in the door must

have a minimum of 36 square inches.

These openings must not be obstruct-

ed. (Louvered door with equivalent air

opening is acceptable.)

FRONT VIEW

CLOSET DOOR

i(7.6cm) (91.4cm)

36 '+

_ 2" (5.1 crn) _ ................................. (91.4 cm)

SIDE VIEW

3" (7.6 cm)

_I,WARNING WARNING-

The dryer must

be exhausted to

the outside to

reduce the risk

of fire when

installed in an alcove or closet.

Minimum installation clearances. If possible, more clearance is recommended.

MOBILE HOME INSTALLATION

The installation of the dryer in mobile homes must conform to the Manufactured Home Construction and Safety

Standard Title 24 CFR, Part 32-80 {formerly the Federal standard for Mobile Home Construction and Safety, Title

24, HUD (Part 280), 1975} for the United States,) or CSA Standards Z240 (for Canada).

When installing a dryer in a mobile home, prowsions for anchoring the dryer to the floor must be made. An

anchor bracket kit is available with instructions (see Accessories). Locate in an area that has adequate make

up air. A minimum of 25 square inches (63.5 cm) of unobstructed opening is required.

All mobile home installations must be exhausted to the outside with the exhaust duct termination securely

fastened to the mobile home structure, using materials that will not support combustion. The exhaust duct

may not terminate beneath the mobile home. See the section on exhausting for more information.

EXHAUSTING

Exhausting the dryer to the outside will prevent large amounts of lint and moisture from being blown into the room.

In the United States:

• all gas dryers must be exhausted to the outside.

° electric dryers located in a confined area such as a bedroom, bathroom, or closet must be exhaust-

ed to the outside.

° electric dryers not located in a confined area may be exhausted to the inside (see nonexhausted

installations).

In Canada:

° all gas and electric dryers must be exhausted to the outside.

Outside the U.S. and Canada:

• refer to local codes.

Page 2

Page 4

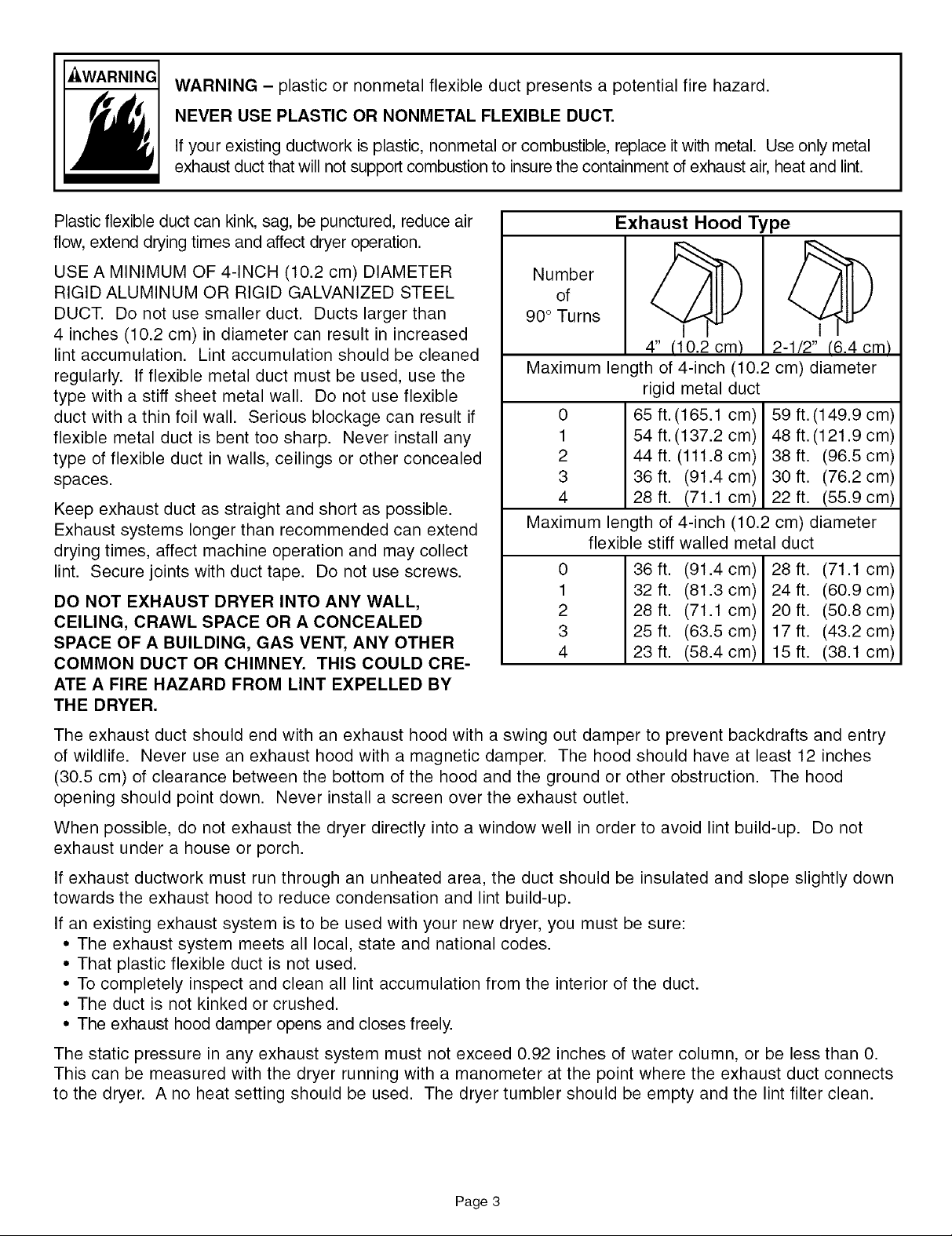

-&WARNING

WARNING - plastic or nonmetal flexible duct presents a potential fire hazard.

NEVER USE PLASTIC OR NONMETAL FLEXIBLE DUCT.

If your existing ductwork is plastic, nonmetal or combustible, replace it with metal. Use only metal

exhaust duct that will not support combustion to insure the containment of exhaust air, heat and lint.

Plastic flexible duct can kink, sag, be punctured, reduce air

flow, extend drying times and affect dryer operation.

USE A MINIMUM OF 4-INCH (10.2 cm) DIAMETER

RIGID ALUMINUM OR RIGID GALVANIZED STEEL

DUCT. Do not use smaller duct. Ducts larger than

4 inches (10.2 cm) in diameter can result in increased

lint accumulation. Lint accumulation should be cleaned

regularly. If flexible metal duct must be used, use the

type with a stiff sheet metal wall. Do not use flexible

duct with a thin foil wall. Serious blockage can result if

flexible metal duct is bent too sharp. Never install any

type of flexible duct in walls, ceilings or other concealed

spaces.

Keep exhaust duct as straight and short as possible.

Exhaust systems longer than recommended can extend

drying times, affect machine operation and may collect

lint. Secure joints with duct tape. Do not use screws.

DO NOT EXHAUST DRYER INTO ANY WALL,

CEILING, CRAWL SPACE OR A CONCEALED

SPACE OF A BUILDING, GAS VENT, ANY OTHER

COMMON DUCT OR CHIMNEY. THIS COULD CRE-

ATE A FIRE HAZARD FROM LINT EXPELLED BY

THE DRYER.

Exhaust Hood Type

Number

of

90 ° Turns

I

4" (10.2 cm)

Maximum length of 4-inch

rigid metal duct

0 65 ft.(165.1 cm)

1 54 ft. (137.2 cm)

2 44 ft. (111.8 cm)

3 36 ft. (91.4 cm)

4 28 ft. (71.1 cm)

Maximum length of 4-inch

flexible stiff walled

0

1

2

3

4

36 ft.

32 ft.

28 ft.

25 ft.

23 ft.

(91.4 cm) 28 ft.

(81.3 cm) 24 ft.

(71.1 cm) 20 ft.

(63.5 cm) 17 ft.

(58.4 cm) 15 ft.

1

2-1/2" ('6.4 cm_

(10.2 cm) diameter

59 ft. (149.9 cm)

48 ft. (121.9 cm)

38 ft. (96.5 cm)

30 ft. (76.2 cm)

22 ft. (55.9 cm)

(10.2 cm) diameter

metal duct

(71.1 cm)

(60.9 cm)

(50.8 cm)

(43.2 cm)

(38.1 cm)

The exhaust duct should end with an exhaust hood with a swing out damper to prevent backdrafts and entry

of wildlife. Never use an exhaust hood with a magnetic damper. The hood should have at least 12 inches

(30.5 cm) of clearance between the bottom of the hood and the ground or other obstruction. The hood

opening should point down. Never install a screen over the exhaust outlet.

When possible, do not exhaust the dryer directly into a window well in order to avoid lint build-up. Do not

exhaust under a house or porch.

If exhaust ductwork must run through an unheated area, the duct should be insulated and slope slightly down

towards the exhaust hood to reduce condensation and lint build-up.

If an existing exhaust system is to be used with your new dryer, you must be sure:

• The exhaust system meets all local, state and national codes.

• That plastic flexible duct is not used.

• To completely inspect and clean all lint accumulation from the interior of the duct.

• The duct is not kinked or crushed.

• The exhaust hood damper opens and closes freely.

The static pressure in any exhaust system must not exceed 0.92 inches of water column, or be less than 0.

This can be measured with the dryer running with a manometer at the point where the exhaust duct connects

to the dryer. A no heat setting should be used. The dryer tumbler should be empty and the lint filter clean.

Page 3

Page 5

Inspect and clean the interior or the exhaust system at least once a year. Disconnect electrical service prior

to cleaning. Check the gas line on gas dryers anytime the dryer is moved.

Frequently check to be sure the exhaust hood damper opens and closes freely.

NONEXHAUSTED INSTALLATIONS

If the electric dryer is not exhausted to the outside, the exhaust must not terminate directly behind the dryer.

Use a rectangular vent kit along with a dacron mesh lint bag (see Accessories). Maintain a 6" (15.2 cm)

clearance between the back of the control panel and the wall. Although the lint screen and lint bag will retain

most of the lint, a certain amount will be expelled into the laundry area.

WARNING: IF THE DRYER IS NOT EXHAUSTED TO THE OUTSIDE, SOME FINE LINT WILL BE

EXPELLED INTO THE LAUNDRY AREA. AN ACCUMULATION OF DUST OR LINT IN ANY AREA OF THE

HOME CREATES A FIRE HAZARD. ANY LINT ACCUMULATIONS MUST BE CLEANED FREQUENTLY.

GAS REQUIREMENTS

Use only Natural or LP (liquid propane) gases.

THE INSTALLATION MUST CONFORM WITH LOCAL CODES, OR IN THE ABSENCE OF LOCAL CODES,

WITH THE NATIONAL FUEL GAS CODE ANSI/Z223.1, LATEST REVISION (FOR THE UNITED STATES),

OR WITH THE CAN/CGA-B149 INSTALLATION CODES (FOR CANADA).

Gas dryers are equipped with a burner orifice for operation on NATURAL gas. If the dryer is to be operated

on LP (liquid propane) gas, it must be converted for safe and proper performance and must be

converted by a qualified service technician. Conversion kits from NATURAL to LP, or LP to NATURAL are

available through your local Maytag dealer (see Accessories). If other conversions are required, check with

the local gas utility for specific information concerning conversion requirements.

A 1/2" (1.27 cm) gas supply line is recommended and must be reduced to connect to the 3/8" (1.0 cm) gas line

on the dryer.

The National Fuel Gas Code requires that an accessible, approved manual gas shut off valve be installed

within 6 feet of the dryer.

Gas Dryers installed in residential garages must be elevated 18 inches (46 cm) above the floor.

Additionally, a 1/8" (.3 cm) N.P.T. (National Pipe Thread) plugged tapping, accessible for test gauge

connection, must be installed immediately upstream of the gas supply connection to the dryer.

The dryer must be disconnected from the gas supply piping system during any pressure testing of the system.

DO NOT re-use old flexible metal gas line. Flexible gas line must be design certified by American Gas

Association (CGA in Canada). NOTE: Any pipe joint compound used must be resistant to the action of any

liquefied petroleum gas.

NOTE: As a courtesy, most local gas utilities will inspect a gas appliance installation.

GAS IGNITION -

This dryer uses an automatic ignition system to ignite the burner. There is no constant burning pilot.

COMMONWEALTH OF MASSACHUSETTS

INSTALLATION INSTRUCTIONS

This gas dryer must be installed by a licensed

plumber or gas fitter

A "T" handle manual gas valve must be installed in

the gas supply line to this gas dryer.

If a flexible gas connector is used to install this gas

dryer, the connector must have a maximum length

of 3 feet. (36 inches)

Gas leaks may occur in your system and result in

a dangerous situation. Gas leaks may not be

detected by smell alone. Gas suppliers recom-

mend you purchase and install a UL approved

gas detector. Install and use in accordance with

the manufacturer's instructions.

Page 4

Page 6

ELECTRICAL REQUIREMENTS

NOTE: Wiring diagram is located inside the control console.

Export models (not U.S. or Canada): See Additional Instructions for Export Models on the other side of this sheet.

I_I,WARNING] WARNING - To prevent unnecessary risk of fire, electrical shock or personal injury, all

_ bsence of local codes, with the National Electrical Code, ANSI/NFPA (for the United

wiring and grounding must be done in accordance with local codes, or in the

States) or the Canadian Electrical Code CSA C22.1 (for Canada).

GROUNDING

This dryer must be grounded. In the event of malfunction or breakdown, the ground will reduce the risk of

electrical shock by providing a path of least resistance for electrical current.

GAS MODELS

This appliance is equipped with a cord having an

equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet

that is properly installed and grounded in accordance

with all local codes and ordinances.

Do not modify the plug provided with the appliance - if

it will not fit the outlet, have a proper outlet installed by

a qualified electrician.

if a separate ground is required by local codes, a grounding kit (Part No. 12001875) is available. It contains

ground wire, clamp, ground screw and washer. Connect ground wire to back of unit with the cabinet ground

screw and washer. Secure other end of ground wire to a suitable external ground connection. The wire may

be secured with the clamp to a grounded COLD metal water pipe.

NEVER CONNECT GROUND WIRE TO PLASTIC PLUMBING LINES, GAS LINES OR HOT WATER PIPES.

_'WARNING

WARNING - Improper connection of

the equipment grounding conductor can

result in a risk of electric shock. Check

with a qualified electrician or serviceman

if you are in doubt as to whether the

appliance is properly grounded.

U.S. electric models are shipped with a ground strap connected from the neutral

terminal block post to the frame of the dryer. If local codes prohibit the use of the

ELECTRIC MODELS 1_

ground strap, the dryer must be grounded in accordance with local codes.

If a power cord is not used and the electric dryer is to be permanently wired,

the dryer must be connected to a grounded metal, permanent wiring system;

or an equipment grounding conductor must be run with the circuit conductors

and connected to the equipment grounding terminal.

ELECTRICAL CONNECTIONS

BEFORE OPERATING OR TESTING, follow all grounding instructions in Grounding Section.

An individual branch (or separate) circuit serving only this appliance is recommended. DO NOT USE AN

EXTENSION CORD.

Ground

Screw

GAS MODELS - U.S. and Canada

A 120 volt, 60 Hz AC, approved electrical service, with a 15 ampere fuse or circuit breaker is required.

ELECTRIC MODELS - U.S. Only

Most U.S. dryers, as manufactured, require a 120/240 volt, 60 Hz AC approved electrical service. Some require

120/208 volt, 60 Hz approved electrical service. The electric service requirements can be found on the data

label located on the front behind the door. A 30 ampere fuse or circuit breaker on both sides of the line is

required.

Page 5

Page 7

A 120/240 volt U.S. electric dryer must be converted if it is to operate on a 120/208 volt electrical system.

A heating element conversion kit is available (see Accessories).

If a power cord is used, the cord should be plugged into a 30 ampere receptacle.

The power cord is NOT provided with U.S. electric model dryers.

IMPORTANT: When permitted by local codes, the dryer electrical supply may be connected by means of a

new power supply cord kit, marked for use with clothes dryer, that is U.L. listed, rated at 120/240 volts

minimum, 30 amperes with three No. 10 copper wire conductors terminated with closed loop terminals, open-

end spade lugs with turned up ends or with tinned leads.

Do not reuse a power supply cord from an old dryer. The power cord electric supply wiring must be retained

at the dryer cabinet with a suitable UL listed strain relief.

If the dryer is to be installed in a mobile home or an area where local codes do not permit grounding through

neutral, only a 4 conductor power cord, rated and terminated as above, may be used.

ELECTRIC MODELS - Canada Only

A 120/240 volt, 60 Hz AC approved electrical service fused through a 30 ampere fuse or circuit breaker on

both sides of the line is required.

All Canadian models are shipped with the power cord attached. The power cord should be plugged into a

30 ampere receptacle.

NOTE: It is not permissible to convert a dryer in Canada to 208 volts.

REPLACEMENT PARTS AND ACCESSORIES

If your dryer requires replacement parts or accessories, contact the dealer from whom you purchased your

dryer or Maytag Customer Service, Box 2370, Cleveland, Tennessee 37320-2370, phone 423-472-3333,

for information on the nearest authorized Maytag Parts Distributor.

INSTALLATION

Parts and fiterature are packaged inside of dryer drum.

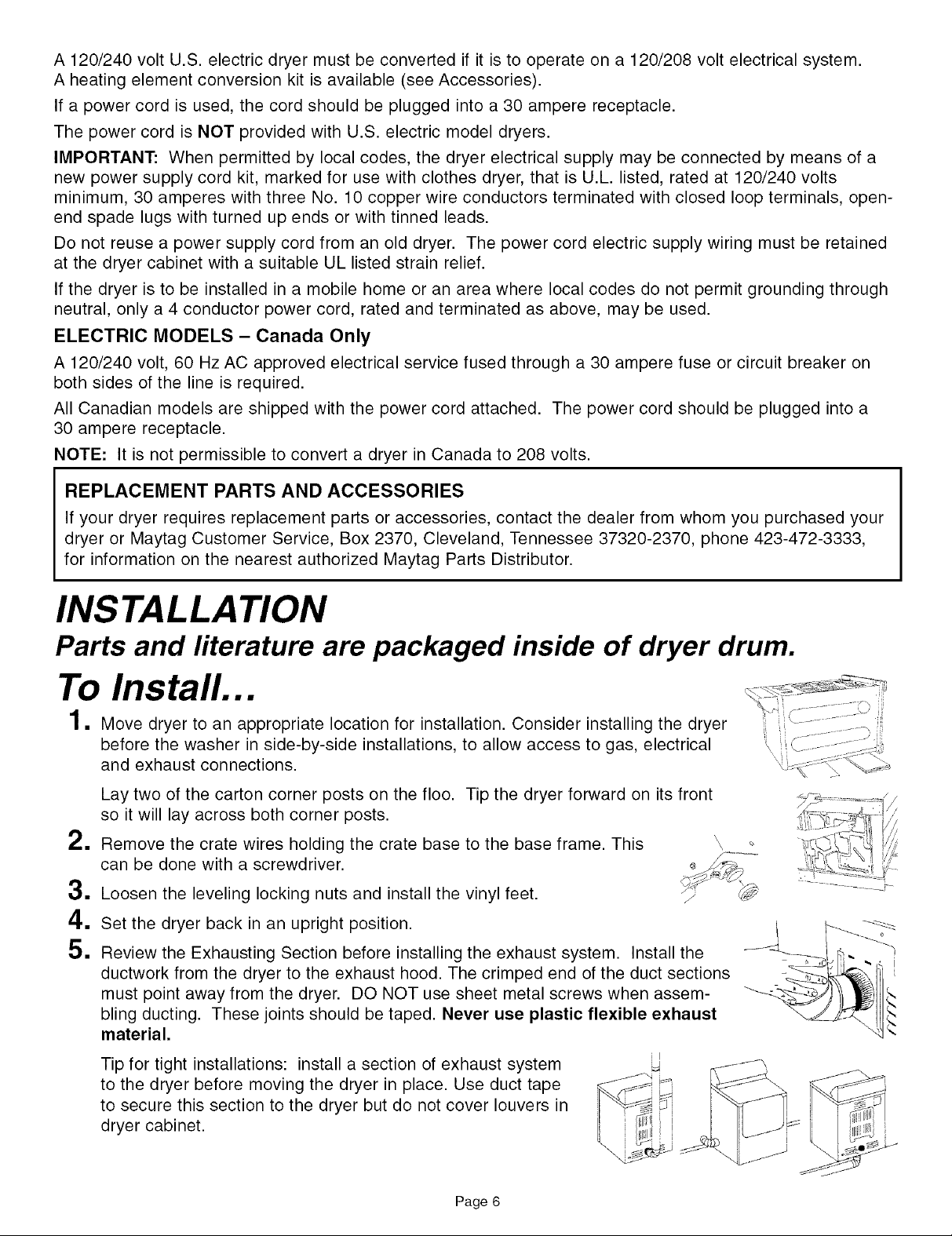

To Install...

I. Move dryer to an appropriate location for installation. Consider installing the dryer

before the washer in side-by-side installations, to allow access to gas, electrical

and exhaust connections.

Lay two of the carton corner posts on the floo. Tip the dryer forward on its front

so it will lay across both corner posts.

2. Remove the crate wires holding the crate base to the base frame. This '_,

can be done with a screwdriver.

3. Loosen the leveling locking nuts and install the vinyl feet.

4. Set the dryer back in an upright position.

5. Review the Exhausting Section before installing the exhaust system. Install the

ductwork from the dryer to the exhaust hood. The crimped end of the duct sections

must point away from the dryer. DO NOT use sheet metal screws when assem-

bling ducting. These joints should be taped. Never use plastic flexible exhaust

material.

Tip for tight installations: install a section of exhaust system

to the dryer before moving the dryer in place. Use duct tape

to secure this section to the dryer but do not cover louvers in

dryer cabinet.

Page 6

, /

Page 8

&WARNING ° Improper connection of the equipment-grounding conductor can result in a risk of electrical

shock. Check with a qualified electrician or serviceman if you are in doubt as to whether

the appliance is properly grounded. Do not modify the plug provided with the appliance -

if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

• To prevent unnecessary risk of fire, electrical shock or personal injury, all wiring and

grounding must be done in accordance with the National Electrical Code ANSI/NFPA, No.

70-Latest Revision (for U.S.) or the Canadian Electrical code CSA C22.1 - Latest Revision and local

codes and ordinances. It is the personal responsibility and obligation of the appliance owner to provide

adequate electrical services for this appliance.

• All gas installations must be done in accordance with the National Fuel Gas Code ANSI/Z2231 - Latest

Revision (for the United States) or the CAN/CGA- B149 Installation Codes - Latest Revision (for

Canada) and local codes and ordinances.

1m

Review Gas Requirements Section.

Remove the pipe thread protective cap.

Apply pipe joint compound or about 1 1/2 wraps of Teflon tape over all threaded

connections. NOTE: Pipe joint compound must be resistant to the action of any liquefied

petroleum gas.

Connect the gas supply to the dryer. An additional fitting is required to connect the 3/4"

(1.9 cm) female thread end of a flexible connector to the 3/8" (1 cm) male threaded end

on the dryer. Securely tighten the gas line fitting over threads.

Turn on the gas supply. Check all gas connections for leaks using a soap solution. If

bubbles occur, tighten the connections and recheck. DO NOT use an open flame to

check for gas leaks.

1m

Review Electrical Requirements Section.

BEFORE OPERATING OR TESTING, follow the grounding instructions in the Grounding Section.

U.S. MODELS:

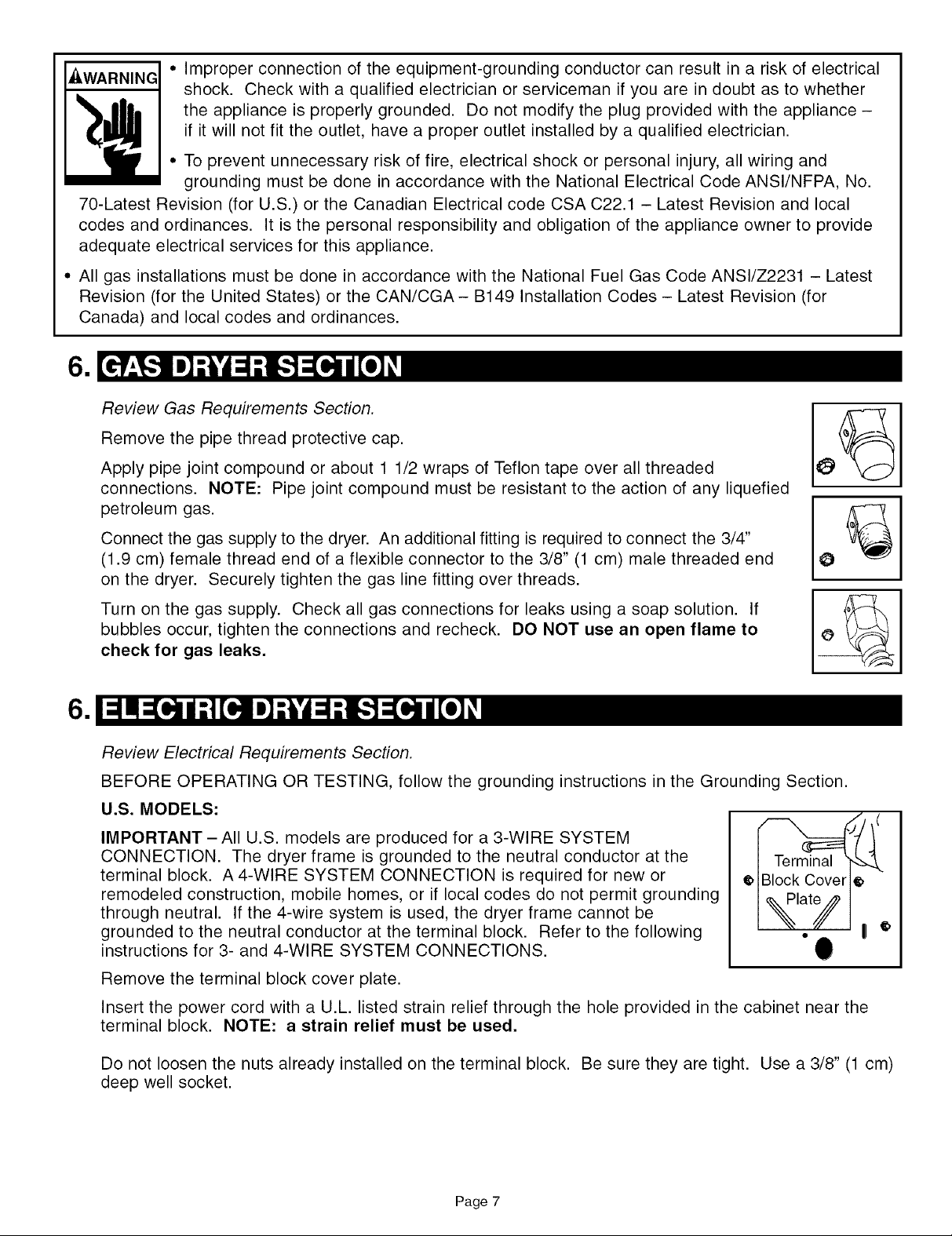

IMPORTANT - All U.S. models are produced for a 3-WIRE SYSTEM

CONNECTION. The dryer frame is grounded to the neutral conductor at the

terminal block. A 4-WIRE SYSTEM CONNECTION is required for new or

remodeled construction, mobile homes, or if local codes do not permit grounding

through neutral. If the 4-wire system is used, the dryer frame cannot be

grounded to the neutral conductor at the terminal block. Refer to the following

instructions for 3- and 4-WIRE SYSTEM CONNECTIONS.

Remove the terminal block cover plate.

IBIock Covel

I 'ate/

t

"O

Insert the power cord with a U.L. listed strain relief through the hole provided in the cabinet near the

terminal block. NOTE: a strain relief must be used.

Do not loosen the nuts already installed on the terminal block. Be sure they are tight. Use a 3/8" (1 cm)

deep well socket.

Page 7

Page 9

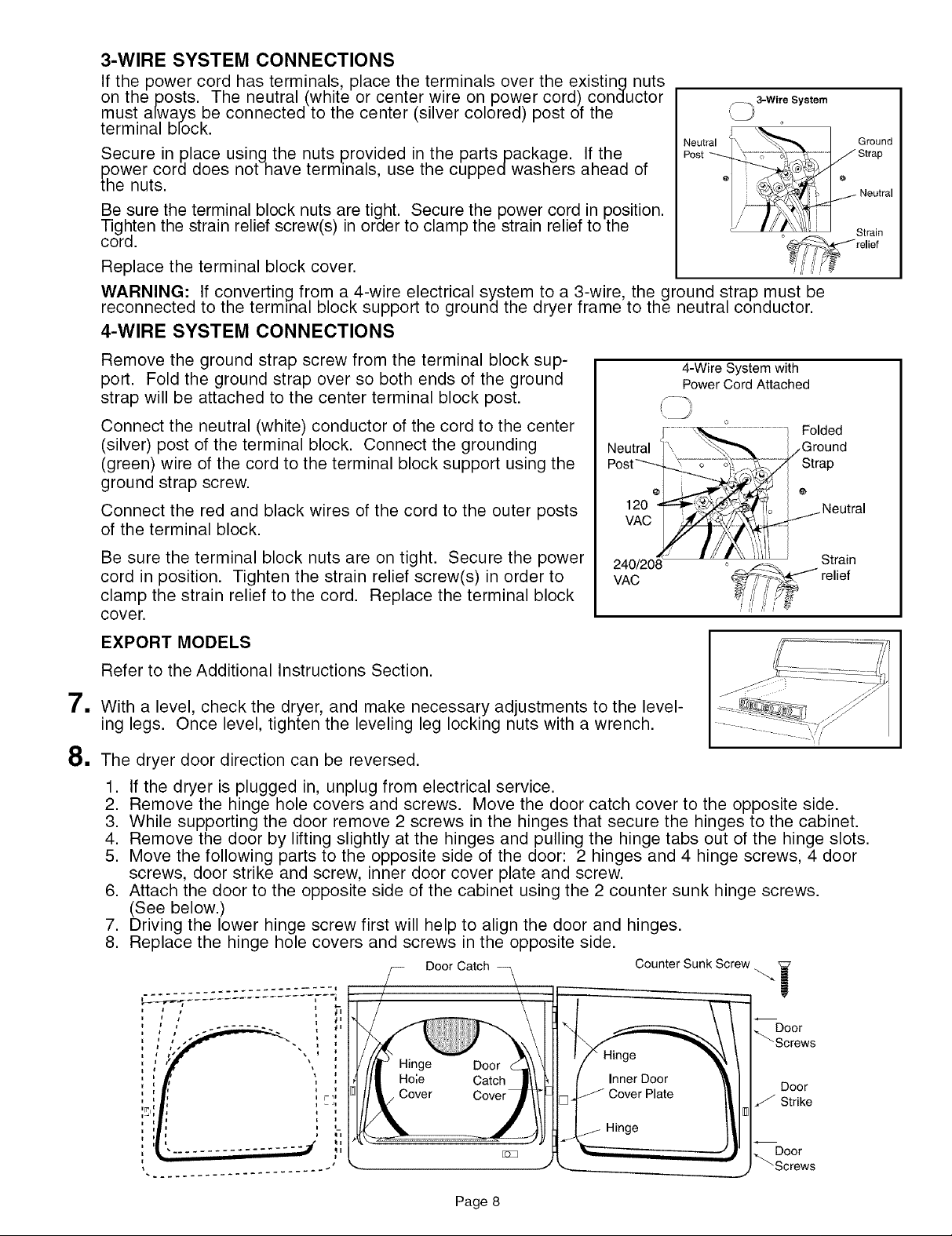

3-WIRE SYSTEM CONNECTIONS

If the power cord has terminals, place the terminals over the existing nuts

on the posts. The neutral (white or center wire on power cord) conductor _3-WireSystem

must always be connected to the center (silver colored) post of the \ _

terminal block. °

Secure in place using the nuts provided in the partspackage. If the

power cord does not have terminals, use the cupped washers ahead of

the nuts.

Be sure the terminal block nuts are tight. Secure the power cord in position.

Tighten the strain relief screw(s) in order to clamp the strain relief to the

cord.

Replace the terminal block cover.

WARNING: If converting from a 4-wire electrical system to a 3-wire the ground strap must be

reconnected to the term nab OCKsupport to ground the aryer frame to the neutra conauctor.

4-WIRE SYSTEM CONNECTIONS

Strain

Remove the ground strap screw from the terminal block sup-

port. Fold the ground strap over so both ends of the ground

4-Wire System with

Power Cord Attached

strap will be attached to the center terminal block post.

Connect the neutral (white) conductor of the cord to the center

'\j

(silver) post of the terminal block. Connect the grounding

Neutral Ground

(green) wire of the cord to the terminal block support using the

ground strap screw.

Connect the red and black wires of the cord to the outer posts

of the terminal block.

120

VAC

Be sure the terminal block nuts are on tight. Secure the power

cord in position. Tighten the strain relief screw(s) in order to

VAC

clamp the strain relief to the cord. Replace the terminal block

cover.

EXPORT MODELS

Refer to the Additional Instructions Section.

7. With a level, check the dryer, and make necessary adjustments to the level-

ing legs. Once level, tighten the leveling leg locking nuts with a wrench.

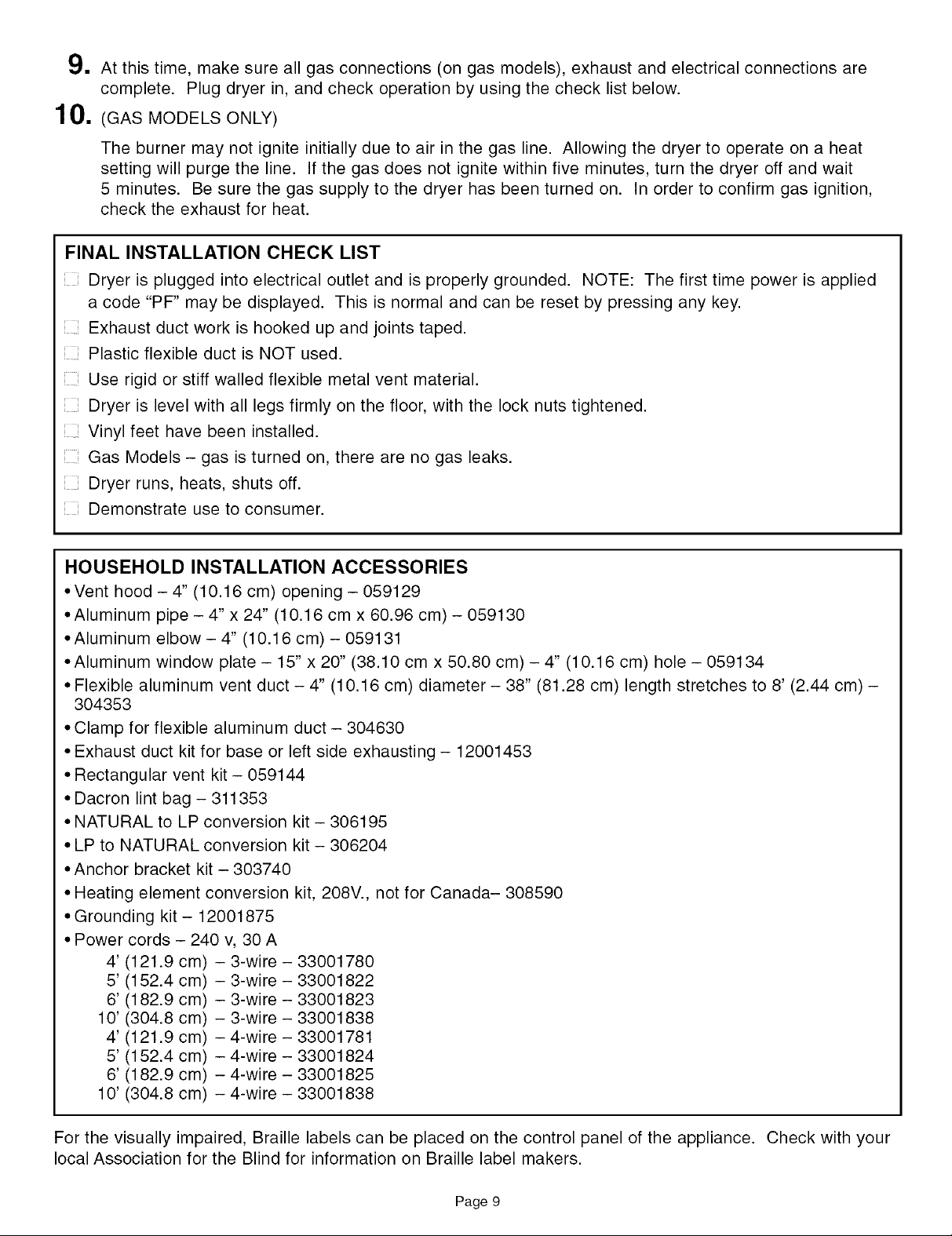

8, The dryer door direction can be reversed.

1. If the dryer is plugged in, unplug from electrical service.

2. Remove the hinge hole covers and screws. Move the door catch cover to the opposite side.

3. While supporting the door remove 2 screws in the hinges that secure the hinges to the cabinet.

4. Remove the door by lifting slightly at the hinges and pulling the hinge tabs out of the hinge slots.

5. Move the following parts to the opposite side of the door: 2 hinges and 4 hinge screws, 4 door

screws, door strike and screw, inner door cover plate and screw.

6. Attach the door to the opposite side of the cabinet using the 2 counter sunk hinge screws.

(See below.)

7. Driving the lower hinge screw first will help to align the door and hinges.

8. Replace the hinge hole covers and screws in the opposite side.

Door Catch

Counter Sunk Screw _ i

Folded

Strain

relief

, ' [,,

,';"'t _..,,,

i i

i i i - _1

i i i _ i

i i i i i_

IrPi Ili _ i

i

i rlJ

Door

_"Screws

Door

Page 8

Page 10

At this time, make sure all gas connections (on gas models), exhaust and electrical connections are

complete. Plug dryer in, and check operation by using the check list below.

(GAS MODELS ONLY)

The burner may not ignite initially due to air in the gas line. Allowing the dryer to operate on a heat

setting will purge the line. If the gas does not ignite within five minutes, turn the dryer off and wait

5 minutes. Be sure the gas supply to the dryer has been turned on. In order to confirm gas ignition,

check the exhaust for heat.

FINAL INSTALLATION CHECK LIST

Dryer is plugged into electrical outlet and is properly grounded. NOTE: The first time power is applied

a code "PF" may be displayed. This is normal and can be reset by pressing any key.

Exhaust duct work is hooked up and joints taped.

Plastic flexible duct is NOT used.

Use rigid or stiff walled flexible metal vent material.

Dryer is level with all legs firmly on the floor, with the lock nuts tightened.

Vinyl feet have been installed.

Gas Models - gas is turned on, there are no gas leaks.

Dryer runs, heats, shuts off.

Demonstrate use to consumer.

HOUSEHOLD INSTALLATION ACCESSORIES

• Vent hood - 4" (10.16 cm) opening - 059129

• Aluminum pipe - 4" x 24" (10.16 cm x 60.96 cm) - 059130

• Aluminum elbow - 4" (10.16 cm) - 059131

• Aluminum window plate - 15" x 20" (38.10 cm x 50.80 cm) - 4" (10.16 cm) hole - 059134

• Flexible aluminum vent duct - 4" (10.16 cm) diameter - 38" (81.28 cm) length stretches to 8' (2.44 cm) -

304353

• Clamp for flexible aluminum duct - 304630

• Exhaust duct kit for base or left side exhausting - 12001453

• Rectangular vent kit - 059144

• Dacron lint bag - 311353

• NATURAL to LP conversion kit - 306195

• LP to NATURAL conversion kit - 306204

• Anchor bracket kit - 303740

• Heating element conversion kit, 208V., not for Canada- 308590

• Grounding kit- 12001875

• Power cords - 240 v, 30 A

4' (121.9 cm - 3-wire

5' (152.4

6' (182.9

10' (304.8

4' (121.9

5' (152.4

6' (182.9

10' (304.8

cm - 3-wire - 33001822

cm - 3-wire - 33001823

cm - 3-wire - 33001838

cm - 4-wire - 33001781

cm - 4-wire - 33001824

cm - 4-wire - 33001825

cm - 4-wire - 33001838

- 33001780

For the visually impaired, Braille labels can be placed on the control panel of the appliance. Check with your

local Association for the Blind for information on Braille label makers.

Page 9

Page 11

(not U.S. or Canada)

Contact the distributor that sold the appliance or: Maytag International, 8700 W. Bryn Mawr Avenue, Chicago,

Illinois USA 60631,773-714-0100, for information on product, shipping damage, replacement parts and

accessories.

Maytag dryer models manufactured for operation on 60 Hz AC are not designed for use on 50 Hz AC

electrical service and conversion of the product from 60 to 50 Hz operation is not recommended. For

additional information on 50 Hz products, contact Maytag International.

The electric service requirements can be found on the data label located on the front of the dryer behind the

door.

EXPORT ELECTRIC MODELS

Export electric models are manufactured for operation on either 230/240 volt, 50 Hz or 220 volt, 60 Hz

approved electric service. A two-wire approved electrical service with a 30 ampere fuse or circuit breaker is

required. The dryer must be properly grounded with a ground wire.

IMPORTANT: When permitted by local codes, the dryer electrical supply may be connected by means of a

new power supply cord kit, marked for use with clothes dryers, that is agency listed, rated at 240 volts

minimum, 30 amperes with two No. 10 copper wire conductors terminated with closed loop terminals, open-

end spade lugs with turned up ends or with tinned leads.

Do not reuse a power supply cord from an old dryer. The power cord or electric supply wiring must be

retained at the dryer cabinet with a suitable agency listed strain relief.

2-WIRE AND GROUND SYSTEM CONNECTIONS

2-Wire and Ground System

Remove the terminal block cover plate.

Insert the power cord with an agency listed strain relief through

the hole provided in the cabinet near the terminal block. Note, a

strain relief must be used.

Do not loosen the nuts already installed on the terminal block.

Neutral

Post"

Power

Cord

Ground

Be sure they are tight. Use a 3/8" (1 cm) deep well socket.

Secure the power cord ground wire to the terminal block

/Wire

support using the ground screw.

If the power cord has terminals, place the terminals over the

existing nuts on the posts. The neutral wire in power cord

must be connected to the center (silver colored) post of the

terminal block.

Neutral ""

Power

cord

_- and

strain

relief

Secure in place using the nuts provided in the parts package.

If the power cord does not have terminals, use the cupped

washers ahead of the nuts.

Be sure the terminal block nuts are tight. Secure the power cord in position. Tighten the strain relief screw(s) in

order to clamp the strain relief to the cord.

Replace the terminal block cover.

BEFORE OPERATING OR TESTING, be sure the machine is properly grounded.

EXPORT GAS MODELS

Export gas models are manufactured for operation on either 230/240 volt, 50 Hz or 220 volt, 60 Hz AC

approved electrical service with a 15 ampere fuse or circuit breaker.

Export gas models have been manufactured for use with natural gas having a higher heating value of

approximately 1025 BTU per cubic foot. Conversion to LP gas with a higher heating value of approximately

2500 BTU per cubic foot must be performed by a qualified service technician. A conversion kit is available.

Page 10

Page 12

Lire event de commencer...

Outils necessaires

• Ruben en Teflon ou p&te& joints

(modeles a gaz seulement)

• Couteau

• Cle & tubes (modeles #,gaz seule.

merit)

• Tourne-ecrous

• Niveau

• Tournevis (standard)

• Ruben adhesif

• Cle & mollette

La responsabilite de la mise en service revient au proprietaire de la secheuse.

TOUTEFOIS, LES PRESTATIONS DE SERVICE APR#S-VENTE DUES .&,UNE CONFIGURATION, UN

RCGLAGE OU UN RACCORDEMENT INADCQUATS SONT .&.LA CHARGE DE L'INSTALLATEUR.

Veiller & avoir tout le necessaire pour assurer une mise en service correcte de I'appareil.

1. UNE PRISE MURALE AVEC MISE ,&,LA TERRE est necessaire. Voir sous <,Caracteristiques electriques _>.

2. UN CORDON €:LECTRIQUE pour secheuses electriques (sauf les modules destines au marche canadien).

3. LES CONDUITES DE GAZ (s'il s'agit d'une secheuse & gaz) doivent 6tre conformes aux codes Iocaux

et nationaux.

4. LES CONDUITS D'¢VACUATION doivent 6tre en metal rigide ou en metal flexible & parois rigides. Voir sous

<,Caracteristiques de I'evacuation _>.

3/4 po

(1,9 cm)

@@ @@

ARTICLES FOURNIS

@ @

Secheuse

electrique

seulement

Secheuse

gaz seulement

T

43 1/4 po

(109,9 cm)

minimum

Conduite

de gaz

36 1/4 po

(92,1 cm)

minimum

1

1 1/2 po

(3,81 cm) -'_

IMPORTANT POUR L'INSTALLATEUR

LIRE SOIGNEUSEMENT LES INSTRUCTIONS QUI SUIVENT AVANT DE COMMENCER LA MISE EN SERVICE

DE LA S¢CHEUSE. LES CONSERVER POUR ReFeRENCE ULTCRIEURE.

DCMONTER LA PORTE DE TOUT APPAREIL MCNAGER, TEL QUE LES S¢CHEUSES, MIS AU REBUT, AFIN

D'¢VITER QU'UN ENFANT NE SE GLISSE DANS L'APPAREIL, NE S'Y TROUVE ENFERM¢ ET NE SUFFOQUE.

hd / (9,2 cm) / (6,2 cm) d ¢ L,

6 13/16 po 1'6vacuation

_ Base de I f T /

17,3 cm ..... 22 1/4 po (8,7 cm)

z/ 1/zpo ,__ _565cm_ '_ 1__(34,3cm)_ 27p0 ,_

(69,9 cm) ' ' (68,9 cm)

. ._ [[[[[[[[[L[[

3 5/8 pe T 2 7/16 po

3/8po(1 cm) _ (41'6P°m) _' _

minimum A _i, T 3 1/4 po I _ Base

I_-

3 7/16 po _,- 13 1/2 po -_1

CONSIDI RATIONS CONCERNANT L'EMPLACEMENT

"--' F-]

(8,3 cm)

d'evacuation

I

La secheuse doit 6tre placee de telle sorte qu'il y ait suffisamment de place & I'avant pour y mettre et en enlever le linge,

et un degagement suffisant & I'arriere pour la conduite d'evacuation.

Cette secheuse a et6 congue en usine pour une evacuation par I'arriere. Pour une evacuation par le dessous ou sur le

c6te gauche, utiliser le necessaire d'evacuation (voir sous ,_Accessoires ,,). Les instructions sont incluses avec le

necessaire.

Page 11

Page 13

II est important de s'assurer que la piece a un apport d'air d'appoint suffisant. L'endroit ou se trouve la secheuse ne doit

pas obstruer le passage de I'air de combustion ou de ventilation.

Avec les secheuses & gaz, un degagement suffisant, indique sur la plaque signaletique, doit _tre prevu de fa(_on& assu-

rer un apport d'air adequat pour la combustion et le bon fonctionnement de la secheuse.

NE PAS INSTALLER OU ENTREPOSER LA S¢:CHEUSE DANS UN ENDROIT OU ELLE EST EXPOSEE ,_ L'EAU

ET/OU AUX INTEMPC:RIES. LA PIC:CE DANS LAQUELLE SE TROUVE LA S¢:CHEUSE DOlT €:TRE LIBRE DE TOUTE

SUBSTANCE COMBUSTIBLE, D'ESSENCE ET DE TOUTAUTRE LIQUIDE OU VAPEUR INFLAMMABLE. UNE

S¢:CHEUSE PRODUIT DE LA CHARPIE COMBUSTIBLE ET LA PROXlMITE DE LA S¢:CHEUSE DOlT €:TRE GARDEE

LIBRE DE TOUTE CHARPIE.

MISE EN SERVICE DANS UNE ALCOVE OU UNE ARMOIRE

Ne pas placer d'autre appareil utilisant un combustible dans la m_me armoire que la secheuse.

Chaque ouverture dans la porte doit avoir une surface minimum de 36 po2(91,4 cm2). Cette ouverture ne doit pas _tre

obstruee. (Une porte & volets avec ouverture equivalente est acceptable.)

PORTE DE L'ARMOIRE

_,DANGER DANGER :

L'evacuation de

-- 36 po2

(91,4 cm)

CO

T

17po

(43,2 mrn)

cendie Iorsqu'elle est dans une

alc6ve ou une armoire.

±

0 po

',ocm_

i i1

VUE FRONTALE

INSTALLATION EN MAISON MOBILE

L'installation d'une secheuse dans une maison mobile doit _tre conforme aux normes - Manufactured Home Construction

and Safety Standard ,,, titre 24 CFR, partie 32-80 (prec6demment - Federal Standard for Mobile Home Construction and

Safety ,,, titre 24, HUD [partie 280], 1975) aux €:tats-Unis, et aux normes Z240 de I'ANC au Canada.

Lors de I'installation d'une secheuse dans une maison mobile, il faut prevoir son ancrage au plancher. Un necessaire de

pattes de fixation avec instructions de montage est disponible (voir sous ,, Accessoires _,).Placer la secheuse de fa(_on&

ce que son emplacement lui assure un apport d'air d'appoint suffisant. Une ouverture non obstruee d'un minimum de

25 po2(63,5 cm) est exigee.

Toute installation dans une maison mobile doit avoir un conduit d'evacuation exterieur et I'extremit6 du conduit se trouvant

& I'exterieur doit _tre solidement fixee & la structure de la maison mobile & I'aide de materiaux ininflammables. Le conduit

d'evacuation ne doit pas sortir sous la maison mobile. Voir les explications concernant I'evacuation pour plus de details.

0 po

__ _ cm)

i

_1 _ 2 po (5,1 cm)

VUE LATleRALE

_ 3 po (7,5 cm)

__ 36 po2

(91,4 cm)

Degagements minimums necessaires. Des

degagements de plus grandes dimensions

sont recommandes.

la secheuse doit

se faire vers I'ex-

terieur pour

reduire les

risques d'in-

I VACUATION

L'evacuation de la secheuse sur I'exterieur evite I'evacuation de la charpie et de quantites importantes d'humidite dans la piece.

Aux Etats-Unis :

* L'evacuation de toute secheuse a gaz doit se faire a rexterieur.

° Quand la secheuse electrique est installee dans une piece fermee telle qu'une chambre a coucher, une

salle de bains ou un placard, revacuation doit se faire a rexterieur.

* Dans le cas d'une secheuse electrique qui ne se trouve pas dans une piece fermee, revacuation peut

se faire dans la piece (voir sous ,, Installations sans conduit d'evacuation _).

Au Canada :

° Toutes les secheuses, electriques et a gaz, doivent avoir une evacuation donnant sur I'exterieur.

A I'ext_rieur du Canada et des Etats-Unis :

* Consulter les codes Iocaux.

Page 12

Page 14

-&DANGER

DANGER - Les conduits en plastique et en materiau non metallique flexibles presentent des risques

d'incendie.

NE JAMAIS UTILISER DE CONDUITS EN PLASTIQUE OU EN MATI_RIAU NON MI_TALLIQUE

FLEXIBLE.

Si le conduit existant est en plastique ou en materiau non metallique ou combustible, le remplacer par

un conduit metallique. Utiliser uniquement un conduit metallique qui ne permettra pas la combustion

pour canaliser I'air d'evacuation, la chaleur et la charpie.

Les conduits flexibles en plastique peuvent se deformer, se

trouver ecras6s, perces. IIs peuvent reduire I'ecoulement de

Fair, prolonger le temps de sechage et affecter le bon fonc-

tionnement de la secheuse.

POUR DES RESULTATS OPTIMUMS, UTILISER UN CON-

DUIT D'UN DIAMETRE MINIMUM DE 4 PO1 (0,2 CM), EN

ALUMINIUM RIGIDE OU EN ACIER GALVANISE RIGIDE.

Ne pas utiliser un conduit d'un diametre plus petit. Les con-

duits d'un diametre superieur & 4 po (10,2 cm) de diametre

peuvent provoquer une plus grande accumulation de charpie.

Toute accumulation de charpie doit _tre nettoyee reguliere-

ment. Si un conduit en metal flexible doit _tre utilise, il est

pref6rable d'en employer un & paroi en t61e rigide. Ne pas

utiliser de conduit flexible & parois en fine feuille d'aluminium.

De serieux blocages peuvent se produire si le conduit flexible

se trouve trop fortement courb& Ne jamais installer de con-

duit flexible dans les murs, les plafonds ou tout autre espace

clos d'un b&timent ou il sera invisible.

Faire en sorte que le conduit soit aussi droit et court que pos-

sible. S'il est plus long que recommand& cela peut prolonger

la duree du sechage, affecter le fonctionnement de la

secheuse ou entrafner I'accumulation de charpie. Recouvrir

les joints de ruban isolant. Ne pas utiliser de vis.

NE PAS I_VACUER L'AIR D'UNE SI_CHEUSE DANS UN

MUR, UN PLAFOND, UN VIDE SANITAIRE OU L'ESPACE

CLOS D'UN BATIMENT, NI DANS UN CONDUIT DE VENTI-

LATION, UNE EVACUATION DE GAZ OU UNE CHEMINI_E. LA CHARPIE EXPULSI_E POURRAIT CRI_ER

RISQUES D'INCENDIE.

Le conduit d'evacuation doit se terminer par une hotte d'evacuation equip6e d'un clapet pivotant & sens unique pour eviter

les retours d'air et I'entree d'animaux dans le conduit. Ne jamais utiliser de hotte d'evacuation &clapet magnetique. La hotte

doit _tre placee de fa(;on & ce qu'il y ait un espace d'au moins 12 po (30,5 cm) entre le bas de la hotte et le sol ou autre

obstruction. L'ouverture de la hotte doit pointer vers le bas. Ne jamais installer de grille ni de filtre sur la sortie d'air.

Autant que possible, la hotte ne doit pas s'evacuer directement dans une fosse de fen_tre, pour eviter I'accumulation de

charpie. Ne pas faire deboucher I'evacuation sous une maison ou une galerie.

Si le conduit d'evacuation doit traverser une piece non chauffee, I'isoler et lui donner une legere pente vers la hotte

d'evacuation pour reduire la condensation et I'accumulation de charpie.

Si un systeme d'evacuation existant doit _tre utilise pour la secheuse, veiller A ce que :

• le systeme d'evacuation soit conforme A tousles codes Iocaux, regionaux et nationaux

• du conduit flexible en plastique ne soit pas utilise ;

• I'interieur du conduit soit inspecte & fond et toute accumulation de charpie soit enlevee

• le conduit ne soit pas plie ou ecras6 ;

• le clapet de la hotte d'evacuation s'ouvre et se ferme librement.

La contre-pression d'un conduit d'evacuation ne doit pas depasser 0,92 po de colonne d'eau (0,228 kPa) ni _tre inferieure &

O.On peut la mesurer, & I'aide d'un manometre, au point ou le conduit d'evacuation est raccorde & la secheuse. Utiliser un

reglage ou il n'y a pas de production de chaleur. Le tambour doit _tre vide et le filtre & charpie propre.

Verifier et nettoyer I'interieur des conduits au moins une fois par an. Debrancher la secheuse ou couper le secteur avant

de proceder au nettoyage. Dans le cas de secheuses & gaz, verifier la conduite de gaz chaque fois que la secheuse est

deplacee.

Verifier frequemment que la hotte d'evacuation s'ouvre et se ferme librement.

Nombre

de coudes

Longueur maximum d'un conduit rigide metallique

Longueur maximum d'un conduit

de 4 po (10,2 cm) de diametre

Type de hotte d'evacuation

& 90°

4 po (10,2 cm) 2 1/2 po (6,4 cm)

de 4 po (10,2 cm) de diametre

0

1

2

3

4

0

1

2

3

4

65 pi (165,1 cm)

54 pi (127,2 cm)

44 pi (111,8 cm)

36 pi (91,4 cm)

28 pi (71,1 cm)

36 pi (91,4 cm)

32 pi (81,3 cm)

28 pi (71,1 cm)

25 pi (63,5 cm)

23 pi (58,4 cm)

1

59 pi (149,9 cm)

48 pi (121,9 cm)

38 pi (96,5 cm)

30 pi (76,2 cm)

22 pi (55,9 cm)

metallique flexible

& parois rigides

28 pi (71,1 cm)

24 pi (60,9 cm)

24 pi (50,8 cm)

17 pi (43,2 cm)

15 pi (38,1 cm)

DES

Page 13

Page 15

INSTALLATIONS SANS CONDUIT D'I_VACUATION

Si la secheuse (modele electrique) n'est pas evacu6e sur I'exterieur, il ne faut pas que I'evacuation aboutisse derriere

celle-ci. Installer un deflecteur rectangulaire ainsi qu'un filet & charpie en dacron (voir sous ,, Accessoires ,,). Maintenir

un espace de degagement de 6 po (15,2 cm) entre I'arriere du tableau de commande et lemur. Bien que le filtre et le

filet & charpie retiennent la plus grande partie de la charpie, une certaine quantite se trouvera evacu6e dans la piece.

ATTENTION : Sl L'I_VACUATION DE LA SI_CHEUSE NE SE FAIT PAS SUR L'EXTI_RIEUR, UNE FINE CHARPIE

SERA I_VACUI_E DANS LA PII_CE. TOUTE ACCUMULATION DE POUSSlI_RE OU DE CHARPIE REPRI_SENTE UN

RISQUE D'INCENDIE. TOUTE ACCUMULATION DE CHARPIE DOlT I_TRE NETTOYI_E FRI_QUEMMENT.

ALIMENTATION EN GAZ

Utiliser uniquement du ga7 naturel ou de petrole liquefi6 (GPL).

L'INSTALLATION DOlT ETRE CONFORME AUX CODES LOCAUX OU, .&.DCFAUT, AU ,, NATIONAL FUEL GAS

CODE _,ANSI Z223.1, DERNI#RE I_DITION (I_TATS-UNIS) OU AUX CODES CAN/AGC-B149 (CANADA).

Les secheuses & gaz sont equip6es d'orifices de brQleurs prevus pour le gaz NATUREL. Si la s_cheuse doit 6tre util-

isle avec du GPL (propane liquide), elle doit 6tre convertie _ ce gaz pour fonctionner correctement et sans danger.

La conversion doit _tre faite par un technicien qualifi& Des necessaires de conversion GAZ NATUREL-GPL ou GPL-

GAZ NATUREL sont disponibles aupres de votre detaillant Maytag (voir sous _,Accessoires ,,). Pour toute autre conver-

sion, obtenir tousles renseignements et specifications necessaires aupres de votre fournisseur de gaz.

Une conduite de gaz de 1/2 po (1,27 cm) est recommandee et elle doit _tre reduite pour pouvoir _tre raccordee & la con-

duite de gaz de 3/8 po (1,0 cm) de la secheuse.

Le ,, National Fuel Gas Code ,>(code du gaz) exige qu'un robinet d'arr_t manuel acceptable et homologue soit installe &

moins de 6 pi (1,83 m) de la secheuse.

Les s_cheuses fonctionnant dans un garage r_sidentiel

doivent _tre surdlevdes de 18 po (46 cm) par rapport au

plancher.

Par ailleurs, une prise & prelevement de 1/8 po (0,3 m) NPT

(National Pipe Thread) doit _tre accessible pour le raccorde-

ment sur un manometre & des fins de test. Cette prise doit _tre

installee immediatement en amont de I'arrivee de gaz & la

secheuse.

La secheuse doit _tre desolidaris6e de la conduite de gaz pen-

dant tout test de pression.

NE PAS reutiliser une ancienne conduite metallique flexible.

Une conduite flexible doit _tre d'une conception homologuee

par I'American Gas Association (CGA/AGC au Canada).

REMARQUE : Toute p&te &joints utilisee doit resister & I'action

de tout gaz de petrole liquefi&

REMARQUE : La plupart des compagnies de gaz locales veri-

fient I'installation d'appareils menagers fonctionnant sur le gaz &

titre gracieux.

ALLUMAGE DU GAZ-

Cette secheuse utilise un systeme d'allumage automatique pour allumer le brQleur. Elle n'a pas de veilleuse.

LA REPUBLIQUE D'INSTRUCTIONS

D'INSTALLATION DE MASSACHUSETTS

Ce gaz plus sec doit _tre installe par un plombier

autorise ou un monteur de gaz UN "T" contr61e la

soupape de gaz manuelle doit _tre installee dans la

ligne de provision de gaz & ce gaz plus sea Si un con-

necteur flexible de gaz est utilise pour installer ce gaz

plus sec, le connecteur doit avoir une Iongueur maxi-

mum de 3 pieds. (36 pouces)

Des fuites de gaz peuvent se produire et aboutir & une

situation dangereuse. Les fuites de gaz ne peuvent

pas _tre detectees simplement & I'odeur. Les four-

nisseurs de gaz recommandent d'acheter et de poser

un detecteur de gaz homologue UL. Le poser et I'utilis-

er conformement aux consignes du fabricant

ALIMENTATION EN I LECTRICITI

REMARQUE : Le schema de c&blage se trouve & I'interieur de la console de commande.

Modeles destines & I'exportation (ni au Canada ou aux €:tats-Unis) : Voir ci-contre les instructions supplementaires pour

les modeles destines & I'exportation.

-&DANGER

DANGER : Pour eviter tout risque inutile d'incendie, d'electrocution ou de blessures, tout le c_blage

et la raise _ la terre doivent 6tre effectu_s conform_ment aux codes Iocaux ou, _ d_faut, au

,, National Electrical Code _,ANSI/NFPA (l"_tats-Unis) ou au Code canadien de I'_lectricit_ ANC

C22.1 (Canada).

Page 14

Page 16

MISE LA TERRE

Cette secheuse doit _tre mise & la terre. En cas de mauvais fonctionnement ou de panne, la mise & la terre reduit les

risques d'electrocution en offrant une voie de moindre resistance au courant electrique.

MODELES GAZ

Cette secheuse est munie d'un cordon comportant un con-

ducteur de mise & la terre et une prise avec borne de terre.

La prise doit _tre branchee sur une prise murale appropriee

correctement installee et reliee & la terre conformement aux

codes et reglements Iocaux.

Ne pas modifier la prise de courant fournie avec la machine.

Si elle ne convient pas & la prise murale, faire installer une prise murale adaptee par un electricien qualifi&

Si les codes Iocaux exigent une mise & la terre separ6e, un necessaire de mise & la terre est disponible (piece no

12001875). II contient un fil de terre, un attache-ills, une vis de mise & la terre et une rondelle. Connecter le fil de terre

au dos de I'appareil & I'aide de la vis de mise & la terre et de la rondelle. Fixer I'autre extremit6 du fil de terre & une con-

nexion de terre externe qui convient. Le fil peut _tre fixe & I'aide d'un attache-ills & un tuyau metallique d'alimentation en

eau FROIDE relie & la terre.

PLASTIQUE, DES CONDUITES DE GAZ OU ,&.UNE ARRIVEE D'EAU CHAUDE.

.DANGER

DANGER : La mauvaise connexion du

conducteur de mise & la terre peut

entrafner des risques d'electrocution.

En cas de doute sur la bonne mise & la

terre de la secheuse, consulter un elec-

tricien ou un r@arateur qualifi&

,E SOO,,EOTE 'EF E SE ETE EA ESOO, UTES E UE,

MODELES I:!:LECTRIQUES

Les modeles electriques americains sont dotes d'une barrette de mise & la terre qui

relie la borne neutre au ch&ssis de la secheuse. Si, cependant, les barrettes de mise

& la terre sont interdites par les codes Iocaux, la secheuse doit 6tre reliee & la terre

conformement aux codes Iocaux.

Si un cordon d'alimentation n'est pas utilise et que la secheuse electrique doit _tre

alimentee en permanence, elle doit _tre branchee sur un c&blage metallique perma-

nent relie & la terre ou bien un conducteur de mise & la terre doit _tre passe avec le_

ills electriques et relie & la borne de terre qui se trouve sur le panneau arriere.

Vis de mise

la terre

CONNEXIONS ELECTRIQUES

AVANT DE FAIRE FONCTIONNER LA SI_CHEUSE OU DE LA TESTER, suivre toutes les instructions de mise & la terre.

II est recommande de brancher la secheuse sur un circuit separ& NE PAS UTILISER DE RALLONGE.

MODELES .&.GAZ - I_tats-Unis et Canada

La secheuse requiert une installation de 120 Vet 60 Hz proteg6e par un fusible de 15 A ou un disjoncteur.

MODI_LES I_LECTRIQUES - I_tats-Unis seulement

La plupart des secheuses destinees au marche americain sont con(_ues pour fonctionner sur une installation homo-

Ioguee de 120/240 V, 60 Hz CA. Certaines fonctionnent sur une installation homologuee de 120/208 V, 60 Hz. Les

normes concernant I'alimentation en electricit6 se trouvent sur I'etiquette apposee & I'avant derriere la porte. II est neces-

saire de poser un fusible de 30 A ou un disjoncteur des deux c6tes de la ligne.

Pour fonctionner sur une installation homologuee de 120/208 V, une secheuse electrique americaine de 120/240 V devra

6tre convertie & ce type d'installation. Un necessaire de conversion de I'el6ment chauffant est disponible (voir sous

_ Accessoires ,_).

Si un cordon d'alimentation est utilise, il doit _tre branche sur une prise murale d'une capacite de 30 A.

Le cordon d'alimentation N'EST PAS fourni pour les modeles commerciaux aux €:tats-Unis.

IMPORTANT : Lorsque les codes Iocaux le permettent, I'alimentation electrique de la secheuse peut _tre assuree au

moyen d'un cordon d'alimentation special pour secheuse homologue UL pour usage sur une installation de 120/240 Vet

30 A minimum, compose de trois ills conducteurs en cuivre de jauge 10 se terminant par une cosse & boucle fermee ou

& griffes ouvertes relevees ou dont les extremites sont etamees.

Ne pas reutiliser de cordon d'alimentation provenant d'une vieille secheuse. Le c&blage d'alimentation electrique du cor-

don doit _tre dote d'une retenue mecanique & bride homologuee UL.

Si la secheuse doit _tre mise en service dans une maison mobile ou une zone ou les codes Iocaux n'autorisent pas la

mise & la terre par le neutre, seul un cordon & 4 ills repondant aux specifications de puissance et termine tel qu'indique

ci-dessus peut _tre utilis&

Page 15

Page 17

MODI_LES I_LECTRIQUES - Canada seulement

La secheuse requiert une installation de 120/240 Vet 60 Hz proteg6e par un fusible de 30 A ou un disjoncteur des deux

c6tes de la ligne.

Tous les modeles canadiens ont un cordon d'alimentation installe en usine. Le cordon d'alimentation doit 6tre branche

sur une prise murale d'une capacite de 30 A.

REMARQUE • II n'est pas permis de convertir une secheuse au 208 V au Canada.

PII_CES DE RECHANGE ET ACCESSOIRES

Si la secheuse requiert des pieces de rechange ou des accessoires, contacter le detaillant ou elle a et6 achetee ou

le Service-clients Maytag, P.O. Box 2370, Cleveland, Tennessee 37320-2370, €:tats-Unis, ou tel6phoner au

423-472-3333 pour connaftre le distributeur de pieces detach6es Maytag agre6 le plus proche.

MISE EN SERVICE

Les pieces et la documentation se trouvent dans le tambour de la secheuse.

Pour effectuer la mise en service...

1.

Mettre la secheuse & un emplacement approprie pour effectuer la mise en service. Lorsque ,_<......._.: .....

la machine & laver et la secheuse sont placees c6te & c6te, il est recommande de faire I'in- &_--F ..............:.;

stallation de la secheuse avant celle de la machine & laver pour permettre le raccordement ' " ......

au gaz et & I'electricit6 ainsi que I'evacuation. ._

Placer les deux montants d'angle en carton & plat sur le plancher, basculer la secheuse vers

I'avant et la coucher de fa(;on & ce qu'elle repose sur les montants.

2. Enlever les fils de retenue fixant la base de la caisse au bas du ch&ssis & I'aide d'un tournevis.

1

Desserrer les vis de blocage des pieds reglables avant et poser les pieds en vinyle.

4.

Redresser la secheuse.

5.

€:tudier la section sur I'evacuation de I'air avant d'effectuer la pose des conduits d'e-

vacuation. Poser les conduits d'evacuation & partir de la secheuse vers la bofte _ F.-_-_-.:

murale. La partie devant _tre inser6e dans I'autre des sections de conduits doit pointer dans _ ___ ! '_.. ---Lq

la direction opposee & celle de la secheuse. NE PAS utiliser de vis & t61e pour I'assemblage -_;'__-_c#,_" _/_[

audesconduits.d,_vacuationAssujettir les raccords & I'aide de ruban adh6sif. Ne jamais utiliser de mat_ri-flexible en plastique..._ -__i

Conseil pour les espaces exigus : Monter le con- _ i_

duit sur la secheuse avant de la mettre en place.

Fixer le conduit sur la secheuse & I'aide de ruban

adhesif en veillant & ne pas couvrir les volets de I

ventilation de la carrosserie de la secheuse.

&DANGER • Une connexion inadequate du conducteur de mise & la terre peut provoquer I'electrocution. Consulter

un electricien ou un reparateur en cas de doute sur la bonne mise & la terre de la machine. Ne pas

modifier la prise de courant fournie avec la machine. Si elle ne convient pas & la prise murale, faire

installer une prise murale adaptee par un electricien qualifi&

• Pour eviter tout risque inutile d'incendie, d'electrocution ou de blessure, tous branchements et mises &

la terre doivent _tre conformes au ,, National Electrical Code ,, ANSI/NFPA n° 70, derniere edition

d

(€:tats-Unis), ou au Code canadien de I'electricit6 ANC C22.1, derniere edition, ainsi qu'aux codes et reglements

Iocaux. La responsabilite et le devoir de prevoir une alimentation electrique adequate pour cette secheuse reviennent

au proprietaire.

• L'installation du gaz doit _tre conforme au ,_National Fuel Gas Code ,, ANSI Z223.1, derniere edition, (€:tats-Unis) ou

aux codes CAN/AGC-B149, derniere edition, (Canada) ainsi qu'aux codes et reglements Iocaux.

Page 16

Page 18

1

Revoir la section sur I'installation de gaz.

Enlever le manchon protecteur du filetage.

Enduire tous les filetages de p&te A joints ou les couvrir d'environ un tour et demi de ruban en Teflon.

REMARQUE • La p&te A joints doit _tre prevue pour resister A I'action de tout gaz de petrole liquefi&

Raccorder la secheuse A la conduite de gaz. Un raccord supplementaire est necessaire pour visser

I'extremit6 femelle de 3/4 po (1,9 cm) d'un connecteur flexible sur I'extremit6 m&le de 3/8 po (1,0 cm)

de la secheuse. Bien serrer les raccords de la conduite de gaz.

Ouvrir I'arrivee de gaz. Verifier qu'aucun des raccords ne fuit A I'aide d'une solution de savon et

d'eau. Si des bulles apparaissent, resserrer les raccords et reverifier. NE PAS utiliser une flamme

nue pour v_rifier les fuites de gaz.

1

Revoir la section sur I'installation electrique.

AVANT D'UTILISER LA SC:CHEUSE OU DE VERIFIER SON FONCTIONNEMENT, observer les consignes de

mise & la terre de la section Mise & la terre.

MODELES AMERICAINS :

IMPORTANT : Tousles modeles americains sont con_us pour une CONNEXION ,_ 3

FILS. Le ch&ssis de la secheuse est relie au conducteur neutre au niveau du bornier. _ du bornier

Une CONNEXION ,_ 4 FILS est necessaire pour une construction neuve ou renov6e, une

maison mobile, ou si les codes Iocaux ne permettent pas la mise A la terre par le conduc-

teur neutre. Si un systeme A4 ills est utilis& le ch&ssis de la secheuse ne peut _tre relie •

au conducteur neutre au niveau du bornier. Voir les instructions suivantes concernant les e

CONNEXIONS ,_ 3 ET ,_ 4 FILS.

Enlever les couvercles du bornier.

Inserer le cordon d'alimentation equip6 d'une retenue mecanique & bride homologuee UL & travers le trou prevu &

cet effet dans la carrosserie pres du bornier. REMARQUE : Une retenue m_canique _ bride doit 6tre utilis_e.

Ne pas desserrer les ecrous dej& installes sur le bornier. S'assurer qu'il sont bien serres. Utiliser une douille d'une

profondeur de 3/8 po (1,0 cm).

CONNEXIONS .&,3 FILS

Si le cordon d'alimentation est muni de bornes, placer celles-ci

sur les ecrous se trouvant sur la borne. Le fil neutre (fil blanc ou

fil situe au centre du cordon d'alimentation) doit toujours _tre

relie & la borne centrale (de couleur argent) du bornier.

Fixer en place avec les ecrous compris dans le necessaire de

pieces. Si le cordon d'alimentation n'est pas muni de bornes,

utiliser des rondelles avant les ecrous.

S'assurer que les ecrous du bornier sont bien serres. Fixer le

cordon d'alimentation en place. Serrer les vis de la retenue

mecanique &bride pour fixer celle-ci au cordon.

Remettre le couvercle du bornier en place.

DANGER • En cas de conversion d'un systeme & 4 ills & un sys-

teme & 3 ills, la barrette de mise & la terre doit _tre reconnectee

au support du bornier pour mettre le ch&ssis de la secheuse & la

masse sur le neutre.

Borne

neutre

@

Systeme a 3 fils

o

/& la terre

@

Conducteur

_ / I//,_ &bride

de mise

neutre

Barrette

Page 17

Page 19

CONNEXIONS A 4 FILS

Enlever la barrette de mise & la terre du support du bornier. La

plier de fagon & ce que les deux extremit6s soient fixees & la

borne centrale du bornier.

Raccorder le conducteur neutre (blanc) du cordon & la borne

centrale (couleur argent) du bornier. Raccorder le fil (vert) de

mise & la terre du cordon au support du bornier & I'aide de la vis

de la barrette de mise & la terre.

Raccorder les fils rouge et noir du cordon aux bornes des deux

extremit6s du bornier.

Veiller & ce que les ecrous du bornier soient bien serres. Fixer le

cordon d'alimentation en place. Serrer le(s) vis de la retenue

mecanique &bride de fa(_on& serrer la bride sur le cordon.

Remettre le couvercle du bornier en place.

MODELES DESTIN¢:S .&.L'EXPORTATION

Consulter la section ,, Informations complementaires ,_,

7. ,&,I'aide d'un niveau, verifier que la secheuse est de niveau et

ajuster les pieds reglables comme il convient. Une fois la

secheuse de niveau, serrer les contre-ecrous des pieds

reglables & I'aide d'une cl&

Borne \\

neutre _'_" _y

VCA o &_ride

Systeme a 4 fils avec

cordon d'alimentation

en place

0

Barrette

de mise &

/ la terre

repli6e

@

Conducteul

I neutre

1

La direction d'ouverture de la porte de la secheuse peut

_tre inversee.

1. Si la secheuse est branchee, la debrancher du secteur.

2. Enlever les obturateurs des orifices pour charnieres et les ..........

vis. Deplacer I'obturateur du Ioquet de I'autre c6t& ------- ....

3. Tout en tenant la porte, enlever les 2 vis qui se trouvent

dans les charnieres et les fixent & la carrosserie.

4. Enlever la porte en la soulevant legerement au niveau des charnieres et en enlevant les languettes des

charnieres de leurs fentes en tirant.

5. Faire passer les pieces suivantes du c6te oppose de la porte : 2 charnieres et leurs 4 vis, 4 vis de la porte,

g&che du Ioquet de la porte et sa vis, plaque d'habillage de I'interieur de la porte et sa vis.

6. Monter la porte du c6te oppose a I'aide des deux visa charnieres a t_te fraisee. (Voir ci-dessous.)

7. Si la vis de la charniere inferieure est inser6e en place la premiere, il sera plus facile d'aligner la porte et les

charnieres.

8. Remettre les obturateurs des orifices pour charnieres et les vis en place du c6te oppos&

Obturateur de G&che du verrou de la porte _7

I'orifice

i tl#

i t .- .... .

b

:/..°

i

,s,,

i I

i I F l_

i_ i I Ji

ijIi i i

i I i i

I !

la porte

i

i

Vis &t_te

frais_e

Page 18

Page 20

1

,_ ce point, s'assurer que le raccordement au gaz (modeles & gaz), I'evacuation et le raccordement & I'electricit6

sont completement termines. Brancher la secheuse et verifier son fonctionnement & I'aide de la liste de verifica-

tion ci-dessous.

10. (MODC:LES ,_ GAZ SEULEMENT)

Le brQleur peut ne pas s'allumer au depart en raison de la presence d'air dans la conduite de gaz. Faire tourner la

secheuse sur un cycle ou il y a production de chaleur pour eliminer Fair de la conduite. Si le brQleur ne s'allume pas

dans les 5 minutes, arr6ter la secheuse et attendre 5 minutes. Verifier que I'arrivee de gaz A la secheuse est

ouverte. Confirmer que le brQleur est allume en s'assurant qu'il y a production de chaleur au niveau de I'evacuation.

LISTE DE VITRIFICATION FINALE

La secheuse est branchee dans une prise electrique et elle est correctement reliee A la terre. REMARQUE : la

premiere lois que la machine est mise en marche, un code - PF ,>sera affiche. Ceci est normal et peut 6tre

reinitialis6 en appuyant sur n'importe quelle touche.

Le raccordement de la conduite d'evacuation est effectue et les joints sont recouverts de ruban adhesif.

Absence de conduits flexibles en plastique.

Utilisation de conduits rigides ou de conduits flexibles A parois rigides pour I'evacuation.

La secheuse est de niveau, elle repose fermement sur ses quatre pieds et les contre-ecrous des pieds reglables

sont bien serres.

Les embouts en vinyle des pieds ont et6 poses.

Modeles A gaz : le gaz est ouvert, il n'y a pas de fuites de gaz.

La secheuse tourne, produit de la chaleur et s'eteint.

Demontrer le fonctionnement de la secheuse A I'utilisateur.

ACCESSOIRES D'INSTALLATIONS COMMERCIALES

• Hotte de ventilation - ouverture de 4 po (10,16 cm) - 059129

• Tuyau en aluminium - 4 x 24 po (10,16 cm x 60,96 cm) - 059130

• Coude en aluminium - 4 po (10,16 cm) - 059131

• Plaque de fen6tre en aluminium - 15 x 20 po (38,10 cm x 50,80 cm) - ouverture de 4 po (10,16 cm) - 059134

• Conduite d'aeration en aluminium flexible - 4 po (10,16 cm) de diametre - 38 po (81,28 cm) pouvant s'etirer jusqu'A

8 pi (2,44 cm) - 304353

• Pince pour conduite en aluminium flexible - 304630

• Necessaire de conduite pour base ou evacuation du c6te gauche - 12001453

• Necessaires d'aeration rectangulaires - 059144

• Filet A charpie en Dacron - 311353

• Necessaire de conversion du gaz NATUREL au GPL - 306195

• Necessaire de conversion du GPL au gaz NATUREL - 306204

• Necessaire de support de pivot - 303740

• Necessaire de conversion de la resistance 208 V, non homologue au Canada - 308590

• Necessaire de mise A la terre - 12001875

• Cordons d'alimentation - 240 V, 30 A

4pi 121,9cm 3

5pi 152,4cm 3

6 pi 182,9 cm 3

10 pi 304,8 cm 3

4pi 121,9cm 4

5pi 152,4cm 4

6 pi 182,9 cm 4

lOpi 304,8cm 4

fils - 33001780

fils - 33001822

fils - 33001823

fils - 33001838

fils - 33001781

fils - 33001824

fils - 33001825

fils - 33001838

Les non-voyants peuvent apposer des etiquettes en Braille sur le panneau de commande de I'appareil. Consulter

votre Association locale des non-voyants pour de plus amples renseignements concernant les fabricants d'etiquettes

en Braille.

Page 19

Page 21

(ni aux I tats-Unis ni au Canada)

Communiquer avec le distributeur qui a vendu I'appareil ou avec : Maytag International, 8700 W. Bryn Mawr Avenue,

Chicago, Illinois 60631 €:tats-Unis, tel6phone, 773-714-0100, pour route information concernant le produit, les dommages

attribuables & I'expedition, les pieces de rechange et les accessoires.

Les modeles de secheuse Maytag fabriques pour fonctionner sur une alimentation en 60 Hz CA ne sont pas con£us pour

fonctionner sur une alimentation en 50 Hz CA et leur conversion du 60 Hz au 50 Hz est deconseill6e. Pour plus de ren-

seignements sur les appareils fonctionnant sur le 50 Hz, communiquer avec Maytag International.

Les normes d'installation electrique peuvent _tre consultees sur I'etiquette se trouvant &I'avant de la secheuse, derriere

la porte.

MODI_LES I_LECTRIQUES DESTINIES A L'EXPORTATION

Les modeles electriques destines &I'exportation sont fabriques pour fonctionner sur une alimentation approuvee de

230/240 V, 50 Hz ou 220 V, 60 Hz. Une alimentation electrique bifilaire avec fusible de 30 A ou disjoncteur est neces-

saire. La secheuse doit 6tre reliee correctement & la terre avec un fil de mise & la terre.

IMPORTANT : Lorsque les codes Iocaux le permettent, I'alimentation electrique de la secheuse peut 6tre assuree au

moyen d'un cordon d'alimentation special pour secheuse homologue UL pour usage sur une installation de 240 Vet 30 A

minimum et compose de deux fils conducteurs en cuivre de jauge 10 se terminant par une cosse & boucle fermee ou &

griffes ouvertes relevees ou dont les extremites sont etamees.

Ne pas reutiliser de cordon d'alimentation provenant d'une vieille secheuse. Le c&blage d'alimentation electrique du cor-

don doit _tre dote d'une retenue mecanique & bride homologuee par

un organisme appropri&

CONNEXIONS DU SYSTI ME DE MISE A LA TERRE A

2 FILS

Enlever la plaque du bornier.

Passer le cordon d'alimentation avec retenue mecanique & bride

homologue dans le trou se trouvant pres du bornier. Prendre note

qu'une retenue m_canique _ bride doit _tre utilis_e.

Ne pas desserrer les ecrous dej& installes sur le bornier. S'assurer

qu'il sont bien serres. Utiliser une douille de 3/8 (1,0 cm).

Fixer le fil de mise & la terre du cordon d'alimentation au support du

bornier & I'aide de la vis de mise & la terre.

Si le cordon d'alimentation est muni de bornes, placer celles-ci sur

les ecrous se trouvant sur les bornes. Le fil neutre du cordon d'ali-

mentation doit _tre relie & la borne centrale (de couleur argent) du

bornier.

Conducteur'

Systeme de mise a la terre a 2 fils

Borne

neutre

neutre

Cordon

d'alimentation

avec

retenue

mecanique

_,_ / a bride

Fil de mise

la terre du

cordon

Fixer en place avec les ecrous compris dans le necessaire de

pieces. Si le cordon d'alimentation n'est pas muni de bornes, utiliser les rondelles bombees avant les ecrous.

S'assurer que les ecrous du bornier sont bien serres. Fixer le cordon d'alimentation en place. Serrer la ou les vis de la

retenue mecanique & bride pour la fixer au cordon.

Remettre le couvercle du bornier en place.

AVANT DE TESTER OU DE FAIRE FONCTIONNER LA MACHINE, s'assurer qu'elle est correctement mise & la terre.

MODI_LES A GAZ DESTINIES A L'EXPORTATION

Les modeles & gaz destines & I'exportation sont con_us pour fonctionner sur une alimentation homologuee de 230/240 V,

50 Hz ou 220 V, 60 Hz CA, avec un fusible de 15 A ou un disjoncteur.

Les modeles & gaz destines & I'exportation ont ere congus pour fonctionner sur un gaz naturel dont la puissance de

chauffage la plus elevee est d'environ 1025 BTU/pP (38 190 kJ/ms) La conversion au propane liquide dont la puissance

de chauffage la plus elevee est d'environ 2 500 BTU/pP (93 147 kJ/m_)doit _tre effectuee par un technicien qualifi& Un

necessaire de conversion est disponible.

Page 20

Page 22

Lea esto antes de comenzar...

Herramientas necesarias para la instalacion

• Cinta de tefl6n o compuesto

para juntas de tubos (gas

solamente)

• Navaja de uso general

• Llave inglesa (gas solamente)

• Llave de tuercas

• Nivel

• Desarmador (estbndar)

• Cinta para tubos

• Llave ajustable

El comprador es responsable de la instalacibn correcta de la lavadora.

NO OBSTANTE, LAS LLAMADAS DE SERVICIO EFECTUADAS COMO CONSECUENCIA DE UNA INSTALACION

DEFICIENTE SON RESPONSABILIDAD DEL INSTALADOR.

Asegurese de tener todo Io necesario para una instalaci6n apropiada.

1. Se requiere una TOMA DE CORRIENTE CONECTADA A TIERRA. Vea los requisitos de electricidad.

2. CABLE ELECTRICO para secadoras electricas (excepto CanadA).

3. LfNEAS DE GAS (si es secadora de gas) deben hacerse de acuerdo con los c6digos nacional y locales.

4. SISTEMA DE ESCAPE - utilice tuberfa de escape de metal rfgido o flexible con pared rfgida. Consulte los

Requerimientos de escape en esta secci6n.

PIEZAS SUMINISTRADAS

@@

@

Secadora el_ctrica

solamente

@@

@

Secadora de

gas solamente

_ 3/4 pulgada

(1,9 cm)

T

43 1/4

pulgadas

(109,9 cm)

minimo

36 1/4

pulgadas

(92,1 cm)

minimo

3/8 pulgada --_

1

1 1/2 pulgadas

(3,81 cm)

INFORMACION IMPORTANTE PARA EL INSTALADOR

SIRVASE LEER LAS SIGUIENTES INSTRUCCIONES CON CUIDADO ANTES DE COMENZAR A INSTALAR LA

LAVADORA. ESTAS INSTRUCCIONES DEBEN CONSERVARSE PARA REFERENCIA FUTURA.

QUITE LAS PUERTAS DE TODOS LOS APARATOS DESECHADOS PARA EVITAR EL PELIGRO DE QUE ALGIJN

NINO SE ASFIXIE.

6 13/16 pulgadas de Bajo

(17,3 cm)

( 27 1/2 pulgadas

Escape

(69,9 cm)

(1 cm) minima

t

22 1/4 pulgadas

4._ (65,5 cm) "-_

3 5/8

pulgadas

(9,2 cm)

J __

16 pulgadas _

(40,6 cm)

f

T 2 7/16

Tuberia

de gas

pulgadas

(6,2 cm)

t

3 7/16

pulgadas

(8,7 cm)

'_ | 3 1/4 pulgadas Escape

I_- (8,3 cm) I de Bajo

4.- 13 1/2 pulgadas

I _ (34,3 cm) 27 pulgadas),.

"Fq

&-----.-&

[EEEE[EE E

[[[[[[

,..J L.

(68,9 cm)

Page 21

Page 23

CONSIDERACIONES DE UBICACION

Esta secadora debe colocarse de manera que quede suficiente espacio al frente para cargar la secadora, y suficiente

espacio detras de la lavadora para el sistema de escape.

Esta secadora tiene un escape posterior adaptado de fAbrica. Para cambiar el escape por abajo o por el lado izquierdo,

use el juego de accesorios de escape (vea Accesorios). Las instrucciones se incluyen con el juego.

Es importante asegurarse de que el cuarto cuente con ventilacion adecuada. El Area donde se coloque la secadora no

debe obstruir el flujo de combustion ni el aire de ventilacion.

En las secadoras de gas debe haber un espacio libre adecuado segun aparece en la placa de datos para asegurar la

cantidad adecuada de aire y asegurarse de que haya suficiente aire para la combustion y el funcionamiento correcto de

la secadora.

LA SECADORA NO DEBE INSTALARSE NI ALMACENARSE EN UN D,REA EN DONDE ESTARD, EXPUESTAAL AGUA

Y/O A LA INTEMPERIE. EL/_,REA DE LA SECADORA DEBE MANTENERSE LIMPIAY LIBRE DE MATERIALES COM-

BUSTIBLES, GASOLINA Y OTROS VAPORES Y L[QUIDOS INFLAMABLES. LA SECADORA PRODUCE PELUSA

COMBUSTIBLE. EL/_,REAALREDEDOR DE LA SECADORA DEBE MANTENERSE LIBRE DE PELUSA.

INSTALACION EN CUARTOS DE LAVADO O EN HUECOS

El cuarto de lavado en donde este instalado un aparato no debe tener otro aparato

que use combustible, instalado allf mismo.

Toda abertura en la puerta debe tener un mfnimo de 36 pulgadas cuadradas

(91,4 cm). Estas aberturas no deben estar obstruidas. (Las puertas con rejillas que

tengan aberturas equivalentes son aceptables.)

PUERTA DEL CUARTO DE LAVADO

,\

}.

_ulgadas

m 36

36

cuadradas

(91,4 cm)

pulgadas

cuadradas

(91,4cm)

Espacios libres mfnimos de instalacion. Se

recomienda mas espacio libre, si es posible.

0

(oc_

VISTA FRONTAL

OO

_-17

pulgadas

43,2cm)

o

_ ,#_crn)

F_ i

_l b_-- 2 pulgadas

(5,1 cm)

VISTA LATERAL

3 ]_

pulgad_

(7,6cml

,__0"

3 pulgadas

(7,6 cm)

ADVERTENCIA -

La secadora debe

tener un escape

hacia afuera para

reducir el riesgo

de incendio cuan-

do se instale en un cuarto de

lavado o en un hueco.

INSTALACION EN CASAS MOVILES

La instalacion de la secadora en casas moviles debe estar en conformidad con el tftulo 24 CFR, Parte 32-80, de las nor-

mas de construccion y seguridad de casas (previamente conocida como el tftulo 24, HUD [Parte 280] de las normas fed-

erales para la construccion y la seguridad de casas moviles, 1975) para los Estados Unidos, o las normas CSA Z240

para CanadA.

Cuando instale una secadora en una casa movil, deben tomarse medidas para anclar la secadora al piso. Se encuentra

disponible un juego de soporte de anclaje con instrucciones (vea Accesorios). Coloquela en un Area que tenga venti-

lacion adecuada. Se requiere un mfnimo de 25 pulgadas cuadradas (63,5 cm) de abertura sin obstrucciones.

Toda instalacion en casas moviles debe tener el escape hacia afuera con la terminacion firmemente sujeta a la estruc-

tura de la casa movil, usando materiales que no favorezcan la combustion. El ducto de escape no debe terminar debajo

de la casa movil. Vea la seccion sobre escape para obtener mas informaci6n.

Page 22

Page 24

ESCAPE

El escape de la secadora hacia afuera es obligatorio para evitar que se esparzan grandes cantidades de humedad y de

pelusa en el cuarto.

En Estados Unidos:

° todas las secadoras de gas deben tener el escape hacia afuera.

° las secadoras eldctricas ubicadas en Areas confinadas tales como una recamara, un ba6o, o un cuarto de

lavado deben tener el escape hacia afuera.

° las secadoras eldctricas que no estan ubicadas en un Area confinada pueden tener el escape hacia adentro

(vea instalaciones sin escape).

En CanadA:

° todas las secadoras de gas y eldctricas deben tener el escape hacia afuera.

Fuera de EE.UU. y CanadA:

° consulte los cbdigos locales.

-_ADVERTENCIA

El ducto de plastico flexible se puede doblar, ablandar o agu-

jerar. Tambien puede reducir el flujo de aire de salida, alargar

el tiempo de secado o en general afectar la operaci6n total

de secado.

USE UN TUBO DE ALUMINIO RfGIDO CON UN DIAMETRO

MiNIMO DE 4 PULGADAS (10,2 CM) O DE ACERO GALVA-

NIZADO RfGIDO. No use un ducto mas peque6o. Los tubos

con un diametro mayor de 4 pulgadas (10,2 cm) pueden pro-

ducir una mayor acumulacion de pelusa. Es preciso que

limpie periodicamente la acumulacion de pelusa. Si es nece-

sario utilizar un tubo de metal flexible, es preferible que util-

ice el tipo de tubo que tenga una pared metalica rigid& No

use un ducto flexible con una pared de hoja metalica delga-

da. Se puede producir un bloqueo severo si el ducto metalico

flexible se dobla demasiado. Nunca instale ningun tipo de

ducto flexible en paredes, techos u otros espacios ocultos.

Mantenga los tubos del escape Io mas derechos y cortos

posible. Los sistemas de escape mas largos de Io recomen-

dado pueden aumentar los tiempos de secado, afectar el fun-

cionamiento de la secadora y acumular pelusa. Asegure las

uniones con cinta para tuberias. No utilice tornillos.

NO DIRIJA EL ESCAPE DE LA SECADORA HACIA LA

PARED, EL TECHO, LOS ESPAClOS ANGOSTOS, NI LOS