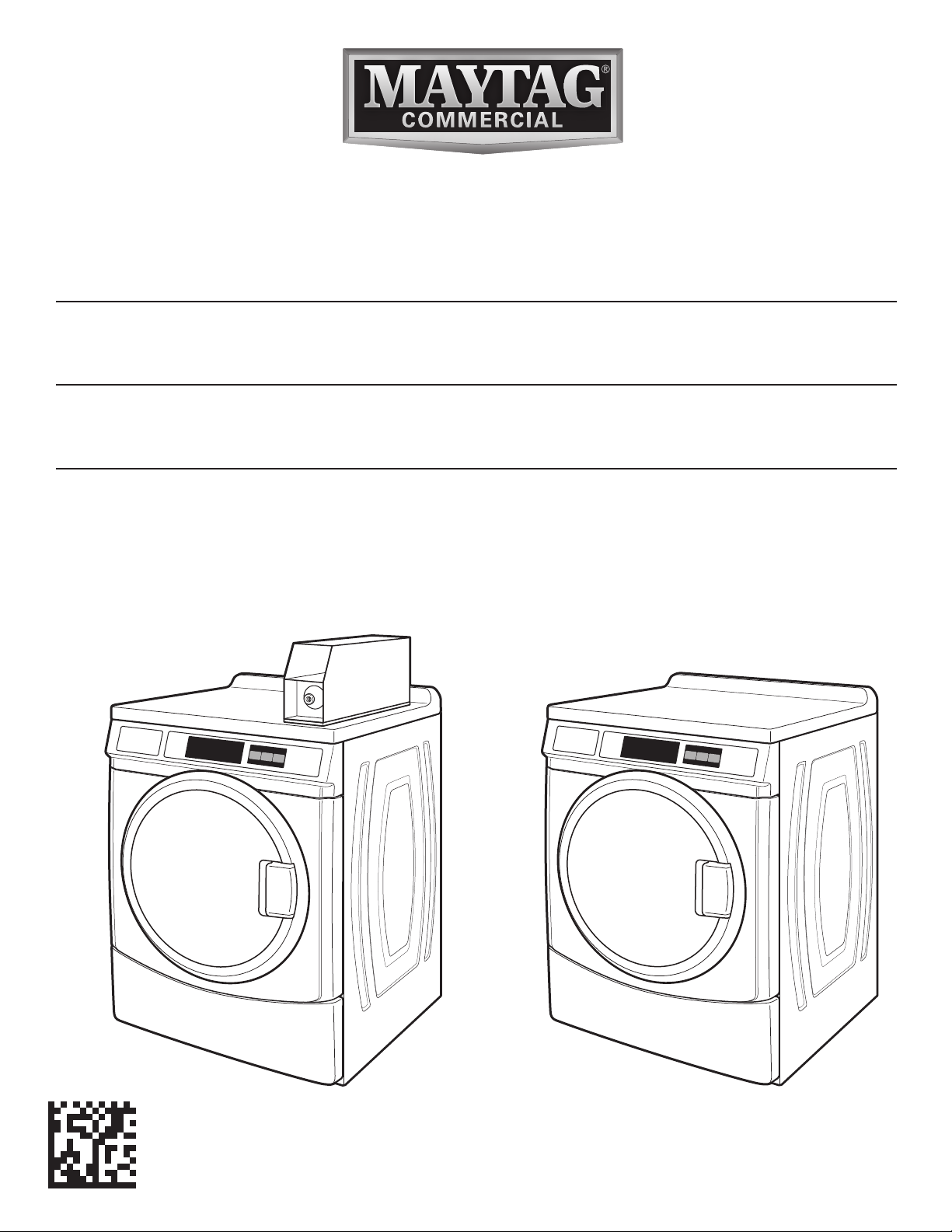

INSTALLATION INSTRUCTIONS

COMMERCIAL DRYER – GAS OR ELECTRIC

INSTRUCTIONS D’INSTALLATION

SÉCHEUSE COMMERCIALE – À GAZ OU ÉLECTRIQUE

Table of Contents/Table des matières ................................................................................ 2

www.maytagcommerciallaundry.com

W11311968A

TABLE OF CONTENTS

TABLE DES MATIÈRES

DRYER SAFETY .......................................................................... 2

INSTALLATION REQUIREMENTS ............................................. 5

Tools and Parts ......................................................................... 5

Location Requirements ............................................................. 6

Electrical Requirements ............................................................ 7

Gas Supply Requirements ..................................................... 10

Venting Requirements ........................................................... 11

Leveling .................................................................................. 13

INSTALLATION INSTRUCTIONS – GAS DRYER ................. 14

Make Gas Connection ............................................................. 14

Gas Supply Line ....................................................................... 14

Connect Vent ........................................................................... 15

Complete Installation .............................................................. 15

INSTALLATION INSTRUCTIONS – ELECTRIC DRYER ...... 16

Power Supply Cord (U.S.A. Only) ........................................... 16

Direct Wire Method (U.S.A. Only) ............................................ 20

Connect Vent ........................................................................... 23

Complete Installation .............................................................. 23

REVERSING THE DOOR SWING .......................................... 24

Remove the Door Assembly ................................................... 24

Reverse Hinge ......................................................................... 24

Reverse The Strike .................................................................. 25

Reinstall The Door .................................................................. 25

MAINTENANCE INSTRUCTIONS ......................................... 25

ELECTRONIC CONTROL SETUP ......................................... 26

WARRANTY ............................................................................ 30

SÉCURITÉ DE LA SÉCHEUSE .................................................. 31

EXIGENCES D’INSTALLATION ................................................. 34

Outils et pièces ........................................................................ 34

Exigences d’emplacement ...................................................... 35

Spécifications électriques ........................................................ 36

Spécifications de l’alimentation en gaz ................................... 39

Exigences concernant l’évacuation ......................................... 40

Nivellement............................................................................... 42

INSTRUCTIONS D’INSTALLATION – SÉCHEUSE À GAZ ...... 43

Raccordement au gaz ............................................................. 43

Canalisation d’alimentation en gaz ......................................... 43

Raccordement du conduit d’évacuation ................................. 44

Fin de l’installation ................................................................... 44

INSTRUCTIONS D’INSTALLATION – SÉCHEUSE

ÉLECTRIQUE .............................................................................. 45

Cordon d’alimentation (É.-U. seulement) ................................ 45

Méthode de raccordement direct (É.-U. seulement) .............. 49

Raccordement du conduit d’évacuation ................................. 52

Fin de l’installation ................................................................... 52

INVERSION DU SENS D’OUVERTURE DE LA PORTE .......... 53

Retrait de la porte .................................................................... 53

Inversion de la charnière.......................................................... 53

Inversion de la gâche ............................................................... 54

Réinstallation de la porte ......................................................... 54

INSTRUCTIONS D’ENTRETIEN ................................................ 55

RÉGLAGE DE LA CARTE DE CIRCUITS ÉLECTRONIQUE ... 55

GARANTIE ................................................................................... 60

DRYER SAFETY

■ It is recommended that the owner post, in a prominent location, instructions for the customer’s use in the event the customer smells

gas. This information should be obtained from your gas supplier.

■ Post the following warning in a prominent location.

2

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death or property

damage.

–

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

–

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Clear the room, building, or area of all occupants.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

•

instructions.

If you cannot reach your gas supplier, call the fire department.

•

–

Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

3

In the State of Massachusetts, the following installation instructions apply:

■ Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gas fitter qualified or licensed by

the State of Massachusetts.

■ Acceptable Shut-off Devices: Gas Cocks and Ball Valves installed for use shall be listed.

■ A flexible gas connector, when used, must not exceed 4 feet (121.9 cm).

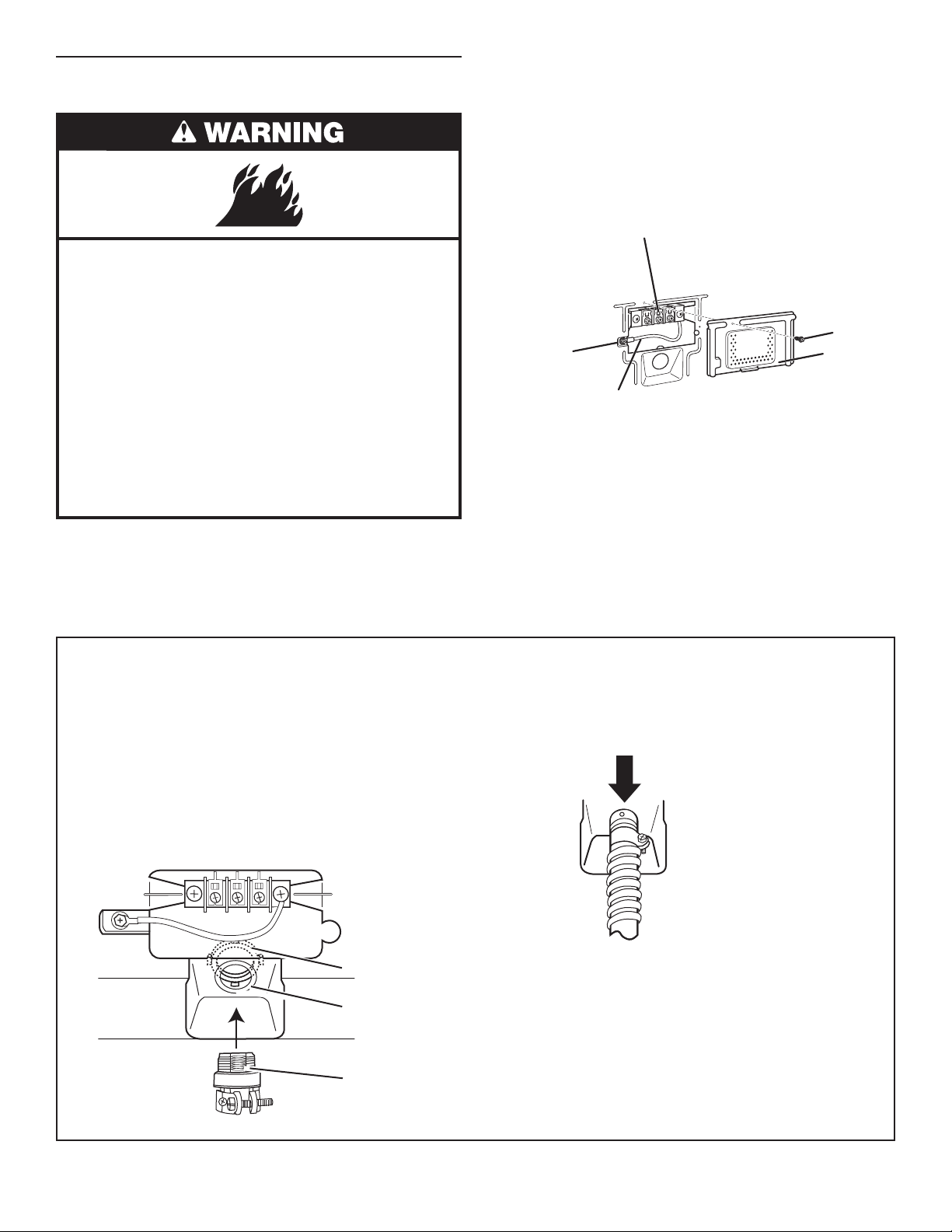

Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to a

chemical reaction that could cause a load to catch re.

To reduce the risk of re due to contaminated loads, the

nal part of a tumble dryer cycle occurs without heat

(cool down period). Avoid stopping a tumble dryer before

the end of the drying cycle unless all items are quickly

removed and spread out so that the heat is dissipated.

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, Part 1, CSA C22.1.

4

INSTALLATION REQUIREMENTS

Tools & Parts

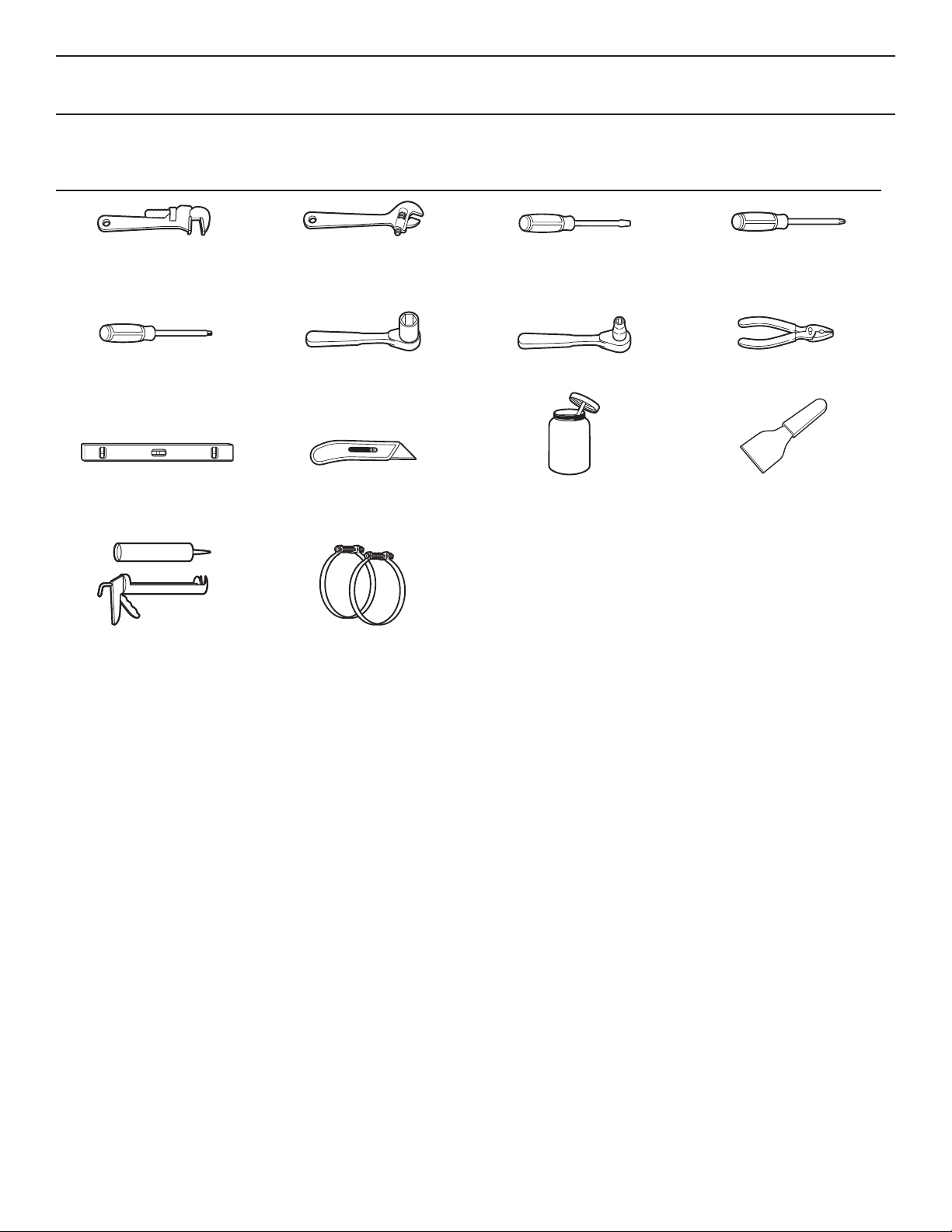

Tools Needed:

8" or 10" 8" or 10" Flat-blade screwdriver Phillips screwdriver

Pipe wrench Adjustable wrench

that opens to 1"

TORX T20®† security 1" Hex-head 5⁄16" Socket wrench Pliers

screwdriver or bit socket wrench (that open to 19/16")

Level Utility knife Pipe-joint compound Putty knife

resistant to Propane gas

Caulk gun and caulk Vent clamps

(for installing new exhaust vent)

Parts supplied:

Remove parts bag from dryer drum. Check that all parts were

included.

■ Foot boot (4)

■ Dryer foot (4)

■ PD models: Cam for service door lock

Optional parts not included:

■ 279810 Long dryer foot

■ LP Kit W10402145

■ 208 V electric element:

U.S. – W10206352A, Canada – W10206351A

PR models: Card reader bezel, card reader wire harness,

hardware

†® TORX and T20 are registered trademarks of Acument Intellectual Properties, LLC.

5

Location Requirements

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not install in a garage.

Failure to do so can result in death, explosion, or fire.

IMPORTANT: Do not install or store the dryer where it will be

exposed to the weather. Proper installation is your responsibility.

You will need:

■ A grounded electrical outlet located within 6 ft. (1.8 m) of

where the power cord is attached to the back of the dryer.

See “Electrical Requirements.”

■ A level oor with a maximum slope of 1" (25 mm) under entire

dryer. Installing the dryer on soft oor surfaces, such as

carpets or surfaces with foam backing, is not recommended.

If installing a gas dryer:

IMPORTANT: Observe all governing codes and ordinances.

■ Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

■ Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

“Recessed Area and Closet Installation Instructions” below

for minimum spacing requirements.

NOTE: The dryer must not be installed in an area where it will

be exposed to water and/or weather.

Recessed Area and Closet Installation Instructions

This dryer may be installed in a recessed area or closet.

For recessed area and closet installations, minimum clearances

can be found on the warning label on the rear of the dryer.

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes

and ordinances.

If closet door is installed, the minimum unobstructed air opening

in the top and bottom is required. Louvered doors with equivalent

air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

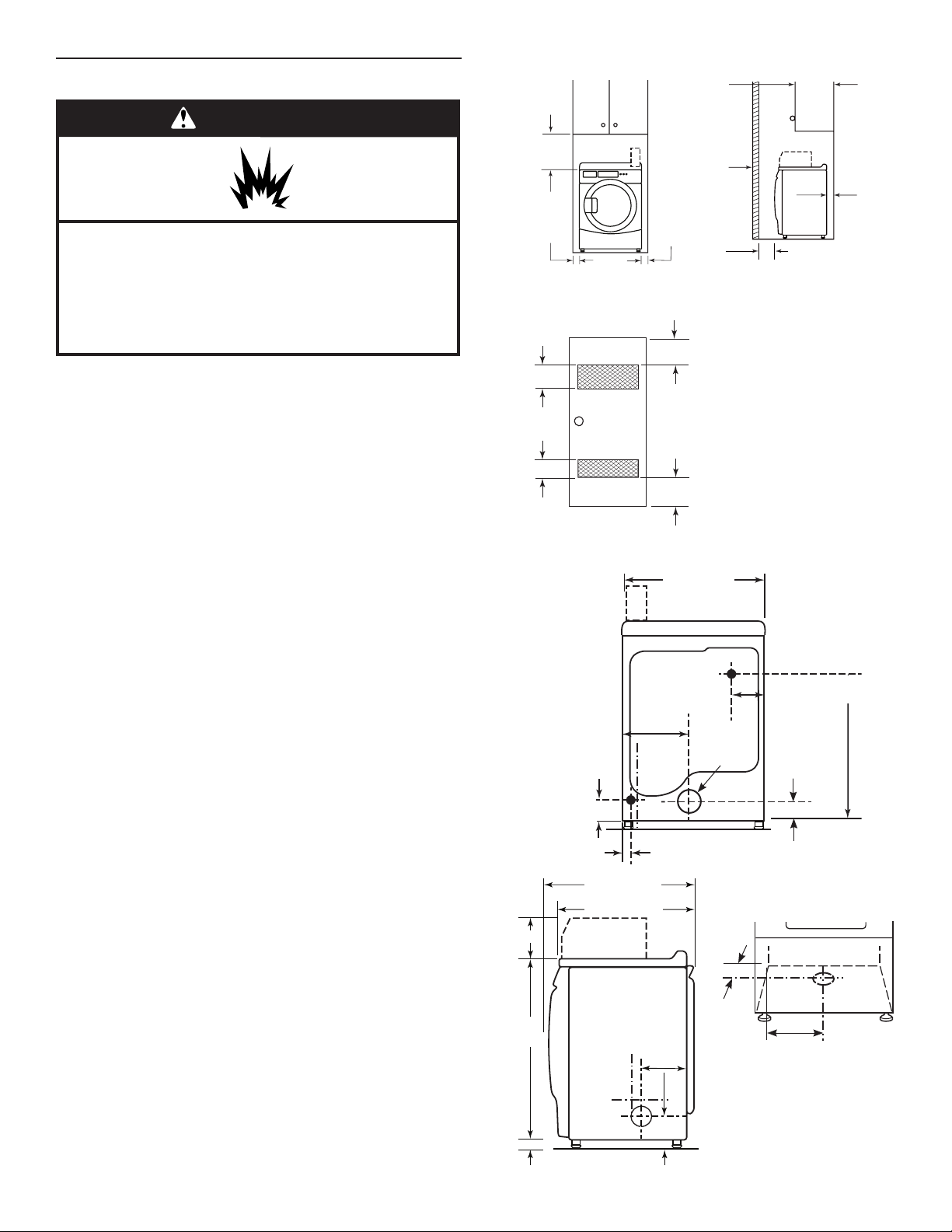

Minimum Installation Clearances

14"

(356 mm)

max.

15"

(381 mm)*

0" (0 mm)

Closet

door

0" (0 mm)

1" (25 mm)

Recessed front view Closet side view

* Additional clearances for wall, door, and oor moldings may be required

or if external exhaust elbow is used.

3" (76 mm)

48 in2.

(310 cm2)*

Front

View

24 in2

(155 cm2)*

closet

door

3" (76 mm)

* Opening is the minimum

for a closet door.

Louvered doors with

equivalent air openings

are acceptable.

Product Dimensions 27" (68.6 cm) Dryer

27" (686 mm)

61⁄4"

(159 mm)

41⁄4"

(108 mm)

BOTTOM

EXHAUST

141⁄8"

(359 mm)

77⁄8"

(200 mm)

35"

(889 mm)

63⁄4"

(152 mm)

11⁄4"

(32 mm)

29" (736 mm)

271⁄4" (695 mm)

SIDE VIEW

LEFT OR

RIGHT SIDE

EXHAUST

ELECTRIC

BACK

VIEW

13"

(330 mm)

4" (102 mm)

dia.

GAS

EXHAUST

71⁄4"

(184 mm)

101⁄4"

(260 mm)

0"

(0 mm)

283⁄4"

(733 mm)

3/4" (21 mm)

41⁄4" (108 mm)

6

Electrical Requirements – Gas Dryer

IMPORTANT: The dryer must be electrically grounded in

accordance with local codes and ordinances or, in the absence

of local codes, with the National Electrical Code, ANSI/NFPA 70,

latest edition, or Canadian Electrical Code, CSA C22.1. If codes

permit and a separate ground wire is used, it is recommended

that a qualied electrical installer determine that the ground path

is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

■ Do not ground to a gas pipe.

■ Do not have a fuse in the neutral or ground circuit.

■ A 120 V, 60 Hz, AC only, 15 or 20 A, fused electrical circuit

is required. A time-delay fuse or circuit breaker is also

recommended. It is recommended that a separate circuit

serving only this dryer be provided.

■ This dryer is equipped with a power supply cord having a

3-prong grounding plug.

■ To minimize the possibility of shock, the cord must be

plugged into a mating, 3 prong, grounding-type outlet,

grounded in accordance with local codes and ordinances.

If a mating outlet is not available, it is the personal

responsibility and obligation of the customer to have the

properly grounded outlet installed by a qualied electrician.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that the

ground path is adequate.

■ Check with a qualied electrician if you are not sure the dryer

is properly grounded.

Gas Dryer Grounding

7

Electrical Requirements –

Electric Dryer (U.S.A. Only)

It is your responsibility:

■ To contact a qualied electrical installer.

■ To be sure that the electrical connection is adequate and in

conformance with the National Electrical Code, ANSI/NFPA

70-latest edition and all local codes and ordinances.

■ The National Electrical Code requires a 4-wire power supply

connection for homes built after 1996, dryer circuits involved

in remodeling after 1996, and all mobile home installations.

■ A copy of the above code standards can be obtained from:

National Fire Protection Association, One Batterymarch Park,

Quincy, MA 02269.

■ To supply the required 3 or 4 wire, single phase, 120/240 V,

60 Hz., AC only electrical supply (or 3 or 4 wire, 120/208 V

electrical supply, if specied on the serial/rating plate) on a

separate 30 A circuit, fused on both sides of the line. A time

delay fuse or circuit breaker is recommended. Connect to an

individual branch circuit. Do not have a fuse in the neutral or

grounding circuit.

■ Do not use an extension cord.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that

the ground path is adequate.

Electric Dryer Grounding

Electrical Connection

To properly install your dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

■ This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The neutral ground conductor is

permanently connected to the neutral conductor (white wire)

within the dryer. If the dryer is installed with a 4-wire electrical

supply connection, the neutral ground conductor must be

removed from the external ground connector (green screw),

and secured under the neutral terminal (center or white wire)

of the terminal block. When the neutral ground conductor is

secured under the neutral terminal (center or white wire) of the

terminal block, the dryer cabinet is isolated from the neutral

conductor.

■ If local codes do not permit the connection of a neutral

ground wire to the neutral wire, see “Optional 3-wire

connection” section.

■ A 4-wire power supply connection must be used when the

appliance is installed in a location where grounding through

the neutral conductor is prohibited. Grounding through the

neutral is prohibited for (1) new branch-circuit installations

(2) areas where local codes prohibit grounding through the

neutral conductor.

8

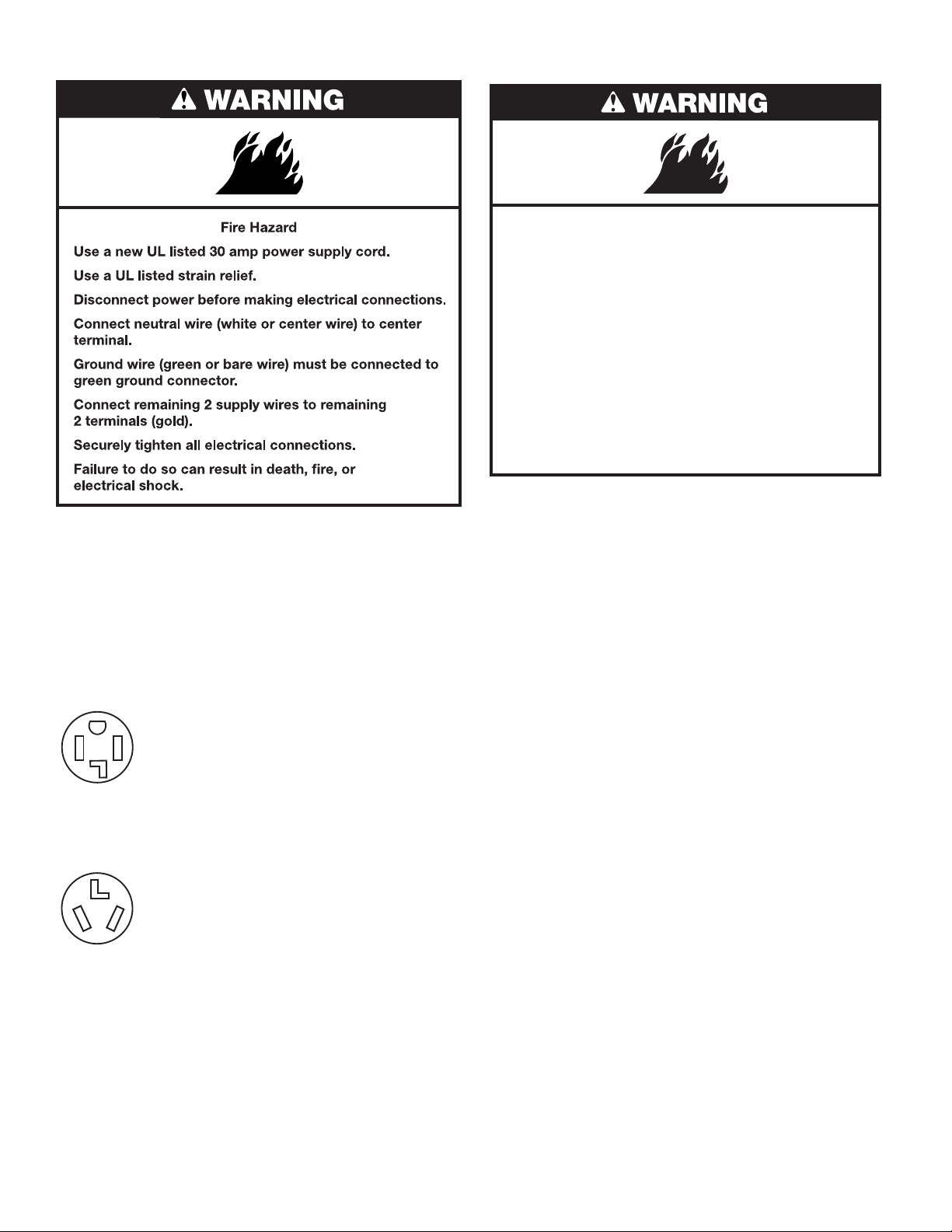

Electric Dryer Power Supply Cord

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

■ A UL listed 30 A power supply cord, rated 120/240 V

minimum. The cord should be type SRD or SRDT and be at

least 4 ft. (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or “U” shaped spade terminals

with upturned ends.

■ A UL listed strain relief.

Direct Wire

Fire Hazard

Use 10 gauge copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected

to green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire)

and be:

■ Flexible armored cable or nonmetallic sheathed copper

cable (with ground wire), covered with exible metallic

conduit. All current-carrying wires must be insulated.

■ 10-gauge solid copper wire (do not use aluminum).

■ At least 5 ft. (1.52 m) long.

If your outlet looks like this:

Then choose a 4-wire power supply cord with ring

or spade terminals and UL listed strain relief. The

4-wire power supply cord, at least 4 ft. (1.22 m)

long, must have four 10-gauge copper wires and

match a 4-wire receptacle of NEMA Type 14-30R.

4-Wire

Receptacle

(14-30R)

The ground wire (ground conductor) may be either

green or bare. The neutral conductor must be

identied by a white cover.

If your outlet looks like this:

Then choose a 3-wire power supply cord with ring

or spade terminals and UL listed strain relief. The

3-wire power supply cord, at least 4 ft. (1.22 m)

long, must have three 10-gauge copper wires and

match a 3-wire receptacle of NEMA Type 10-30R.

3-Wire

Receptacle

(10-30R)

9

Electrical Requirements – Canada only

It is your responsibility:

■ To contact a qualied electrical installer.

■ To be sure that the electrical connection is adequate

and in conformance with the Canadian Electrical Code,

C22.1 – latest edition and all local codes. A copy of the

above codes standard may be obtained from: Canadian

Standards Association,178 Rexdale Blvd., Toronto, ON

M9W 1R3 CANADA.

■ To supply the required 4 wire, single phase, 120/240 V,

60 Hz., AC only electrical supply on a separate 30 A circuit,

fused on both sides of the line. A time-delay fuse or circuit

breaker is recommended. Connect to an

individual branch circuit.

■ This dryer is equipped with a CSA International

Certied Power Cord intended to be plugged

into a standard 14-30R wall receptacle. The

cord is 5 ft (1.52 m) in length. Be sure wall

receptacle is within reach of dryer’s nal

location.

■ Do not use an extension cord.

If you are using a replacement power supply cord, it is

recommended that you use Power Supply Cord Replacement

Part Number 9831317. For further information, please

reference the service numbers located in the “Assistance or

Service” section.

4-Wire

Receptacle

(14-30R)

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualied electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not t the outlet, have a proper outlet

installed by a qualied electrician.

Gas Supply Requirements

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 13" (33 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

IMPORTANT: Observe all governing codes and ordinances.

This installation must conform with all local codes and

ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1/NFPA 54 or CAN/CSA B149.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

The design of this dryer has been certied by CSA International

for use at altitudes up to 10,000 feet (3048 m) above sea level at

the B.T.U. rating indicated on the model/serial plate. Burner input

adjustments are not required when the dryer is operated up to

this elevation.

When installed above 10,000 feet (3048 m), a four percent (4%)

reduction of the burner B.T.U. rating shown on the model/serial

plate is required for each 1,000 foot (305 m) increase in elevation.

For assistance when converting to other gas types and/or

installing above 10,000 feet (3048 m) elevation, contact your

local service company.

Type of Gas

This dryer is equipped for use with natural gas. It is designcertied by CSA International for propane and butane gases with

appropriate conversion. No attempt shall be made to convert

the dryer from the gas specied on the serial/rating plate for use

with a different gas without consulting the serving gas supplier.

Conversion must be done by a qualied service technician.

Gas conversion kit part number is W10402145. This part number

is also available on a label on the gas valve burner base.

10

SAVE THESE INSTRUCTIONS

Venting Requirements

WARNING: To reduce the risk of re, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

■ The dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or exible vent shall be used for

exhausting.

■ Only a 4" (102 mm) heavy, metal exhaust vent and clamps

may be used.

■ Do not use an exhaust hood with a magnetic latch.

■ Use clamps to seal all joints. Do not use screws or other

fastening devices that extend into the interior of the duct

and catch lint. Do not use duct tape.

■ Do not use plastic or metal foil vent.

Rigid metal vent:

■ Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent (acceptable only if accessible to clean):

■ Must be fully extended and supported in nal dryer location.

■ Remove excess to avoid sagging and kinking that may result

in reduced airow and poor performance.

■ Do not install in enclosed walls, ceilings, or oors.

■ The total length should not exceed 7

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home or business.

Exhaust hood must be at least 12" (305 mm) from the ground

or any object that may be in the path of the exhaust (such as

owers, rocks, or bushes).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

exible metal vent.

Plan installation to use the fewest number of elbows and turns.

3

/4 ft. (2.4 m).

Allow as much room as possible when using elbows or making

turns. Bend vent gradually to avoid kinking.

Vent outlet is located at the back of the dryer, at bottom center.

The vent can be routed up, down, left, right, behind the dryer,

or straight out the back of the dryer. See “Product Dimensions”

in the “Location Requirements” section.

Make-up air:

Although each single-load dryer should have an unobstructed

outdoor air opening of 24 in2 (154 cm2) (based on 1 square

inch [6.5 cm2] per 1,000 Btu [252 kcal]), common make-up air

openings are also acceptable. Set up common openings so that

the make-up air is distributed equally to all of the dryers. Keep

in mind that the coverage area must be increased by 33% to

account for use of registers or louvers over the openings. Also,

make-up air openings should not be installed near the location

of exhaust vents exiting the building.

Vent System Length

Maximum length of vent system depends upon the type of

vent used, number of elbows, and type of exhaust hood.

The maximum length for rigid vent is shown in the chart.

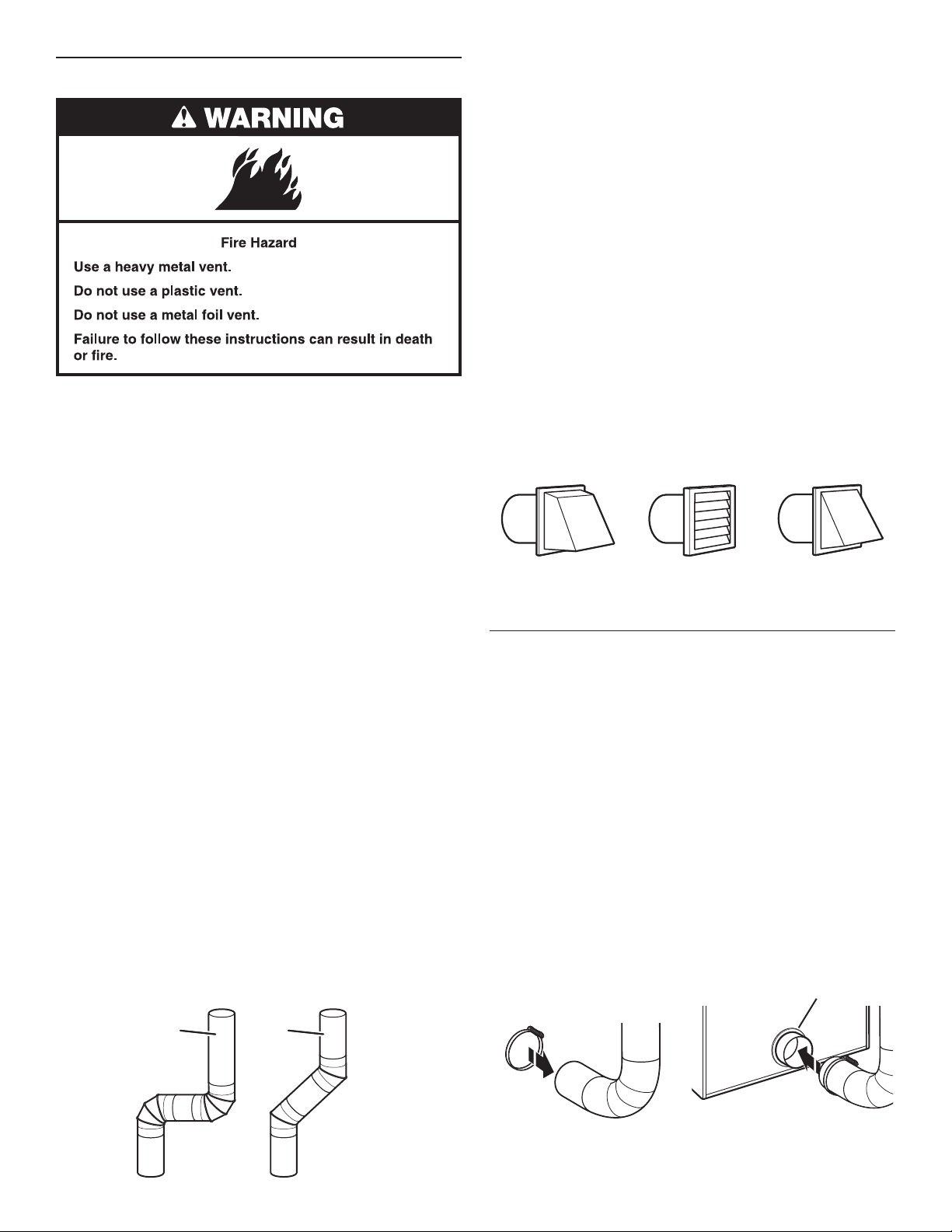

Maximum Vent Length

4" (102 mm) Diameter Exhaust Hoods

Box Louvered

21⁄2" (63.5 mm) Angled

Vent System Chart (Rigid Metal Vent)

No. of 90° Box Hood and

Turns Louvered Style Angled Hood Style

0 130 ft. (39.6 m) 129 ft. (39.3 m)

1 125 ft. (38.1 m) 119 ft. (36.3 m)

2 115 ft. (35.1 m) 109 ft. (33.2 m)

3 106 ft. (32.3 m) 100 ft. (30.5 m)

4 98 ft. (29.9 m) 92 ft. (28.0 m)

For vent systems not covered by the vent specication chart,

see your parts distributor.

Provision must be made for enough air for combustion and

ventilation. (Check governing codes and ordinances.) See

“Recessed Area and Closet Installation Instructions” in the

“Location Requirements” sections.

A 4" (102 mm) outlet hood is preferred. However, a 21⁄2" (64 mm)

outlet exhaust hood may be used. A 21/2" (64 mm) outlet creates

greater back pressure than other hood types. For permanent

installation, a stationary vent system is required.

Connect Vent

1. If connecting to existing vent, make sure the vent is clean.

2. Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer.

Vent Collar

Good

Better

NOTE: Do not remove vent collar.

11

3. Tighten hose clamp with Phillips screwdriver.

4. Make sure the vent is secured to exhaust hood with

a 4" (102 mm) clamp.

5. Move dryer into nal position. Do not crush or kink vent.

Make sure dryer is level.

Multiple Dryer Venting

■ A main vent can be used for venting a group of dryers. The

main vent should be sized to remove 200 CFM of air per

dryer. Large-capacity lint screens of proper design may be

used in the main vent if checked and cleaned frequently. The

room where the dryers are located should have make-up air

equal to or greater than the CFM of all the dryers in the room.

■ A back-draft damper kit is needed and is available from a

commercial laundry distributor; it should be installed in the

vent of each dryer to prevent exhausted air from returning into

the dryers and to keep the exhaust in balance within the main

vent. Unobstructed return air openings are required.

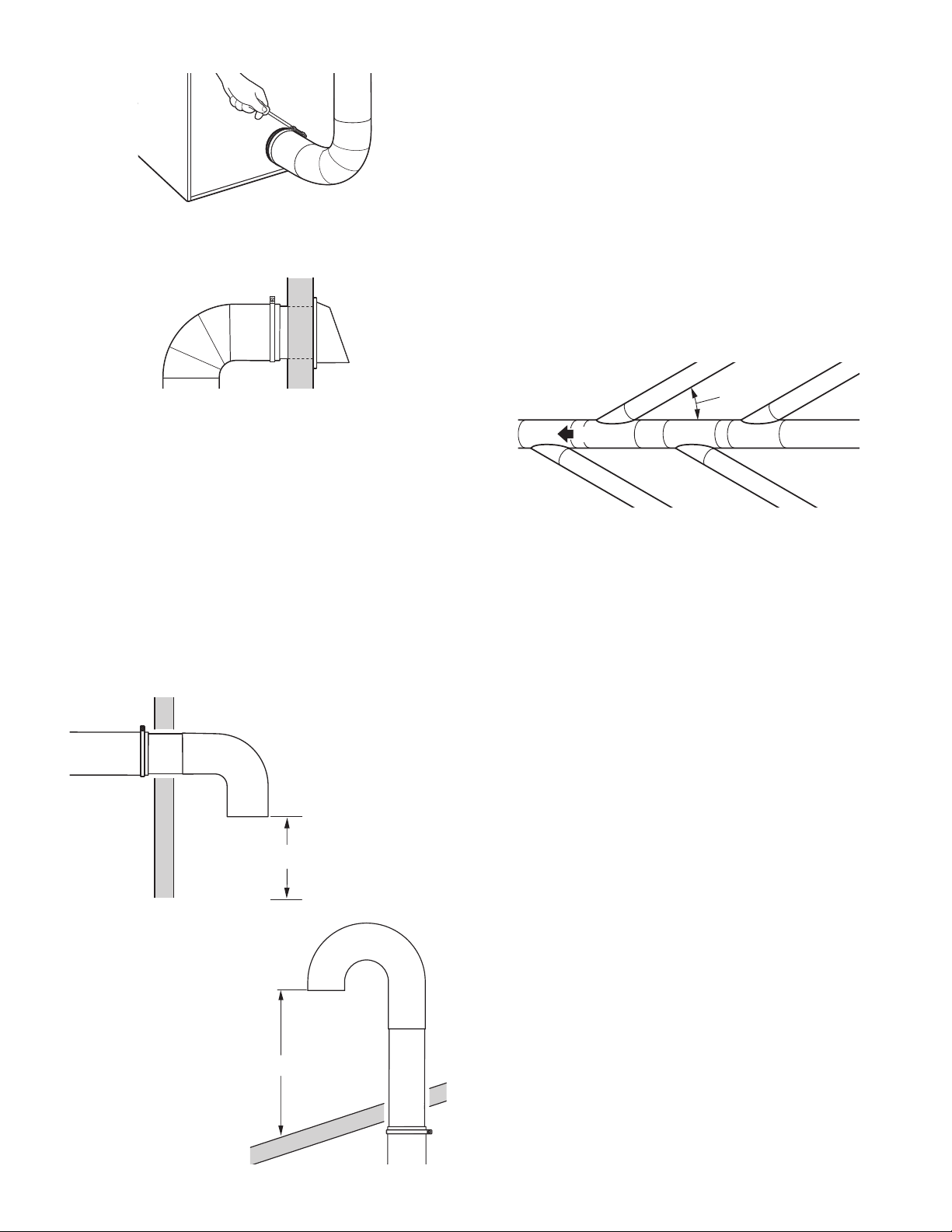

Each vent should enter the main vent at an angle pointing in the

direction of the airow. Vents entering from the opposite side

should be staggered to reduce the exhausted air from interfering

with the other vents.

The maximum angle of each vent entering the main vent should

be no more than 30°.

NOTE: Testing for proper ventilation should be done with a

Manometer. Minimum: 0.01" (0.2 mm). Maximum: 0.6" (16 mm).

For vent systems not covered by the vent specication chart,

see your parts distributor.

If dryer is installed in a conned area, such as a bedroom,

bathroom, or closet, provision must be made for enough air

for combustion and ventilation. (Check governing codes and

ordinances.) See “Recessed Area and Closet Installation

Instructions” in the “Location Requirements” section.

A 4" (102 mm) outlet hood is preferred. However, a 21⁄2" (64 mm)

outlet exhaust hood may be used. A 21⁄2" (64 mm) outlet creates

greater back pressure than other hood types. For permanent

installation, a stationary vent system is required.

If An Exhaust Hood Cannot Be Used

The outside end of the main vent should have a sweep elbow

directed downward.

* Minimum

clearance above

12" min.

(305 mm)*

any accumulation

of snow, ice,

or debris such

as leaves

30˚ max.

Air ow

Air flow

Keep air openings free of dry cleaning uid fumes. Fumes create

acids which, when drawn through the dryer heating units, can

damage dryers and items being dried.

A clean-out cover should be located on the main vent for periodic

cleaning of the vent system.

If the main vent travels

vertically through the roof,

rather than through the

wall, install a 180° sweep

elbow on the end of the

vent at least 2 ft. (610 mm)

above the highest part of

the building. The opening in

the wall or roof shall have a

diameter 1/2" (13 mm) larger

than the vent diameter. The

vent should be centered in

the opening.

Do not install screening or

cap over the end of the vent.

12

24" min.

(610 mm)

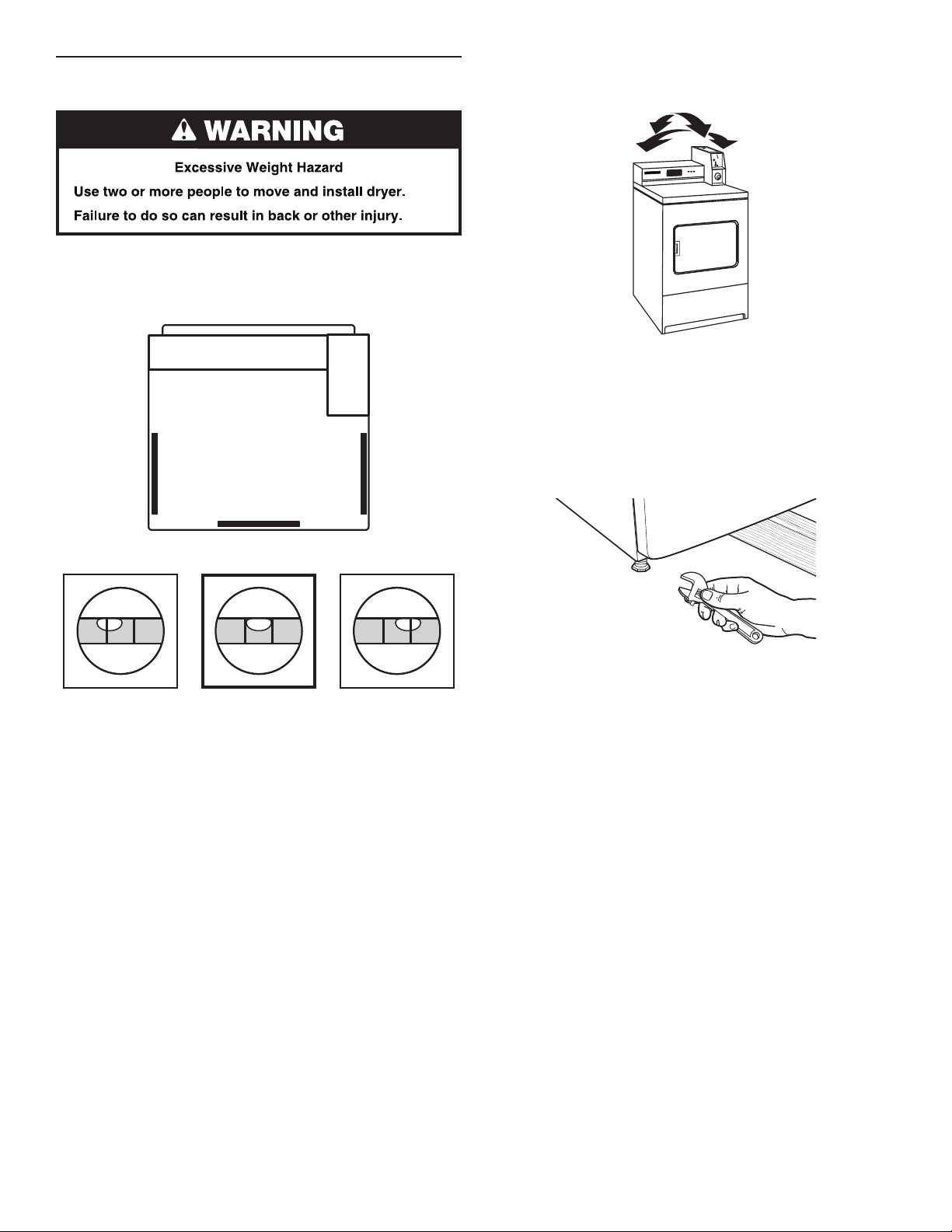

Leveling

Leveling your dryer properly reduces excess noise and vibration.

1. Remove cardboard from beneath dryer. Place a level on top

edges of dryer, checking each side and front. If not level,

tip dryer and adjust legs up or down as shown in Step 3,

repeating as necessary.

2. Grip dryer from top and rock back and forth, making sure all

four legs are rmly on oor. Repeat, rocking dryer from side

to side. If dryer rocks, go to Step 3 and adjust leveling legs.

(appearance may vary)

3. If dryer is not level, use a 1" or 25 mm open-end or adjustable

wrench to turn the leveling leg counterclockwise to lower the

dryer or clockwise to raise the dryer. Recheck levelness of

dryer and that all four legs are rmly in contact with the oor.

Repeat as needed.

HELPFUL TIP: You may want to prop up front of dryer about

4" (102 mm) with a wood block or similar object that will

support weight of dryer.

(appearance may vary)

Not Level LEVEL Not Level

13

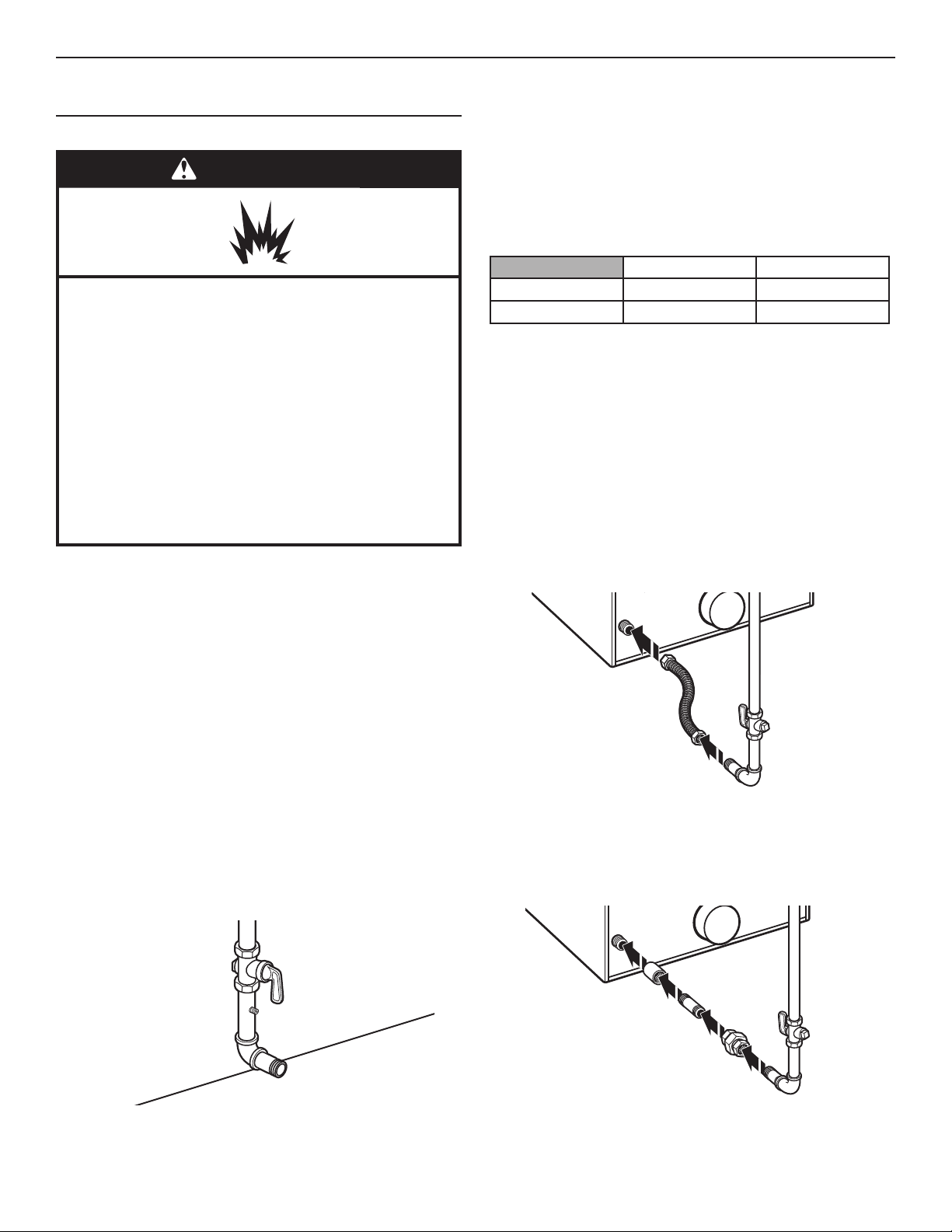

INSTALLATION INSTRUCTIONS – GAS DRYER

Make Gas Connection

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 13" (33 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

1. Remove red cap from gas pipe.

2. Connect gas supply to dryer. Use pipe-joint compound

resistant to the action of propane for gas connections.

If exible metal tubing is used, be certain there are no kinks.

If necessary for service, open the toe panel by removing the

21⁄4" hex-head screws from the bottom of the panel. Then lift

up on the panel while pulling the bottom of the panel away

from the dryer.

3. Open the shutoff valve in the gas supply line.

4. Test all connections by brushing on an approved

noncorrosive leak-detection solution. Bubbles will show

a leak. Correct any leak found.

Gas Supply Pressure Testing

A 1/8" (3 mm) NPT minimum plugged tapping, accessible for

gauge testing, must be installed immediately downstream of the

installed shut-off valve to the dryer (as shown above). The dryer

must be disconnected from the gas supply piping system during

any pressure testing of the system at test pressures in excess of

1/2" psig (352 kg/m2). The expected pressures for the gas supply

are listed in inches of water in the table below:

Natural Gas Propane Gas

Minimum

Maximum

Alternate method

■ The gas supply may also be connected using 3/8" approved

copper or aluminum tubing. If the total length of the supply

line is more than 20 ft. (6.1 m), larger tubing will be required.

If using natural gas, do not use copper tubing. Pipe joint

compounds that resist the action of Propane gas must be

used.

Flexible metal appliance connector:

■ It is recommended that a new exible stainless steel gas line,

design-certied by CSA International, be used for connecting

the dryer to the gas supply line. (The gas pipe, which extends

through the lower rear of the dryer, is provided with 3/8"male

pipe thread.)

5.2" (132.1 mm) 8.0" (203.2 mm)

10.5" (266.7 mm) 13.0" (330.2 mm)

Gas Supply Line

Recommended method

■ Provide a gas supply line of 1/2" rigid (IPS) pipe to the dryer

location. Pipe joint compounds that resist the action of

Propane gas must be used. Do not use TEFLON®† tape. With

Propane gas, piping or tubing size can be 1/2" minimum.

Usually, Propane gas suppliers determine the size and

materials used in the system.

†®TEFLON is a registered trademark of Chemours.

14

■ Do not kink or damage the exible stainless steel gas line

when moving the dryer.

Rigid pipe connection:

The rigid pipe connection requires a combination of pipe ttings

to obtain an in-line connection to the dryer.

■ Must include a shutoff valve:

DC

A B

The supply line must be equipped with a manual shutoff

valve installed within 6 ft. (1.8 m) of dryer in accordance

with National Fuel Gas Code, ANSI Z223.1. In Canada,

an individual manual shutoff valve must be installed in

accordance with the B149 installation codes CAN/CGA

B149.1 and CAN/CGA B149.2. This valve should be located

in the same room as the dryer. It should be in a location that

allows ease of opening and closing. Do not block access to

shutoff valve. The valve is for turning on or shutting off gas

to the dryer.

A. Gas supply line

B. Shutoff valve in “open” position

C. To dryer

D. NPT 1/8" min. plugged tapping

■ Installed in a conned area:

If the dryer is installed in a conned area such as a

bathroom or closet, provision must be made for enough

air for combustion and ventilation. Check governing codes

and ordinances or refer to the “Recessed Area and Closet

Installation Instructions” in the “Location Requirements”

section.

Complete Installation

1. With dryer in nal position, place level on top of the dryer, rst

side to side; then front to back. If the dryer is not level, adjust

the legs of the dryer up or down until the dryer is level.

2. Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended grounding

method. See “Electrical Requirements.”

3. Check that all parts are now installed. If there is an extra part,

go back through the steps.

4. Check that you have all of your tools.

5. Dispose of/recycle all packaging materials.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 or 4 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Connect Vent

1. Using a 4" (102 mm) clamp, connect vent to exhaust outlet

on the dryer. If connecting to existing vent, make sure the

vent is clean. The dryer vent must t over the dryer exhaust

outlet and inside the exhaust hood. Make sure the vent is

secured to exhaust hood with a 4" (102 mm) clamp.

2. Using two or more people, move dryer to desired installation

location. Do not crush or kink vent, and remove any excess

exible vent to improve airow. Make sure dryer is level.

3. Check to be sure there are no kinks in the exible gas line.

6. Plug into a grounded outlet, or connect power.

7. Check dryer operation:

Insert coins. Select a cycle. Using the WHITES & COLORS

cycle, let the dryer run for at least ve minutes. Dryer will stop

when time is used up.

Note: Dryer door must be closed for dryer to operate.

When door is open, dryer stops, but timer continues to run.

To restart dryer, close door and reselect a cycle.

8. If the burner does not ignite and there is no heat inside the

dryer, shut off dryer for ve minutes. Check that all gas supply

valves are in the “ON” position and that the electrical cord is

plugged in. Repeat ve-minute test.

9. If drying time is too long, make sure that the lint screen is

clean and that there are no obstructions to airow in the dryer

vent system.

15

D

C

INSTALLATION INSTRUCTIONS – ELECTRIC DRYER

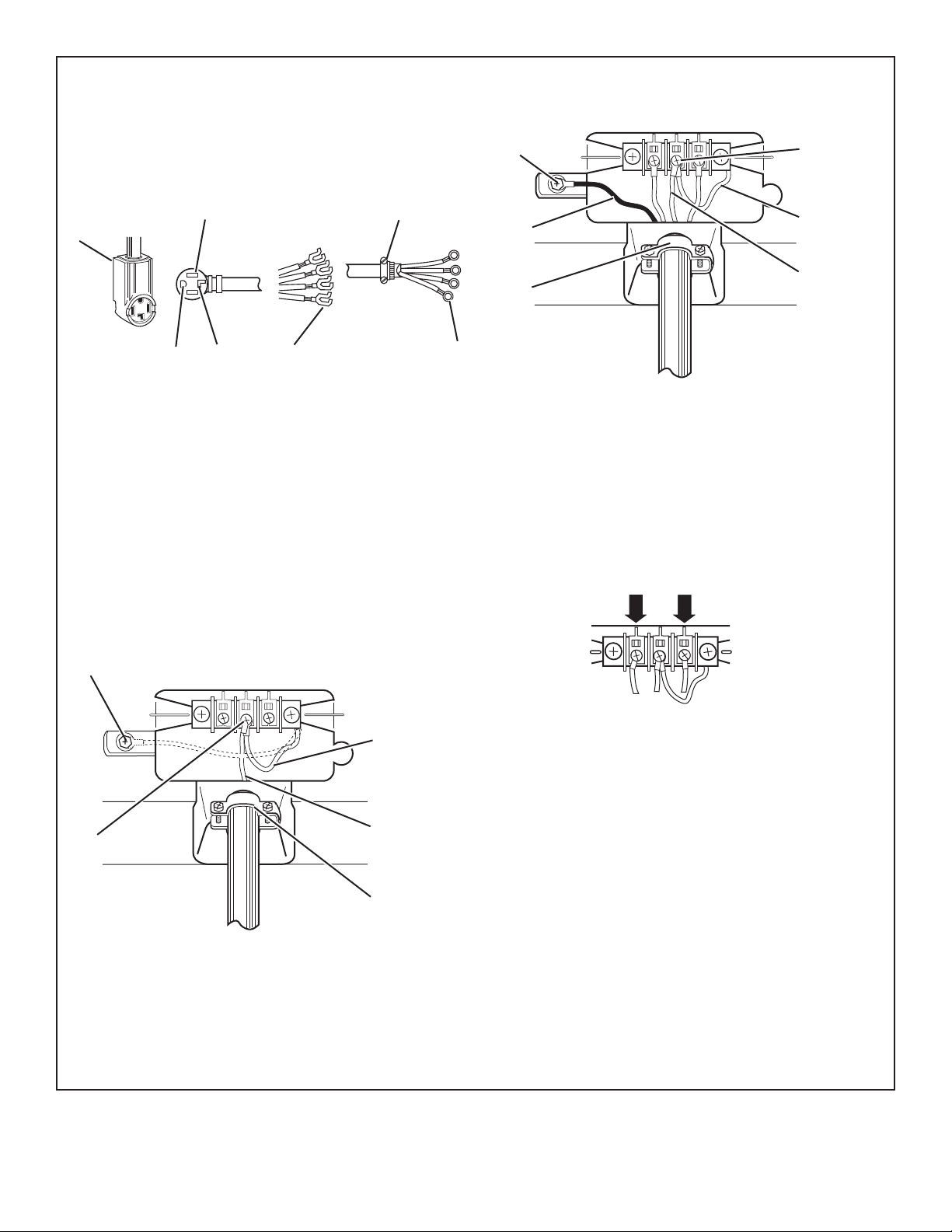

Power Supply Cord (U.S.A. Only)

1. Disconnect power.

2. Remove the hold-down screw and terminal block cover.

B

E

A. Terminal block cover

B. External ground

conductor screw

3. Install strain relief.

C. Center terminal block screw

D. Hold-down screw

E. Neutral ground wire

A

16

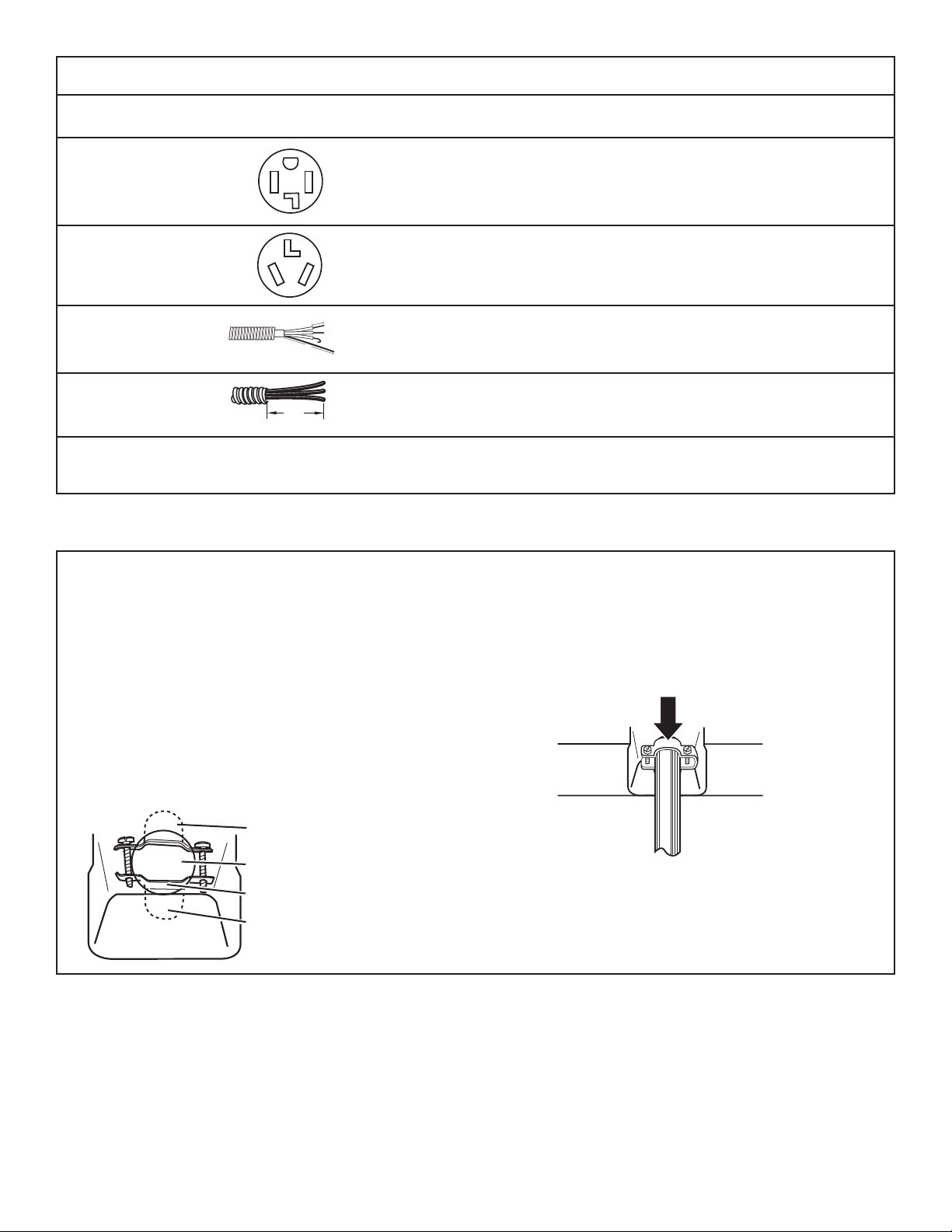

Electrical Connection Options

(127 mm)

If your location has: And you will be Go to Section

connecting to:

4-wire receptacle A UL listed, 120/240 V 4-wire connection:

(NEMA Type 14-30R) minimum, 30 A, Power supply cord

dryer power supply cord*

3-wire receptacle A UL listed, 120/240 V 3-wire connection:

(NEMA type 10-30R) minimum, 30 A, Power supply cord

dryer power supply cord*

4-wire direct A fused disconnect or 4-wire connection:

circuit breaker box* Direct Wire

1"

(25 mm)

5"

3-wire direct A fused disconnect or 3-wire connection:

circuit breaker box* Direct Wire

31⁄2

”

(89 mm)

*If local codes do not permit the connection of a cabinet-ground conductor to the neutral wire, go to “Optional 3-wire

connection” section.

Power supply cord strain relief:

■ Remove the screws from a 3/4" (19 mm)

UL listed strain relief (UL marking on

strain relief). Put the tabs of the two clamp

sections into the hole below the terminal

block opening so that one tab is pointing

up and the other is pointing down, and

hold in place.

Tighten strain relief screws enough to hold

the two clamp sections together.

A

B

C

A. Strain relief tab

pointing up

B. Hole below terminal

block opening

C. Clamp section

D. Strain relief tab

pointing down

D

■ Put power supply cord through the strain

relief. Be sure that the wire insulation on

the power supply cord is inside the strain

relief. The strain relief should have a tight

t with the dryer cabinet and be in a

horizontal position. Do not further tighten

strain relief screws at this point.

17

Power supply cord,

4-wire connection:

IMPORTANT: A 4-wire connection is

required for mobile homes and where local

codes do not permit the use of 3-wire

connections.

B

A

3. Connect ground wire (B) (green or bare)

of power supply cord to external ground

conductor screw (A). Tighten screw.

A

F

B

C

D

E

F

C

D

A. 4-wire receptacle (NEMA type 14-30R)

B. 4-prong plug

C. Ground prong

D. Neutral prong

E. Spade terminals with upturned ends

F.

3/4"

(19 mm) UL listed strain relief

G. Ring terminals

E

1. Remove center terminal block screw (B).

2. Remove neutral ground wire (C) from

external ground conductor screw (A).

Connect neutral ground wire and

the neutral wire (white or center wire)

of power supply cord under center

terminal block screw (B). Tighten screw.

A

B

G

A. External ground conductor screw

B. Ground wire (green or bare) of power supply cord

C.

3/4"

(19 mm) UL listed strain relief

D. Center terminal block screw

E. Neutral ground wire

F. Neutral wire (white or center wire)

4. Connect the other wires to outer terminal

block screws. Tighten screws.

C

5. Tighten strain relief screws.

6. Insert tab of terminal block cover into

slot of dryer rear panel. Secure cover

with holddown screw.

7. You have completed your electrical

D

connection. Now go to “Venting

Requirements.”

18

E

A. External ground conductor screw - Dotted line shows position

of NEUTRAL ground wire before being moved to center

terminal block screw.

B. Center terminal block screw

C. Neutral ground wire

D. Neutral wire (white or center wire)

E.

3/4"

(19 mm) UL listed strain relief

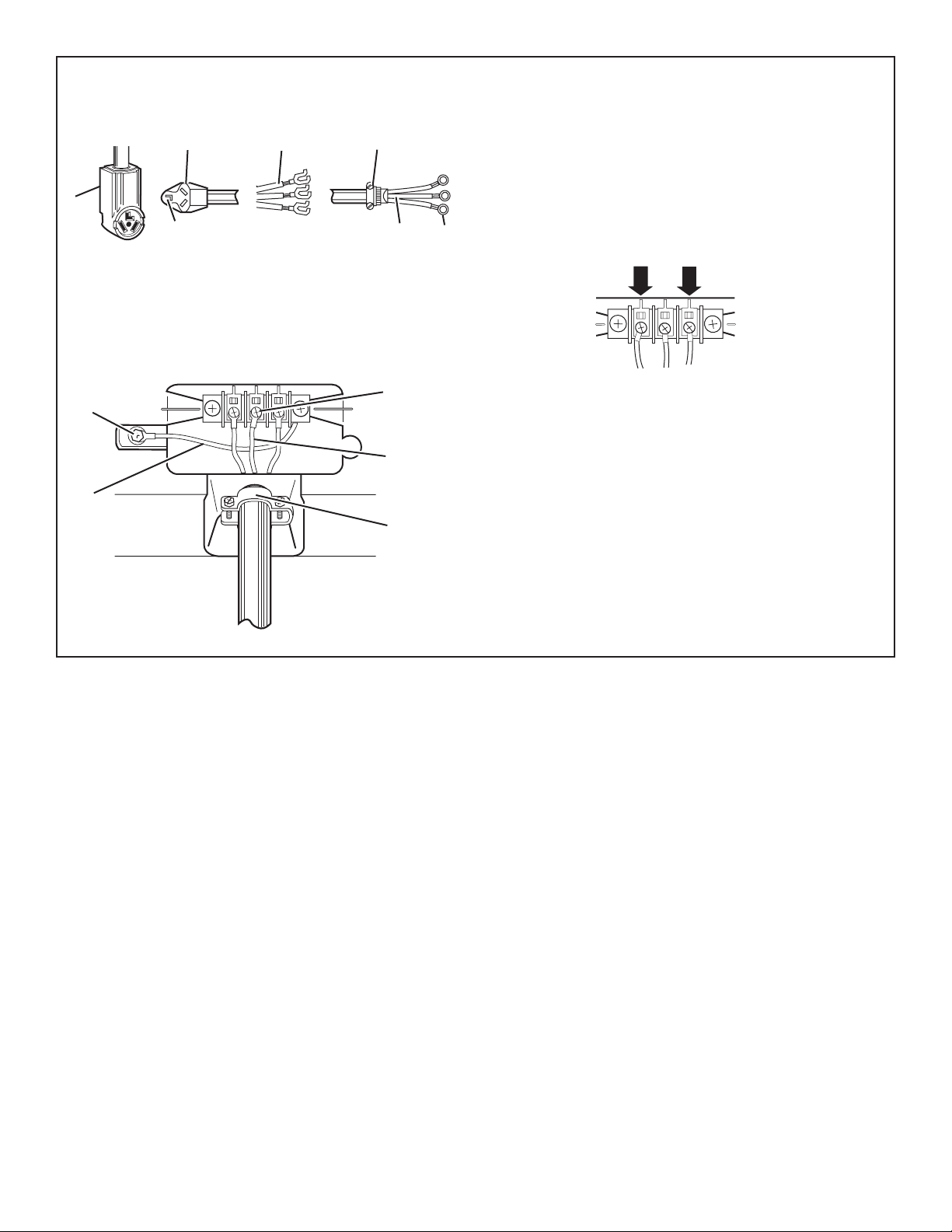

Power supply cord,

3-wire connection:

B

A

C

A. 3-wire receptacle (NEMA type 10-30R)

B. 3-wire plug

C. Neutral prong

D. Spade terminals with upturned ends

E. 3/4" (19 mm) UL listed strain relief

F. Ring terminals

G. Neutral (white or center wire)

Use where local codes permit connecting

cabinet-ground conductor to neutral wire.

1. Loosen or remove center terminal

D

E

block screw (C).

2. Connect neutral wire (white or center

wire) of power supply cord (D) to the

center terminal screw (C) of the terminal

block. Tighten screw.

3. Connect the other wires to outer terminal

G

F

block screws. Tighten screws.

A

C

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into

slot of dryer rear panel. Secure cover

D

B

E

A. External ground conductor screw

B. Neutral ground wire

C. Center terminal block screw

D. Neutral wire (white or center wire)

E. 3/4" (19 mm) UL listed strain relief

with holddown screw.

6. You have completed your electrical

connection. Now go to “Venting

Requirements.”

19

D

C

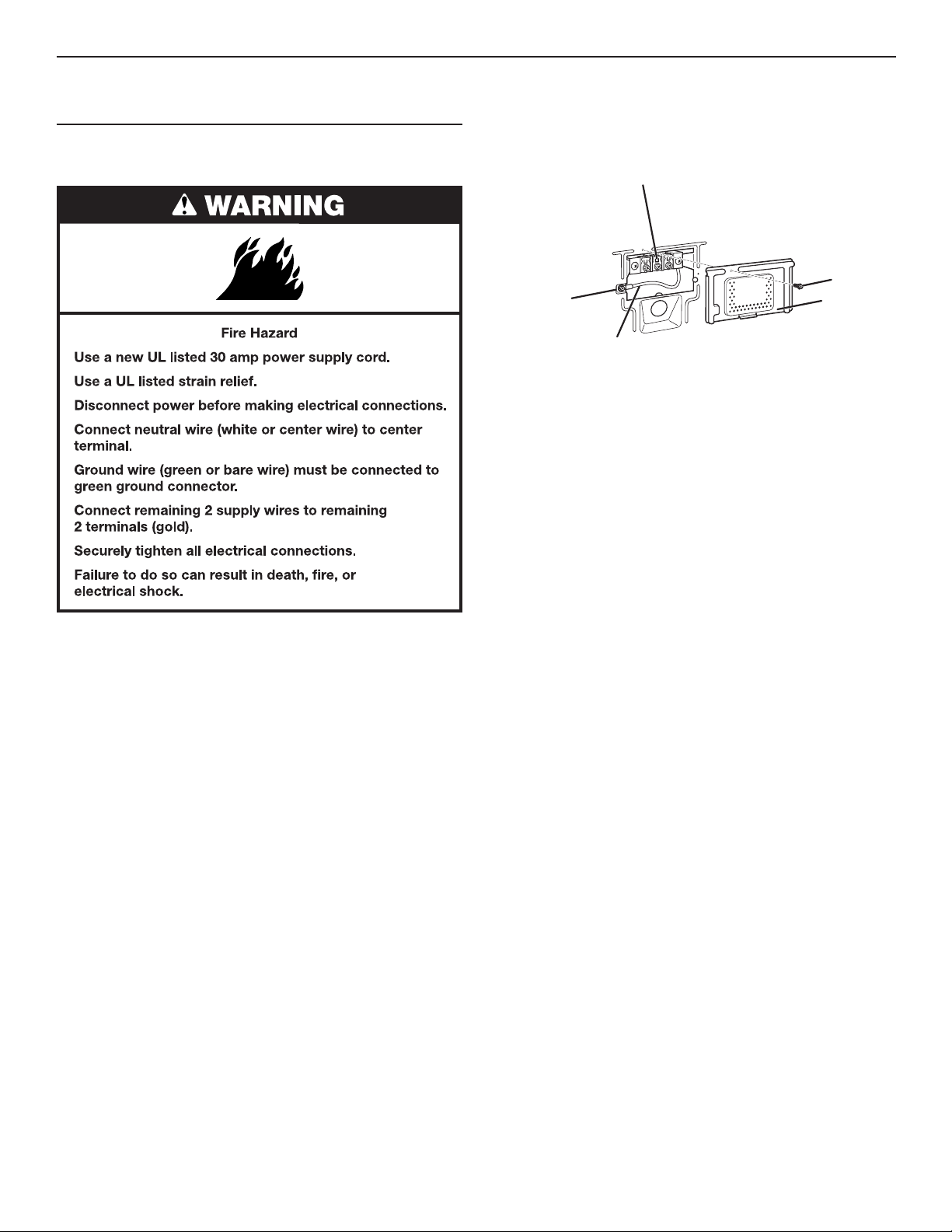

Direct Wire Method (U.S.A. Only)

Fire Hazard

Use 10 gauge copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected

to green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

Direct wire cable must match power supply (4-wire or 3-wire)

and be:

■ Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), protected with exible metallic conduit.

All current-carrying wires must be insulated.

■ 10-gauge solid copper wire (do not use aluminum).

■ At least 5 ft. (1.52 m) long.

1. Disconnect power.

2. Remove hold-down screw and terminal block cover.

B

E

A. Terminal block cover

B. External ground

conductor screw

C. Center terminal block screw

D. Hold-down screw

E. Neutral ground wire

A

3. Install 3/4" conduit connector into the hole below the terminal

block opening. Connect exible metallic conduit and tighten

connector screw. Install direct wire cable through the exible

metallic conduit.

4. Complete installation following instructions for your type

of electrical connection:

• Four-wire (recommended method)

• Three-wire (if four-wire is not available)

Direct wire strain relief:

■ Unscrew the removable conduit

connector (A) and any screws from a

3/4" (19 mm) UL listed strain relief

(UL marking on strain relief). Put the

threaded section of the strain relief

through the hole (B) below the terminal

block opening. Reaching inside the

terminal block opening, screw the

removable conduit connector onto the

strain relief threads (C).

■ Put direct wire cable through the strain

A

B

4. Now complete installation following

4-wire (recommended)

3-wire (if 4-wire is not available)

A. Removable conduit connector

C

B. Hole below terminal block opening

C. Strain relief threads

relief. The strain relief should have a

tight t with the dryer cabinet and be in

a horizontal position. Tighten strain relief

screw against the direct wire cable.

instructions for your type of electrical

connection:

20

Direct Wire,

4-wire connection:

IMPORTANT: A 4-wire connection is

required for mobile homes and where local

codes do not permit the use of 3-wire

connections.

Direct wire cable must have 5 ft (1.52 m)

of extra length so dryer can be moved

if needed.

Strip 5" (127 mm) of outer covering from end

of cable, leaving bare ground wire at

5" (127 mm). Cut 11⁄2" (38 mm) from 3

remaining wires. Strip insulation back

1" (25 mm). Shape ends of wires into a

hook shape.

1"

(25 mm)

3. Connect ground wire (green or bare) of

direct wire cable (B) to external ground

conductor screw (A). Tighten screw.

A

B

C

D

E

F

5"

(127 mm)

When connecting to the terminal block,

place the hooked end of the wire under the

screw of the terminal block (hook facing

right), squeeze hooked end together and

tighten screw, as shown.

1. Remove center terminal block screw.

2. Remove neutral ground wire (C) from

external ground conductor screw (A).

Connect neutral ground wire and place

the hooked end (hook facing right) of

the neutral wire (white or center wire) of

direct wire cable (D) under the center

screw (B) of the terminal block. Squeeze

hooked ends together. Tighten screw.

A

A. External ground conductor screw

B. Ground wire (green or bare) of power supply cable

C.

3/4"

(19 mm) UL listed strain relief

D. Center terminal block screw

E. Neutral ground wire

F. Neutral wire (white or center wire)

4. Place the hooked ends of the other

direct wire cable wires under the outer

terminal block screws (hooks facing

right). Squeeze hooked ends together.

Tighten screws.

B

C

5. Tighten strain relief screw.

6. Insert tab of terminal block cover into

slot of dryer rear panel. Secure cover

with holddown screw.

7. You have completed your electrical

D

connection. Now go to “Venting

Requirements.”

A. External ground conductor screw - Dotted line shows

position of NEUTRAL ground wire before being moved

to center terminal block screw.

B. Center terminal block screw

C. Neutral ground wire

D. Neutral wire (white or center wire)

E. 3/4" (19 mm) UL listed strain relief

E

21

Direct wire,

3-wire connection:

Use where local codes permit connecting

cabinet-ground conductor to neutral wire.

Direct wire cable must have 5 ft (1.52 m)

of extra length so dryer can be moved

if needed.

Strip 31/2

from end of cable. Strip insulation back 1"

(25 mm). If using 3-wire cable with ground

wire, cut bare wire even with outer covering.

Shape ends of wires into a hook shape.

When connecting to the terminal block,

place the hooked end of the wire under the

screw of the terminal block (hook facing

right), squeeze hooked end together, and

tighten screw, as shown.

" (89 mm) of outer covering

"

1

(25 mm)

1

"

2

⁄

3

(89 mm)

1. Loosen or remove center terminal

block screw (C).

2. Place the hooked end of the neutral wire

(white or center wire) of direct wire cable

(D) under the center screw of terminal

block (hook facing right). Squeeze

hooked end together. Tighten screw.

A

B

A. External ground conductor screw

B. Neutral ground wire

C. Center terminal block screw

D. Neutral wire (white or center wire)

E. 3/4" (19 mm) UL listed strain relief

C

D

E

3. Place the hooked ends of the other

direct wire cable wires under the

outer terminal block screws (hooks

facing right). Squeeze hooked ends

together. Tighten screws.

4. Tighten strain relief screw.

5. Insert tab of terminal block cover into

slot of dryer rear panel. Secure cover

with holddown screw.

6. You have completed your electrical

connection. Now go to “Venting

Requirements.”

22

Optional,

3-wire connection:

Use for direct wire or power supply

cord where local codes do not permit

connecting cabinet-ground conductor

to neutral wire.

1. Remove center terminal block screw (B).

2. Remove neutral ground wire (C) from

external ground conductor screw (A).

Connect neutral ground wire and the

neutral wire (white or center wire) of

power supply cord/cable (D) under

center terminal block screw. Tighten

screw.

3. Connect the other wires to outer terminal

block screws. Tighten screws.

4. Tighten strain relief screws.

5. Connect a separate copper ground

wire (F) from the external ground

conductor screw (A) to an adequate

ground.

6. Insert tab of terminal block cover into

slot of dryer rear panel. Secure cover

with holddown screw.

A

A. External ground conductor screw

B. Center terminal block screw

C. Neutral ground wire

D. Neutral wire (white or center wire)

E. 3/4" (19 mm) UL listed strain relief

F. Grounding path determined by a qualied

electrician

B

C

D

E

F

Connect Vent

1. Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must t over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 4" (102 mm) clamp.

2. Move dryer into nal position. Do not crush or kink vent,

and remove any excess exible vent to improve airow.

Make sure dryer is level.

Complete Installation

1. With dryer in nal position, place level on top of the dryer,

rst side to side; then front to back. If the dryer is not level,

adjust the legs of the dryer up or down until the dryer

is level.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 or 4 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

2. Plug in dryer or reconnect power.

3. Check dryer operation:

Insert coins. Select a cycle. Using the WHITES & COLORS

cycle, let the dryer run for at least ve minutes. Dryer will

stop when time is used up.

NOTE: Dryer door must be closed for dryer to operate.

When door is open, dryer stops, but timer continues to run.

To restart dryer, close door and reselect a cycle.

4. If drying time is too long, make sure that the lint screen is

clean, and that there are no obstacles to airow in the dryer

vent system.

5. Now start the dryer and allow it to complete a full cycle

to make sure it is working properly.

23

REVERSING THE DOOR SWING

Door swing can be changed from a right-side opening

to left-side opening, if desired.

Place a towel or soft cloth on top of the dryer or workspace

to prevent scratching the surface.

Remove the Door Assembly

1. Remove 3 of the 4 screws that hold the door hinge on the

front panel of the dryer. Partially loosen the remaining screw

with keyhole opening and lift the door off the screw.

A.

Loosen

screw

with

keyhole

opening

B.

A. Dryer front panel

B. Door assembly

Reverse Hinge

1. Use a small at-blade screwdriver to remove 2 plug strips

from the inner door. Slide the head of the screwdriver under

the plugs, being certain not to scratch the inner door surface.

Lift up.

2. Remove the 4 screws that attach to the inner door hinge and

move the hinge to the other side. Reinstall the 4 screws.

2. Lay the door assembly on a previously prepared at surface

with the inside (inner door assembly) facing up.

3. Remove the 6 Phillips head screws to release the outer door

assembly from the inner door assembly, as indicated below.

See illustration. It is important that you remove only the 6

indicated screws.

4. Lift the inner door assembly off the outer door assembly.

5. Rotate outer door 180°.

Door hinge

3. Reinstall plug strips on opposite side of the inner door.

4. Check for ngerprints on the glass. Clean glass if necessary.

5. Place the inner door assembly inside the outer door

assembly. To t correctly, the inner door assembly edge ts

completely inside the outer door assembly edge.

6. Reassemble the inner and outer door assemblies with the

6 screws.

24

Reverse The Strike

Reinstall The Door

1. Use a small at-blade screwdriver to remove plug strip

from the dryer door opening. Slide the head of the

screwdriver under the plugs, being certain not to scratch

the dryer surface. Lift the plastic strip from the dryer slowly

to prevent distortion of the plug strip.

2. Remove the strike using a Phillips screwdriver.

3. Insert strike on the opposite side.

B.

A.

A. Plug strip

B. Door strike

1. Reattach door to dryer front panel with the 4 screws.

Partially install the screw with keyhole opening rst, and t

the keyhole opening in the hinge over the screw. Then install

the remaining 3 screws and tighten all 4 screws.

A.

Install this

screw rst

B.

A. Dryer front panel

B. Door assembly

2. Check for ngerprints on the glass. Clean glass if necessary.

3. Close door and check that it latches securely.

MAINTENANCE INSTRUCTIONS

Maintenance instructions:

■ Clean lint screen after each cycle.

■ Removing accumulated lint:

• From inside the dryer cabinet:

Lint should be removed every 2 years or more often,

depending on dryer usage. Cleaning should be done

by a qualied person.

• From the exhaust vent:

Lint should be removed every 2 years, or more often,

depending on dryer usage.

■ Keep area around dryer clear and free from combustible

materials, gasoline, and other ammable vapors and liquids.

■ Keep dryer area clear and free from items that would obstruct

the ow of combustion and ventilation air.

If dryer does not operate, check the following:

■ Electrical supply is connected.

■ Circuit breaker is not tripped or house fuse is not blown.

■ Door is closed. Listen closely to hear the door switch activate.

■ Control is set up properly and display shows cycle time.

■ Cycle selection button has been pushed rmly.

■ For gas dryers, check that gas supply shutoff valves are set

in open position.

If you need assistance:

Contact your authorized Maytag® Commercial Laundry

distributor. To locate your authorized Maytag® Commercial

Laundry distributor, or for web inquiries, visit

www.MaytagCommercialLaundry.com.

If you cannot locate your distributor, the Commercial Laundry

Support Center will answer any questions about operating or

maintaining your dryer not covered in the Installation Instructions.

Just dial 1-800 NO BELTS (1-800-662-3587)—the call is free.

When you call, you will need the dryer model number and serial

number. Both numbers can be found on the serial-rating plate

located in the dryer door opening.

25

ELECTRONIC CONTROL SETUP

GENERAL USER INFORMATION

Scrolling “out of order” showing in display, followed

by a failure code

This condition indicates the dryer is inoperative.

‘0 Minutes’ showing in display

This condition indicates the dryer cannot be operated. Coins

dropped or debit inputs during this condition will be stored in escrow

but cannot be used until normal operation is restored by opening

and closing the door. If the door switch fails, it must be replaced

before normal operation can be restored.

Cold Start (initial rst use)

Dryer is programmed at the factory as follows:

■ 45 minutes dry time for PR models.

■ 5 minutes per quarter for PD models.

■ $1.50 dry price (xed cycle with top off – PD Models).

■ $0.00 dry price (xed cycle – PR Models).

Warm Start (after power failure)

A few seconds after power is restored, if a cycle was in progress

at the time of the power failure, ‘RESELECT CYCLE’ will ash

in the display. This is to indicate the need for a fabric setting

key pad to be pressed to restart dryer.

Pricing

After the door is opened and closed following the completion

of a cycle, the display indicates the cycle price (unless set for free

operation). As coins or debit inputs arrive, the display will change

to lead the user through the initiation of a cycle.

There are four (4) types of pricing:

Fixed ‘Vend’ Pricing

A dryer set up for ‘Fixed Cycle’ operation can only accept additional

time accumulated by increments equal to the length of a complete

dry cycle. A maximum of 75 minutes may be purchased; no

additional credit is given when 75 minutes is in the display.

Accumulator Pricing

If the price is set to one coin 1, then accumulator mode is in effect.

Cycle time can be purchased one coin at a time (PD models) up to

the maximum time of 75 minutes.

Fixed Cycle With Top Off Pricing

A dryer set to offer ‘Top Off’ capability will allow time to be added

to an existing dry cycle in increments equal to the number of minutes

of dry time per quarter (coin 1), up to 75 minutes, regardless of the

cost required to start the dryer. No credit is given for coins or debit

inputs entered when the control is displaying 75 minutes.

PR Models: In Enhanced Debit Mode, the top off price can be set

independently (see VALUE OF COIN 2), and the top off time is

calculated according to the following equation:

top off price = top off time

full cycle price full cycle length

Penny increment offset is not applied to top off purchases.

Free Cycles

This is established by setting the cycle price to zero. When this

happens, ‘SELECT CYCLE’ will appear rather than a cycle price.

Any cycle started as a free cycle will automatically terminate when

the door is opened.

Debit Card Ready

This dryer is debit card ‘cable’ ready. It will accept a variety of debit

card systems, but does NOT come with a debit card reader. Refer

to the debit card reader manufacturer for proper dryer set-up. In

models converted to a Generation 1 debit card system, debit pulses

represent the equivalent of one coin (coin 1).

CONTROL SET-UP PROCEDURES

IMPORTANT: Read all instructions before operating.

The fabric setting key pads along with the digital display are used

to set-up the dryer controls.

The display can contain 4 numbers and/or letters and a decimal

point. These are used to indicate the set-up codes and related code

values available for use in programming the dryer.

How to use the key pads to program the controls

1. The WHITES & COLORS key pad is used to adjust the

values associated with set-up codes. Pressing and releasing this

key pad will increment the value by one (1). Rapid adjustment is

possible by holding the key pad down.

2. The PERM. PRESS key pad will advance through the set-up

codes. Pressing and releasing this key pad will advance to the next

available set-up code. Holding the key pad down will automatically

advance through the set-up codes at a rate of one (1) per second.

3. The DELICATES key pad is used to select or deselect options.

Start Operating Set-Up

■ PD Models: Insert service access door key, turn, and lift to remove

service access door.

■ PR Models: Once a Gen. 2 debit card reader is installed (according

to the reader manufacturer’s instructions), the set-up mode can be

entered by inserting a manual set-up card (supplied by the reader

manufacturer) into the card slot. If manual set-up card is not available,

manual set-up mode cannot be entered. However, diagnostic mode

can be entered by removing connector AA1 on the circuit board.

IMPORTANT: The console must not be opened unless power is

rst disconnected from the dryer. To access connector AA1:

Unplug dryer or disconnect power.

g

Open console, disconnect jumper on AA1, close console.

g

Plug in dryer or reconnect power.

g

■ PR Models Set-up as PN can use the Service Access Code.

This code can be entered to access service mode without

removing the console. It only functions on dryers set up for 0

vend price without any Special Pricing set-up, and the Coin/Debit

Option must be set to “J._d”.

The alternative Service Access Code to enter set-up mode is:

Press the left key pad, right key pad, left key pad, right key pad,

and right key pad.

The dryer is now in the set-up mode.

NOTE: Prior to operation, a payment system or an OPL kit

must be installed.

Before proceeding, it is worth noting that, despite all the options

available, an owner can simply choose to uncrate a new

commercial dryer, hook it up, plug it in, and have a dryer that

operates.

■ PD dryers have a factory default of xed cycle price with top off.

■ PR dryers have a factory default of free cycle operation so they

can be run without readers or coins.

26

DISPLAY

After the dryer has been installed and plugged in, the display will

show ‘0 minutes.’

Once the dryer has been plugged in and the dryer door opened

and closed, the display will show the price. In PR models set for free

cycles, the display will ash ‘SELECT CYCLE’ and the cycle time.

PD Models

PRICE

PR Models

SET-UP CODES

The set-up code is indicated by the one or two left hand characters.

The set-up code value is indicated by the two or three right hand

characters.

NOTE: The rst line of each code indicates the factory default

for PD models. The set-up codes for PR models are the same

except where noted.

CODE EXPLANATION

6 0 6

606

600

Press PERM. PRESS key pad once to advance to next code.

g

705

705

745

Press PERM. PRESS key pad once to advance to next code.

g

800

800

8fc

Press PERM. PRESS key pad once to advance to next code.

g

900

900

90c

Press PERM. PRESS key pad once to advance to next code.

g

REGULAR CYCLE PRICE

Represents the number of quarters (coin 1) needed to start

the dryer; may adjust from 0-39 (See b.xx set-up for VALUE

OF COIN 1). Advance from 0-39 by pressing WHITES &

COLORS. Factory default of 6 quarters = $1.50.

PR MODELS: Factory default of 6 00, or 0 quarters.

REGULAR DRY TIME

PD MODELS: Represents the number of minutes per quarter (coin 1).

Factory default of 5 minutes per coin.

Example: 6 quarters x 5 minutes = 30 minutes.

By pressing the WHITES & COLORS key pad, value adjusts

from 1-75 minutes.

PR MODELS: Represents the cycle length for free cycles.

As example: ‘7 45’ = 45 minutes.

TYPE OF DRYER PRICING

Fixed Cycle with Top Off. For detailed description, see General

User Information.

PR MODELS ONLY: Factory default of FC. Fixed Cycle.

For detailed description, see General User Information.

Use DELICATES key pad to make this selection.

CYCLE COUNTER OPTION

This option is either Selected ‘ON’ or Not Selected ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’ and not able to be deselected. Press DELICATES

key pad 3 consecutive times to select ‘ON’. Once selected ‘ON’

it cannot be deselected.

CODE EXPLANATION

1.00

1.00

1.0c

1. c0

Press PERM. PRESS key pad once to advance to next code.

g

2.00

2.00

2.s p

If SPECIAL PRICING OPTION is selected, there is access to codes

‘3.’ through ‘9.’

Press PERM. PRESS key pad once to advance to next code.

g

OPTIONS TO USE IF SPECIAL PRICING IS SELECTED:

3. 0 6

3. 0 6

3. 0 0

Press PERM. PRESS key pad once to advance to next code.

g

4. 0 5

4.05

4. 4 5

Press PERM. PRESS key pad once to advance to next code.

g

5.00

5.00

Press PERM. PRESS key pad once to advance to next code.

g

6.00

6.00

Press PERM. PRESS key pad once to advance to next code.

g

MONEY COUNTER OPTION

This option is either Selected ‘ON’ or Not Selected ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’.

Press DELICATES key pad 3 consecutive times to select

‘ON’ and 3 consecutive times to remove (Not Selected ‘OFF’.)

Counter resets by going from ‘OFF’ to ‘ON’.

Selected ‘ON’ and not able to be deselected.

To select ‘ON’ and not able to be deselected, first select ‘ON’,

then within two seconds press DELICATES twice, WHITES &

COLORS once, and exit the set-up mode.

SPECIAL PRICING OPTIONS

This option is either Selected ‘ON’ or Not Selected ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’. Press DELICATES key pad once for this

selection.

SPECIAL CYCLE PRICE

Represents the number of quarters (coin 1) needed to start

the dryer; may adjust from 0-39. (See b.xx set-up for VALUE

OF COIN 1). Advance from 0-39 by pressing WHITES &

COLORS. Factory default of 6 quarters = $1.50.

PR MODELS: Factory default of 0 quarters.

SPECIAL DRY TIME

PD MODELS: Represents the number of minutes per quarter (coin 1).

Factory default of 5 minutes per coin.

Example: 6 quarters x 5 minutes = 30 minutes.

By pressing the WHITES & COLORS key pad, the value

can be adjusted from 1-75 minutes.

PR MODELS: Represents the fixed cycle time in minutes.

As example: ‘4 45’ = 45 minutes.

TIME-OF-DAY CLOCK, MINUTES

This is the TIME-OF-DAY CLOCK, minute setting; select

0-59 minutes by pressing WHITES & COLORS key pad.

TIME-OF-DAY CLOCK, HOURS

NOTE: Uses military time – 24 hr. clock.

This is the TIME-OF-DAY CLOCK, hour setting; select

0-23 hours by pressing WHITES & COLORS key pad.

27

CODE EXPLANATION

OPTIONS TO USE IF SPECIAL PRICING IS SELECTED (continued):

7. 0 0

7. 0 0

Press PERM. PRESS key pad once to advance to next code.

g

8. 0 0

8. 0 0

Press PERM. PRESS key pad once to advance to next code.

g

9. 1 0

9. 1 0

Press PERM. PRESS key pad once to advance to next code.

g

a.00

a. 0 0

a. s c

Press PERM. PRESS key pad once to advance to next code.

g

6.05

6.05

Press PERM. PRESS key pad once to advance to next code.

g

c.20

c.20

c.05

Press PERM. PRESS key pad once to advance to next code.

g

SPECIAL PRICE START HOUR

NOTE: Uses military time – 24 hr. clock.

This is the start hour, 0-23 hours. Select START HOUR

by pressing WHITES & COLORS key pad.

SPECIAL PRICE STOP HOUR

NOTE: Uses military time – 24 hr. clock.

This is the stop hour; 0-23 hours. Select STOP HOUR

by pressing WHITES & COLORS key pad.

SPECIAL PRICE DAY

This represents the day of the week and whether special

pricing is selected for that day. A number followed by ‘0’

indicates no selection that particular day (9.10). A number

followed by an ‘S’ indicates selected for that day (9.1S).

Days of week (1-7) can be chosen by pressing the

WHITES & COLORS key pad. Press DELICATES key pad

once to select special pricing for each day chosen.

When exiting setup code ‘9.’, the display must show current

day of week:

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1 = Sunday 1S

20 Day 2 = Monday 2S

30 Day 3 = Tuesday 3S

40 Day 4 = Wednesday 4S

50 Day 5 = Thursday 5S

60 Day 6 = Friday 6S

70 Day 7 = Saturday 7S

VAULT VIEWING OPTION

This option is either Selected ‘ON’ or Not Selected ‘OFF’.

Not Selected ‘OFF’.

Selected ‘ON’. Press DELICATES key pad once for this

selection. When selected, the money and/or cycle counts

will be viewable (if counting is selected) when the coin box

is removed.

VALUE OF COIN 1

This represents the value of coin 1 in number of nickels.

05 = $0.25.

By pressing WHITES & COLORS key pad, there is the

option of 1-199 nickels.

With coin slide activation, this represents the total vend price

in nickels. Example: b.30 = $1.50.

VALUE OF COIN 2

PD MODELS: This represents the value of coin 2 in number

of nickels. 20 = $1.00.

By pressing WHITES & COLORS key pad, there is the

option of 1-199 nickels.

PR MODELS: For models using Enhanced Debit, this field

represents the value of top off in nickels, or $.25.

Factory default of C.05; represents 5 x $.05, or $.25.

CODE EXPLANATION

8.00

8.00

8. c s

Press PERM. PRESS key pad once to advance to next code.

g

e.00

e.00

e.ac

Press PERM. PRESS key pad once to advance to next code.

g

j.c8

j. c8

j. c8

j. c8

j. e8

Press PERM. PRESS key pad once to advance to next code.

g

l. 0 0

l. 0 0

l. p s

Press PERM. PRESS key pad once to advance to next code.

g

8. c e

8. c e

8.0 0

Press PERM. PRESS key pad once to advance to next code.

g

0.00

0.00

Press PERM. PRESS key pad once to advance to next code.

g

COIN SLIDE OPTION

This option is either Selected ‘ON’ or Not Selected ‘OFF’.

Replacement of metercase will be needed for coin slide mounting.

Not Selected ‘OFF’.

Selected ‘ON’.

NOTE: This option needs to be set to ‘00’ unless the

metercase has been changed to accept a coin slide device.

Press DELICATES key pad 3 consecutive times for this

selection. When coin slide mode is selected, set ‘b.’ equal to

value of vend price in nickels. Set ‘6 XX’ (REGULAR CYCLE

PRICE) and ‘3.XX’ (SPECIAL CYCLE PRICE) to number of

slide operations.

NOTE: If the installer sets up ‘CS’ on a coin drop model,

the dryer will not register coins inserted.

ADD COINS OPTION

This option is either Selected ‘ON’ or Not Selected ‘OFF’. This

option causes the customer display to show the number of coins

(coin 1) to enter, rather than the dollars-and-cents amount.

Not Selected ‘OFF’.

Selected ‘ON’.

Press DELICATES key pad 3 consecutive times for this selection.

PR MODELS: In enhanced debit mode, this option is

not selectable.

COIN/DEBIT OPTION

Both coin & debit selected. Press DELICATES key pad

3 consecutive times to change this selection.

Coins selected, debit disabled. Press DELICATES key pad

3 consecutive times to change this selection.

Debit Card selected, coin disabled. This is the factory default

for PR models.

PR SET UP AS PN MODELS ONLY: Must be set for ‘_d.’

Press DELICATES key pad 3 consecutive times to change

this selection.

Enhanced debit is self-selected when a Generation 2 card

reader is installed in the dryer. The ‘Ed’ option cannot be

manually selected or deselected.

PRICE SUPPRESSION OPTION

This option is either Selected ‘ON’ or Not Selected ‘OFF’. This

option causes the customer display to show ‘AVAILABLE’ or

‘ADD’ rather than the amount of money to add. (Used mainly

in debit installations.)

Not Selected ‘OFF’.

Selected ‘ON’. Press DELICATES key pad once for this selection.

CLEAR ESCROW OPTION

This option is either Selected ‘ON’ or Not Selected ‘OFF’.

When selected, money held in escrow for 30 minutes without

further escrow or cycle activity will be cleared.

Selected ‘ON’.

Not Sele cted ‘OFF’. Press DELICATES key pad once to deselect

this option.

PENNY INCREMENT OFFSET

This represents the penny increment price offset used

in Generation 2 (Enhanced Debit) PR models. Choose from

0-4 pennies by pressing the WHITES & COLORS key pad.

28

If cycle counter (9 0C) is selected, the following is true:

1 00 Represents the number of cycles in HUNDREDS. 1 02 = 200

2 00 Represents the number of cycles in ONES. 2 25 = 225

TOTAL CYCLES = 225

This is ‘VIEW ONLY’ and cannot be cleared.

Press the PERM. PRESS button once to advance

to next code.

If money counter (1.0C or 1.C0) is selected, the following is true:

3 00 Number of dollars in HUNDREDS. 3 01 = 100.00

4 00 Number of dollars in ONES. 4 68 = 168.00

5 00 Number of CENTS. 5 75 = 100.75

TOTAL = $168.75

END OF SET-UP PROCEDURES

EXIT FROM SET-UP MODE

■ PD MODELS: Reinstall service access door.

■ PR MODELS: Remove set-up card.

■ PR MODELS where AA1 connector was removed:

1. Unplug dryer or disconnect power.

2. Open console, reinsert jumper into AA1, close console.

3. Plug in dryer or reconnect power.

■ PR MODELS WHERE SERVICE ACCESS CODE WAS USED:

Set-up mode can be exited by using procedures from Service

Access Code (see page 24).

g Wait for 2 minutes without activating any dryer inputs.

g Disconnect and then re-connect power.

29

MAYTAG® COMMERCIAL WASHER, DRYER, STACKED

T

1.

2.

3.

4.

5.

6.

7

8.

9.

10.

11.

12.

T

DRYER/DRYER, COMMERCIAL STACK LAUNDR Y,

AND MULTI-LOAD COIN OPERATED COMMERCIAL

WASHERS AND DRYERS WARRANTY

LIMITED WARRANTY (PARTS ONLY – LABOR NOT INCLUDED)

For the first five years from the original date of purchase, when this commercial appliance is installed, maintained, and operated according

to the instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (hereafter “Maytag”) will pay for factory

specified replacement parts to correct defects in materials or workmanship that existed when this commercial appliance was purchased.

This limited warranty does not include labor.

YOU R SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN.

Maytag recommends that you use an “in network” service provider to diagnose and repair your Commercial Laundry product. Maytag will not

be responsible under this warranty to provide additional replacement parts as a result of incorrect diagnosis or repair by an “out of network”