Commercial

Multi-Load

Dryers

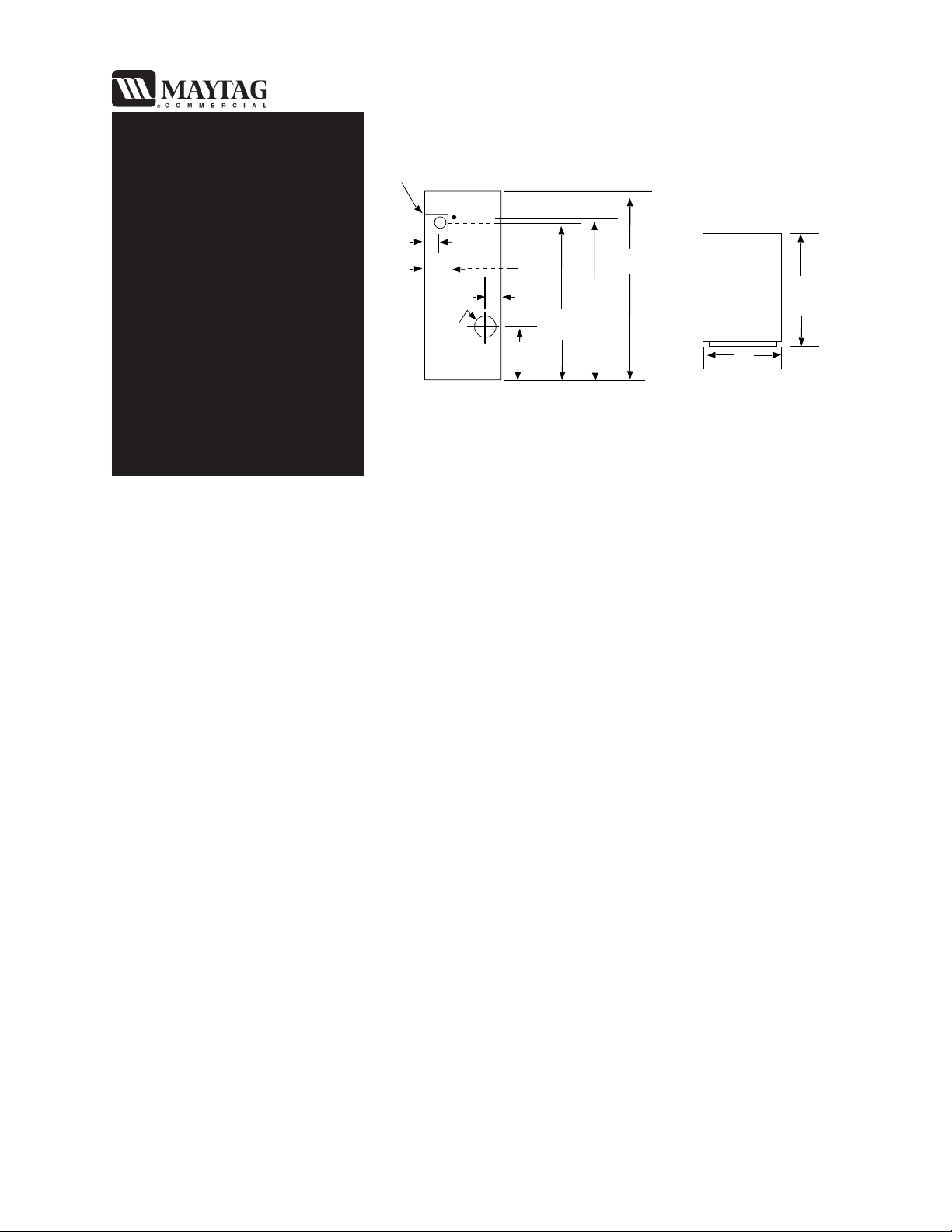

PRODUCT DIMENSIONS

ELECTRICAL CONN.

GAS INLET

Models

MDG30MC2

MDG30PC2

MDG30PNA

MDG30MNA

6"

15.2 cm

8"

20.3 cm

EXHAUST

DIAMETER

11 1/2"

29.2 cm

6"

15.2 cm

20 1/4"

51.4 cm

62 1/2"

158.8 cm

63"

160 cm

72"

182.9 cm

43"

109.2 CM

31 3/8"

79.7 cm

REAR VIEW TOP VIEW

PRODUCT SPECIFICATIONS

• Drive motor: 1/2 H.P. (.373 Kw)

• Air flow: 600 cubic feet (17 cubic meters) per minute.

• Amperage Draw: 9.8 amps (approximate).

• Heat source: 90,000 BTU/Hr. (22,680 kcal/hr.).

• Flush to side wall installation possible, 24" rear clearance suggested for ease of maintenance.

• Tumbler Capacity: 12.3 cu. ft. (.348 cu.m.)

• Tumbler Diameter: 30" (76.2 cm)

• Tumbler Depth: 30" (76.2 cm)

• Door Opening: 21 1/2" Dia. (54.61 cm)

• Weight: Crated: 550 lbs. (250 Kg)

Uncrated: 500 lbs. (227 Kg)

• Gas Inlet 1/2" I.D.

ELECTRICAL REQUIREMENTS

• 120 volts, 60 Hz single phase, (some 240 volts, 50 Hz models available for export).

• Individual branch circuit serving only the dryer is recommended.

• Minimum wire size required, awg. 12 with a 20 amp fuse or comparable circuit breaker. Copper

wire only.

• Dryer must be installed and grounded in accordance with National Electrical Codes and local

codes and ordinances.

COMMERCIAL MULTI LOAD DRYERS - MDG30, MC2, PC2, PNA, and MNA

6-107/02

EXHAUST REQUIREMENTS

Exhaust duct work should be designed and installed by a qualified professional. Improperly sized duct work will

create excessive back pressure which results in slow drying, increased use of energy, and shutdown of the burner by the

airflow (sail) switch, burner hi-limit chamber hi-heat protector thermostat.

Where possible, it is suggested to provide a separate (single) exhaust duct for each dryer.

CAUTION: IMPROPERLY SIZED OR INSTALLED EXHAUST DUCT WORK CAN

CREATE A POTENTIAL FIRE HAZARD.

CAUTION: DRYER MUST BE EXHAUSTED TO THE OUTDOORS.

The exhaust duct work should be laid out in such a way that the work travels as directly as possible to the outdoors with

as few turns as possible. The shape of the duct work

provided. Single or independent dryer venting is recommended.

is not critical so long as the minimum cross section area is

It is suggested that the use of 90° turns

The duct work should be smooth inside with no projections from sheet metal screws or other obstructions which will

collect lint. When adding ducts, the ducts to be added should overlap the duct which it is connected. ALL duct work

joints must be taped to prevent moisture and lint from escaping into the building. Additionally, inspection doors

should be installed at strategic points in the exhaust duct work for periodic inspection and cleaning.

IMPORTANT: When connecting duct work to the dryer exhaust duct, be sure that when screws are

used they

do not restrict the operation (both opening and closing) of the damper.

be avoided; use 30° or 45° angles instead.

NOTE: When the exhaust duct passes through a wall, ceiling, or roof made of combustible materials,

the opening must be 2-inches larger (all the way around) than the duct. The duct must be

centered within this opening.

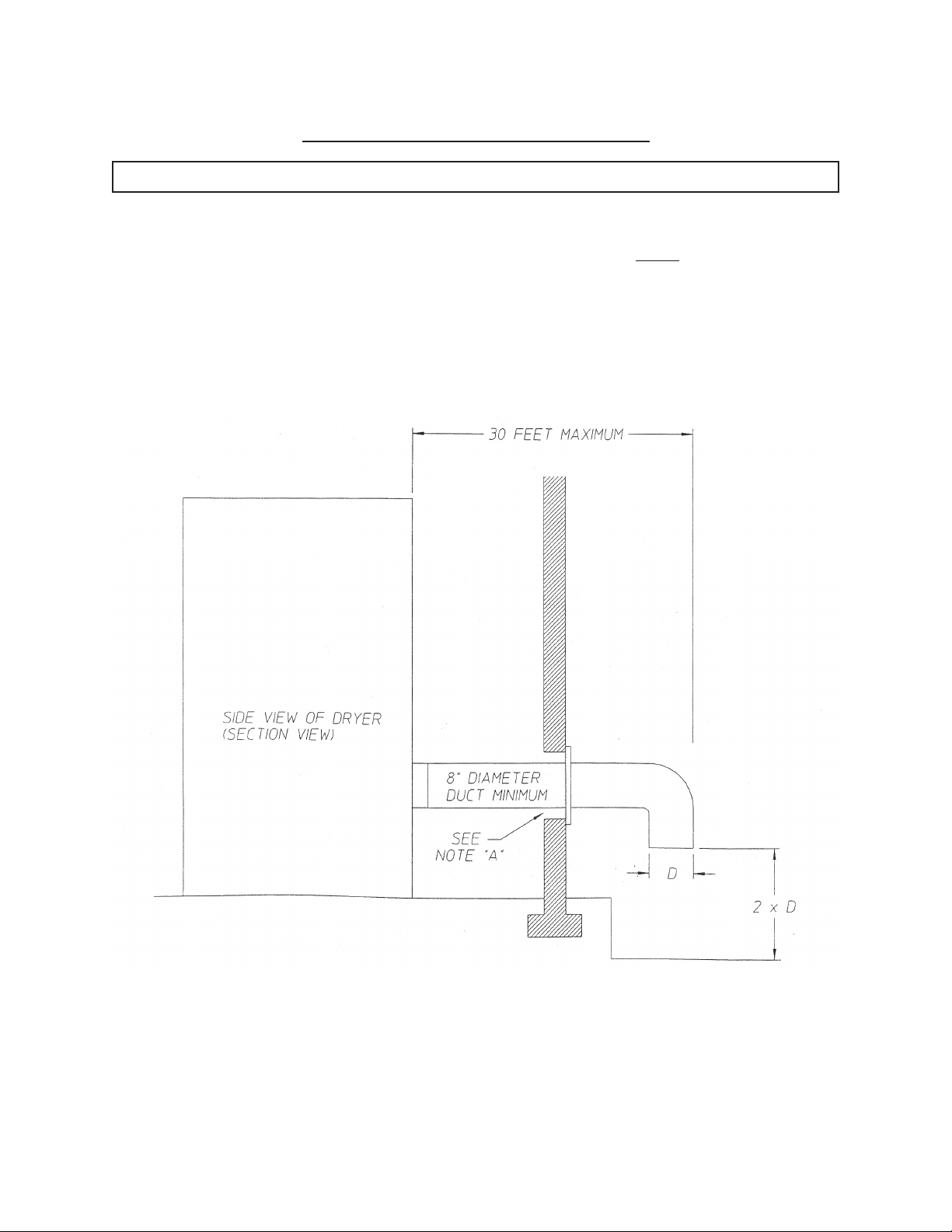

To protect the outside end of horizontal duct work from the weather, a 90° elbow bent downward should be installed

where the exhaust exits the building. If the duct work travels vertically up though the roof, it should be protected from

the weather by using a 180° turn to point the opening downward. In either case, allow at least twice the diameter of the

duct between the duct opening and the nearest obstruction (i.e., roof of ground level).

IMPORTANT: DO NOT use screens or caps on the outside of opening of exhaust duct work.

IMPORTANT: Exhaust back pressure measured by a manometer at the dryer exhaust are must not

exceed 0.3 inches of water column (W.C.)

COMMERCIAL MULTI LOAD DRYERS - MDG30, MC2, PC2, PNA, and MNA

6-207/02

SINGLE DRYER VENTING

IMPORTANT: For exhaust duct runs over 30 feet a minimum diameter size of 10 inches must be used

HORIZONTAL VENTING

When horizontal single 8-inch venting is used, the duct work to the outlet cannot

below). This calculation of 30 feet compensates or allows for the use of a maximum of only one (1) elbow.

REMINDER - Stay below 0.3” WC back pressure.

Illus. A

exceed 30 feet (refer to Illus. A

HORIZONTAL SINGLE DRYER

VENTING 8 INCH DUCTING

NOTE A. OPENING MUST BE TWO (2) INCHES LARGER THAN THE DUCT (ALL THE

WAY AROUND). THE DUCT MUST BE CENTERED WITHIN THIS OPENING.

6-307/02COMMERCIAL MULTI LOAD DRYERS - MDG30, MC2, PC2, PNA, and MNA

Loading...

Loading...